Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

277results about "Refining with metal oxides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sorbent composition, process for producing same and use in desulfurization

A particulate adsorbent composition comprising a mixture of zinc oxide, silica, alumina and substantially reduced valence cobalt for use in desulfurizing a cracked gasoline or diesel fuel feed stream in a desulfurization zone by: The desulfurization zone contacts the feed stream, then separates the resulting low sulfur content stream and the sulfurized adsorbent, regenerates and activates the separated adsorbent, and then returns to the desulfurization zone.

Owner:CHINA PETROLEUM & CHEM CORP

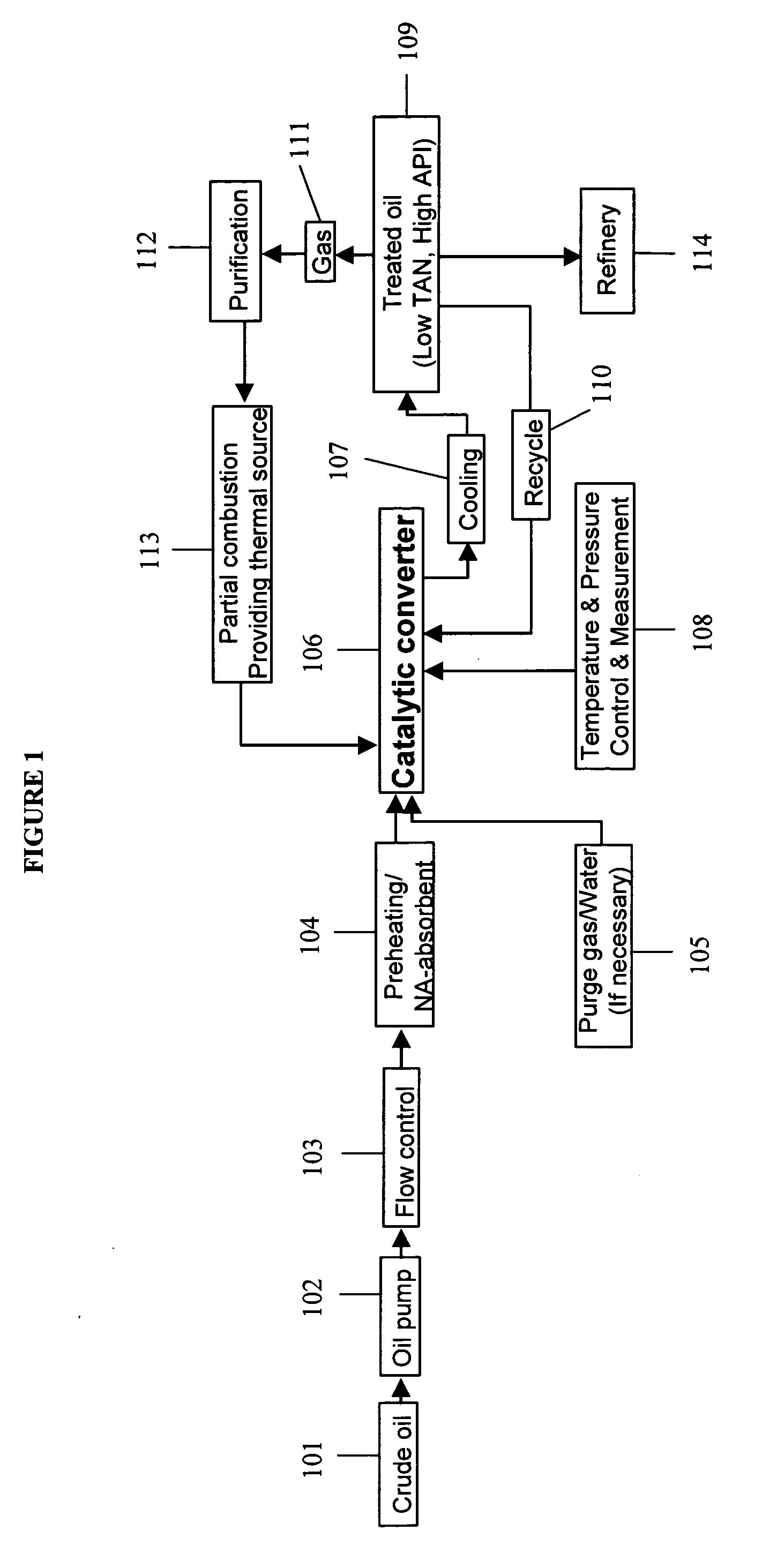

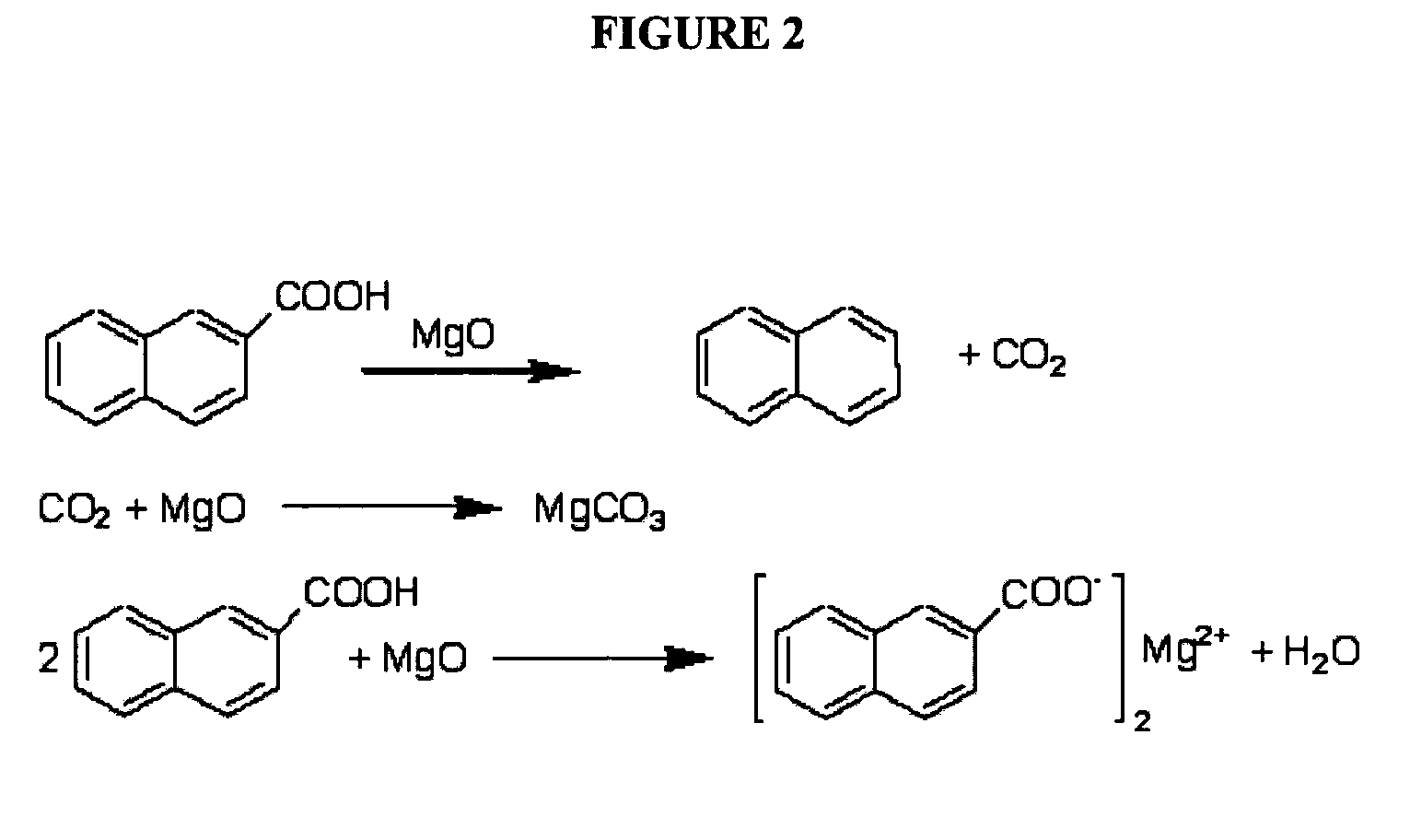

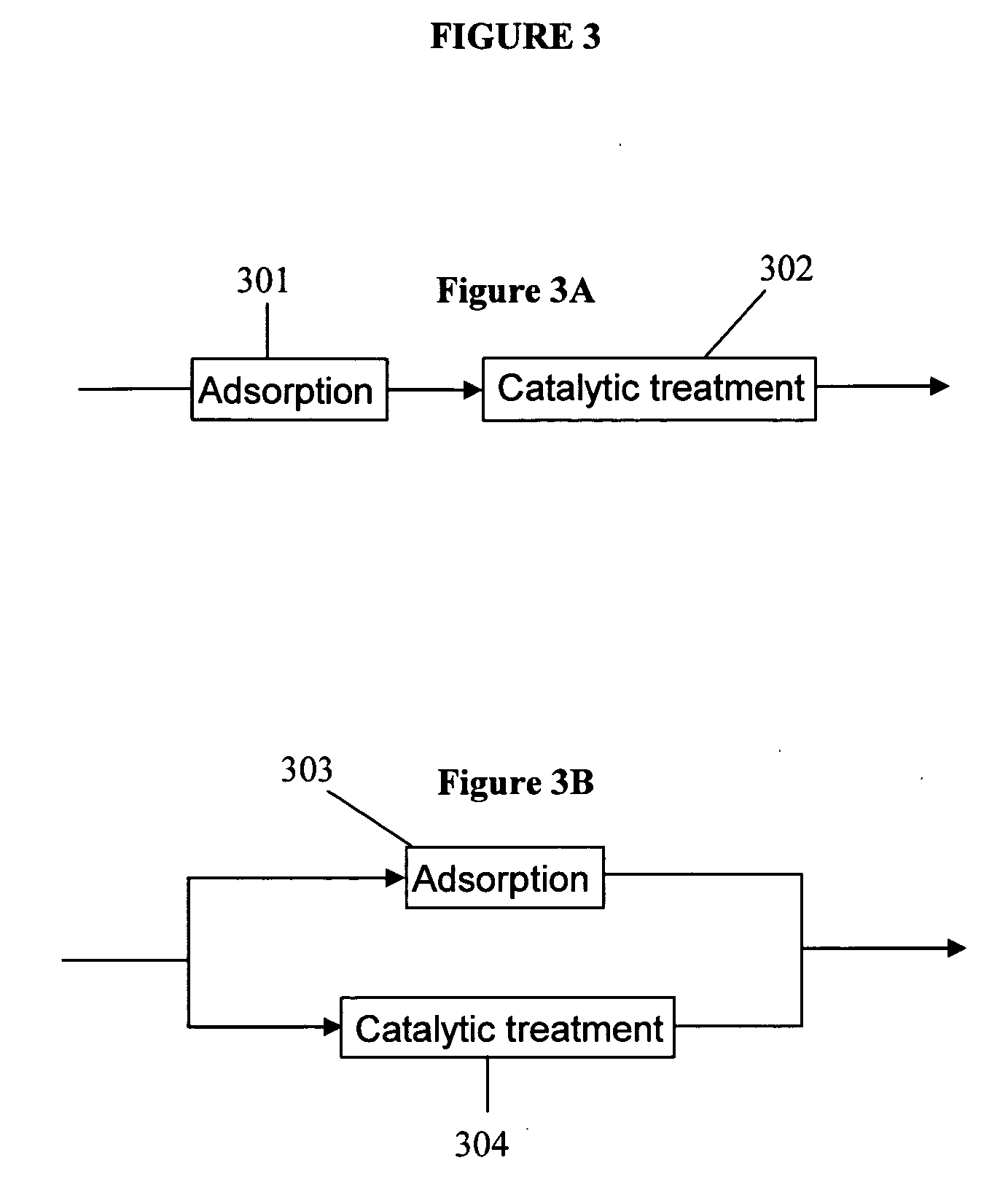

Process to upgrade oil using metal oxides

InactiveUS20060016723A1Reduce acidityReduce the numberRefining with metalsLiquid organic insulatorsHydrocotyle bowlesioidesCarboxylic acid

Described herein are compositions and methods for using metal oxides to upgrade oil. Metal oxides may be used as catalysts to reduce the TAN of the oil by converting carboxylic acids such as naphthenic acids into non-corrosive products. In some cases, the conversion occurs by a decarboxylation of the carboxylic acid to produce CO2. A second process promoted by metal oxides is hydrocarbon cracking. Cracking decreases the viscosity and increases the API, and produces lower molecular-weight hydrocarbons that are useful for many fuels and lubricants. Reductions in TAN and the increases in API improve the quality of increase the value of oil.

Owner:CALIFORNIA INST OF TECH

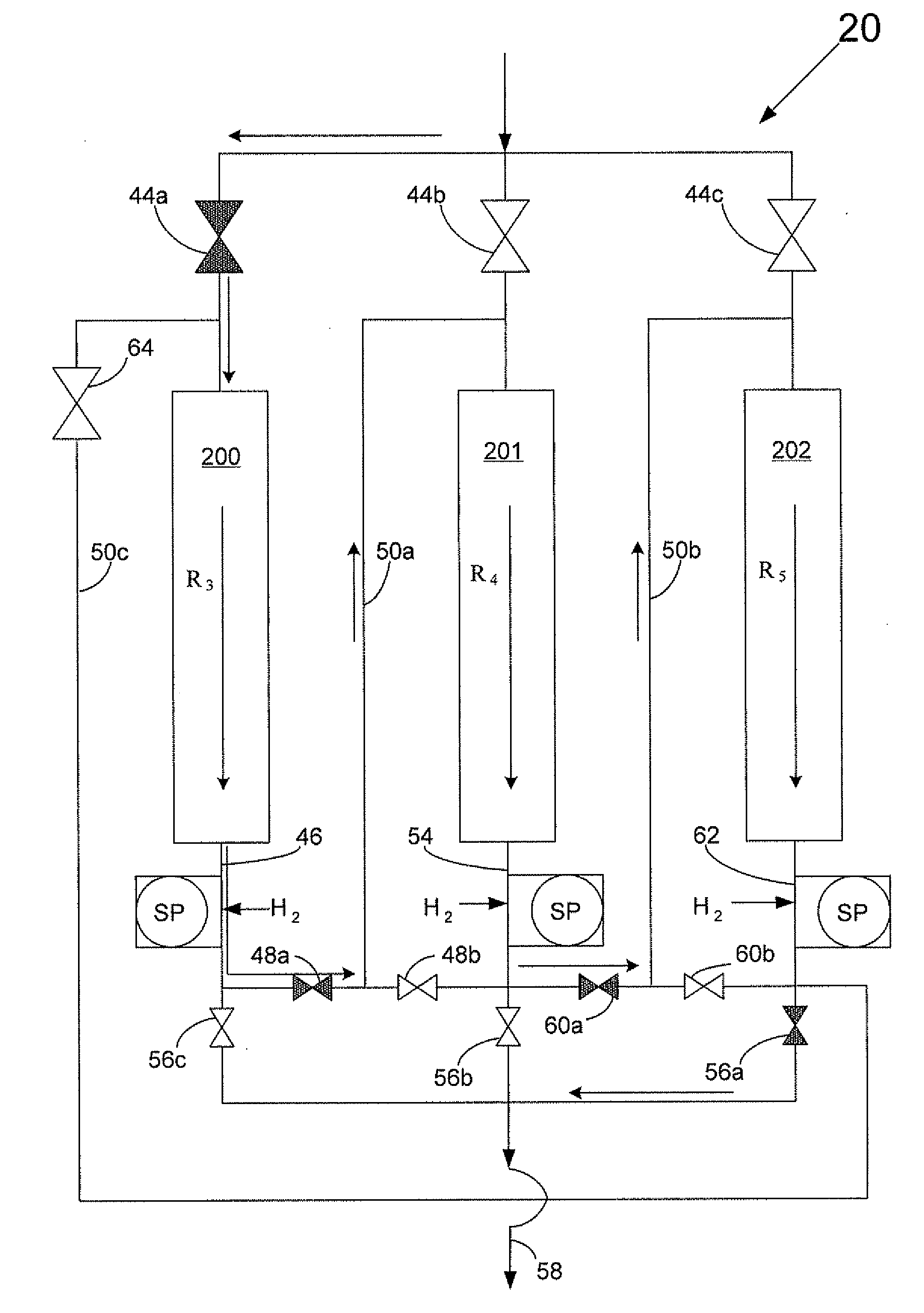

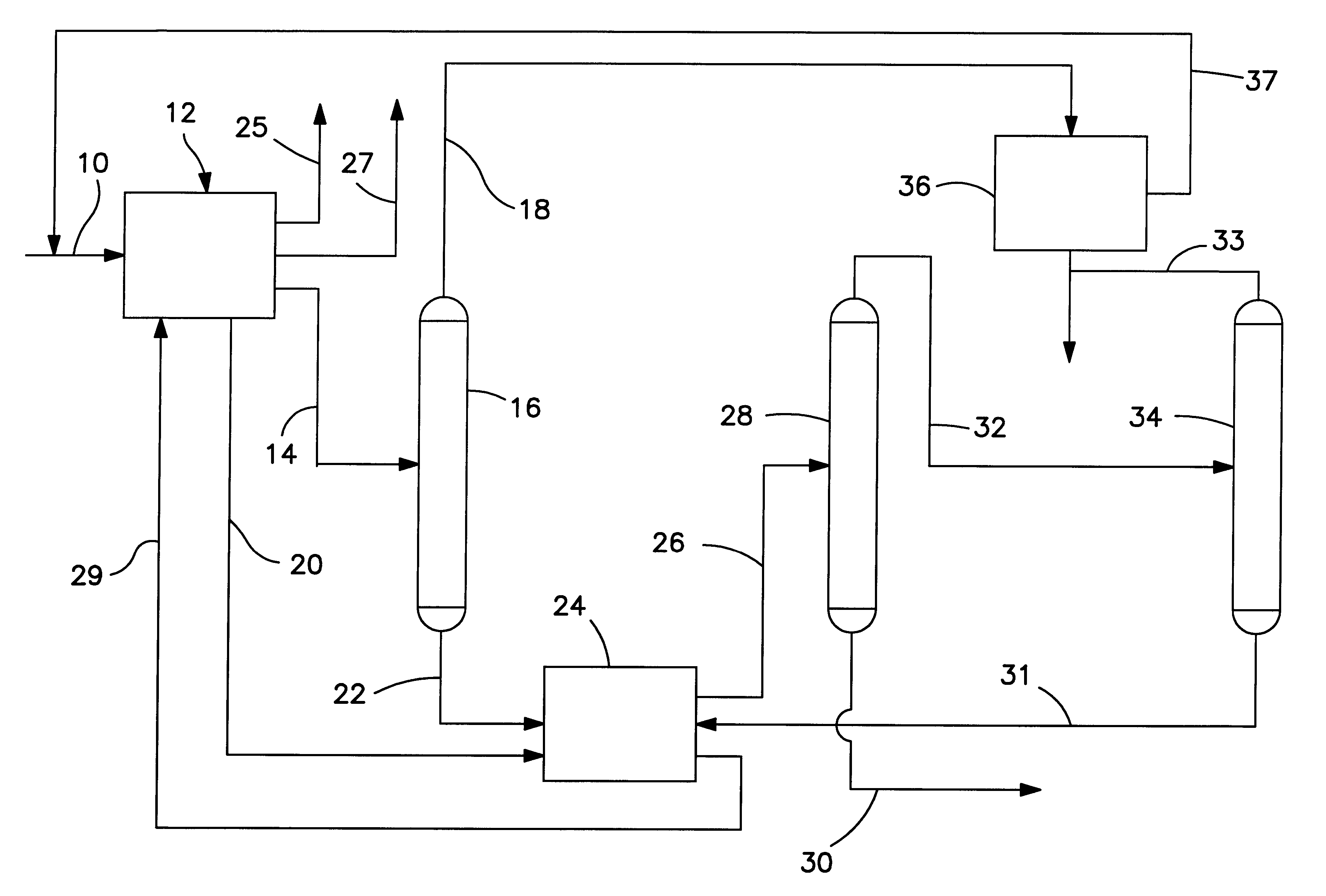

Process for catalytic hydrotreating of sour crude oils

ActiveUS20090139902A1Improve catalyst utilizationImproves HDS activityTreatment with hydrotreatment processesFilter regenerationHydrodesulfurizationSulfur

