Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

893 results about "Strength of materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Strength of materials, also called mechanics of materials, deals with the behavior of solid objects subject to stresses and strains. The complete theory began with the consideration of the behavior of one and two dimensional members of structures, whose states of stress can be approximated as two dimensional, and was then generalized to three dimensions to develop a more complete theory of the elastic and plastic behavior of materials. An important founding pioneer in mechanics of materials was Stephen Timoshenko.

High-performance thermal insulation material and preparation method thereof

The invention provides a high-performance thermal insulation material and a preparation method thereof. The thermal insulation material comprises silicon dioxide aerogel and a fiber material, wherein, the silicon dioxide aerogel takes silicon dioxide hydrosol as a raw material, and is prepared by adding a catalyst. The method comprises the following steps: sol preparing, sol dipping, gelating, gel ageing, hydrophobization treating and drying and the like. The method can conveniently and selectively prepare the materials of planes, abnormal-shape surfaces and multiple sizes, has simple and convenient operation and small environmental pollution. The material has excellent mechanical performance, good high-temperature stability and heat insulation performance, and has wide application prospect in the fields of civilian industries, space flight and aviation industries, military industries and the like.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

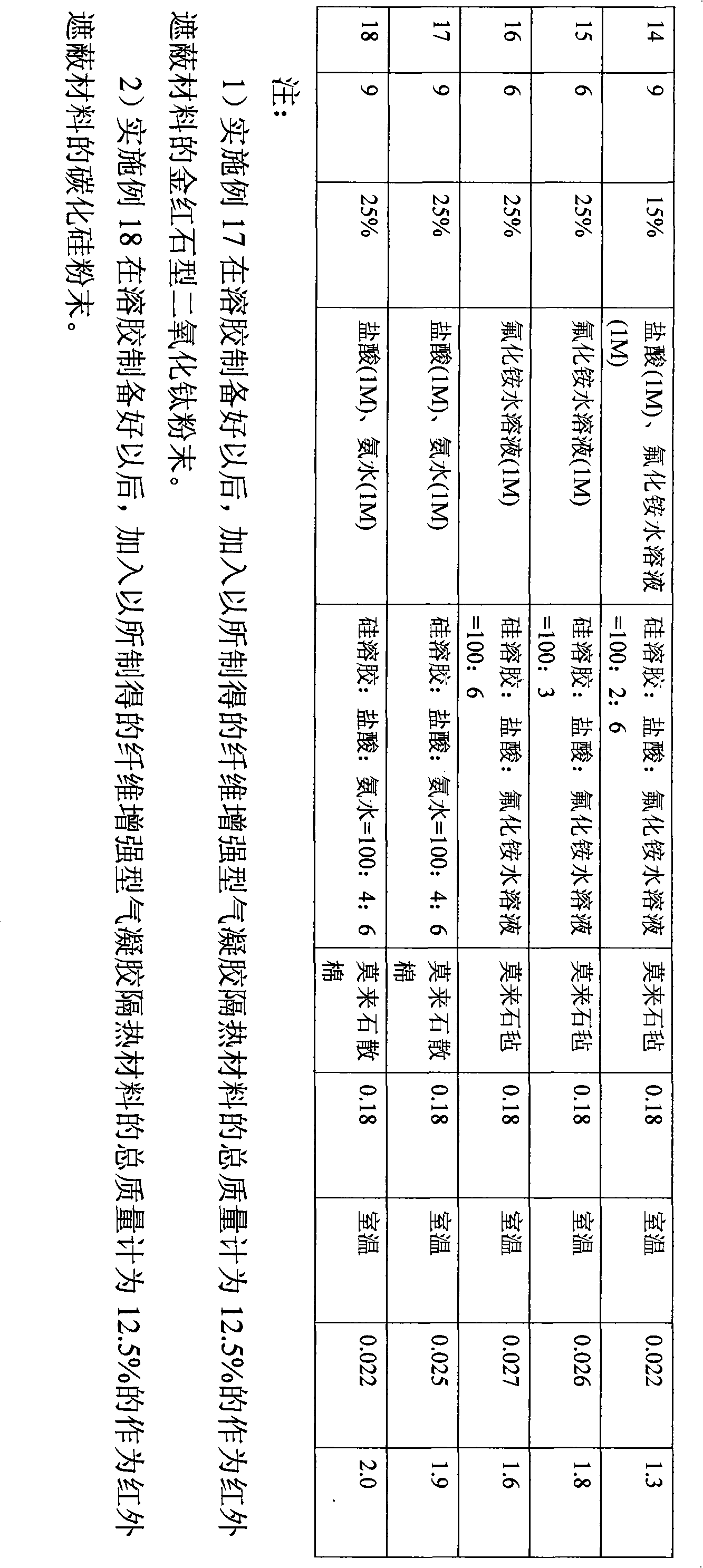

Epoxy resin adhesive for manufacturing blades of wind driven generator and preparation method thereof

ActiveCN101851481AHigh strengthHigh modulusNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyWind driven

The invention discloses an epoxy resin adhesive for manufacturing blades of a wind driven generator and a preparation method thereof. The epoxy resin adhesive is prepared by combining a resin part and a curing agent part, wherein the resin part comprises epoxy resin, a dilutent, filler, a thixotropic agent and an auxiliary agent; the curing agent part comprises an amine curing agent, filler and athixotropic agent; and the filler comprises a powdery filler part and a fibrous filler part. The epoxy resin adhesive prepared by using the general epoxy resin has high strength, particularly furtherimproves the strength of materials by adding the fibrous filler, improves the anti-cracking performance of the materials, meets the special requirements of the blades of wind driven generators with megawatt or more on the materials and has low material cost and high economy.

Owner:四川东树新材料有限公司

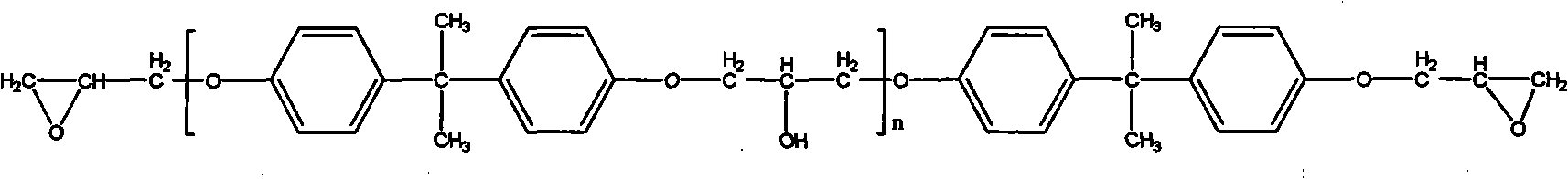

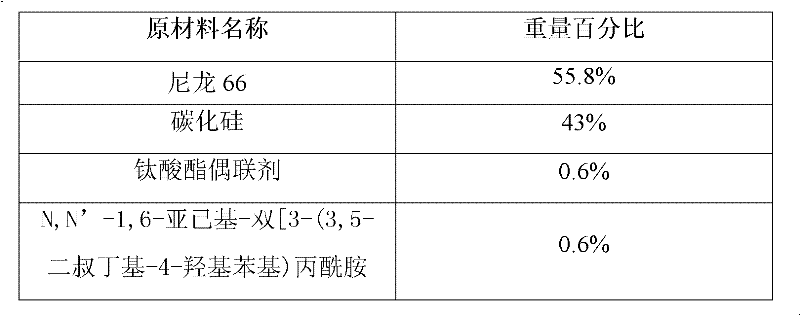

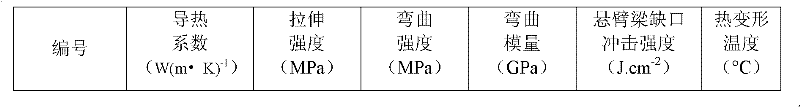

Nylon 66 composite material with high heat conductivity and preparation method thereof

ActiveCN102408710AGood dispersionEvenly dispersedHeat-exchange elementsStrength of materialsNylon 66

The invention discloses a nylon 66 composite material with high heat conductivity, comprising the following substances based on weight percentages: 70-42% of nylon 66, 27-55% of heat conduction filler, 0.5-1.5% of coupling agent and 0.5-1.5% of anti-oxidant. In addition, the invention also discloses a preparation method for the nylon 66 composite material with high heat conductivity, wherein the method adds a processing step on the heat conduction filler based on the conventional method. The nylon 66 composite materials with high heat conductivity prepared by the invention can better keep themechanical property of the nylon 66 composite material and largely raise the heat conductivity at the same time. In comparison with the heat conductivity of the nylon 66 composite material prepared from the heat conduction filler without processing, the heat conductivity of the nylon 66 composite material prepared from the processed heat conduction filler is raised by about 30-50%.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

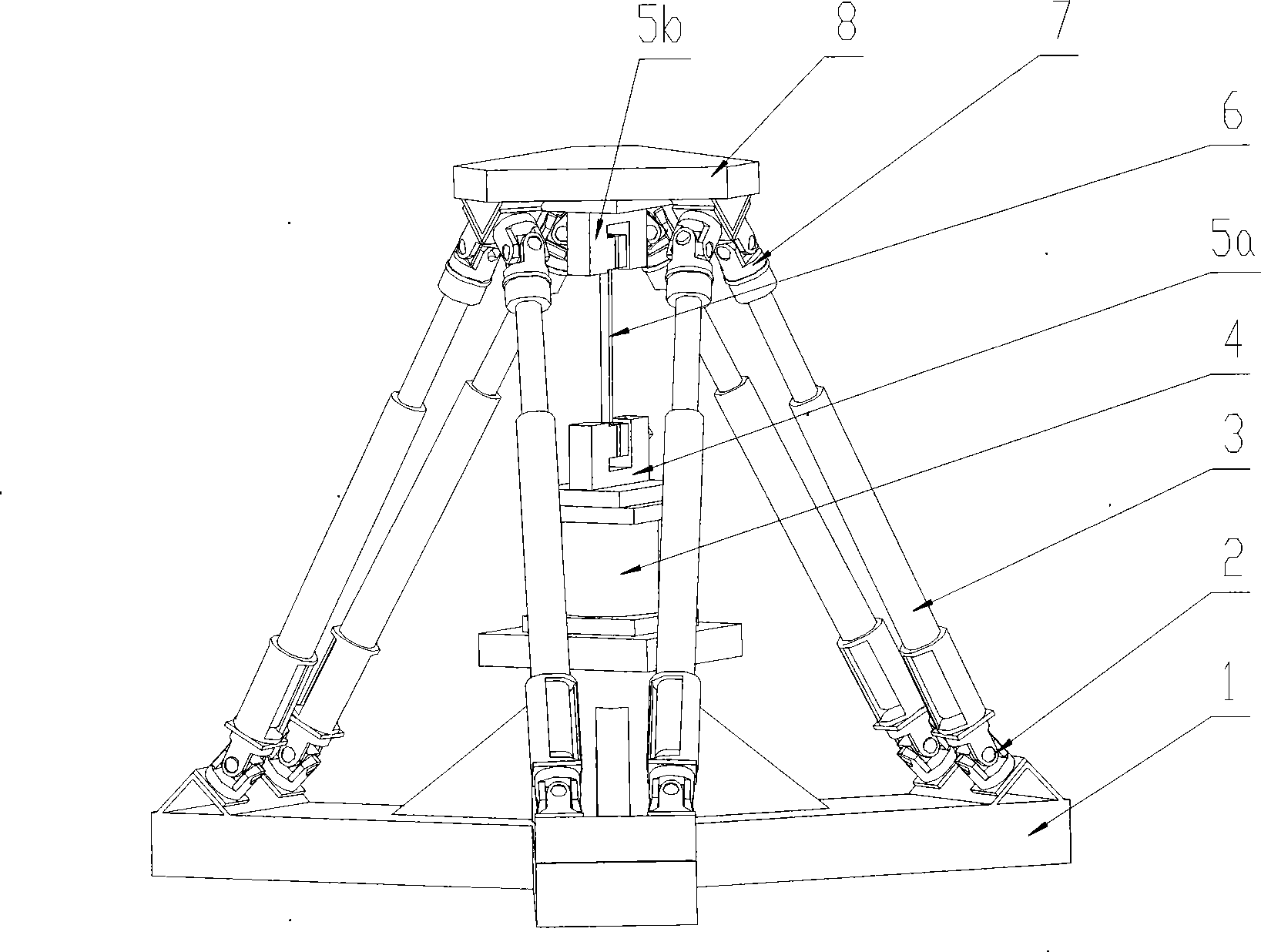

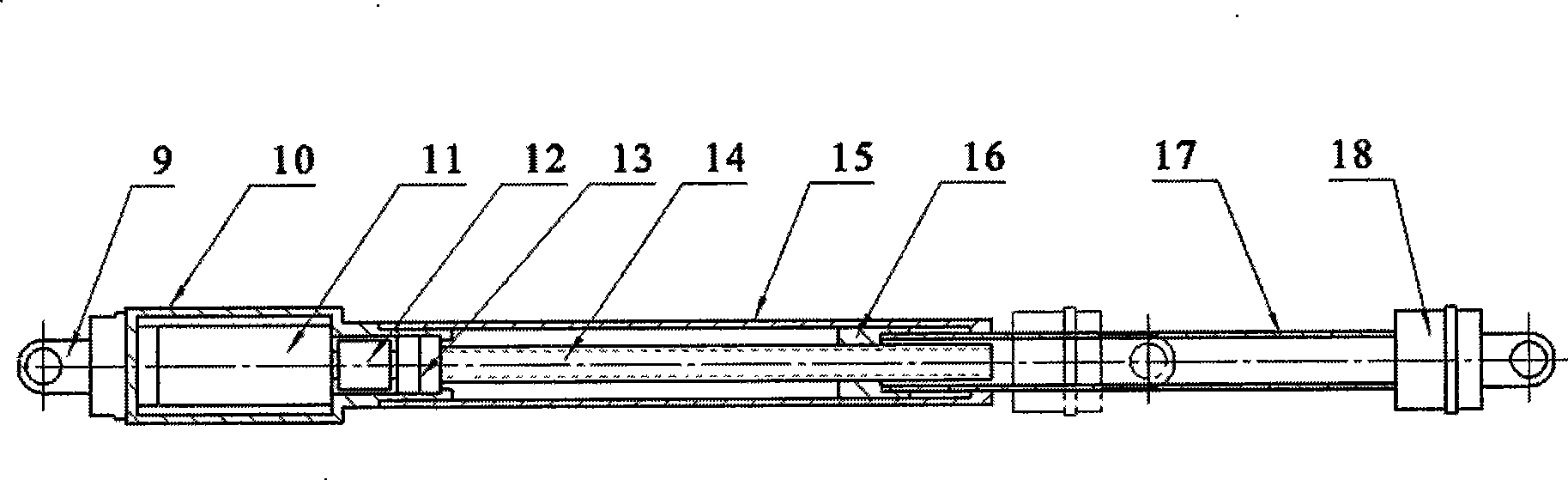

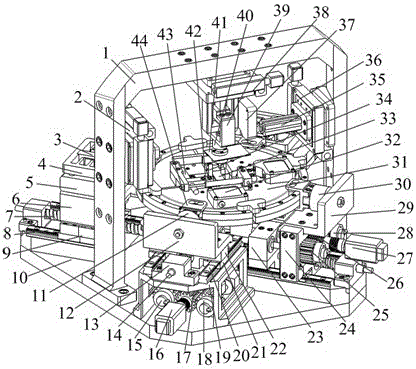

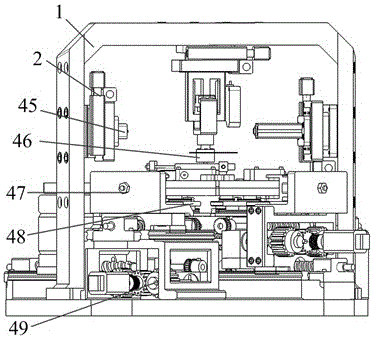

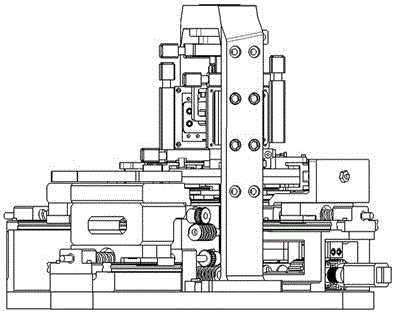

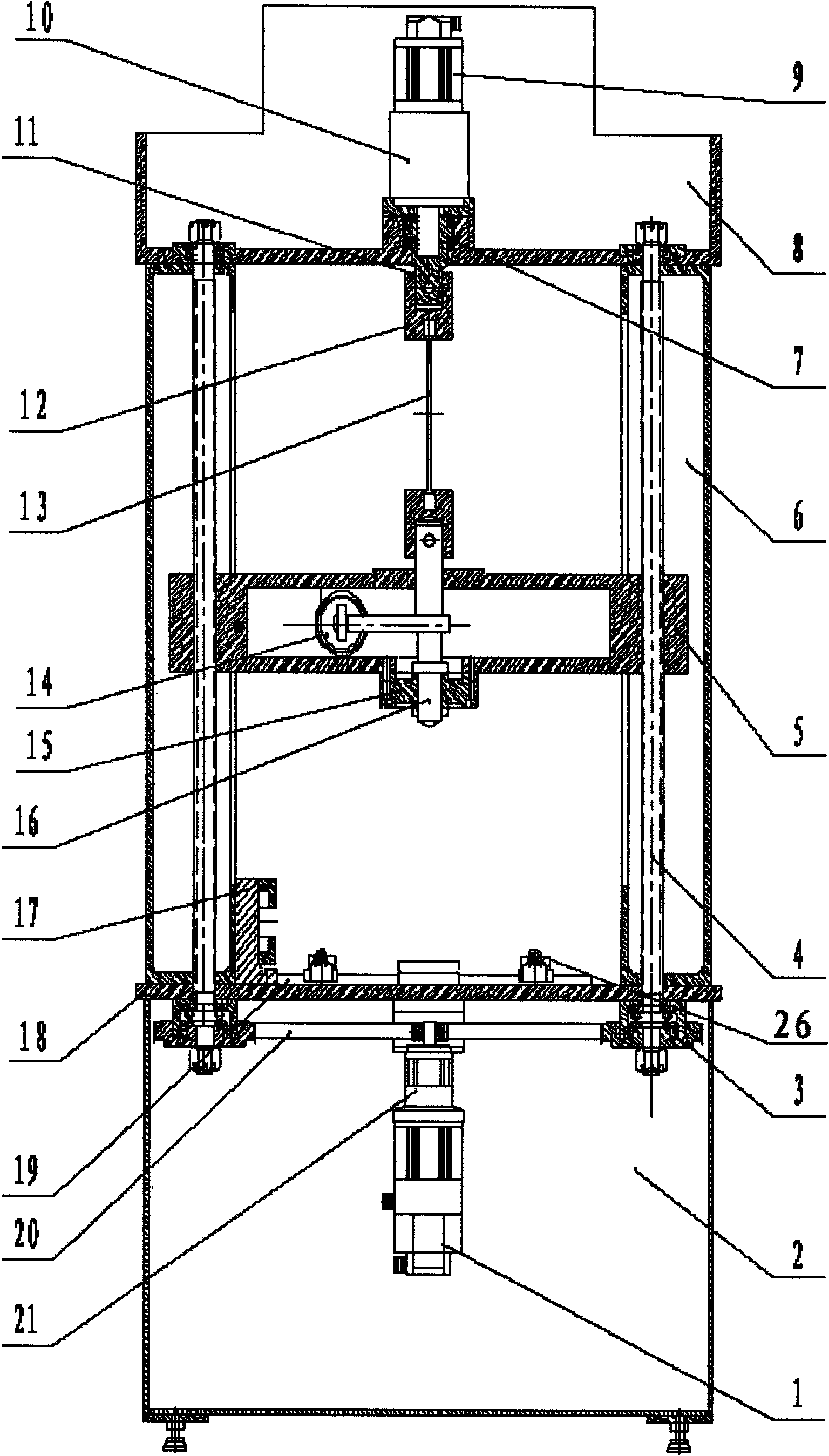

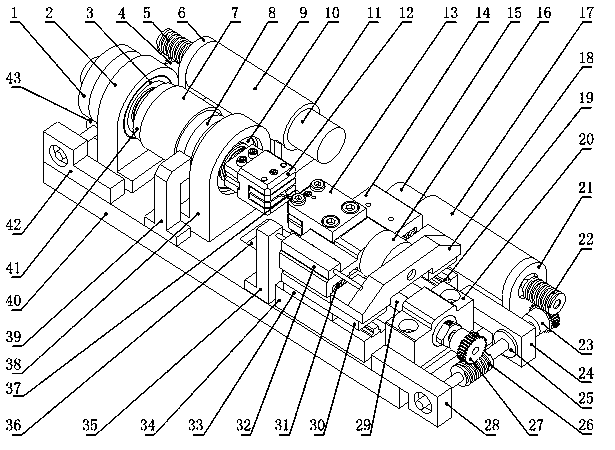

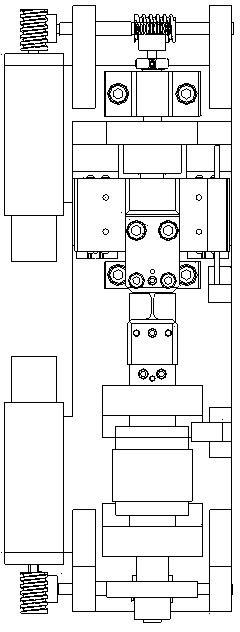

Six-dimension loading material mechanical test machine

InactiveCN101451933AAccurate stress-strain distribution dataAccurate location of dangerous partsStrength propertiesStrength of materialsEngineering

Six-dimensional loading testing machine for materials mechanics disclosed by this invention can realize dynamic and static material mechanics performance test for three-dimensional force and three-dimensional moment. A basic platform is fixed with six Hooke hinges, the movable platform is fixed with six spherical hinges. The test piece is clamped by an upper clamp and a lower clamp. The upper clamp is fixedly connected with the movable platform capable of moving therewith. The lower clamp is fixed on a six-dimensional force sensor. The test piece receives load via the upper and lower clamps. Movement of the movable platform is realized by six retracting rods. Driven by respective actuating motor, the retracting rod parts can realize precise axial retraction. With combination of the six retracting rods, various movement driving processes can be realized on the clamps to exert various single or combined load on the test piece, in order to realize dynamic and static material mechanics performance test for three-dimensional force and three-dimensional moment.

