Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

424 results about "High saturation magnetization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

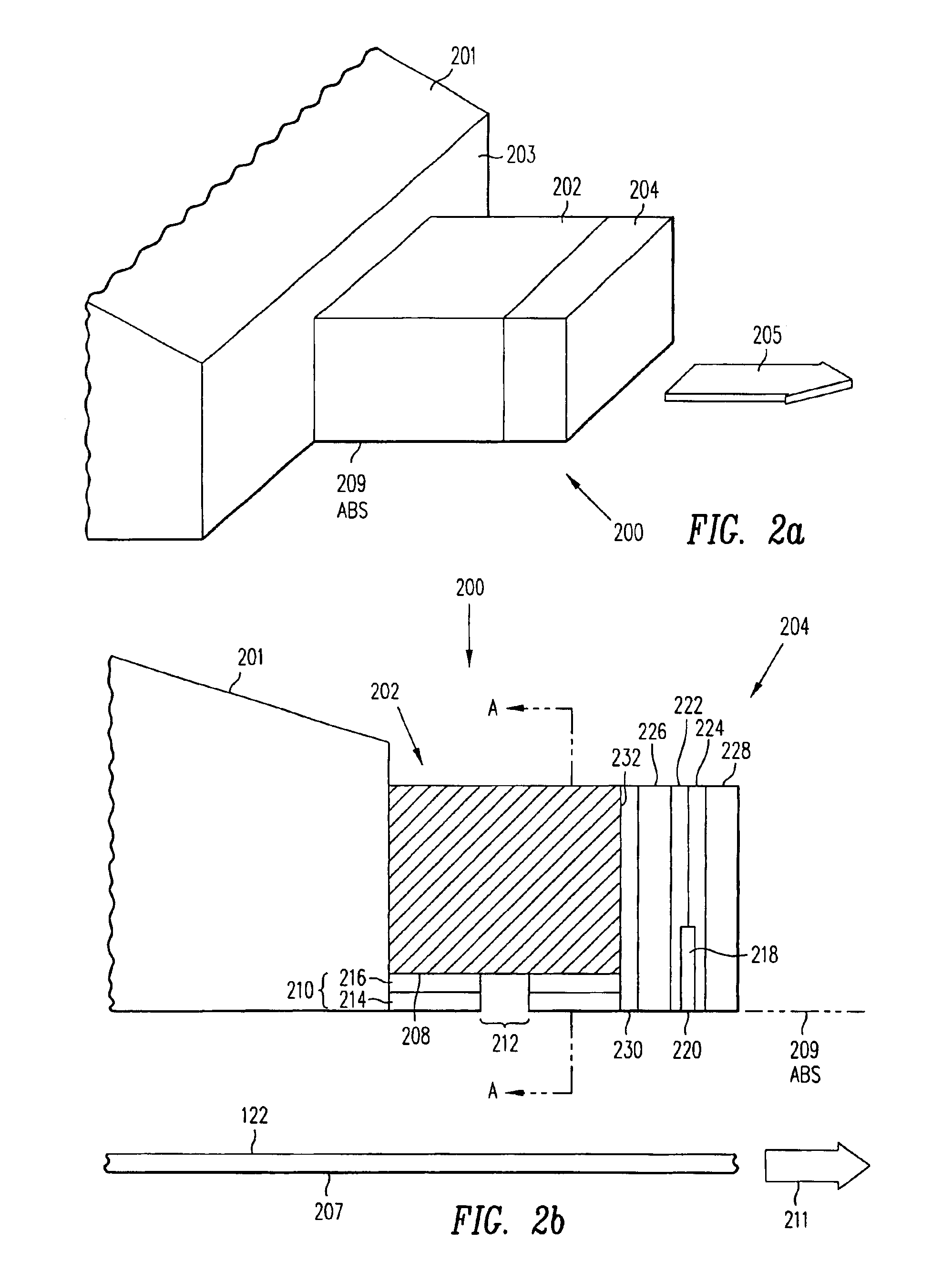

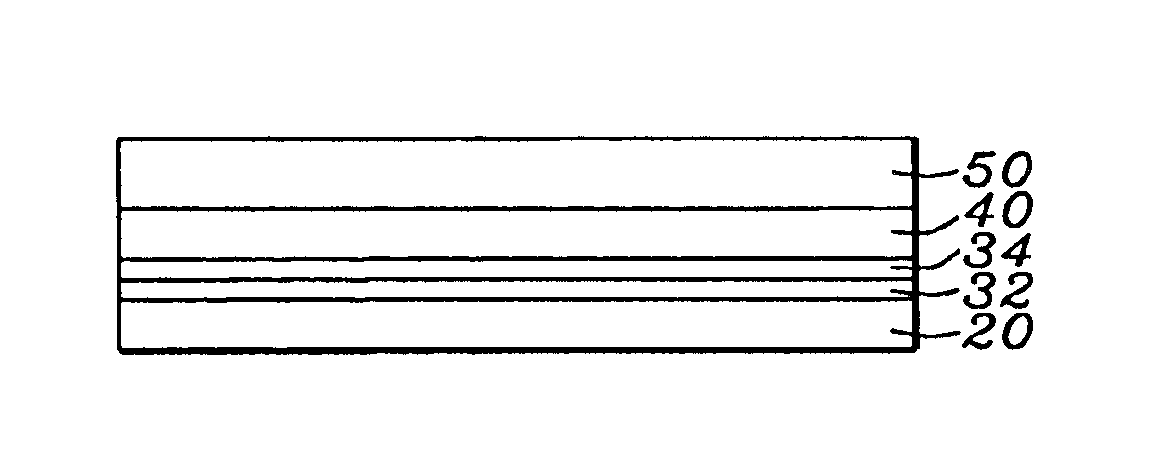

Magnetic media with improved exchange coupling

InactiveUS6899959B2Easy and fast switchingImprove thermal stabilityDifferent record carrier formsRecord information storageInter layerMagnetic media

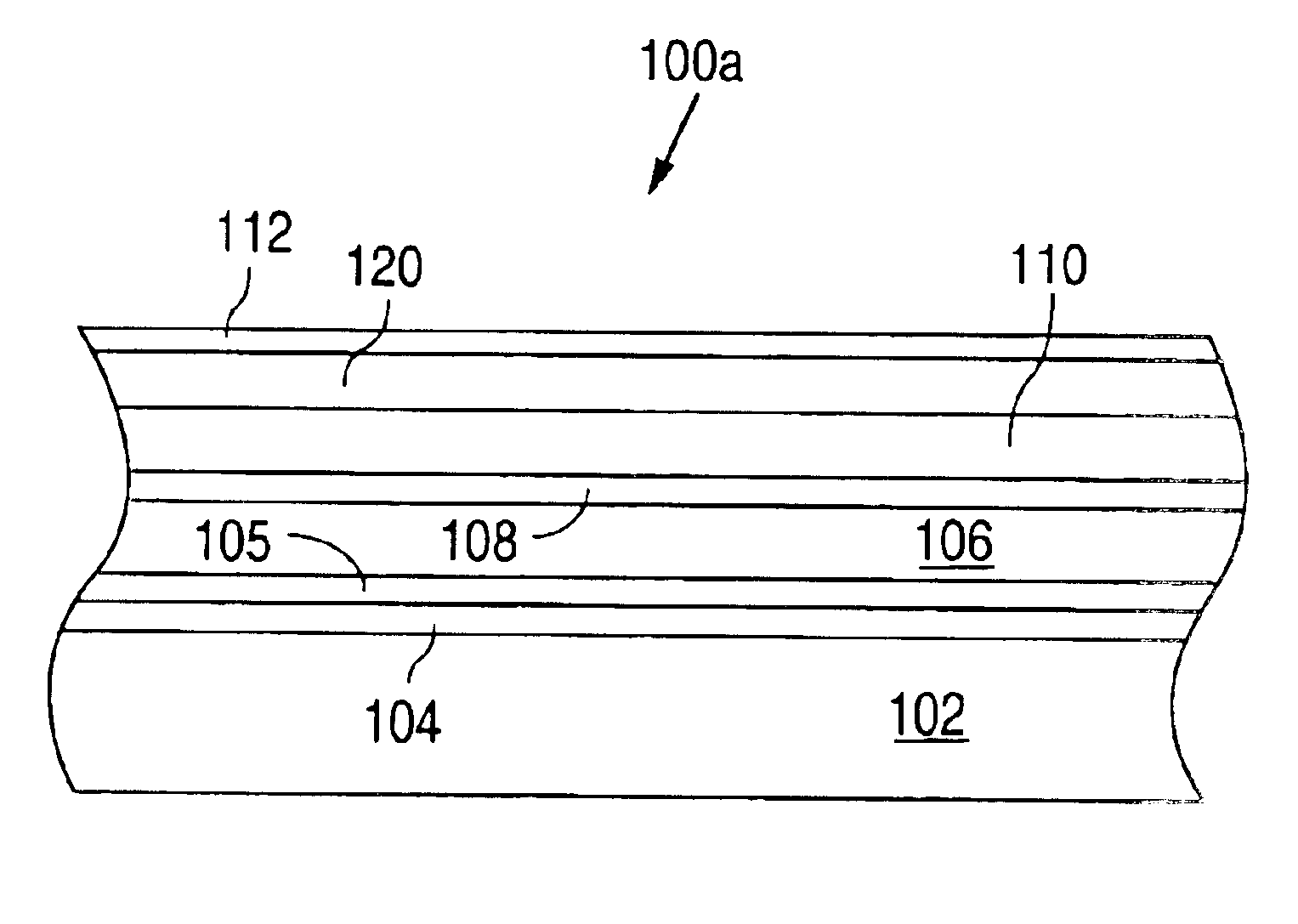

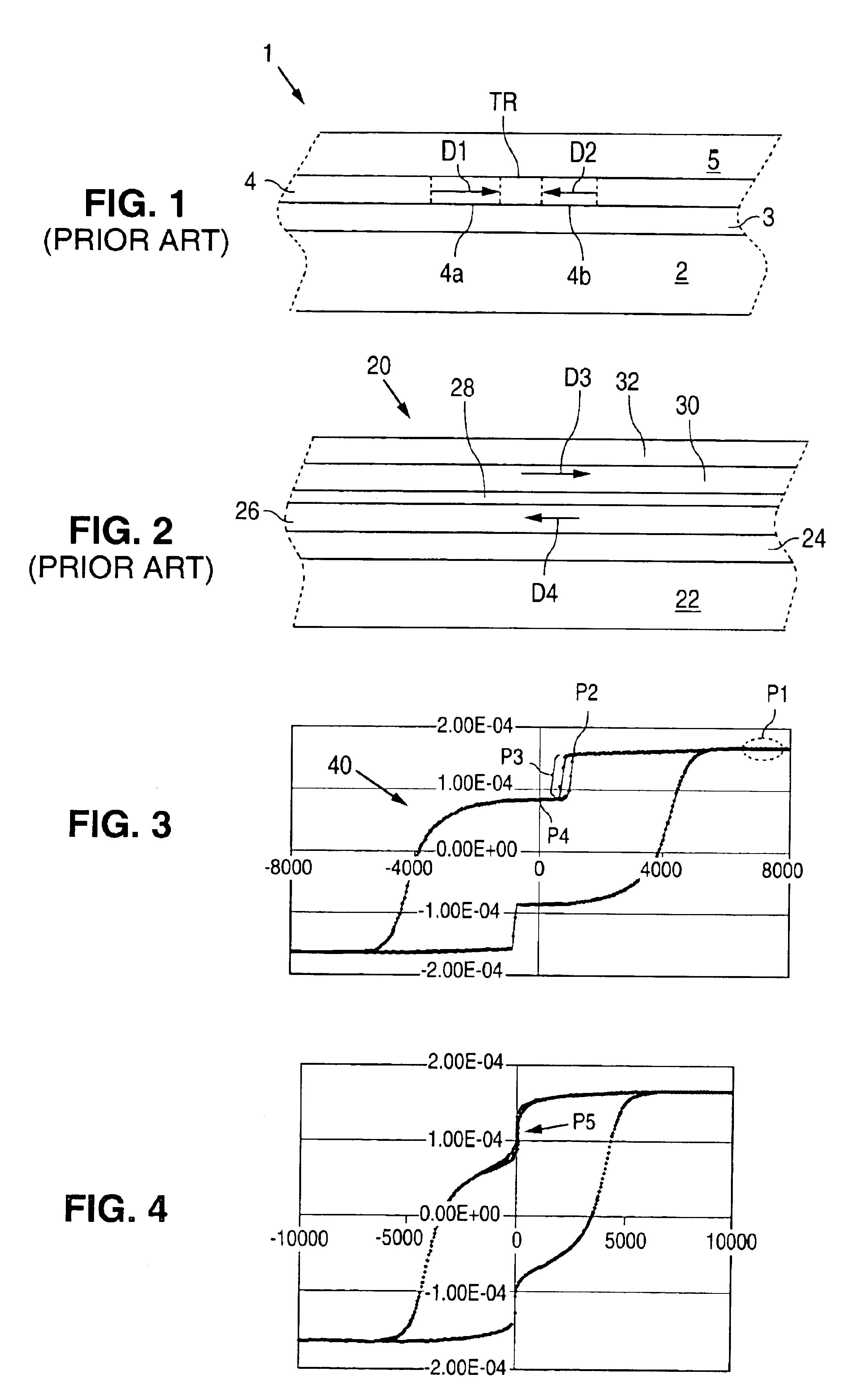

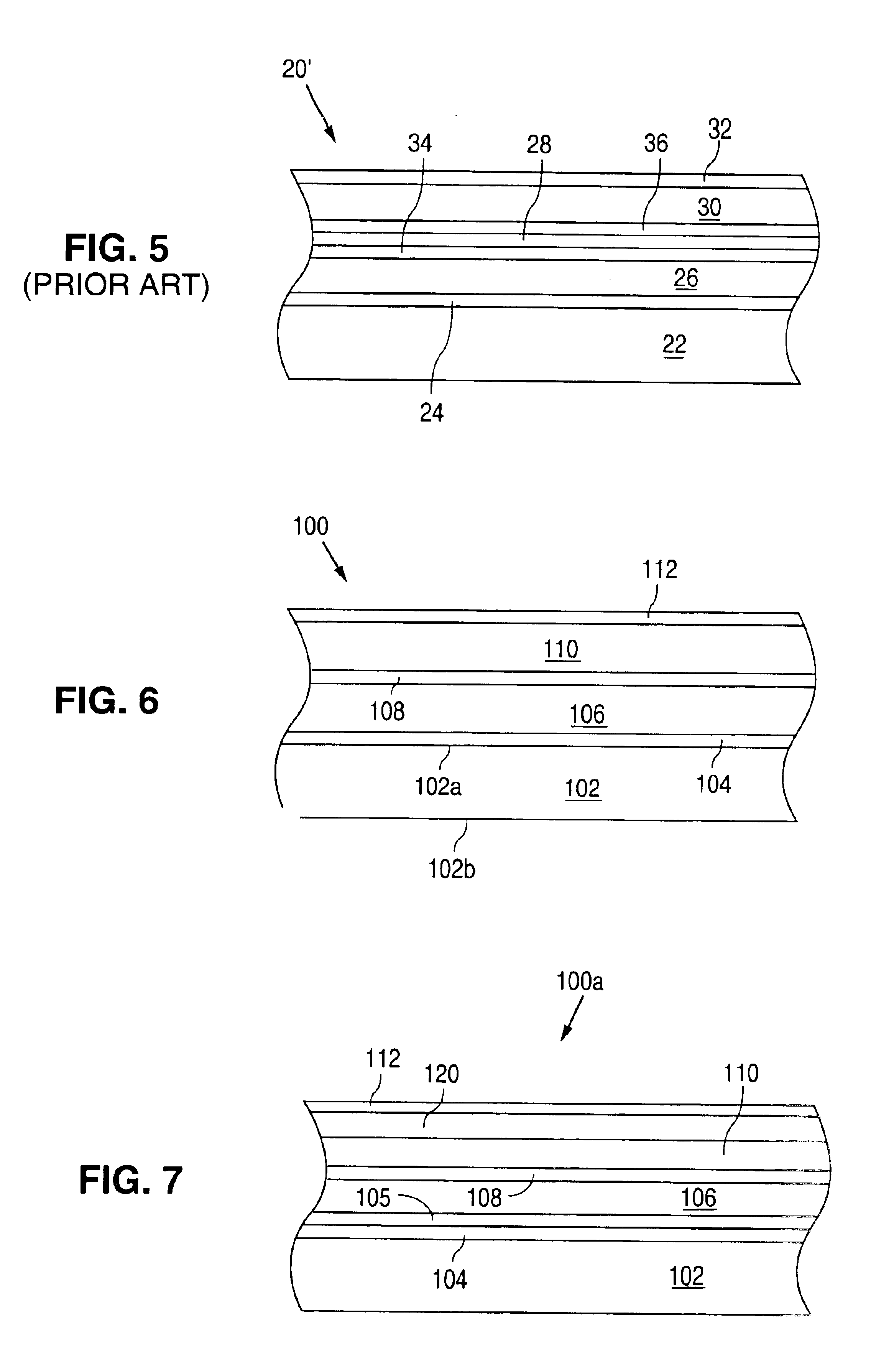

A magnetic recording medium includes a substrate, an underlayer, a lower magnetic layer formed on the underlayer, an intermediate layer, and an upper magnetic layer formed on the intermediate layer. The intermediate layer is typically Ru, and promotes antiferromagnetic coupling between the upper and lower magnetic layers. The upper and lower magnetic layers are typically Co alloys. The lower magnetic layer has a high saturation magnetization Ms to promote high exchange coupling between the upper and lower magnetic layers. The dynamic coercivity of the lower magnetic layer is lower than the exchange field to ensure rapid switching of the lower magnetic layer.

Owner:WESTERN DIGITAL TECH INC

‘Thermal spring’ magnetic recording media for writing using magnetic and thermal gradients

InactiveUS6881497B2Avoid thermal instabilityRapid coolingSoldering apparatusRecord information storageMagnetic gradientMagnetic media

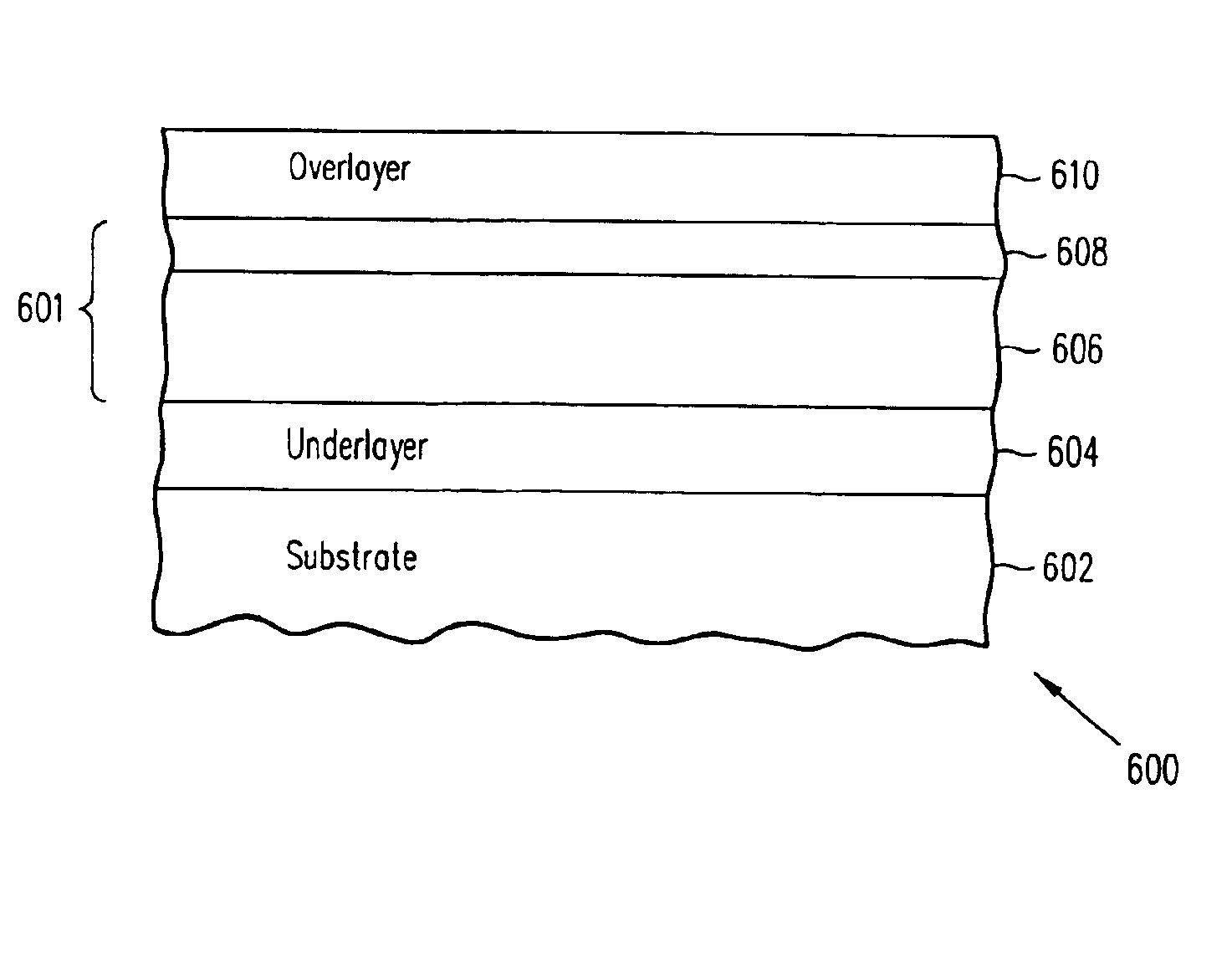

A thermal spring magnetic medium is provided having first and second stacks providing two exchange coupled ferromagnetic layers having different Curie temperatures. The first stack has a high magneto-crystalline anisotropy, a relatively low saturation magnetization and a low Curie temperature. The second stack has a relatively low magneto-crystalline anisotropy, a high saturation magnetization and a high Curie temperature. Preferably the first stack includes an alloy of Fe—Pt or Co—Pt, and the second stack includes an allow of Co—Pt or Co—Pd. A disk drive system having the novel medium is also provided.

