Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about "Bromide preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

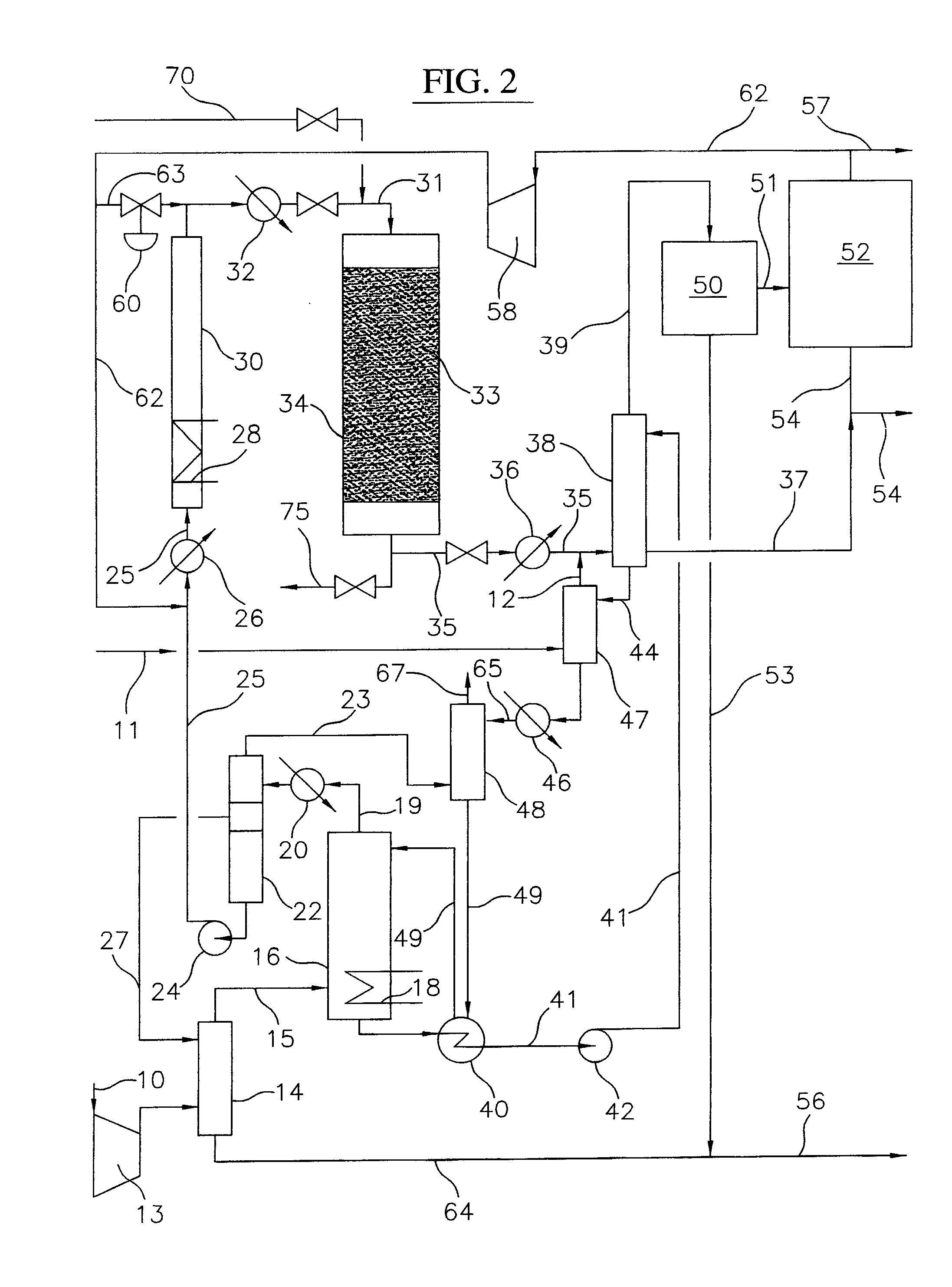

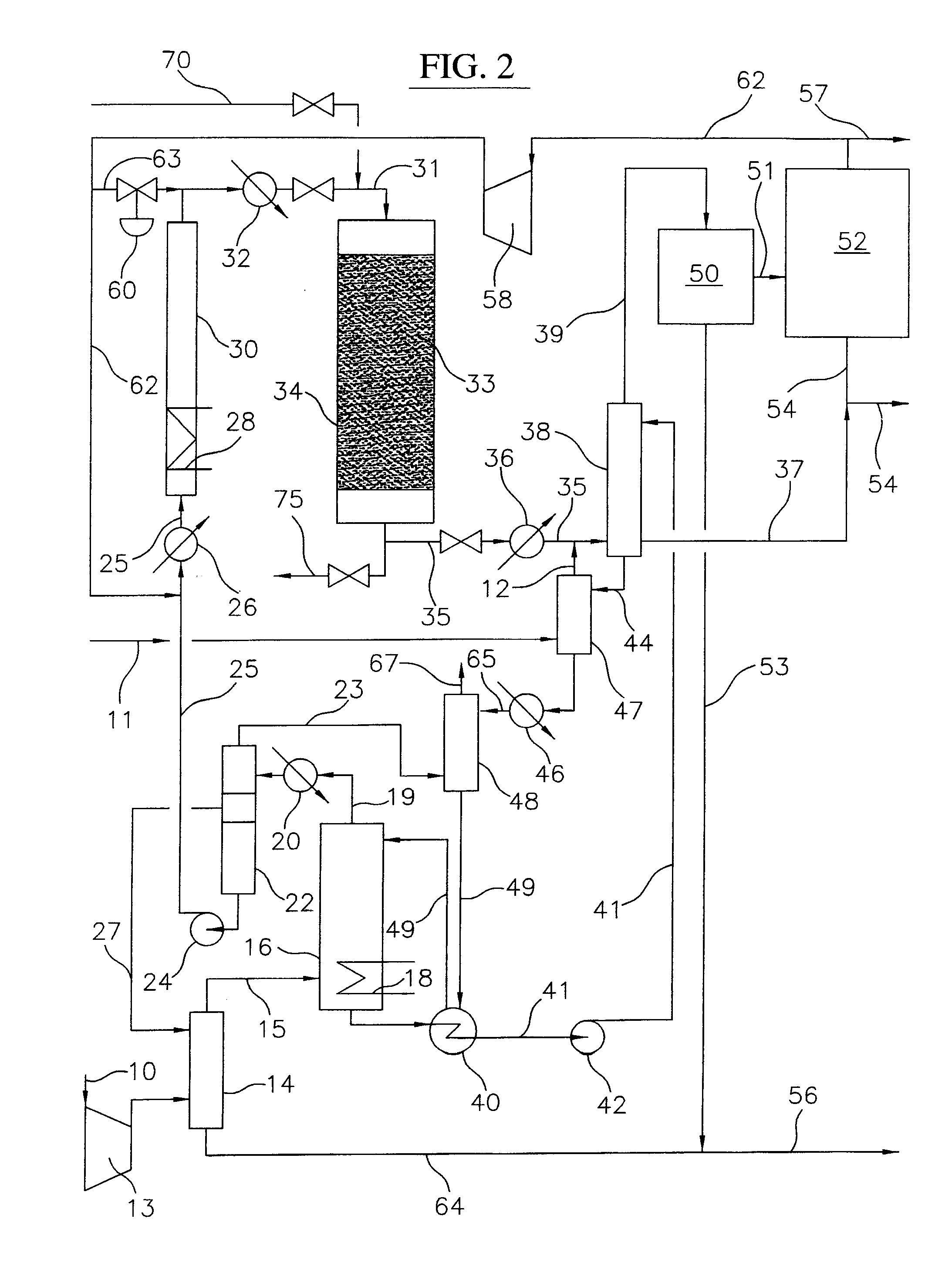

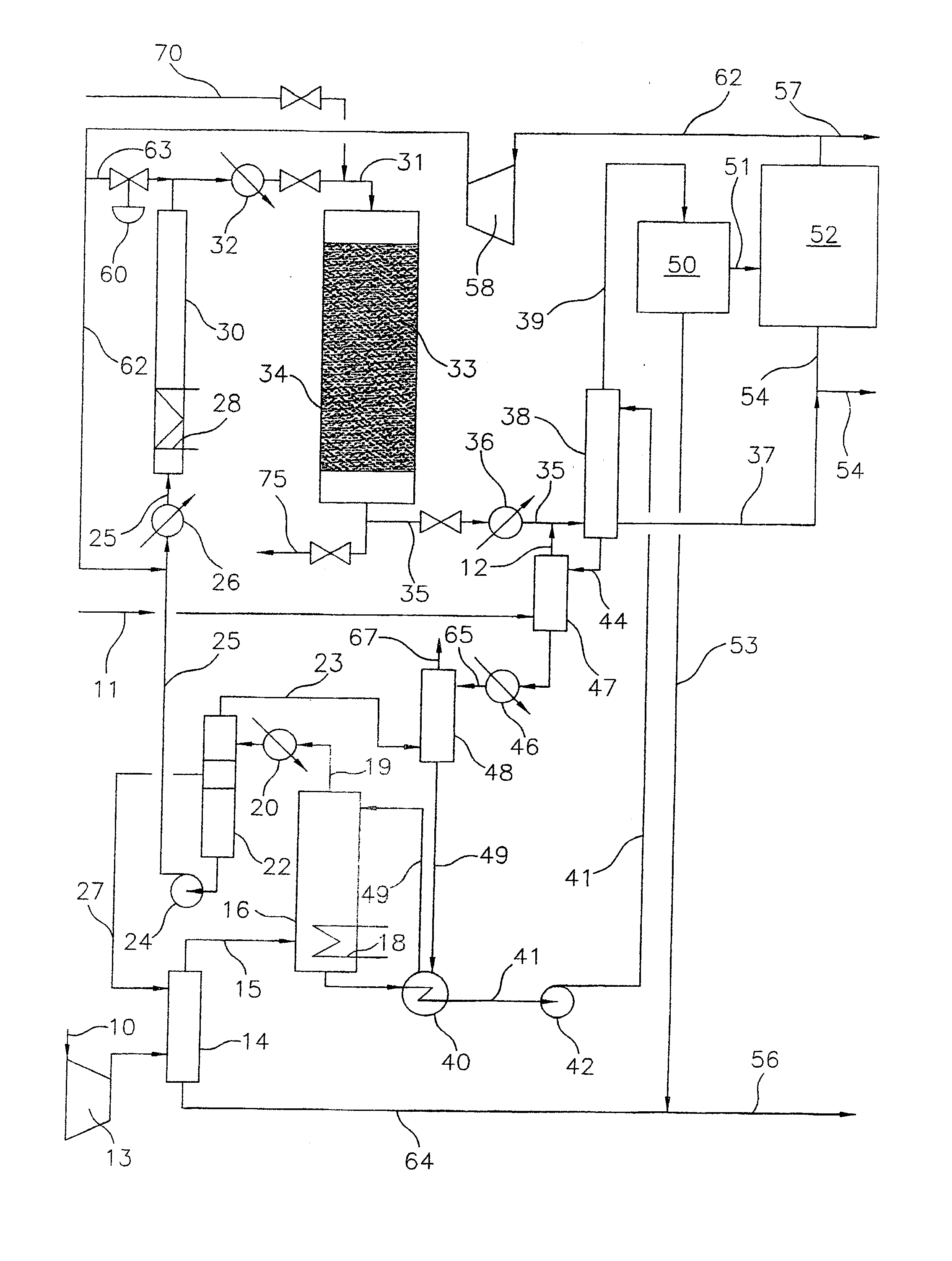

Process for converting gaseous alkanes to liquid hydrocarbons

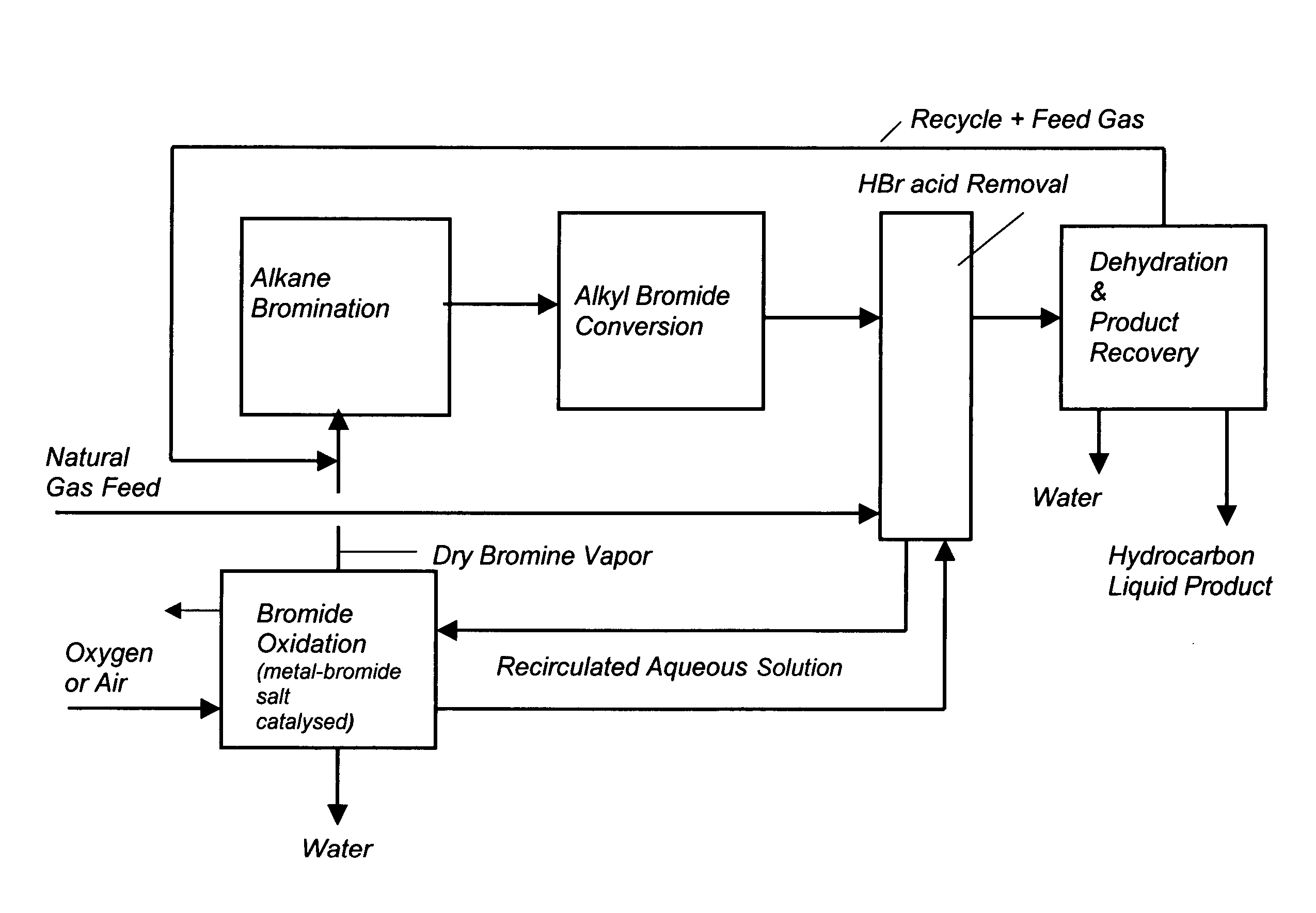

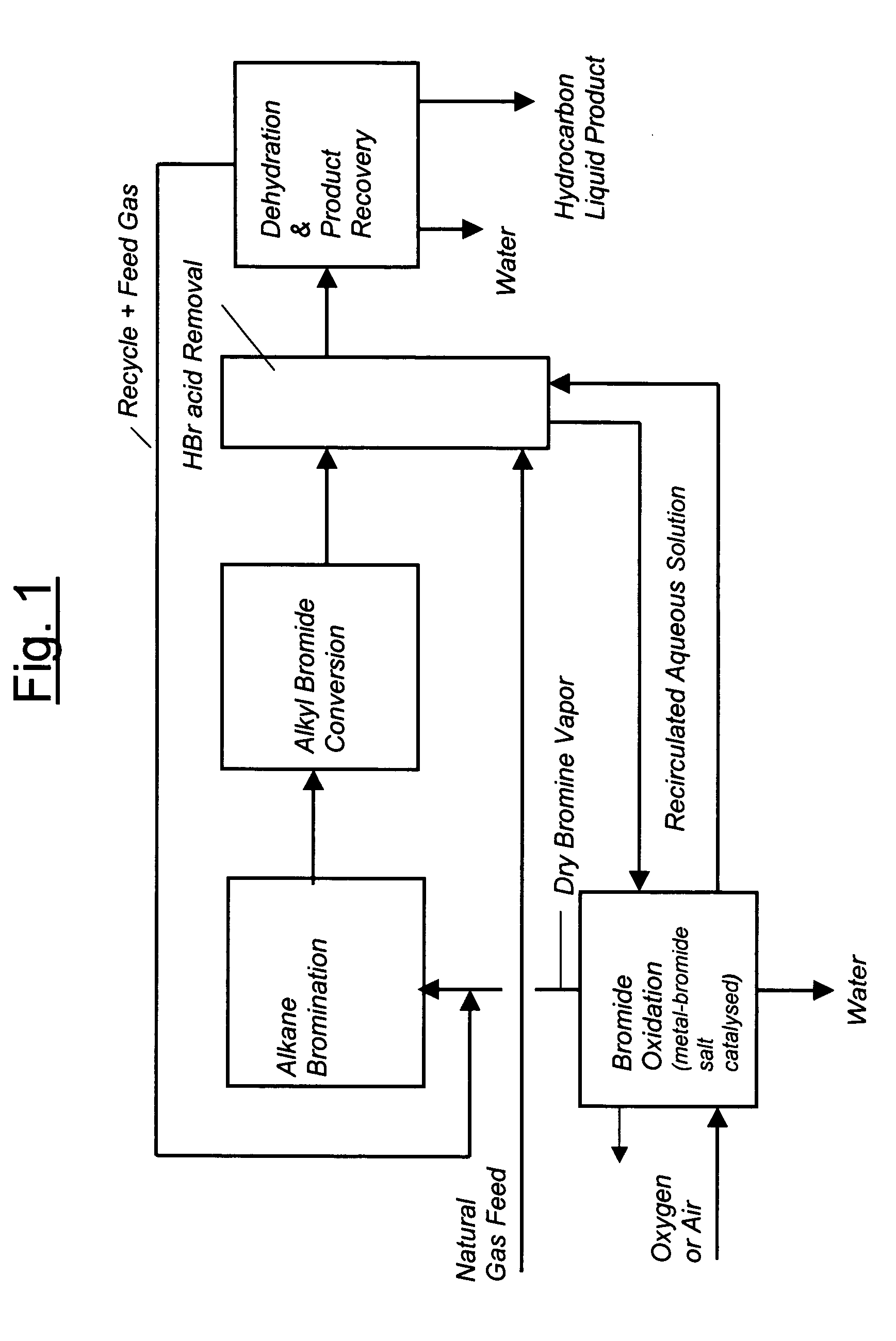

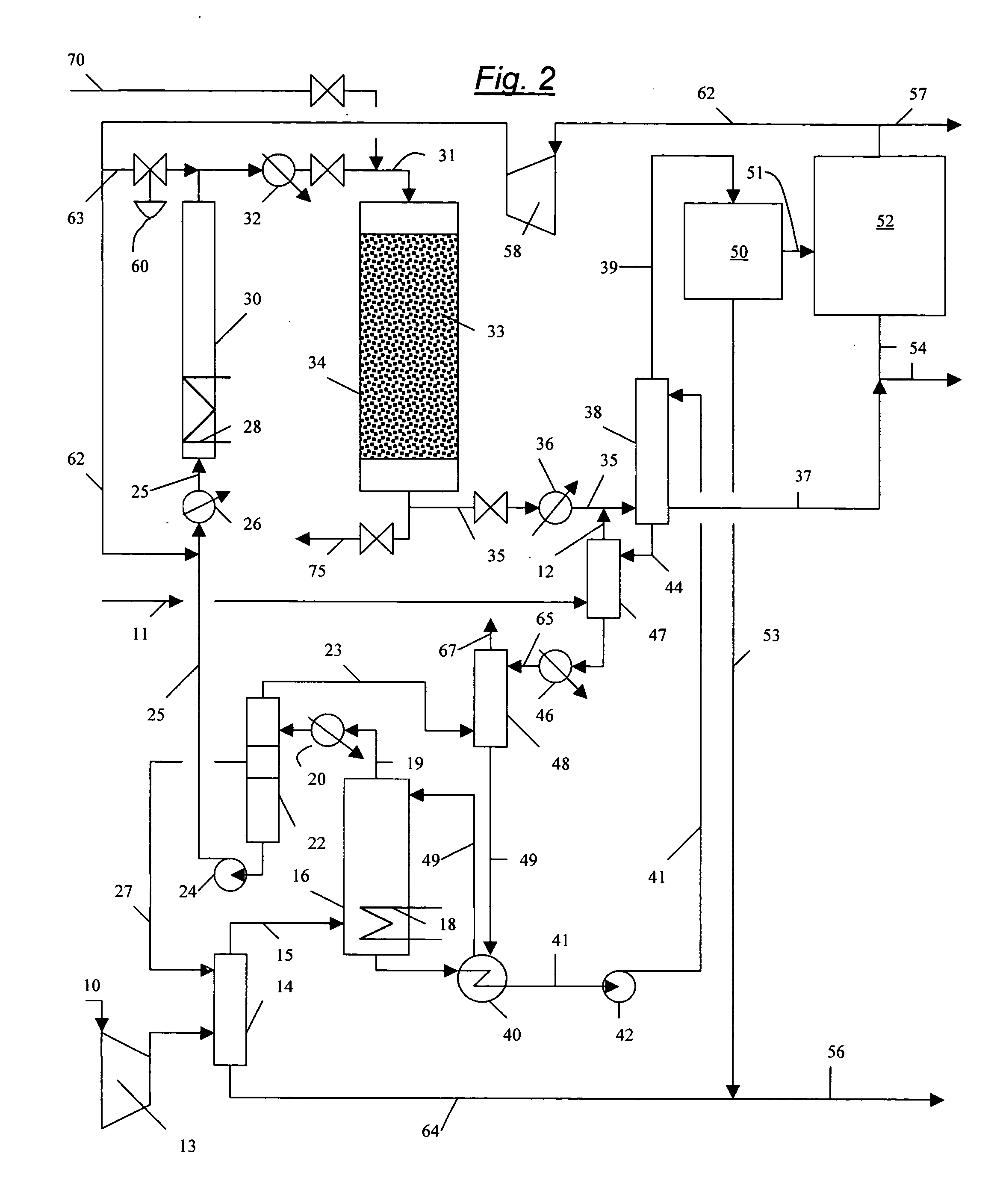

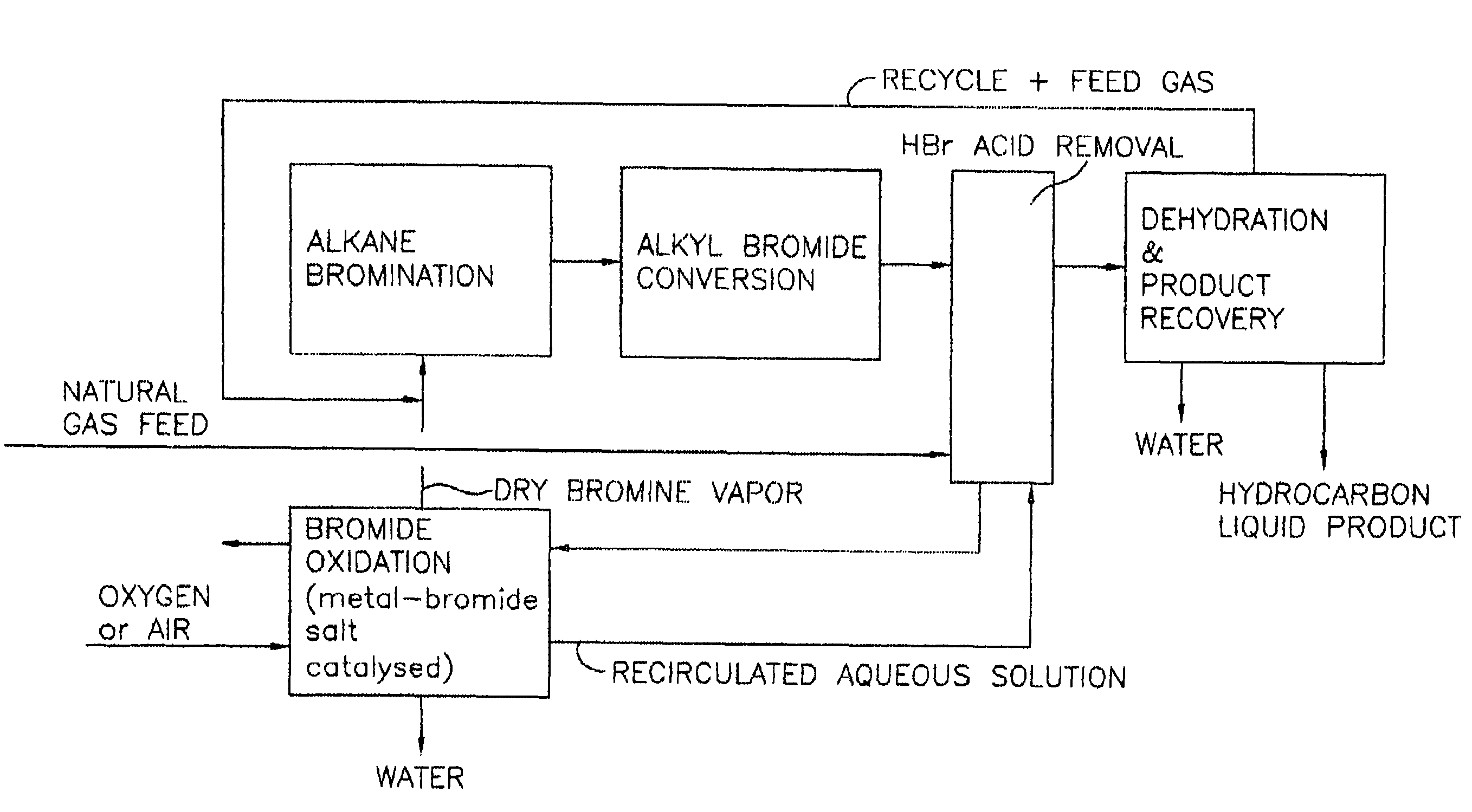

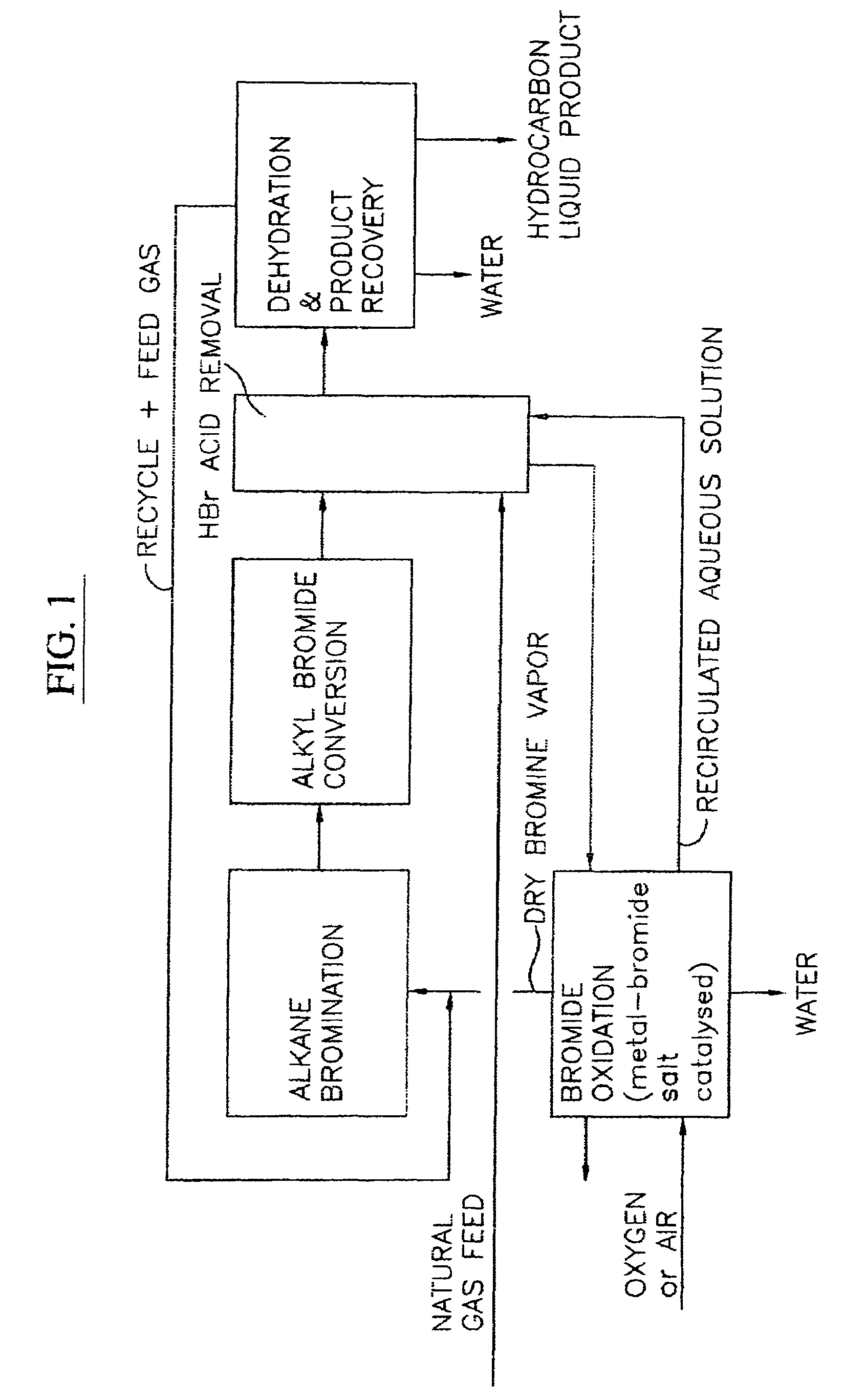

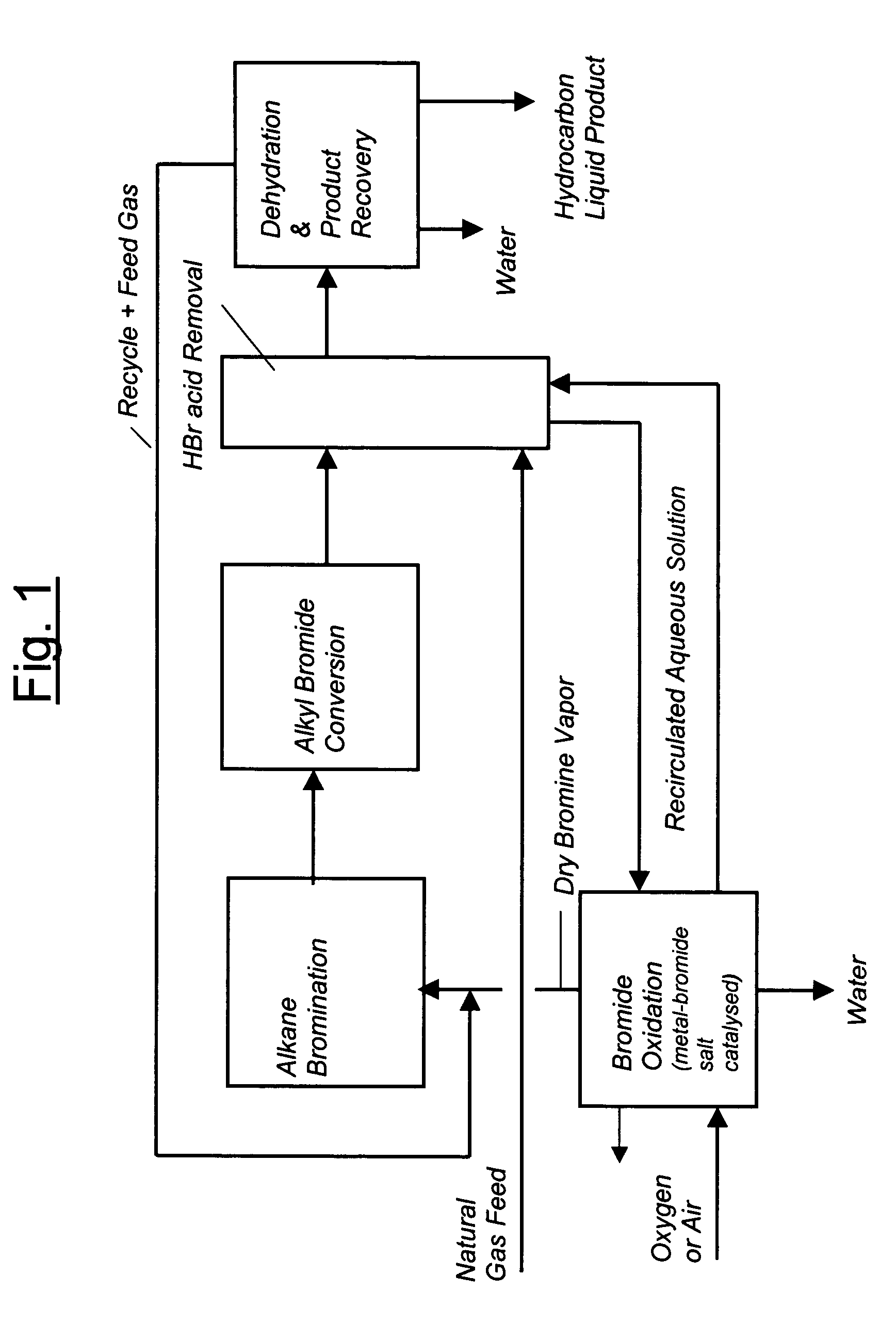

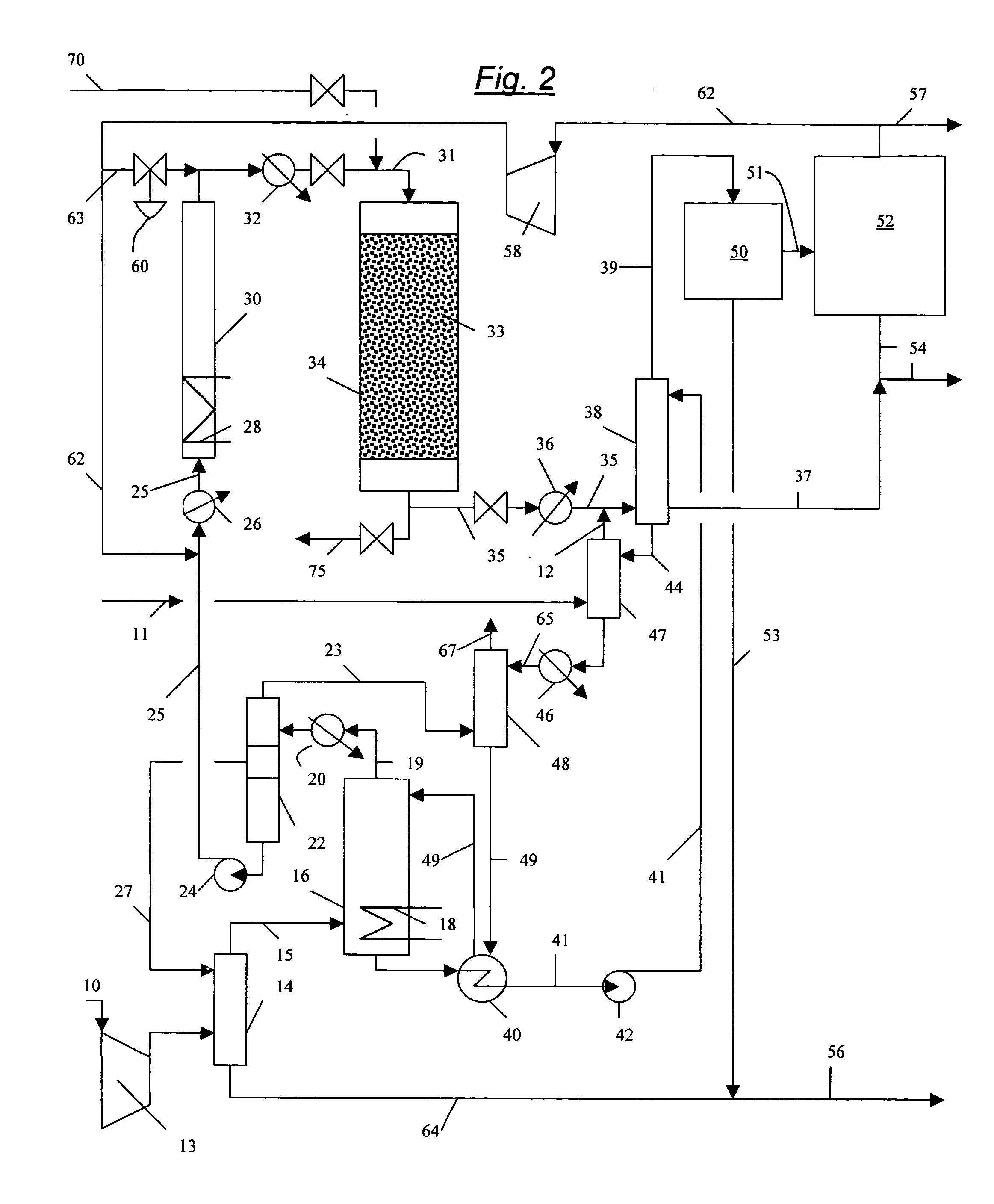

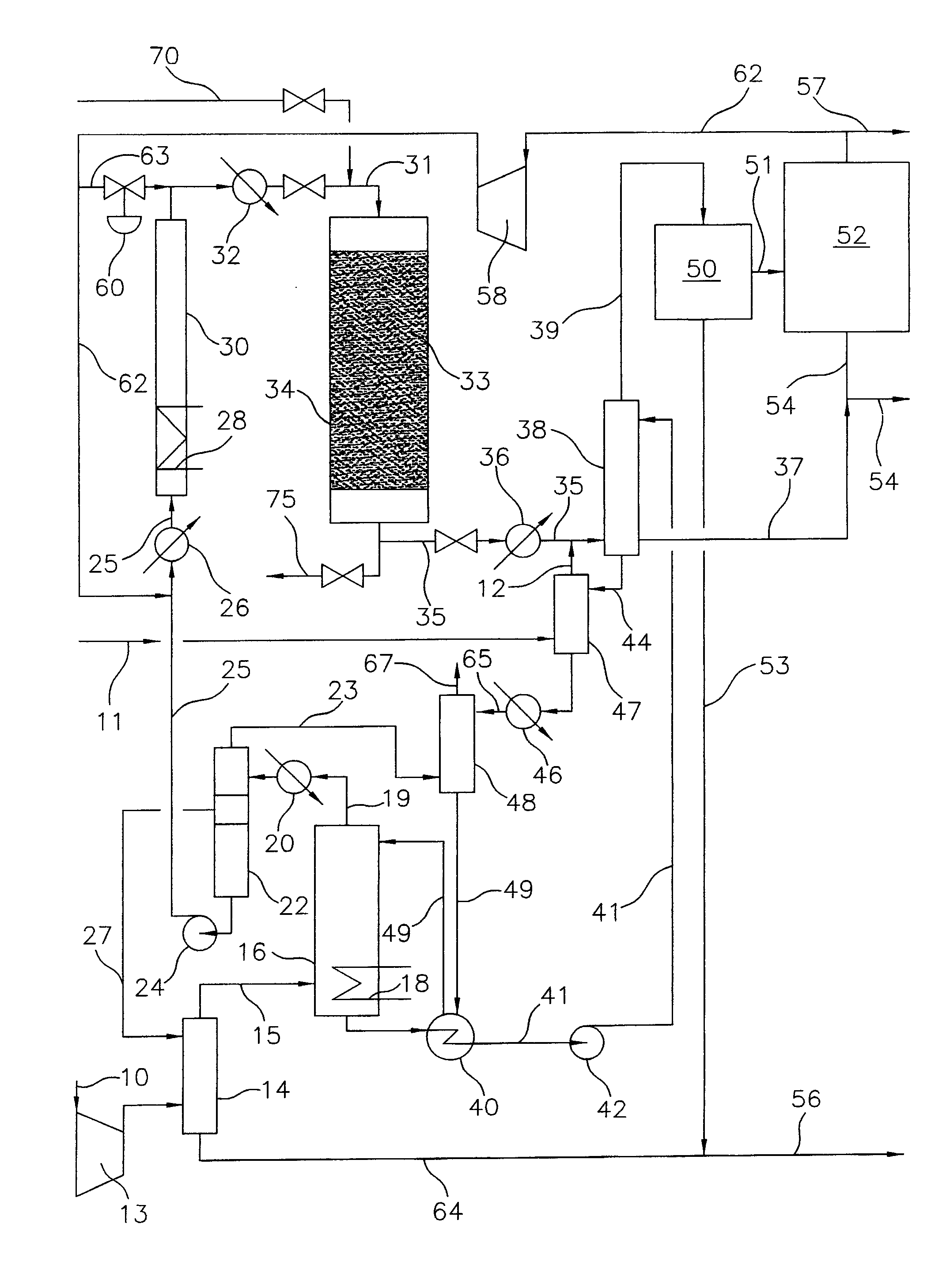

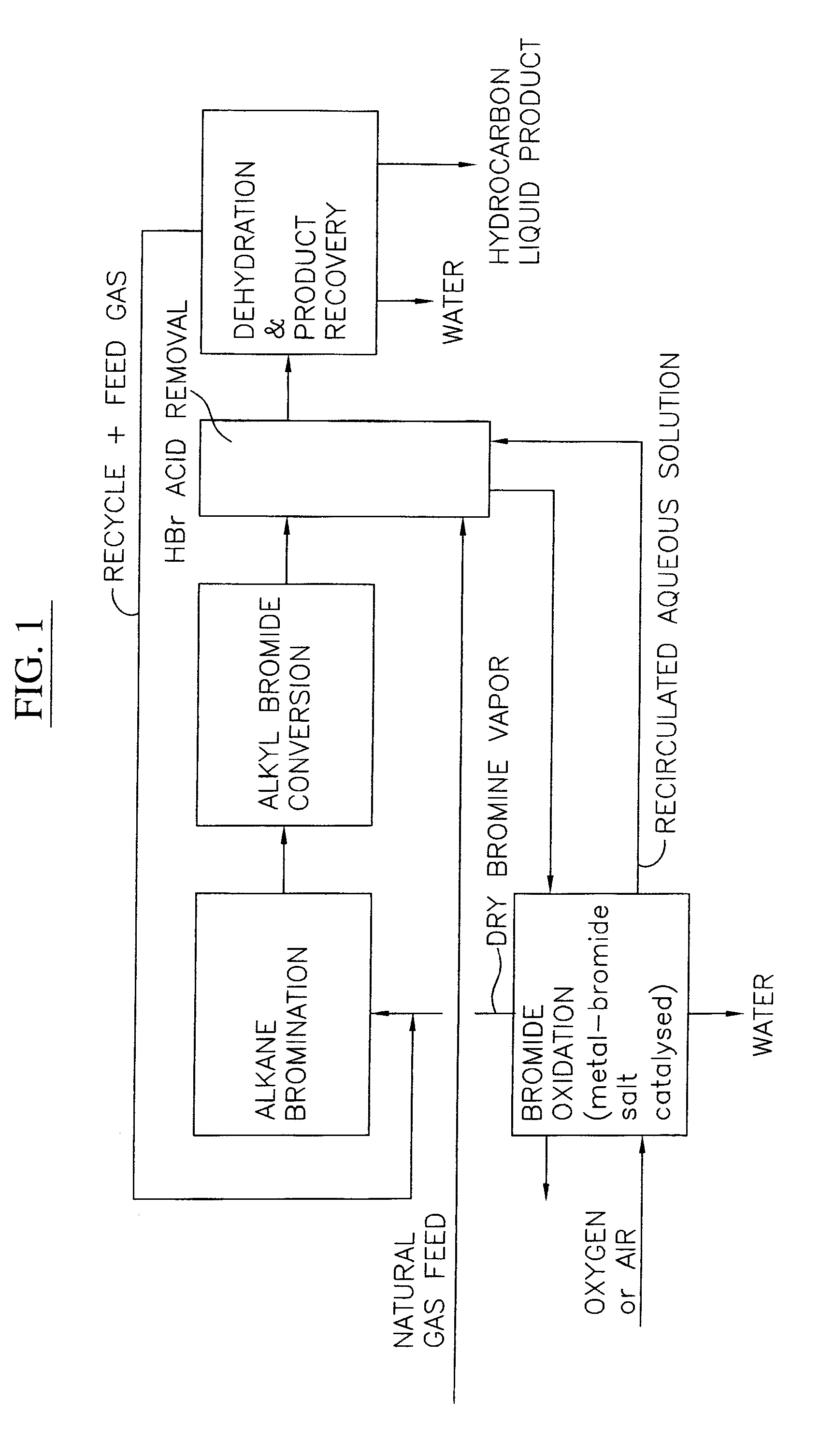

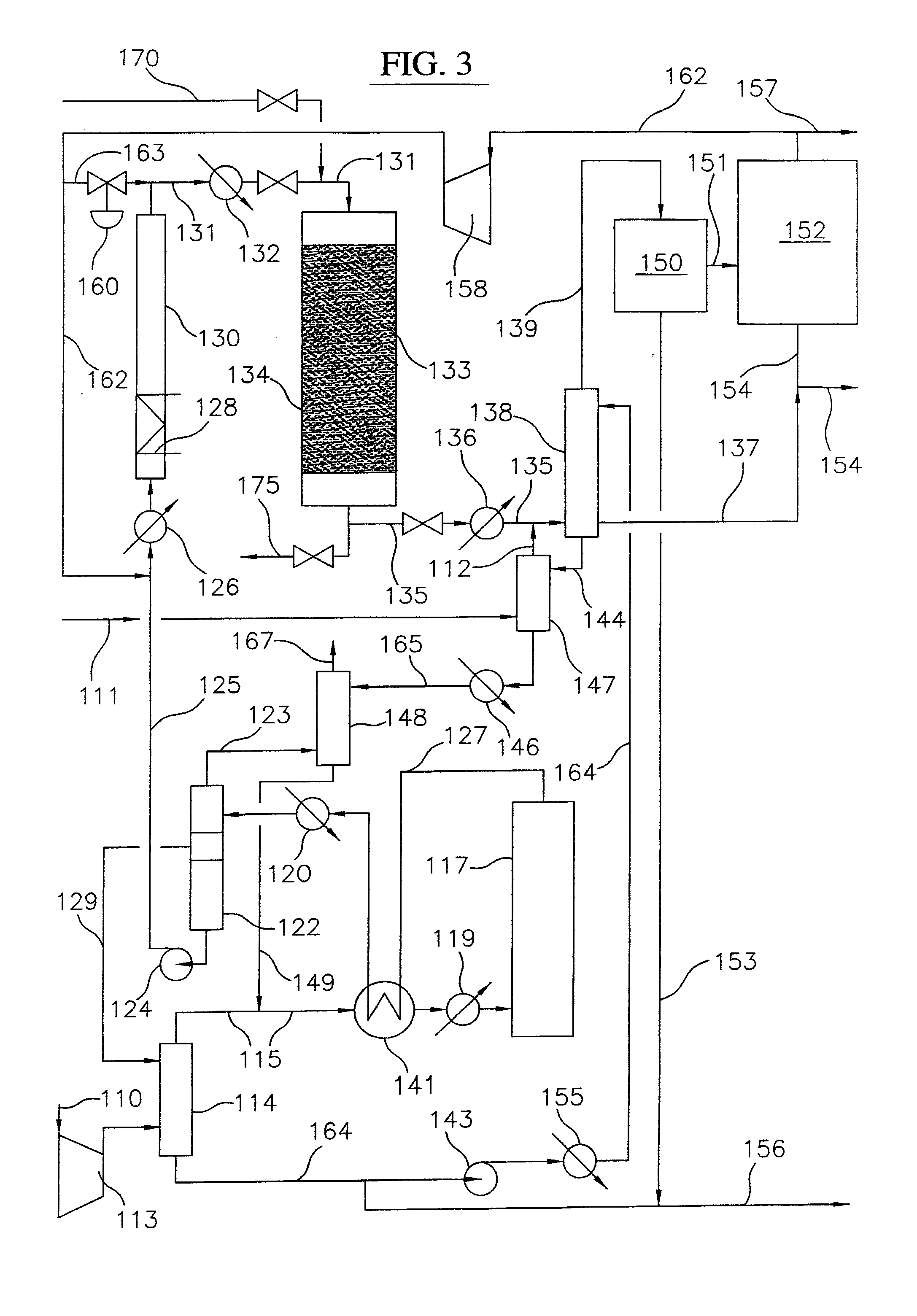

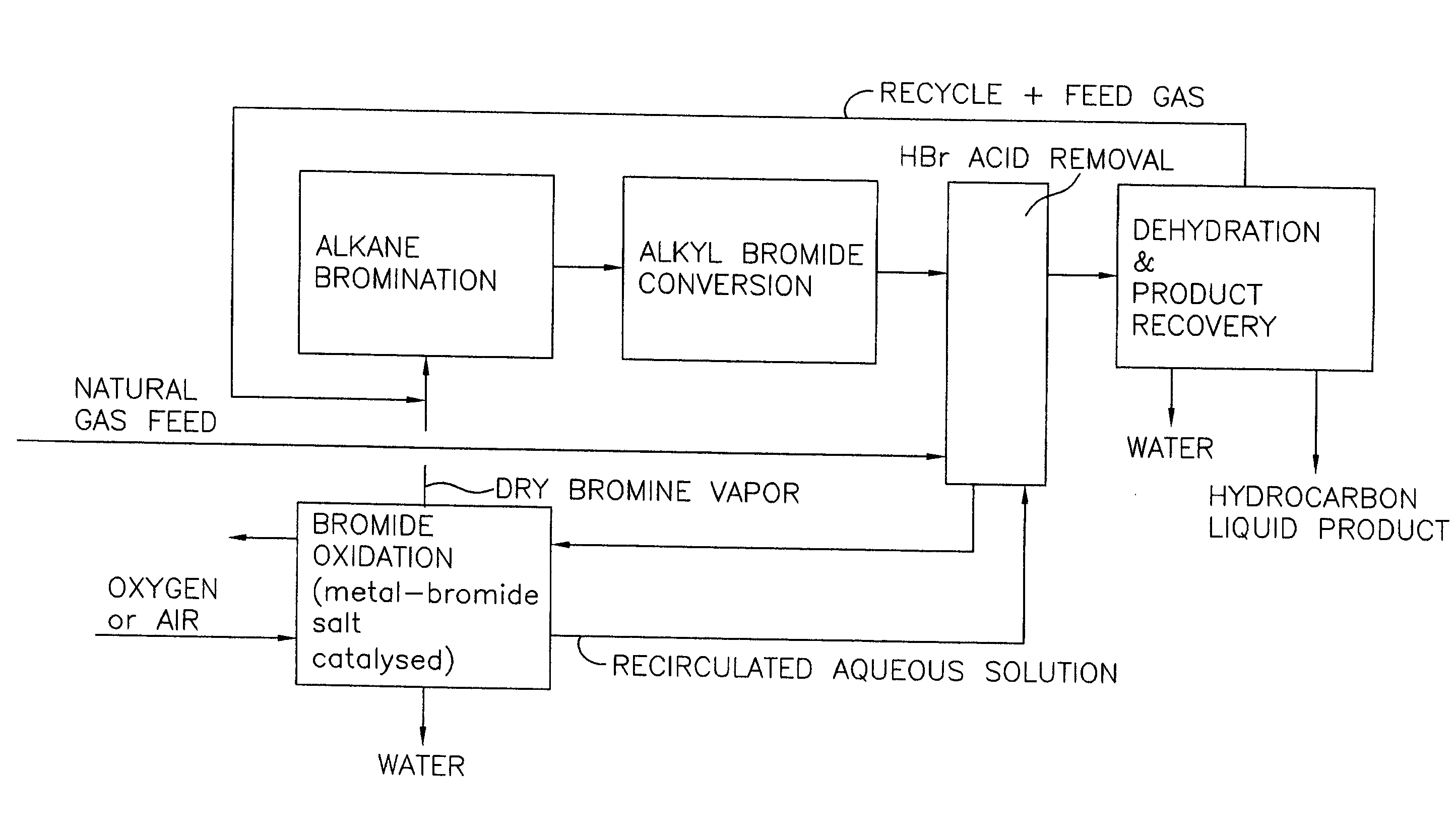

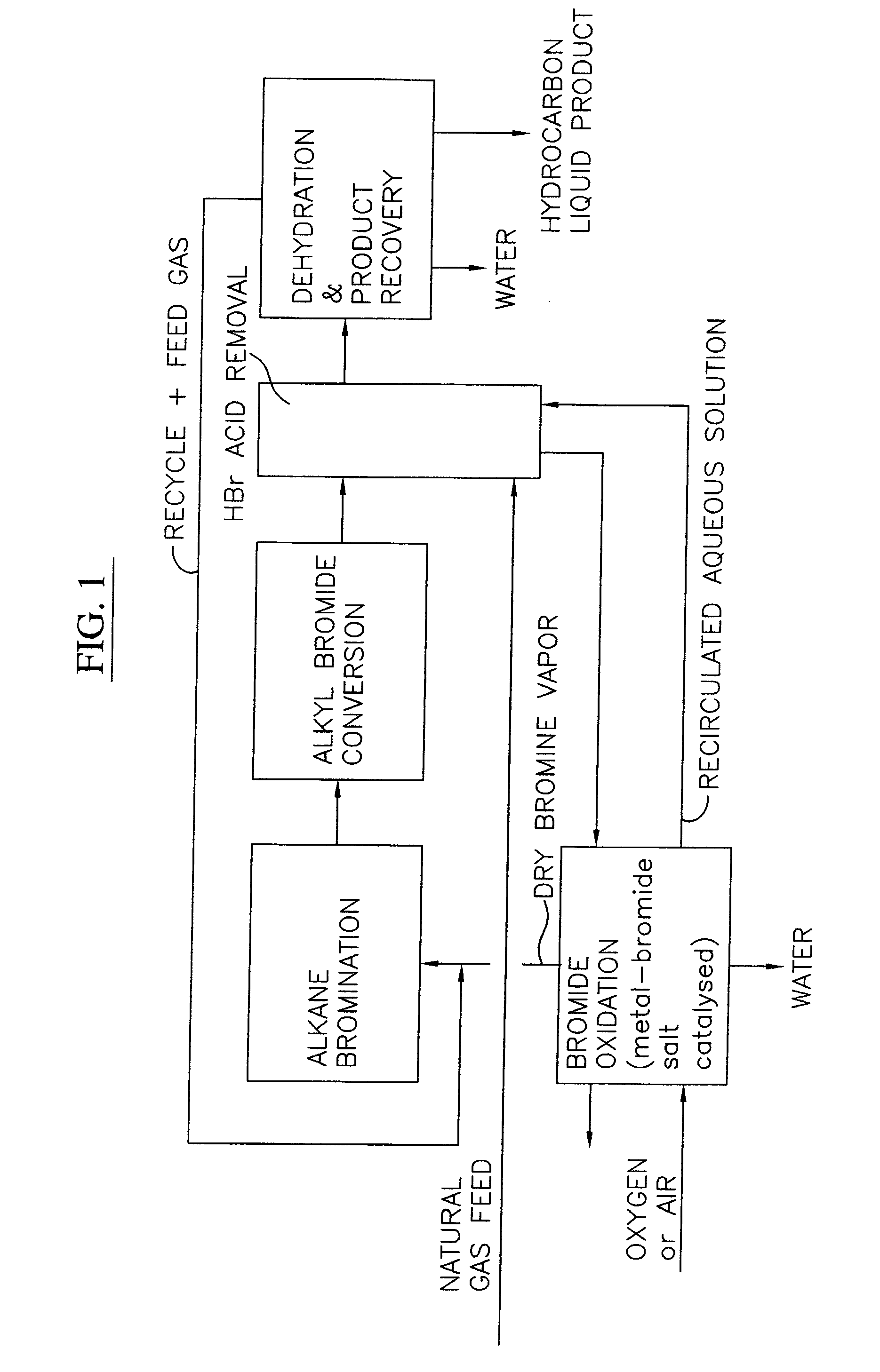

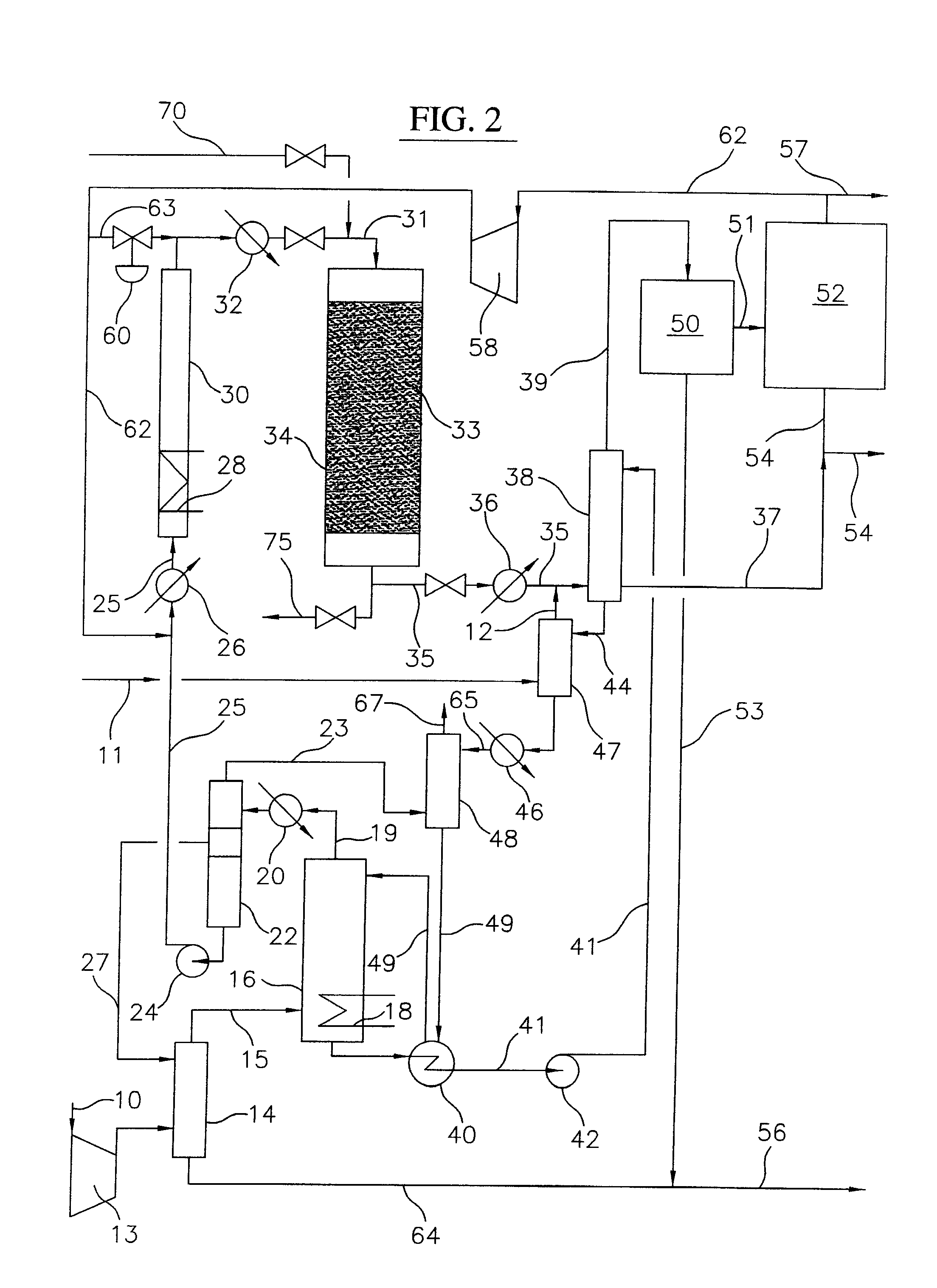