Owner:BEIJING FORESTRY UNIVERSITY +3

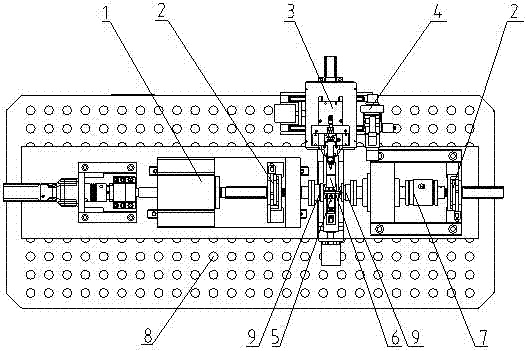

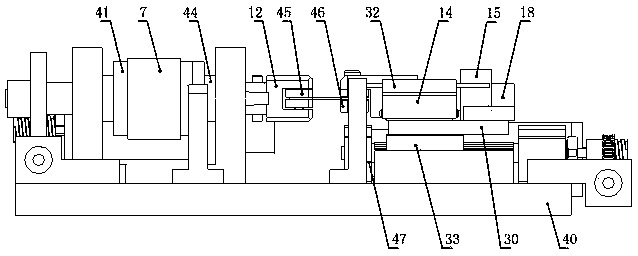

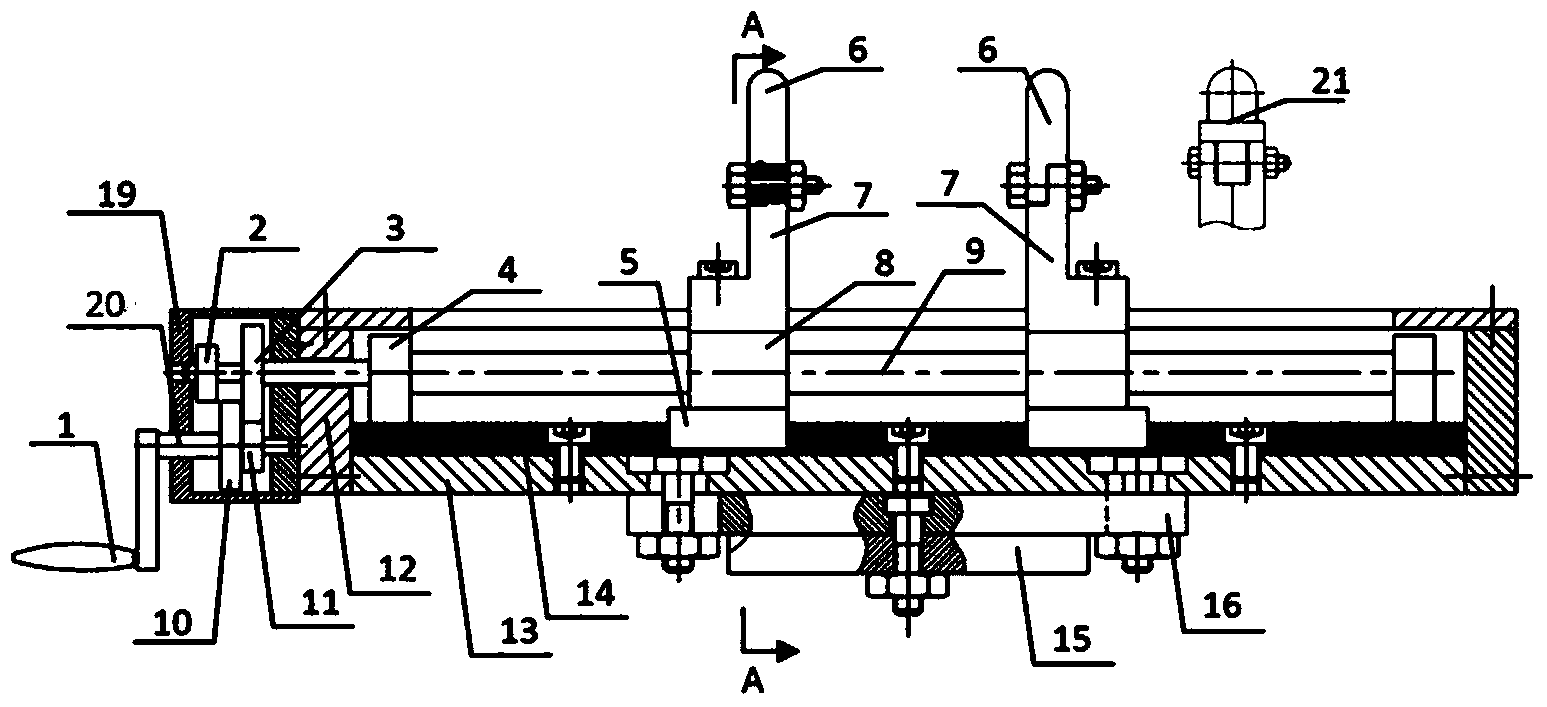

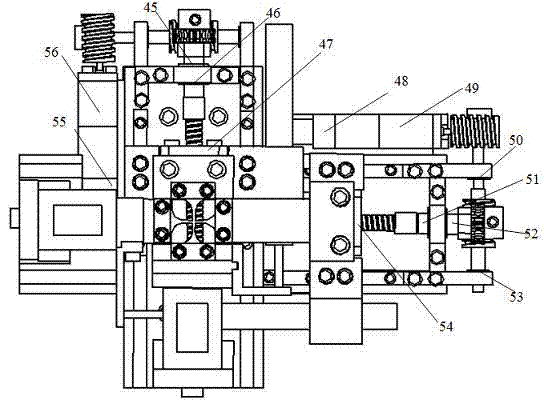

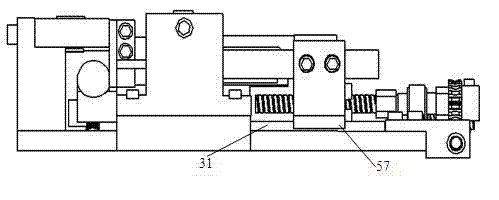

Material mechanical property in-situ testing system and method in dynamic and static load spectrum

ActiveCN106226152AImprove compatibilityCompact structureMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesEngineeringMultiple modes

The invention relates to a material mechanical property in-situ testing system and method in a dynamic and static load spectrum, and belongs to the field of mechanical tests. The system integrates the following functions: a static testing function of biaxial drawing and shearing in an orthogonal plane, a shearing static testing function, a double shaft pull-pull mode fatigue testing function, and a static / dynamic press testing function. A complicated static / dynamic load spectrum can be established. Multi-mode composite load mechanical property evaluation can be performed on a film material or a block material, for example: high-cycle fatigue tests based on double-shaft pre-stretching load and impact press tests based on double-shaft stretching-shearing pre-load. At the same time, special defects are pre-fabricated on the central area and cross shaped arm area of a test piece; the analysis functions of a variable-zoom optical imaging system or a digital speckle strain analysis system can be utilized; the provided system and method can also be used to research the deformation behavior and cracking expansion rules of micro defects in a component under a multi-dimensional stress, and an evaluation tool is provided for performance degradation rules of products and optimized preparation method of materials.

Owner:JILIN UNIV

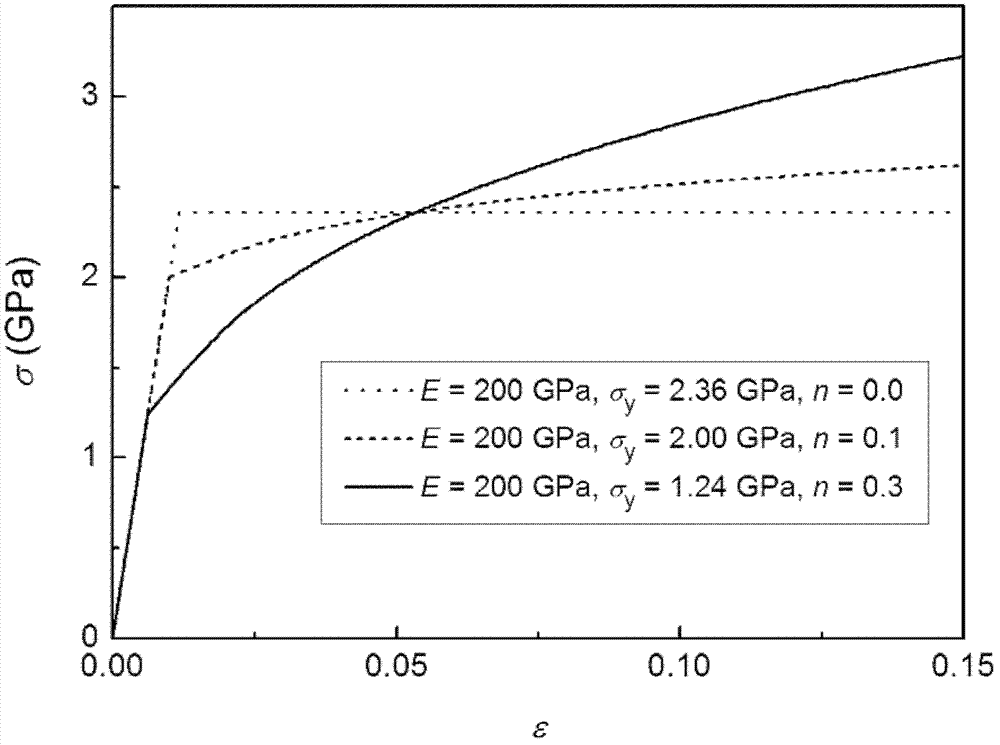

Process for characterizing elastoplasticity of metal material through indentation method

The invention discloses a process for characterizing the elastoplasticity of a metal material by introducing an extra residual area through an indentation method, belonging to the field of researches on the mechanical properties of a material. Experiment devices required by the method mainly comprise an indentor, and an atomic force microscope or a three-dimensional optical imaging system. The method mainly comprises the following steps: indenting a material to be tested through the indentor to obtain an indention load displacement curve, extracting relevant parameters from the indention load displacement curve, substituting the extracted parameters to an established model, and calculating to obtain the elastoplasticity of the material. The method mainly has the following advantages: different materials having similar indention curves can be successfully separated, and the obtained solution is only; and the solution obtained through back-stepping has a high precision. So the only high-precision elastoplasticity of the indented material can be obtained through back-stepping by utilizing the theoretic model in the invention.

Owner:XIANGTAN UNIV

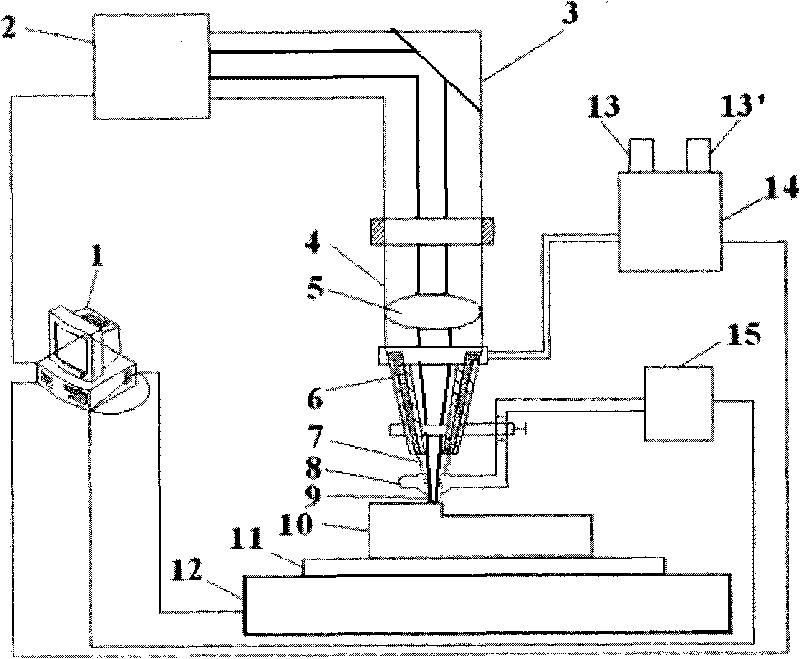

In-situ testing machine for microcosmic performance of multi-load and multi-physical-field coupling material

ActiveCN103499483AEfficient combinationSimulate micromechanical propertiesMaterial strength using tensile/compressive forcesInvestigating material hardnessMicro imagingPhysical field

The invention relates to an in-situ testing machine for the microcosmic performance for a multi-load and multi-physical-field coupling material, belonging to the technical field of material mechanics property testing. The in-situ testing machine comprises a micro / nanometer-precision driving / transmission module, a 'mechanical-electric-thermal-magnetic' loading module and a control module, is integrated with a high-field-depth 3D (three dimensional) micro-imaging lens, a Raman spectrometer and a visual in-situ monitoring module and is capable of dynamically monitoring deformational behaviors, damage mechanisms and performance evolvement rules of the material in a loading process. The in-situ testing machine has the advantages that the whole structure is compact, and the space layout is saved; the loads of four manners including 'stretching / compression-torsion-bending-indentation' can be singly loaded, two or more loads can be combined to be loaded as well, and externally-applied physical fields such as heat, electricity, magnetism and the like can be combined to maximally simulate the real working conditions of components of the material, and effective measures and methods are provided for testing the micromechanical performance of the material under a service-approximating condition.

Owner:JILIN UNIV

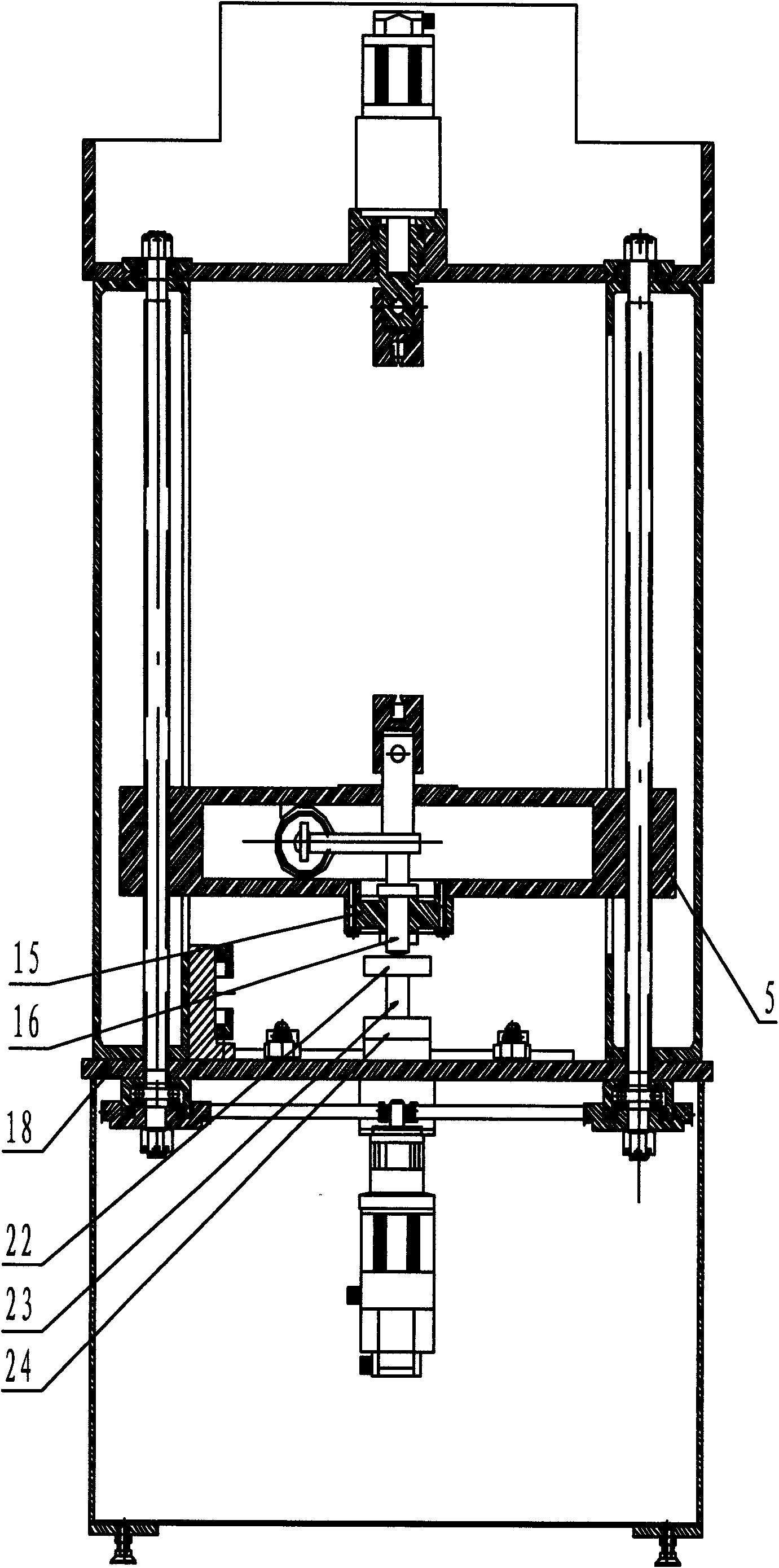

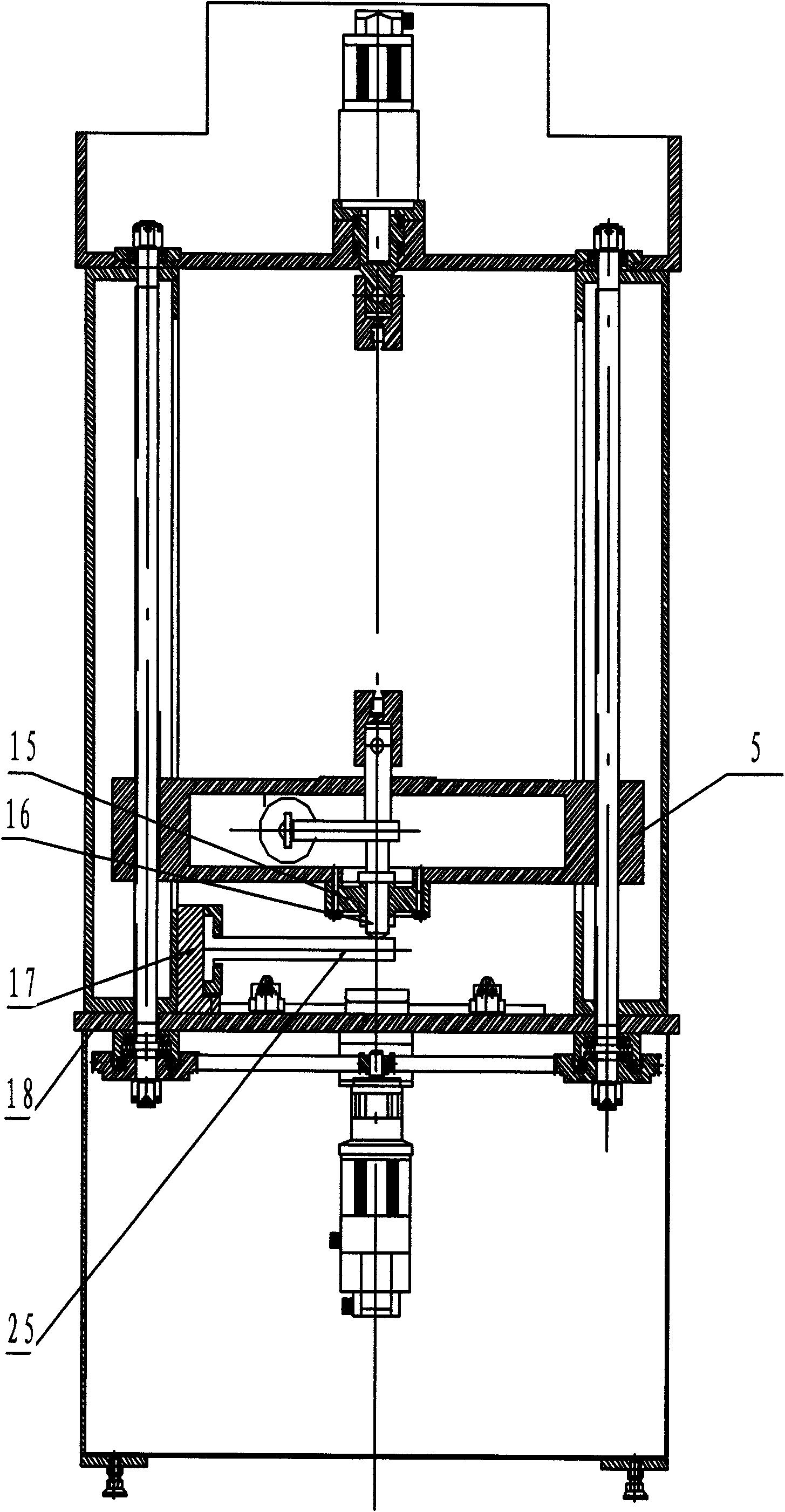

Multifunctional material mechanics testing machine with functions of tension torsion and pressure torsion

