Laminated coil

A stacked coil technology, applied in coil manufacturing, transformer/inductor coil/winding/connection, inductor, etc., can solve the problem of the overall shape of the laminated body becoming larger, so as to improve coil characteristics, reduce DC resistance, Effect of Improving DC Superposition Characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

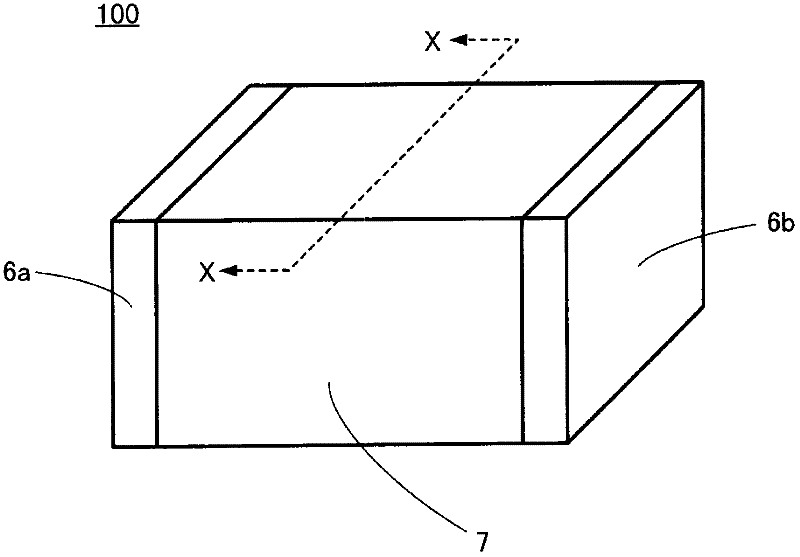

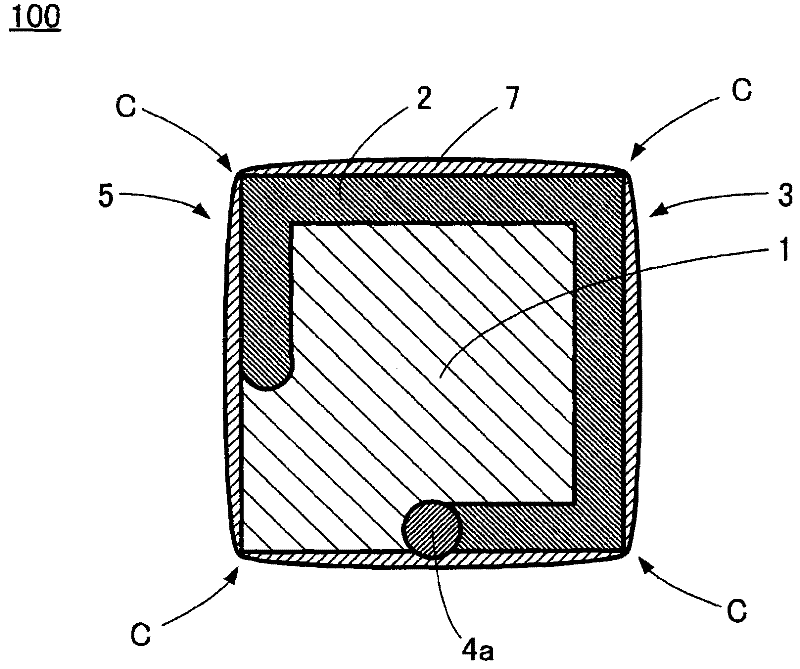

[0053] Figure 1 ~ Figure 3 A laminated coil 100 according to an embodiment of the present invention is shown. in, figure 1 is a stereogram, figure 2 yes figure 1 Cross-sectional view of the dotted line X-X part, image 3 It is an exploded perspective view. In addition, in image 3 In , illustration of the external electrodes 6a, 6b and the insulating film 7 is omitted.

[0054] Such as Figure 1~3 As shown, in the laminated coil 100 , a rectangular insulating layer 1 having four corners C and a coil pattern 2 are laminated and integrated to form a laminated body 3 . The size of the laminated body 3 is arbitrary, for example, it is 0.6 mm in the vertical direction, 1.0 mm in the horizontal direction, and 1.9 mm in length.

[0055] For the insulating layer 1 , a magnetic material such as ferrite or a nonmagnetic material such as dielectric ceramic is used. When a magnetic material is used for the insulating layer 1, the laminated coil 100 is a magnetic core type. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com