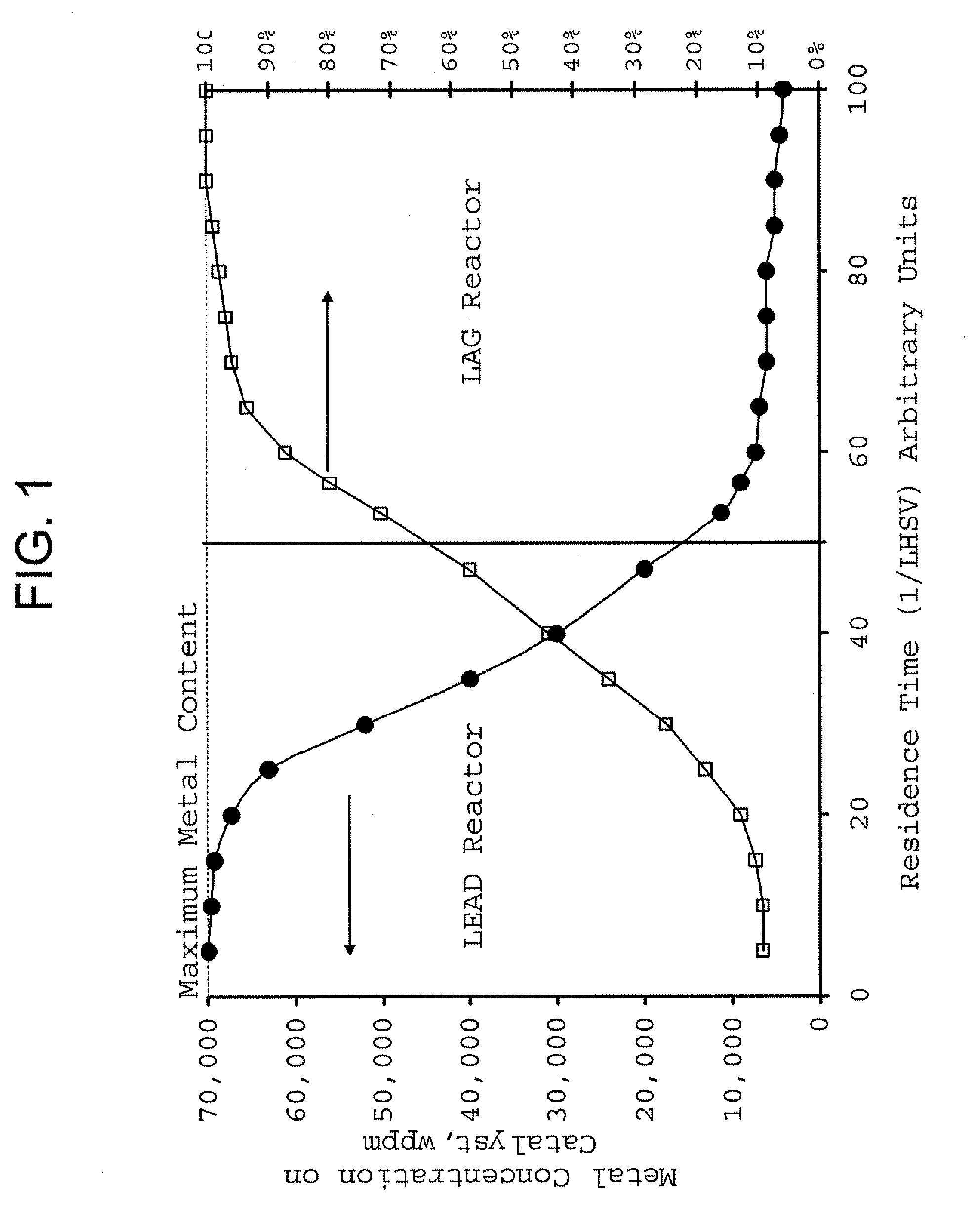

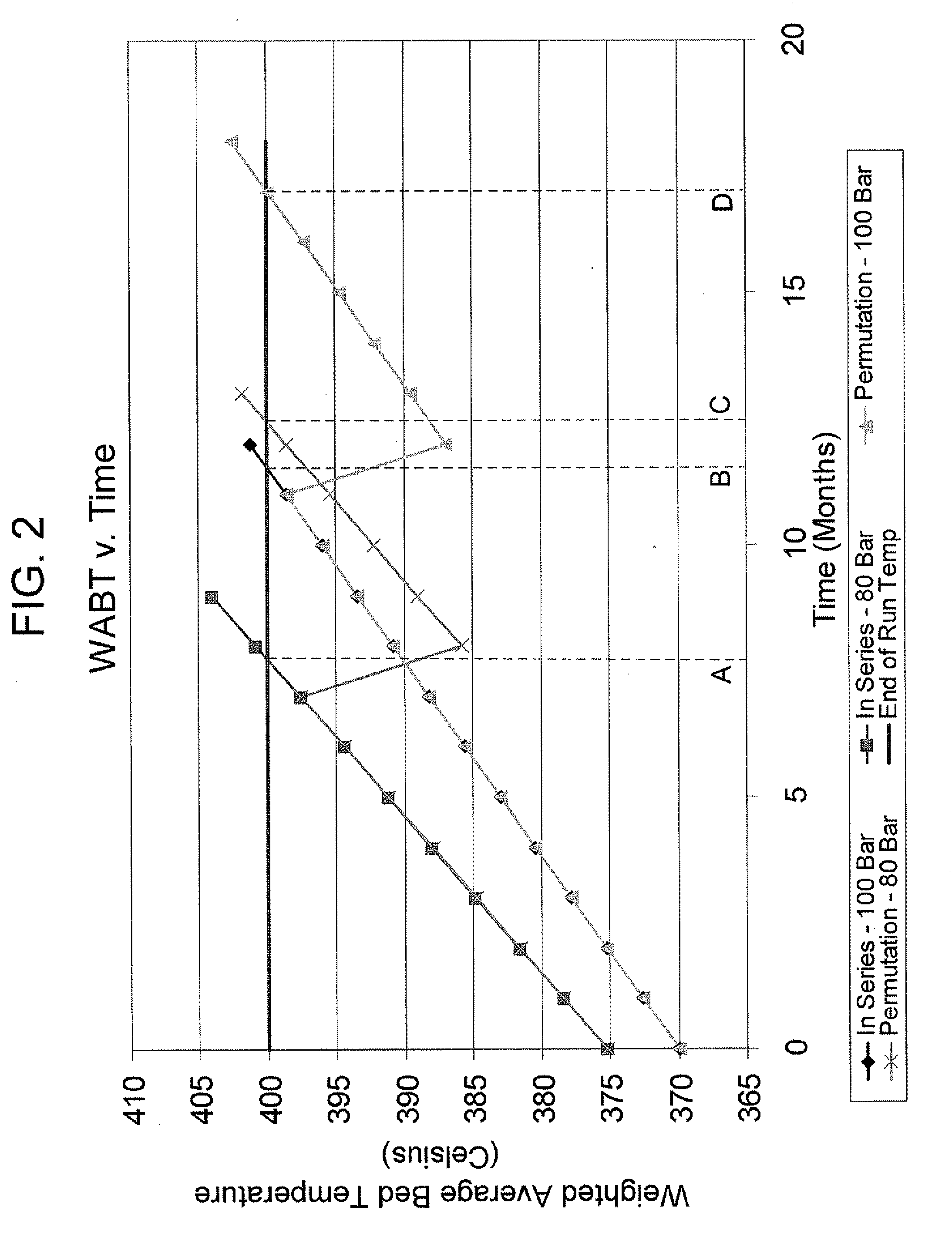

A continuous process for upgrading sour crude oil by treating the sour crude oil in a two step process that includes a hydro-demetallization section and a hydro-desulfurization section, both of which are constructed in a permutable fashion so as to optimize the operating conditions and catalyst lifespan to produce a high value crude oil having low sulfur and low organometallic impurities.