InactiveCN101625296ARealize pull torsionRealize functionMaterial strength using steady torsional forcesTorsion testTension compression

The invention relates to a material mechanics testing machine, belonging to the technical field of the material mechanics testing machine. The material mechanics testing machine is characterized in that the upper end and the lower end of the stander are provided with a lift motor and a torsion motor; the two motors form into one set of dynamic loading system and are controlled as well as coordinated to realize a tension torsion test and a pressure torsion test by an external electrical control system; a guide screw is arranged between the work table and an upper beam, wherein the upper end of the guide screw is fixed at the upper bean, and the lower end of the guide screw is driven by a synchronous belt wheel in a connection way; a middle beam is arranged between the work table and the upper beam; the middle beam is respectively provided with a tension compression rod and a tension compression sensor as well as a torsion sensor, wherein the tension compression sensor and the torsion sensor are communicated with a computer; the upper part of the wok table is provided with a slide way with a slide pillow; one side of the work table, near the vertical rod, is provided with a support seat; and the lower part of a torsion reduction machine is fixedly provided with a hanging rod, wherein the lower part of the hanging rod is provided with a clamp head. The two motors in the one set of dynamic loading system are simultaneously coordinated and controlled by the electrical control system to realize the functions of tension torsion and pressure torsion, and the rotate speeds of the two motors are adjusted by the electrical control system to meet the requirement of different experiments, digitally process the collection and the transmission of a parameter to be tested, and truly and exactly display the parameter on a screen.

Owner:孙仙山 +1

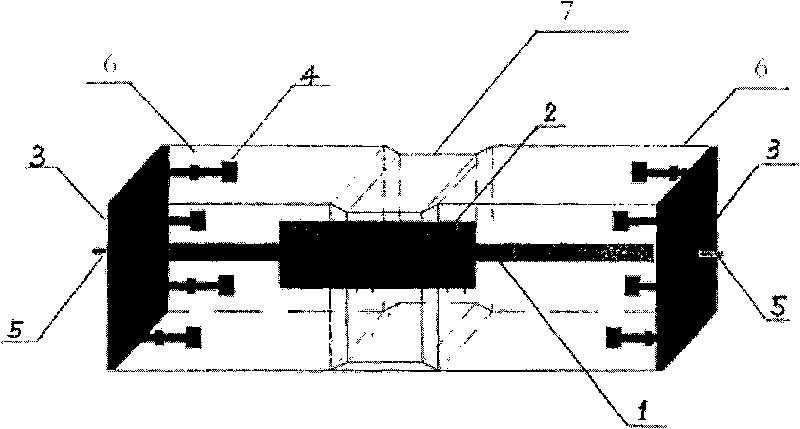

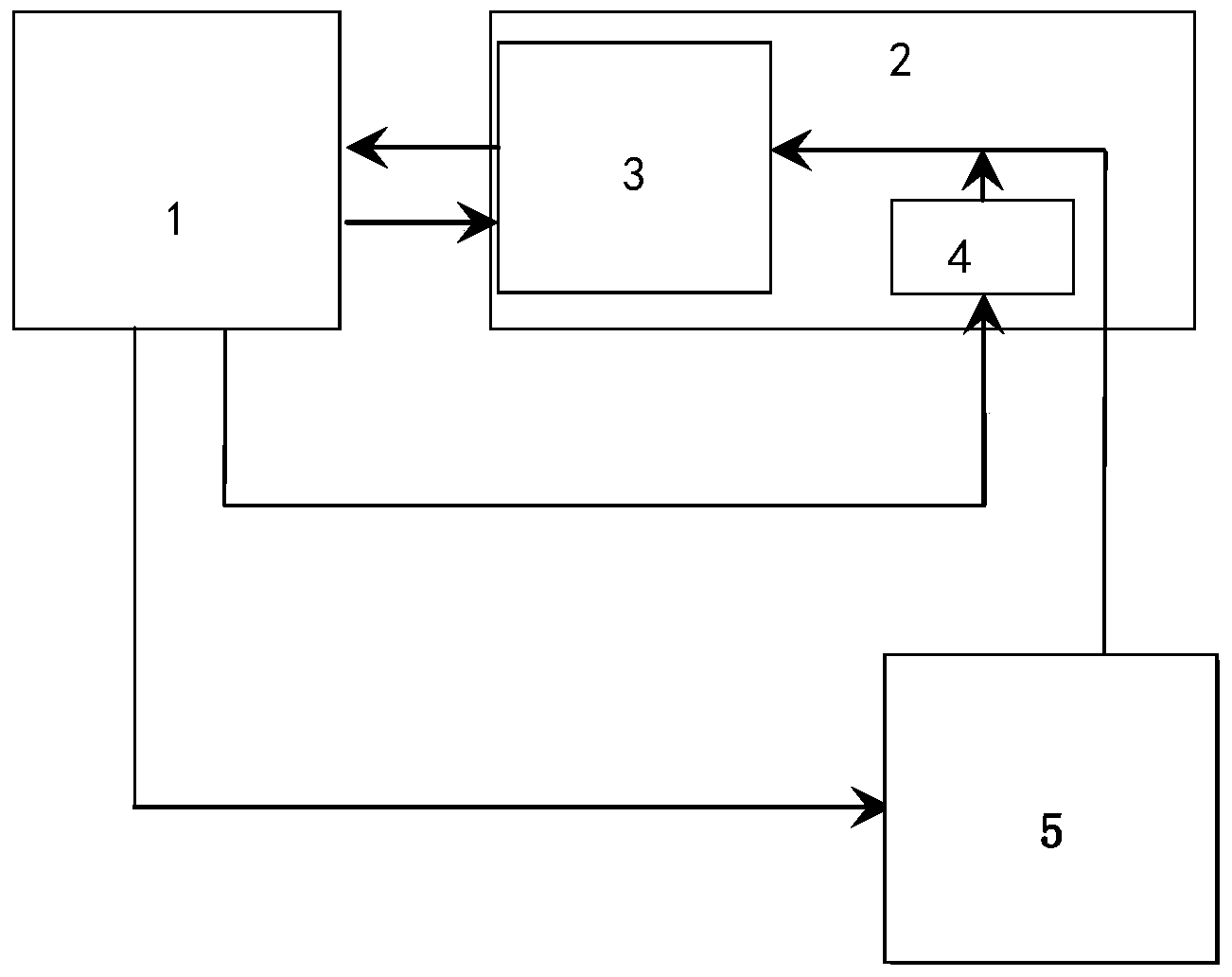

Test device for surface deformation and material and test method thereof

InactiveCN101672749AHeating up fastFast mechanical loadingMaterial strength using tensile/compressive forcesUsing optical meansOptical testStrength of materials

The invention discloses a test device for surface deformation of a material and a test method thereof, wherein the device comprises a material mechanical property test machine, an infrared fast heating device, a surface deformation optical test system, a temperature collecting device, a vacuum system and a clamp. The clamp fixes a sample in a vacuum chamber of the vacuum system and is connected with the material mechanical property test machine, the infrared fast heating device supplies thermal load for the sample, and the surface deformation optical test system measures the surface deformation of the sample. The device and the test method can simultaneously heat, apply stress and synchronously test deformation field in the surface. The coupling simulation of an aero-engine under service environment with high temperature and loading level, and the surface deformation condition of the structural material with high temperature under the environment are tested.

Owner:BEIHANG UNIV

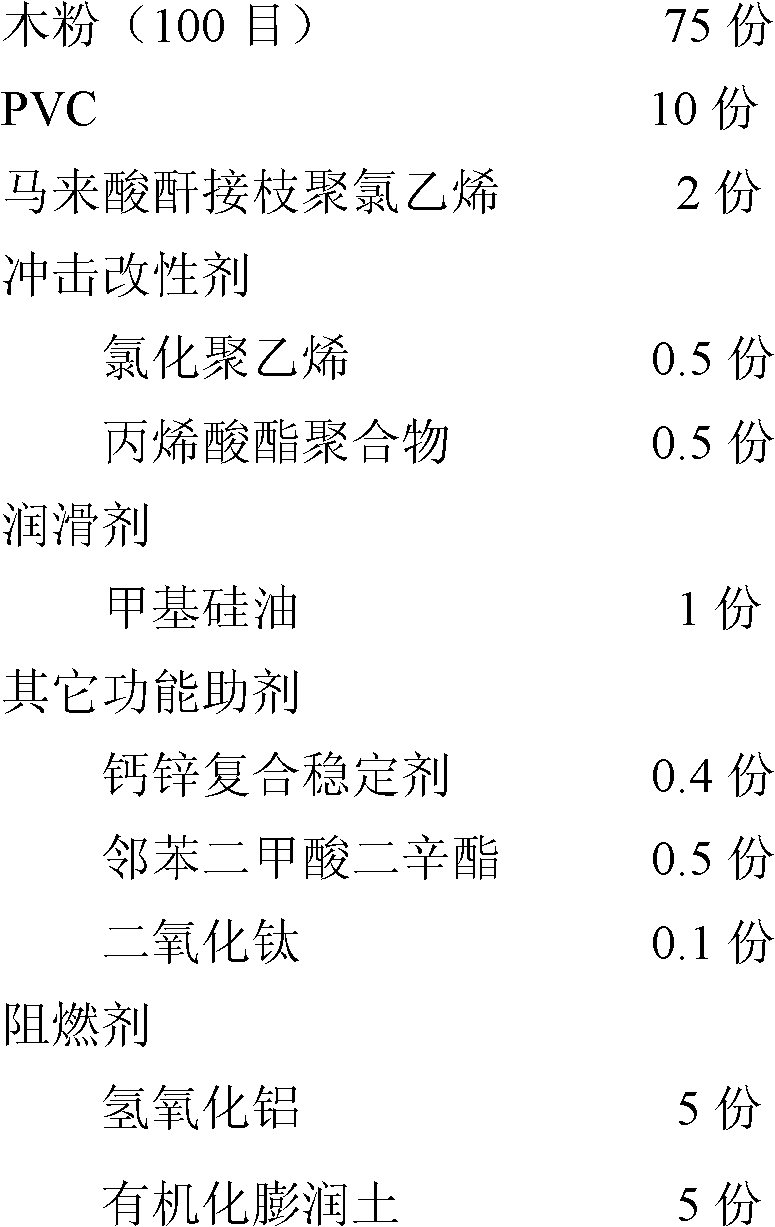

High-efficiency flame retardant wood plastics composite and preparation method thereof

The invention discloses a high-efficiency flame retardant wood plastics composite. The high-efficiency flame retardant wood plastics composite is prepared from 50 to 75 weight parts of wood powder, 10 to 30 weight parts of plastic resin, 1 to 5 weight parts of interfacial compatibilizer, 0.5 to 2 parts of impact modifier, 1 to 3 weight parts of lubricant, 1 to 5 weight parts of other functional aid, and 10 to 30 weight parts of flame retardant. The preparation method comprises the following steps of: degreasing and drying wood powder, organically modifying bentonite and zinc borate and mechanically grinding, mixing in a high-speed mixing machine to obtain premix, and mixing and plasticizing in a double-roll plasticator and performing compression molding. The bentonite and the zinc borate which are treated organically and aluminum hydroxide are compounded to form a novel fire retardant, the mechanical property of the material is kept, the flame retardant effect of the wood plastics composite is improved and the using amount of the aluminum hydroxide is greatly reduced; and the bentonite and the zinc borate are organically ultrafined, the problem that an inorganic additive is not easily compatible with other components so as to influence the mechanical property of the composite is solved and the flame retardant requirement of the wood plastics composite is met.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

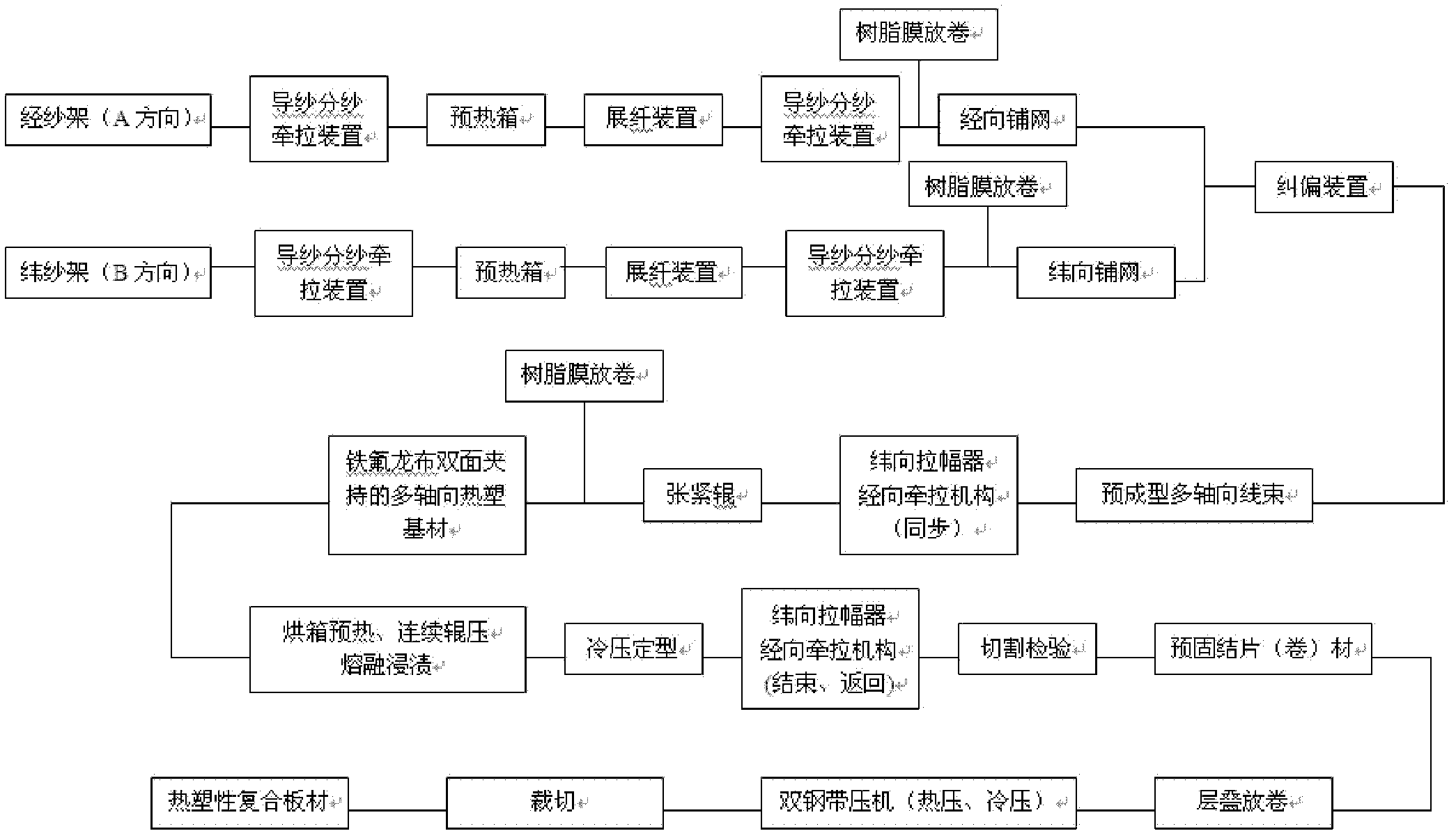

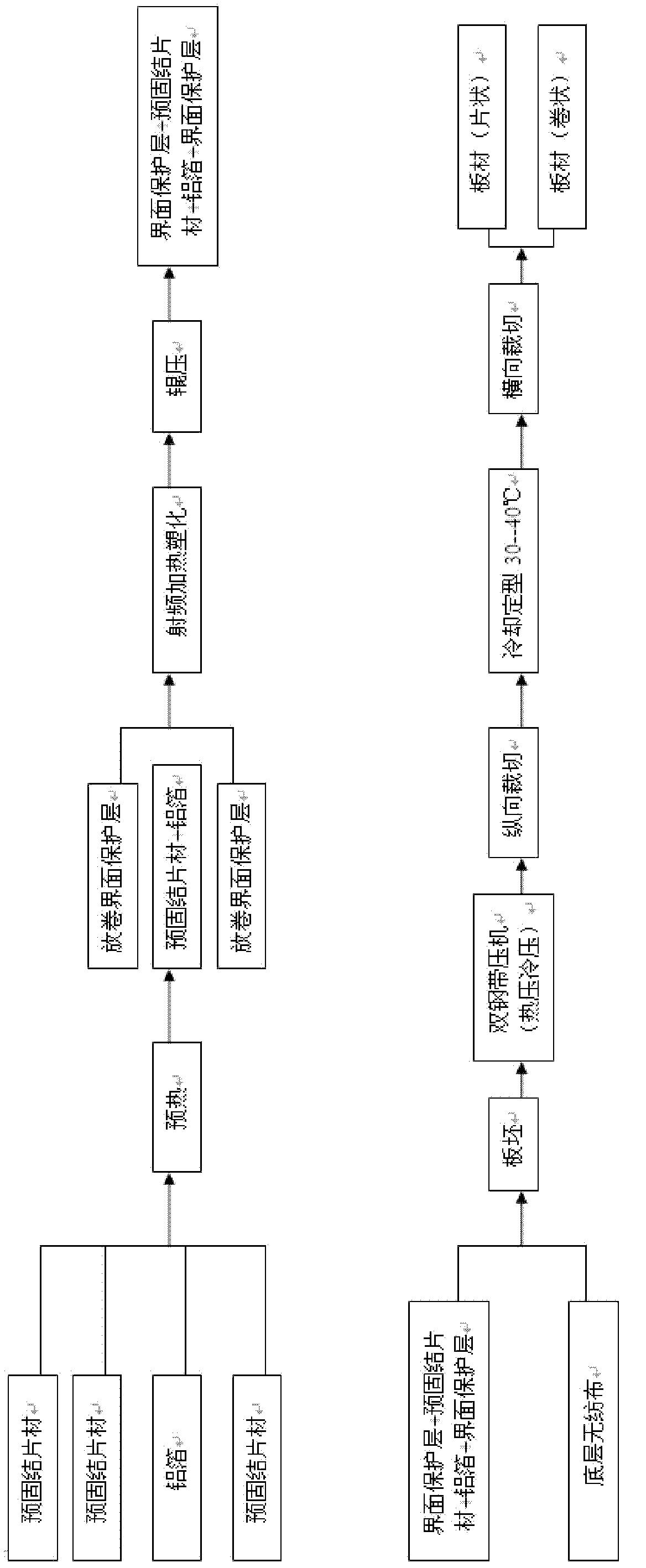

Method for preparing continuous fiber multiaxial fabric reinforced thermoplastic composite material

InactiveCN102218828AGuaranteed to be straightAvoid breakingSynthetic resin layered productsLaminationAviationHoneycomb

The invention discloses a method for preparing a continuous fiber multiaxial fabric reinforced thermoplastic composite material. The prepared continuous fiber multiaxial reinforced thermoplastic preconsolidating material is taken as a base material of the composite board, and combined with other functional materials for forming a novel material system which can be used for producing multiaxial fabric reinforced thermoplastic composite materials for different industries and solving the technical bottleneck that different materials have different composite bonding difficulties. According to the invention, the prepared composite material is constructed by continuous fiber multiaxial direaction; materials have the characteristics of resilience and uniform stressing on different directions. In addition, light sandwich panel formed by a honeycomb core material provides higher impact strength of materials, which is suitable for preparing structural parts and interior decorative parts in the field of railway car containers of navigation and aviation. The product of light-weight flame retardant can be recovered and used, and is more suitable for industrialization scale production of the warp knitting industry organization.

