Preparation method of mercury removing bromide

A kind of bromide, mercury removal technology, applied in the direction of bromide preparation, calcium/strontium/barium bromide, magnesium bromide, etc., can solve problems such as difficult to realize industrialization, difficult to operate, and reduce production costs and production energy consumption. , easy to achieve the effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

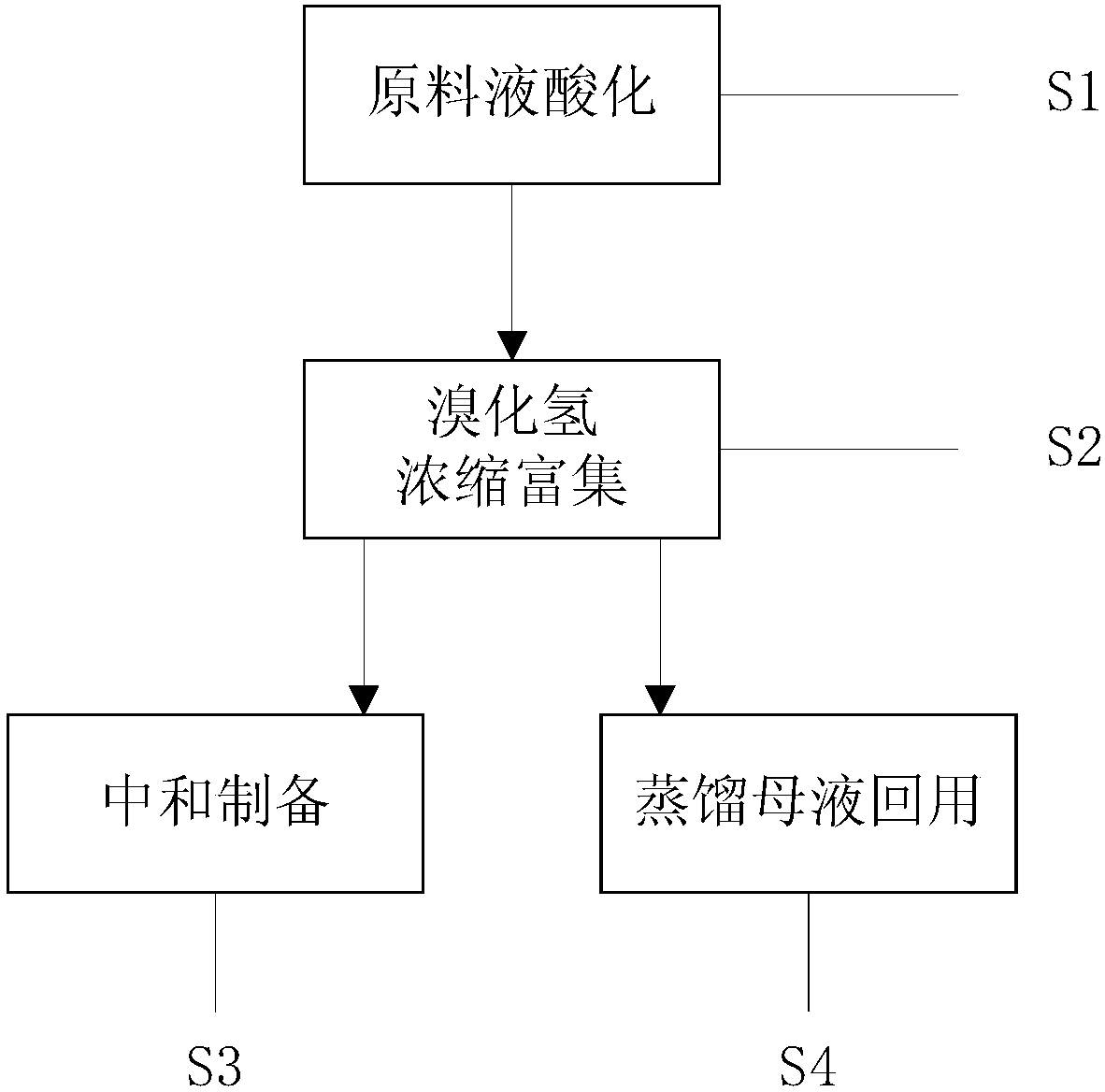

[0027] According to the mass ratio of concentrated sulfuric acid and bromine of 1:1, add concentrated sulfuric acid and bromine-extracting enriched liquid to the still; after mixing uniformly, heat and distill the above-mentioned mixed liquid to obtain enriched and concentrated hydrobromic acid and distillation Mother liquor; calcium hydroxide in the concentrated hydrobromic acid, the amount of calcium hydroxide added is determined according to the amount of hydrogen bromide, the ratio of the amount of calcium hydroxide added to the amount of hydrogen bromide is 1 :1. After the stirring reaction is complete, an aqueous bromide solution for mercury removal can be obtained; the mother liquor of distillation is returned to the bromine extraction step for acidification of seawater and brine.

Embodiment 2

[0029] According to the mass ratio of concentrated sulfuric acid and bromine of 3:1, add concentrated sulfuric acid and bromine-extracting enriched liquid into the distillation kettle; after mixing uniformly, heat and distill the above-mentioned mixed liquid to obtain enriched and concentrated hydrobromic acid and distillation Mother liquor; Magnesium oxide in the concentrated hydrobromic acid, the amount of magnesium oxide added is determined according to the amount of hydrogen bromide, and the ratio of the amount of magnesium oxide added to the amount of hydrogen bromide is 1:1. After the stirring reaction is complete, an aqueous solution of bromide for mercury removal can be obtained; the mother liquor of distillation is returned to the bromine extraction step for acidification of seawater and brine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com