Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

161results about How to "Improve DC Superposition Characteristics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

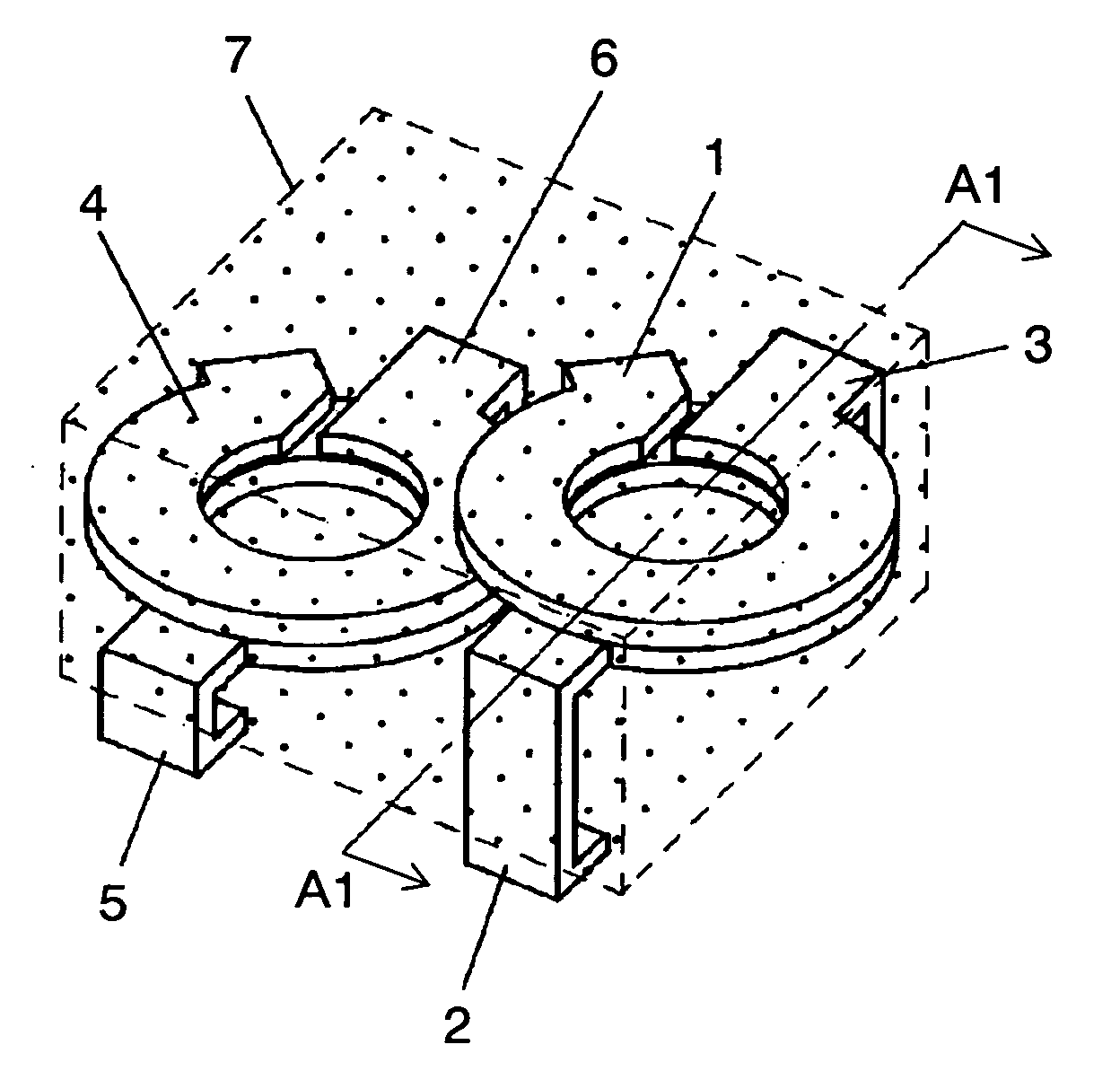

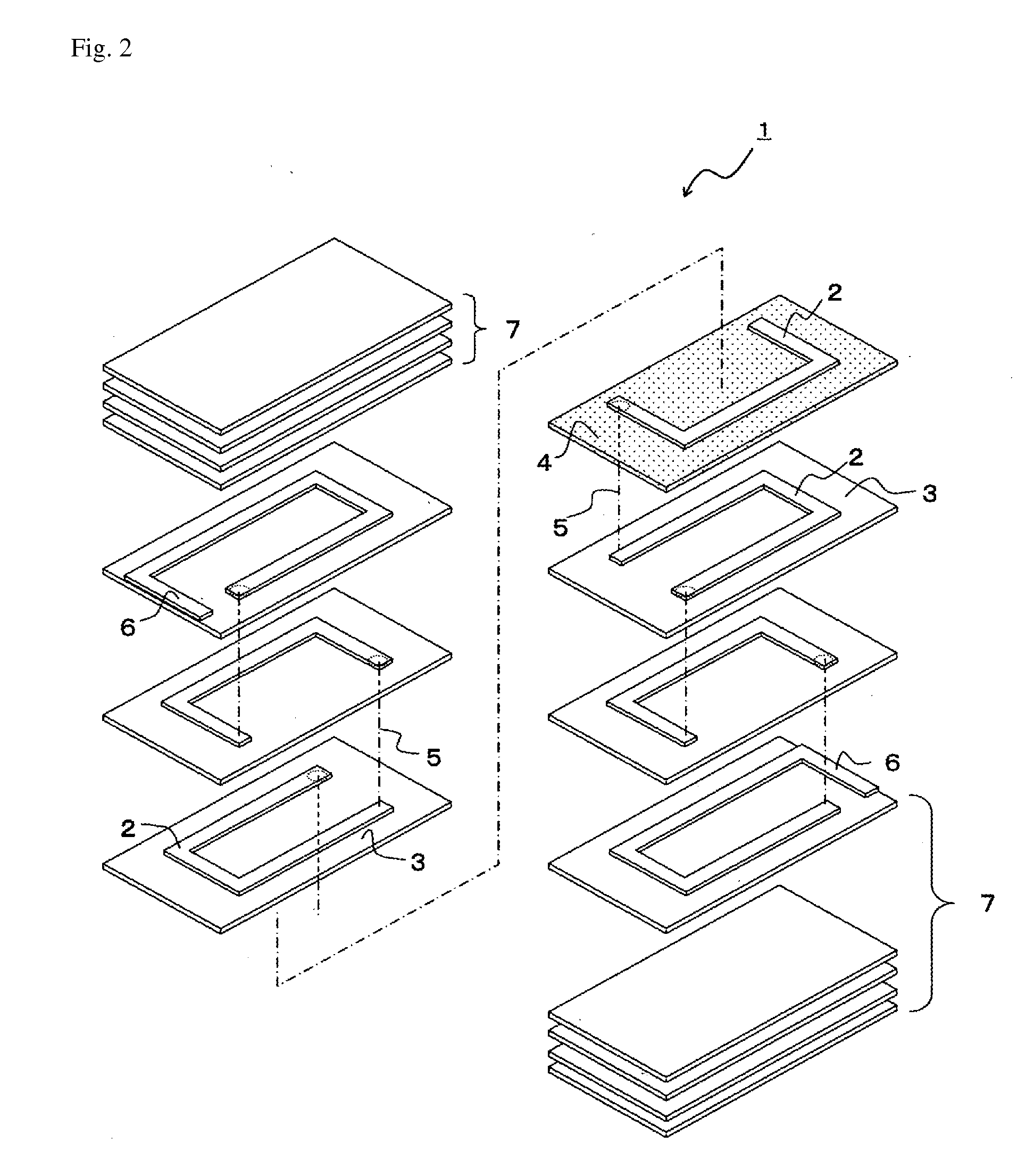

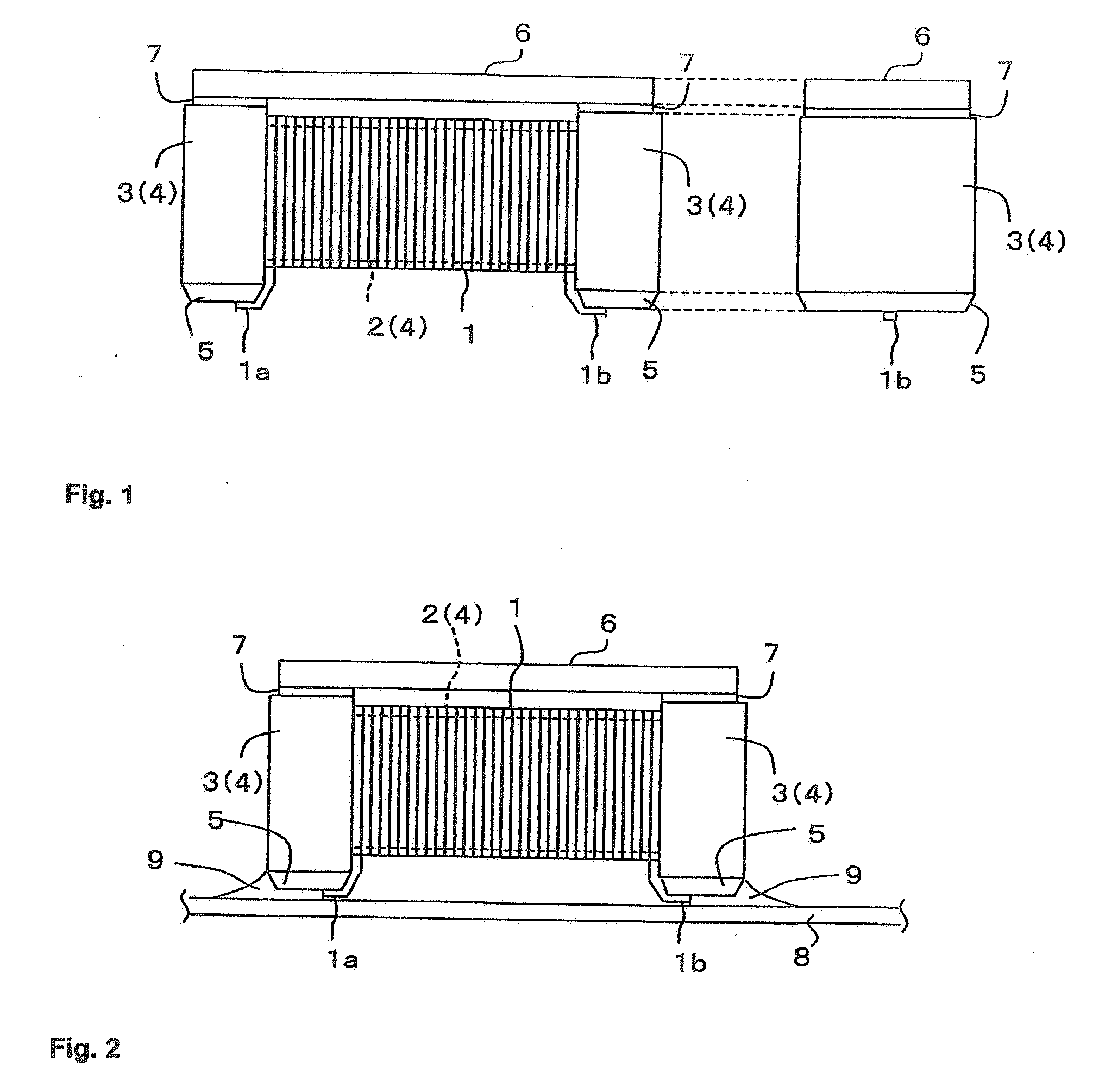

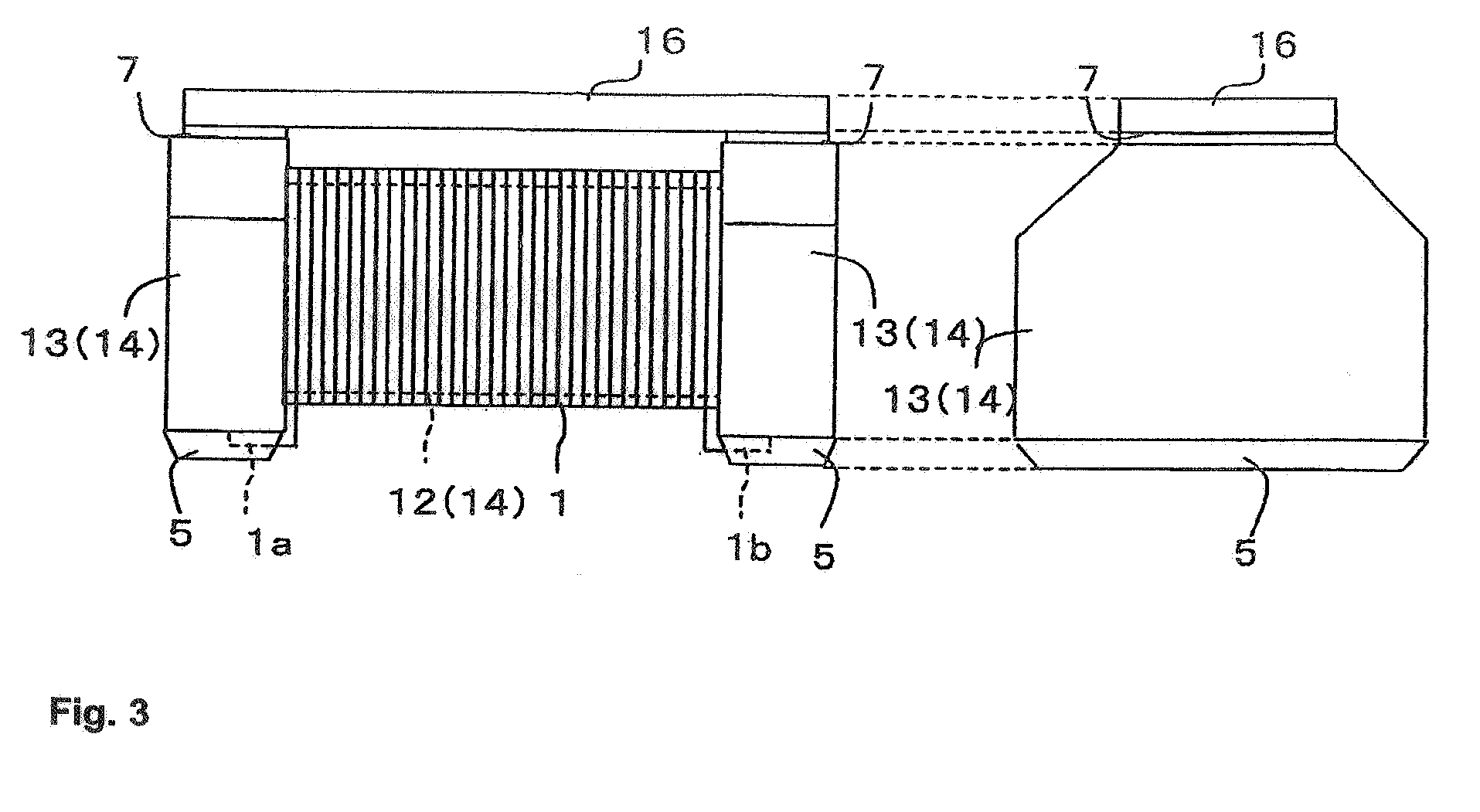

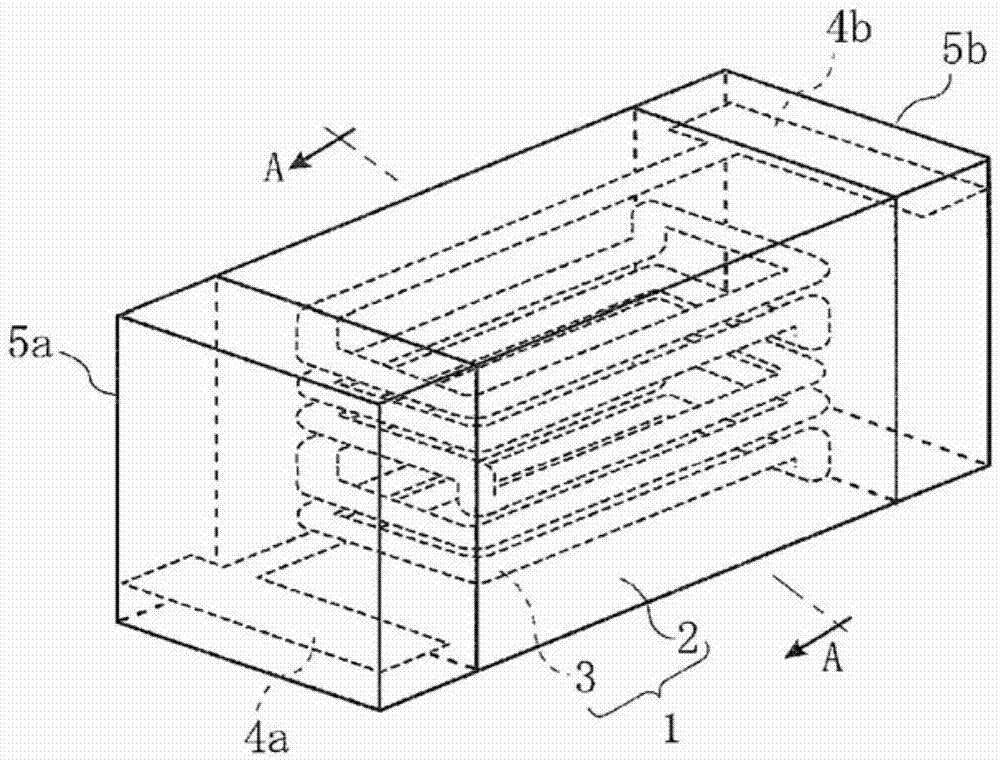

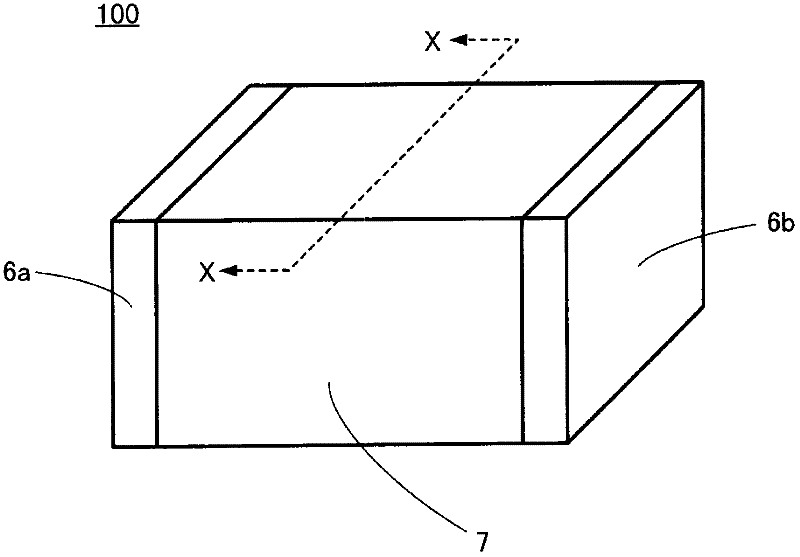

Multiple choke coil and electronic equipment using the same

InactiveUS20060145804A1Small sizeReduce thicknessTransformers/inductances casingsTransformers/inductances coils/windings/connectionsEngineeringMetal sheet

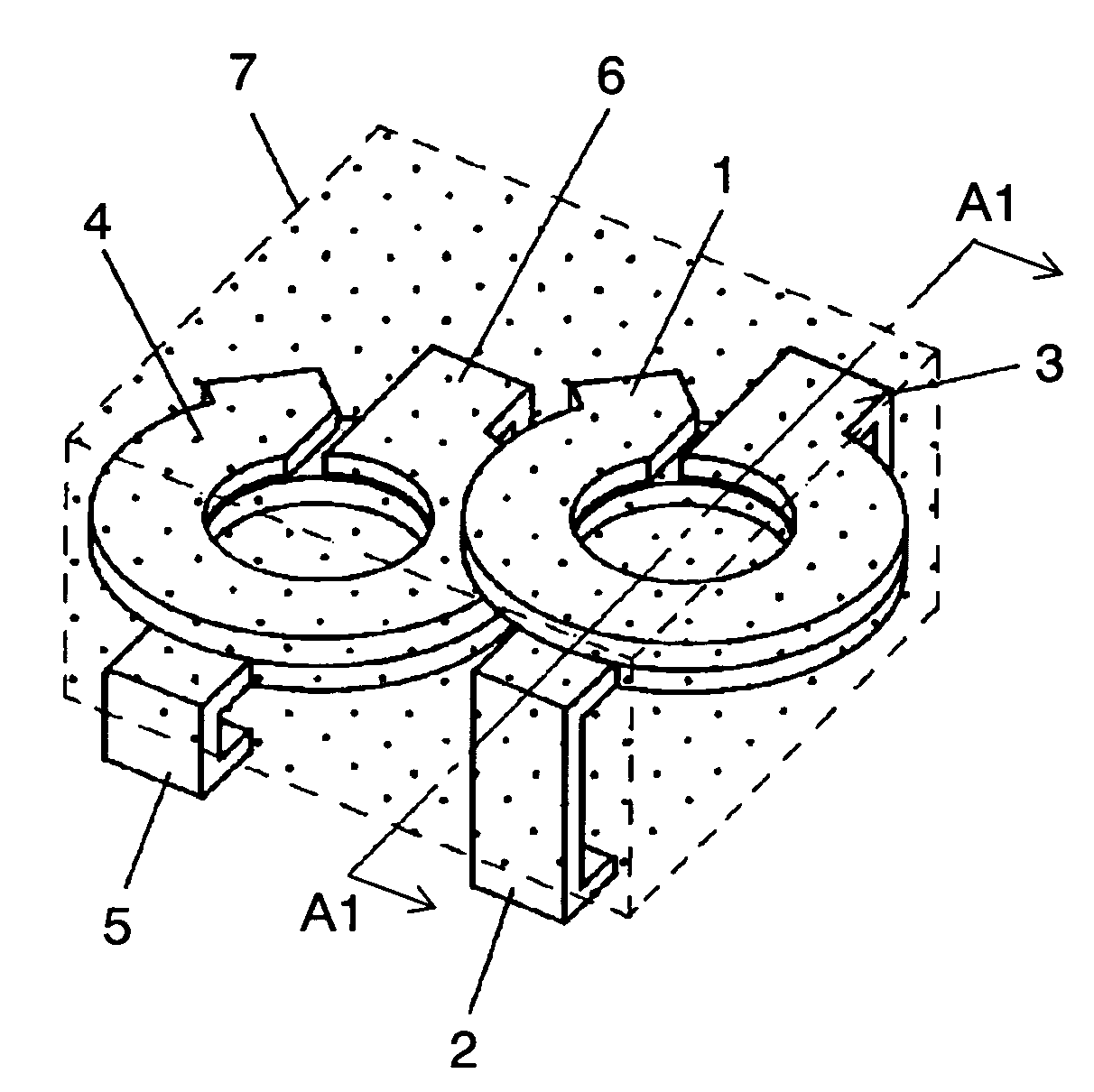

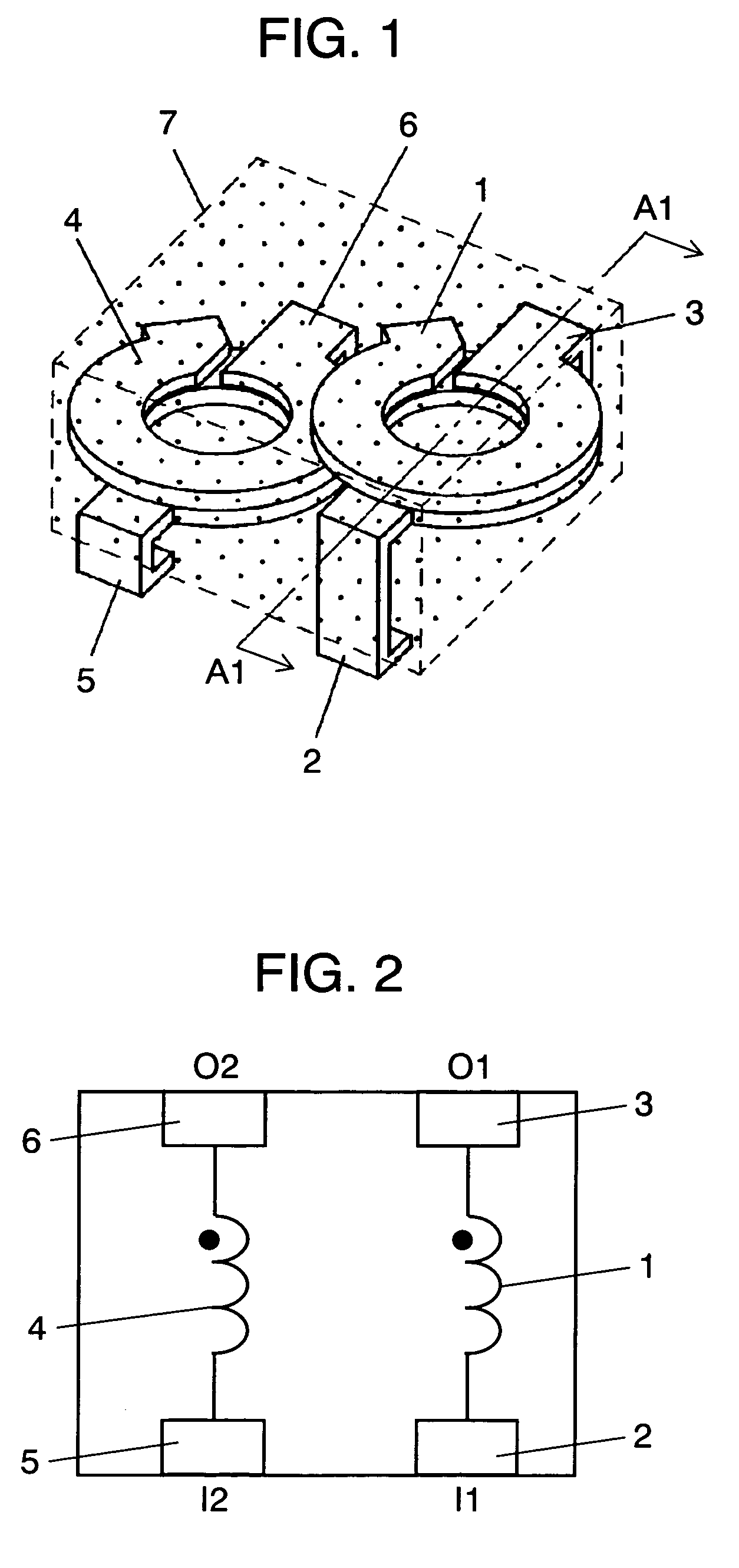

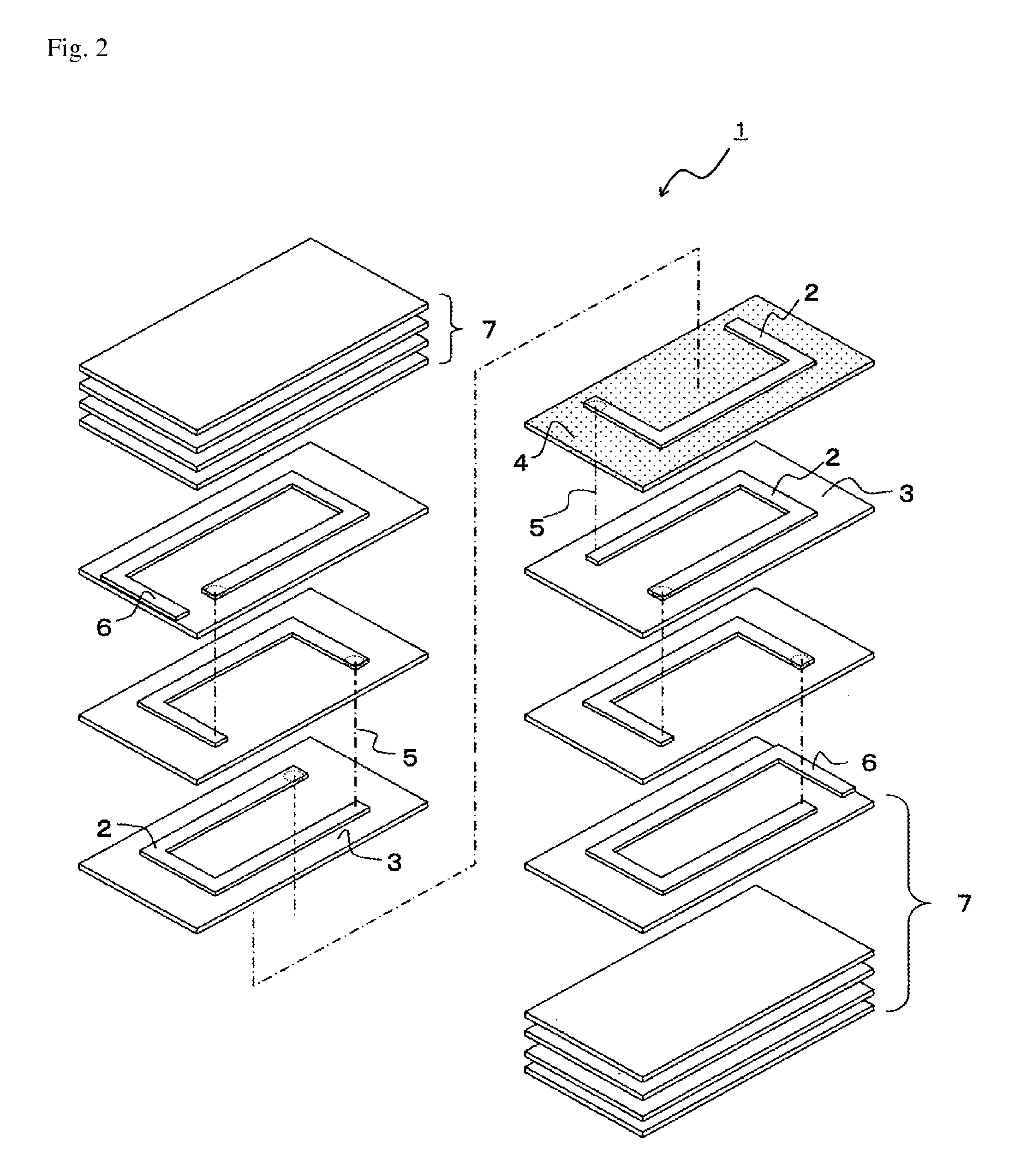

The invention is comprised of a coil group arranging a plurality of terminal-integrated type coils (1), (4) formed by bending a metal sheet in a preset development form and having a predetermined positional relationship, and a magnetic material (7) burying therein the coil group. For example, axes of the plurality of coils (1), (4) constituting the coil group, are arranged in parallel wherein the center point of at least one coil selected from the plurality of coils (1), (4) and the center point of a coil other than the selected coil are in an staggered arrangement. Due to this, an array type choke coil can be realized which is thin overall and operable with a large current in a high frequency band.

