Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

149results about "Refining with non-metals" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

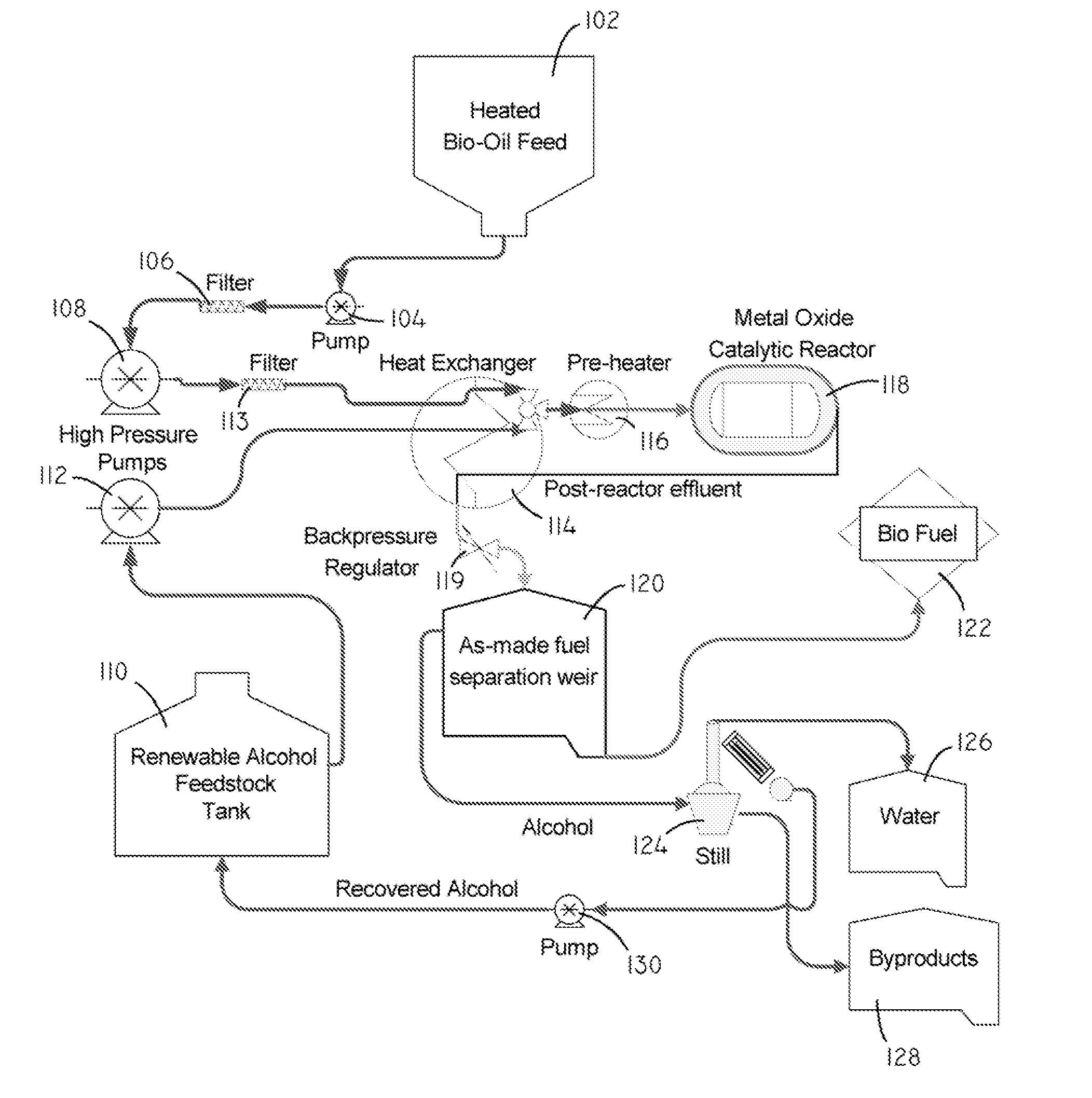

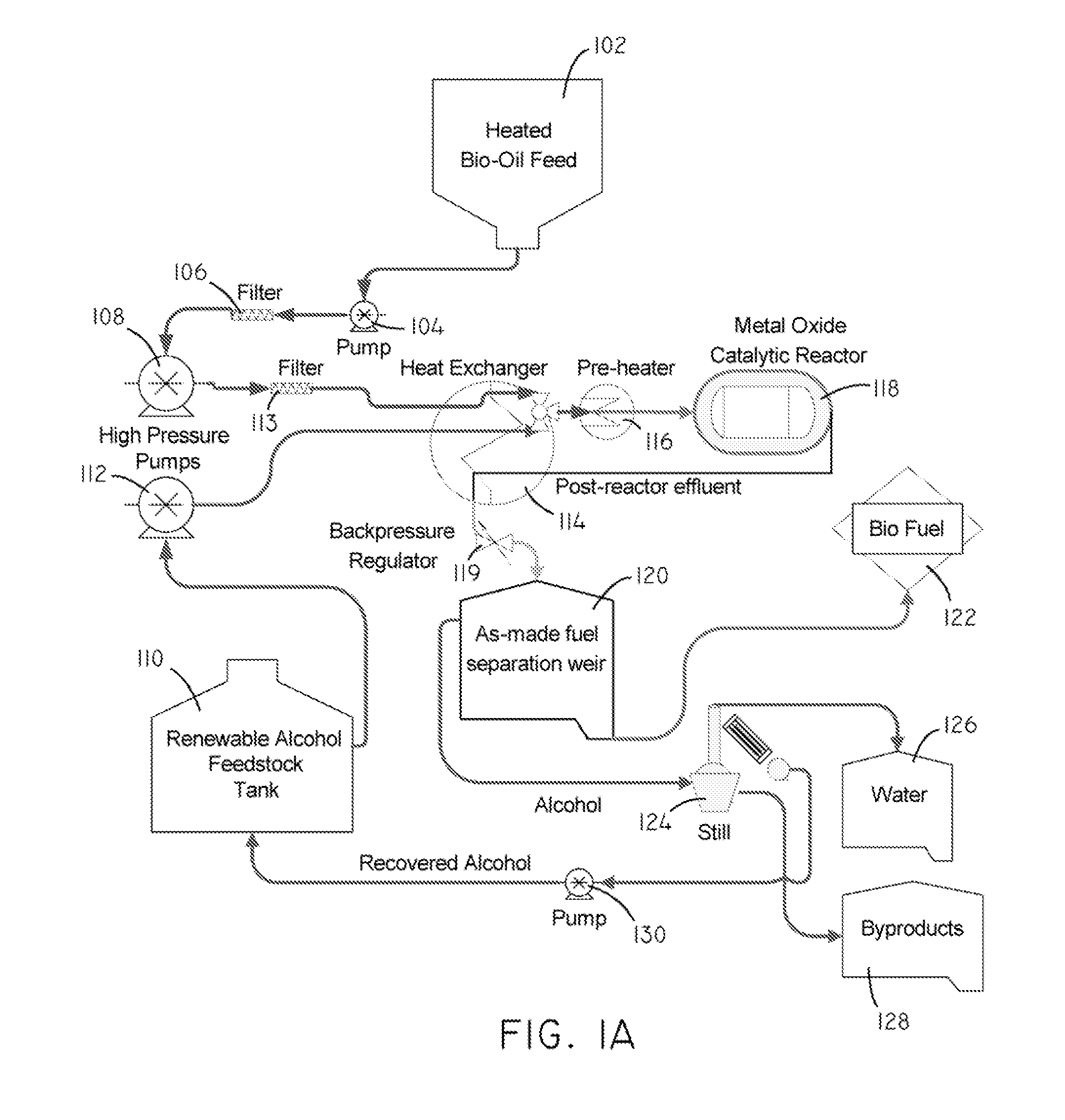

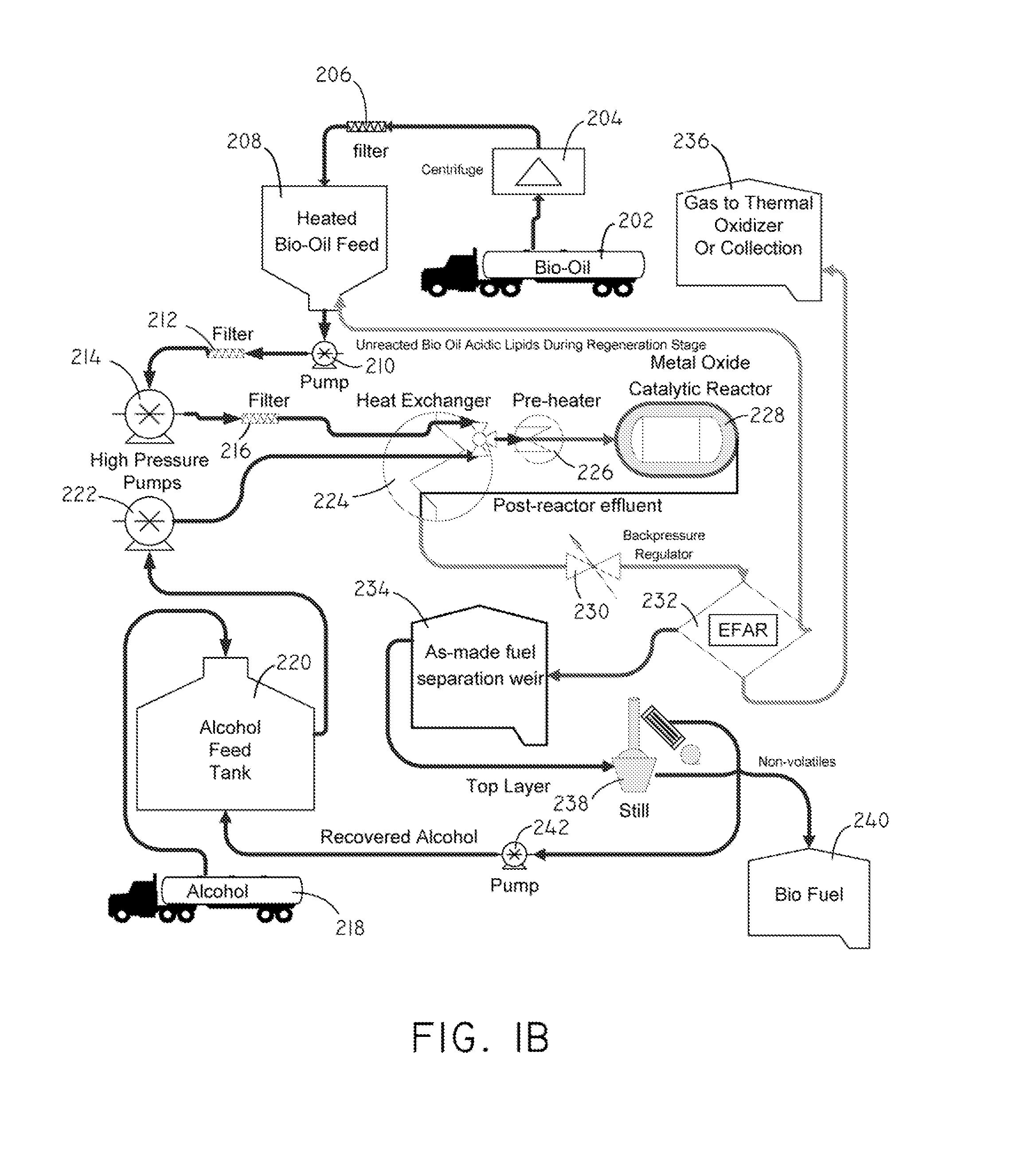

Systems and methods for producing fuels from biomass

The present invention relates to systems and methods for producing fuels. In an embodiment, the invention includes a method of producing a diesel-equivalent fuel, including pyrolyzing biomass to form a pyrolysis oil and contacting the pyrolysis oil and an alcohol with a metal oxide catalyst at a temperature of greater than about 60 degrees Celsius. In an embodiment, the invention includes a method of refining pyrolysis oil including contacting pyrolysis oil and an alcohol with a metal oxide catalyst at a temperature of greater than about 60 degrees Celsius. In an embodiment, the invention includes a system for processing biomass into fuel including a pyrolysis chamber defining an interior volume; a first heating element configured to heat the pyrolysis chamber; a refining chamber in selective fluid communication with the pyrolysis chamber, the refining chamber defining an interior volume, a metal oxide catalyst disposed within the interior volume; and a second heating element configured to heat the refining chamber. Other embodiments are also described herein.

