Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

433 results about "Slow heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Die forging method of high-temperature alloy

ActiveCN101332484ASolve the shortcomings of slow heatingImprove insulation effectForging/hammering/pressing machinesThermal insulationWorking temperature

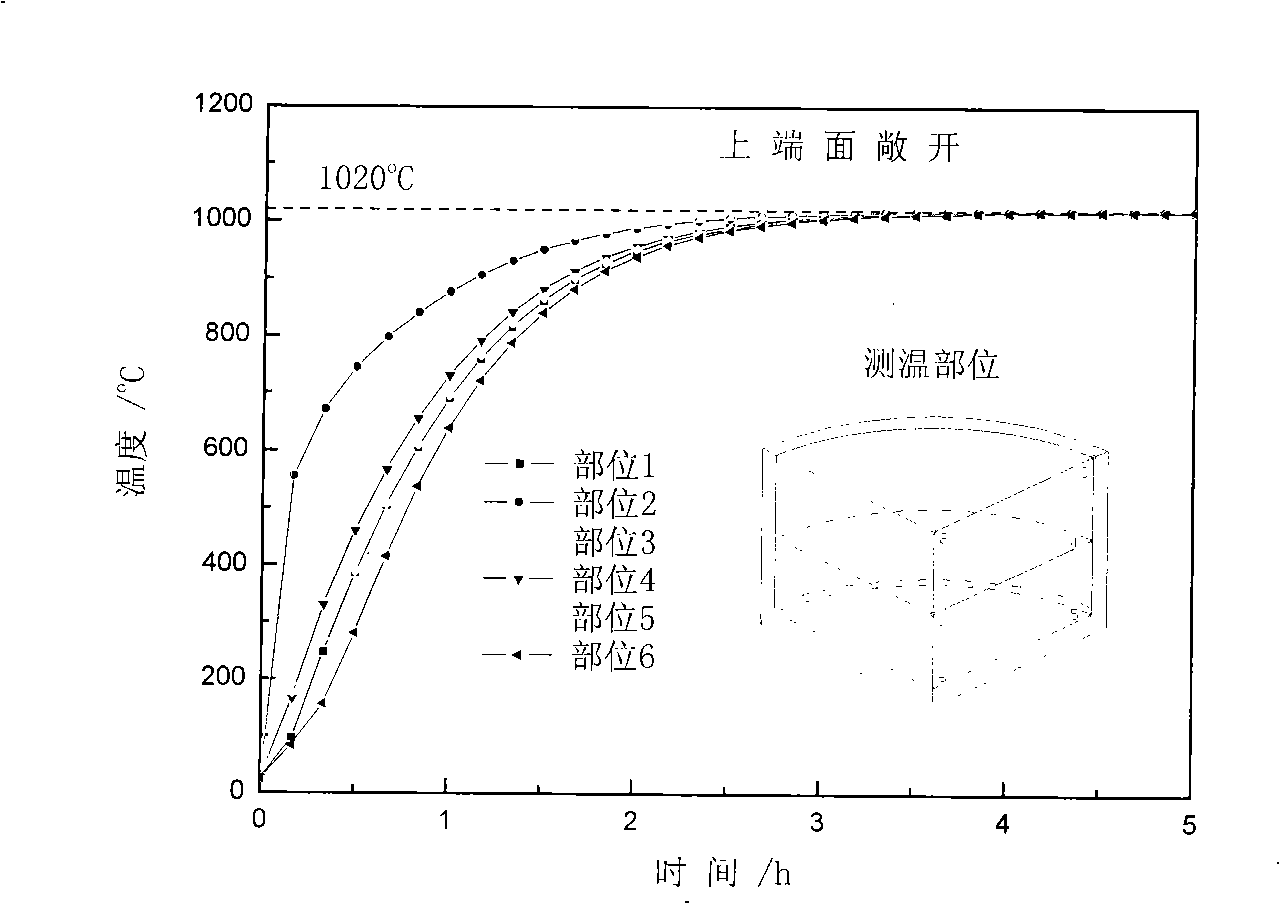

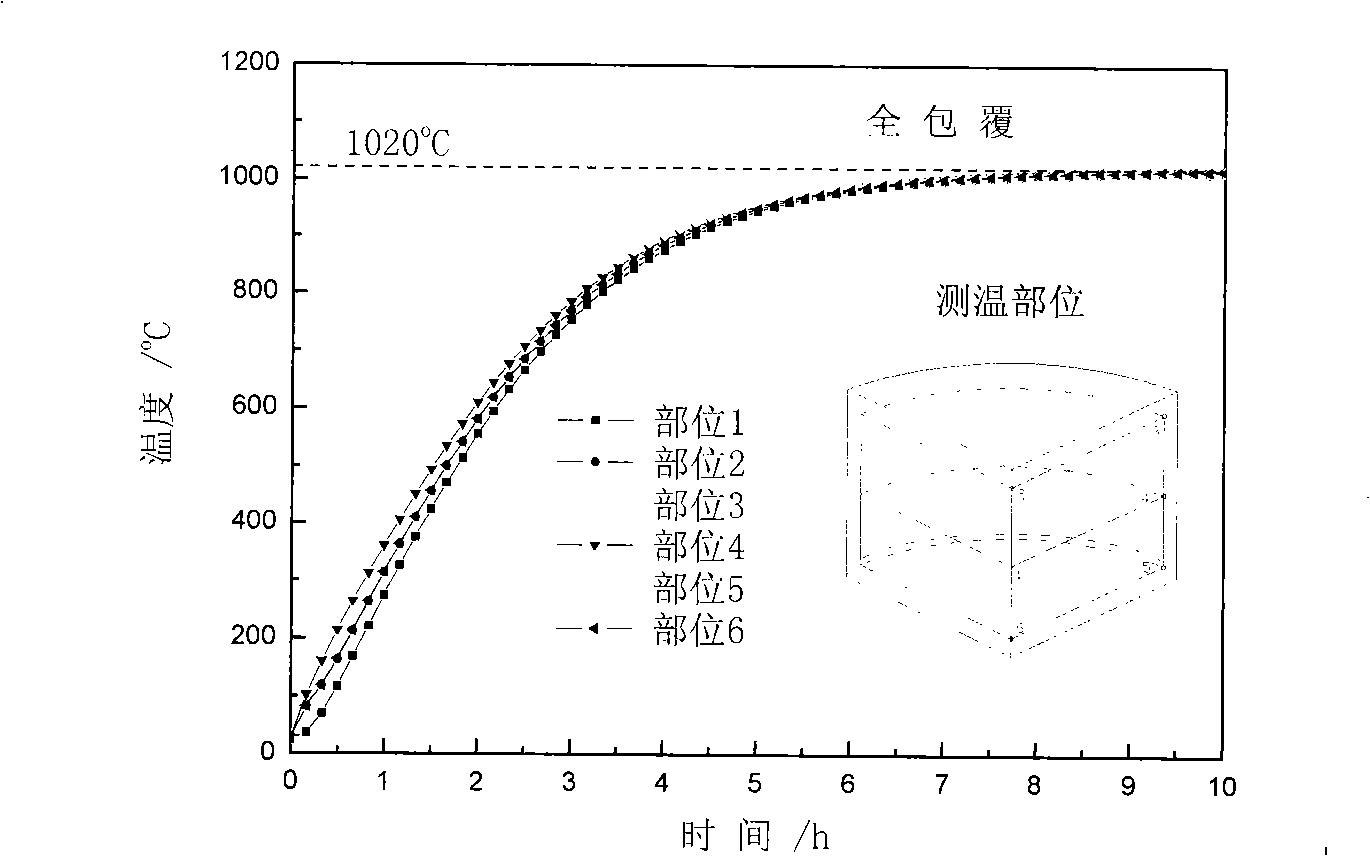

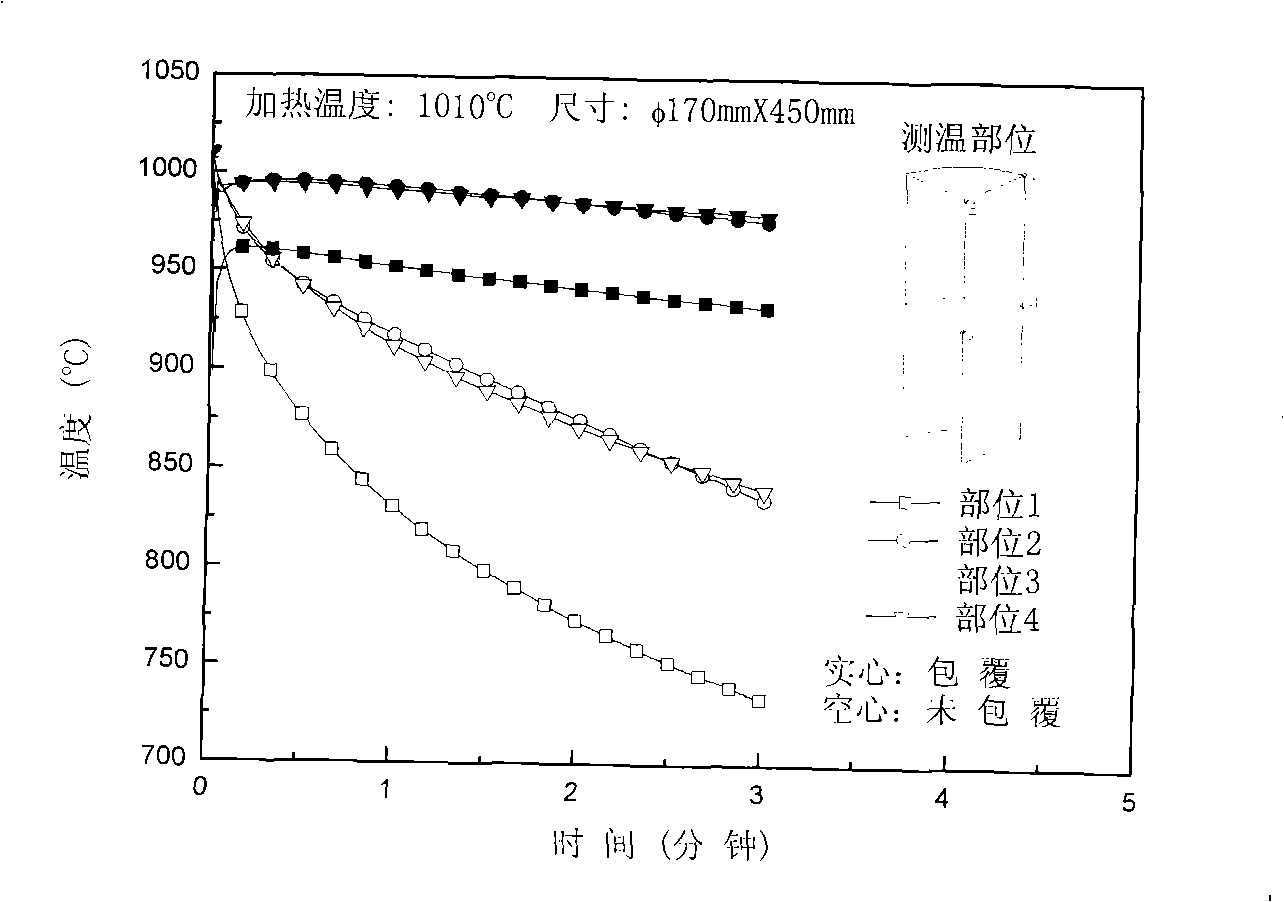

The invention discloses a die forging method of a high-temperature alloy; the method comprises the following steps: a) die forging stock is in thermal insulation and heat preservation, and clad with thermal insulation cotton; b) heating of the die forging stock: the die forging stock clad with the thermal insulation cotton is heated in a heating furnace and preserved at a temperature, the heating temperature is 900-1200 DEG C, and the heat preservation time is not less than 30 minutes; c) heating of a die: the die is put into a press, and heated to the working temperature of 600-650 DEG C in the heating furnace of the press; d) die forging: the die forging stock is taken out of the heating furnace and sent to an oil press or a hydraulic press for die forging, the amount of deformation is 40-80%, and the die forging speed is 1-5mm / s. The die forging method of the invention solves the problem of slow heating-up of the die forging stock in the heating furnace resulting from the existing 'compound jacketing' mode, improves the heat preservation effect of workpiece, and lower the cost for the application of heat insulating materials; the die forging method adopts a lower die temperature, which sufficiently eliminates the problems of short service life of the hot press forging die and great production difficulty, and facilitates producing the alloy forged pieces conforming to finecrystalline requirements.

Owner:宝武特种冶金有限公司

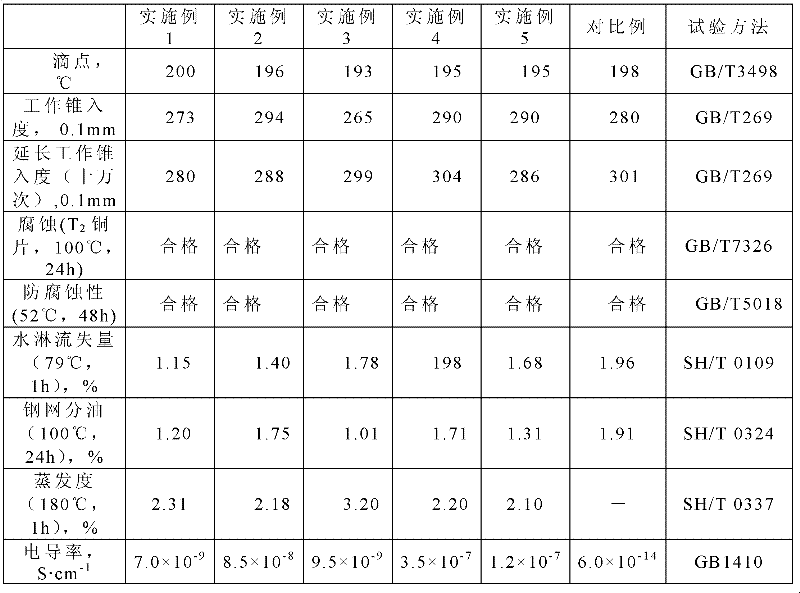

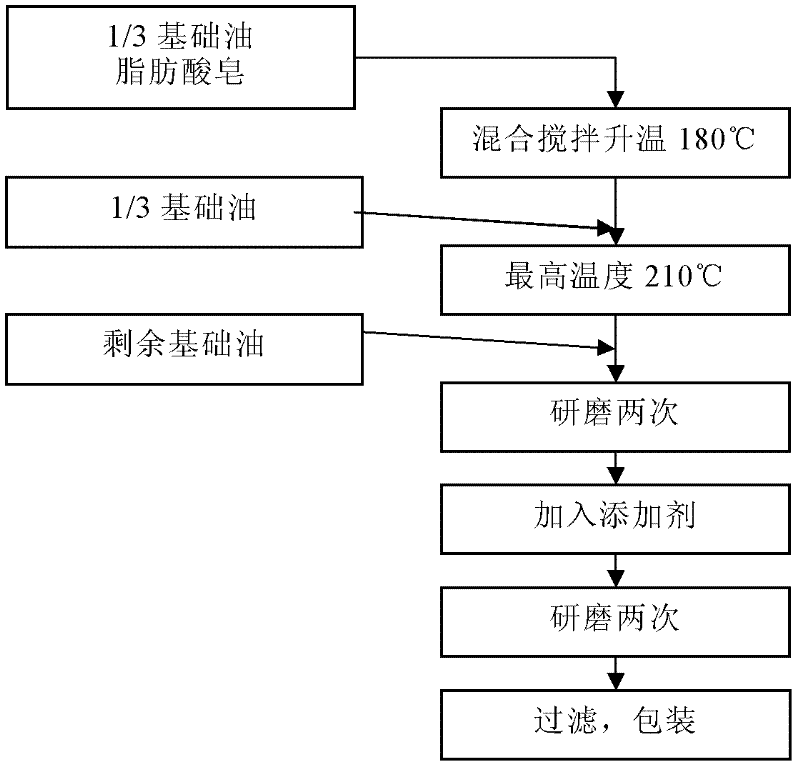

Electric lubricating grease and preparation method thereof

ActiveCN102604722AImprove conductivityImprove the protective effectLubricant compositionFatty acidSOAP

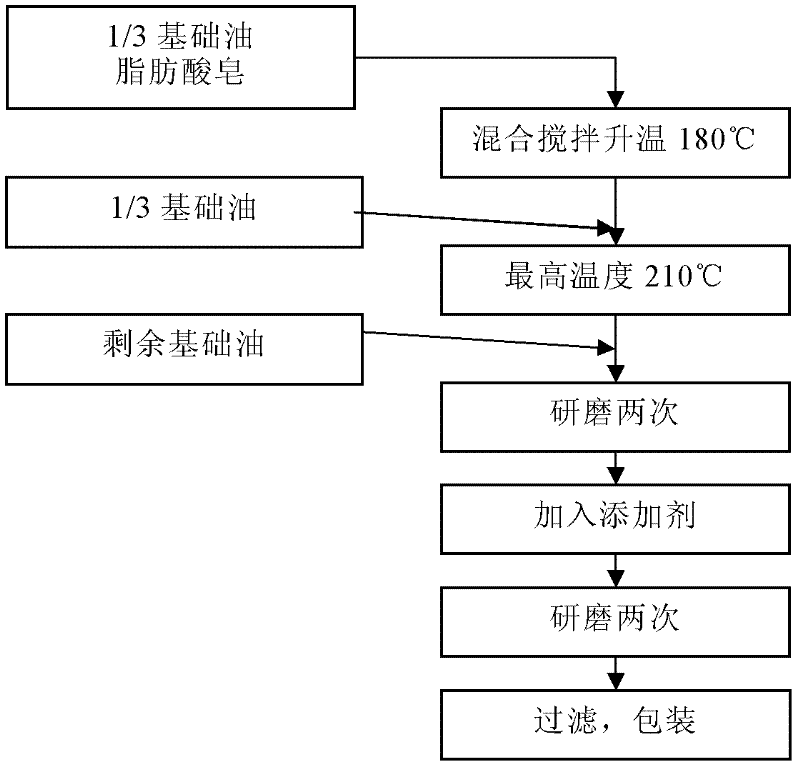

The invention relates to electric lubricating grease and a preparation method thereof, and in particular relates to electric lubricating grease used for a terminal in the electric locomotive and power industries and a preparation method thereof. A fatty acid soap-type thickening agent is weighed in proportion and is added into base oil to be mixed, stirring and slow heating are carried out, then the base oil is continuously added, stirring and heating are continuously carried out, and then the base oil is added, and mixing is carried out and homogenizing by virtue of a homogenizer or grinding by virtue of a grinding machine is carried out, thus base ester is obtained; and an anti-oxidation additive, an anti-corrosion additive, an anti-rust additive, a conductive additive and an anti-static additive are sequentially added into the obtained base ester and mixed; and then the mixture is homogenized by virtue of the homogenizer or ground by virtue of the grinding machine; and finally filtering and packaging are carried out to obtain the electric lubricating grease product. The lubricating grease provided by the invention has excellent conductive performance, contact condition of an electric contact is effectively improved, and antiseptic and antirust performances of the electric contact are obviously improved. The electric lubricating grease product can be widely applied to the electric contact of an electric locomotive and a power supply system.