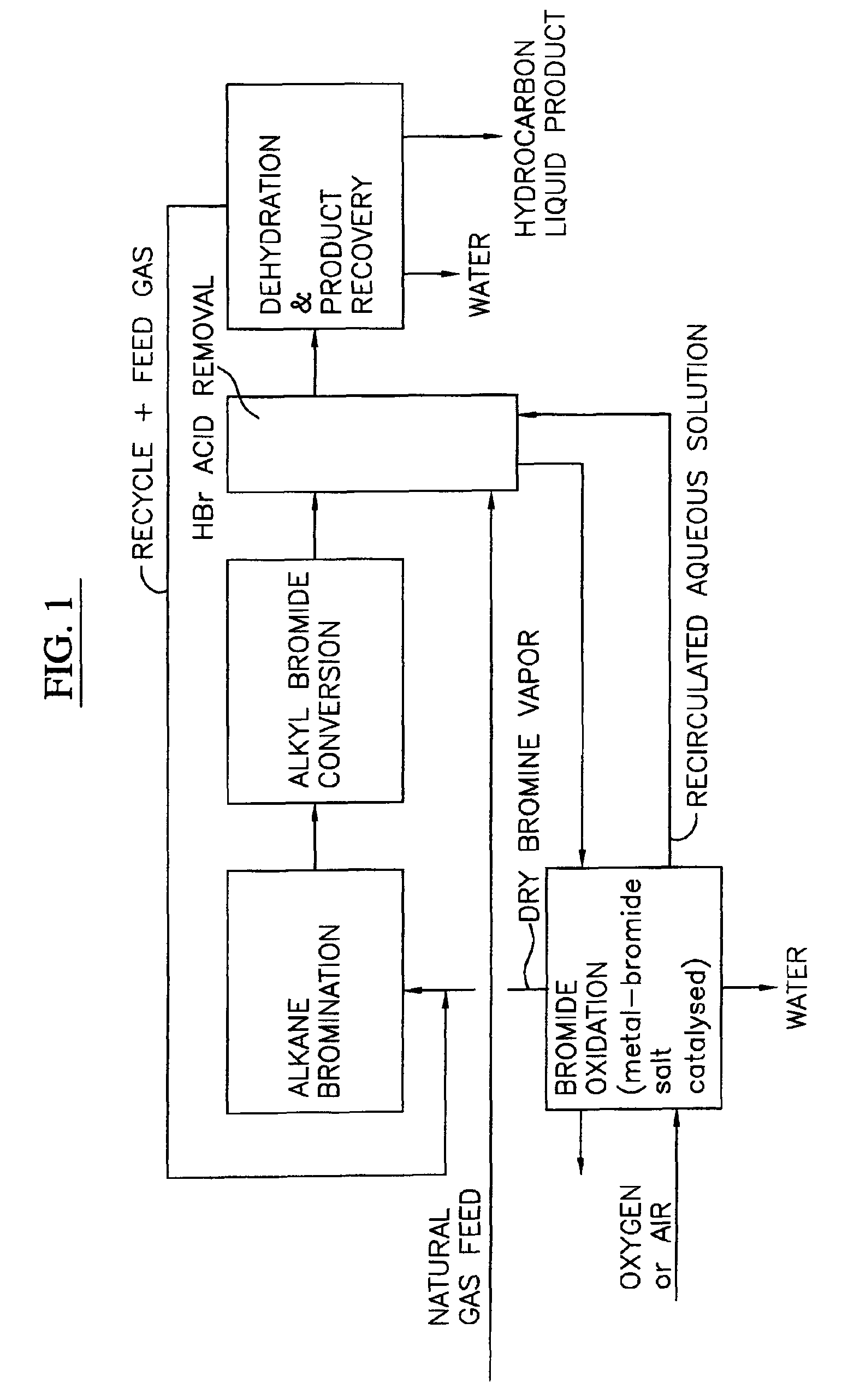

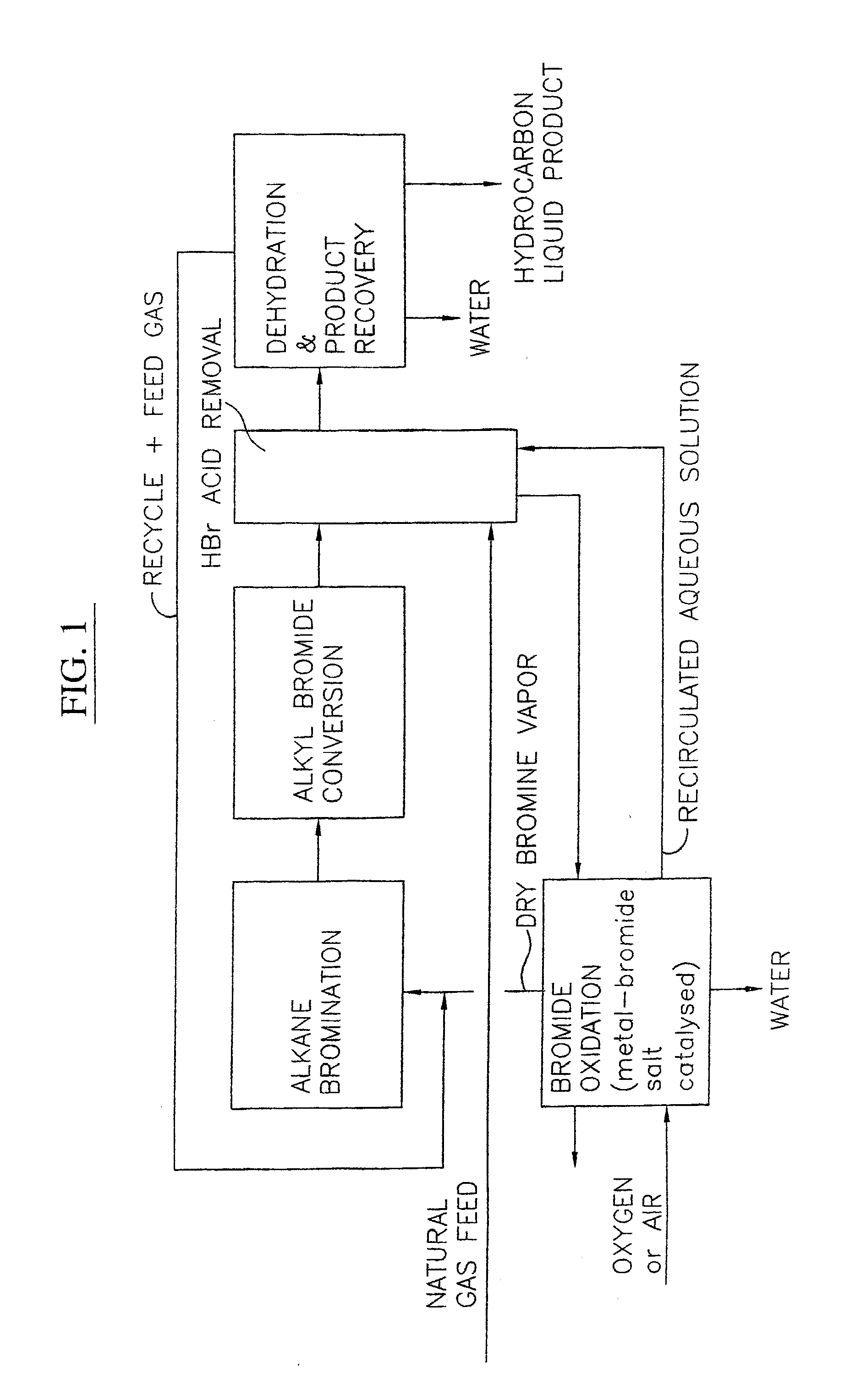

A process for converting gaseous alkanes to liquid hydrocarbons wherein a gaseous feed containing alkanes is reacted with a dry bromine vapor to form alkyl bromides and hydrobromic acid vapor. The mixture of alkyl bromides and hydrobromic acid are then reacted over a synthetic crystalline alumino-silicate catalyst, such as a ZSM-5 zeolite, at a temperature of from about 150° C. to about 400° C. so as to form higher molecular weight hydrocarbons and hydrobromic acid vapor. Hydrobromic acid vapor is removed from the higher molecular weight hydrocarbons. A portion of the propane and butane is removed from the higher molecular weight hydrocarbons and reacted with the mixture of alkyl bromides and hydrobromic acid over the synthetic crystalline alumino-silicate catalyst to form C5+ hydrocarbons.

