High-hardness extruded silicone rubber composition and preparation method thereof

A silicone rubber composition and extrusion-type technology are applied in the field of high-hardness extrusion-type silicone rubber composition and its preparation, which can solve the problems of high vulcanization speed, affect the appearance of mixed rubber products, low decomposition temperature, etc., and achieve enhanced Effects of crosslinking density, suppression of secondary vulcanization hardness reduction, and elongation improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

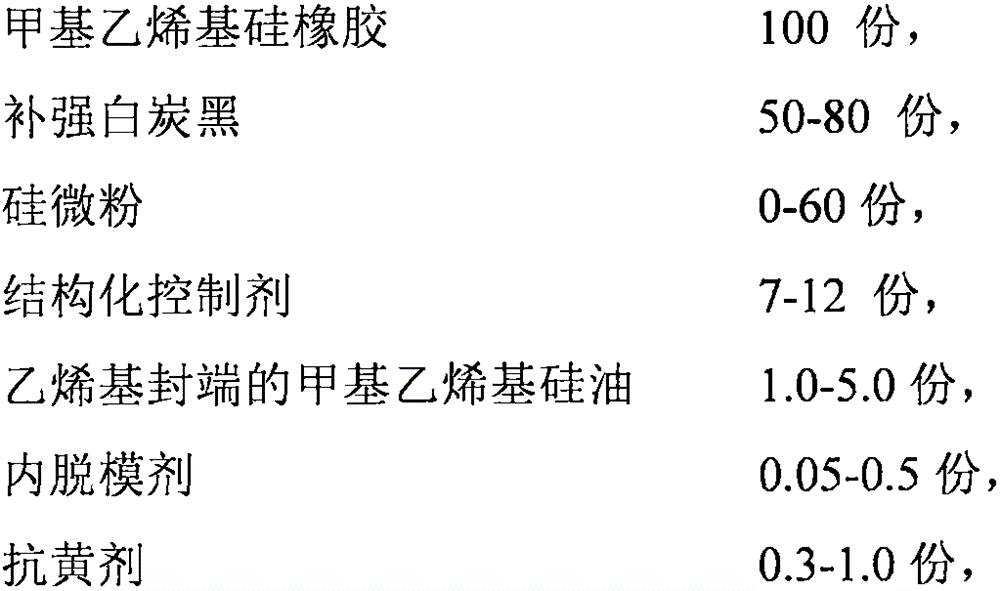

Method used

Image

Examples

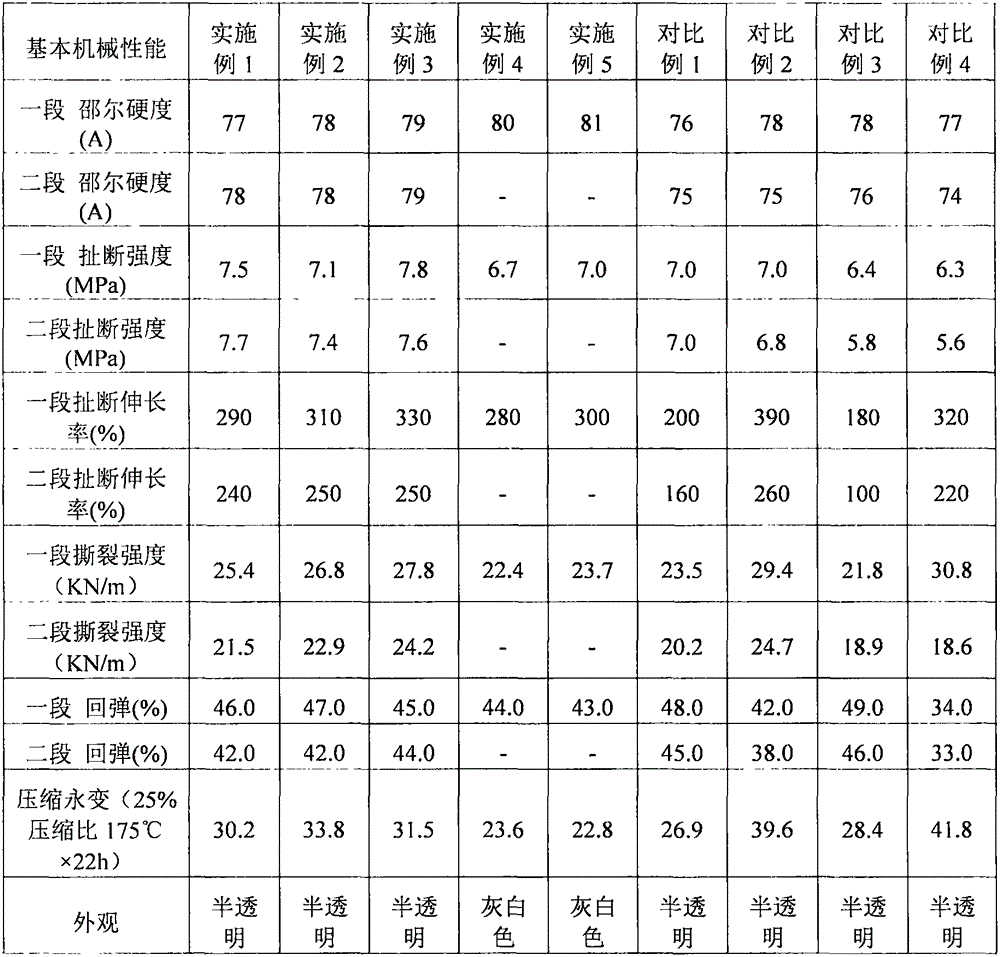

Embodiment 1

[0024] 100 parts of methyl vinyl silicone rubber with an average molecular weight of 666,000 and an average vinyl content of 0.5% (40 parts of methyl vinyl silicone rubber with a molecular weight of 700,000 and a vinyl content of 0.03%, and ethylene with a molecular weight of 650,000 56 parts of methyl vinyl silicone rubber with a base content of 0.16%, molecular weight of 550,000, 4 parts of methyl vinyl silicone rubber with a vinyl content of 10.0%, 5 parts of hydroxyl silicone oil (viscosity at 25°C is 25mm 2 / s, the hydroxyl content is 8.5% (mass content)), 1 part of vinyl hydroxy silicone oil (viscosity at 25°C is 30mm 2 / s, the hydroxyl content is 6.0%, the vinyl content is 7.0% (mass content)), 3 parts of dimethyl dimethoxy silicone oil and other structural control agents and 0.08 parts of release agent stearic acid are put into preheating and heat preservation at one time In the kneader at 60°C for 1 hour, add the specific surface area of 180m2 in 8 times 2 / g, 75 p...

Embodiment 2

