High-performance antibiosis wood plastic composite material and preparation method thereof

A wood-plastic composite material, high-performance technology, applied in the field of wood-plastic composite materials, can solve problems such as poor antibacterial performance, and achieve the effects of reduced decomposition, high mechanical properties, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

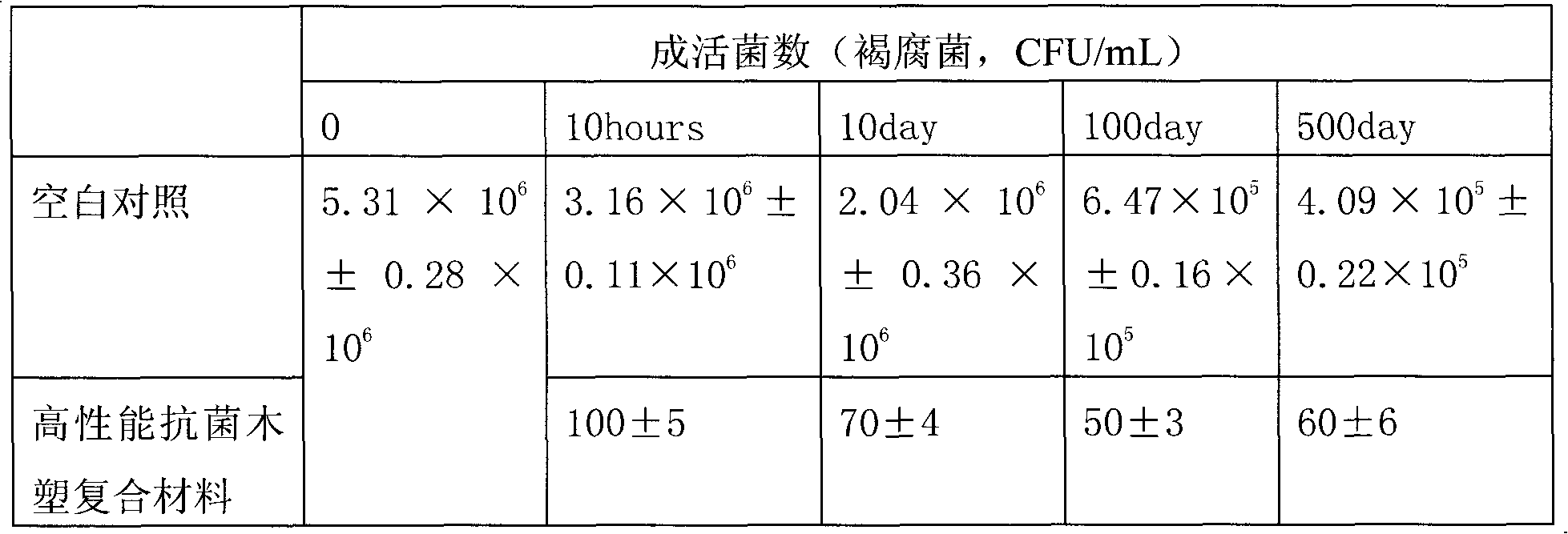

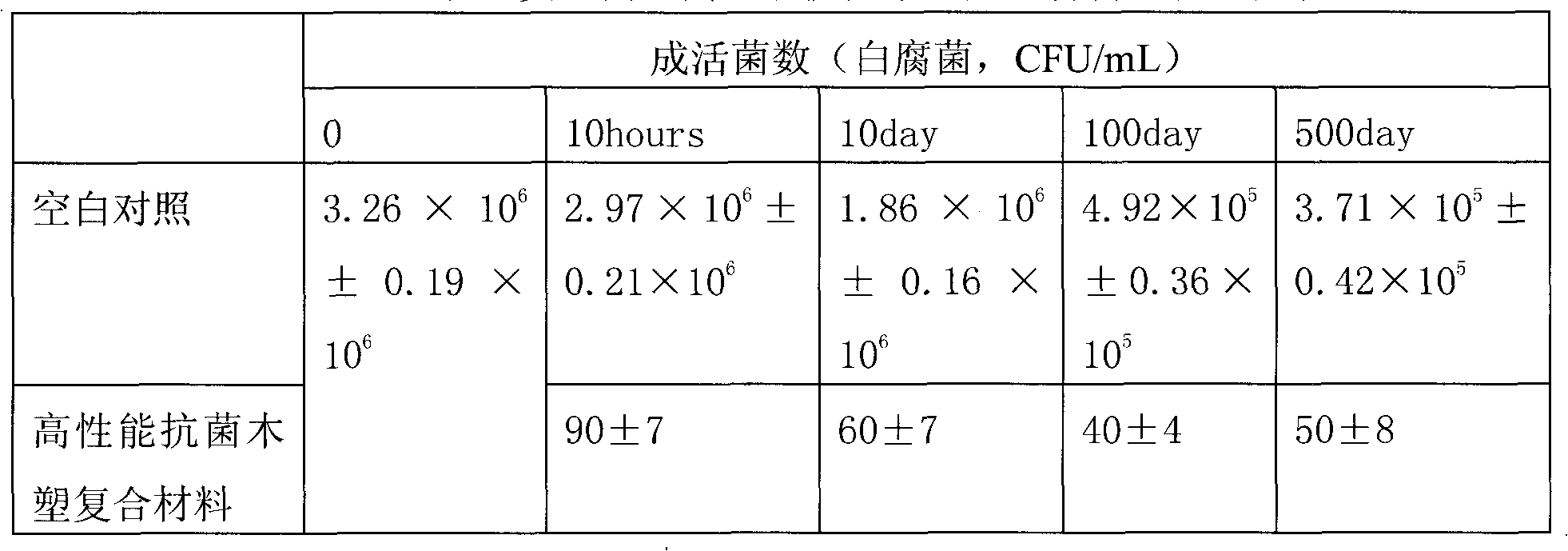

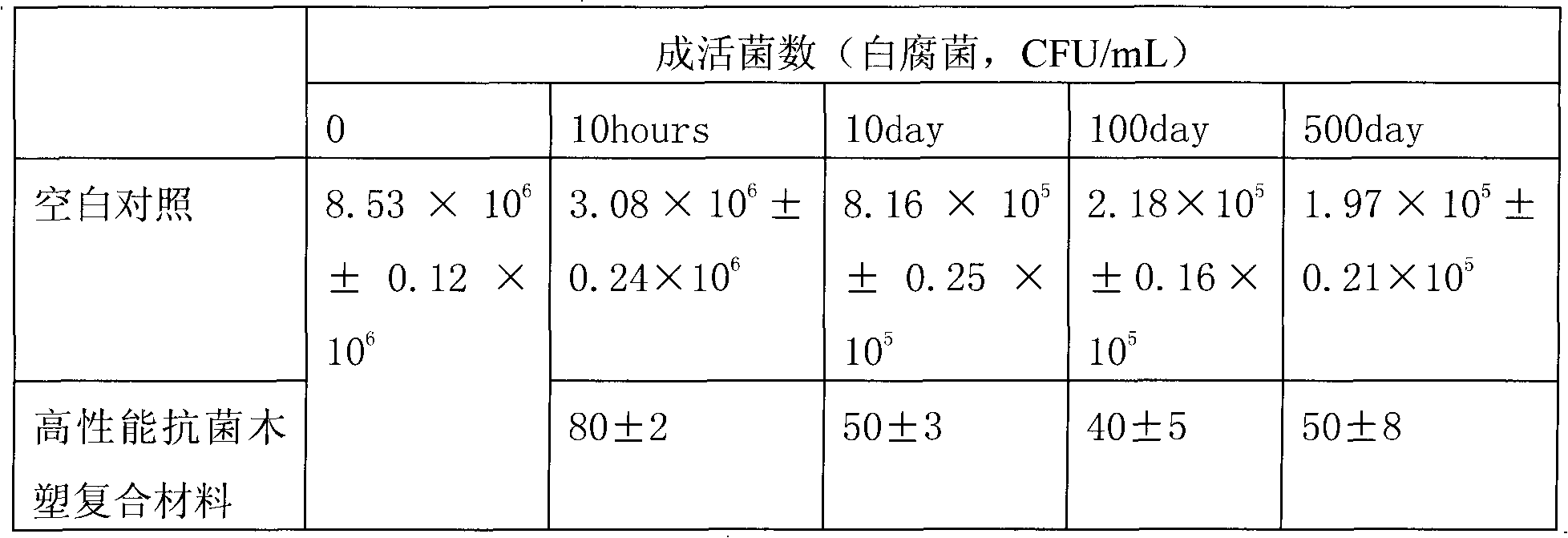

Examples

Embodiment 1

[0037] Weigh 100 parts of recycled PE plastic powder with a particle size of 10 mesh according to the weight ratio, and the particle size is 60 mesh. 20 parts of wood powder grafted on the surface of methyl-4-ethyl-1,3-oxazolidin-2-one, 80 parts of activated calcium carbonate, 10 parts of compatibilizer PE-g-MAH, 6 parts of calcium stearate 8 parts of zinc stearate, 10 parts of PE wax, 3 parts of antioxidant 1010, 4 parts of light stabilizer 770, and 2 parts of toner. Mix at high speed for 18 minutes at speeds per minute. The mixed material is released and added to a parallel twin-screw extruder for extrusion and granulation. The temperatures