Owner:无锡中石油润滑脂有限责任公司

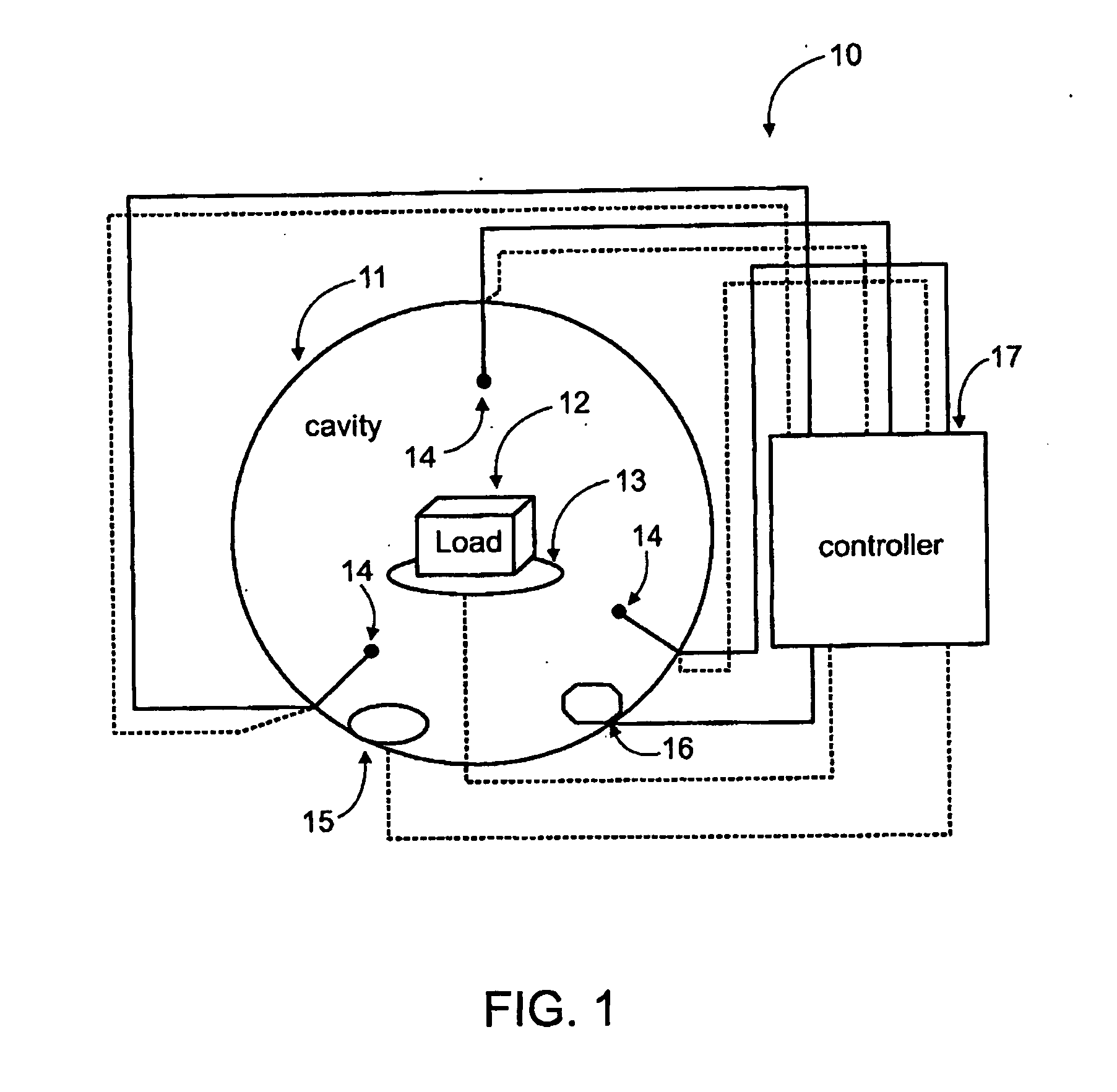

Device and method for heating using RF energy

ActiveUS20110198343A1Increasing temperature gapIncrease rate of changeMicrowave heatingDomestic cooking appliancesEngineeringSlow heating

Owner:JOLIET 2010 LTD

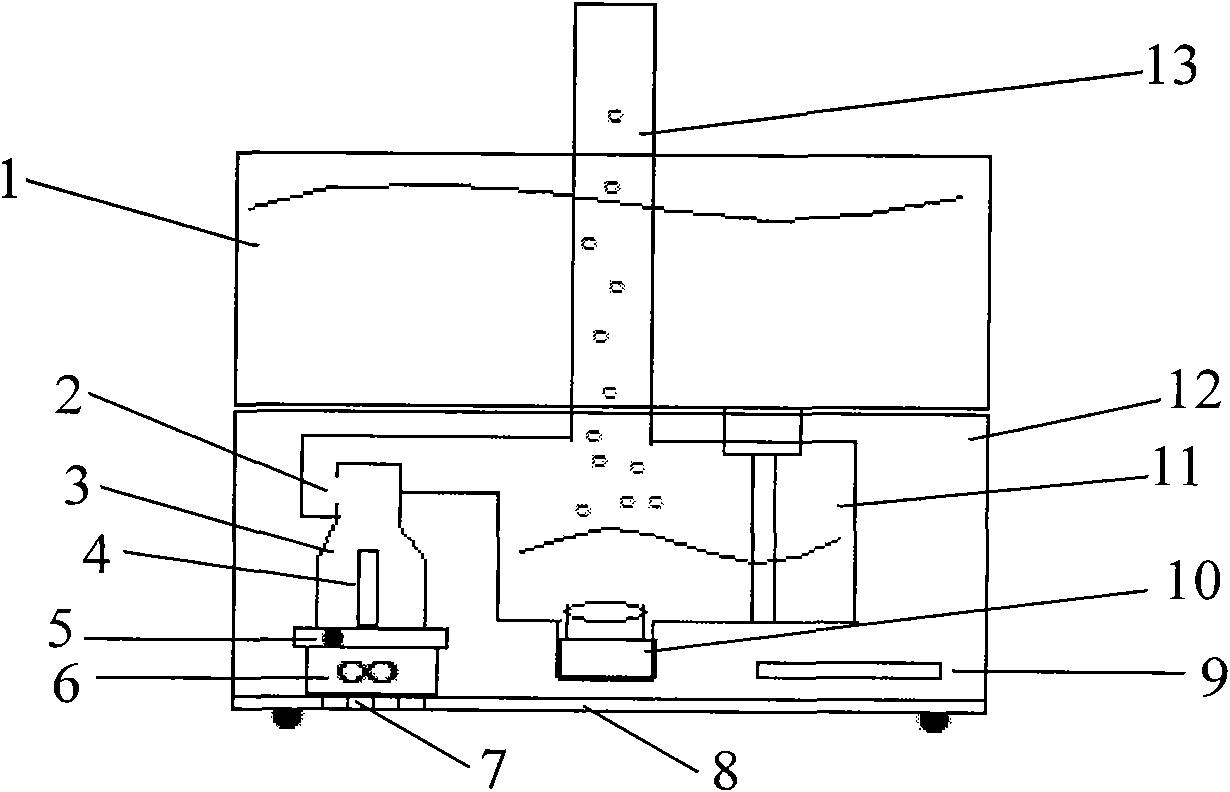

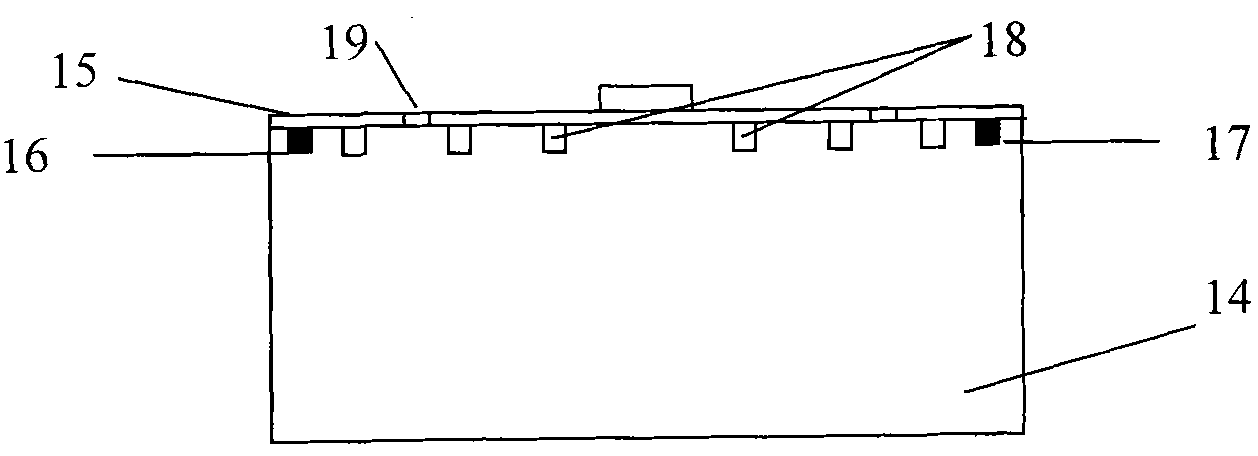

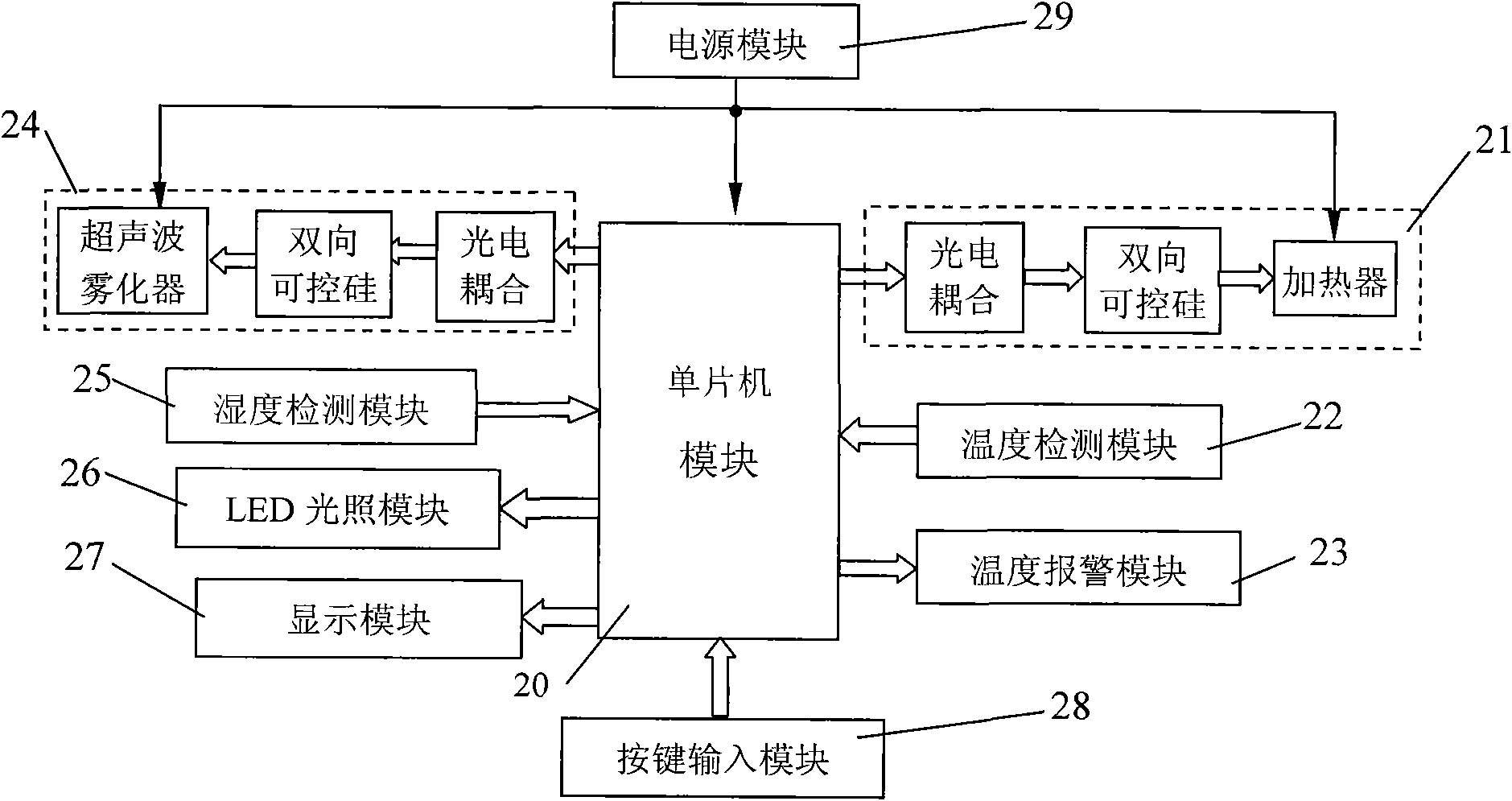

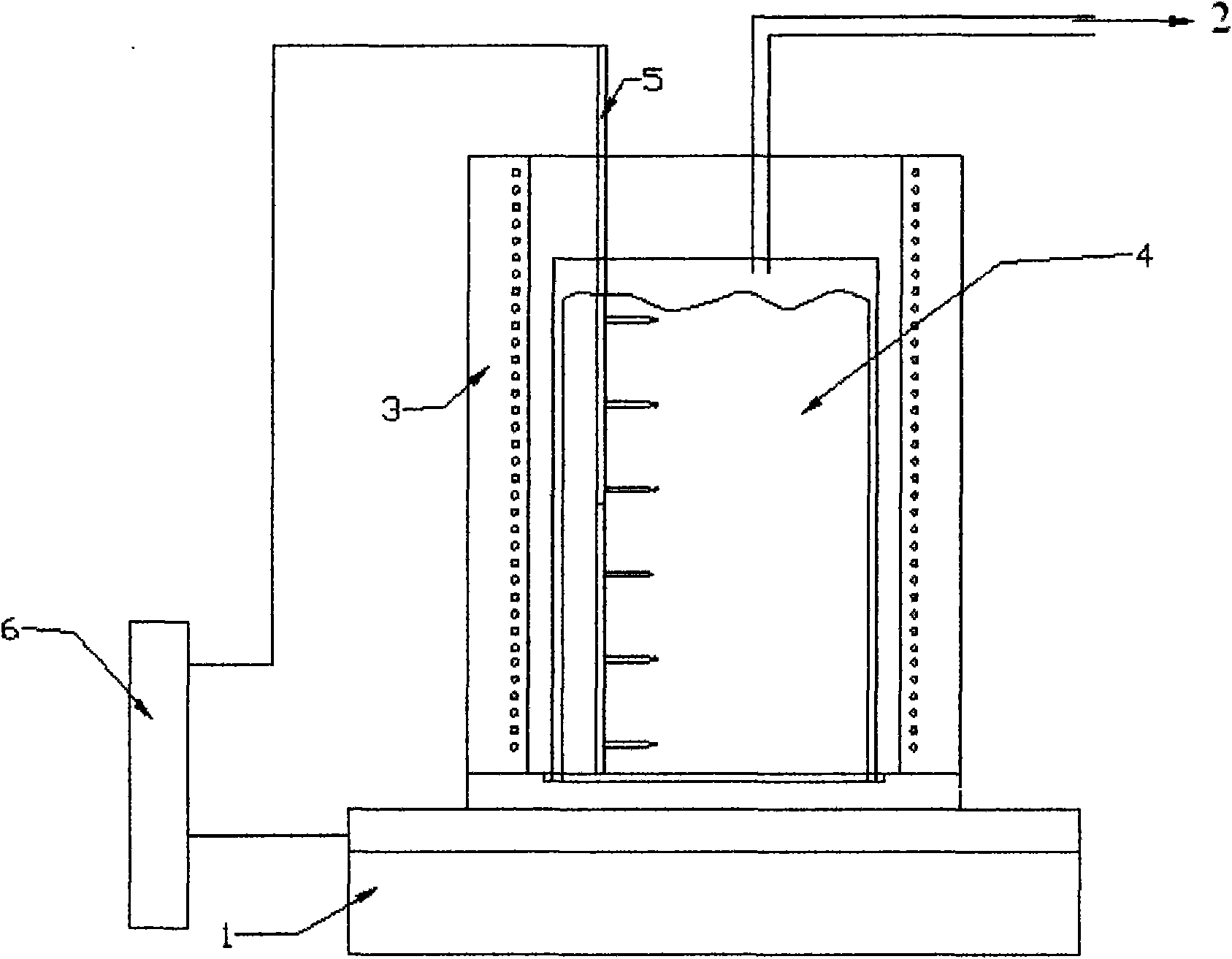

Intelligent cultivation method and device for producing bean sprouts

InactiveCN101926279AGuaranteed uniformitySufficient oxygenAgriculture gas emission reductionCultivating equipmentsHigh energyControl signal

The invention discloses an intelligent cultivation method for bean sprouts. An incubator, a water tank, a base and a control system are provided, and the method comprises the following steps of control on heating, humidification and illumination. For the heating and humidification control, PID closed-loop control is adopted; a temperature and humidity sensor is installed in the incubator; a single chip processes a detected temperature and humidity signal and outputs a corresponding control signal; and a temperature and humidity control module realizes accurate control on the temperature and humidity in the incubator. The heating method is characterized in that air is directly heated by a heating rod, water is atomized by an ultrasonic atomizer, and then the hot air and the water mist are mixed by a fan at the bottom of a heating room and delivered mixture to the incubator. The illumination control is realized by using an LED lamp. The invention solves the problems of non-uniform spraying, excessive waste water, slow heating, high energy consumption, inaccurate temperature and humidity control and the like in the existing bean sprout cultivation device, and is applied to the devices such as a bean sprout incubator, a seed incubator, a household bean sprout growing machine, etc.