Owner:SULZER MANAGEMENT AG

Process for converting gaseous alkanes to liquid hydrocarbons

Owner:SULZER MANAGEMENT AG

Process for converting gaseous alkanes to olefins and liquid hydrocarbons

InactiveUS20060100469A1High selectivityAvoid disadvantagesBromide preparationRefining with non-metalsAlkaneBromine

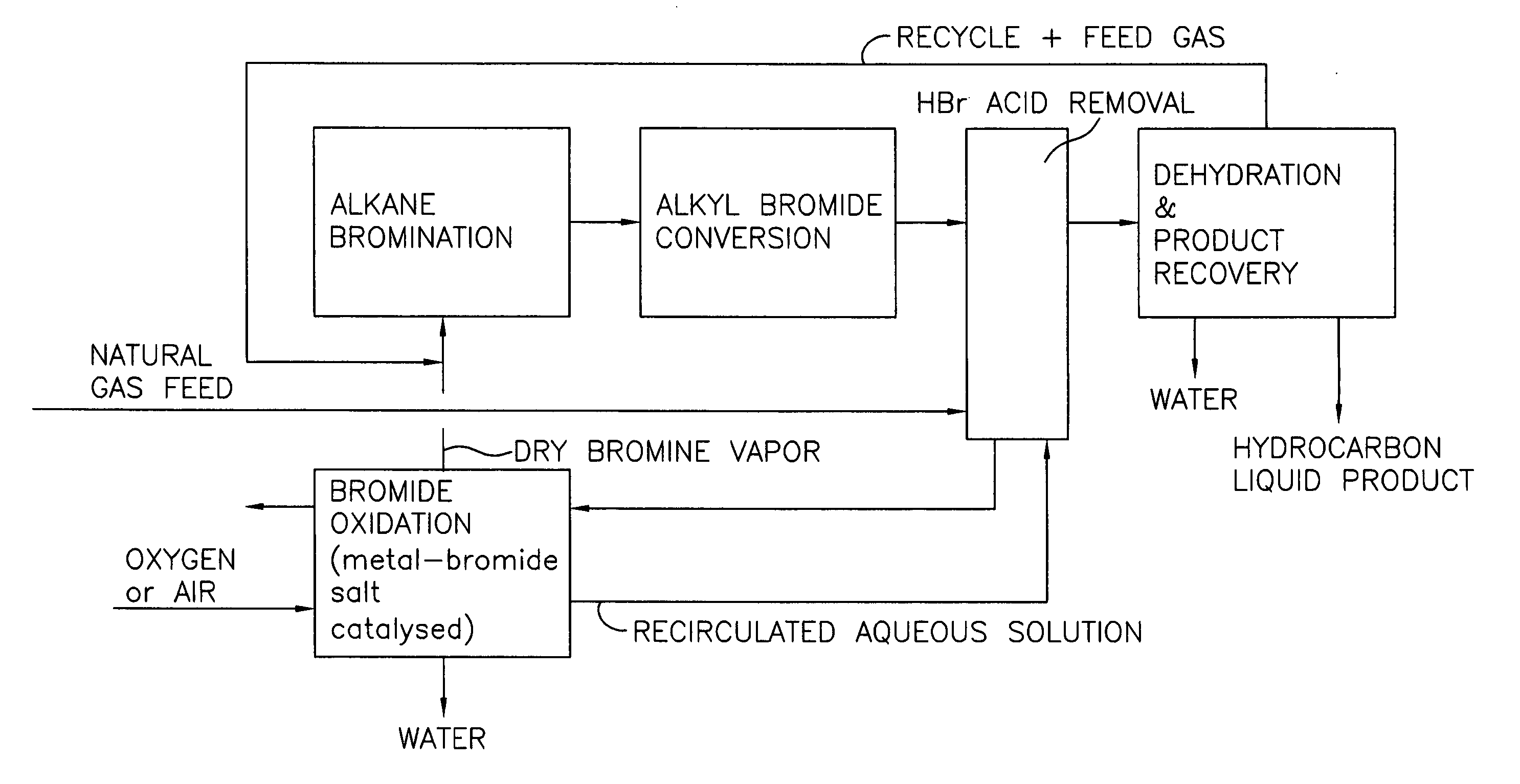

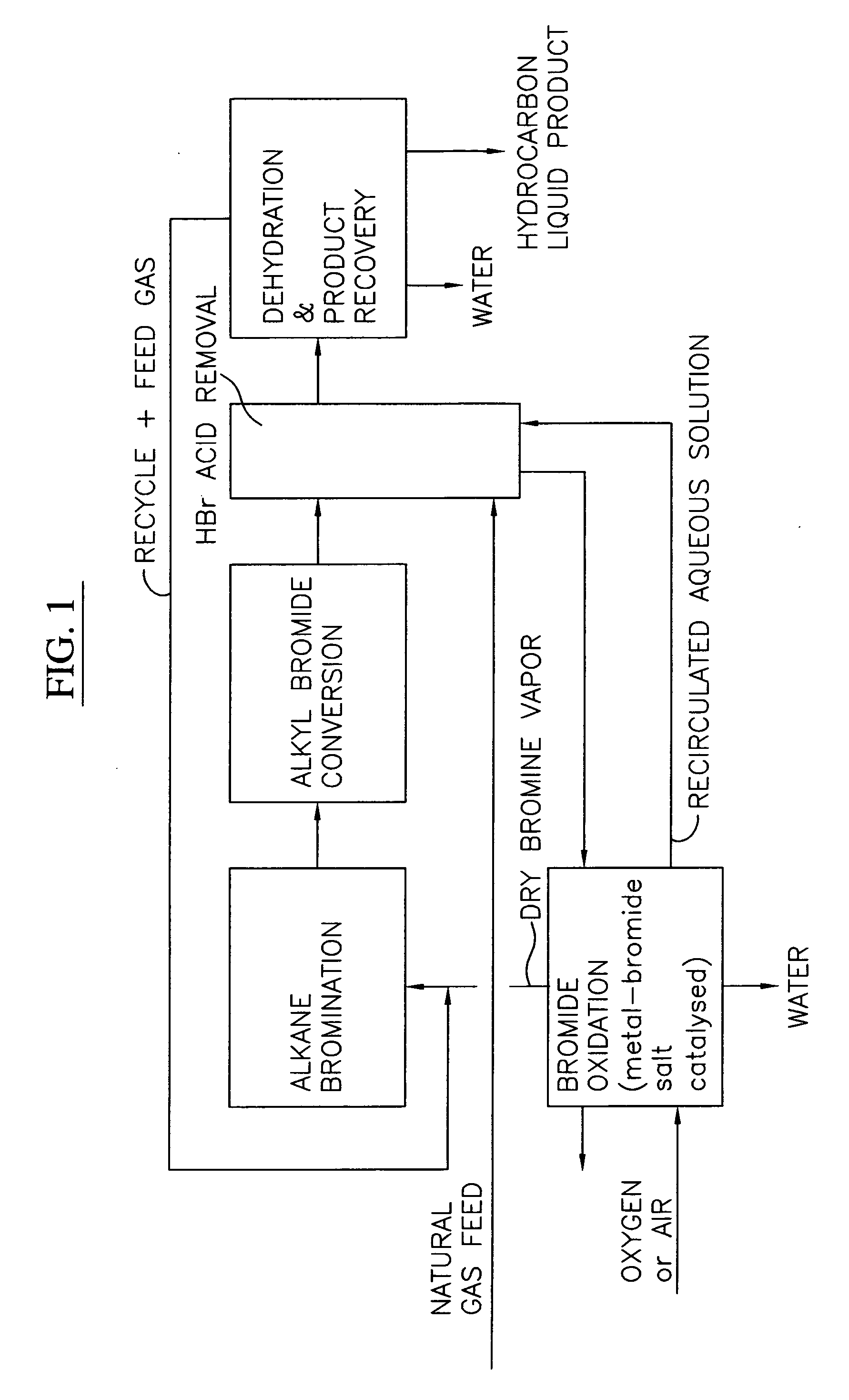

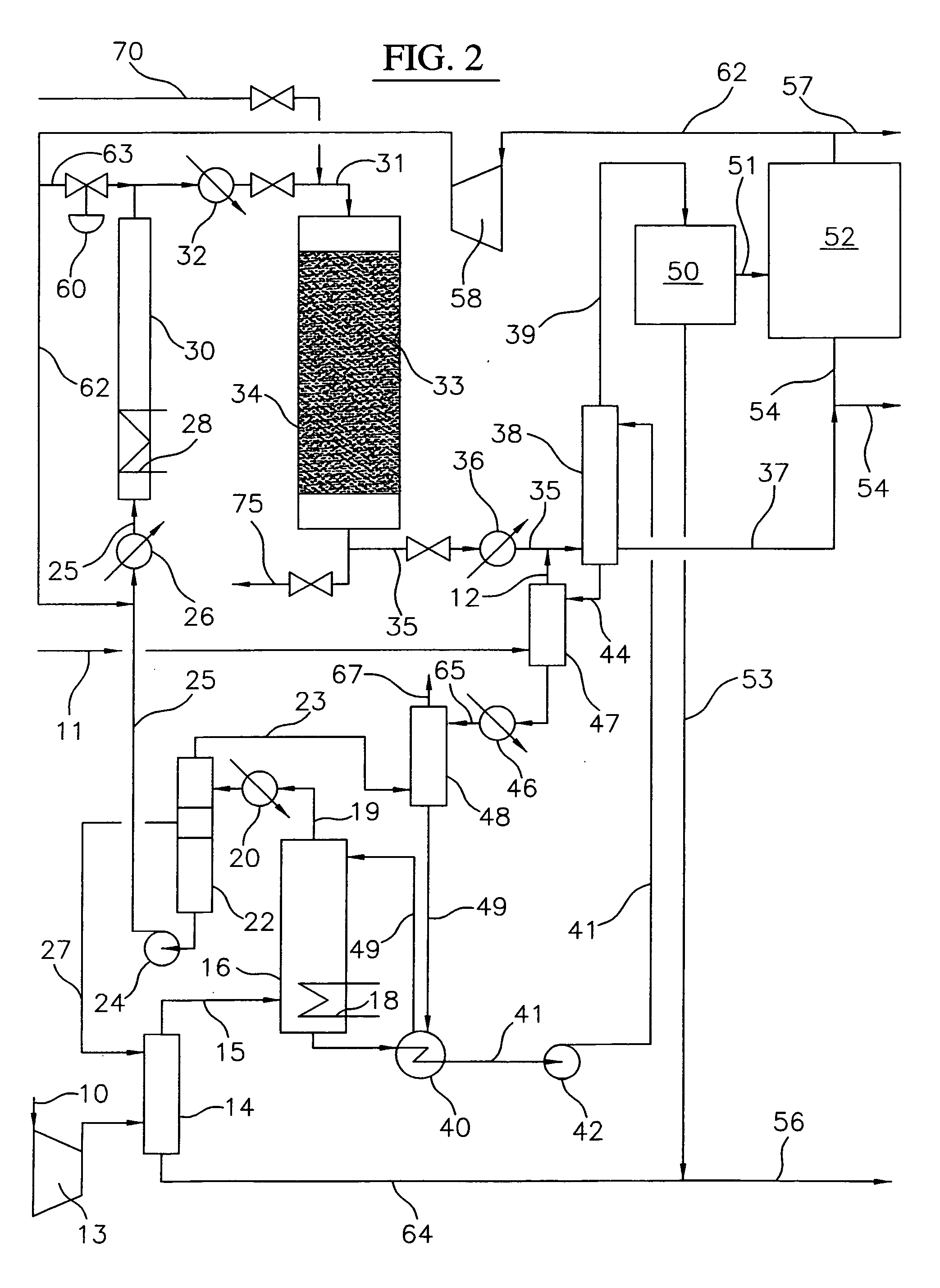

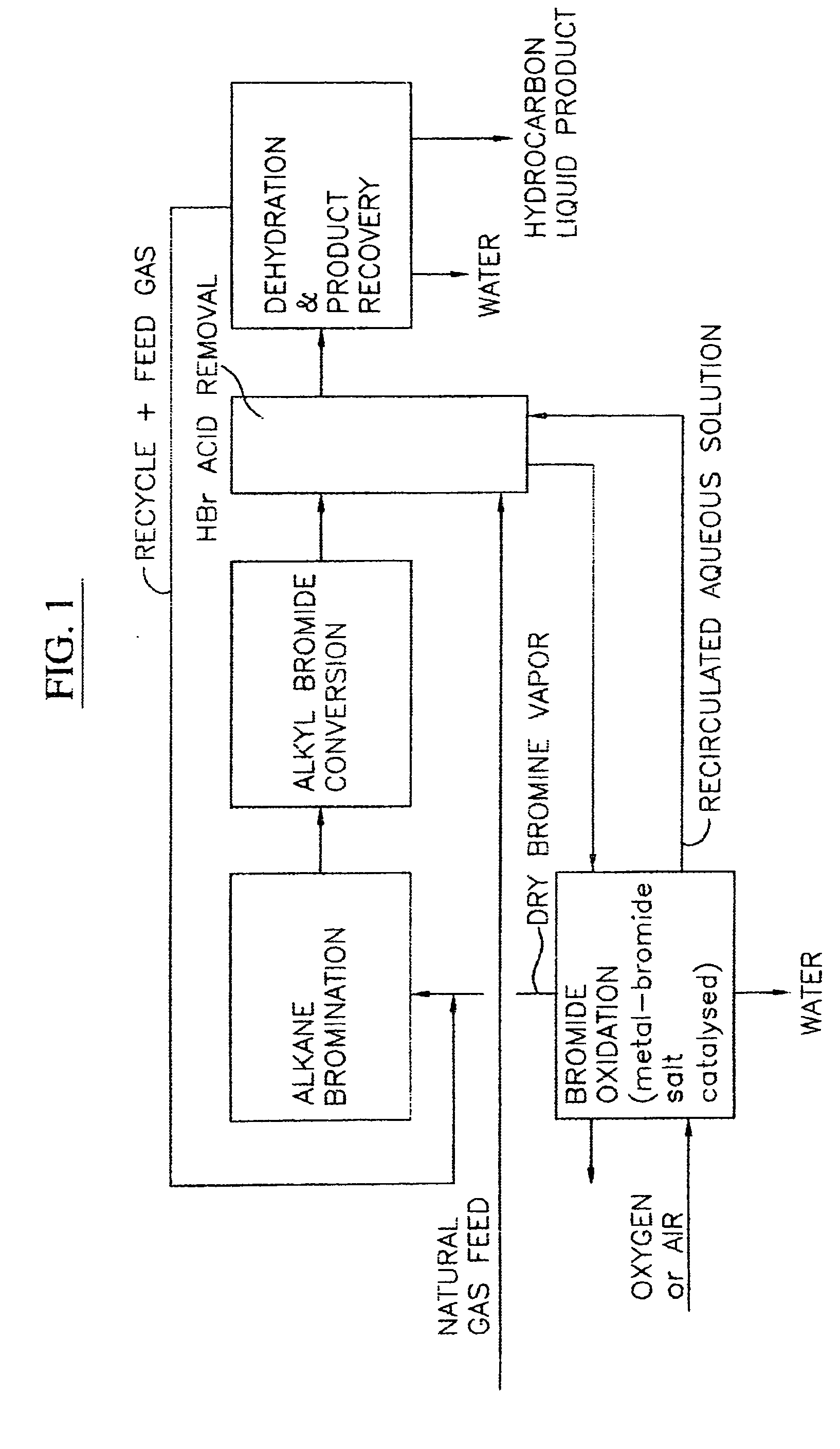

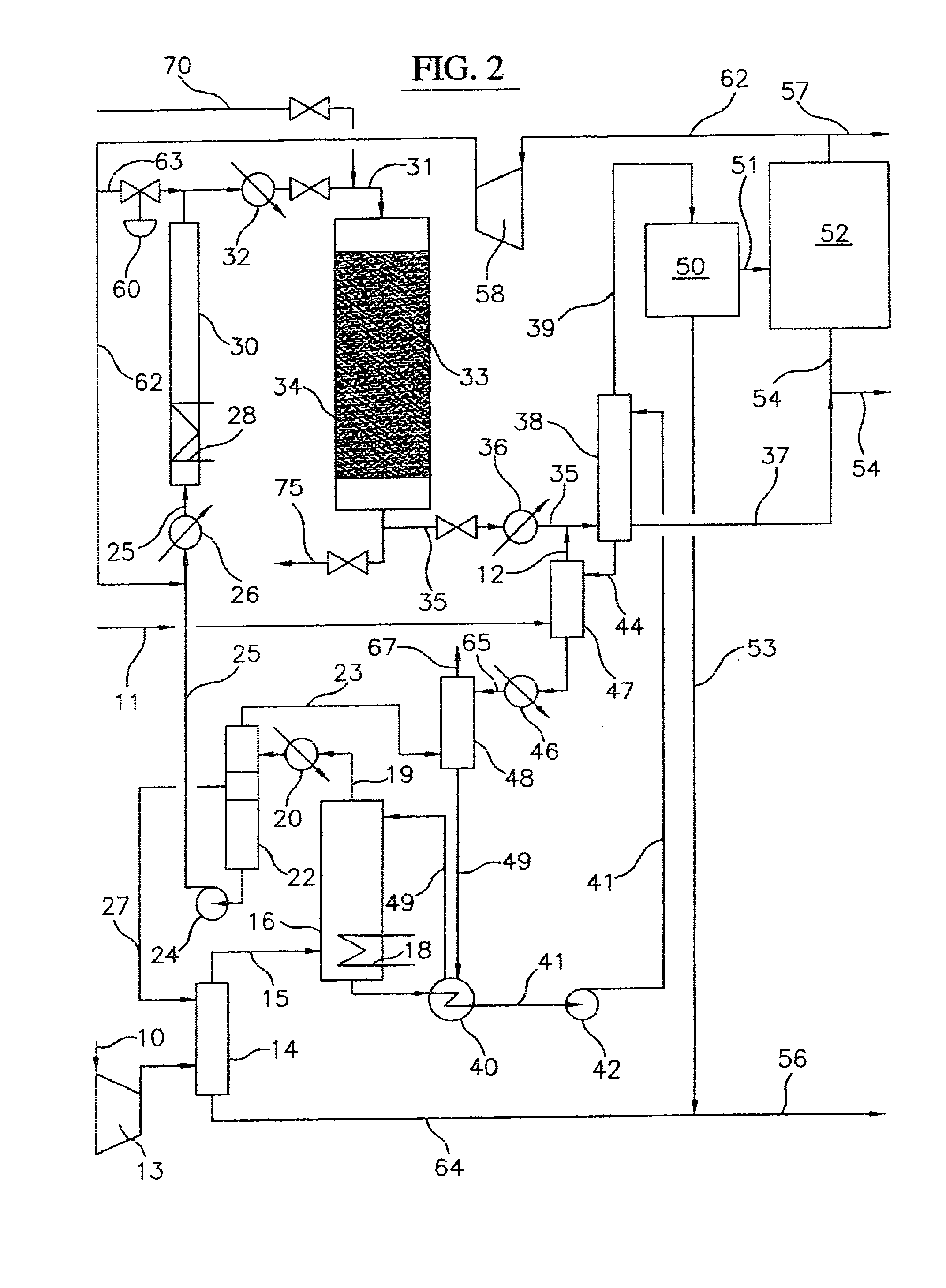

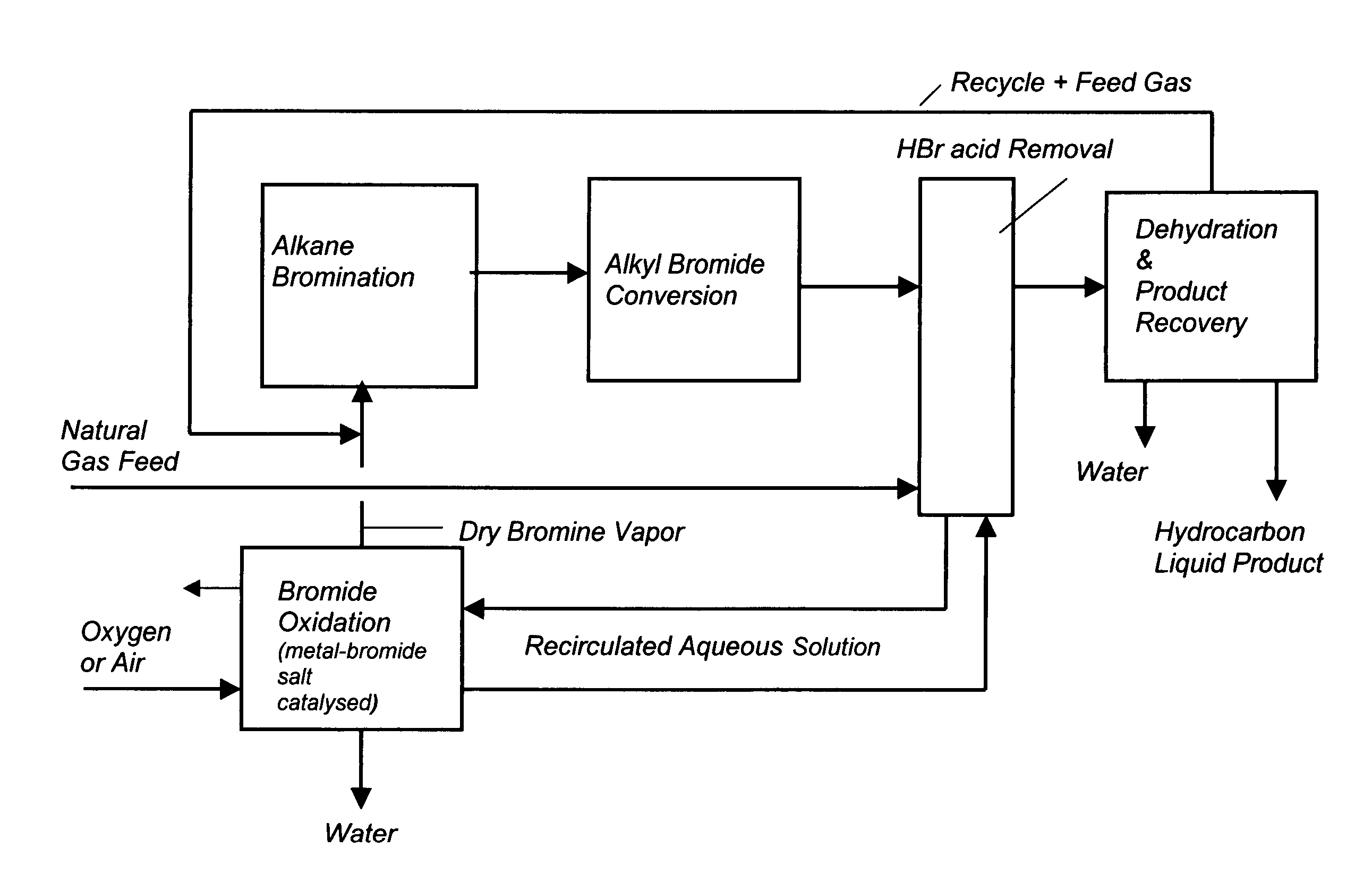

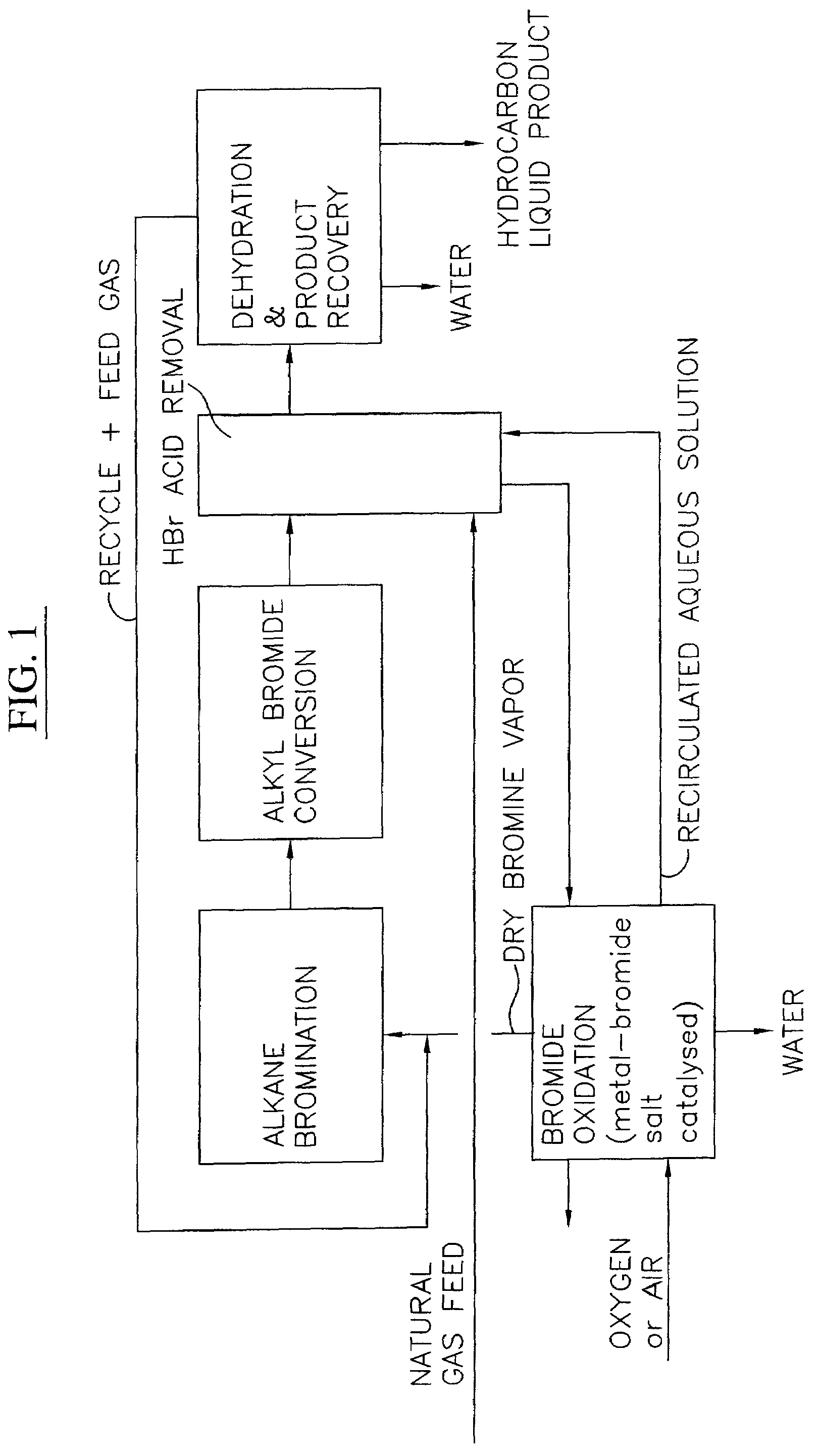

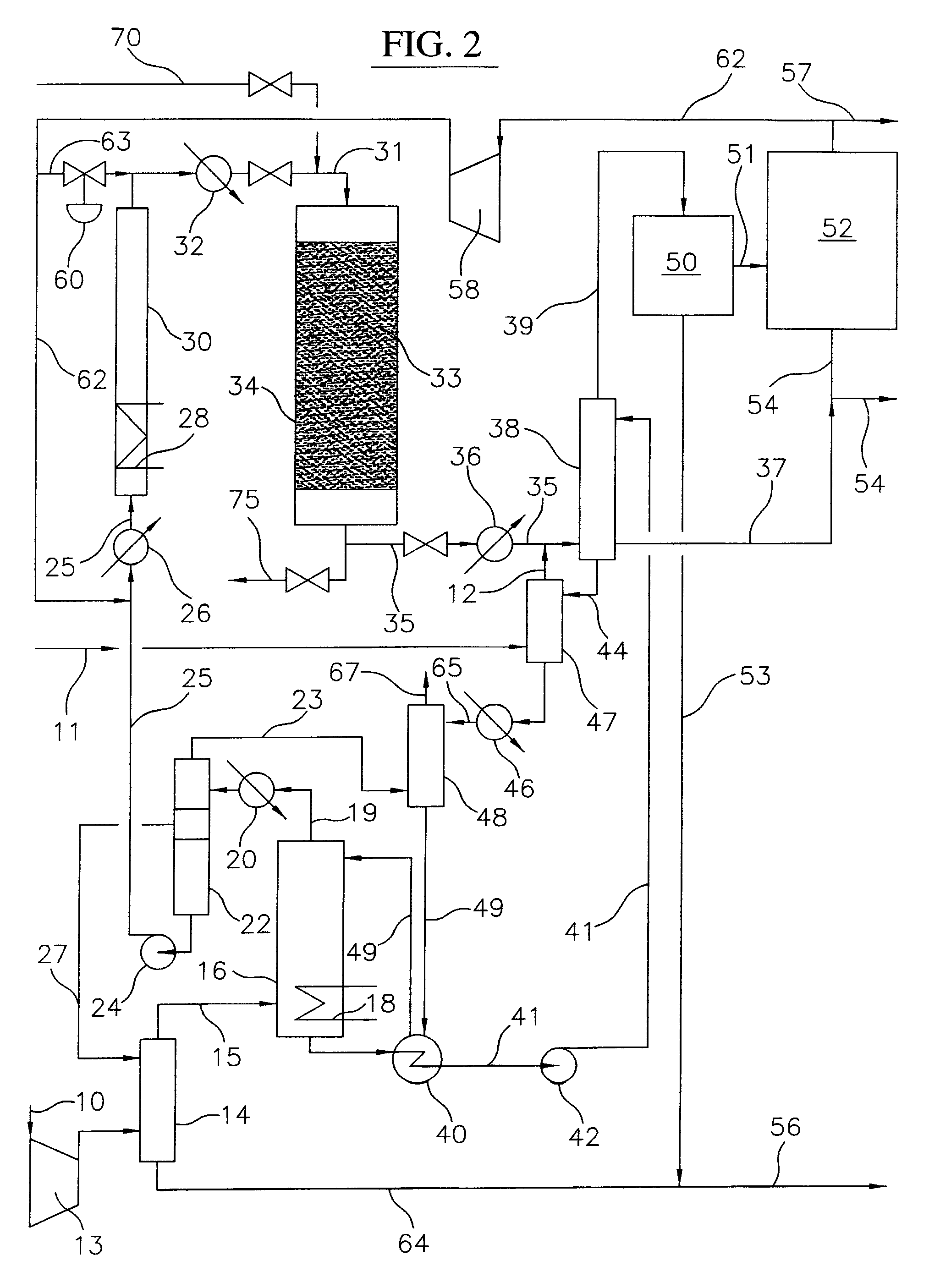

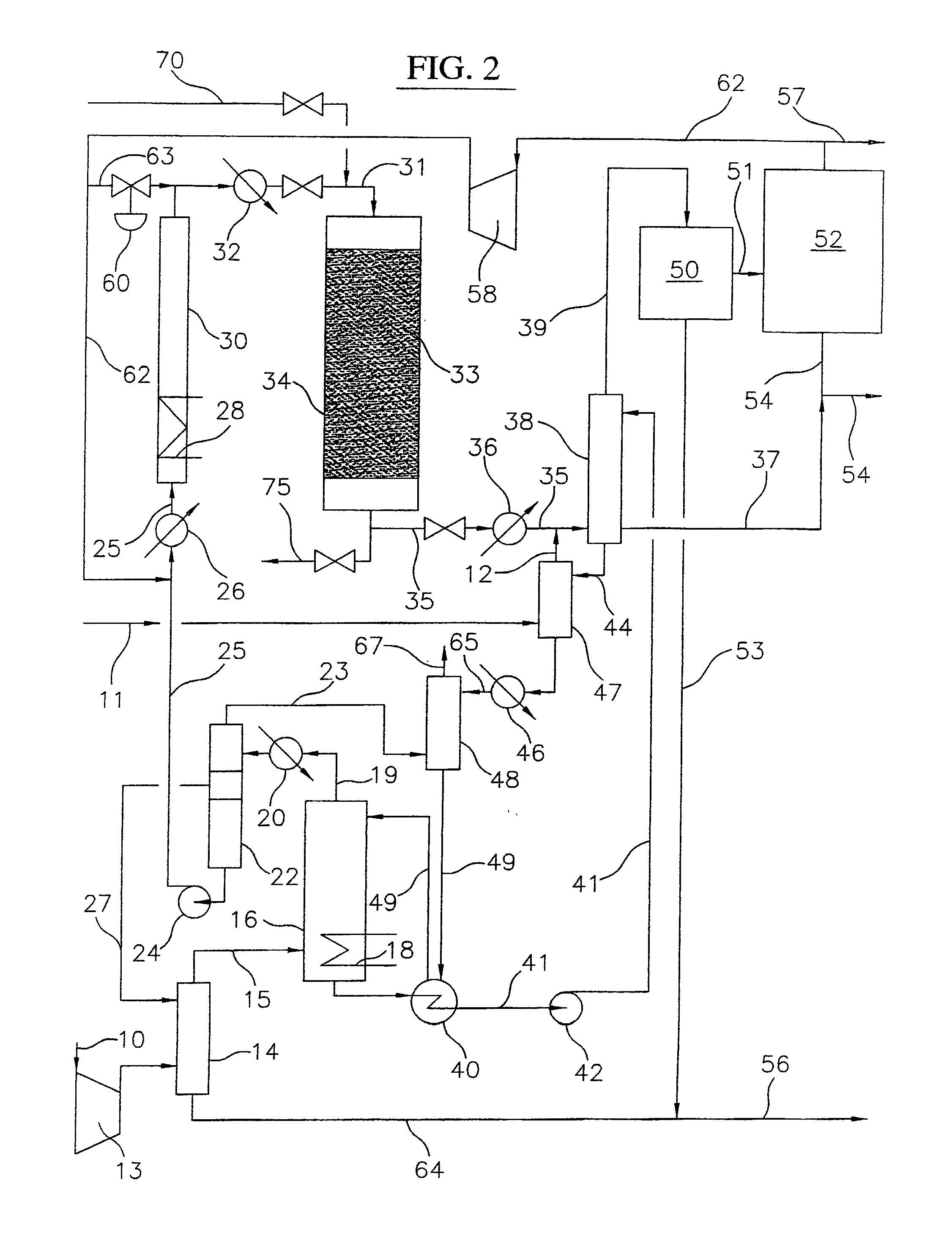

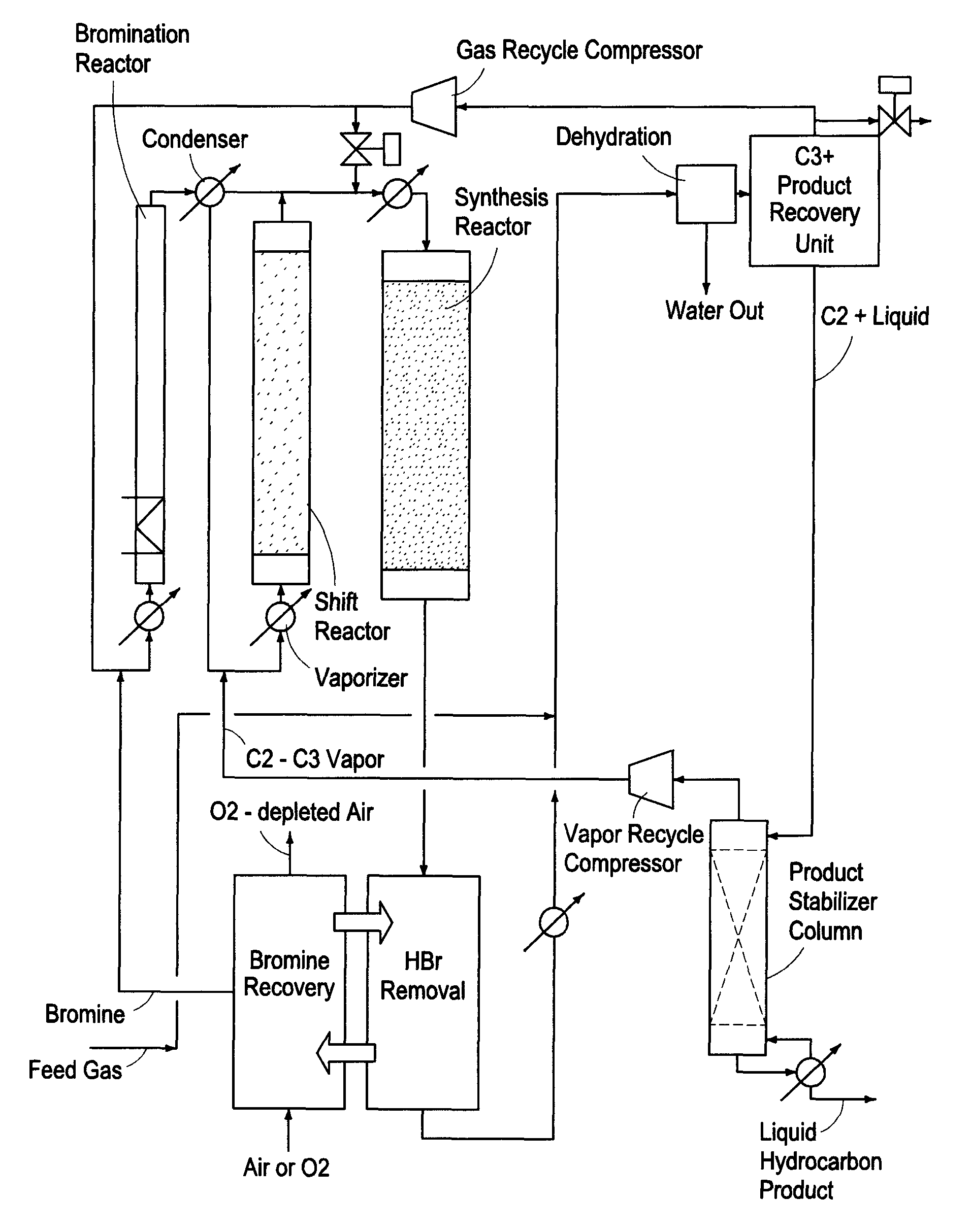

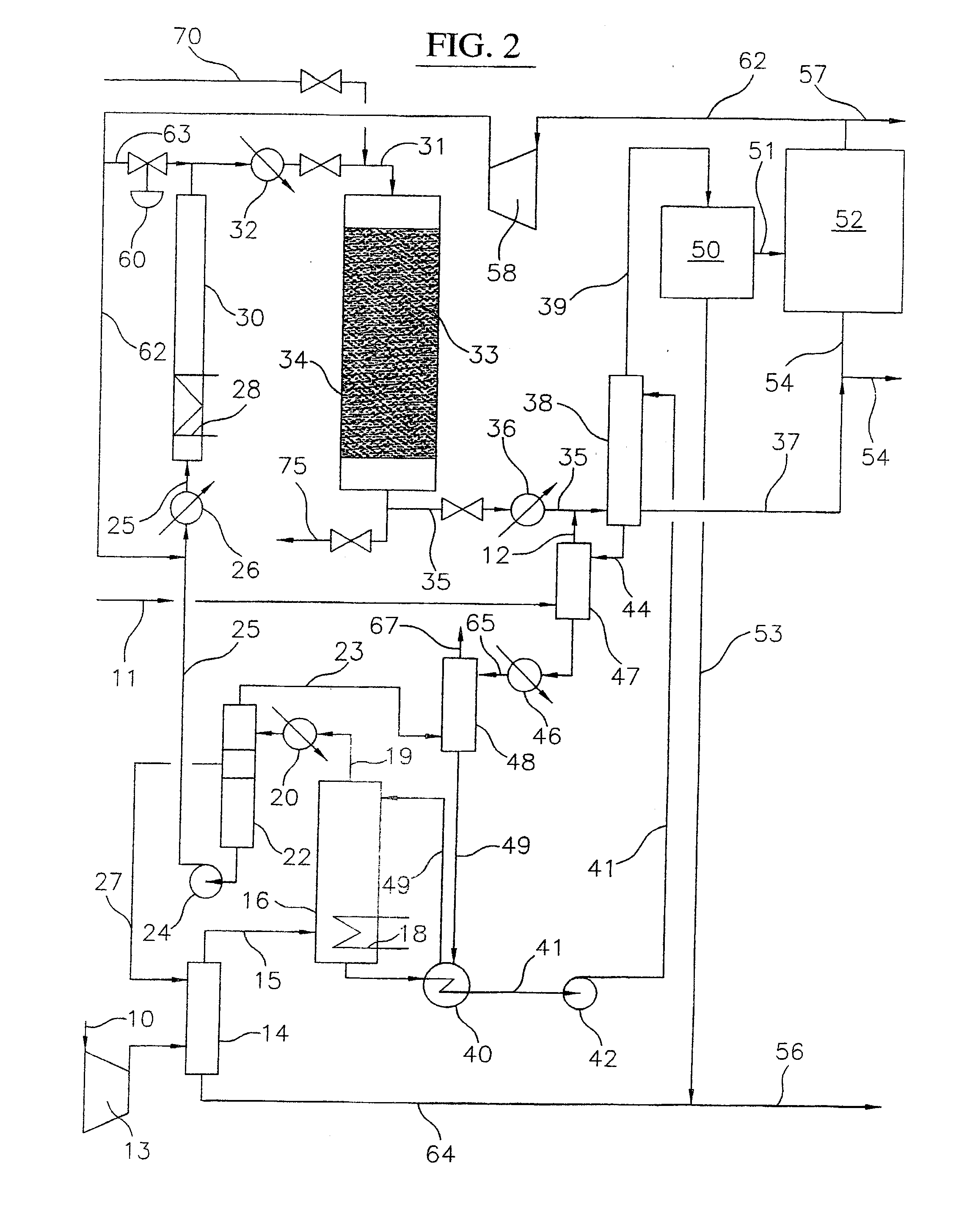

A process for converting gaseous alkanes to olefins and liquid hydrocarbons wherein a gaseous feed containing alkanes is reacted with a dry bromine vapor to form alkyl bromides and hydrobromic acid vapor. The mixture of alkyl bromides and hydrobromic acid are then reacted over a synthetic crystalline alumino-silicate catalyst, such as an X or Y type zeolite, at a temperature of from about 250° C. to about 500° C. so as to form olefins, higher molecular weight hydrocarbons and hydrobromic acid vapor. Various methods are disclosed to remove the hydrobromic acid vapor from the higher molecular weight hydrocarbons and to generate bromine from the hydrobromic acid for use in the process.

Owner:MARATHON GTF TECH

Process for converting gaseous alkanes to liquid hydrocarbons

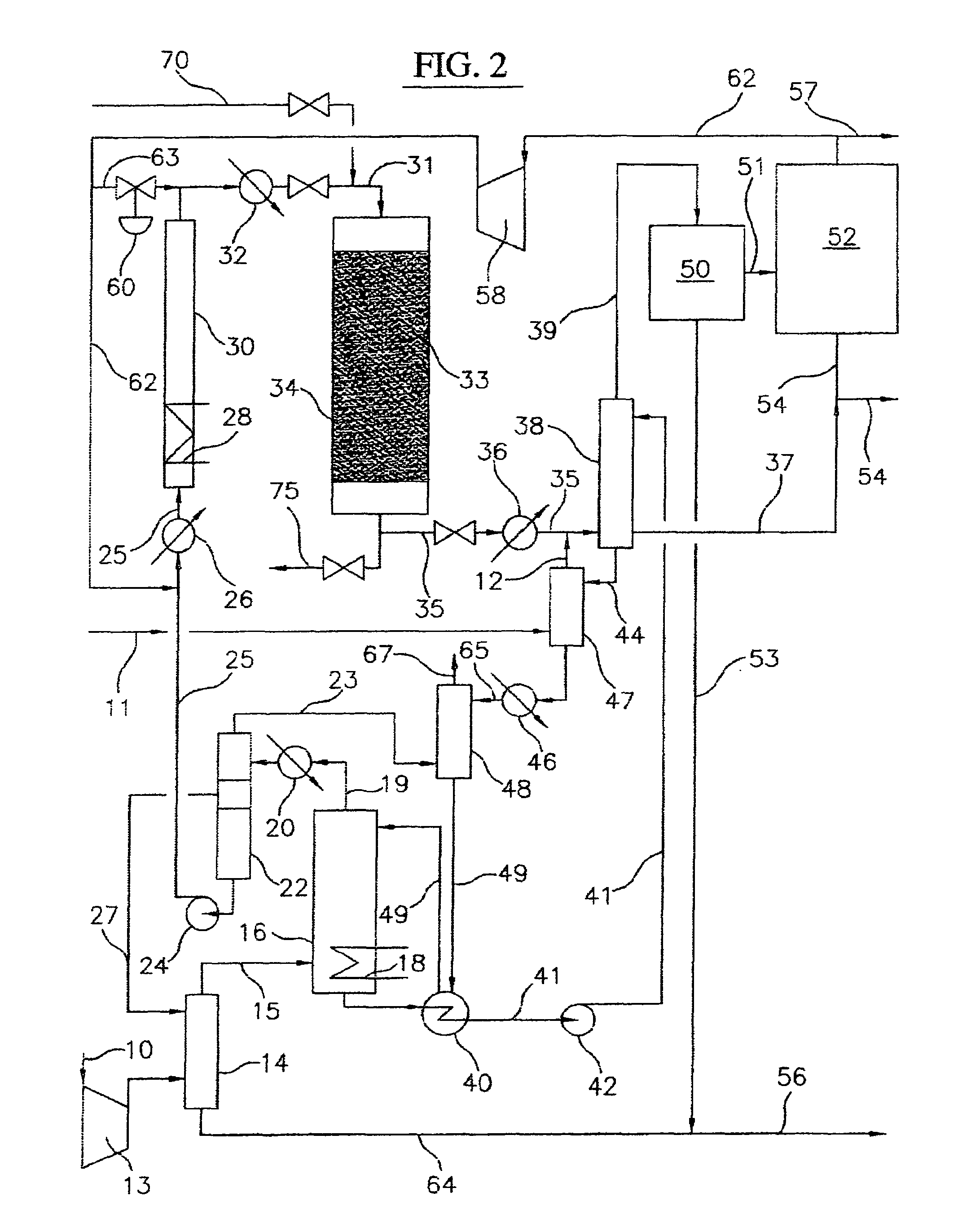

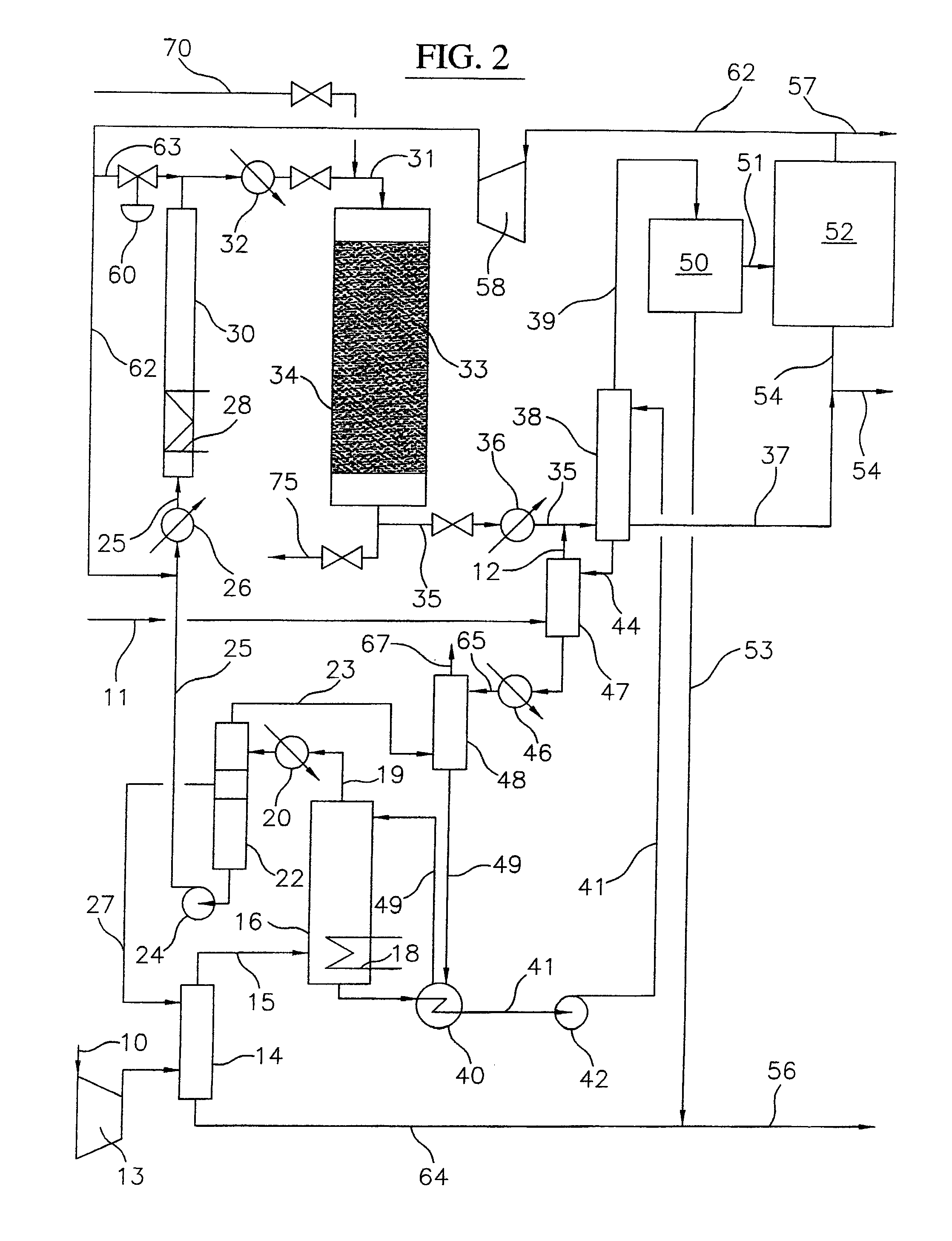

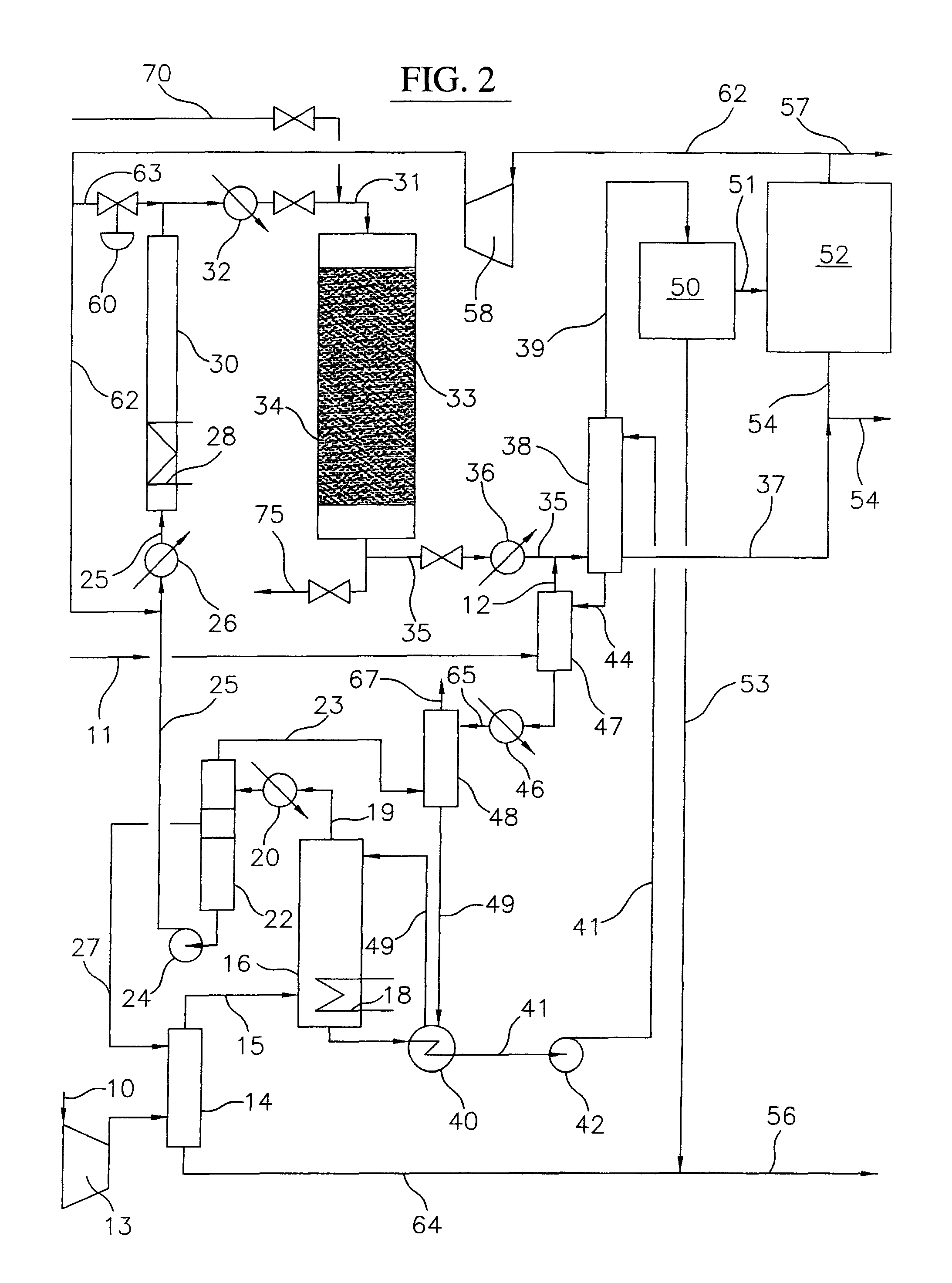

A process for converting gaseous alkanes to liquid hydrocarbons wherein a gaseous feed containing alkanes is reacted with a dry bromine vapor to form alkyl bromides and hydrobromic acid vapor. The mixture of alkyl bromides and hydrobromic acid are then reacted over a synthetic crystalline alumino-silicate catalyst, such as a ZSM-5 zeolite, at a temperature of from about 150° C. to about 450° C. so as to form higher molecular weight hydrocarbons and hydrobromic acid vapor. Propane and butane which comprise a portion of the products may be recovered or recycled back through the process to form additional C5+ hydrocarbons. Various methods are disclosed to remove the hydrobromic acid vapor from the higher molecular weight hydrocarbons and to generate bromine from the hydrobromic acid for use in the process.

