Method for preparing iron coated multi-layer graphene nano composite material by performing gaseous decomposition on pentacarbonyl iron

A technology of nanocomposite materials and multilayer graphene, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of high saturation magnetization, unfavorable popularization and application, serious agglomeration, etc., and achieve strong magnetic performance and application Wide range of effects with low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Take 20 mg of graphite oxide and put it in a crucible, wrap it with tin foil paper, push it into a tube furnace at 300 ° C for 3 minutes of thermal expansion treatment, put 1000 mg of the obtained multi-layer graphene into a four-necked flask, and connect the four-necked flasks to Condenser, temperature controller, mechanical stirrer, air inlet pipe. Nitrogen was introduced for 10 minutes to remove the air, and at a stirring speed of 180 r / min, the four-neck flask was slowly heated to 220° C. with an electric heating mantle for condensation and reflux. Continue with N 2 As a guide gas, guide iron pentacarbonyl vapor into a four-necked flask for thermal decomposition, N 2 The flow rate was 120ml / min, and the reaction lasted 60min. in N 2 Gradually lowered to room temperature under protection, and the obtained light-weight sample was the carbonyl-iron-iron-coated multilayer graphene nanocomposite.

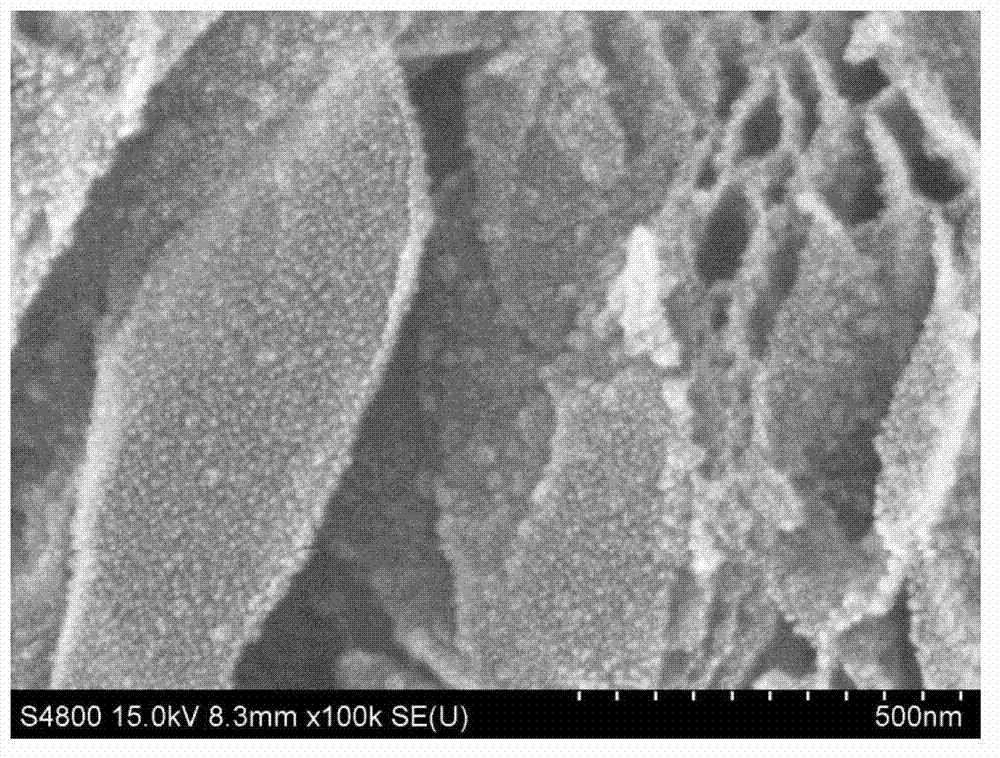

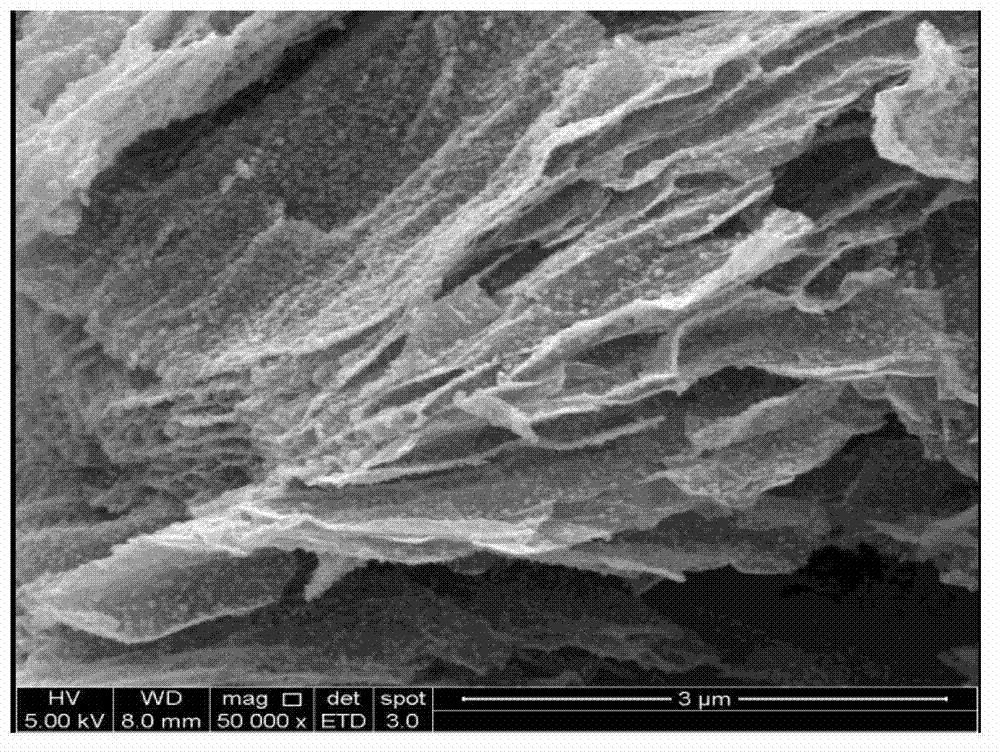

[0031] figure 1 and 2 High-magnification and low-magnification sca...

Embodiment 2

[0036] Take 20 mg of graphite oxide and put it in a crucible, wrap it with tin foil paper, push it into a tube furnace at 500 ° C for 5 minutes of thermal expansion treatment, and obtain multi-layer graphene. Put 1000 mg of multi-layer graphene into a four-necked flask. The flask is connected with a condenser tube, a temperature controller, a mechanical stirrer and an air inlet tube respectively. Nitrogen (N 2 ) for 10 minutes, and under the condition of a stirring speed of 180r / min, use an electric heating mantle to slowly heat the four-neck flask to 240°C for condensation and reflux. Use N 2 As a guide gas, guide carbonyl iron vapor into the four-necked flask for decomposition, N 2 The flow rate was 120ml / min, and the reaction lasted 180min. in N 2 Gradually lower to room temperature under protection. The obtained sample is the iron-coated multilayer graphene nanocomposite material.

[0037] Figure 4 It is a transmission electron microscope image of the iron-coated g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com