Owner:SAUDI ARABIAN OIL CO

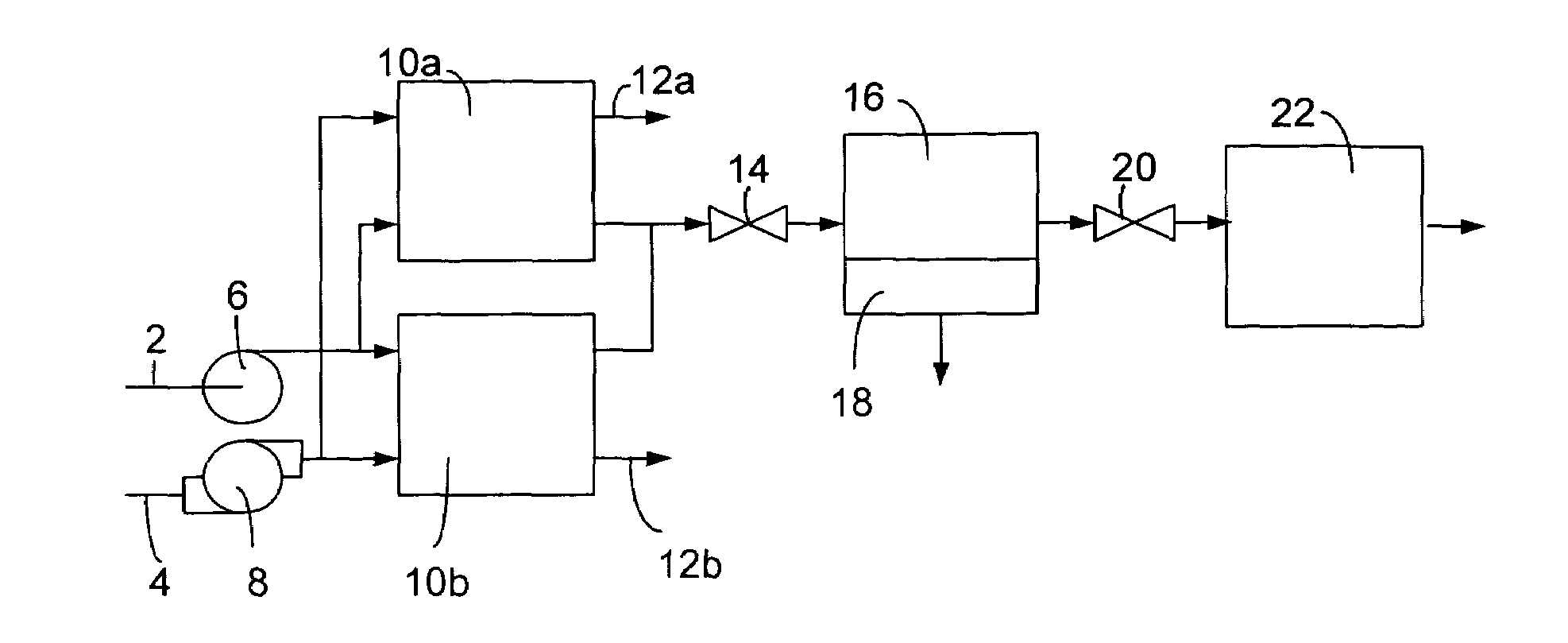

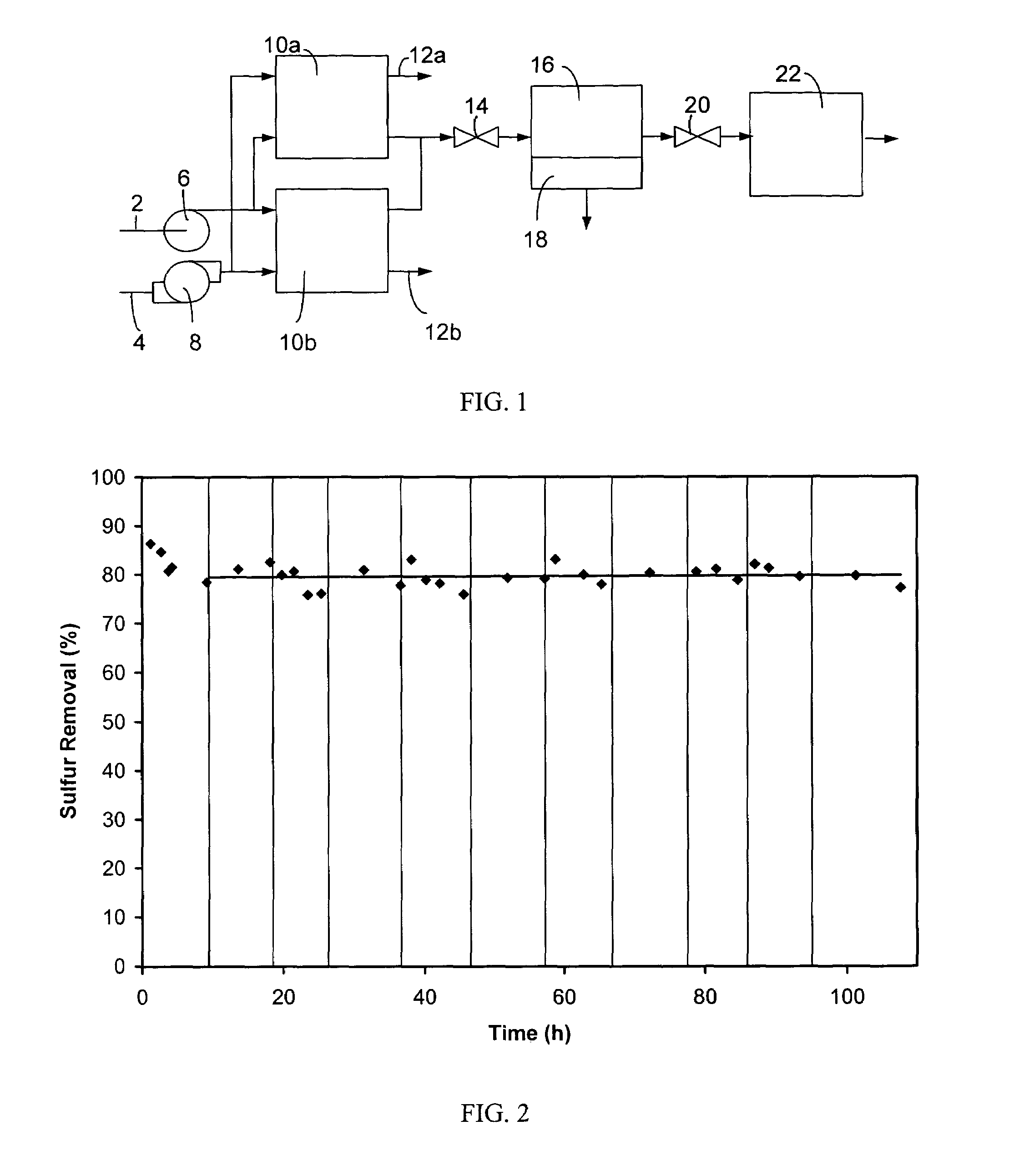

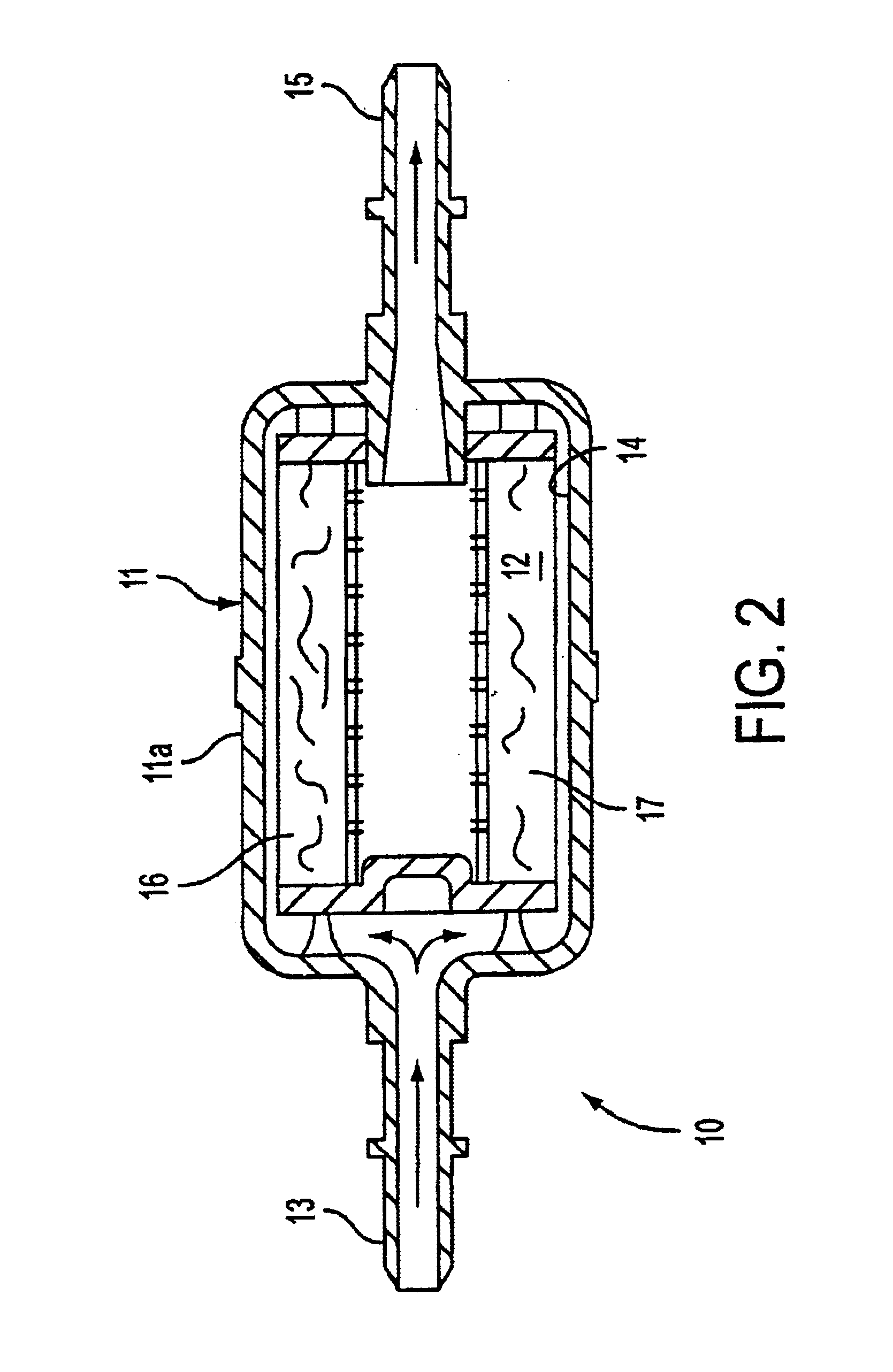

Method for desulfurizing a fuel for use in a fuel cell power plant

A fuel processing system is operable to remove substantially all of the sulfur present in an undiluted hydrocarbon fuel stock supply used to power a fuel cell power plant in a mobile environment, such as an automobile, bus, truck, boat, or the like, or in a stationary environment. The power plant hydrogen fuel source can be gasoline, diesel fuel, naphtha, light hydrocarbon fuels such as butane, propane, natural gas, or other like fuels which contain relatively high levels of organic sulfur compounds such as mercaptans, sulfides, disulfides, and the like. The undiluted hydrocarbon fuel supply is passed through a nickel desulfurizer bed wherein essentially all of the sulfur in the organic sulfur compounds react with the nickel reactant, and are converted to nickel sulfide while the desulfurized organic remnants continue through the remainder of the fuel processing system. The system does not require the addition of steam or a hydrogen source to the fuel stream prior to the desulfurizing step. The system operates at relatively low temperatures and can be used to desulfurize either a liquid or a gaseous fuel stream.

Owner:UNITED TECH CORP

Oxidative desulfurization of sulfur-containing hydrocarbons

InactiveUS20050150819A1Reduce sulfur contentLow sulfurRefining with oxygen compoundsRefining with metal oxidesGas phaseOxygen