Owner:SULZER MANAGEMENT AG

Process for converting gaseous alkanes to liquid hydrocarbons

A process for converting gaseous alkanes to liquid hydrocarbons wherein a gaseous feed containing alkanes is reacted with a dry bromine vapor to form alkyl bromides and hydrobromic acid vapor. The mixture of alkyl bromides and hydrobromic acid are then reacted over a synthetic crystalline alumino-silicate catalyst, such as a ZSM-5 zeolite, at a temperature of from about 150° C. to about 400° C. so as to form higher molecular weight hydrocarbons and hydrobromic acid vapor. Hydrobromic acid vapor is removed from the higher molecular weight hydrocarbons. A portion of the propane and butane is removed from the higher molecular weight hydrocarbons and reacted with the mixture of alkyl bromides and hydrobromic acid over the synthetic crystalline alumino-silicate catalyst to form C5+ hydrocarbons.

Owner:SULZER MANAGEMENT AG

Processes for converting gaseous alkanes to liquid hydrocarbons

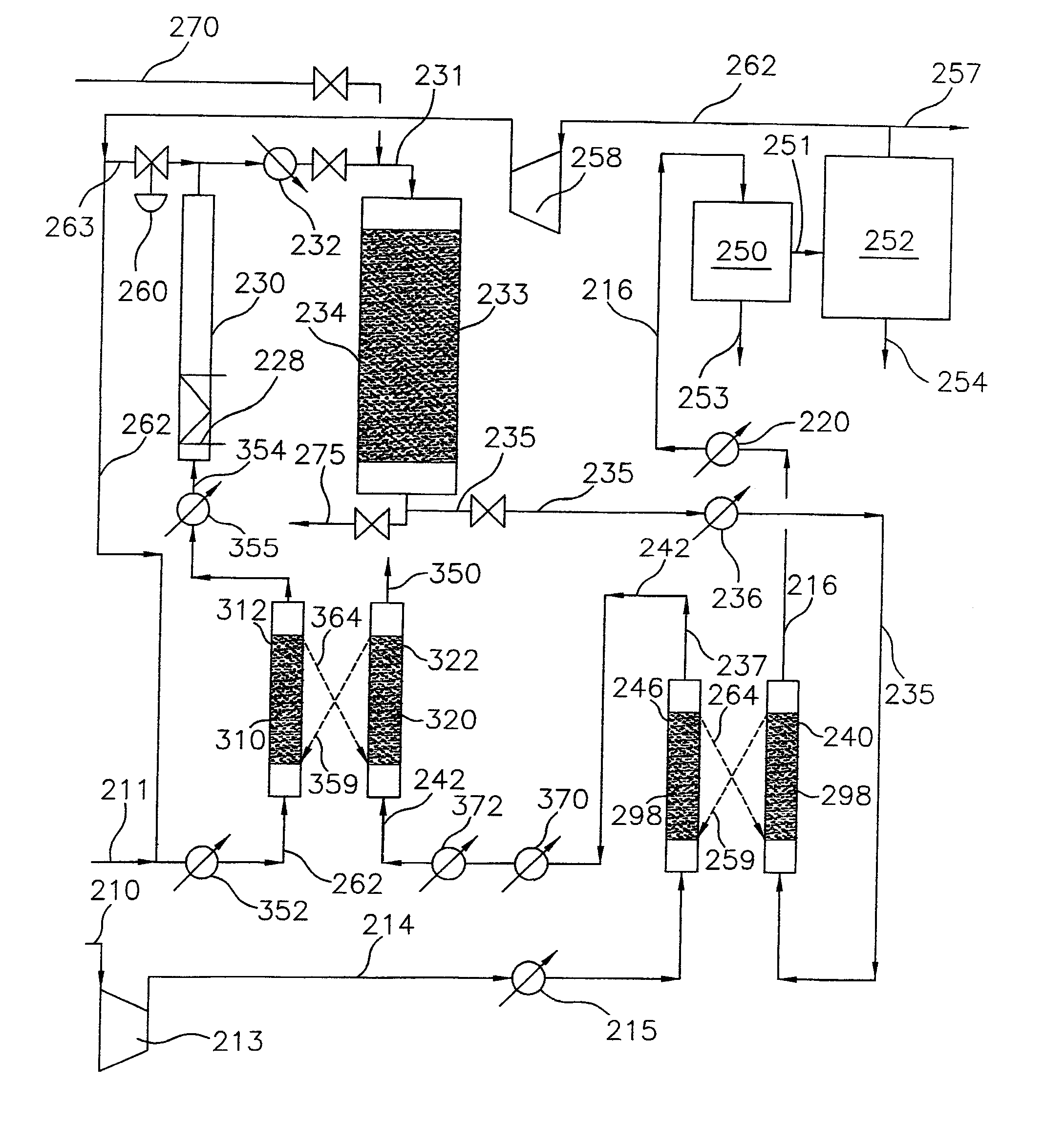

A process for converting gaseous alkanes to olefins, higher molecular weight hydrocarbons or mixtures thereof wherein a gaseous feed containing alkanes is thermally reacted with a dry bromine vapor to form alkyl bromides and hydrogen bromide. Poly-brominated alkanes present in the alkyl bromides are further reacted with methane over a suitable catalyst to form mono-brominated species. The mixture of alkyl bromides and hydrogen bromide is then reacted over a suitable catalyst at a temperature sufficient to form olefins, higher molecular weight hydrocarbons or mixtures thereof and hydrogen bromide. Various methods are disclosed to remove the hydrogen bromide from the higher molecular weight hydrocarbons, to generate bromine from the hydrogen bromide for use in the process, and to selectively form mono-brominated alkanes in the bromination step.

