Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

186results about How to "Reduce stray capacitance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

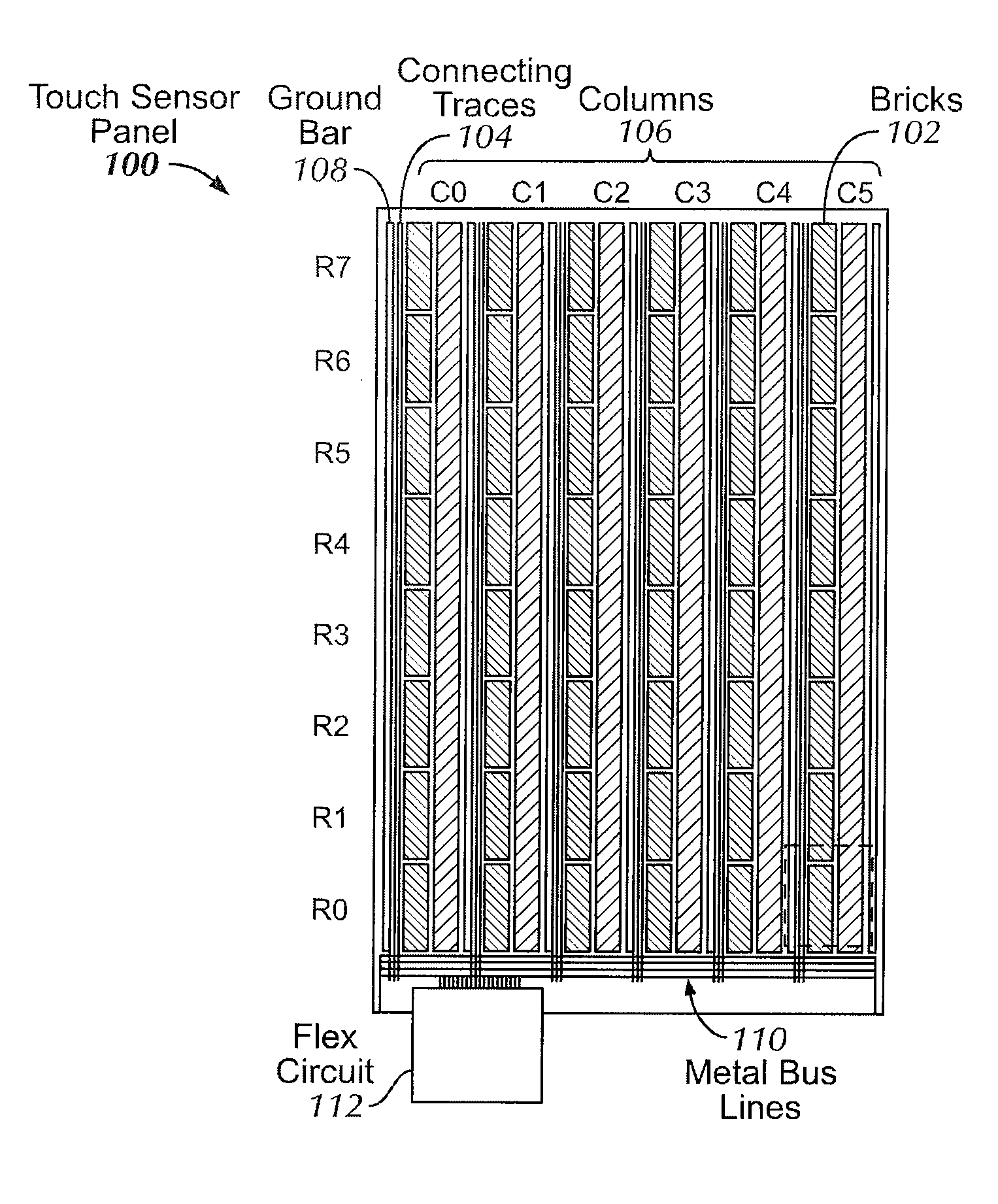

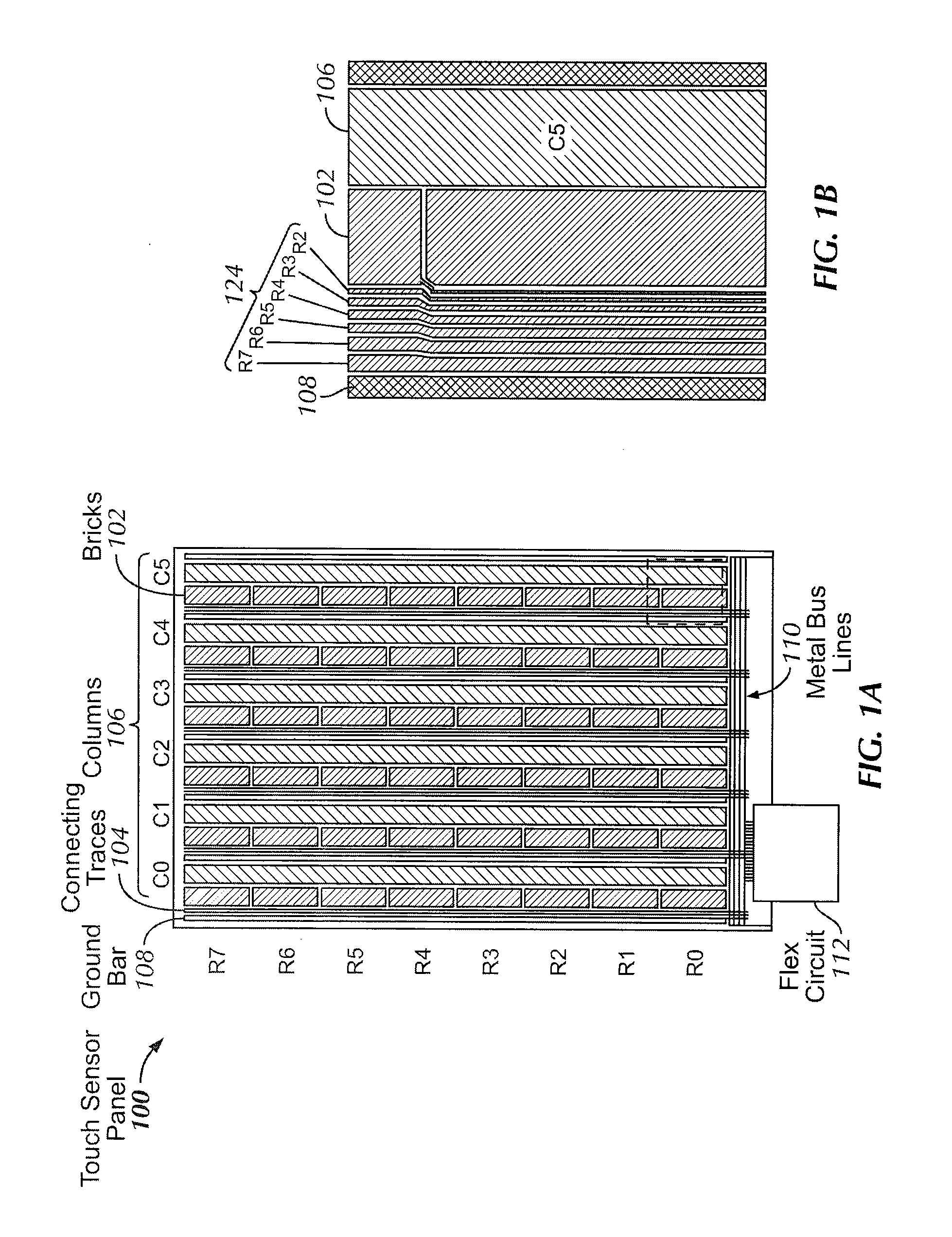

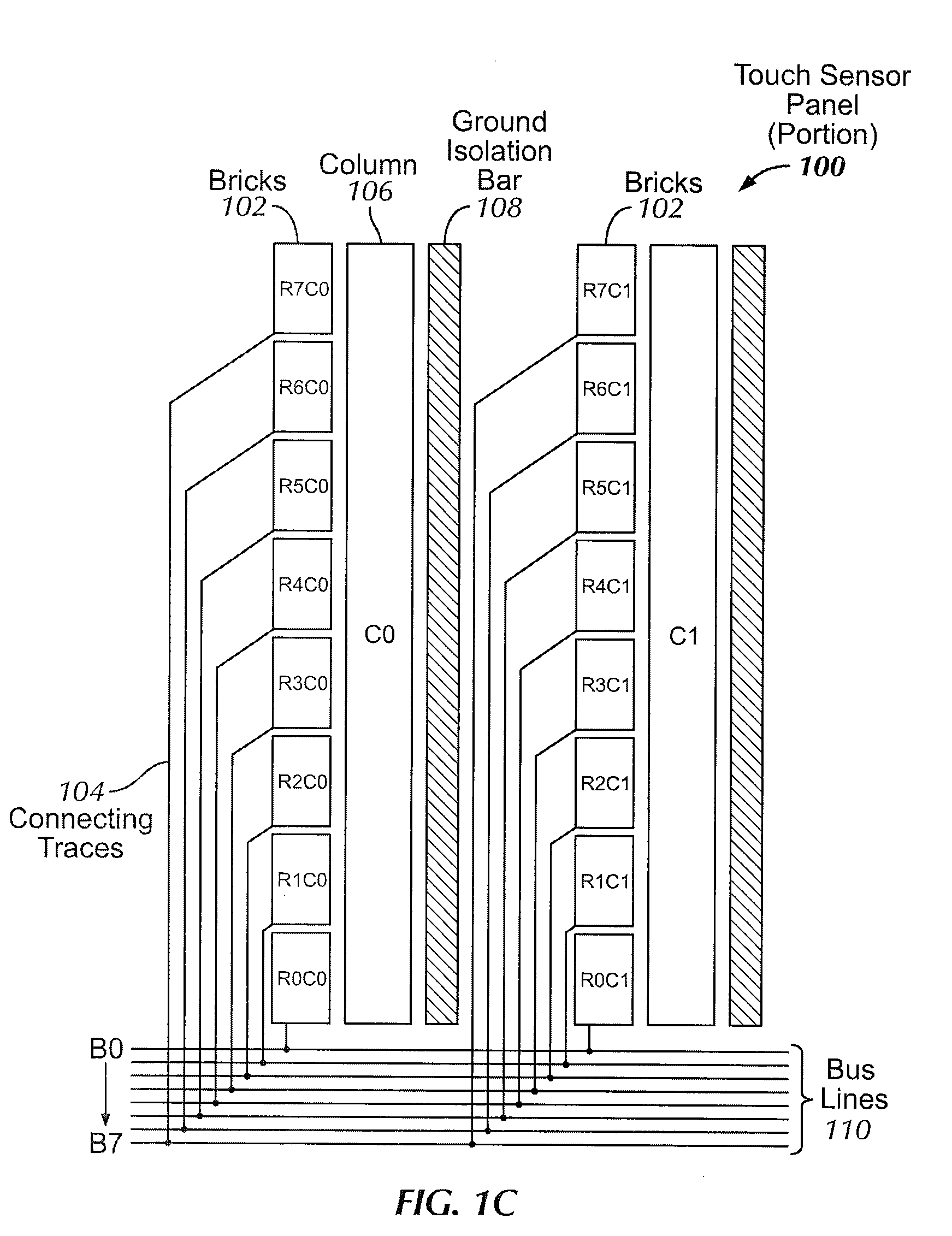

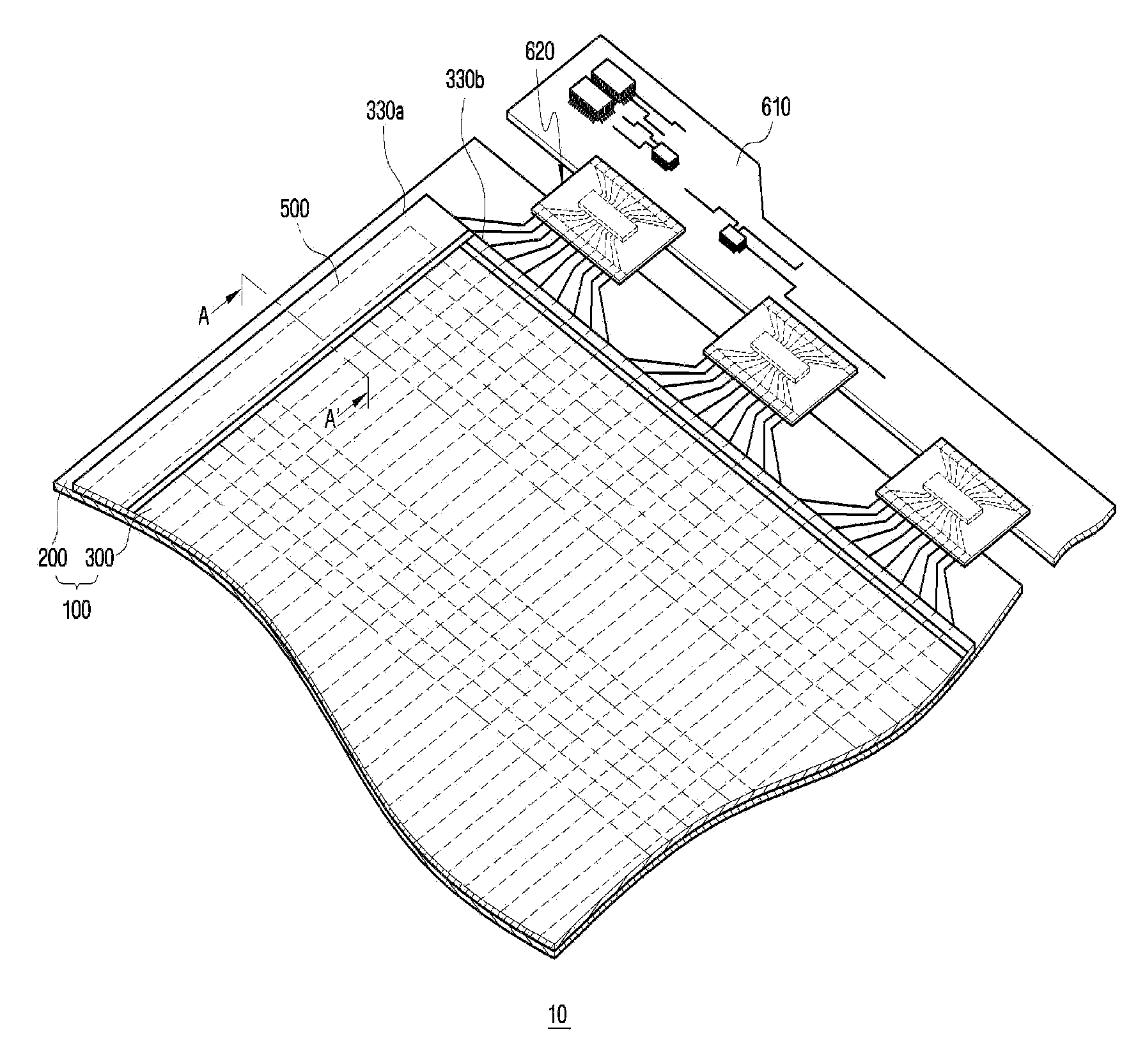

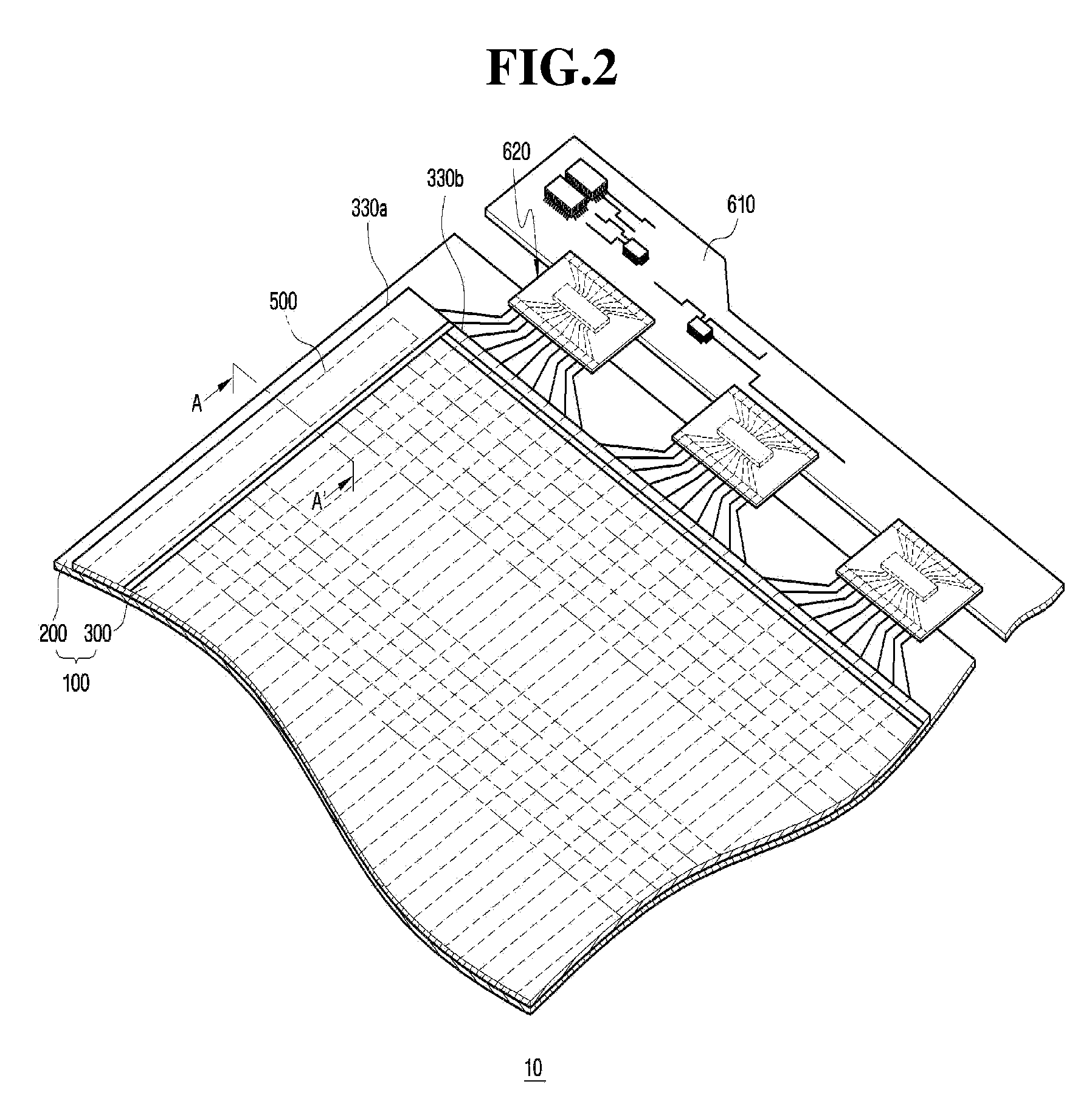

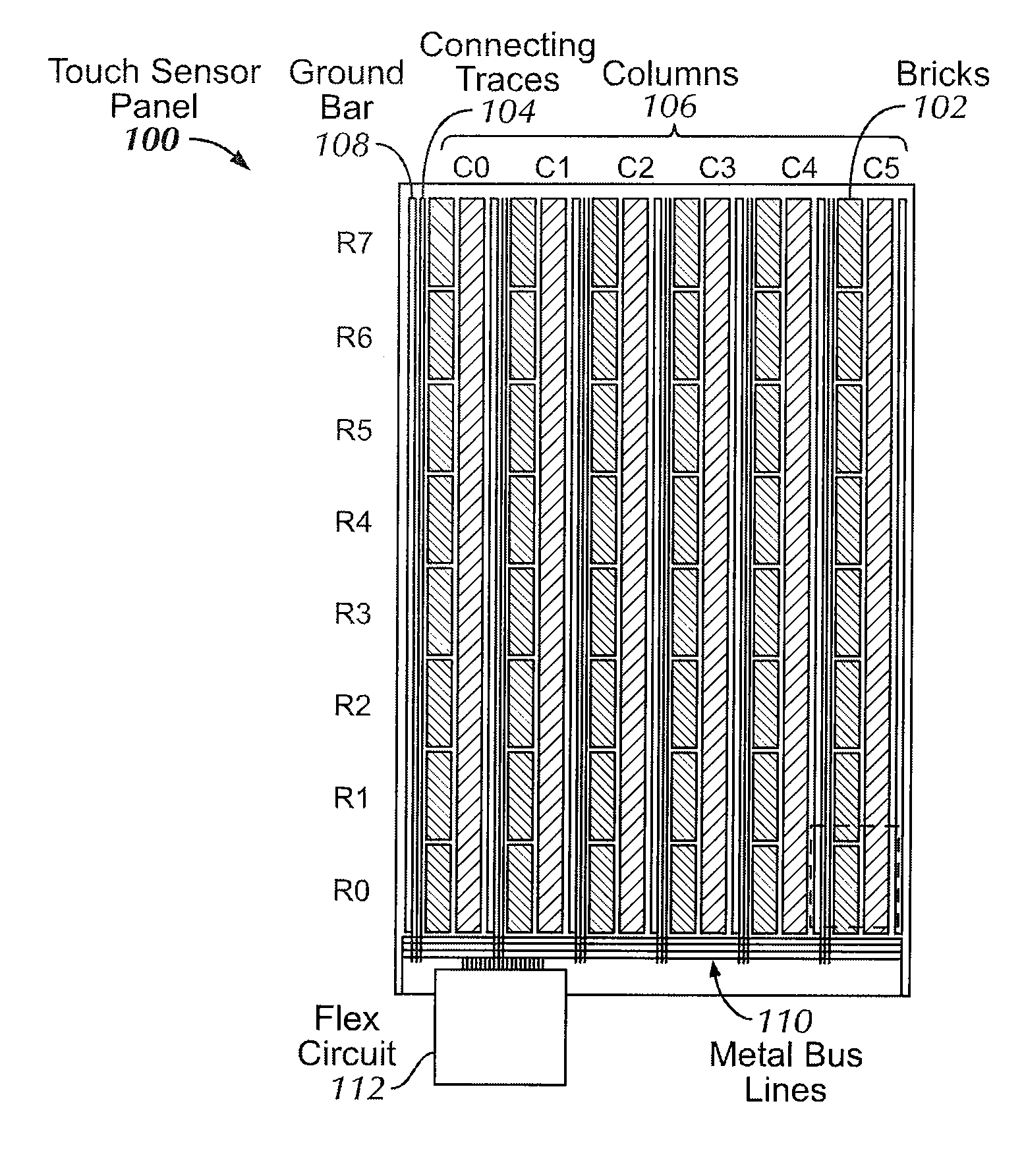

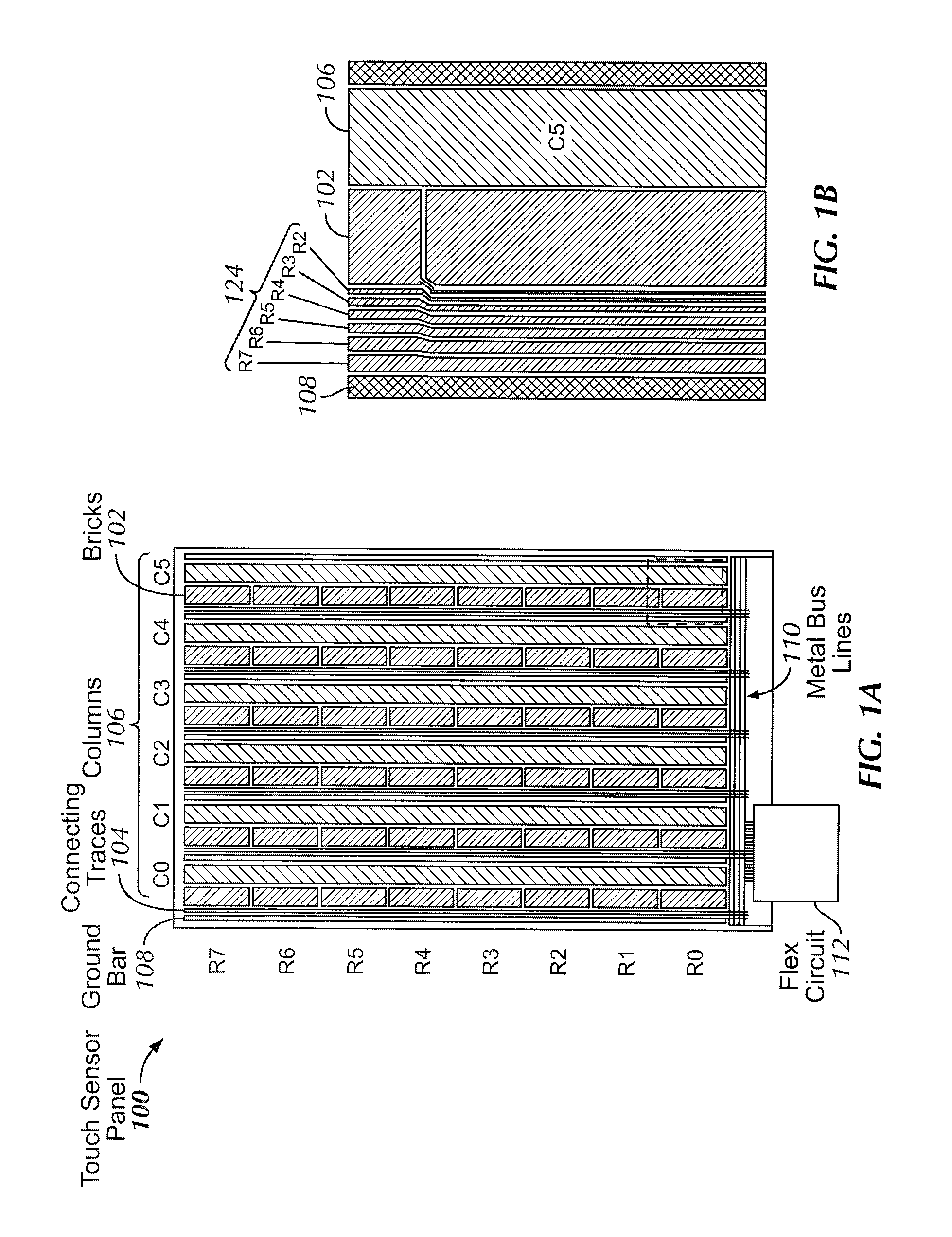

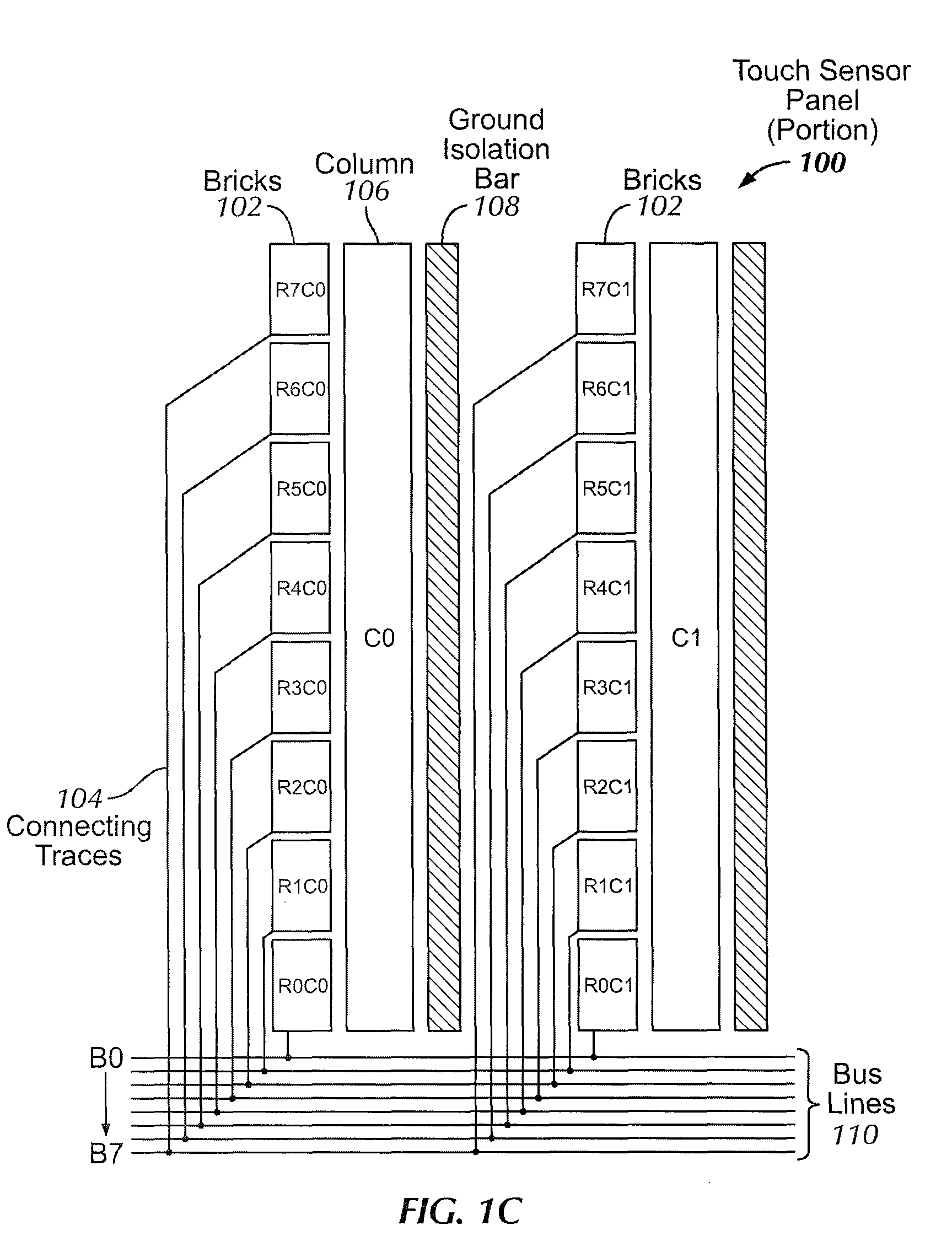

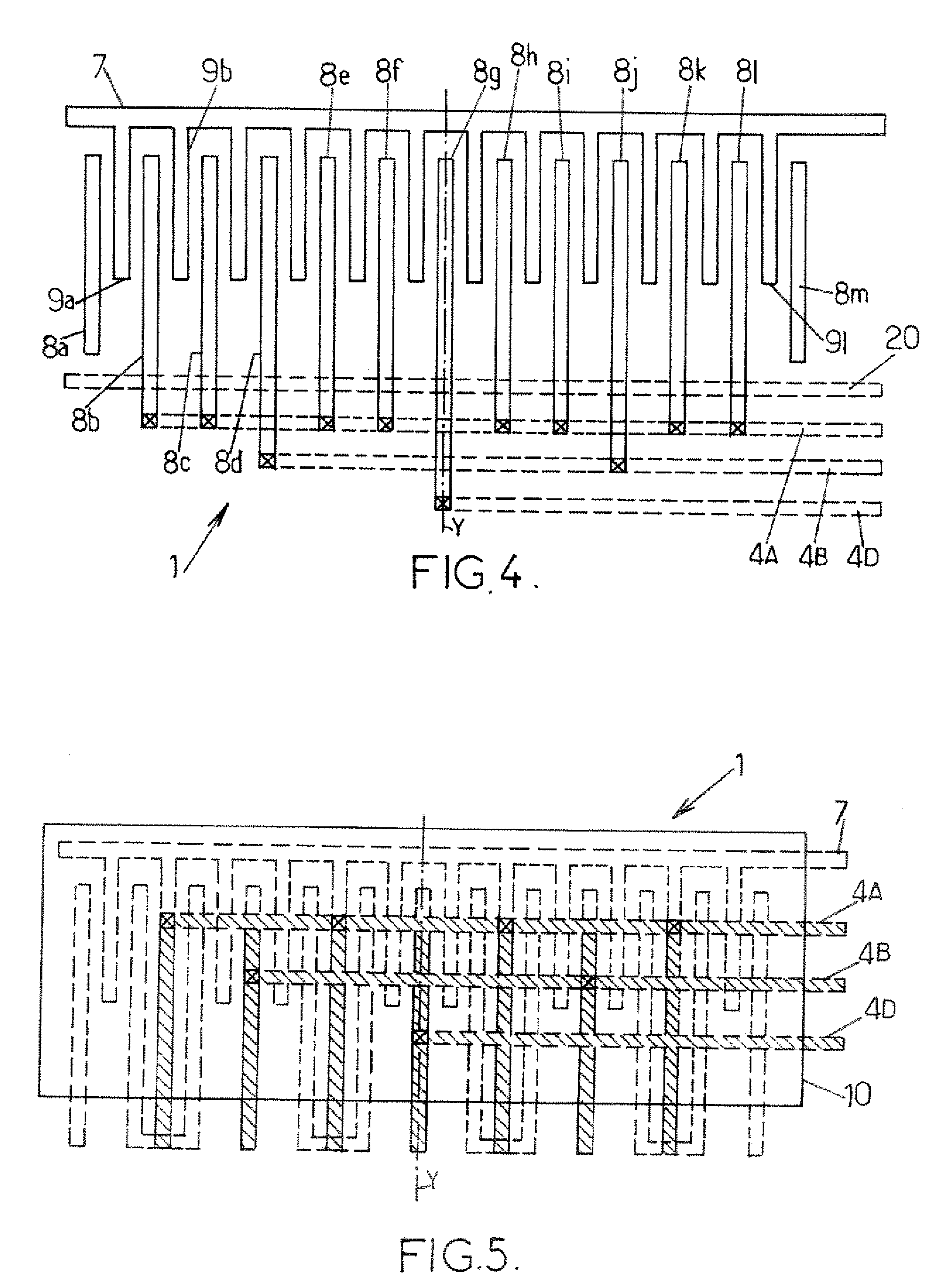

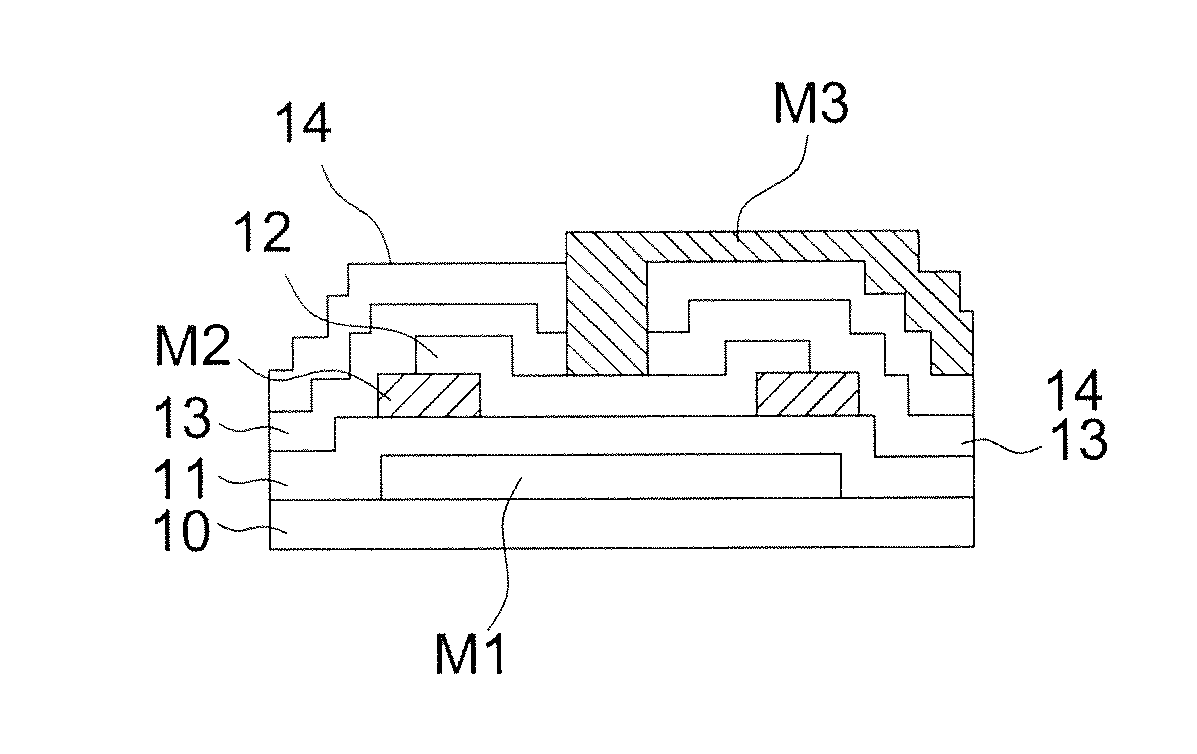

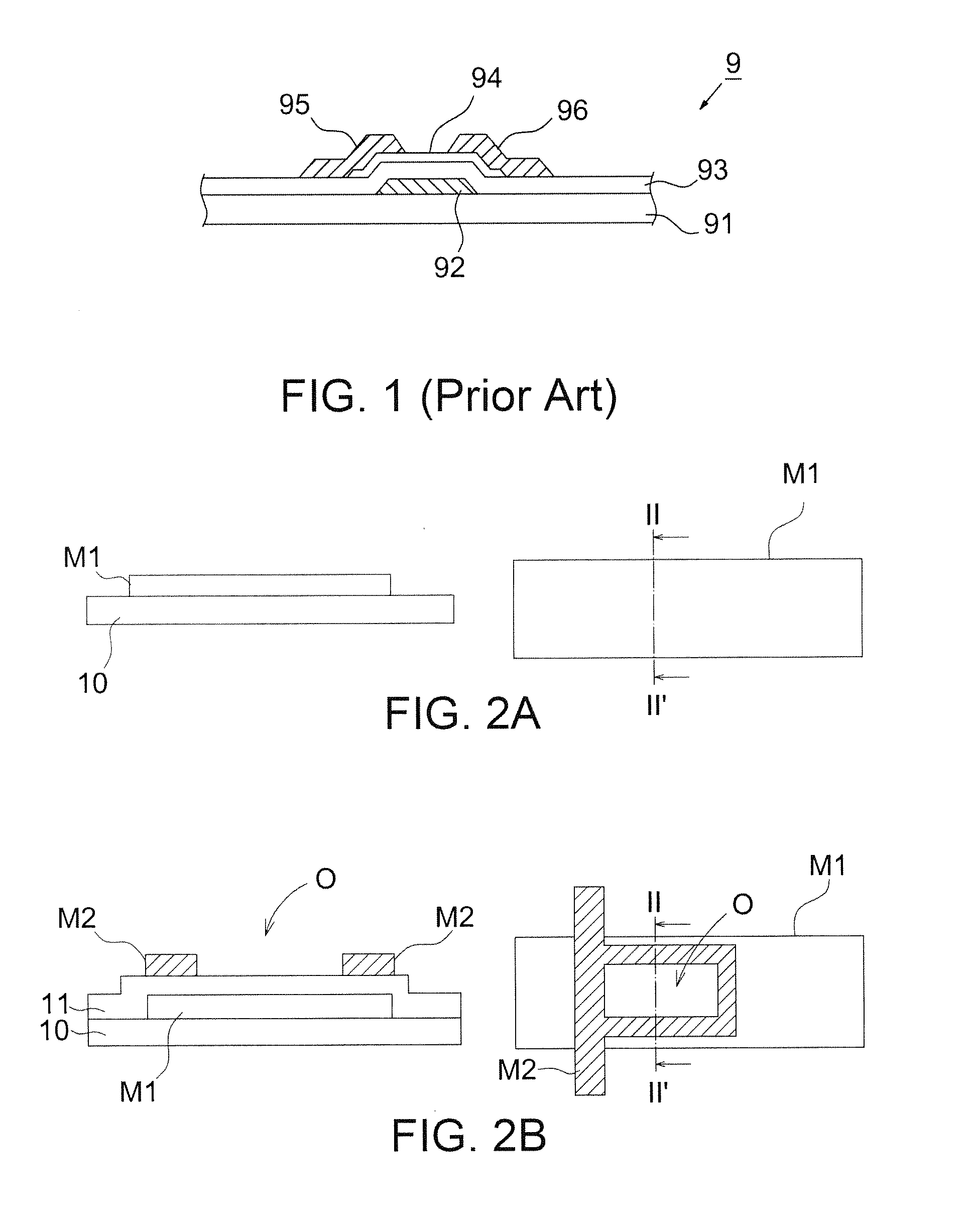

Brick Layout and Stackup for a Touch Screen

ActiveUS20090314621A1Reduce dynamic range budgetDifficult to makeElectronic switchingInput/output processes for data processingSensor arrayBrick

A touch sensor panel is disclosed having an array of co-planar single-layer touch sensors fabricated on a single side of a substrate. The sense (or drive) lines can be fabricated in a single strip as columnar or zig-zag patterns in a first orientation, and the drive (or sense) lines can be fabricated as rows of polygonal (e.g. brick-shaped or pentagonal) conductive areas in a second orientation. Each sense (or drive) line in the first orientation can be coupled to a separate metal trace in the border area of the touch sensor panel, and each polygonal area in the second orientation can also be coupled to a metal trace in the border area of the touch sensor panel. The metal traces can allow both the row and column lines to be routed to the same edge of the substrate for flex circuit attachment.