Owner:WESTERN DIGITAL TECH INC

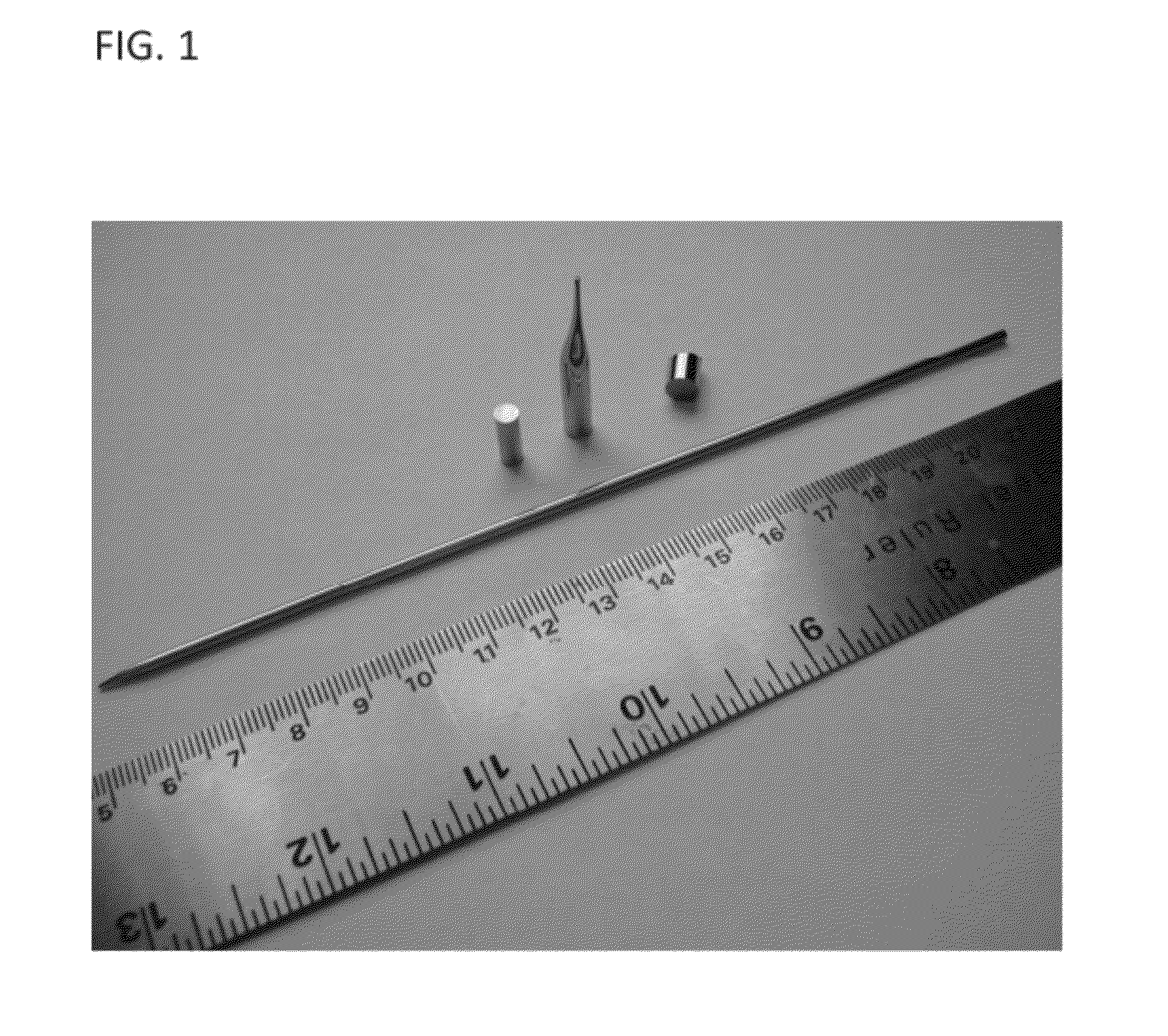

Tough iron-based bulk metallic glass alloys

A family of iron-based, phosphor-containing bulk metallic glasses having excellent processability and toughness, methods for forming such alloys, and processes for manufacturing articles therefrom are provided. The inventive iron-based alloy is based on the observation that by very tightly controlling the composition of the metalloid moiety of the Fe-based, P-containing bulk metallic glass alloys it is possible to obtain highly processable alloys with surprisingly low shear modulus and high toughness. Further, by incorporating small fractions of silicon (Si) and cobalt (Co) into the Fe—Ni—Mo—P—C—B system, alloys of 3 and 4 mm have been synthesized with high saturation magnetization and low switching losses.

Owner:CALIFORNIA INST OF TECH

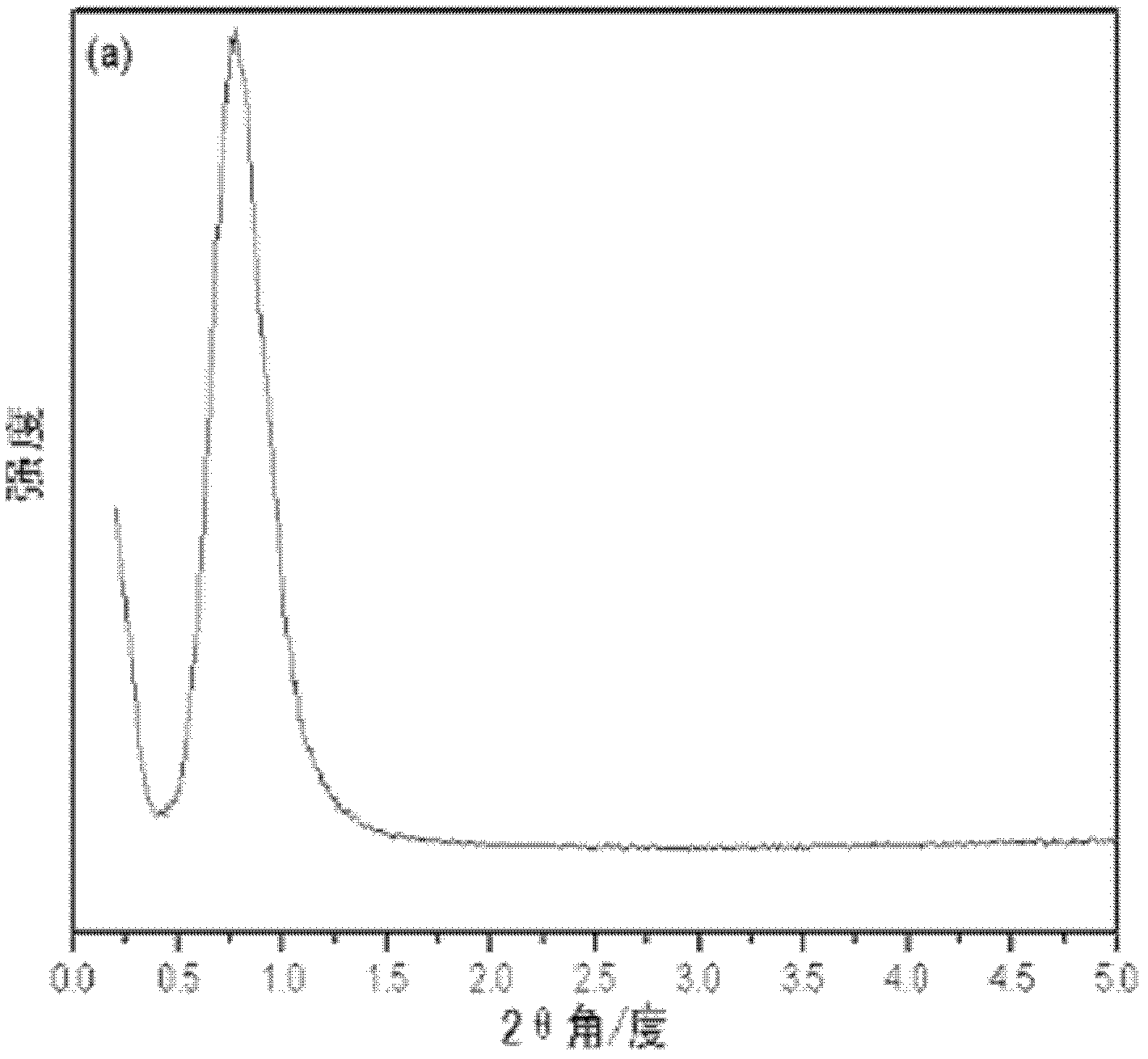

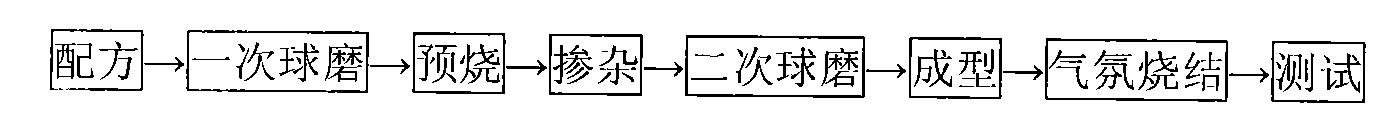

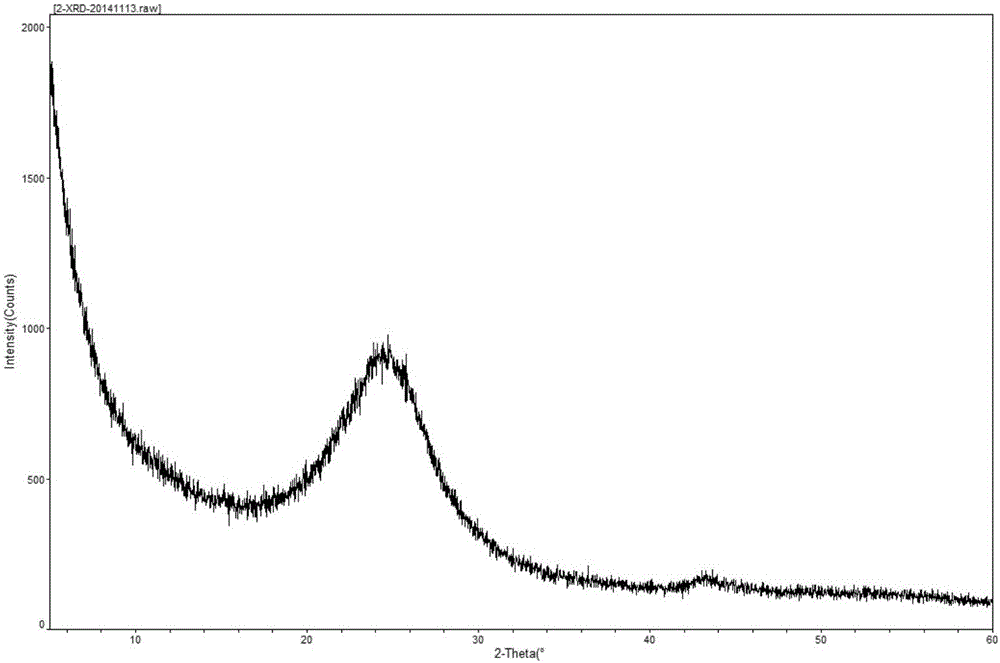

High saturation magnetization intensity Fe-based nanocrystalline magnetically soft alloy material and preparation method thereof

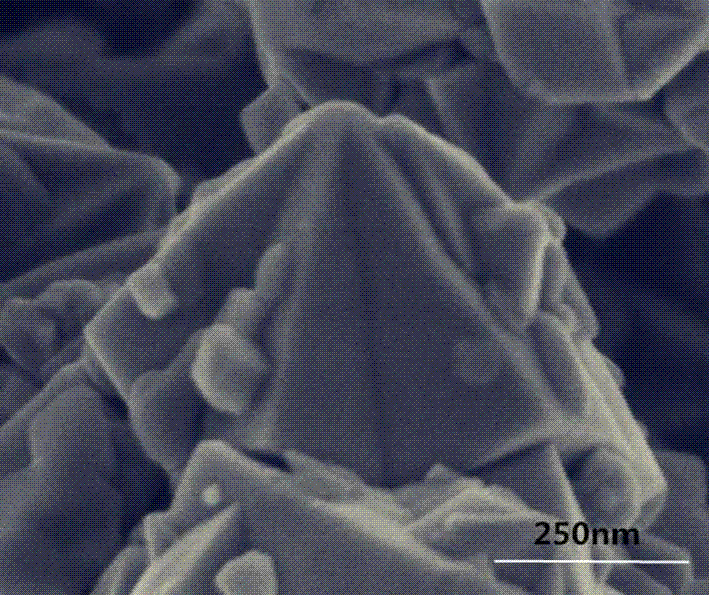

ActiveCN101834046AHigh saturation magnetizationReduce contentMagnetic materialsMagnetizationMicrostructure