Owner:PANASONIC CORP

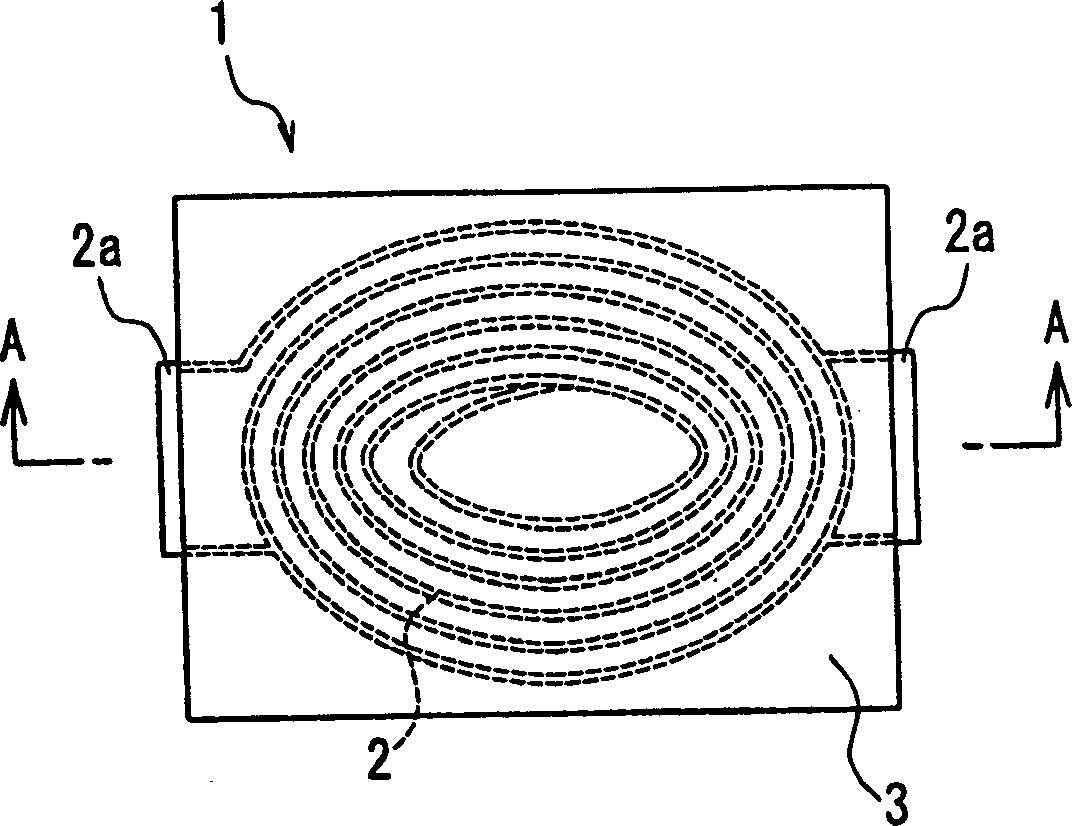

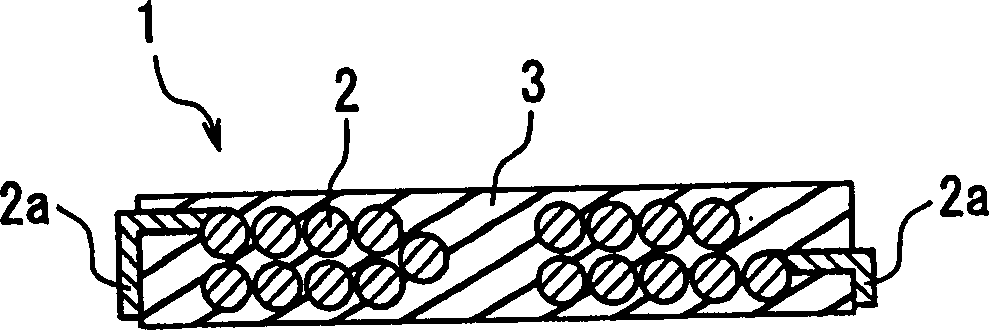

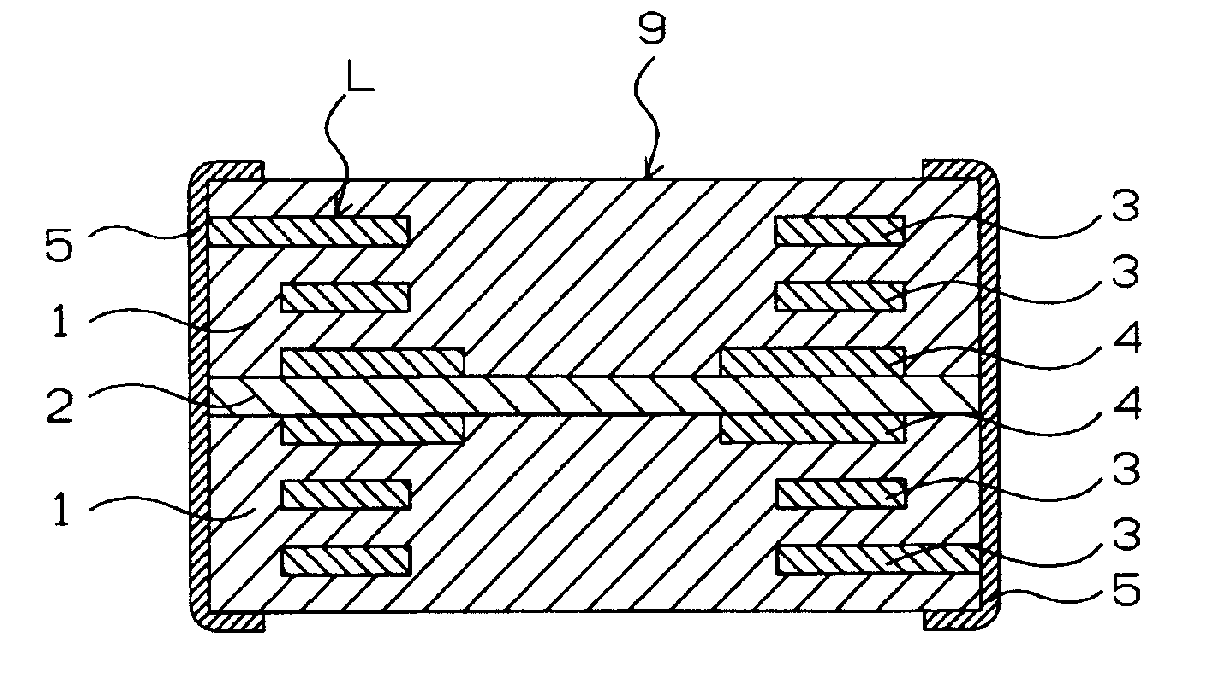

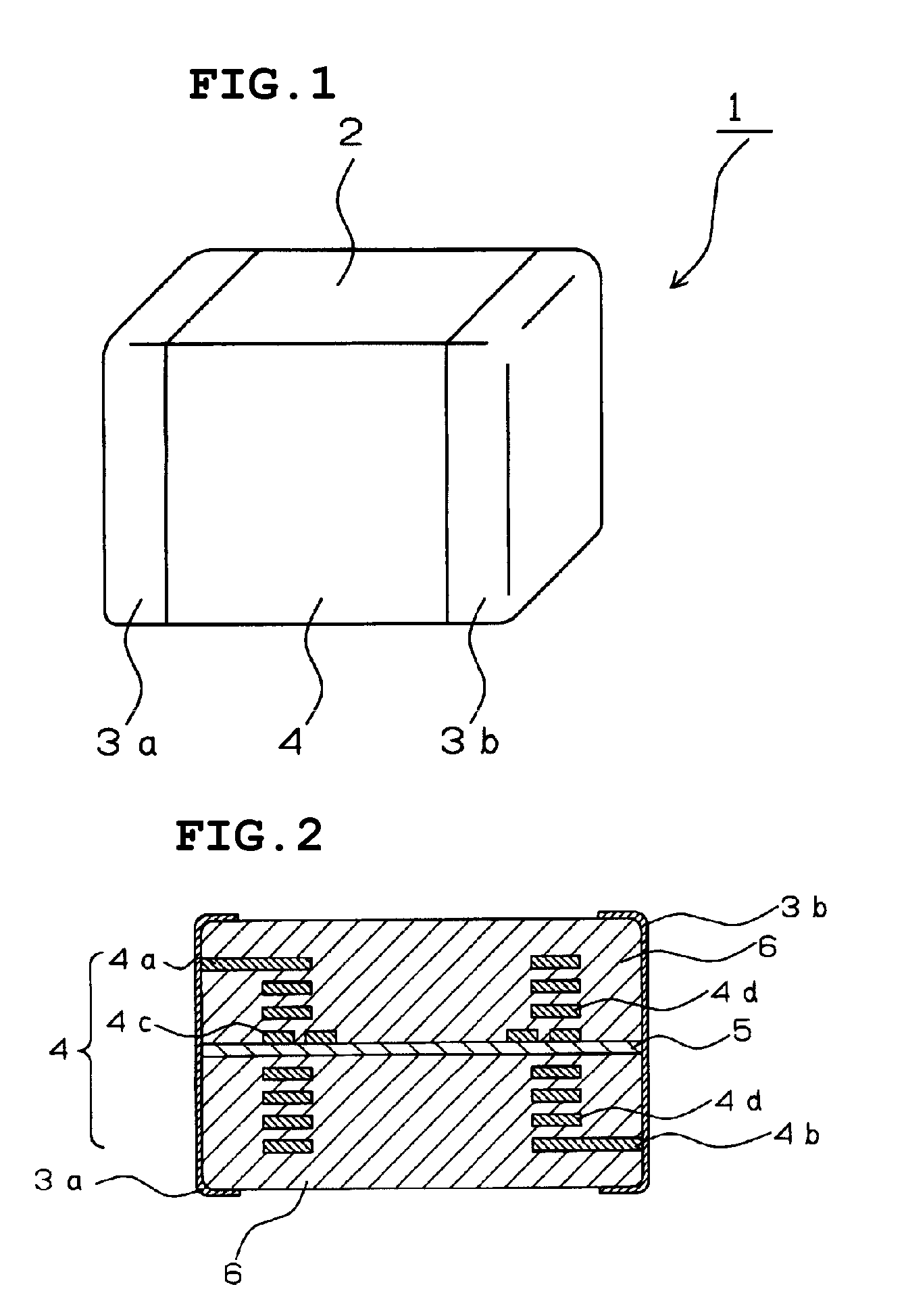

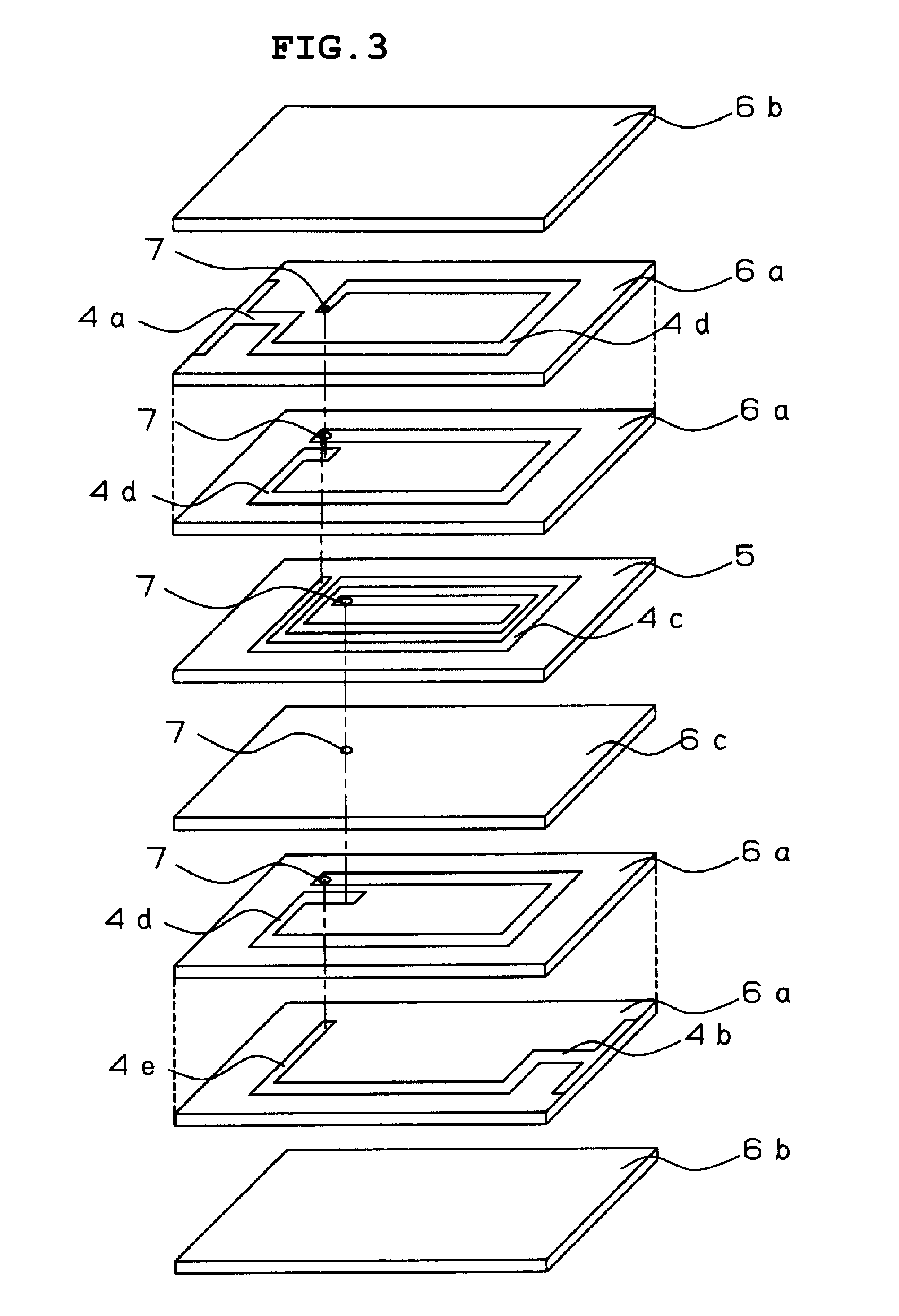

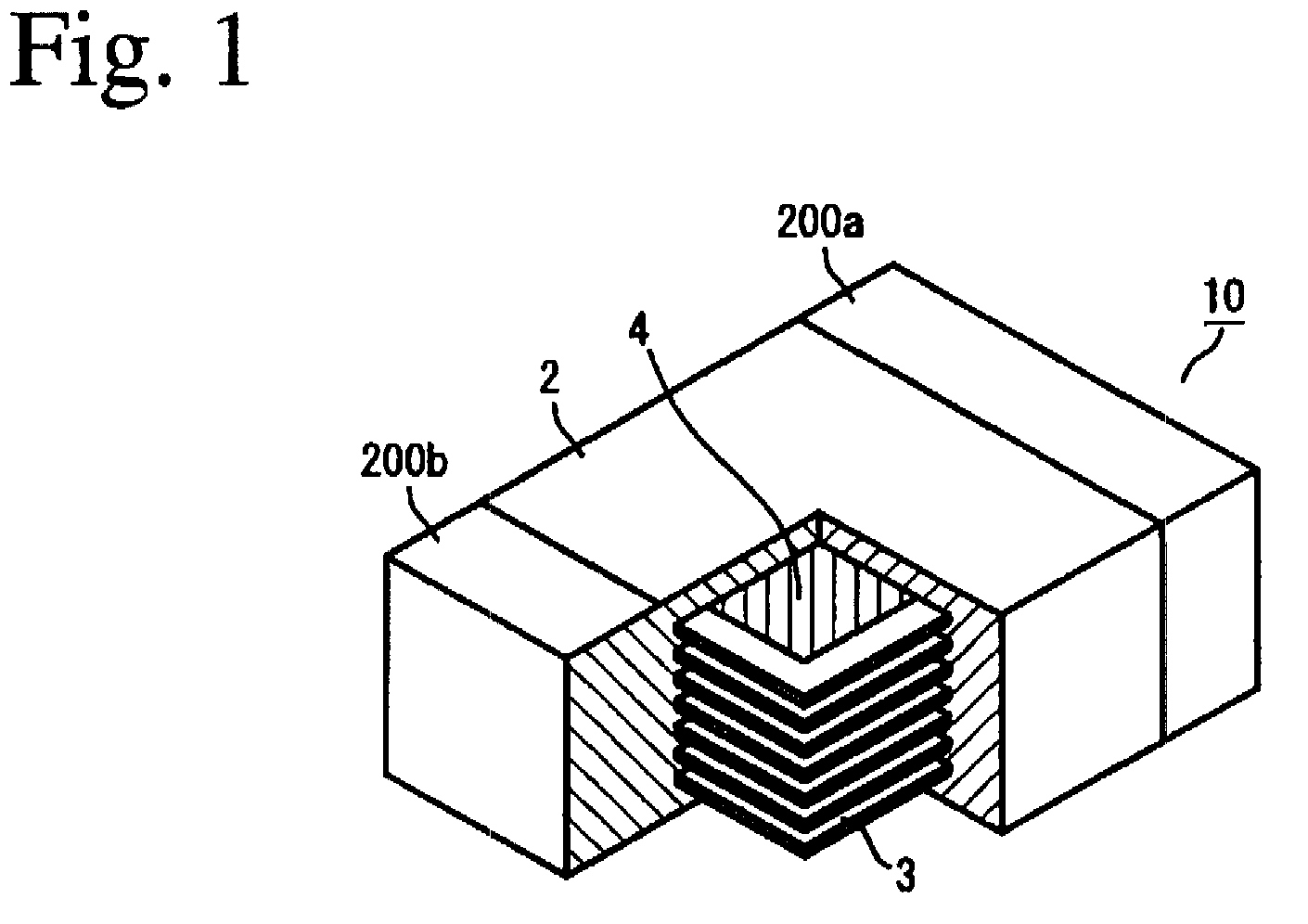

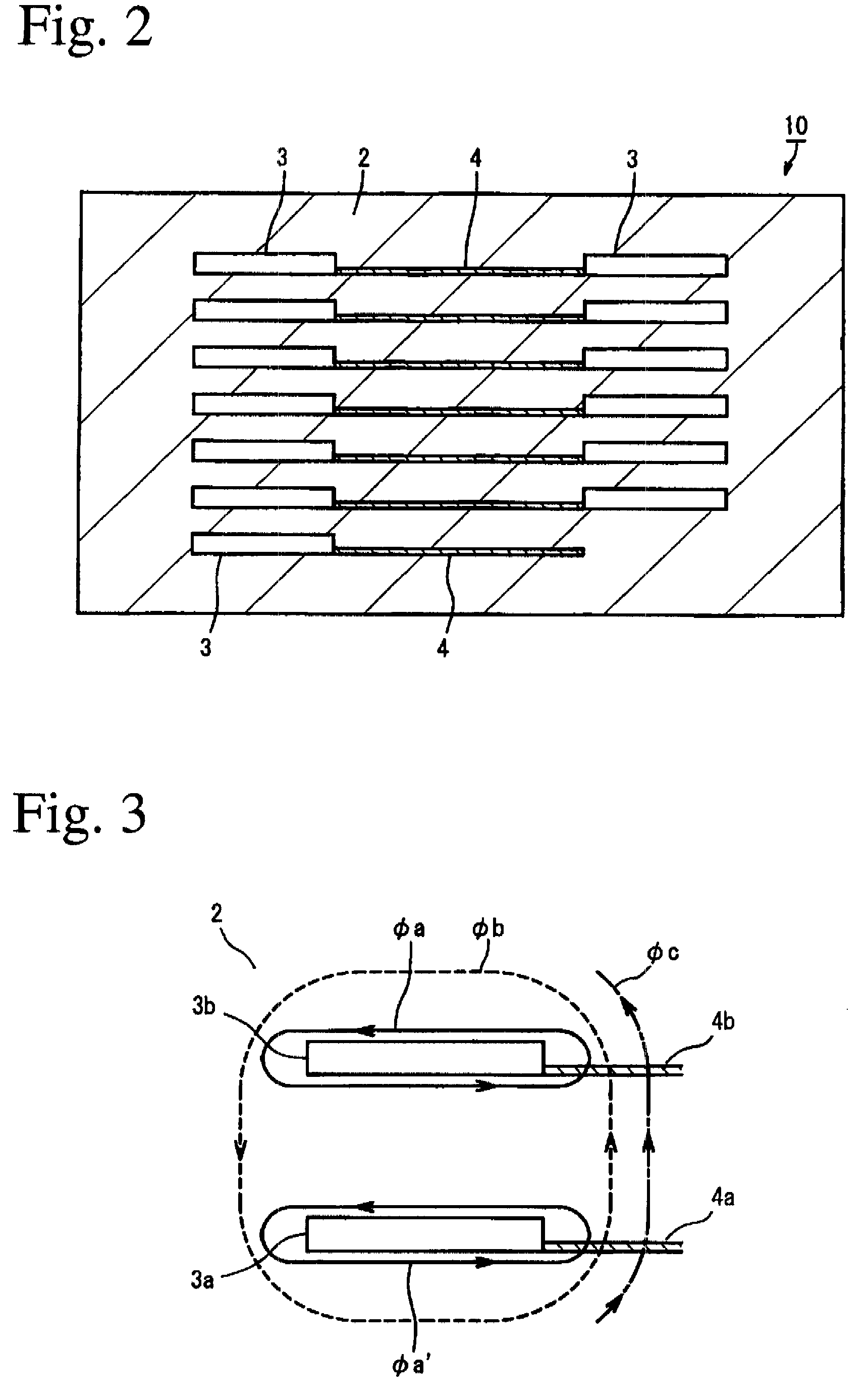

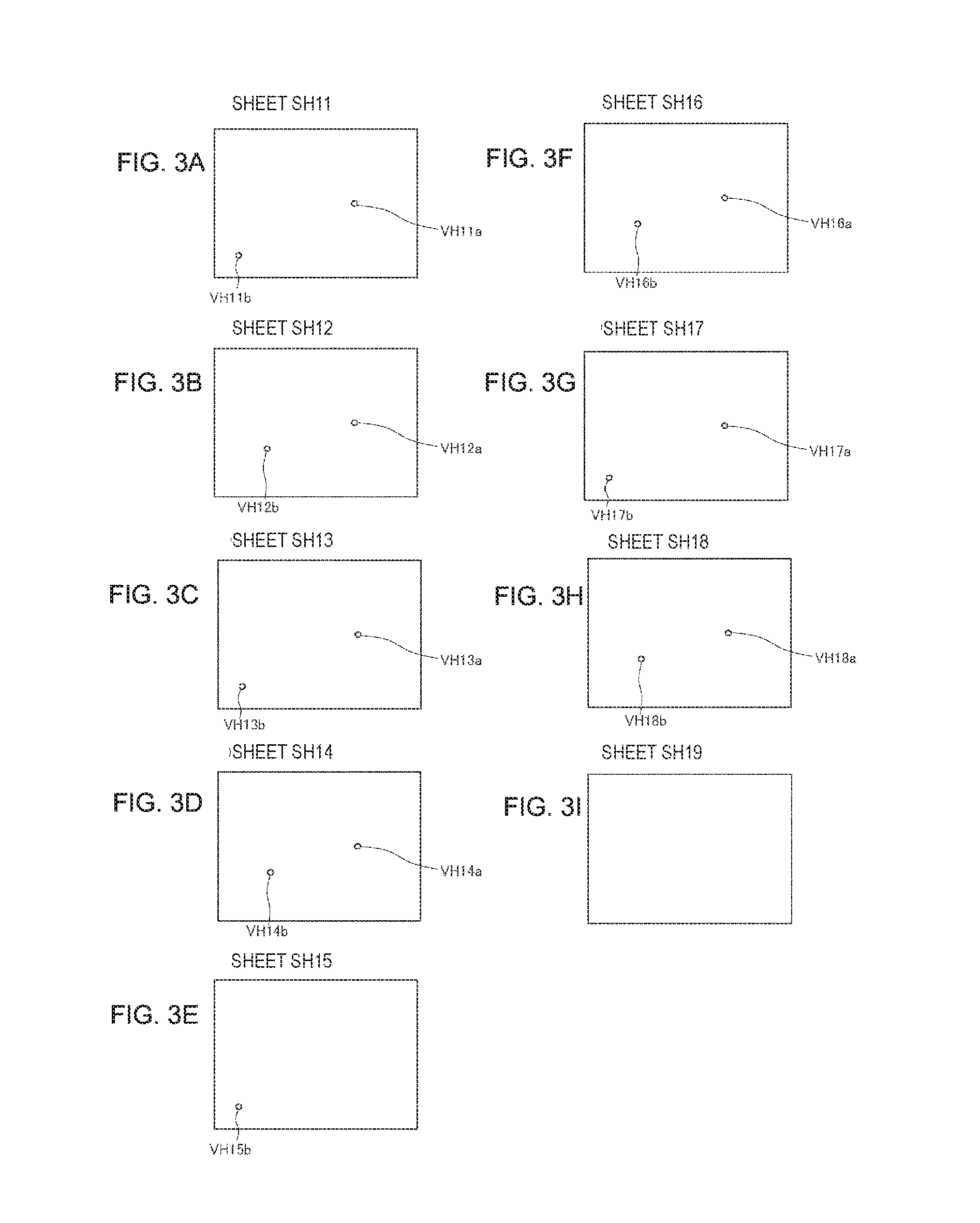

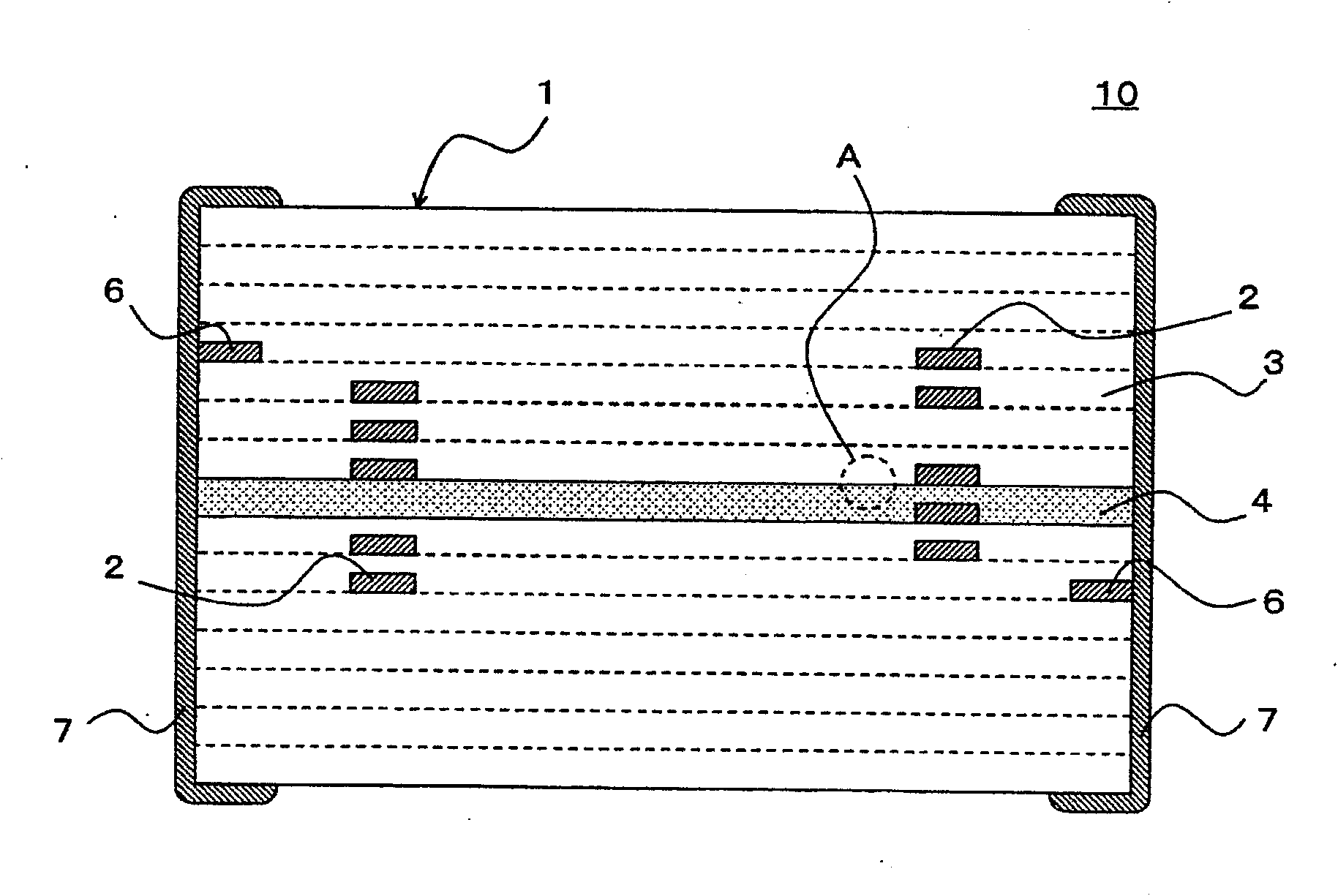

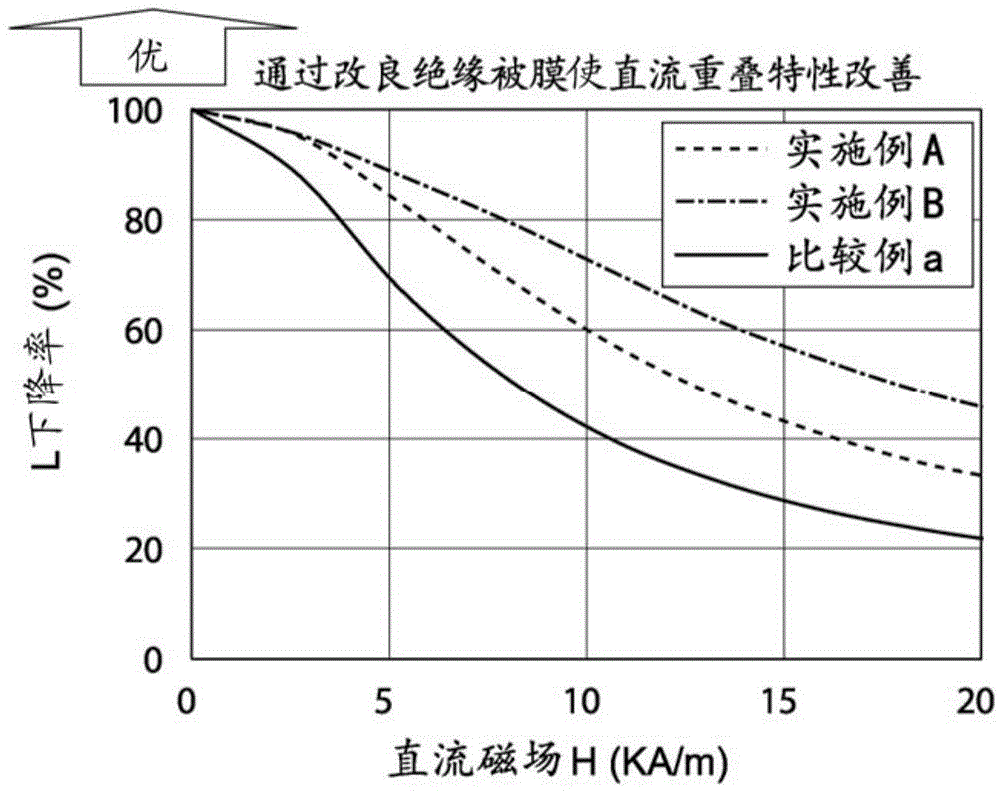

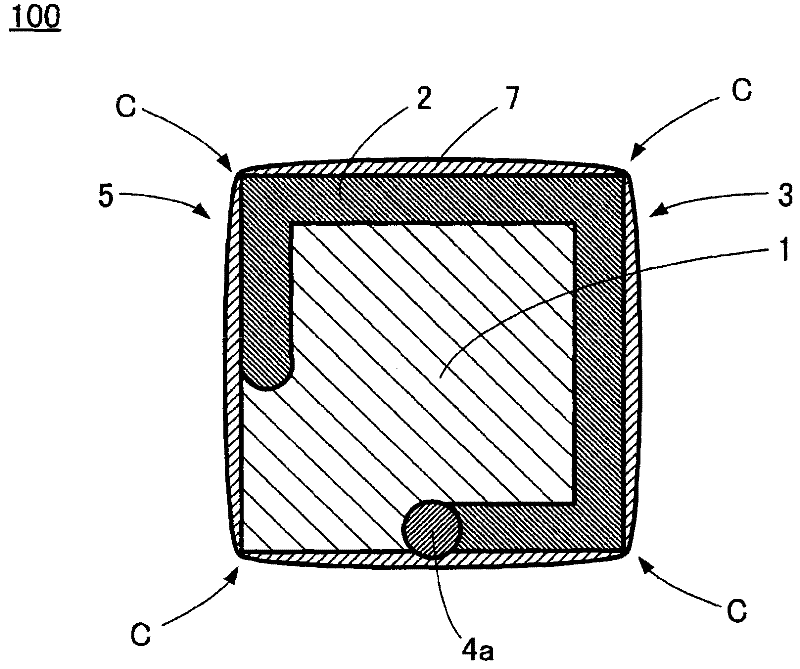

Laminated inductor, method for manufacturing the laminated inductor, and laminated choke coil

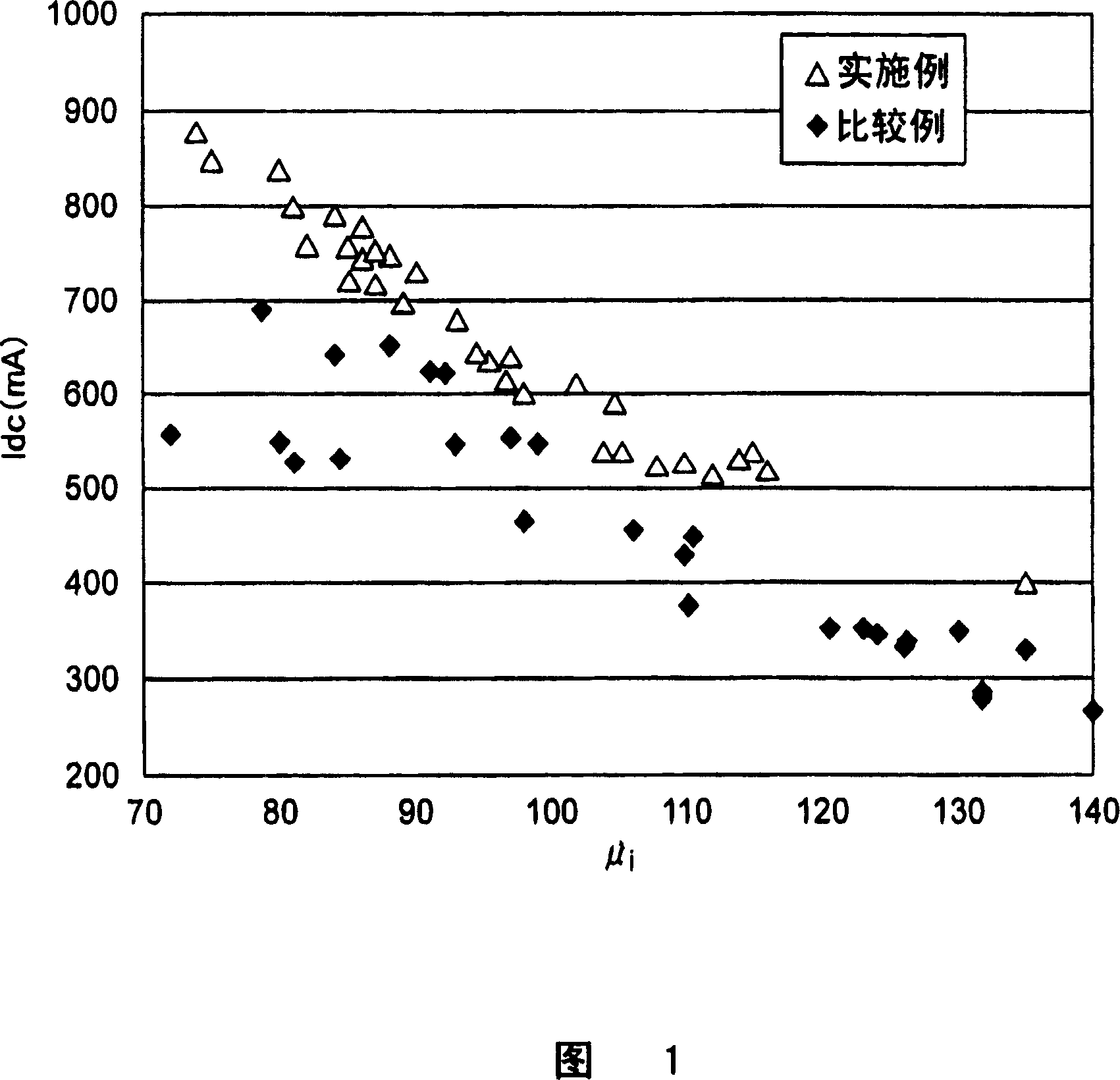

ActiveUS20110133881A1Improve DC Superposition CharacteristicsInhibitionTransformers/inductances coils/windings/connectionsCoatingsDielectricSuperimposition

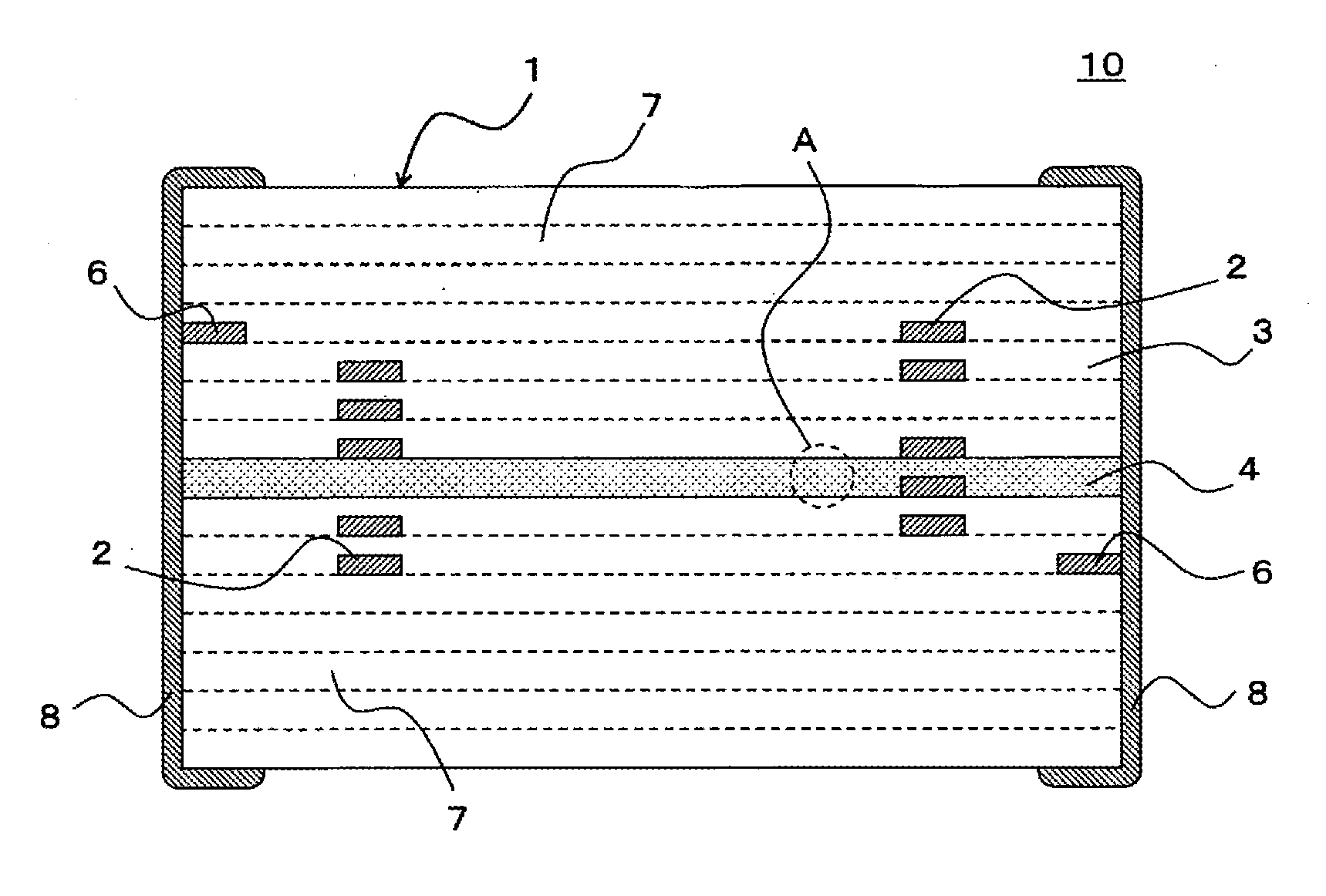

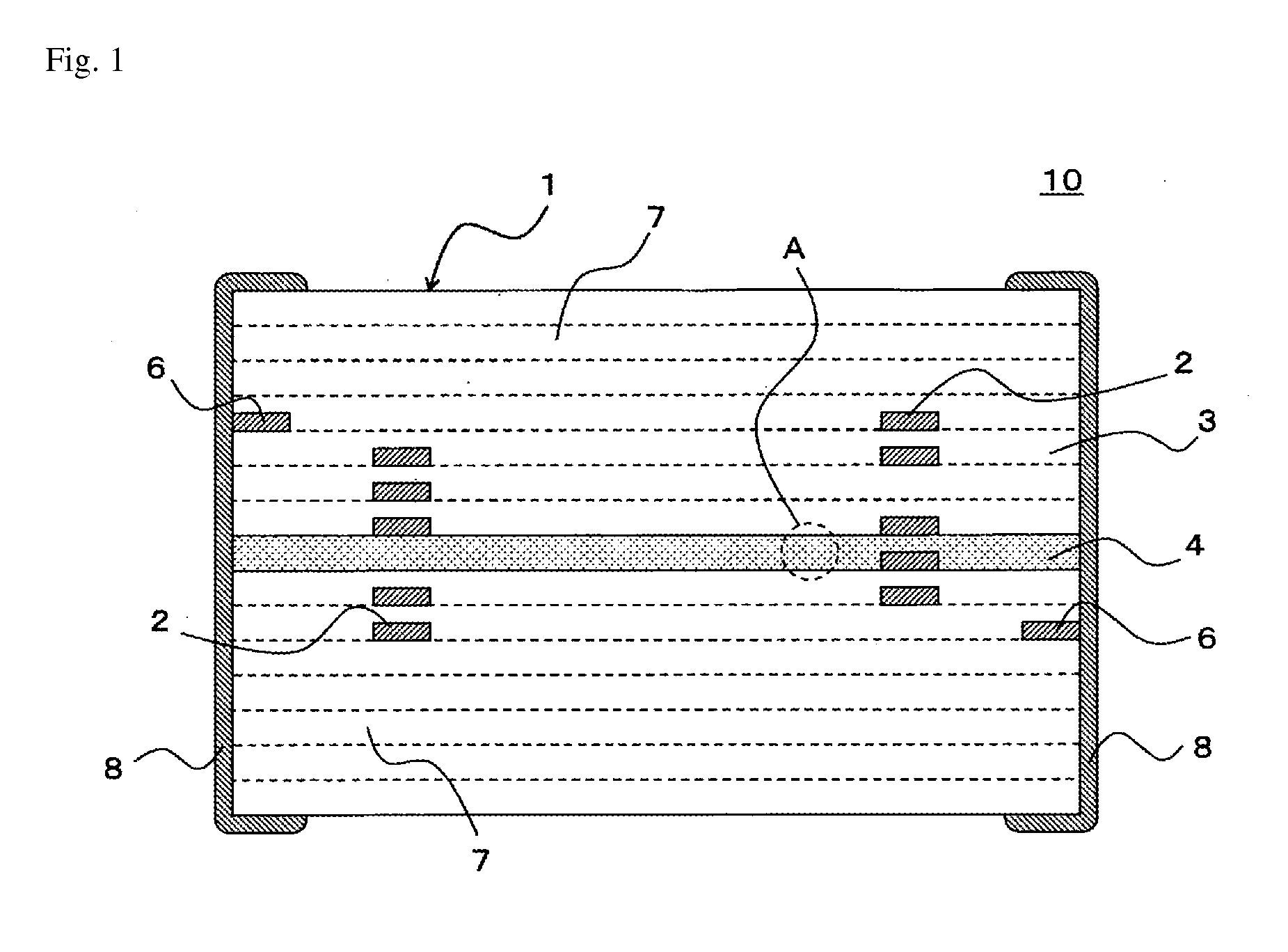

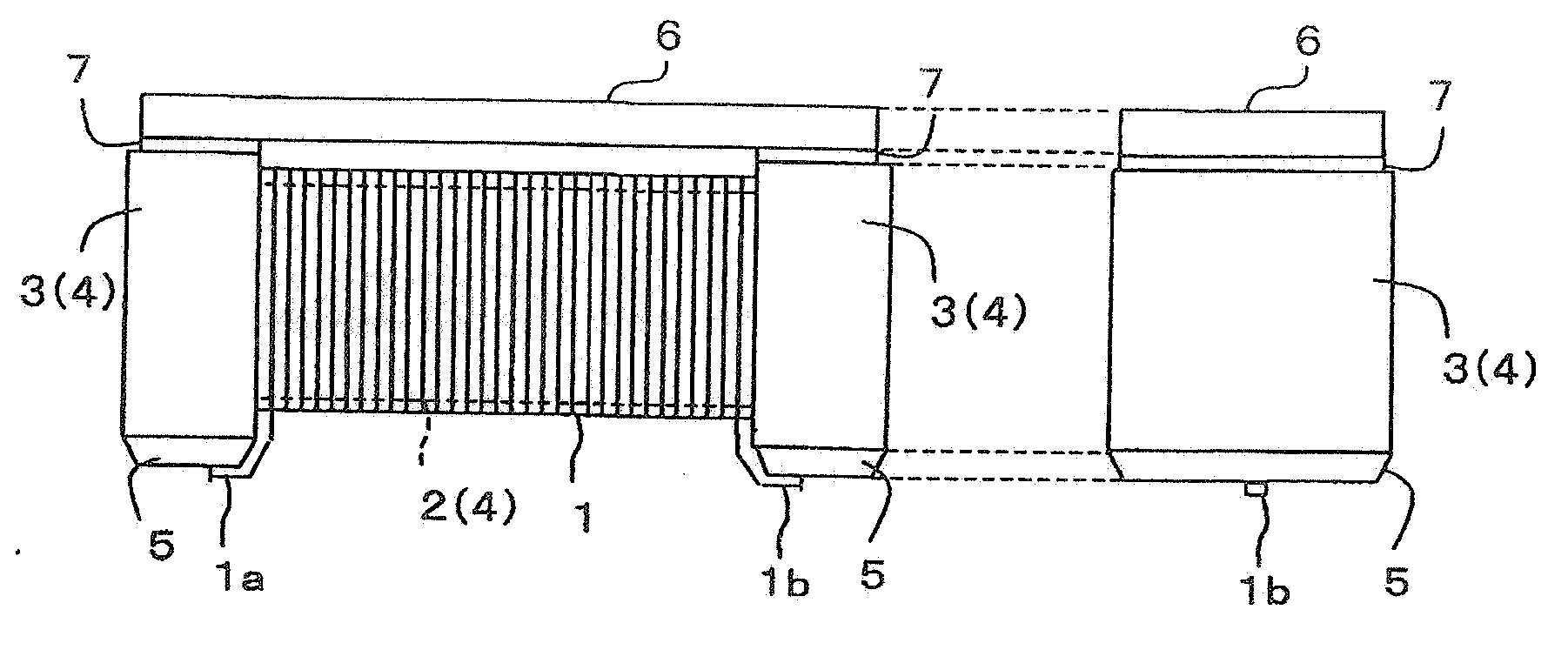

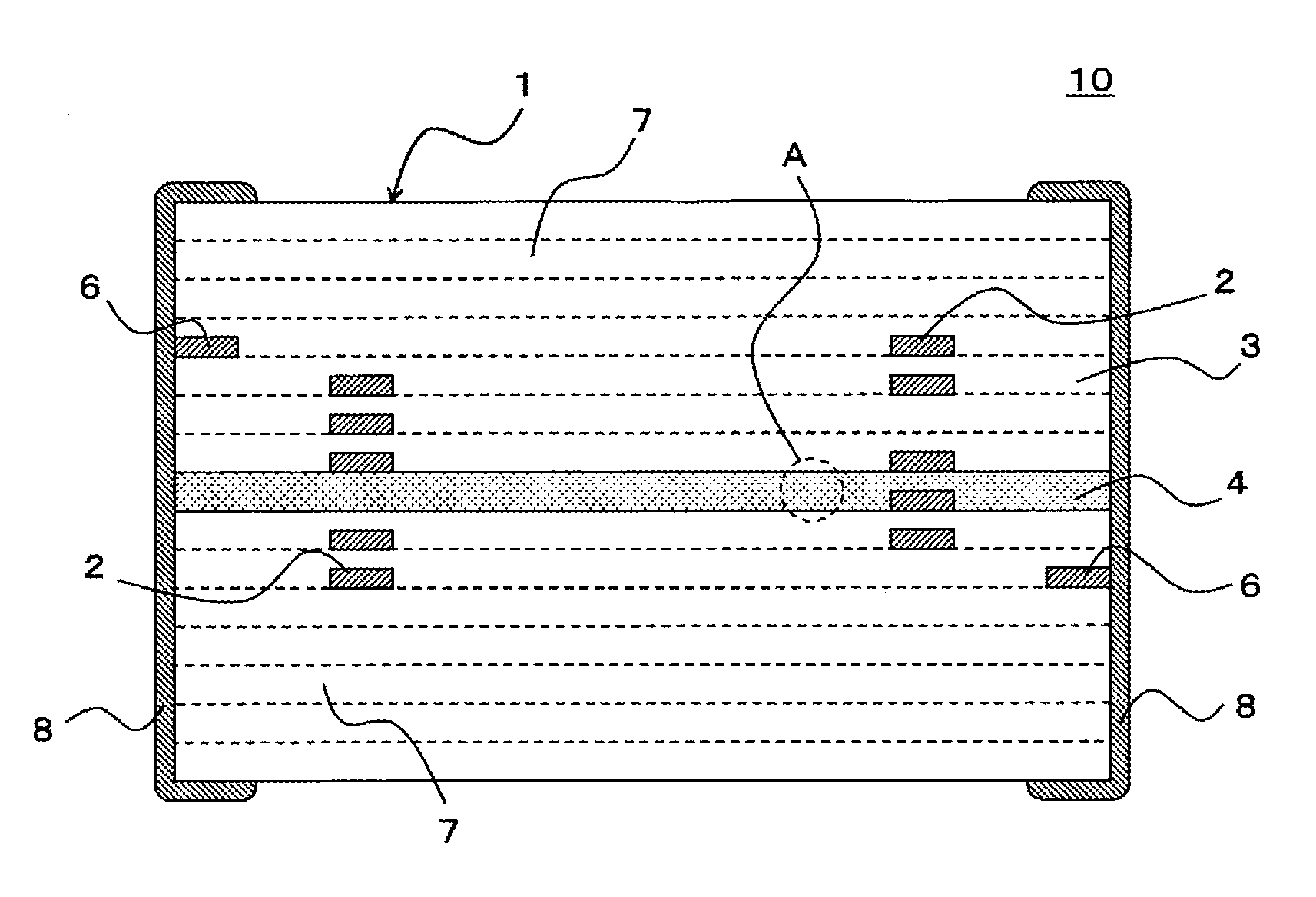

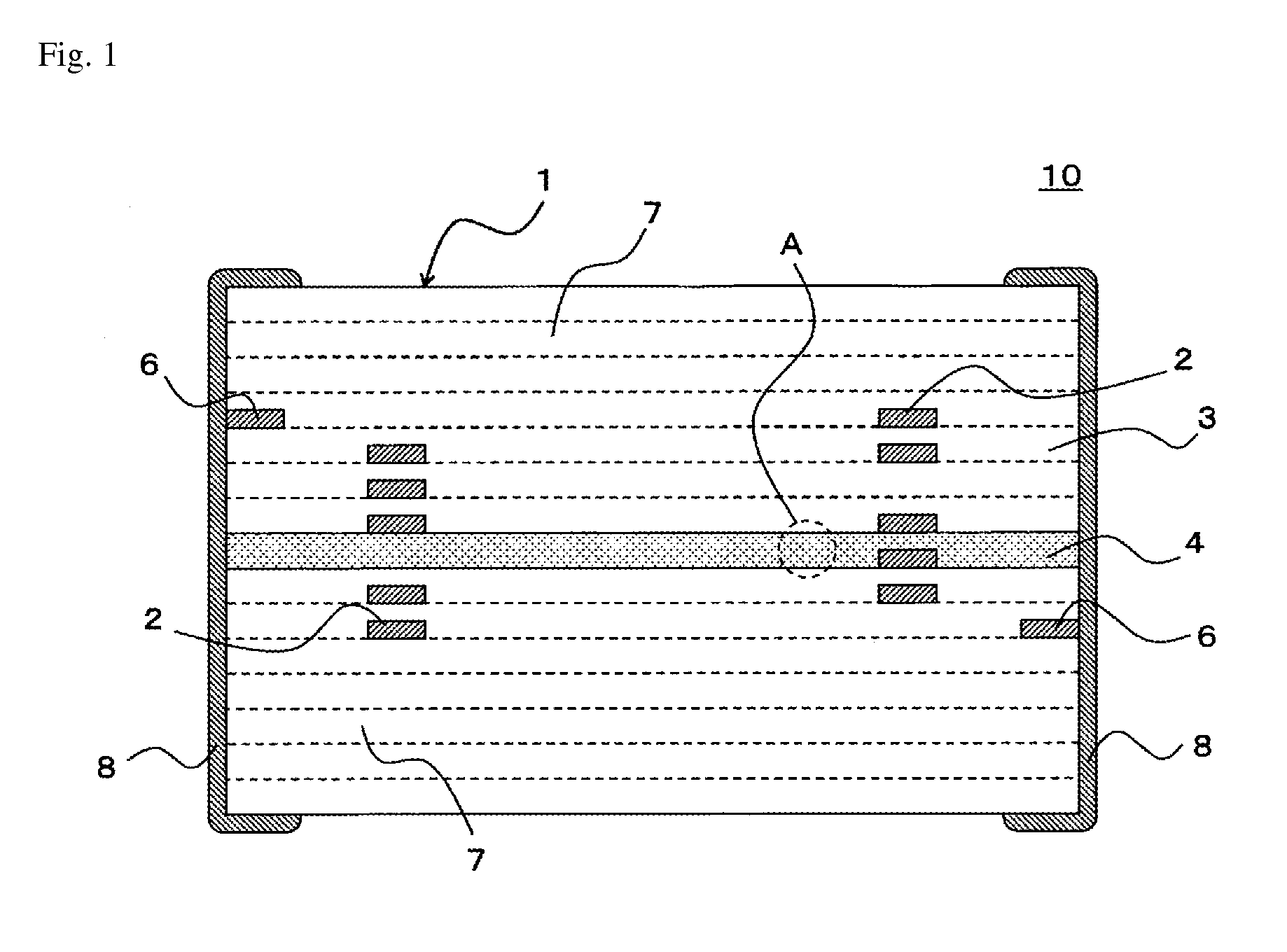

Disclosed is a laminated inductor that has good direct current superimposition characteristics, does not cause a variation in temperature characteristics, suppresses the occurrence of delamination, and can be stably manufactured. Also disclosed are a method for manufacturing the laminated inductor and a laminated choke coil. A laminated inductor (10) for use as a choke coil in a power supply circuit includes a rectangular parallelepiped-shaped laminated chip (1) and at least one pair of external electrodes (8) that are provided at the end of the laminated chip (1) and are conductively connected to the end of a coil. The laminated chip (1) includes a plurality of magnetic material layers (3) formed of an Ni—Zn—Cu ferrite, a plurality of conductive layers (2), which are laminated through the magnetic material layers (3) to constitute a coil, and at least one nonmagnetic layer (4) formed of a Ti—Ni—Cu—Mn—Zr—Ag-base dielectric material and formed in contact with a plurality of the magnetic material layers (3).