Owner:APPLE INC

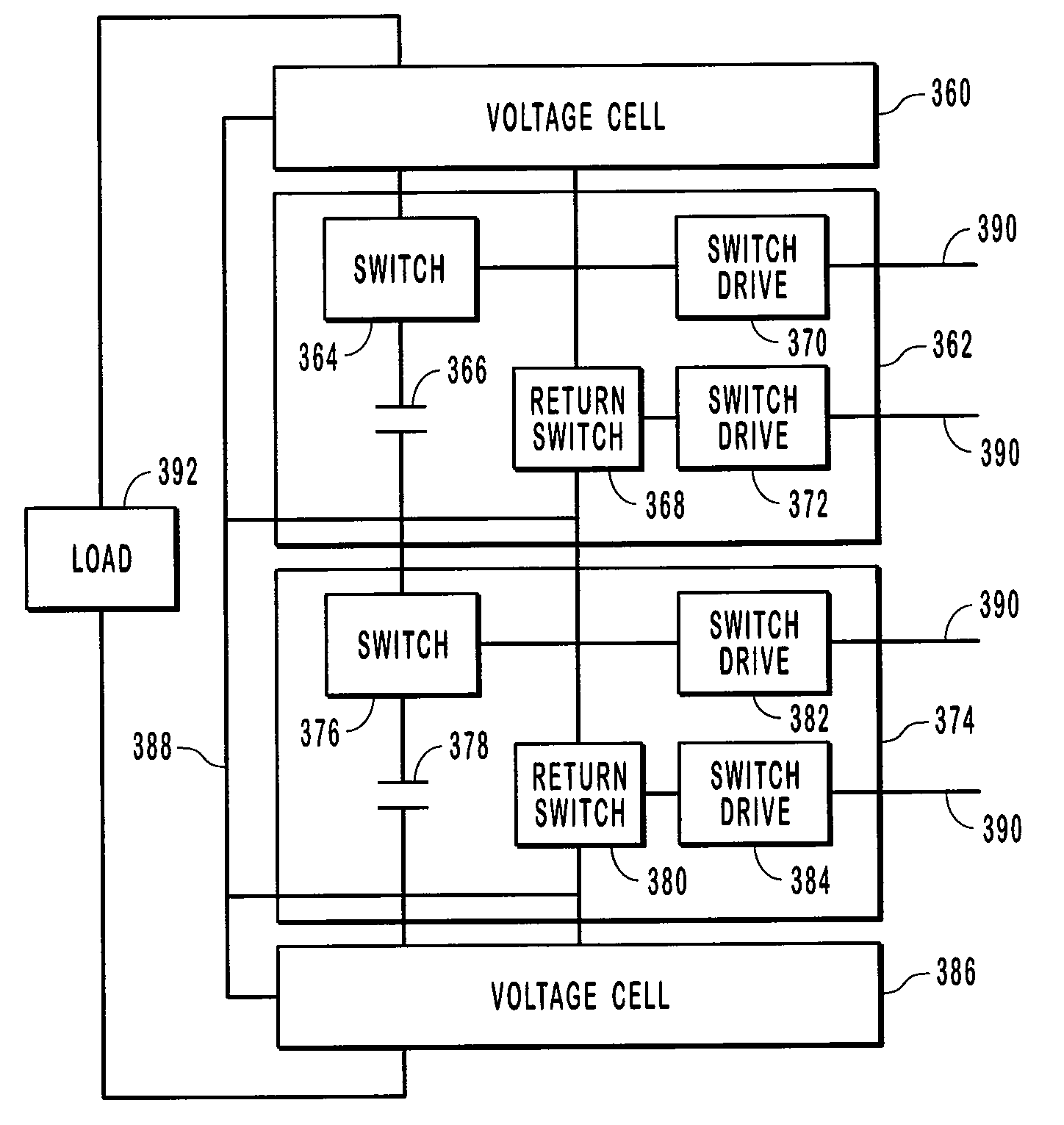

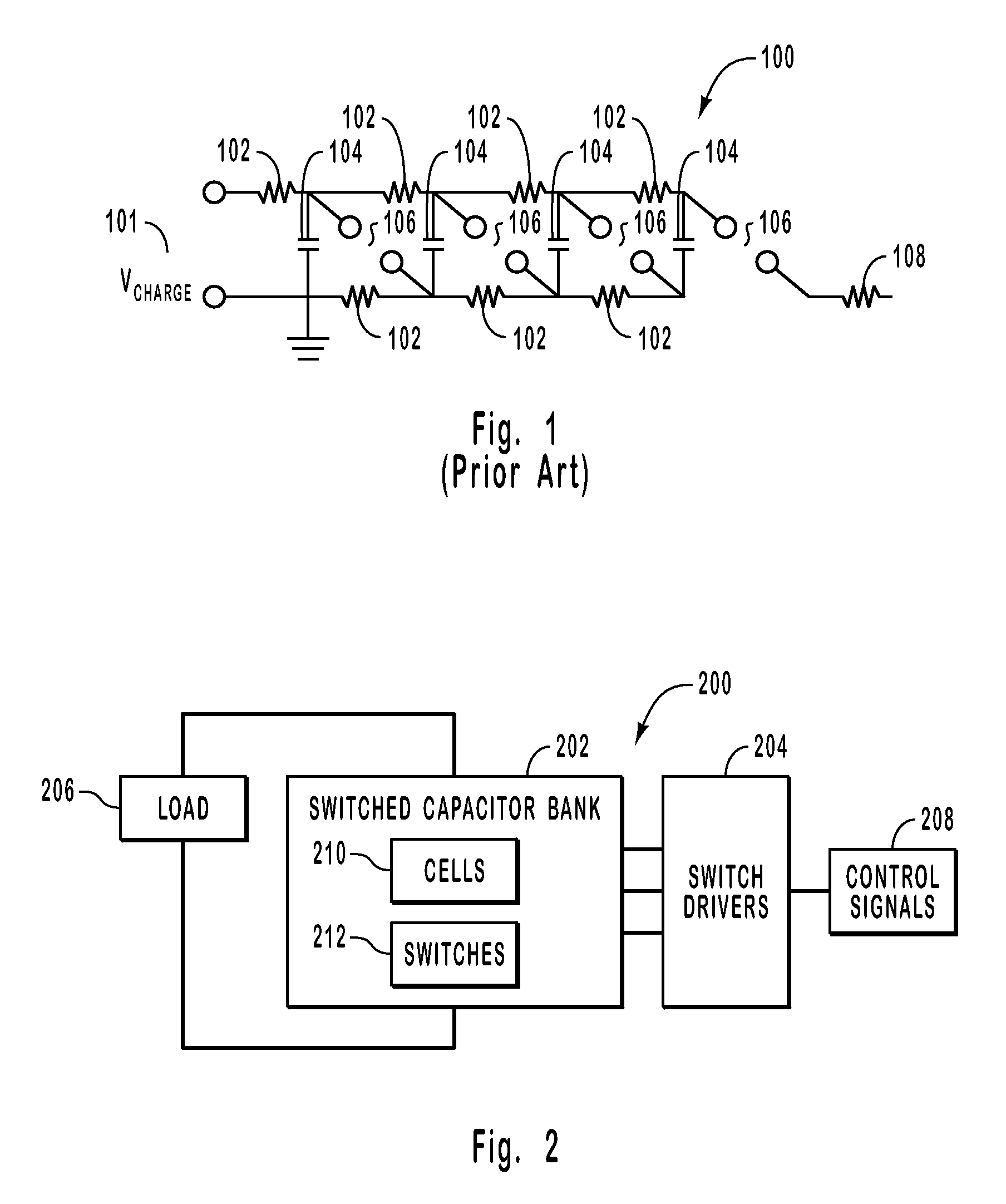

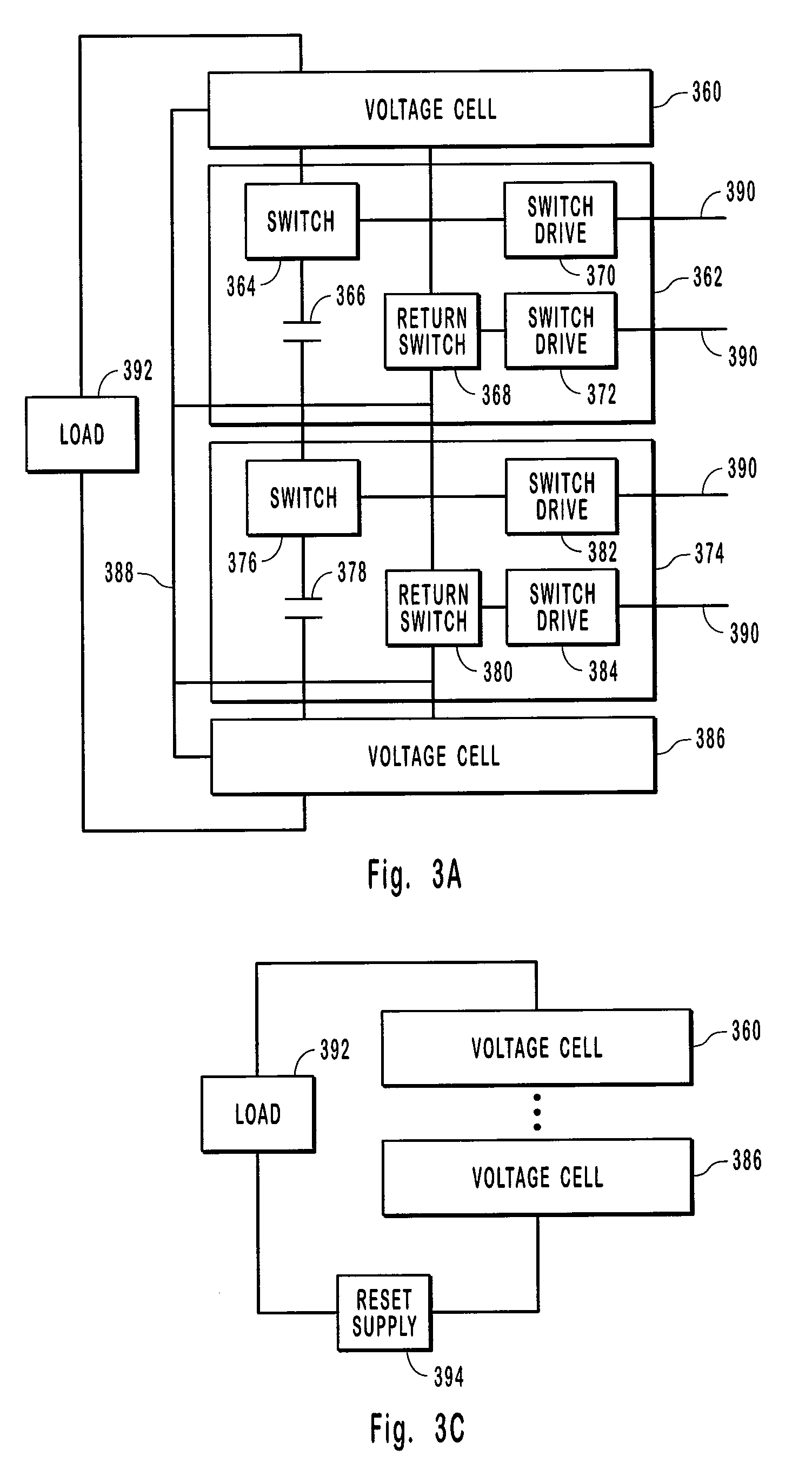

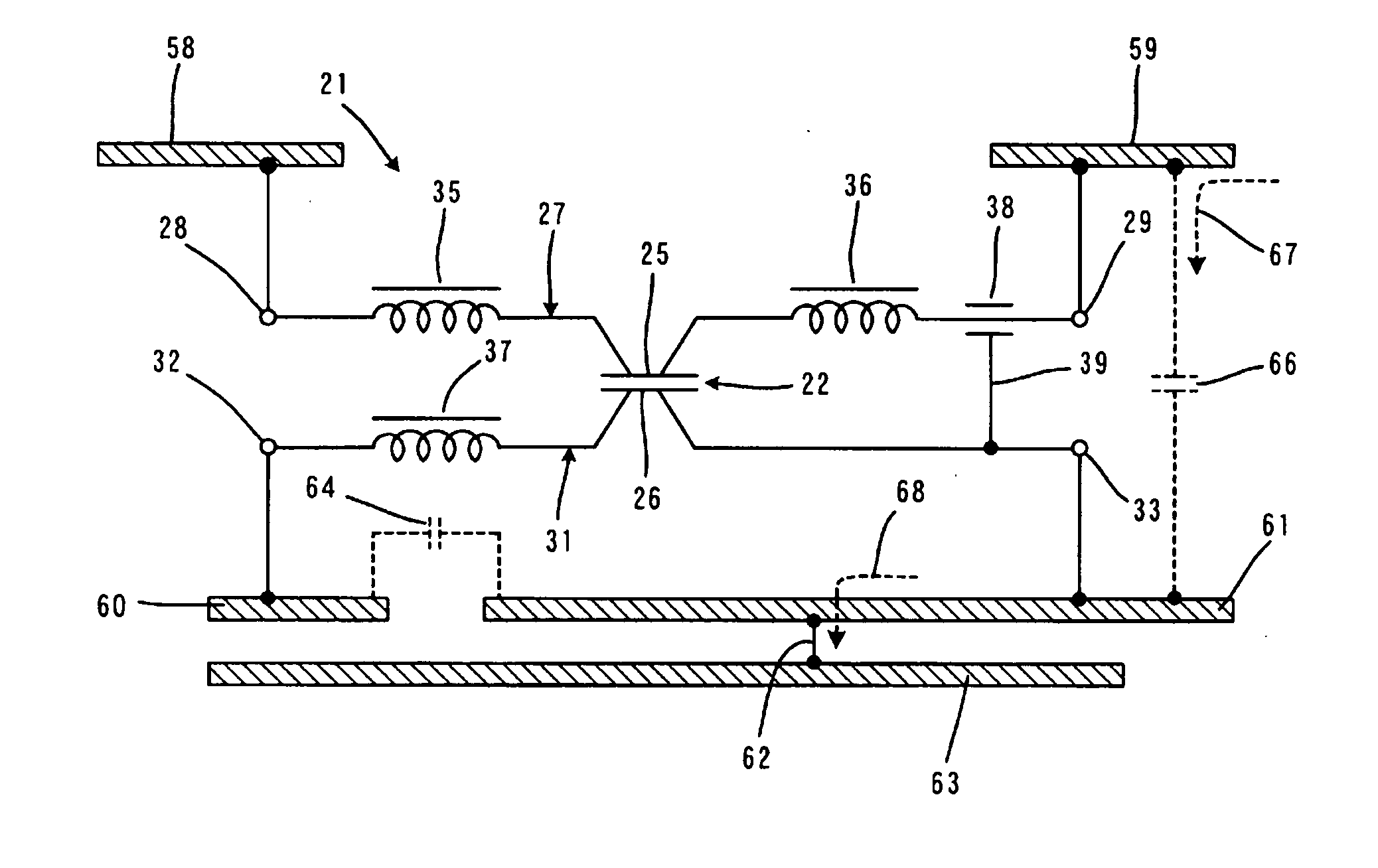

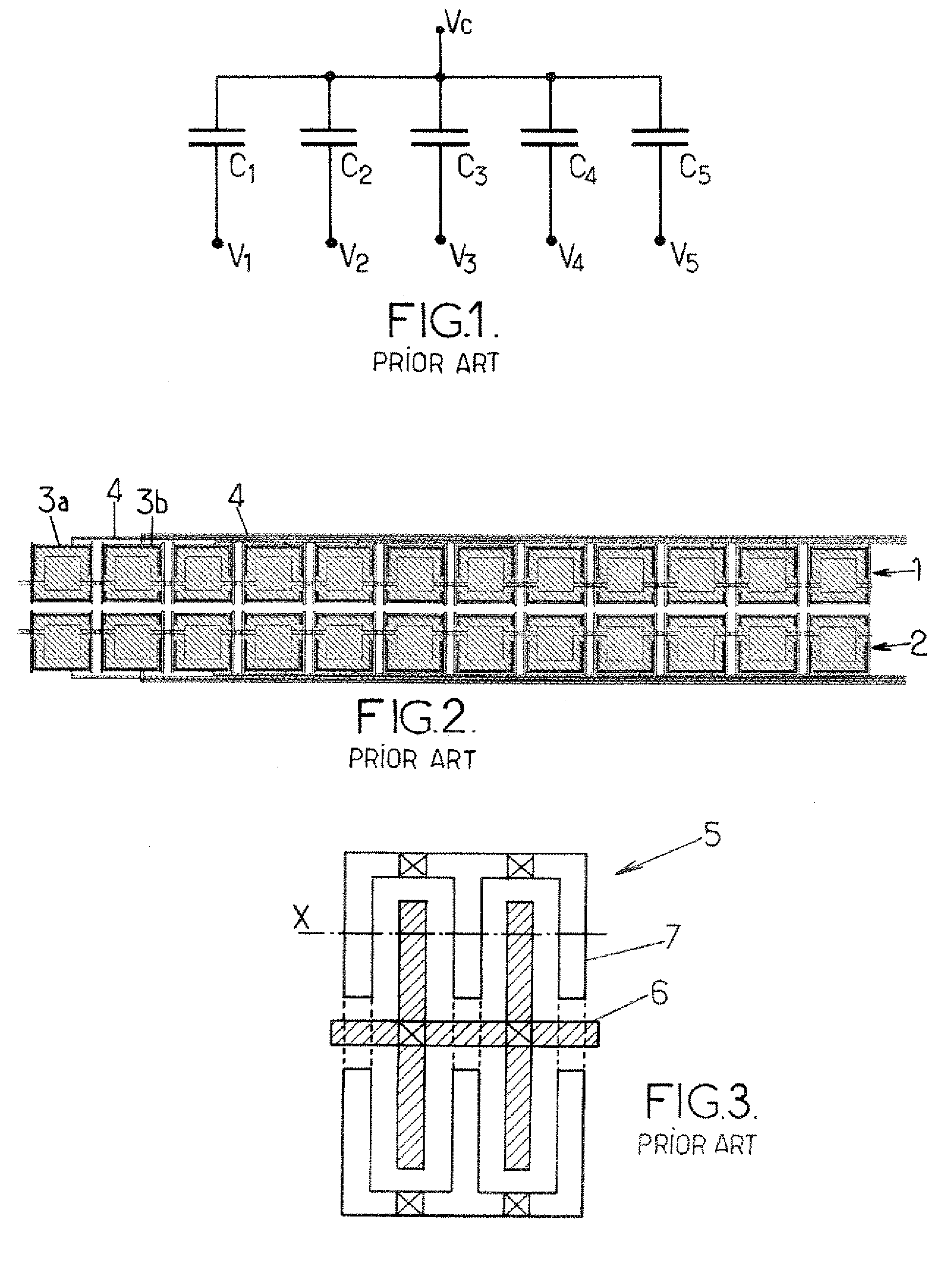

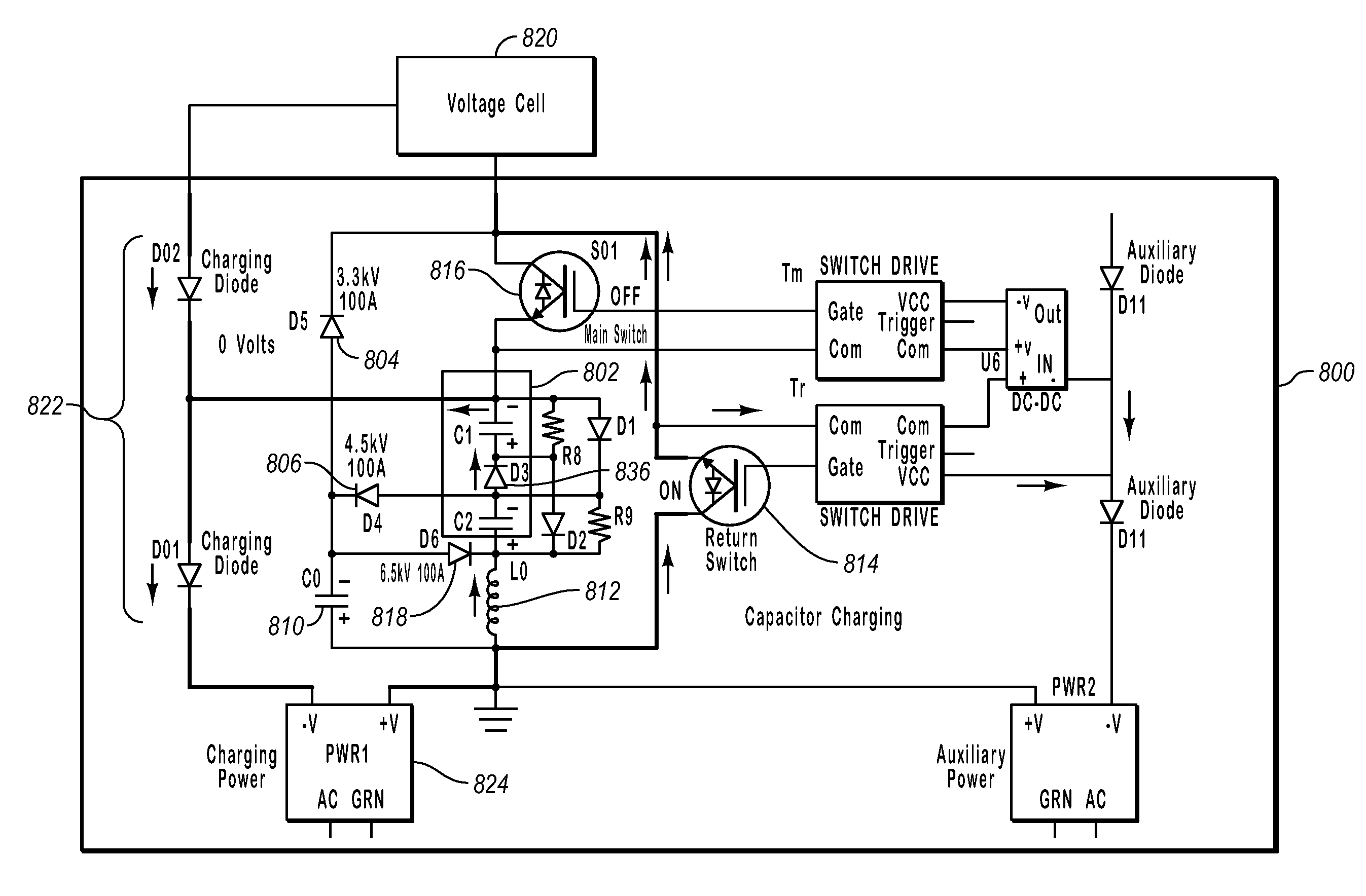

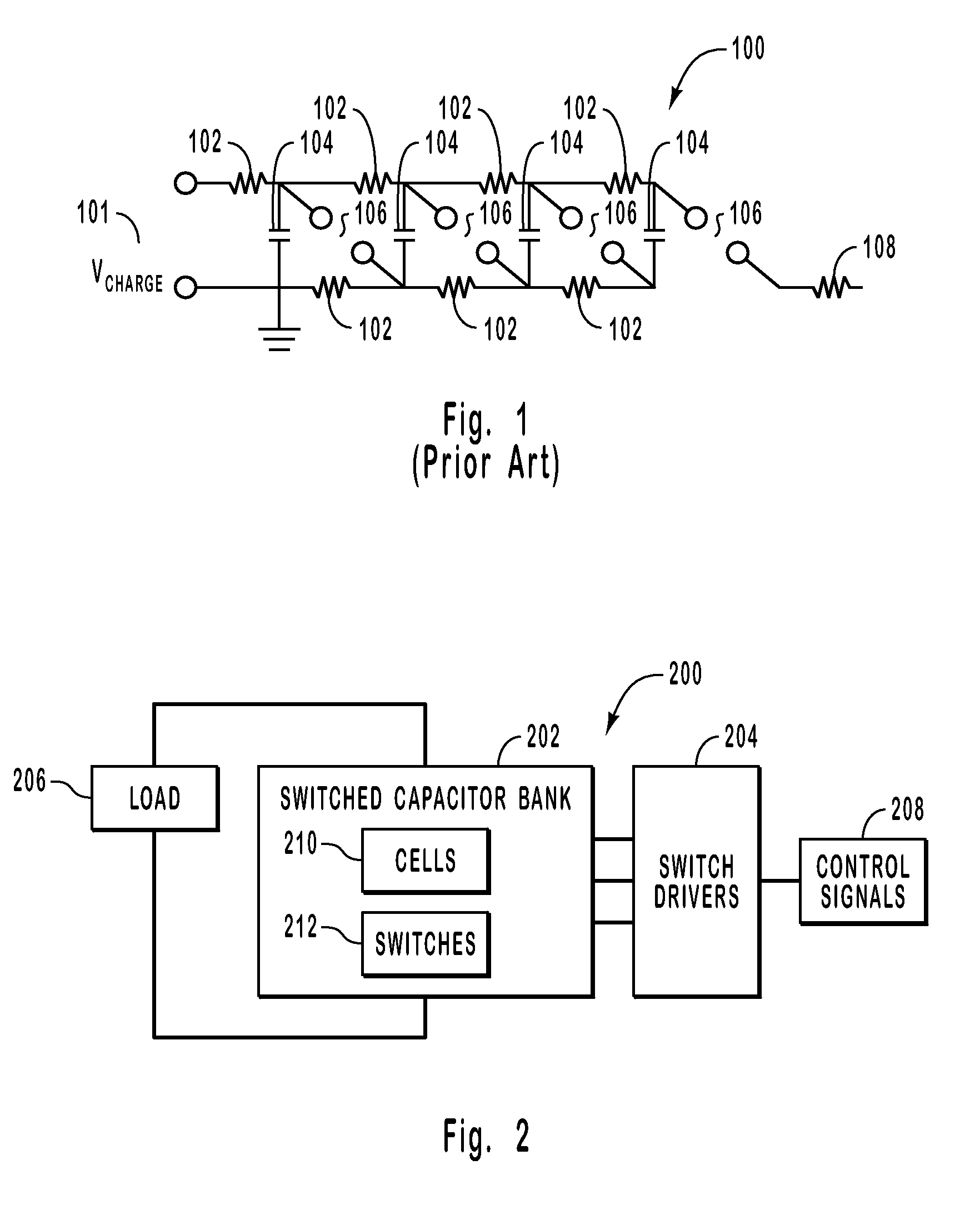

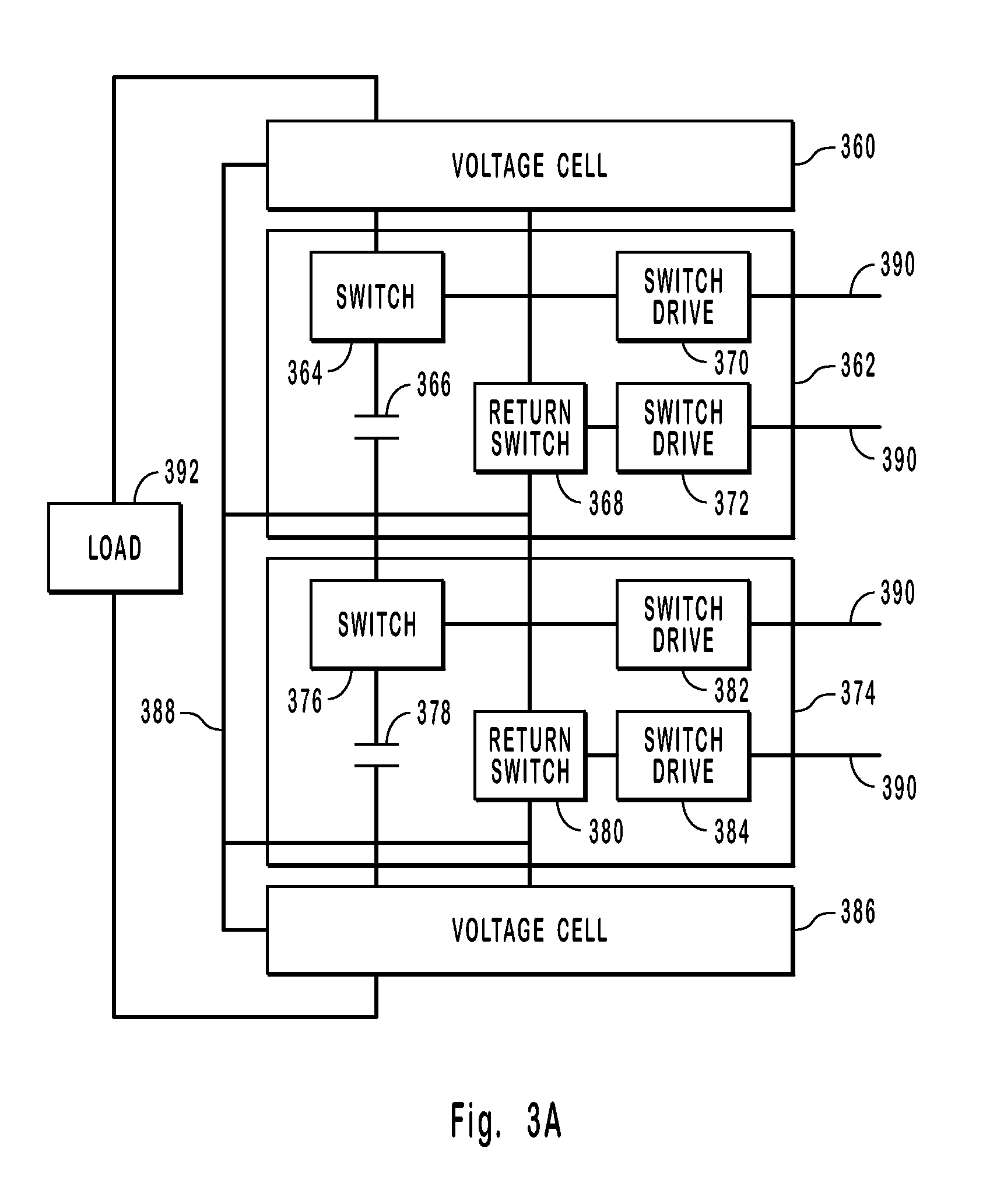

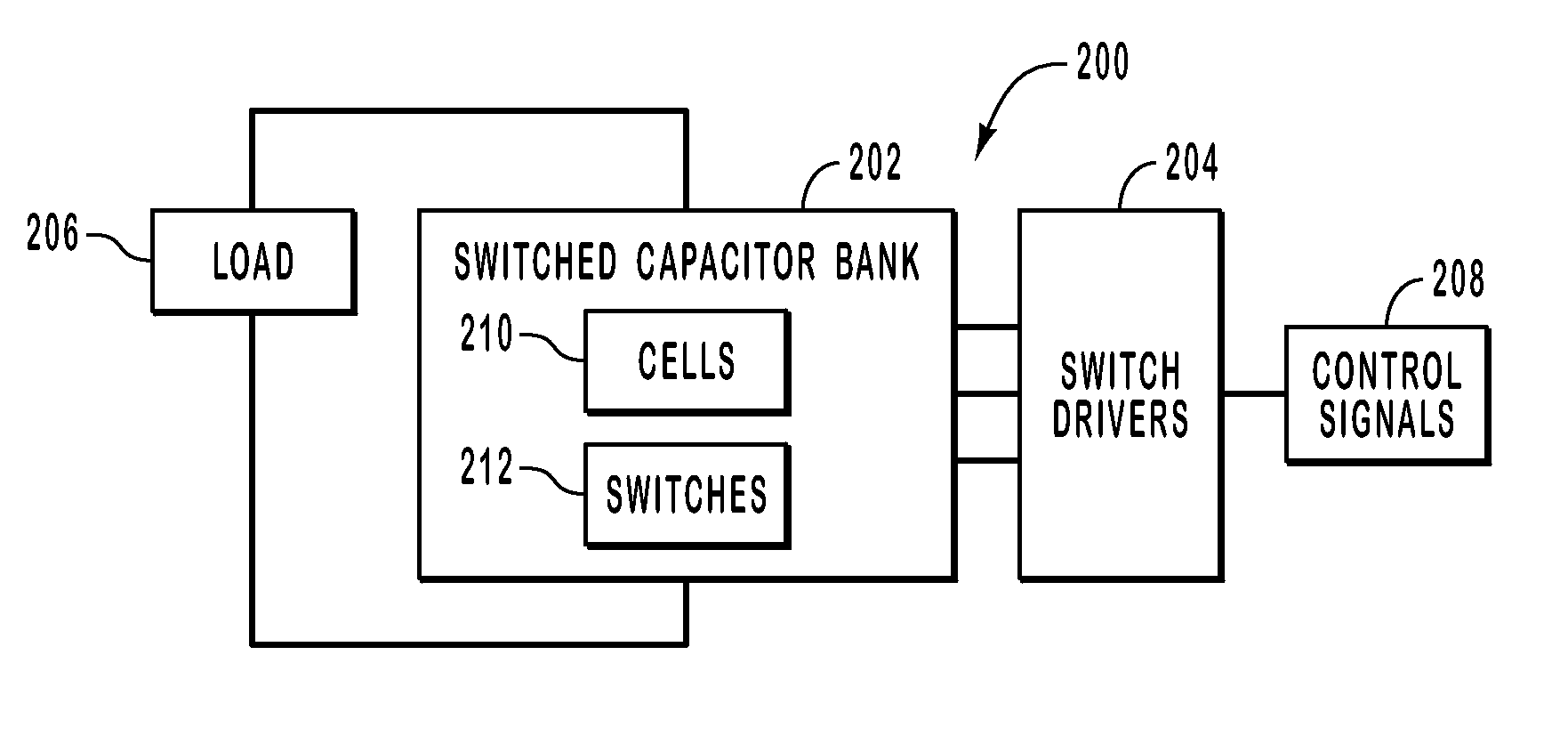

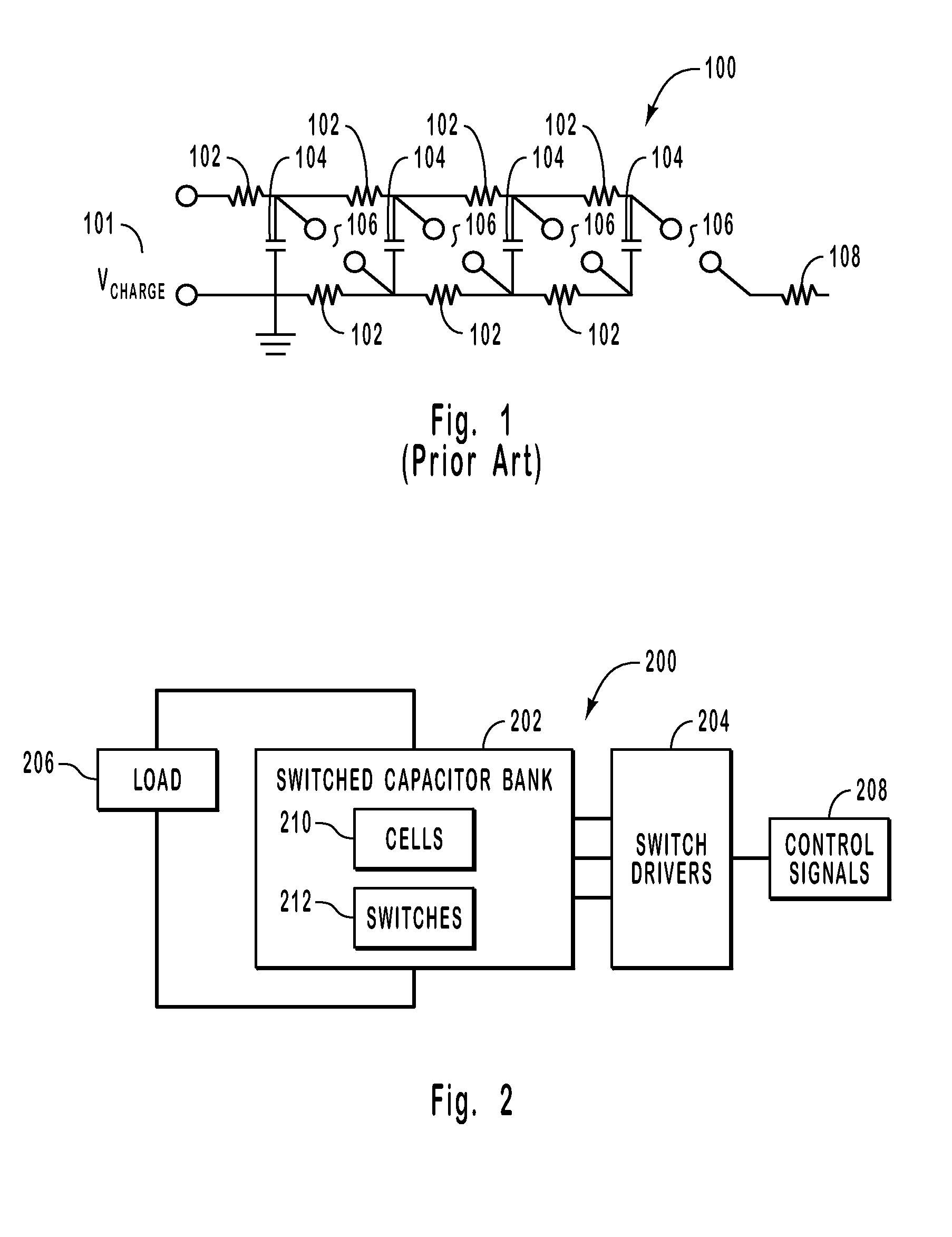

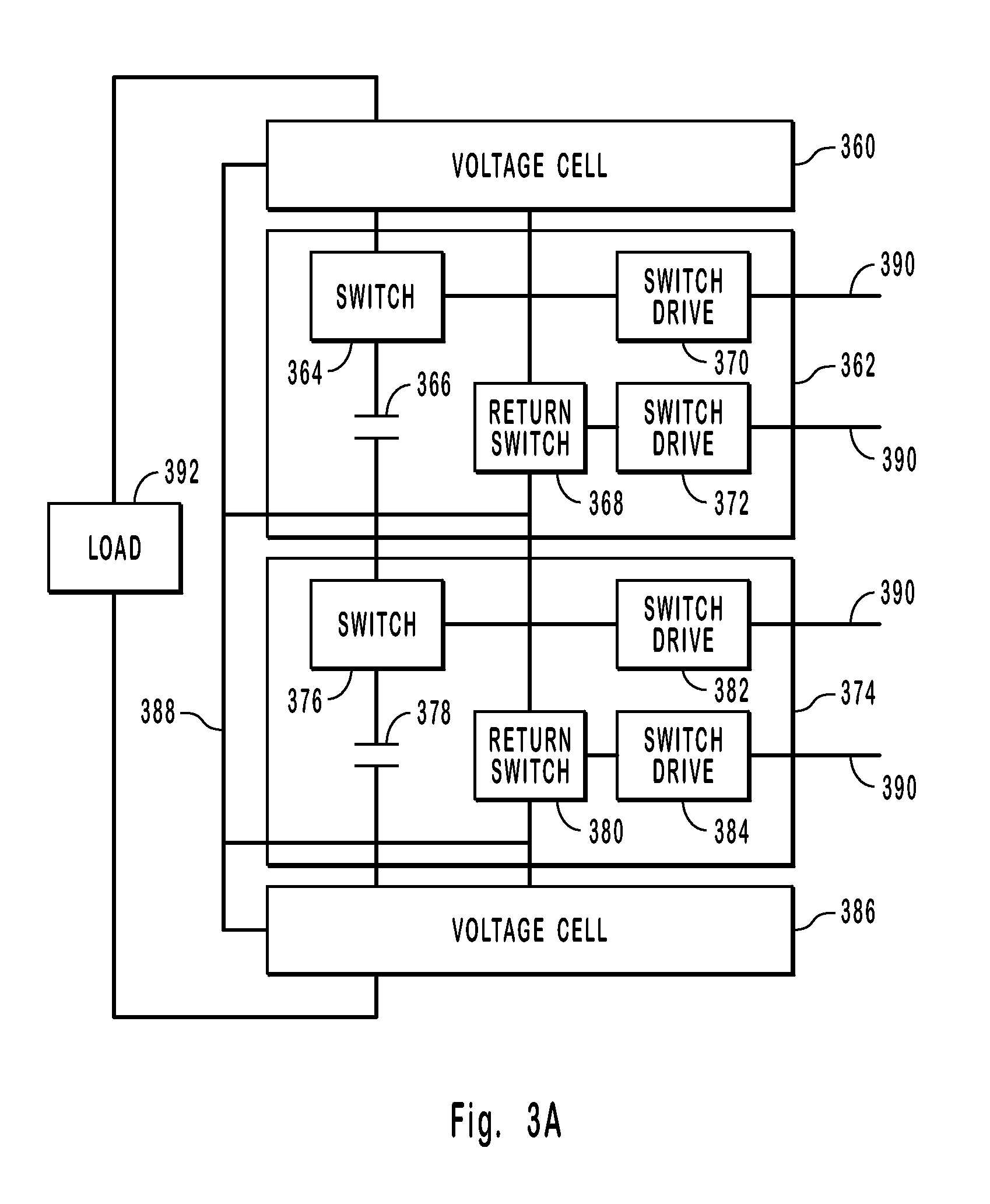

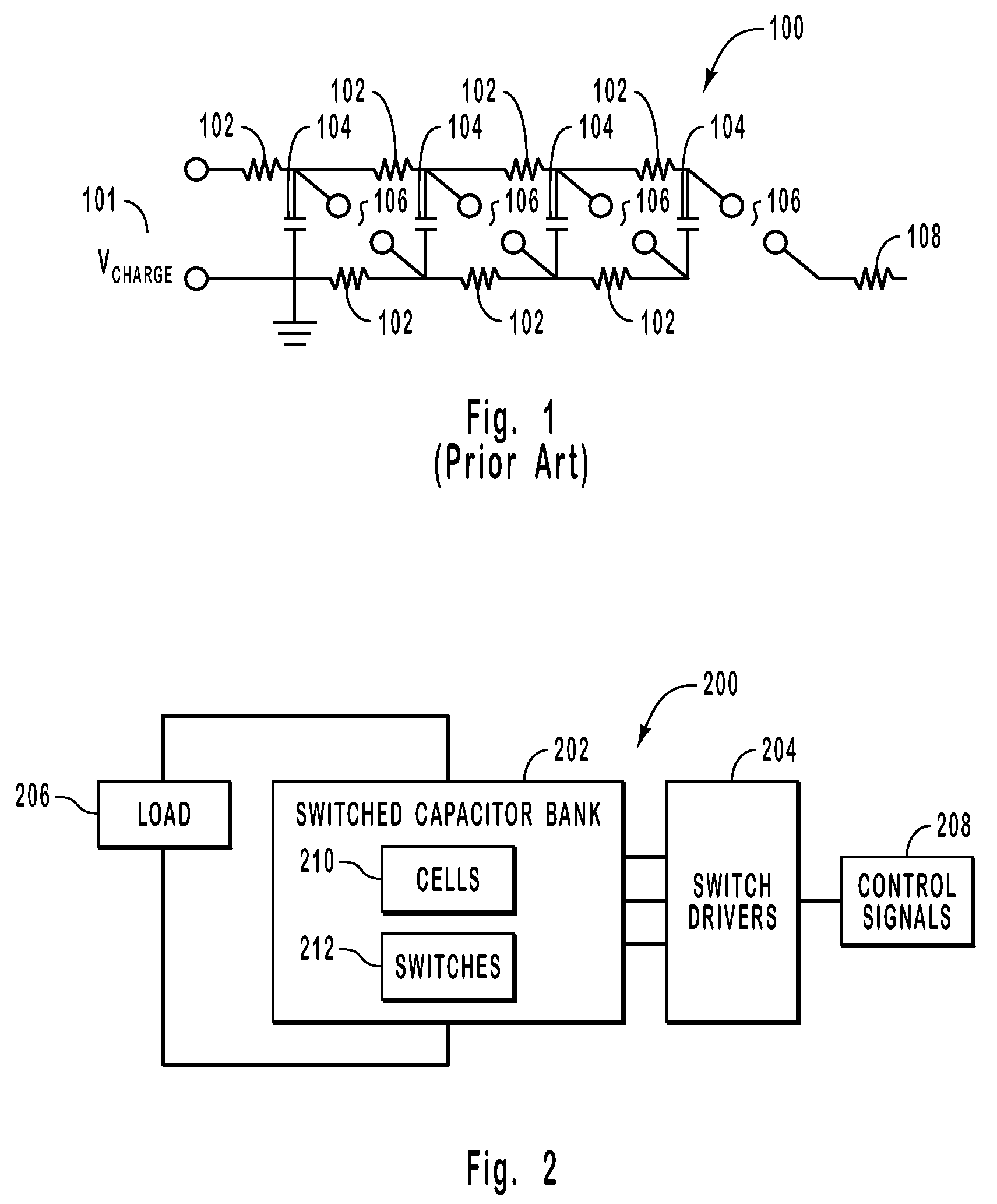

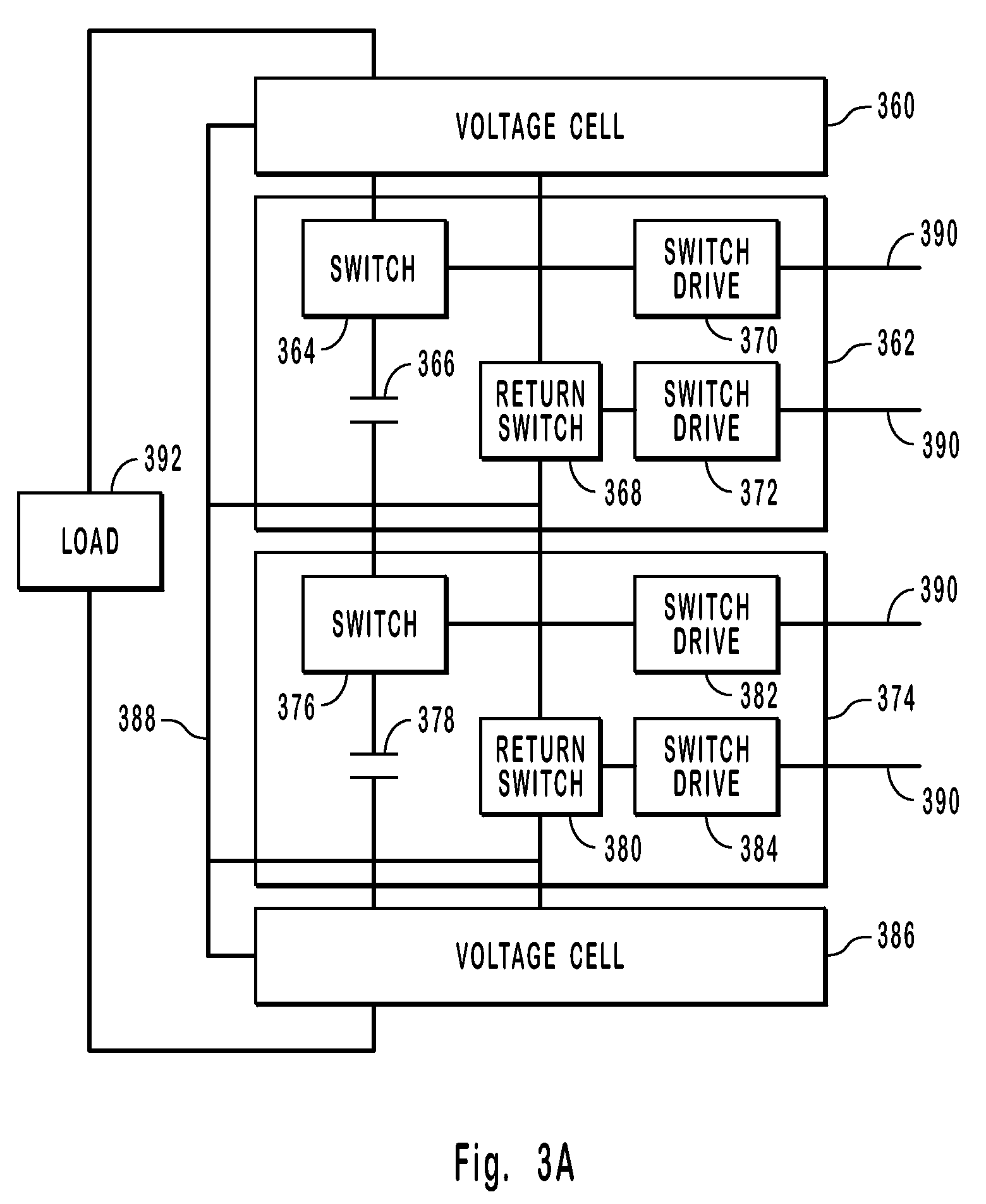

High voltage pulsed power supply using solid state switches

ActiveUS7301250B2Reduce stray capacitanceShortened fall timeApparatus without intermediate ac conversionPulse generation by energy-accumulating elementBalancing networkCapacitance

Systems and methods for generating a high voltage pulse. A series of voltage cells are connected such that charging capacitors can be charged in parallel and discharged in series. Each cell includes a main switch and a return switch. When the main switches are turned on, the capacitors in the cells are in series and discharge. When the main switches are turned off and the return switches are turned on, the capacitors charge in parallel. One or more of the cells can be inactive without preventing a pulse from being generated. The amplitude, duration, rise time, and fall time can be controlled with the voltage cells. Each voltage cell also includes a balance network to match the stray capacitance seen by each voltage cell.

Owner:STANGENES IND INC

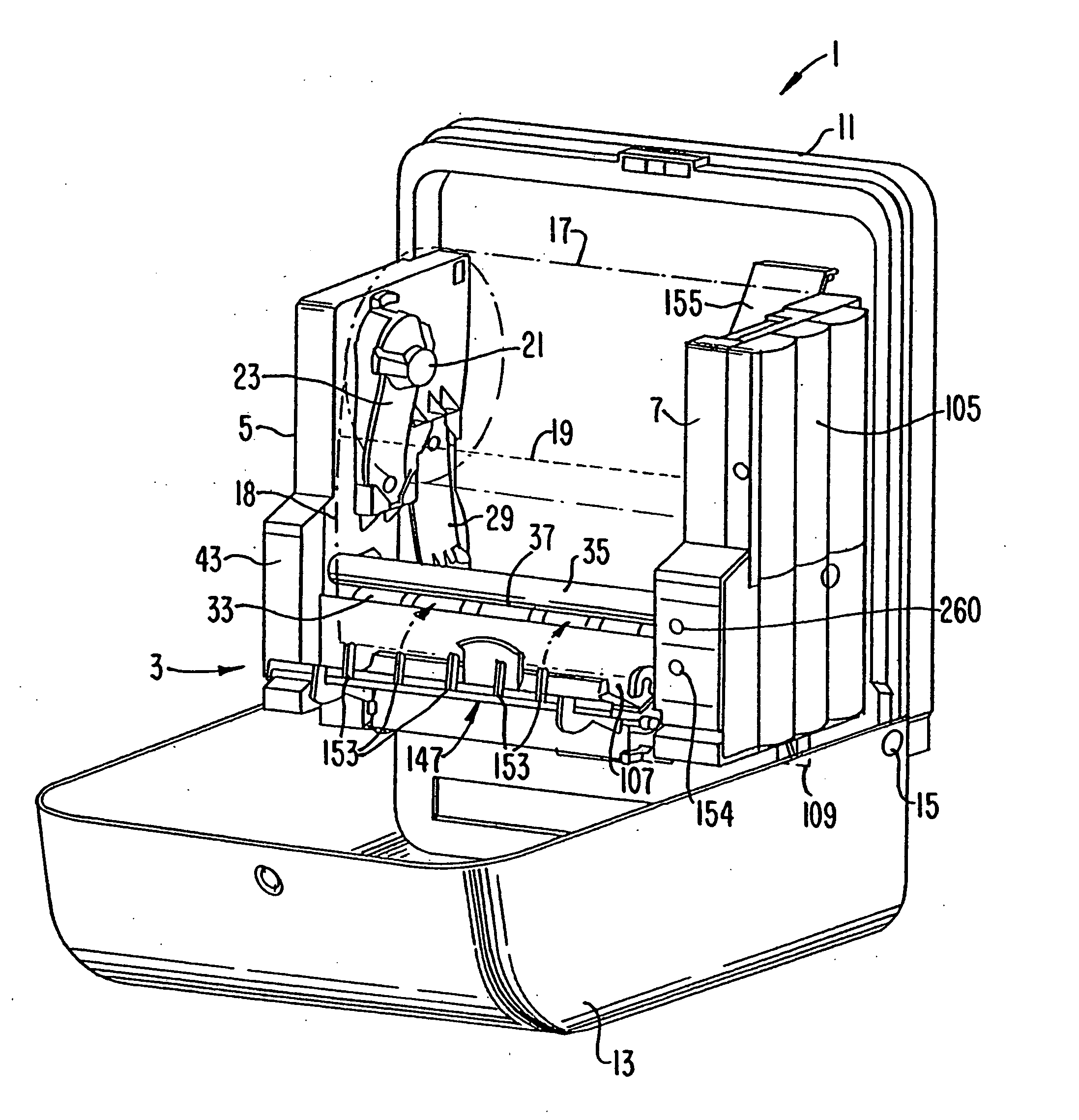

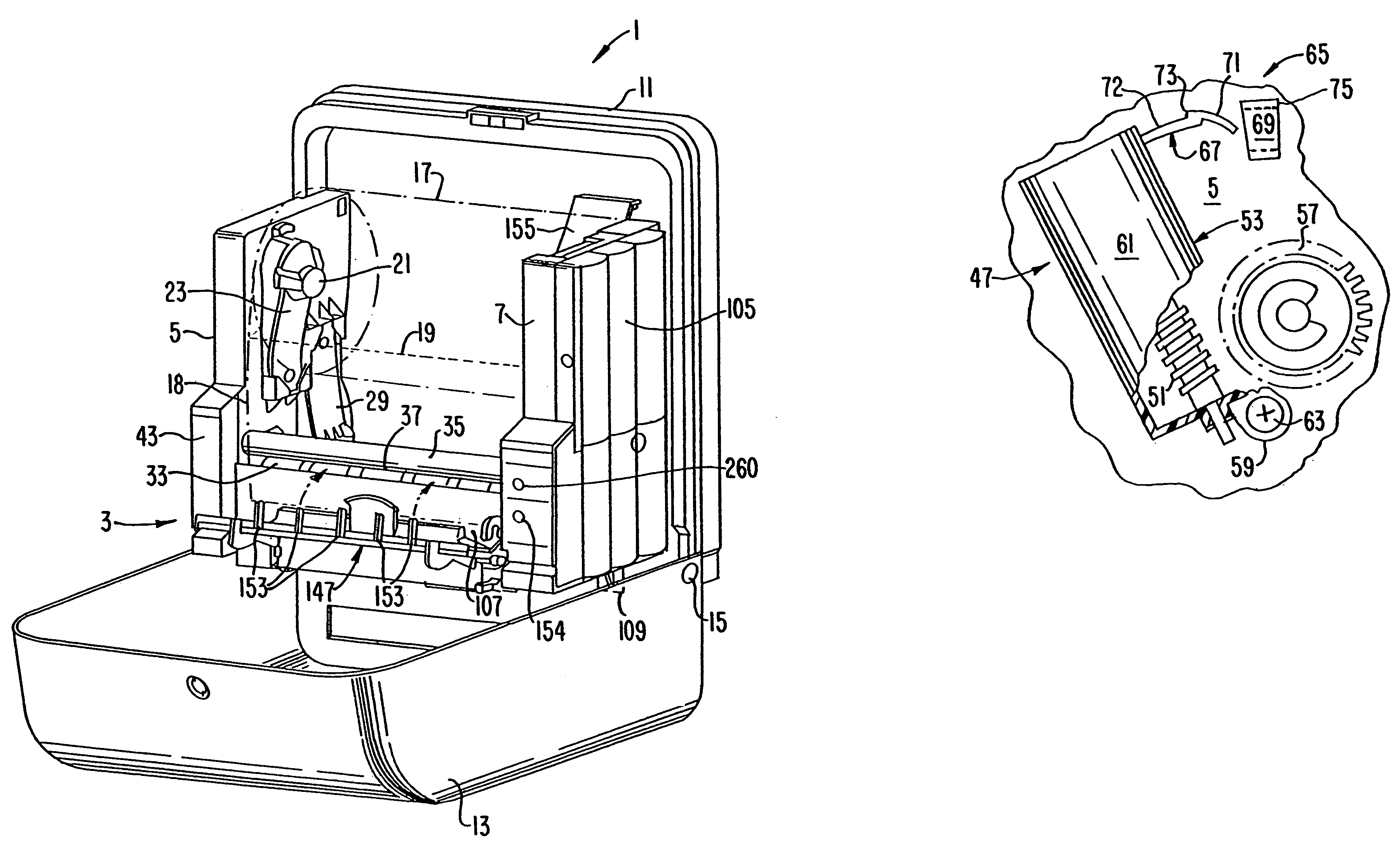

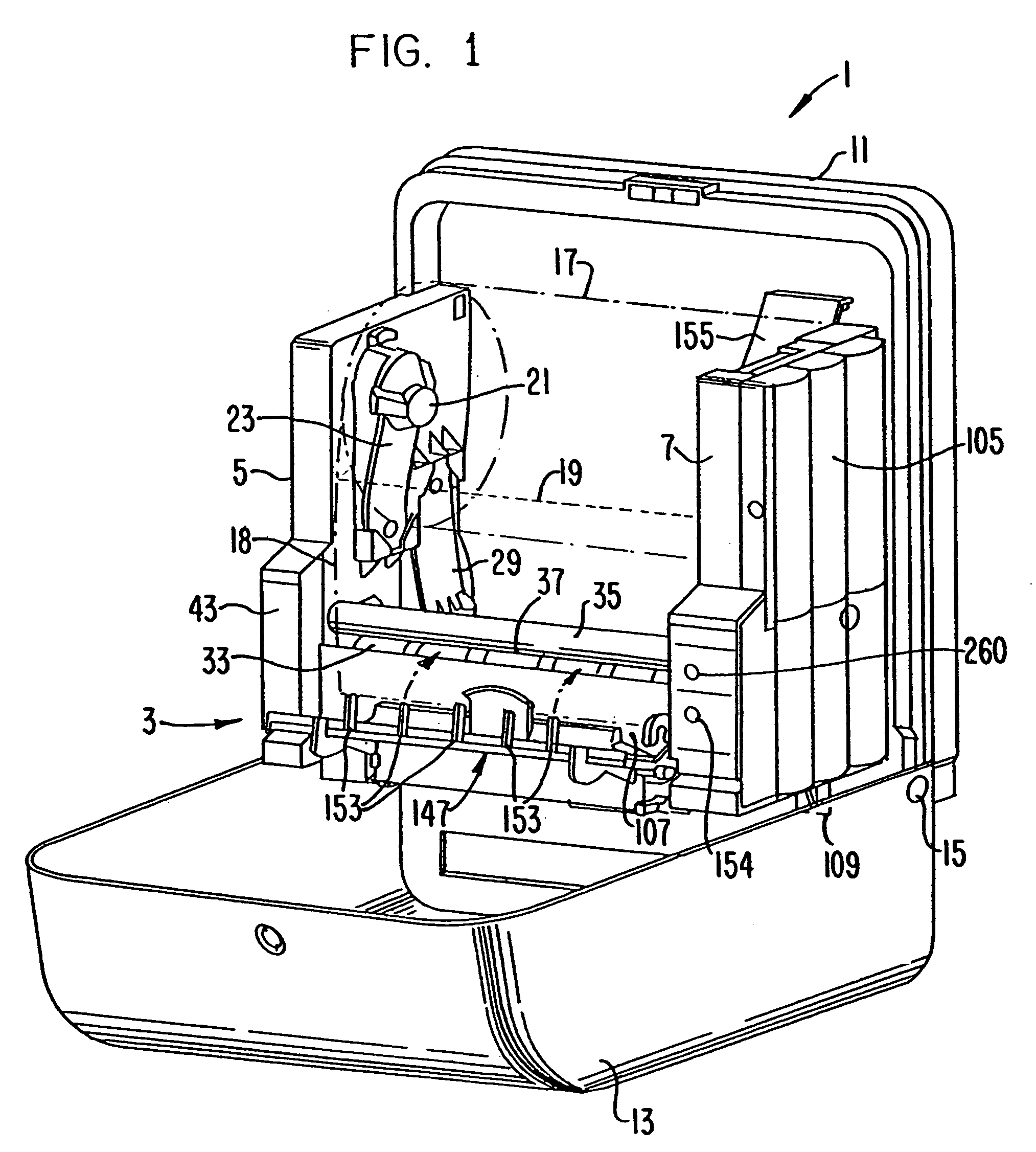

Apparatus and methods usable in connection with dispensing flexible sheet material from a roll

InactiveUS20050150992A1Improve convenienceImprove simplicityFilament handlingMetal-working apparatusTransfer mechanismCapacitance