Owner:HUAZHONG AGRI UNIV

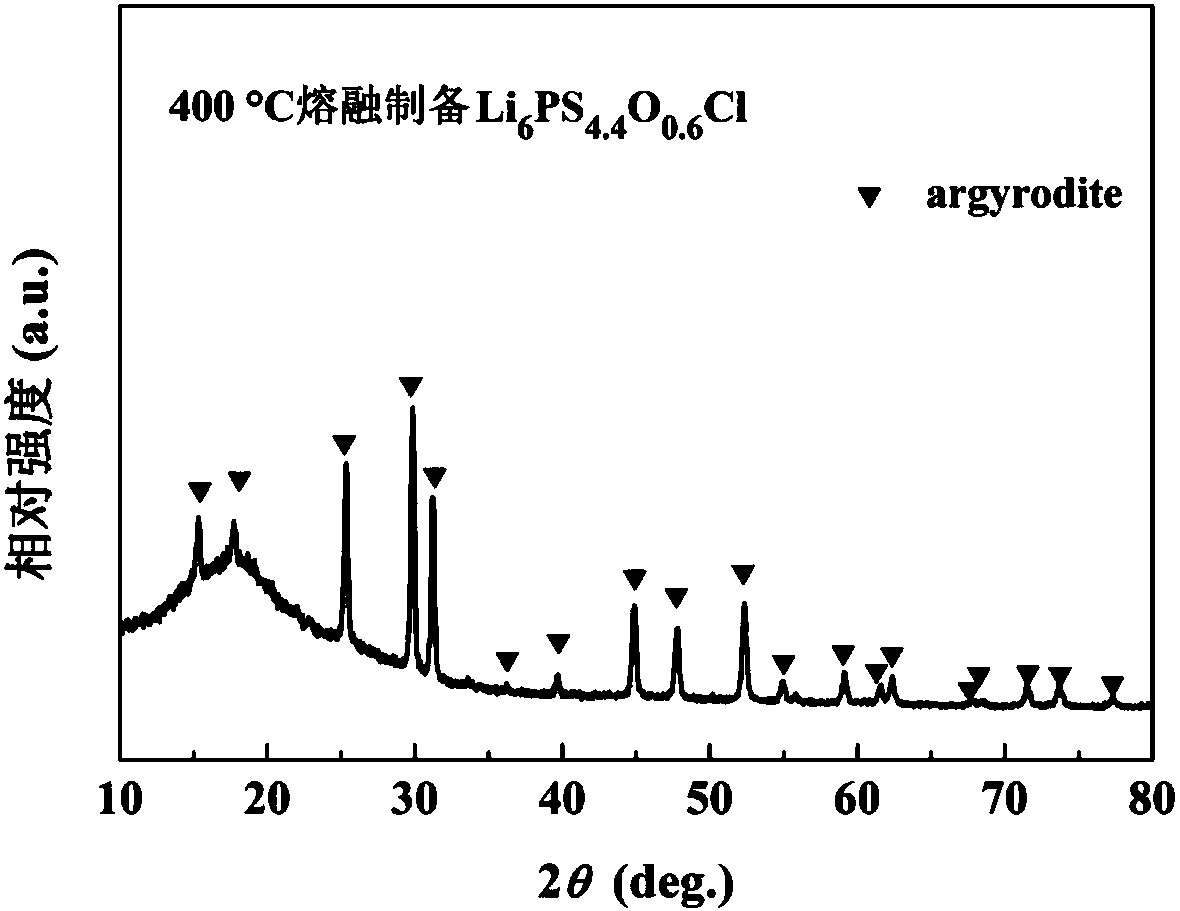

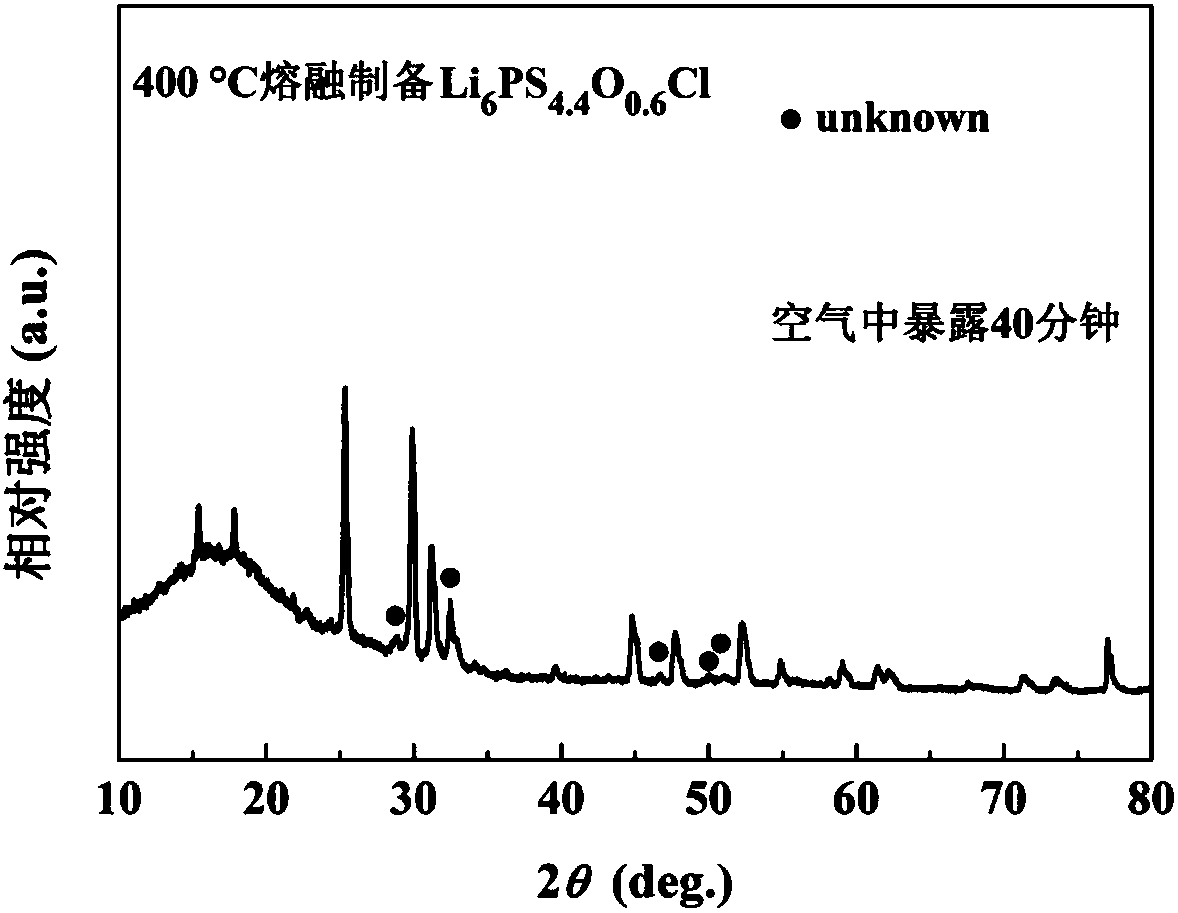

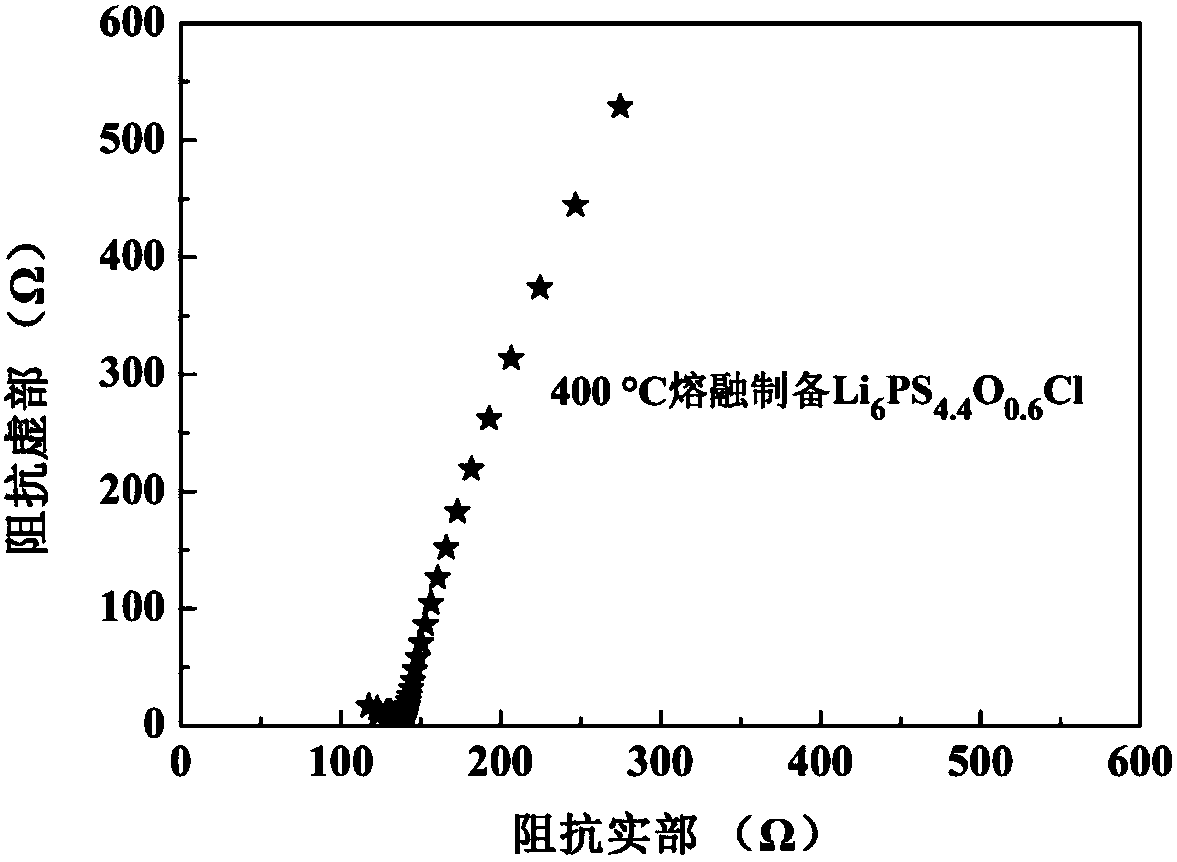

Sulfide solid electrolyte based on oxygen doping and preparation method of sulfide solid electrolyt

ActiveCN108493479AImprove stabilityImprove ionic conductivitySolid electrolytesLi-accumulatorsLithium chloridePhosphorus pentasulfide

The invention provides a sulfide solid electrolyte based on oxygen doping. The sulfide solid electrolyte is prepared from the chemical ingredients, in percentage by mass: 36-60% of lithium sulfide orlithium selenide, 18-48% of phosphorus pentasulfide or phosphorus selenide, 1-23% of metal oxide or specific nonmetallic oxide and 8-37% of lithium chloride, lithium bromide or lithium iodide. The preparation method of the sulfide solid electrolyte mainly comprises the steps that the raw materials are sufficiently blended and subjected to tabletting, then placed in a quartz tube to be burned and sealed, the product is placed in a muffle furnace and heated to be 400-600 DEG C at a slow heating rate, the optimal heating rate is 0.3 DEG C / minute, heat preservation is conducted for 12-48 hours, and then the product is cooled to reach the room temperature; and the product is ground to be powder, and the sulfide solid electrolyte based on oxygen doping is prepared. The sulfide solid electrolyteis easy to prepare and high in repeatability, the prepared solid electrolyte has the high ionic conductivity and good stability to the air and positive and negative electrodes.

Owner:YANSHAN UNIV

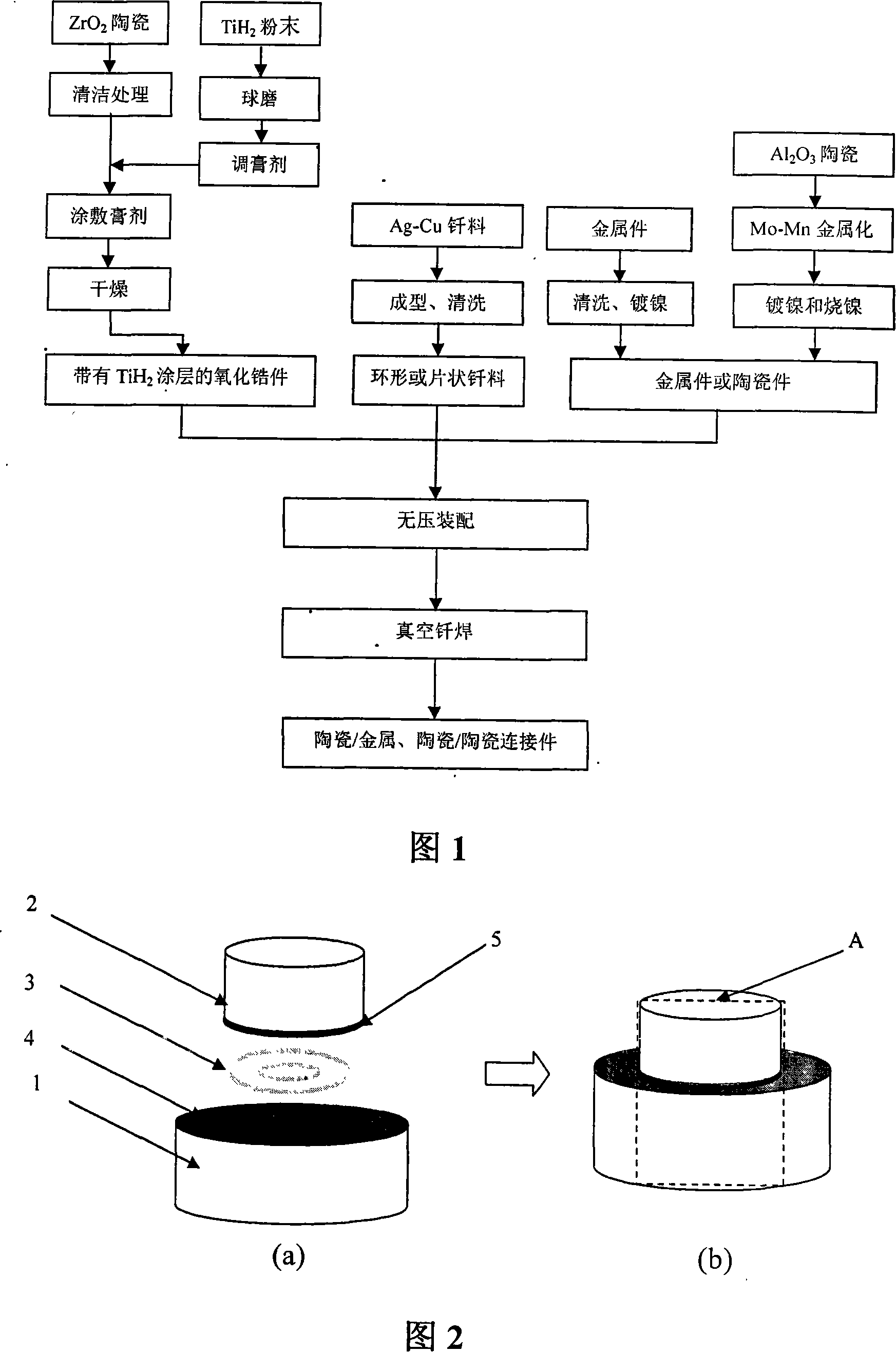

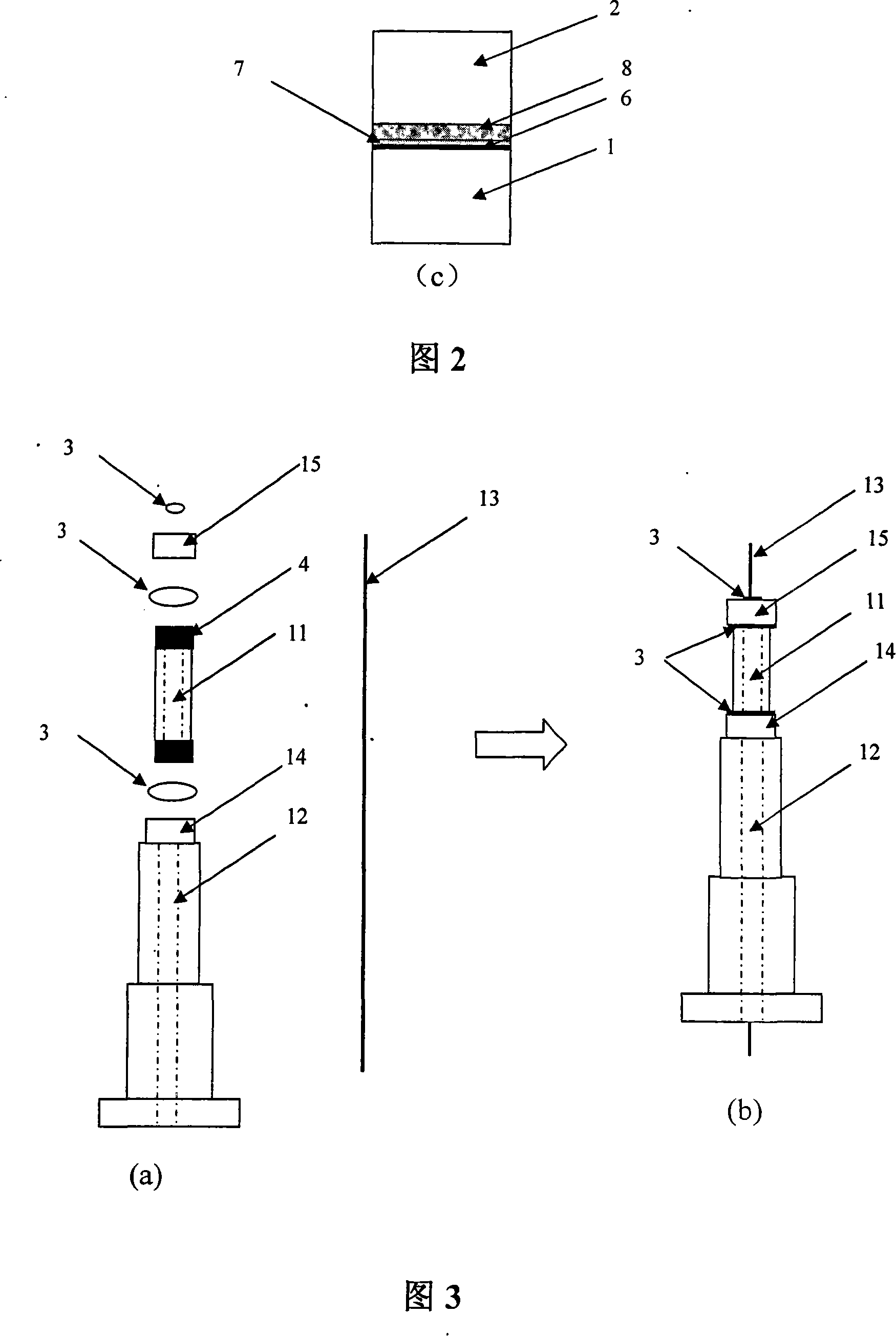

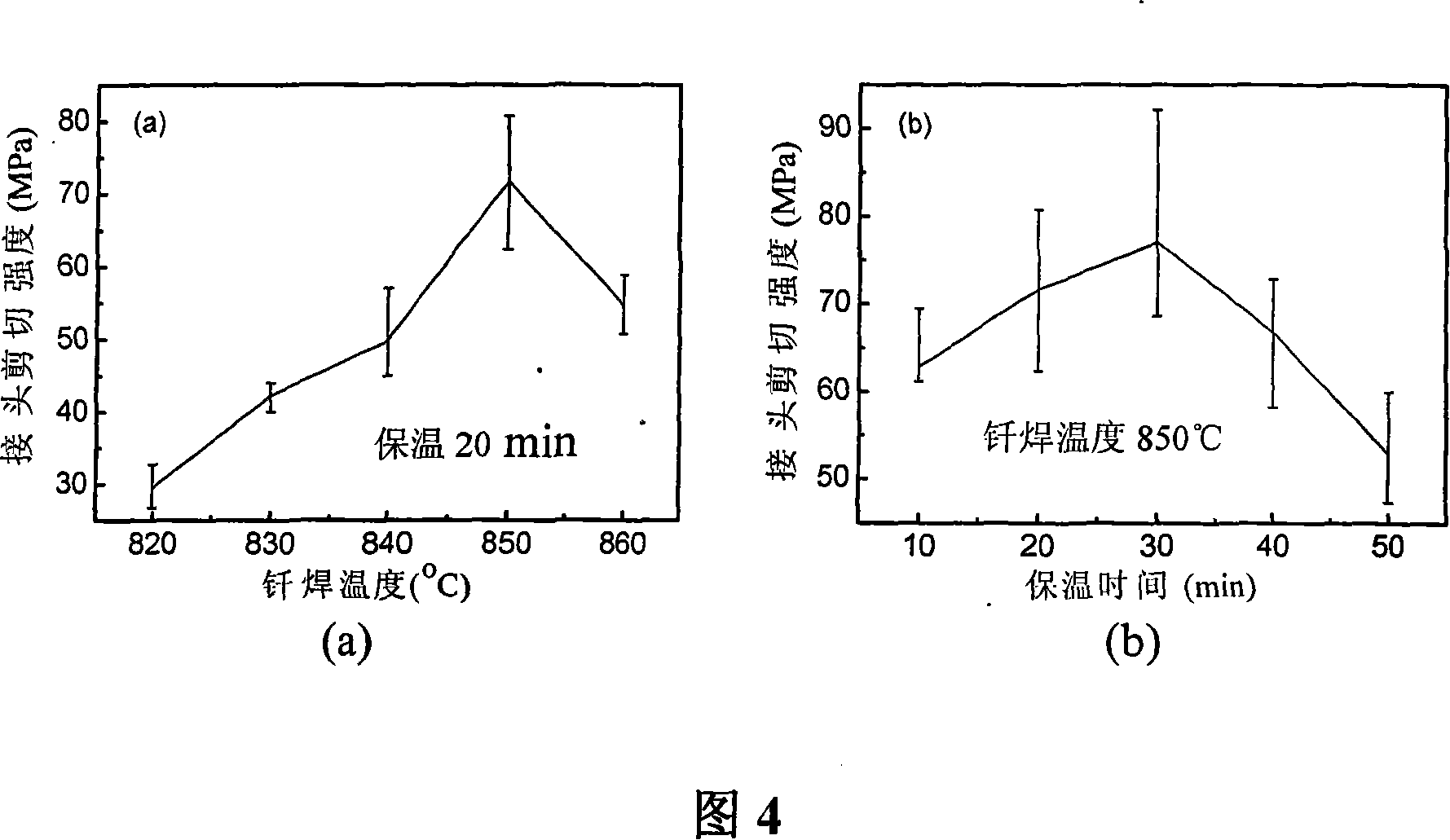

Non-pressure braze welding method for ZrO2 ceramic and stainless steel or Al2O3 ceramic

The present invention discloses process of non-pressure brazing between ZrO2 ceramic and stainless steel or Al2O3 ceramic. The process includes the following steps: 1. preparing TiH2 brazing paste; 2. painting TiH2 brazing paste; 3. treating the brazed surface in stainless steel and ceramic workpiece; and non-pressure assembling and vacuum brazing. It features the vacuum brazing step including reaching vacuum degree superior to 8x10<-3> Pa, maintaining for certain time in at least two temperatures including one temperature higher than the vacuum decomposition temperature of TiH2 and the brazing temperature, slow heating before reaching the brazing temperature and slow cooling to room temperature. The process is simple, low in cost, and widely applicable.