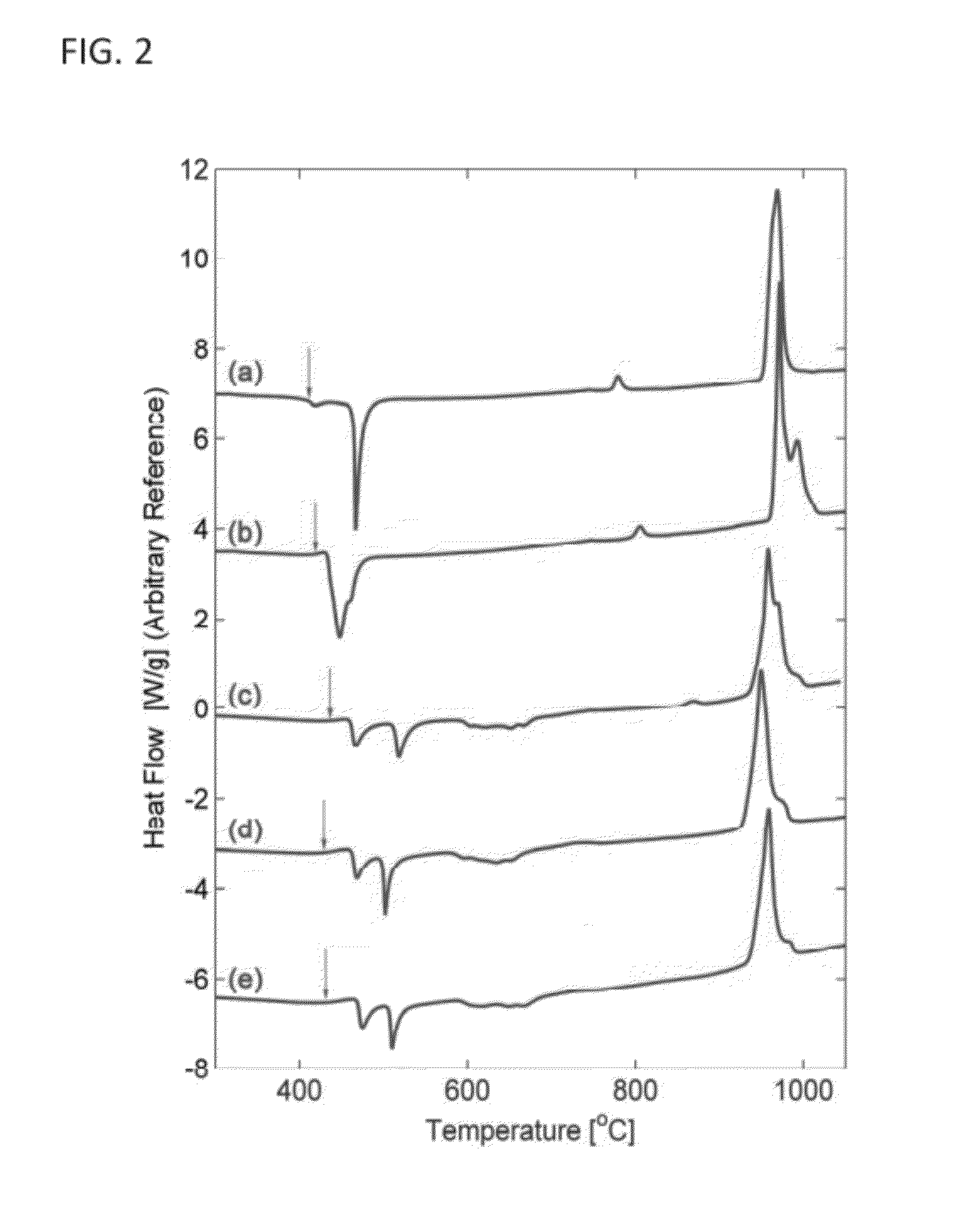

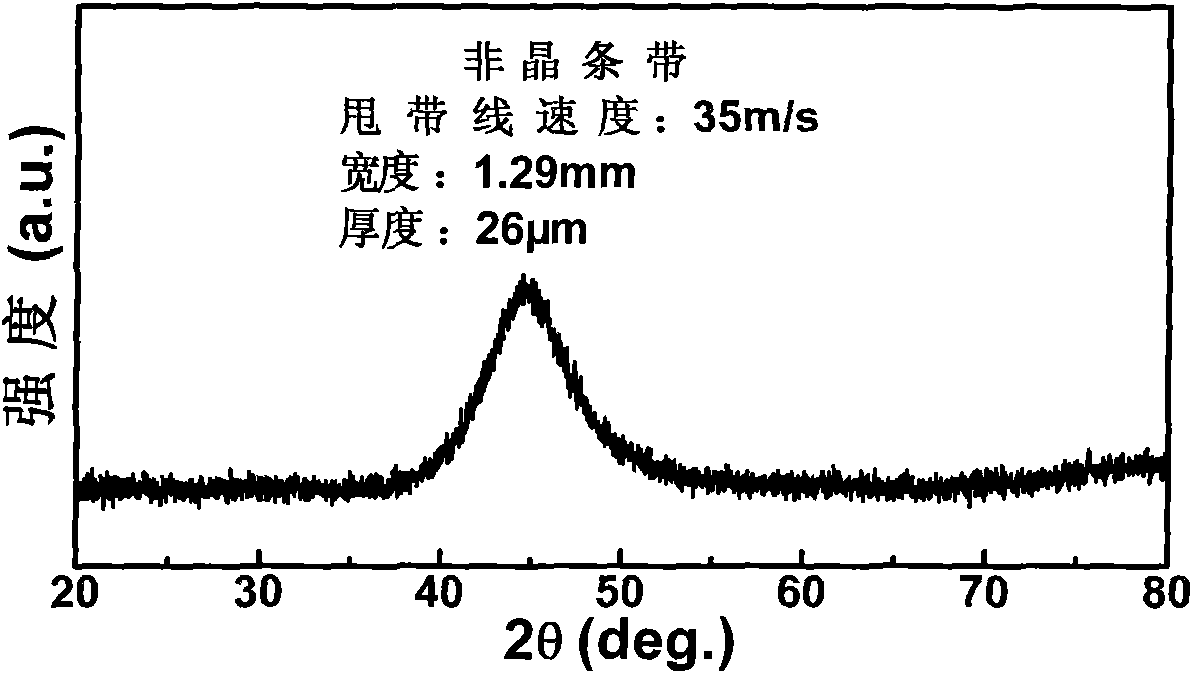

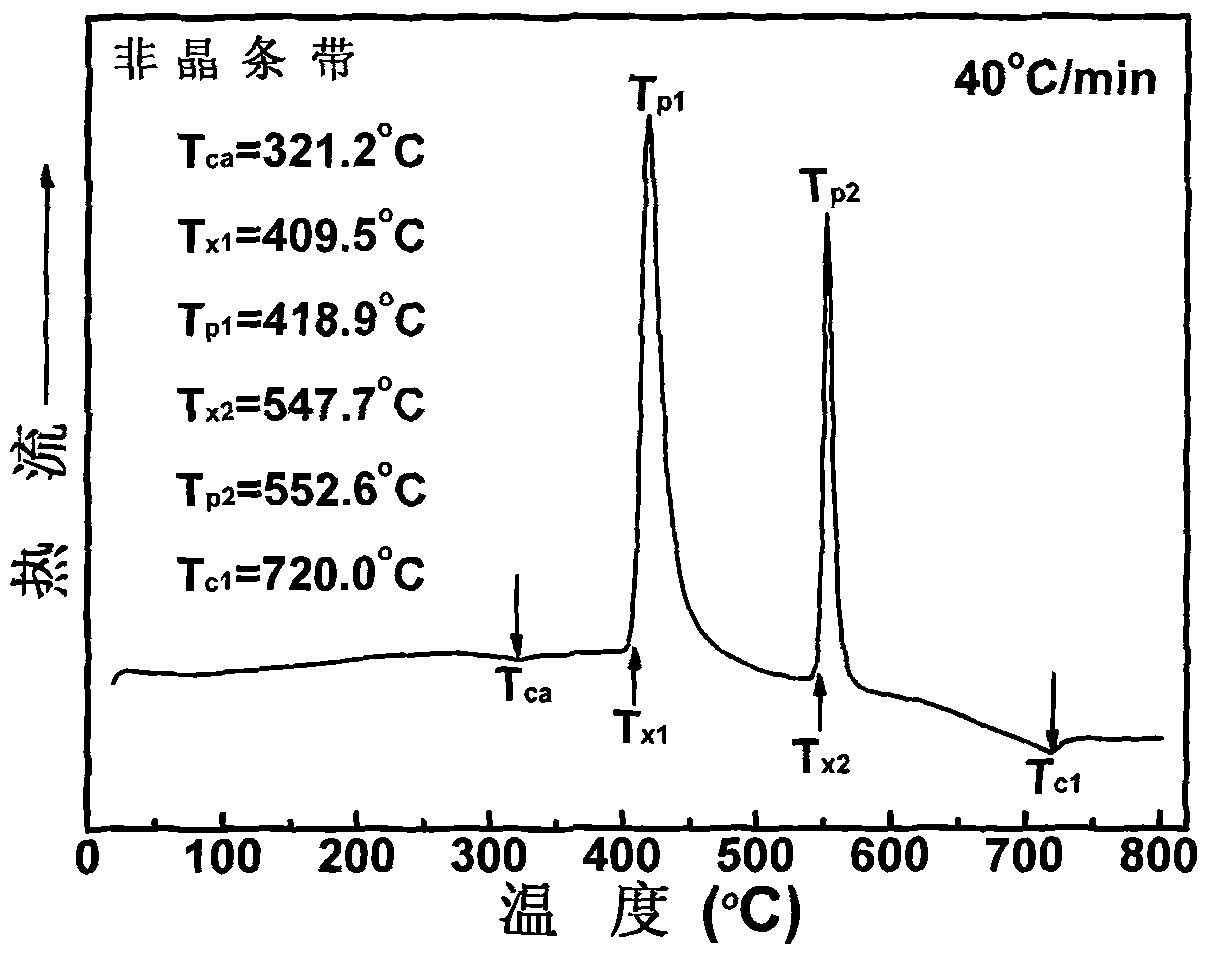

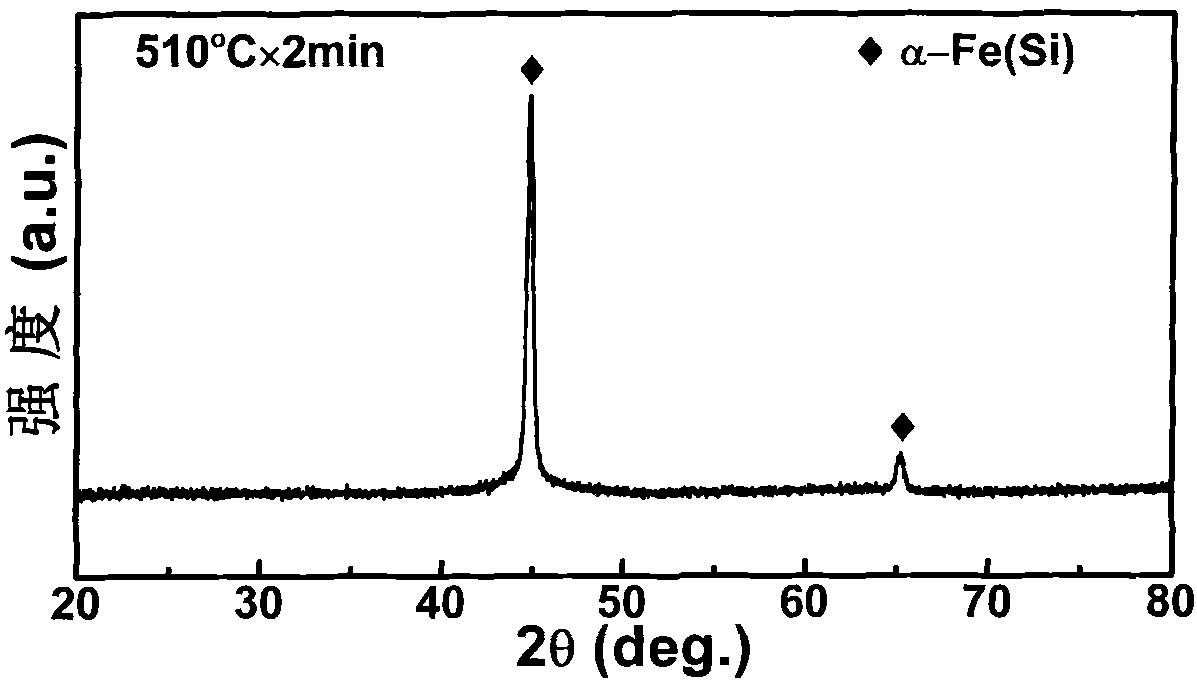

The invention relates to a high saturation magnetization intensity Fe-based nanocrystalline magnetically soft alloy material and a preparation method thereof. The high saturation magnetization intensity Fe-based nanocrystalline magnetically soft alloy material is a FexSiyBzPaCub alloy comprising ferrum, silicon, boron, phosphorus and copper, wherein x, y, z, a and b in the formula respectively represent atom percentage content of each corresponding component, x=70-90%, y=1-15%, z=1-20 %, a=1-20% and b=0.1-1%, and x+y+z+a+b=100%; the microstructure of the Fe-based nanocrystalline magnetically soft alloy is as follows: a body-centered cubic Alpha-Fe(Si) nanocrystalline phase with the size of 1-35nm and an amorphous phase rich in phosphorus and boron coexist, and the amorphous phase is the basic phase. The preparation method comprises steps of: preparing proportioned raw materials into an alloy ingot, preparing into amorphous alloy and carrying out other procedures to obtain the high saturation magnetization intensity Fe-based nanocrystalline magnetically soft alloy. The invention can greatly enhance the saturation magnetization intensity of the nanocrystalline magnetically soft alloy, maintain lower coercivity and effectively reduce cost of raw materials simultaneously.

Owner:朗峰新材料启东有限公司

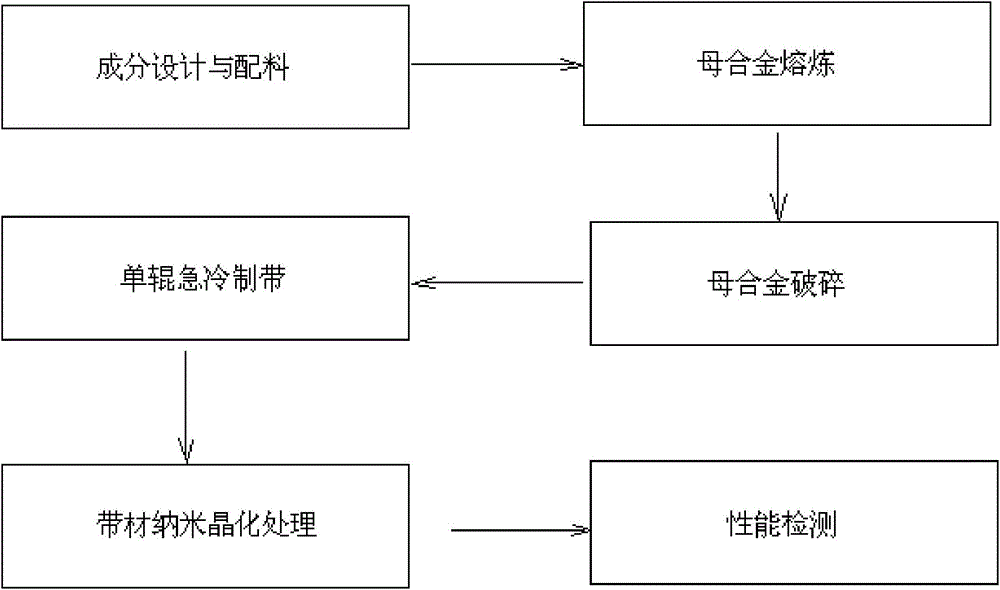

High-saturated magnetization intensity Fe-based amorphous nanocrystalline soft magnetic alloy and its preparation method

InactiveCN102732811AHigh saturation magnetizationSolve the problem of low saturation magnetic inductionMagnetic materialsMagnetizationCopper

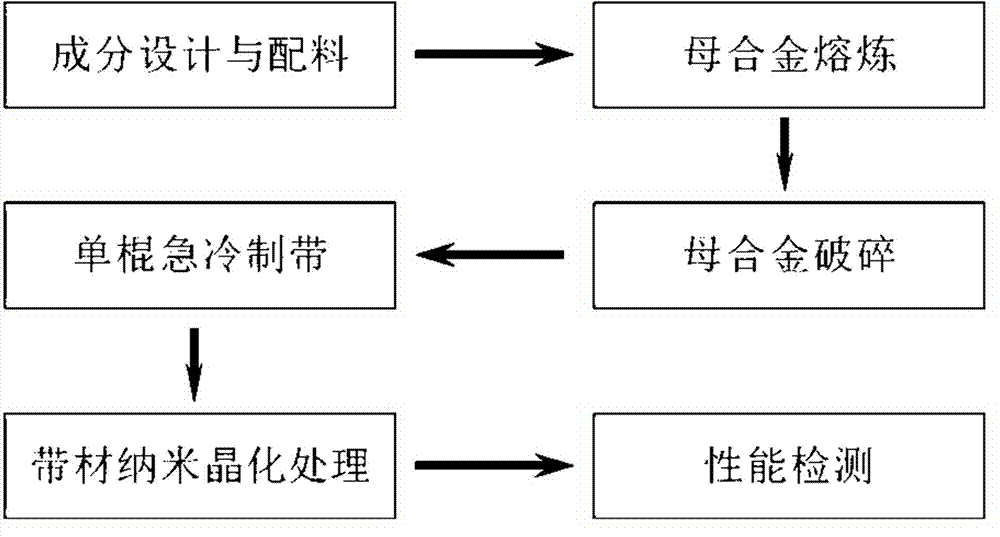

The invention discloses a high-saturated magnetization intensity Fe-based amorphous nanocrystalline soft magnetic alloy and its preparation method. The alloy is prepared from the following components, by mole, 68-90% of Fe, 0-6% of X, 0-2% of Cu, 3-20% of Si, 4-20% of B and 0-10% of P, wherein the X comprises one or more of Al, Cr, Mn and Ti. The preparation method of the alloy comprises the technological steps of component designing and burdening, mother alloy melting, mother alloy fragmentation, band preparation through single-roller quenching, and band nanocrystallization processing. The preparation method of the invention can solve a problem of low saturated magnetic induction intensity of present Fe-based amorphous nanocrystalline soft magnetic alloys.

Owner:四川大学苏州研究院

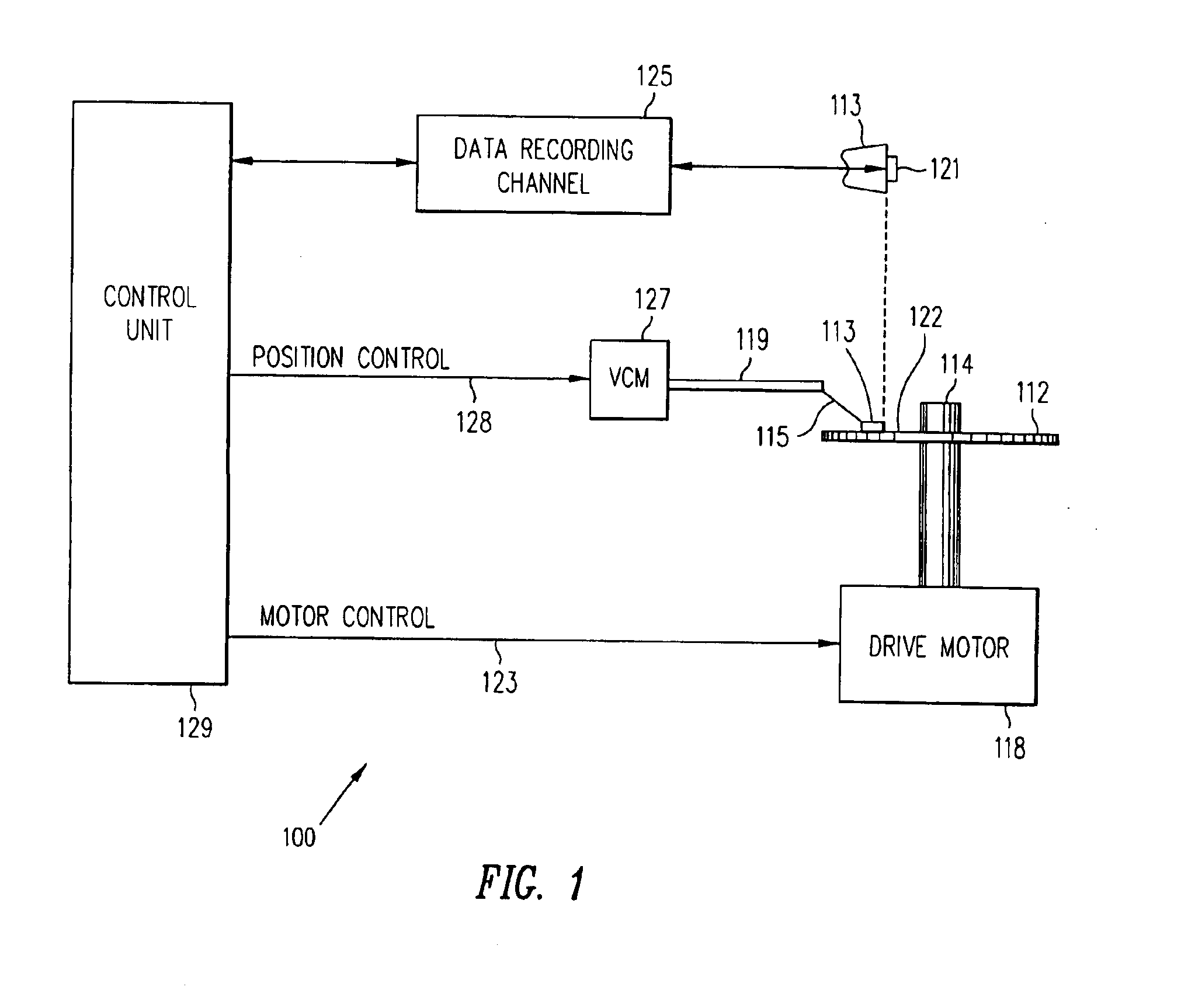

Thermally assisted magnetic recording system and method of writing using magnetic and thermal gradients

InactiveUS6950260B2Avoid thermal instabilityRapid coolingCombination recordingRecord information storageMagnetic field gradientMagnetic media