[0028] 100 parts of methyl vinyl silicone rubber with an average molecular weight of 663,000 and an average vinyl content of 0.54% (45 parts of methyl vinyl silicone rubber with a molecular weight of 680,000 and a vinyl content of 0.05%, a molecular weight of 680,000, vinyl 50 parts of methyl vinyl silicone rubber with a content of 0.23%, molecular weight of 600,000, 5 parts of methyl vinyl silicone rubber with a vinyl content of 8.0%, 4.5 parts of hydroxyl silicone oil (viscosity at 25°C is 25mm2 / s, hydroxyl The content is 8.5% (mass content)), 1 part of methylphenyldimethoxysilane, 2.5 parts of dimethyldiethoxy silicone oil and other structural control agents and 0.1 part of release agent zinc stearate once input In the kneader that is preheated and kept at 80°C for 1 hour, add it in 8 times with a specific surface area of 175m 2 73 parts of precipitated white carbon black YX813 (produced by Fujian Yuanxiang Co., Ltd.) with an average particle size of 1.5 μm, each componen...

Embodiment 3

[0031] 100 parts of methyl vinyl silicone rubber with an average molecular weight of 670,000 and an average vinyl content of 0.49% (50 parts of methyl vinyl silicone rubber with a molecular weight of 700,000 and a vinyl content of 0.03%, a molecular weight of 650,000, vinyl 45 parts of methyl vinyl silicone rubber with a base content of 0.50%, molecular weight of 550,000, 5 parts of methyl vinyl silicone rubber with a vinyl content of 5.0%, 4.0 parts of hydroxyl silicone oil (viscosity at 25°C is 25mm 2 / s, the hydroxyl content is 8.5% (mass content)), 2 parts of hexamethyldisilazane, 2.5 parts of dimethyldiethoxy silicone oil and other structural control agents and 0.06 parts of release agent calcium stearate Put it into the kneader that is preheated and kept at 60°C for 1 hour, and add it in 8 times with a specific surface area of 180m 2 / g, 60 parts of precipitated silica TMG (produced by Jilin Tonghua Co., Ltd.) with an average particle size of 1 μm, and a specific surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com