Owner:SARTEC

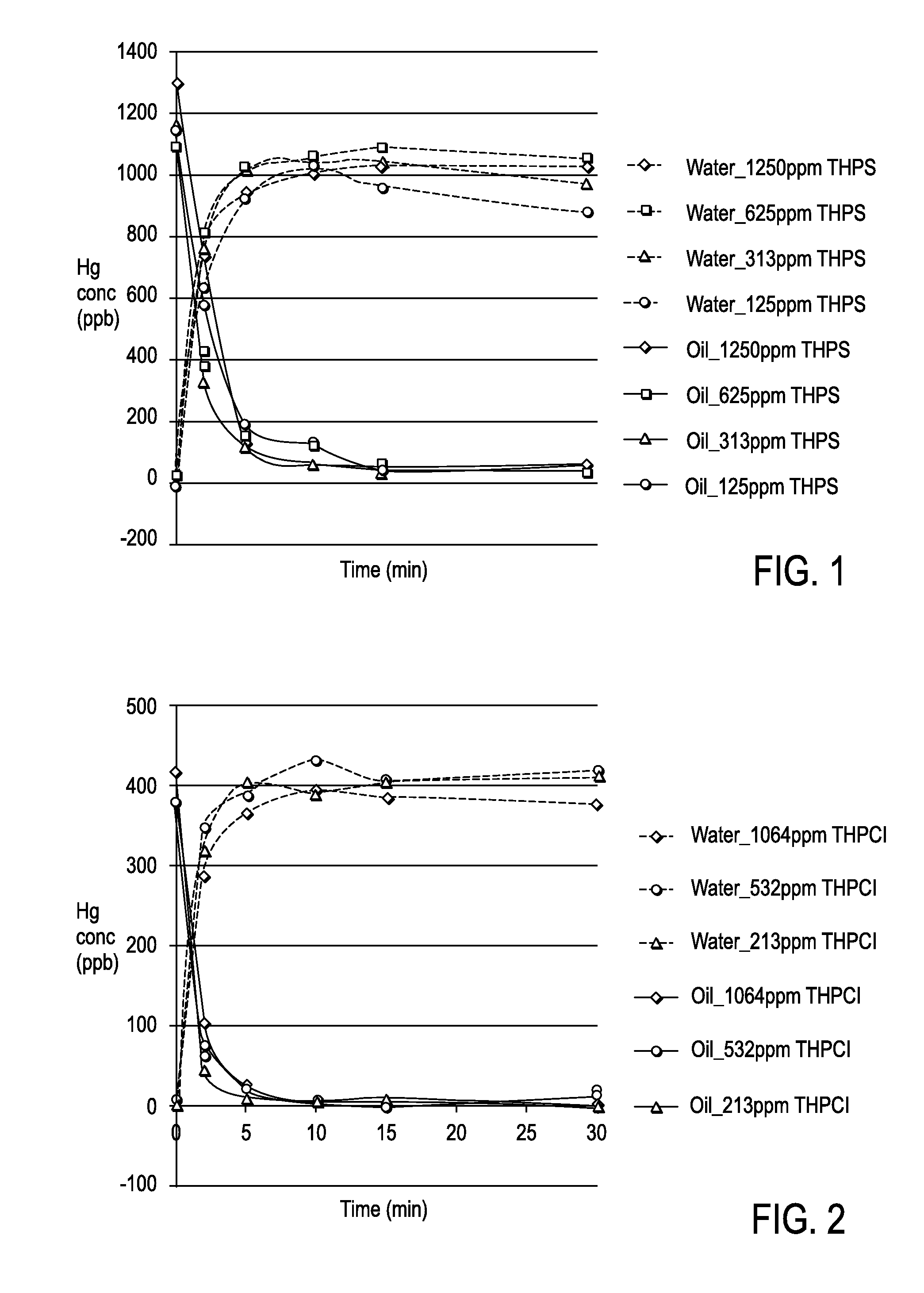

Process for removing mercury from liquid hydrocarbons

InactiveUS6537443B1Reduce concentrationEasy maintenanceRefining with non-metalsRefining with metal saltsParticulatesNatural-gas condensate

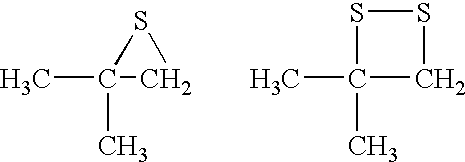

Mercury is removed from crude oils, natural gas condensates and other liquid hydrocarbons by first removing colloidal mercury and solids that contain adsorbed mercury and then treating the hydrocarbons with an organic or inorganic compound containing at least one sulfur atom reactive with mercury. The sulfur compound reacts with dissolved mercury that contaminates the hydrocarbons to form mercury-containing particulates that are then removed from the hydrocarbons to produce a purified product having a reduced mercury content. Preferably, the treating agent is an organic sulfur-containing compound such as a dithiocarbamate or sulfurized isobutylene.

Owner:UNION OIL OF CALIFORNIA

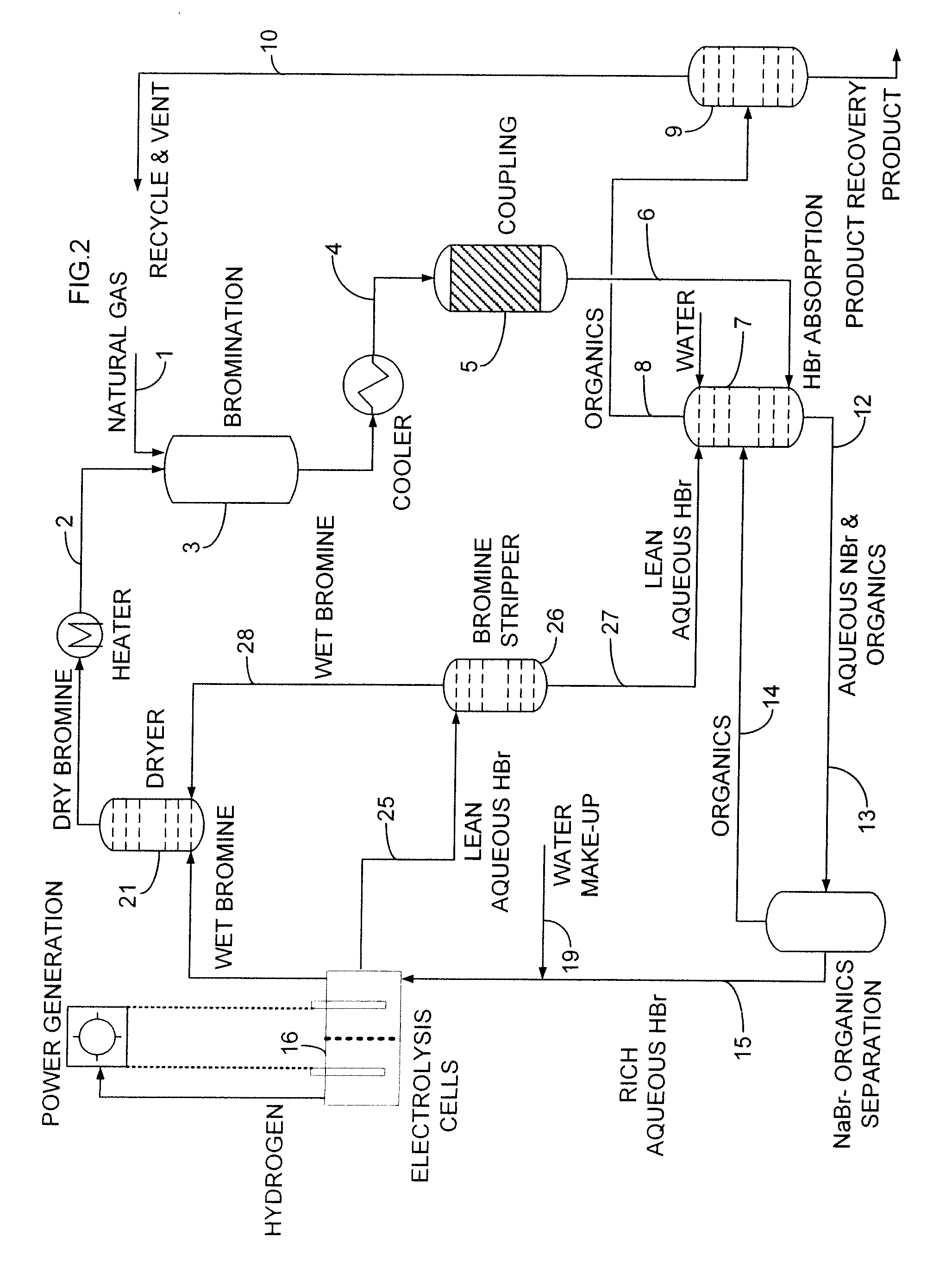

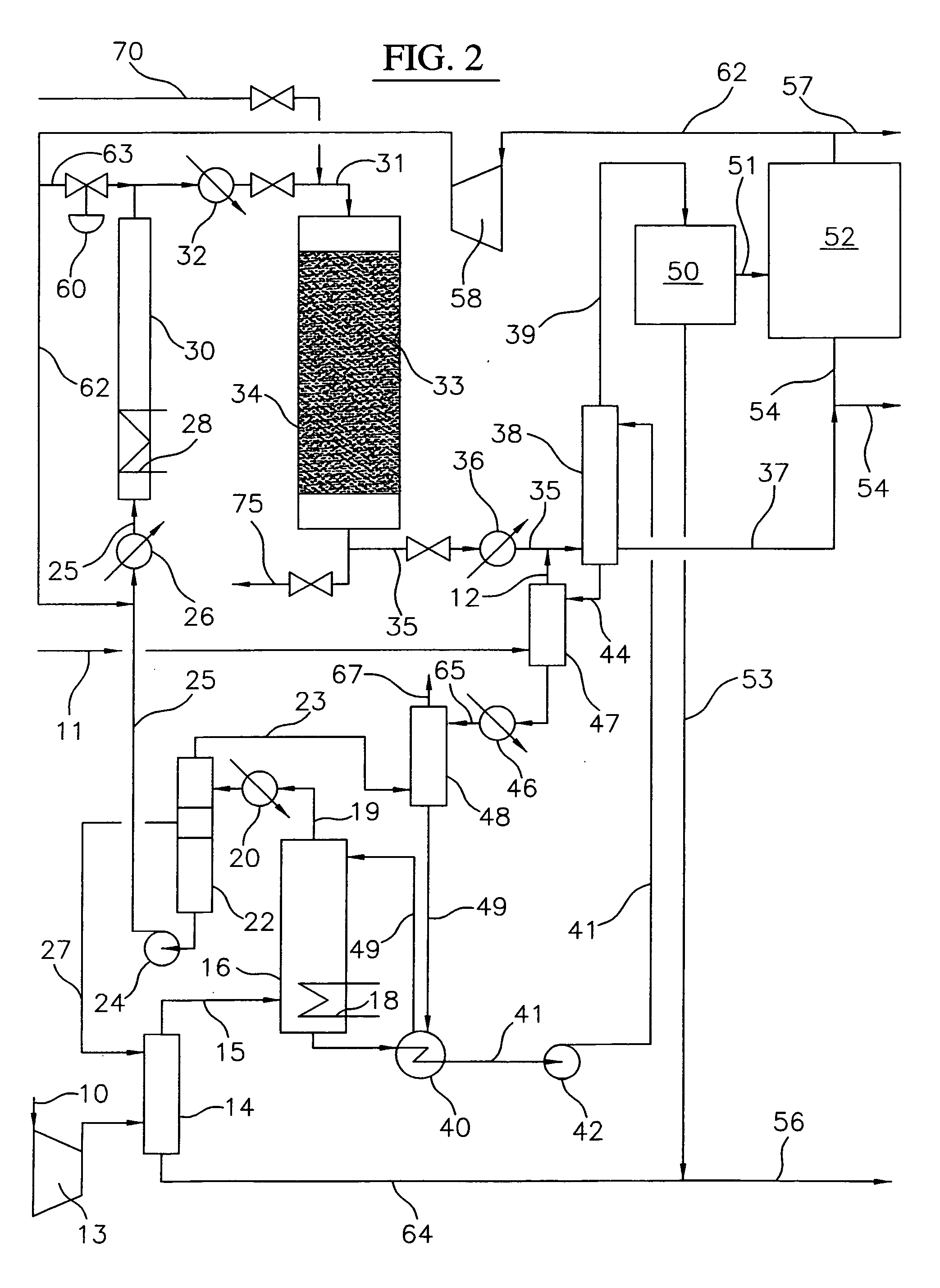

Process for converting hydrocarbon feedstocks with electrolytic recovery of halogen

InactiveUS20080314758A1Improve efficiencyReduced Power RequirementsSolid-state devicesHydroxy compound preparationHalogenHydrocotyle bowlesioides

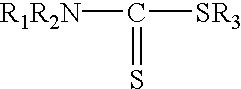

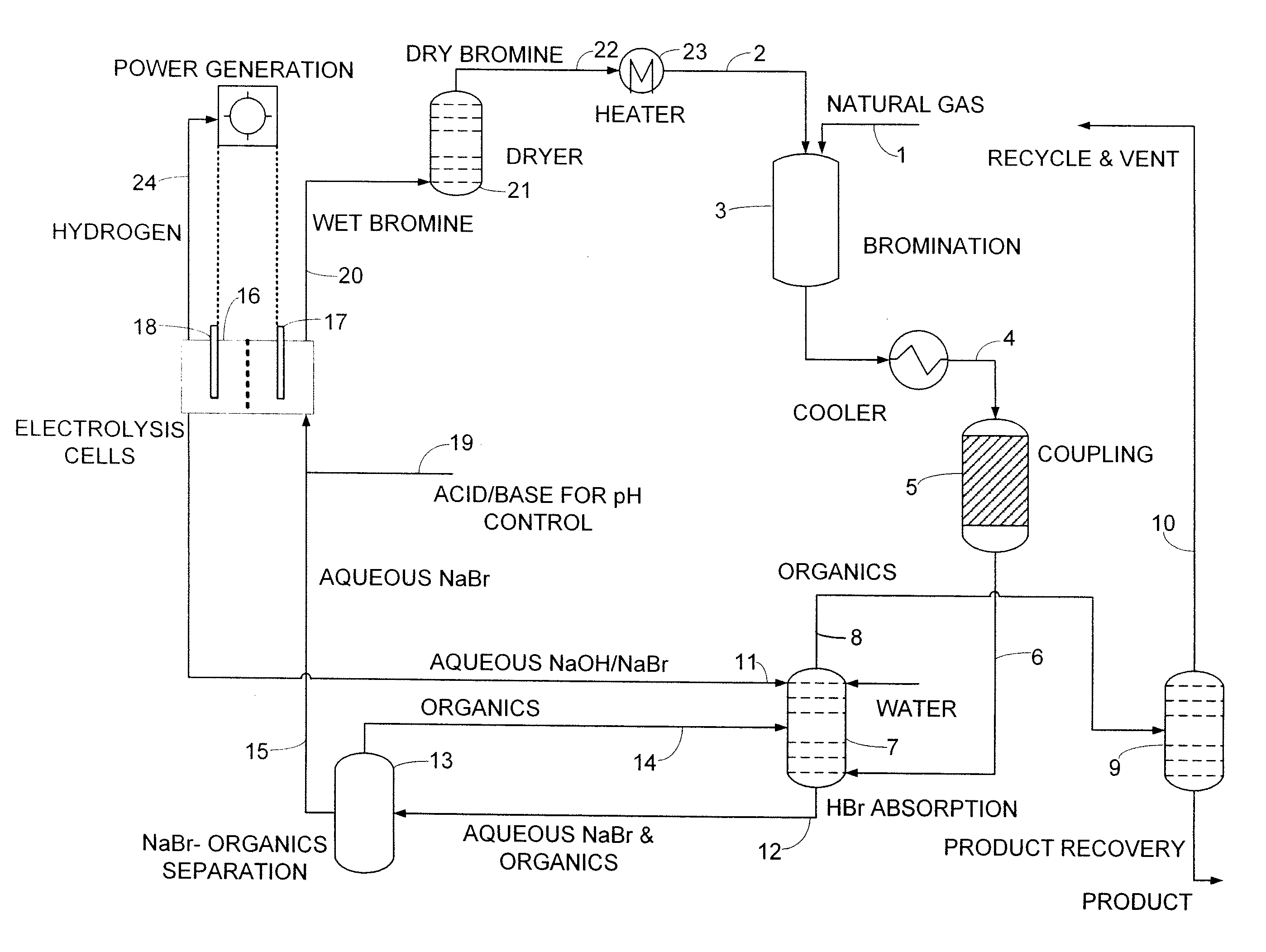

An improved continuous process for converting methane, natural gas, and other hydrocarbon feedstocks into one or more higher hydrocarbons, methanol, amines, or other products comprises continuously cycling through hydrocarbon halogenation, product formation, product separation, and electrolytic regeneration of halogen, optionally using an improved electrolytic cell equipped with an oxygen depolarized cathode.