Owner:SULZER MANAGEMENT AG

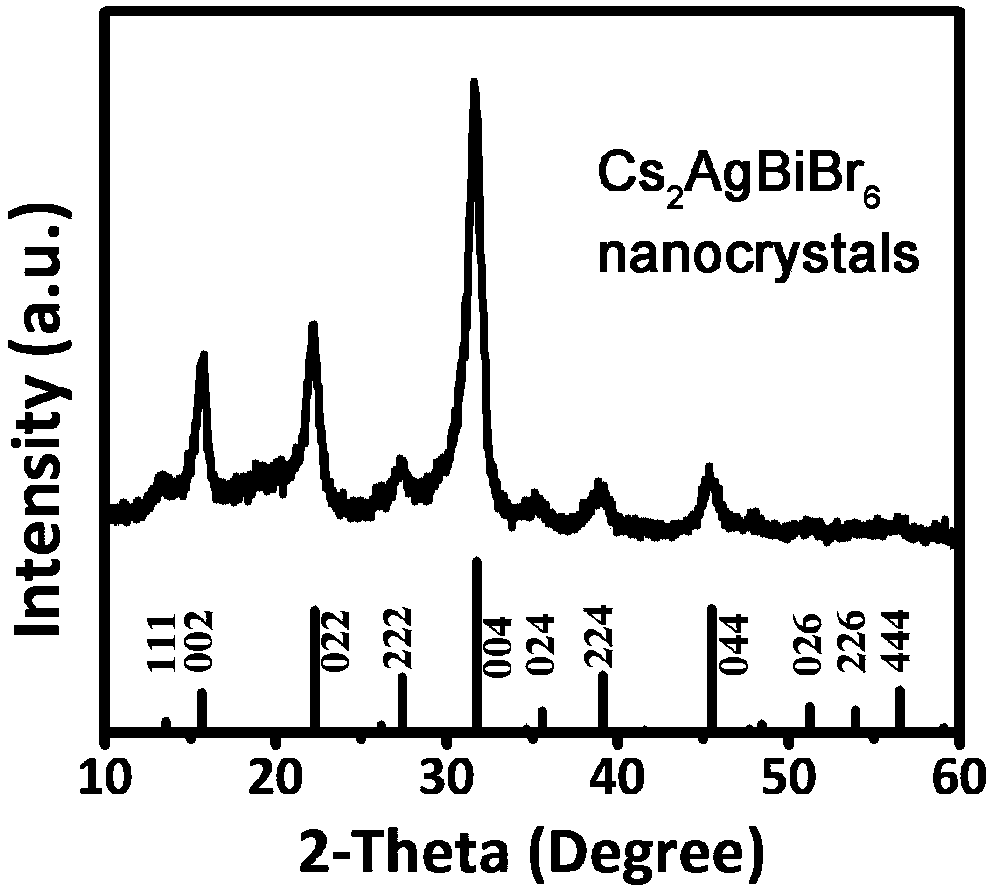

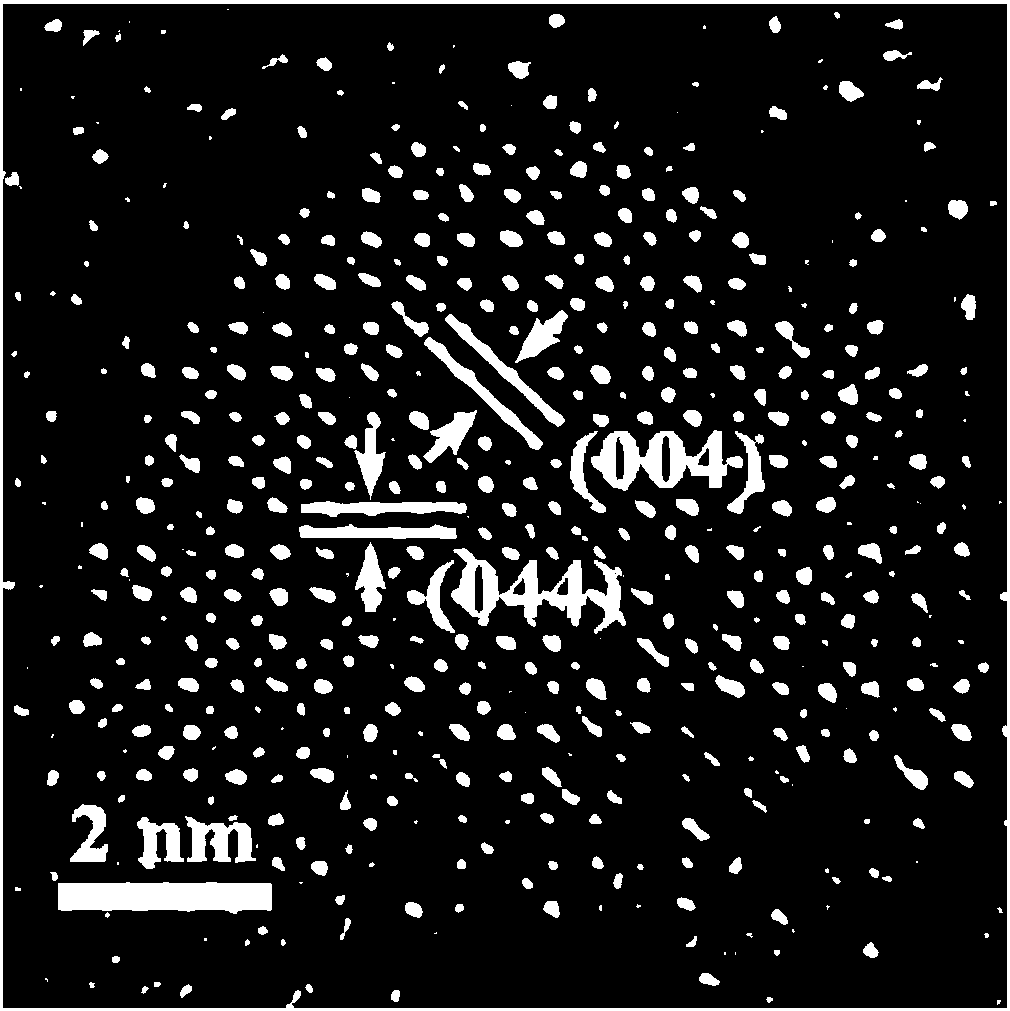

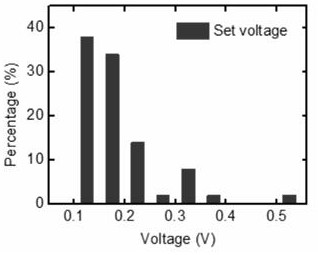

Preparation method of stable lead-free all-inorganic double perovskite A2BB'X6 nanocrystals

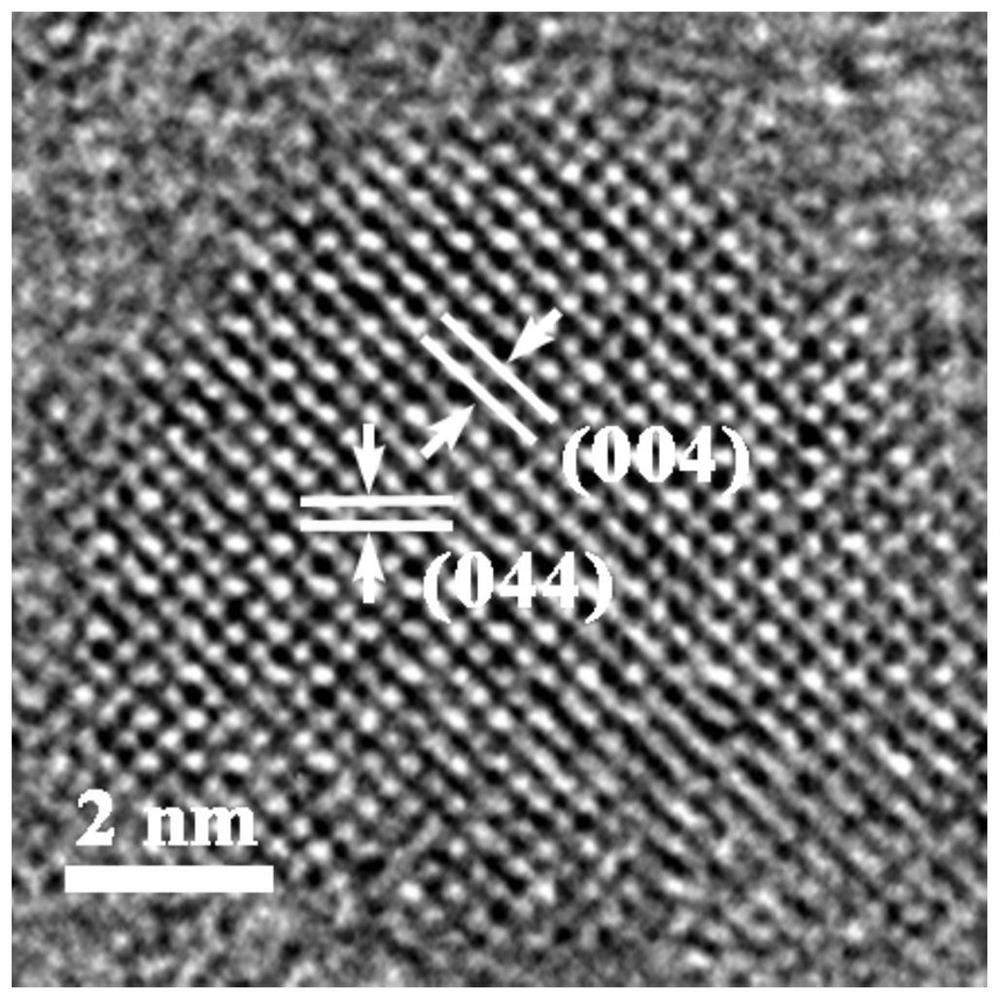

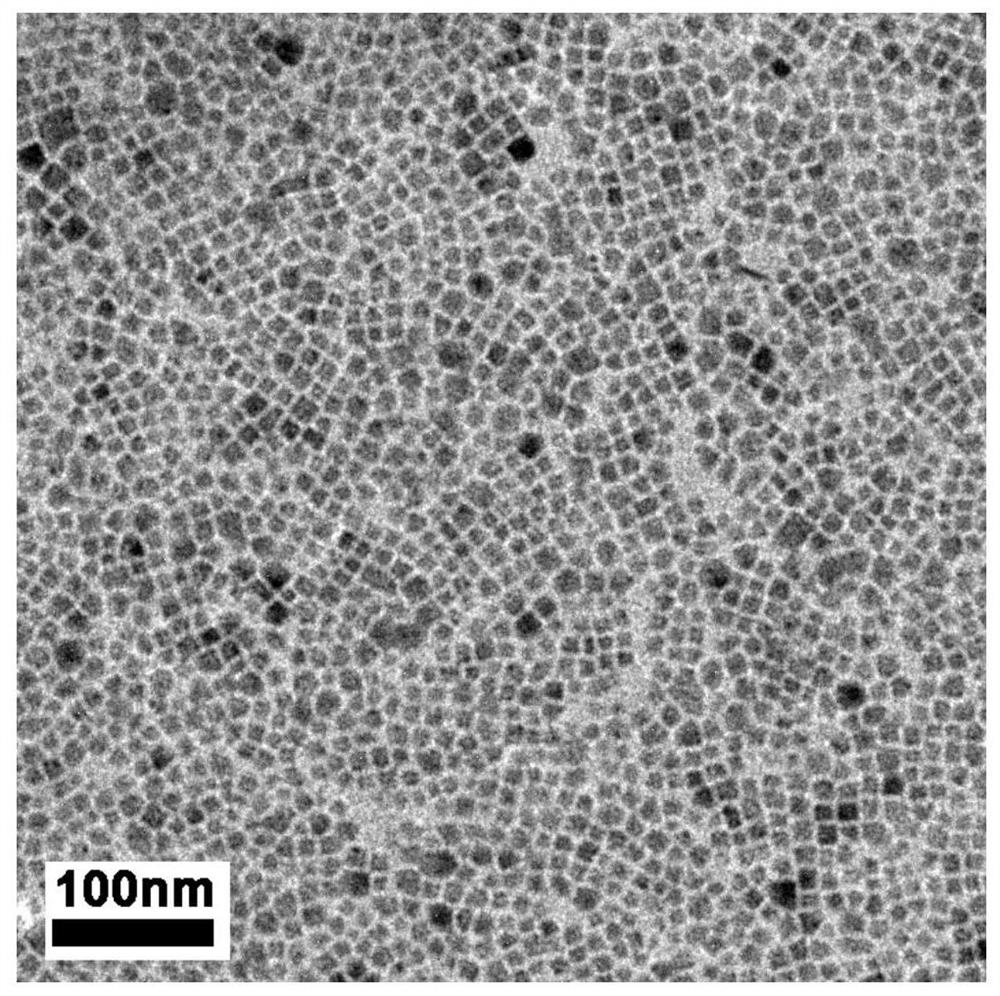

ActiveCN107934916AGood reproducibilityGood dispersionBromide preparationHydrocarbon from carbon oxidesReaction temperaturePhysical chemistry

The invention discloses a preparation method of stable lead-free all-inorganic double perovskite A2BB'X6 nanocrystals. The method adopts a thermal injection technology to synthesize the nanocrystals,and concretely comprises the following steps: mixing a metal precursor salt, a reaction solvent oleic acid, oleylamine, octadecene and other raw materials, carrying out vacuum heating and stirring ata certain temperature for a certain period of time, rising the temperature to a suitable reaction temperature under the protection of N2, rapidly injecting the obtained hot oleate solution of A into areaction system, and then rapidly cooling the system to room temperature by using ice bath to finally obtain the A2BB'X6 perovskite nanocrystals having a uniform size. The method has the advantages of simplicity, convenient, good reappearance and environmental protection, and the obtained product has the advantages of uniform size, good dispersion, high stability and excellent photocatalytic performance, and can be applied to the fields of photocatalysis, photodetectors, laser, solar cells and the like.

Owner:SUN YAT SEN UNIV

Processes for converting gaseous alkanes to liquid hydrocarbons

A process for converting gaseous alkanes to olefins, higher molecular weight hydrocarbons or mixtures thereof wherein a gaseous feed containing alkanes is reacted with a dry bromine vapor to form alkyl bromides and hydrobromic acid vapor. The mixture of alkyl bromides and hydrobromic acid is then reacted over a suitable catalyst at a temperature sufficient to form olefins, higher molecular weight hydrocarbons or mixtures thereof and hydrobromic acid vapor. Various methods are disclosed to remove the hydrobromic acid vapor from the higher molecular weight hydrocarbons, to generate bromine from the hydrobromic acid for use in the process, and to selectively form monobrominated alkanes in the bromination step.

Owner:SULZER MANAGEMENT AG

Nano-scale metal halide scintillation materials and methods for making same

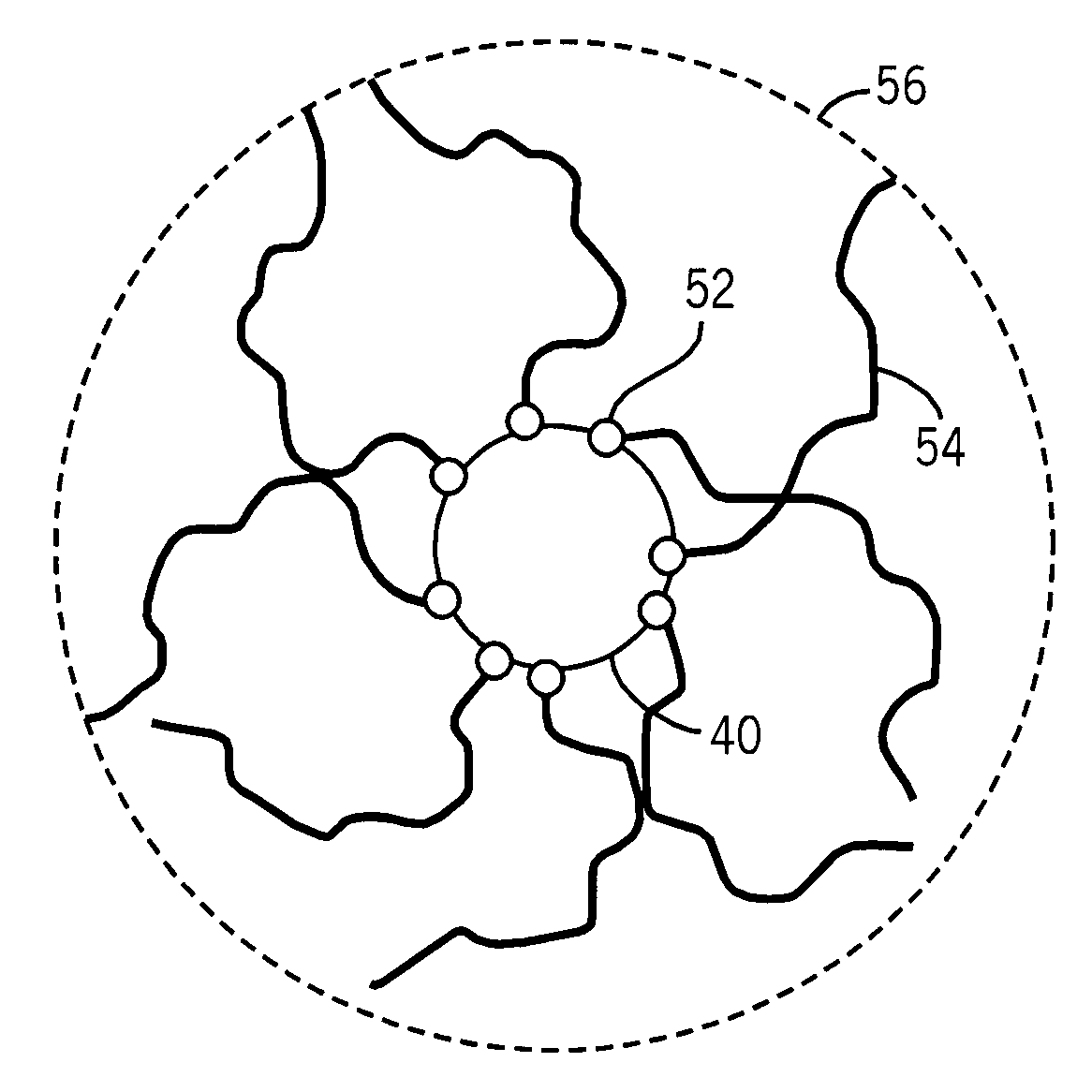

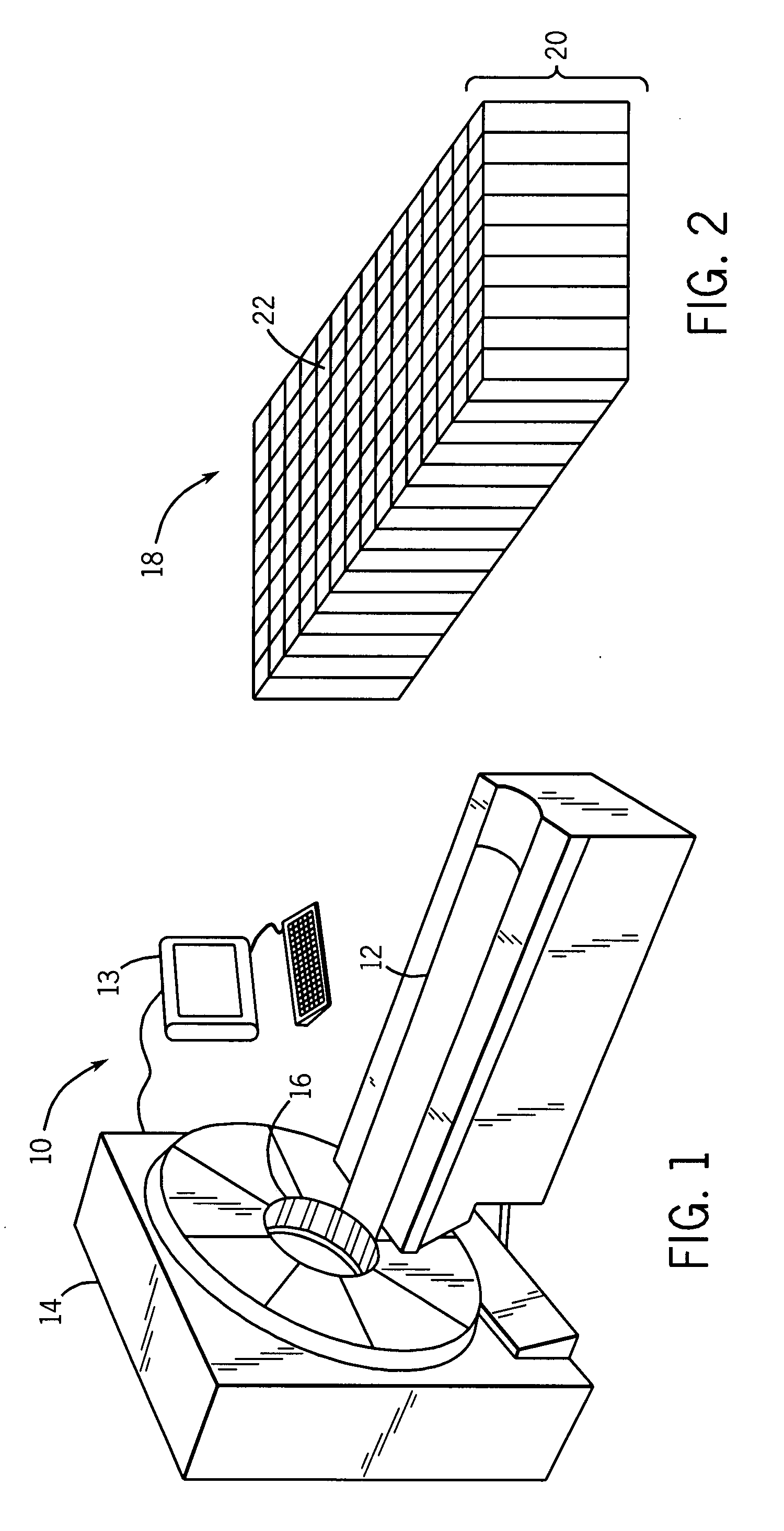

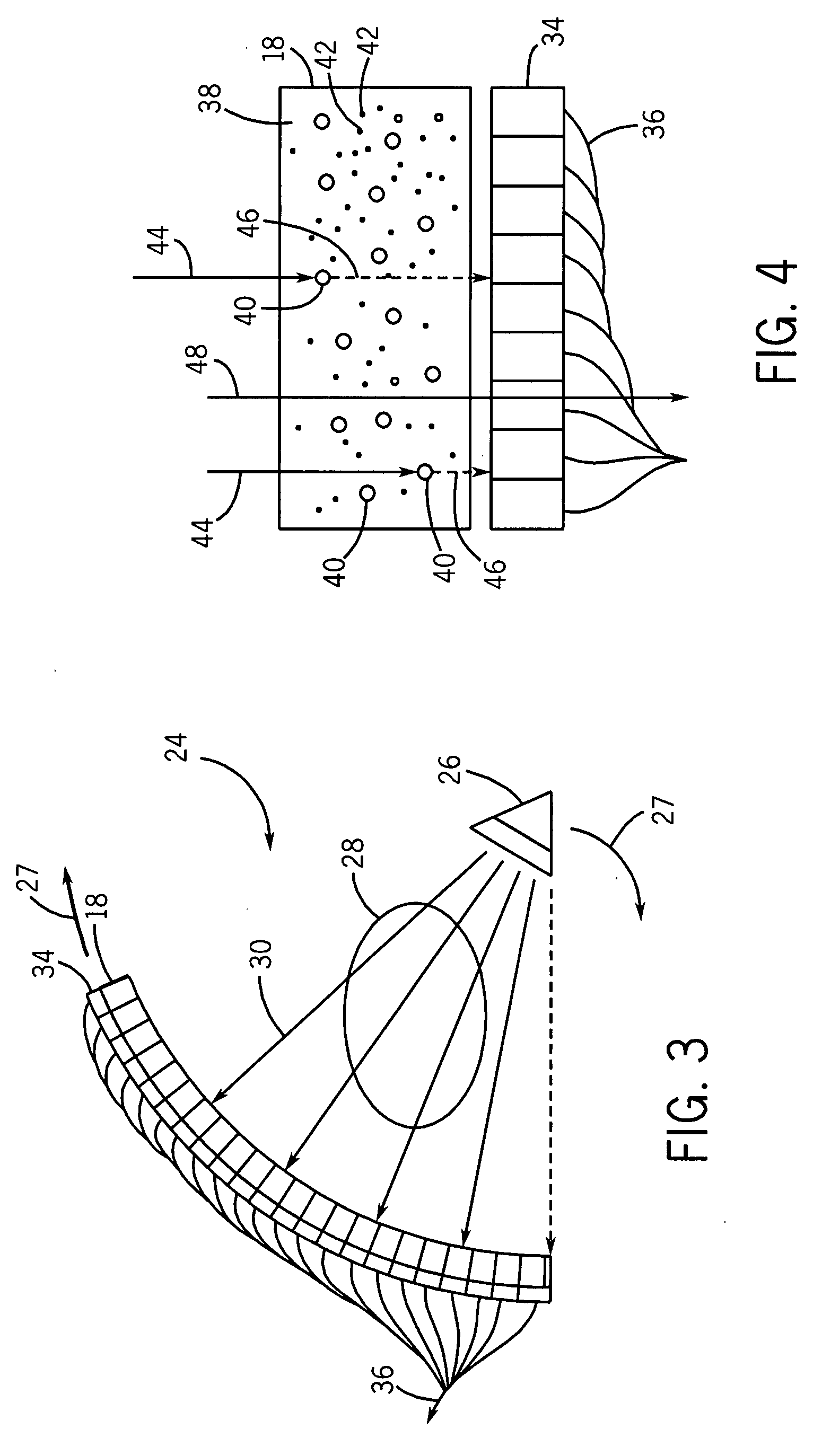

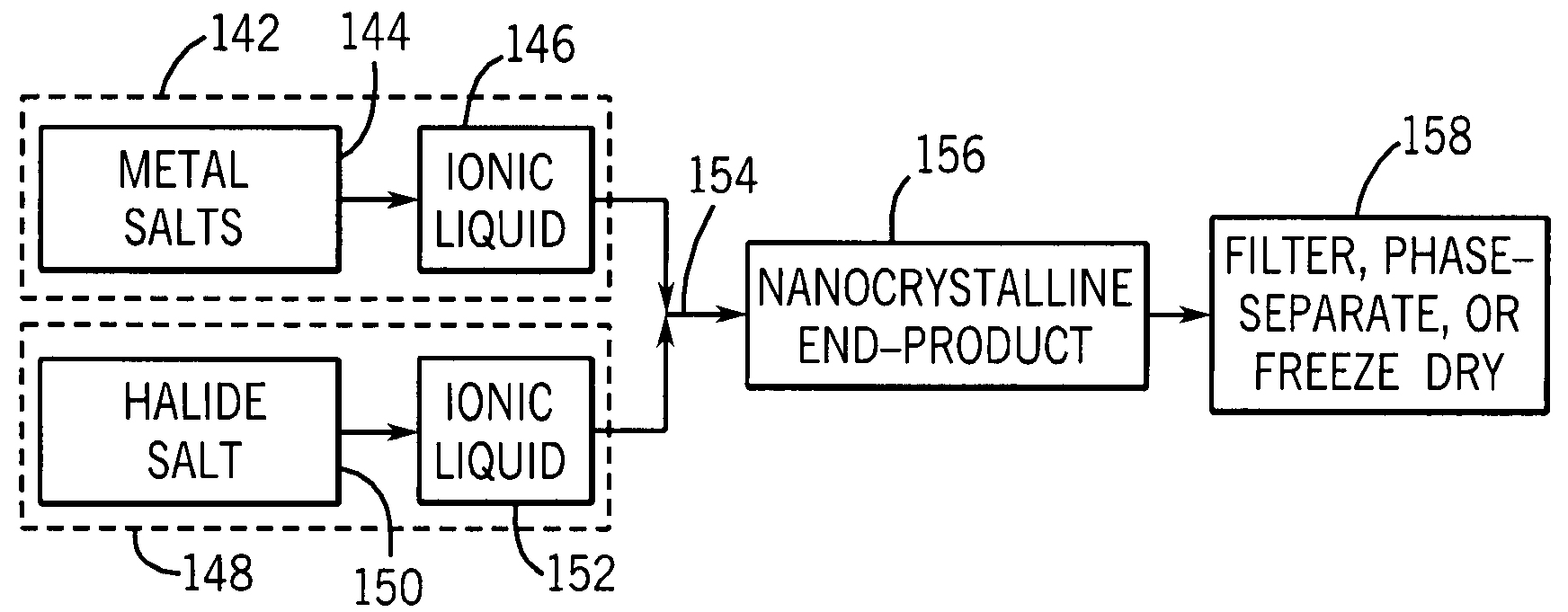

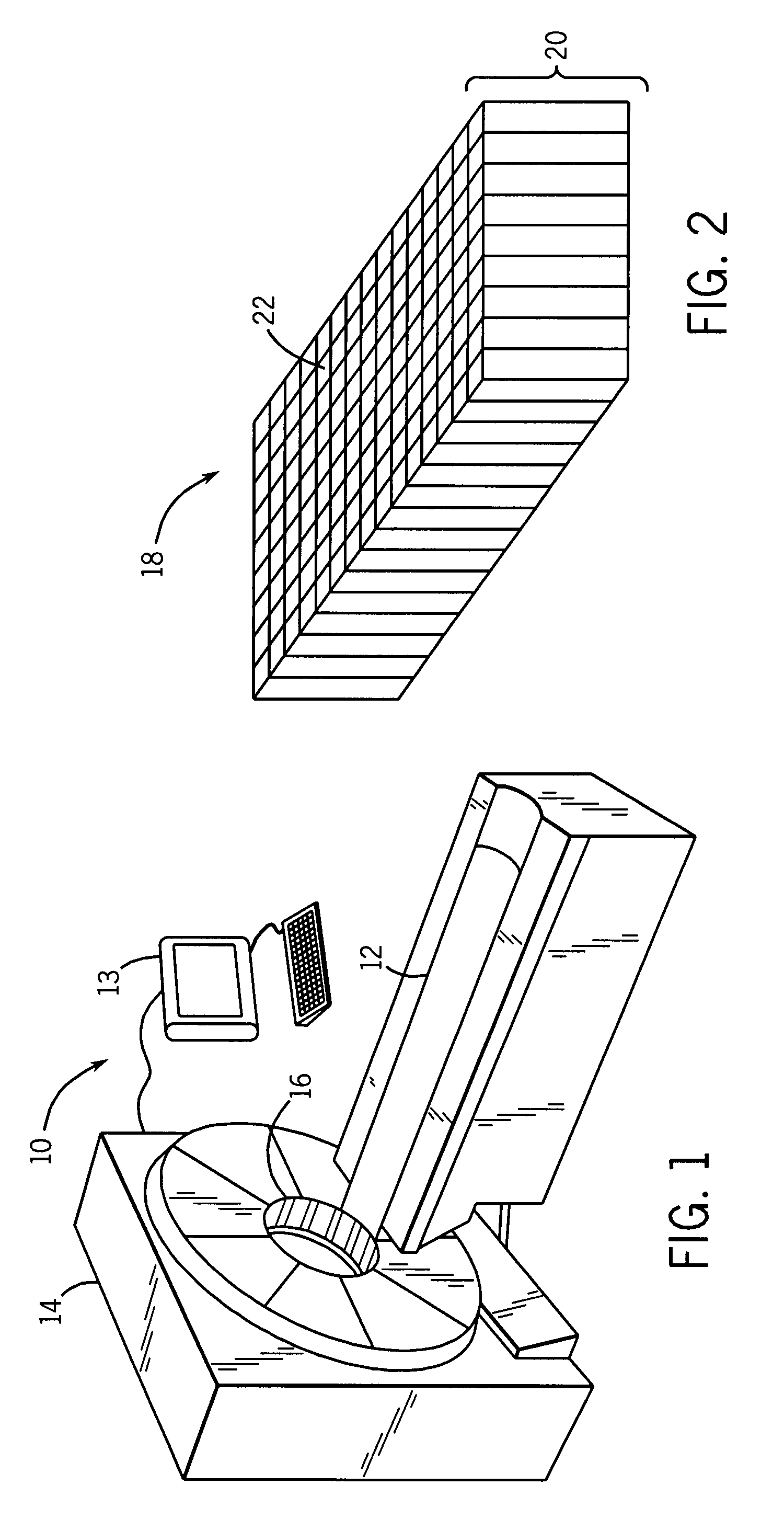

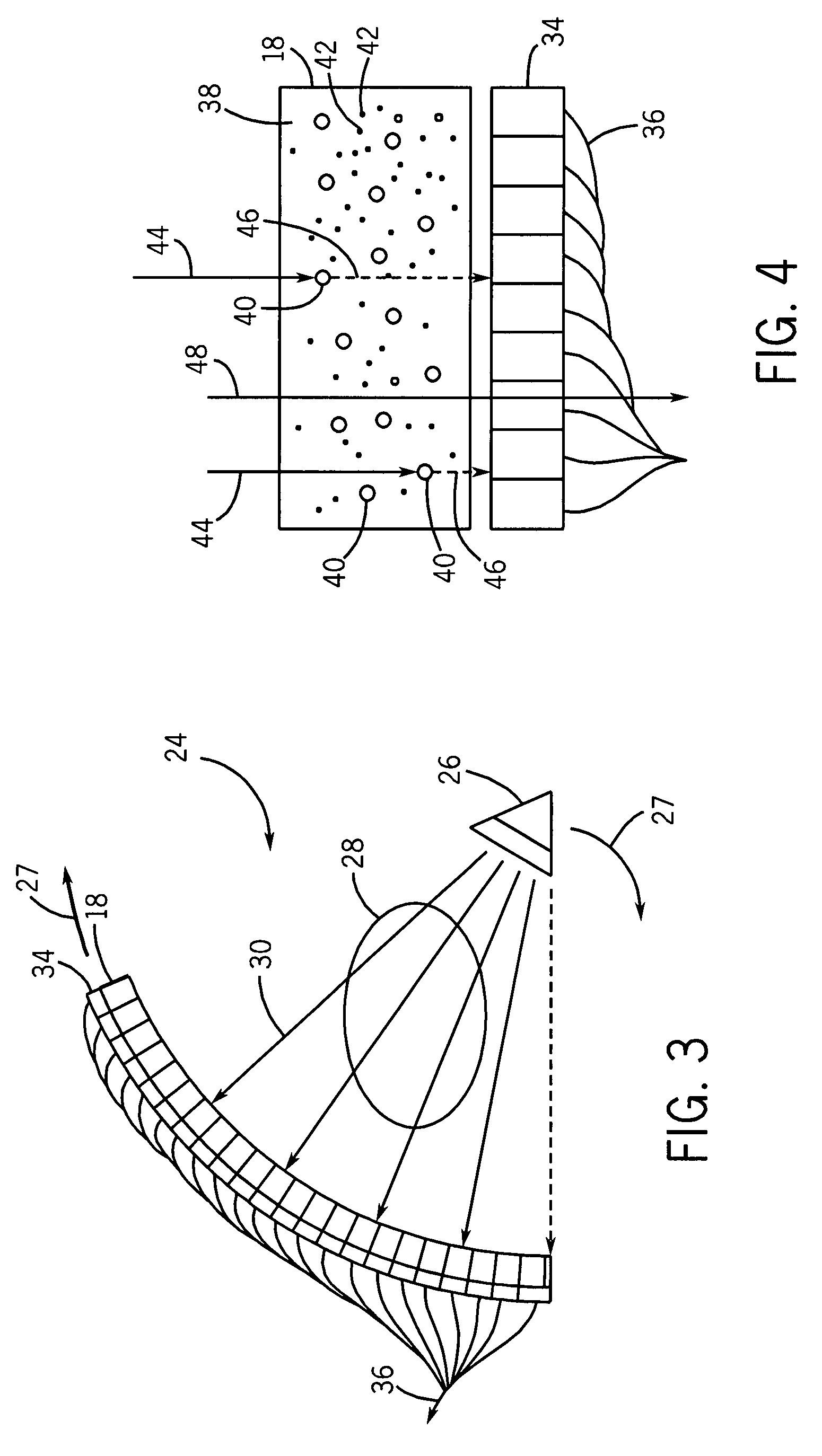

Crystalline scintillator materials comprising nano-scale particles of metal halides are provided. The nano-scale particles are less than 100 nm in size. Methods are provided for preparing the particles. In these methods, ionic liquids are used in place of water to allow precipitation of the final product. In one method, the metal precursors and halide salts are dissolved in separate ionic liquids to form solutions, which are then combined to form the nano-crystalline end product. In the other methods, micro-emulsions are formed using ionic liquids to control particle size.