Owner:XI AN JIAOTONG UNIV

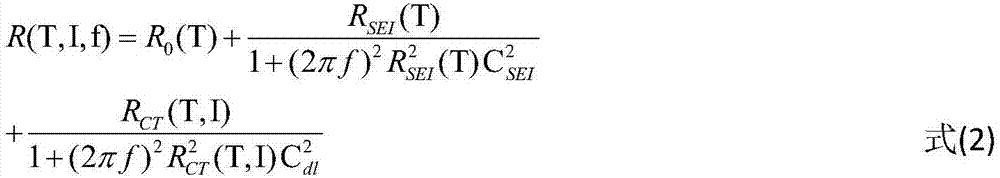

Power battery alternating current varying current gradient heating method

The invention relates to a power battery alternating current varying current gradient heating method. The method is characterized in that the alternating current excitation current amplitude is timely calculated and updated according to the temperature of an existing power battery packet, the external environment temperature, and the terminal voltage and other detection signals of power batteries, and is applied to two ends of every battery in order to guarantee that the terminal voltages of the batteries do not exceed limits and the current is positioned in the born current range allowed by the batteries, so the low-temperature working performances of the power batteries are improved. The heating method solves the problems of slow heating speed, poor effects, voltage exceeding limits in the heating process and affection of the life of the batteries of existing battery heating methods in low temperature environment, has the advantages of good effect, high robustness and good safety, and provides guarantee for the reliable running of the power batteries.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Concrete super retarder and preparation method thereof

InactiveCN102206057AImprove attachment functionImprove compactnessMass ratioUltimate tensile strength

The invention belongs to the technical field of civil engineering material, and relates to a novel concrete super retarder and a preparation method thereof. A technical scheme of the present invention comprises that: the concrete super retarder adopts hydroxyethylidene diphosphonic acid (HEDP), amino trimethylene phosphonic acid (ATMP) and water as raw materials, wherein a mass ratio of the three raw materials is 6:1:13. The preparation method comprises sequential adding the HEDP, the ATMP and the water into a stirring vessel, followed by slow heating to a temperature of 35-45 DEG C and uniform stirring. With the present invention, production technology of the concrete super retarder is simple, comprehensive production cost of the concrete super retarder is low, and later strength of the concrete is not reduced but is improved. An addition proportion of the concrete super retarder in the concrete is 0.05%-0.5% of mass of cementitious materials, such that the concrete can have an initial setting time of 0-120 hours, and the later strength of the concrete is unaffected after completing retarding. The concrete super retarder is widely applicable for a plurality of fields such as concrete construction in summer and mass concrete construction. According to the present invention, generations of temperature cracks are effectively prevented, slump loss is decreased, and long distance transport of the concrete is easy to be performed.

Owner:DALIAN UNIV OF TECH

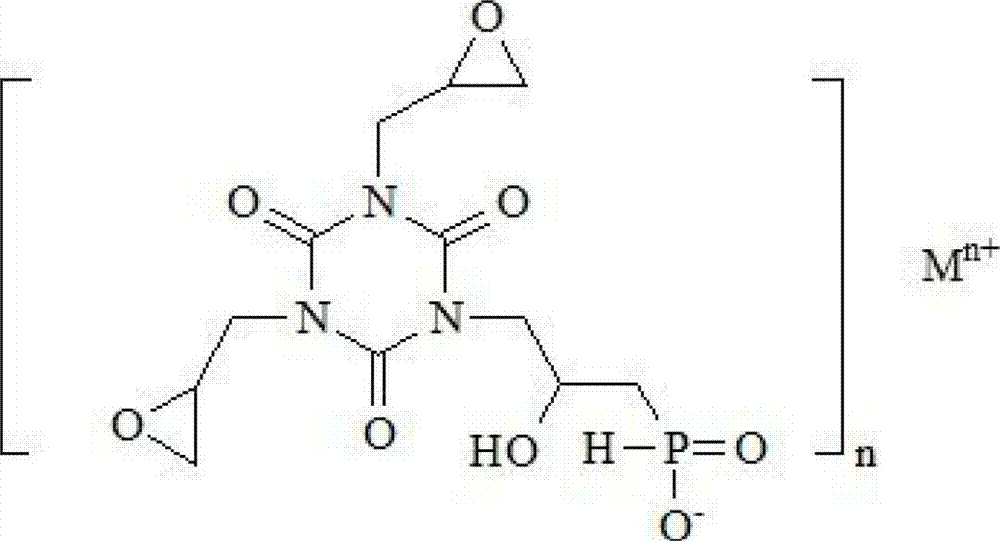

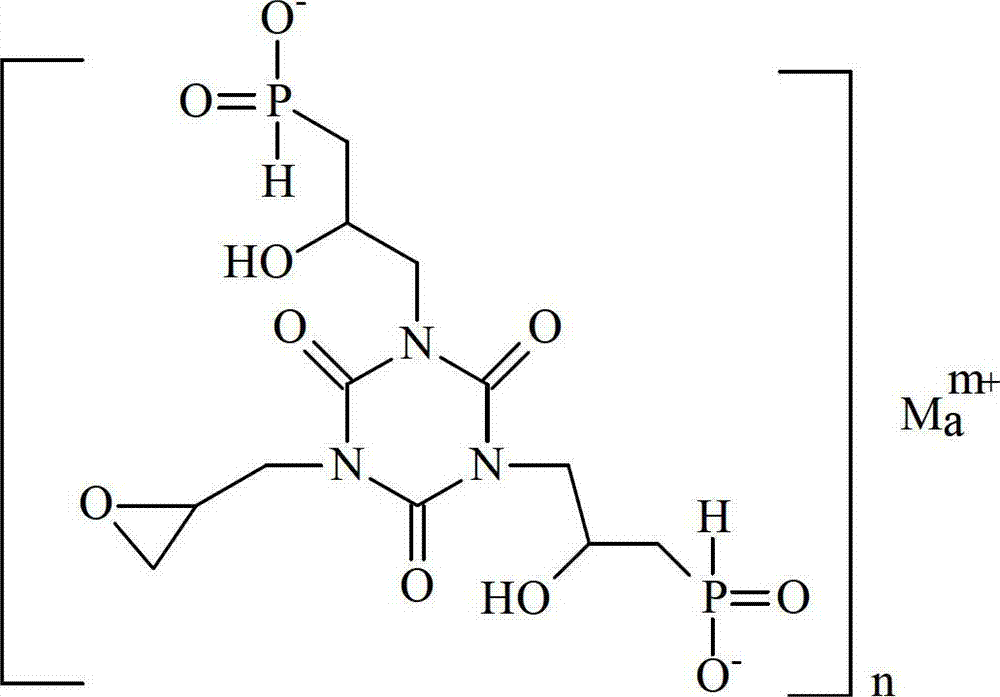

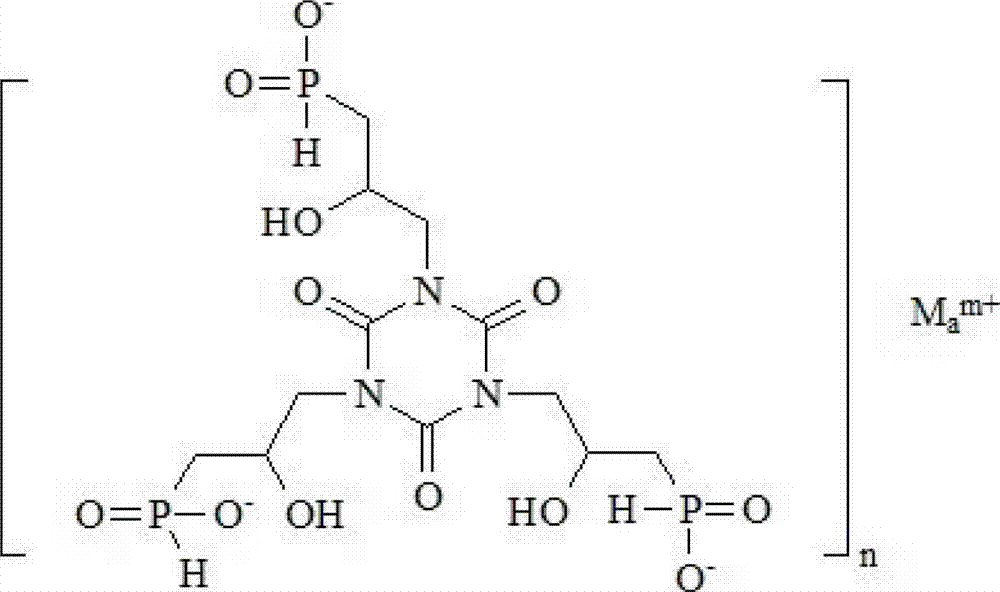

Halogen-free flame retardant and preparation method thereof

ActiveCN103030836AImprove flame retardant performanceIn line with the trend of non-halogenationGroup 5/15 element organic compoundsPolyethylene terephthalate glycolPolymer science

The invention relates to a halogen-free flame retardant and a preparation method thereof. The flame retardant is formed by combining one or two of the following three organic hypophosphite compounds containing triazine ring structures at any mass ratio. The preparation method of the halogen-free flame retardant comprises the following steps of adding triglycidyl isocyanurate and hypophosphite into a reaction vessel, taking ethanol, ethylene glycol or glacial acetic acid as a solvent, heating slowly and maintaining a reaction, conducting suction filtration, washing and drying after the reaction is finished, and obtaining the halogen-free flame retardant. The halogen-free flame retardant is prepared by taking hypophosphite and triglycidyl isocyanurate (TGIC) as main raw materials, and has the characteristics that the raw materials are easy to obtain, a process is simple and easy to run, and the production and the operation are safe. The prepared halogen-free flame retardant and a composition are good in thermostability and excellent in comprehensive property; various colors can be blended; the halogen-free flame retardant and the composition can be applied to flame retarding PBT (polybutylece terephthalate) engineering plastics, PA6 (polyamide6) or PET(polyethylene terephthalate) and the like, and are good in application prospect.

Owner:湖南美莱珀科技发展有限公司

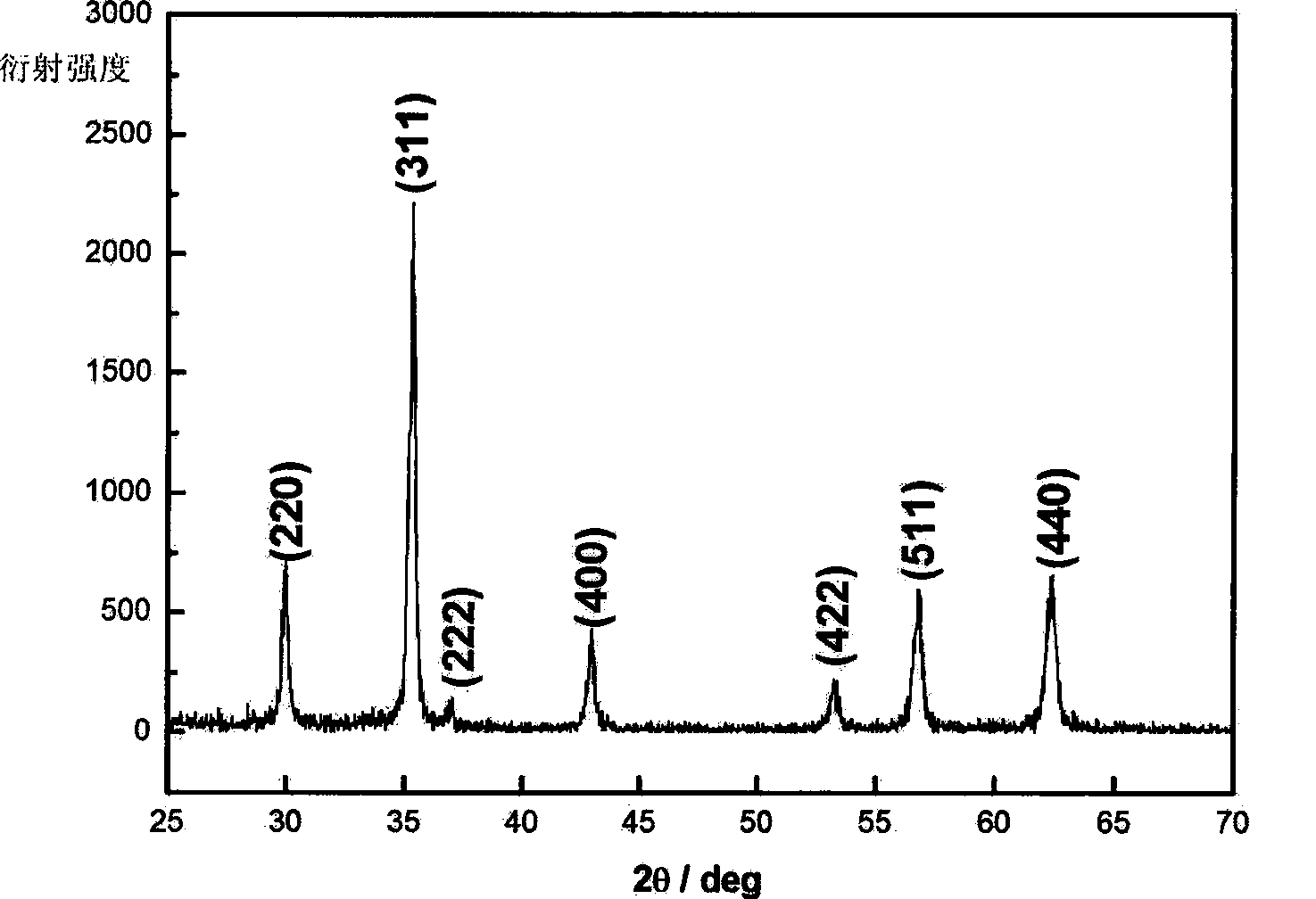

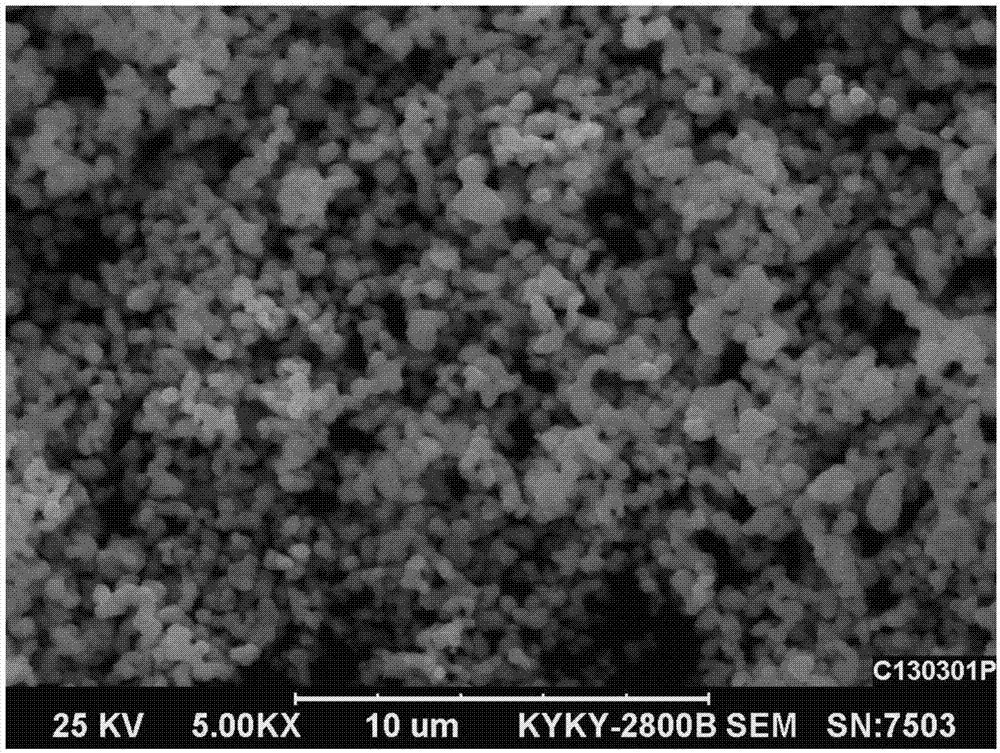

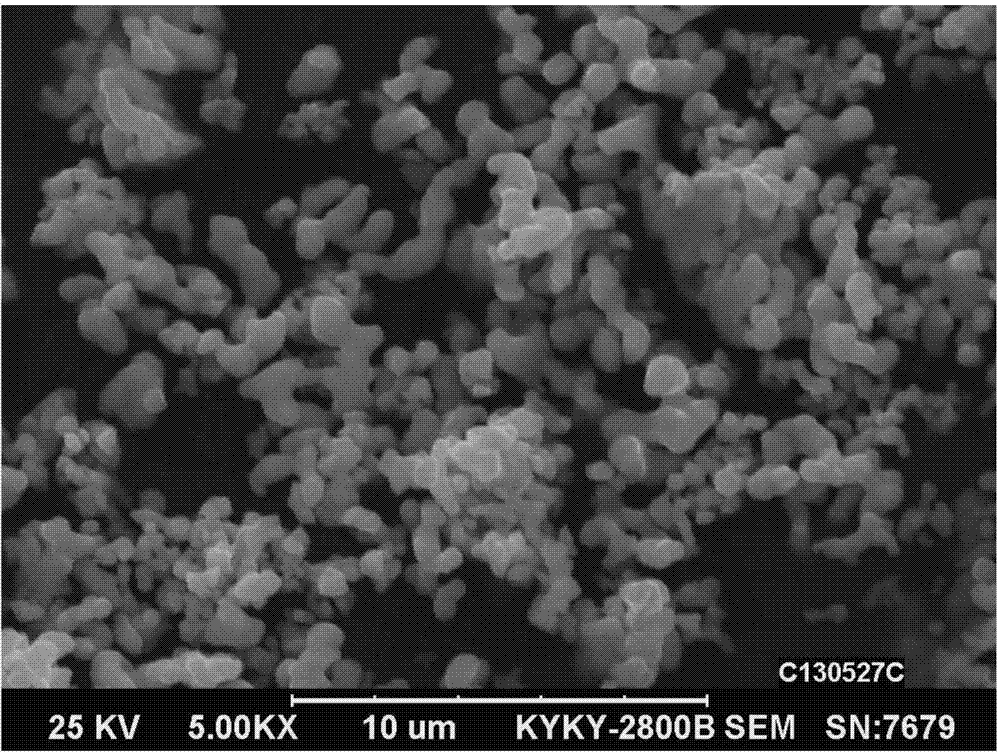

Method for directly preparing MnZn ferrite material from nanocrystalline MnZn powder