Owner:TAIYO YUDEN KK

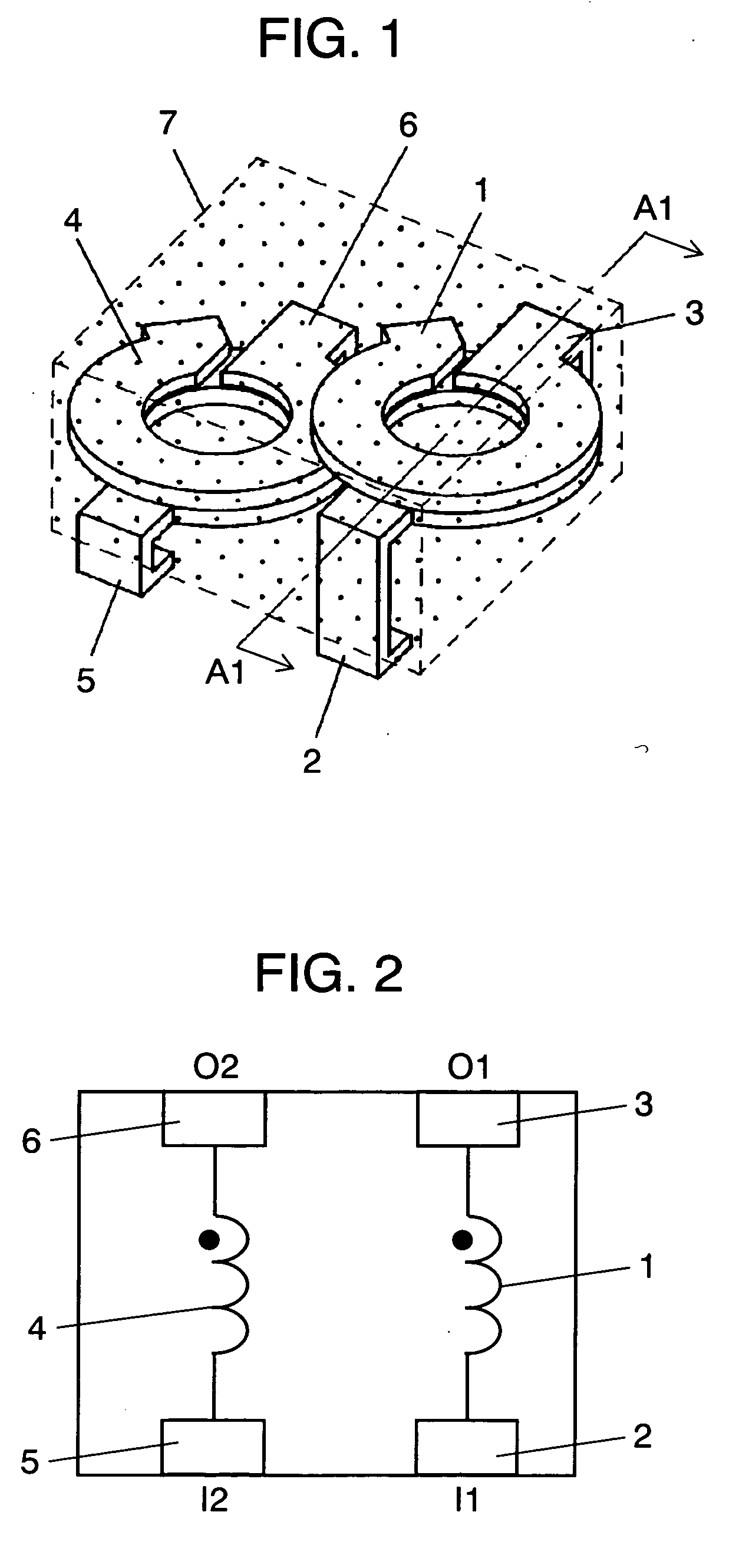

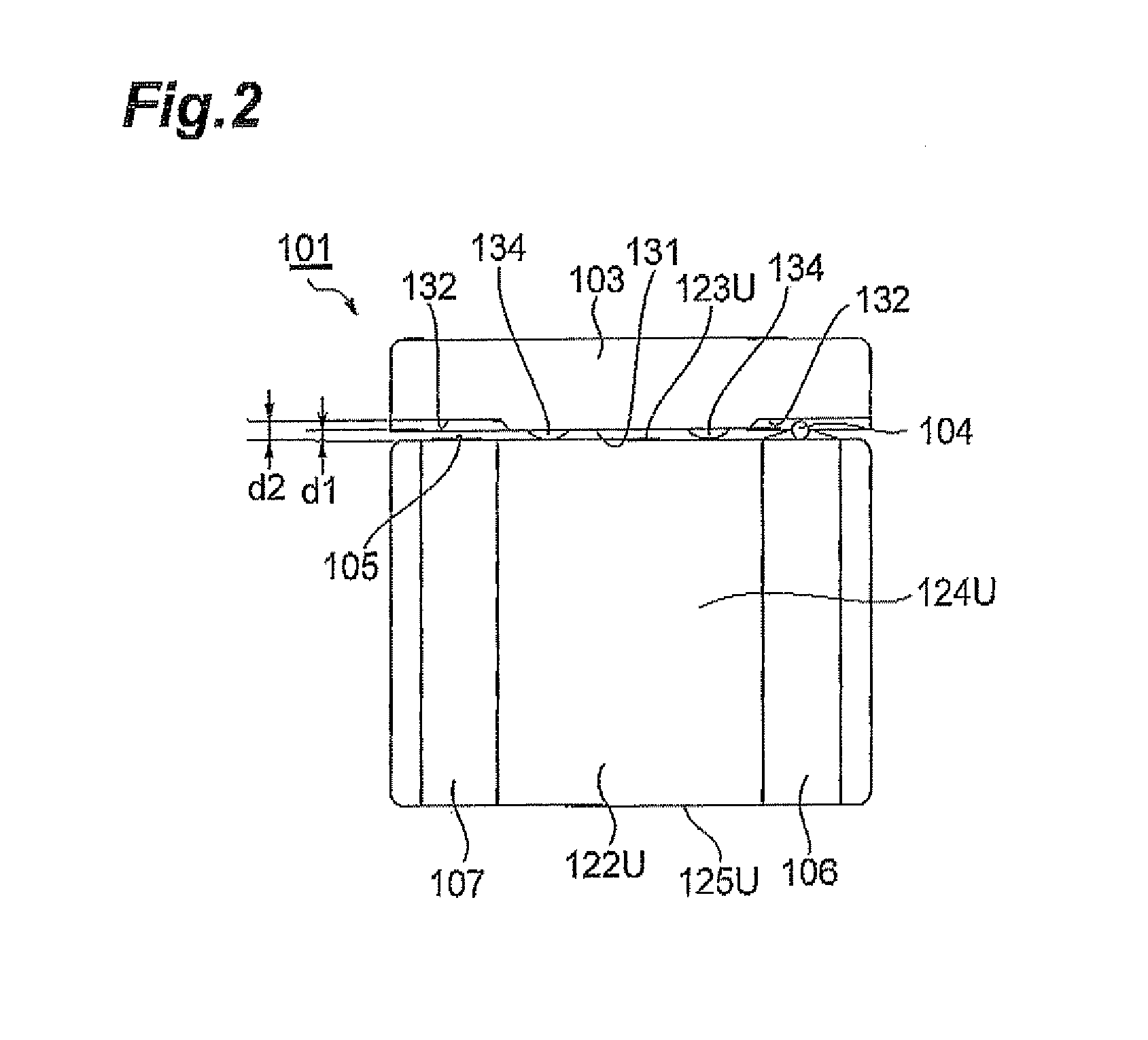

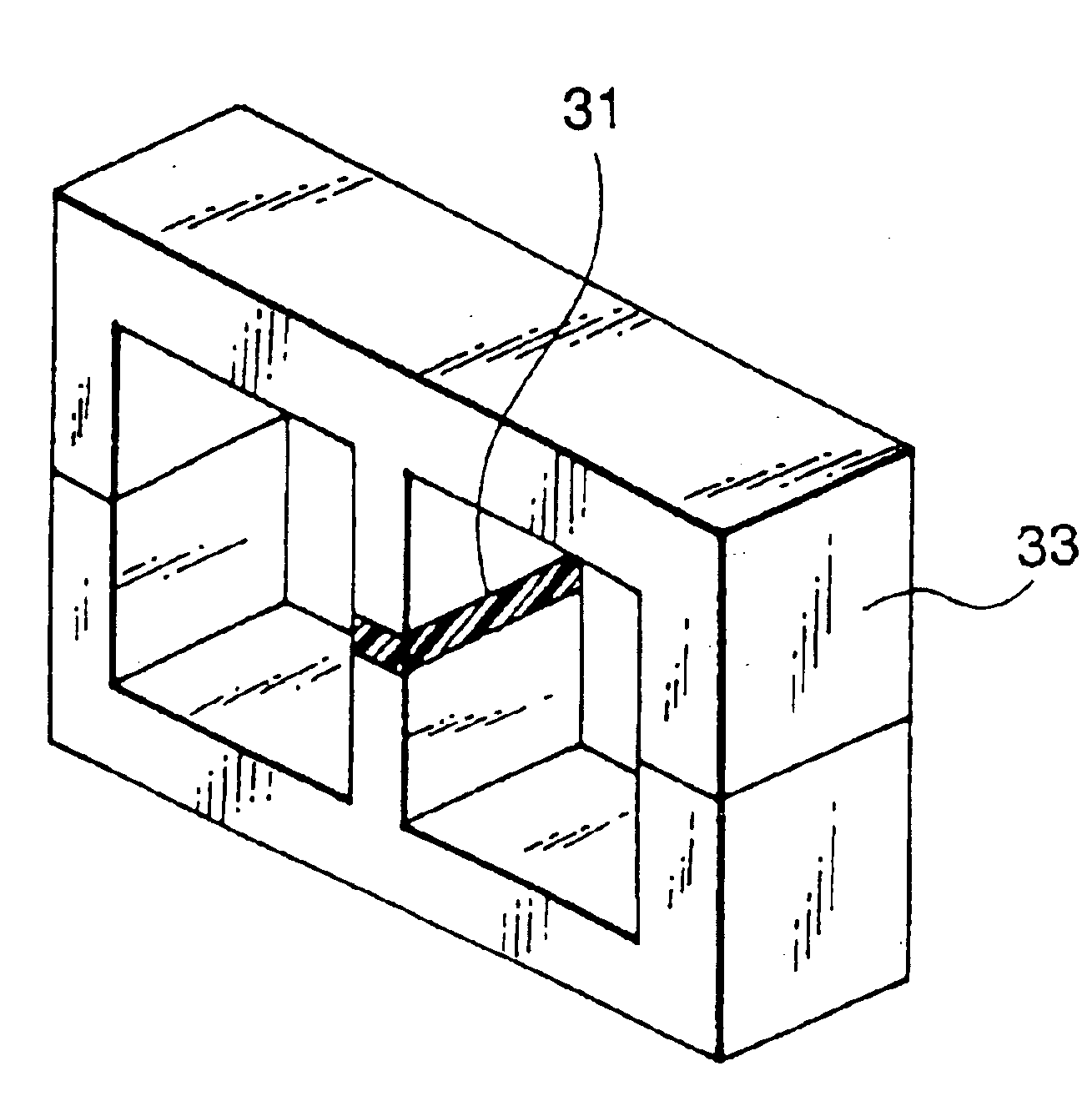

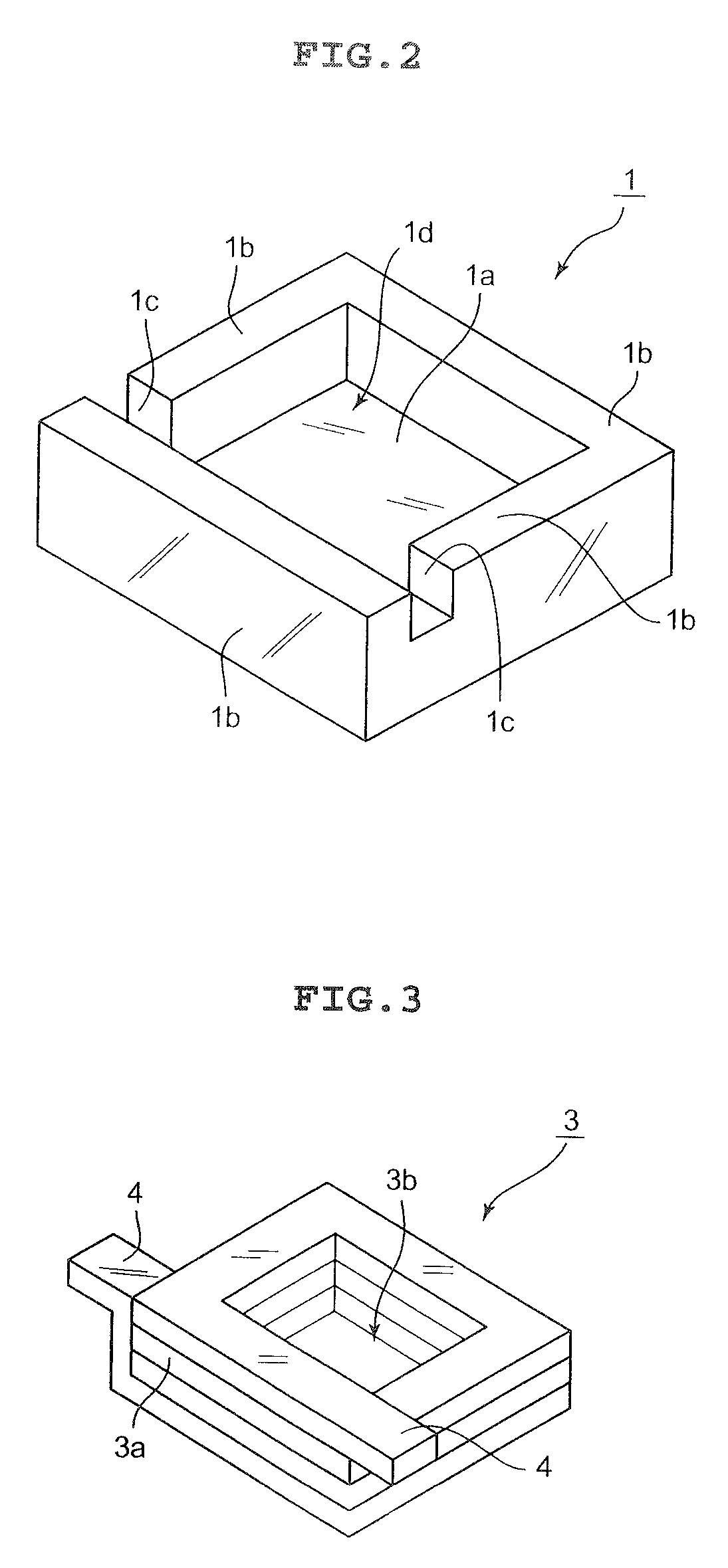

transformer

ActiveUS20120133469A1Improve DC Superposition CharacteristicsReduce stray capacitanceTransformers/inductances coils/windings/connectionsCores/yokesTransformerEddy current

A transformer that improves the DC superposition characteristic without incurring eddy-current losses. In the transformer, a part of a plate-like core opposing a top face of a flange of a drum core is formed with a first opposing portion opposing none of input and output terminals and a second opposing portion opposing the input and output terminals. A first gap is formed between the top face and the first opposing portion by a spacer. A second gap greater than the first gap is formed by a recess of the plate-like core provided so as to correspond to the second opposing portion. This allows magnetic fluxes to pass between the top face and the first opposing portion where the gap is formed and inhibits them from passing between the plate-like core and the input and output terminals where the second gap greater than the first gap is formed.

Owner:TDK CORPARATION

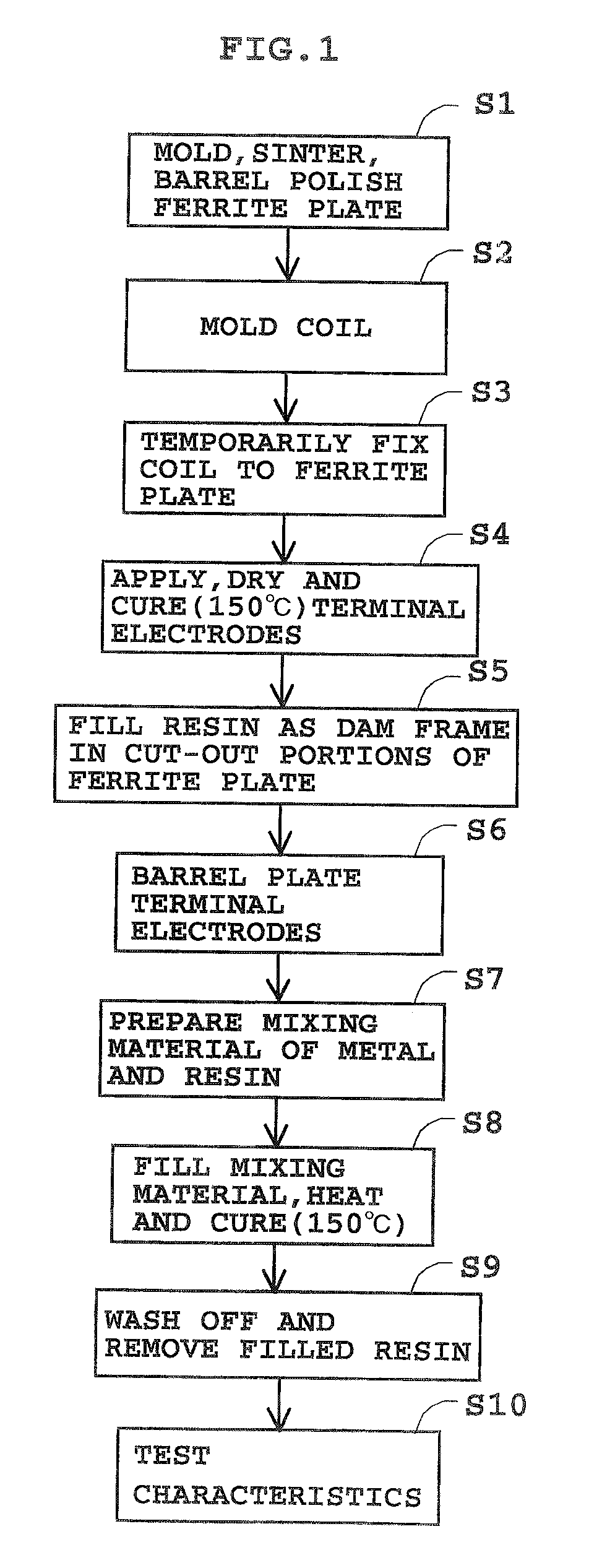

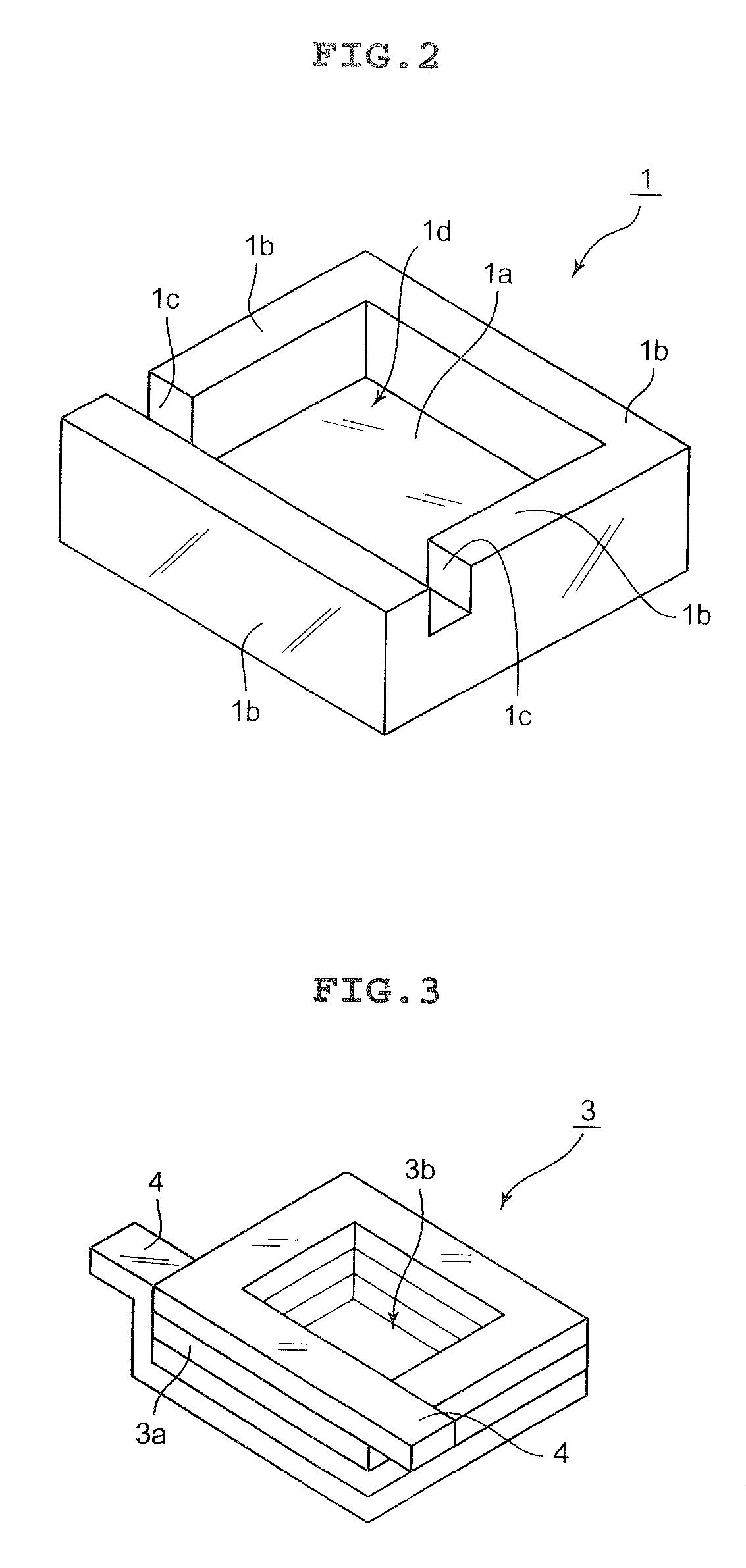

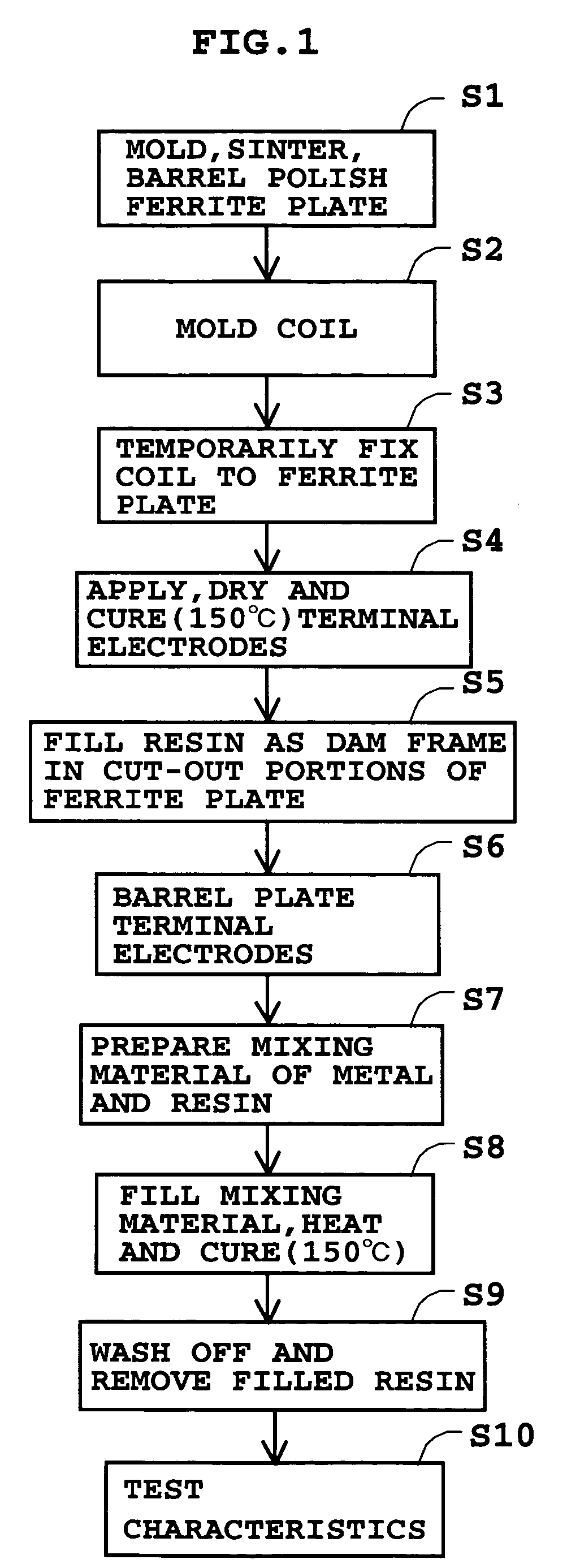

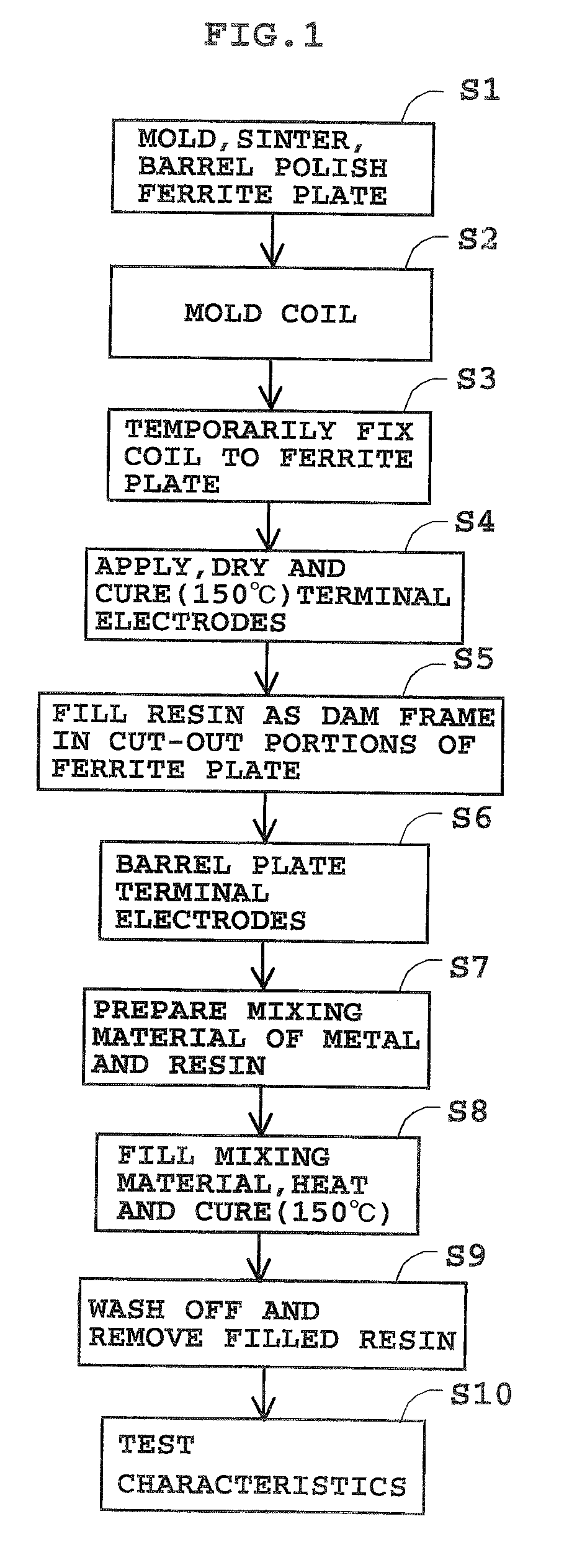

Magnetic element and method of manufacturing magnetic element

ActiveUS20060186978A1Improve permeabilityEasy to manufactureTransformers/inductances casingsTransformers/inductances coils/windings/connectionsElectrical conductorEngineering