Owner:GENERAL ELECTRIC CO

Process for converting gaseous alkanes to liquid hydrocarbons

Embodiments disclose a process for converting gaseous alkanes to higher molecular weight hydrocarbons, olefins or mixtures thereofs wherein a gaseous feed containing alkanes may be reacted with a dry bromine vapor to form alkyl bromides and hydrobromic acid vapor. The mixture of alkyl bromides and hydrobromic acid then may be reacted over a synthetic crystalline alumino-silicate catalyst, such as a ZSM-5 or an X or Y type zeolite, at a temperature of from about 250° C. to about 500° C. so as to form hydrobromic acid vapor and higher molecular weight hydrocarbons, olefins or mixtures thereof. Various methods are disclosed to remove the hydrobromic acid vapor from the higher molecular weight hydrocarbons, olefins or mixtures thereof and to generate bromine from the hydrobromic acid for use in the process.

Owner:MARATHON GTF TECH

Process for converting gaseous alkanes to olefins and liquid hydrocarbons

ActiveUS20080200740A1High selectivityAvoid disadvantagesHydrogen bromideBromide preparationAlkaneBromine

A process for converting gaseous alkanes to olefins and higher molecular weight hydrocarbons wherein a gaseous feed containing alkanes is reacted with a dry bromine vapor to form alkyl bromides and hydrobromic acid vapor. The mixture of alkyl bromides and hydrobromic acid are then reacted over a synthetic crystalline alumino-silicate catalyst, such as an X or Y type zeolite, at a temperature of from about 250° C. to about 500° C. so as to form olefins, higher molecular weight hydrocarbons and hydrobromic acid vapor. Various methods are disclosed to remove the hydrobromic acid vapor from the higher molecular weight hydrocarbons and to generate bromine from the hydrobromic acid for use in the process.

Owner:SULZER MANAGEMENT AG

Processes for converting gaseous alkanes to liquid hydrocarbons

A process for converting gaseous alkanes to olefins, higher molecular weight hydrocarbons or mixtures thereof wherein a gaseous feed containing alkanes is reacted with a dry bromine vapor to form alkyl bromides and hydrobromic acid vapor. The mixture of alkyl bromides and hydrobromic acid is then reacted over a suitable catalyst at a temperature sufficient to form olefins, higher molecular weight hydrocarbons or mixtures thereof and hydrobromic acid vapor. Various methods are disclosed to remove the hydrobromic acid vapor from the higher molecular weight hydrocarbons, to generate bromine from the hydrobromic acid for use in the process, and to selectively form monobrominated alkanes in the bromination step.

Owner:SULZER MANAGEMENT AG

Process for converting gaseous alkanes to liquid hydrocarbons

Embodiments disclose a process for converting gaseous alkanes to higher molecular weight hydrocarbons, olefins or mixtures thereofs wherein a gaseous feed containing alkanes may be reacted with a dry bromine vapor to form alkyl bromides and hydrobromic acid vapor. The mixture of alkyl bromides and hydrobromic acid then may be reacted over a synthetic crystalline alumino-silicate catalyst, such as a ZSM-5 or an X or Y type zeolite, at a temperature of from about 250° C. to about 500° C. so as to form hydrobromic acid vapor and higher molecular weight hydrocarbons, olefins or mixtures thereof. Various methods are disclosed to remove the hydrobromic acid vapor from the higher molecular weight hydrocarbons, olefins or mixtures thereof and to generate bromine from the hydrobromic acid for use in the process.

Owner:MARATHON GTF TECH

Process for converting gaseous alkanes to olefins and liquid hydrocarbons

ActiveUS8008535B2High selectivityAvoid disadvantagesBromide preparationHydrogen bromideAlkaneAlkyl bromide

A process for converting gaseous alkanes to olefins and higher molecular weight hydrocarbons wherein a gaseous feed containing alkanes is reacted with a dry bromine vapor to form alkyl bromides and hydrobromic acid vapor. The mixture of alkyl bromides and hydrobromic acid are then reacted over a synthetic crystalline alumino-silicate catalyst, such as an X or Y type zeolite, at a temperature of from about 250° C. to about 500° C. so as to form olefins, higher molecular weight hydrocarbons and hydrobromic acid vapor. Various methods are disclosed to remove the hydrobromic acid vapor from the olefins and higher molecular weight hydrocarbons and to generate bromine from the hydrobromic acid for use in the process.

Owner:SULZER MANAGEMENT AG

Processes for converting gaseous alkanes to liquid hydrocarbons

A process for converting gaseous alkanes to olefins, higher molecular weight hydrocarbons or mixtures thereof wherein a gaseous feed containing alkanes is thermally reacted with a dry bromine vapor to form alkyl bromides and hydrogen bromide. Poly-brominated alkanes present in the alkyl bromides are further reacted with methane over a suitable catalyst to form mono-brominated species. The mixture of alkyl bromides and hydrogen bromide is then reacted over a suitable catalyst at a temperature sufficient to form olefins, higher molecular weight hydrocarbons or mixtures thereof and hydrogen bromide. Various methods are disclosed to remove the hydrogen bromide from the higher molecular weight hydrocarbons, to generate bromine from the hydrogen bromide for use in the process, and to selectively form mono-brominated alkanes in the bromination step.

Owner:SULZER MANAGEMENT AG

Process for preparing element halides

InactiveCN101061060AFast heating rateEfficient heatingBromide preparationChloride preparationTraffic accidentVehicle detection

To specify vehicles carrying persons who can be eyewitnesses in the event of a traffic accident. This vehicle detection apparatus is for detecting any vehicle located in the vicinity of an accident site at the time of occurrence of an accident and comprises a vehicle information storage part for storing vehicle identifiers; a one's own vehicle impact detection storage part for storing information about witnessing vehicles; a vehicle information reader part for obtaining vehicle identifiers from the vehicle information storage part of another vehicle detection apparatus; and an impact detection part for detecting impact and for obtaining the vehicle identifiers from the vehicle information reader part upon detection of the impact to store the vehicle identifiers as information about the eyewitnessing vehicles in the one's own vehicle impact detection storage part. Thus when detecting impact on a vehicle, the apparatus can obtain the identification numbers of nearby vehicles and specify any vehicles carrying persons who can be eyewitnesses of the traffic accident.

Owner:WACKER CHEM GMBH

Nano-scale metal halide scintillation materials and methods for making same

Crystalline scintillator materials comprising nano-scale particles of metal halides are provided. The nano-scale particles are less than 100 nm in size. Methods are provided for preparing the particles. In these methods, ionic liquids are used in place of water to allow precipitation of the final product. In one method, the metal precursors and halide salts are dissolved in separate ionic liquids to form solutions, which are then combined to form the nano-crystalline end product. In the other methods, micro-emulsions are formed using ionic liquids to control particle size.

Owner:GENERAL ELECTRIC CO

Processes for converting gaseous alkanes to liquid hydrocarbons using microchannel reactor

A process for converting gaseous alkanes to olefins, higher molecular weight hydrocarbons or mixtures thereof wherein a gaseous feed containing alkanes may be thermally or catalytically reacted with a dry bromine vapor to form alkyl bromides and hydrogen bromide. Poly-brominated alkanes present in the alkyl bromides may be further reacted with methane over a suitable catalyst to form mono-brominated species. The mixture of alkyl bromides and hydrogen bromide may then be reacted over a suitable catalyst at a temperature sufficient to form olefins, higher molecular weight hydrocarbons or mixtures thereof and hydrogen bromide. Various methods and reactions are disclosed to remove the hydrogen bromide from the higher molecular weight hydrocarbons, to generate bromine from the hydrogen bromide for use in the process, to store and subsequently release bromine for use in the process, and to selectively form mono-brominated alkanes in the bromination step. One or more of the reactions of the processes of the present invention may be conducted in a microchannel reactor.

Owner:GTC TECHNOLOGY US LLC

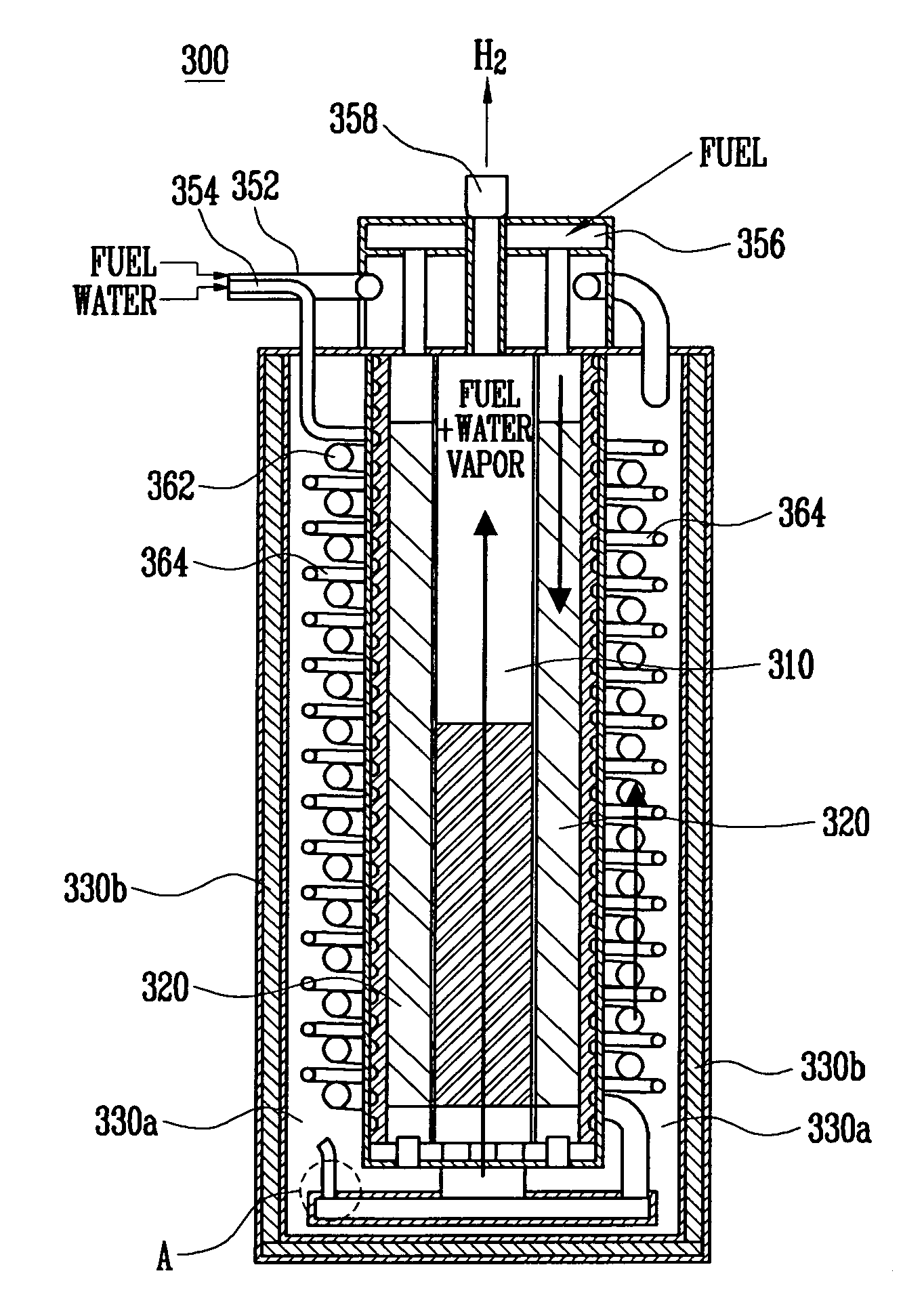

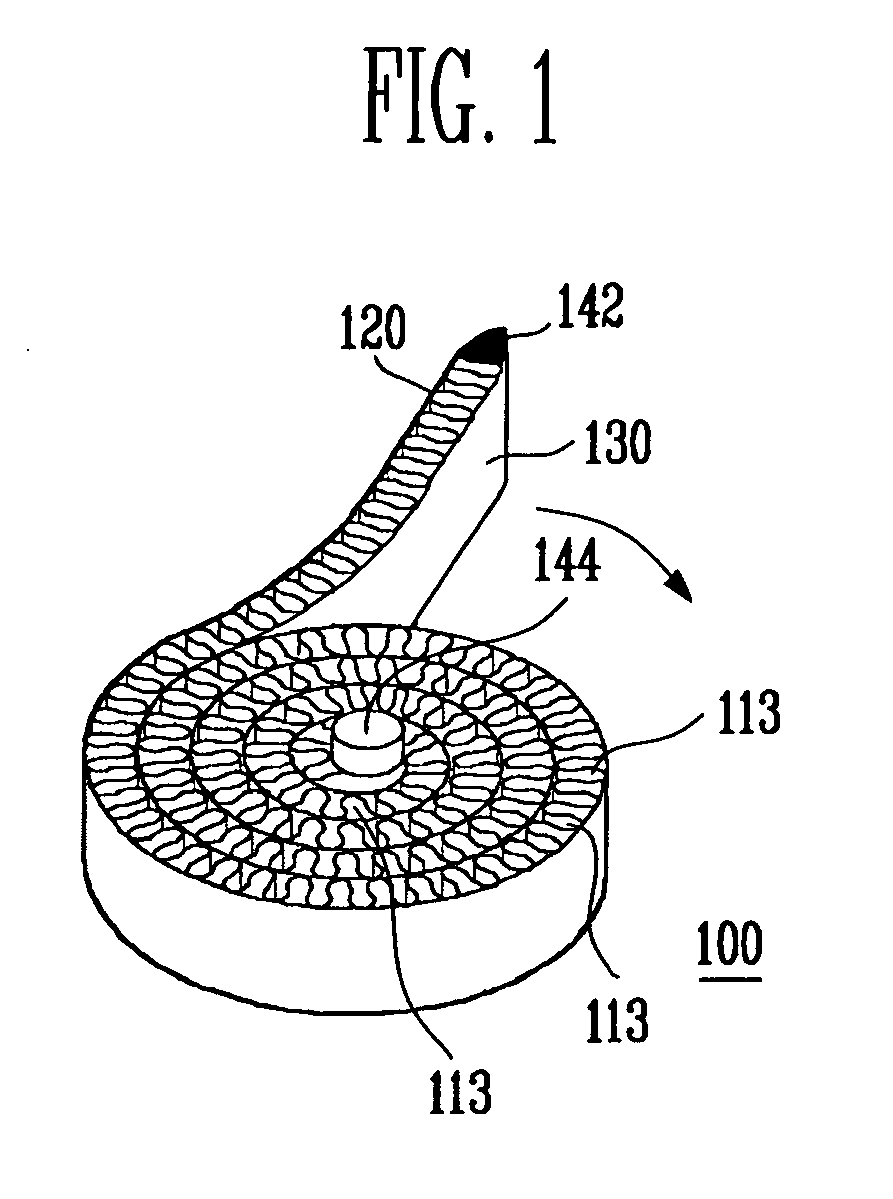

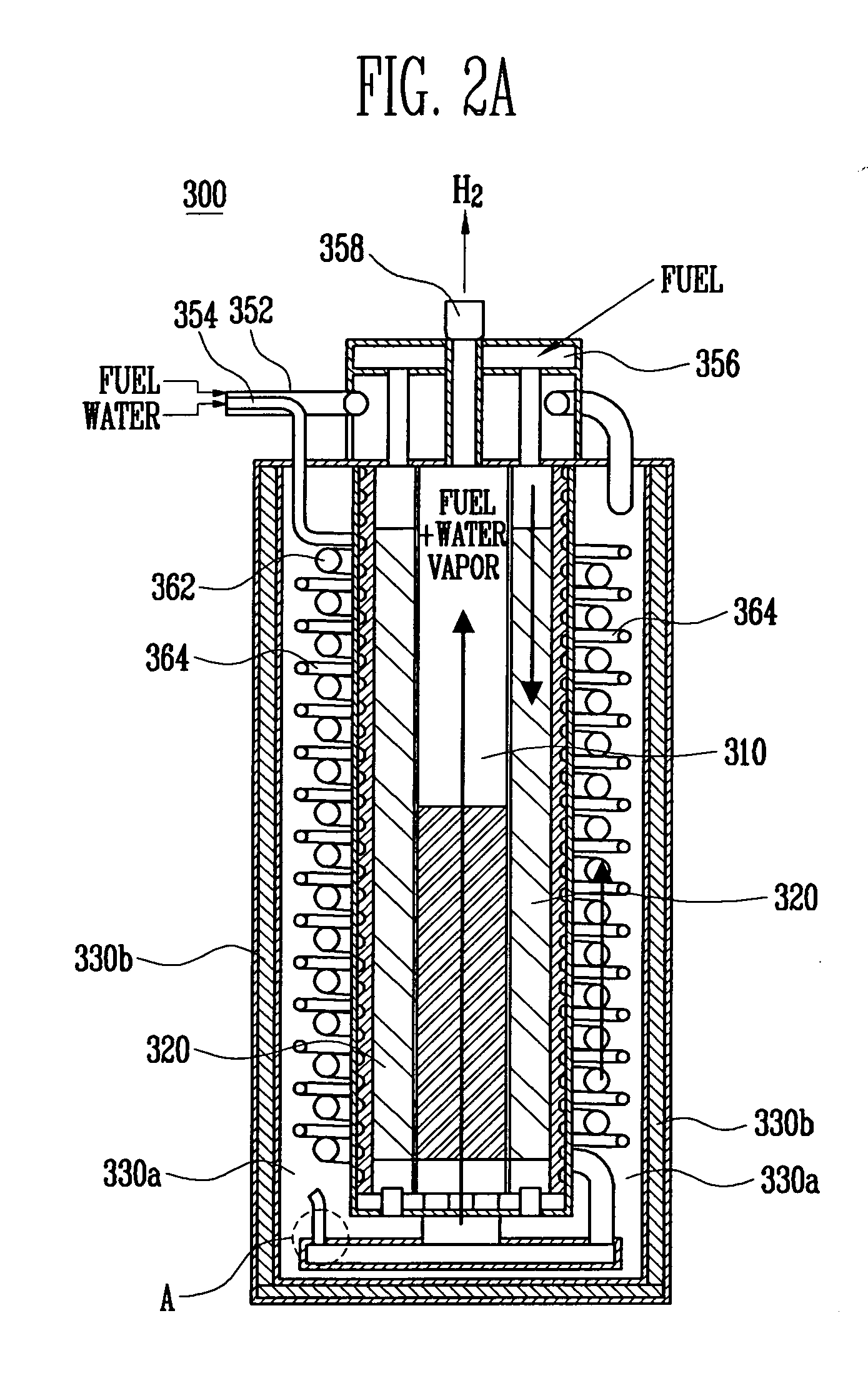

Reaction vessel and reaction device

The present invention relates to a reaction vessel for fuel cells, and more particular to a reaction vessel capable of obtaining reaction temperature promptly at the time of initial operation and a reaction device to form a reforming device of the fuel cell using the same. The reaction device of the present invention includes a reaction vessel that includes a monolithic chain. The monolithic chain has a first wall, a second wall, and a layer of pleats interposed between the first wall and the second wall. A plurality of openings are formed on each of the top side and the bottom side of the monolithic chain. One of the first wall and the second wall being made of an insulating material. The layer of pleats is made of a conductive material, and electric power is applied to generate heat at initial reaction operation. Once the reaction is activated, the reaction vessel produces heat through an oxidation reaction.

Owner:SAMSUNG SDI CO LTD

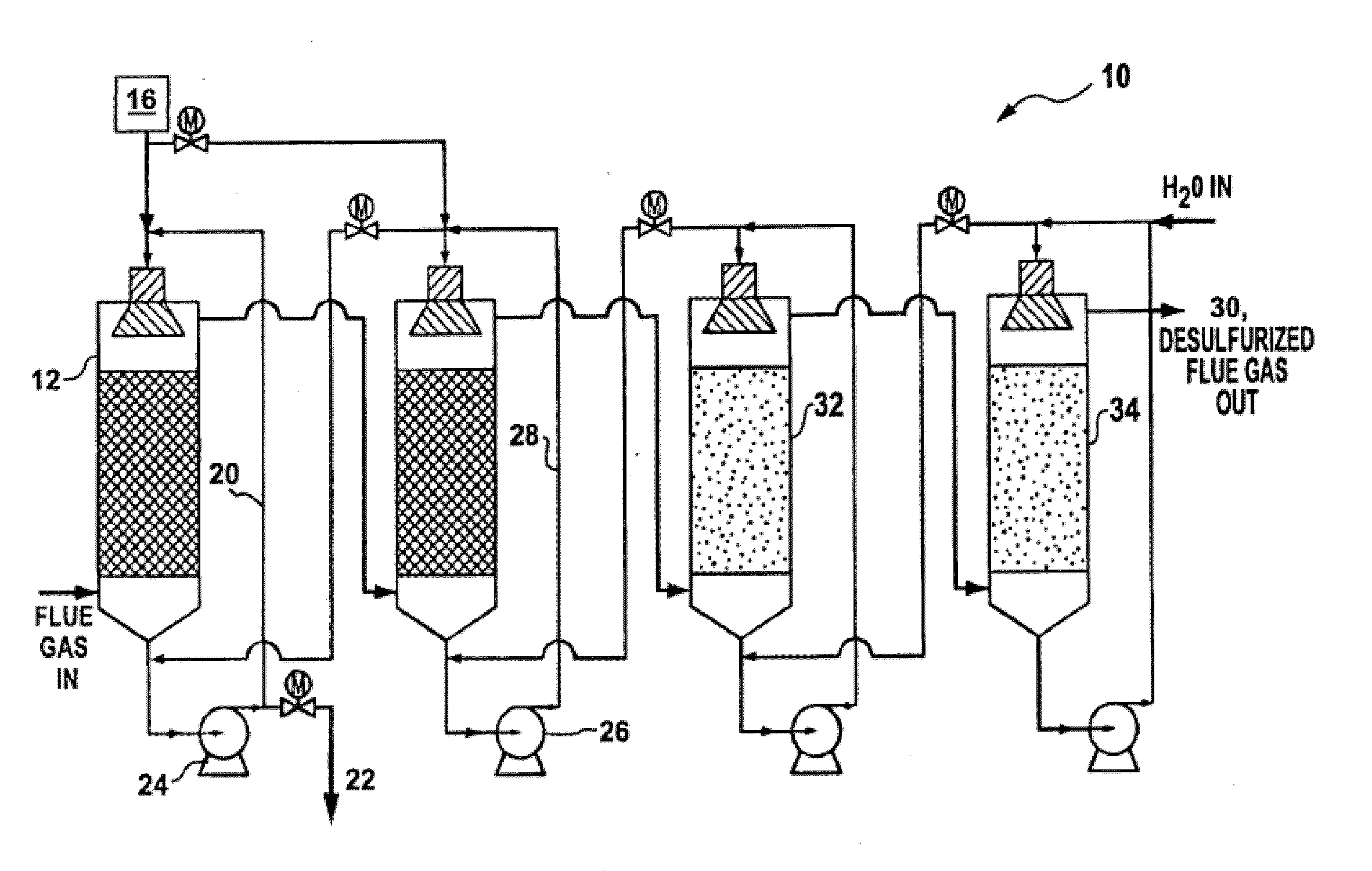

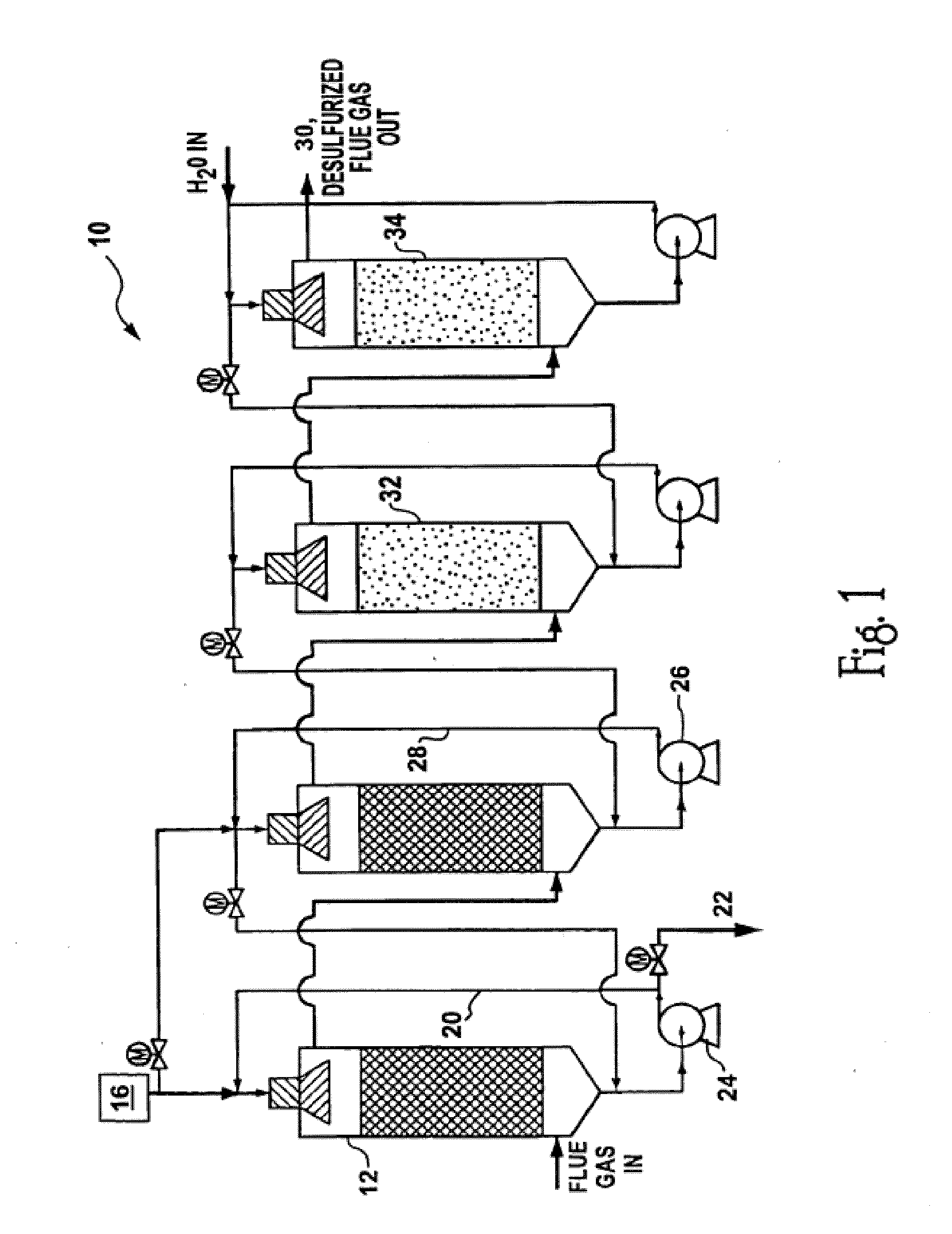

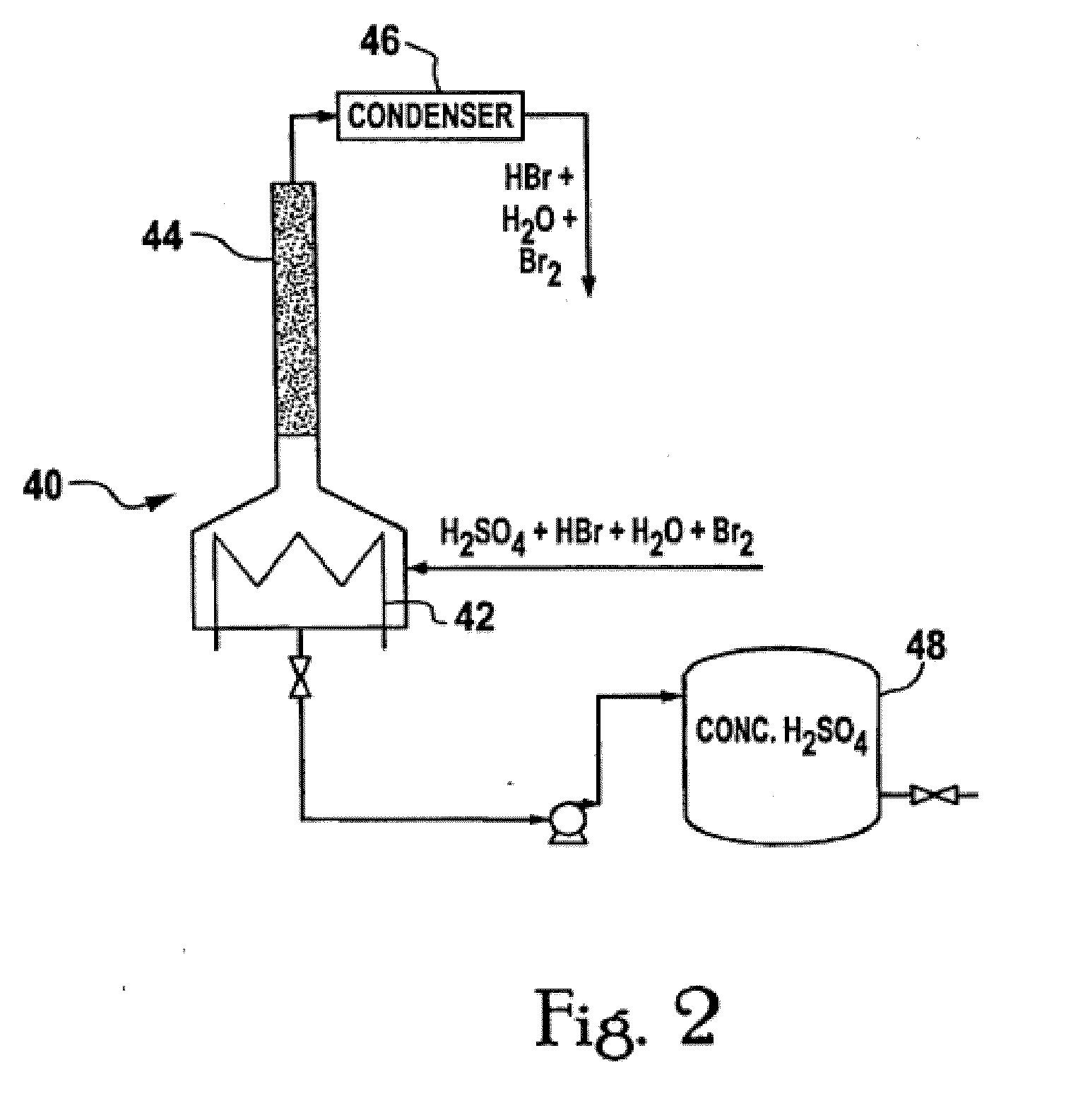

Method for processing stack gas emissions

Apparatus and methods for augmenting the Mark 13a process of Van Zelzen et al., by providing for the addition of dispatchable energy storage and / or additional waste stream treatments. Sulfur-containing stack gas emissions from the burning of fossil fuels for electricity production are cleaned, removing the sulfur by use of the Bunsen reaction. The process produces hydrogen and sulfuric acid as byproducts. The hydrogen output of the process can be used to co-produce electricity in a reversible fuel cell, and optionally can be stored so that electricity can be produced during periods of high demand. Optionally the hydrogen can be reacted with air-nitrogen or nitrogen from the combustion gasses to produce ammonia. The sulfuric acid can optionally be reacted with iron or aluminum to produce iron or aluminum sulphates and additional electricity. In addition, mercury removal from the gas emissions from burning fossil fuels (primarily coal) can be performed.