Owner:CHANGZHOU HONGFA ZONGHENG ADVANCED MATERIAL TECH

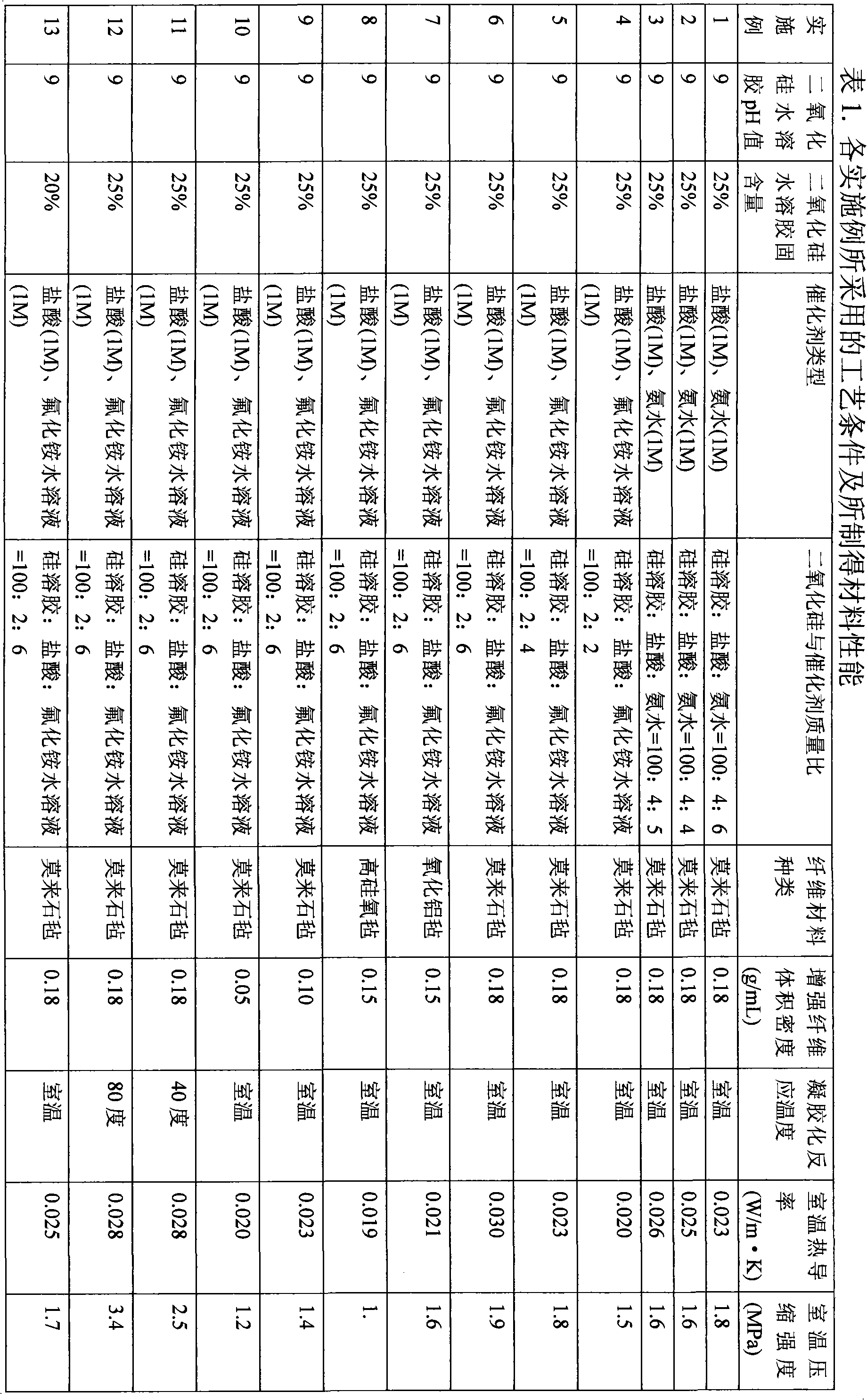

Key technology scheme according to improvement for insulation and material mechanics performance of aerated concrete

The invention relates to a key technical scheme for promoting thermal insulation and material mechanical performances of aerated concrete, which belongs to the building envelope insulation technical field. The invention promotes the performances of the aerated concrete in two steps to facilitate the concrete to be capable of satisfying the requirements of the national construction energy saving (50-80 percent) standard: the first step is to improve the thermal insulation performance until the stem thermal conductivity coefficient is smaller than or equal to 0.05W / (m question mark K); the second step is to strengthen the material mechanical performance until the cube compressive strength is larger than or equal to 3.5MPa and larger than or equal to 2.0MPa after 100 times of freeze-thaw. The first step includes: firstly, minimizing the density of the aerated concrete; secondly, maximizing the porosity; thirdly, optimizing the pore structure. The second step includes: firstly, enhancing additive; secondly, strengthening fibers; thirdly, optimizing the coordination; fourthly, optimizing the mixing process; fifthly, improving the maintenance method (including CO2, variable pressure steam nourishing, middle temperature and high humidity and strength agent surface maintenance).

Owner:SOUTHEAST UNIV +1

Method for preparing continuous fiber cloth reinforced silica ceramic-based composite material

The invention discloses a method for preparing a continuous fiber cloth reinforced silica ceramic-based composite material. The method comprises the following steps: (1) sewing n layers of fiber cloth together; (2) further sewing; (3) repeatedly sewing; (4) adjusting the thickness; (5) dipping the fiber cloth by adopting a water-alcohol solution of ethyl orthosilicate or silica sol; (6) treating at the temperature of 70-90 DEG C for 12-24 hours, drying at the temperature of 110-130 DEG C for 4-8 hours, and drying at the temperature of 140-160 DEG C for 2-4 hours; (7) repeating the steps (5) and (6) for 1-7 times; (8) adding the mixture into a high temperature furnace, and treating for 1-2 hours; and (9) repeating the steps (5) to (8) for 1-5 times, thereby obtaining the product. The composite material system disclosed by the invention is excellent in mechanical property, dielectric property and ablation property, the cost is low, and the mechanical property of the fiber reinforced silica composite material can be obviously improved.

Owner:NAT UNIV OF DEFENSE TECH

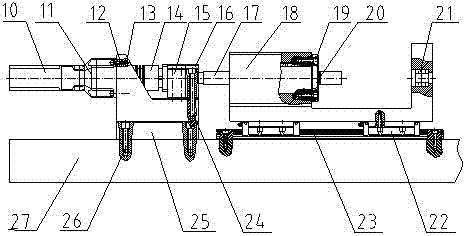

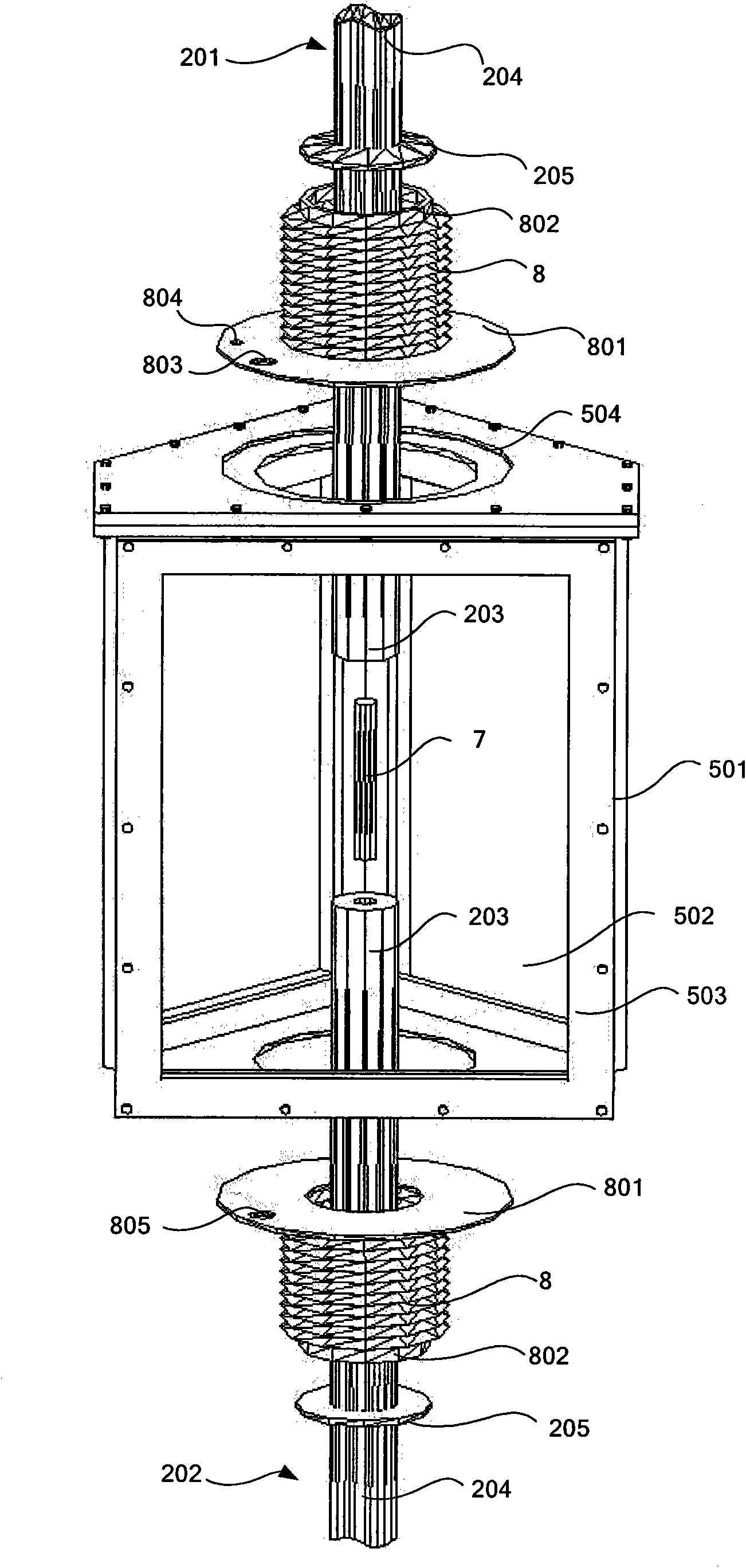

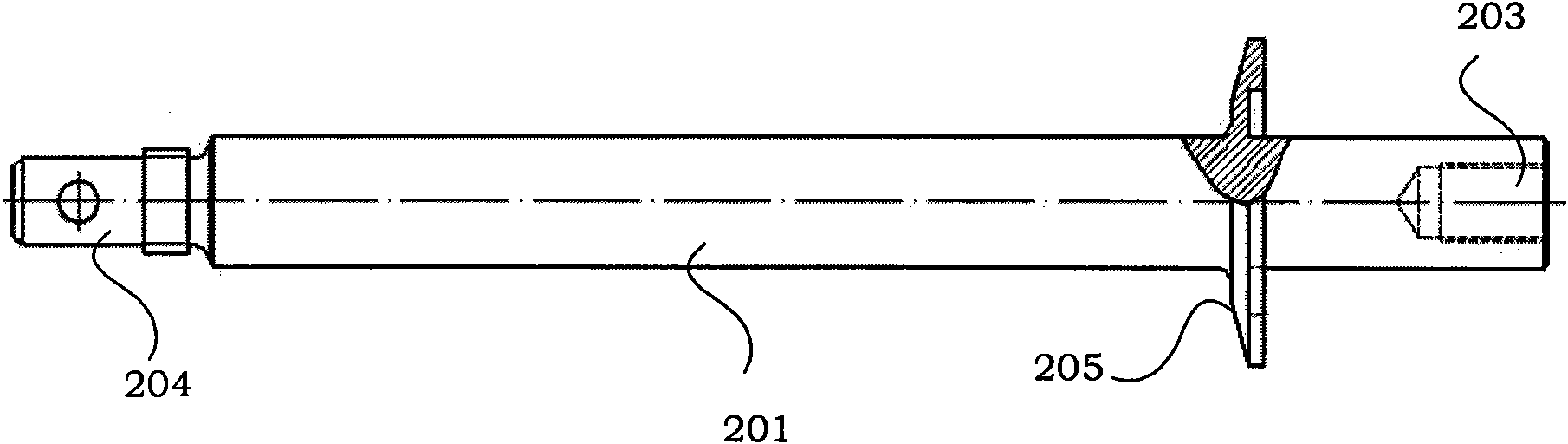

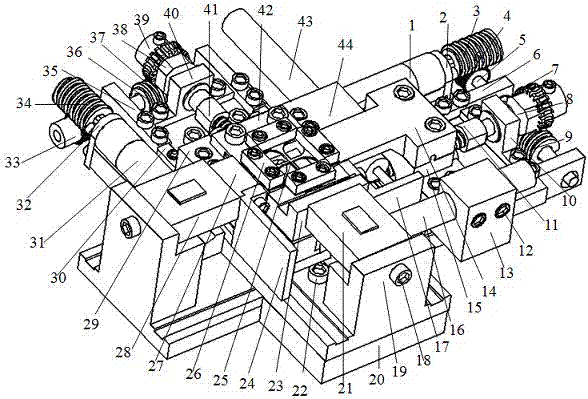

In-situ pull/press-torque combined load material micromechanics test platform

ActiveCN103528887AReduce volumeCompact structureMaterial strength using tensile/compressive forcesMaterial strength using steady torsional forcesMicro nanoGrating

The invention relates to an in-situ pull / press-torque combined load material micromechanics test platform and belongs to the field of material mechanics tests. The in-situ pull / press-torque combined load material micromechanics test platform consists of a base, a precise loading unit, a detection control unit and a clamping and connecting unit, wherein the precise loading unit comprises a torque loading unit and a pull-press loading unit and can be used for realizing the independent and combined loading of pull-press loads and torque loads; aiming at the pull-press loads and the torque loads, the detection control unit respectively uses a pull pressure sensor and a torque sensor to perform load detection and is combined with a contact-type capacitance displacement sensor, a circular grating ruler and a photoelectric encoder so as to monitor and control a loading mechanism. The in-situ pull / press-torque combined load material micromechanics test platform is compact in structure, small in size and controllable in strain rate, and can be used for performing in-situ monitoring on microtexture structural changes, deformation damage mechanisms and performance evolution laws of a material under the action of the combined load, so that an effective test method for revealing the nanoscale mechanics characteristics and damage mechanisms of the material under an approximate service condition is provided.

Owner:JILIN UNIV

Method for rapidly preparing gradient metal ceramic composite material by laser induction hybrid cladding

InactiveCN101709468AIncrease profitImprove efficiencyMetallic material coating processesStrength of materialsMechanical property

The invention relates to a method for rapidly preparing a gradient metal ceramic composite material by laser induction hybrid cladding, which is characterized by comprising the following steps of: (1) generating a 3-D CAD solid model of a gradient metal ceramic composite material component by utilizing special CAD software or a reverse technology in a computer; (2) generating a processing program; (3) controlling the distance between the surface of a base material surface and an induction coil within the range of 2-10 mm; (4) locating a focused CO2 laser beam in an induction heating area; and (5) lifting a laser induction hybrid cladding processing head to the distance equal to the thickness of a CAD 2-D sheet. The invention has the advantages that: (1) a bulk metal ceramic composite material part the ceramic phase of which is continuously tunable along the material thickness direction within 0-100percent by weight is obtained; (2) the use ratio of laser energy and laser cladding efficiency are greatly improved; (3) the metal ceramic composite material with compact tissue but without cracks is obtained; (4) special tools and fixtures are not needed in the manufacturing process, and the flexibility is high; and (5) the mechanical property, the abrasive resistance and the corrosion resistance of the gradient metal ceramic composite material are greatly improved.