A powered dispenser for dispensing individual sheet segments from a continuous roll of sheet material provided with spaced tear lines comprises a powered feed mechanism, a releasable, powered drive mechanism, a powered transfer mechanism, a pair of web sensing sensors, a capacitive sensing system providing automatic sensitivity adjustment, and control circuitry. A dual power supply system provides a mechanical lock-out functionality, and the control system is protected from electrostatic build-up on the surface of the feed roller. The web sensor, and an antenna plate of the capacitive sensing system, are provided on respective printed circuit boards mounted in overlying relation. Utilizing signals received from the pair of web sensors and the capacitive sensing system, the control circuitry senses the presence of a user to activate the powered drive mechanism, and prevents further dispensing of the sheet material until a previously dispensed segment is separated from the roll. The web sensors detection of a leading edge of the sheet material initiates a predetermined interval of sheet material advancement providing a proper placement of successive tear lines. Various approaches may be utilized to accommodate inadvertent sheet “tabbing” scenarios. The web sensors, together with the control circuitry, are also used to detect the depletion, or absence, of a working roll of sheet material, whereupon the control circuitry controls the powered transfer mechanism to automatically transfer the web feed supply from a depleted working roll to a reserve roll. The powered transfer mechanism may include a motor driven transfer bar, or provide motor driven release of a spring biased transfer bar. Another arrangement allows for ready release of a roll core, and drop of the same into an open dispenser cover for removal.