Owner:REACTION 35 LLC

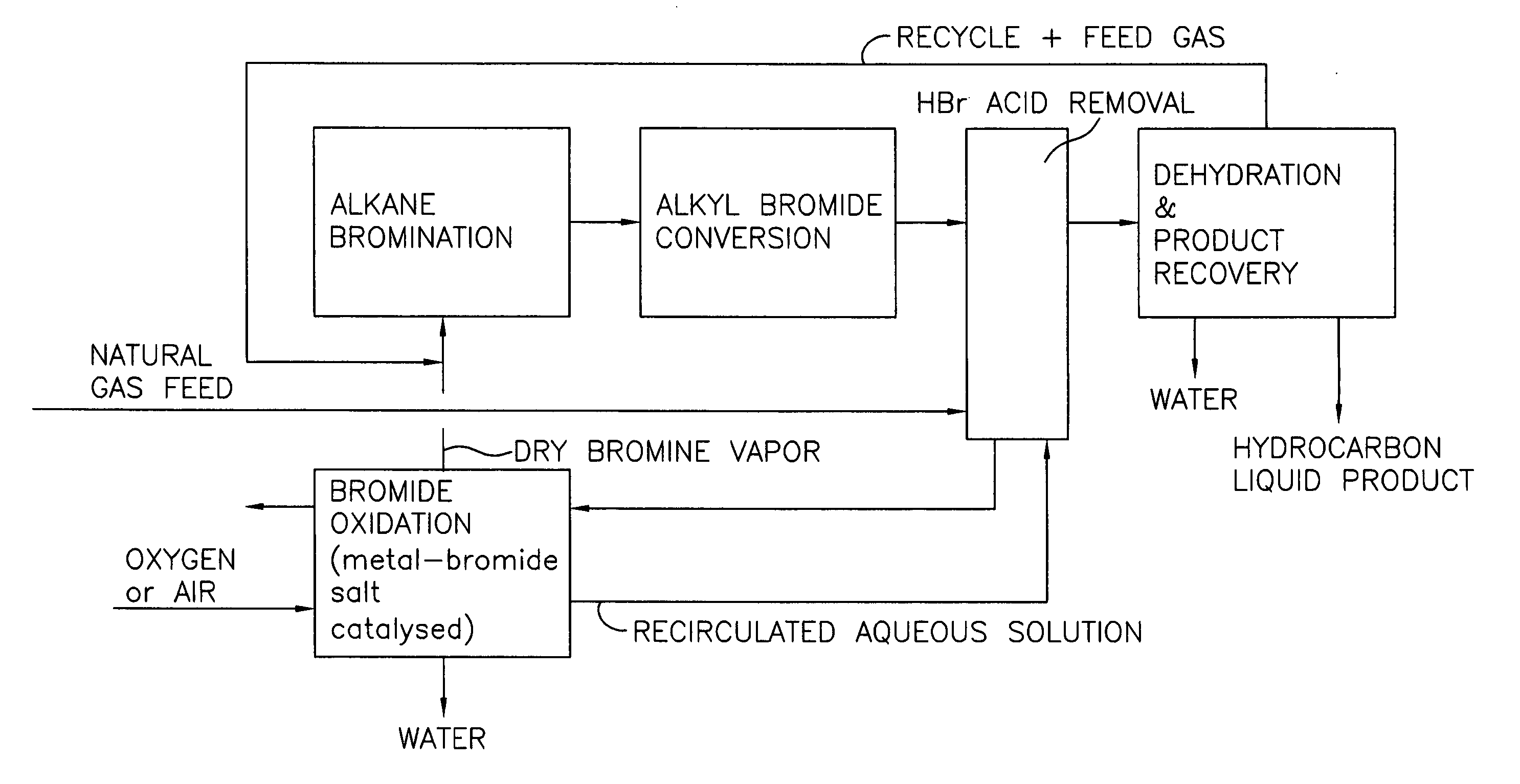

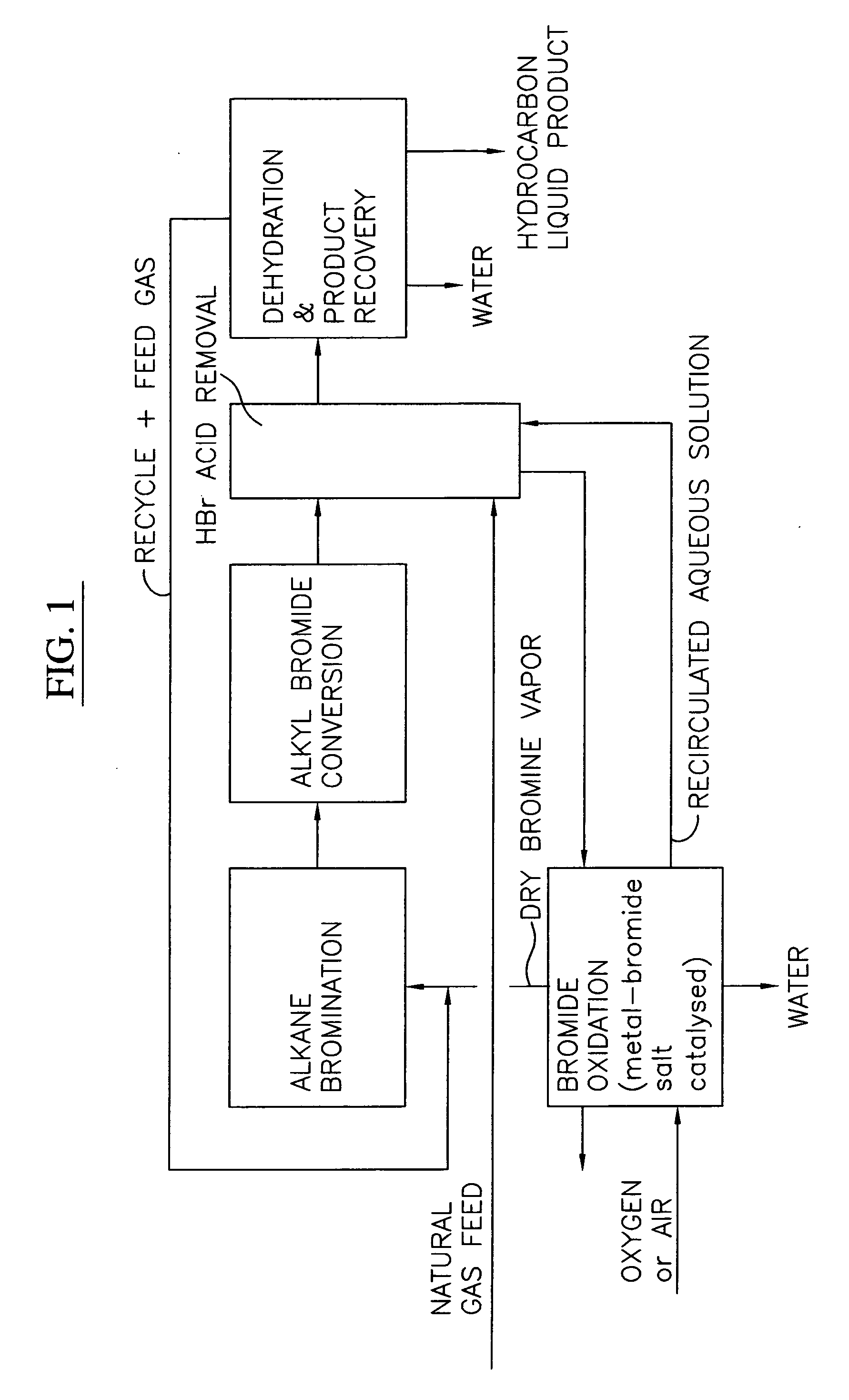

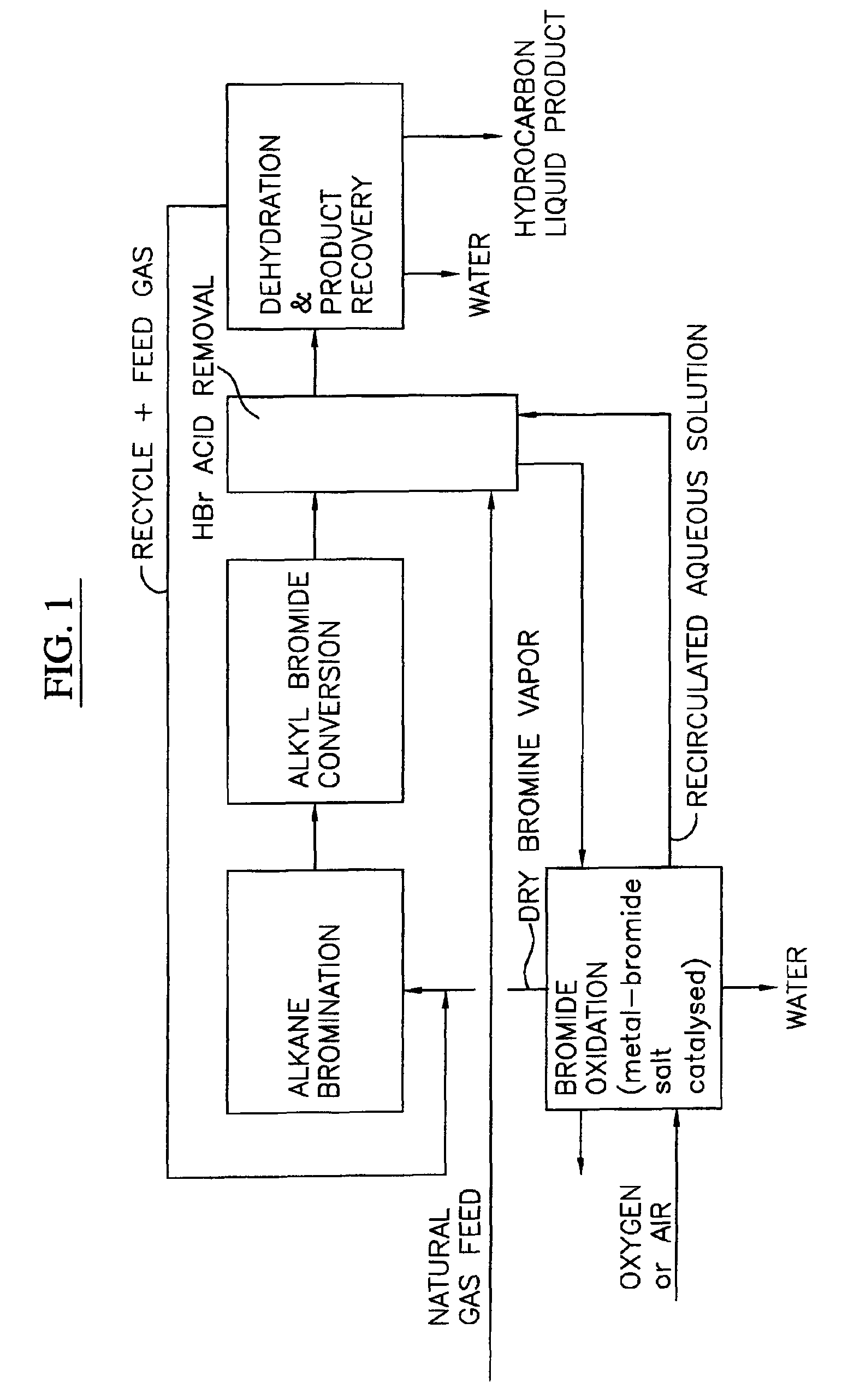

Process for converting gaseous alkanes to olefins and liquid hydrocarbons

InactiveUS20060100469A1High selectivityAvoid disadvantagesBromide preparationRefining with non-metalsAlkaneBromine

A process for converting gaseous alkanes to olefins and liquid hydrocarbons wherein a gaseous feed containing alkanes is reacted with a dry bromine vapor to form alkyl bromides and hydrobromic acid vapor. The mixture of alkyl bromides and hydrobromic acid are then reacted over a synthetic crystalline alumino-silicate catalyst, such as an X or Y type zeolite, at a temperature of from about 250° C. to about 500° C. so as to form olefins, higher molecular weight hydrocarbons and hydrobromic acid vapor. Various methods are disclosed to remove the hydrobromic acid vapor from the higher molecular weight hydrocarbons and to generate bromine from the hydrobromic acid for use in the process.