The invention discloses a preparation method for directly preparing a high-frequency low-power-consumption material by nanocrystalline MnZn ferrite particles and belongs to the preparation technical field of ferrite magnetic materials. The preparation method comprises the following operation steps: step one: preparing nanocrystalline MnZn powder; step two: pressing into annular biscuit; and step three: sintering into a product. The biscuit pressed in the step two is put in a vacuum furnace, balanced oxygen partial pressure protection is adopted for the biscuit in the heat preservation and cooling processes, and finally the biscuit is naturally cooled to room temperature, thus obtaining the high-frequency low-power-consumption MnZn ferrite. The key point of the preparation lies in combination of quick heating and slow heating in the heating process, which is favorable for elimination and densification of air holes, and causes the crystal particles to be uniform in the processes of slow heating and heat preservation. In the method, the nanocrystalline MnZn powder is prepared by adopting a sol-gel spontaneous combustion method by direct sintering without a presintering re-ball milling process, the cycle is short and the process is relatively simple, thus reducing energy consumption and lowering labor cost. The nanocrystalline MnZn powder particles prepared by the sol-gel method have the advantages of even particles, huge activity, even and non-segregating components and high yield.

Owner:SHANGHAI UNIV

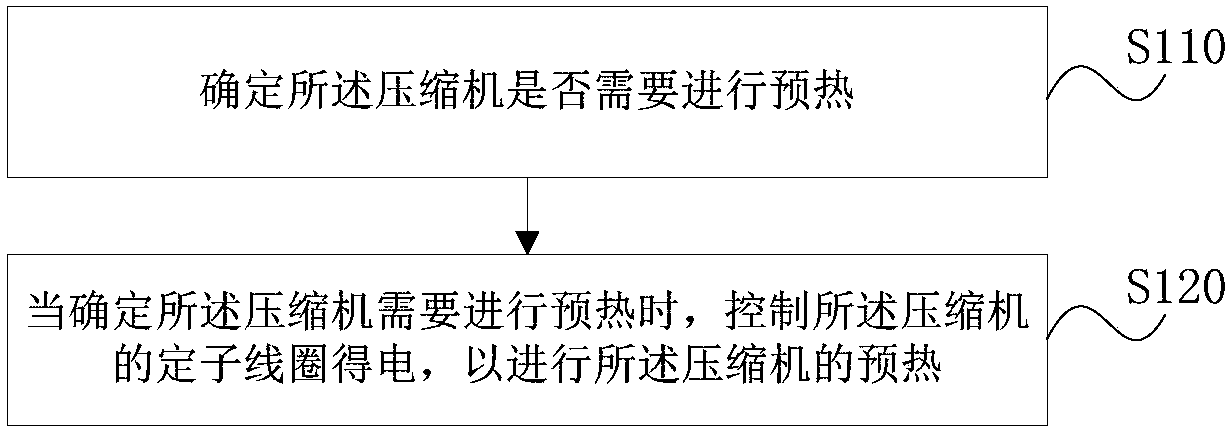

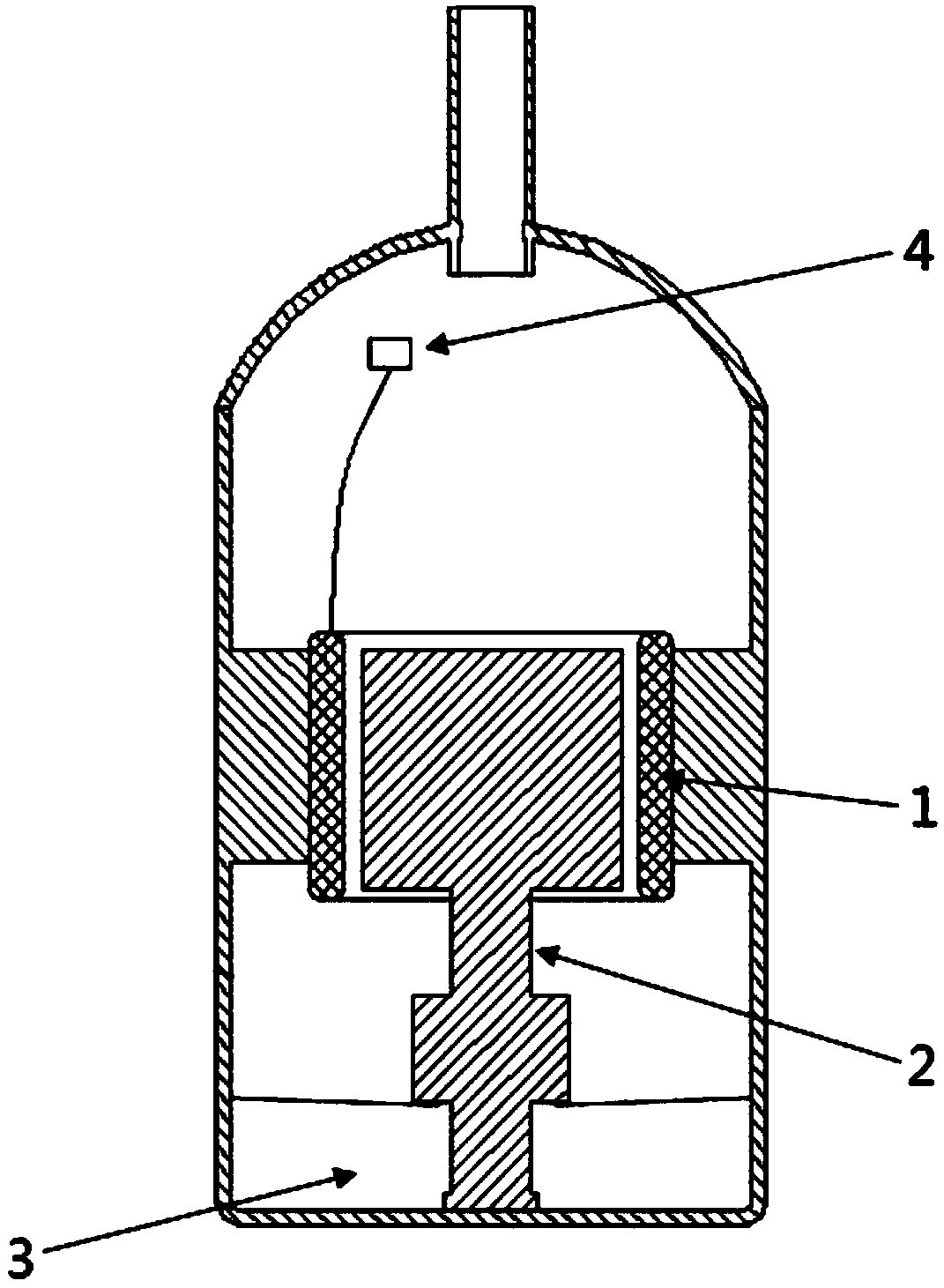

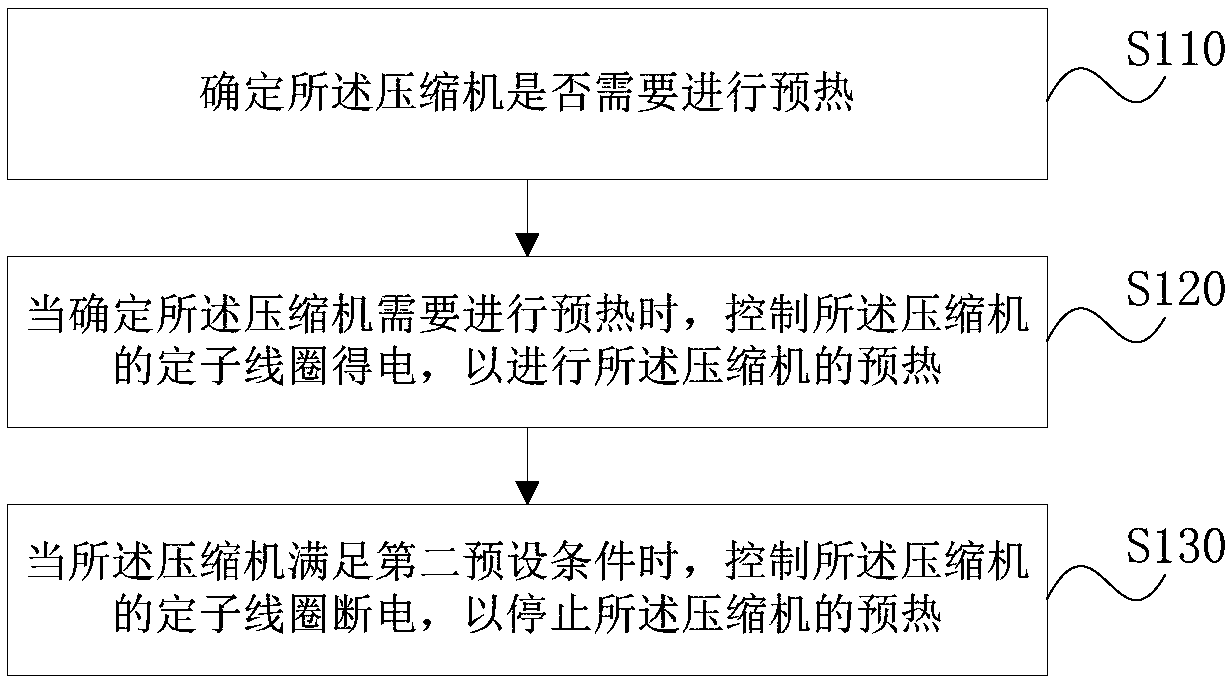

Preheating control method, device, storage medium and device for compressor

InactiveCN108374777AEfficient preheatingPositive displacement pump componentsPump controlElectricityStator coil

The invention provides a preheating control method, a device, a storage medium and a device for a compressor. The preheating control method comprises the following steps that whether the compressor needs preheating or not is determined; when the compressor is determined to be preheated, a stator coil of the compressor is controlled to generate electricity, so that the stator coil emits heat and then the heat is transmitted to an oil pool of the compressor through a rotor crankshaft of the compressor to preheat the compressor. According to the scheme, fast and efficient preheating of the oil temperature of the compressor can be realized and an original oil heating belt can be replaced, the problems of low heating efficiency and slow heating speed when an oil heating belt is used for preheating the compressor are solved.

Owner:GREE ELECTRIC APPLIANCES INC

Powder metallurgy method for preparing high-density complicated shape titanium alloy product

A powder metallurgy method for producing titanium alloy products with high density and a complicated shape by using Ti powder and additive powder containing Al, V, Fe, and Mo elements as raw materials, comprising mixing the Ti powder with a certain granularity proportion and the additive powder with a certain component range evenly, preparing powder green bodies by using a cold press forming method, using a multi-stage heating technique giving priority to middle-low temperature quick heating and high temperature slow heating during sinter process, performing quenching immediately after the heating process is completed, thereby prepares the Ti alloy sintering blank, and the titanium alloy products with high density and a complicated shape are finally produced by forge work and subsequent anneal process. Since the powder metallurgy technique has the characteristics of near net shape and easily control components, alloying is realized easily. At the same time, the high-usage of raw material is provided, the raw material cost and processing cost are saved, and the production energy consumption is reduced greatly. The method is suitable for producing titanium alloy products with high density and a complicated shape.

Owner:GUIZHOU TAIYI TECH DEV

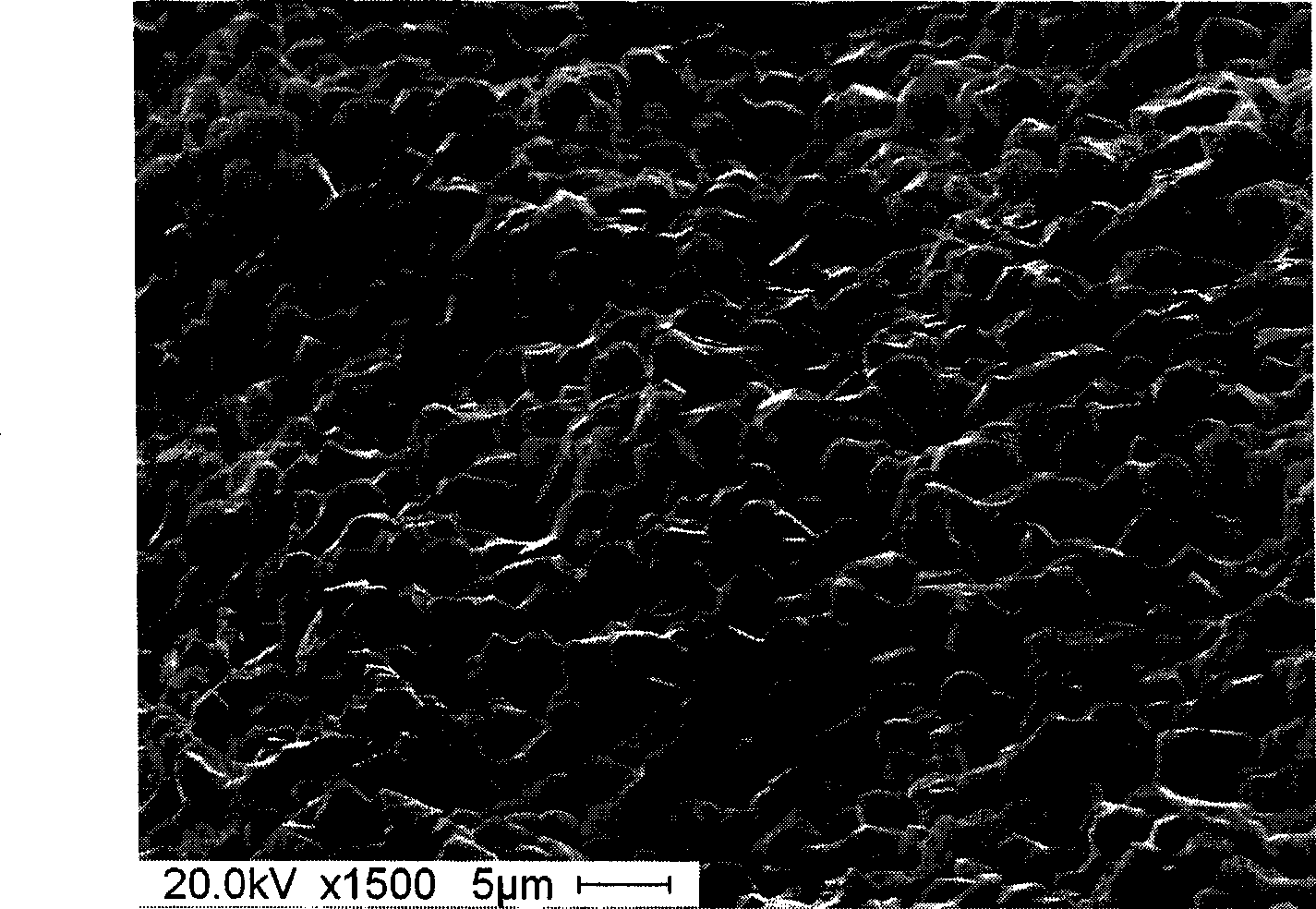

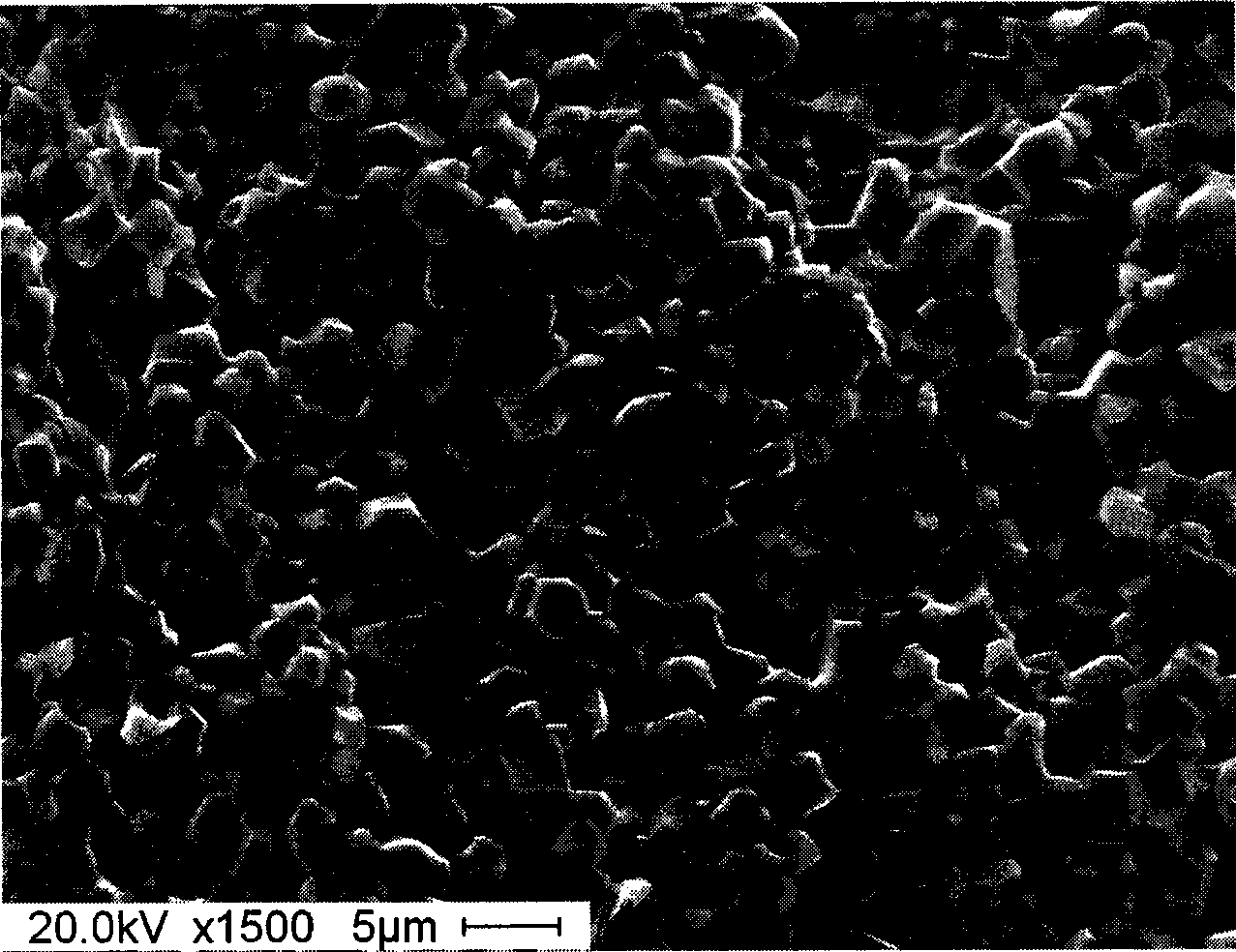

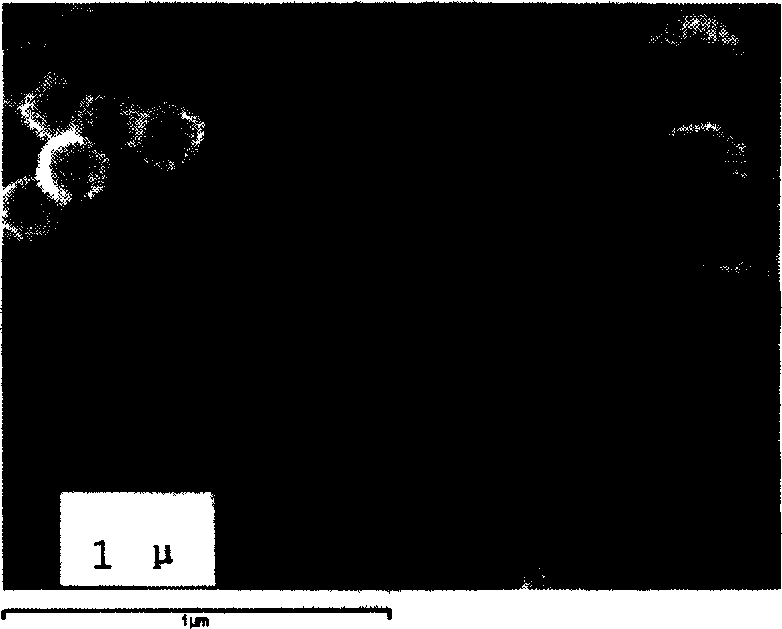

Magnetic iron oxide hollow microsphere particle having mesoporous structure and making method and uses thereof

