System and method for testing mechanical properties of conductor material at high-temperature vacuum environment

A conductor material, high-temperature vacuum technology, applied in the direction of applying stable tension/pressure to test the strength of materials, analyzing materials, and conducting material analysis through optical means, which can solve inaccurate temperature measurement, difficulty in strain measurement, slow heating rate, etc. problem, to achieve the effect of accurate measurement, high test efficiency and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

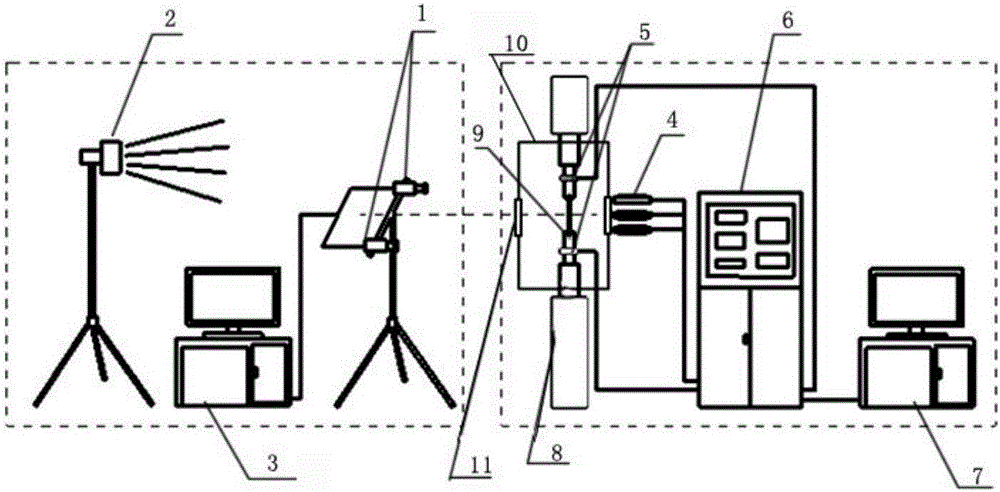

[0049] Such as figure 1 , 4 As shown, a system for testing the mechanical properties of conductor materials in a high-temperature vacuum environment, including a high-temperature deformation test subsystem, a temperature control subsystem and a loading subsystem,

[0050] The high temperature deformation testing subsystem includes two CCD cameras 1, LED blue light sources 2 and a first computer 3, the two CCD cameras 1 are connected to the first computer 3 through data lines, and the LED blue light sources 2 are used for collecting image data Supplement monochromatic blue light in the process, and add narrow-band blue light filters in front of the lenses of the two CCD cameras 1 at the same time, and the first computer 3 records and saves the image data collected by the two CCD cameras 1;

[0051] The temperature control subsystem includes a double colorimetric pyrometer 4, an electrode 5, a temperature control box 6 and a second computer 7. The double colorimetric pyrometer ...

Embodiment 2

[0054] The test method for testing the mechanical properties of conductor materials under a high-temperature vacuum environment obtained by the system of Example 1 is as follows:

[0055] (1) Make high-temperature speckles on the surface of the material by spraying with a brush, first dry at room temperature, and then dry in a drying oven at 92°C for 2 hours; check the appearance of the sample, number and record the surface state of the sample, and use Measure the width and thickness of any three places in the gauge length area of the sample with a caliper, take the average value, and record the data as shown in Table 1; install the sample to ensure that the sample axis coincides with the tensile axis of the testing machine;

[0056] Table 1

[0057]

[0058] (2) Adjust the upper, middle and lower sections of the double colorimetric pyrometer so that the indicating lasers are respectively hit on the upper, middle and lower sections of the sample, and ensure that the faste...

Embodiment 3

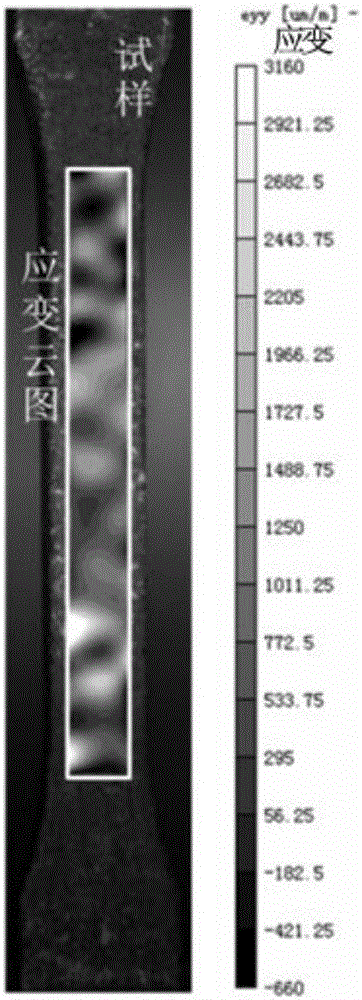

[0084] The test method adopted in this implementation is the same as that in Example 2, the difference is that the sample is compressed by a mechanical testing machine, and the results obtained are as follows Figure 6 and Figure 7 As shown, the test data results are shown in Table 2:

[0085] Table 2

[0086]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com