Owner:MARATHON GTF TECH

Hydrocarbon oil demetalizing agent, and preparing method and use method thereof

InactiveCN1454967AEasy to separateReduce oil contentRefining with non-metalsRefining with acid-containing liquidsPetroleumChemistry

The present invention relates to a hydrocarbon oil demetallization agent, its preparation method and application method. Said hydrocarbon oil demetallization agent comprises demetallization agent, demulsifier and demetallization adjuvant. Its application method includes the following steps: fully mixing hydrocarbon oil demetallization agent or its aqueous solution and hydrocarbon oil according to a certain ratio and adopting conventional electric desalting process to make treatment so as to obtain demetallized hydrocarbon oil. At the same time of desalting it can remove other metal ions of calcium, magnesium, iron, vanadium and nickel, etc. from hydrocarbon oil, so that its oil and water separation effect is good.

Owner:PETROCHINA KARAMAY PETROCHEMICAL CO LTD

Catalysts having selected pore size distributions, method of making such catalysts, methods of producing a crude product, products obtained from such methods, and uses of products obtained

ActiveUS20090255850A1Long useful lifeMinimal hydrogen consumptionRefining with non-metalsRefining with metalsPore diameterPeriodic table

A catalyst and a method of preparation of said catalyst is described herein. The catalyst includes one or more metals from Columns 6-10 of the Periodic Table and / or one or more compounds of one or more metals from Columns 6-10 of the Periodic Table, a pore size distribution with a median pore diameter ranging from 105 Å to 150 Å, with 60% of the total number of pores in the pore size distribution having a pore diameter within 60 Å of the median pore diameter, with at least 50% of its pore volume in pores having a pore diameter of at most 600 Å, and between 5% and 25% of its pore volume in pores having a pore diameter between 1000 Å and 5000 Å. Methods of producing said catalyst are described herein. Crude products and products made from said crude products are described herein.

Owner:SHELL OIL CO

Catalysts having selected pore size distributions, method of making such catalysts, methods of producing a crude product, products obtained from such methods, and uses of products obtained

ActiveUS8114806B2Long useful lifeHigh viscosityRefining with non-metalsLiquid organic insulatorsPore diameterPeriodic table

A catalyst and a method of preparation of said catalyst is described herein. The catalyst includes one or more metals from Columns 6-10 of the Periodic Table and / or one or more compounds of one or more metals from Columns 6-10 of the Periodic Table, a pore size distribution with a median pore diameter ranging from 105 Å to 150 Å, with 60% of the total number of pores in the pore size distribution having a pore diameter within 60 Å of the median pore diameter, with at least 50% of its pore volume in pores having a pore diameter of at most 600 Å, and between 5% and 25% of its pore volume in pores having a pore diameter between 1000 Å and 5000 Å. Methods of producing said catalyst are described herein. Crude products and products made from said crude products are described herein.

Owner:SHELL OIL CO

Desulfurization method and novel sorbents for same

InactiveCN1382201AOctane dropReduce hydrocarbon contentSolid sorbent liquid separationAlkali metal oxides/hydroxidesParticulatesSorbent

Provided is a particulate sorbent composition comprising a zinc titanate support loaded with a promoter metal in a substantially reduced valence state selected from the group consisting of cobalt, nickel, iron, manganese, copper, molybdenum, tungsten, silver, tin and vanadium, or mixtures thereof , for desulfurizing a cracked gasoline or diesel fuel feed stream in a desulfurization zone by contacting said feed stream in a desulfurization zone with a particulate adsorbent composition and then subjecting the resulting low sulfur content The stream is separated from the sulfided sorbent, which is then regenerated and activated before being recycled back to the desulfurization zone.

Owner:CHINA PETROLEUM & CHEM CORP

Process, method, and system for removing heavy metals from fluids

InactiveUS20130306521A1Enhanced surface contactIncrease surface areaRefining with non-metalsRefining with metal saltsThioureaHydrazine compound

Trace amount levels of heavy metals such as mercury in crude oil are reduced by contacting the crude oil with a sufficient amount of a reducing agent to convert at least a portion of the non-volatile mercury into a volatile form of mercury, which can be subsequently removed by any of stripping, scrubbing, adsorption, and combinations thereof. In one embodiment, at least 50% of the mercury is removed. In another embodiment, the removal rate is at least 99%. In one embodiment, the reducing agent is selected from sulfur compounds containing at least one sulfur atom having an oxidation state less than +6; ferrous compounds; stannous compounds; oxalates; cuprous compounds; organic acids which decompose to form CO2 and / or H2 upon heating; hydroxylamine compounds; hydrazine compounds; sodium borohydride; diisobutylaluminium hydride; thiourea; transition metal halides; and mixtures thereof.

Owner:CHEVROU USA INC

Method of converting effluents of renewable origin into fuel of excellent quality by using a molybdenum-based catalyst

ActiveUS20100163458A1Yield maximizationOptimization mechanismRefining with non-metalsMolecular sieve catalystsHydrodeoxygenationActive phase

The invention is concerned with a supported or unsupported catalyst comprising an active phase constituted by a sulfur-containing group VIB element, the group VIB element being molybdenum, and a hydrodeoxygenation process with a yield of hydrodeoxygenation product which is greater than or equal to 90% of charges from renewable sources using a catalyst according to the invention.

Owner:INST FR DU PETROLE

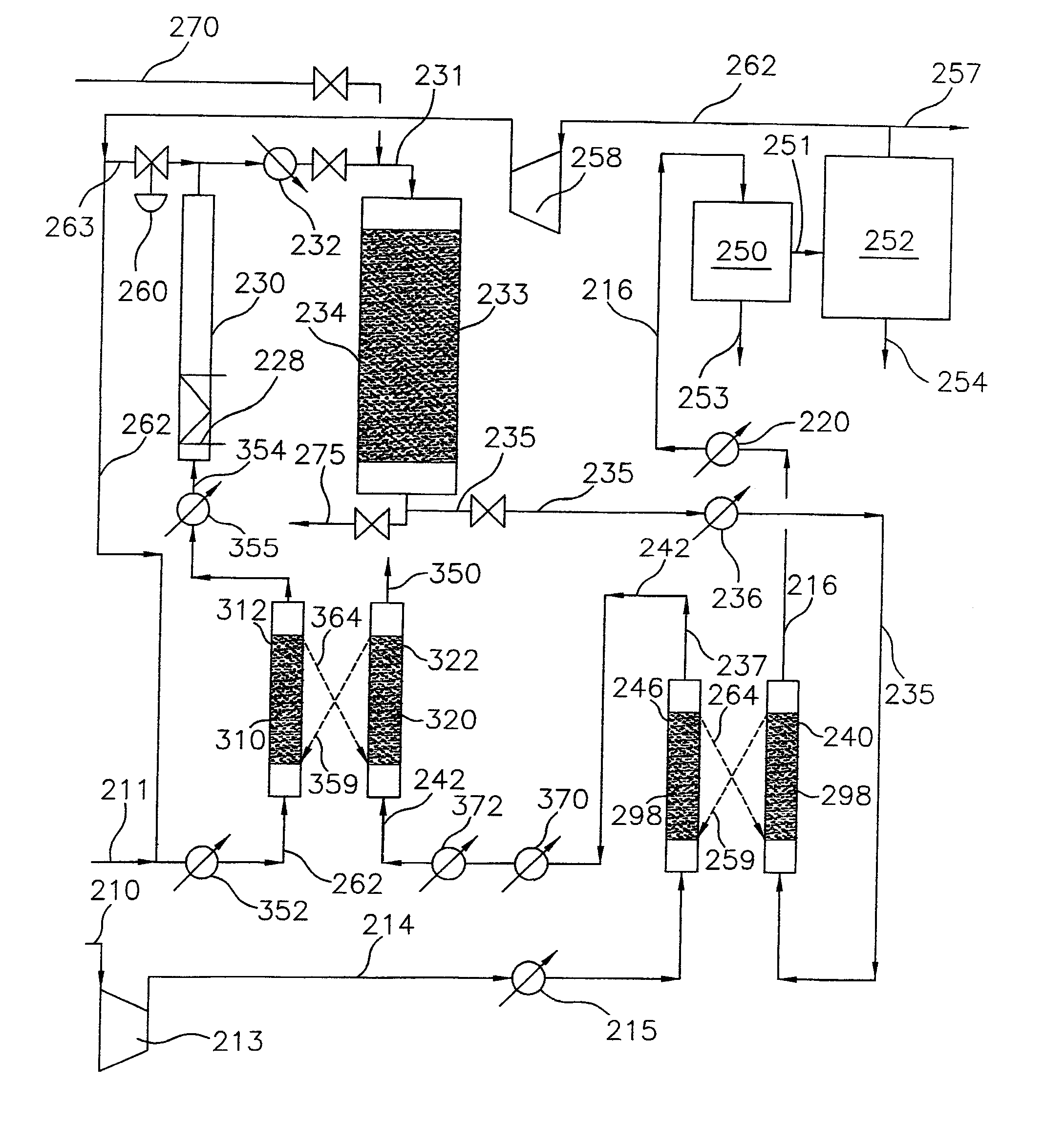

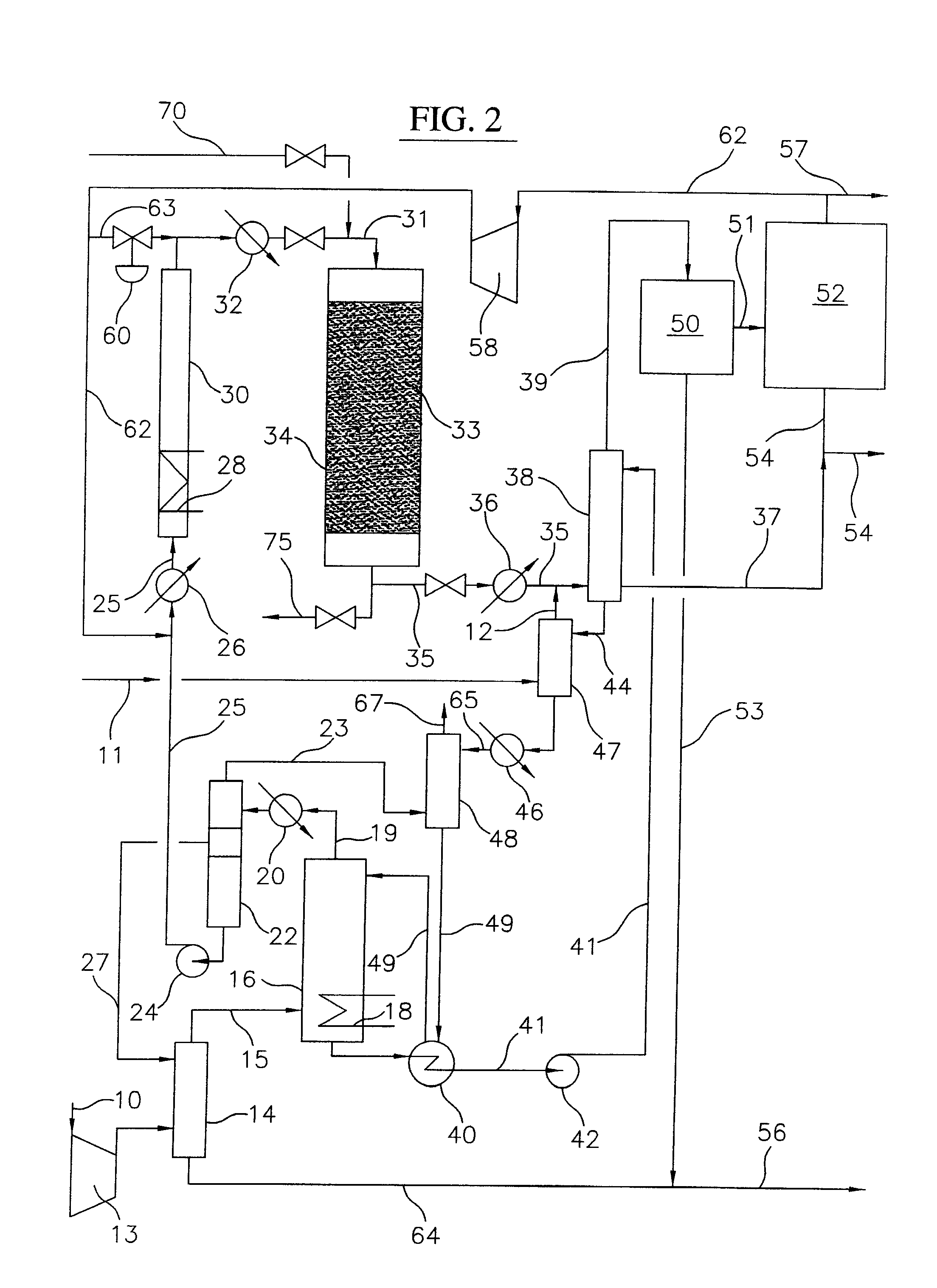

Process for converting gaseous alkanes to olefins and liquid hydrocarbons

ActiveUS20080200740A1High selectivityAvoid disadvantagesHydrogen bromideBromide preparationAlkaneBromine

A process for converting gaseous alkanes to olefins and higher molecular weight hydrocarbons wherein a gaseous feed containing alkanes is reacted with a dry bromine vapor to form alkyl bromides and hydrobromic acid vapor. The mixture of alkyl bromides and hydrobromic acid are then reacted over a synthetic crystalline alumino-silicate catalyst, such as an X or Y type zeolite, at a temperature of from about 250° C. to about 500° C. so as to form olefins, higher molecular weight hydrocarbons and hydrobromic acid vapor. Various methods are disclosed to remove the hydrobromic acid vapor from the higher molecular weight hydrocarbons and to generate bromine from the hydrobromic acid for use in the process.

