Flexible resistive random access memory based on lead-free all-inorganic perovskite thin film and prepared through chemical vapor deposition

A chemical vapor deposition, resistive memory technology, applied in the preparation of bromide, chemical instruments and methods, lead halide, etc., can solve the problems of many film defects, limited application prospects, etc., to achieve high stability, excellent electrical performance, high The effect of bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

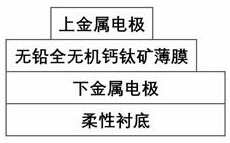

[0030] 1) Select a PET flexible substrate, and deposit a metal film with a thickness of 100nm on it as the lower metal electrode;

[0031] 2) Select a tube furnace with dual temperature zones to synthesize lead-free all-inorganic perovskite films, put lead bromide and cesium bromide powders in two quartz crucibles in the same molar ratio, and then put the quartz crucibles together The adjacent one is placed in the high temperature zone of the tube furnace, and the flexible substrate is placed in the low temperature zone. During the whole growth process, the flow rate of high-purity argon gas is 200 sccm; the high temperature zone is raised from room temperature to 750°C within 90 minutes, and kept for 2 minutes; at the same time, the low temperature zone is heated from room temperature to 250°C in 35 minutes, and Continue to heat up to 300°C in 60 minutes; after natural cooling, a lead-free all-inorganic perovskite film is obtained as the storage layer of the device;

[0032]...

Embodiment 2

[0040] 1) Select a PET flexible substrate, and deposit a metal film with a thickness of 100nm on it as the lower metal electrode;

[0041] 2) Select a tube furnace with dual temperature zones to synthesize lead-free all-inorganic perovskite films, put lead bromide and cesium bromide powders in two quartz crucibles in the same molar ratio, and then put the quartz crucibles together The adjacent one is placed in the high temperature zone of the tube furnace, and the flexible substrate is placed in the low temperature zone. During the whole growth process, the flow rate of high-purity argon gas is 200 sccm; the high temperature zone is raised from room temperature to 600°C within 90 minutes, and kept for 2 minutes; at the same time, the low temperature zone is heated from room temperature to 300°C in 35 minutes, and Continue to heat up to 350°C in 30 minutes; after natural cooling, a lead-free all-inorganic perovskite film is obtained as the storage layer of the device;

[0042]...

Embodiment 3

[0044] 1) Select a PI flexible substrate, and deposit a metal film with a thickness of 100nm on it as the lower metal electrode;

[0045]2) Select a tube furnace with dual temperature zones to synthesize lead-free all-inorganic perovskite films, put lead bromide and cesium bromide powders in two quartz crucibles in the same molar ratio, and then put the quartz crucibles together The adjacent one is placed in the high temperature zone of the tube furnace, and the flexible substrate is placed in the low temperature zone. During the whole growth process, the flow rate of high-purity argon gas is 200 sccm; the high temperature zone is raised from room temperature to 750°C within 90 minutes, and kept for 2 minutes; at the same time, the low temperature zone is heated from room temperature to 250°C in 35 minutes, and Continue to heat up to 300°C in 60 minutes; after natural cooling, a lead-free all-inorganic perovskite film is obtained as the storage layer of the device;

[0046] 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com