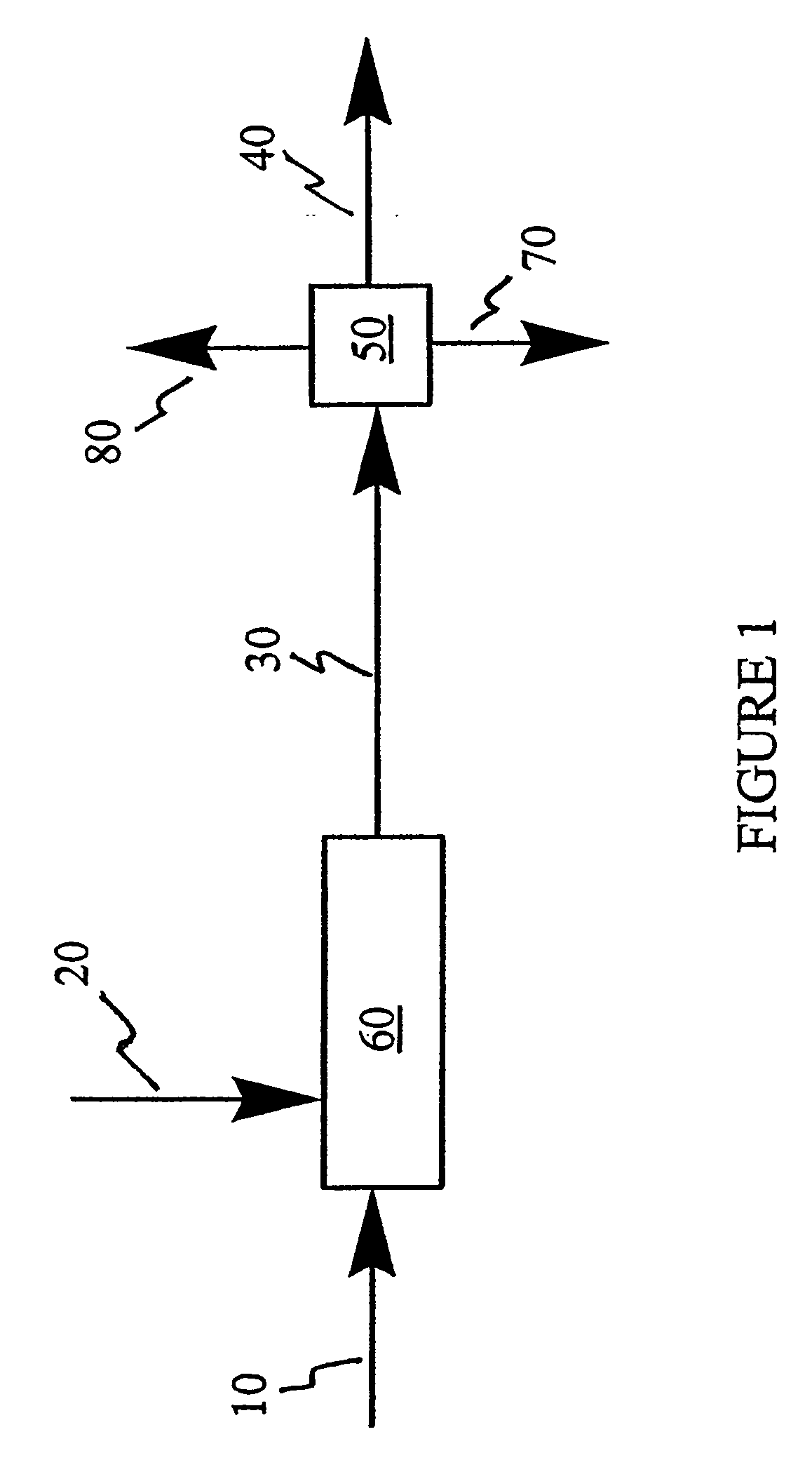

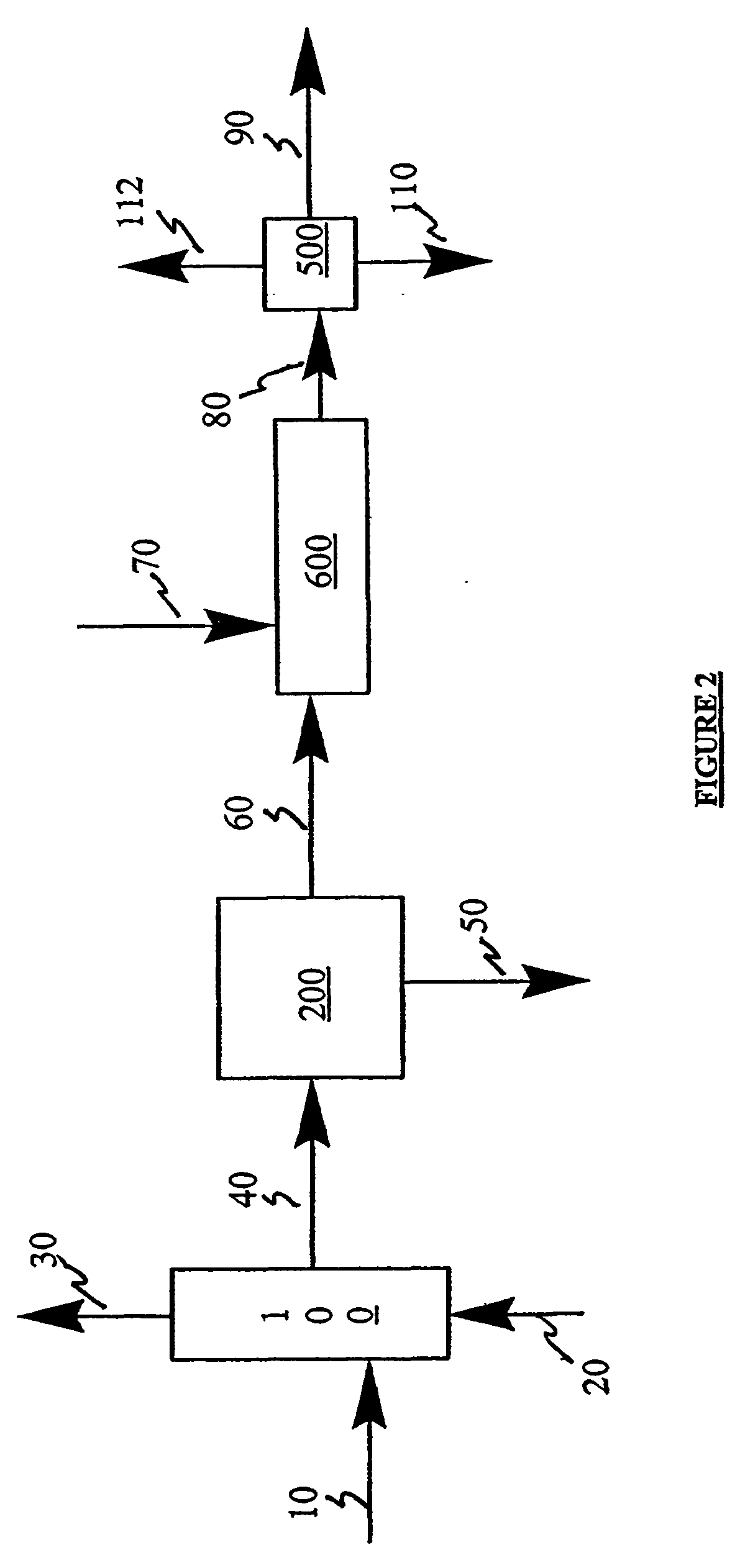

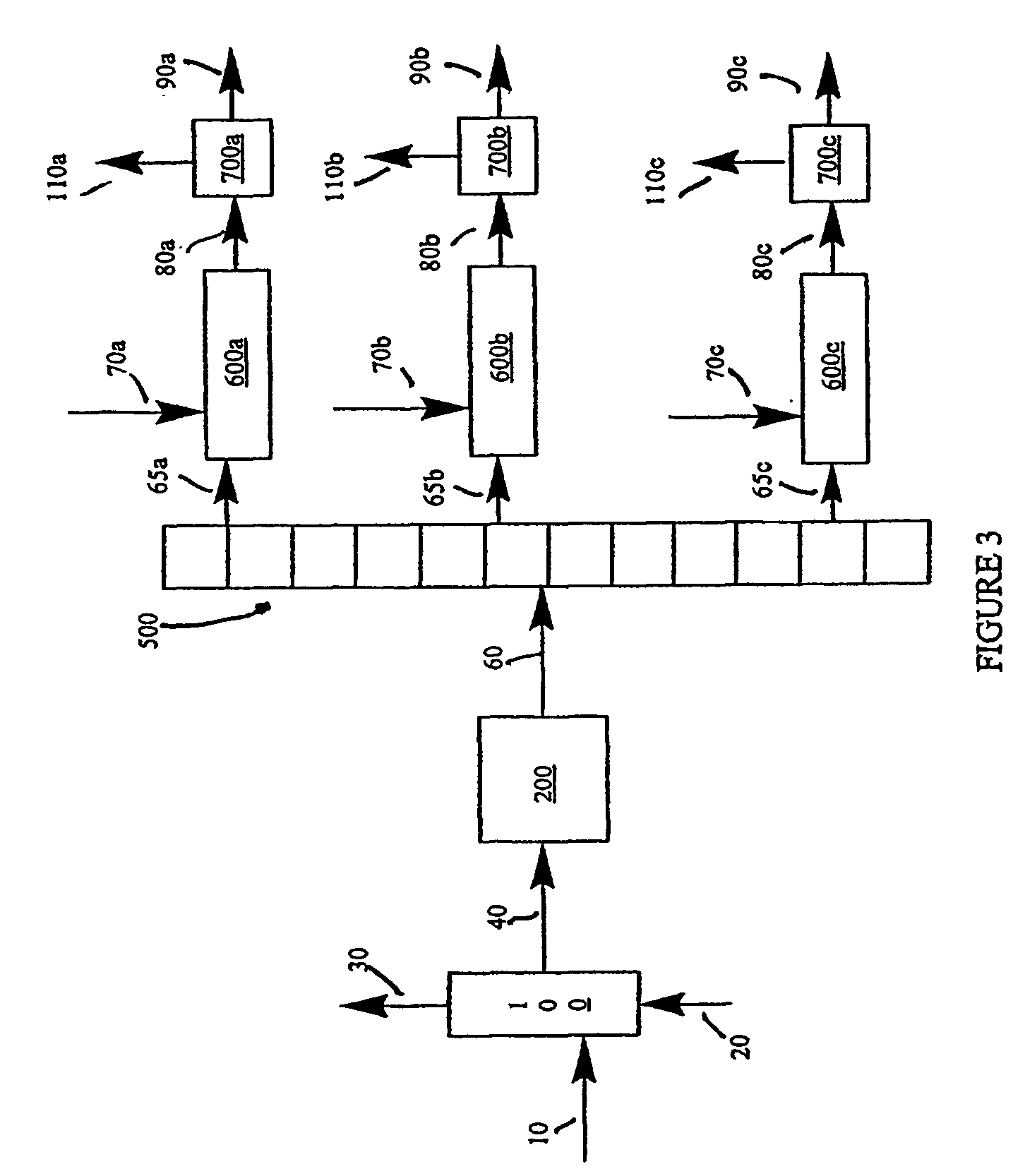

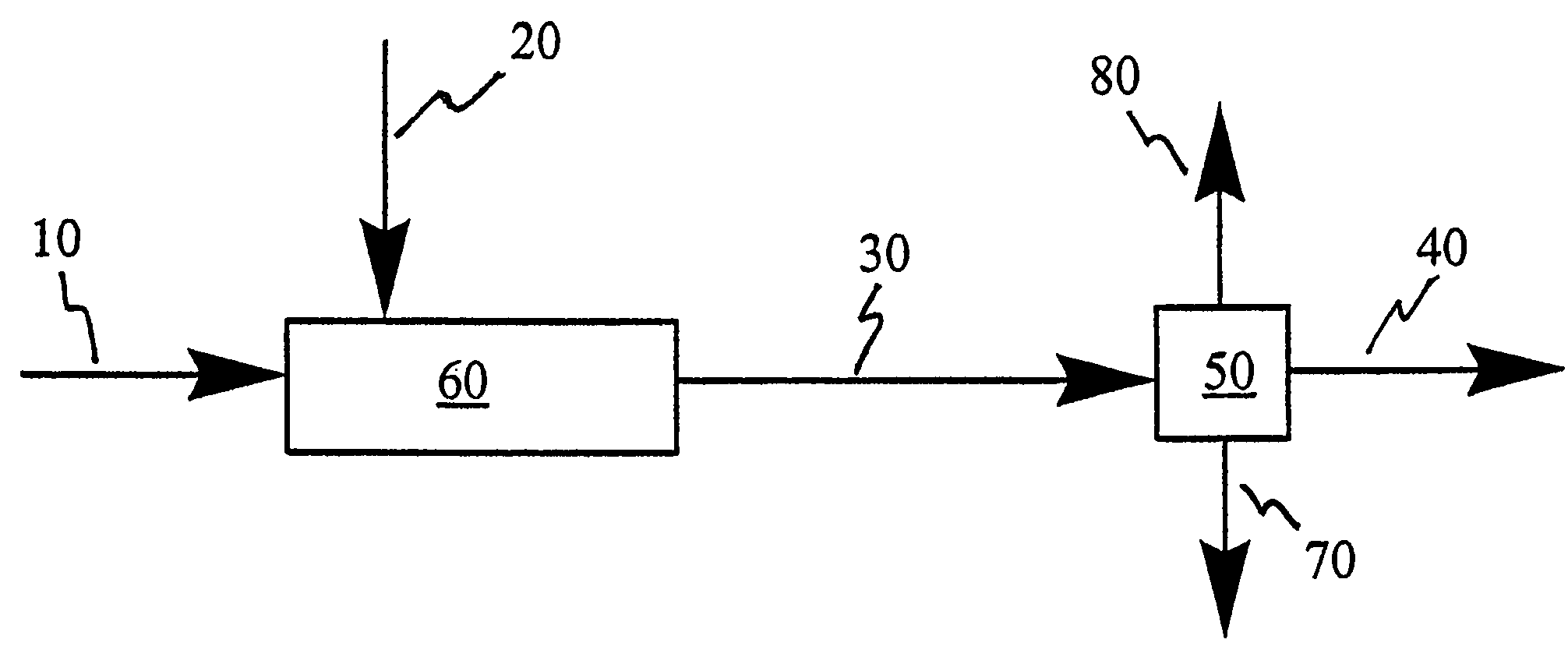

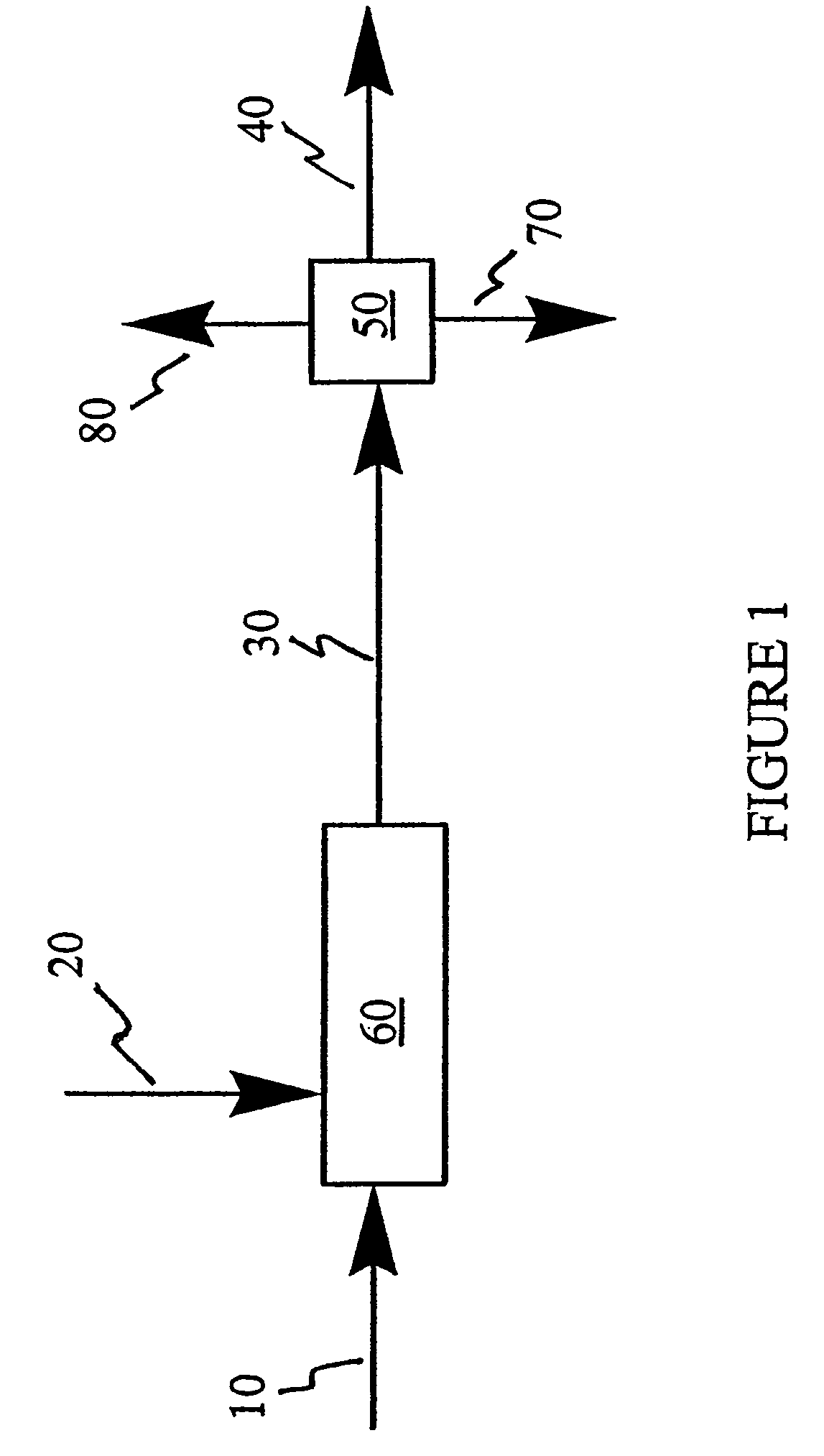

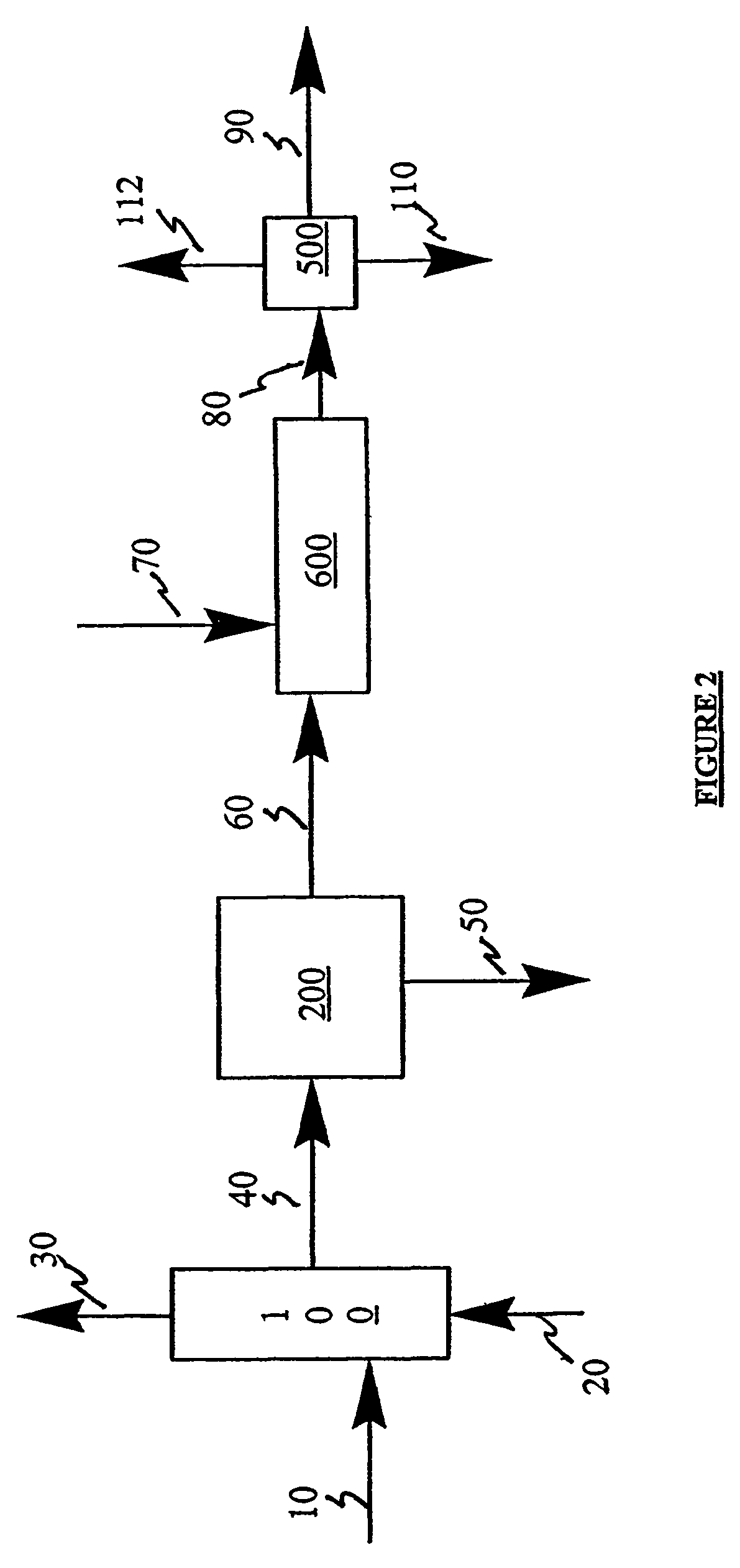

A method for desulfurizing a hydrocarbon stream (10) containing heterocyclic sulfur compounds, which process comprises contacting the heterocyclic sulfur compounds in the gas phase (60) in the presence of oxygen (70) with a supported metal oxide catalyst, or with a bulk metal oxide catalyst (600) to convert at least a portion of the heterocyclic sulfur compounds to oxygenated products as well as sulfur-deficient hydrocarbons and separately recovering the oxygenated products separately from a hydrocarbon stream with substantially reduced sulfur.

Owner:LEHIGH UNIVERSITY

Process for preparing bitumen compositions with reduced hydrogen sulfide emission

InactiveUS20050145137A1Reduce evolutionEmission reductionRefining with metalsRefining with metal saltsScavengerCadmium Cation

In methods of preparing asphalt including asphalt / elastomeric polymer compositions, it has been discovered that the emission or evolution of H2S can be reduced by adding certain H2S scavengers to the asphalt mixture, but that not every known H2S scavenger can be effective in this method. Particularly helpful H2S scavengers include inorganic metal salts. Suitable inorganic or organic metal salt H2S scavengers include, but are not necessarily limited to those where the metal of the salt is zinc, cadmium, mercury, copper, silver, nickel, platinum, iron, or magnesium, and mixtures of these salts.

Owner:FINA TECH

Oxidative desulfurization of sulfur-containing hydrocarbons

A method for desulfurizing a hydrocarbon stream (10) containing heterocyclic sulfur compounds, which process comprises contacting the heterocyclic sulfur compounds in the gas phase (60) in the presence of oxygen (70) with a supported metal oxide catalyst, or with a bulk metal oxide catalyst (600) to convert at least a portion of the heterocyclic sulfur compounds to oxygenated products as well as sulfur-deficient hydrocarbons and separately recovering the oxygenated products separately from a hydrocarbon stream with substantially reduced sulfur.