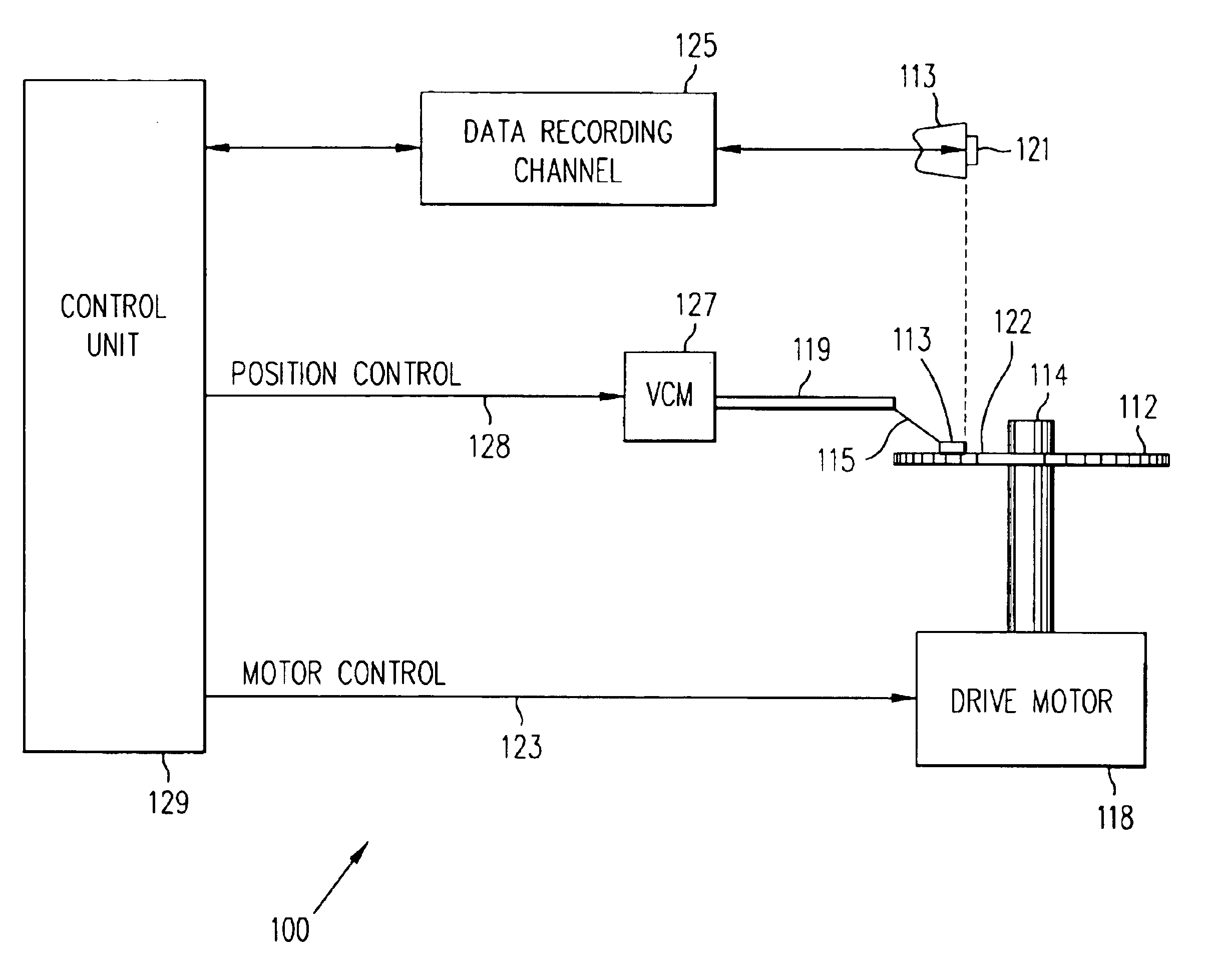

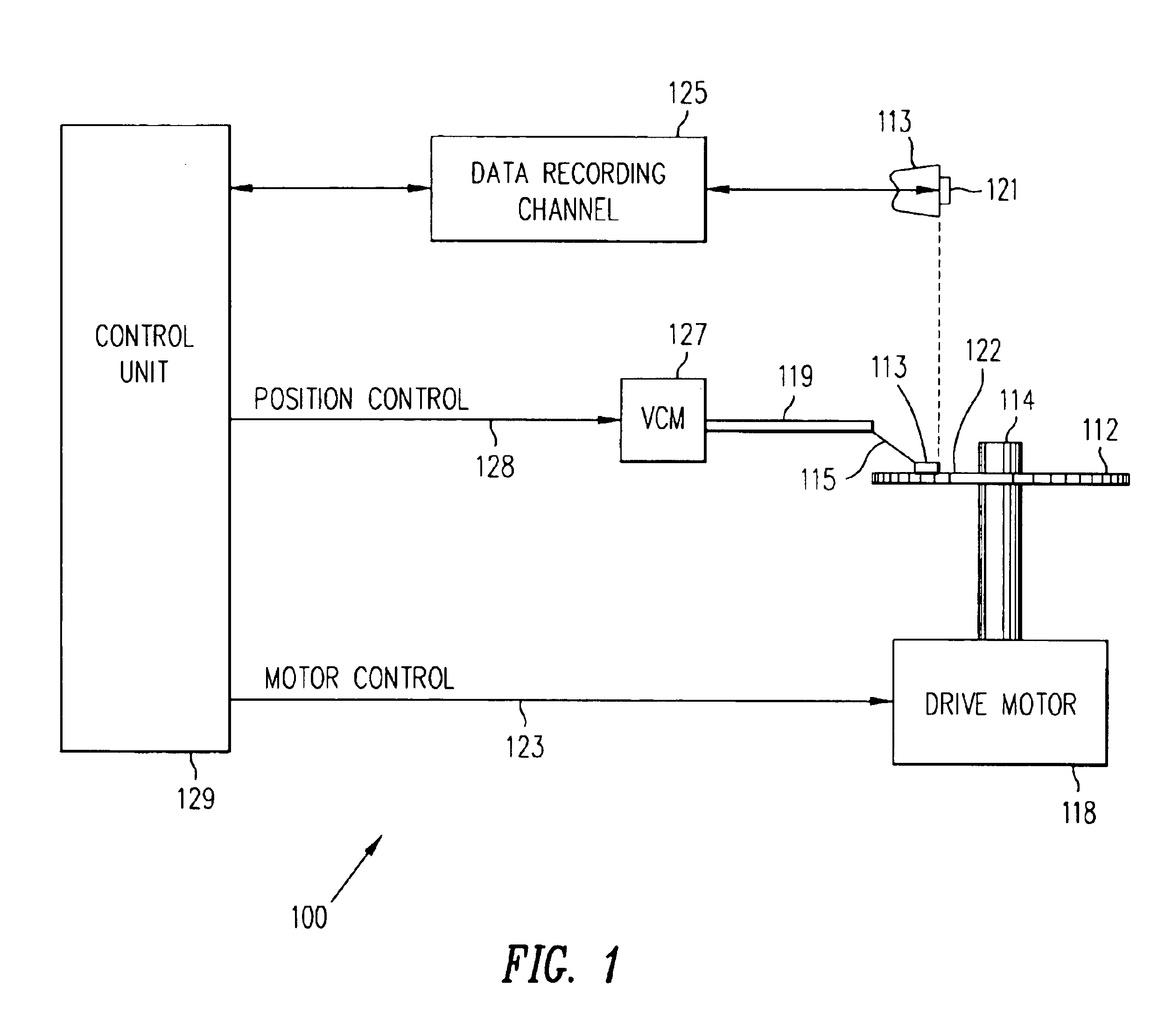

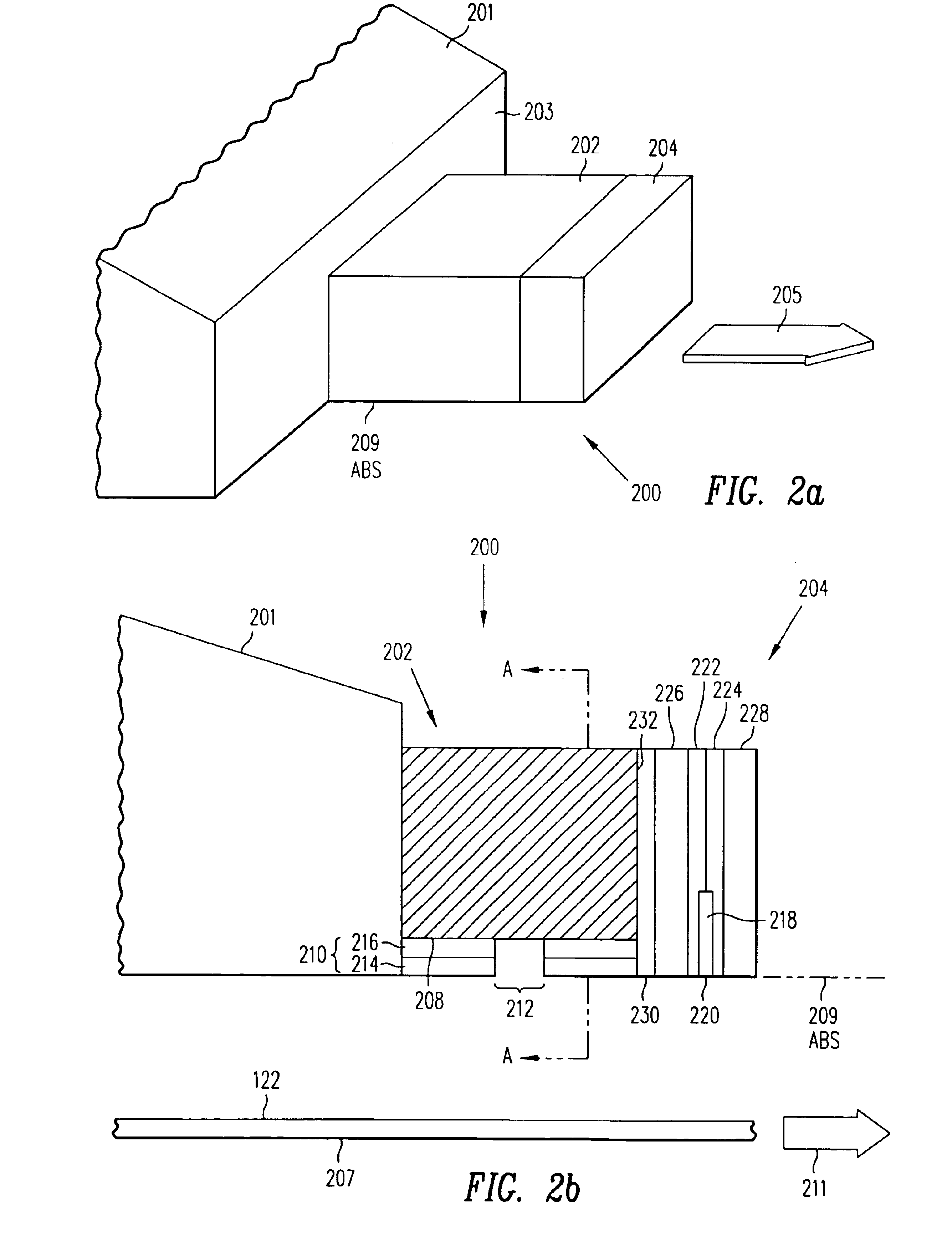

A magnetic recording system is provided having a write head employing a combination of magnetic write field gradient and thermal gradient to write data on a ‘thermal spring’ magnetic recording media. The write head comprises a magnetic element using a write current to induce a magnetic write field at the magnetic media and a thermal element using a very small aperture laser to heat a portion of the media. The thermal spring magnetic media comprises [comprises] first and second stacks providing two exchange coupled ferromagnetic layers having different Curie temperatures [The first stack has a high magneto-crystalline anisotropy, a relatively low saturation magnetization and a low Curie temperature.] [The second stack has a relatively low magneto-crystalline anisotropy, a high saturation magnetization and a high Curie temperature.] The magnetic field gradient and the thermal gradient are arranged to substantially overlap at the trailing edge of the heated portion of the magnetic media allowing data at high density with high thermal stability to be recorded on the rapidly cooling thermal spring magnetic recording media.

Owner:WESTERN DIGITAL TECH INC

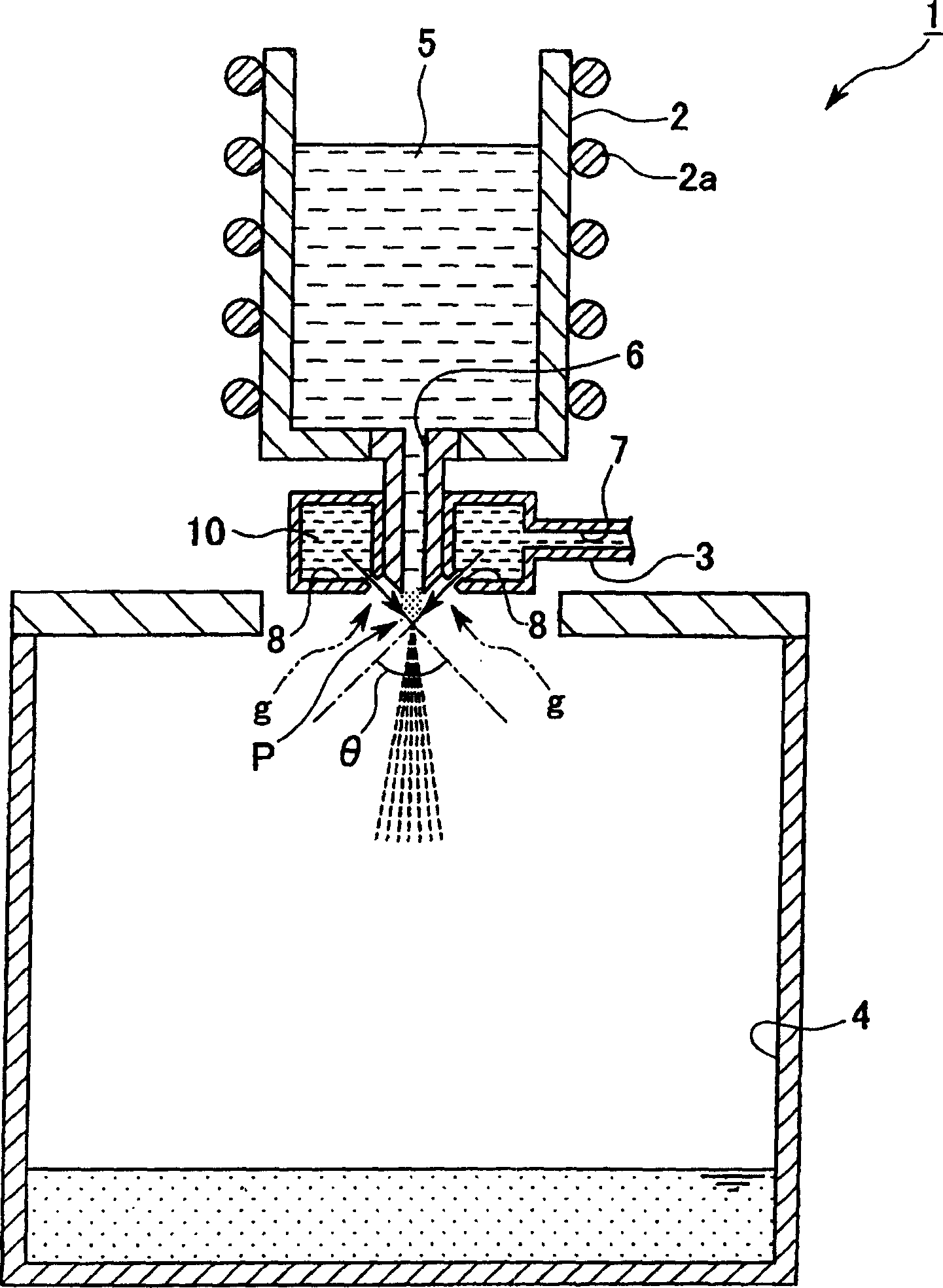

Noncrystalline soft magnetic alloy powder and dust core, electricwale absorber using the same

ActiveCN1487536AExcellent soft magnetic propertiesSpeed up coolingInorganic material magnetismCores/yokesMetallurgyAmorphous phase

Provided is amorphous soft magnetic alloy powder which has high saturation magnetization and low core loss and which is almost spherical and manufactured by water atomization method, and to provide a green compact core and radio wave absorber using the same. This amorphous soft magnetic alloy powder is formed substantially spherical by the water atomization method. The powder mainly consists of Fe and contains at least P, C and B, and is formed of amorphous soft magnetic alloy powder consisting of an amorphous phase with a temperature interval DeltaTx of the supercooled liquid of >= 20K. A green compact core is formed by solidifying the granulated mixture of this amorphous soft magnetic alloy powder, insulator and lubricant. The radio wave absorber is formed by mixing the amorphous soft magnetic alloy powder the particles of which is flattened and insulator.

Owner:ALPS ALPINE CO LTD

Method for preparing magnetic mesoporous carbon nanometer microspheres with high adsorption property

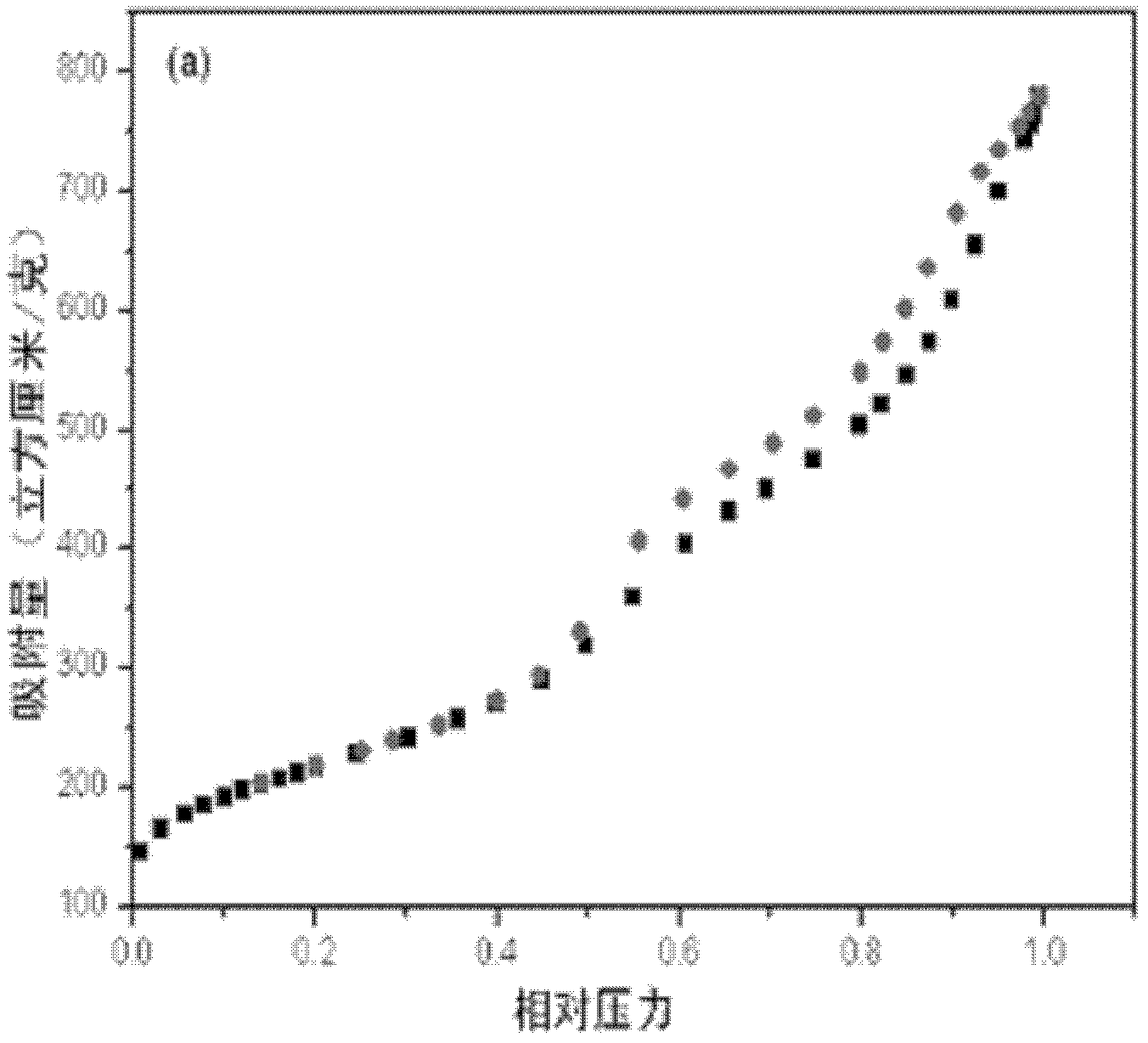

InactiveCN102614819AImprove featuresHigh Magnetization SaturationOther chemical processesAlkali metal oxides/hydroxidesMicrosphereSolvent

The invention discloses a method for preparing magnetic mesoporous carbon nanometer microspheres with high adsorption property, relates to a method for preparing carbon nanometer microspheres, and aims to solve the problems of complex operation and high time and energy consumption in the process of preparing magnetic mesoporous carbon by the conventional method. Fe3O4 nanometer microspheres are introduced into mesoporous carbon by a solvothermal method, and mesoporous carbon microspheres with high saturation magnetization degree are prepared and used for removing pollutants such as dyes during water treatment. The magnetic mesoporous carbon nanometer microspheres have the large pore diameter of 4.3nm, the high specific surface area of 741.8m<2> / g, the large pore volume of 1.20cm<3> / g and the high magnetic saturation degree of 7.15emu / g, and can be applied to the fields of water treatment, catalyst carriers, biomedicine and the like.