Owner:GPCP IP HLDG LLC

Apparatus and methods usable in connection with dispensing flexible sheet material from a roll

InactiveUS7114677B2Improve simplicity and convenienceImprove efficiencyFilament handlingMetal-working apparatusCapacitanceLeading edge

A powered dispenser for dispensing individual sheet segments from a continuous roll of sheet material provided with spaced tear lines comprises a powered feed mechanism, a releasable, powered drive mechanism, a powered transfer mechanism, a pair of web sensing sensors, a capacitive sensing system providing automatic sensitivity adjustment, and control circuitry. A dual power supply system provides a mechanical lock-out functionality, and the control system is protected from electrostatic build-up on the surface of the feed roller. The web sensor, and an antenna plate of the capacitive sensing system, are provided on respective printed circuit boards mounted in overlying relation. Utilizing signals received from the pair of web sensors and the capacitive sensing system, the control circuitry senses the presence of a user to activate the powered drive mechanism, and prevents further dispensing of the sheet material until a previously dispensed segment is separated from the roll. The web sensors detection of a leading edge of the sheet material initiates a predetermined interval of sheet material advancement providing a proper placement of successive tear lines. Various approaches may be utilized to accommodate inadvertent sheet “tabbing” scenarios. The web sensors, together with the control circuitry, are also used to detect the depletion, or absence, of a working roll of sheet material, whereupon the control circuitry controls the powered transfer mechanism to automatically transfer the web feed supply from a depleted working roll to a reserve roll. The powered transfer mechanism may include a motor driven transfer bar, or provide motor driven release of a spring biased transfer bar. Another arrangement allows for ready release of a roll core, and drop of the same into an open dispenser cover for removal.

Owner:GPCP IP HLDG LLC

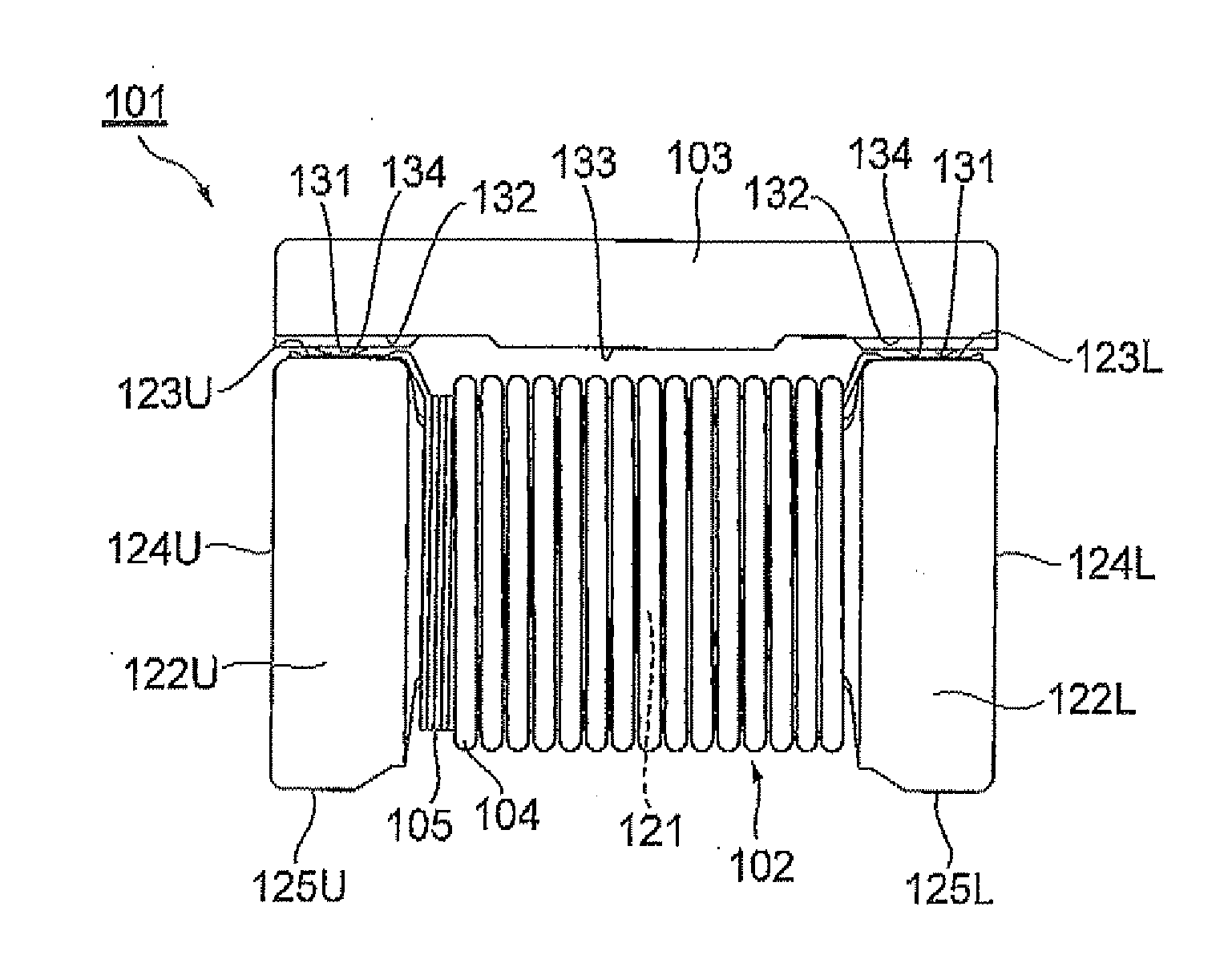

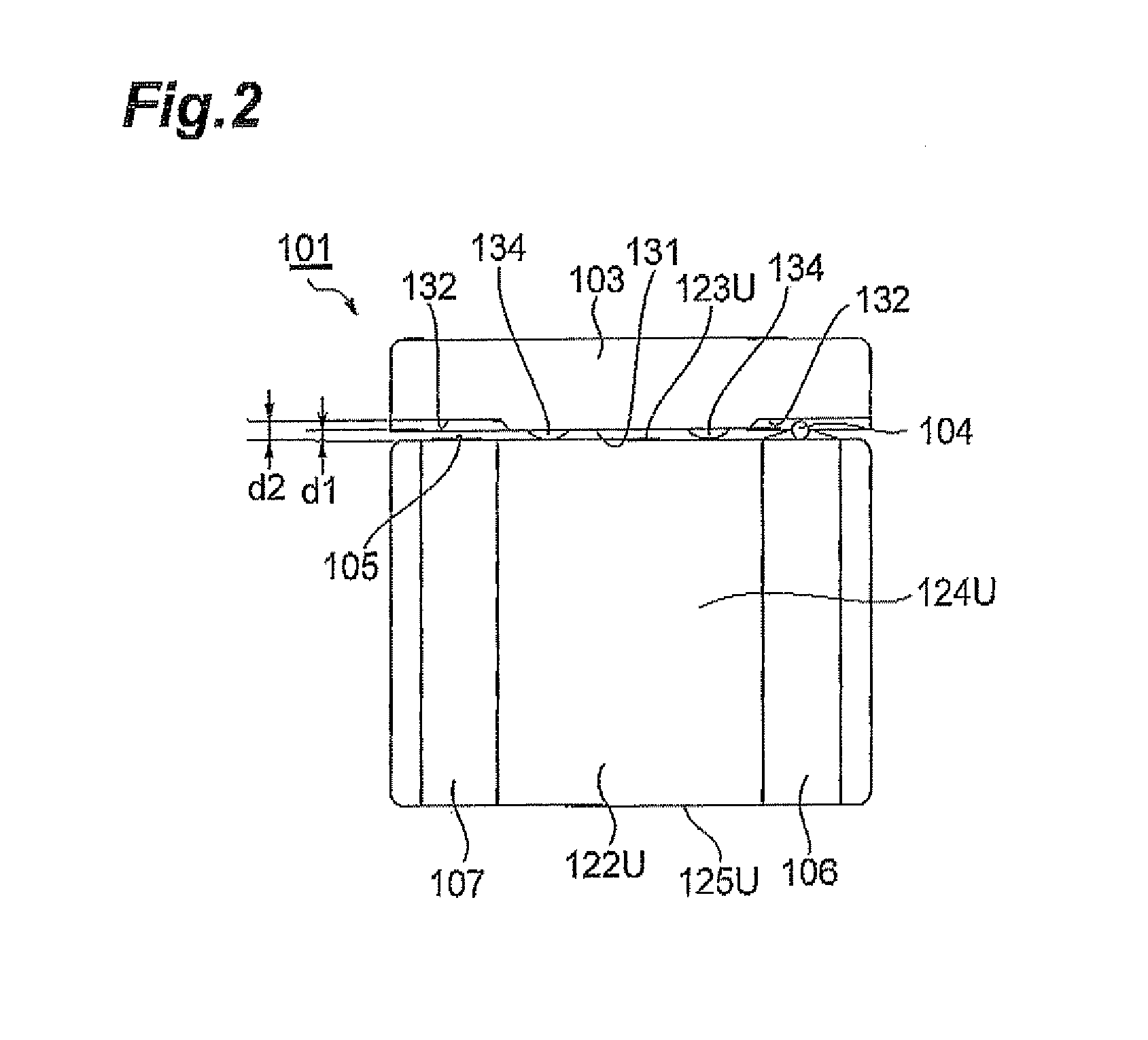

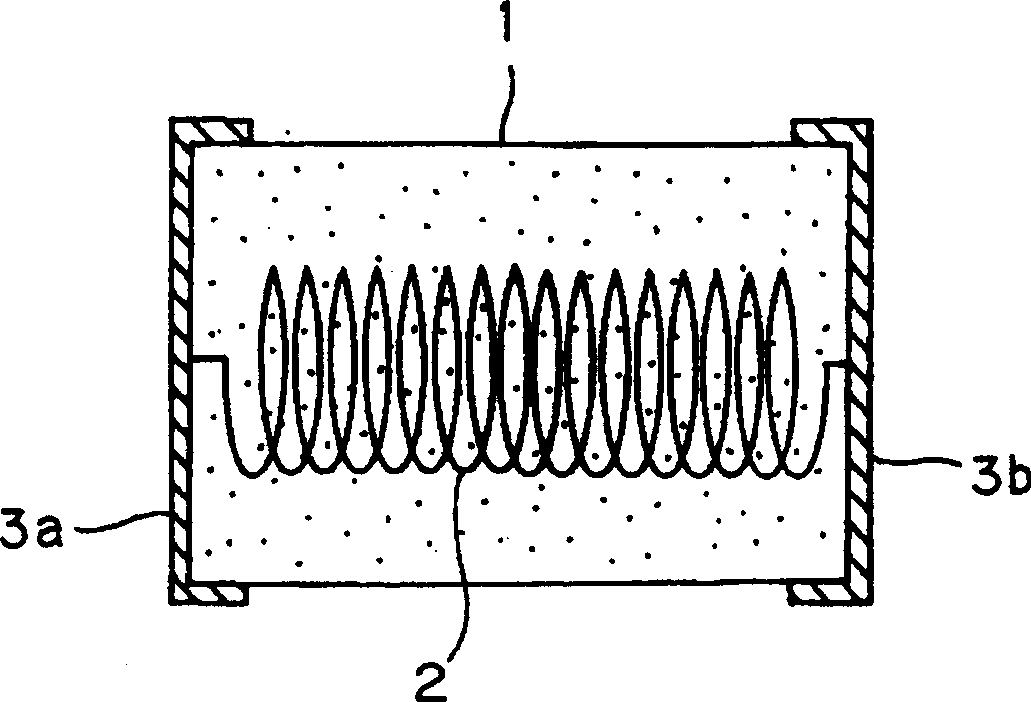

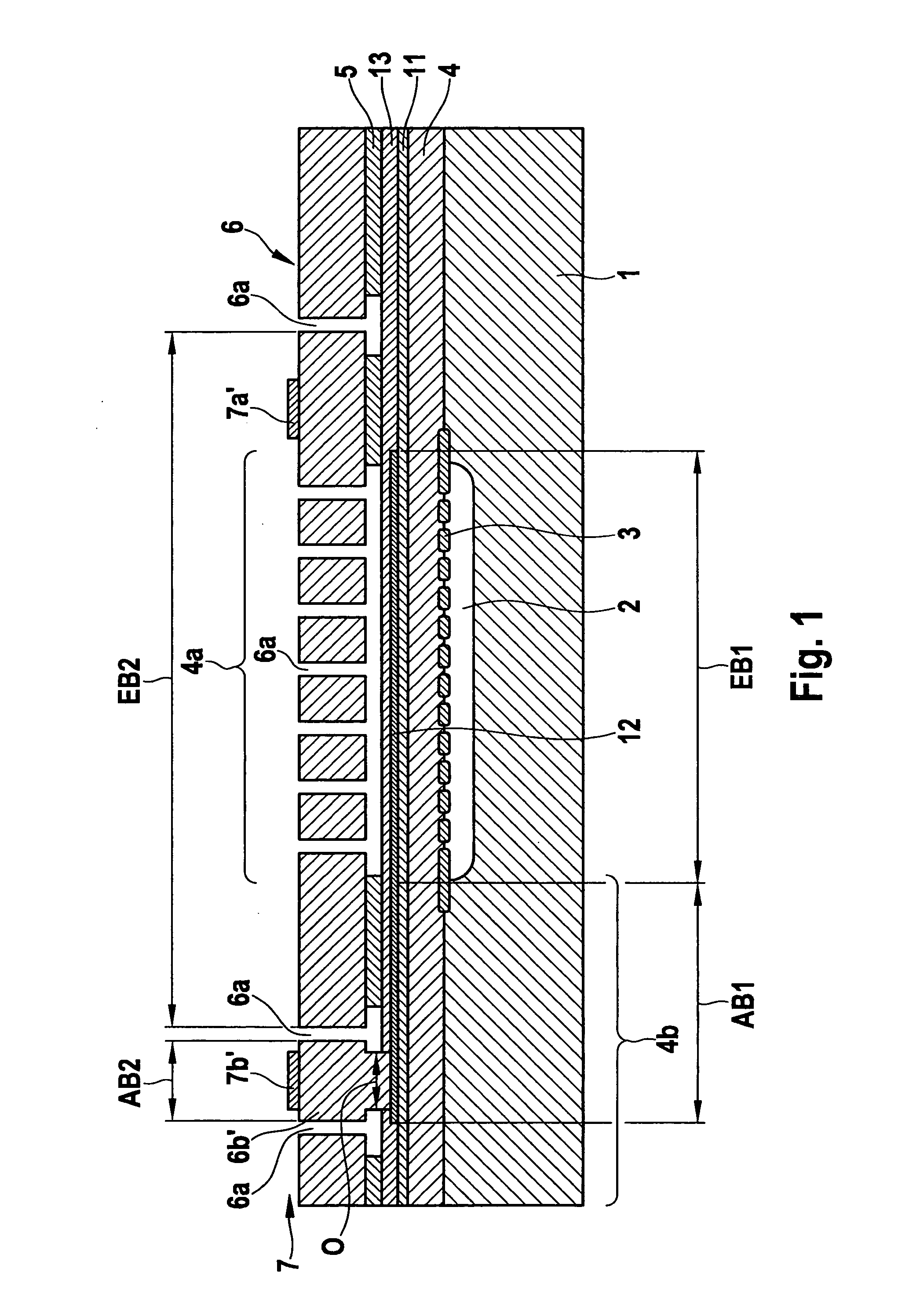

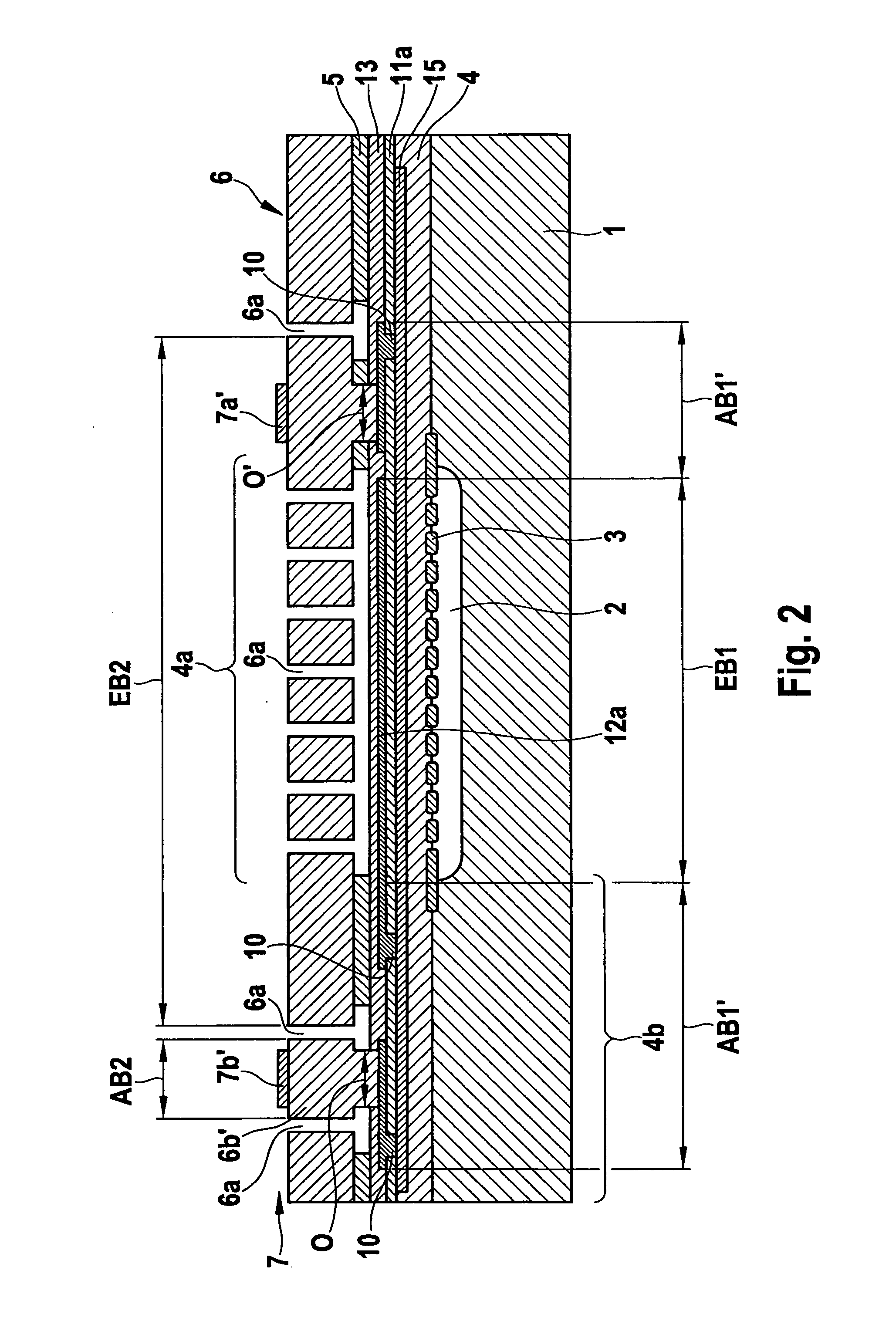

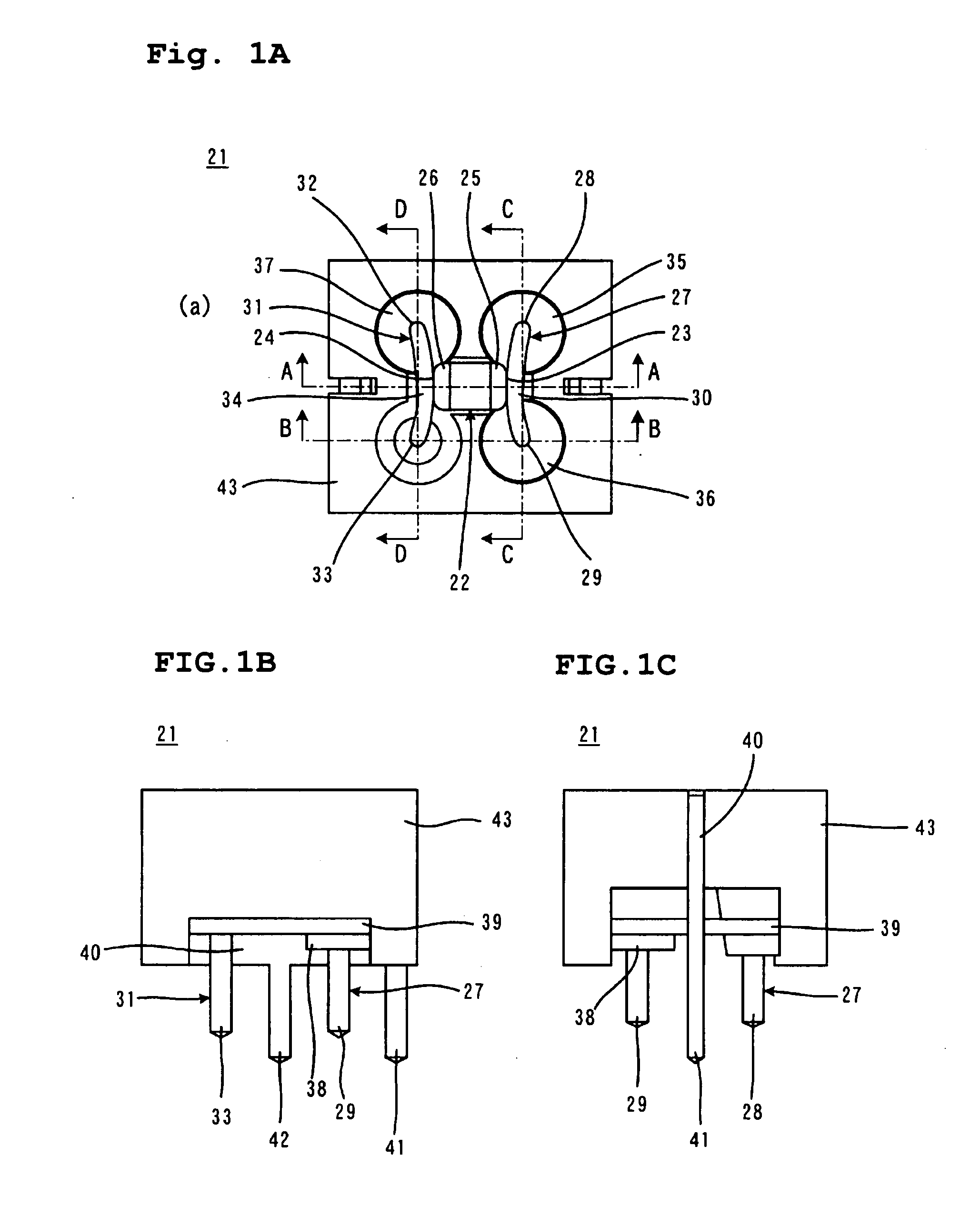

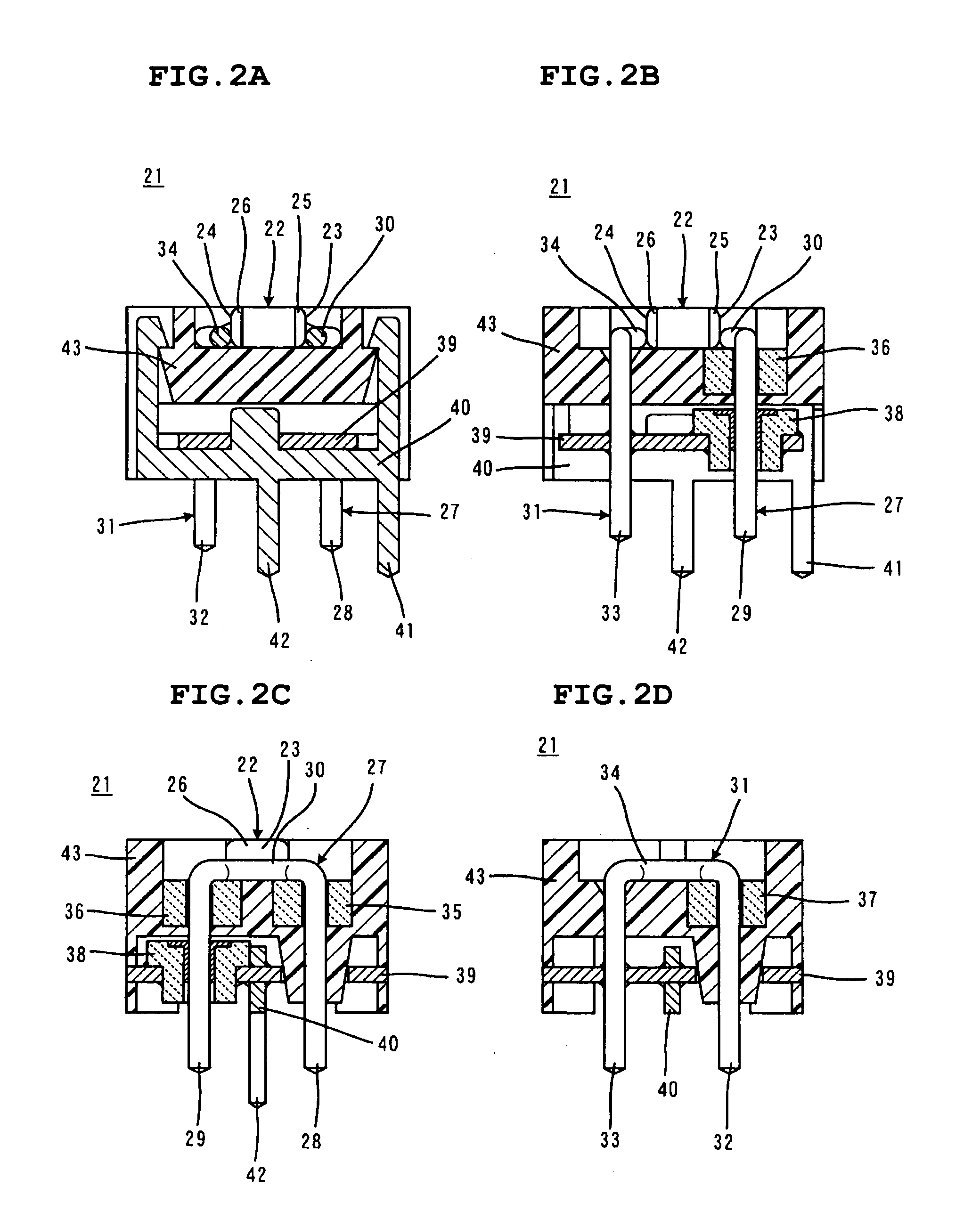

transformer

ActiveUS20120133469A1Improve DC Superposition CharacteristicsReduce stray capacitanceTransformers/inductances coils/windings/connectionsCores/yokesTransformerEddy current

A transformer that improves the DC superposition characteristic without incurring eddy-current losses. In the transformer, a part of a plate-like core opposing a top face of a flange of a drum core is formed with a first opposing portion opposing none of input and output terminals and a second opposing portion opposing the input and output terminals. A first gap is formed between the top face and the first opposing portion by a spacer. A second gap greater than the first gap is formed by a recess of the plate-like core provided so as to correspond to the second opposing portion. This allows magnetic fluxes to pass between the top face and the first opposing portion where the gap is formed and inhibits them from passing between the plate-like core and the input and output terminals where the second gap greater than the first gap is formed.