Owner:SUMIDA CORP

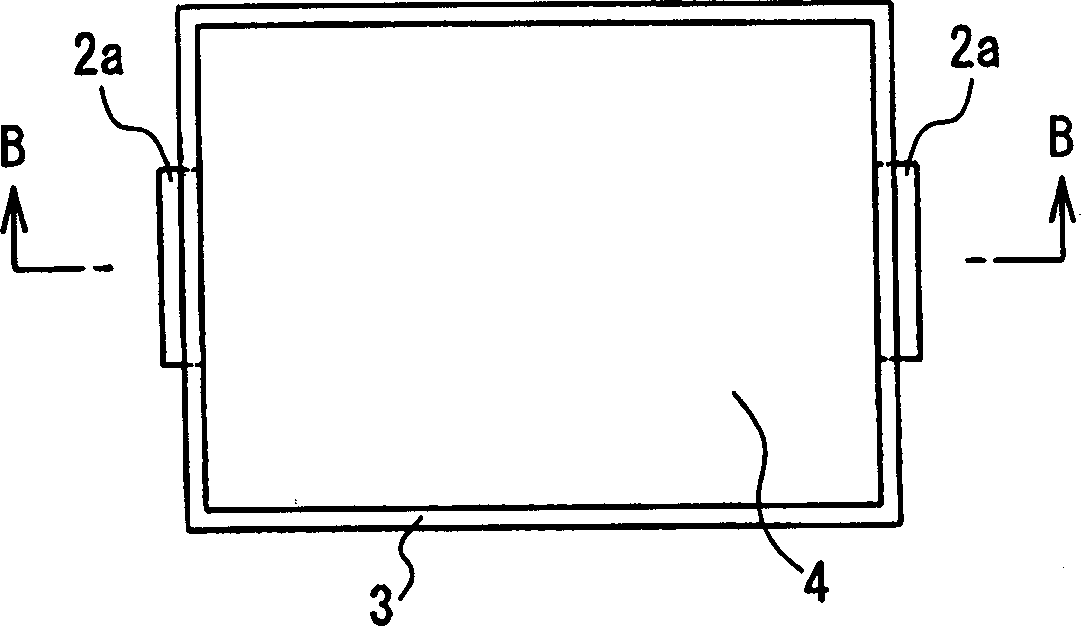

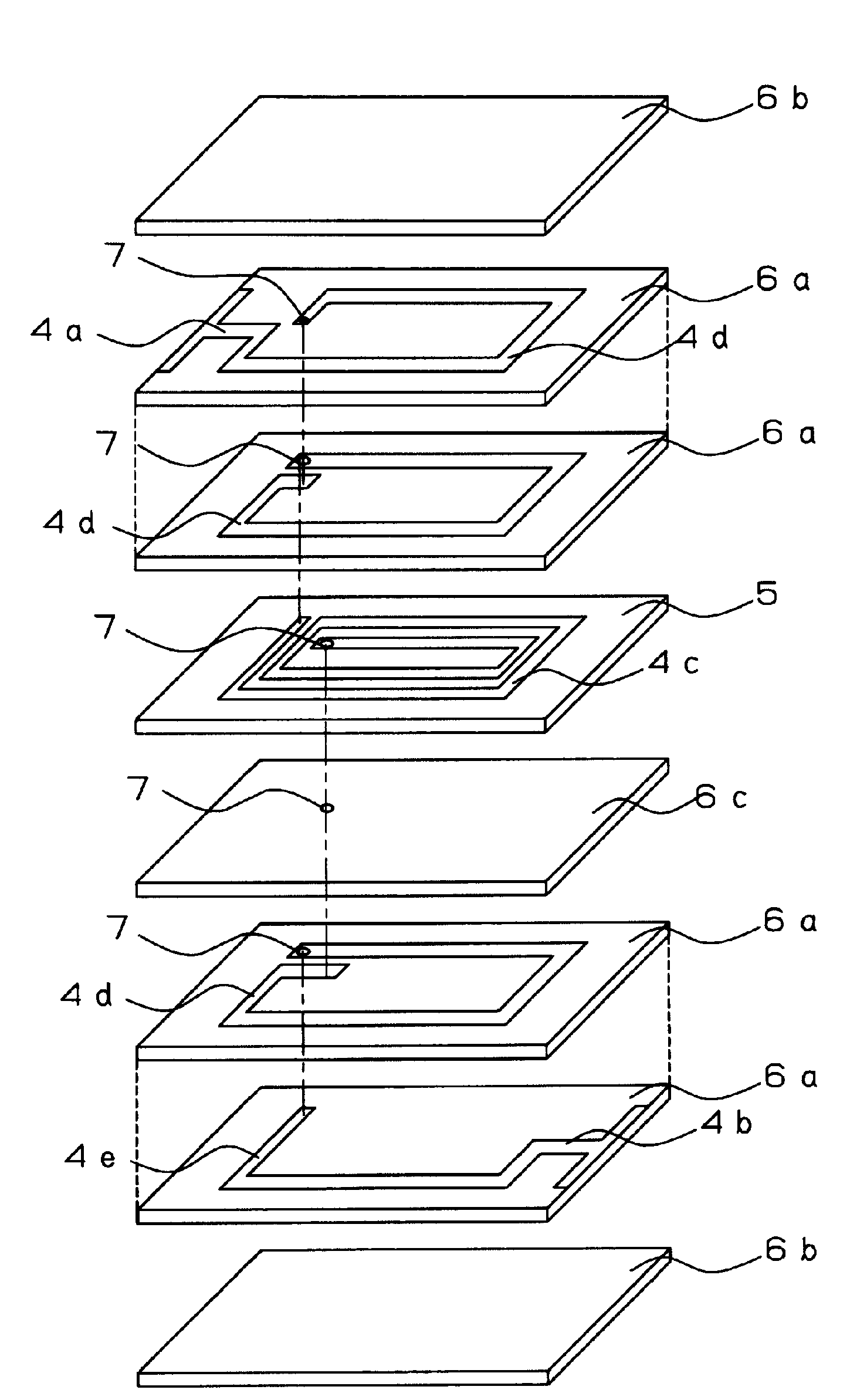

Multiple choke coil and electronic equipment using the same

InactiveUS7259648B2Improve DC Superposition CharacteristicsSmall sizeTransformers/inductances casingsTransformers/inductances coils/windings/connectionsEngineeringMetal sheet

The invention is comprised of a coil group arranging a plurality of terminal-integrated type coils (1), (4) formed by bending a metal sheet in a preset development form and having a predetermined positional relationship, and a magnetic material (7) burying therein the coil group. For example, axes of the plurality of coils (1), (4) constituting the coil group, are arranged in parallel wherein the center point of at least one coil selected from the plurality of coils (1), (4) and the center point of a coil other than the selected coil are in an staggered arrangement. Due to this, an array type choke coil can be realized which is thin overall and operable with a large current in a high frequency band.

Owner:PANASONIC CORP

Chip inductor

InactiveUS20070063804A1Effectively preventing magnetic leakageImprove DC Superposition CharacteristicsNanomagnetismTransformers/inductances casingsInductorEngineering

A chip inductor includes: a winding; a ferrite-based drum core having flange parts on both ends of a winding shaft around which the winding is wound; electrodes fixed to the flange parts on both ends of the winding shaft and for electrically connecting both ends of the winding to a mounting board; and a magnetic shield plate for connecting both flange parts in a region other than the electrodes wherein the magnetic shield plate is a plate member containing an iron-based amorphous powder.

Owner:SUMIDA CORP

Coil component

InactiveCN101615490AFlexibleNo brittle failureTransformers/inductances coils/windings/connectionsPrinted inductancesIn planeHigh resistance

A coil component is provided, and the coil component for an inductor is deformable dependent on flex of a flexible printed board due to elapse of time when mounted thereon, and has high resistance against dropping impact and has an inductance value. The coil component includes an anisotropic compound magnetic sheet which is layered on at least any one or both of the upper surface and the lower surface of an air core coil formed spirally in a plane and which is composed of flat or needle-shaped soft magnetic metal powder, which has a major axis and a minor axis and is dispersed in a resin material, the major axis of which corresponds to an in-plane direction of the air core coil.

Owner:SUMIDA CORP

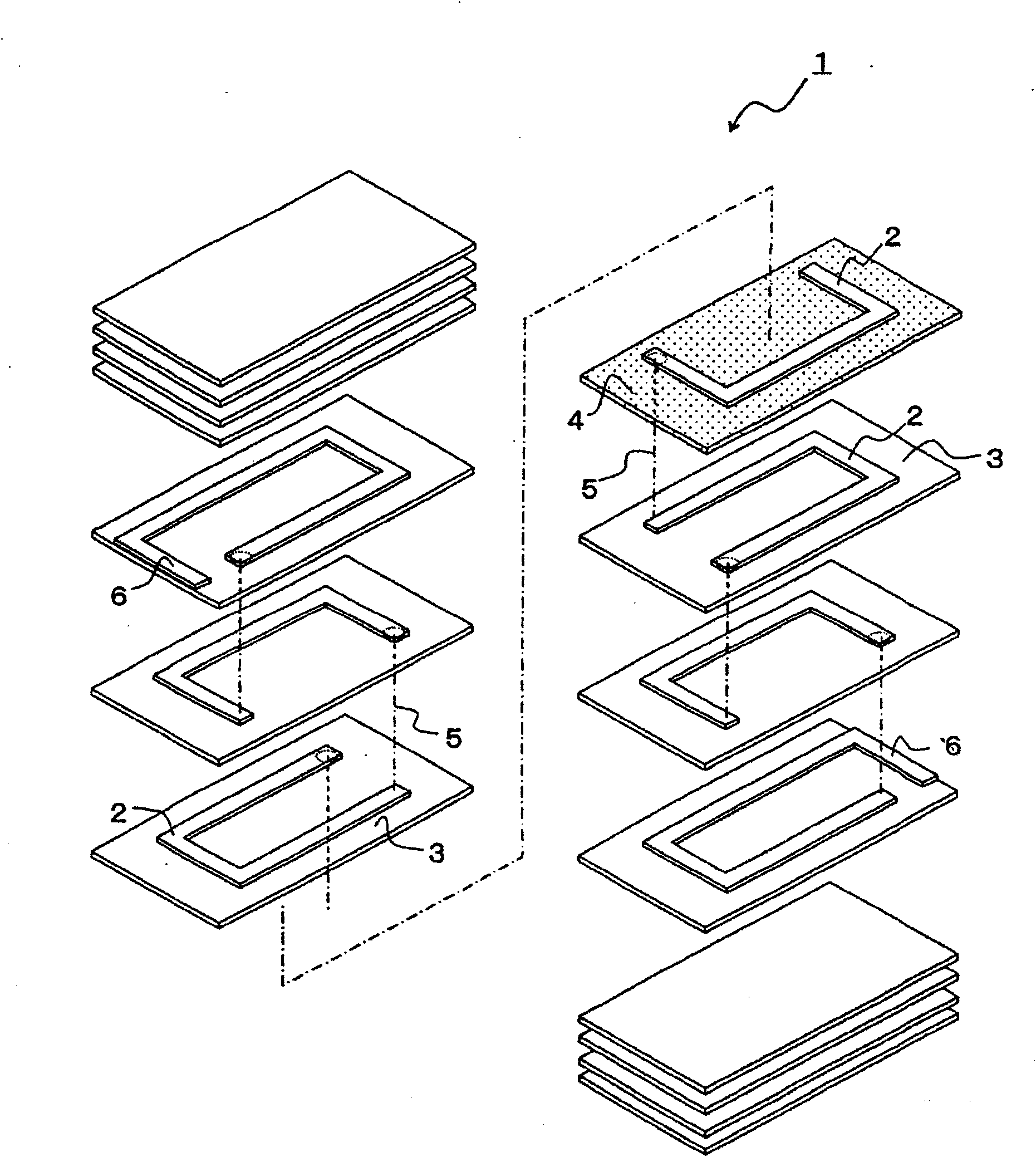

Magnetic element and its manufacture, power supply module therewith

InactiveCN1407564AReduce magnetic lossIncrease the inductance valueTransformers/inductances coils/windings/connectionsEncapsulation/impregnationElectrical conductorComputer module

A magnetic device includes a sheet-type coil including a planar conductive coil and an insulating substance; and a sheet-type first magnetic member disposed on at least one of upper and lower surfaces of the sheet-type coil, where a magnetic permeability of the insulating substance is smaller than a magnetic permeability of the first magnetic member. The magnetic device preferably includes a second magnetic member provided at a predetermined area of the sheet-type coil, the second magnetic member being made of a resin containing a magnetic powder and having a permeability larger than the insulating substance and smaller than the first magnetic member. The predetermined area is at least one position selected from a center portion and a peripheral portion of the sheet-type coil where a conductor constituting the planar conductive coil is not present. Further, a power supply module of the present invention includes the magnetic device according to the present invention.

Owner:PANASONIC CORP

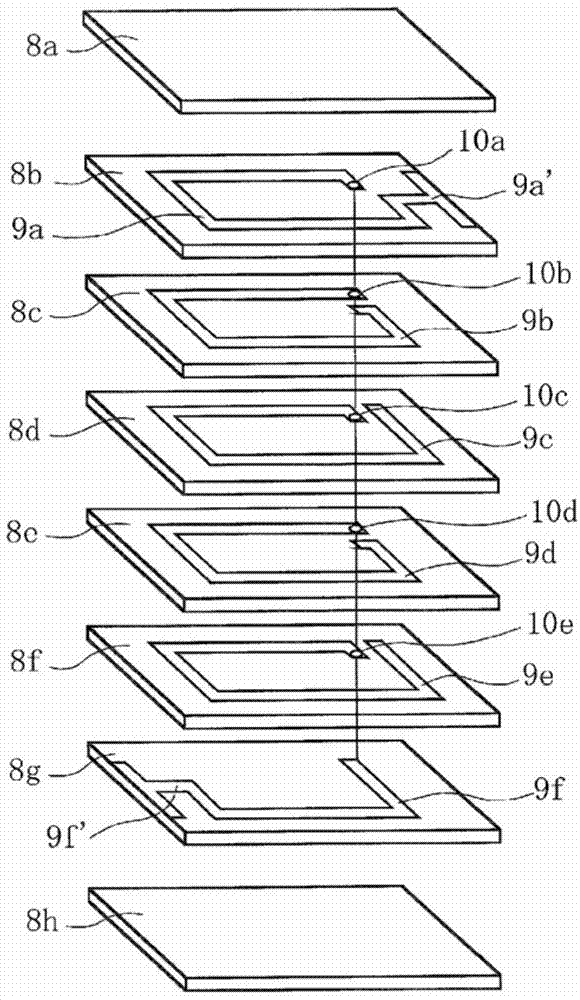

Laminated coil

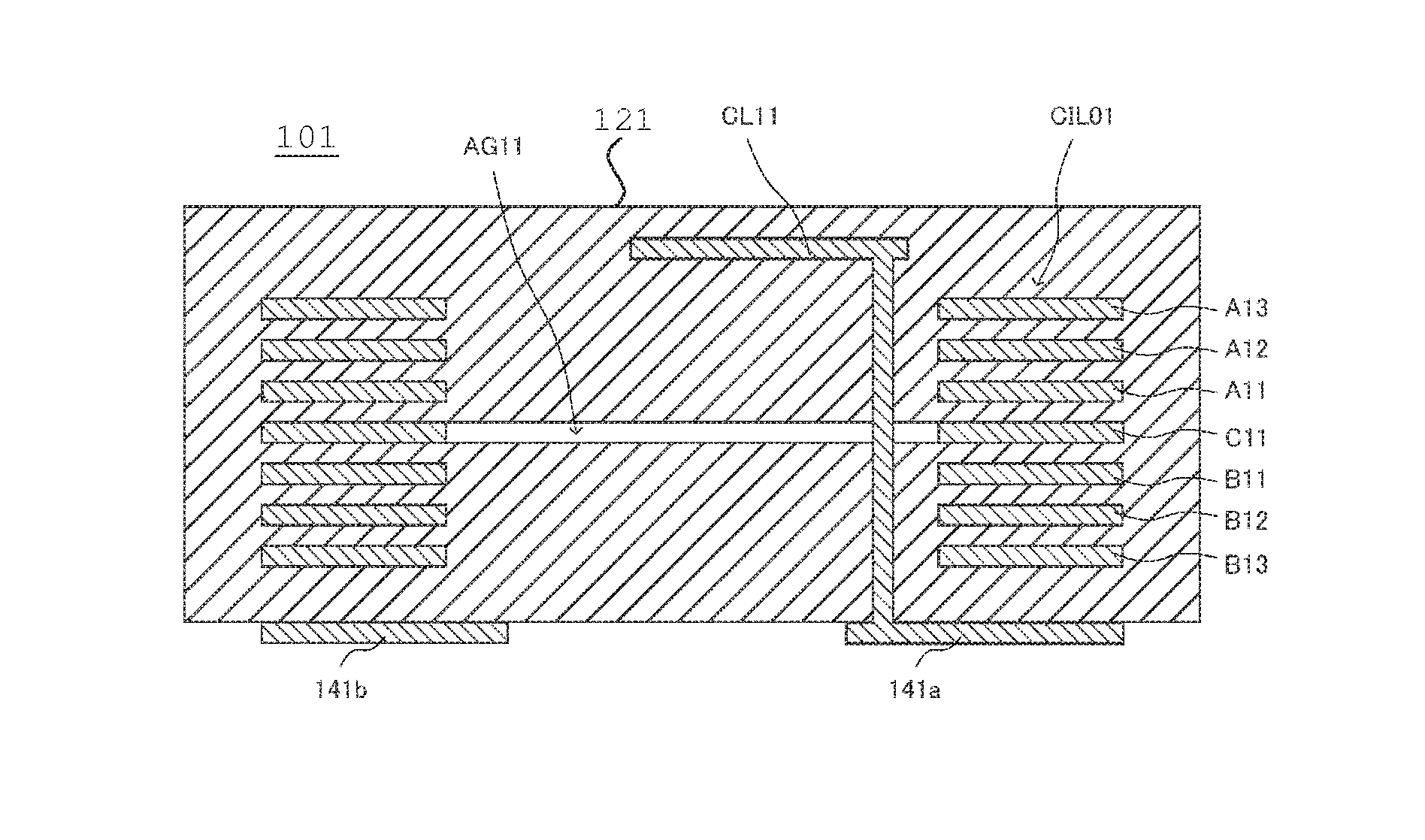

ActiveUS7719398B2Improve DC Superposition CharacteristicsPreventing reduction of inductanceTransformers/inductances coils/windings/connectionsCores/yokesElectrical conductorNon magnetic

A laminated coil includes a laminated body having magnetic body sections that are provided on both main surfaces of a non-magnetic body section and include a plurality of stacked magnetic layers, the non-magnetic body section including at least one non-magnetic layer, and a coil including helically connected coil conductors provided in the laminated body. The conductor width of at least one of the coil conductors provided inside the non-magnetic body sections and the coil conductors provided on both main surfaces of the non-magnetic body sections is greater than the conductor width of the other coil conductors in the laminated body.

Owner:MURATA MFG CO LTD

Laminated coil

ActiveUS7304557B2Improve DC Superposition CharacteristicsTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresElectrical conductorEngineering

Owner:MURATA MFG CO LTD

Laminate device and module comprising same

ActiveUS7907044B2Stable inductanceImprove DC Superposition CharacteristicsTransformers/inductances coils/windings/connectionsPrinted inductancesEngineeringMagnetic layer

Owner:HITACHI METALS LTD

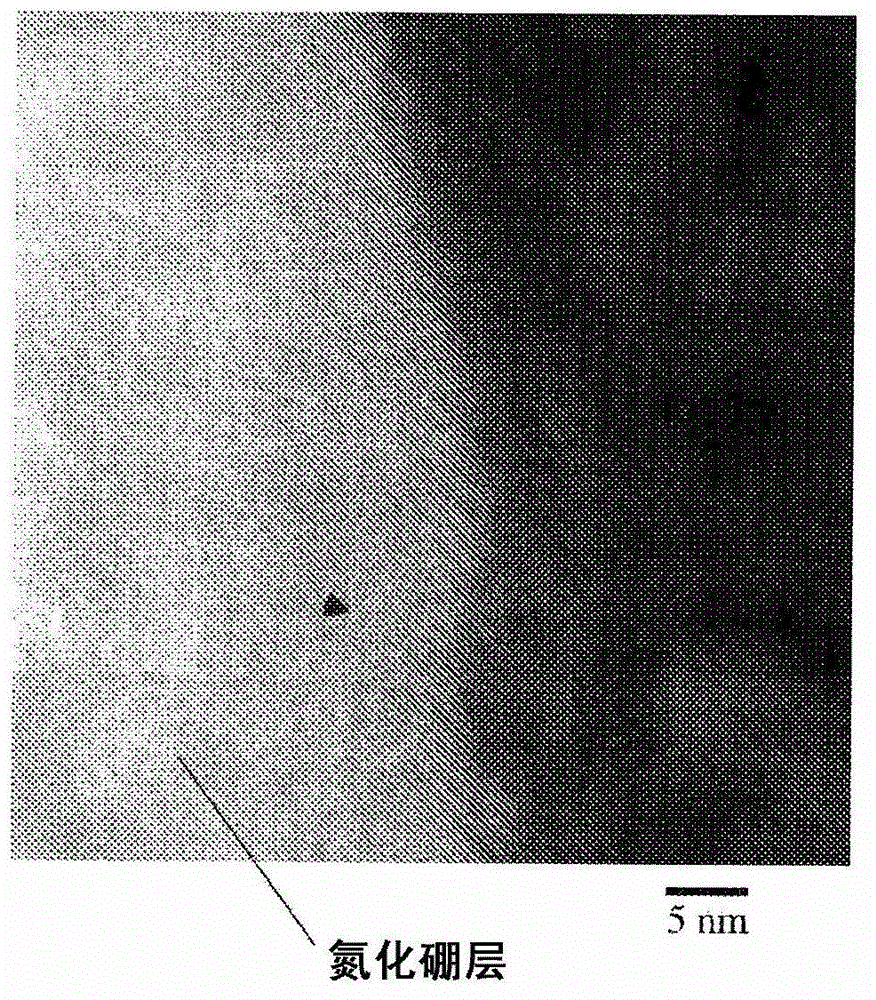

Composite soft magnetic powder, method for producing same, and powder magnetic core using same

InactiveCN103339694AHigh densityHigh saturation magnetizationTransportation and packagingMetal-working apparatusBoron nitrideNon magnetic

This composite soft magnetic powder comprises soft magnetic ferrous core particles, which have a particle size of 2-100 [mu]m, and a layer, which has boron nitride as the primary constituent and covers at least a portion of the surface of the soft magnetic ferrous core particles, the covering layer being a polycrystalline layer that comprises boron nitride microcrystalline grains having an average crystal grain size of 3-15 nm and differing crystal axis orientations and that has an average thickness that is no greater than 6.6% of the average particle size of the soft magnetic ferrous core particles. The composite soft magnetic powder is produced by means of (1) mixing an iron nitride powder having an average particle size of 2-100 [mu]m and a boron powder having an average particle size of 0.1-10 [mu]m, (2) heat treating the obtained mixed powder at a temperature of 600-850 DEG C in a nitrogen atomosphere, and (3) eliminating the non-magnetic components.

Owner:HITACHI METALS LTD

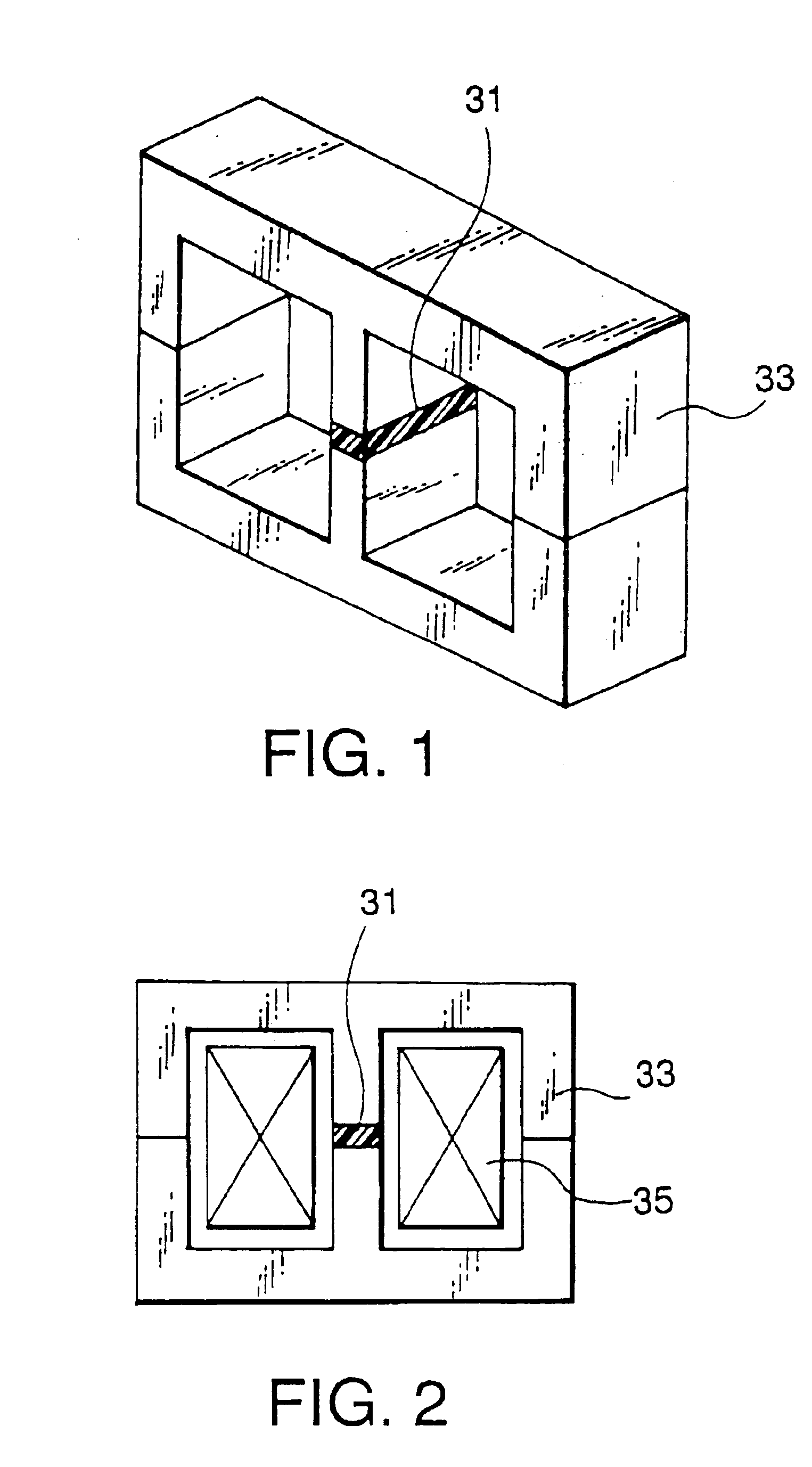

Magnetic core including magnet for magnetic bias and inductor component using the same

InactiveUS6906608B2Improve DC Superposition CharacteristicsReduce thicknessTransformers/inductances casingsVariable inductancesInductorRare-earth magnet

An inductor component according to the present invention includes a magnetic core including at least one magnetic gap having a gap length of about 50 to 10,000 μm in a magnetic path, a magnet for magnetic bias arranged in the neighborhood of the magnetic gap in order to supply magnetic bias from both sides of the magnetic gap, and a coil having at least one turn applied to the magnetic core. The aforementioned magnet for magnetic bias is a bonded magnet containing a resin and a magnet powder dispersed in the resin and having a resistivity of 1 Ω·cm or more. The magnet powder includes a rare-earth magnet powder having an intrinsic coercive force of 5 KOe or more, a Curie point of 300° C. or more, the maximum particle diameter of 150 μm or less, and an average particle diameter of 2.0 to 50 μm m and coated with inorganic glass, and the rare-earth magnet powder is selected from the group consisting of a Sm—Co magnet powder, Nd—Fe—B magnet powder, and Sm—Fe—N magnet powder.

Owner:TOKIN CORP

Method for preparing iron silicon soft magnetic alloy powder core

InactiveCN102974821AImprove magnetic propertiesMeet performance requirementsInorganic material magnetismEpoxySilicon alloy

The invention discloses a method for preparing an iron silicon soft magnetic alloy powder core. The method for preparing the iron silicon soft magnetic alloy powder core comprises the steps of 1, melting an iron silicon alloy by adopting a rapid solidification strip casting furnace, and preparing the alloy into powder by using a ring hammer mill after rapid quenching; 2, mixing the powder with atomized iron silicon alloy powder, and sieving the resultant powder; 3, performing surface treatment on the powder in a protective atmosphere furnace; 4, adding phosphoric acid, deionizer water, isopropanol and normal silicate ester, mixing, stirring and drying in a frying way; 5, pressing the powder into the powder core by using a hydraulic press; 6, performing protective atmosphere heat treatment on the powder core; and 7, performing protective treatment on the surface of the powder core through the reinforcement of epoxy resin and the spray painting. The iron silicon soft magnetic alloy powder core prepared by the method is high in cost performance and has the advantages of direct current overlapping characteristic, high-frequency low-loss and good characteristic; and in addition, the better magnetic performance still can be kept under a high temperature.