Owner:HARBIN INST OF TECH

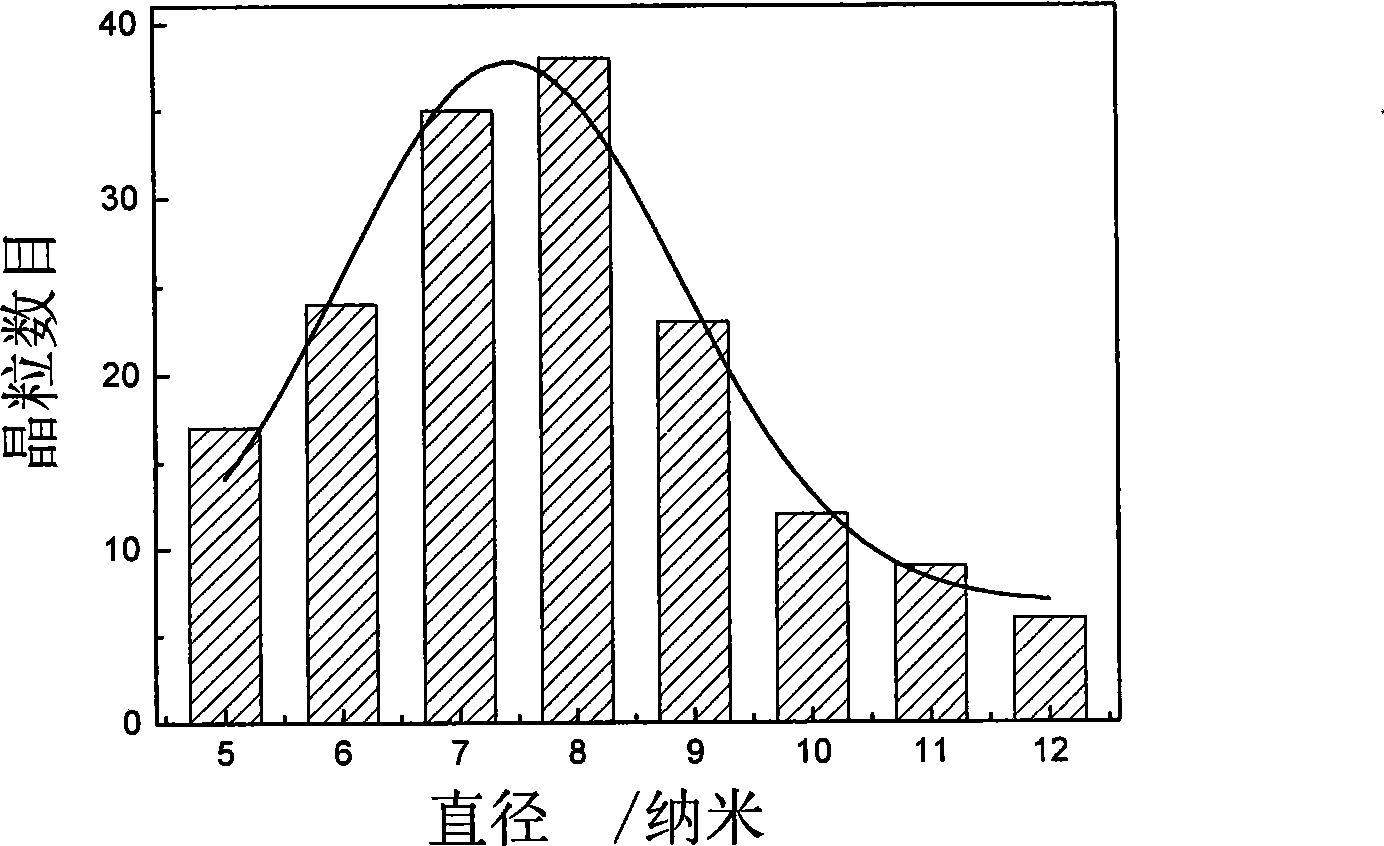

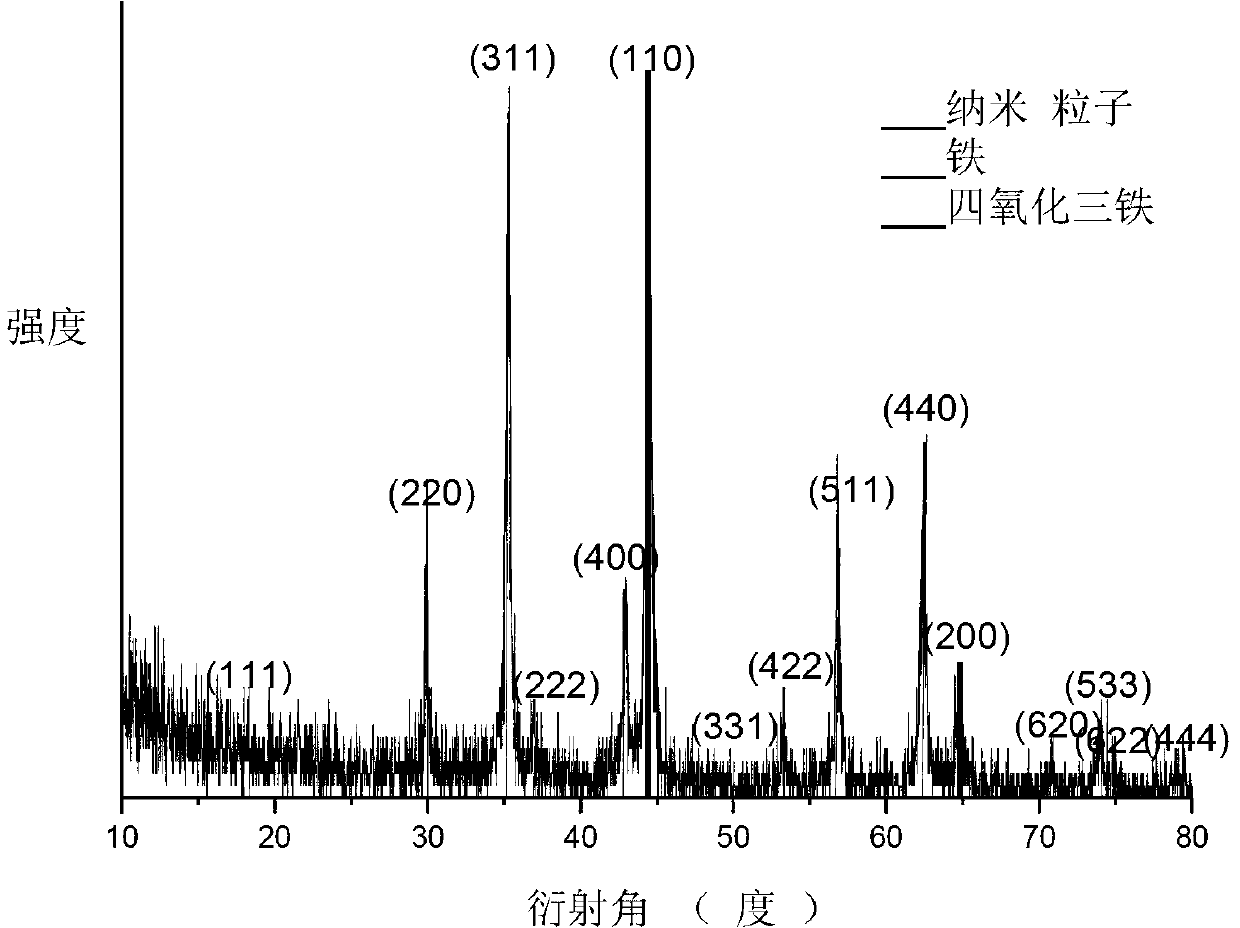

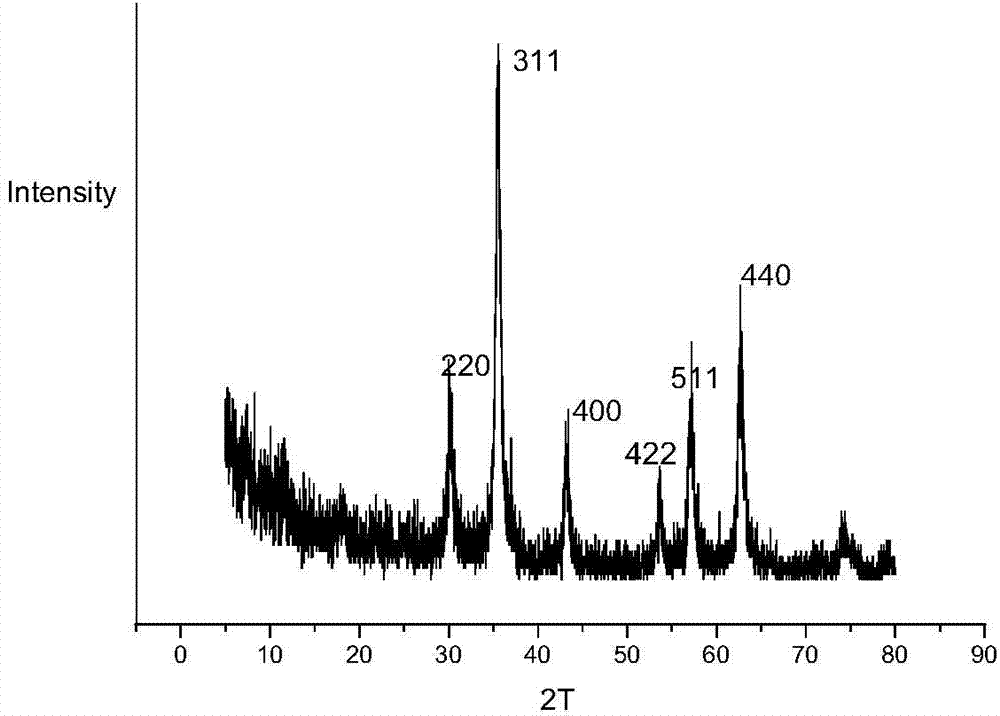

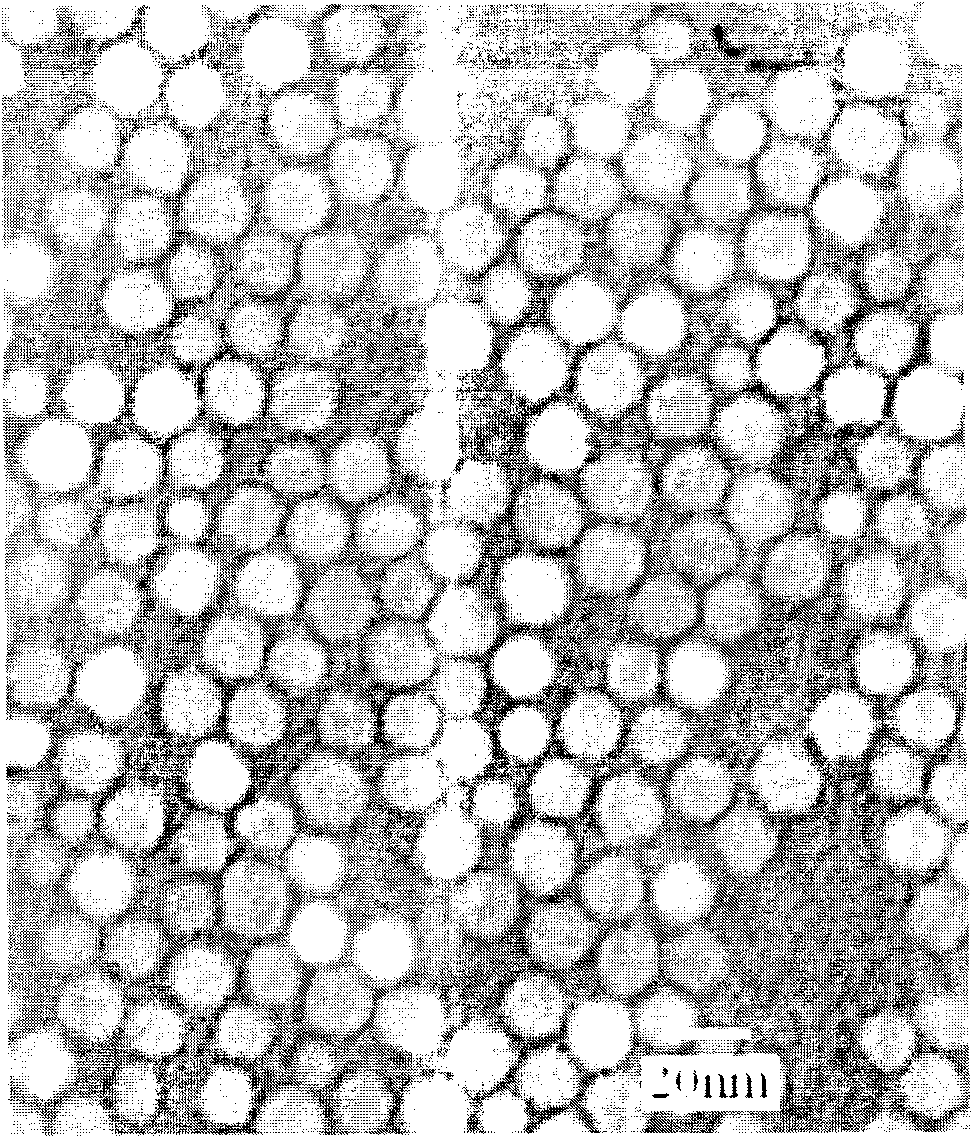

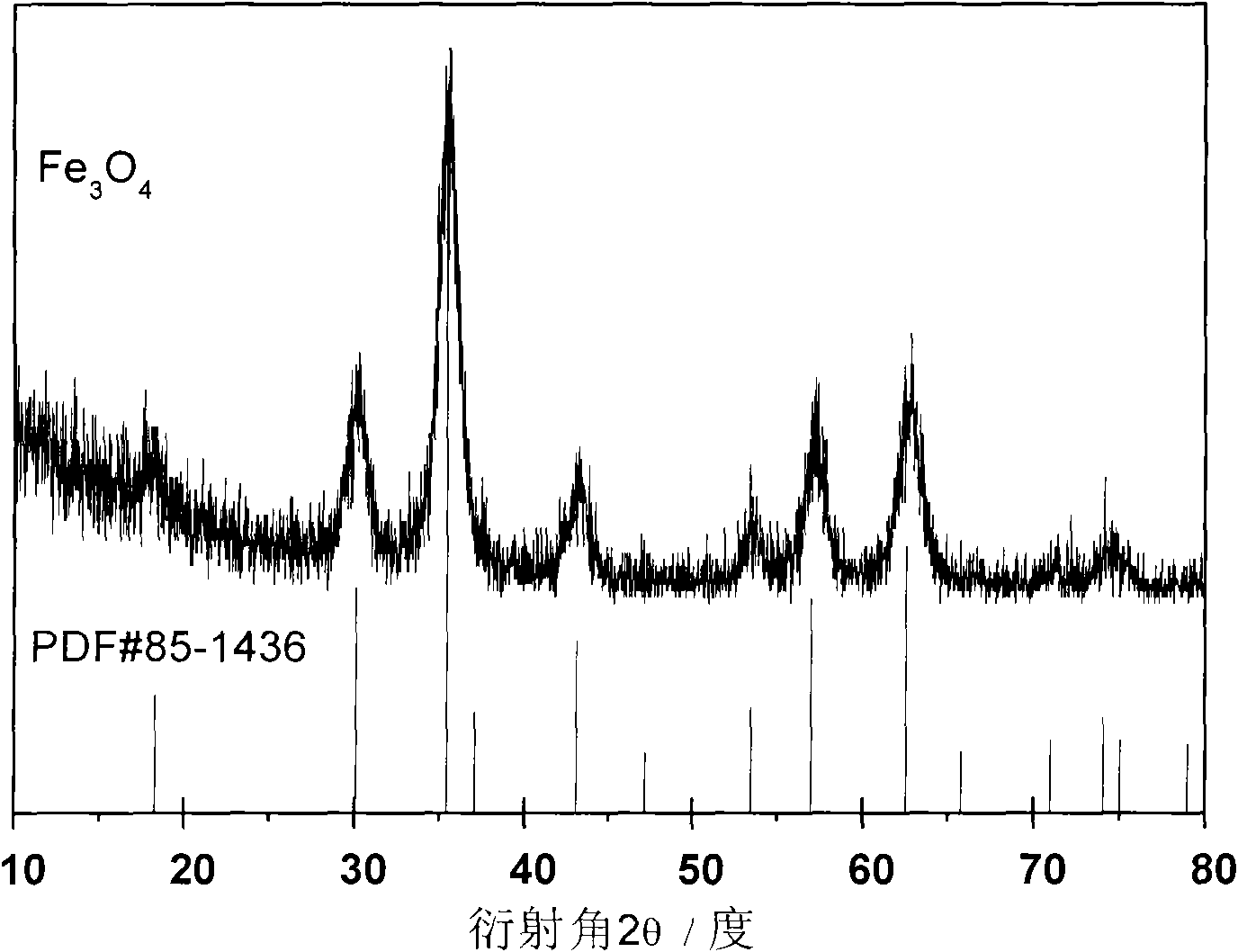

Nano-crystalline Fe*O* particles with high absorption capacity and preparation method thereof

InactiveCN101445277AImprove adsorption capacityImprove propertiesOther chemical processesFerroso-ferric oxidesChemical reactionHigh absorption

The invention relates to nano-crystalline Fe3O4 particles with high absorption capacity and a preparation method thereof which belong to the field of material science. The microstructure of the particles comprises equiaxed nano-grains, and the particle size of the nano-grains is 5-100nm; the average particle size is 8-25nm, and the saturated magnetization MS is 6.7-7.2 multiplied by 10<minus 3>A / m. The preparation method is as follows: solution containing ferric ions and ferrous ions is prepared, ammonia solution is added under nitrogen atmosphere, ultrasonic waves are transmitted to carry out the ultrasonic dispersion, and heating, stirring and reaction are carried out; solids are washed till neutral by water under the condition of a magnetic field; water is removed by drying after the centrifugal separation. The invention utilizes the simple chemical reaction co-precipitation technology and combines the ultrasonic stirring, the centrifugal separation, the vacuum drying and other technologies to obtain the Fe3O4 powder materials with the average particle size of 8-25nm and the higher saturated magnetization.

Owner:NORTHEASTERN UNIV

High stability and high magnetism quenched R-Fe-B base permanent magnetic alloy powder

The high stability and high magnetism quenched R-Fe-B base permanent magnetic alloy powder has the basic expression of RxFe100-x-y-z-vMzCovBy, where R is light RE element(s) Nd, Pr and La, and M is element(s) of Nb, Zr, Ti, etc; and consists of main R2Fe14B phase and small amount of superfine auxiliary Fe-alpha-M-beta phase. Adding Nb and other transition elements to form small amount of superfine auxiliary Fe-alpha-M-beta phase during fast solidification can inhibit over nucleation and growth of Nd2Fe14B crystal grain, improve the performance of the quenched material, fine the Nd2Fe14B crystal grain and raise the temperature stability and antioxidant process of the material. In addition, the permanent magnetic alloy powder has obviously raised intrinsic coercive force, high saturated magnetization, high residual magnetism and other advantages.

Owner:DONGFANG MICRON & NANOMETER SCI TECH

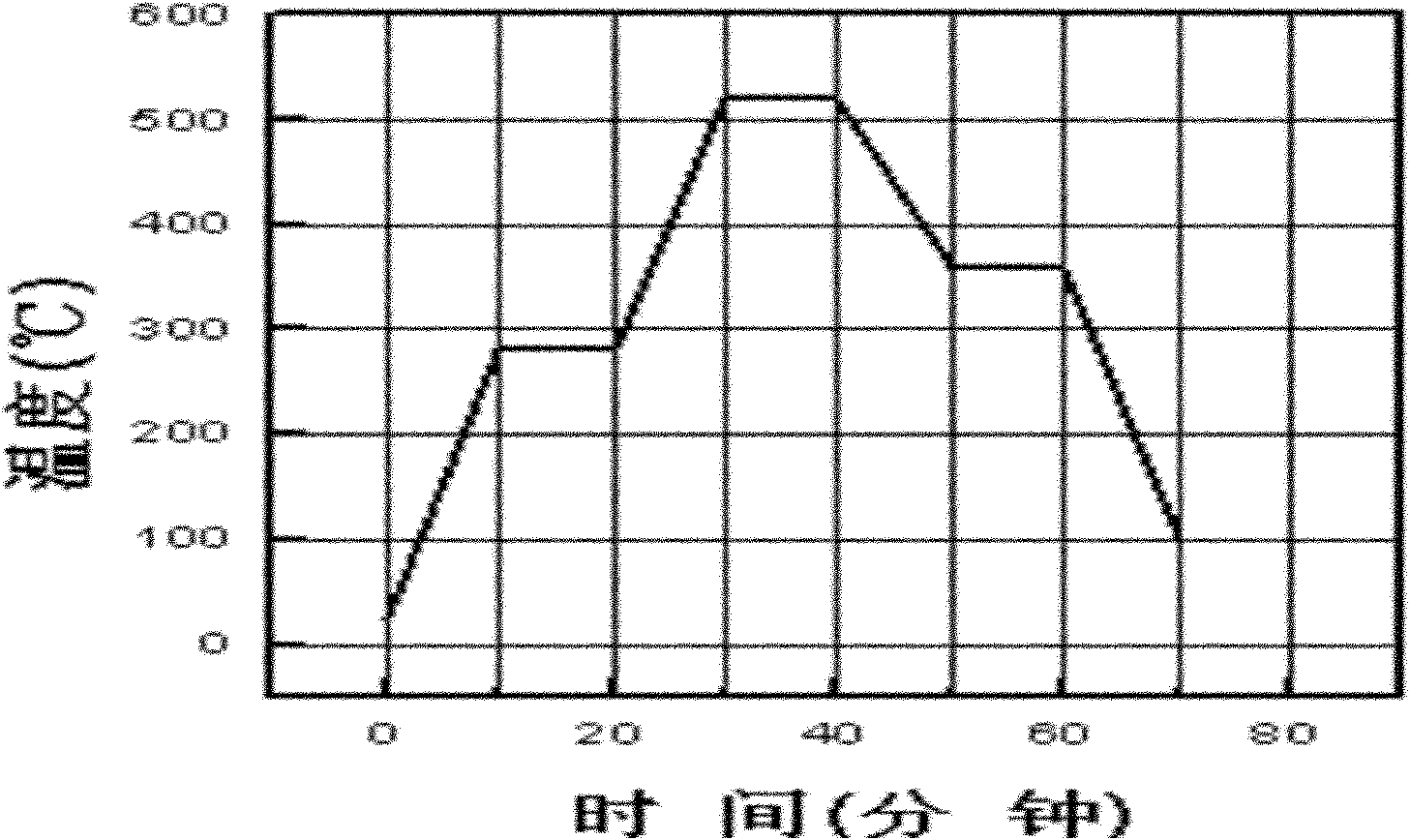

High-thermal-stability insulated coating treatment method of metal soft magnetic composite material

ActiveCN104028749AThickness is easy to controlImprove antioxidant capacityInorganic material magnetismAdhesiveOperability

Owner:ZHEJIANG UNIV

Fe@Fe3O4 nanoparticles having photothermal function, and preparation method and application thereof

ActiveCN103341165AGood dispersionGood lookingEnergy modified materialsNanotechnologySolubilityDispersity

The invention discloses Fe@Fe3O4 nanoparticles having a photothermal function, and a preparation method and an application thereof, and belongs to the field of medical science materials. The preparation method is significantly characterized by comprising: firstly, utilizing octadecene as a solvent, utilizing Fe(CO)5 as an iron source, utilizing oleyl amine as a surfactant and a stabilizer, and preparing an Fe nanomaterial having good dispersity by high temperature pyrolysis; sequentially, adding (CH3)3NO at the high temperature for oxidization to form one layer of Fe3O4 shell on the surface layer of each Fe nanoparticle, and then improving water solubility by a ligand exchange method to obtain the Fe@Fe3O4 composite material as a photothermal reagent and having high magnetization strength. The composite material has the advantages of uniform particle size, high saturation magnetization strength, and controllable morphology, and has excellent dispersion and excellent stability in aqueous solution. The reaction time is short, the raw materials are easy to get, and operation processes are convenient. On the basis of the raw materials, the Fe@Fe3O4 nanoparticles are developed to connect PEG to the surface of the material, so that the Fe@Fe3O4 nanoparticles can be applied to biological bodies. The invention provides the application of the Fe@Fe3O4 nanoparticles in the field of tumor photothermal therapy.

Owner:SHANGHAI NORMAL UNIVERSITY

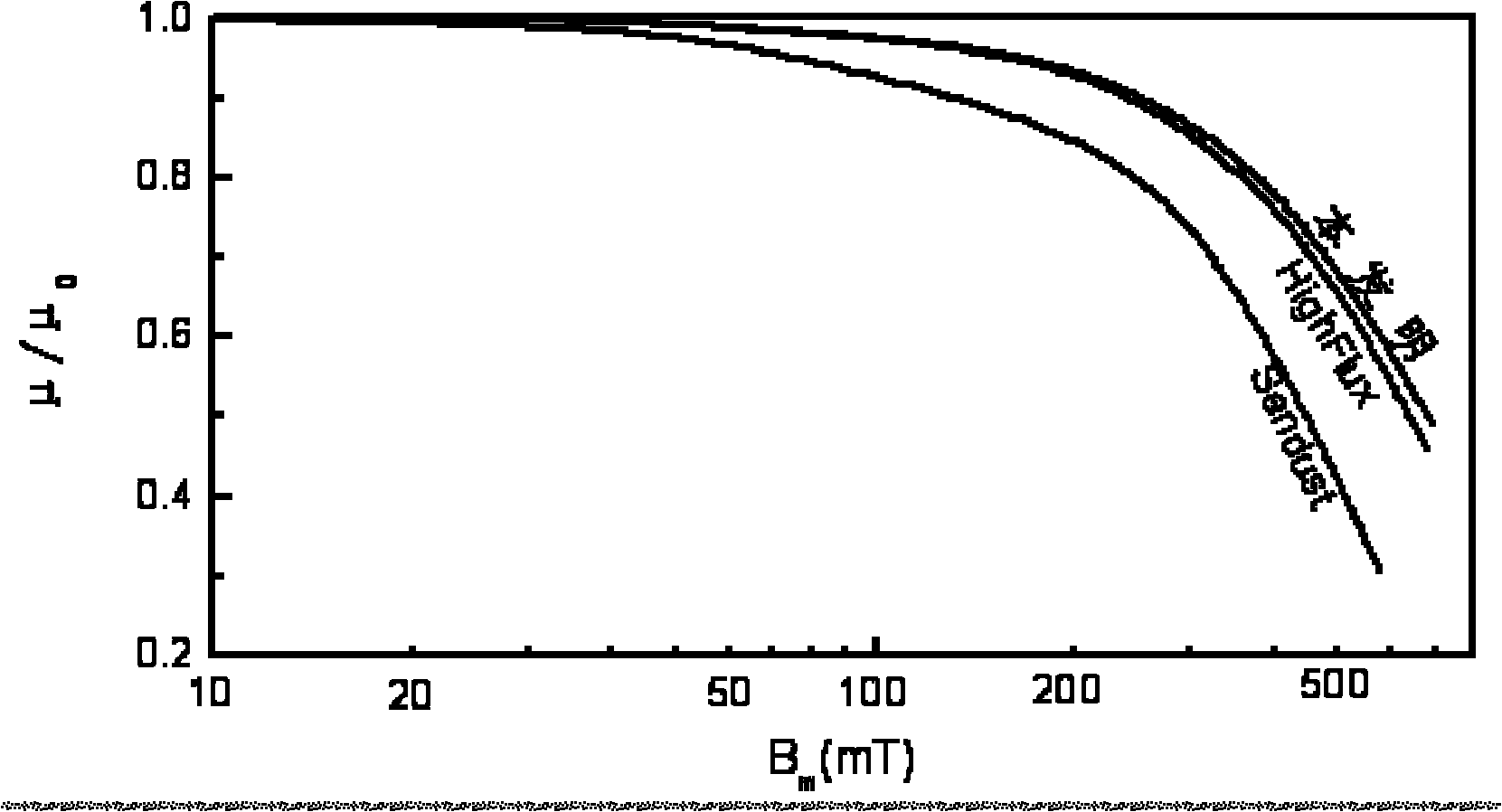

Soft magnetic alloy powder, magnetic powder core and preparation methods of soft magnetic alloy powder, magnetic powder core

ActiveCN101892425AHigh saturation magnetic inductionReduce lossInorganic material magnetismUltimate tensile strengthHigh saturation magnetization

The embodiment of the invention provides soft magnetic alloy powder. The components of the soft magnetic alloy powder meet the following formula in mass percentage: Fe100- x-y-zSixCyMz, wherein x is more than 2 and less than 8, y is more than 0.5 and less than 3, z is more than 1 and less than 5, and M is at least one of Cr, V, Al and Mn. The embodiment of the invention also provides a magnetic powder core which is prepared from the soft magnetic alloy powder. The soft magnetic alloy powder contains a great amount of Fe, so that saturation magnetic induction strength is higher; the powder contains an adequate amount of Si and C, so that the powder has high soft magnetic property; and the powder contains M (M is at least one of Cr, V, Al and Mn), so that the powder has good process characteristics. The soft magnetic alloy powder and the magnetic powder core having high saturation magnetic induction strength and low loss are obtained so as to obviously improve the characteristics of the DC superposition characteristic of the magnetic core and solve the problem of magnetic core heating.