InactiveCN1632889AControl thicknessThe method is time-saving and efficientInorganic material magnetismInductances/transformers/magnets manufactureIron saltsMicrosphere

This invention belongs to a compound particle inorganic hollow micro particle process technique field. This invention uses the method of two iron salt liquid control hydrolyze to process the hole magnetic ferric oxide to cover on the organic ball of polystyrene to get the nucleus or shell structure magnetic ferric oxide compound ball. It uses slow heating method and non-oxygen conditions to sinter the compound particles and the organic material in the particles to get the whole hole magnetic ferric oxygen hollow micro ball particles.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

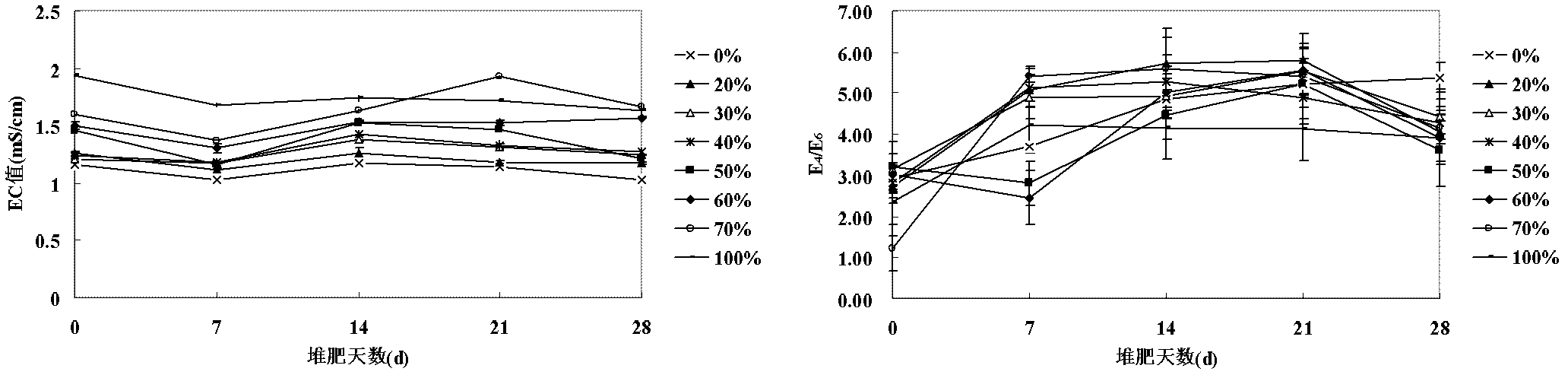

Method for changing kitchen garbage into fertilizer

ActiveCN102826878AFast heating rateReduce generationBio-organic fraction processingOrganic fertiliser preparationFecesLivestock manure

The invention discloses a method for changing kitchen garbage into a fertilizer. The method provided by the invention comprises the following steps of: mixing livestock manure, crop straw and kitchen garbage to obtain a mixture; and fermenting the mixture to obtain the fertilizer. An appropriate proportion of kitchen garbage is added into pig manure and straw which are used as main materials of compost, thus solving problems of unventilated defect, slow heating and generation of a lot of leachate and the like by individually composting. It shows through a fermenter composting test that heating speed of compost can be accelerated by the addition of residual kitchen garbage into straw and pig compost and simultaneously the generation of leachate can be greatly minimized. Germination rate indexes of residual kitchen garbage compost products added in any proportion are all greater than 80%, and the compost products all reach the putrescibility standard. Considering temperature, leachate, putrescibility and odor discharge together as a whole, the percentage of the added residual kitchen garbage is supposed to be controlled within 30% to 60%. In addition, by the adoption of the method, delivering quantity of house refuse can be effectively minimized, resources are saved, generation of malodorous gases is controlled, and the goal of energy saving and emission reduction is realized.

Owner:CHINA AGRI UNIV

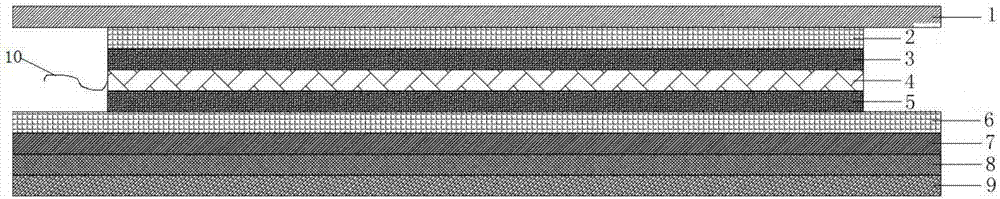

Composite graphene far-infrared floor heating brick and floor heating device

InactiveCN107178815AReduce energy consumptionHigh thermoelectric conversion rateHeating fuelLighting and heating apparatusBrickInsulation layer

The invention relates to a composite graphene far-infrared floor heating brick and a floor heating device, and relates to the technical field of decorative materials. A composite graphene far-infrared floor heating brick comprises fourteen layers of structures which are a ceramic tile layer, a first resin adhesive layer, a first pc flame-retardant insulation layer, a high-performance composite graphene heating film, a second pc flame-retardant insulation layer, a second resin adhesive layer, an aluminium foil layer, a glass fibre layer and a silicone rubber coating layer sequentially from top to bottom, wherein the high-performance composite graphene heating film is connected with an electric connection wire. A floor heating device comprises a plurality of the composite graphene far-infrared floor heating bricks which are arranged in parallel. The composite graphene far-infrared floor heating brick disclosed by the invention is thin and occupies a small indoor height, a heating layer clings to a floor tile layer, and is fast in heating and less in energy consumption, and the problems of large occupied indoor height and slow heating of a traditional floor heating device are solved.

Owner:李禹志

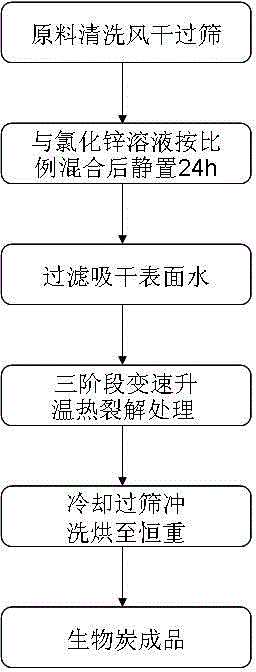

Method for preparing biochar by taking organic solid wastes of agriculture and forestry as raw materials in wet thermal cracking manner

InactiveCN104087326AWide variety of sourcesLower requirementBiofuelsSpecial form destructive distillationMoistureBiochar

The invention relates to a method for preparing biochar by taking organic solid wastes of agriculture and forestry as raw materials in a wet thermal cracking manner. The method comprises the following steps: cleaning, airing, crushing and screening raw materials, and then mixing and stirring the raw materials with 0.20mol / L zinc chloride solution according to the ratio of 1 to 10, and filtering the mixture after standing for 24 hours, wherein the moisture content of the raw materials is controlled between 45.23% and 69.65%; then putting the raw materials into a tubular atmosphere furnace, and carrying out heating cracking by taking nitrogen of which the flow rate is 0.1m<3> / h as a protective gas, wherein at the first stage, quick heating to 200 DEG C, and then heat preservation for 10 minutes are performed, and the heating rate is 50 DEG C / min; the second stage is a slow heating process, the heating rate is 5 DEG C / min, and heating to 350 DEG C and heat preservation for an hour are performed; the third stage is a slow heating stage, the heating rate is 1 DEG C / min, and heat preservation is performed for 2 hours after heating to 400 DEG C; finally screening the solid substances by a 200-mesh sieve; rinsing and baking into constant weight, so as to obtain a biochar product. The method is wide in raw material source, simple in process, and high in biochar yield; the produced biochar has excellent adsorptive property; the production additional value can be increased by tar, smoke and the like generated in the preparation process; the production cost is reduced.

Owner:ANHUI SCI & TECH UNIV

Copper-cerium solid solution catalyst for methane catalytic combustion, and preparation method thereof

InactiveCN101811054AGood effectLower combustion temperatureGaseous fuelsMetal/metal-oxides/metal-hydroxide catalystsAir atmosphereCerium

The invention aims to provide an effective copper-cerium solid solution catalyst for methane catalytic combustion, and a preparation method thereof. A preparation process of the catalyst comprises the following steps: weighing Ce(NO3)3.6H2O and Cu(NO3)2.3H2O according to a general formula CuxCe1-xO2, wherein x is between 0.1 and 0.9; dissolving Ce(NO3)3.6H2O and Cu(NO3)2.3H2O in deionized water to ensure that the total concentration of metal ions is 1 mol / L; adding citric acid in the same weight with the metal ions; stirring uniformly; standing the obtained product for 3 to 12 hours; slowly heating the obtained product in an oil bath at 50 to 80 DEG C to form gel; drying the obtained product for 12 hours at 110 to 150 DEG C; and roasting the obtained product for 4 to 12 hours in an air atmosphere at 500 to 800 DEG C to obtain a finished product of the catalyst. When the catalyst is used for methane catalytic combustion reaction, air is adopted as oxidant, so the combustion reaction is low in light-off temperature, low in complete combustion temperature and capable of ensuring the complete combustion of methane at 550 DEG C. The catalyst is a solid solution catalyst taking copper oxide or cerium oxide as active components, thereby having high content of active components and low price. The catalyst is prepared by a citric acid complexing sol-gel method, and has the advantages of easily operated preparation method, uniformly dispersed active components and good stability.

Owner:EAST CHINA UNIV OF SCI & TECH

Wicker mould and moth preventing treatment method

The invention discloses a wicker mould and moth preventing treatment method. The method comprises the following steps: 1) wickers are aired for 2-3 days under the sun at a temperature of 26-30 DEG C; 2) the aired wickers are put in a mixed treating agent (1), are slowly heated for 2-3 hours with soft fire, and are taken out for airing 1-2 hours; 3) the aired wickers are put in a mixed treating agent (2), are slowly heated for 1 hour with soft fire, and are taken out to put in a drying oven for drying 0.5-1 hour; and 4) dipping-slow heating with soft fire-drying-dipping-slow heating with soft fire-drying is circulated and repeated for two times according to the step 3). The method is simple in process and low in cost, and largely prolongs the service time of wickerwork manufactured by the wickers through adopting the double-layer protection; the mothproof time can reach above 8 years; and the wickerwork manufactured by the wickers can keep specific bamboo flavor, and has no any side effect on human bodies.