Owner:LEHIGH UNIVERSITY

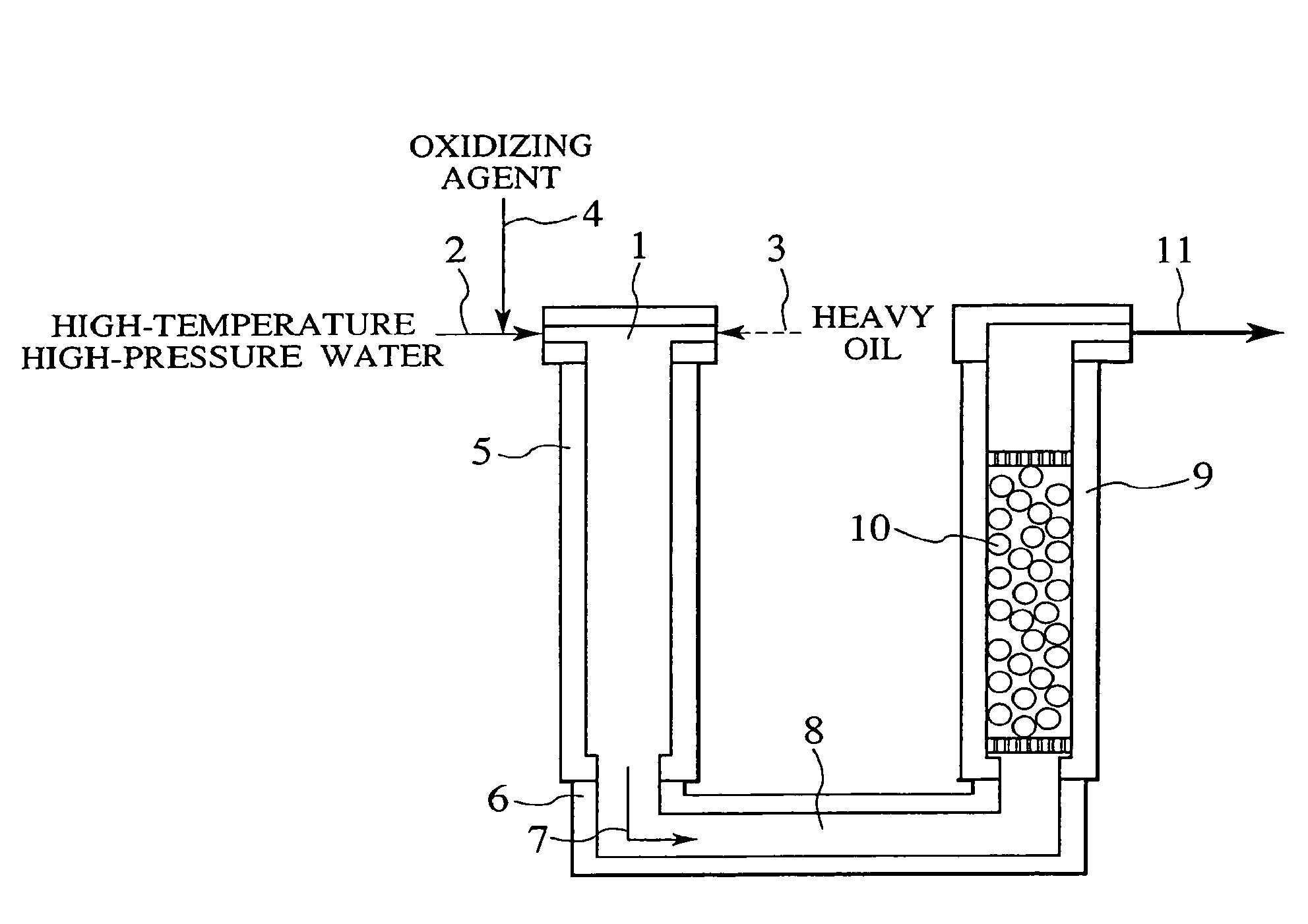

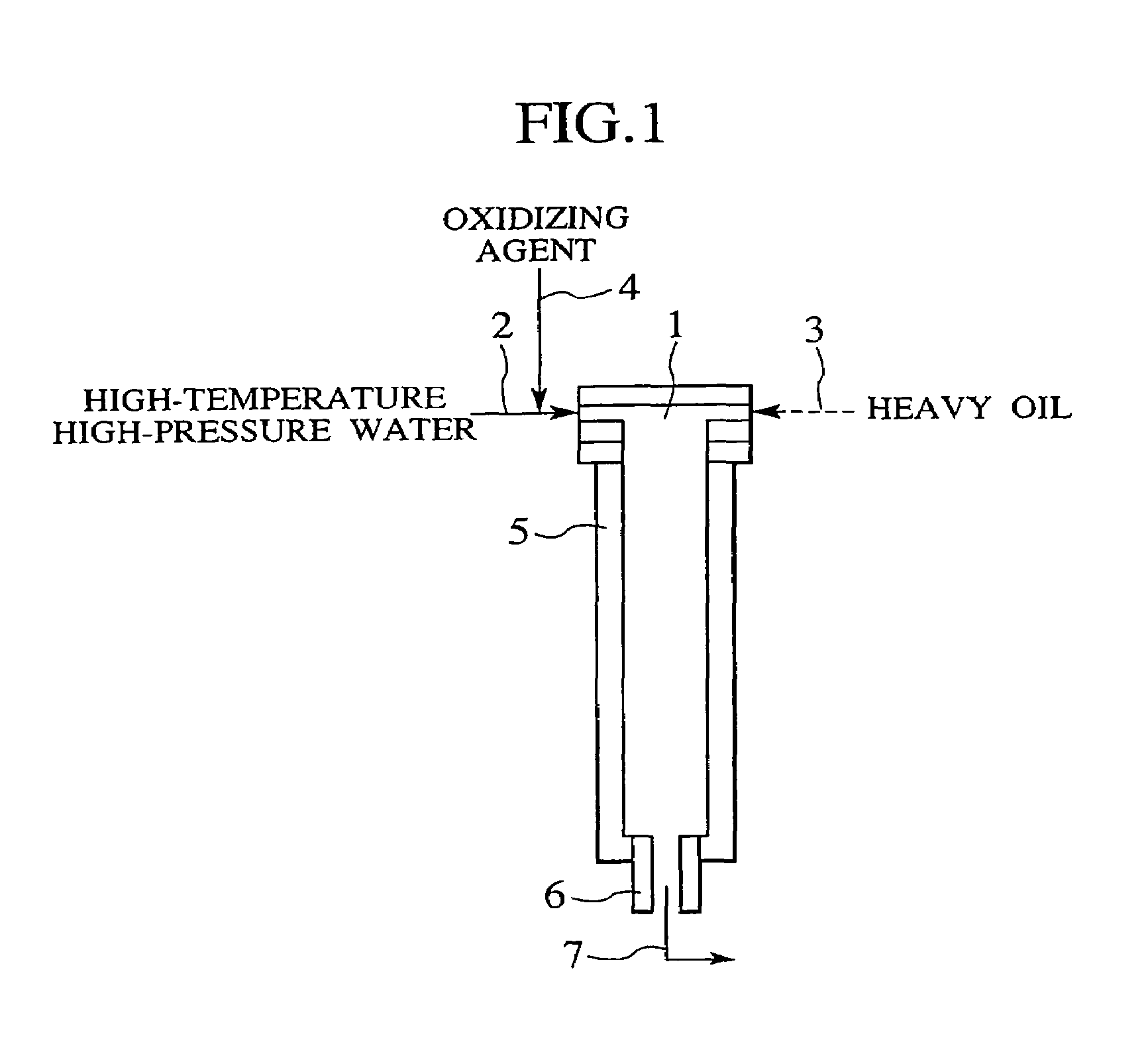

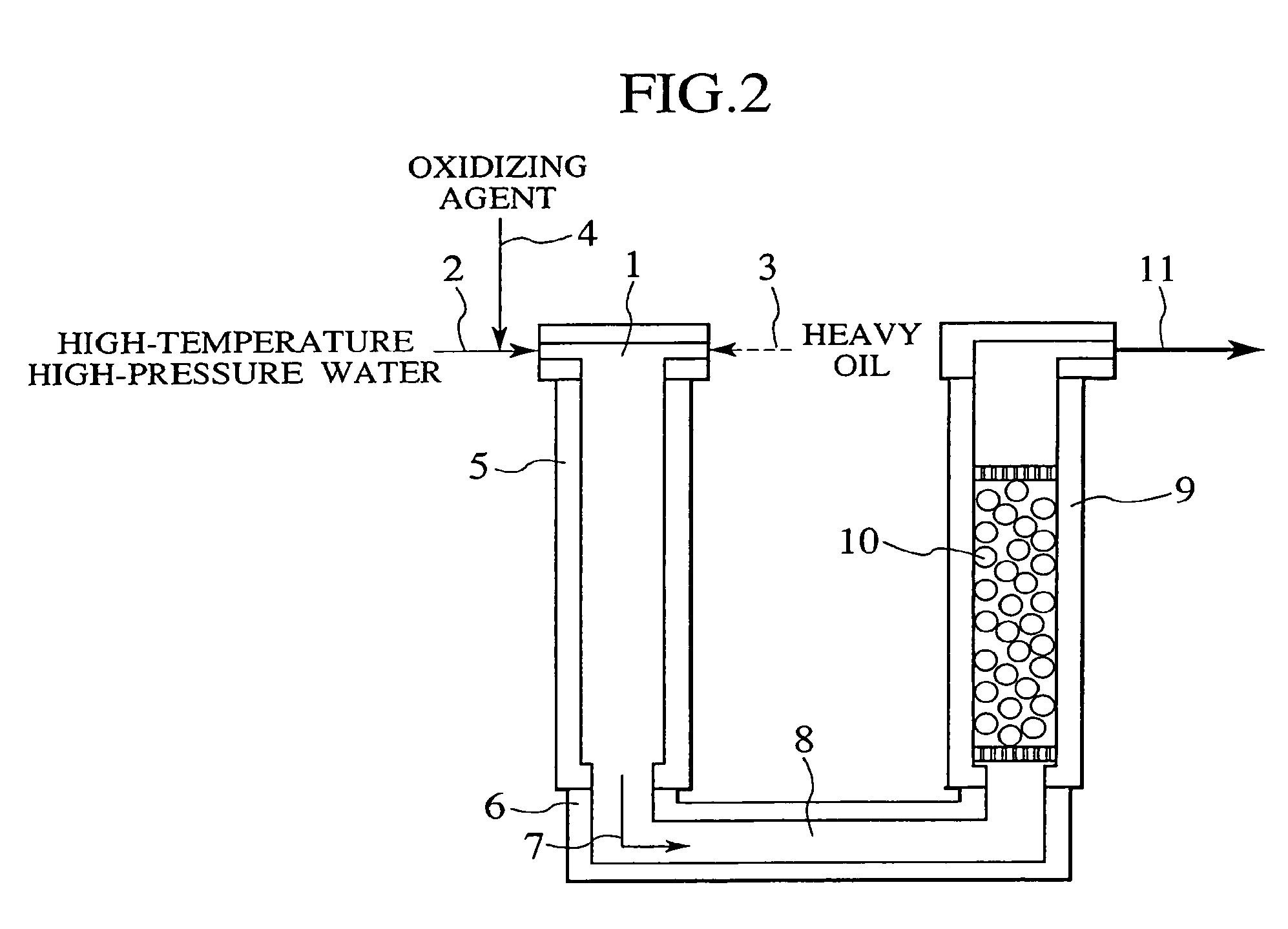

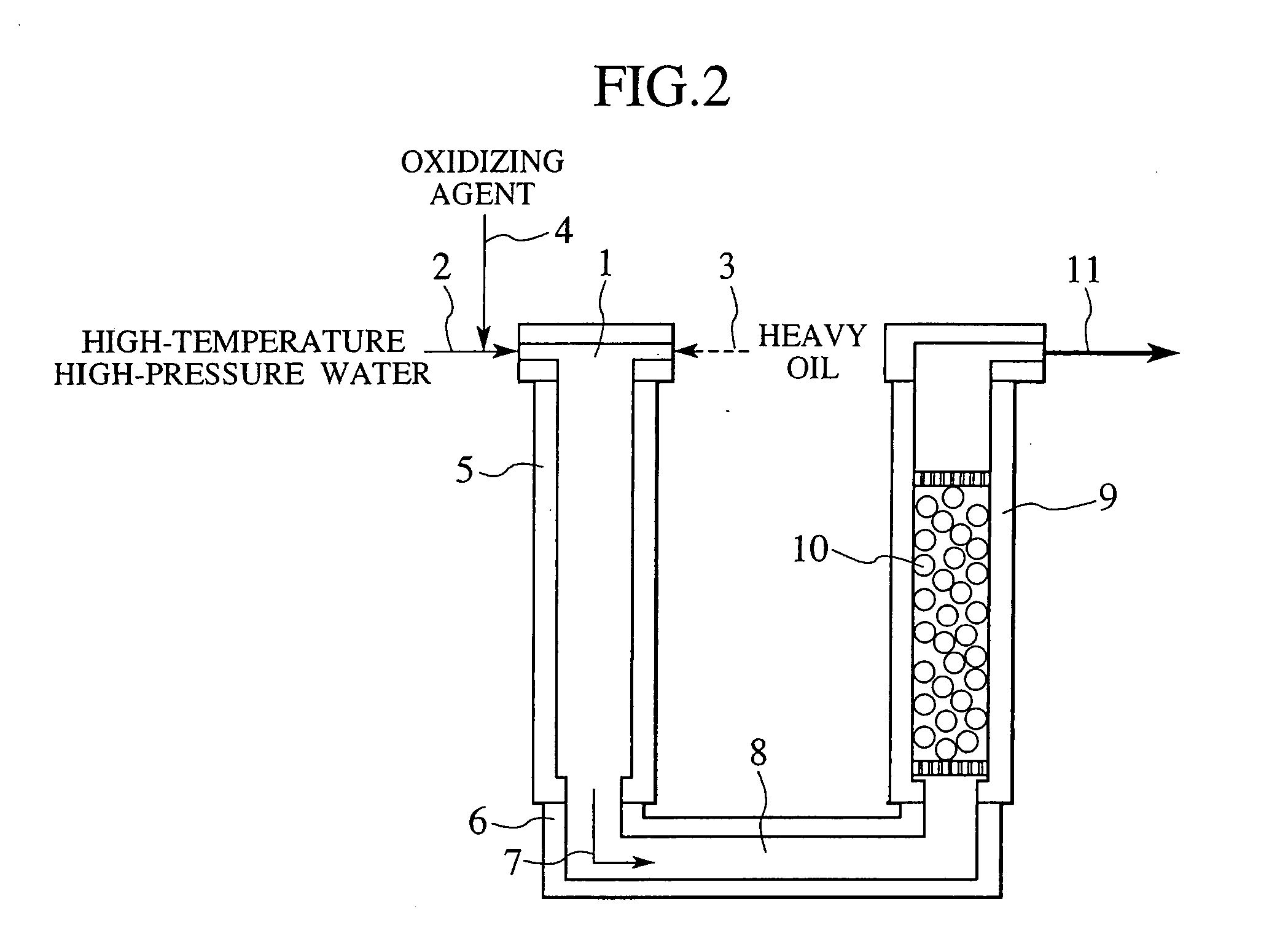

Process and apparatus for treating heavy oil with supercritical water and power generation system equipped with heavy oil treating apparatus

InactiveUS7264710B2Thermal non-catalytic crackingPressurized chemical processScavengerAfter treatment

The reforming of heavy oil with supercritical water or subcritical water is accomplished by mixing together supercriticai water, heavy oil, and oxidizing agent, thereby oxidizing vanadium in heavy oil with the oxidizing agent at the time of treatment with supercritical water and separate vanadium oxide. The separated vanadium oxide is removed by the scavenger after treatment with supercritical water. In this way it is possible to solve the long-standing problem with corrosion of turbine blades by vanadium which arises when heavy oil is used as gas turbine fuel.

Owner:HITACHI LTD

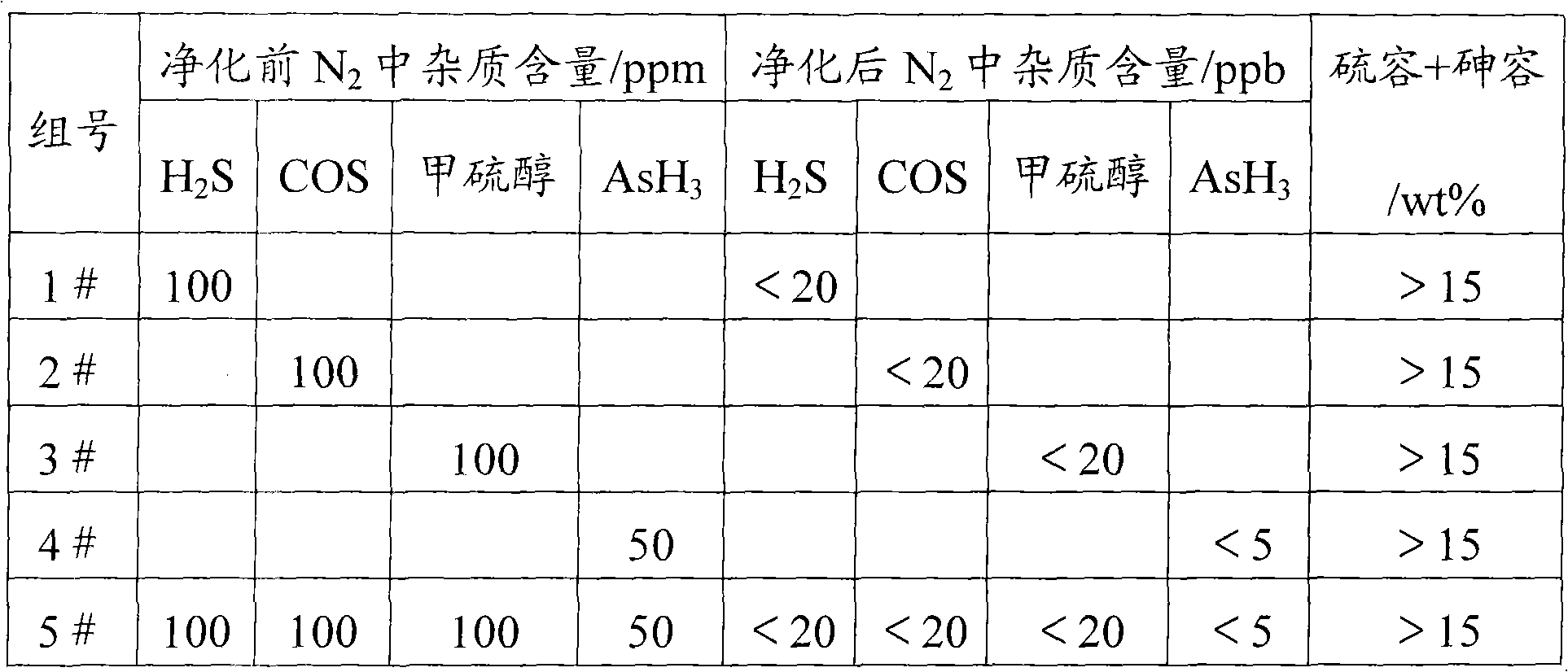

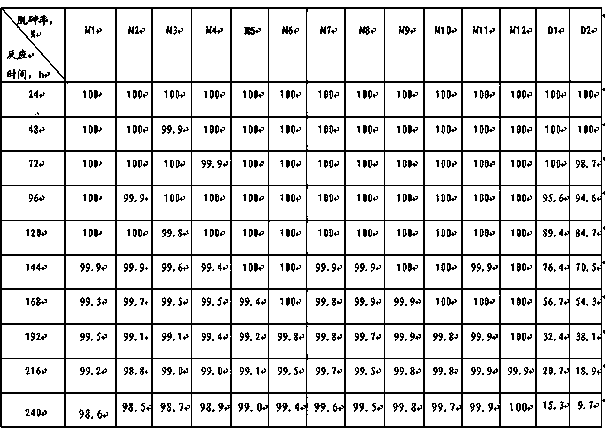

Normal temperature compound desulfuration and dearsenization agent and preparation method thereof

ActiveCN101591554AHigh desulfurization and arsenic removal efficiencyFull accessRefining with metal oxidesActive componentSulfur

The invention relates to a desulfuration and dearsenization agent, which comprises a carrier and active components; wherein, the carrier can be formed by a single carrier, or by two or more carriers, and the carrier accounts for 10-80wt% of the total weight of the desulfuration and dearsenization agent; the active components comprises 0.1-40wt% of lead oxide, 0.1-60wt% of magnetic Fe21.333O32 and0.1-40wt% of copper oxide. The invention further discloses a preparation method of the desulfuration and dearsenization agent. The desulfuration and dearsenization agent prepared by the invention has high sulfur capacity and arsenic capacity with desulfuration and dearsenization rate being higher than 99%.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Production of olefins

InactiveUS6858133B2High purityHigh yieldLiquid crystal compositionsCatalytic crackingAlkeneSulfur containing

A process for desulfurising an olefin-containing hydrocarbon feedstock including sulfur-containing hydrocarbon compounds as impurities, the process comprising passing a hydrocarbon feedstock containing one or more olefins through a reactor containing a crystalline silicate selected from the group consisting of an MFI-type crystalline silicate having a silicon / aluminum atomic ratio of at least 180 and an MEL-type crystalline silicate having a silicon / aluminum atomic ratio of from 150 to 800 which has been subjected to a steaming step to produce an effluent with an olefin content of lower molecular weight than that of the feedstock and removing hydrogen sulphide from the effluent.

Owner:ATOFINA RES SA

Process for sulfur adsorption using copper-containing catalyst

The present invention is a method for the adsorption of sulfur-containing compounds from a hydrocarbon feedstream, and in particular, an olefin feedstream. The method comprises contacting the sulfur-containing compound with a copper oxide / zinc oxide / aluminum oxide catalyst optionally promoted with a metal.