Owner:HEATON HARLEY L +4

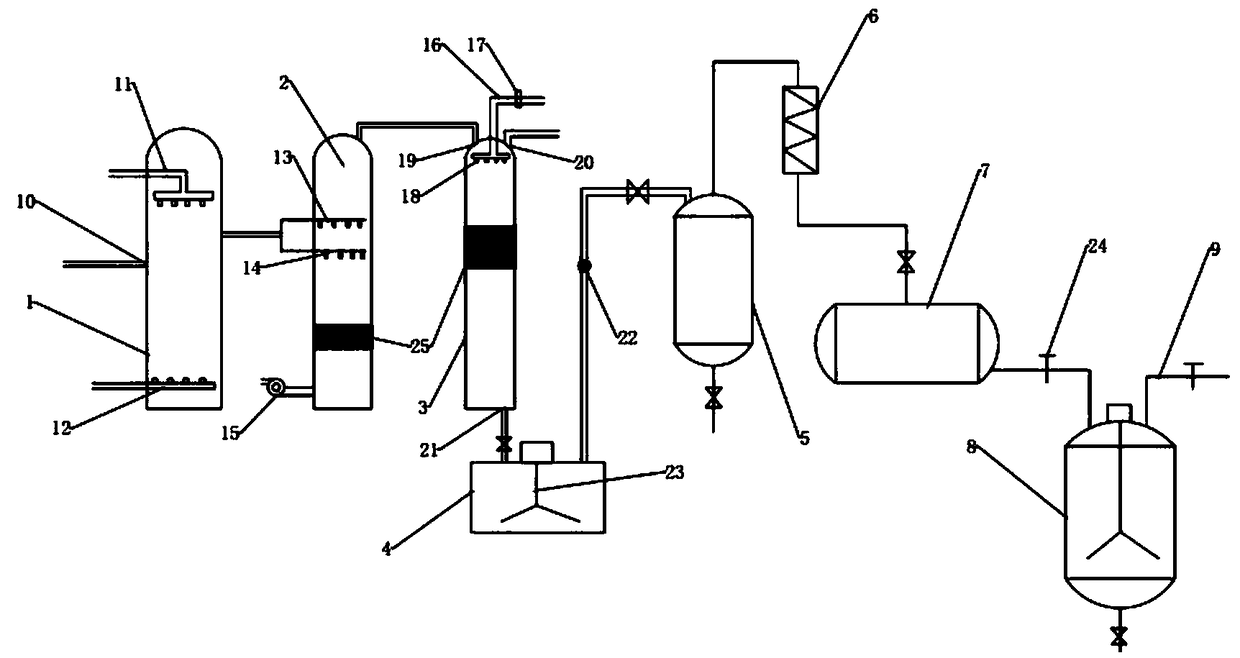

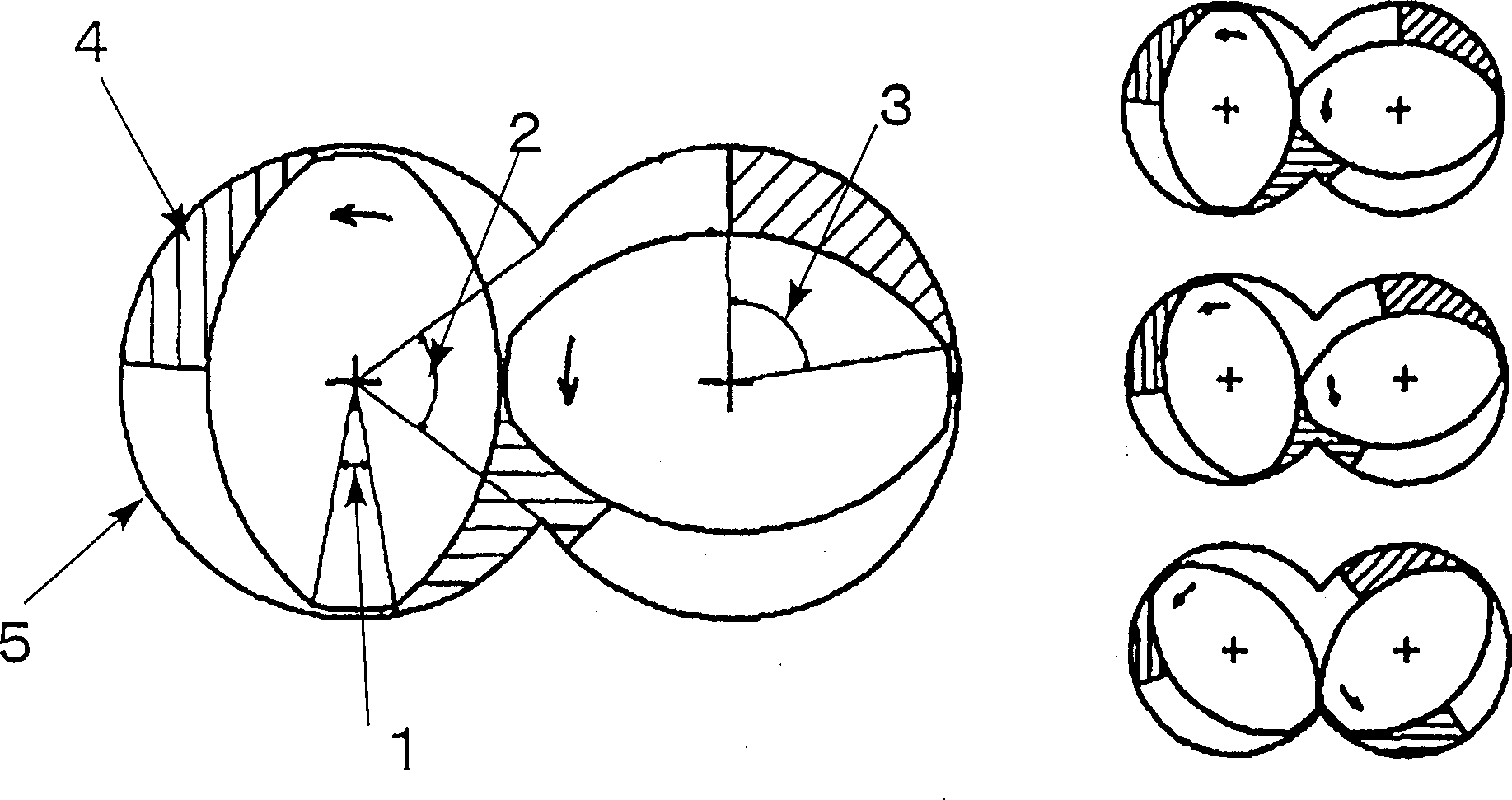

Production system for producing bromide by neutralization method

InactiveCN109179331AIncrease concentrationHigh extraction rateHydrogen bromideBromide preparationFractionating columnTower

The invention discloses a production system for producing bromide by a neutralization method, and belongs to the technical field of inorganic bromide production. The system comprises a mixed reactor,a blow-out tower, an absorption tower, a dehydration tank and a distillation tower which are sequentially connected through a pipeline. The top of the distillation tower is connected to one end of a condenser, the other end of which is connected to a hydrobromic acid storage tank; the hydrobromic acid storage tank is connected to a bromination reactor, and the hydrobromic acid storage tank is connected to the bromination reactor through a hydrobromic acid pipeline; and the top of the bromination reactor is connected to a lye pipeline. The system can continuously produce hydrobromic acid from brine and increase the concentration of hydrobromic acid by dehydration and distillation to meet the requirements of metal bromide production.

Owner:WEIFANG RIXING CHEM

Method for treaitng resin composition

A method for treating a resin composition which comprises kneading a resin composition comprising a part by weight of a thermoplastic resin, 0 to 0.7 parts by weight of a treating agent capable of hydrogenating a halogen and a halogenated compound at 280 to 450 °C in the presence of a metal compound which combines with a halogen atom to form a halogenated metal compound having a boilding or sublimating temperature of 450 °c or lower under atmospheric pressure, to thereby convert the halogenated compound to a halogenated metal compound, and separating the halogenated metal compound and a mixture of the thermoplastic resin with the treating agent capable of hydrogenating a halogen and recovering them. The method can be employed for treating a resin waste without converting it to a gas or an oil, to remove halgoens and metal oxides from it and recover them in a short treatment time in good yield and to recover a treated resin for reuse as a solid fuel in good yield.

Owner:ASAHI KASEI KK

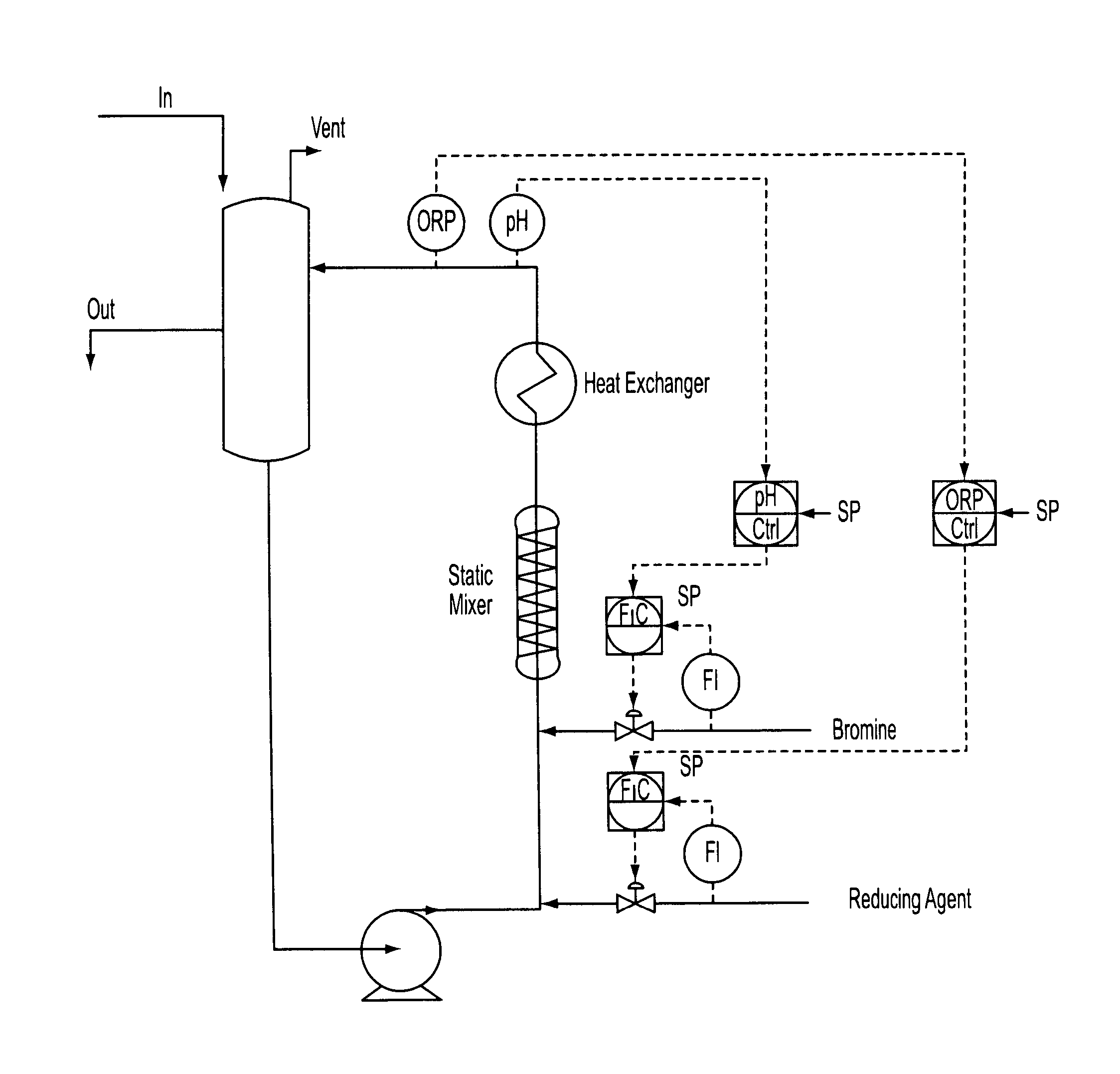

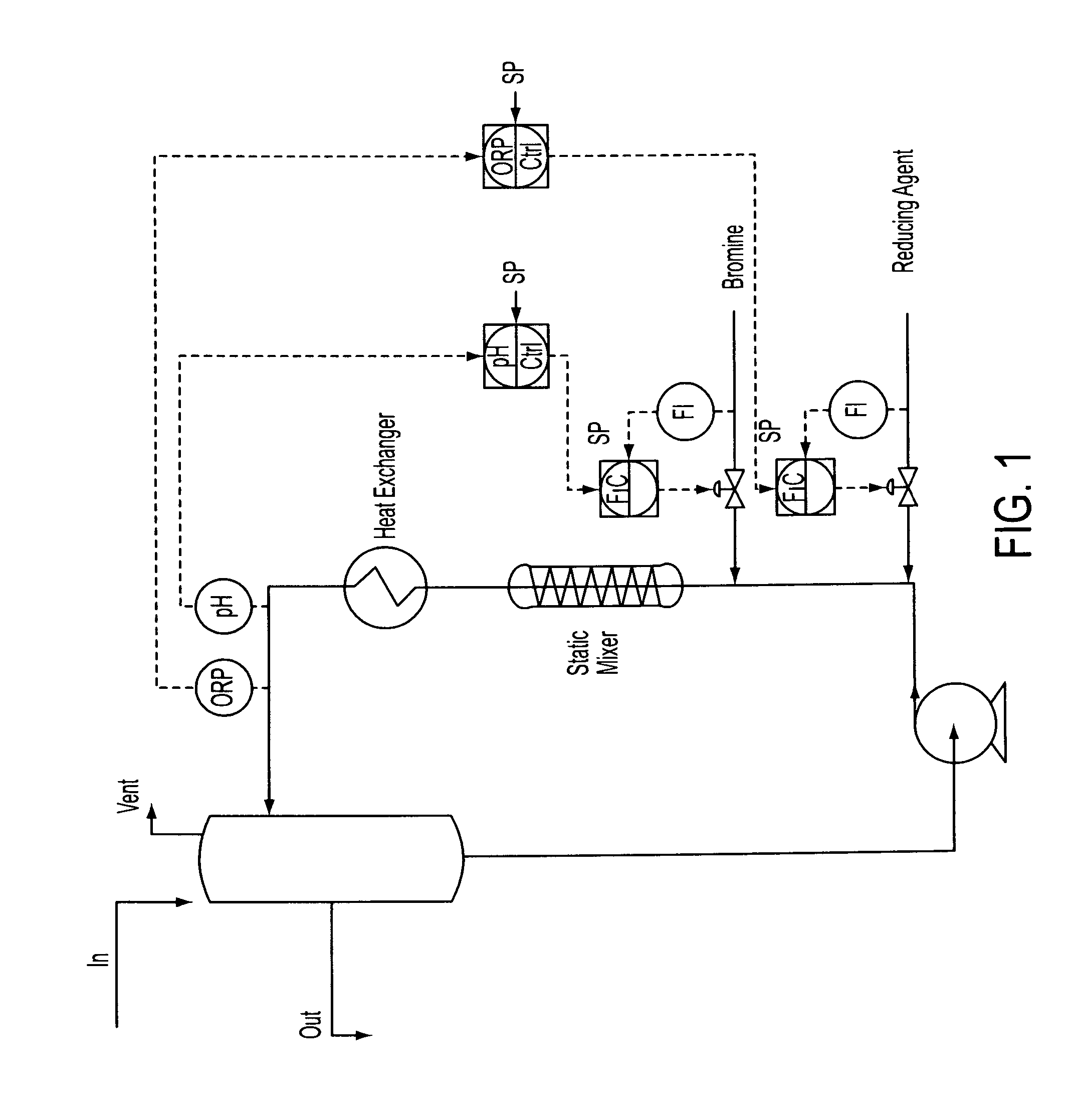

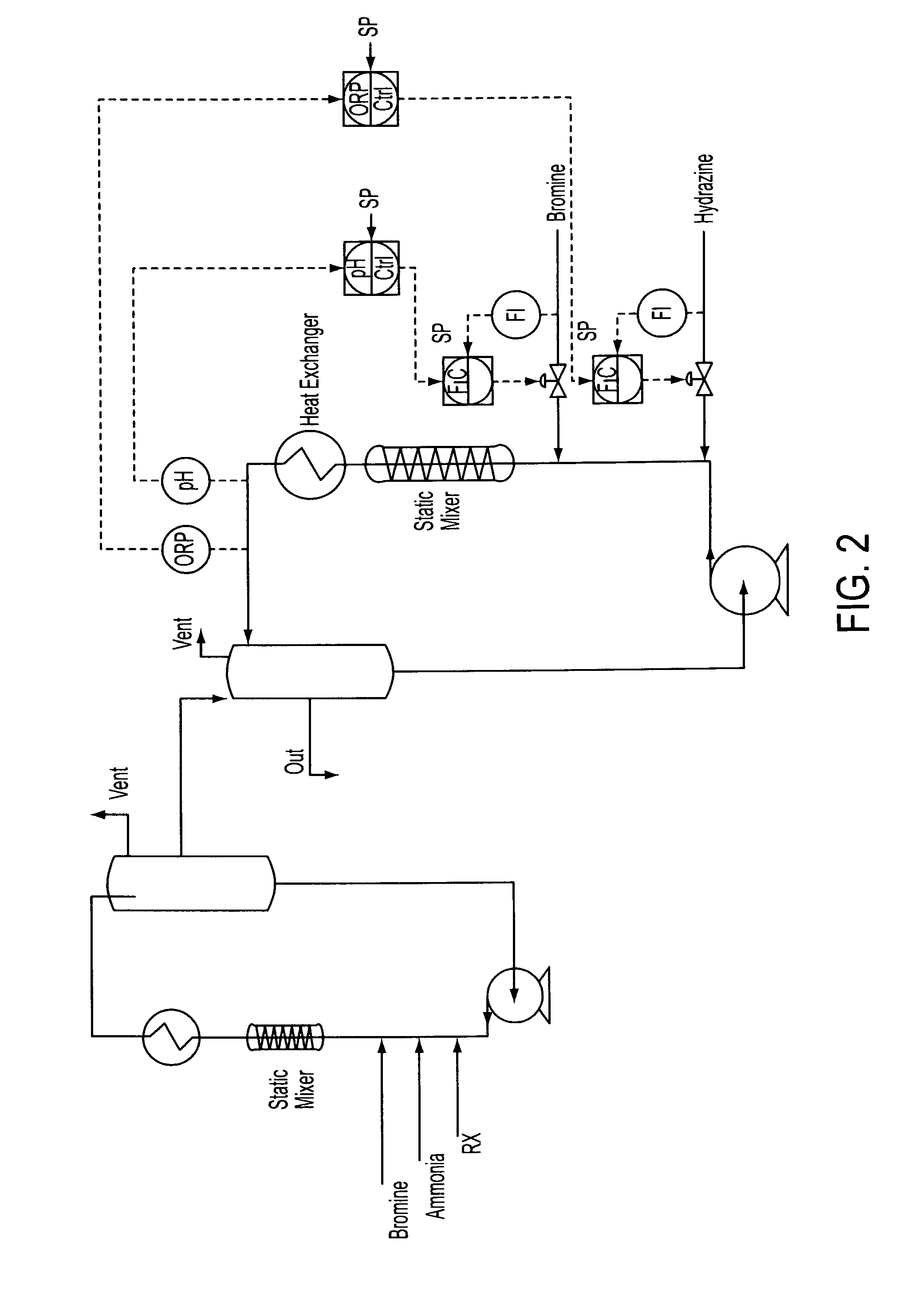

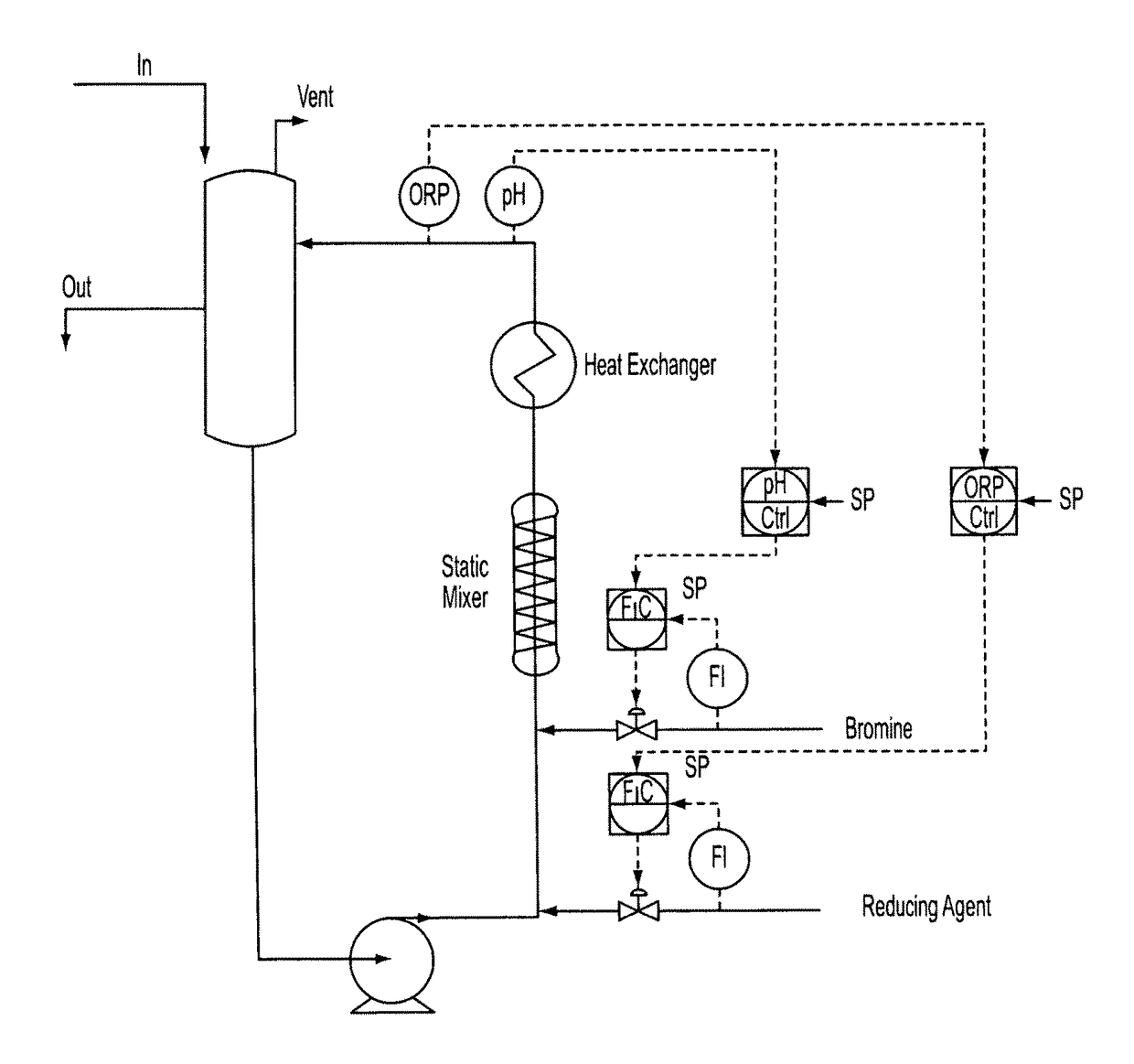

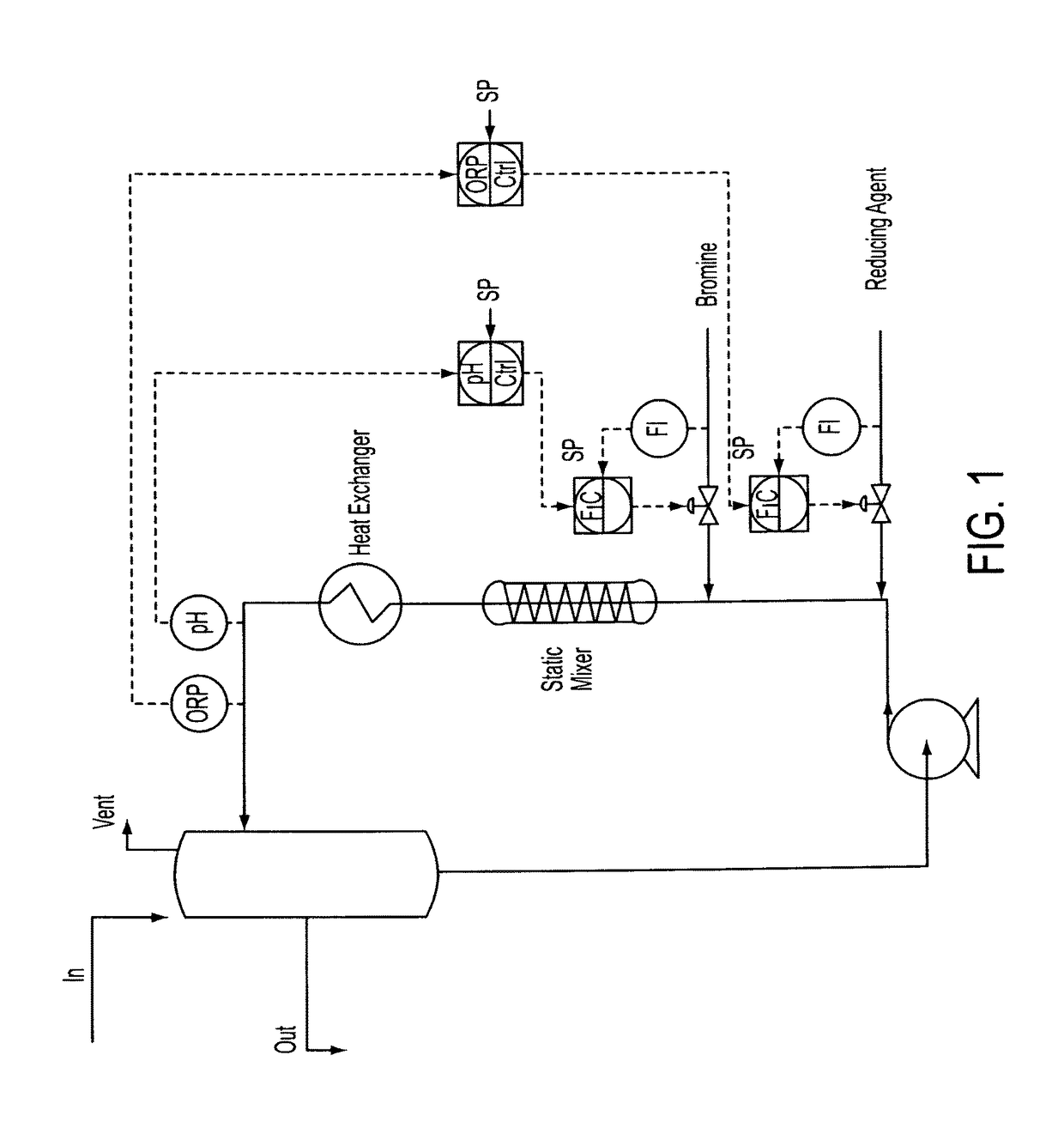

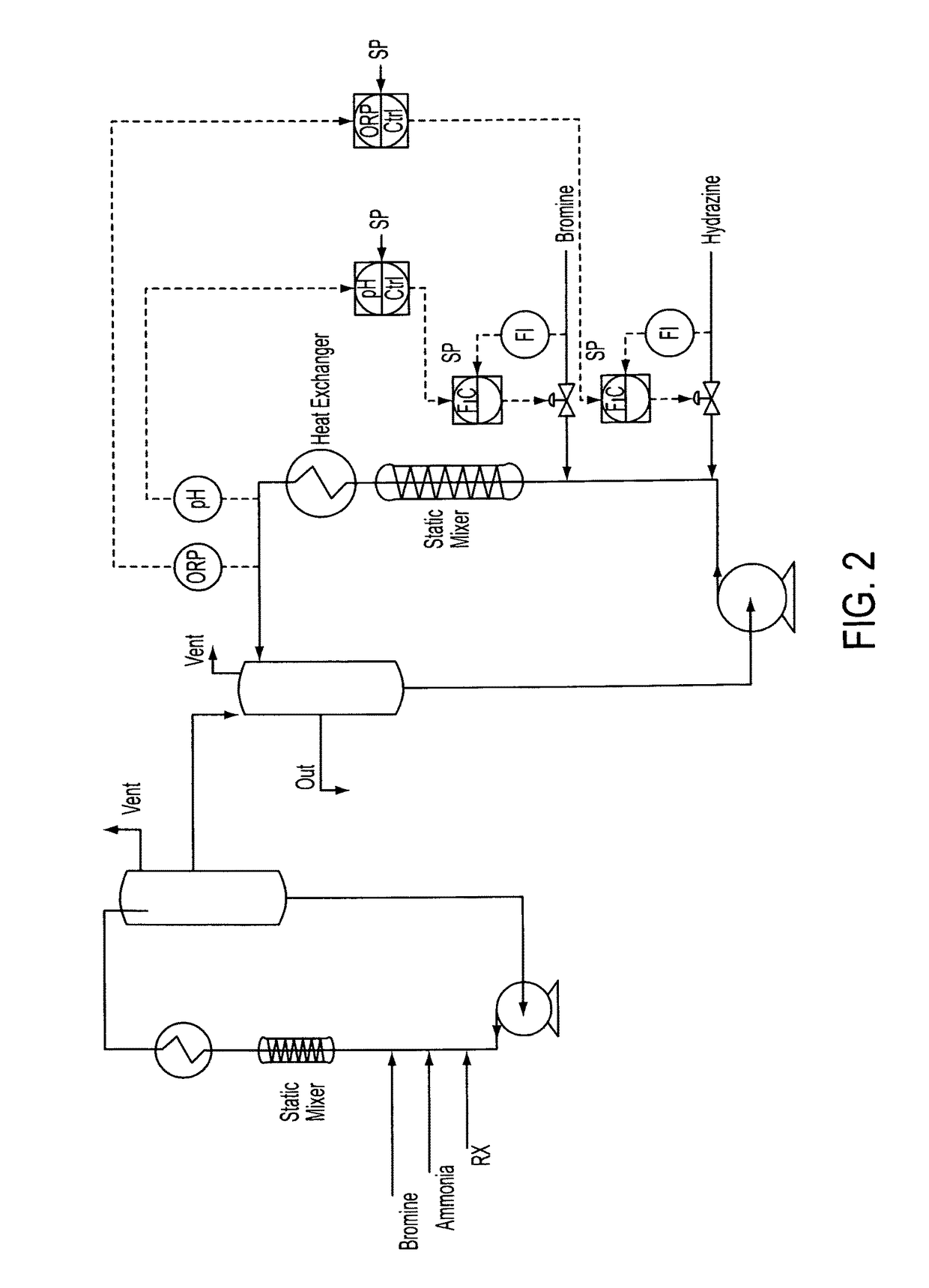

Method for Making Bromides

ActiveUS20150158734A1Faster and efficient productionReduce wasteProcess control/regulationBromide preparationBromineSodium bromide

Bromine containing compounds, such as calcium bromide, sodium bromide and the like, are prepared in high purity and more quickly with less waste by using a process with two bromination stages and often a third step wherein the crude product mixture can be adjusted to meet specific product requirements. In the first bromination stage, the majority, but not all, of a substrate is brominated usiung a reductive bromination reaction, the remaining unreacted substrate is converted to product in the second stage through another a reductive bromination reaction, although the specific reagents may be different, wherein the addition of bromine and a reducing agent are carefully monitored.