Owner:武汉中磁浩源科技有限公司

Iron base non-crystalline material and preparation method thereof

ActiveCN105986202AImprove performanceHigh saturation magnetizationVacuum evaporation coatingSputtering coatingSurface layerCrystalline materials

The invention provides an iron base non-crystalline material and a preparation method thereof. The iron base non-crystalline material has components of Fe100-a-b-cMcBbAa, wherein M is any one or more of Si, Zr, Nb, Cr, P, Al, Co, Ni and Ti, A is N and / or C, a is not less than 0.5 and not more than 2 at%, b is not less than 9 and not more than 14 at%, and c is not less than 0 and not more than 10 at%; the non-crystalline material comprises a non-crystalline basal body layer and a surface layer positioned on the non-crystalline basal body layer; and the surface layer is a FeA enriched layer. The non-crystalline basal body layer in the iron base non-crystalline material is used for providing basic performances of the iron base non-crystalline material; and through auxiliary cooperation of the performances of the surface layer, the performances of the iron base non-crystalline material can be enhanced, the saturation magnetization is improved, the coercive force is reduced, and the overall performances of the iron base non-crystalline material are improved.

Owner:GRIREM ADVANCED MATERIALS CO LTD

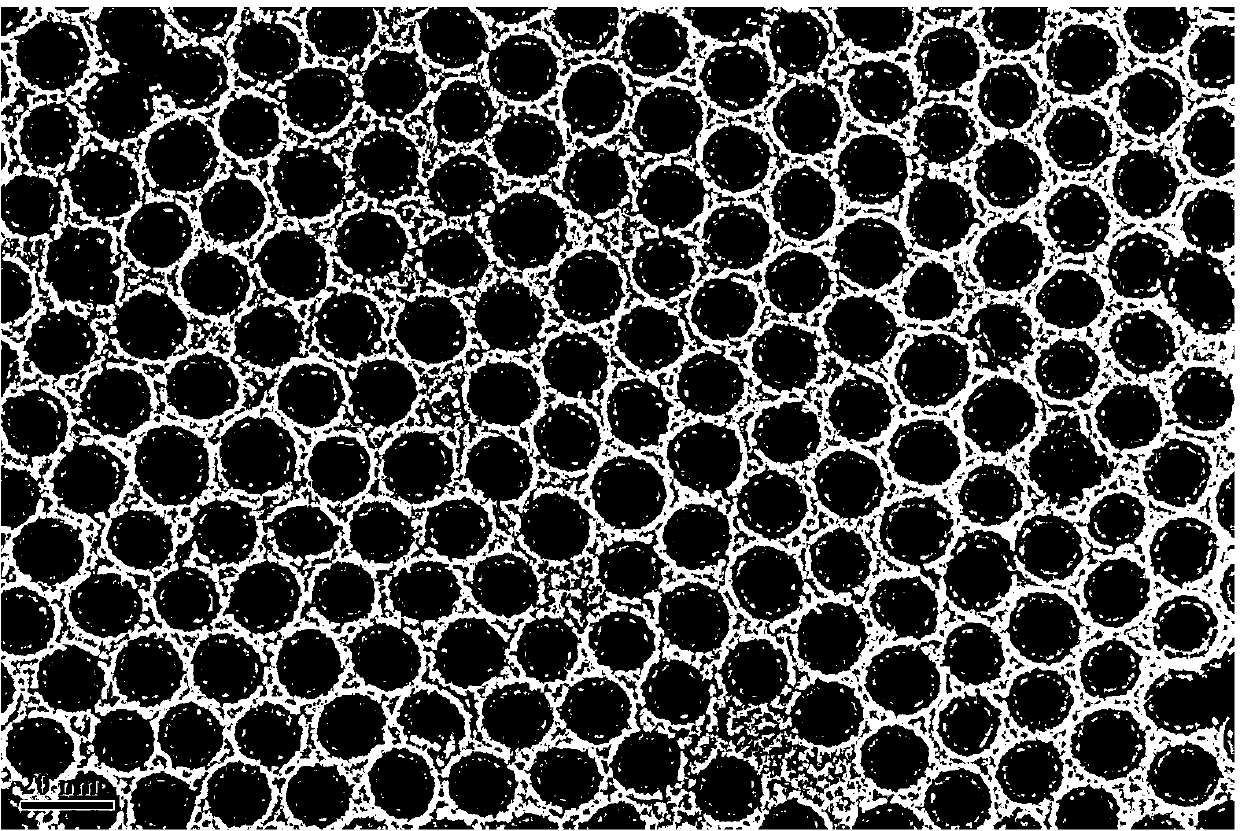

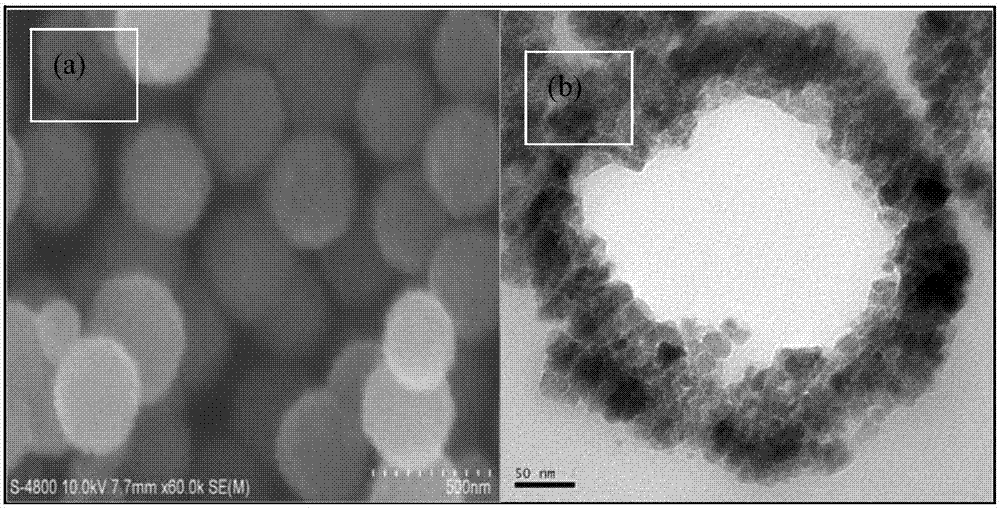

Preparation method for superparamagnetism ferroferric oxide sub-micron hollow microsphere

InactiveCN103663571ASuperparamagneticHigh saturation magnetizationInorganic material magnetismFerroso-ferric oxidesMicrospherePolyethylene glycol

The invention relates to a preparation method for a superparamagnetism ferroferric oxide sub-micron hollow microsphere. The preparation method comprises the following steps: 1) taking a reducing agent, an iron source and an alkali source, and dissolving into distilled water; 2) dissolving a surfactant into a solution obtained from step 1); 3) introducing a solution obtained from step 2) into a reaction kettle, reacting in a drying oven, performing natural cooling to room temperature for seasoning, water washing, alcohol washing, and drying in a vacuum drying box, so that the superparamagnetism ferroferric oxide sub-micron hollow microsphere is obtained. The preparation method has the following good effects: 1) according to the invention, the ferroferric oxide sub-micron hollow microsphere is compounded, and has superparamagnetism, high saturation magnetization and excellent oxidation resistance; 2) dispersing agents such as PEG (polyethylene glycol) and PVP (polyvinylpyrrolidone) are adopted to solve the problem of magnetic microsphere agglomeration, so that the ferroferric oxide sub-micron hollow microsphere with uniform particle size is obtained; 3) according to the invention, adopted raw materials is cheap, so that cost is minimized.

Owner:WUHAN UNIV OF TECH

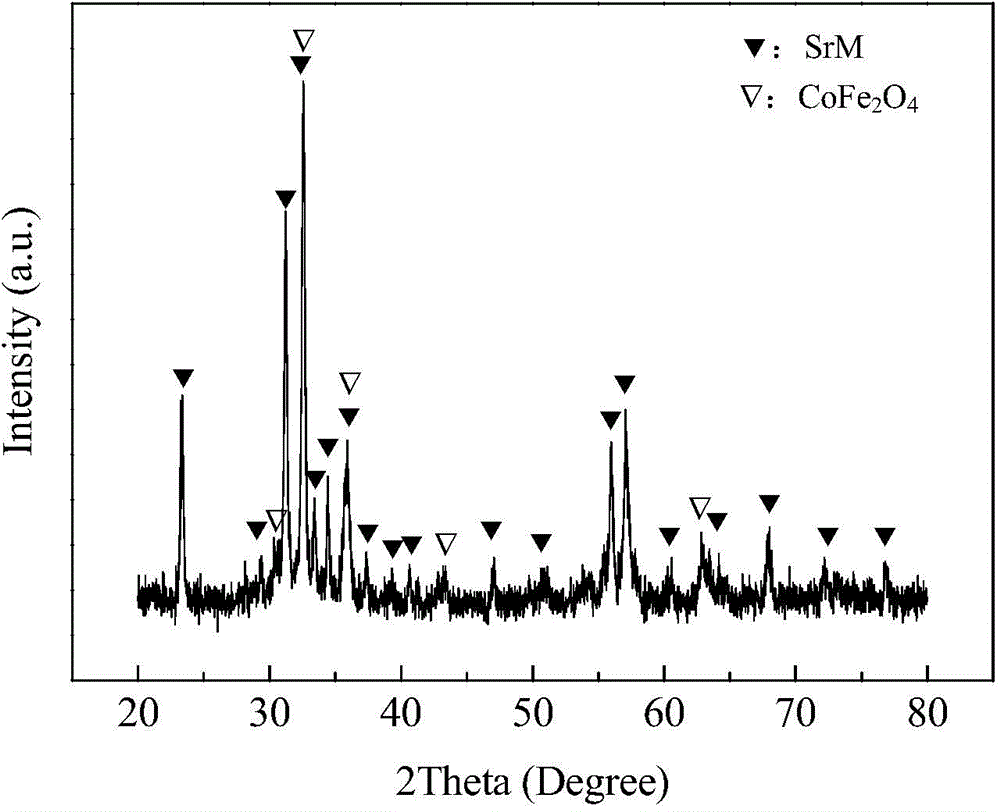

Composite permagnetferrite with functions of two-phase exchange coupling and keeping high coercive force

The invention discloses a composite permagnetferrite with functions of two-phase exchange coupling and keeping high coercive force and belongs to the technical field of preparation of magnetic ferrites. The composite ferrite is prepared by pressing SrFe12O19 ferrite nano-powder and CoFe2O4 ferrite nano-powder which are prepared by adopting a hydrothermal method alone and subjected to acid washing according to a certain mass ratio to form circular sheets, and finally calcining at the temperature of 700-900 DEG C for 2h respectively. The ferrite containing two phases displays single-phase magnetic behavior to the outside, namely the exchange coupling effect exists. As the composite ferrite adopts a CoFe2O4 ferrite with high saturation magnetization and coercive force as a 'soft magnetic phase', the composite ferrite is conductive to improving the saturation magnetization and can ensure that the composite ferrite can still keep the high coercive force which is 152.5kA / m (about 1915Oe) at least after be calcined.

Owner:扬州华翀电力电子科技有限公司

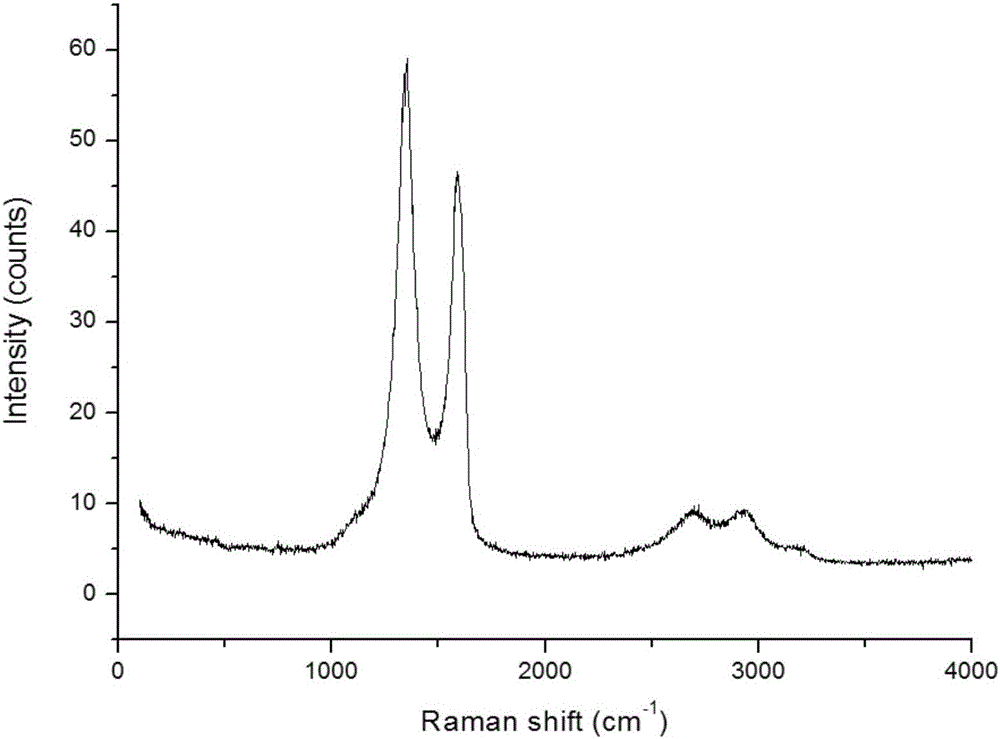

Iron-plated graphene and preparation method

InactiveCN106028768APromote absorptionImprove shielding effectMagnetic/electric field screeningHigh absorptionImpedance matching

The invention discloses a method for preparing iron-coated graphene. The improved Hummer method is used to prepare graphene, and then graphene, reducing agent, iron salt, stabilizer, complexing agent, surface treatment agent and pH regulator are used as raw materials, and the The iron / graphene composite material is prepared by in-situ reduction method; the iron-coated graphene provided by the invention has high electromagnetic wave absorption effect, and is an iron / graphene composite material with stable performance, and is applied to a new type of intelligent anti-interference electric meter box; the iron / Graphene composites can combine the high Snooker frequency, high saturation magnetization of iron particles and the better impedance matching of graphene, electric dipole polarization relaxation, etc., which can bring a wider absorption frequency band and Stronger absorption strength, better absorption and shielding effects can be obtained according to the frequency band and strength information of the jammer.

Owner:STATE GRID CHONGQING ELECTRIC POWER CO ELECTRIC POWER RES INST +1

Titanium-doped barium ferrite ceramic material and preparation method thereof

The invention discloses a titanium-doped barium ferrite ceramic material and a preparation method thereof. Densification sintering of the ceramic material is achieved through titanium doping, and electron hopping and a nonuniform conduction structure are formed through the replacement of iron ions to titanium ions. The ceramic has high residual magnetization, and great dielectric constant can be produced by utilizing the nonuniform conduction structure. The preparation method of the titanium-doped barium ferrite ceramic comprises the following steps of: preparing a ceramic precursor through a citrate sol-gel method, and then molding and sintering at high temperature to obtain the titanium-doped barium ferrite ceramic, wherein the molar ratio of titanium to barium is controlled between 0.4 and 0.8; and the molar ratio of iron to barium is between 11.6 and 11.2. According to the titanium-doped barium ferrite ceramic material and preparation method thereof, the process is simple, the cost is low, and meanwhile extremely high dielectric constant, high saturation magnetization and residual magnetization can be obtained. The residual magnetization acts as an important multifunctional material and can be used for developing preparation of relative electronic components.

Owner:ZHEJIANG UNIV

Low-loss LiZn ferrite material for phase shifter and preparation method thereof

InactiveCN101552072ALow coercivityReduce dielectric lossInorganic material magnetismDielectric lossMagnetization

A low-loss LiZn ferrite material for a phase shifter relates to the technical field of preparation of ferrite materials. The low-loss LiZn ferrite material consists of main materials, additives and binding agents, calculated by Fe2O3, ZnO, Mn3O4 and Li2CO3, the main materials comprise 64-71 mol percent of Fe2O3, 15-22 mol percent of ZnO, 0.8-1.5 mol percent of Mn3O4 and 9.9-12 mol percent of Li2CO3; relative to the main materials, the additives are calculated by Bi2O3, BST and Nb2O5, and the proportion is 0.5-3.0 wt percent of Bi2O3, 0.1-0.5 wt percent of BST and 0.05-0.4 wt percent of Nb2O5. The invention reduces the coercivity and the dielectric loss, and improves the saturation magnetization, thus realizing the low temperature preparation of the LiZn ferrite material with low coercivity, low dielectric loss and high saturation magnetization.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

High-saturation-magnetization iron-base amorphous nanocrystal soft magnetic alloy and preparation method thereof

InactiveCN104561841ASolve the problem of low saturation magnetic inductionHigh saturation magnetizationFurnace typesMagnetic materialsMagnetization transferHigh saturation magnetization

The invention relates to a high-saturation-magnetization iron-base amorphous nanocrystal soft magnetic alloy and a preparation method thereof. The alloy is expressed as FeaMbCucSixByPz, wherein M is one or more of Al, Cr, Mn, Ti and V; and 68<=a<=90, 0<=b<=6, 0<=c<=2, 3<=x<=20, 4<=y<=20, 0<=z<=10, and a+b+c+x+y+z=100. Compared with the prior art, the product has the advantages of high saturation magnetization and the like.