Owner:SULZER MANAGEMENT AG

Method of converting effluents of renewable origin into fuel of excellent quality by using a molybdenum-based catalyst

ActiveUS8546626B2Lightweight productionControl crackingRefining with non-metalsMolecular sieve catalystsHydrodeoxygenationActive phase

The invention is concerned with a supported or unsupported catalyst comprising an active phase constituted by a sulfur-containing group VIB element, the group VIB element being molybdenum, and a hydrodeoxygenation process with a yield of hydrodeoxygenation product which is greater than or equal to 90% of charges from renewable sources using a catalyst according to the invention.

Owner:INST FR DU PETROLE

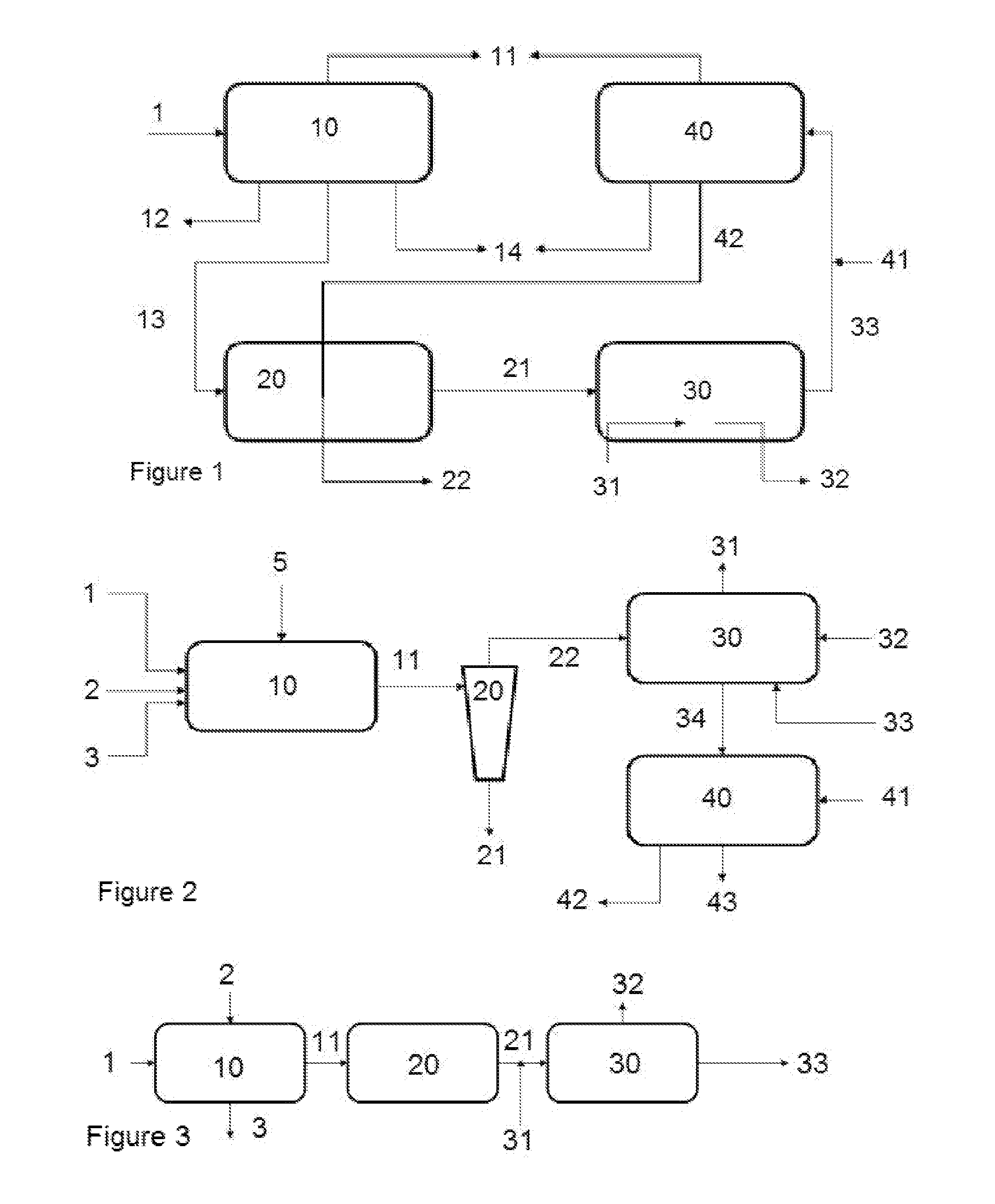

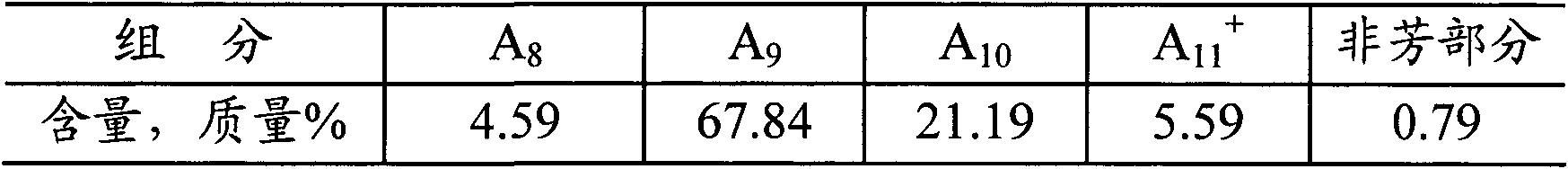

Aromatization method for producing light aromatics

ActiveCN101993320AImprove conversion rateWide variety of sourcesRefining with non-metalsRefining with metalsHydrogenAromatization

The invention relates to an aromatization method for producing light aromatics, which comprises the step of making C4 hydrocarbon and C9+ heavy aromatics which are used as raw materials react with aromatization catalysts at 400 to 600 DEG C through sufficient contact under the condition without hydrogen. The method can greatly improve the yield of the light aromatics, can also reduce the dry gas yield and can provide an economic and effective path of processing remained light aromatics and heavy aromatics resources for the refinery.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for Removing Nickel and Vanadium From Hydrocarbons

Nickel and / or vanadium can be removed or transferred from a hydrocarbon phase to a water phase using an Extractant Composition selected from an isocyanate, a thiocyanate, a cyanides, mercaptides, nitrites, and mixtures thereof. The Extractant Composition may also include at least one mineral acid, a solvent, and other additives. The invention permits transfer of vanadium and nickel from a hydrocarbon into an aqueous phase with little or no hydrocarbon phase undercarry into the aqueous phase. The composition is particularly useful in treating crude oil.

Owner:BAKER HUGHES INC

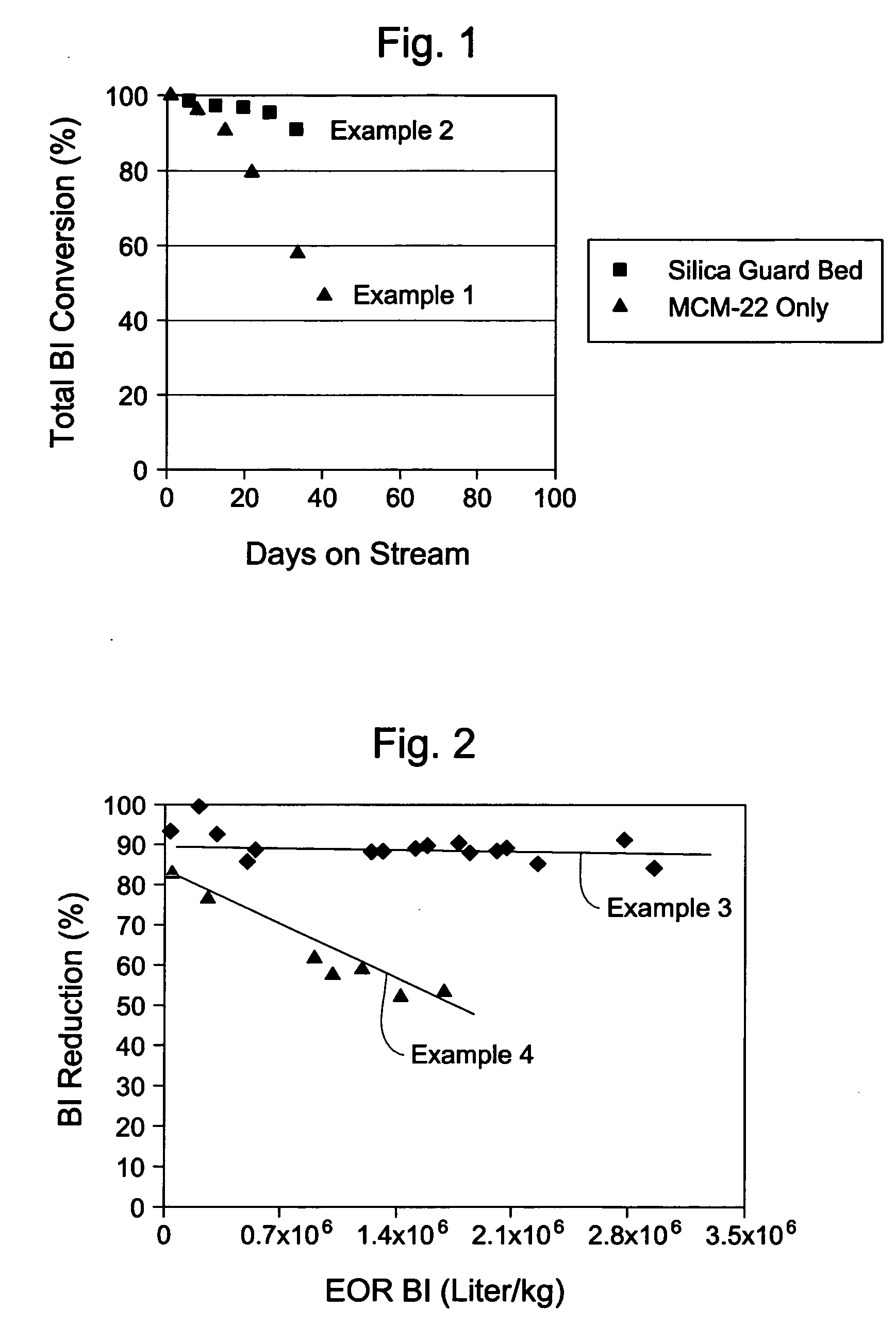

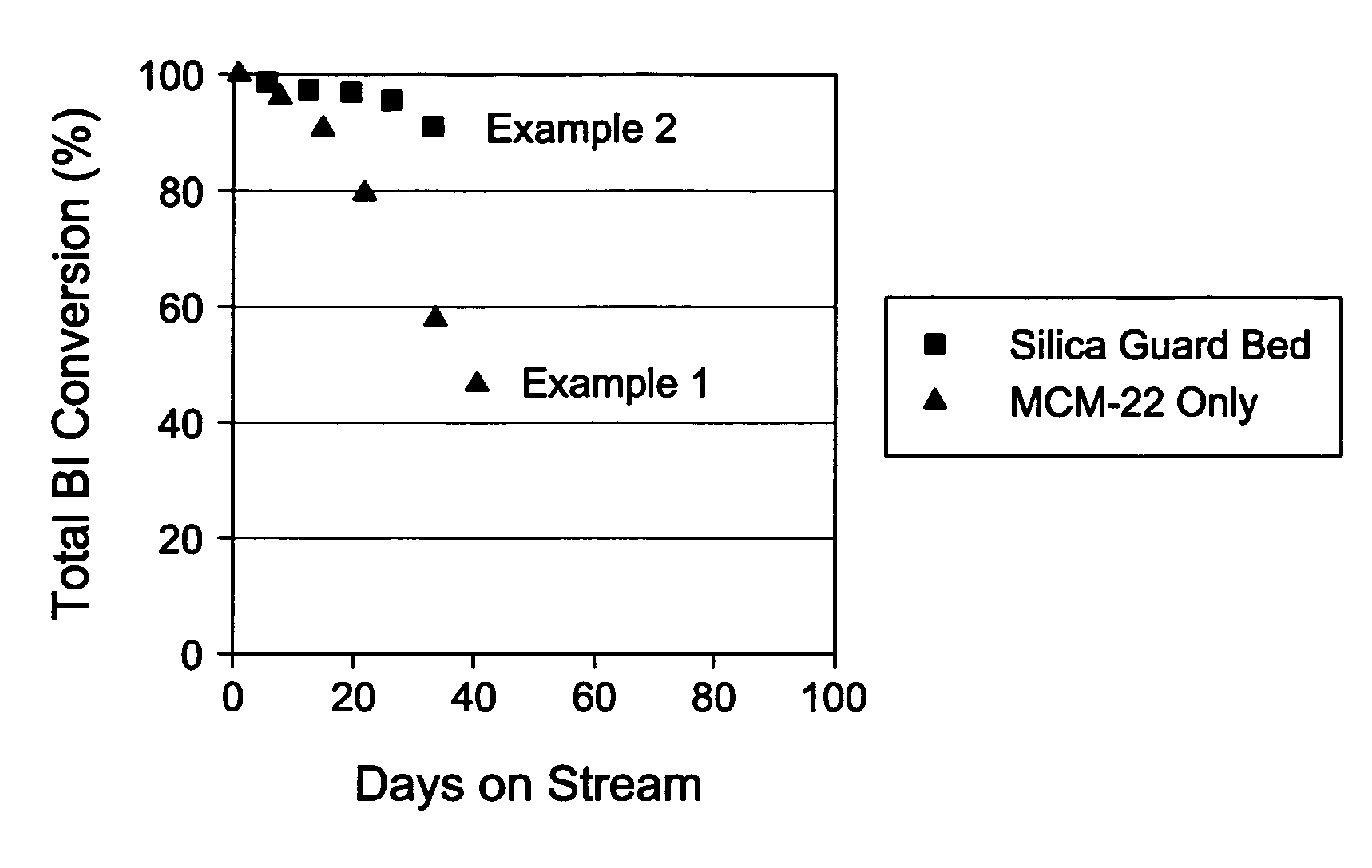

Process for reducing Bromine Index of hydrocarbon feedstocks

InactiveUS20070112240A1Reducing Bromine IndexRefining with non-metalsRefining with metalsMolecular sieveBromine

This invention relates to a process for reducing the Bromine Index of a hydrocarbon feedstock having less than 5 wppm oxygenates-oxygen, comprising the step of contacting the feedstock with a catalyst at conversion conditions to form a first effluent, wherein the catalyst includes a molecular sieve having a zeolite structure type of MWW.