Owner:TDK CORPARATION

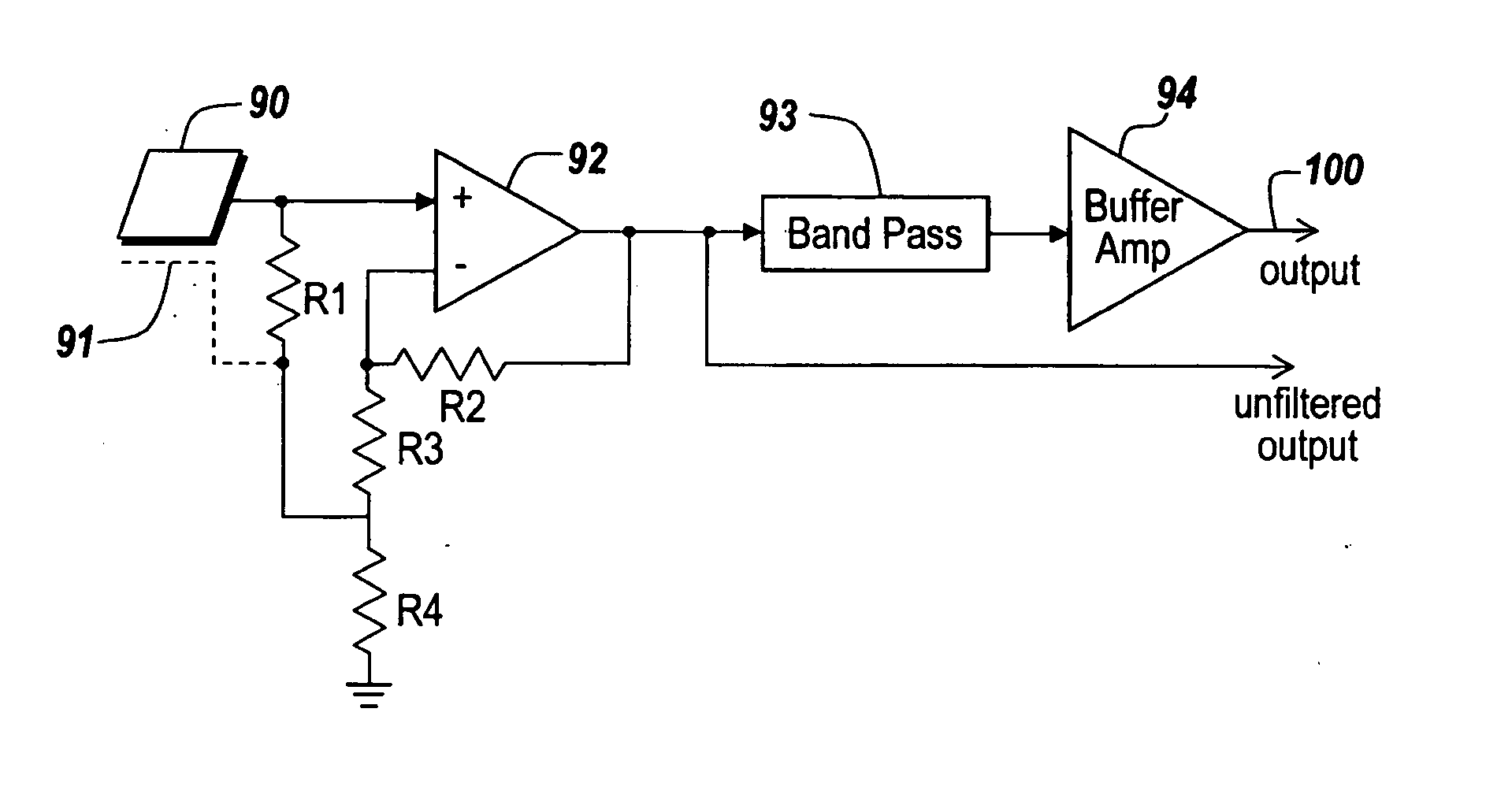

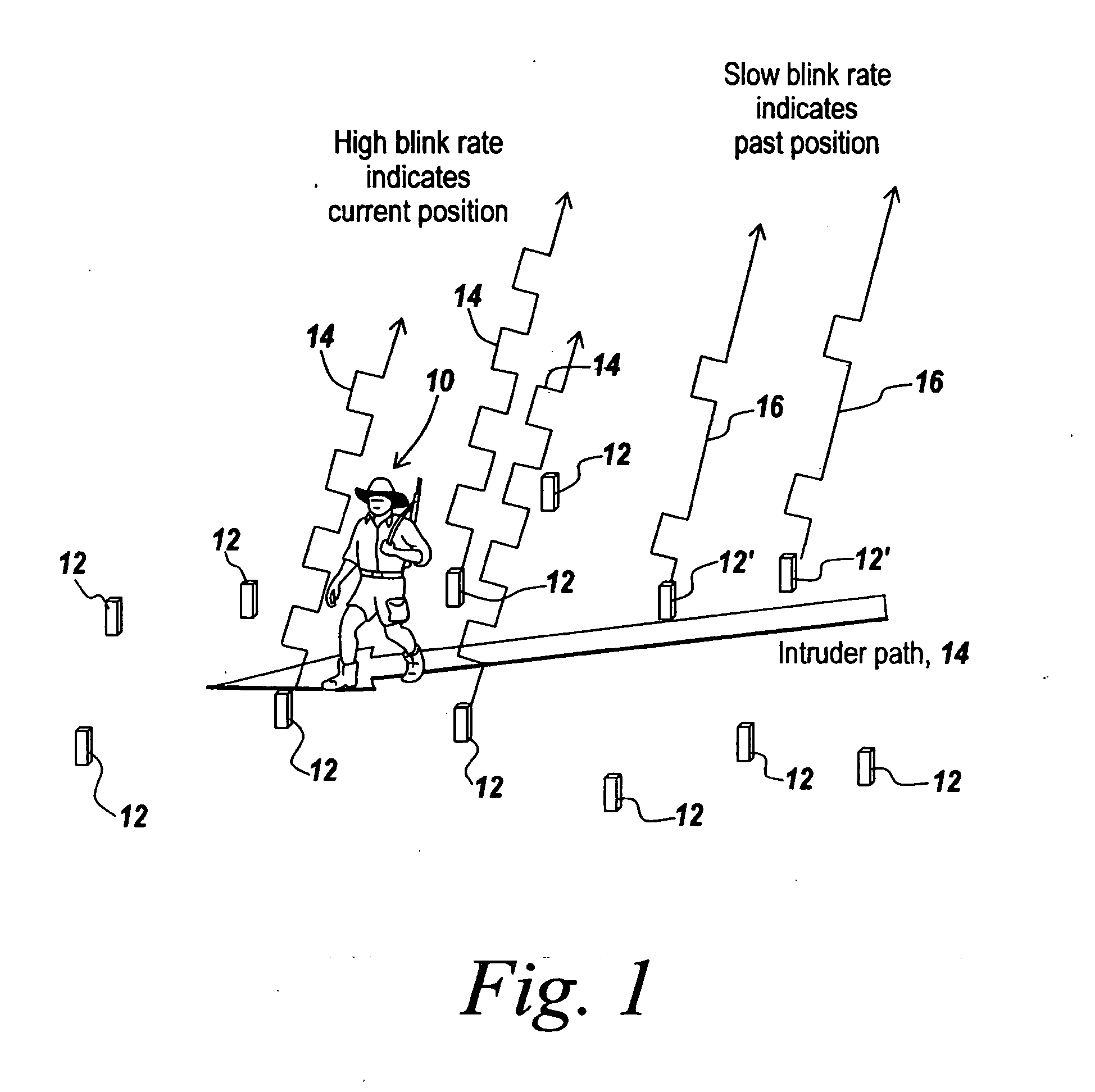

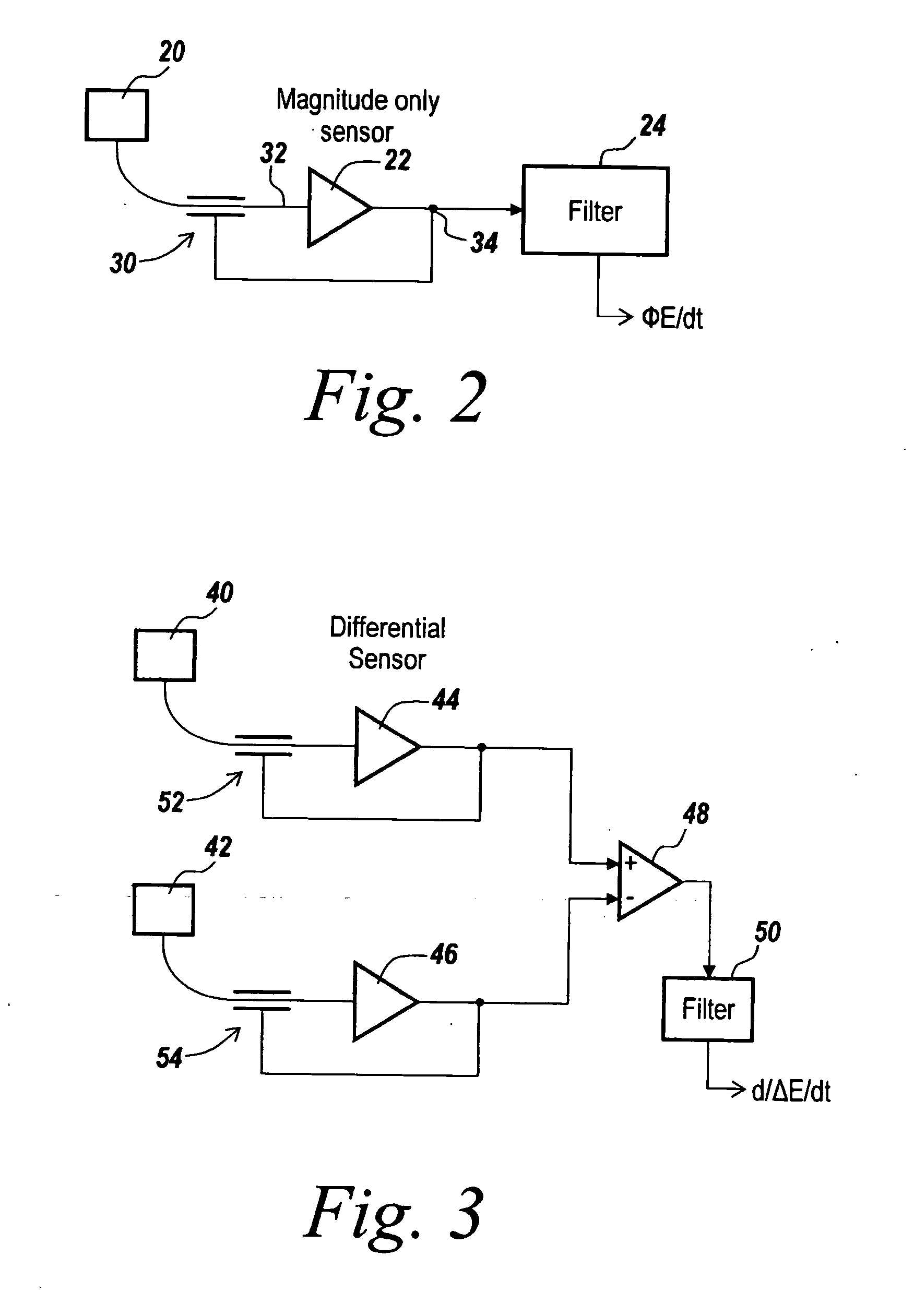

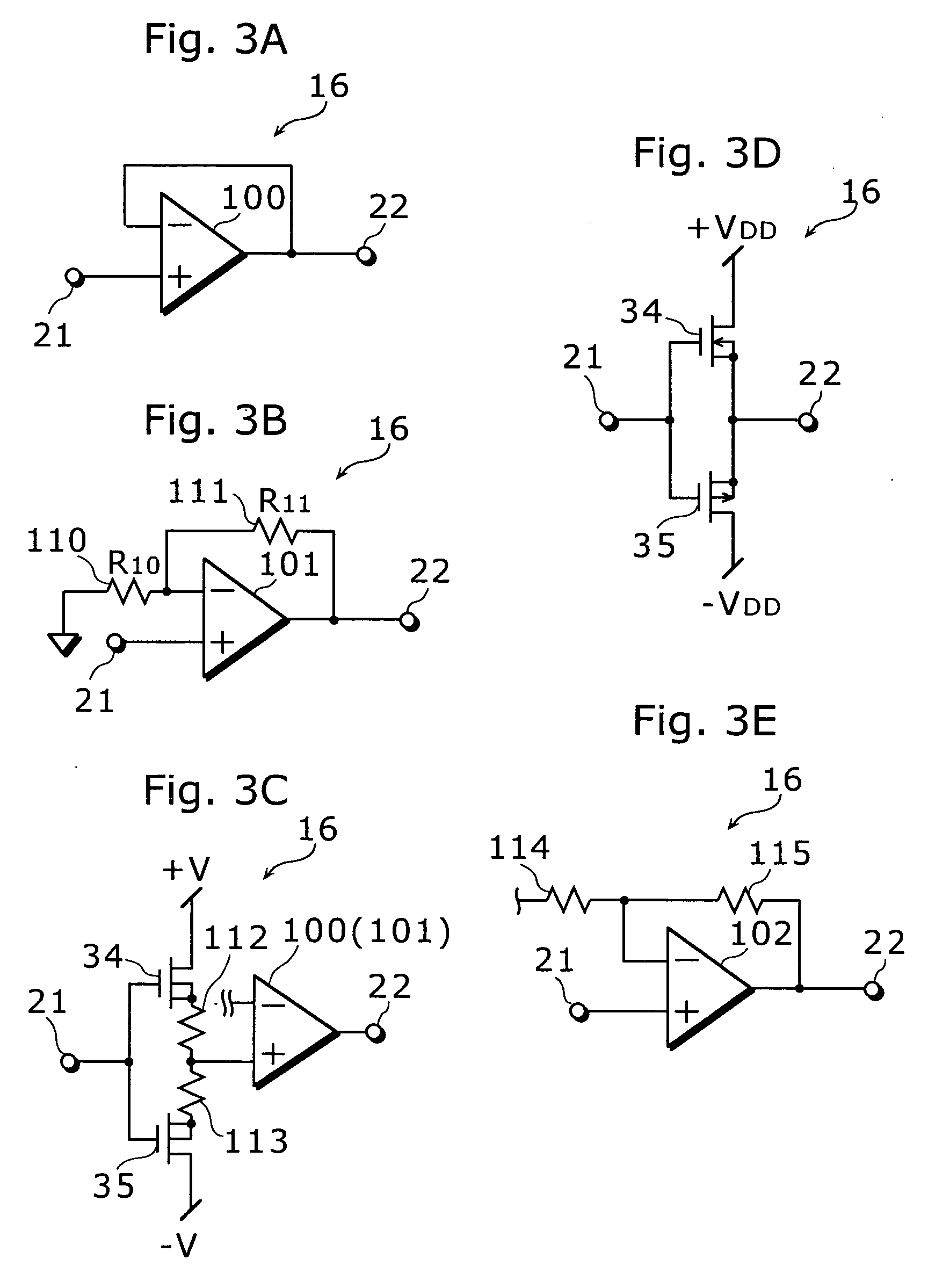

Method and apparatus for detecting individuals using electrical field sensors

InactiveUS20060261818A1Reduce stray capacitanceReduce outputConcealed burglar systemsVisible signalling systemsElectric field sensorGeolocation

A robust, easily deployable, covert, passive intrusion detection system uses one or more E-field sensors to detect the presence of a moving individual and to provide an indication of the presence of the individual adjacent the sensor based on E-field distortion produced by the individual. Single-ended and differential E-field sensors with noise canceling and a guarding circuit provide sufficient sensitivity, with filtering from 0.5 Hz to 8.0 Hz selecting only human intruders. Either visible or invisible flashing light sources at the sensor indicate the presence of a moving individual at the sensor, thus to provide intruder location without the necessity of providing a geolocation system.

Owner:BAE SYST INFORMATION & ELECTRONICS SYST INTERGRATION INC

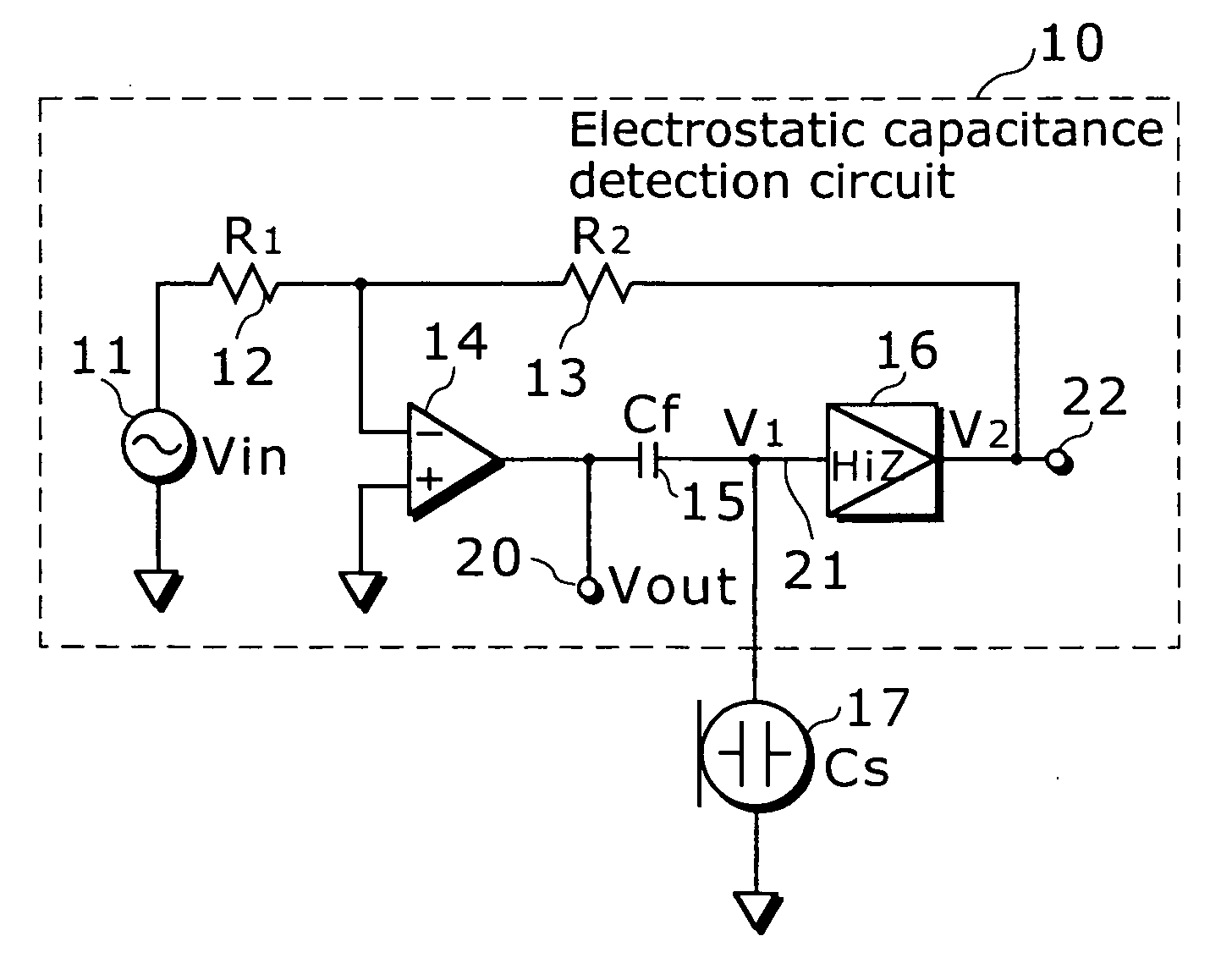

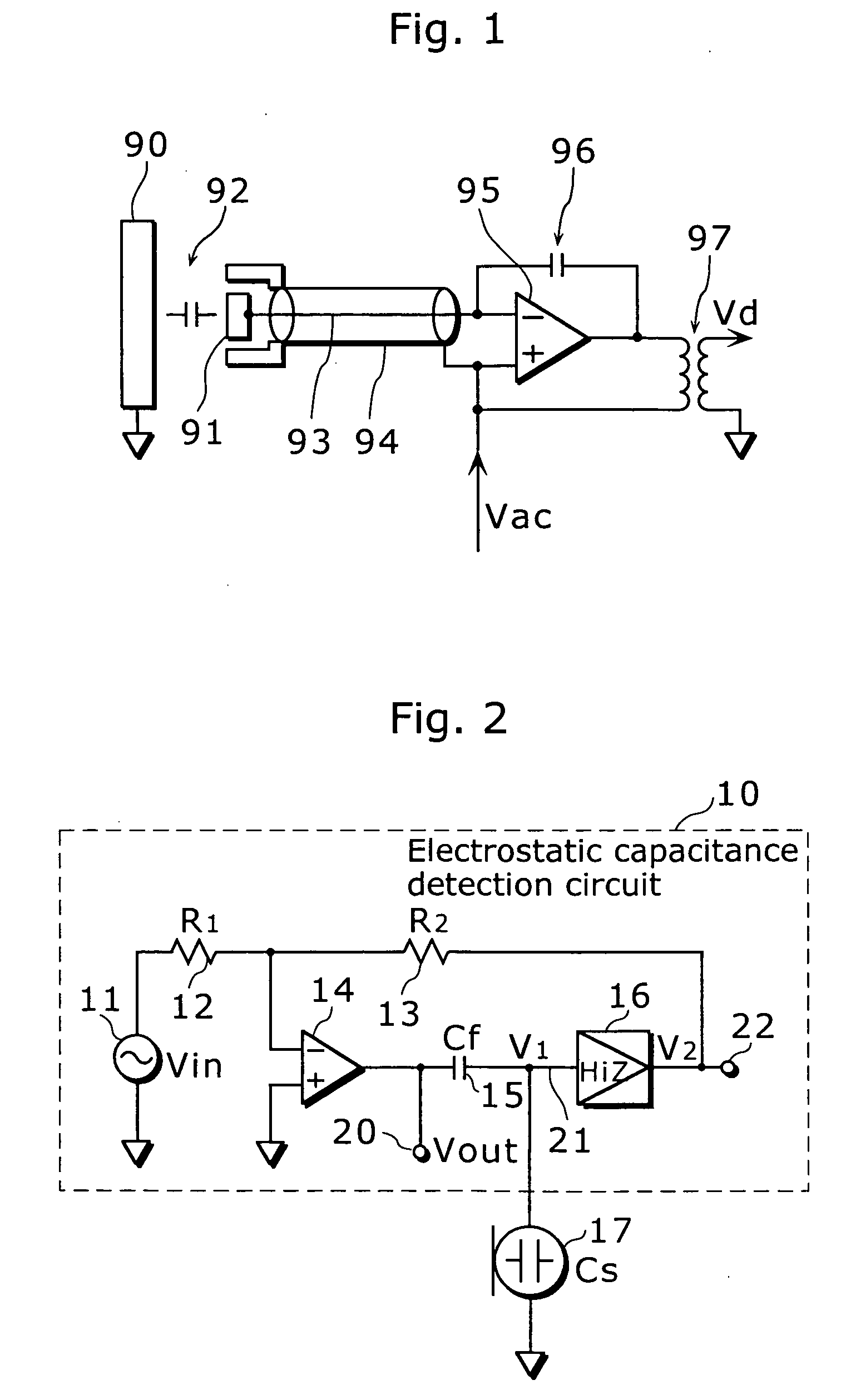

Capacitance measuring circuit capacitance measuring instrument and microphone device

InactiveUS20050017737A1Reduce mixReduce stray capacitanceElectrical apparatusResistance/reactance/impedenceCapacitanceVoltage generator

An electrostatic capacitance detection circuit 10 comprises an AC voltage generator 11, an operational amplifier 14 of which non-inverting input terminal is connected to specific potential (a ground in this example), an impedance converter 16, a resistance (R1) 12 connected between the AC voltage generator 11 and an inverting input terminal of the operational amplifier 14, a resistance (R2) 13 connected between the inverting input terminal of the operational amplifier 14 and an output terminal of the impedance converter 16, and an impedance element (a capacitor) 15 connected between an output terminal of the operational amplifier 14 and an input terminal of the impedance converter 16, and a capacitor to be detected 17 is connected between the input terminal of the impedance converter 16 and specific potential. The electrostatic capacitance detection circuit 10 and the capacitor 17 are located adjacently.

Owner:TOKYO ELECTRON LTD

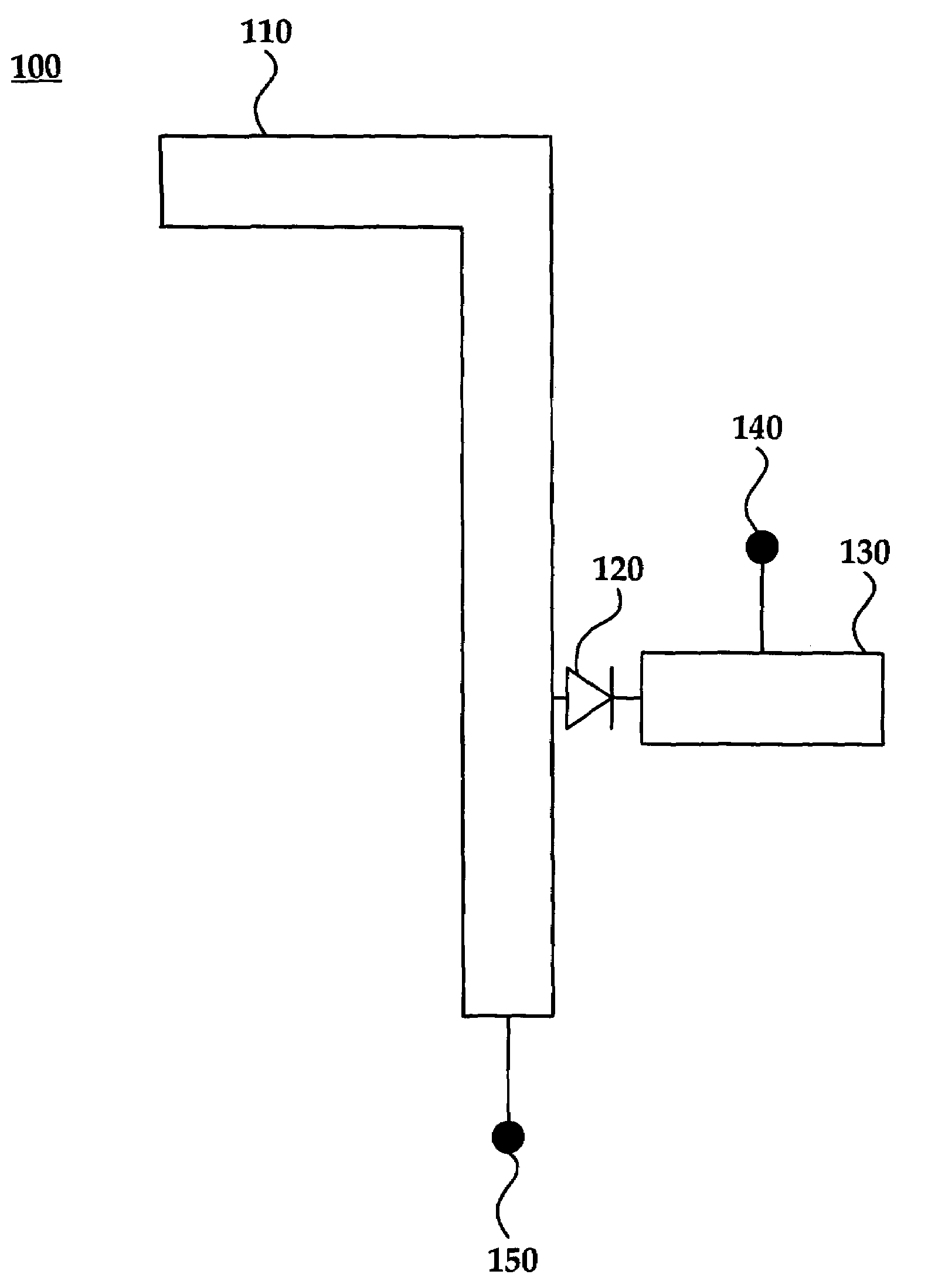

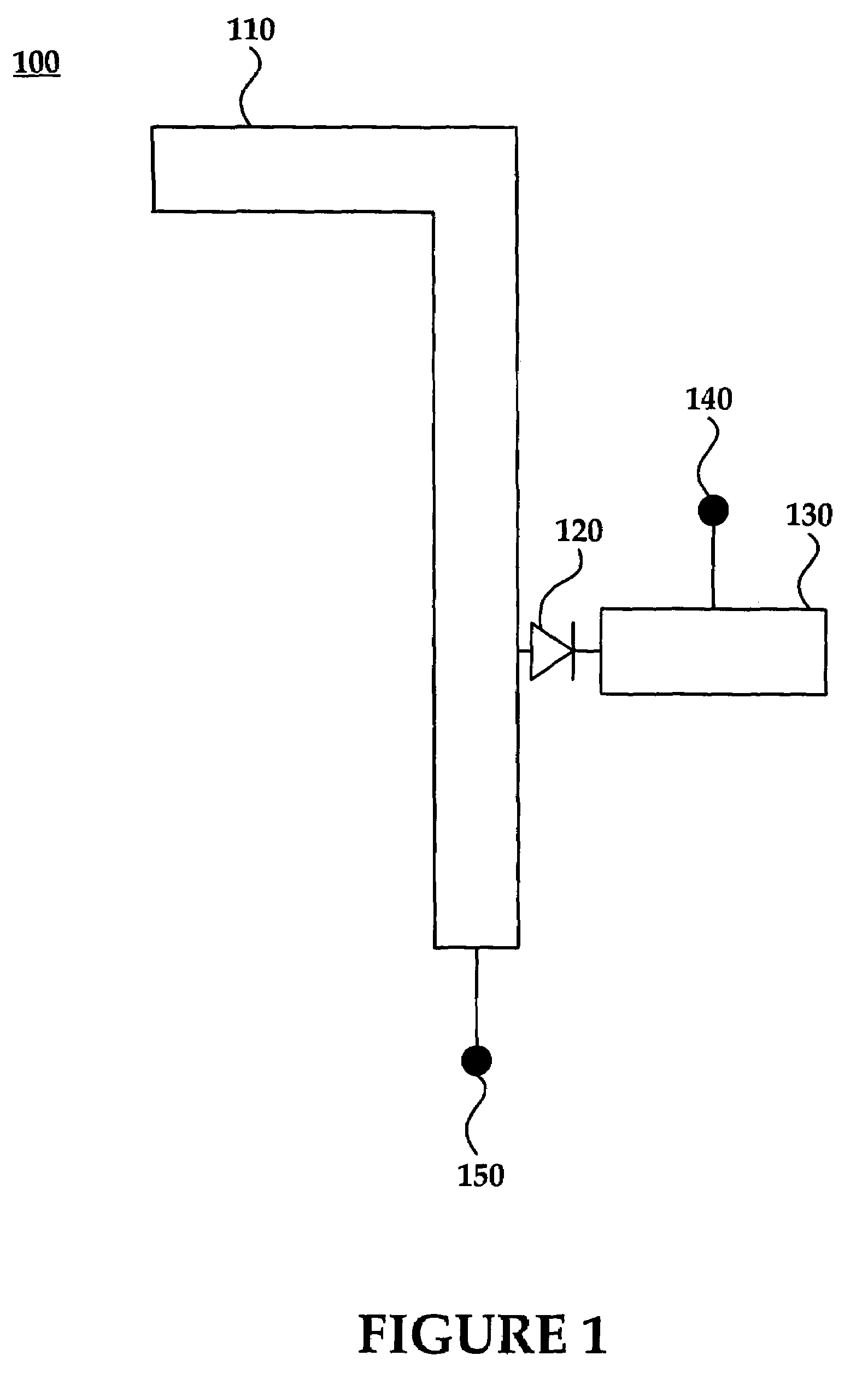

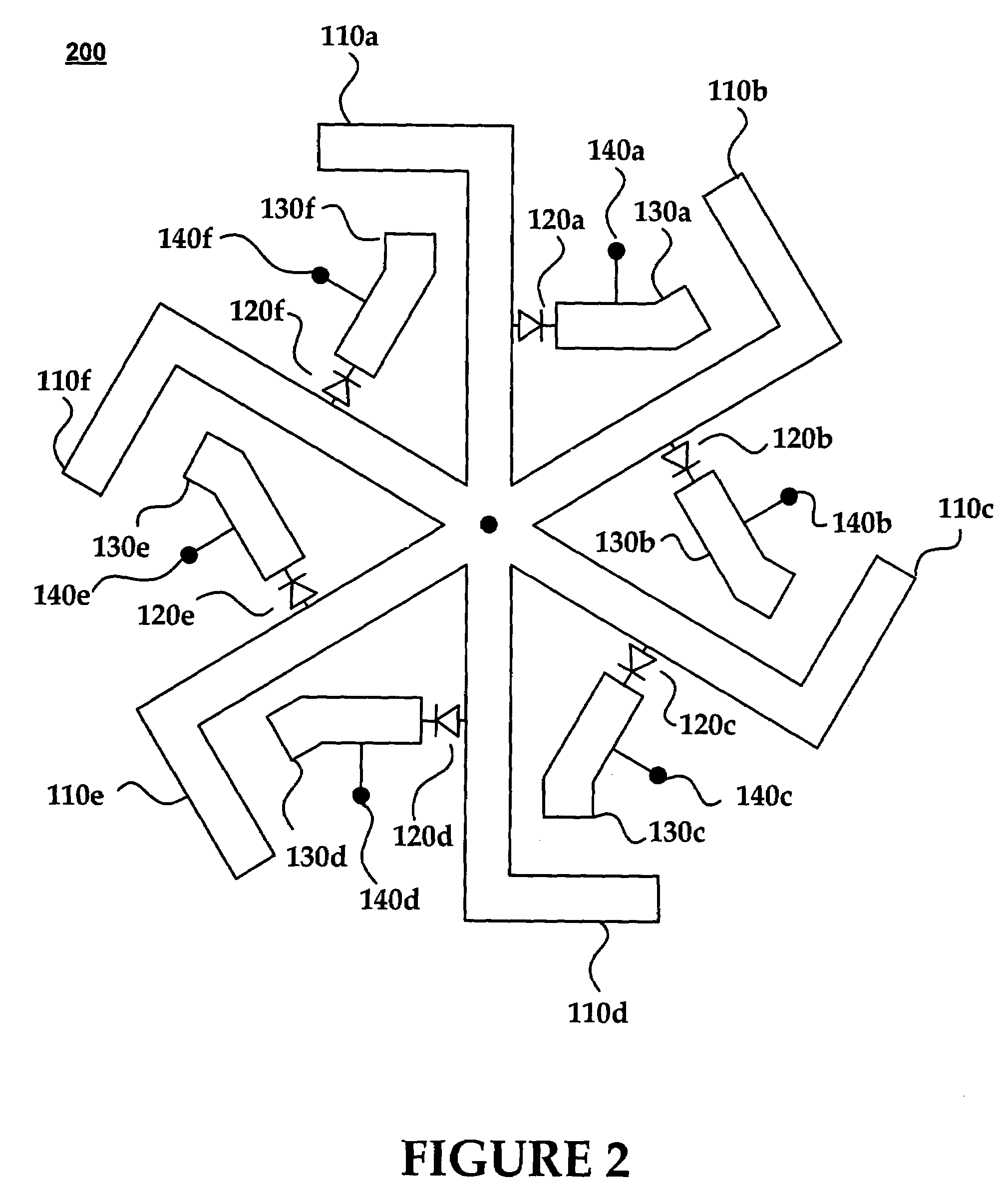

Reducing stray capacitance in antenna element switching

InactiveUS7696946B2Reduce stray capacitanceMultiple-port networksAntenna arraysCapacitanceEngineering

An antenna array may include an antenna element configured to receive an RF signal. A PIN diode may selectively couple the antenna element to an RF source. Biasing the PIN diode may cancel the received RF signal at a stub coupled to the diode thereby reducing stray capacitance of the PIN diode. A method for switching antenna elements is also disclosed. A PIN diode coupled to an antenna element is biased thereby reflecting the received RF signal out-of-phase within a stub such that the signal is canceling and stray capacitance of the PIN diode is reduced.