of each section of the extruder are: 140°C, 170°C, 190°C, 190°C, 195°C and 195°C (head temperature) , the screw speed is 30 rpm. The pellets are made into standard specimens by pressing, and various mechanical properties and antibacterial properties are tested. The formula, test standards and results are shown in Table 7, and each comp...

Embodiment 2

[0044] Weigh 100 parts of recycled PP plastic powder with a particle size of 20 mesh according to the weight ratio. 40 parts of bamboo powder grafted on the surface of methyl-4-ethyl-1,3 oxazolidin-2-one, 60 parts of activated calcium carbonate, 15 parts of compatibilizer PP-g-MAH, 8 parts of calcium stearate 6 parts, 6 parts of zinc stearate, 6 parts of PE wax, 4 parts of antioxidant 1076, 4 parts of light stabilizer, 3 parts of toner, put the above raw materials into a high-speed mixer, at 95 ° C, 100 rpm Mix at high speed for 12 minutes at rpm. The mixed material is released and added to a parallel twin-screw extruder for extrusion and granulation. The temperatures of each section of the extruder are: 180°C, 200°C, 210°C, 210°C, 215°C and 215°C (head temperature) , the screw speed is 35 rpm. The pellets are made into standard specimens by pressing, and various mechanical properties and antibacterial properties are tested. The formula, test standards and results are shown...

Embodiment 3

[0048] Weighing 100 parts of recycled PVC plastic powder with a particle size of 30 mesh according to the weight ratio, the particle size is 200 mesh, and the surface is passed through methacryloyloxyethyl-trimethylammonium chloride and 1-propenyl-hydantoin. Grafted bran 80 parts, activated calcium carbonate 40 parts, compatibilizer CPE-g-MAH 30 parts, calcium stearate 8 parts, zinc stearate 8 parts, PE wax 10 parts, antioxidant 300 5 parts , 5 parts of light stabilizer 765, 4 parts of toner, put the above raw materials into a high-speed mixer, and mix at a high speed for 16 minutes at 105°C and a speed of 80 rpm. The mixed material is released and added to a parallel twin-screw extruder for extrusion and granulation. The temperatures of each section of the extruder are: 160°C, 180°C, 190°C, 190°C, 195°C and 195°C (head temperature) , the screw speed is 40 rpm. The pellets are made into standard specimens by pressing, and various mechanical properties and antibacterial proper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com