Owner:NANCHANG HANGKONG UNIVERSITY

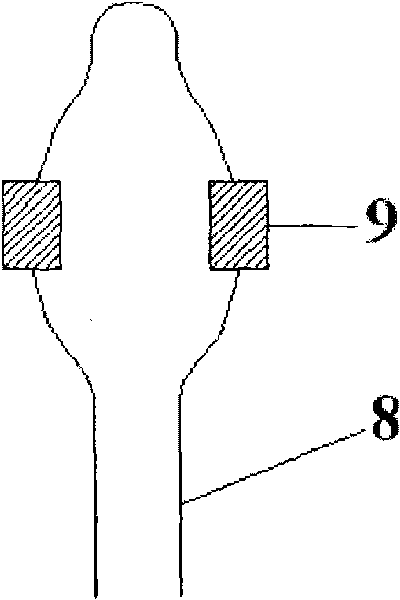

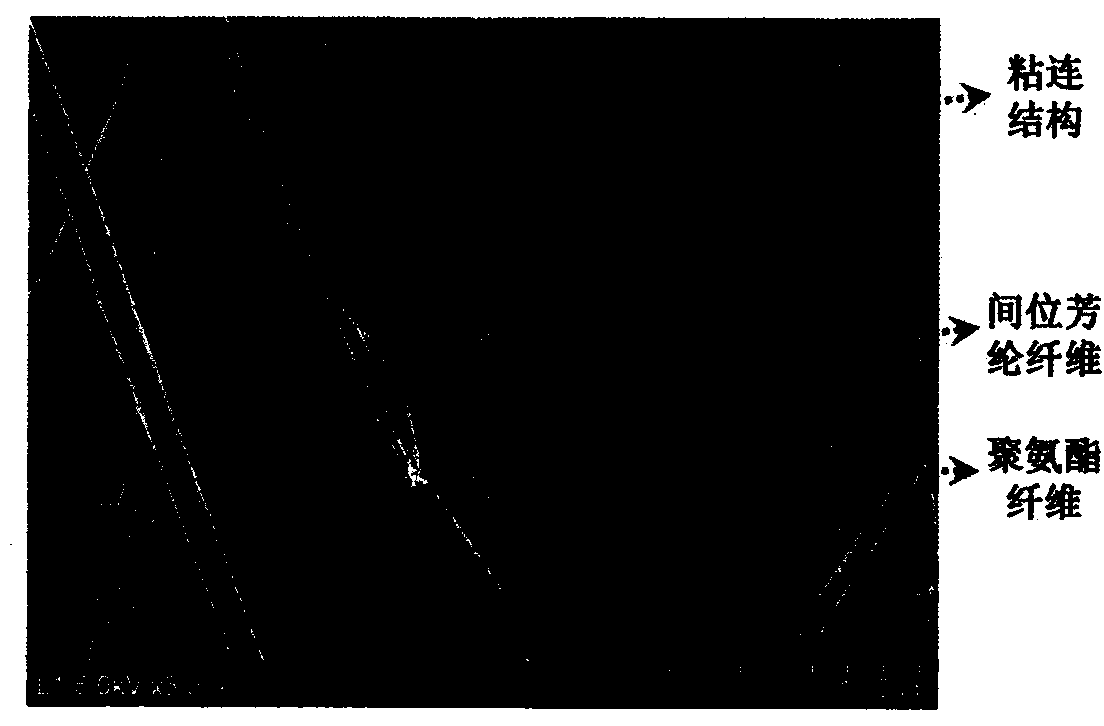

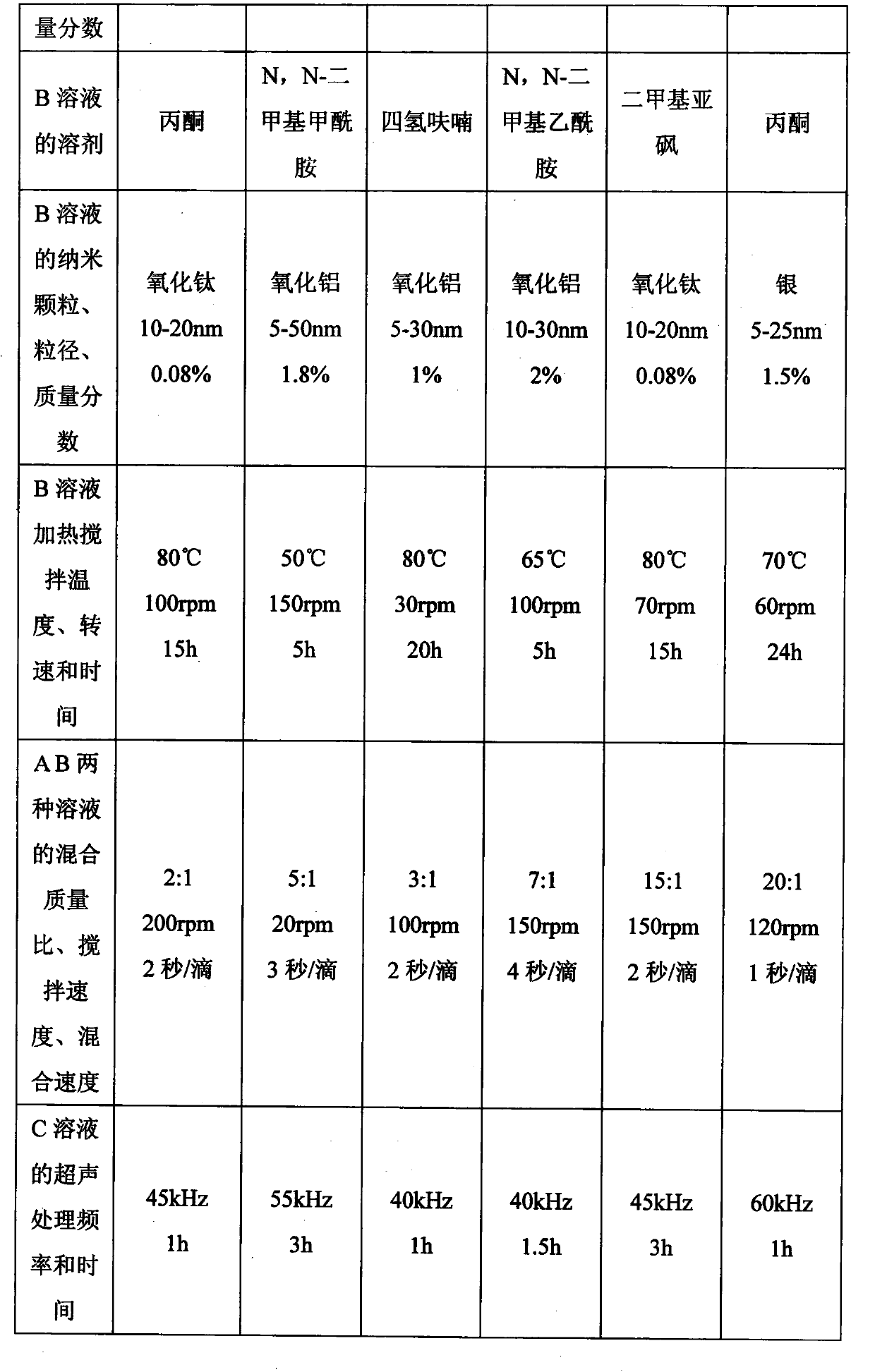

Preparation method for multi-component net-shaped nanofiber membrane

ActiveCN103806221AIncreased interaction surface areaImprove the degree of purificationFilament/thread formingNon-woven fabricsOrganic solventHalogen

The invention relates to a preparation method for a multi-component net-shaped nanofiber membrane. The preparation method includes the detailed steps that step1, mixing and beating are performed on meta-position aramid fibers, halogen salt and organic solvent by the mass ratio of 1:0.004-0.4:2.996-18.6, and a meta-position aramid fiber solution is prepared through mixing; step2, functionality high-molecular polymers and the solvent are mixed by the mass ratio of 1:5.4-98.99, then nano-particles are added, and heating and mixing are performed to prepare a functionality high-molecular solution, wherein the mass fraction of the nano-particles in the solution is 0.01-5%; step3, the meta-position aramid fiber solution obtained in the step1 and the functionality high-molecular solution obtained in the step2 are mixed by the mass ratio of 1:0.05-0.5 in a dripping mode, and then ultrasonic treatment is performed to obtain a spinning solution; step4, under the conditions of 20 DEG C-30 DEG C indoor temperature and 20-70% relative humidity, the spinning solution is used for electrostatic spinning, and finally the multi-component net-shaped nanofiber membrane with a 5nm-20nm net-shaped nanofiber diameter and reaches over 95% in net-shaped structure coverage rate is obtained. The preparation technology is simple and low in cost, tensile strength of material reaches 100MPa-2000MPa, and the functionality advantage is remarkable.

Owner:DONGHUA UNIV

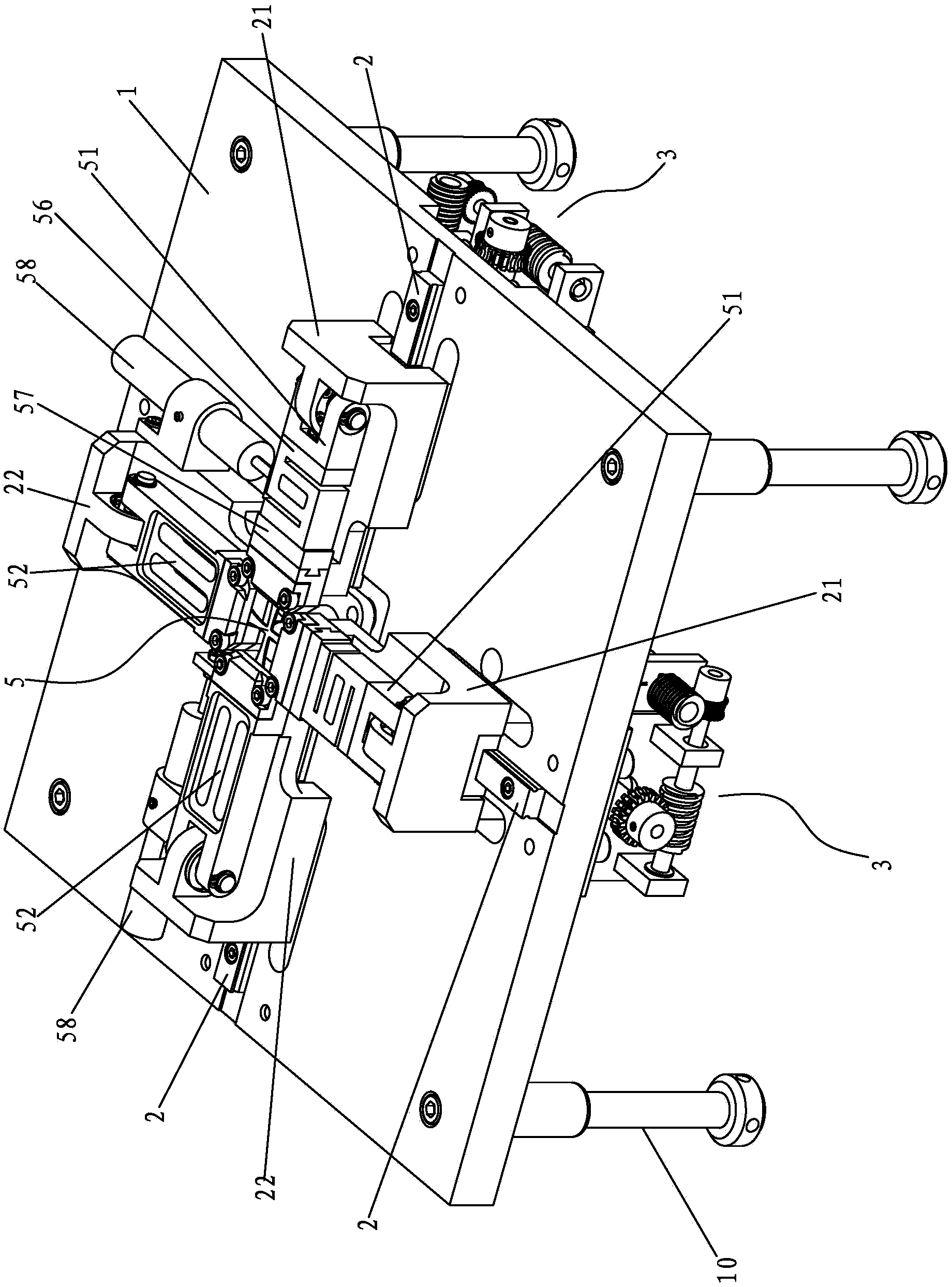

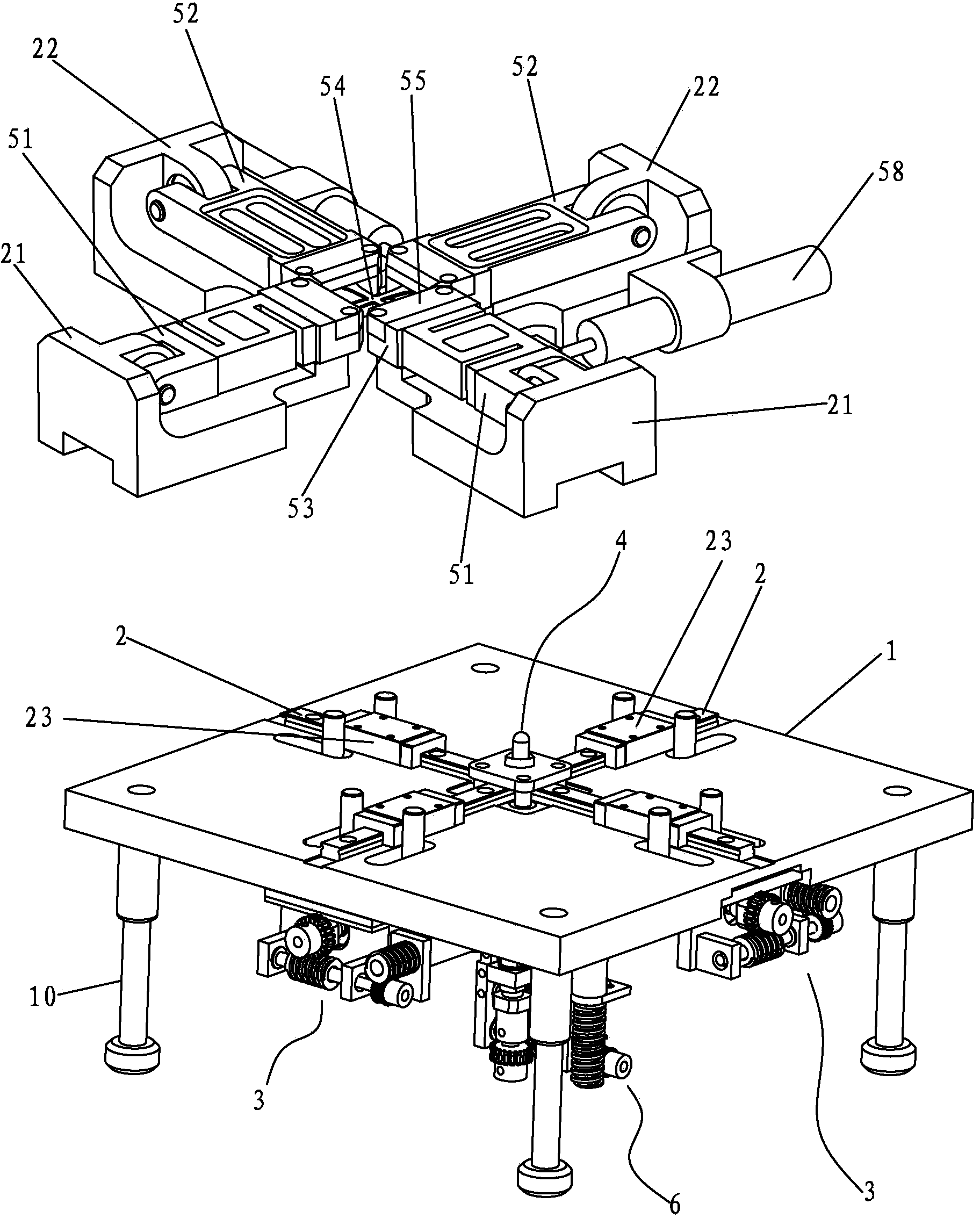

Testing device for mechanical property of material

InactiveCN103487315AFacilitate in-depth researchCompact structureStrength propertiesStress levelStrength of materials

The invention discloses a testing device for a mechanical property of a material. Slide rails vertical to each other are arranged on a working platform along the X axis and the Y axis; a first drawing seat and a second drawing seat for drawing a test piece are arranged on the slide rails along the X-axis direction and / or the Y-axis direction; a clamping device is arranged between the first drawing seat and the second drawing seat; a bending mechanism for applying bending load to the test piece along a Z direction is arranged below the clamping device; a tensile load is applied to the test piece through a control tensile load driving device; a bending load is applied to the test piece through a control bending load driving device; the testing on the mechanical property of the material in a biaxial drawing and bending composite load mode can be realized on the test piece; the provided composite load mode conforms to the stress level of the test piece under the actual working condition. Meanwhile, pure tensile test and pure three-point bending test can also be performed; biaxial drawing load and three-point bending load can be loaded independently or loaded in sequence; the testing device has the characteristics of compact structure and high compound degree.

Owner:JILIN UNIV

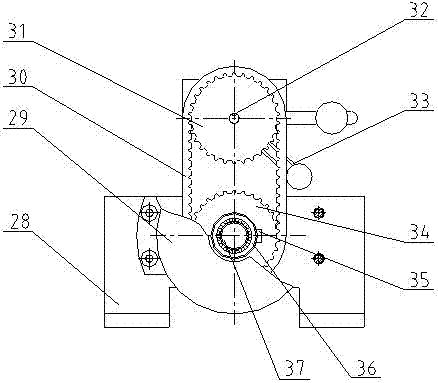

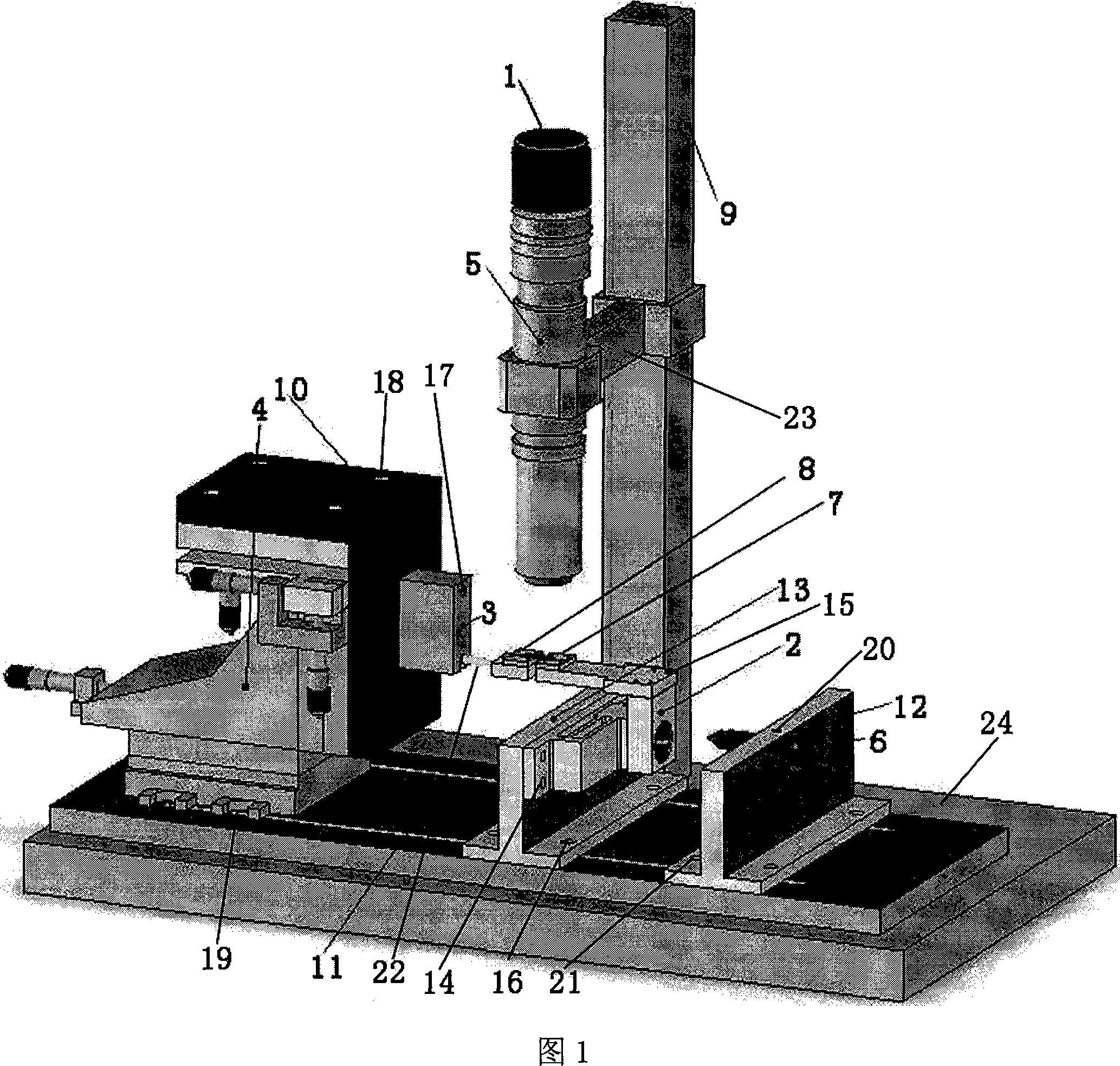

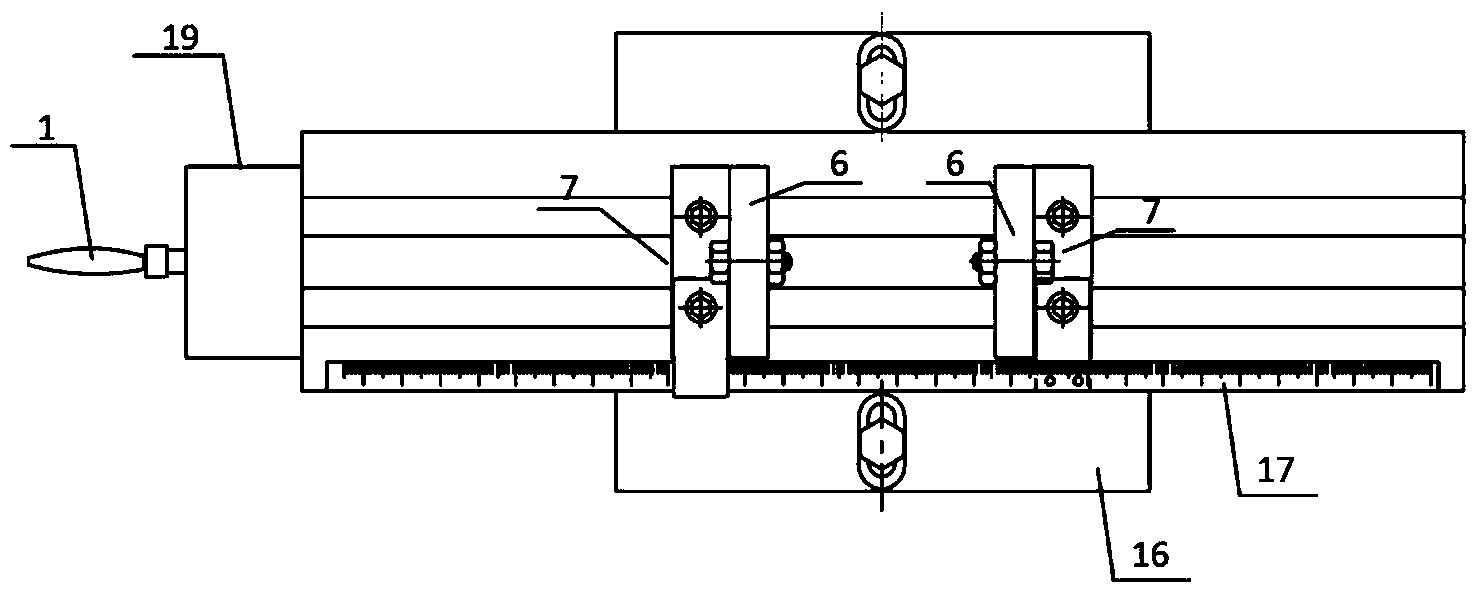

Micro-element dynamic performance off-chip tensile test experimental bench

InactiveCN101216390AImprove unfavorable characteristicsAccurate measurement dataStrength propertiesElectricityStrength of materials

An off-chip tensile test experimental platform for micro-component mechanical property belongs to the field of micro-component mechanical property test in a micro-electro-mechanical system. The experimental platform comprises a piezoelectric drive unit, a micro-force detection unit, a displacement detection unit, a sample arranging and adjusting unit, an image monitoring and collecting unit and a pedestal. The piezoelectric drive unit consists of a package structure with a piezoelectric ceramic actuator arranged therein and a support. The micro-force detection unit consists of a force sensor and a force sensor support plate. The displacement detection unit is composed of a displacement sensor and a displacement sensor support. The sample arranging and adjusting unit consists of a five-dimensional micro-positioning stage, a movable stage and a static stage. The image monitoring and collecting unit consists of a CCD camera, a microscope and a microscope stand. The off-chip tensile test experimental platform for micro-component mechanical property overcomes the disadvantages of the prior tensile test experimental device, and has the advantages of low cost, simple structure, higher accuracy and smooth upgrade to satisfy the requirement of off-chip tensile test of micro-component mechanical property.