Owner:GUANGDONG IRON & STEEL INST

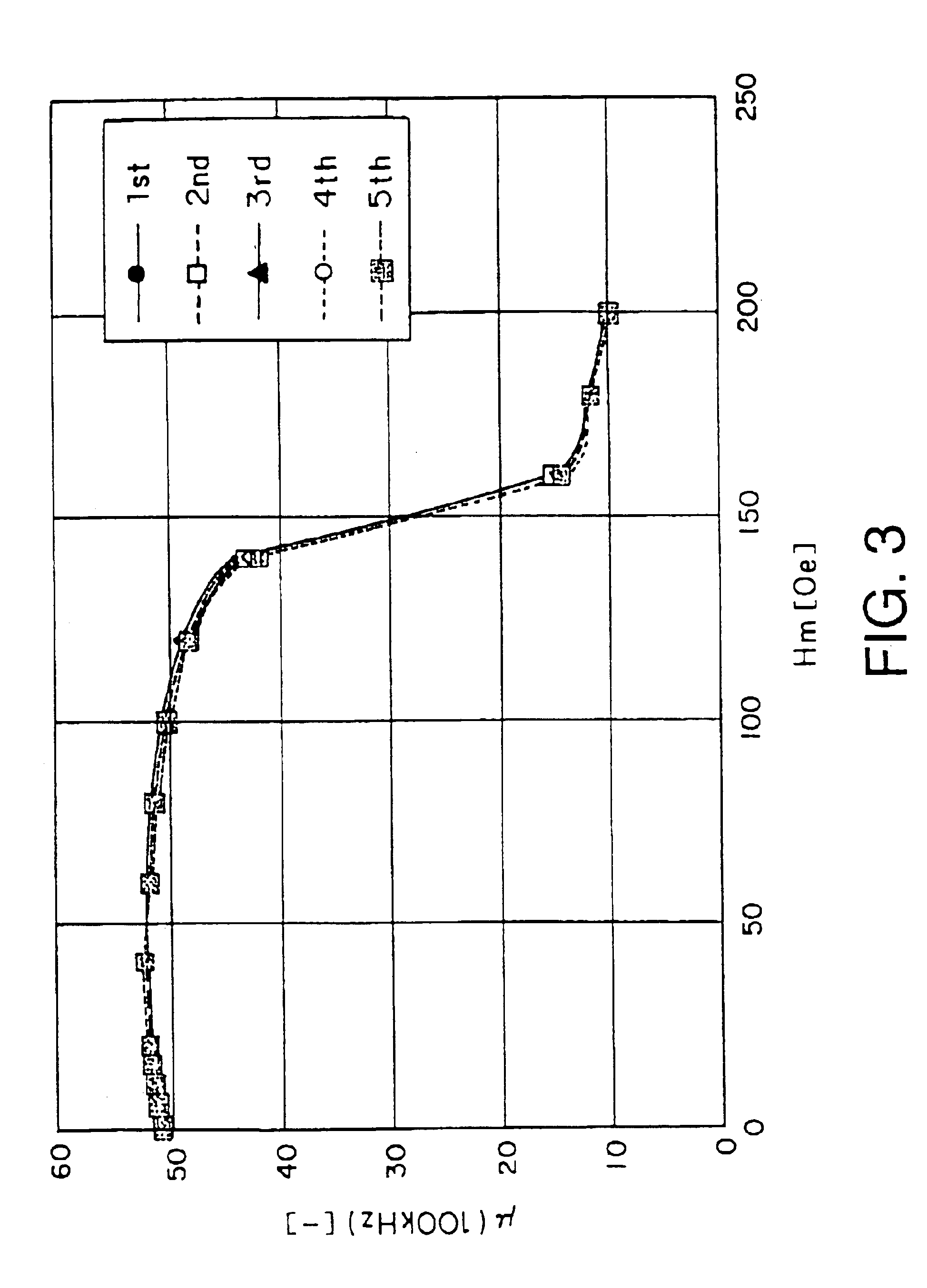

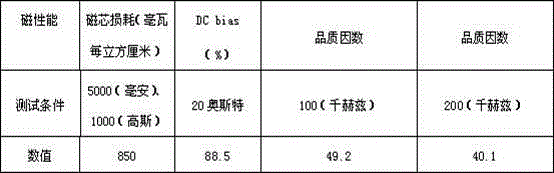

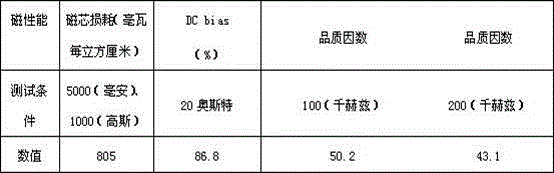

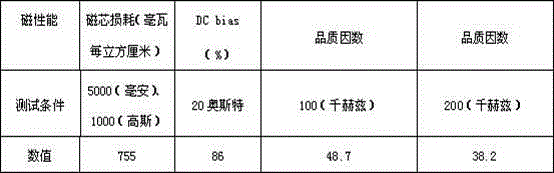

Highly saturated magnetic flux density and low loss NiMnZn power ferrite and method for preparing the same

InactiveCN101183582AReasonable designImprove DC Superposition CharacteristicsInorganic material magnetismVolumetric Mass DensityMagnetic flux

The invention relates to a Ni-Mn-Zn ferrite and the preparation method, in particular to a high saturation magnetic flux density low Ni-Mn-Zn power loss ferrite and the preparation method. The main technical proposal of the invention is: the ferrite comprises components with the following molar percentage: Fe2O3:53 to 55mol%, MnO:35 to 37mol%, ZnO:5 to 8mol%, NiO:2 to 4mol%. The invention has an advantage of providing a high saturation magnetic flux density low Ni-Mn-Zn power loss ferrite with reasonable design, high saturation magnetic flux density, high frequency and low power loss.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

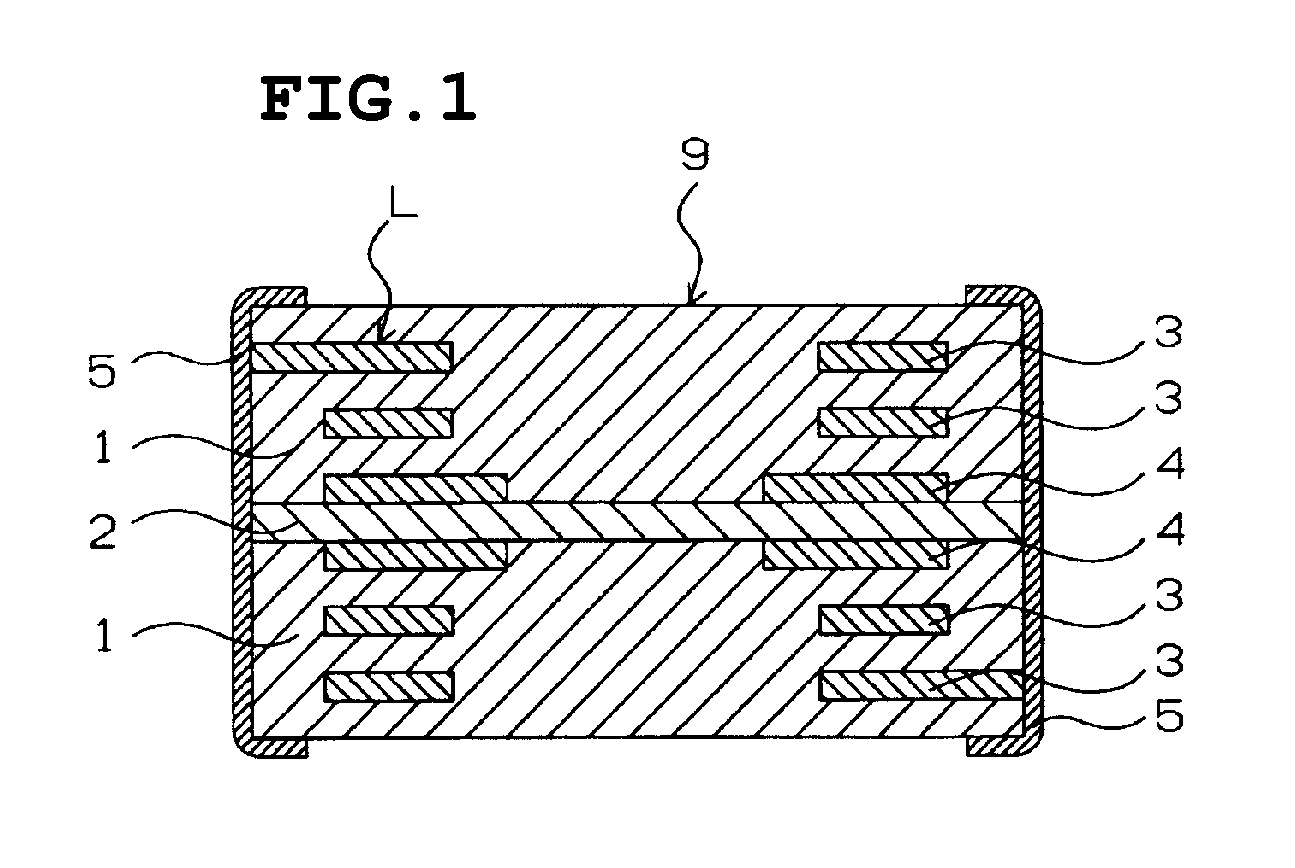

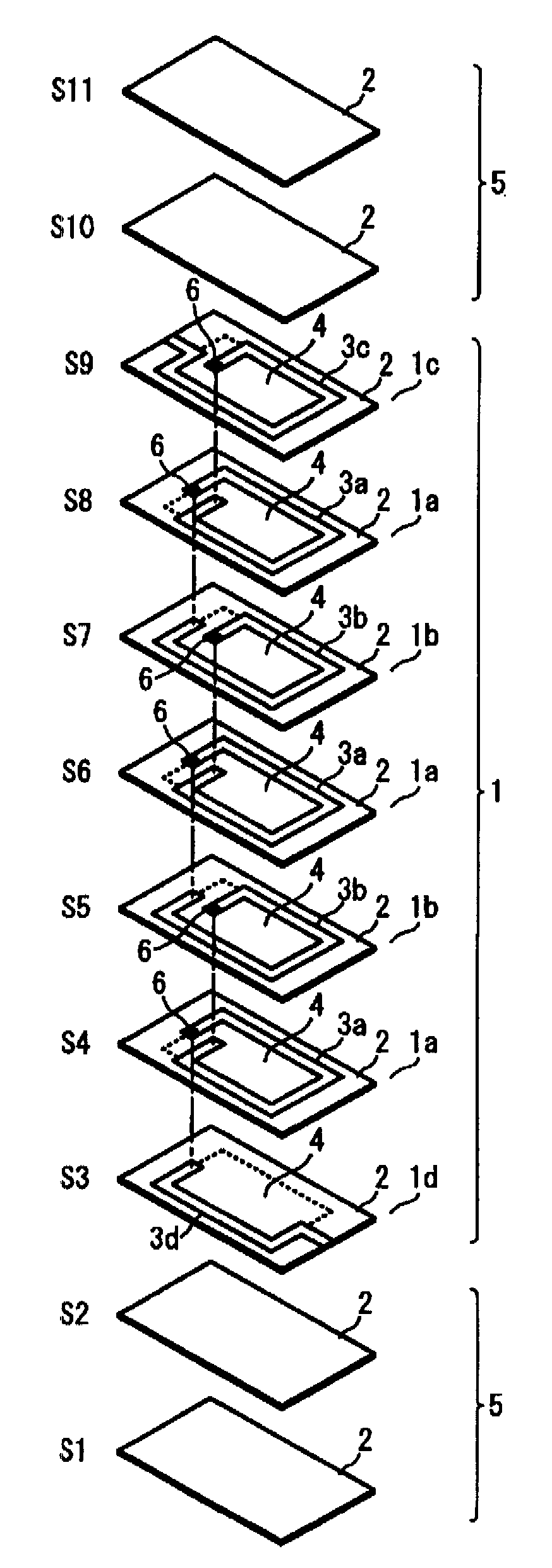

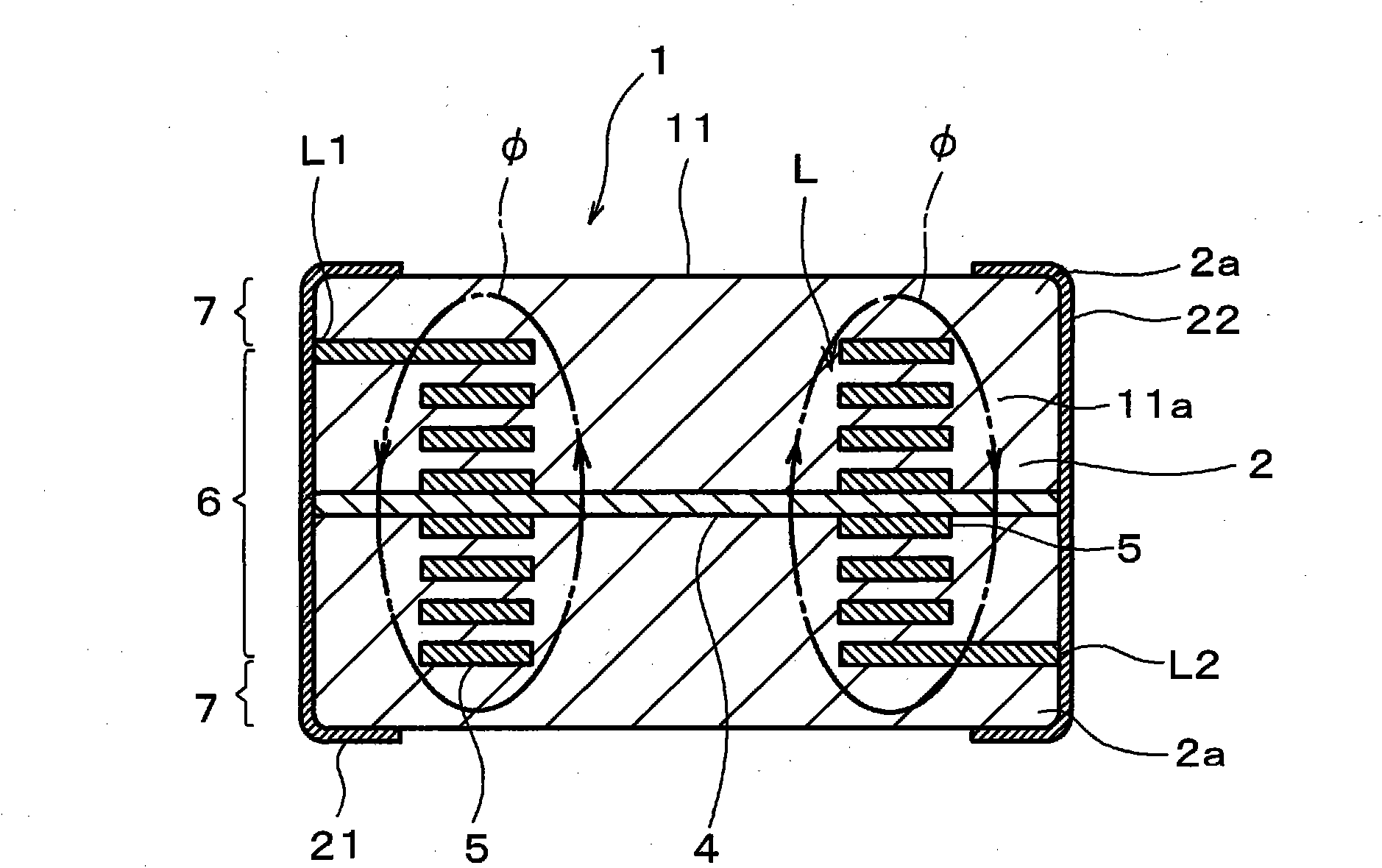

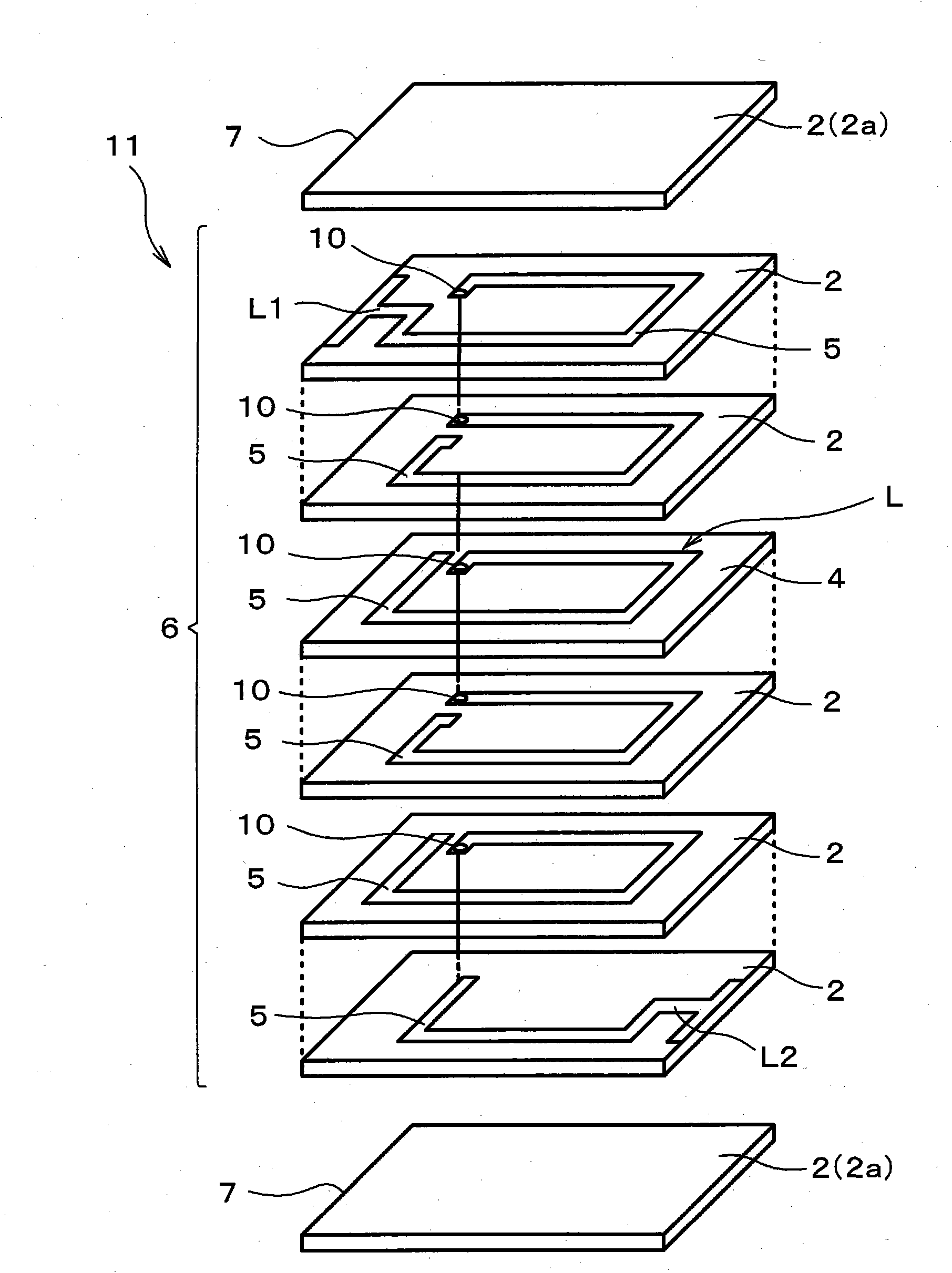

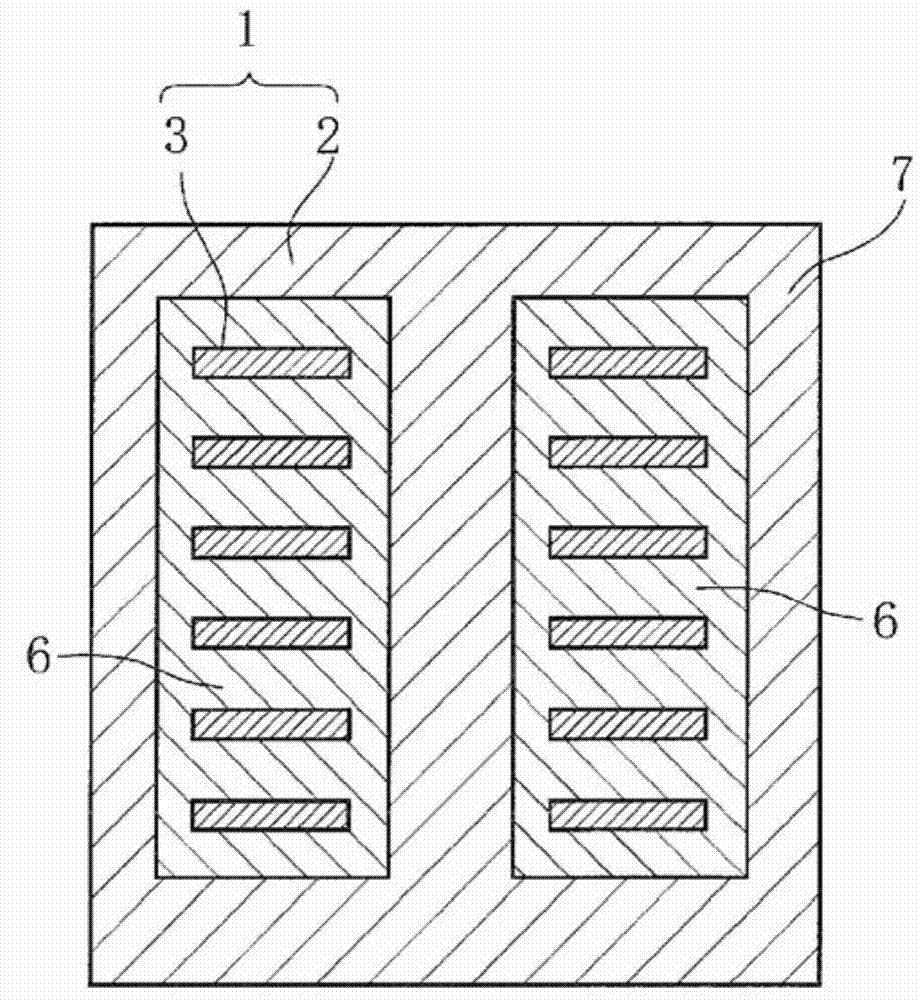

Open magnetic circuit stacked coil component and process for producing the open magnetic circuit stacked coil component

ActiveCN101911221AReduced variance in sintering shrinkageSuppress defects such as cracksInorganic material magnetismTransformers/inductances detailsSuperimpositionEngineering

Disclosed is an open magnetic circuit stacked coil component that is less likely to cause defects between a nonmagnetic layer and a magnetic layer, causes no significant deterioration in temperature characteristics of inductance, even when the thickness of the nonmagnetic layer is reduced, and has excellent direct-current superimposition characteristics. An open magnetic circuit stacked coil component (1) comprises a laminate (11), formed of magnetic layers (2) stacked on top of each other, a coil (L) provided within the laminate (11), and a nonmagnetic layer (4) provided within the laminate (11) so as to cross a magnetic path formed by energization of the coil (L). The nonmagnetic layer is formed of a nonmagnetic material of a Zn-Cu-based ferrite. The magnetic layer is formed of a magnetic material. The magnetic material comprises 100 parts by weight of an Ni-Zn-Cu-based magnetic ferrite material and 0.1 to 2.0 parts by weight, in terms of Co3O4, of Co added to the Ni-Zn-Cu-based magnetic ferrite material. According to the above constitution, the difference in firing shrinkage between the magnetic layer and the nonmagnetic layer can be reduced to suppress the occurrence of cracks and the like, and, even when Ni is diffused from the magnetic layer to thenonmagnetic layer upon firing, the temperature characteristics of the inductance are rendered flat.

Owner:MURATA MFG CO LTD

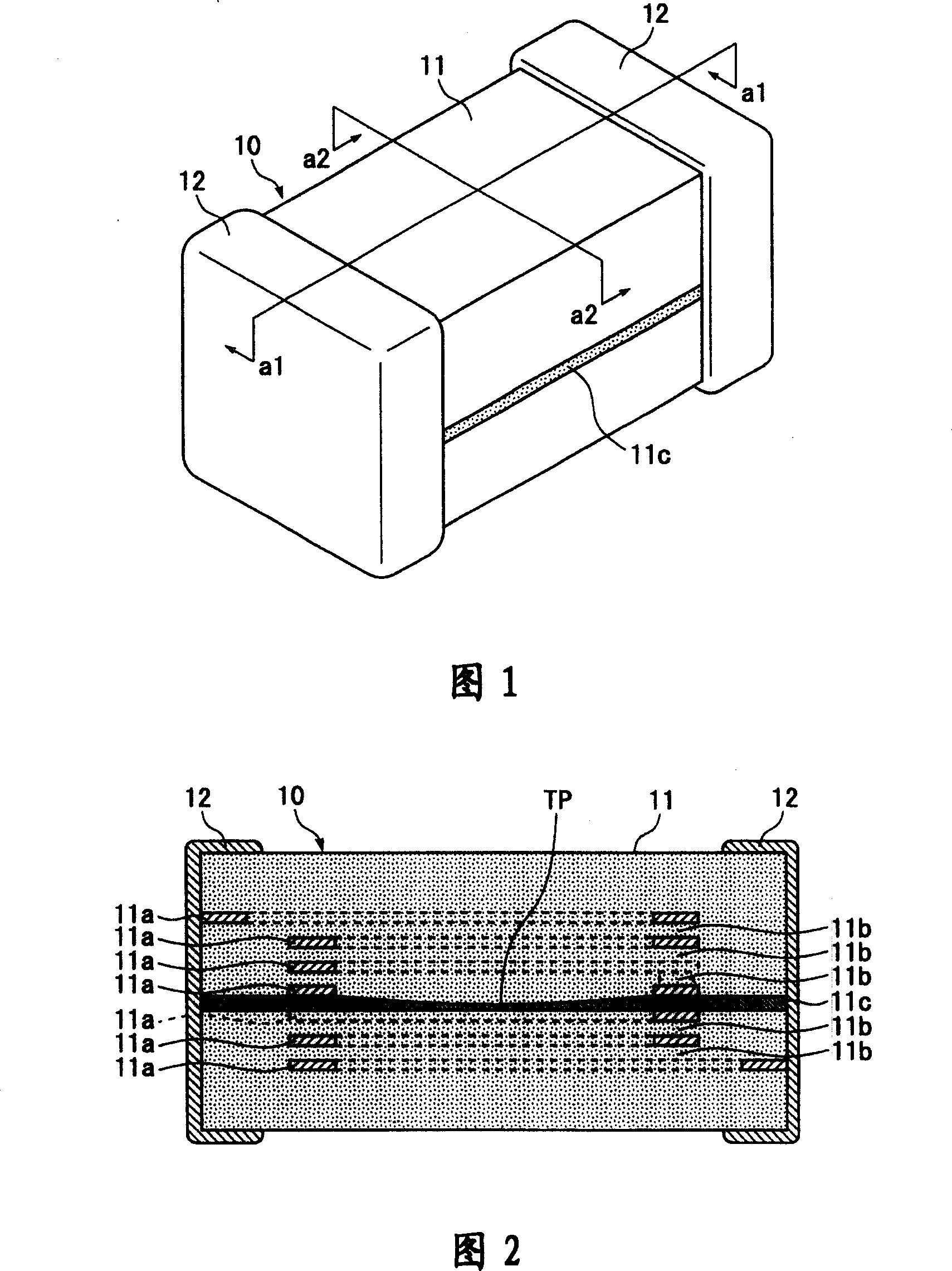

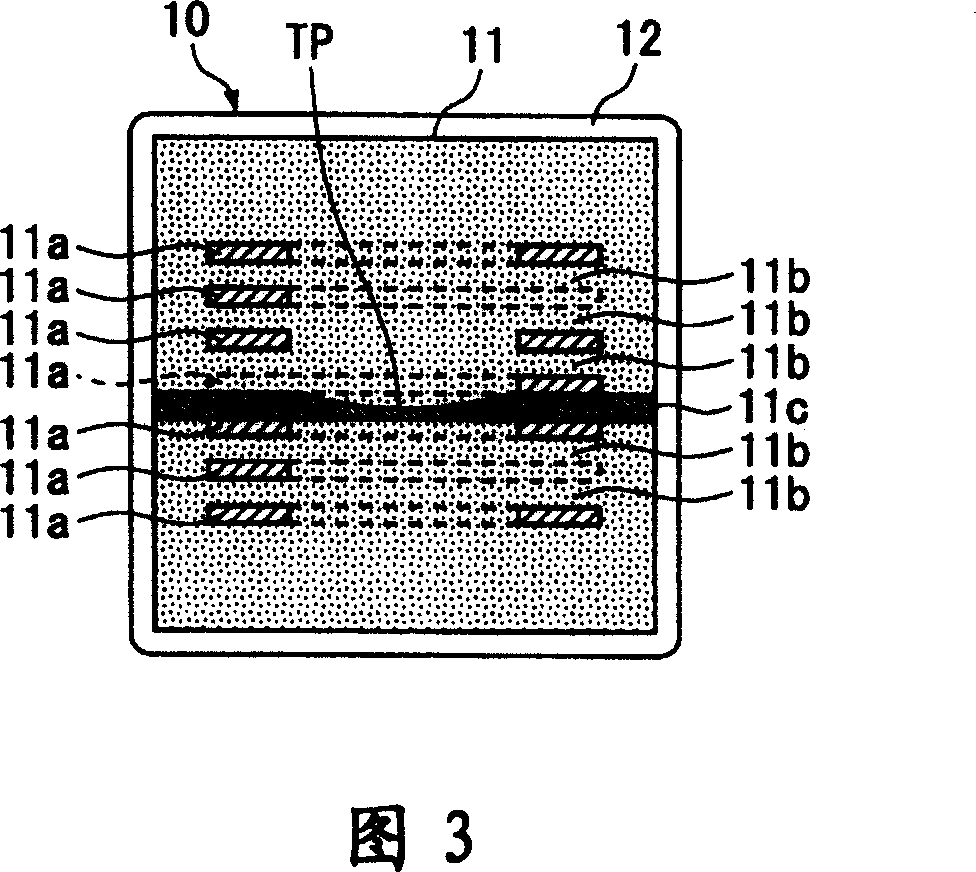

Multilayer inductor

InactiveCN1983473APrevent inductance from decreasingImprove DC Superposition CharacteristicsInductance with magnetic coreCores/yokesElectrical conductorDc current

The present invention provides a multilayer inductor capable of improving DC superposition characteristics and preventing a decrease in inductance value. The increase in magnetic flux density is suppressed by the magnetic flux pass suppression layer (11c) arranged so as to block the magnetic flux passing through the inside of the coil, so that magnetic saturation when a direct current is applied can be suppressed and the direct current superposition characteristic can be improved. Furthermore, by making the thickness of the coil central part where the magnetic flux passes through the suppressing layer (11c) thinner than the thickness of the conductor layer near part, it is possible to reduce the reluctance of the coil central part where the magnetic flux density is low, and prevent the inductance value from being affected by the reluctance. And lower.