Owner:ARRIS ENTERPRISES LLC

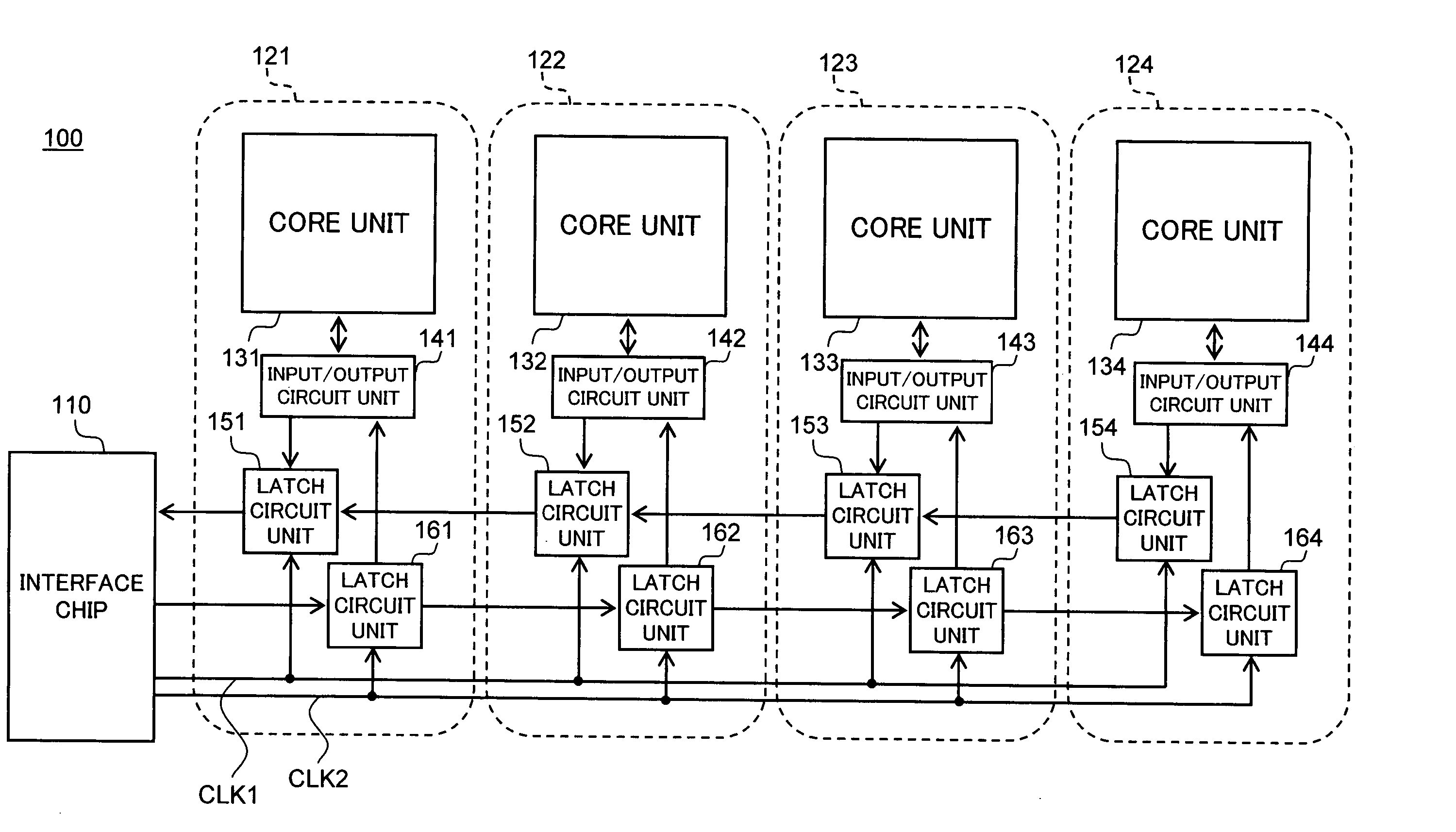

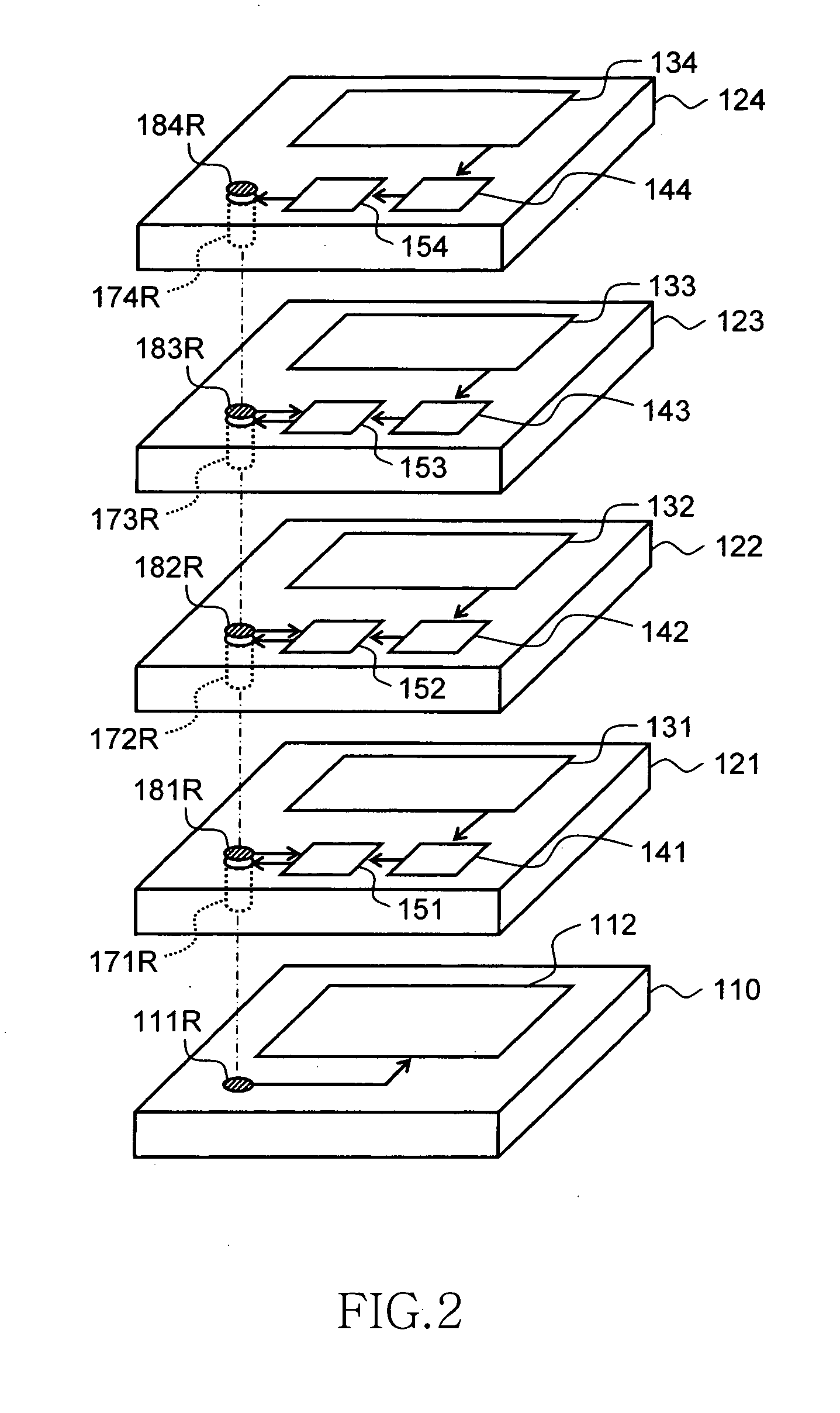

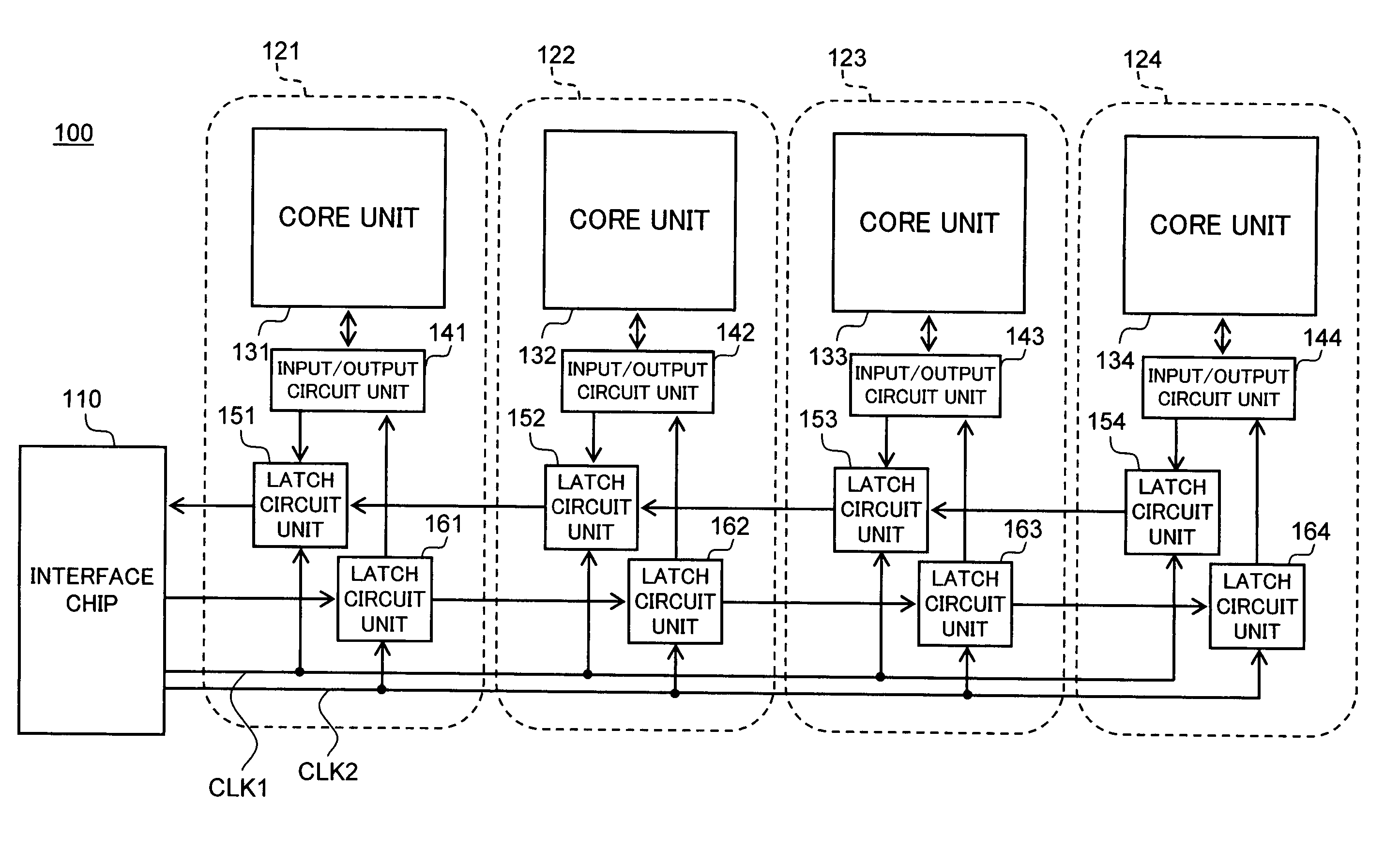

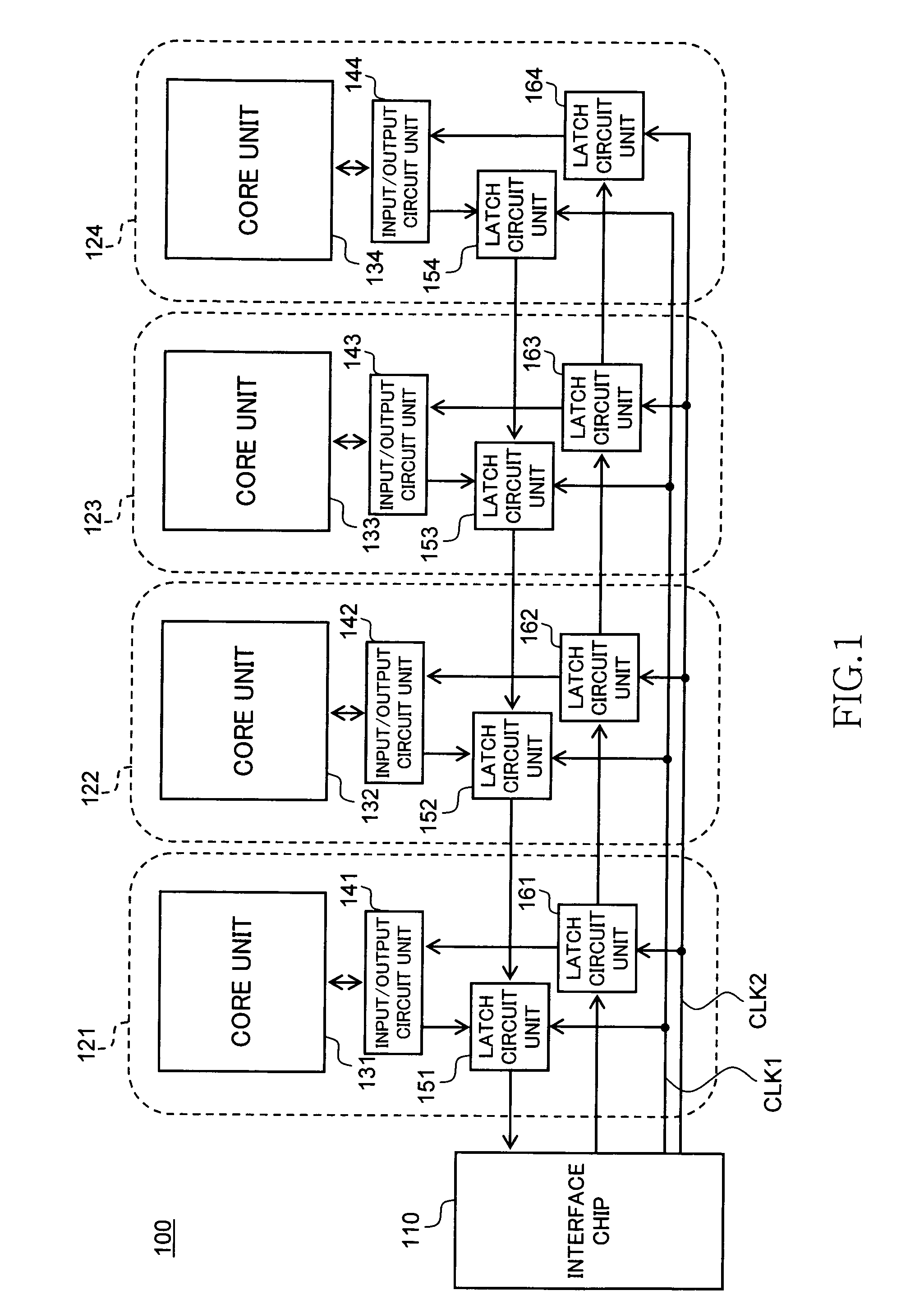

Semiconductor storage device

ActiveUS20070005876A1Increase speedOvercome problemsSemiconductor/solid-state device detailsSolid-state devicesData transmissionSemiconductor memory

Data transfer speed is increased in a semiconductor storage device in which the core unit and the interface unit are separate chips. The device has a plurality of core chips through in which a memory cell is formed, and an interface chip in which a peripheral circuit is formed for the memory cell. The plurality of core chips through have latch circuit units through for temporarily storing data to be outputted by the memory cell, and latch circuit units through for temporarily storing data to be inputted to the memory cell, respectively, and these latch circuit units through and latch circuit units through are connected in a cascade to the interface chip. Since the plurality of latch circuit units connected in a cascade can thereby perform a pipeline operation, it becomes possible to achieve high-speed data transfer.