Owner:DALIAN UNIV OF TECH

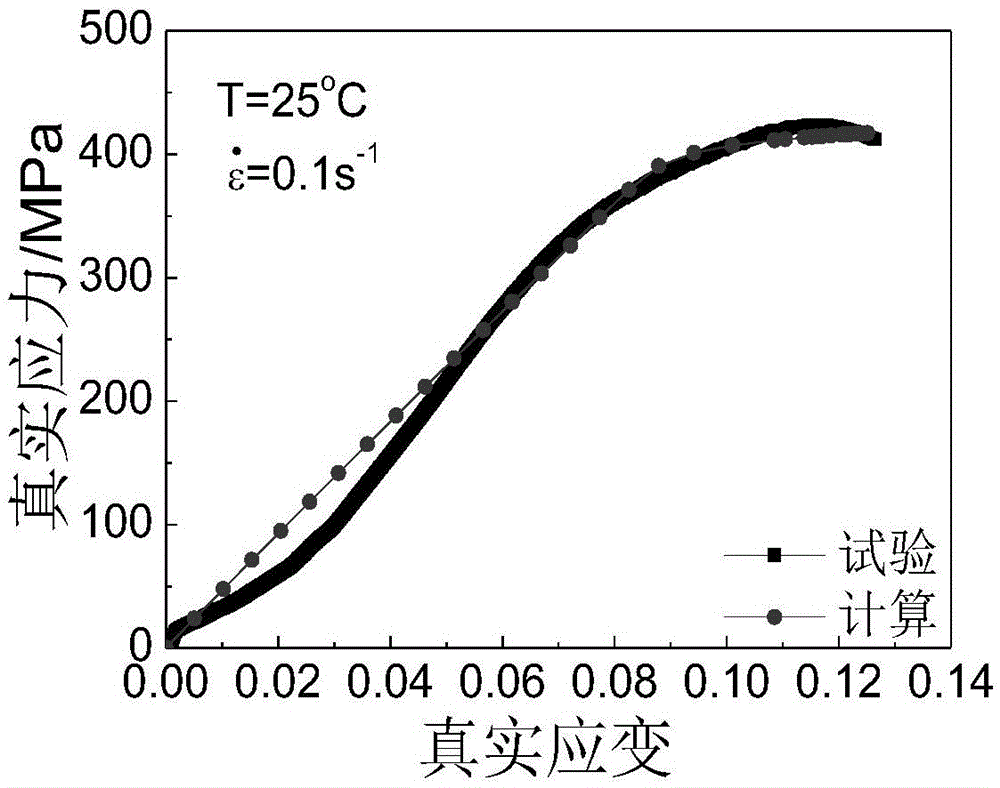

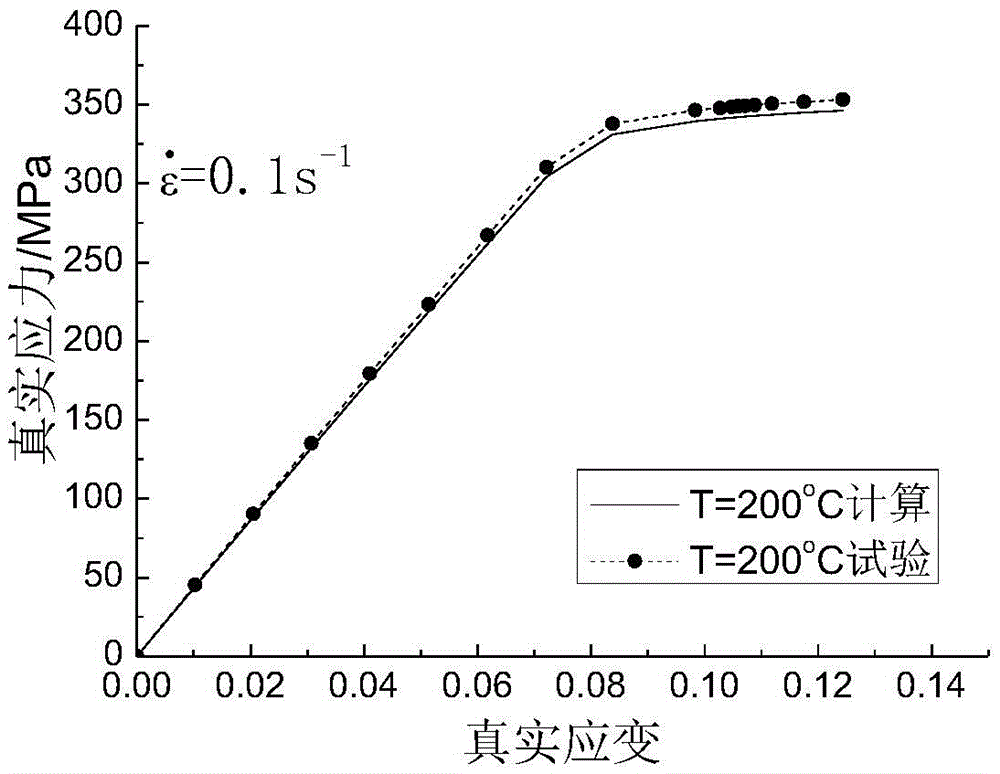

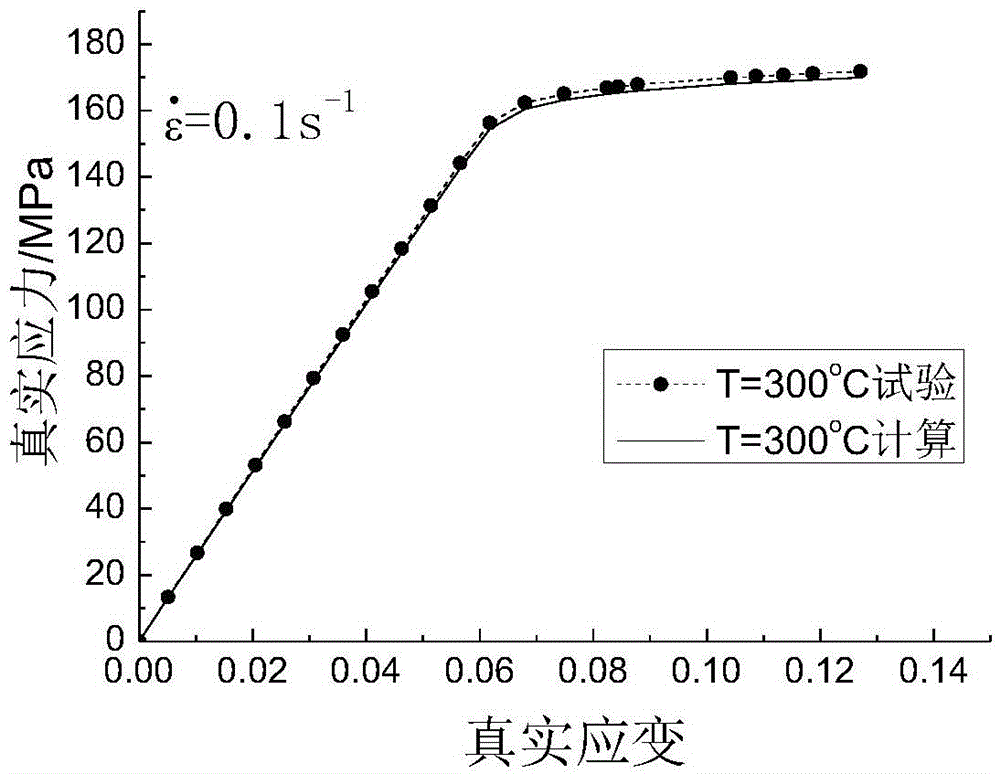

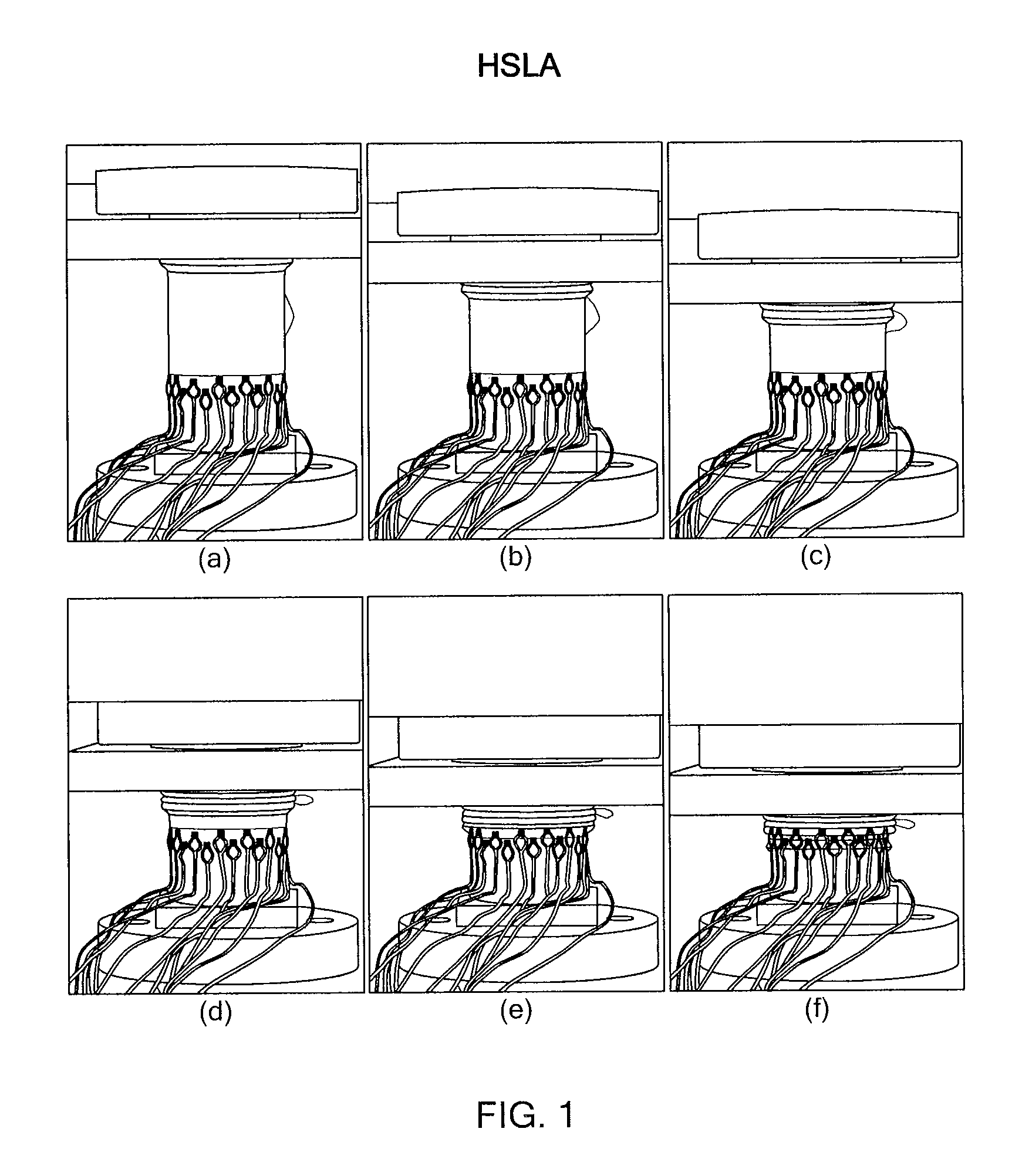

Method for establishing constitutive model for aluminum alloy thermal elastoplastic deformation simulation

InactiveCN105426595AHigh precisionComputer aided designSpecial data processing applicationsStrength of materialsModel parameters

The invention discloses a method for establishing a constitutive model for aluminum alloy thermal elastoplastic deformation simulation. The method comprises the following steps: (1) selecting the constitutive model; (2) determining model parameters; and (3) substituting the parameters into a constitutive model equation, and determining the constitutive model equation. The method has the advantages that the establishment of the constitutive model fills up the blank of simulating a relationship between the mechanical performance and temperature of a material used in machining of a 7A52 aluminum alloy heat machine with a numerical simulation method all the time, improves the accuracy of 7A52 aluminum alloy thermal elastoplastic deformation simulation, lays an important basis for confirming a 7A52 aluminum alloy hot working process and studying a metal plastic deformation theory, and has an important significance for practical application of 7A52 aluminum alloy.