Owner:TAIYO YUDEN KK

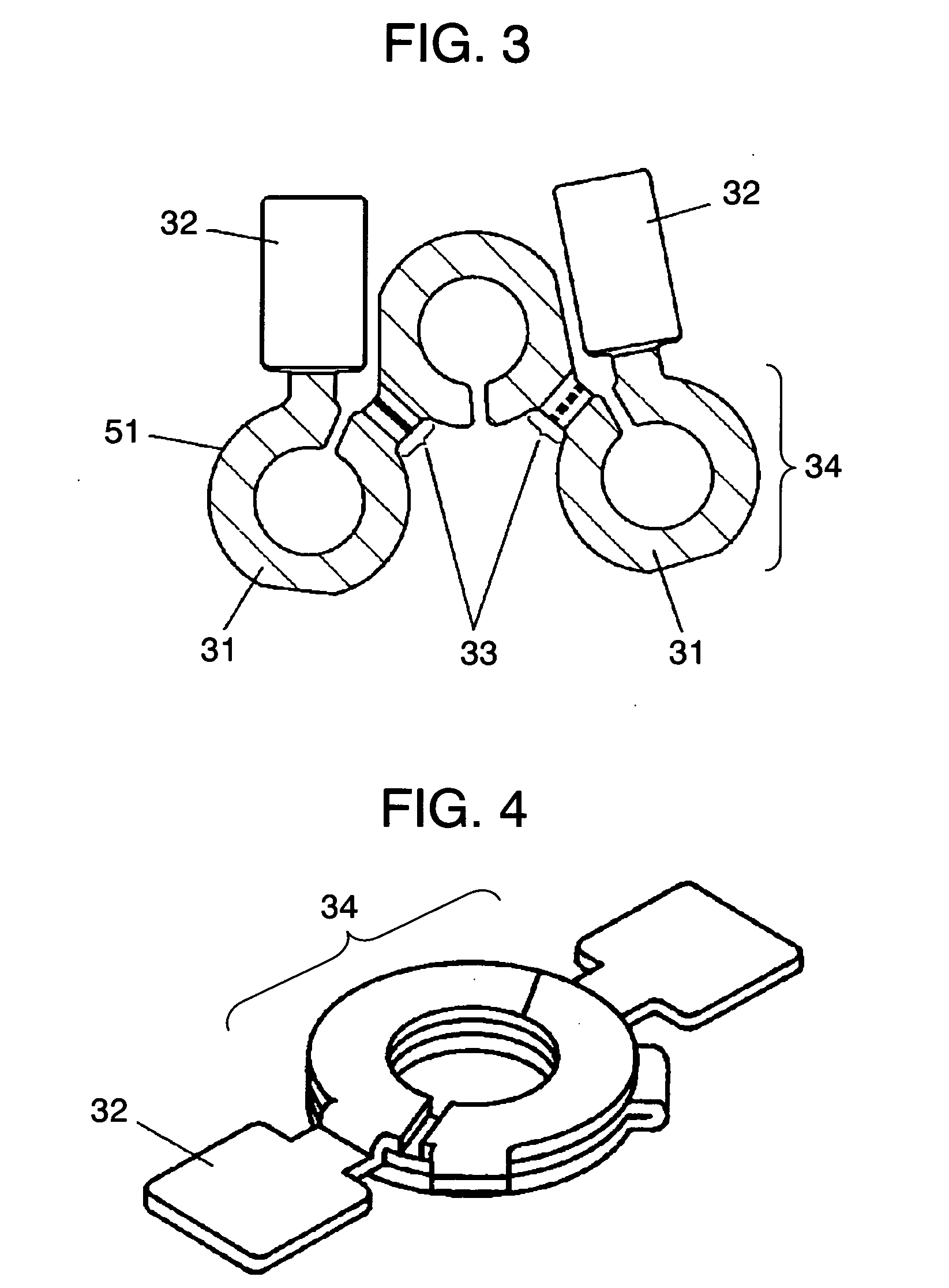

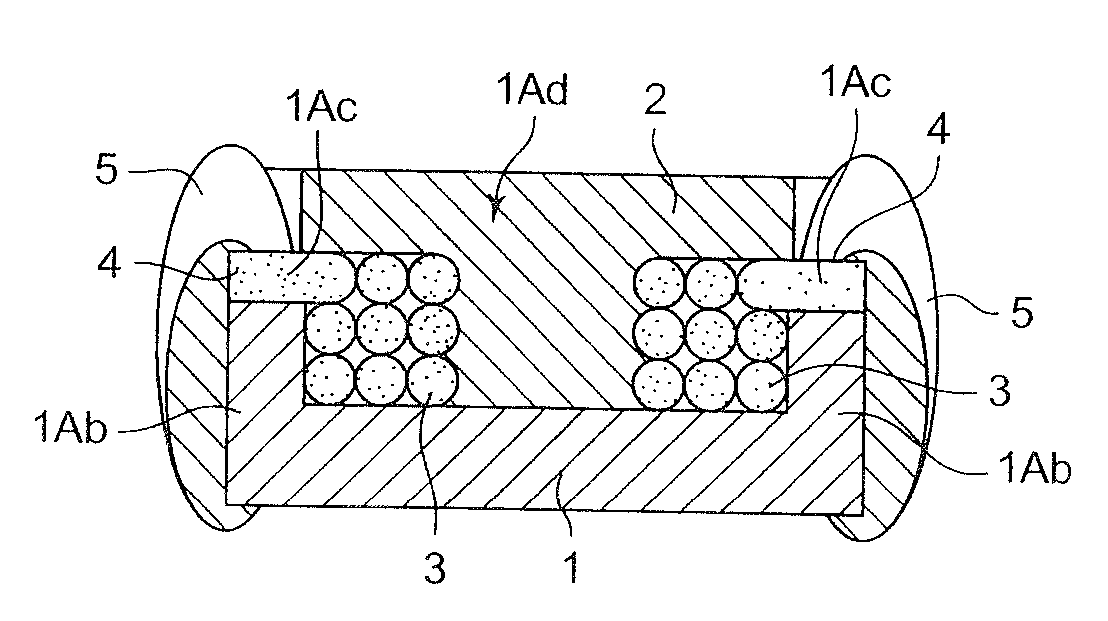

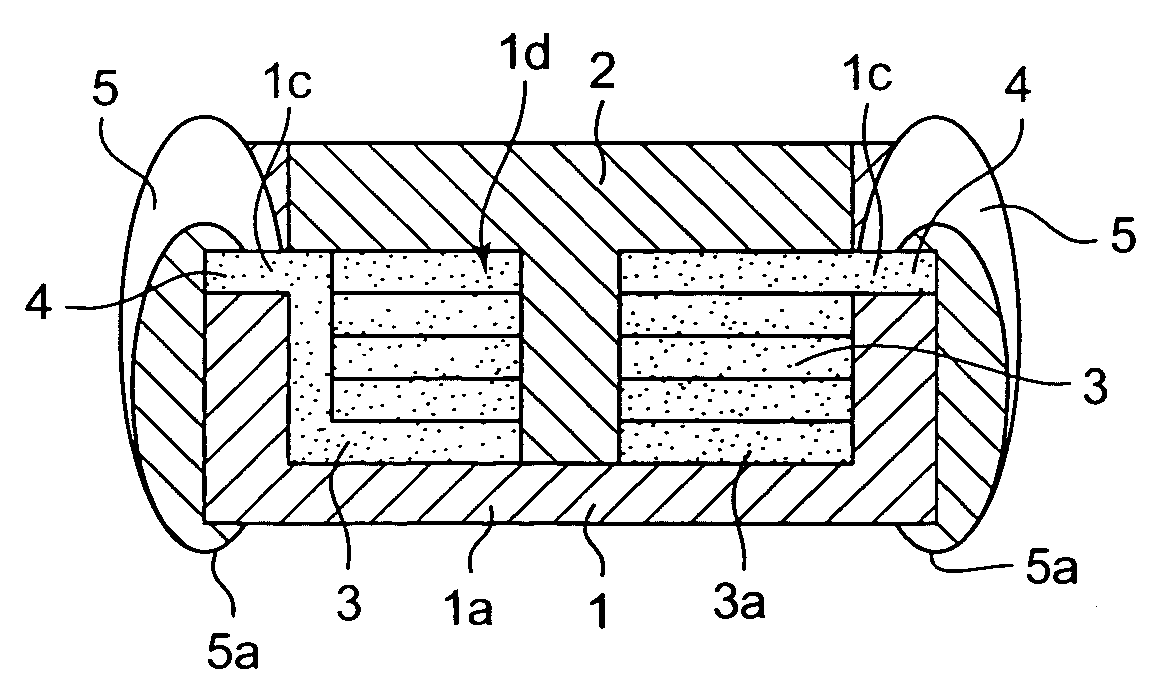

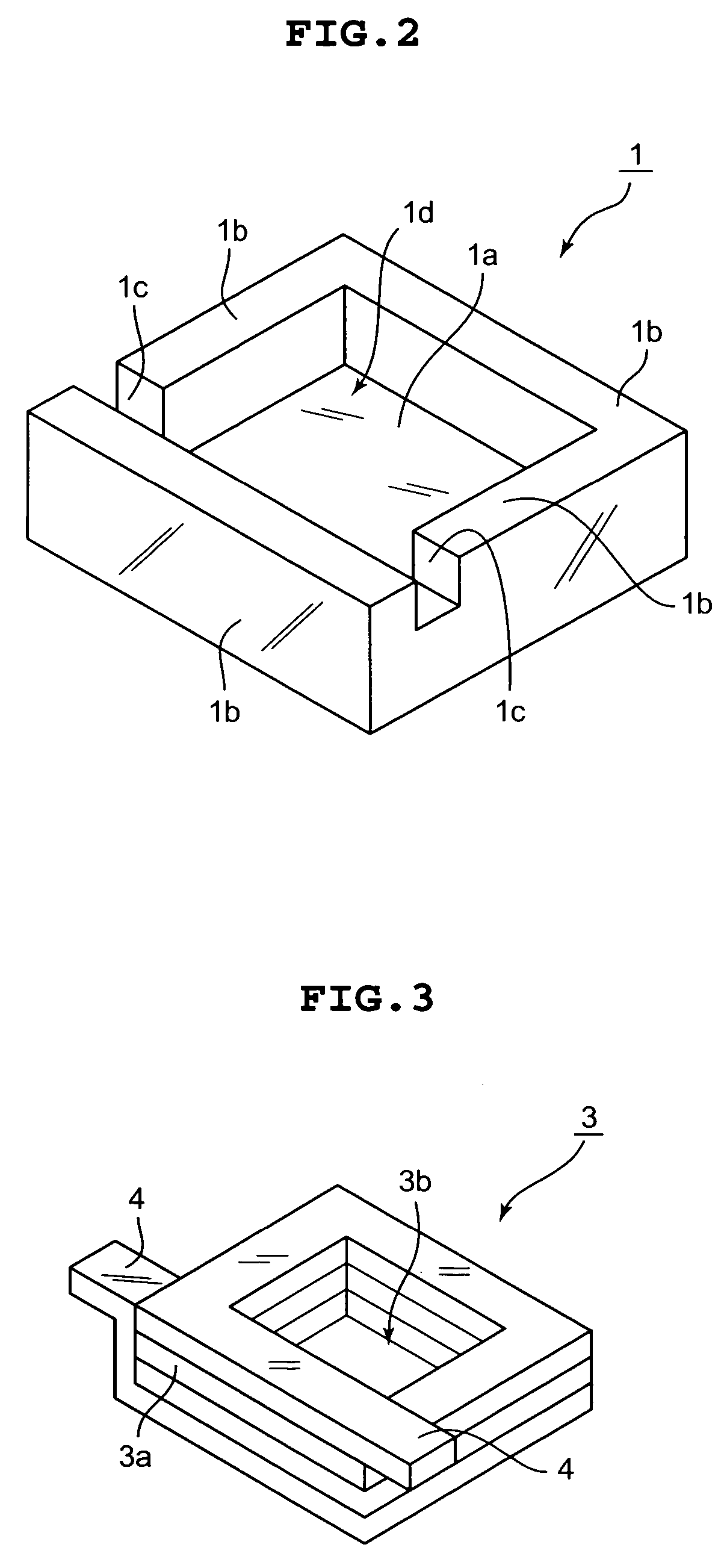

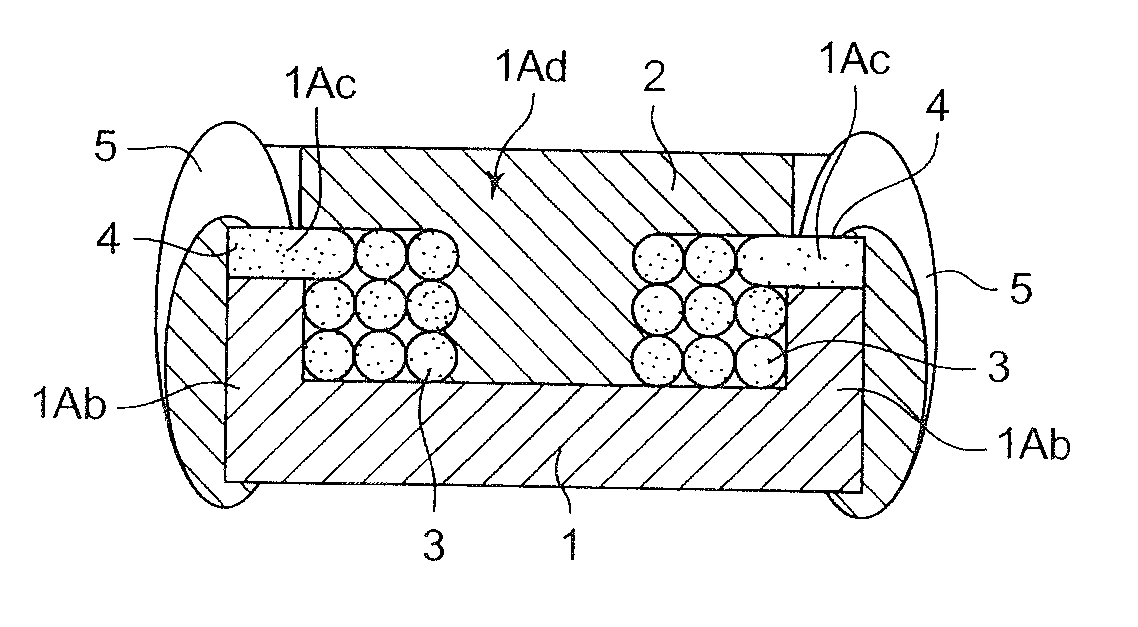

Magnetic element and method of manufacturing magnetic element

ActiveUS20060119461A1Easy to manufactureImprove permeabilityTransformers/inductances casingsTransformers/inductances coils/windings/connectionsElectrical conductorFilling ratio

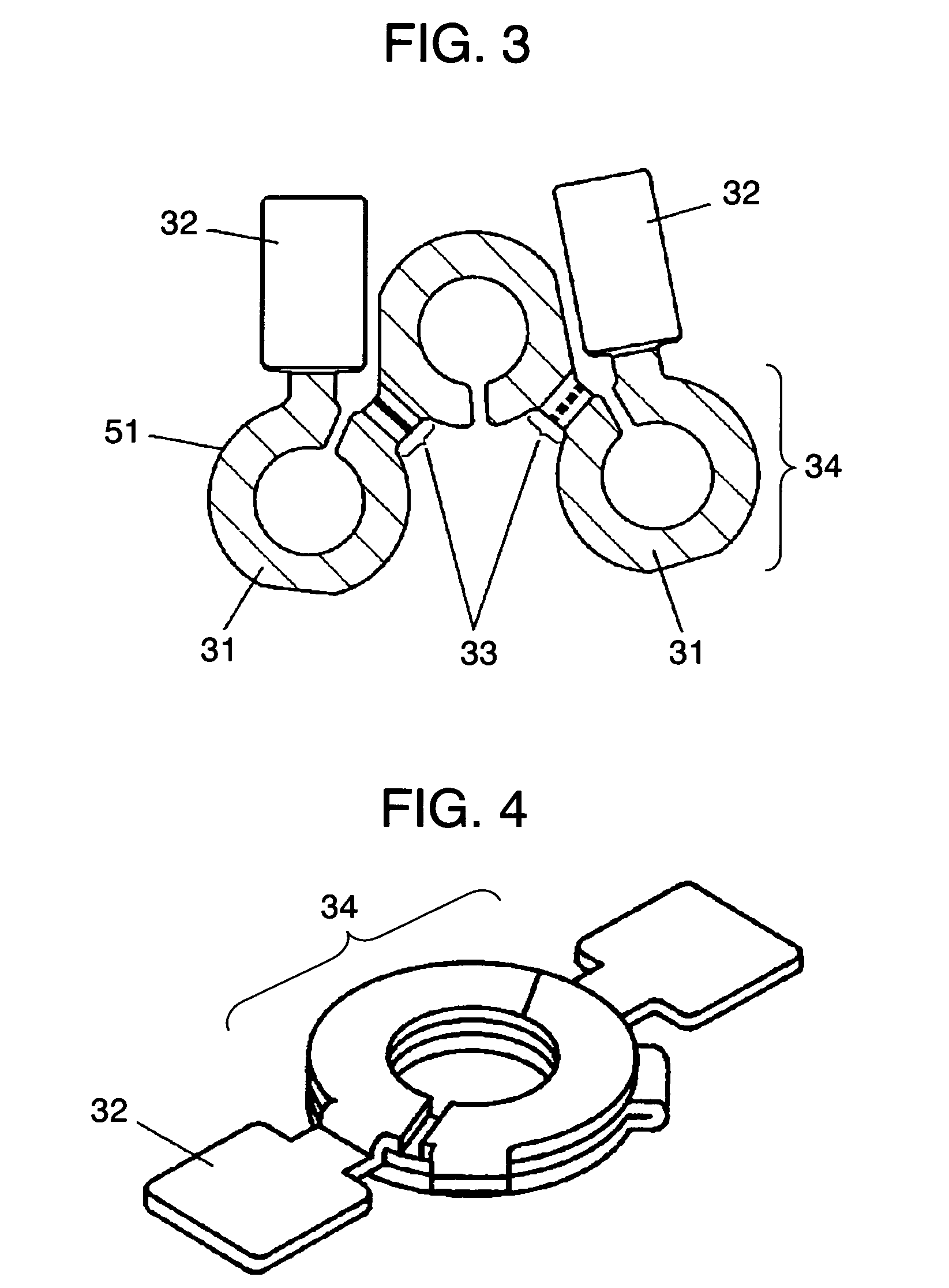

There are provided a magnetic element capable of enhancing magnetic permeability of a magnetic member, improving a direct current superposition characteristic, and improving production efficiency and a method of manufacturing the magnetic element. The magnetic element includes a coil (30) formed of a conductor having an insulating film, a first core member (20) constituted of insulative soft magnetic ferrite and covering the coil (30), and a second core member (50) having soft magnetic metal powder as material and surrounded by the first core member (20). Furthermore, the magnetic element includes a third core member (40) which has soft magnetic metal powder as material and a higher filling ratio of the soft magnetic metal powder than the second core member 50 and is surrounded by the first core member (20).

Owner:SUMIDA CORP

Laminated inductor, method for manufacturing the laminated inductor, and laminated choke coil

ActiveUS8587400B2Improve DC Superposition CharacteristicsInhibitionTransformers/inductances coils/windings/connectionsCoatingsDielectricSuperimposition

Owner:TAIYO YUDEN KK

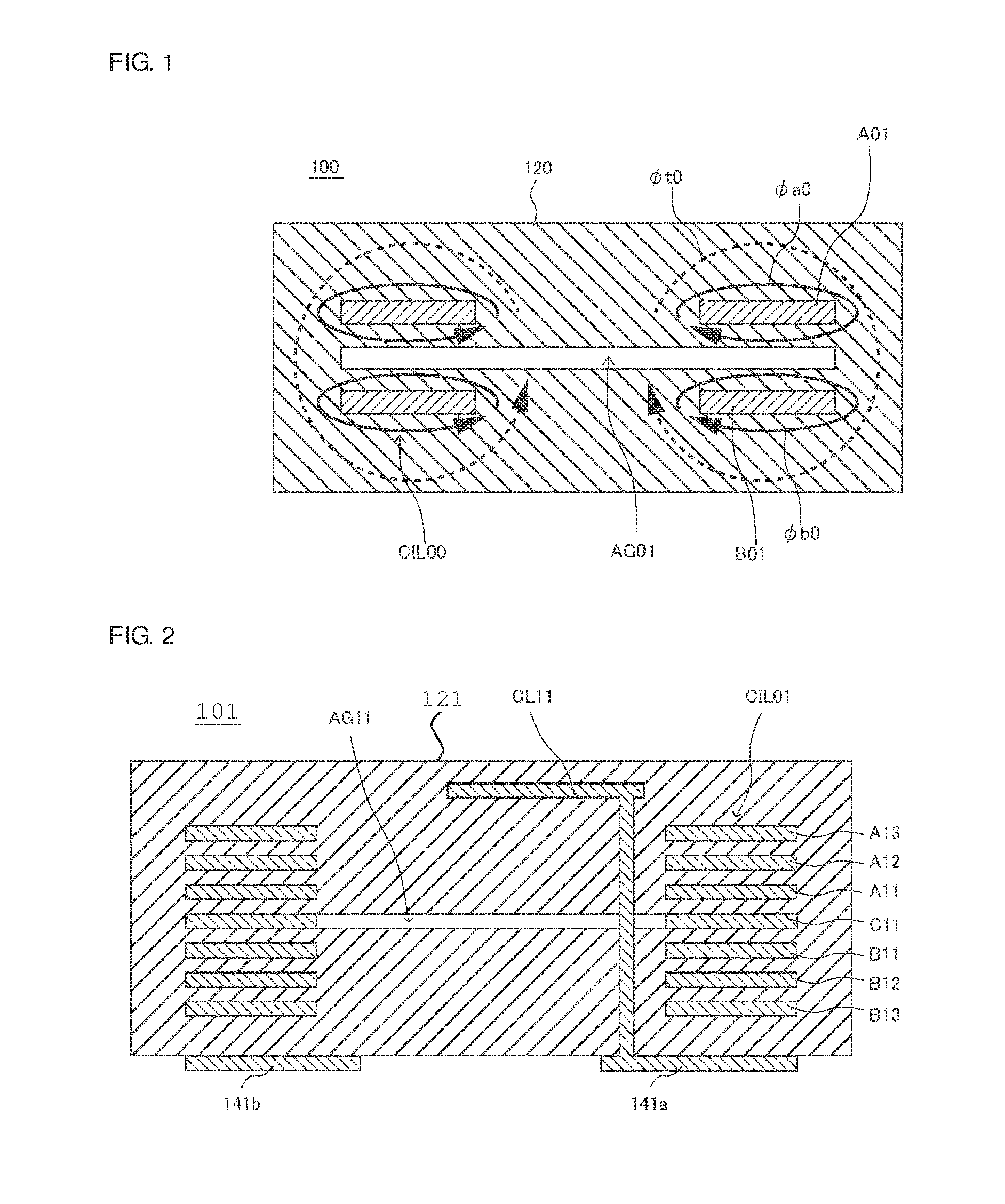

Lamination coil component and coil module

InactiveUS20170025220A1Improve DC Superposition CharacteristicsIncrease the burdenTransformers/inductances coils/windings/connectionsCores/yokesElectrical conductorEngineering

Owner:MURATA MFG CO LTD

Magnetic element and method of manufacturing magnetic element

ActiveUS20060186979A1Improve permeabilityEasy to manufactureTransformers/inductances casingsTransformers/inductances coils/windings/connectionsElectrical conductorFilling ratio

There are provided a magnetic element capable of enhancing magnetic permeability of a magnetic member, improving a direct current superposition characteristic, and improving production efficiency and a method of manufacturing the magnetic element. The magnetic element includes a coil (30) formed of a conductor having an insulating film, a first core member (20) constituted of insulative soft magnetic ferrite and covering the coil (30), and a second core member (50) having soft magnetic metal powder as material and surrounded by the first core member (20). Furthermore, the magnetic element includes a third core member (40) which has soft magnetic metal powder as material and a higher filling ratio of the soft magnetic metal powder than the second core member 50 and is surrounded by the first core member (20).

Owner:SUMIDA CORP

Multilayer inductor and method for manufacturing the same

InactiveCN102017028AStable productionImprove DC Superposition CharacteristicsMagnetic materialsCeramic layered productsDielectricInductor

Disclosed is a multilayer inductor using an Ni-Zn-Cu ferrite, which has improved temperature characteristics and is free from structural defects. A method for manufacturing the multilayer inductor is also disclosed. The multilayer inductor is characterized by comprising: a multilayer body (1) having a rectangular solid shape, which comprises a plurality of magnetic layers (3, 3) composed of an Ni-Zn-Cu ferrite, a plurality of conductive layers (2, 2) forming a coil by being laminated via the magnetic layers, and at least one non-magnetic layer (4) so formed as to be in contact with the plurality of magnetic layers (3, 3) and composed of a Ti-Ni-Cu-Mn-Zr dielectric; and at least a pair of external electrodes (7, 7) arranged on the ends of the multilayer body (1) and electrically connected to the ends of the coil.