Owner:EXXONMOBIL CHEM PAT INC

Method and system for controlling the amount of Anti-fouling additive for particulate-induced fouling mitigation in refining operations

InactiveUS20100163461A1Reducing particulate-induced foulingImprove efficiencyThermal non-catalytic crackingRefining with non-metalsParticulatesFouling mitigation

A method and system for controlling fouling in a hydrocarbon refining process that includes measuring a level of a particulate in a process stream of the hydrocarbon refining process in communication with a hydrocarbon refinery component, identifying an effective amount of additive capable of reducing particulate-induced fouling based at least in part on the measured level of the particulate in the process stream, and introducing the effective amount of additive to the hydrocarbon refining process.

Owner:WRIGHT CHRIS A +5

Process for reducing Bromine Index of hydrocarbon feedstocks

This invention relates to a process for reducing the Bromine Index of a hydrocarbon feedstock having less than 5 wppm oxygenates-oxygen, comprising the step of contacting the feedstock with a catalyst at conversion conditions to form a first effluent, wherein the catalyst includes a molecular sieve having a zeolite structure type of MWW.

Owner:EXXONMOBIL CHEM PAT INC

Process, method, and system for removing heavy metals from fluids

InactiveUS20120067786A1Mercury is reducedReduce its mercury concentrationRefining with non-metalsRefining with halogen compoundsRedoxWater soluble

Trace element levels of heavy metals such as mercury in crude oil are reduced by contacting the crude oil with an iodine source, generating a water soluble heavy metal complex for subsequent removal from the crude oil. In one embodiment, the iodine source is generated in-situ in an oxidation-reduction reaction, by adding the crude oil to an iodine species having a charge and a reductant or an oxidant depending on the charge of the iodine species. In one embodiment with an iodine species having a positive charge and a reducing reagent, a complexing agent is also added to the crude oil to extract the heavy metal complex into the water phase to form water soluble heavy metal complexes which can be separated from the crude oil, for a treated crude oil having reduced levels of heavy metals.

Owner:CHEVROU USA INC

Gel assisted separation method and dewatering/desalting hydrocarbon oils

InactiveUS20060016727A1Refining with non-metalsDewatering/demulsification with chemical meansChemistryHydrocarbon

A method for separating polar hydrocarbon compounds from a hydrocarbon oil containing polar hydrocarbon compounds comprising the steps of: a) forming a gel in the hydrocarbon oil, and thereafter b) separating the gel from the hydrocarbon oil to produce a separated gel and a separated hydrocarbon oil.

Owner:EXXON RES & ENG CO

Method for determining the effectiveness of asphaltene dispersant additives for inhibiting or preventing asphaltene precipitation in a hydrocarbon-containing material subjected to elevated temperature and pressure conditions

ActiveUS20140130581A1High trafficReduce dirtRefining with non-metalsWorking-up pitch/asphalt/bitumen by selective extractionAsphaltene precipitationHigh pressure

Disclosed herein is a method for determining the effectiveness of one or more asphaltene dispersant additives for inhibiting or preventing asphaltene precipitation in a hydrocarbon-containing material subjected to elevated temperature and pressure conditions.

Owner:CHEVROU USA INC

Process for converting gaseous alkanes to olefins and liquid hydrocarbons

ActiveUS8008535B2High selectivityAvoid disadvantagesBromide preparationHydrogen bromideAlkaneAlkyl bromide

A process for converting gaseous alkanes to olefins and higher molecular weight hydrocarbons wherein a gaseous feed containing alkanes is reacted with a dry bromine vapor to form alkyl bromides and hydrobromic acid vapor. The mixture of alkyl bromides and hydrobromic acid are then reacted over a synthetic crystalline alumino-silicate catalyst, such as an X or Y type zeolite, at a temperature of from about 250° C. to about 500° C. so as to form olefins, higher molecular weight hydrocarbons and hydrobromic acid vapor. Various methods are disclosed to remove the hydrobromic acid vapor from the olefins and higher molecular weight hydrocarbons and to generate bromine from the hydrobromic acid for use in the process.

Owner:SULZER MANAGEMENT AG

Process, method, and system for removing heavy metals from fluids

Owner:CHEVROU USA INC

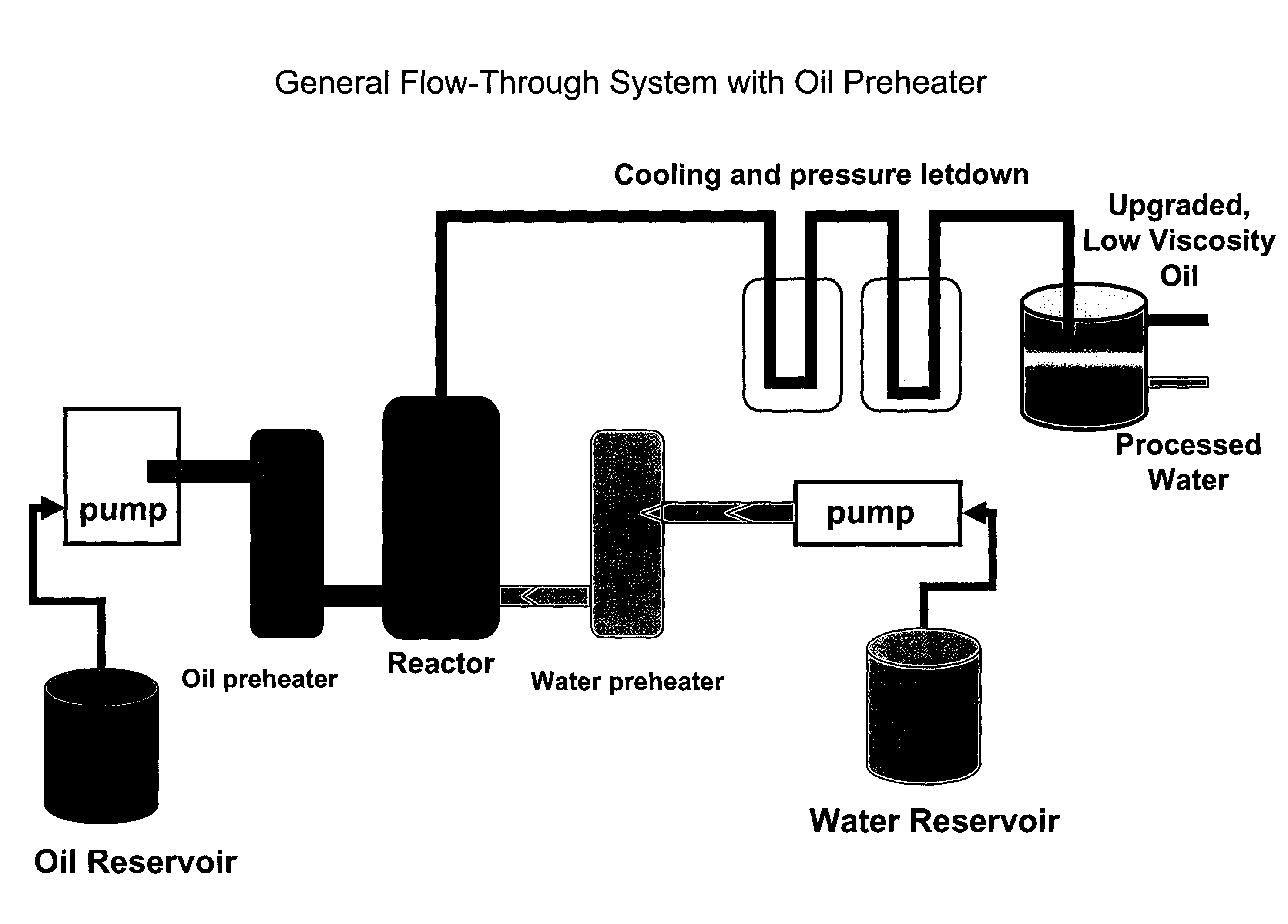

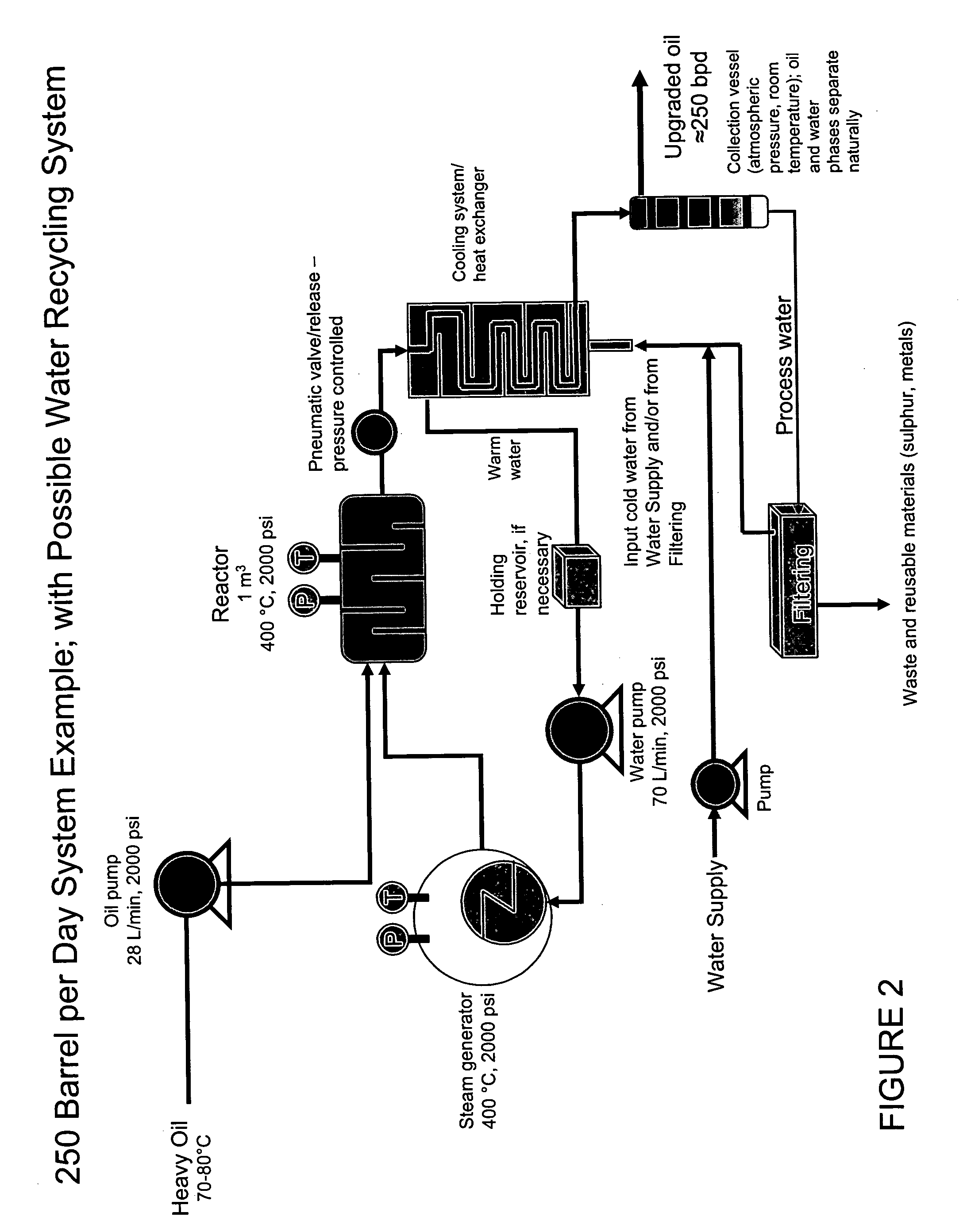

Method for extracting and upgrading of heavy and semi-heavy oils and bitumens

ActiveUS7947165B2Minimize timeSpeed maximizationThermal non-catalytic crackingRefining with non-metalsCoalOil sands

Improvements in the selective extraction of relatively low molecular weight oils from coal, coal liquids, oil shales, shale oils, oil sands, heavy and semi-heavy oils, bitumens, and the like are provided by a continuous process involving contacting the material to be treated with supercritical water in a continuous operation at pressures of from 500 psi to 3000 psi, temperatures of 250° C. to 450° C., and in-reactor dwell times generally in excess of 25 seconds and up to 10 minutes.

Owner:BERKOWITZ BRIAN +3

Process, method, and system for removing heavy metals from fluids

Trace element levels of heavy metals such as mercury in crude oil are reduced by contacting the crude oil with an iodine source, generating a water soluble heavy metal complex for subsequent removal from the crude oil. In one embodiment, the iodine source is generated in-situ in an oxidation-reduction reaction, by adding the crude oil to an iodine species having a charge and a reductant or an oxidant depending on the charge of the iodine species. In one embodiment with an iodine species having a positive charge and a reducing reagent, a complexing agent is also added to the crude oil to extract the heavy metal complex into the water phase to form water soluble heavy metal complexes which can be separated from the crude oil, for a treated crude oil having reduced levels of heavy metals.