Owner:阜南县猛发工艺品有限公司

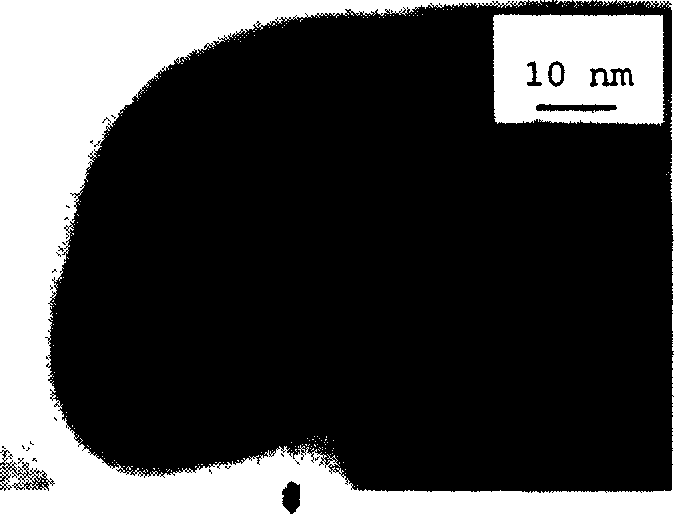

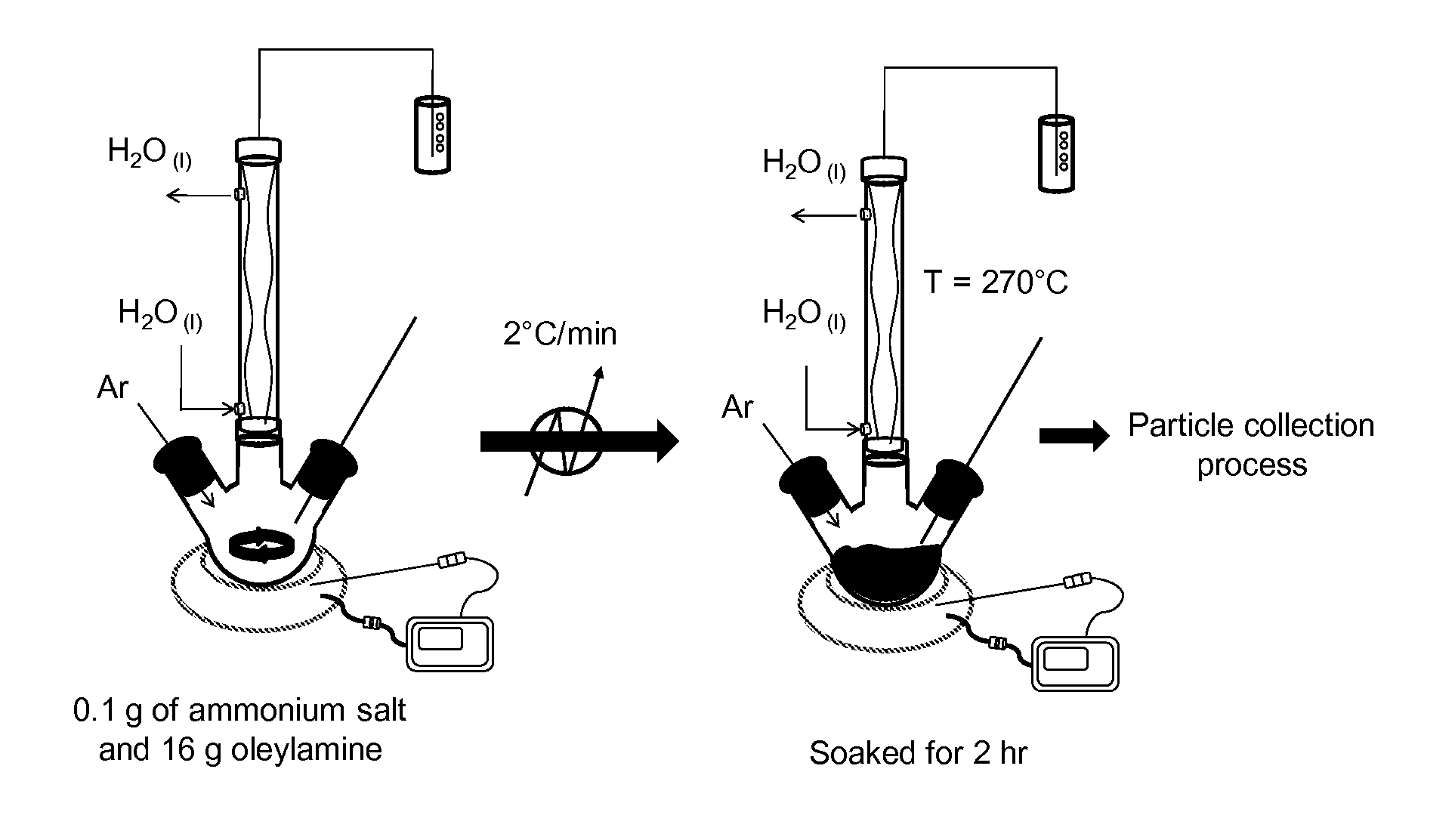

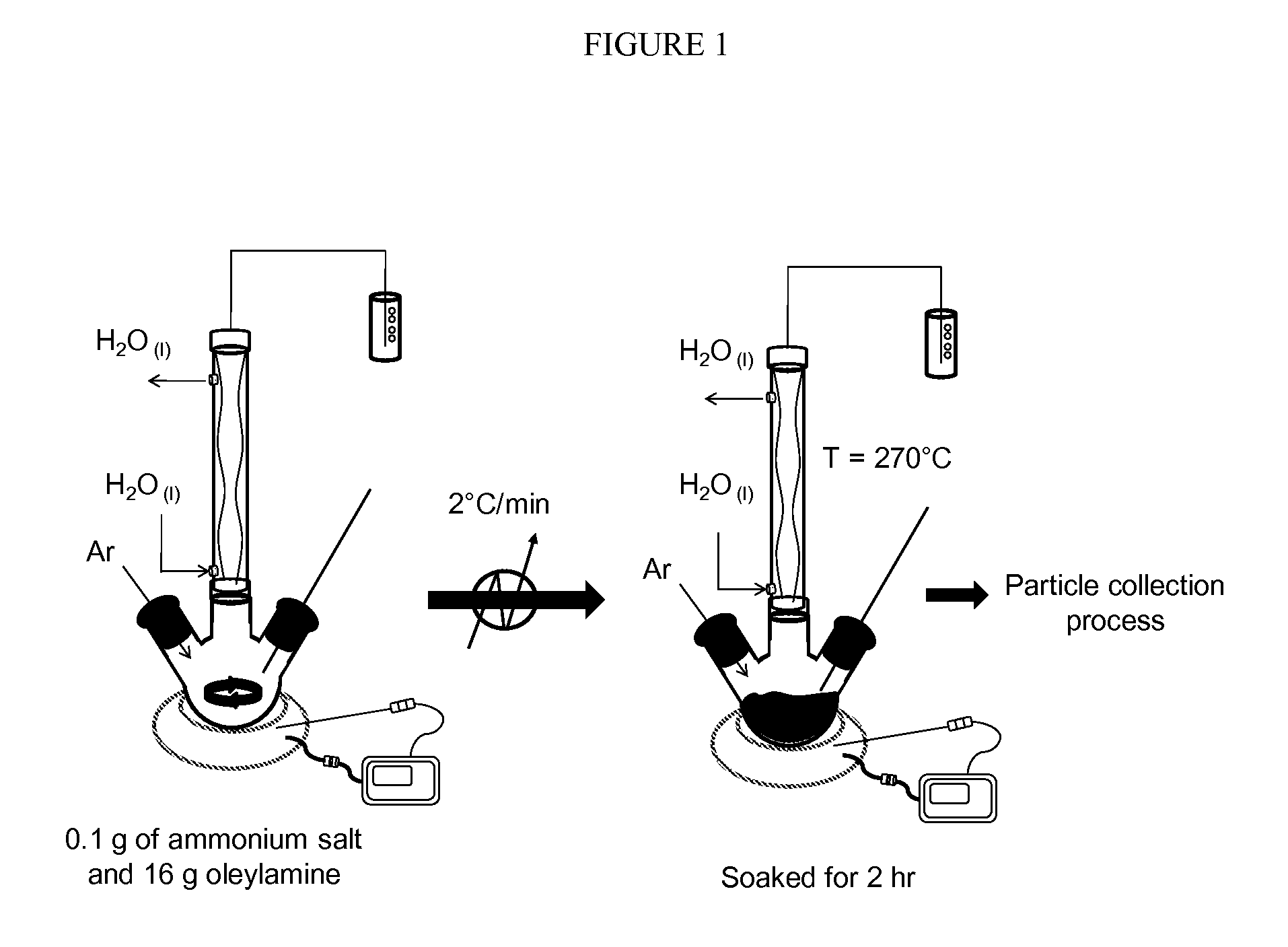

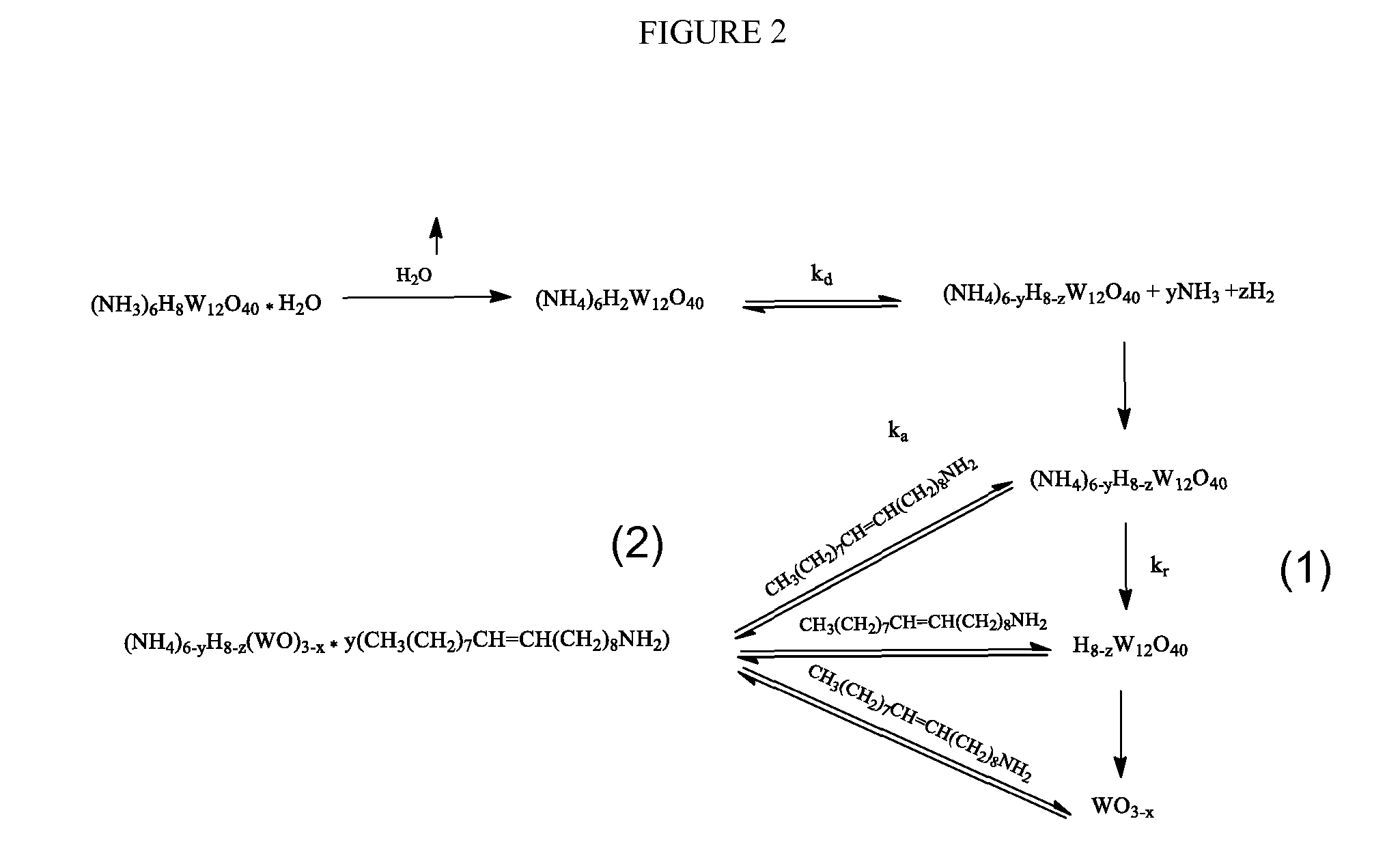

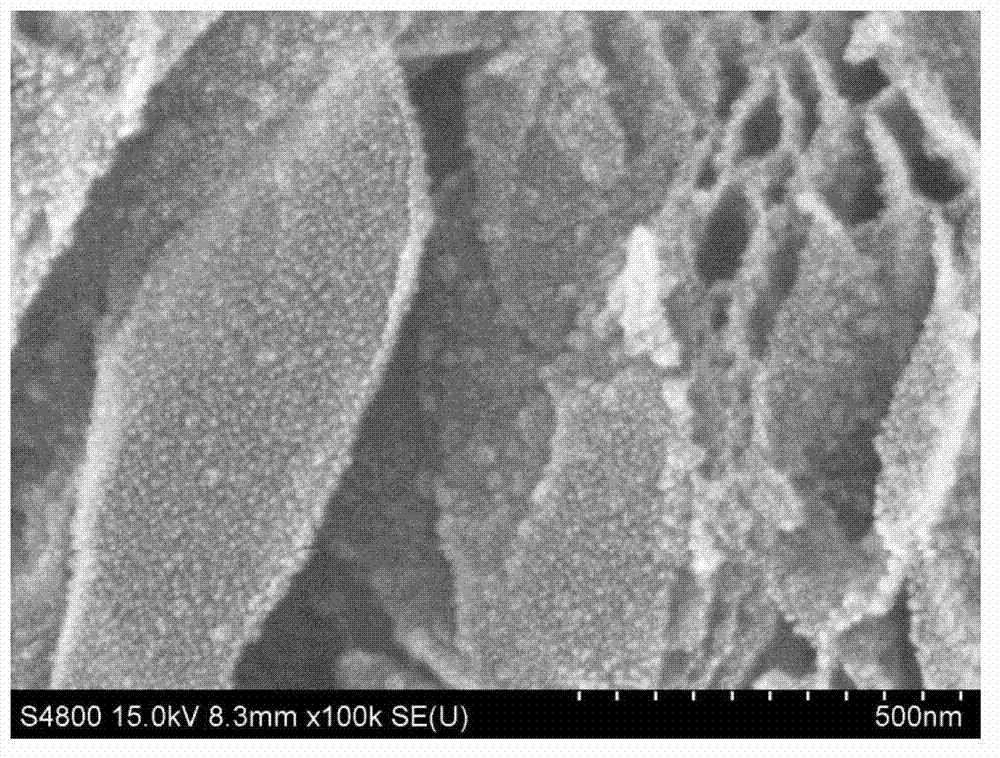

Synthesis of ultrasmall metal oxide nanoparticles

InactiveUS20130090511A1Great catalytic potentialSmall and uniformMaterial nanotechnologyOxide/hydroxide preparationMetal oxide nanoparticlesWater soluble

The invention generally relates to the ultrasmall MOx nanoparticles that are made in a solvothermal method using water soluble inorganic ammonium salt precursors of the MOx and organic amines, and slow heating to generate uniform ultrasmall MOx nanoparticles of 5 nm or less, as well as methods to make and use same.

Owner:RICE UNIV

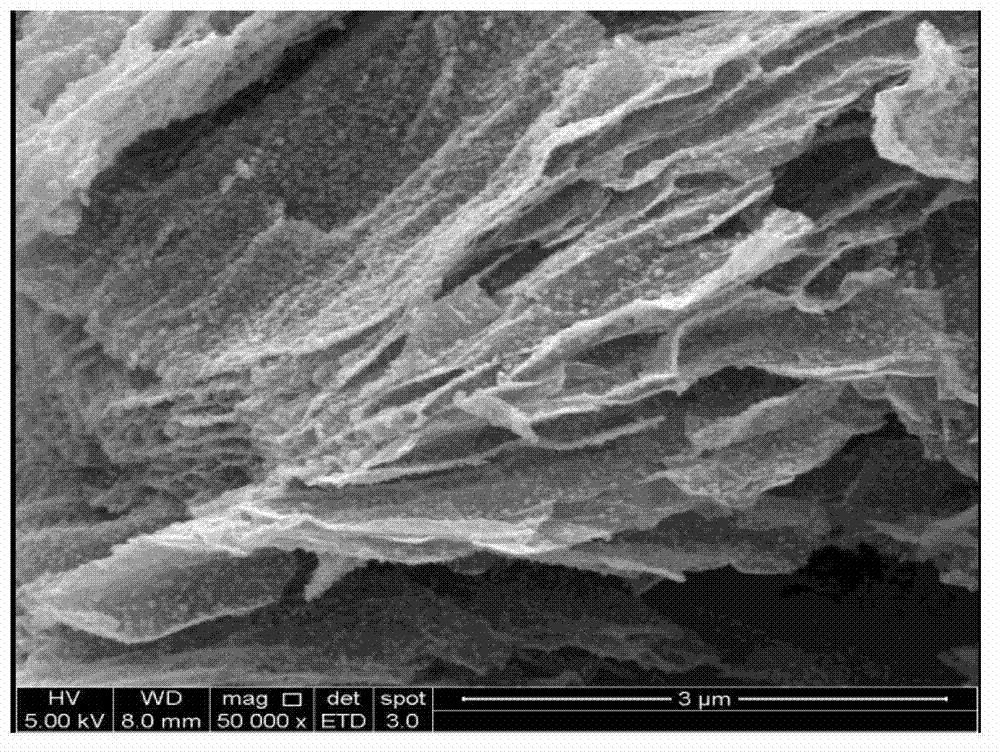

Method for preparing iron coated multi-layer graphene nano composite material by performing gaseous decomposition on pentacarbonyl iron

InactiveCN102887506AGood dispersionImprove antioxidant capacityMaterial nanotechnologyCarbon compoundsNano compositesShielding gas

The invention discloses a method for preparing an iron coated multi-layer graphene nano composite material by performing gaseous decomposition on pentacarbonyl iron. The method comprises the following steps of: 1) performing thermal expansion peeling on graphite oxide which is prepared by Hummers at high temperature to obtain multi-layer graphene; 2) putting a certain amount of multi-layer graphene in a reaction container, introducing protective gas for a certain period of time to discharge air in a flask out, and controlling an electric jacket to slowly heat a four-mouth flask to 200 to 250 DEG C; 3) in the continuous mechanical stirring and refluxing process, introducing pentacarbonyl iron steam into the reaction container at the protective atmosphere, and performing thermal decomposition and refluxing for a certain period of time, wherein the thermal decomposition temperature is 200 to 250 DEG C; and 4) after reaction, cooling to room temperature under the protection of gas to obtain the iron coated multi-layer graphene nano composite material. The process is simple and controllable, the price is low, and the industrial large-scale product is convenient to realize.

Owner:NANJING UNIV

Preparation method for silicon-dioxide-based carbon fiber composite adsorbent

InactiveCN105771887AReduce drying shrinkageImprove adsorption capacityGas treatmentOther chemical processesFiberN dimethylformamide

The invention particularly relates to a preparation method for a silicon-dioxide-based carbon fiber composite adsorbent. Firstly, tetraethyl orthosilicate (TEOS), redistilled water, absolute ethyl alcohol, N,N-dimethylformamide and ammonia water are mixed to prepare sol, then nanometer active carbon fiber is added, an extremely slow heating mode is adopted to heat a mixture to a certain temperature, a gel mixture is obtained and then subjected to aging, solvent exchange and hydrophobic modification, gel is cleaned by n-hexane, drying treatment is performed finally, and the silicon-dioxide-based carbon fiber composite adsorbent is obtained.

Owner:CHANGZHOU UNIV +1

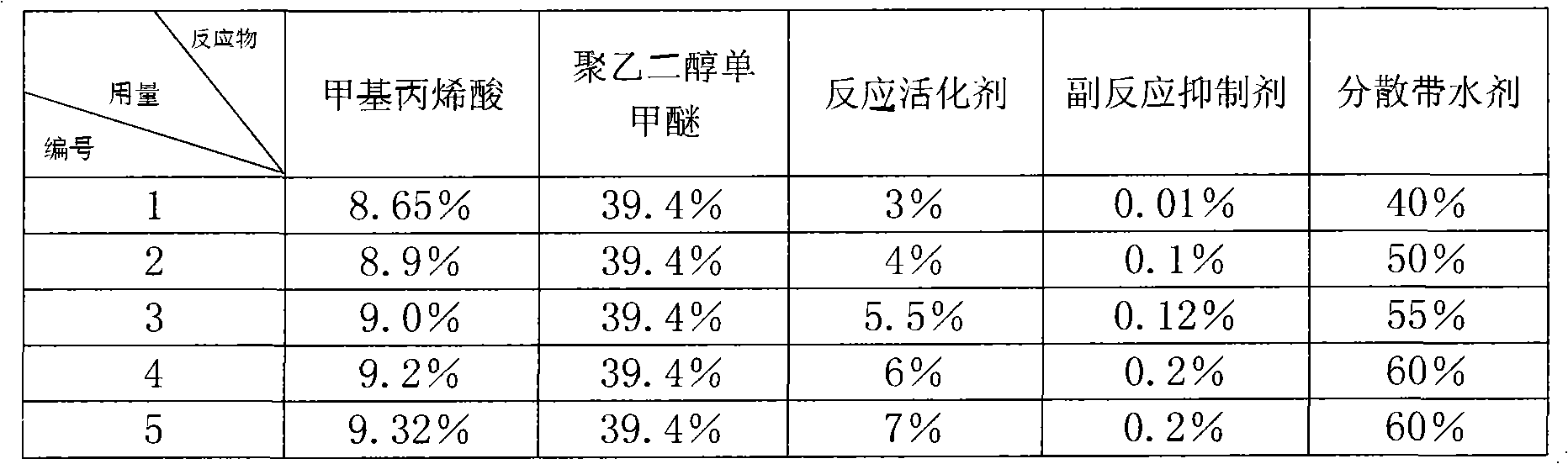

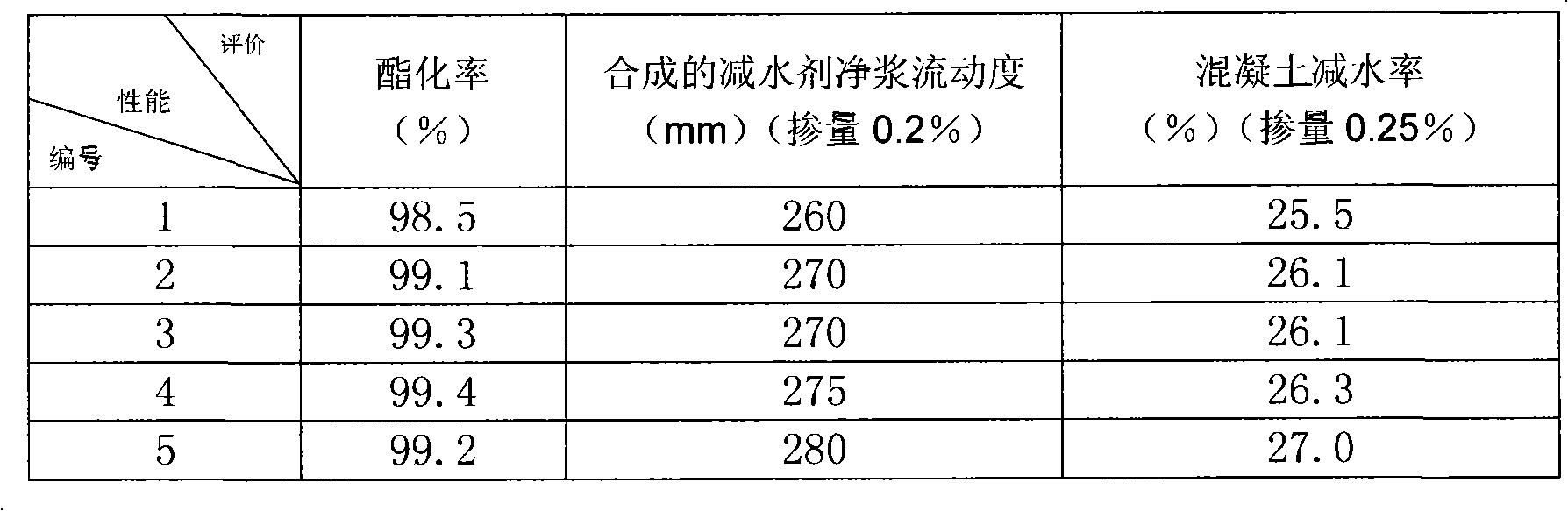

Methylacrylic acid polyethylene glycol single armor ether ester and preparation method thereof

InactiveCN101255113AOrganic compound preparationCarboxylic acid esters preparationMethacrylatePolyethylene glycol

The invention relates to poly ethyleneglycol monomethylether methacrylate which is monomer of polycarboxylic type concrete water-reducer and a preparation method thereof, wherein the reactants components (percentage by weight) comprises: 9. 32by weight of methacrylic acid, 39. 4by weight of Poly(ethylene glycol) Methyl Ether, 3-7by weight of reaction activating agent, 0. 01-0. 2by weight of side reaction suppressing agent, and 40-60by weight of water-carrying agent; adding all the components into a reactor by the proportion, slowly heating up, preserving heat at 80 degree C for 0. 5-1h, slowly raising temperature until the reactants azeotropy, reacting for 6-8h, naturally cooling to room temperature, and removing the impurity to obtain ethyleneglycol monomethylether methacrylate. The synthetic macromer by the method has steady quality, the esterification ratio can reach more than 99, the macromer can be directly used for synthesizing polycarboxylic type concrete water-reducer and other surface active agents, the prepared concrete water-reducer therewith has a high water-reducing ratio, and reaching to more than 28(wherein the mix amount is 0. 25) which has a better performance than like products, can satisfy the require for development of high performance concrete, and has a wide application future.