Owner:HIROSHIMA UNIVERSITY +1

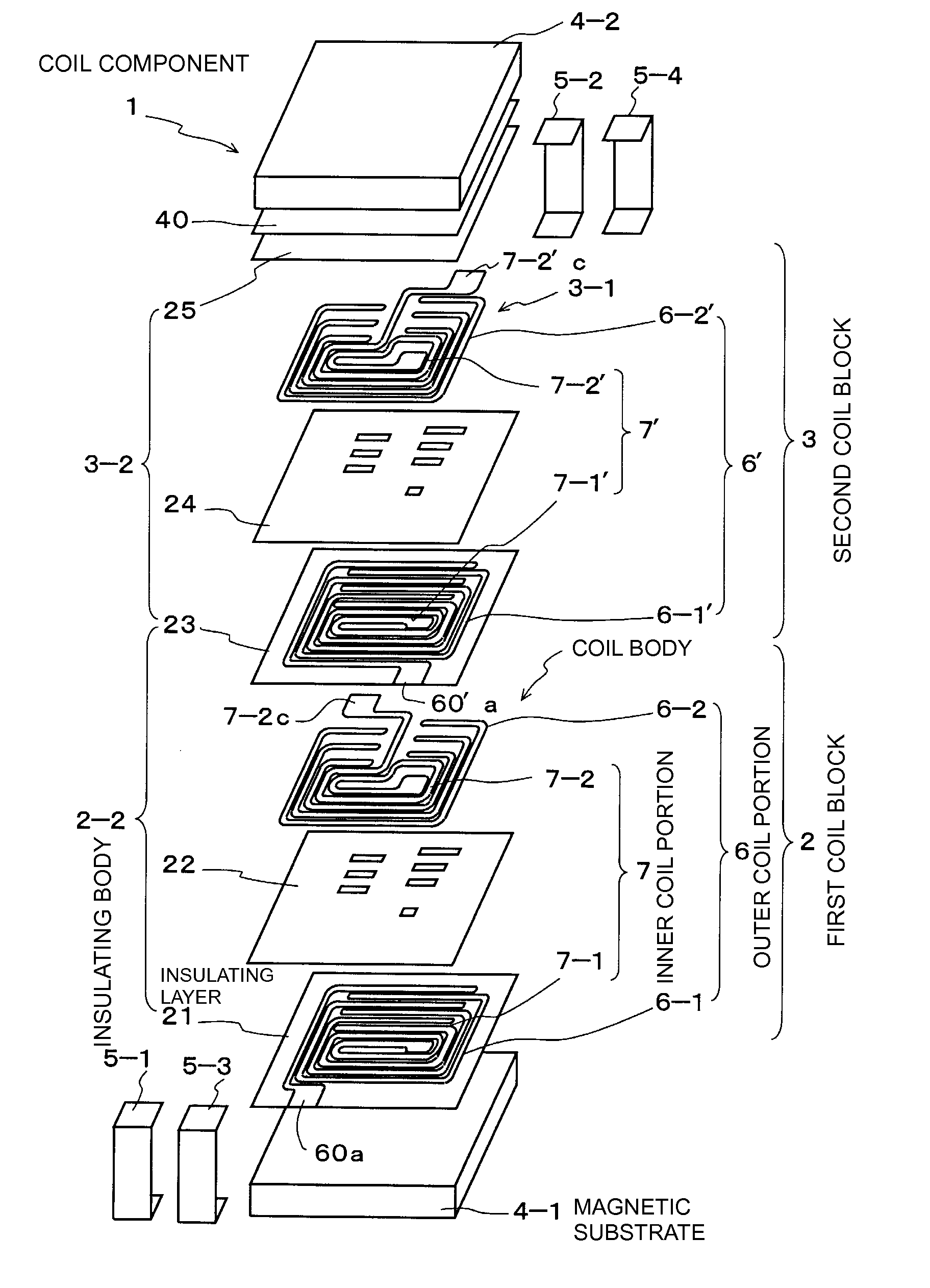

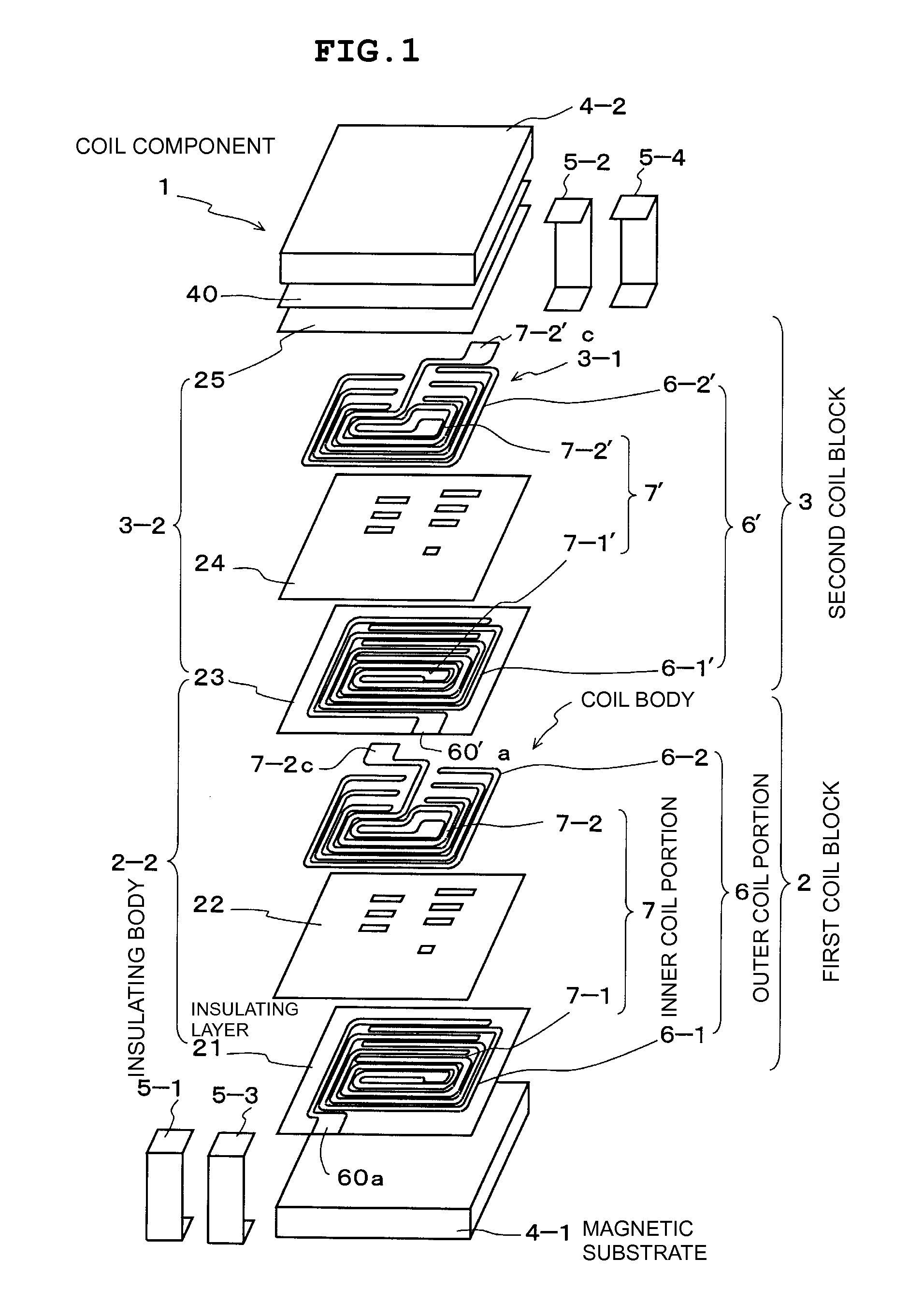

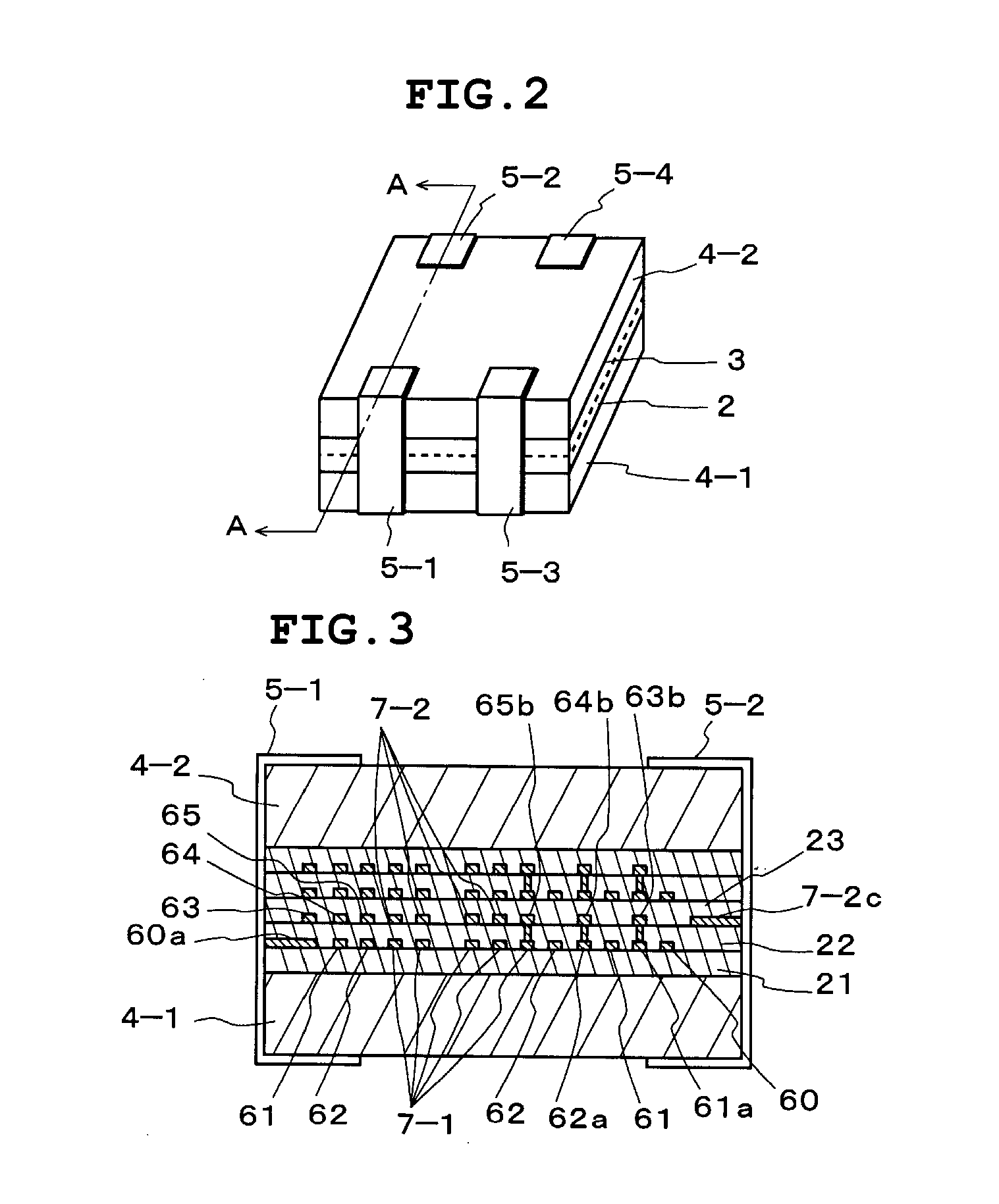

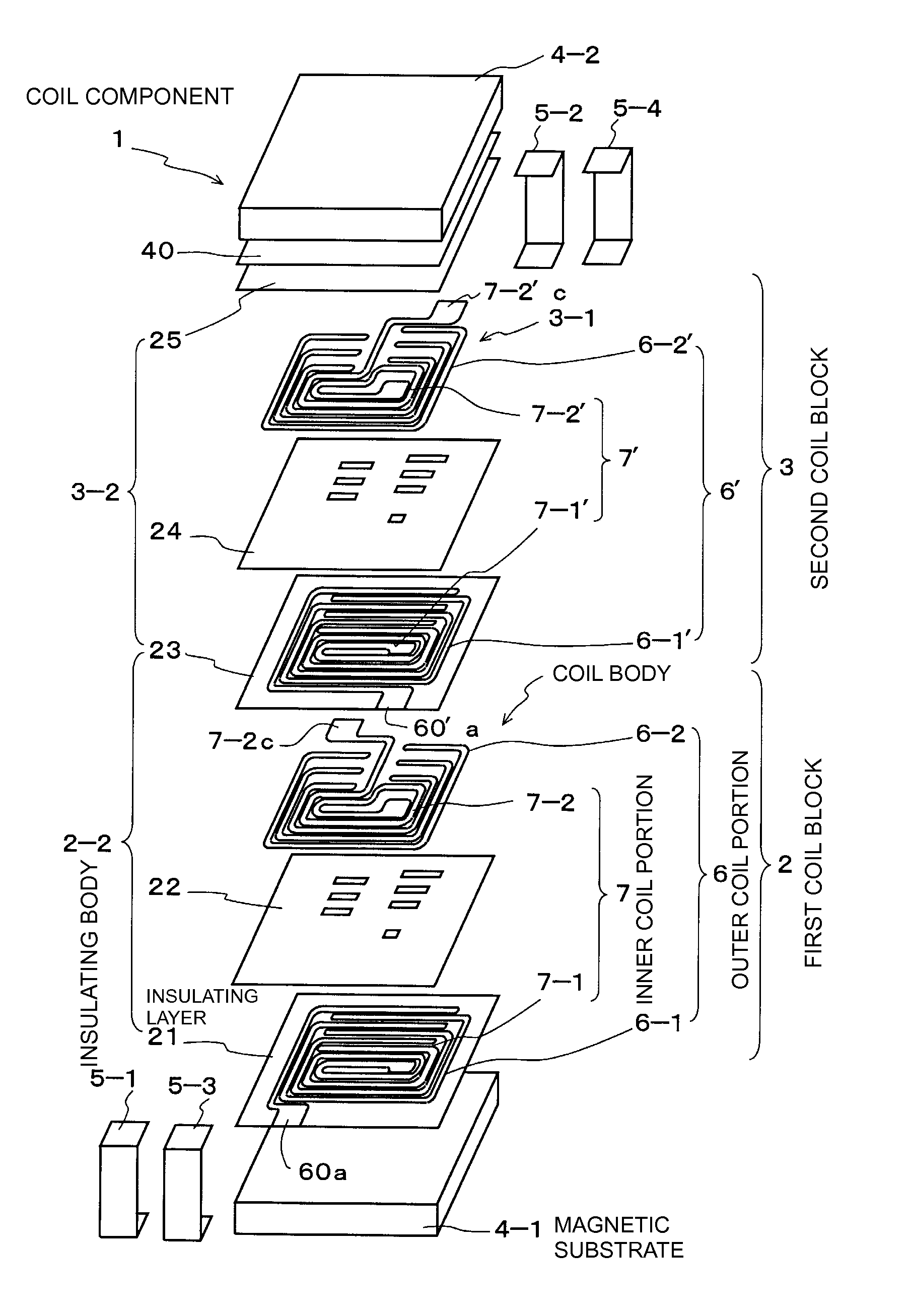

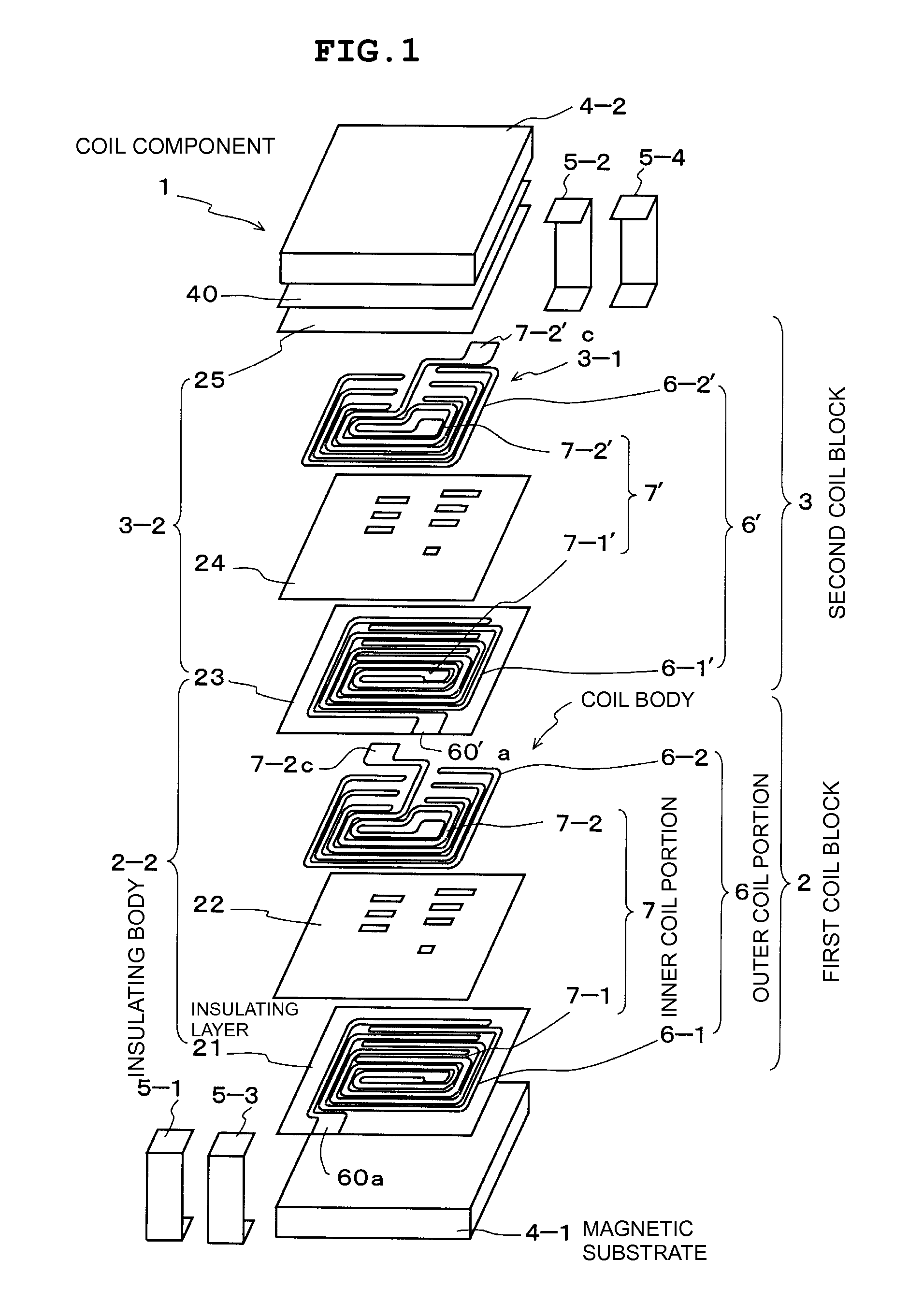

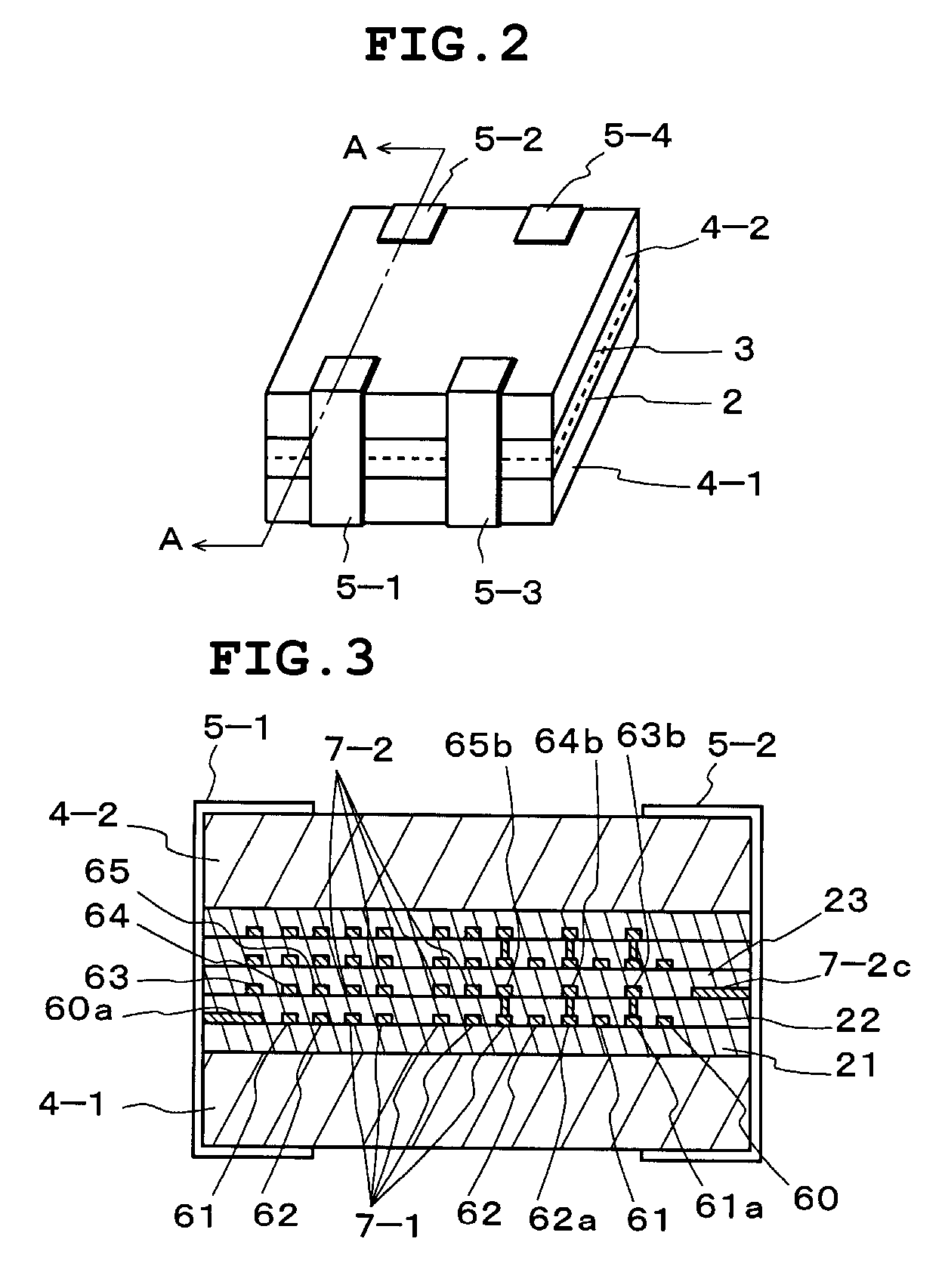

Coil component

ActiveUS20070205856A1Reduce stray capacitanceIncrease inductanceUnwanted magnetic/electric effect reduction/preventionCoilsCapacitanceOuter coil

A coil component includes a first coil block and a second coil block that are sandwiched between magnetic substrates so as to form a chip body, and external electrodes that are attached to the chip body. The first coil block includes a coil body and an insulating body. The coil body includes an outer coil portion and an inner coil portion. The outer coil portion includes a first pattern group and a second pattern group, which are connected helically vertically in an alternating fashion. The inner coil portion includes a first spiral pattern and a second spiral pattern, which are connected to each other in series. In other words, low stray capacitance is achieved by the outer coil portion, while high inductance is achieved by the inner coil portion.

Owner:MURATA MFG CO LTD

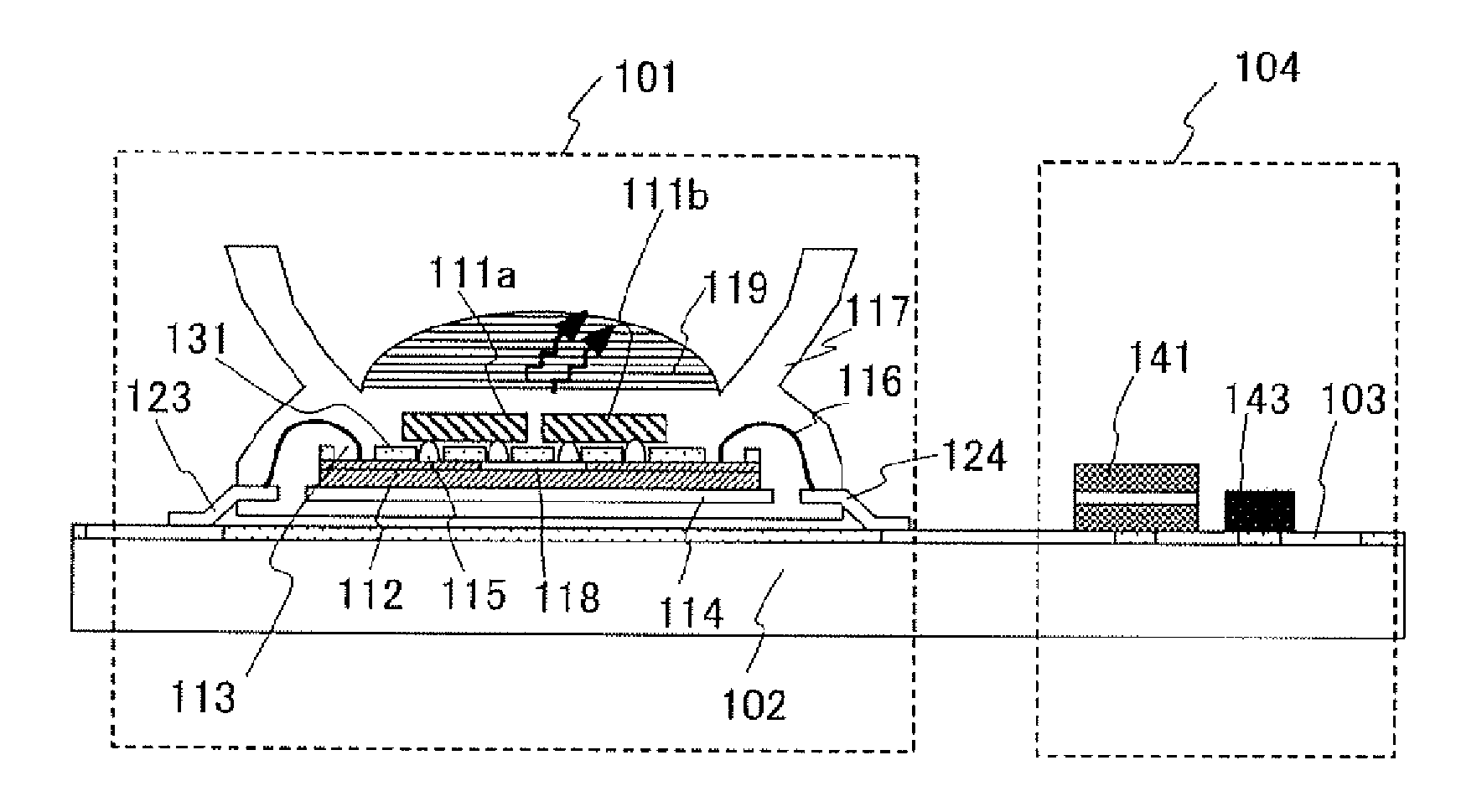

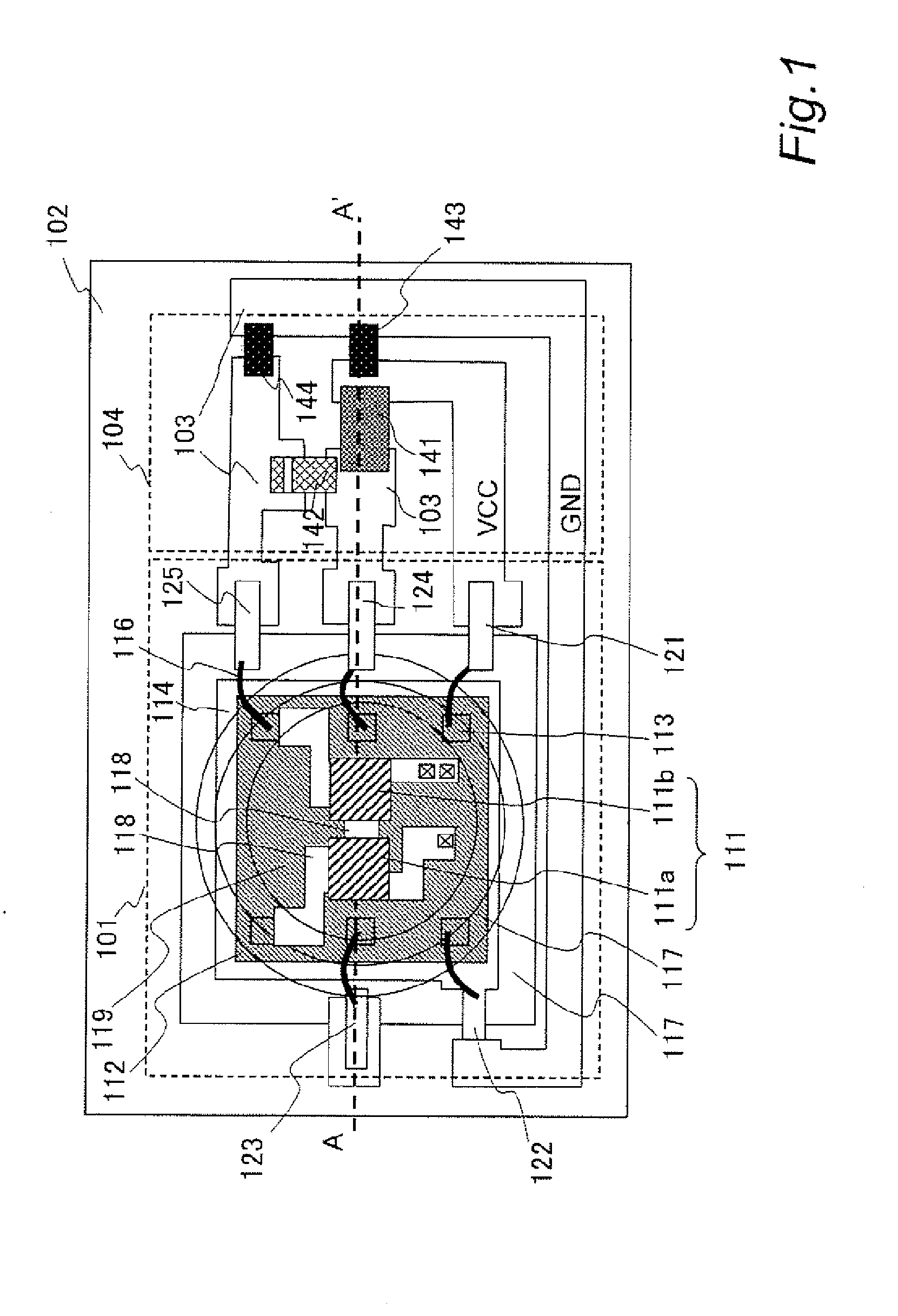

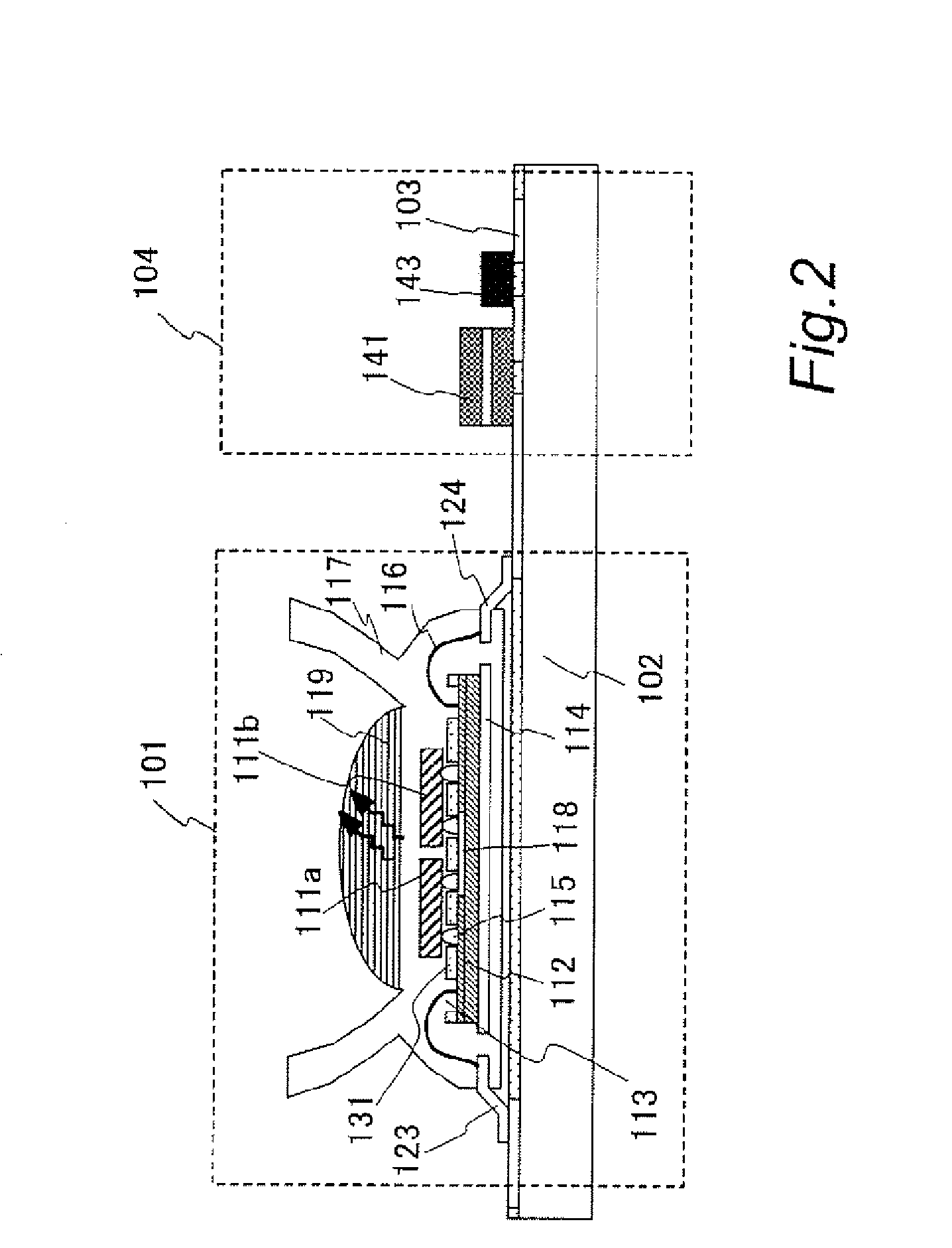

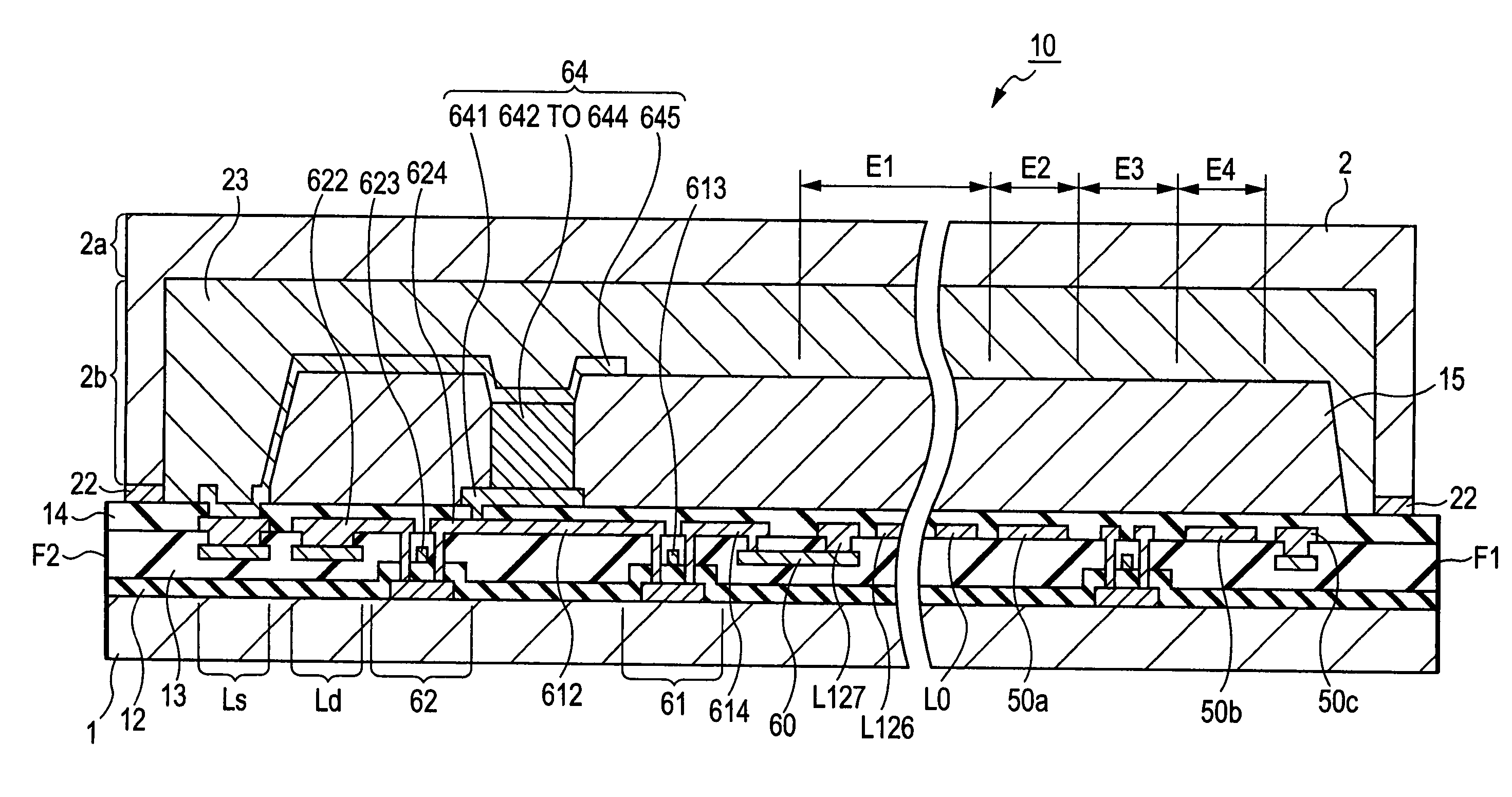

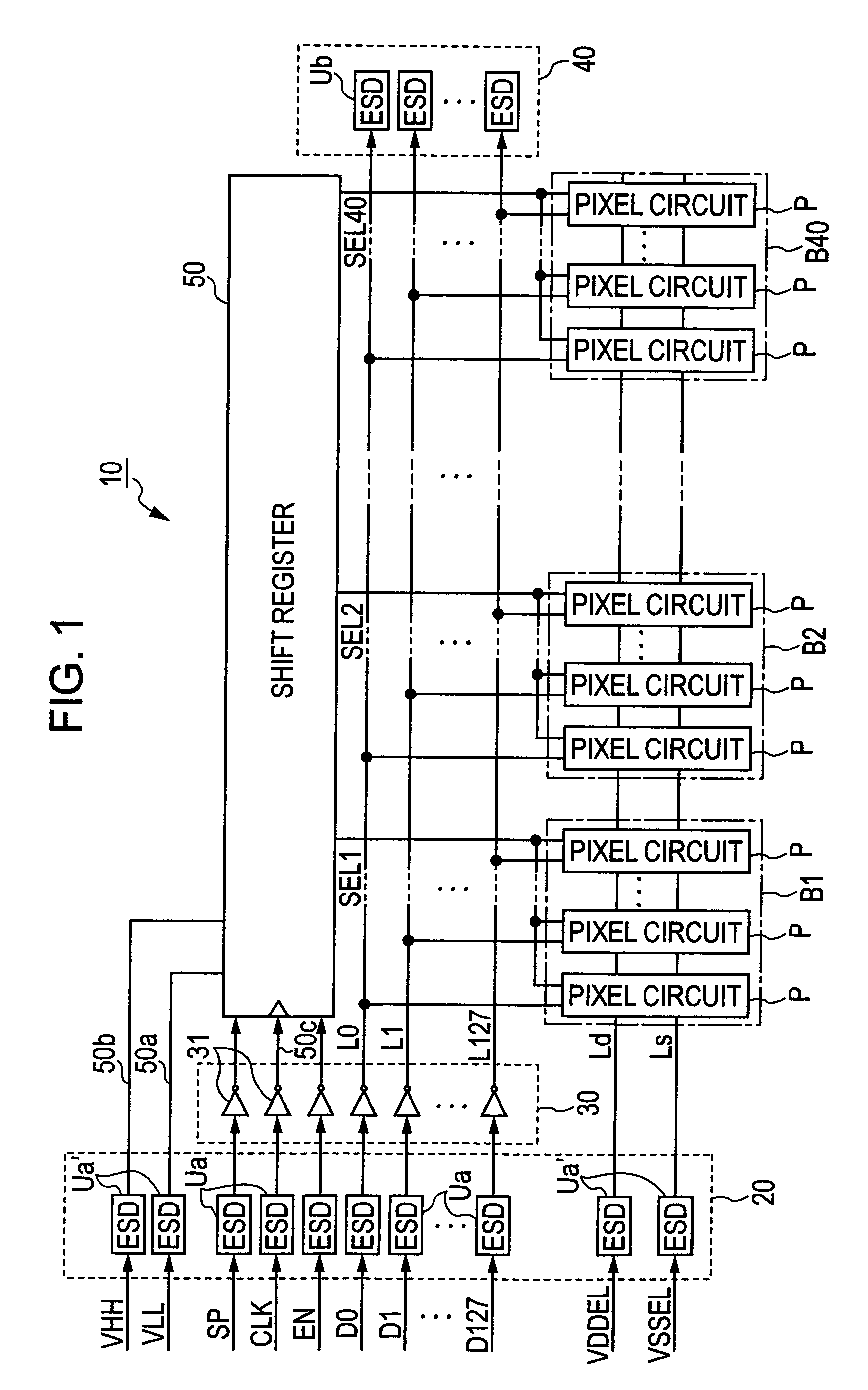

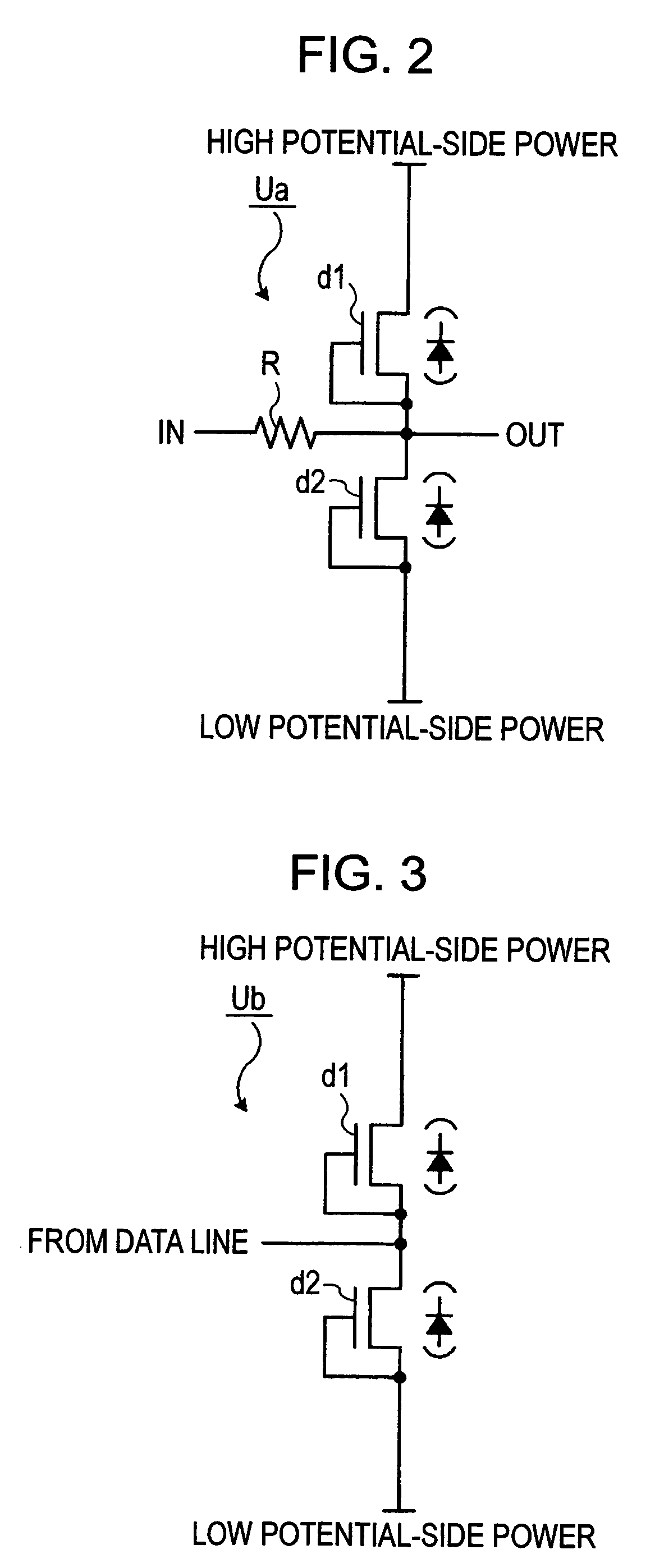

Semiconductor chip for driving light emitting element, light emitting device, and lighting device

InactiveUS20070257901A1Suppression of increase in mounting areaImprove reliabilityElectroluminescent light sourcesSolid-state devicesSemiconductor chipElectric signal

There is provided a light emitting device having a small area for mounting. The light emitting device of the invention includes a light emitting element having an electric signal terminal, that is driven to emit light by an electric signal given to the electric signal terminal from outside, and a semiconductor chip for driving the light emitting element, having a light emitting element drive circuit that is made of a semiconductor, outputs and applies the electric signal to the electric signal terminal. The light emitting elements are mounted on the surface of the semiconductor chip for driving the light emitting element, and a conductive path is provided for mutually connecting a plurality of light emitting elements on the surface of the semiconductor chip for driving the light emitting element.