Owner:CLARIANT INT LTD

Methods and compositions for desulfurization of hydrocarbon fuels

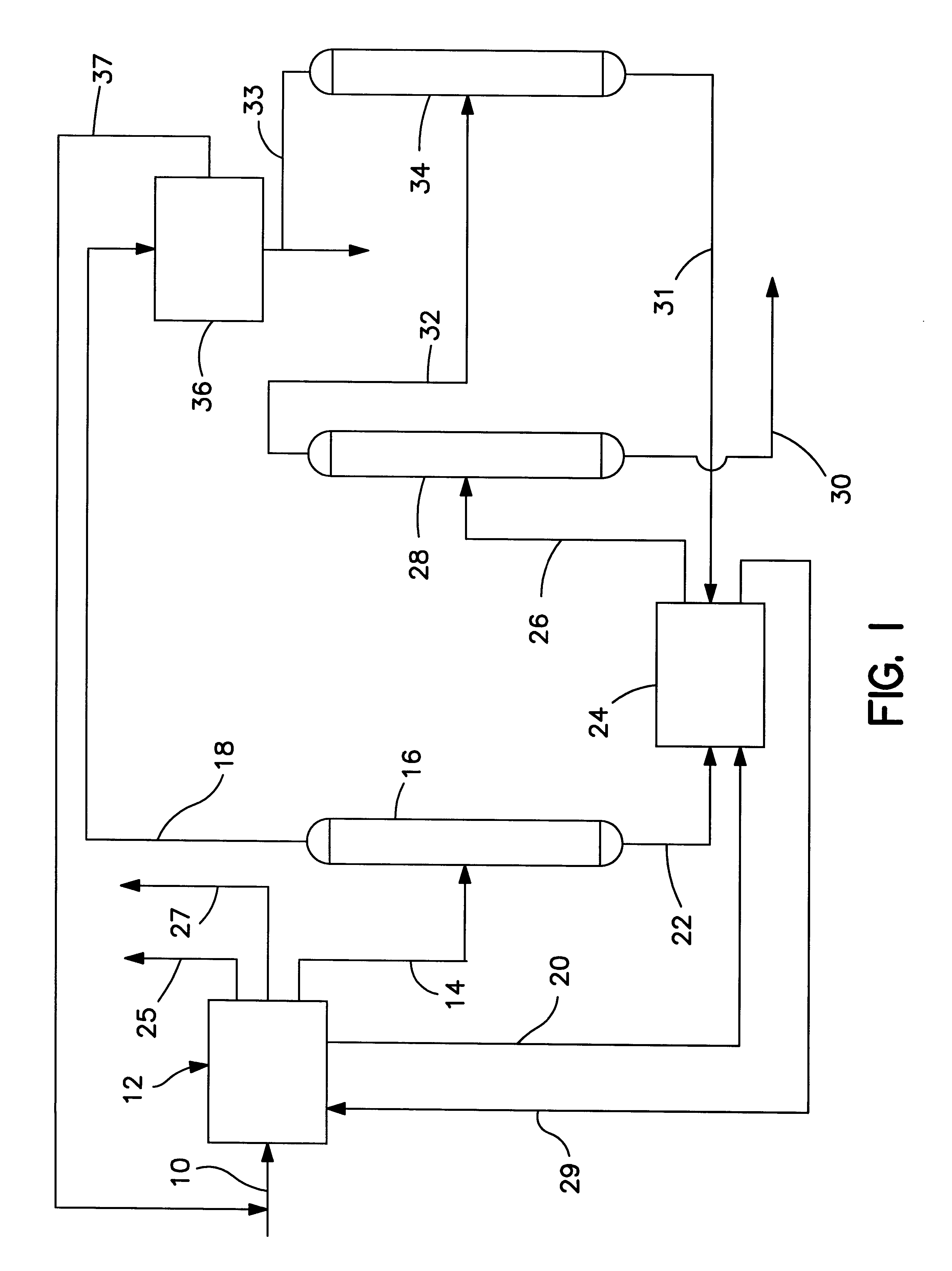

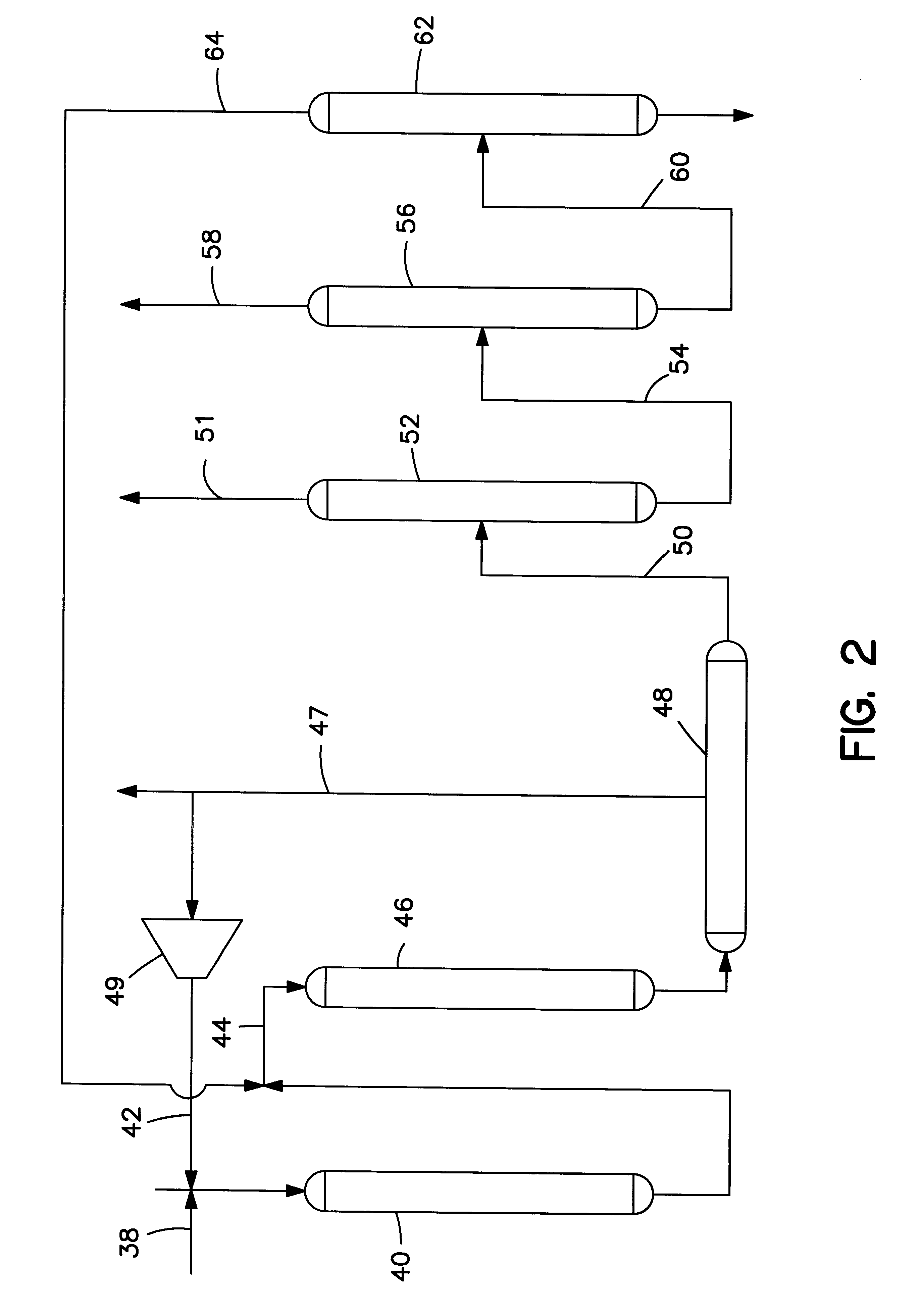

ActiveUS7309416B2Efficient removalHigh activityTreatment with plural serial cracking stages onlyGas treatmentBoiling pointSulfur

Sulfur is removed from a hydrocarbon fuel via contact with a desulfurization agent; the desulfurization agent is then regenerated (wherein sulfur is released) by exposing it to oxygen. The sulfur removal and regeneration processes each can be carried out at relatively moderate temperatures, e.g., from 300 to 600° C., and pressure, e.g., about 0.79 to about 3.5 MPa; and the desulfurization agent can include a transition metal oxide, such as molybdenum oxide. The process can also include the additional steps of cracking the hydrocarbon, separating high-boiling and low-boiling fractions from the reaction product and contacting the lower-boiling fraction with a secondary desulfurization agent.

Owner:ASPEN PRODS GROUP

Process and apparatus for treating heavy oil with supercritical water and power generation system equipped with heavy oil treating apparatus

InactiveUS20070144941A1Thermal non-catalytic crackingPressurized chemical processScavengerAfter treatment

The reforming of heavy oil with supercritical water or subcritical water is accomplished by mixing together supercritical water, heavy oil, and oxidizing agent, thereby oxidizing vanadium in heavy oil with the oxidizing agent at the time of treatment with supercritical water and separate vanadium oxide. The separated vanadium oxide is removed by the scavenger after treatment with supercritical water. In this way it is possible to solve the long-standing problem with corrosion of turbine blades by vanadium which arises when heavy oil is used as gas turbine fuel.

Owner:HITACHI LTD

Desulfurization and novel sorbents for same

InactiveCN1384770AOctane dropReduce hydrocarbon contentRefining with metalsOther chemical processesAluminateCalcium silicate

Particulate sorbent compositions which are suitable for the removal of sulfur from streams of cracked-gasoline or diesel fuel are provided which have increased porosity, improved resistance to deactivation through the addition of a calcium compound selected from the group consisting of calcium sulfate, calcium silicate, calcium phosphate or calcium aluminate to the support system comprised of zinc oxide, silica and alumina having thereon a promotor wherein the promotor is metal, metal oxide or metal oxide precursor with the metal being selected from the group consisting of cobalt, nickel, iron, manganese, copper, molybdenum, tungsten, silver, tin and vanadium or mixtures thereof and wherein the valence of such promotor has been substantially reduced to 2 or less. Process for the preparation such sorbent systems as well as the use of same for the desulfurization of cracked-gasolines and diesel fuels are also provided.

Owner:CHINA PETROLEUM & CHEM CORP

Desulfurization and novel sorbents for same

InactiveUS6955752B2Reduce componentsReduced valenceRefining with metalsOther chemical processesSulfurSorbent

Sorbent compositions for the removal of sulfur from cracked-gasoline and diesel fuels are prepared by the impregnation of a sorbent support comprising zinc oxide, expanded perlite, and alumina with a promotor metal followed by reduction of the valence of the promotor metal in the resulting promotor metal sorbent support composition.

Owner:CHINA PETROCHEMICAL CORP

Manufacture of high purity benzene and para-rich xylenes by combining aromatization and selective disproportionation of impure toluene

InactiveUS6323381B1Reduce acidityEasy to crackHydrocarbon by isomerisationRefining with metal oxidesNaphthaAromatization

A process is set forth for reacting impure toluene to obtain benzene, toluene and a para-rich xylene stream, which are substantially free of close-boiling non-aromatics. The impure toluene comprises at least 70 wt % toluene and between about 0.2 wt % and about 5 wt % close-boiling non-aromatics. The process may also comprise aromatizing a naphtha over a non-acidic catalyst. The impure toluene from the aromatization step is passed over an acidic intermediate pore zeolite to produce a para-rich xylene stream and chemically pure benzene.

Owner:CHEVRON CHEM

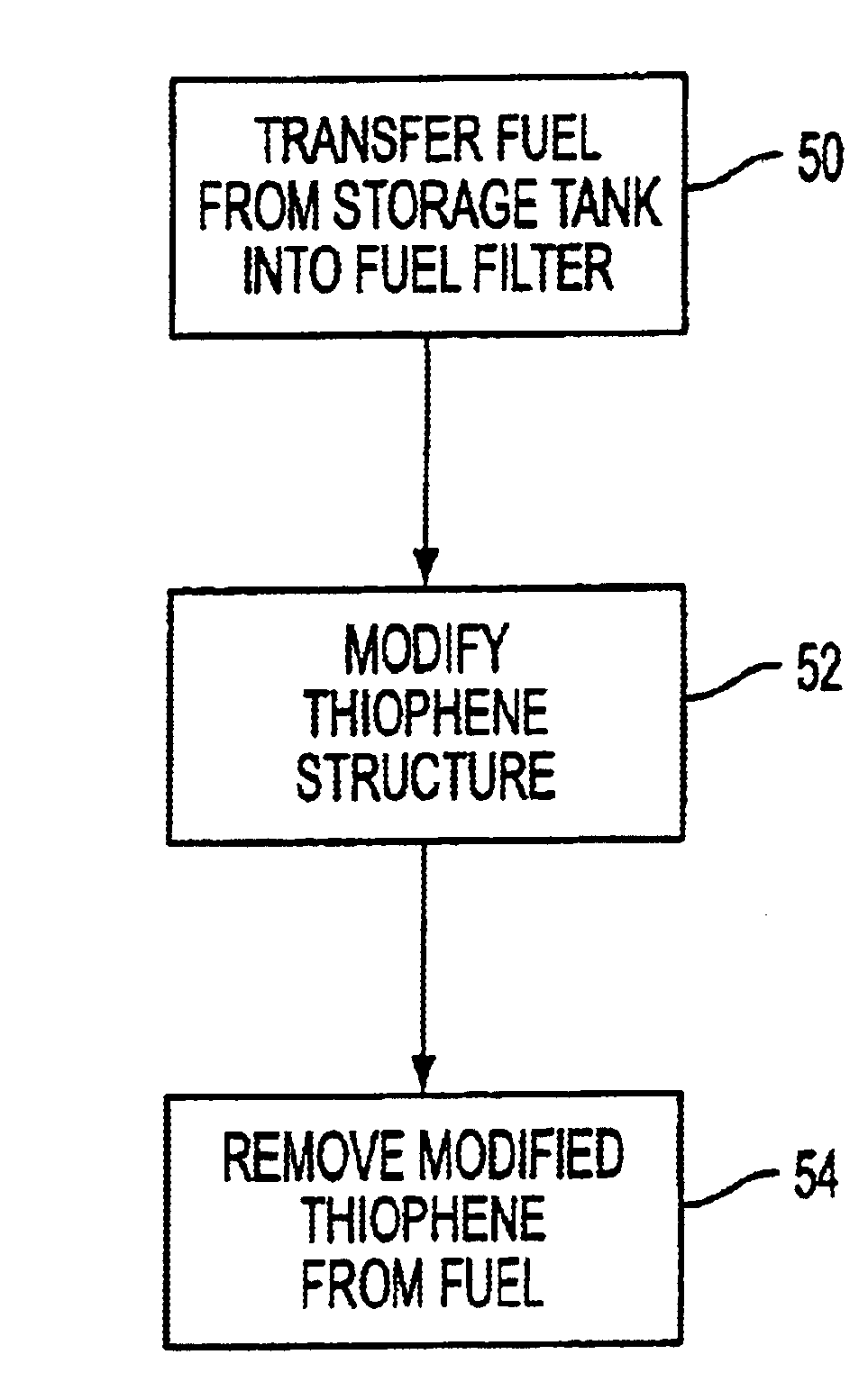

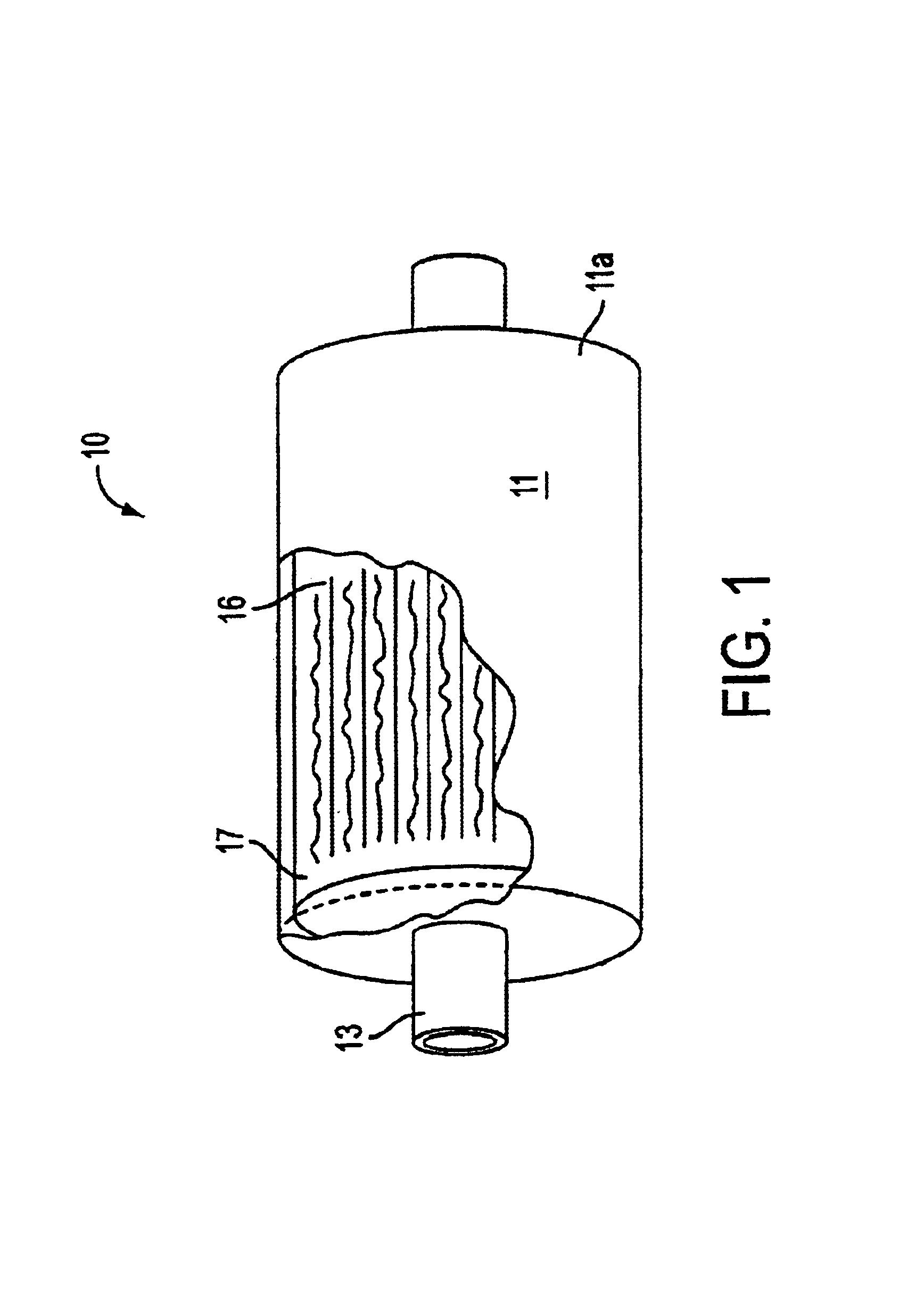

Filter apparatus for removing sulfur-containing compounds from liquid fuels, and methods of using same

InactiveUS6887381B2Reduce concentrationReduce the amount requiredMachines/enginesLoose filtering material filtersFiberSorbent

Owner:FRAM GROUP IP

Desulfurization method and novel sorbents for same

InactiveCN1382201AOctane dropReduce hydrocarbon contentSolid sorbent liquid separationAlkali metal oxides/hydroxidesParticulatesSorbent

Provided is a particulate sorbent composition comprising a zinc titanate support loaded with a promoter metal in a substantially reduced valence state selected from the group consisting of cobalt, nickel, iron, manganese, copper, molybdenum, tungsten, silver, tin and vanadium, or mixtures thereof , for desulfurizing a cracked gasoline or diesel fuel feed stream in a desulfurization zone by contacting said feed stream in a desulfurization zone with a particulate adsorbent composition and then subjecting the resulting low sulfur content The stream is separated from the sulfided sorbent, which is then regenerated and activated before being recycled back to the desulfurization zone.