Owner:INNER MONGOLIA UNIV OF TECH

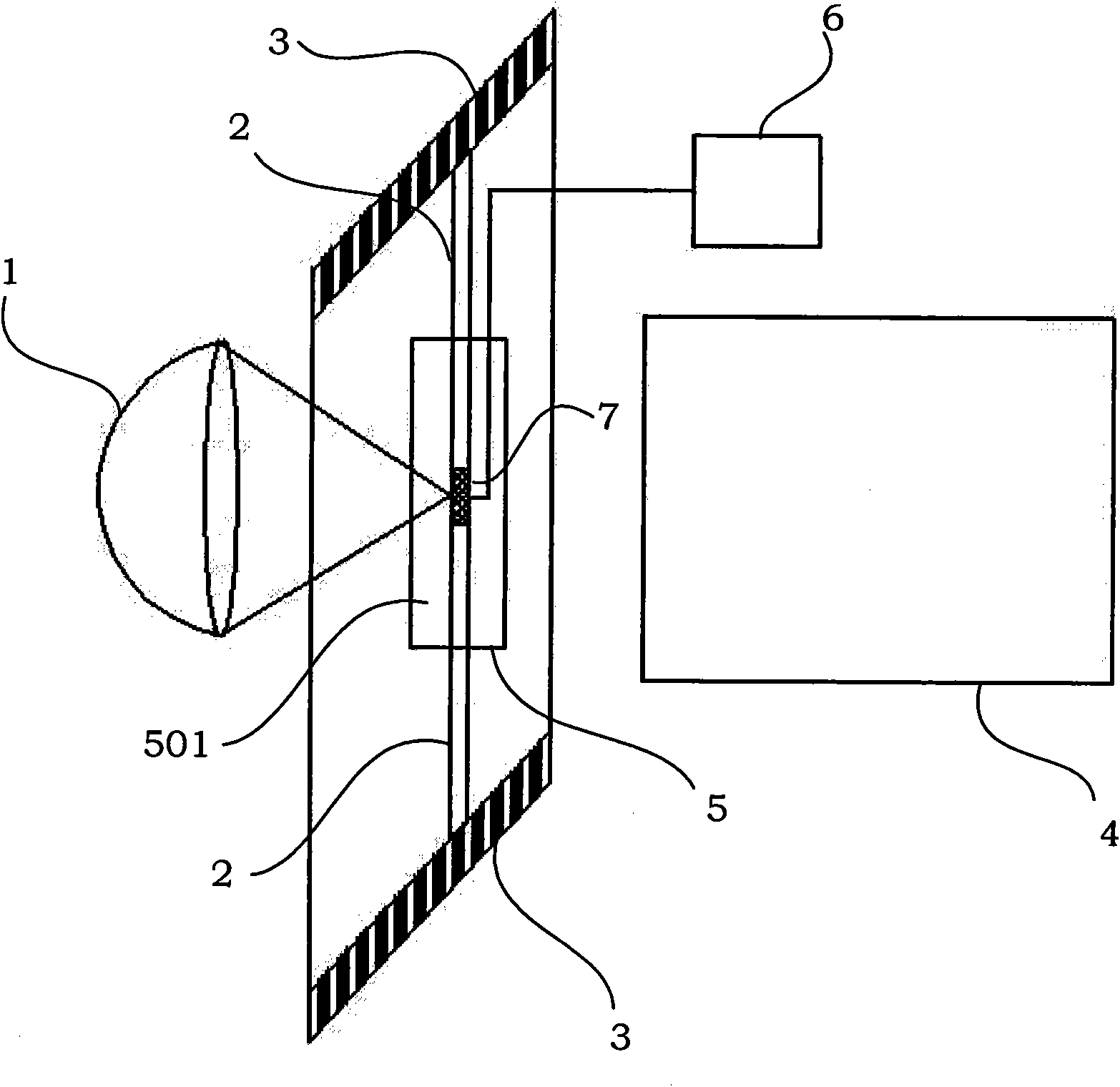

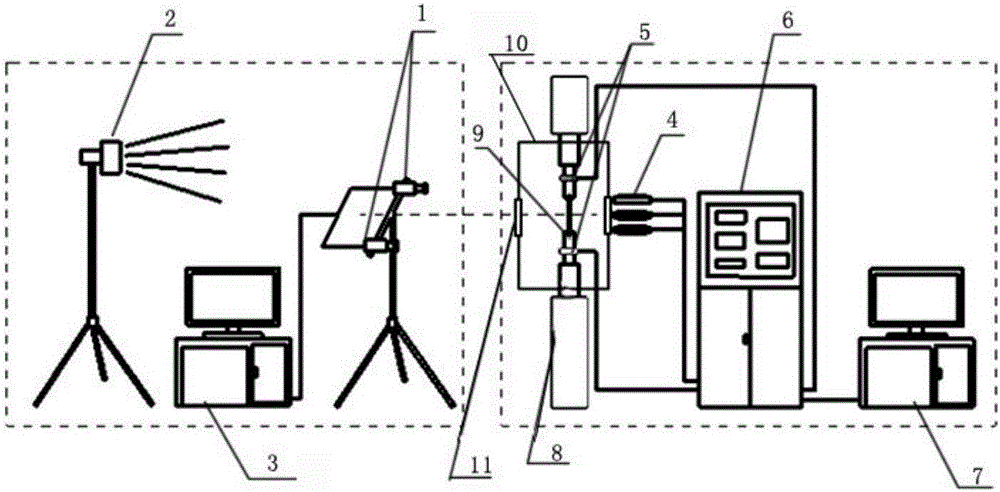

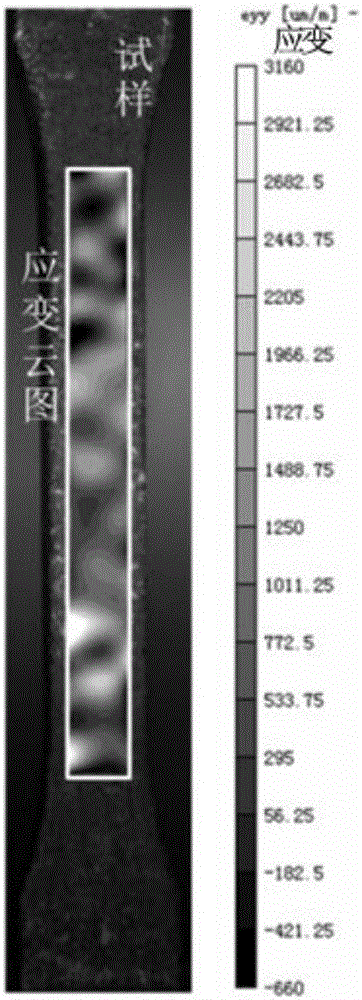

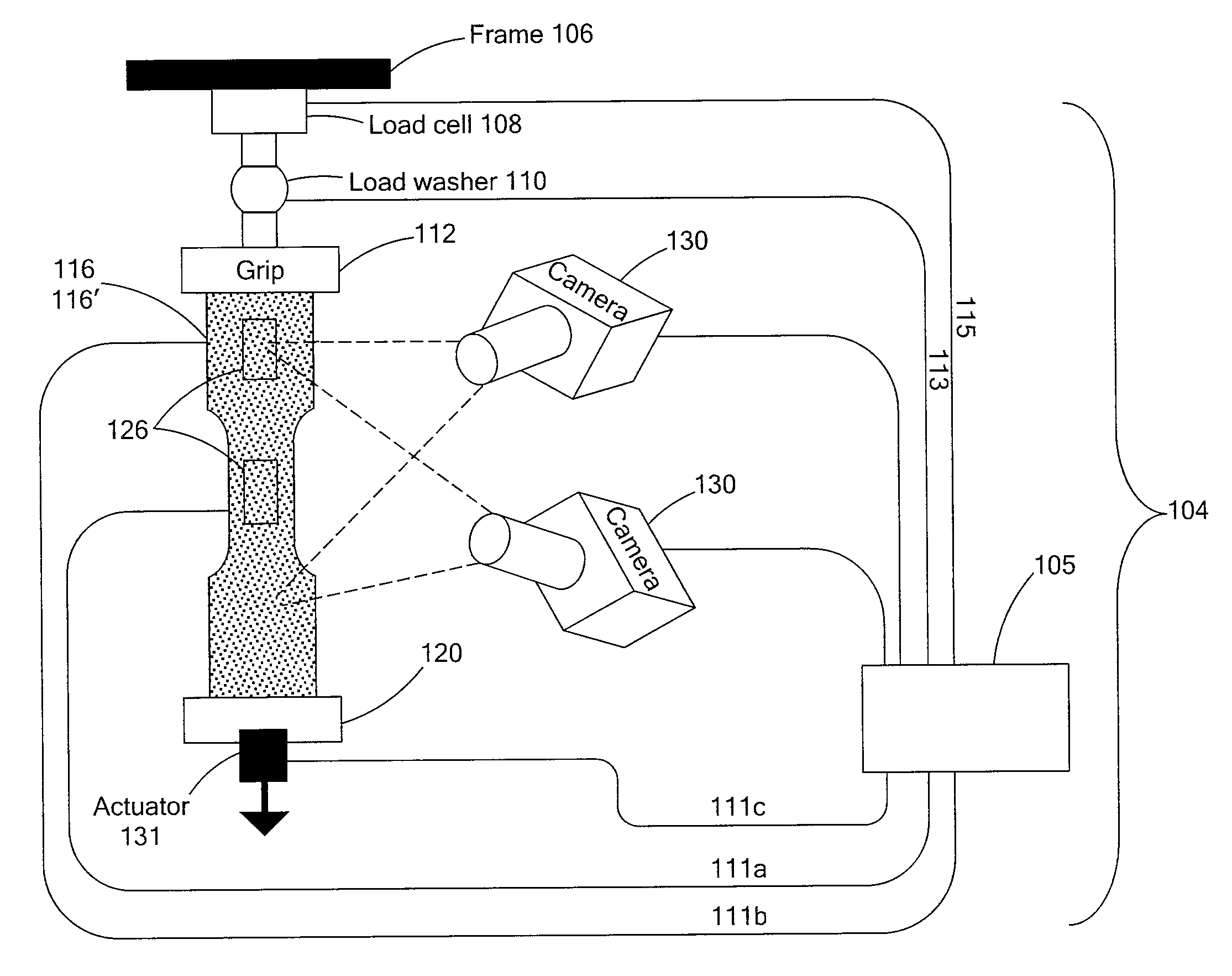

System and method for testing mechanical properties of conductor material at high-temperature vacuum environment

ActiveCN106769525ARealize strain full field testImprove test efficiencyMaterial analysis by optical meansMaterial strength using tensile/compressive forcesElectrical conductorLow voltage

The invention provides a system and method for testing mechanical properties of a conductor material at a high-temperature vacuum environment. According to the system and the method, the problems that the high-temperature strain is difficult to test, the sample heating efficiency is low, and the like are solved. The system comprises a high-temperature strain test subsystem, a temperature control subsystem and a loading subsystem; and a stretch process is carried out in a vacuum environmental chamber, and a sample is loaded by virtue of a mechanical test machine. According to the method, a Joule effect is adopted, a material is put into the vacuum environmental chamber, the normal temperature absolute vacuum degree can reach 0.025Pa, low voltage and high current are introduced to the conductor material so as to rapidly heat the sample, the loading is carried out after reaching a target temperature, meanwhile, data collection is carried out on a high-temperature deformation field by virtue of a DIC strain test technique so as to obtain a strain field of a whole sample scale distance section and a displacement-load curve of the sample, and subsequent processing is carried out so as to obtain high-temperature tensile / compression modulus and tensile strength of the sample. The system and the method have the advantages of high heating speed, uniform temperature field, high deformation measurement precision and the like.

Owner:HARBIN INST OF TECH

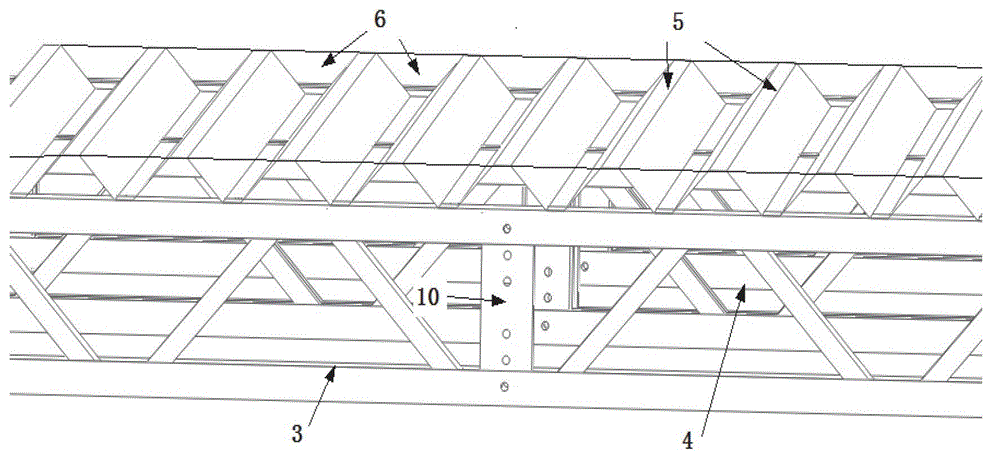

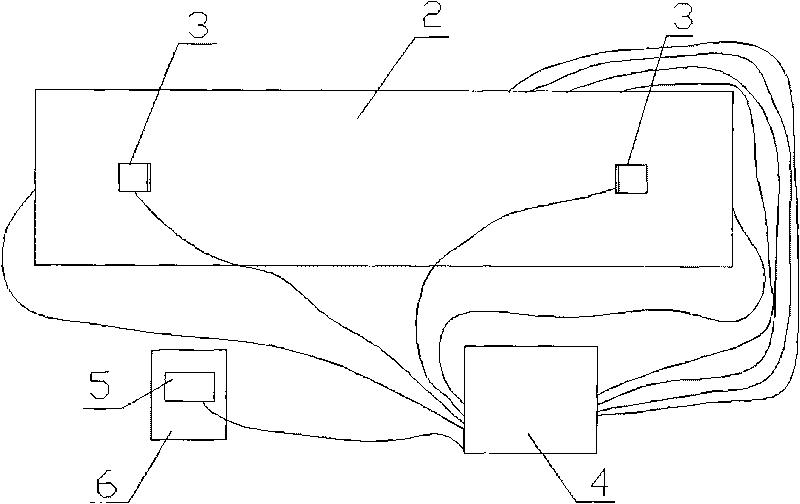

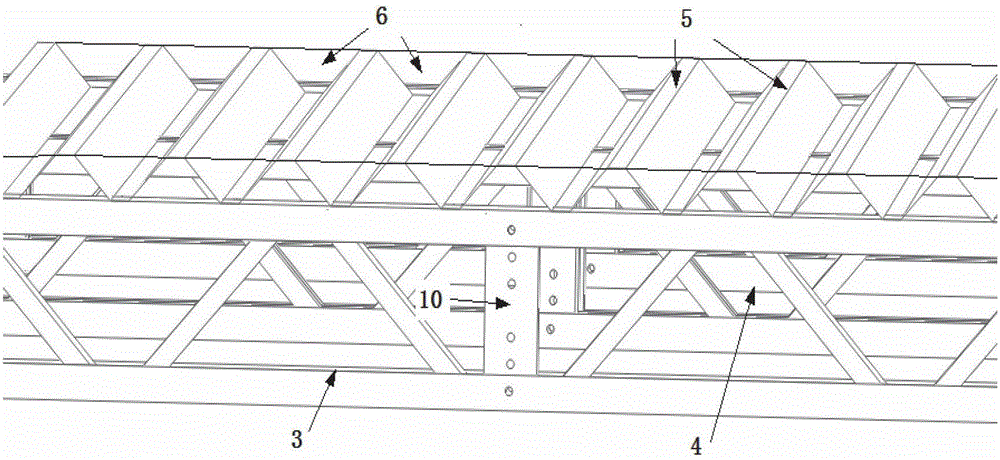

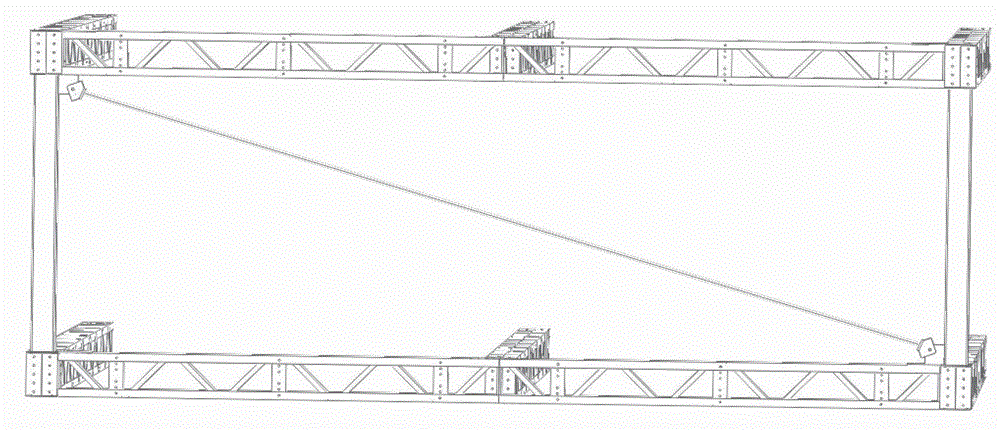

Industrialized assembled multi-story high-rise steel structure centrally-braced system

The invention relates to an industrialized assembled multi-story high-rise steel structure centrally-braced system, belonging to the field of buildings. The industrialized assembled multi-story high-rise steel structure centrally-braced system comprises steel structure main body slab racks, bracing members and columns. Wide beams, narrow beams and slabs are integrally fabricated in a factory. The wide beams and the narrow beams are welded in the factory by using channel steel. Pipelines pass through positions between the web channel steel of the wide beams and the web channel steel of the narrow beams to form base slat racks A, base slab racks B and base slab racks C. High-strength bolts and partial welding only in the factory are adopted for parts where the base slab racks are connected with column bases and the wide beams are connected with the narrow beams. The column bases are connected with the columns through high-strength bolts and flanges. The industrialized assembled multi-story high-rise steel structure centrally-braced system has the advantages that the construction speed is fast, the structure bearing capacity is high, the lateral movement resistance is good, the strength of materials can be fully exerted, the horizontal load is effectively resisted, the structure interlayer displacement is reduced, the environmental pollution caused by welding is reduced and the cost is saved.

Owner:CHINA RAILWAY CONSTR GROUP +1

Expansion/shrinkage stress testing device for cement-based material

ActiveCN101738459AEasy to analyzeEasy to compareMaterial testing goodsElectricityStrength of materials

The invention relates to an expansion / shrinkage stress testing device for a cement-based material, which comprises an inner circular ring and an outer circular ring which are coaxial and have the same height, and a stress testing device and a data acquisition device which are electrically interconnected, wherein the inner circular ring and the outer circular ring are made of the same material; and the stress testing device comprises a plurality of test stress plates which are distributed evenly along the circumferential direction on the outer surface of the outer circular ring and the inner surface of the inner circular ring and are electrically connected with the data acquisition device. When the testing device is used, the cement-based material (such as pure slurry, mortar or concrete) is cast between the two rings. The expansion and shrinkage stress can be calculated according to the analysis of material mechanics by measuring the stress. Compared with the prior method, the testing device has the main advantages that: a, the testing device is simple, and simple and convenient to operate; b, the restraint stress is even; and c, the testing of starting self water addition molding can be implemented, the testing process needs no manpower to move the test piece, and continuous and automatic test can be realized.

Owner:JIANGSU SOBUTE NEW MATERIALS

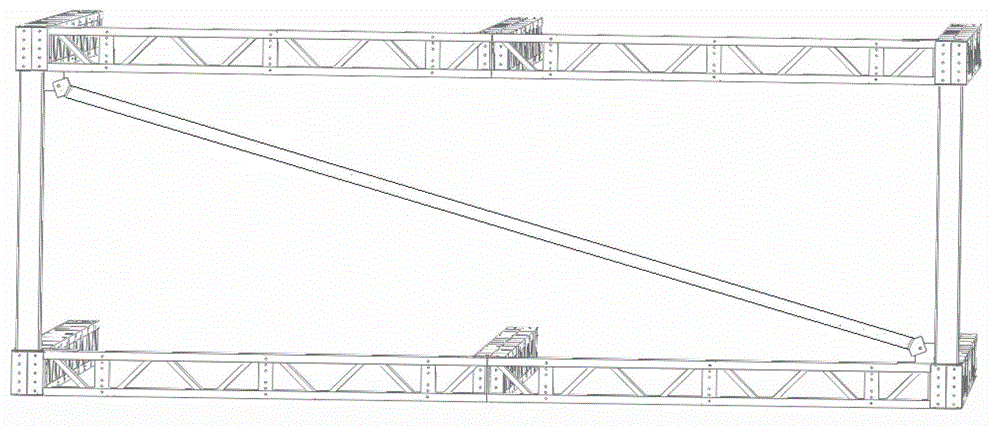

Industrialized assembled multi-story high-rise steel structure prestressed centrally-braced system

ActiveCN102979172ARealize industrializationQuick assemblyBuilding constructionsPre stressStrength of materials

The invention relates to an industrialized assembled multi-story high-rise steel structure prestressed centrally-braced system, belonging to the field of buildings. The industrialized assembled multi-story high-rise steel structure prestressed centrally-braced system comprises steel structure main body slab racks, prestressed bracing members and columns. Wide beams, narrow beams and column bases are assembled in a factory to form base slab racks. The base slab racks and slabs are integrally fabricated. The wide beams and the narrow beams are welded in the factory by using channel steel. Pipelines pass through positions between the web channel steel of the wide beams and the web channel steel of the narrow beams to form base slat racks A, base slab racks B and base slab racks C. High-strength bolts and partial welding only in the factory are adopted for parts where the base slab racks are connected with column bases and the wide beams are connected with the narrow beams. The column bases are connected with the columns through high-strength bolts and flanges. The industrialized assembled multi-story high-rise steel structure prestressed centrally-braced system has the advantages that the construction speed is fast, the structure bearing capacity is high, the lateral movement resistance is good, the strength of materials can be fully exerted, the horizontal load is effectively resisted, the structure interlayer displacement is reduced, the environmental pollution caused by welding is reduced and the cost is saved.

Owner:CHINA RAILWAY CONSTR GROUP +1

Material mechanical characterization method for multiple strains and strain rates

ActiveUS20120287248A1Small sample sizeReduce in quantityMaterial strength using tensile/compressive forcesColor television detailsStrength of materialsEngineering

Owner:UT BATTELLE LLC

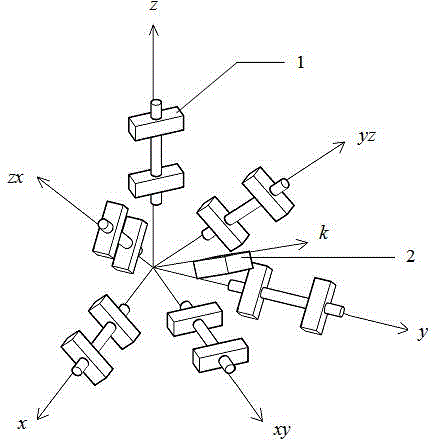

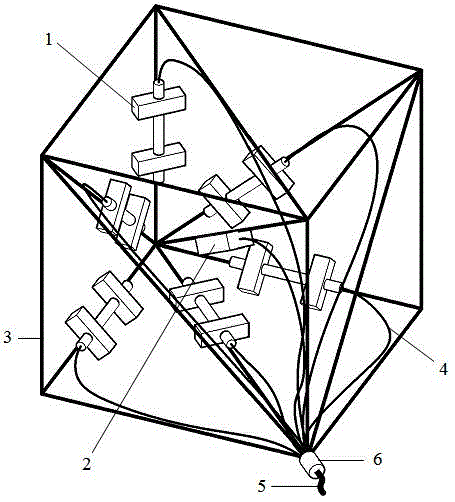

Three-dimensional space stress-strain measurement method based on fiber bragg grating sensor

ActiveCN103954386AFully reflect the stress situationFully understand the stress statusForce measurement by measuring optical property variationUsing optical meansFiberPrincipal stress

The invention discloses a three-dimensional space stress-strain measurement method based on a fiber bragg grating sensor. The method comprises the following steps: arranging six fiber bragg grating strain sub-sensors on the three principal axes of a space coordinate system and the axes of angular bisectors between every two adjacent principal axes respectively; arranging a temperature sub-sensor on the axis k in the body diagonal direction of a cube; working out the strain in the directions of the six fiber bragg grating strain sub-sensors through a decoupling equation set of the fiber bragg grating sensor based on wavelength, wherein the wavelength is measured by the six fiber bragg grating strain sub-sensors and the temperature sub-sensor; obtaining the values of epsilon x, epsilon y, epsilon z, gama xy, gama yz and gama zx through the plane strain relationship formula of the mechanics of materials; substituting the six quantities into a cubic space principal strain equation to obtain the values of the principal strain epsilon 1, epsilon 2 and epsilon 3; obtaining the values of the principal stress sigma 1, sigma 2 and sigma 3 through a physical equation of the elastic mechanics; obtaining the directions of the principal strain and the principal stress through a space strain relationship equation set of the elastic mechanics and a direction cosine relational expression; obtaining the maximum value taw maximum of shear stress through the maximum shear stress formula; obtaining the direction of the maximum shear stress through the relationship between the principal stress and principal shear stress.