Owner:LANXESS SOLUTIONS US INC

Method for preparing oilfield additive calcium bromide

The invention relates to a calcium bromide preparation method, in particular to a method for preparing the oil field additive calcium bromide product by adopting the by-product, namely hydrobromic acid. The method mainly comprises the steps of: lime emulsifying, neutralisation, impurity disposal, settlement, filtering, vaporizing, condensing and discharging. The method has the beneficial effects that the preparation process is simple; the material is cheap and easy for obtaining, the manufacturing cost is reduced; the clarity of the prepared calcium bromide is high, the homogeneity of the solution is good, and the quality is up to the standard, thus having very good economic benefit.

Owner:潍坊强源化工有限公司

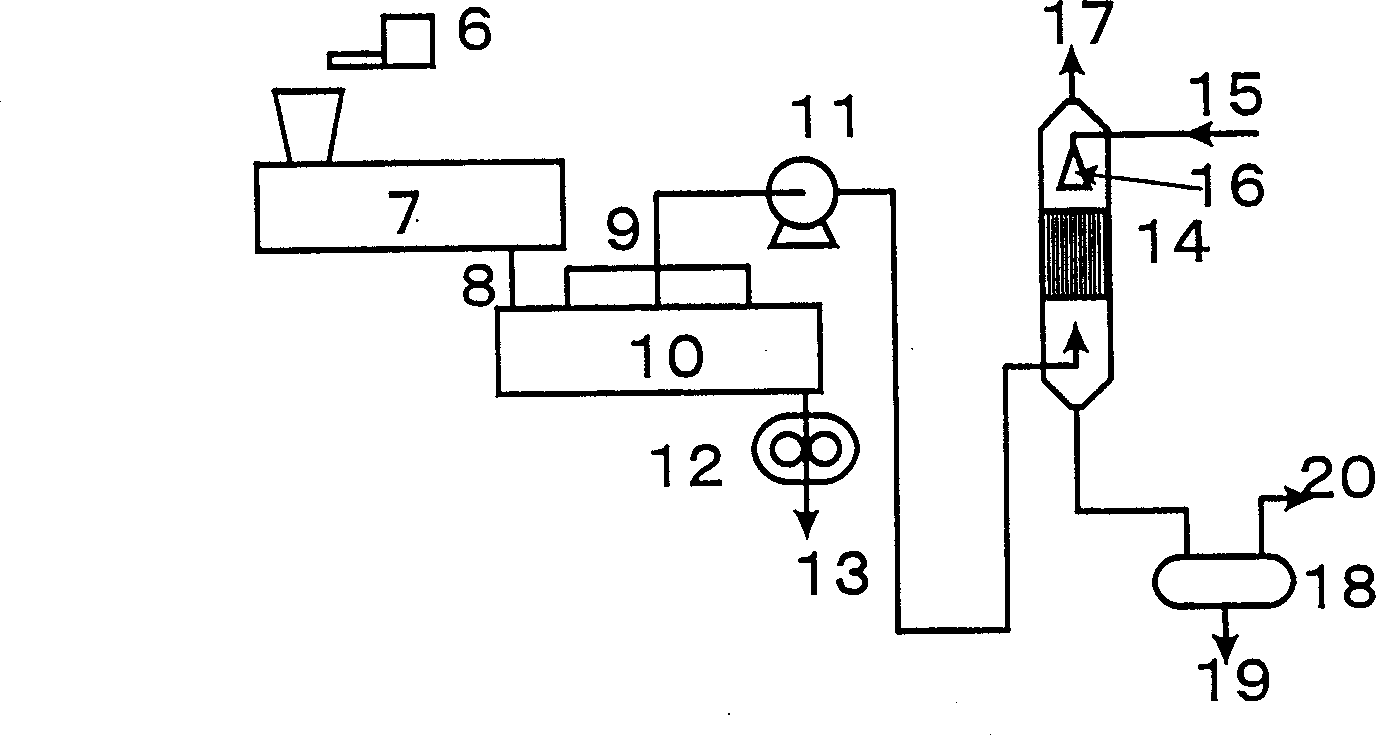

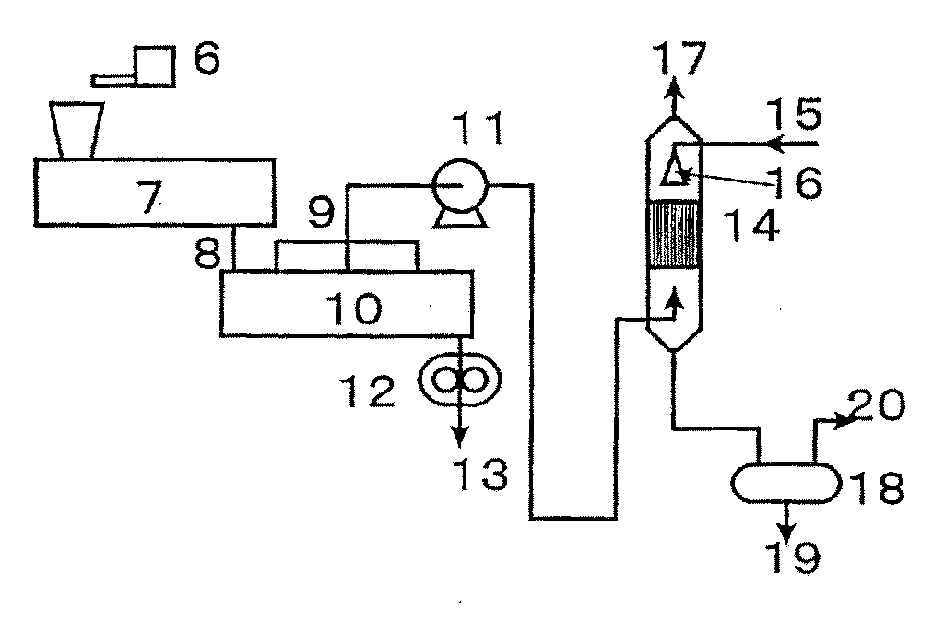

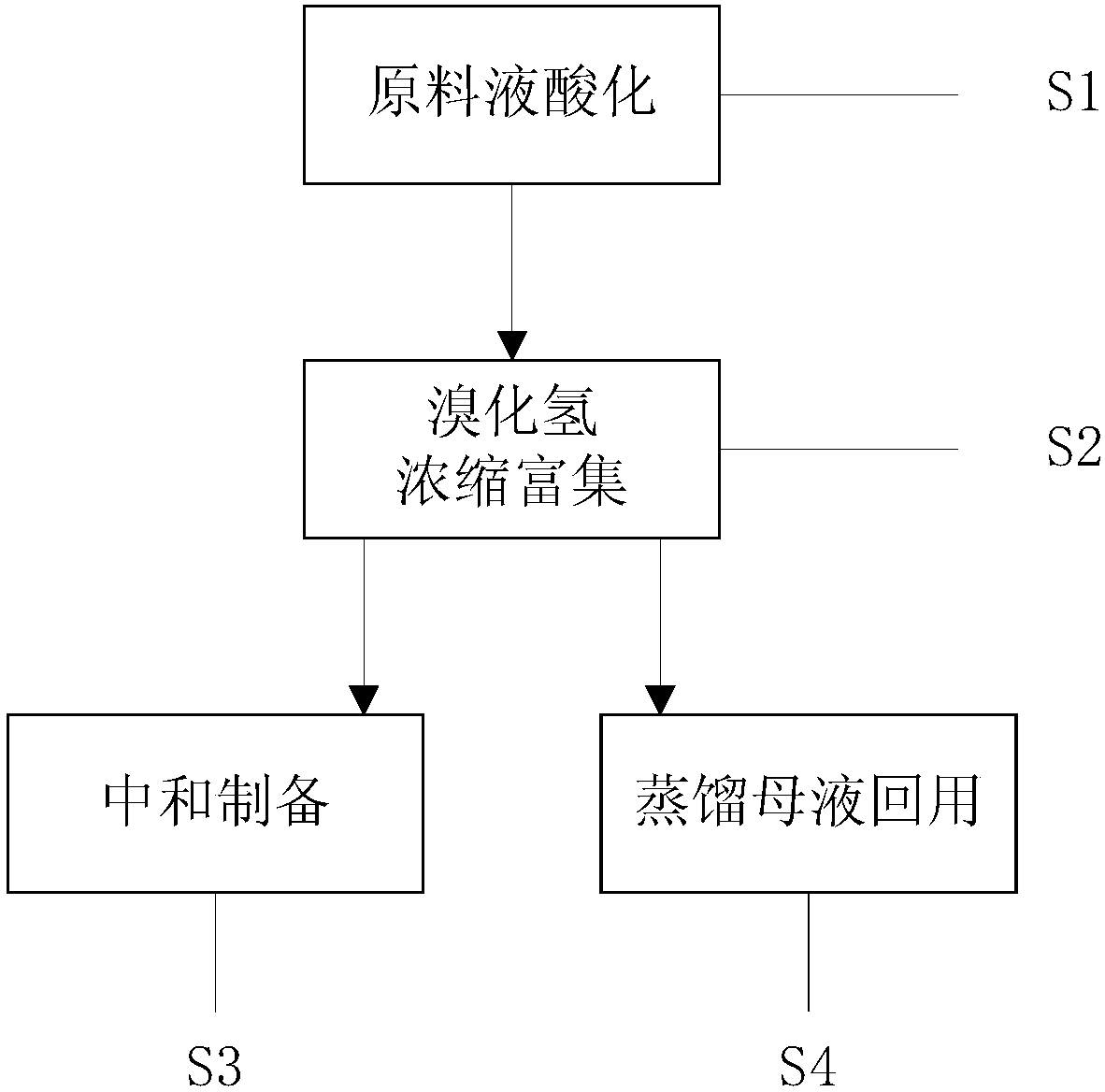

Preparation method of mercury removing bromide

InactiveCN107777668AReduce production energy consumptionReduce manufacturing costBromide preparationMagnesium bromidesAlkali metal oxideHydrogen bromide

The invention discloses a preparation method of a mercury removing bromide. According to the preparation method, hydrogen bromide gathered and separated from seawater and brine-extracted bromine enrichment liquid reacts with alkaline materials to produce the corresponding mercury removing bromide. The preparation method of the mercury removing bromide comprises the technical steps of raw liquid acidization, hydrogen bromide concentration and enrichment, neutralizing preparation and distilling mother liquid recycling, wherein the step of raw liquid acidization comprises adding concentrated sulfuric acid into the seawater and brine-extracted bromine enrichment liquid for acidization; the step of hydrogen bromide concentration and enrichment comprises distilling the acidized bromine enrichment liquid for enrichment; the step of neutralizing preparation comprises neutralizing distilled and separated hydrogen bromide through alkali or alkali metal oxide to obtain the aqueous solution of themercury removing bromide; the step of distilling mother liquid recycling comprises recycling distilling and separating mother liquid back to bromine extraction for acidizing seawater and brine. The preparation method of the mercury removing bromide is simple in process, reduces energy consumption of production of the mercury removing bromide and accordingly has a broad application prospect.

Owner:自然资源部天津海水淡化与综合利用研究所

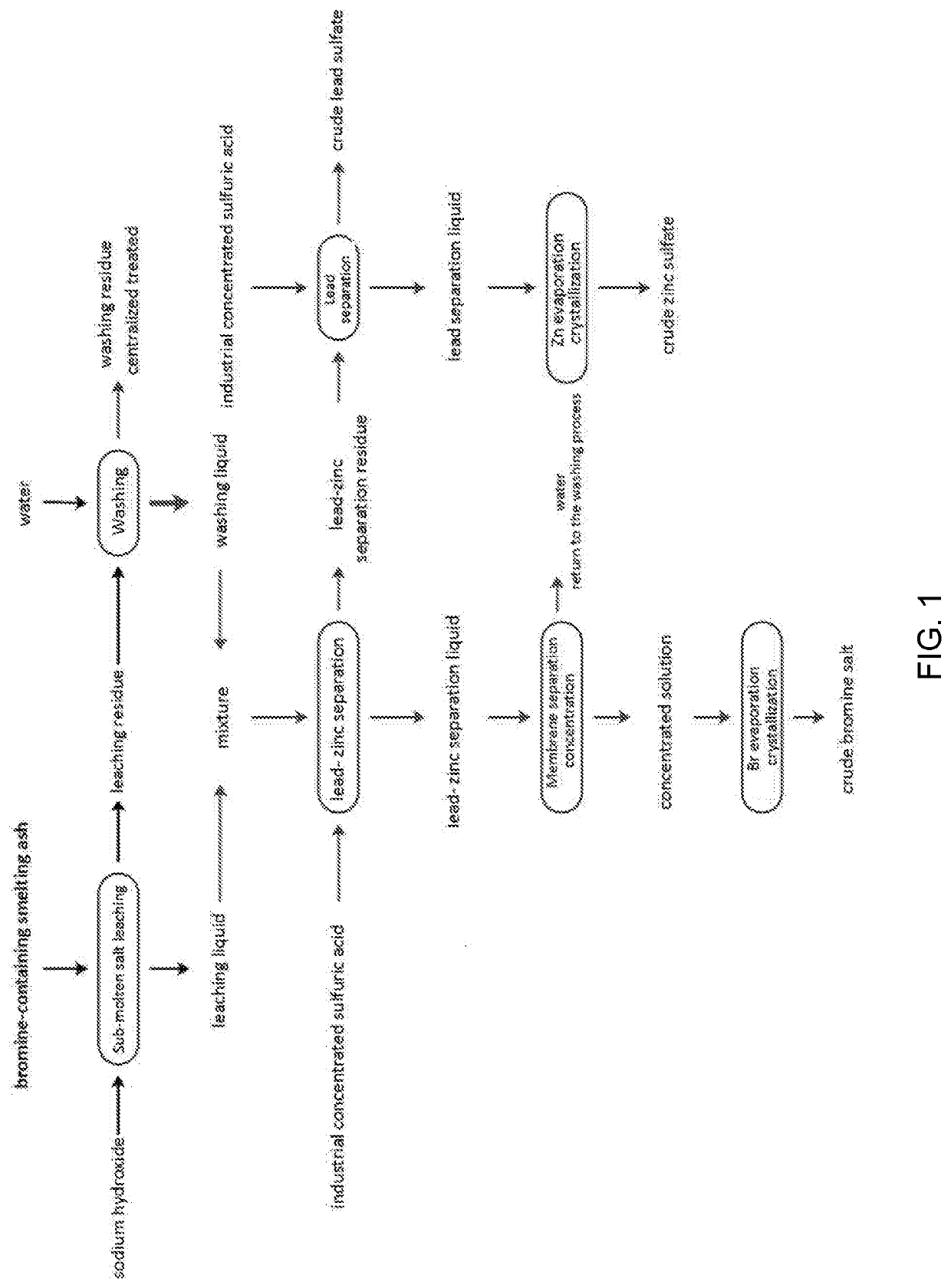

A method of recovering bromide from bromine-containing smelting ash

ActiveUS20200392000A1Effective recoveryEfficient separationBromide preparationZinc sulatesBromineMolten salt

A method of recovering bromide from bromine-containing smelting ash relates to the field of high efficient separation and recovery of bromine by total wet method. It especially relates to the method of high efficiency separation of bromine salt and lead, zinc recovery of circuit board smelting ash by two-step method. It mainly comprising: sub-molten salt leaching, washing, separate Lead and zinc by adjusting the pH of industrial sulfuric acid, membrane separation and concentration, reuse of water, crude bromine salt recovery by evaporation crystallization of bromine salt. Compared with the traditional baking and recycling process of ash, the invention adopts sodium hydroxide submolten salt leaching technology and membrane separation and concentration technology, to reduce the reaction temperature and tailings discharge greatly, which has a good effect of energy saving and emission reduction.

Owner:BEIJING UNIV OF TECH

Method for making bromides

ActiveUS9688543B2Faster and efficient productionHigh purityProcess control/regulationBromide preparationBromineSodium bromide

Bromine containing compounds, such as calcium bromide, sodium bromide and the like, are prepared in high purity and more quickly with less waste by using a process with two bromination stages and often a third step wherein the crude product mixture can be adjusted to meet specific product requirements. In the first bromination stage, the majority, but not all, of a substrate is brominated using a reductive bromination reaction, the remaining unreacted substrate is converted to product in the second stage through another a reductive bromination reaction, although the specific reagents may be different, wherein the addition of bromine and a reducing agent are carefully monitored.

Owner:LANXESS SOLUTIONS US INC

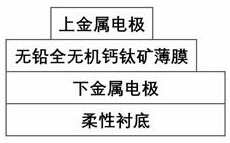

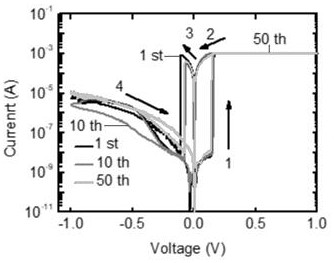

Flexible resistive random access memory based on lead-free all-inorganic perovskite thin film and prepared through chemical vapor deposition

PendingCN111668371AImprove stabilityQuality improvementBromide preparationElectrical apparatusMetallic electrodeThin membrane

The invention provides a chemical vapor deposition method for preparing an environment-friendly flexible resistive random access memory based on a lead-free all-inorganic perovskite thin film, and belongs to the field of nonvolatile memories. The structure of the device sequentially comprises a flexible substrate, a lower metal electrode, a lead-free perovskite resistive random access memory layerand an upper metal electrode from bottom to top. The method comprises the following steps: 1, selecting an appropriate flexible substrate, and depositing a metal conductive film on the flexible substrate to serve as a lower metal electrode; 2, adopting a chemical vapor deposition lead-free all-inorganic perovskite thin film as a resistive random access memory layer; and 3, depositing an upper metal conductive film on the surface of the resistive random access memory layer to serve as an upper metal electrode. According to the preparation method of the environment-friendly flexible resistive random access memory provided by the invention, the lead-free all-inorganic perovskite thin film is synthesized through chemical vapor deposition, and the prepared device has high bending resistance and excellent electrical properties.

Owner:SHAANXI UNIV OF SCI & TECH

A kind of preparation method of stable lead-free all-inorganic double perovskite a2bb'x6 nanocrystals

ActiveCN107934916BGood reproducibilityGood dispersionBromide preparationPhysical/chemical process catalystsPhotodetectorPhysical chemistry

The invention discloses a stable lead-free all-inorganic double perovskite A 2 BB’X 6 Preparation method of nanocrystals. The present invention uses a hot injection method to synthesize nanocrystals: first, mix raw materials such as metal precursor salt, reaction solvent oleic acid, oleylamine and octadecene, vacuum-heat at a certain temperature and stir for a certain period of time, and then stir in N 2 Raise to the appropriate reaction temperature under protection, quickly inject the hot oleate solution of A into the reaction system, and then use an ice bath to quickly cool the system to room temperature, and finally obtain uniformly sized A 2 BB’X 6 Perovskite nanocrystals. The method of the invention is simple, convenient, reproducible, and environmentally friendly. At the same time, the obtained product has uniform size, good dispersion, and high stability, and has excellent photocatalytic performance, and can be used for photocatalysis, photodetectors, lasers, and solar energy. Battery and other fields.

Owner:SUN YAT SEN UNIV

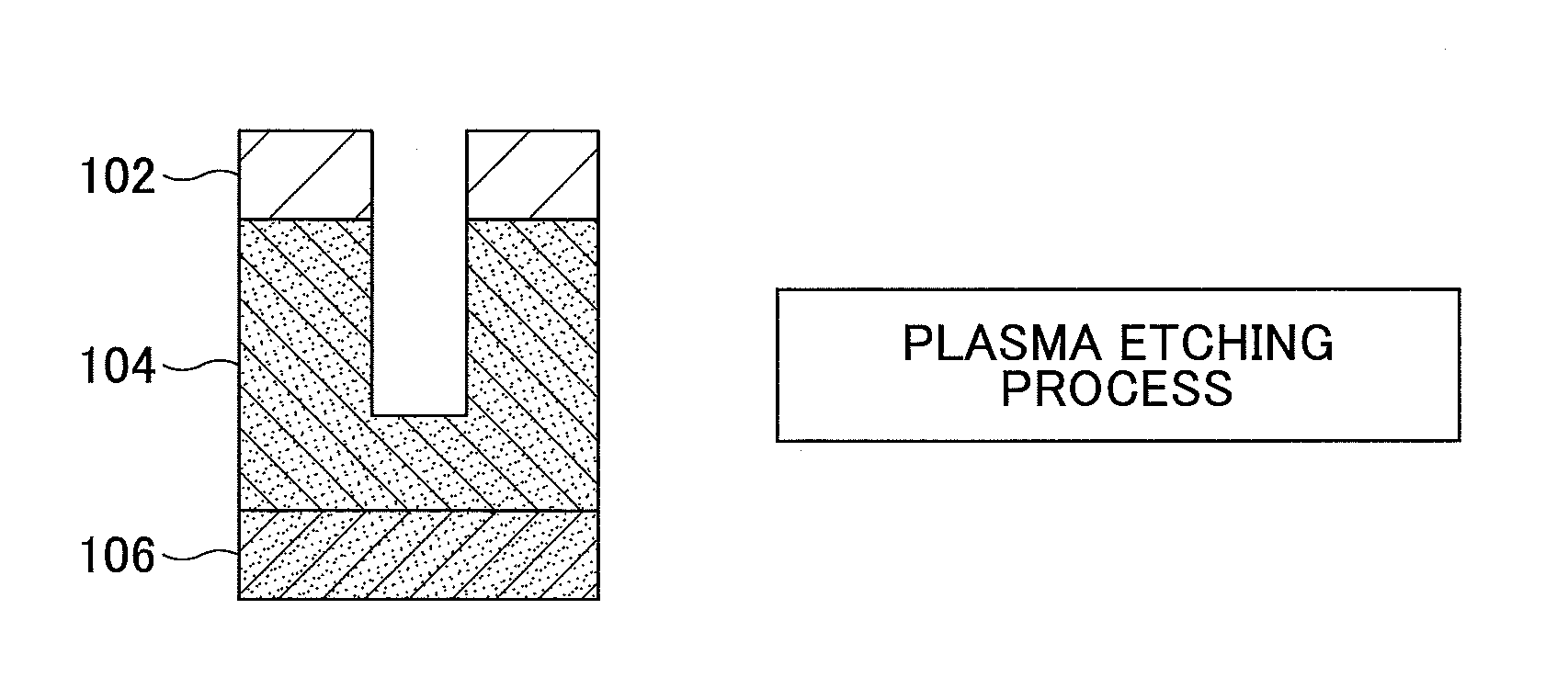

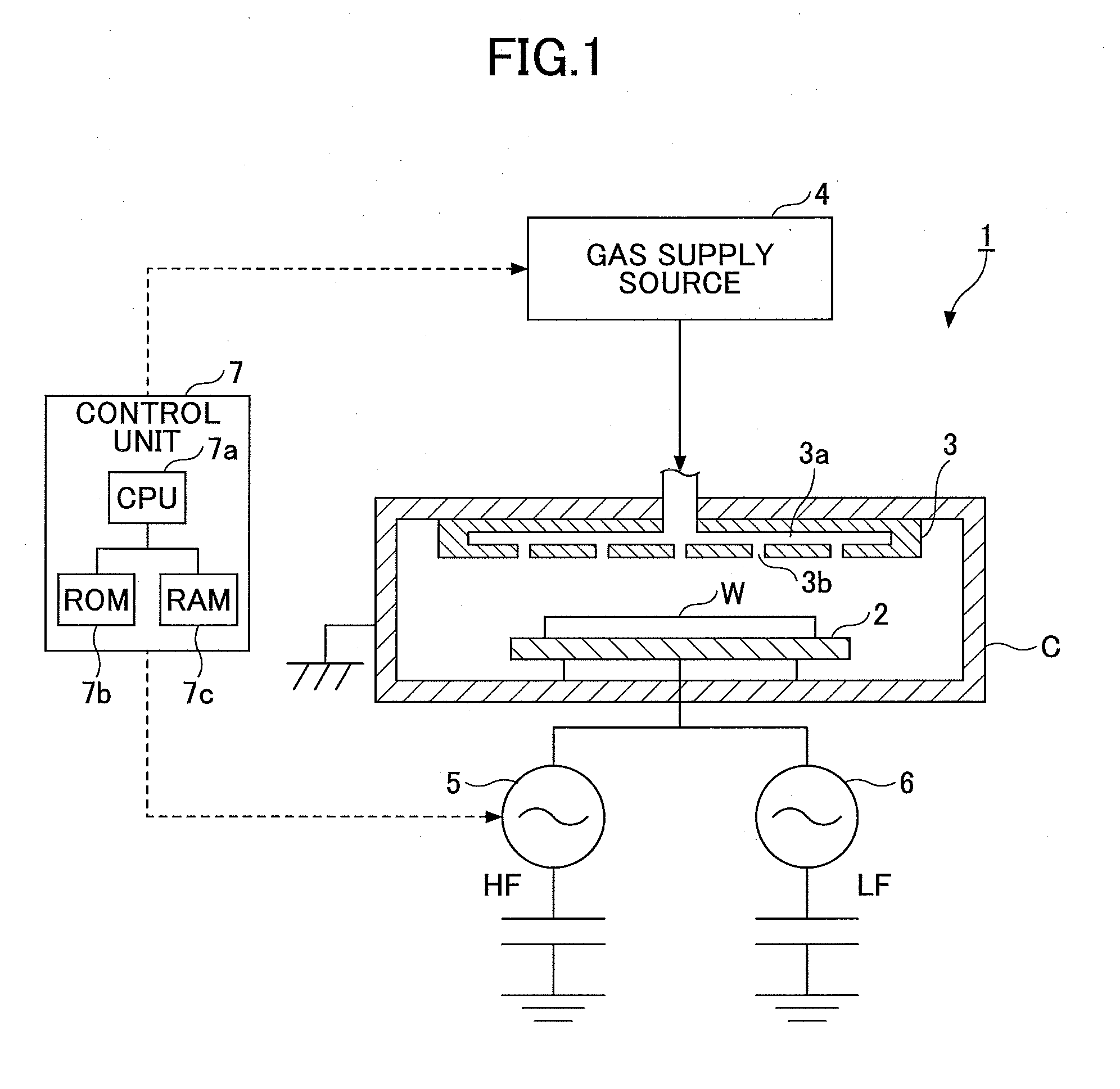

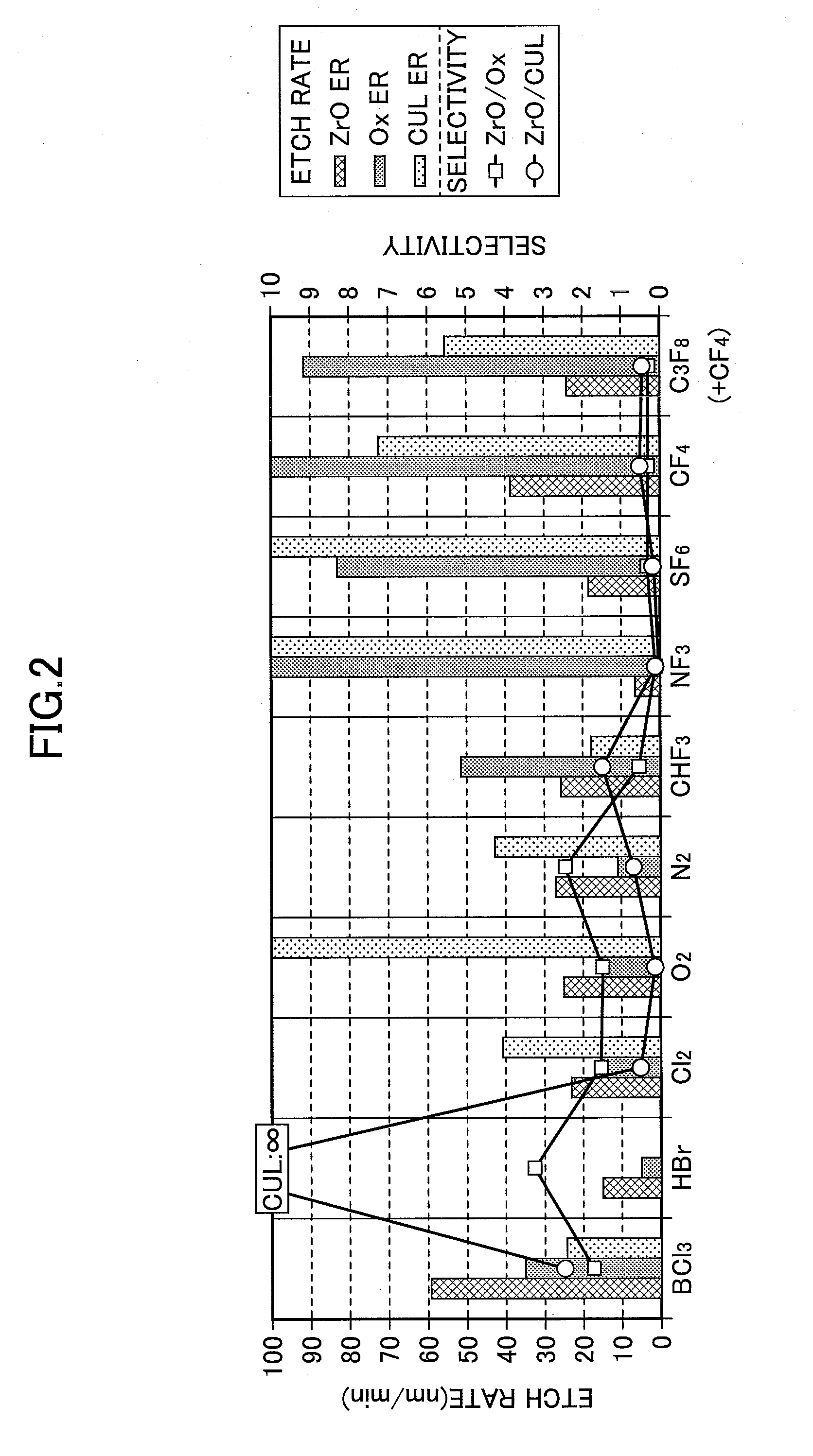

Plasma etching method, pattern forming method and cleaning method

ActiveUS20160300728A1Bromide preparationResistor manufacture by lithographyNoble gasBoron trichloride

A plasma etching method is performed by forming a desired pattern of a mask into a film including a zirconium oxide film by plasma etching with plasma generated from a first gas. The first gas consists of at least one chloride-containing gas of the group of boron trichloride, tetrachloromethane, chloride and silicon tetrachloride, at least one hydrogen-containing gas of the group of hydrogen bromide, hydrogen and methane, and a noble gas. An underlying film of a silicon oxide film or an amorphous carbon film is provided underneath the zirconium oxide film, and an etching selectivity of the zirconium oxide film to the underlying film is greater than or equal to one.

Owner:TOKYO ELECTRON LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com