Owner:WUHAN HUAXUAN HIGH TECH

F6NM martensitic stainless steel cylinder-body forge piece and heat treatment method

ActiveCN107937828AReduce the risk of obsolescenceStable mechanical propertiesMartensitic stainless steelSS - Stainless steel

The invention relates to a F6NM martensitic stainless steel cylinder-body forge piece and a heat treatment method. According to the F6NM martensitic stainless steel cylinder-body forge piece and the heat treatment method, the high strength and the high low temperature impact toughness resistance can be met, cracks are avoided, and meanwhile, cracking and scrap of steel ingots during forging are avoided; and the F6NM martensitic stainless steel cylinder-body forge piece comprises, by mass, no more than 0. 04% of C, 0.30-0.50% of Si, 0.70-1.00% of Mn, 11.5-13.0% of Cr, 3.5-4.5% of Ni, 0.50-0.70%of Mo, 0.04-0.1% of V, no more than 0.020% of P and no more than 0.010% of S. The F6NM martensitic stainless steel cylinder-body forge piece has the advantages that the F6NM martensitic stainless steel cylinder-body forge piece after being subjected to component optimization adopts sectional-type constant-temperature slow heating, the charging temperature, the heating speed and the heat preservation time are strictly controlled, forging is strictly executed according to the new forging process, and heat treatment adopts the special heat treatment process of 550 DEG C constant-temperature heating, 1000 DEG C air quenching and three times of tempering at 690 DEG C, 630 DEG C and 590 DEG C. After production, product inspection dimensions confirm to the customer drawing requirements, a sampleis sampled and sent to a third party for being tested, the mechanical properties meet the index requirements, after multiple times of production, the mechanical properties of the F6NM martensitic stainless steel cylinder-body forge piece are all very stable, and the F6NM martensitic stainless steel production scrap risk is greatly reduced.

Owner:BAODING TECH CO LTD

Heat preservation system and method for batteries of electric vehicle

ActiveCN108281735AFast heatingAvoid problems that affect lifespanAir-treating devicesSecondary cellsElectrical batteryAutomotive battery

The invention provides a heat preservation system and method for batteries of an electric vehicle, belongs to the technical field of electric vehicles and aims at solving the problem that the serviceperformance is affected due to a slow heating rate on the batteries in the prior art. The heat preservation system for the batteries of the electric vehicle comprises a battery heating and heat preservation circulation line, a range extender circulation line and a temperature controller, wherein the battery heating and heat preservation circulation line is formed by connecting a motor circulationline and a battery circulation line through a control valve; the range extender circulation line comprises a first electronic water pump, a heater and a range extender; the battery circulation line isprovided with a temperature sensor; and the range extender circulation line is connected with the motor circulation line through a heat exchanger. The heat preservation method comprises the step as follows: the temperature controller controls the range extender and the heater to simultaneously work according to the temperature, monitored by the temperature sensor, of a battery pack, so that the battery pack is subjected to heating and heat preservation to normal working temperature through the battery heating and heat preservation circulation line or the battery circulation line. According tothe heat preservation system and method, the service performance of the batteries can be improved in a low temperature environment.

Owner:GUIZHOU GEELY ENGINE CO LTD +1

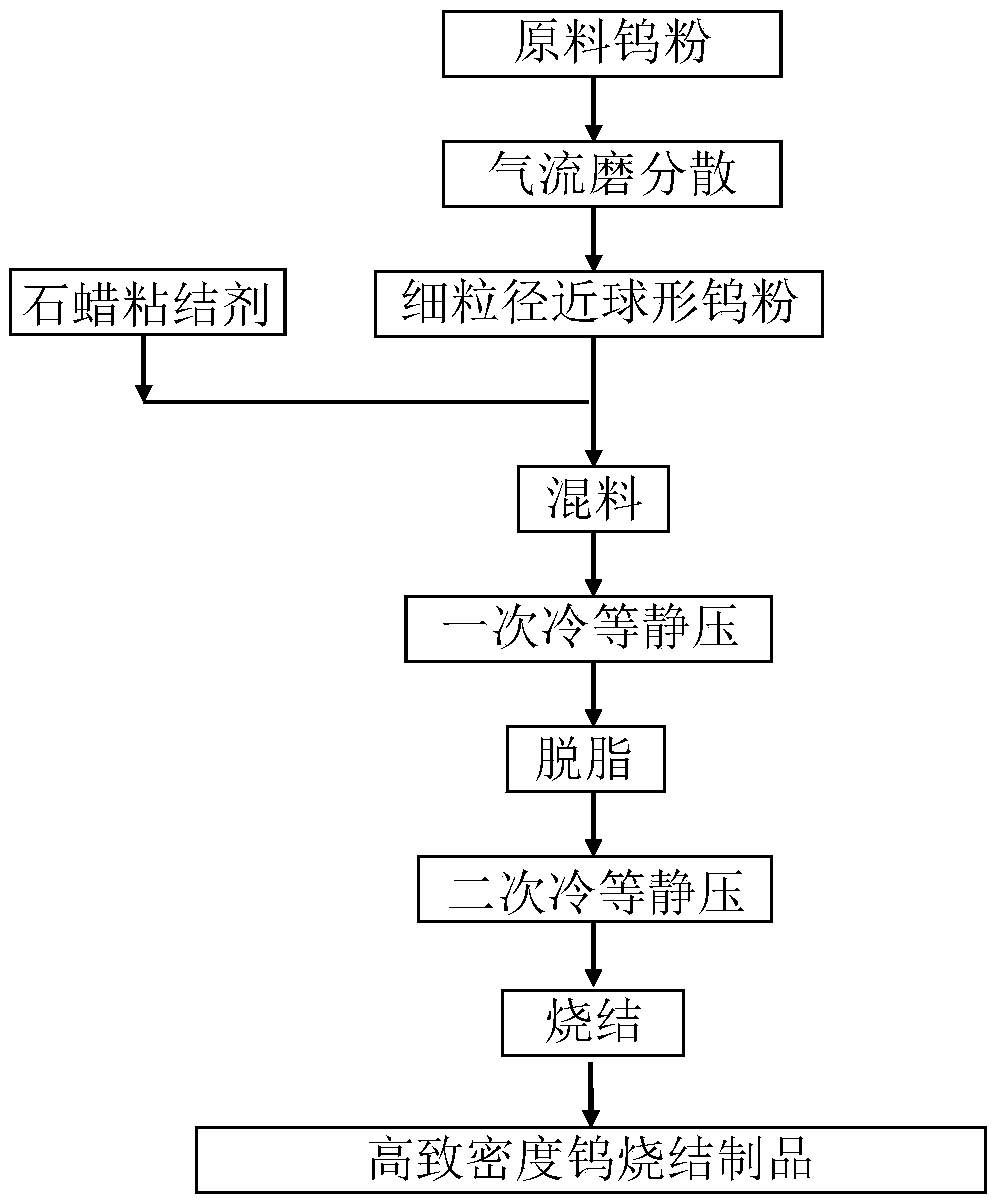

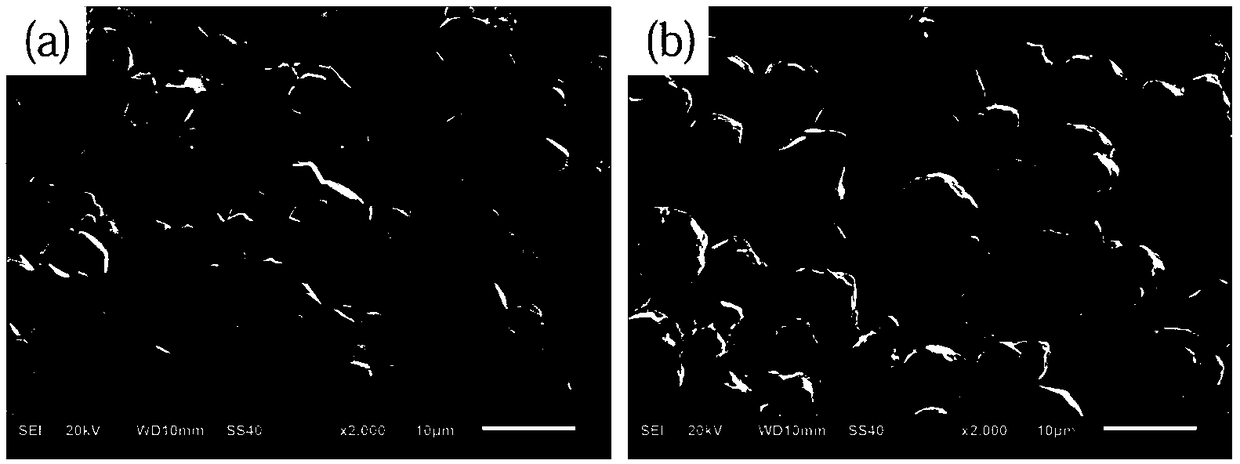

Method for preparing high-density tungsten sintered product

ActiveCN109047780AGood dispersionHigh surface energyTransportation and packagingMetal-working apparatusPrillHydrogen atmosphere

The invention discloses a method for preparing a high-density tungsten sintered product, and belongs to the technical field of powder metallurgy. Tungsten powder is subjected to airflow grinding treatment to obtain fine-grain-size tungsten powder, and the near-spherical fine-particle tungsten powder is uniformly mixed with a paraffin binding agent to obtain a mixture. A secondary cold isostatic pressing process is adopted, the mixed materials are pressed into a secondary blank at a low pressure in a static pressure mode, thermal degreasing is carried out in a hydrogen atmosphere so as to completely remove a binder, isostatic pressing is carried out on the degreased green body at high pressure to form a secondary green body, and a high-density and high-texture-uniformity thick tungsten slabis obtained by adopting a method of slowly heating at low temperature and rapidly heating at a high temperature. Through low-temperature sintering and slow heating, the green body can be sufficientlyrestored to reduce the oxygen content in the green body, the sintering activity of the green body is kept, high-temperature sintering and rapid heating can be achieved, grain growth can be reduced, the problem that a large-size thick tungsten plate is prone to local looseness and cracks is solved, the density of the obtained tungsten plate blank reaches 98% or more, and the uniform consistency ofthe surface of the slab and the central position structure can be ensured.

Owner:UNIV OF SCI & TECH BEIJING

High-speed steel cryogenic treatment process

The invention discloses a high-speed steel cryogenic treatment process which comprises steps as follows: (1), a workpiece which finishes heat treatment and is cooled to the room temperature is suspended above a liquid nitrogen level for 20-35 minutes, or placed in a low-temperature environment at the temperature ranging from subzero 130 DEG C to subzero 120 DEG C and cooled slowly for heat preservation for 30-40 minutes; (2) the workpiece is immersed into liquid nitrogen for cryogenic treatment at the temperature ranging from subzero 196 DEG C to subzero 180 DEG C for 3-5 hours; (3) the workpiece is directly taken out from the liquid nitrogen and placed in a warming device, slowly heated for 30-40 minutes and then placed in the air to be heated to the room temperature for slow heating treatment, wherein the initial temperature of the warming device ranges from subzero 130 DEG C to subzero 120 DEG C, and the temperature of the warming device can be controlled programmatically; (4), the steps are repeated for 2-3 times; and (5) the workpiece is placed in a muffle furnace with a set temperature of 200 DEG C, tempered for one hour and then air-cooled to the room temperature. According to the process, the treatment time is short, the treatment equipment is relatively cheap, and the treatment effect is more ideal.

Owner:SANMING UNIV

Electrical heating type cylindrical raw coal spontaneous combustion testing device and method

The invention discloses an electrical heating type cylindrical raw coal spontaneous combustion testing device and a method. The device comprises an electronic scale, an oxygen passing table arranged at one end of the pipeline of a deoxidation table; one end of the pipeline of the deoxidation table is connected with an air outlet pipe of a furnace cover of a cylindrical electrical heating furnace,a coal dump sample is placed in the cylindrical electrical heating furnace which is placed on the electronic scale; a thermocouple is connected with a data acquisition board which is connected with the electronic scale. The raw coal, granularity of which is the same as that of the raw coal at field, is loaded in the cylindrical electrical heating furnace; 4-6mm distance is kept between the upper part of the coal dump and the top of the cylindrical electrical heating furnace, which leads the coal dump and the oxygen in the air to have enough contact space, and the coal dump is heated; when being heated to a high enough temperature, the coal dump is reacted with a great amount of oxygen to maintain continuous spontaneous combustion, which causes that the amount of the oxygen in the peripheryreduces rapidly, the oxygen absorbing ability of the coal which is easy to spontaneously combust is stronger; the oxygen absorbing ability of the coal which is not easy to spontaneously combust is weak, so that the change of the oxygen amount at the upper part of the coal dump can reflect spontaneous-combustion tendency of the coal sample, and distinguishes spontaneous-combustion tendency of thecoal sample in the slow heating up process.

Owner:XIAN THERMAL POWER RES INST CO LTD

Manufacturing method of transparent pea green-color thin glaze of Ru porcelain

ActiveCN104496416AAchieve breakthroughRich cultural connotationClaywaresAlkaline waterThermal insulation

The invention discloses a manufacturing method of transparent pea green-color thin glaze of Ru porcelain. The manufacturing method comprises the following steps of respectively taking 5-10% of melilith, 10-20% of calcite, 45-65% of white feldspar, 15-22% of black feldspar, 5-10% of quartz and 1-3% of plant ash as glaze materials, crushing the glaze materials to powder of 40 meshes, carrying out grinding, removing floating iron in the glaze slurry by a magnet rod so that glaze is obtained, taking kaolin as a blank material, adding 45-50wt% of water and 0.3-0.5wt% of an alkaline water aqua into the blank material, carrying out wet grinding for 8-13h, preparing a blank from the slurry, sintering the blank to a temperature of 800-900 DEG C, carrying out natural cooling to obtain a biscuit, carrying out glazing on the biscuit, finishing the bottom, the surface glaze layer and a nonuniform part, putting the finished biscuit into a kiln, carrying out gradual heating to a temperature of 1040 DEG C in an oxidation atmosphere, carrying out slow heating to a temperature of 1250 DEG C in a reduction atmosphere, carrying out thermal insulation for 10min, stopping heating and carrying out cooling.

Owner:河南弘汝文化艺术有限公司

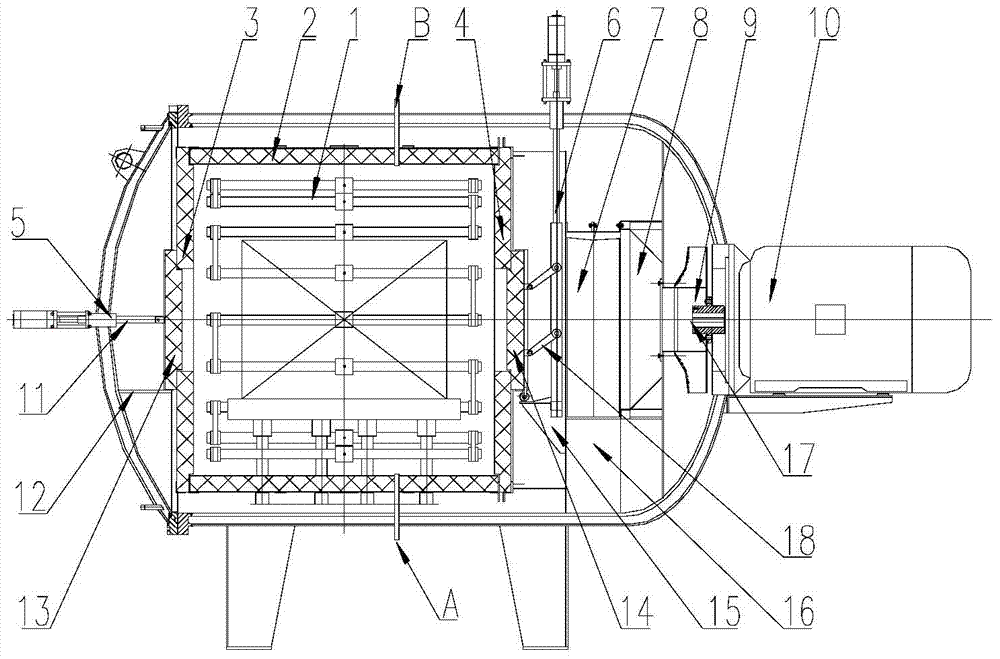

A horizontal high-pressure gas quenching-tempering-nitridation vacuum multipurpose furnace

ActiveCN104195503AAutomate program operationWith manual operation functionSolid state diffusion coatingFurnace typesTemperingEngineering

The invention discloses a horizontal high-pressure gas quenching-tempering-nitridation vacuum multipurpose furnace and relates to the field of metal vacuum thermal treatment. The furnace comprises a vacuum furnace main body, a heating chamber, a wind cooling system, a vacuum unit, a gas supplying system and an electric control system. The heating chamber comprises heating elements, a cylinder, a front cover and a back cover. The front cover and the back cover are provided with wind guiding holes. An air cylinder drives movable doors to open and close the wind guiding holes so as to guarantee circular flowing of cooling gas during tempering and gas quenching and to guarantee a closed structure of the heating chamber during nitridation. The furnace overcomes the disadvantages caused by adoption of metal nitridation tanks adopted by nitridation furnaces at present, namely slow heating and cooling speeds, low atmosphere pressure, and the like. The furnace is provided with using conditions for high-pressure high-flow-rate quenching and tempering, is simple in structure and practical, and truly achieves the using requirements on vacuum multipurpose furnaces.

Owner:北京华翔电炉技术有限责任公司

Method of synthesizing low-oxygen superfine cobalt powder

The invention relates to the preparation of cobalt powder, in particular to a method of synthesizing low-oxygen superfine cobalt powder. The method includes the steps of 1, controlling cobalt salt which is soluble and ammonium bicarbonate or alkali to react at room temperature according to a certain ratio, under the PH value of 6 to 7; 2, stopping addition of the cobalt salt, continuing to add the ammonium bicarbonate to adjust the PH value to above 7.1, performing slow heating to 45 to 60 DEG C, and allowing ageing reaction to form cobalt precursor; 3, subjecting the cobalt precursor to hydrogen reduction under certain conditions, subjecting reduced cobalt powder to cooling and passivation in the protective atmosphere so as to form a dense protective film on the surface of the cobalt powder and to reduce contact area of the cobalt powder with air, and performing jet crushing, mixing, screening and vacuum packaging in the protective atmosphere to obtain low-oxygen superfine cobalt powder. The method has the advantages that particle size and density of the cobalt powder can be controlled and the low-oxygen cobalt powder is convenient to store.

Owner:JINGMEN GEM NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com