Owner:TAIYO YUDEN KK

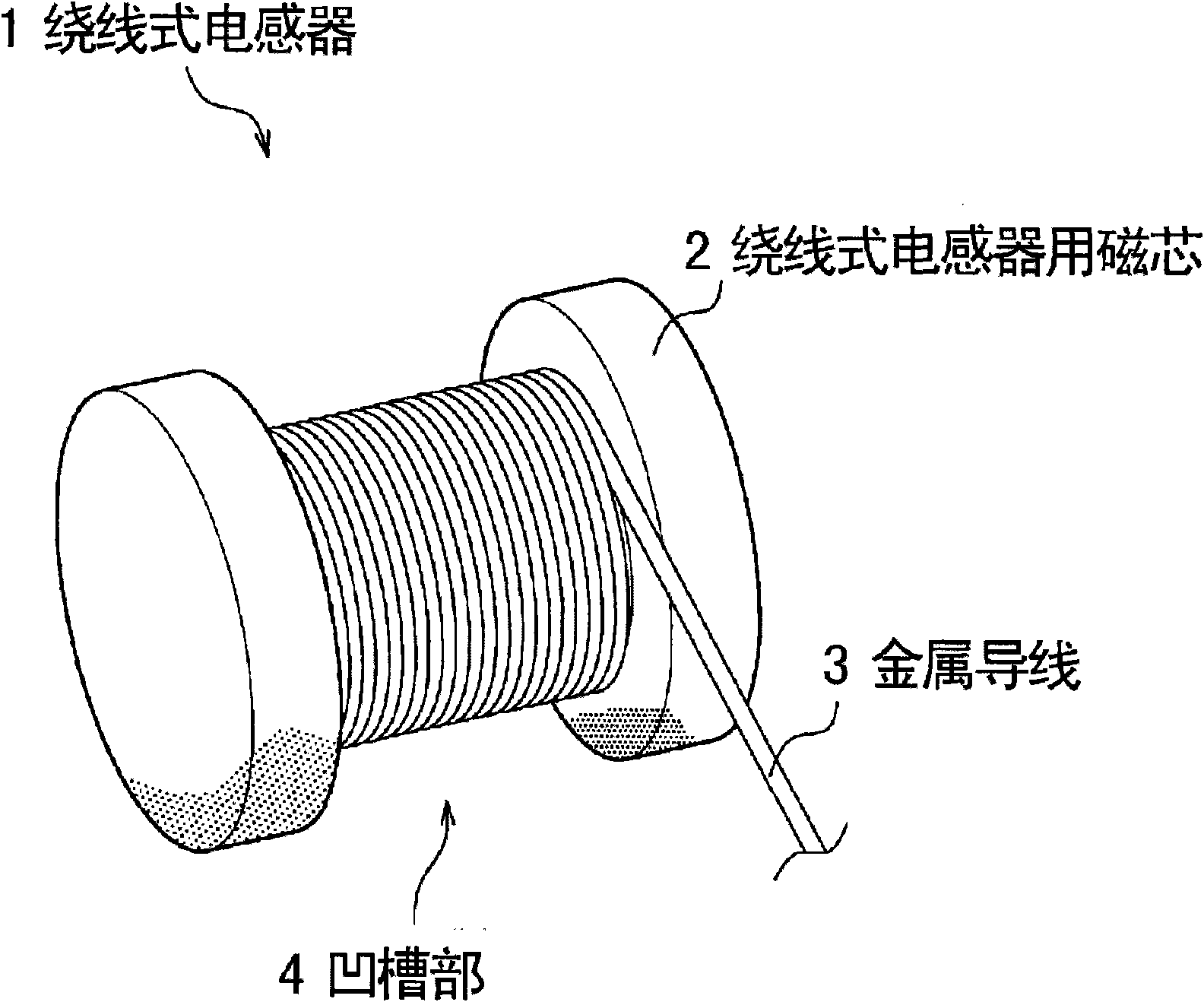

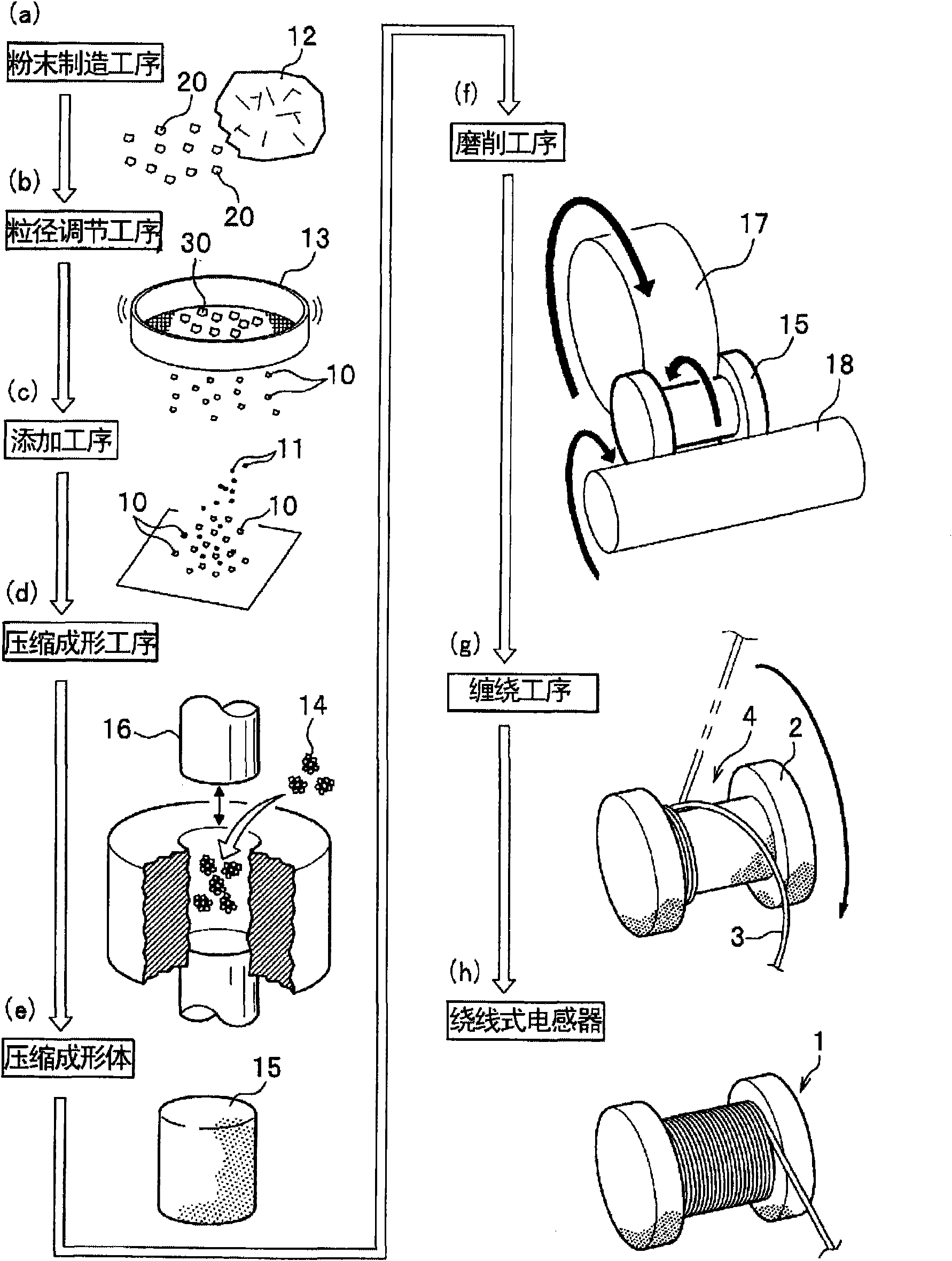

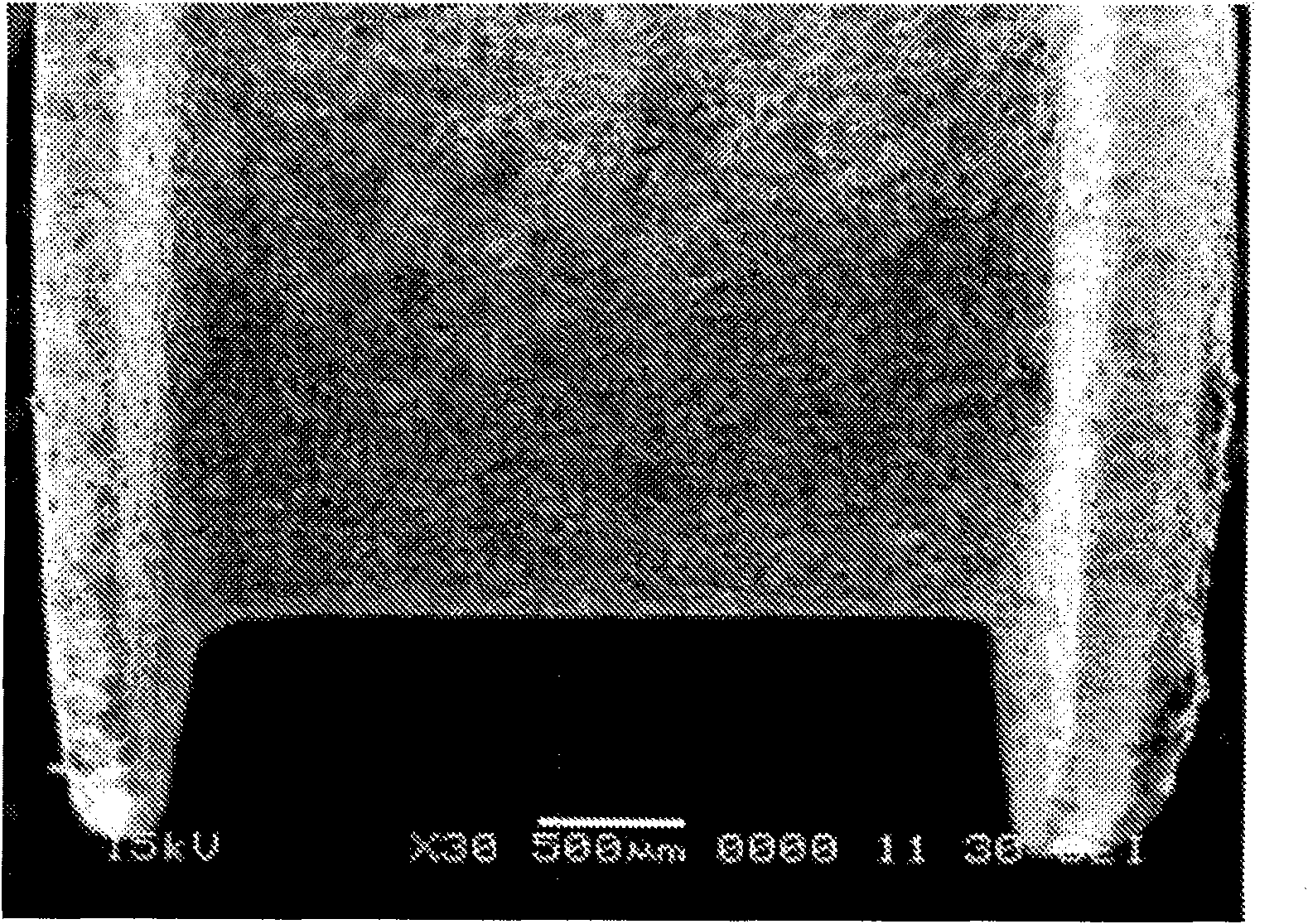

Winding inductor and process for manufacturing the same

InactiveCN101689421ALarge saturation magnetizationImprove DC Superposition CharacteristicsInorganic material magnetismTransformers/inductances detailsCompression moldingAlloy

Using a core based on an Fe alloy there are provided an inductor with enhanced current superposition characteristics and a process for manufacturing the same. There is disclosed a winding inductor including a core for winding inductor obtained by compression molding a mixed magnetic substance powder containing a magnetic substance powder and a binder and grinding the molded item and including a metal conductive wire wound in a core section of the core for winding inductor. One form of the winding inductor is characterized in that the magnetic substance powder in component proportion consists of 4 to 13 wt.% Si, 4 to 7 wt.% Al and the balanceFe and unavoidable impurities and has a particle diameter distribution such that 90% or more of the magnetic substance powder has a particle diameter of 75 ¢mu!m or less.

Owner:TOHO ZINC

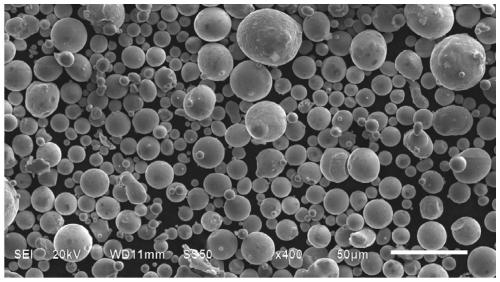

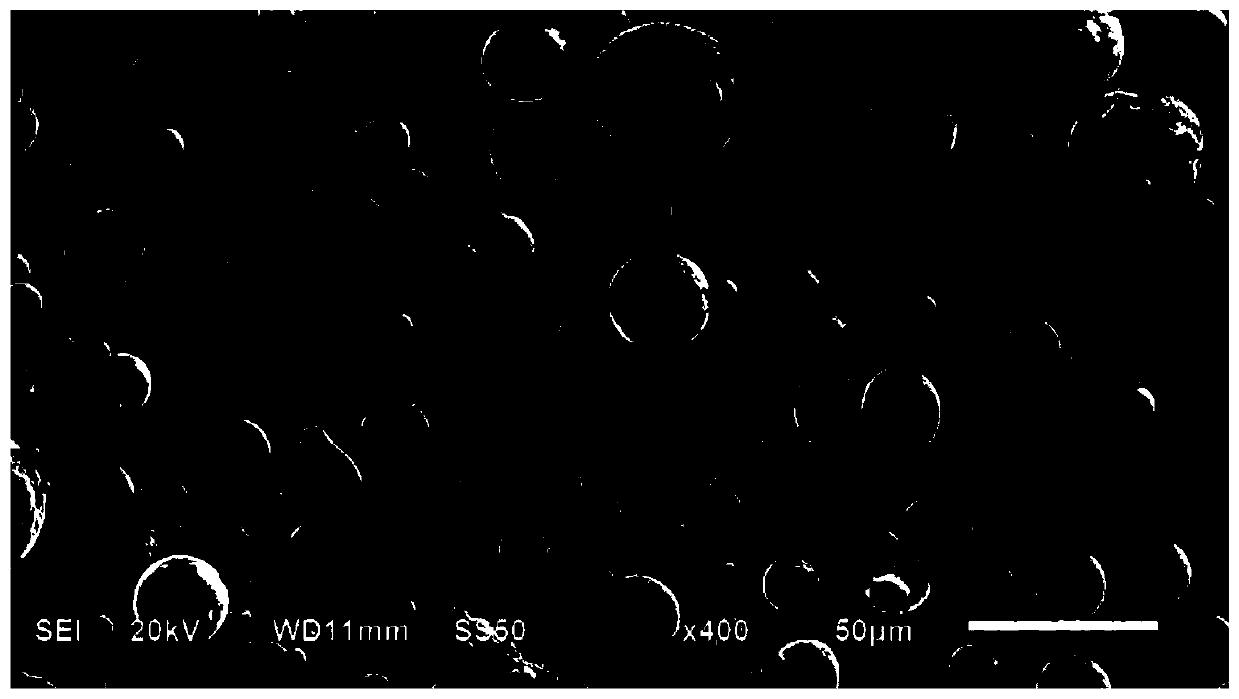

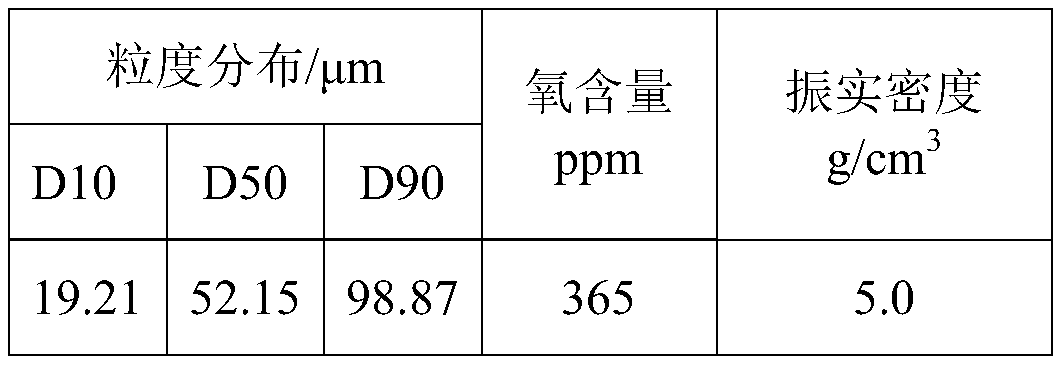

Preparation method of FeSi alloy powder with high direct current superposition characteristics

ActiveCN110039060AHigh tap densityImprove DC Superposition CharacteristicsTransportation and packagingMetal-working apparatusManganeseAlloy

The invention discloses a preparation method of FeSi alloy powder with high direct current superposition characteristics, and belongs to the technical field of alloy powder preparation. The FeSi alloypowder is mainly made of pure iron and metal silicon, and a small amount of manganese and chromium are added. The preparation method comprises the following steps of weighing the ingredients according to a specific proportion, carrying out non-vacuum melting to obtain the alloy melt of required components, and then atomizing to prepare alloy raw powder with an inert gas, obtaining fine powder after the raw powder is collected, screened and graded. According to the preparation method of FeSi alloy powder with high direct-current superposition characteristics, the alloy powder with uniform components and high purity can be obtained, and the powder spherical degree is high; the uniform and compact insulating layer can be easily formed after insulation coating, so that the contact of the alloy matrix is effectively blocked, and the pressed magnetic powder core has good direct-current superposition characteristics.

Owner:马鞍山新康达磁业股份有限公司

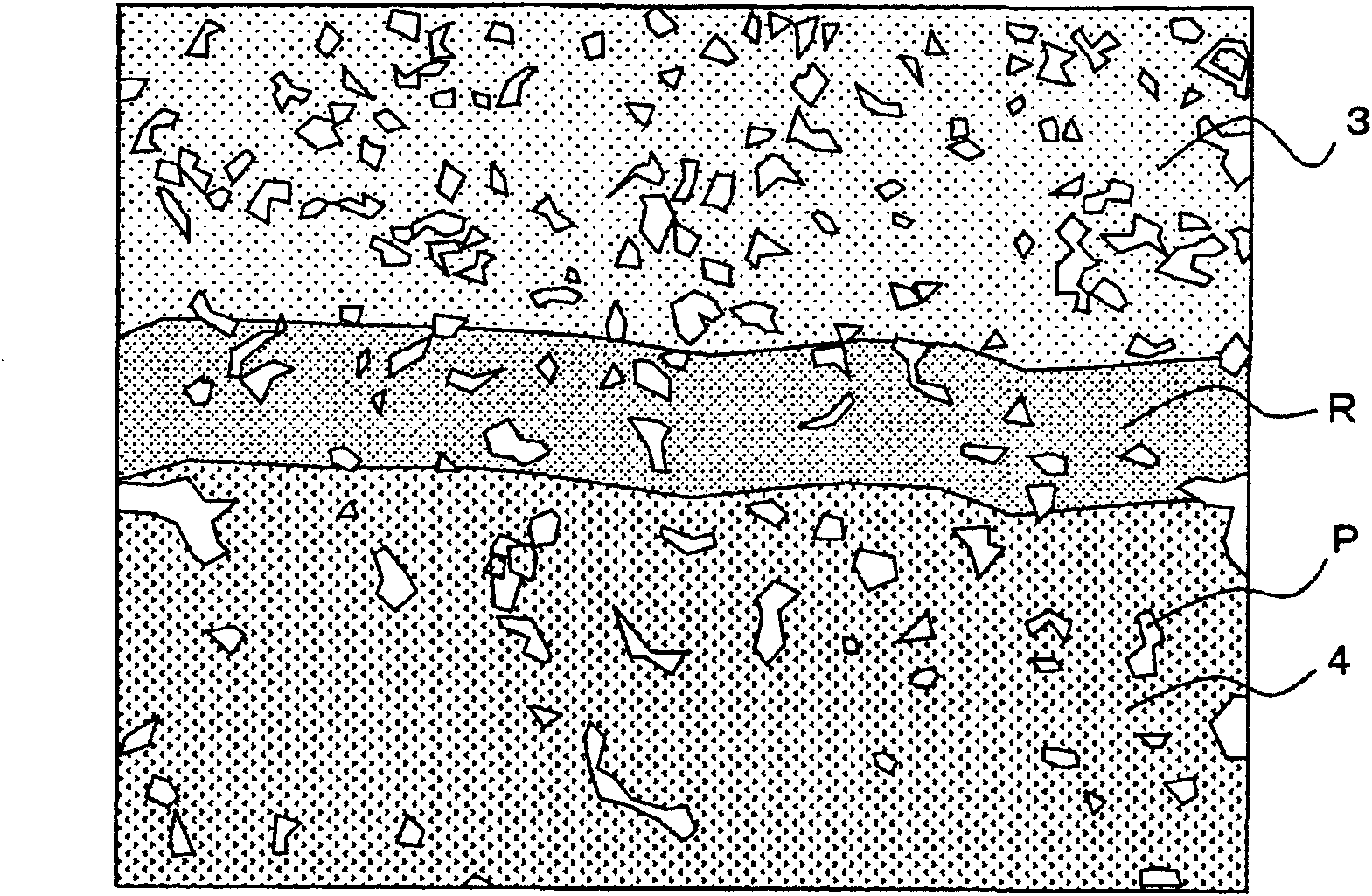

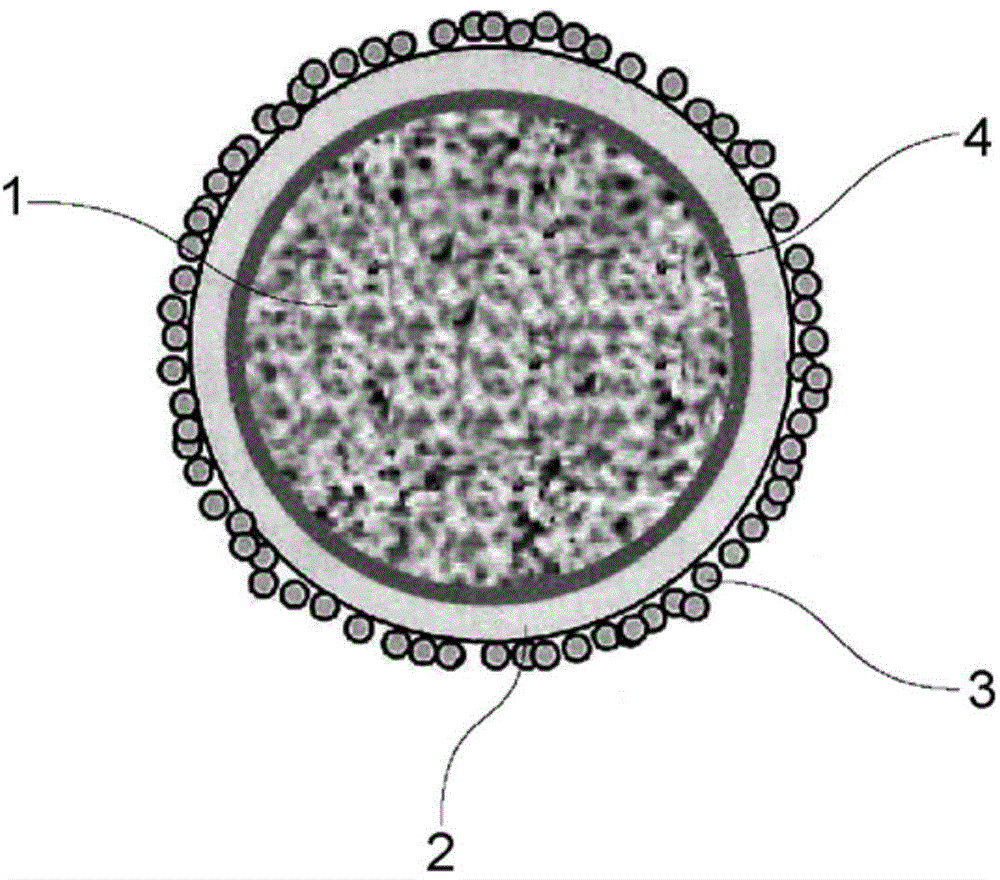

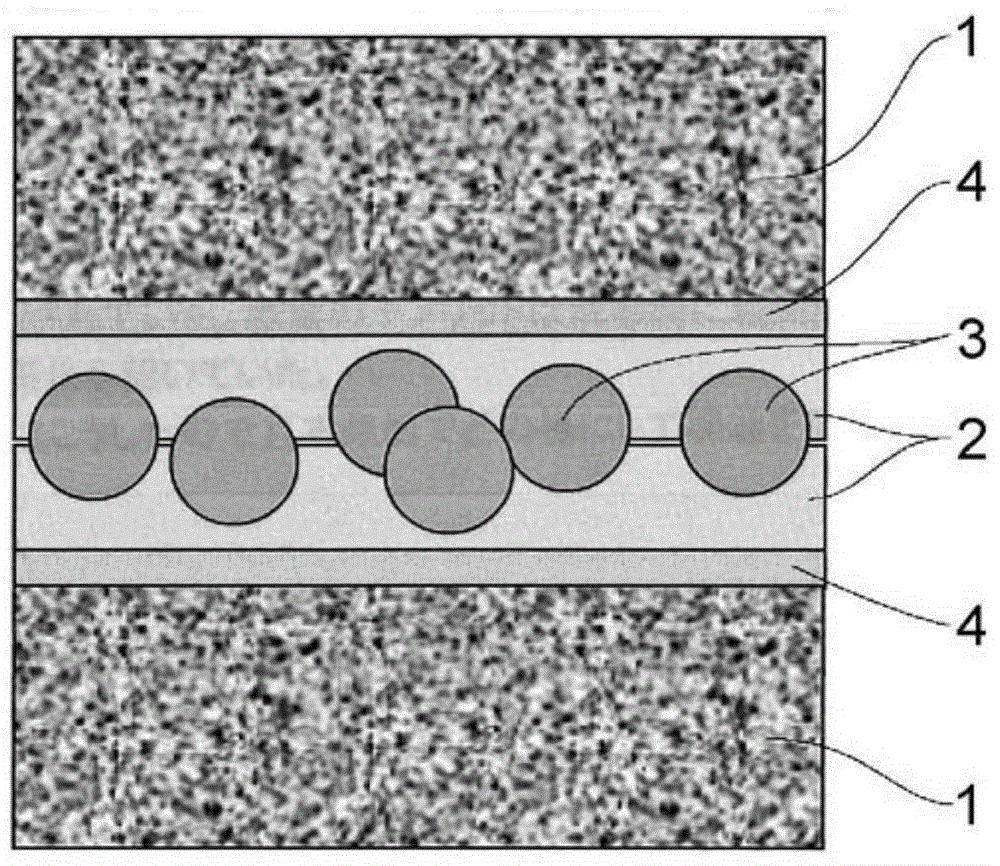

Composite soft magnetic material and production method therefor

InactiveCN103959405AThickness without segregation and uniformityGuaranteed clearanceTransportation and packagingMetal-working apparatusElectrical resistance and conductanceMetallurgy

Provided are a composite soft magnetic material, having favorable DC bias characteristics and high specific resistance, and a production method therefor. An inorganic insulative powder (3) and a coated powder obtained by coating a soft magnetic powder (1) that is coated with an insulative film (4) with a silicone resin (2) are uniformly mixed, and the resultant mixture is molded and fired. By uniformly mixing the inorganic insulative powder (3) and the coated powder obtained by coating the soft magnetic powder that is coated with the insulative film (4) with the silicone resin (2), rupture of the insulative film due to the inorganic insulative material when molding pressed powder is prevented. By uniformly dispersing the inorganic insulative material while high specific resistance is maintained, the gap between molded soft magnetic powder particles is uniformly maintained. As a result, a composite soft magnetic material is provided having high specific resistance and favorable DC bias characteristics.

Owner:DIAMET CORP

Multilayer coil part

ActiveCN103597558AInhibit growthReduced sinterabilityTransformers/inductances coils/windings/connectionsInorganic material magnetismElectrical conductorSize ratio

This multilayer coil part has a magnetic body section (2) that is made of an Ni-Zn system ferrite material and a Cu-based coil conductor (3) that has been wound into a coil shape. The coil conductor (3) is buried inside the magnetic body section (2) to form a part element body (1). The part element body (1) is divided into a first region (6) that is located close to the coil conductor (3) and a second region (7) that comprises the region other than the first region (6). The grain size ratio (D1 / D2) between the average crystal grain size (D1) of the magnetic body section (2) in the first region (6) and the average crystal grain size (D2) of the magnetic body section (2) in the second region (7) is equal to or lower than 0.85. The molar quantity of CuO content in the ferrite material is set to 6 mol% or less, and the ferrite material is baked in a reductive atmosphere with the oxygen partial pressure being equal to or lower than the Cu-Cu2O equilibrium oxygen partial pressure. Thus, a multilayer coil part that exhibits not only little fluctuation of inductance and excellent thermal shock resistance when subjected to a thermal shock or an external stress but also excellent direct-current superposition characteristics can be obtained without requiring any complicated step.

Owner:MURATA MFG CO LTD

Laminated coil

InactiveCN102403087AImprove featuresNo increase in shapeTransformers/inductances casingsTransformers/inductances coils/windings/connectionsEngineeringElectrical and Electronics engineering

Owner:MURATA MFG CO LTD

Method for manufacturing [mu]26 composite magnetic powder core

InactiveCN107369515AGood value for moneyImprove stabilityTransportation and packagingMetal-working apparatusSendustPhosphoric acid

The invention discloses a method for manufacturing a [mu]26 composite magnetic powder core. The technical scheme is as follows: after two or more alloy powders from mechanically crushed sendust, aerosolized sendust, aerosolized iron-silicon, aerosolized iron-nickel and aerosolized iron-nickel-molybdenum are selected and are fully mixed, phosphoric acid passivation treatment and drying are performed, then one or more from silicon oxide, aluminum oxide, calcium oxide and magnesia calcinata, sodium silicate, and deionized water are successively added to the alloy powders subjected to the passivation processing and drying for insulation coating, and afterwards, the [mu]26 composite magnetic powder core is prepared after press molding, heat treatment and surface coating. The alloy powders used in the method have the advantages of mature technology, stable performance and relatively low cost so that the prepared magnetic powder core has quite high cost performance and stability. Such oxides as the silicon oxide, the aluminum oxide, the magnesia calcinata and the like and such inorganic materials as the sodium silicate and the like are used for coating adhesion so that the obtained composite magnetic powder core has the advantages of high stability, high reliability, low cost, high safety and facilitated production.

Owner:天通(六安)新材料有限公司

Method for manufacturing [mu]90 composite magnetic powder core

InactiveCN107369514AImprove power densitySuitable for low voltage and high currentTransportation and packagingMetal-working apparatusSendustLow voltage

The invention discloses a method for manufacturing a [mu]90 composite magnetic powder core. The [mu]90 composite magnetic powder core is made by compounding two or more alloy powders. The alloy powders comprise the following components: mechanically crushed sendust, aerosolized sendust, aerosolized iron-silicon, aerosolized iron-nickel and aerosolized iron-nickel-molybdenum. The manufacturing method comprises the steps of powder compounding, passivation, insulation coating, press molding, heat treatment and surface coating. The alloy powders complement each other in terms of performance so that the performance of the prepared composite powder core is close to that of a commercially available amorphous magnetic powder core. The alloy powders used in the method have the advantages of mature technology, stable performance and relatively low cost so that the prepared magnetic powder core has quite high cost performance and stable characteristics. The composite magnetic powder core with magnetic permeability of [mu]90 has excellent physical properties and magnetic properties. By use of the magnetic powder core prepared by the invention, the development requirements of an existing electronic industry for low-voltage high current, high power density and high frequency are greatly satisfied.

Owner:天通(六安)新材料有限公司

Nicuzn based ferrite and electronic component using the same

ActiveCN1988067ANarrow range of compositionImprove DC Superposition CharacteristicsInorganic material magnetismInductance with magnetic coreCopper oxideElectronic component

An NiCuZn-base ferrite of the invention comprises as main components an iron oxide in an amount of 45.0 to 49.0 mol % on Fe2O3 basis, an copper oxide in an amount of 5.0 to 14.0 mol % on CuO basis and a zinc oxide in an amount of 1.0 to 32.0 mol % on ZnO basis with a nickel oxide accounting for the rest mol % on NiO basis. With respect to the main components, a bismuth oxide is contained in an amount of 0.25 exclusive to 0.40% by weight on Bi2O3 basis, and a tin oxide is contained in an amount of 1.00 to 2.50% by weight on SnO2 basis. The invention ensures a leap upward in direct-current bias characteristics.

Owner:TDK CORPARATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Method for manufacturing [mu]26 composite magnetic powder core Method for manufacturing [mu]26 composite magnetic powder core](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/a9a52e52-c44a-4432-9340-750296d5c074/170720100023.png)