Owner:CHEVROU USA INC

Process, Method, and System for Removing Heavy Metals from Fluids

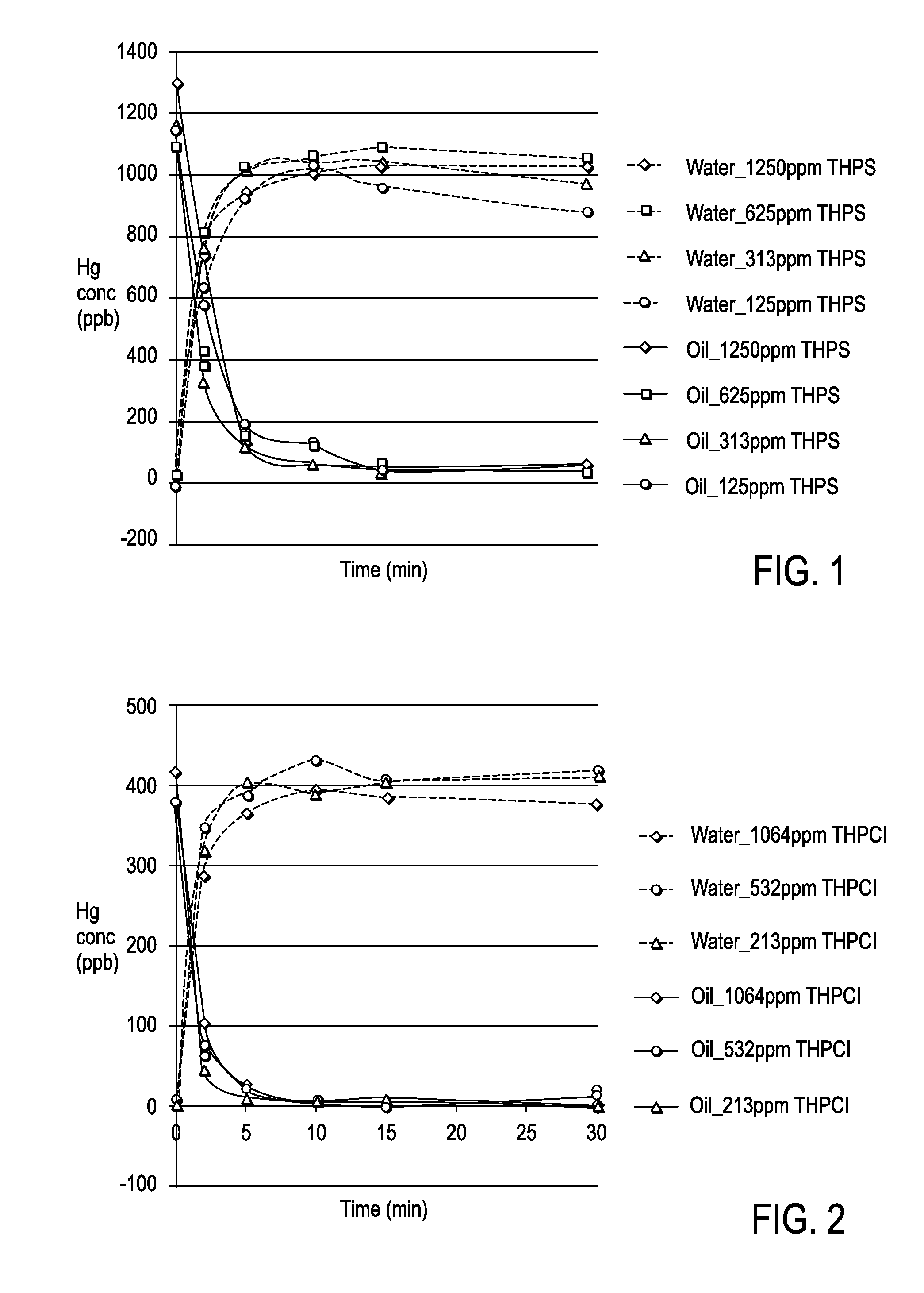

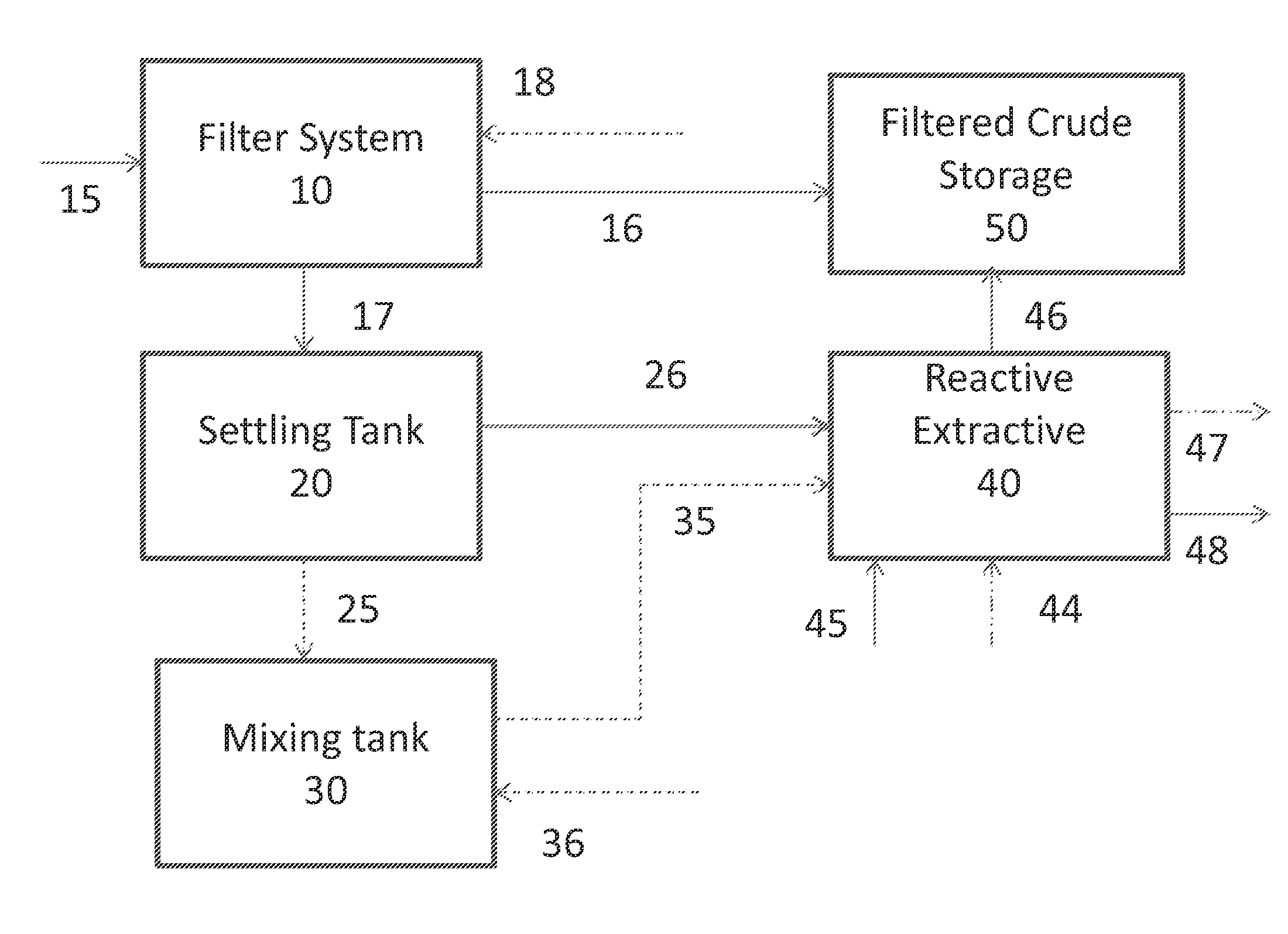

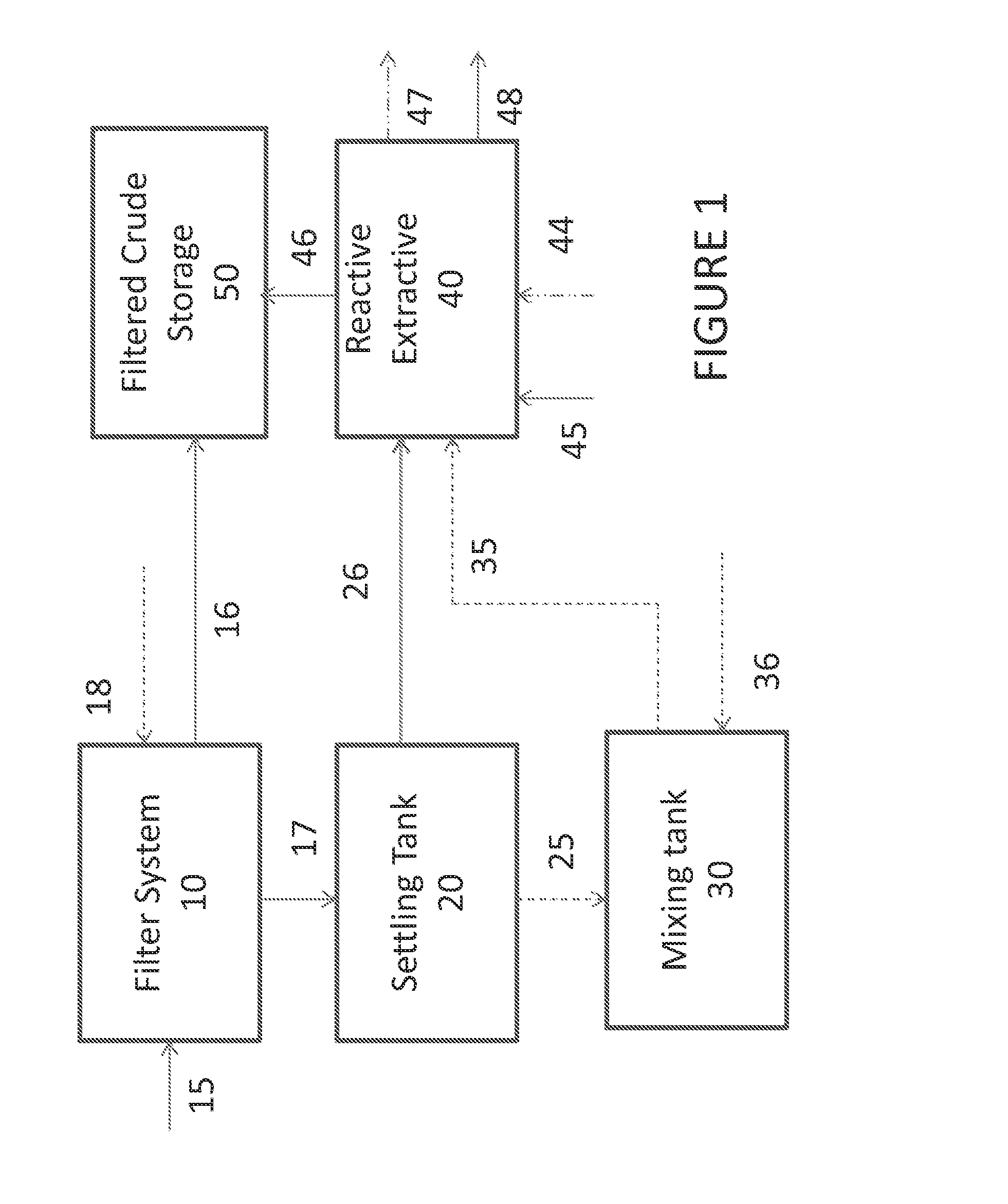

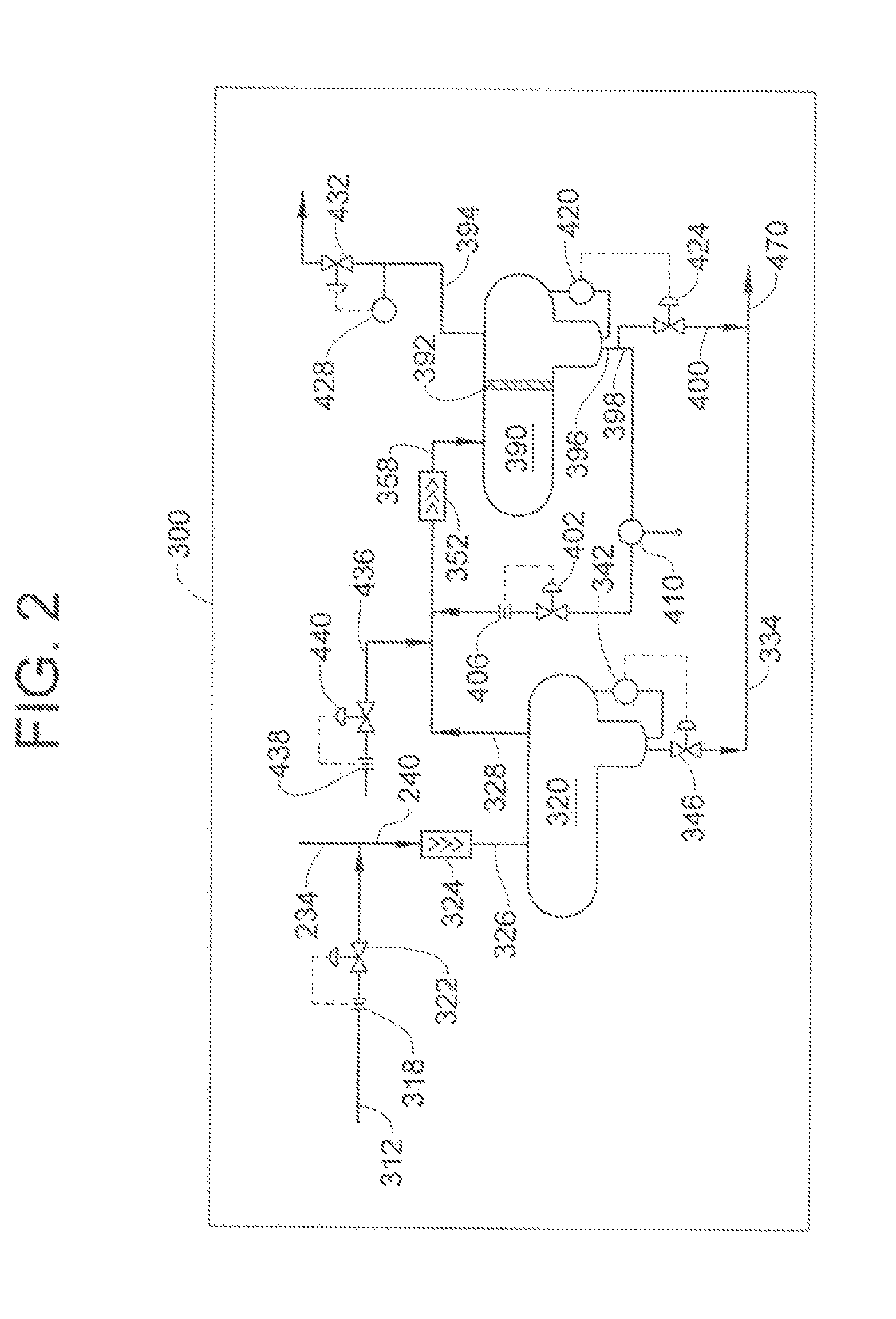

ActiveUS20140262955A1Reduce its mercury concentrationRefining with non-metalsRefining with oxygen compoundsPhosphoniumFiltration