Owner:成都毅莘瑞科技有限公司

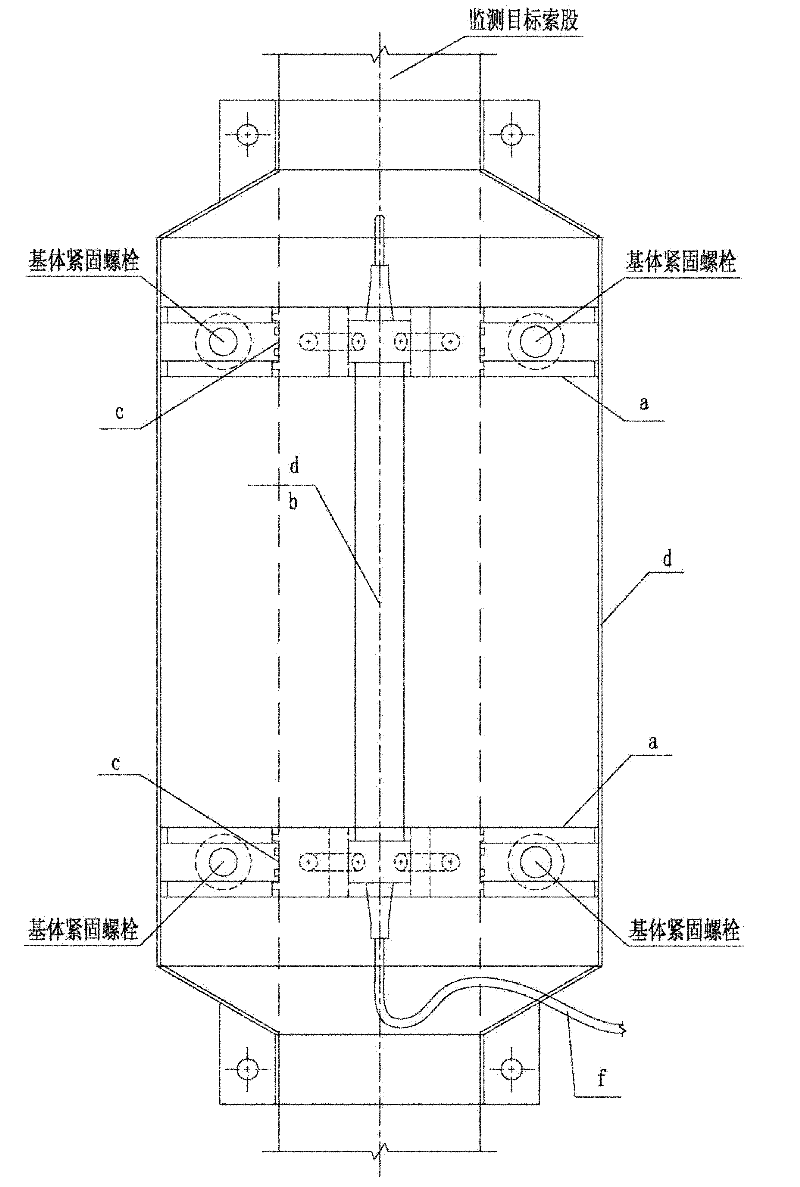

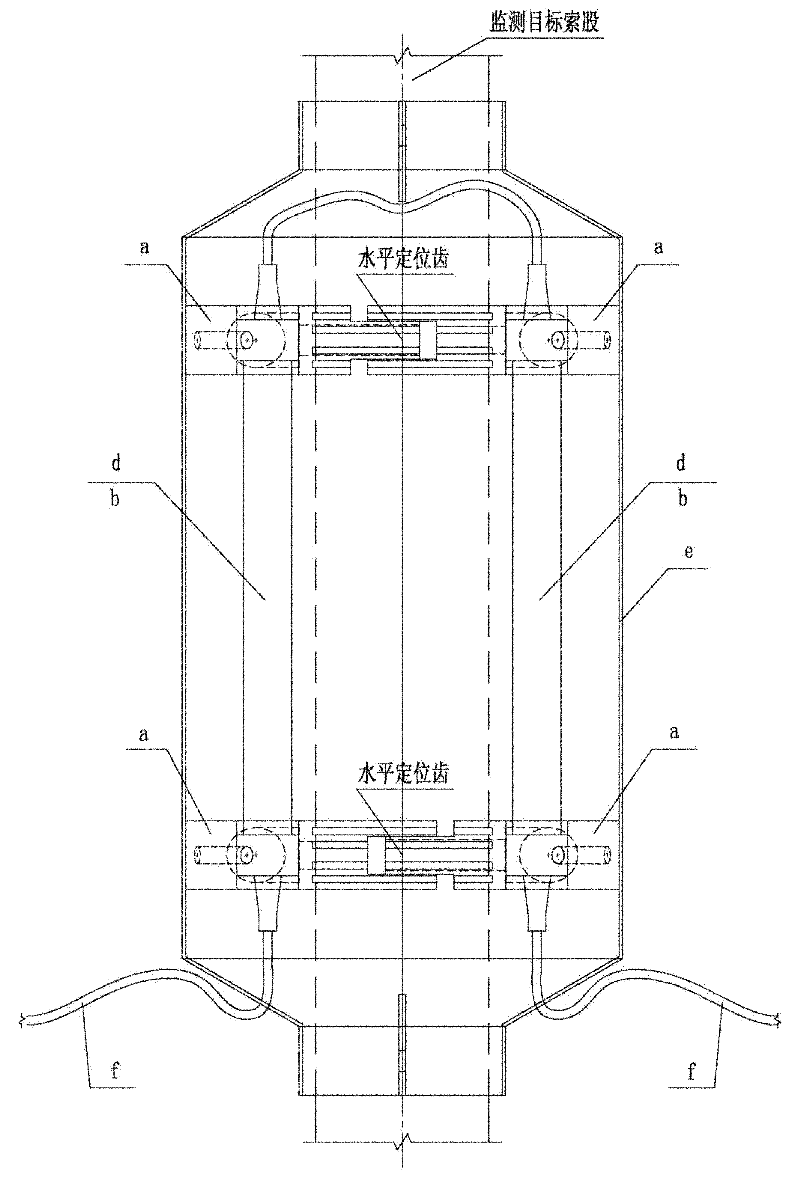

Cable force monitoring device for attached-type stay cable

ActiveCN102162760AImprove connection strengthFree from mechanical damageNon-electrical signal transmission systemsUsing optical meansFiberFiber gratings

Owner:CHINA RAILWAY BRIDGE SCI RES INST LTD +1

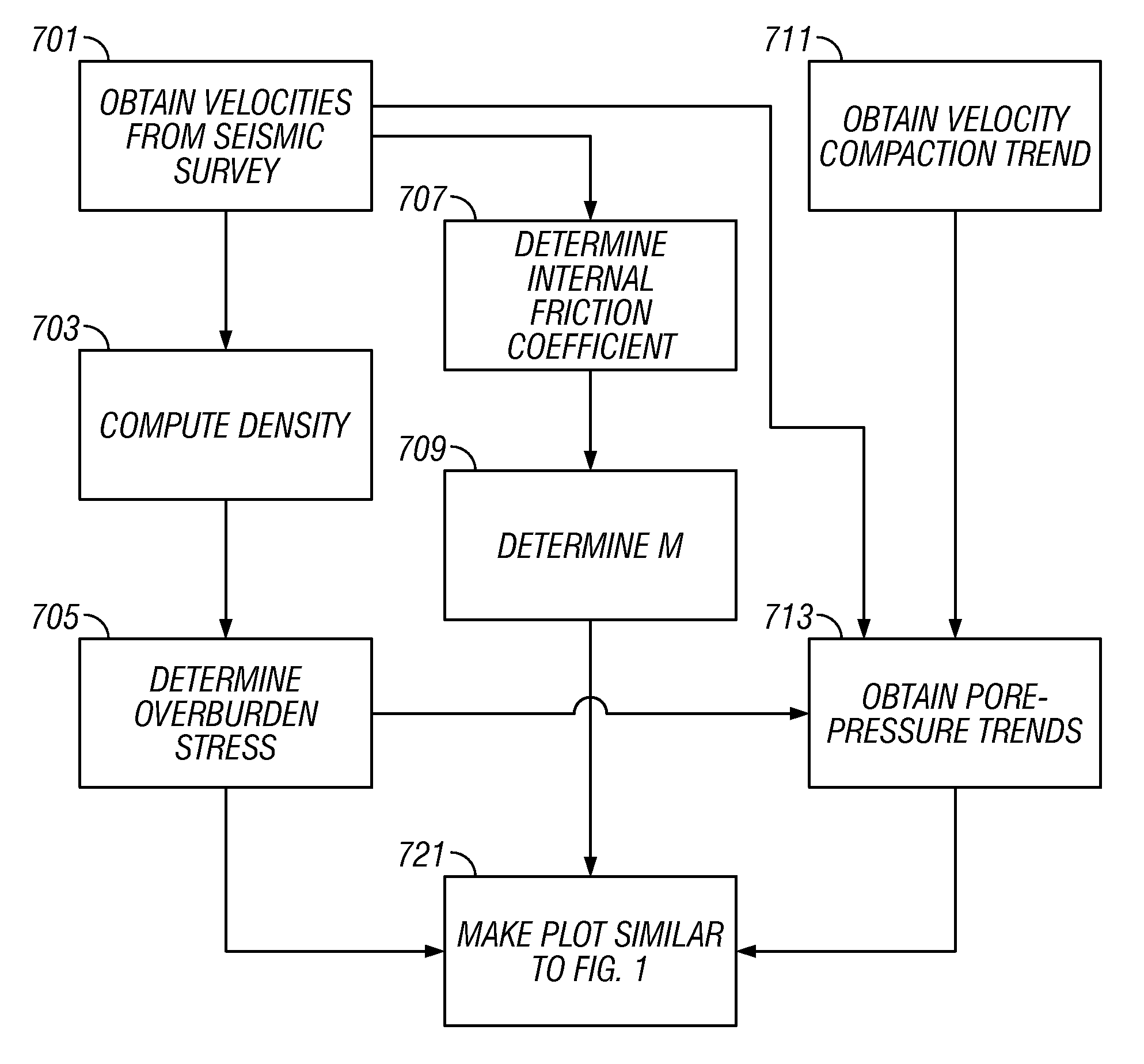

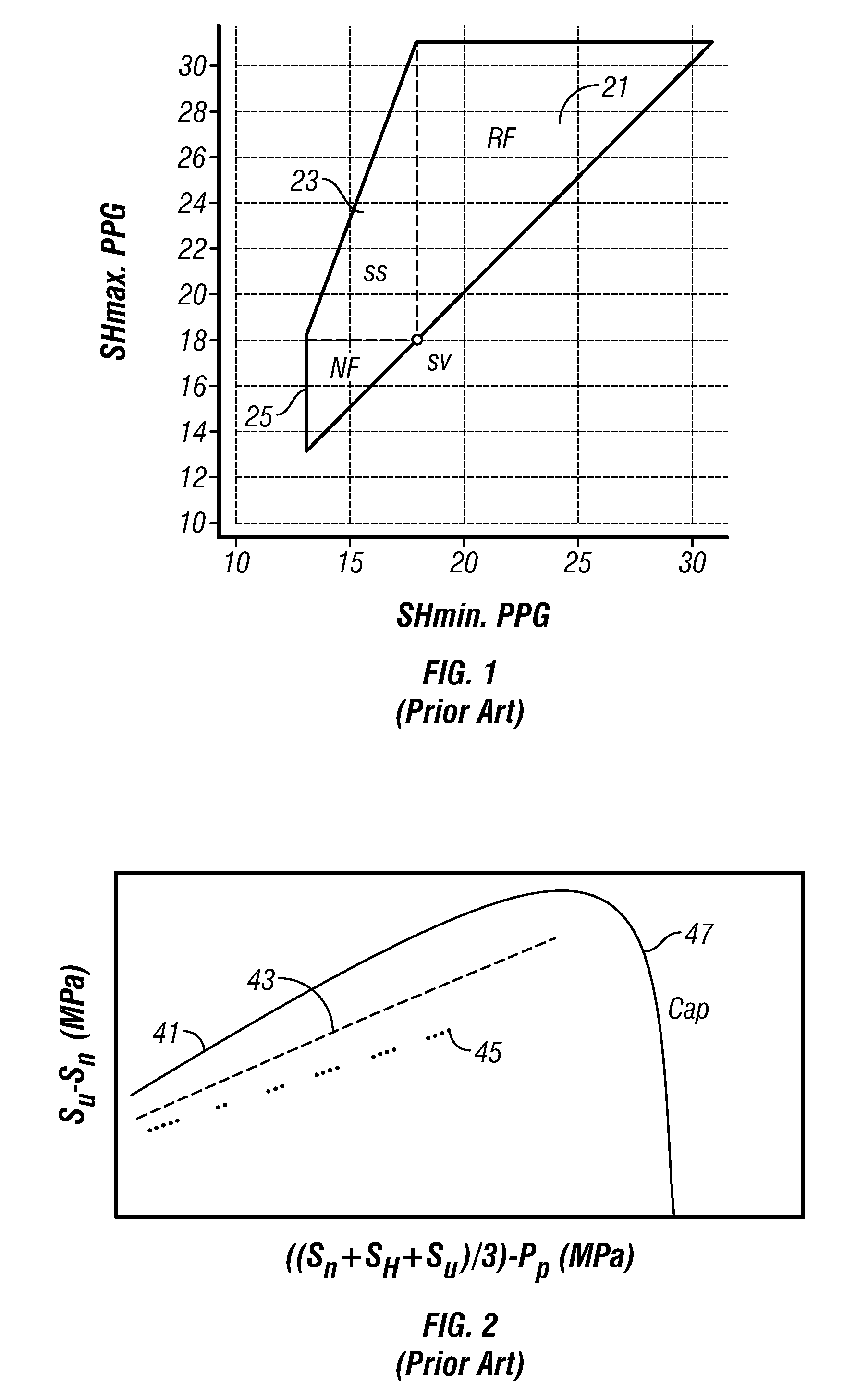

Stress and pore pressure limits using a strength of materials approach

InactiveUS20070118292A1Seismic signal processingSpecial data processing applicationsGeophysicsStrength of materials

Owner:GEOMECHANICS INT

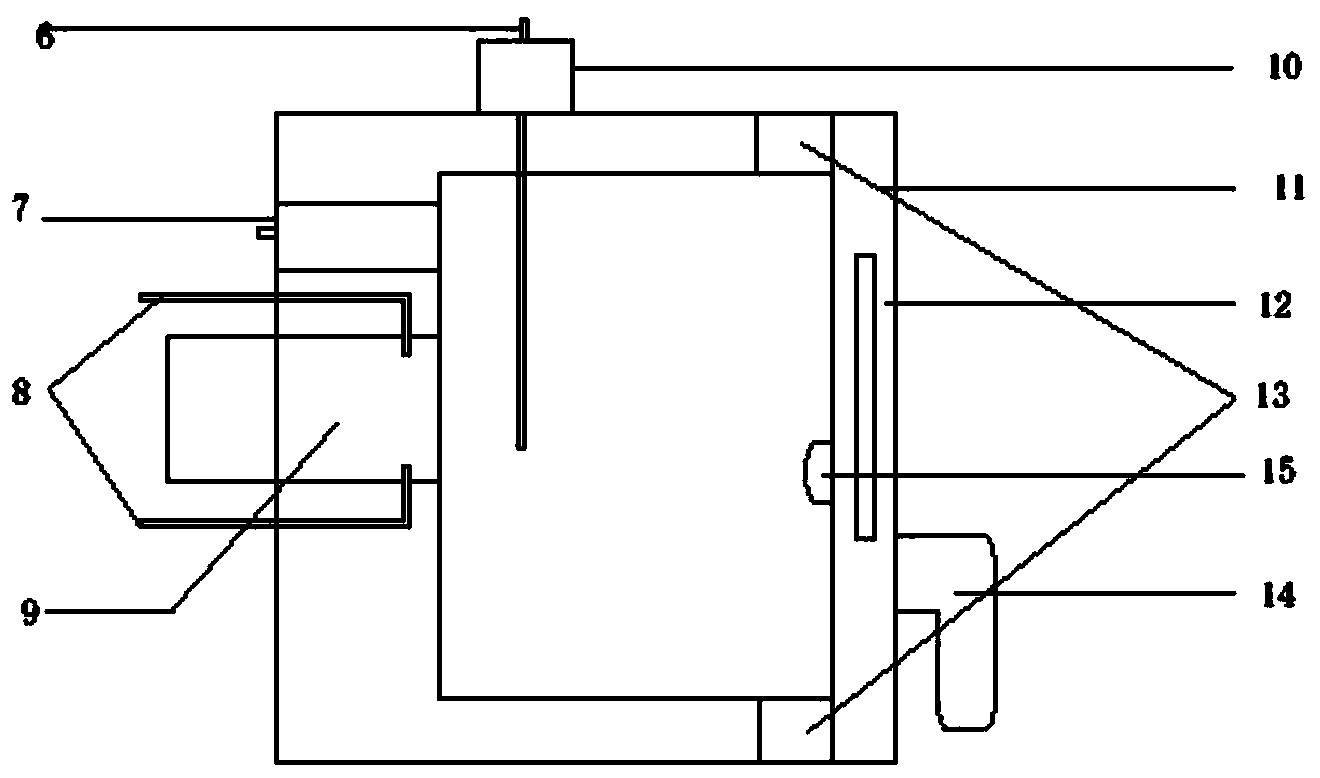

Three/four-point bending performance test general clamp for material

ActiveCN103674692AImprove efficiencyEliminate replacement timeStrength propertiesTest efficiencyFour point flexural test

The invention belongs to clamps for testing material mechanical properties, and relates to a three / four-point bending performance test general clamp for a material. The three / four-point bending performance test general clamp provided by the invention helps to improve the three / four-point bending performance test efficiency, and especially helps to substantially improve the four-point bending performance test efficiency. Under the prerequisite of satisfying domestic and foreign test standards, five technical measures are employed for improving the efficiency of test preparation work, and specifically the five technical measures comprise generalizing the clamp, displaying span in digital manner, arranging scale on a bearer and performing bidirectional centering. The general clamp provided by the invention is capable of finishing three / four-point bending performance tests, so that the clamp replacing time is saved. When the three-point bending performance test is carried out, only an appropriate pressure head needs installing after two pressure-head seats of the clamp are in contact.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

High and low temperature testing apparatus for mechanical test

InactiveCN104266914ARealize mechanical performance testingStable temperatureMaterial strength using tensile/compressive forcesLight equipmentExtreme temperature

The invention relates to a high and low temperature testing apparatus for a mechanical test. The high and low temperature testing apparatus comprises an electric control system, a high and low temperature environment test box, a heating control system and a refrigeration control system. The electric control system is used for controlling the heating control system and the refrigeration control system, so as to enable the temperature in the box to be continuously and controllably changed; the high and low temperature environment test box comprises a stainless steel box body, a box door, a circulating fan, a thermocouple, a heating resistor, a liquid nitrogen access pipe, a thermal-insulating inserting block, a lighting facility, an inspection window and a dismountable defrosting device. The high and low temperature testing apparatus for the mechanical test disclosed by the invention can be combined with a mechanical tester to be used, so as to achieve a mechanical property test of the material at extreme temperature and realize accuracy control of the temperature; meanwhile, the high and low temperature testing apparatus is provided with the heating control system and the refrigeration control system; the apparatus can implement the high-temperature testing environment and the low-temperature testing environment and is convenient to test the influence of the temperature variation on the material mechanical properties; the high and low temperature testing apparatus is further provided with the inspection window, the defrosting device and the lighting facility, so as to observe the destruction process of the specimen during the high and low temperature testing processes.

Owner:DALIAN UNIV OF TECH

Biaxial stretching/compression mode scanning electron microscope mechanical test device

InactiveCN102645370AApplication rate controllableApplied independentlyMaterial strength using tensile/compressive forcesThree levelBall screw

The invention relates to a biaxial stretching / compression mode scanning electron microscope mechanical test device belonging to an electromechanical material performance test instrument. The biaxial stretching / compression mode scanning electron microscope mechanical test device comprises a biaxial loading and transmission unit composed of a high-precision direct current servo motor, a three-level large-reduction-ratio reducing mechanism, a small-lead ball screw nut pair and a guide rail. With the adoption of the biaxial stretching / compression mode scanning electron microscope mechanical test device, precise application of load can be realized in a quasi-static mode at an extremely low velocity, a plurality of types of material performance test modes containing a uniaxial stretching / compression mode, a biaxial constant speed / variable speed synchronous stretching / compression mode, or a biaxial constant speed / variable speed asynchronous stretching / compression mode, and the like can be started by synchronization precision acquisition of four paths of load / displacement signals and combining a closed-loop control strategy taking a load, displacement or deformation signal as a feedback source, and drive units, transmission units and detection units of each shaft are independent and are not interfered with one another. The biaxial stretching / compression mode scanning electron microscope mechanical test device has a compact and exquisite structure and good compatibility with imaging instruments, such as a scanning electron microscope.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com