Owner:CHINA PETROLEUM & CHEM CORP

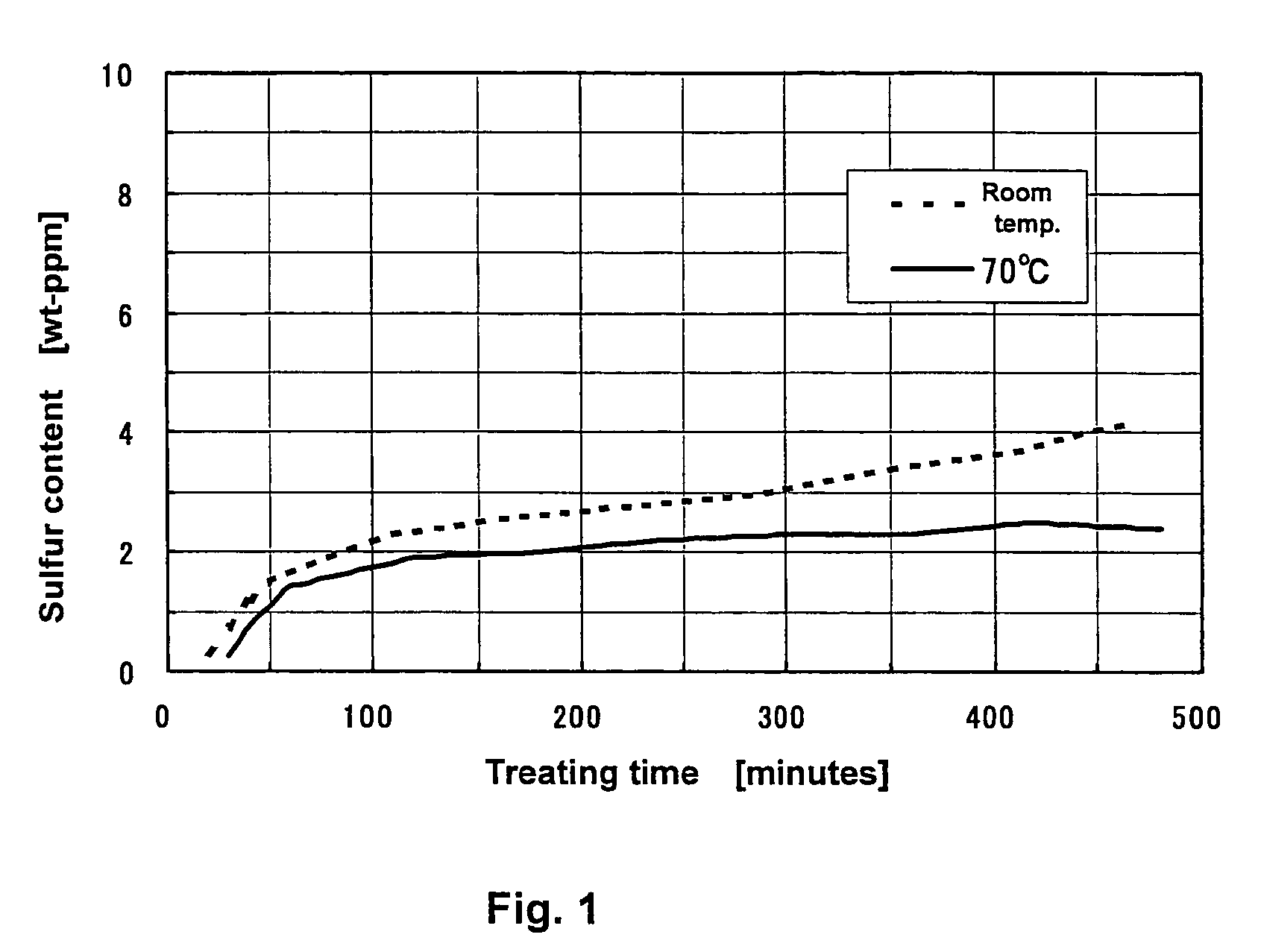

Method of desulfurizing hydrocarbon oil

InactiveUS8021540B2High molecular weightCatalytic naphtha reformingRefining with metal saltsActivated carbonSolid acid

A method of desulfurizing / refining a hydrocarbon oil by which sulfur compounds are diminished to an extremely low concentration at a relatively low equipment cost and operating cost. The method of desulfurizing / refining a hydrocarbon oil comprises bringing a hydrocarbon oil containing at least one sulfur compound selected from the group consisting of thiophene compounds, benzothiophene compounds, and dibenzothiophene compounds and optionally further containing aromatic hydrocarbons into contact with a solid acid catalyst and / or an activated carbon having a transition metal oxide supported thereon to thereby desulfurize the oil. The solid acid catalyst preferably is a solid ultrastrong-acid catalyst selected among sulfuric acid radical / zirconia, sulfuric acid radical / alumina, sulfuric acid radical / tin oxide, sulfuric acid radical / iron oxide, tungstic acid / zirconia, and tungstic acid / tin oxide.

Owner:JAPAN ENERGY CORP

High-accuracy liquid-phase dechlorinating agent and preparation method thereof

ActiveCN105542836AHigh precisionIncrease polarityRefining with metal oxidesHydrocarbon oils treatmentActivated carbonOpen framework

The invention provides a high-accuracy liquid-phase dechlorinating agent. The dechlorinating agent is prepared from the following components in percentage by weight: 5-20 percent of CuO, 5-10 percent of CaO, 4-8 percent of KOH and the balance of modified activated carbon, wherein the modified activated carbon is activated carbon which is subjected to acidification and oxidation. According to the dechlorinating agent, the modified activated carbon is adopted as a carrier, the open-framework structure of the activated carbon can be optimized, the pore volume and specific surface area can be increased, the content of the oxygen-containing functional group on the surface of the activated carbon can be increased, the carrier polarity can be improved, the combination degree between the carrier and the active ingredient can be enhanced, loss of the active ingredient can be reduced, hydrogen chloride which is a polar molecule can be easily and stably adsorbed on the surface of the modified activated carbon having relatively large polarity, and the dechlorinating accuracy can be improved. Furthermore, the reaction activity of the dechlorinating agent and hydrogen chloride can be increased due to the synergistic effect of three active substances in the dechlorinating agent, and maximization of chlorine capacity of the dechlorinating agent can be effectively realized, so that the chlorine capacity of the liquid dechlorinating agent can be more than or equal to 16 percent, and the dechlorinating accuracy is lower than 0.5ppm.

Owner:SHENYANG SANJUKAITE CATALYST

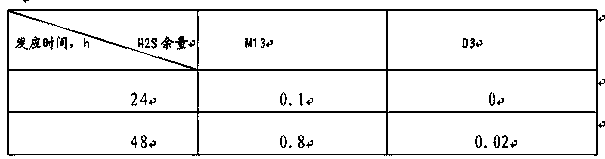

Normal-temperature dearsenic agent as well as preparation method thereof

ActiveCN103566947AGuaranteed arsenic removal activityHigh arsenic removal efficiencyRefining with metal oxidesMetal/metal-oxides/metal-hydroxide catalystsRoom temperatureCopper oxide

The invention relates to a normal-temperature dearsenic agent as well as a preparation method thereof, belonging to the technical field of dearsenic purifying. The normal-temperature dearsenic agent consists of active ingredients and auxiliaries, wherein the auxiliaries are one or more of a binder, a pore-forming agent and an extruding aid; the active ingredients comprise the following components: 40wt%-60wt% of manganese dioxide, 5wt%-15wt% of copper oxide and 5wt%-15wt% of zinc oxide; and content of the auxiliaries is 15wt%-20wt%. In the normal-temperature dearsenic agent disclosed by the invention, the manganese dioxide, the copper oxide and the zinc oxide with proper component content are matched, so that competing reaction of H2S and the copper oxide is restrained, and therefore, a using range of copper-series dearsenic agents is broadened, the copper-series dearsenic agents are enabled to be capable of being suitable for an H2S-contaning substance with arsenic to be removed, dearsenic activity of the dearsenic agent is ensured, dearsenic efficiency is improved, and cost of the dearsenic agent is lowered.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD +1

Method of removing hydrogen sulfide

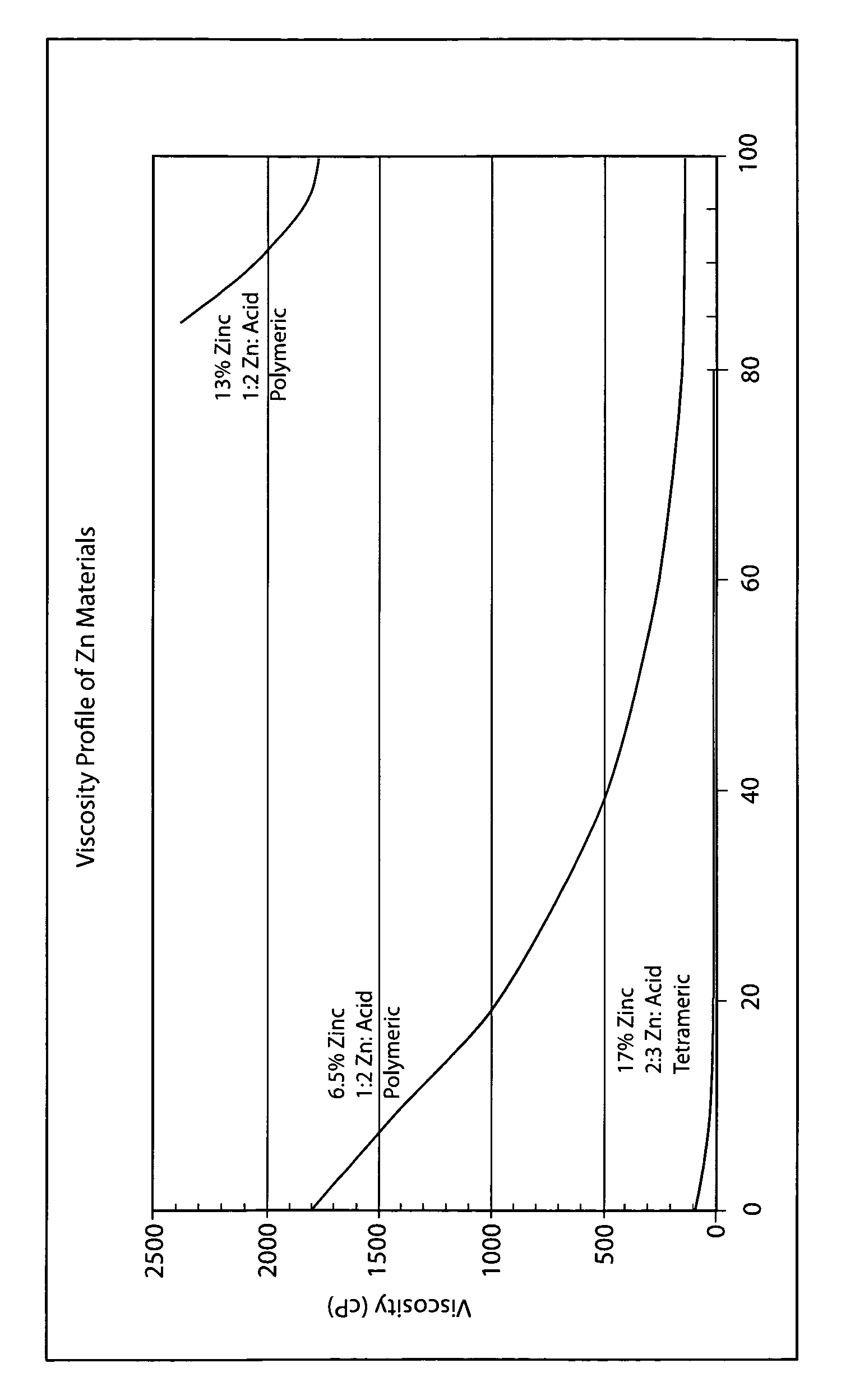

ActiveUS8246813B2Reduce at least 50% of the sulfidesLow viscosityHydrocarbon purification/separationRefining with acid saltsOctanoic AcidsCarboxylic acid

Owner:ECOLAB USA INC

Sorbents for desulfurization

InactiveUS6864215B2Reduced valenceEfficient removalRefining with metalsOther chemical processesOrganic sulfide compoundSorbent

Attrition resistant, sorbent compositions for the removal of elemental sulfur and sulfur compounds, such as hydrogen sulfide and organic sulfides, from cracked-gasoline and diesel fuels are prepared by the impregnation of a sorbent support comprising zinc oxide, expanded perlite, and alumina with a promoter such as nickel, nickel oxide or a precursor of nickel oxide followed by reduction of the valence of the promoter metal in the resulting promoter metal sorbent support composition.

Owner:CHINA PETROCHEMICAL CORP

Oxidatively regenerable adsorbents for sulfur removal

InactiveUS20090065400A1Increase capacityHigh selectivityRare earth metal oxides/hydroxidesGold compoundsSorbentSulfur

Compositions and processes are disclosed for removing sulfur and sulfur compounds from hydrocarbon fuel feedstocks. The feedstock is contacted with a regenerable sorbent such as a compound of the formula TixCeyO2 where 0<x / y≦1 and where 0<x≦1 and 0<y≦1 capable of selectively adsorbing sulfur compounds present in the hydrocarbon feedstock at about 0° C. to about 100° C. such as at about 25° C.

Owner:PENN STATE RES FOUND

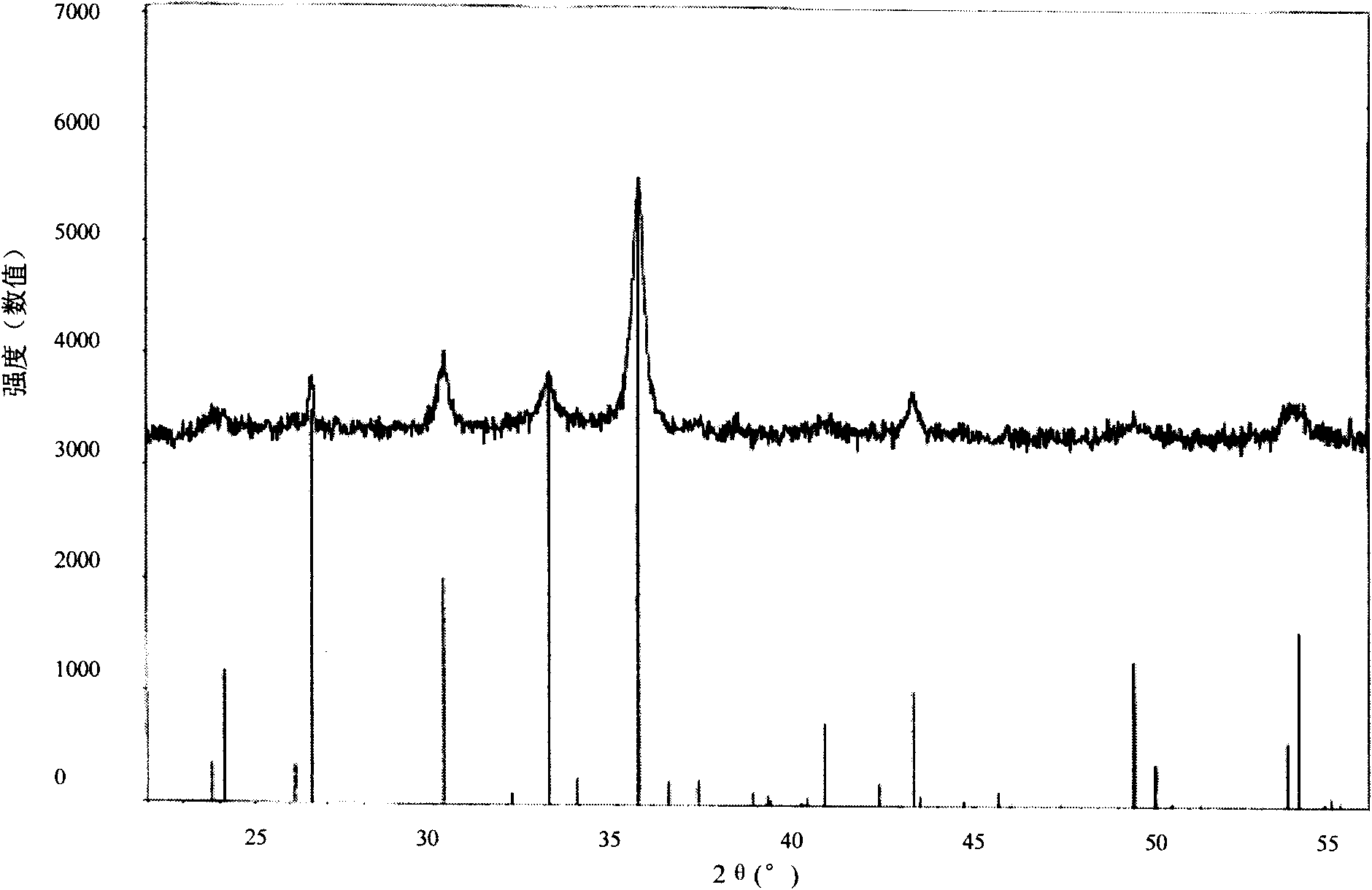

Catalytic compositions useful in removal of sulfur compounds from gaseous hydrocarbons, processes for making these and uses thereof

A catalytic composition is disclosed, which exhibits an X-ray amorphous oxide, with a spinel formula and highly dispersed crystals of ZnO, CuO, and optionally CeO2. The composition is useful in oxidative processes for removing sulfur from gaseous hydrocarbons.

Owner:SAUDI ARABIAN OIL CO +1

Methods and compositions for desulfurization of hydrocarbon fuels

ActiveUS20070175798A1Efficient removalHigh activityTreatment with plural serial cracking stages onlyGas treatmentBoiling pointSulfur

Sulfur is removed from a hydrocarbon fuel via contact with a desulfurization agent; the desulfurization agent is then regenerated (wherein sulfur is released) by exposing it to oxygen. The sulfur removal and regeneration processes each can be carried out at relatively moderate temperatures, e.g., from 300 to 600° C., and pressure, e.g., about 0.79 to about 3.5 MPa; and the desulfurization agent can include a transition metal oxide, such as molybdenum oxide. The process can also include the additional steps of cracking the hydrocarbon, separating high-boiling and low-boiling fractions from the reaction product and contacting the lower-boiling fraction with a secondary desulfurization agent.