Owner:SHANGHAI HANTAO NANO TECH

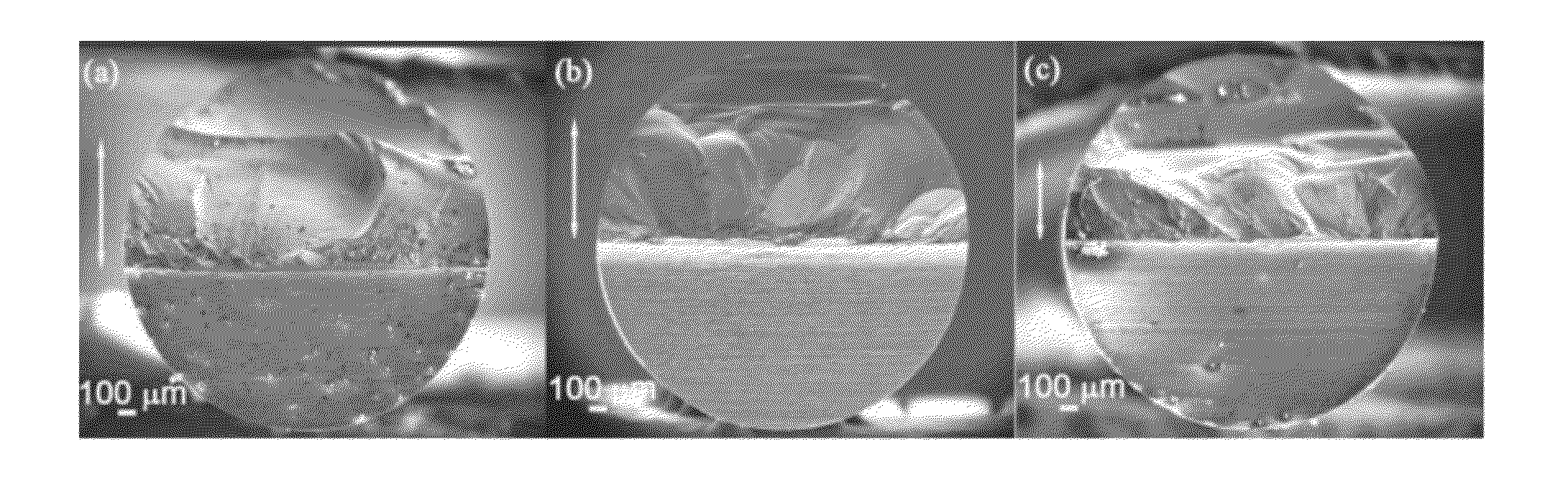

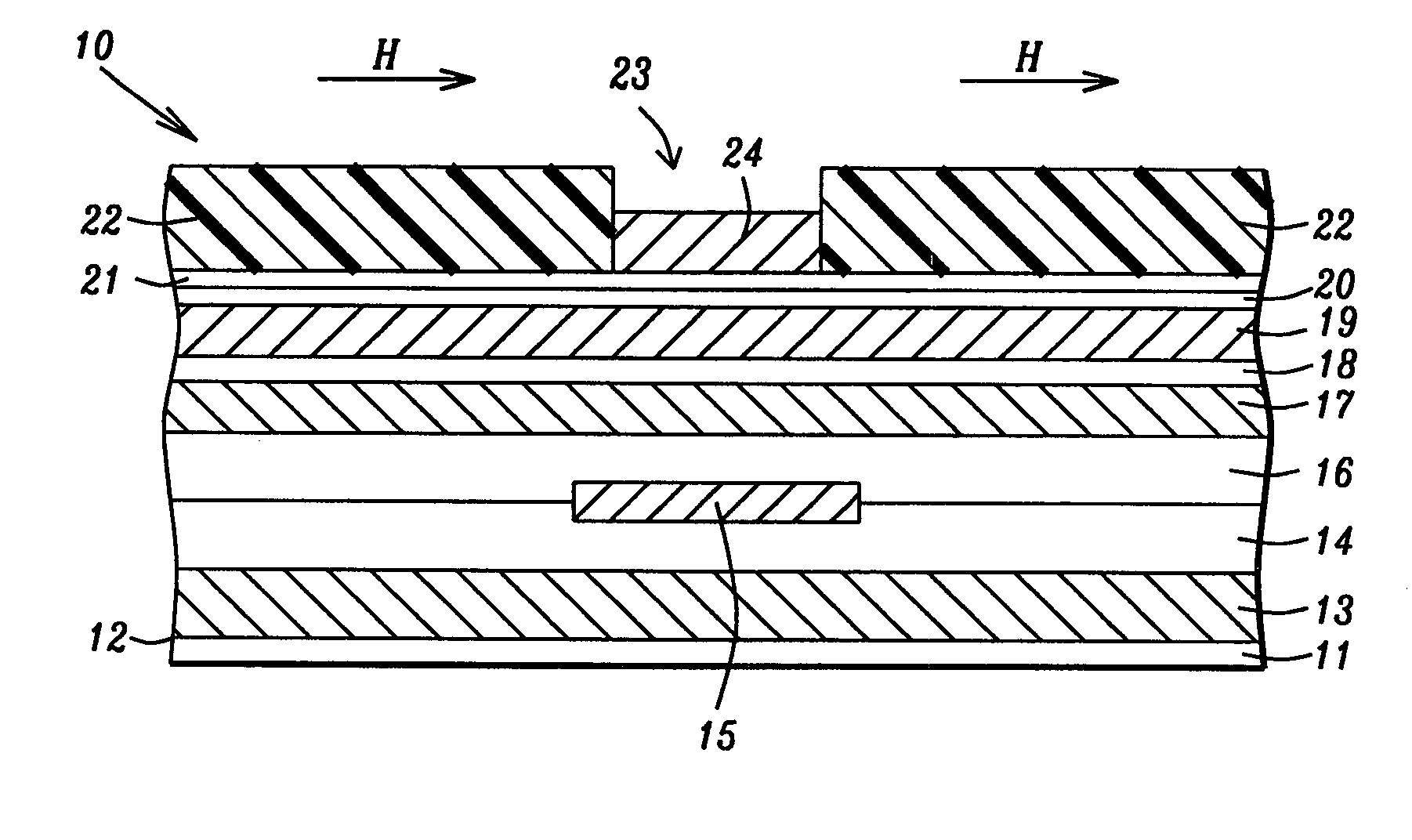

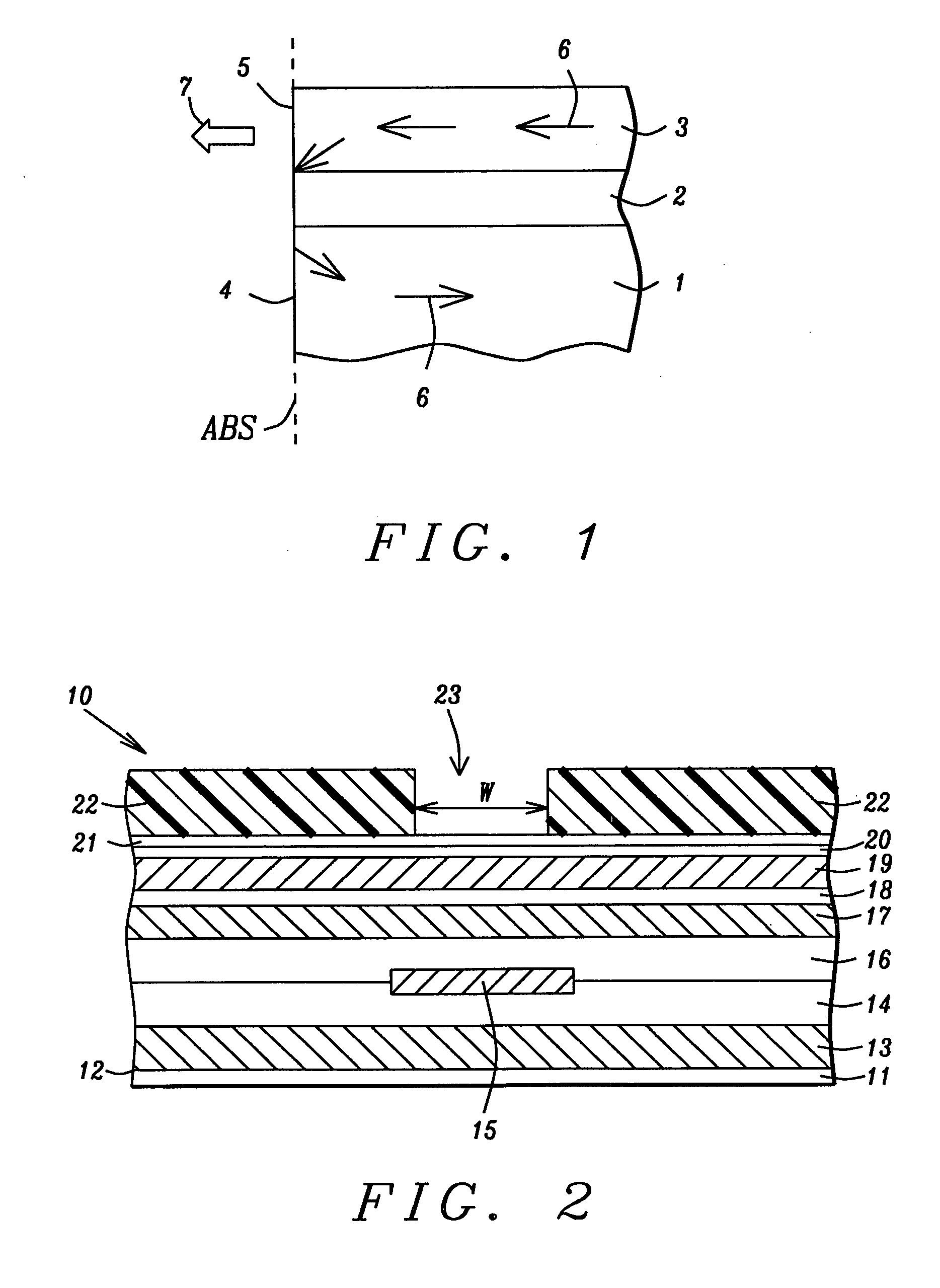

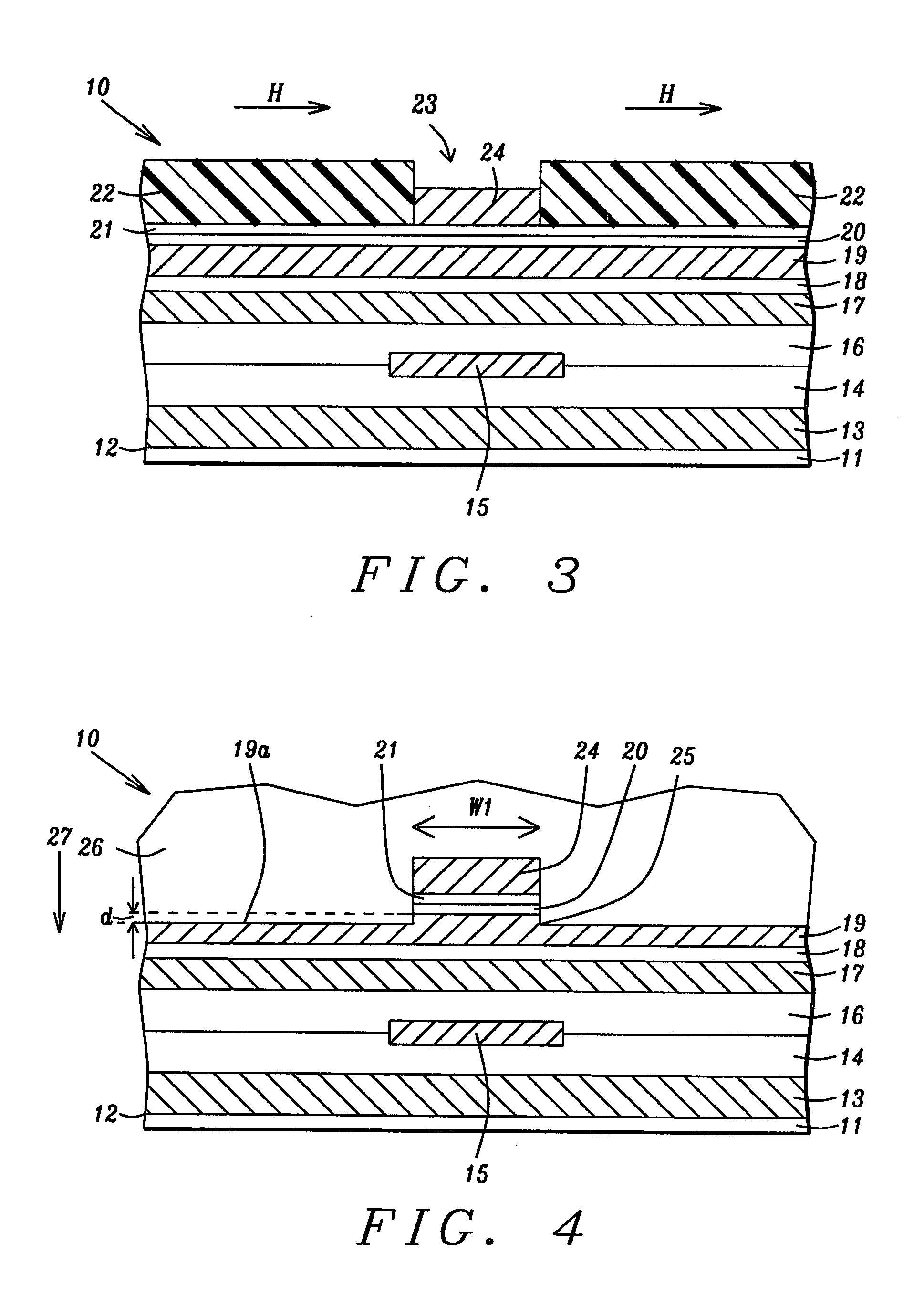

Double layer spacer for antiparallel pinned layer in CIP/CPP GMR and MTJ devices

InactiveUS6870711B1Contribute to of performanceContribute to stabilityElectrical transducersRecord information storageMagnetic stabilityMagnetization

A pinned / pinning layer configuration of the form: AP1 / coupling bilayer / AP2 / AFM, suitable for use in a CIP or CPP GMR sensor, a TMR sensor or an MRAM element, is found to have improved magnetic stability, yield good values of dR / R and have high values of saturation magnetization that can be adjusted to meet the requirements of magnetic field annealing. The coupling bilayer is a layer of Ru / Rh or their alloys, which provides a wide range of coupling strengths by varying either the thickness of the Ru layer or the Rh layer.

Owner:HEADWAY TECH INC

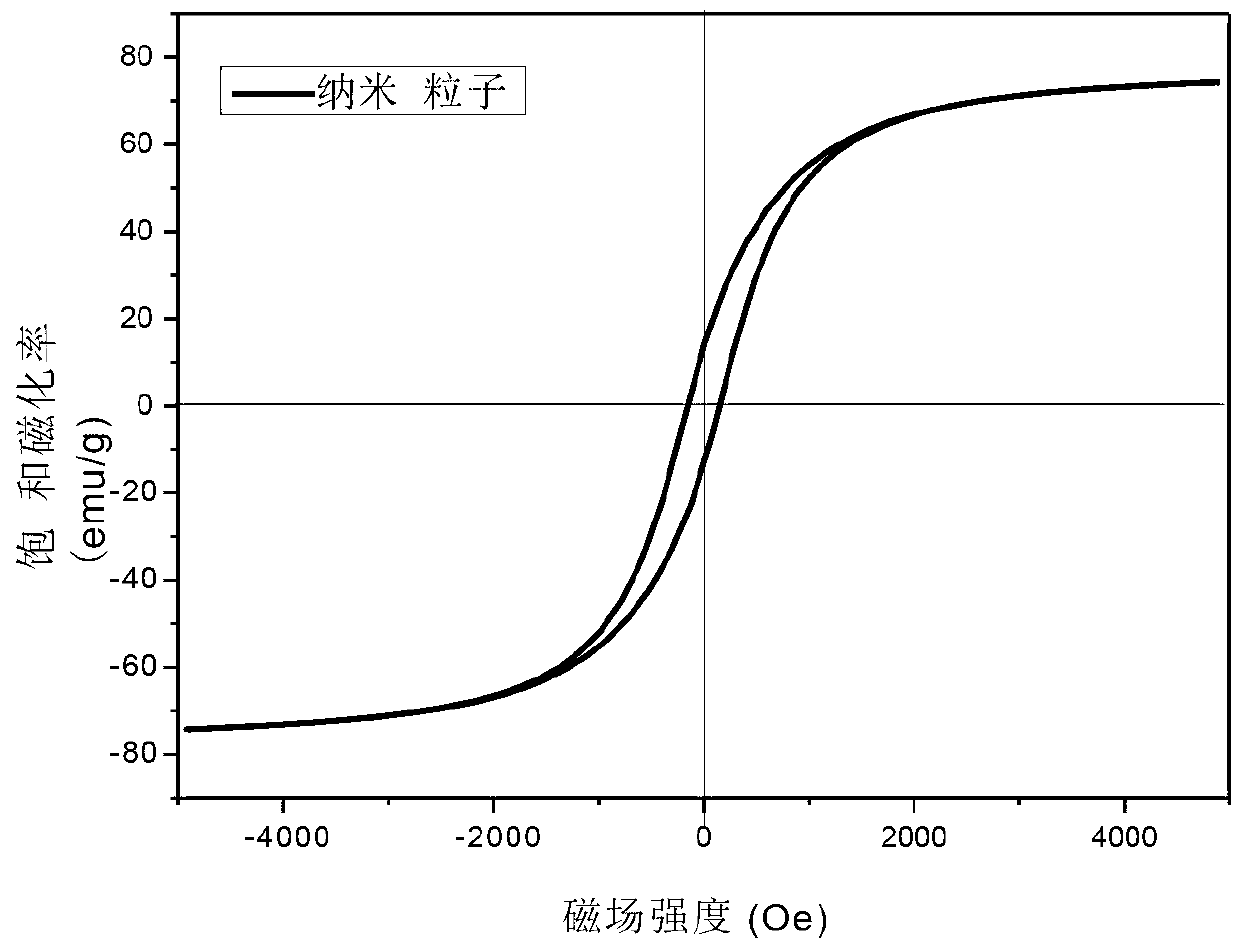

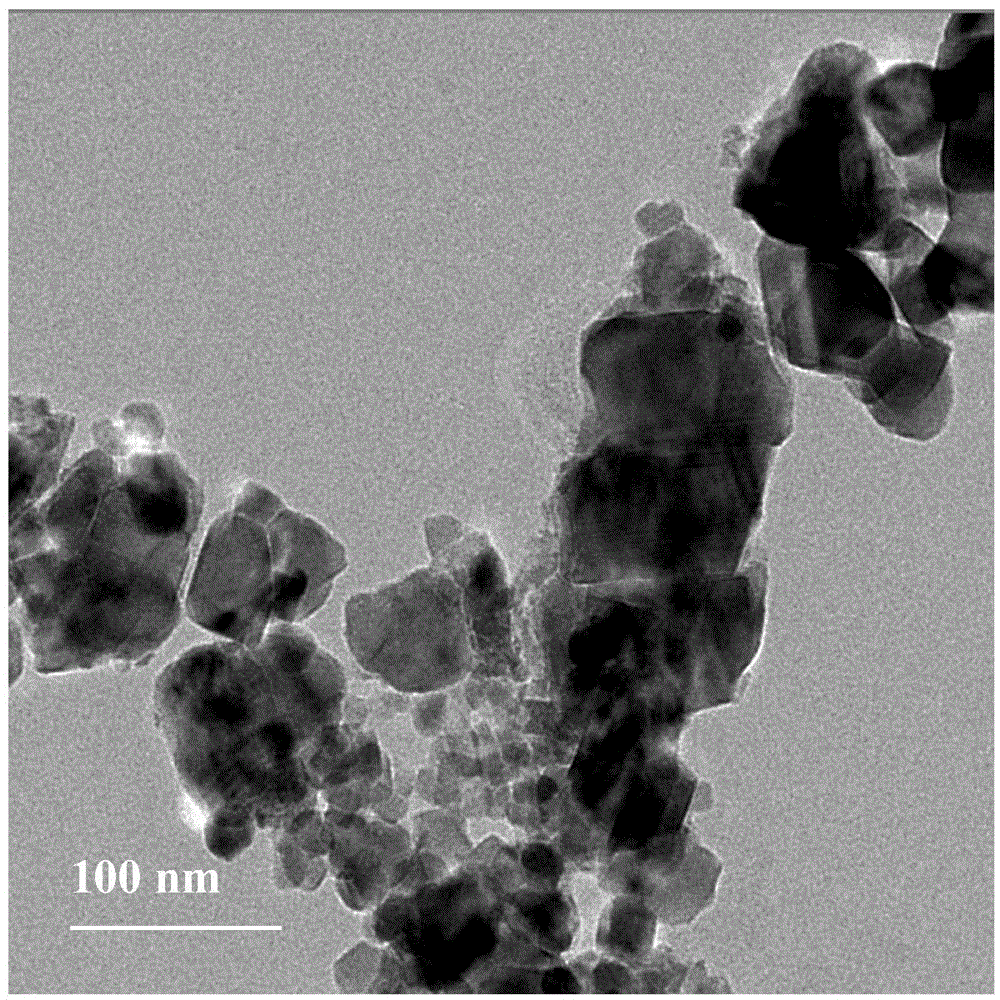

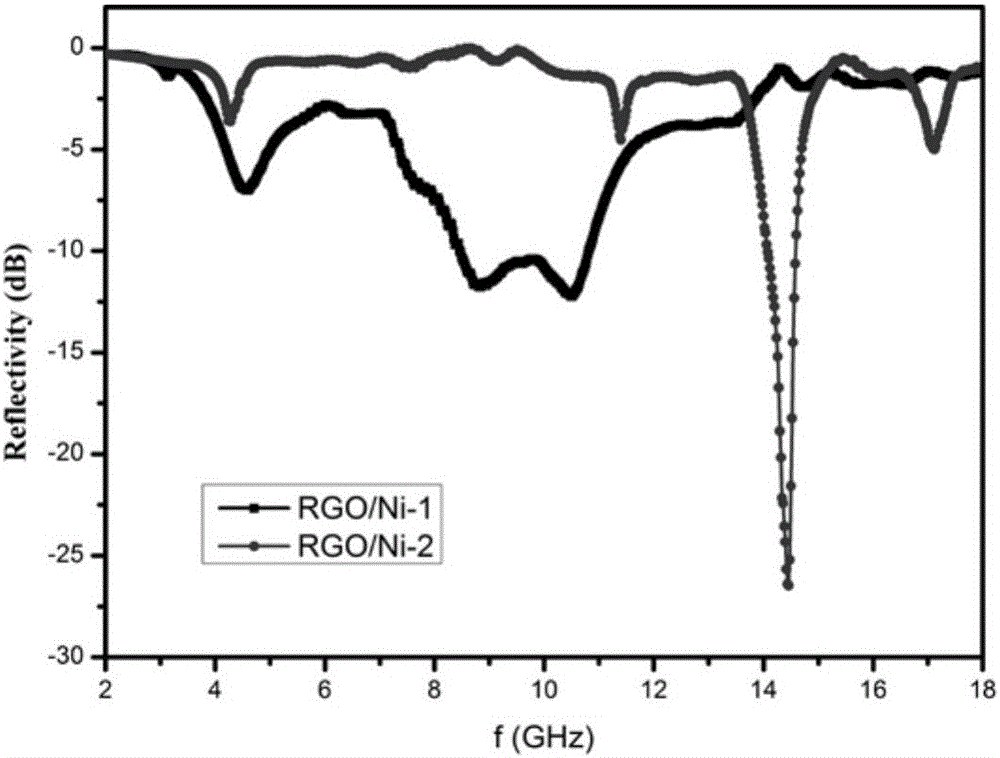

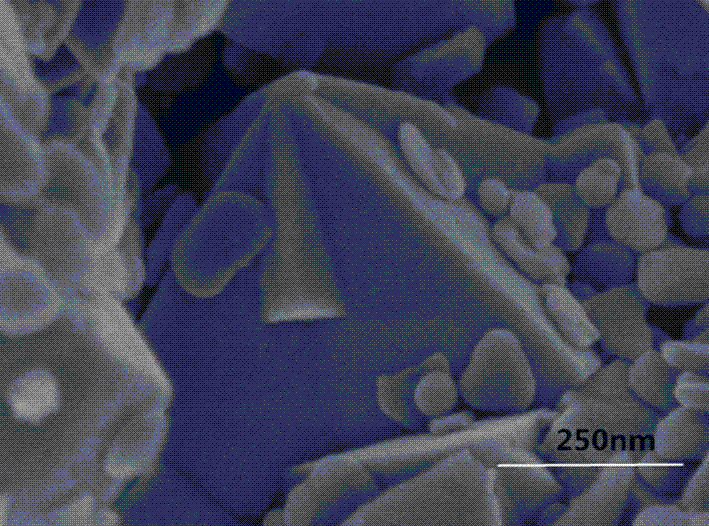

Nano Fe3O4/graphene composite material with high saturation magnetization and electromagnetic shielding function as well as preparation method of composite material

ActiveCN105802579AUniform particle size distributionDimensionally stableMaterial nanotechnologyOther chemical processesElectromagnetic shieldingGreen chemistry

The invention discloses a nano Fe3O4 / graphene composite material with high saturation magnetization and an electromagnetic shielding function as well as a preparation method of the composite material. According to the method, Fe3<+> and Fe2<+> salts are used as iron sources, in combination with urea, reduced graphene oxide and water, the composite material is prepared with a hydrothermal method. The prepared nano Fe3O4 / graphene composite material is evenly distributed nanoparticles of 40-50 nm, the crystal form is complete, the specific saturation magnetization is 75 emu / g or above, and the electromagnetic shielding effectiveness of the composite material can reach 26 dB or above within 2-18 GHz when the filling amount is 50%. The preparation technology is simple, raw materials are wide in source, water is taken as a medium, and the production requirement of green chemistry is met. The composite material is a multifunctional nanomaterial and has broad application prospect in fields of biomedical materials, electromagnetic shielding materials, electrode materials, catalytic materials, sewage treatment and the like.