Trace element levels of mercury in crude oil are reduced by first passing the crude oil through a filtration device to generate filtered crude having a reduced concentration of mercury and a reject stream having a concentrated mercury level. In one embodiment, the filtration device is back-flushed to generate the reject stream. In another embodiment, the reject stream comprises a portion of the retentate from a cross-flow filter device. The reject stream is treated with an extractive agent selected from tetrakis(hydroxymethyl)phosphonium sulfate; tetrakis(hydroxymethyl) phosphonium chloride; an oxidizing agent; an organic or inorganic sulfidic compound to extract a portion of the mercury into a water phase for subsequent removal. In one embodiment, the extractive agent is a reductant to convert non-volatile mercury into volatile mercury.

Owner:CHEVROU USA INC

Process and apparatus for removing hydrogen sulfide

InactiveUS20140091010A1Refining with non-metalsTreatment with plural serial refining stagesNaphthaHydrogen

One exemplary embodiment can be a process for removing hydrogen sulfide from a fractionated hydroprocessed effluent. The process can include stripping a hydroprocessed effluent from a hydroprocessing zone, fractionating the stripped hydroprocessed effluent to obtain a naphtha cut, and sending the naphtha cut to a hydrogen sulfide removal zone. The hydrogen sulfide removal zone can include an amine wash settler, an amine contacting column, or a steam stripper.

Owner:UOP LLC

Synergistic H2S/mercaptan scavengers using glyoxal

The use of neutral aqueous solutions of glyoxal (pH approximately 6 to 8.5) scavenges H2S that is present in natural gas and in oil better than glyoxal alone or base alone. The resulting scavenger combination significantly increases the reaction rate and the overall scavenging efficiency, i.e. capacity over glyoxal used alone. A buffer may be optionally used. In another embodiment, the combination of non-nitrogen-containing surfactants and glyoxal results in a significant increase in the reaction rate and the overall scavenging efficiency, i.e. capacity as compared to glyoxal used alone.

Owner:BAKER HUGHES HLDG LLC

Crude oil desulfurization

ActiveUS20120111769A1Low costReduce usageRefining with non-metalsTransportation and packagingInorganic saltsChemistry

A method of removing sulfur from sour oil by subjecting sour oil having a first sulfur content to high shear in the presence of at least one desulfurizing agent to produce a high shear treated stream, wherein the at least one desulfurizing agent is selected from the group consisting of bases and inorganic salts, and separating both a sulfur-rich product and a sweetened oil product from the high shear-treated stream, wherein the sulfur-rich product comprises elemental sulfur and wherein the sweetened oil product has a second sulfur content that is less than the first sulfur content. A system for reducing the sulfur content of sour oil via at least one high shear device comprising at least one rotor and at least one complementarily-shaped stator, and at least one separation device configured to separate a sulfur-rich product and sweetened oil from the high shear-treated stream.

Owner:HRD CORP +1

Preparation and applications of molecular sieve gasoline desulfurizing agent loaded with functionalized ionic liquid

ActiveCN105327689AAvoid churnGood dispersionRefining with non-metalsOther chemical processesMolecular sieveGasoline

The invention discloses preparation and applications of a molecular sieve gasoline desulfurizing agent loaded with a functionalized ionic liquid. According to a preparation method, the functionalized ionic liquid is anchored or restricted in a molecular sieve via in situ synthesis so as to obtain the molecular sieve gasoline desulfurizing agent loaded with the functionalized ionic liquid, and load capacity of the functionalized ionic liquid on the molecular sieve ranges from 5 to 30%. Introduction of acidic functional groups into the ionic liquid is capable of achieving synergist effect of adsorption of the molecular sieve in gasoline desulphurization; acidic active sites are capable of catalyzing oxidation sulfone forming reaction of a plurality of thiophenic sulfides effectively, and possess excellent promoting effect on subsequent extraction desulphurization. Reaction conditions are mild; operation cost is low; removing effect is excellent; oil product loss and oil product quality decrease caused in desulphurization process are avoided effectively; desulfurizing agent regeneration is convenient to realize; and recycling effect is excellent.

Owner:SOUTH CHINA UNIV OF TECH

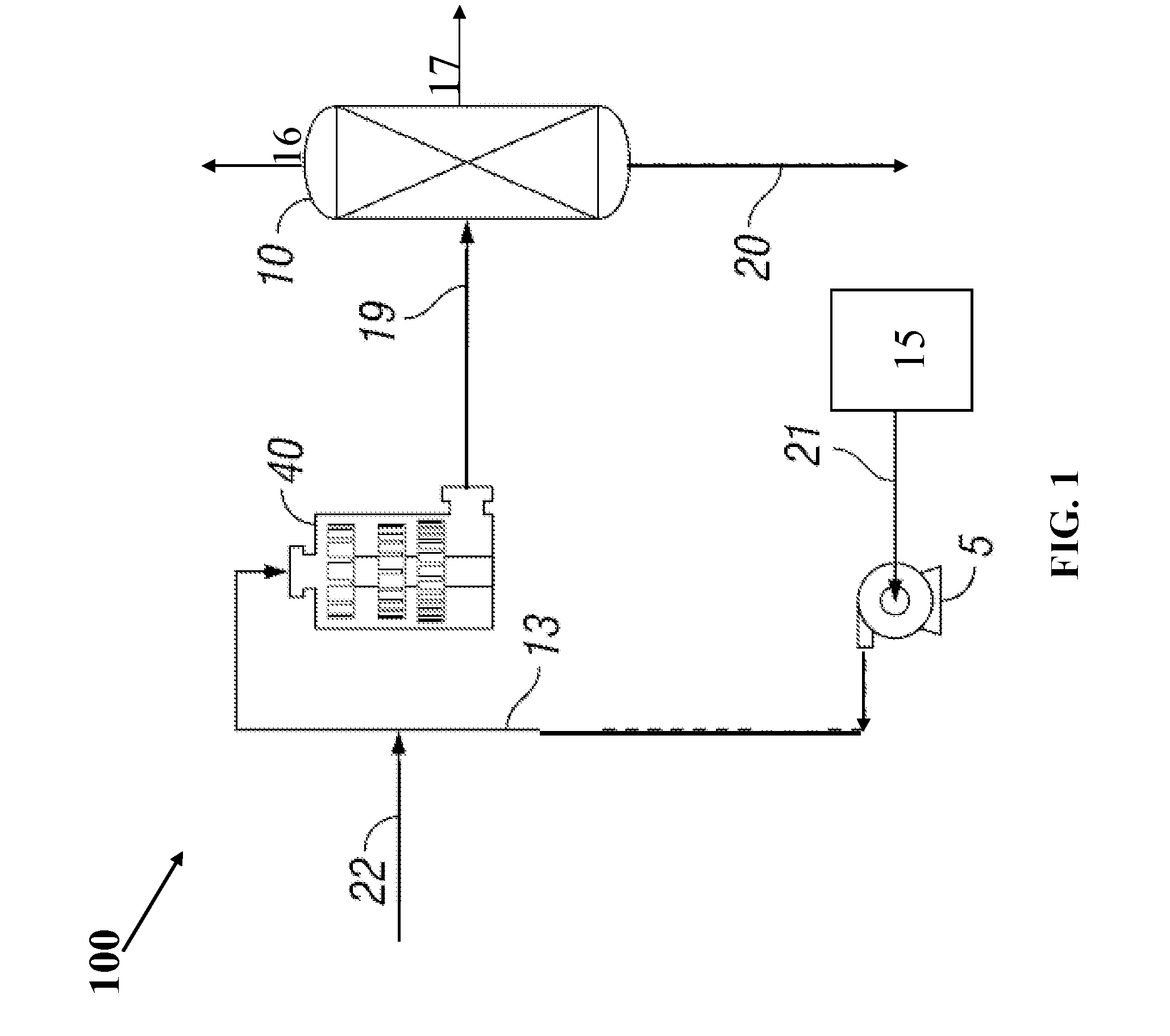

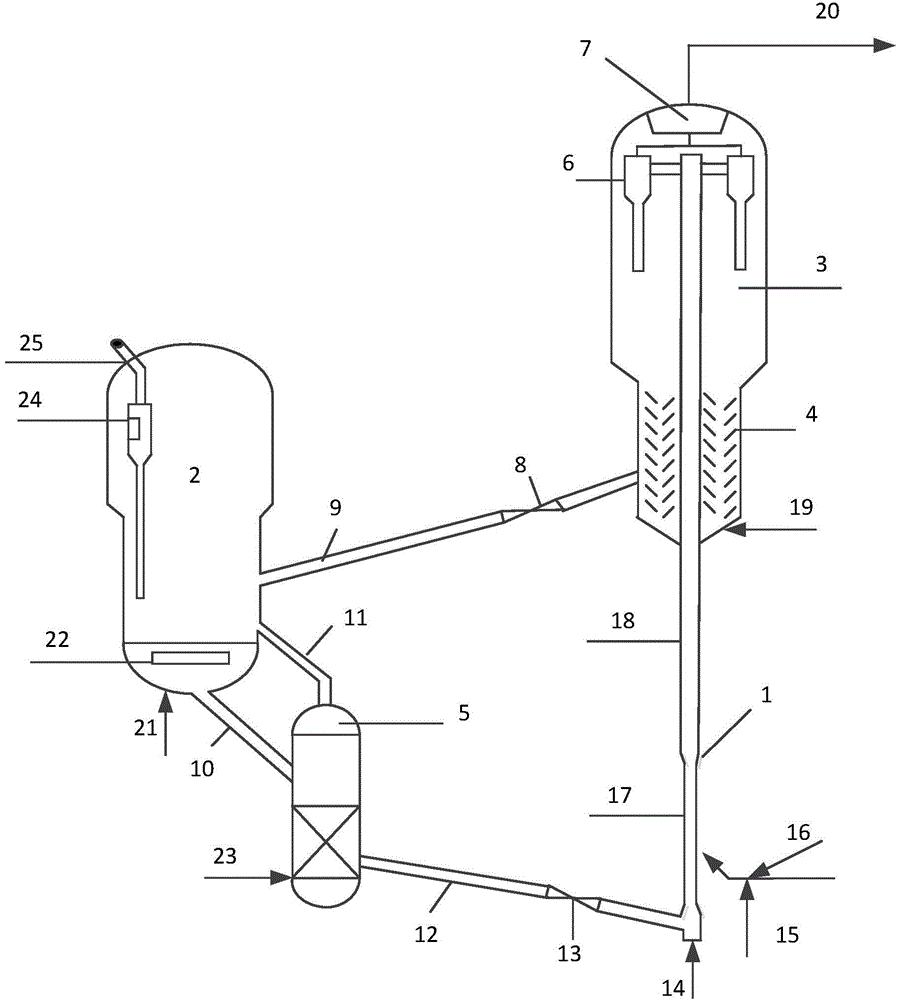

High-chlorine raw material catalytic conversion method

ActiveCN105368483AImprove conversion rateHigh yieldRefining with non-metalsRefining with metalsCatalytic transformationPtru catalyst

The invention relates to a high-chlorine raw material catalytic conversion method, wherein a high temperature regeneration catalyst enters the pre-rising section on the lower portion of a riser reactor, flows upward under the effect of a pre-rising medium, and then enters the oil agent initial contact reaction region on the lower portion of the riser reactor, a pre-heated high-chlorine raw material is introduced into the lower portion of the oil agent initial contact reaction region, the pre-heated high-chlorine raw material and the high temperature regeneration catalyst contact, react and rise, the formed oil agent mixture enters a riser main reaction region, a hydrocarbon conversion reaction is continuously performed in the main reaction region, the formed oil agent mixture is subjected to gas-solid separation through the reactor outlet, the separated catalyst with charcoal is subjected to steam stripping and charring so as to be recycled, and the separated reaction oil gas is conveyed to the subsequent product separation system. According to the present invention, with the method, the high-chlorine raw material can be directly processes, the high-chlorine raw material conversion rate is improved, and the product selectivity is improved; and the method is simple and is easy to perform, and the method can be achieved only by carrying out simple transforming on the conventional catalytic cracking equipment.

Owner:CHINA PETROLEUM & CHEM CORP +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com