Soft magnetic alloy powder, magnetic powder core and preparation methods of soft magnetic alloy powder, magnetic powder core

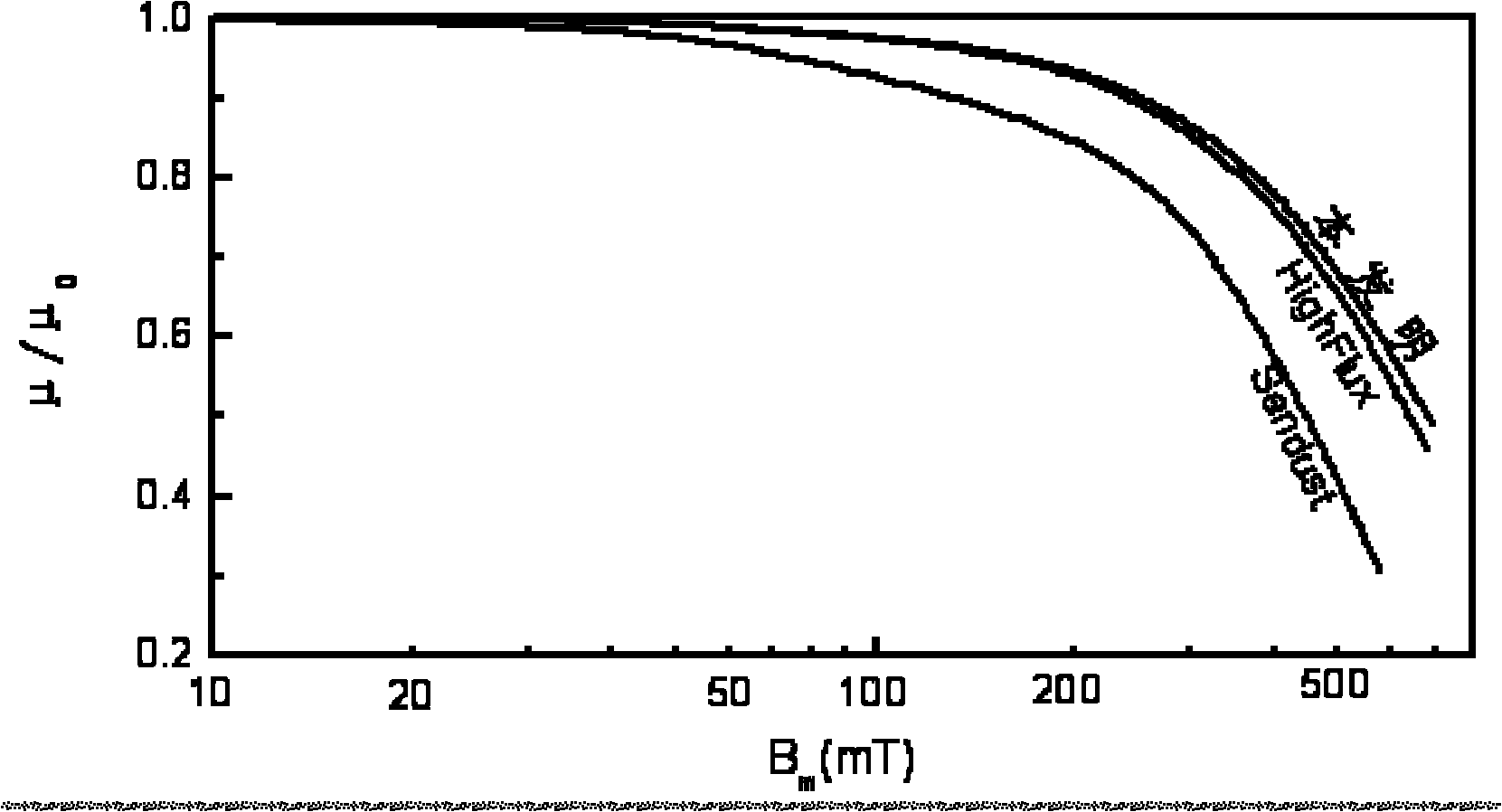

A soft magnetic alloy and powder preparation technology, which is applied in the direction of the magnetism of inorganic materials, can solve the problems of Ni content in HighFlux magnetic core, poor DC superposition characteristics, and unfavorable miniaturization of devices, so as to achieve good DC superposition characteristics and improve DC superposition characteristics, the effect of low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In one embodiment of the present invention, M is selected as Mn, wherein x, y and z can take the following values respectively: x=3.6, y=0.6, z=2, namely the expression of soft magnetic alloy powder is Fe 93.8 Si 3.6 C 0.6 mn 2 .

[0028] Adopt mass percentage as Fe 93.8 Si 3.6 C 0.6 mn 2 The alloy was subjected to water atomization test, and the prepared powder morphology was as follows figure 1 shown. The relevant performance parameters of the powder are listed in the following table:

[0029] Performance parameters

Fe 93.8 Si 3.6 C 0.6 mn 2

3200ppm

[0030] powder bulk density

3.2g / cm 3

powder tap density

4.6g / cm 3

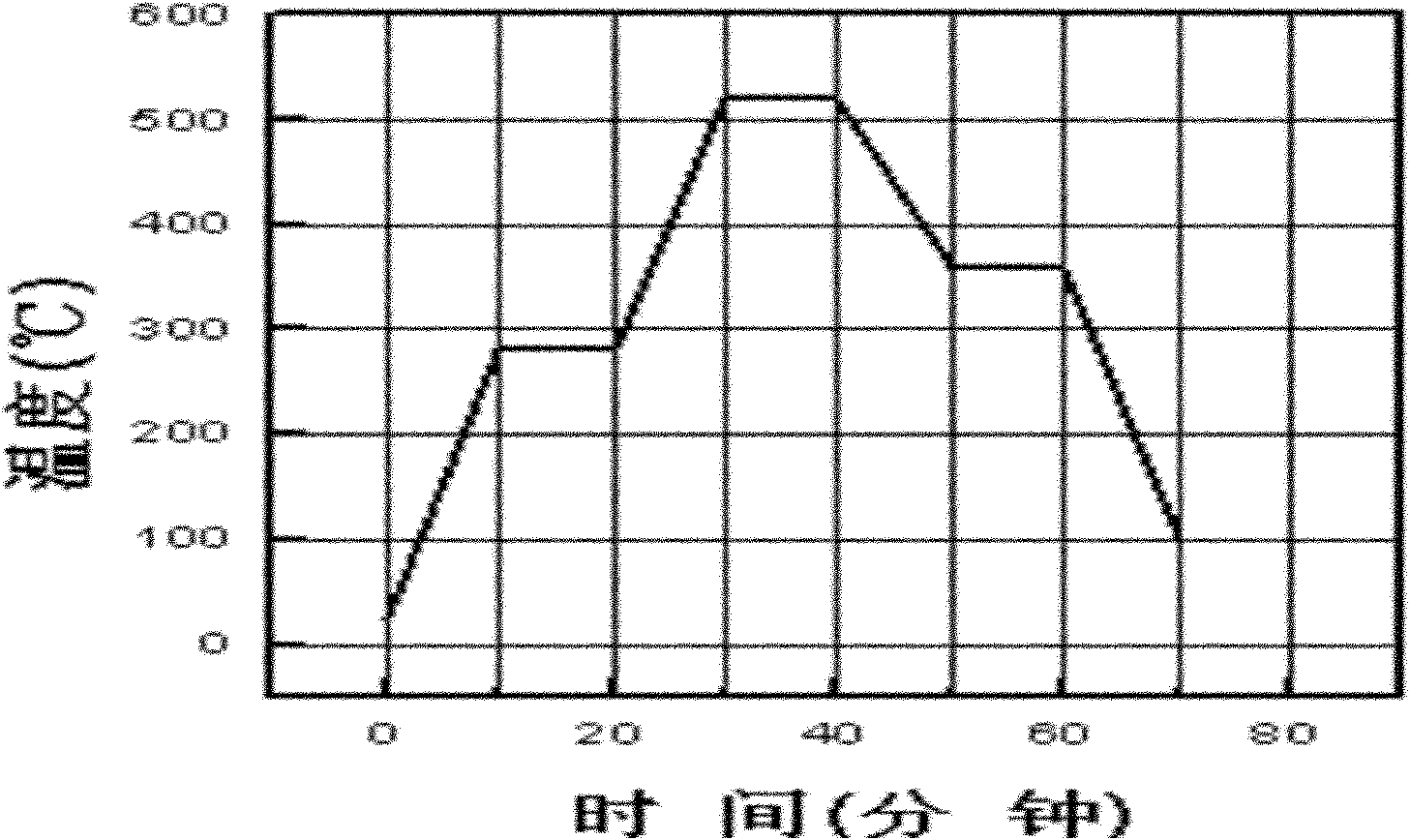

[0031] The powder is passivated with a strong oxidant, and then pressed into a magnetic core after insulation, bonding and lubrication. The magnetic core is isothermally annealed at 520 ° C for 10 minutes in a hydrogen atmosphere. The annealing t...

Embodiment 2

[0036] Adopt the Fe in the composition scope of the present invention 95 Si 2.5 C 1 mn 1.5 , Fe 92.5 Si 5 C 1 mn 1 V 0.5 , Fe 91.4 Si 7 C 0.6 mn 1.5 Alloys and Fe beyond the scope of the alloy composition of the present invention 86 Si 12 C 1 mn 1 Alloys (Si content is too high beyond the scope of the present invention 2<x<8) were subjected to water atomization tests to prepare powders, and the relevant performance parameters of the powders are listed in the following table.

[0037]

[0038] The above powder is passivated with a strong oxidant, and then pressed into a magnetic core after insulation, bonding and lubrication. The magnetic core is isothermally annealed at 520°C for 10 minutes in a hydrogen atmosphere. The annealing process is the same as in Example 1. The properties of the core after annealing are listed in the table below:

[0039]

[0040] It can be seen from the above table that when the Si content is within the scope of the present invent...

Embodiment 3

[0042] In FeSiCM (M is selected from Cr, V, Al and Mn) alloy system, choose M to be Cr, adopt the Fe in the composition scope of the present invention 92 Si 3 C 1 Cr 4 , Fe 92.5 Si 4 C 1.5 Cr 2 , Fe 90 Si 6.5 C 2.5 Cr 1 Alloys and Fe beyond the scope of the composition of the present invention 85 Si 6.5 C 2.5 Cr 6 Alloy (Cr content is too high beyond the scope of the present invention 1 < z < 5 to carry out water atomization test preparation powder, powder related performance parameters are listed in the following table:

[0043]

[0044] Passivate the above powder with a strong oxidant, and press it into a magnetic core after insulation, bonding and lubrication. The magnetic core is isothermally annealed at 520 ° C for 10 minutes under a hydrogen atmosphere. The annealing process is the same as in Example 1. After annealing The properties of the cores are listed in the table below:

[0045]

[0046] It can be seen from the above table that in the FeSiCM (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com