Owner:SOUTH CHINA NORMAL UNIVERSITY

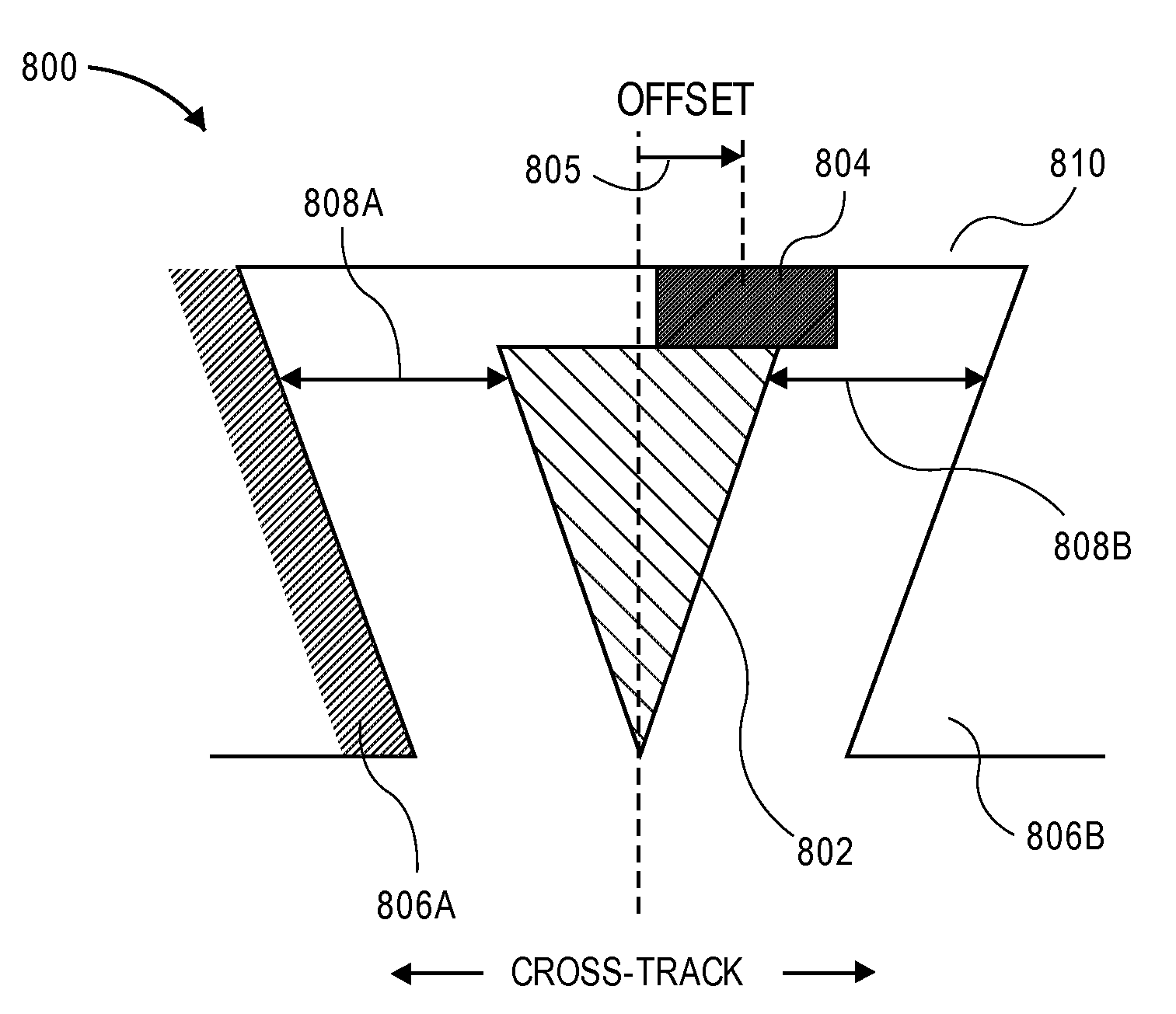

Microwave-assisted magnetic recording head with high saturation magnetization material side shield

ActiveUS9099102B2High gradientHigh magnetizationDisposition/mounting of recording headsRecord information storageHard disc driveShingled magnetic recording

Approaches to improving the signal-to-noise ratio in a microwave-assisted magnetic recording hard disk drive over the entire region from the inner diameter to the outer diameter of the disk, especially in the context of shingled magnetic recording, include a narrower side gap on the side opposing a spin torque oscillator offset direction than the side gap in the offset direction, thereby increasing the gradient of the recording magnetic field in the cross-track direction and reducing the track edge noise of the recording pattern. Embodiments include use of a side shield on the side opposing the offset direction that has a higher saturation magnetization than the side shield on the side in the offset direction, thereby further increasing the gradient of the recording magnetic field in the cross-track direction.

Owner:WESTERN DIGITAL TECH INC

Preparation method of FeCo alloy absorbing material

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Electrodeposition of FeCoNiV films with high resistivity and high saturation magnetization

ActiveUS20050271904A1Easy to implementLiquid applicationVacuum evaporation coatingMagnetizationHigh resistivity

A magnetic layer that may serve as a top pole layer and bottom pole layer in a magnetic write head is disclosed. The magnetic layer has a composition represented by FewCoxNiyVz in which w, x, y, and z are the atomic % of Fe, Co, Ni, and V, respectively, and where w is between about 60 and 85, x is between about 10 and 30, y is between 0 and about 20, z is between about 0.1 and 3, and wherein w+x+y+z=100. An electroplating process having a plating current density of 3 to 30 mA / cm2 is used to deposit the magnetic layer and involves an electrolyte solution with a small amount of VOSO4 which is the V source. The resulting magnetic layer has a magnetic saturation flux density Bs greater than 1.9 Telsa and a resistivity ρ higher than 70 μohms-cm.

Owner:HEADWAY TECH INC

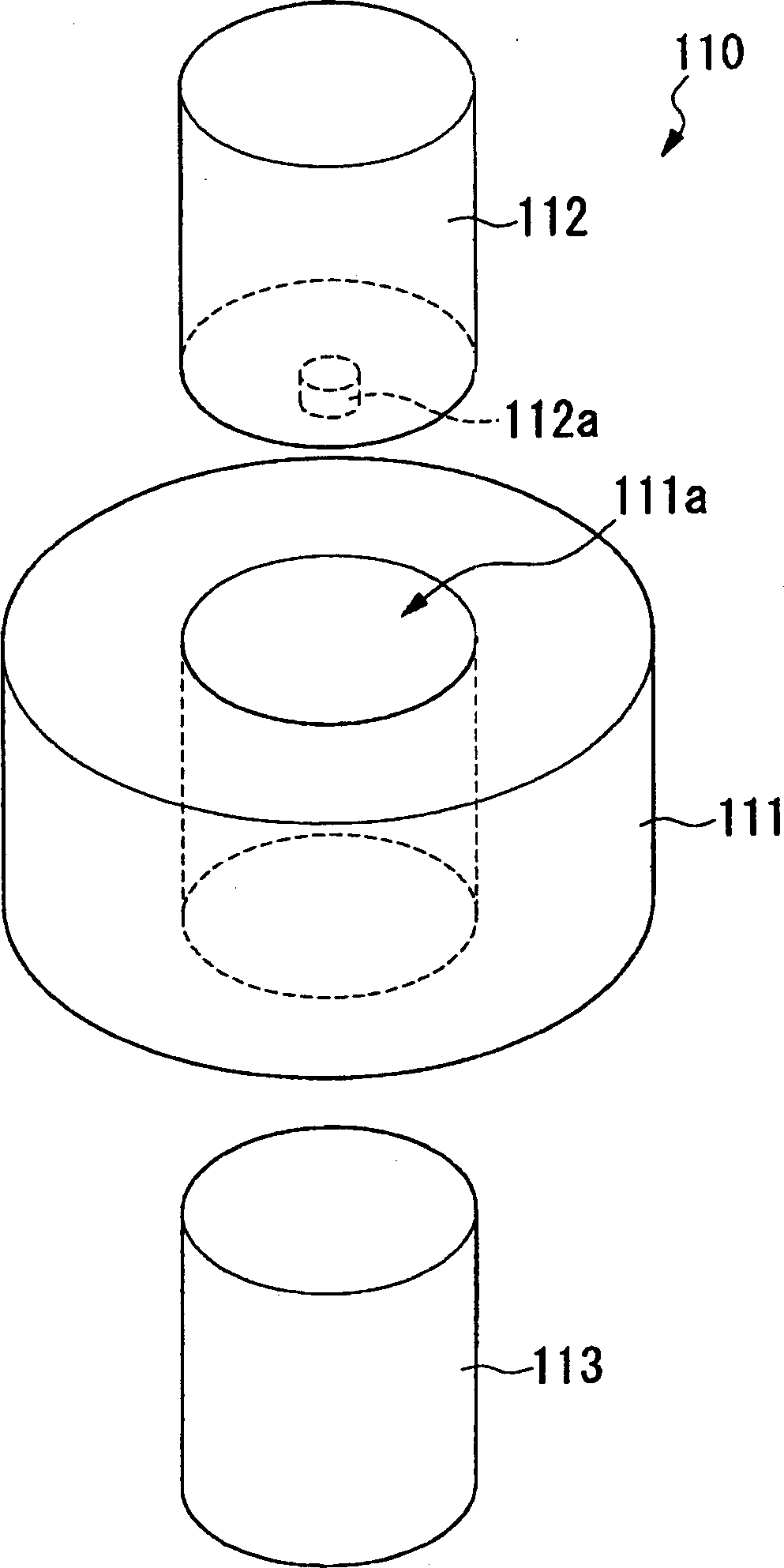

Inhomogeneous nucleation insulation coating processing method of metal soft magnetic composite material

ActiveCN104028747APrecise thickness controlPrecise control of its chemical compositionInorganic material magnetismInsulation layerSpray coating

The invention discloses an inhomogeneous nucleation insulation coating processing method of a metal soft magnetic composite material. The method includes the following steps that (1) particle size distribution is conducted on metal magnetic powder after sieving is conducted; (2) insulation coating is conducted on the distributed metal powder through an inhomogeneous nucleation method, and then the metal powder is dried; (3) the dried magnetic powder and a binding agent are evenly fixed, a release agent is added to conduct dry pressing and forming, and the mixture is pressed to form blank samples; (4) heat preservation is conducted on the blank samples for half an hour to two hours in a protective atmosphere, and air cooling and spray coating are conducted to obtain the target product. The composite powder prepared through the inhomogeneous nucleation method is even and compact in coating and controllable in coating layer thickness, and has high oxidation resistance, high resistivity, high saturation magnetization intensity, the good magnetic property and the good mechanical property; the surface of the metal magnetic powder is evenly coated with an A12O3 insulation layer through the inhomogeneous nucleation method, so that the coating effect is superior to that of an existing method, the operability is high and volume production is facilitated.

Owner:ZHEJIANG UNIV

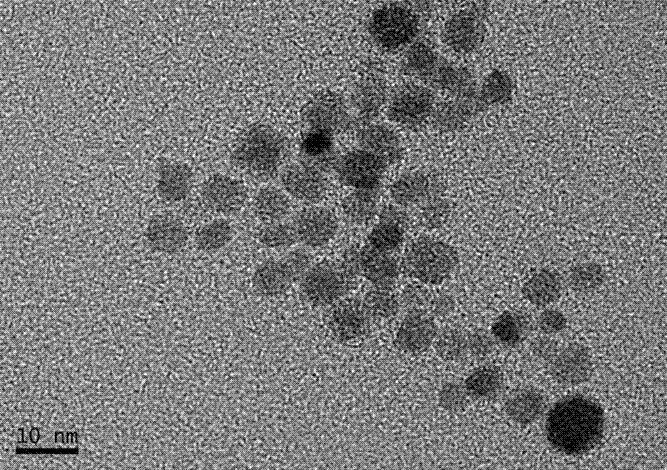

Method for preparing monodisperse Fe3O4 magnetic nanoparticles

InactiveCN101538068AUnprotectedSmall sizeInorganic material magnetismFerroso-ferric oxidesMagnetic markerSuperparamagnetism

The invention provides a method for preparing monodisperse Fe3O4 magnetic nanoparticles. Precursor is Fe2O3 or iron oxide yellow which has the chemical formula of Fe2O3.H2O; stabilizing agent is oleic acid; high temperature organic solvent is 1-octadecylene (b. p. 318DEG C); precipitating agent is prepared by mixing any two of toluene, dimethyl benzene, ethanol, isopropanol and acetone according to the volume ratio of 1:4-2:3; the mol ratio between the precursor and the stabilizing agent is 1:4-1:9; the mol ratio between the precursor and the high temperature organic solvent is 1:10; inert gas protection is not needed, and the Fe3O4 magnetic nanoparticles which have small sizes, monodisperse, narrow distribution, high saturation magnetization intensity and superparamagnetism. The method can be widely applied to biomedicine fields such as magnetic resonance imaging, biological magnetic separation, magnetic target drug carrier, biological magnetic marker and the like, and the high technical fields such as magnetic sealing, aerospace lubrication, magnetic anti-counterfeiting ink material, etc.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

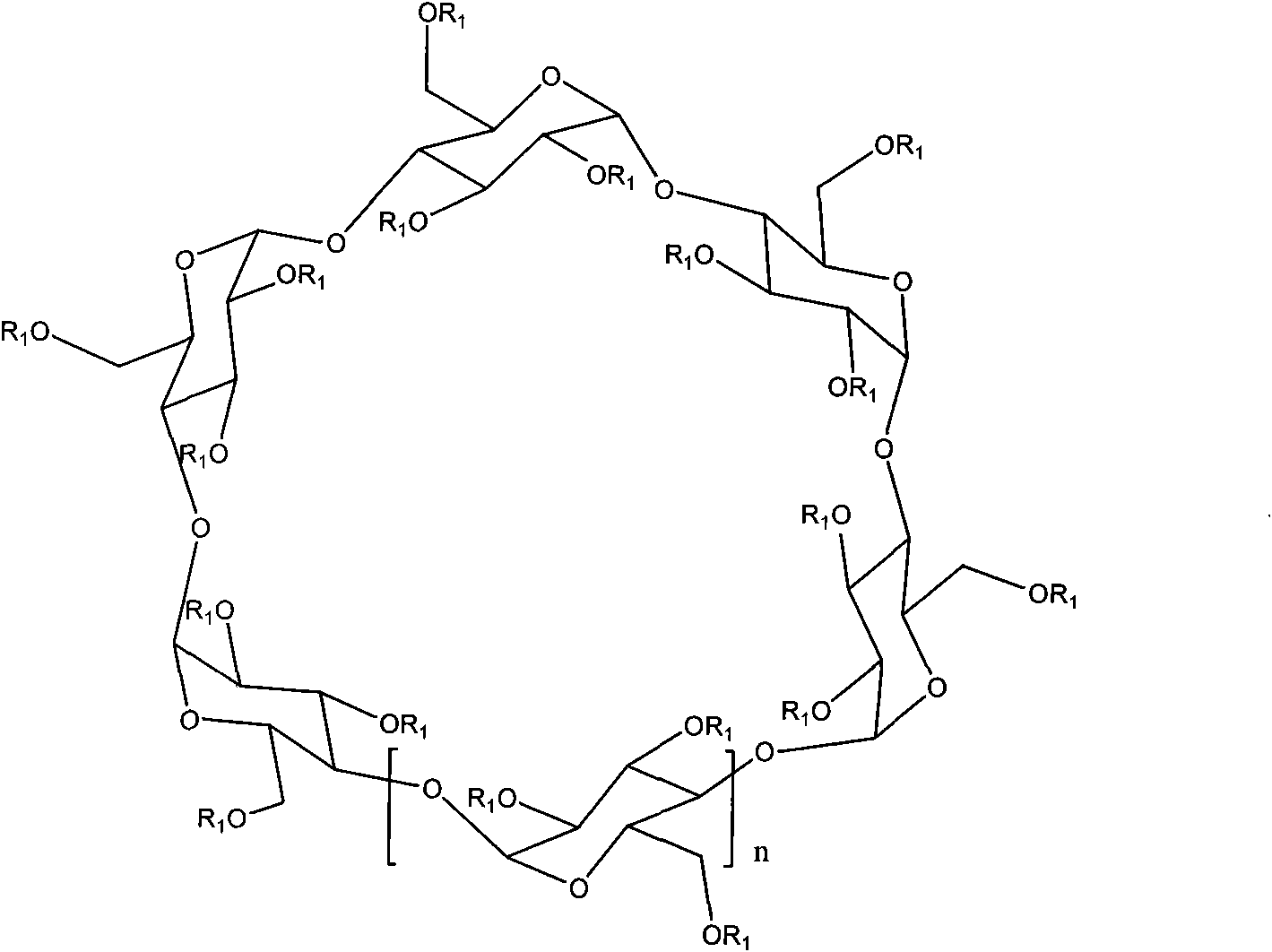

Preparation method of superparamagnetic cyclodextrin composite particles

ActiveCN101579316ASimple post-processingThe method is simplePowder deliveryInorganic non-active ingredientsMagnetite NanoparticlesCyclodextrin

The invention relates to a preparation method of superparamagnetic cyclodextrin composite particles. The preparation method comprises the following steps: firstly preparing a magnetic nanometer particle mixed system, and then, adding cyclodextrin powder; adding the cyclodextrin powder to the obtained magnetic nanometer particle mixed system containing a small amount of water and adjusting the pH value of the magnetic nanometer particle mixed system to be larger than 10 by an aqueous alkali; dispersing the cyclodextrin powder under ultrasound for 5-30 minutes so as to dissolve cyclodextrin; and obtaining the superparamagnetic cyclodextrin composite particles by compounding, increasing the temperature of the reaction system to 40-80 DEG C, fully stirring the reaction system and reacting for 3-20 hours before ending, and magnetically separating and centrifugating or dialyzing the system to be neutral so as to obtain the magnetic cyclodextrin composite particles. The invention aims to utilize active groups of the cyclodextrin and the magnetic nanometer particles and does not need adding a coupling reagent so as to be directly compounded into the magnetic composite particles which have high biological compatibility and saturation magnetization intensity and can slowly release a plurality of medicaments.

Owner:XIAN GOLDMAG NANOBIOTECH

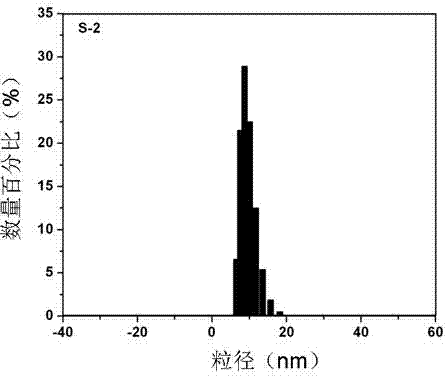

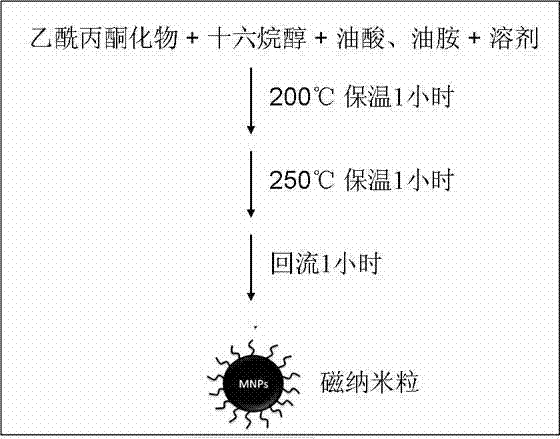

Mn element and Zn element-doped super-paramagnetic ferrite nanoparticles and preparation method thereof

ActiveCN102786299AControlling Saturation MagnetizationRegular shapeMaterial nanotechnologyHexadecaneActive agent

The invention discloses Mn element and Zn element-doped super-paramagnetic ferrite nanoparticles and a preparation method thereof. Manganese element is added or manganese element and zinc element are simultaneously added into a face-centered cubic crystal structure of ferriferrous oxide nanoparticles by using a method of decomposing metal precursor compound at a high temperature; the magnetic performance of the prepared super-paramagnetic nanoparticles is improved by changing the doping amount and the distribution of the metal element; and primarily, the saturation magnetization is improved. The preparation method specifically comprises the following steps of: mixing acetylacetones of Fe and Mn as well as Zn with 1,2-hexadecanol; performing high-temperature decomposition in high-boiling-point solvent by taking oleic acid and oleylamine as surfactants; or performing high-temperature decomposition on composite oleate of Fe, Mn and Zn by taking the oleic acid as the surfactant; heating and preserving heat in stages in argon or nitrogen protective atmosphere to guarantee growth of nanoparticle nuclear; and cooling to room temperature after reaction is finished and settling and centrifuging to finally obtain the super-paramagnetic ferrite nanoparticles which are uniformly dispersed in normal hexane solution.

Owner:SICHUAN UNIV

Microwave composite material and preparation method thereof

InactiveCN101847479AHigh resistivityHigh saturation magnetizationCopper organic compoundsOrganic/organic-metallic materials magnetismHigh resistivityCritical dimension

The invention provides a microwave composite material which is compounded from nano magnets made of ferromagnetic materials and organic materials, wherein the nano magnets are distributed in the organic materials, the size of the nano magnets made of the ferromagnetic materials is greater than the room-temperature superparamagnetic critical dimension of the ferromagnetic materials, and the resistivity of the organic material is greater than 1 ohm. cm. The invention also correspondingly provides multiple methods for preparing the microwave composite material. The microwave composite material has the characteristics of high resistivity and high saturated magnetic intensity, has good flexibility and certain elasticity, and is beneficial to the miniaturization and portability of devices. Besides, the preparation process of the microwave composite material can be compatible with the conventional semiconductor process, and realizes the integral monolithic integrated circuit.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com