High-saturated magnetization intensity Fe-based amorphous nanocrystalline soft magnetic alloy and its preparation method

A nanocrystalline soft magnetic and magnetization technology, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problem of low saturation magnetic induction, and achieve the effect of high saturation magnetization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

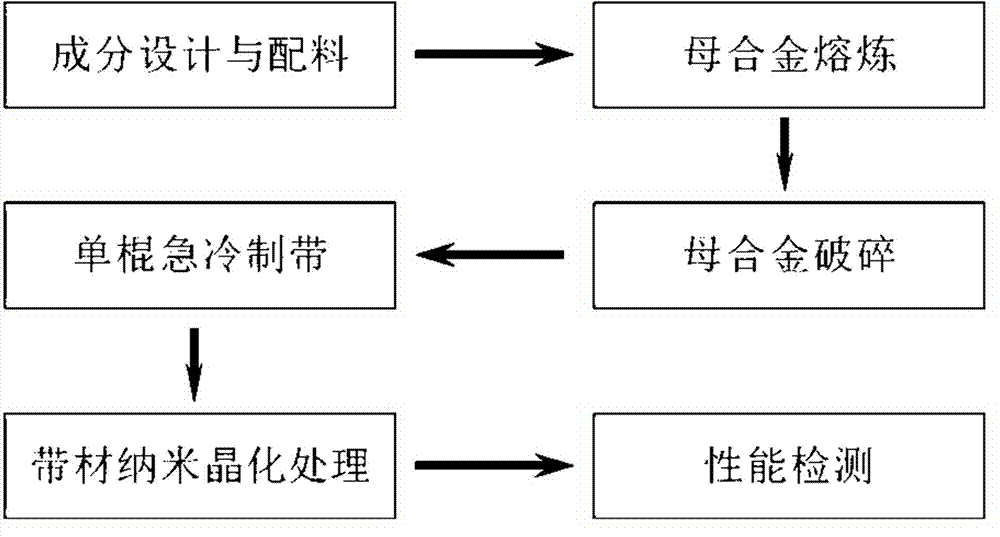

Method used

Image

Examples

Embodiment 1

[0029] 1) Composition design and ingredients:

[0030] Proportion raw materials according to the following molar percentages: 85% iron, 1% aluminum, 0.5% copper, 3.5% silicon, 6% boron, and 4% phosphorus, totaling 5kg;

[0031] 2) Master alloy melting:

[0032] Put the prepared raw materials into the crucible of the vacuum intermediate frequency induction furnace, and conduct intermediate frequency induction melting for 4 times, and stir during the melting process to mix the raw materials evenly, and pour them into alloy ingots to obtain alloy ingots with uniform composition;

[0033] 3) Master alloy broken:

[0034] After mechanically crushing the alloy ingot, put the broken block alloy into acetone solution and alcohol solution for ultrasonic cleaning, take it out and dry it naturally for use;

[0035] 4) Single-rod quenching belt:

[0036] Put the cleaned block alloy into the quartz tube of the quenching strip-making equipment, melt it by induction heating method, and u...

Embodiment 2

[0041] 1) Proportion raw materials according to the following molar percentages: 82% iron, 1% aluminum, 0.5% titanium, 0.5% copper, 0.5% silicon, 8% boron, and 4% phosphorus, totaling 5kg;

[0042] 2) Put the prepared raw materials into the crucible of the vacuum intermediate frequency induction furnace, conduct intermediate frequency induction melting 4 times, and stir during the melting process to mix the raw materials evenly, and pour them into alloy ingots to obtain alloy ingots with uniform composition;

[0043] 3) After mechanically crushing the alloy ingot, put the broken block alloy into acetone solution and alcohol solution for ultrasonic cleaning, take it out and dry it naturally for use;

[0044] 4) Put the cleaned bulk alloy into the quartz tube of the quenching strip-making equipment, melt it by induction heating, and use the single-roller quenching and stripping process to make strips in the air at a speed of 30m / s to obtain An amorphous alloy strip with a width ...

Embodiment 3

[0048] 1) Proportion raw materials according to the following molar percentages: 79% iron, 1.5% chromium, 1.5% manganese, 1.5% copper, 5% silicon, 7.5% boron, and 4% phosphorus, totaling 5kg;

[0049] 2) Put the prepared raw materials into the crucible of the vacuum intermediate frequency induction furnace, conduct intermediate frequency induction melting for 3 times, and stir during the melting process to mix the raw materials evenly, and pour them into alloy ingots to obtain alloy ingots with uniform composition;

[0050] 3) After mechanically crushing the alloy ingot, put the broken block alloy into acetone solution and alcohol solution for ultrasonic cleaning, take it out and dry it naturally for use;

[0051] 4) Put the cleaned bulk alloy into the quartz tube of the quenching strip-making equipment, melt it by induction heating, and use the single-roller quenching and stripping process to make strips in the air at a speed of 35m / s. A thin strip of amorphous alloy with a w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com