Owner:ASPEN PRODS GROUP

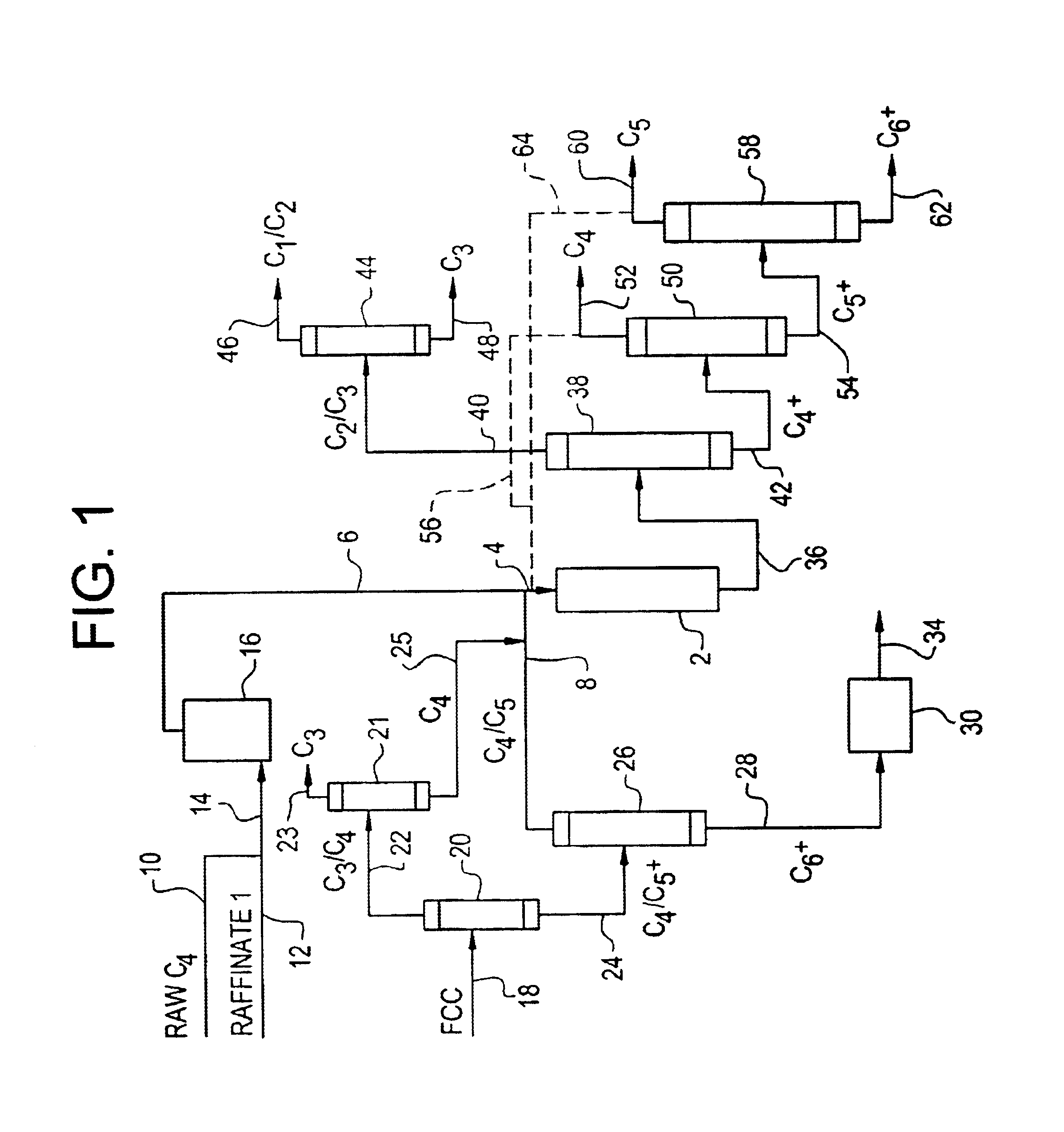

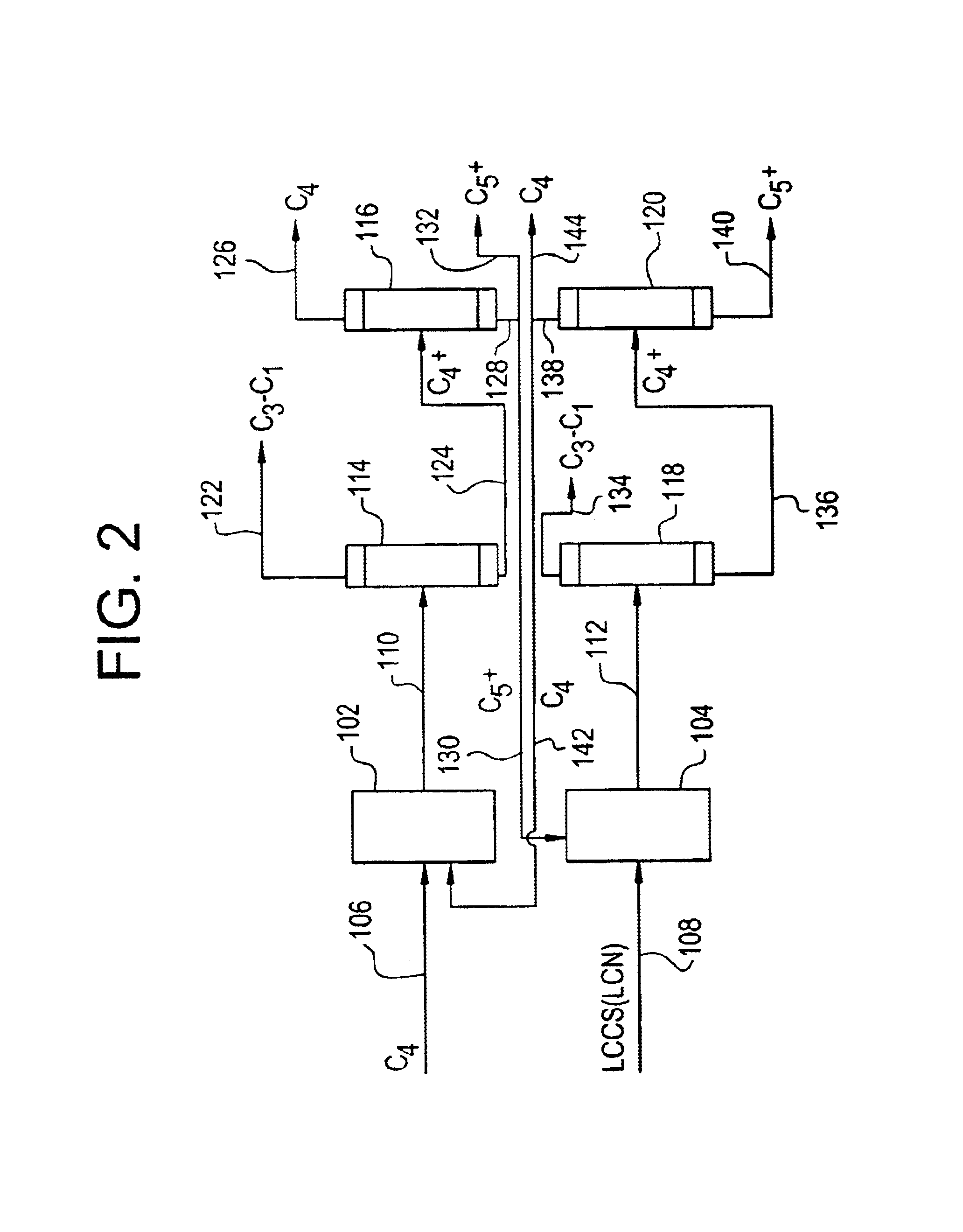

Aromatization method for producing light aromatics

ActiveCN101993320AImprove conversion rateWide variety of sourcesRefining with non-metalsRefining with metalsHydrogenAromatization

The invention relates to an aromatization method for producing light aromatics, which comprises the step of making C4 hydrocarbon and C9+ heavy aromatics which are used as raw materials react with aromatization catalysts at 400 to 600 DEG C through sufficient contact under the condition without hydrogen. The method can greatly improve the yield of the light aromatics, can also reduce the dry gas yield and can provide an economic and effective path of processing remained light aromatics and heavy aromatics resources for the refinery.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for reducing hydrogen sulfide evolution from asphalt and heavy fuel oils

ActiveUS20130092597A1Reducing hydrogen sulfide emissionEfficient reductionRefining with metalsWorking-up pitch/asphalt/bitumen by selective extractionScavengerCarboxylic salt

Hydrogen sulfide evolution from asphalt or heavy fuel oil may be reduced or eliminated using an additive to act as a scavenger. Zinc, in conjunction with an additional metal selected from Fe, Mn, Co, Ni, Cr, Zr, when present in the form of nano-particles of an oxide, borate or carboxylate is an effective component is preventing or mitigating the evolution of hydrogen sulfide. The nano-particles may be used neat or as a dispersion. These metals may also be complexed and used in the form of a solution. Molybdenum, when used with one or both of Fe and Zn is also a useful in any of these forms for the same purpose.

Owner:BAKER HUGHES INC

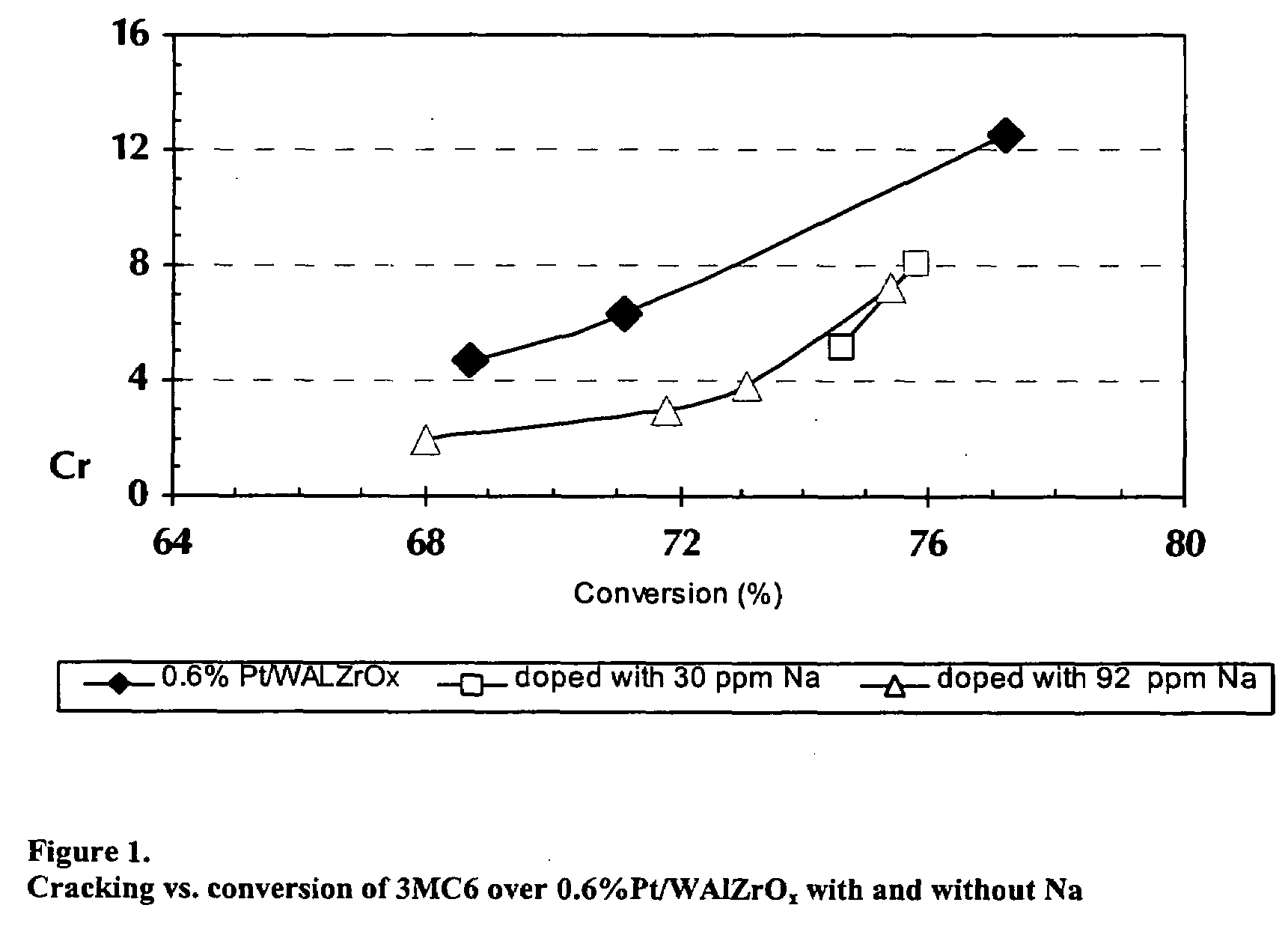

Doped solid acid catalyst composition, process of conversion using same and conversion products thereof

A doped solid acid catalyst composition comprising at least one solid acid catalyst, at least one metal promoter for solid acid catalyst (a), at least one basic dopant for solid acid catalyst (a), at least one noble metal; and, optionally, at least one refractory binder.

Owner:ABB LUMMUS GLOBAL INC

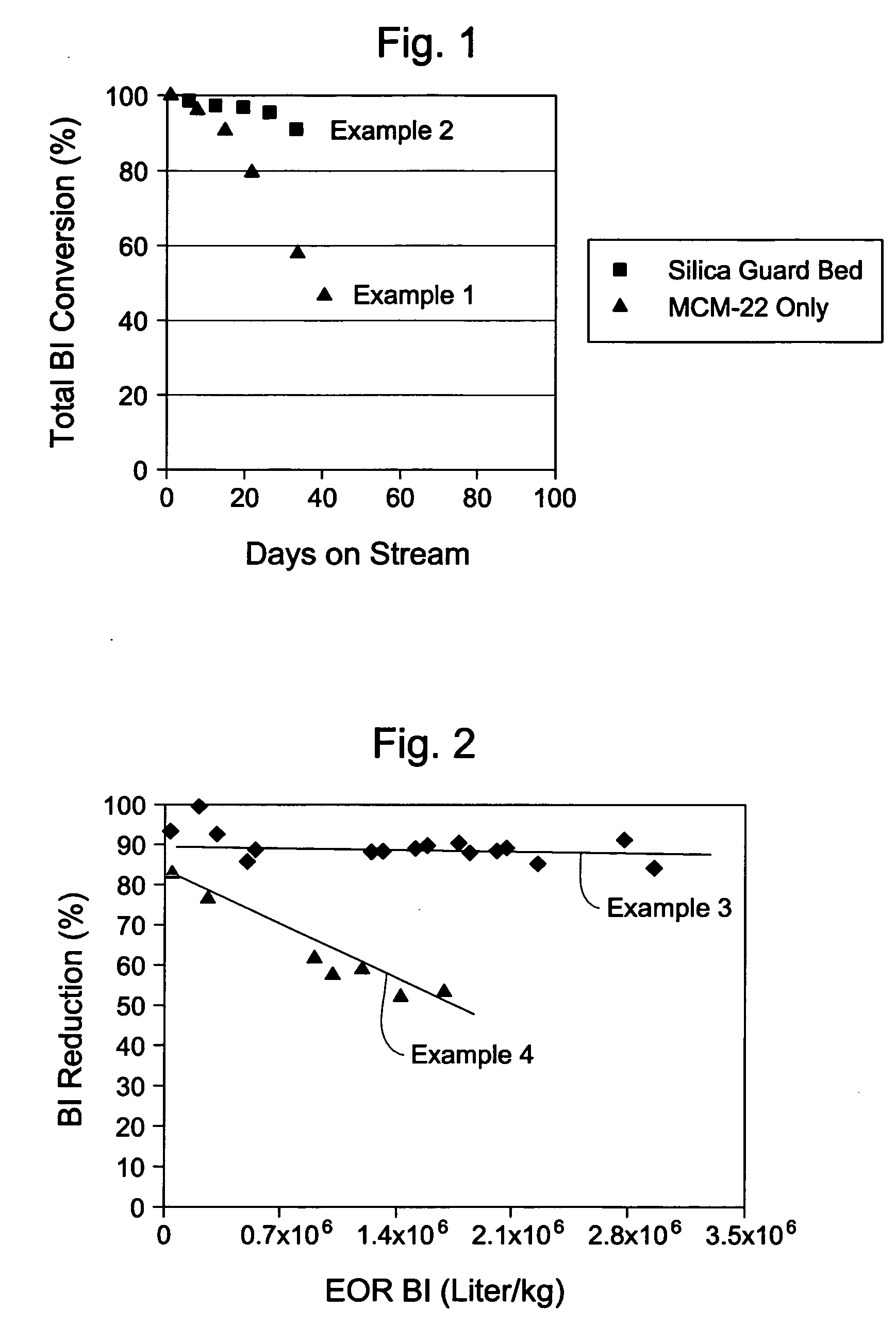

Process for reducing Bromine Index of hydrocarbon feedstocks

InactiveUS20070112240A1Reducing Bromine IndexRefining with non-metalsRefining with metalsMolecular sieveBromine

This invention relates to a process for reducing the Bromine Index of a hydrocarbon feedstock having less than 5 wppm oxygenates-oxygen, comprising the step of contacting the feedstock with a catalyst at conversion conditions to form a first effluent, wherein the catalyst includes a molecular sieve having a zeolite structure type of MWW.

Owner:EXXONMOBIL CHEM PAT INC

Popular searches

Dispersed particle separation Catalyst regeneration/reactivation Silicon compounds Hydrocarbon oils treatment products Liquid carbonaceous fuels Liquid hydrocarbon mixture production Bio-feedstock Refining to eliminate hetero atoms Molecular sieve catalysts Organic-compounds/hydrides/coordination-complexes catalysts

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com