Owner:PANASONIC CORP

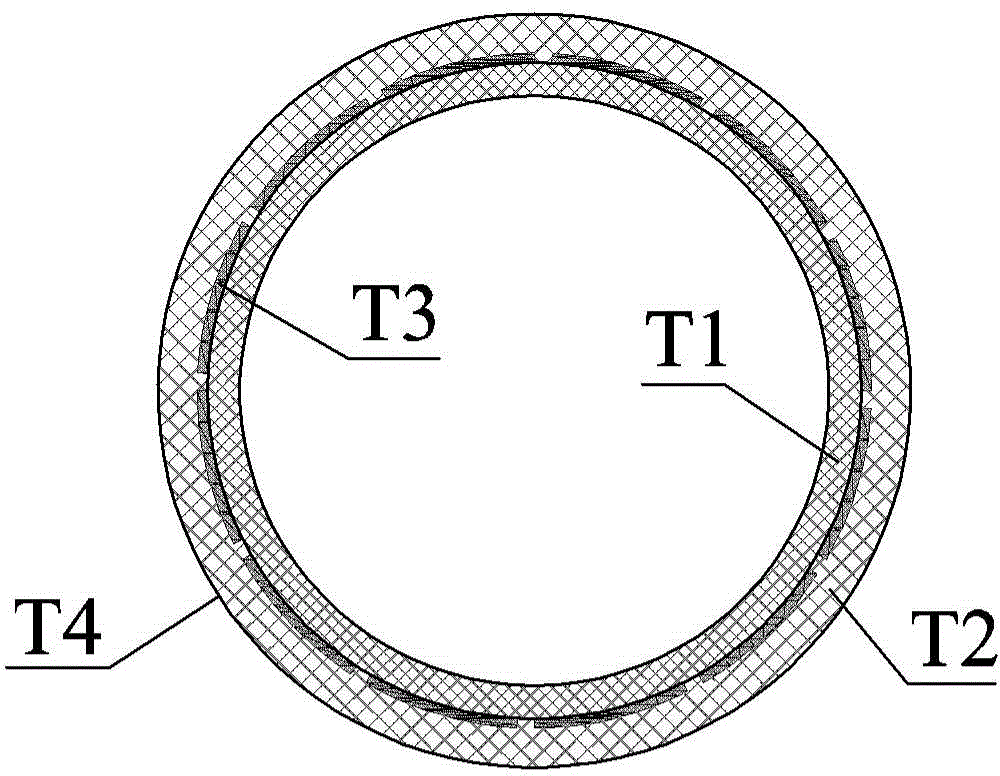

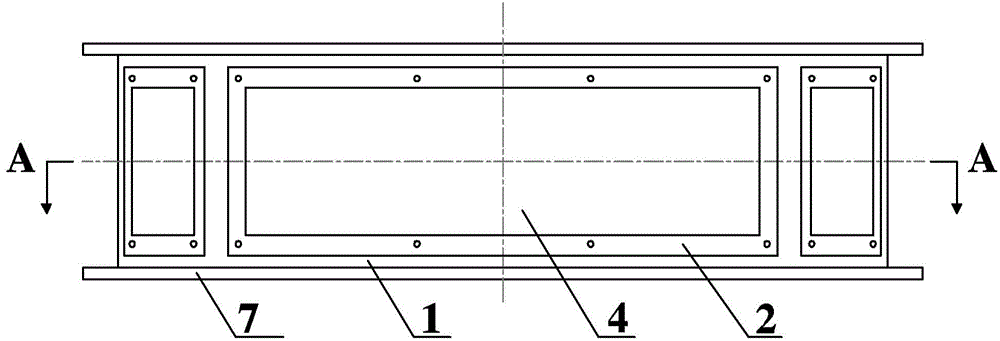

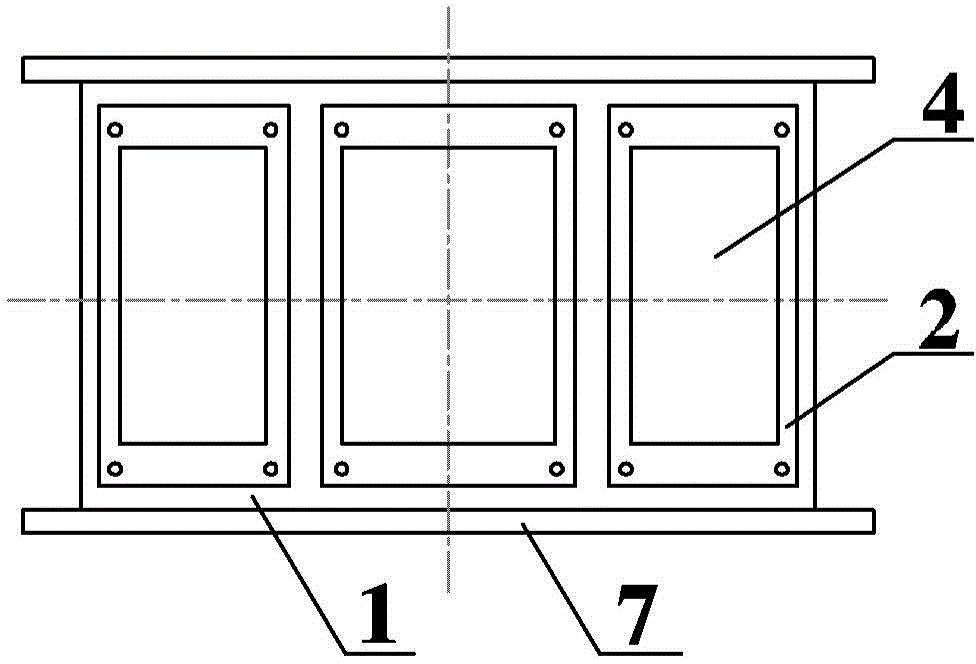

Capacitance tomography sensor

ActiveCN104655692AFlexible installationAvoid direct contactMaterial capacitanceTomographyBiomedical engineering

A capacitance tomography sensor is provided in the invention, wherein a sensor framework is added to the capacitance tomography sensor. A measurement electrode is arranged on an inner wall of the sensor framework to prevent direct contact between the measurement electrode and a to-be-test fluid. A shield electrode group is disposed on an outer side surface of the sensor framework to achieve electrical insulation from the measurement electrodes. By means of the structure, installation of the measurement electrode and the shield electrode group is more flexible.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Ceramic electronic component and manufacturing method thereof

InactiveCN1448968ALow dielectric constantImprove reliabilityMultiple-port networksFixed capacitor dielectricCeramic sinteringMetallurgy

The invention provides a ceramic electronic component having the low dielectric constant of a ceramic sintered body and excellent impedance properties in a GHz zone and capable of obtaining high impedance properties in a wide frequency range, and its manufacturing method. This ceramic electronic component is formed by forming a green compact which includes an electrode therein with a ceramic compound comprising a ceramic raw material, a binder and a spherical or granular combustible material having adhesiveness to the binder. The green compact is fired to form the ceramic sintered compact including the electrode and containing about 35 to 80 volume percent pores. The pores of the ceramic sintered compact are filled with resin or glass.

Owner:MURATA MFG CO LTD

Light-emitting device, image forming apparatus, and display apparatus

ActiveUS7126268B2Suppress brightnessReduce power consumptionDischarge tube luminescnet screensStatic indicating devicesDriving currentLight emitting device

Owner:LUMITEK DISPLAY TECH LTD

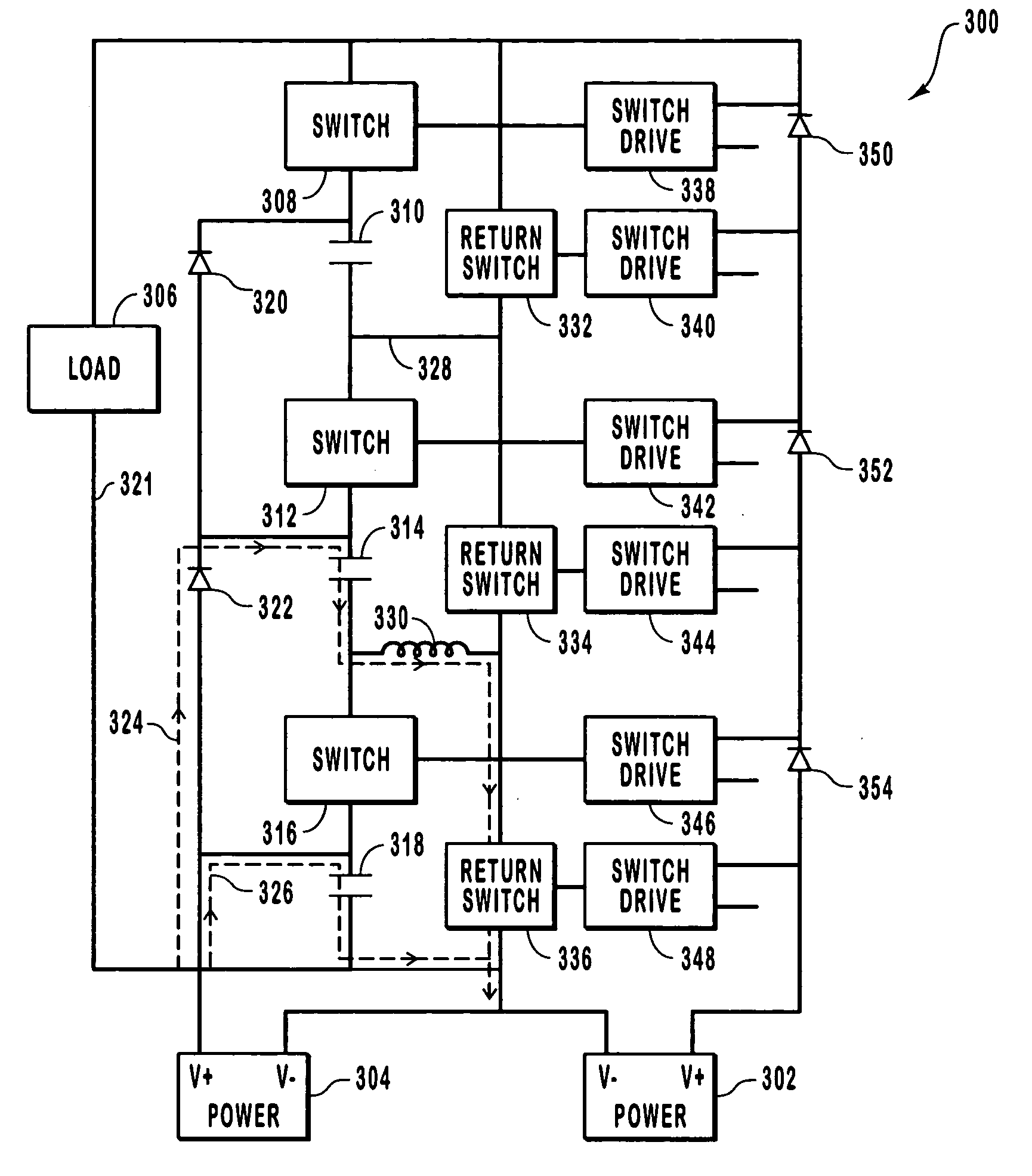

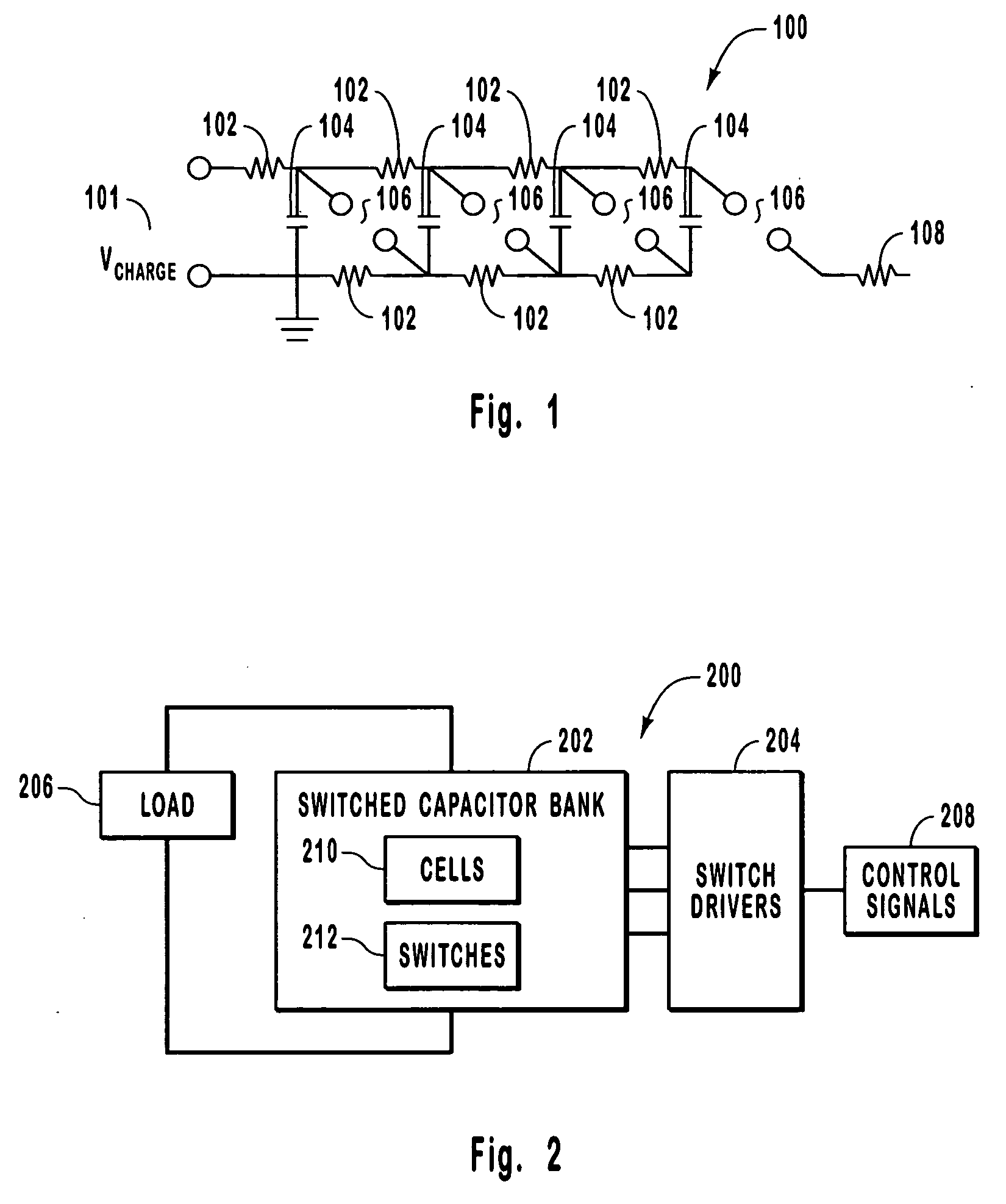

High voltage pulsed power supply using solid state switches

ActiveUS20050248216A1Reduce stray capacitanceShortened fall timeApparatus without intermediate ac conversionPulse generation by energy-accumulating elementCapacitanceBalancing network

Systems and methods for generating a high voltage pulse. A series of voltage cells are connected such that charging capacitors can be charged in parallel and discharged in series. Each cell includes a main switch and a return switch. When the main switches are turned on, the capacitors in the cells are in series and discharge. When the main switches are turned off and the return switches are turned on, the capacitors charge in parallel. One or more of the cells can be inactive without preventing a pulse from being generated. The amplitude, duration, rise time, and fall time can be controlled with the voltage cells. Each voltage cell also includes a balance network to match the stray capacitance seen by each voltage cell.

Owner:STANGENES IND INC

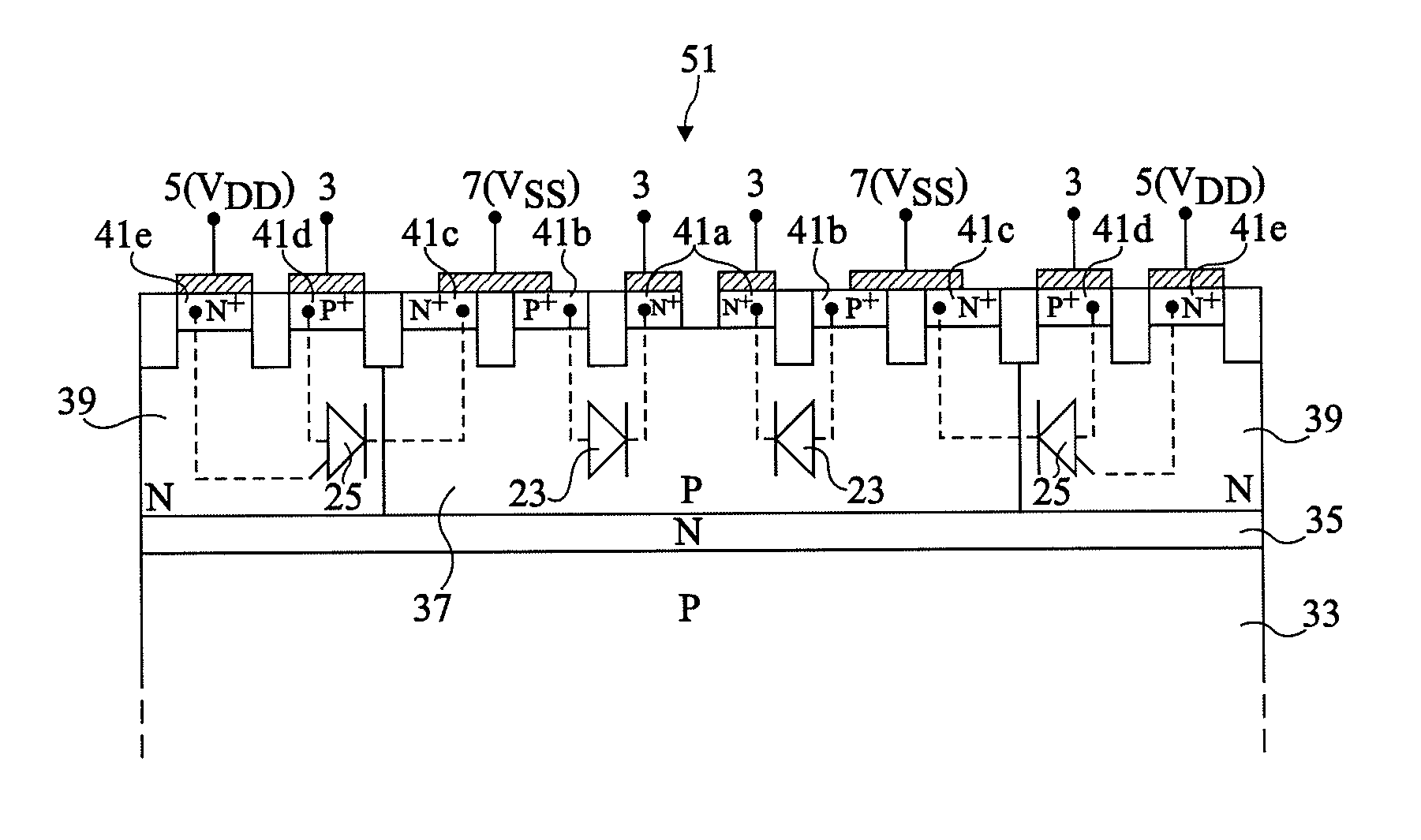

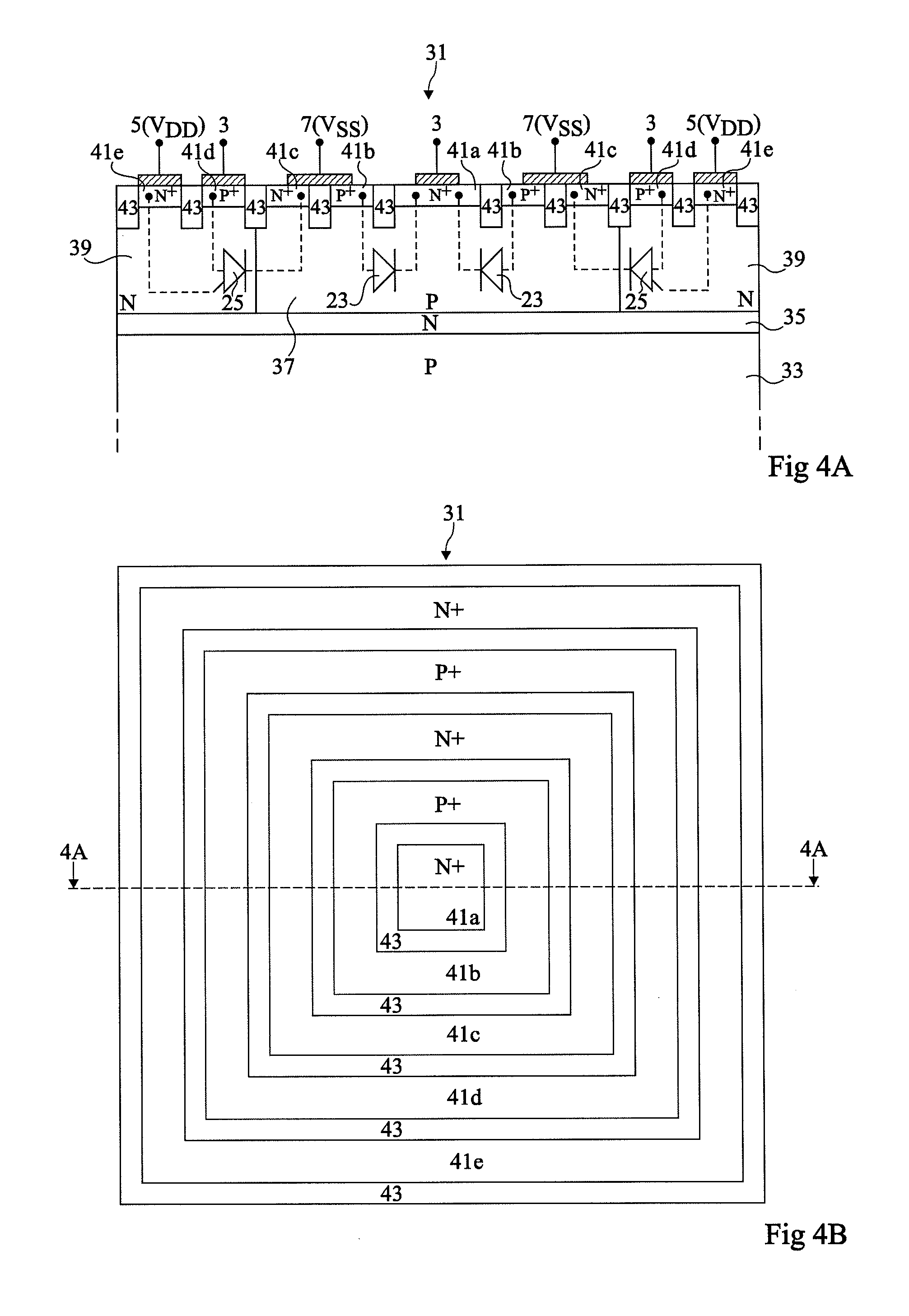

Structure for protecting an integrated circuit against electrostatic discharges

InactiveUS20110042747A1Overcome disadvantagesReduce stray capacitanceTransistorSemiconductor/solid-state device detailsOvervoltageElectrostatic discharge

A structure for protecting an integrated circuit against electrostatic discharges, including a device for removing overvoltages between first and second power supply rails; and a protection cell connected to a pad of the circuit including a diode having an electrode, connected to a region of a first conductivity type, connected to the second power supply rail and having an electrode, connected to a region of a second conductivity type, connected to the pad and, in parallel with the diode, a thyristor having an electrode, connected to a region of the first conductivity type, connected to the pad and having a gate, connected to a region of the second conductivity type, connected to the first rail, the first and second conductivity types being such that, in normal operation, when the circuit is powered, the diode is non-conductive.

Owner:STMICROELECTRONICS SRL

Micromechanical component and corresponding production method

ActiveUS20100164023A1Simple and reliable processCavityFluid pressure measurement by electric/magnetic elementsSemiconductor/solid-state device manufacturingIonMonocrystalline silicon

A micromechanical component having a conductive substrate, a first conductive layer provided above the substrate and that forms, above a cavity provided in the substrate, an elastically deflectable diaphragm region of monocrystalline silicon and an adjacent peripheral region, a circuit trace level provided above the first conductive layer in a manner that is electrically insulated from the first conductive layer, the circuit trace level having above the diaphragm region a first electrode region and having above the peripheral region a first connection region electrically connected to the same, and a second conductive layer that is provided above the circuit trace level, the second conductive layer having above the diaphragm region a second electrode region that is electrically insulated from the first electrode region, and having above the peripheral region a second connection region electrically insulated from the second electrode region and electrically connected to the first connection region. Also provided is a suitable production method.

Owner:ROBERT BOSCH GMBH

Liquid crystal display and method of manufacturing the same

A liquid crystal display capable of reducing the stray capacitance of a non-display region and a method of manufacturing the same. The liquid crystal display includes a first substrate, gate lines and data lines intersecting each other on the first substrate to define pixels, a second substrate arranged opposite to the first substrate, a common electrode formed in a display area of the second substrate in which an image is displayed, and a floating electrode formed in a non-display region of the second substrate in which no image is displayed.

Owner:SAMSUNG DISPLAY CO LTD

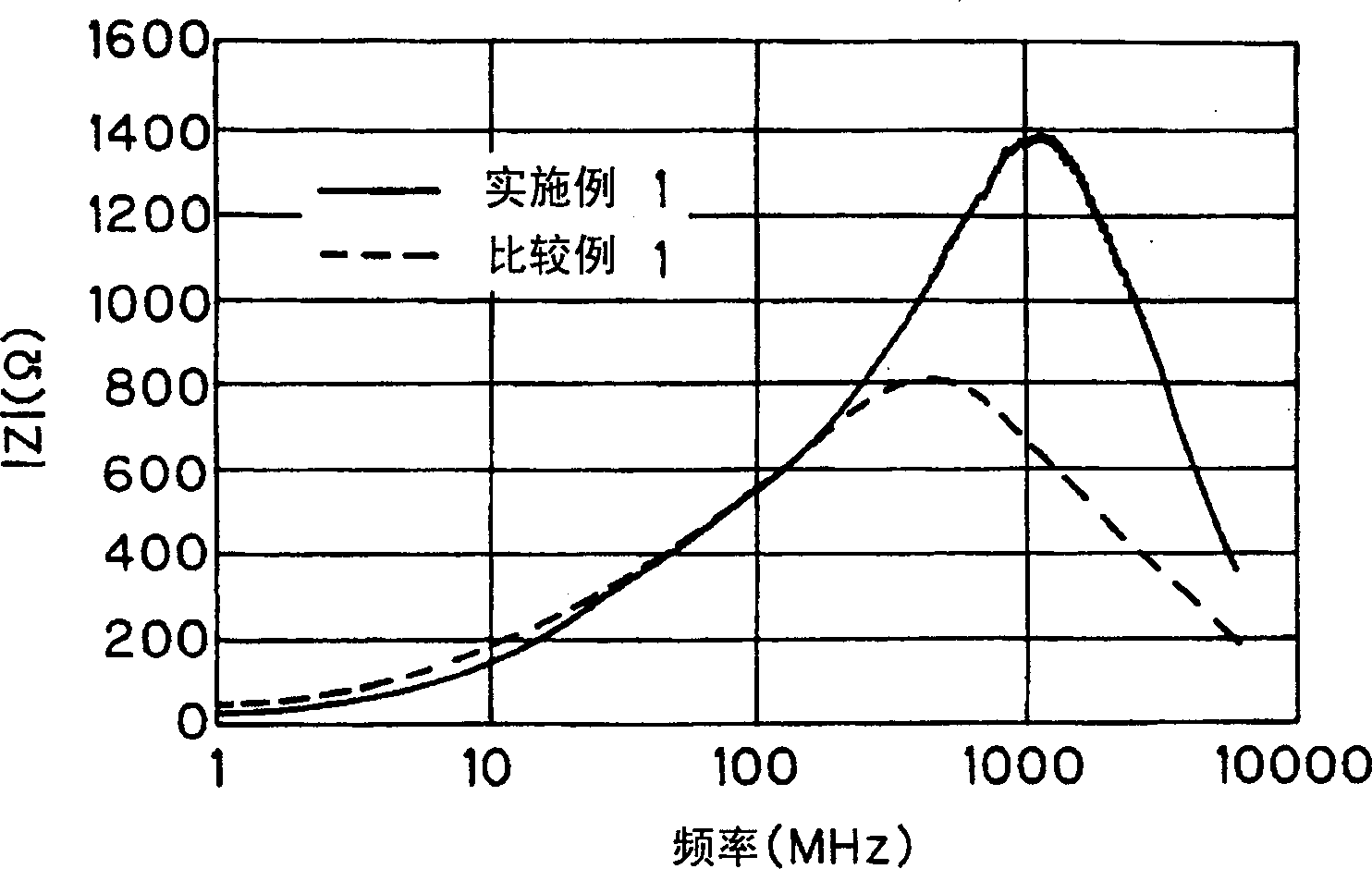

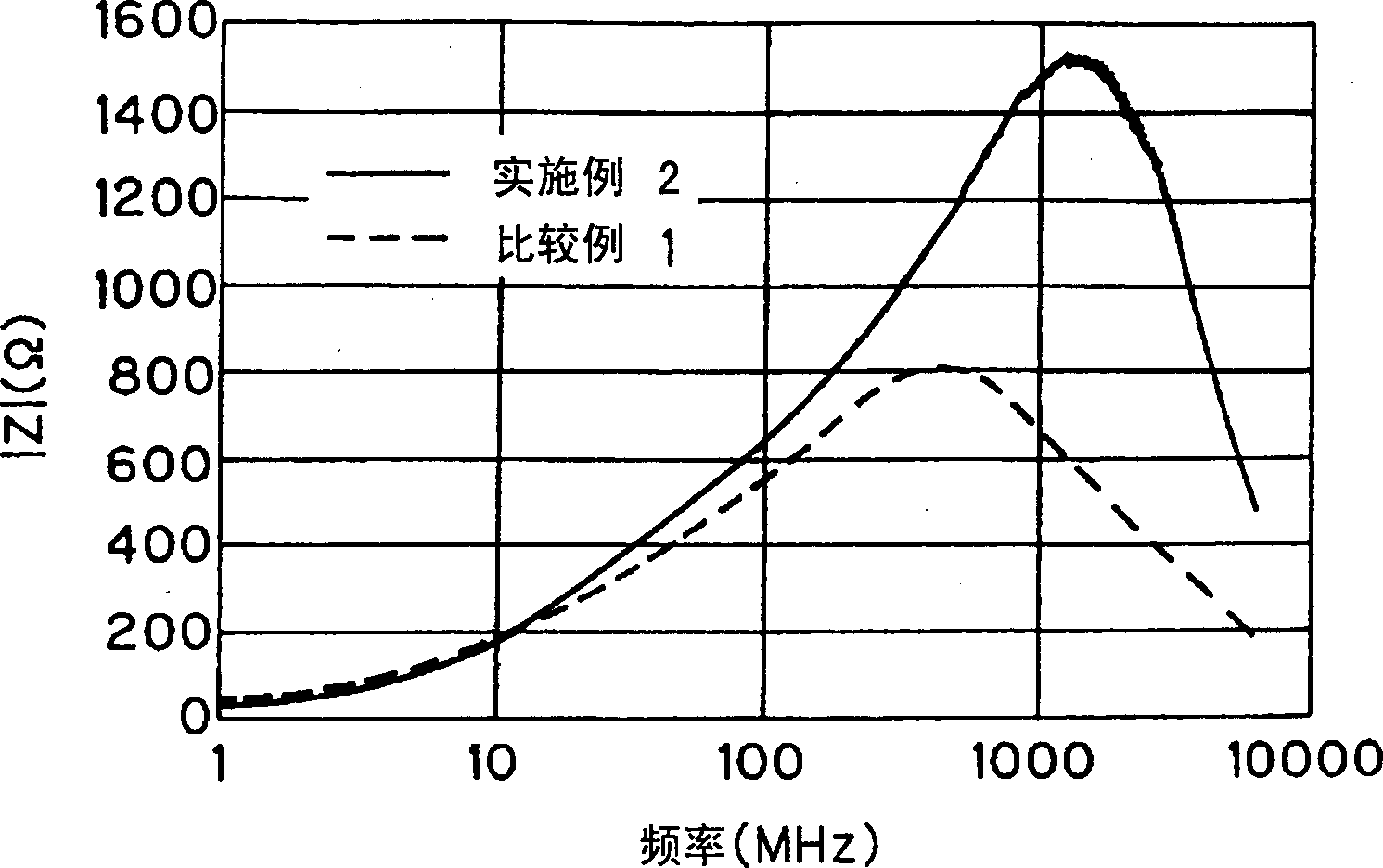

Noise filter mounting structure

ActiveUS20060274472A1Improving impedanceExcellent noise-reducing characteristicMultiple-port networksEmergency protective arrangements for limiting excess voltage/currentParasitic capacitanceElectrical impedance

A noise filter includes a capacitor having a hot side input terminal, a hot side output terminal, a ground side input terminal, and a ground side output terminal. A circuit board includes a hot side input electrode connected to the hot side input terminal, a hot side output electrode connected to the hot side output terminal, a ground side input electrode connected to the ground side input terminal, and a ground side output electrode connected to the ground side output terminal. The impedance of the ground side input terminal seen from the ground side output electrode is larger than both the impedance of the ground side output terminal seen from the ground side output electrode and the impedance of the hot side output terminal seen from the ground side output electrode. For this purpose, a stray capacitance formed between the ground side input electrode and the ground side output electrode is reduced by increasing a gap therebetween. Accordingly, excellent noise-reducing characteristics are provided.

Owner:MURATA MFG CO LTD

Brick layout and stackup for a touch screen

ActiveUS8576193B2Reduce manufacturing costMade thinnerElectronic switchingInput/output processes for data processingSensor arrayBrick

A touch sensor panel is disclosed having an array of co-planar single-layer touch sensors fabricated on a single side of a substrate. The sense (or drive) lines can be fabricated in a single strip as columnar or zig-zag patterns in a first orientation, and the drive (or sense) lines can be fabricated as rows of polygonal (e.g. brick-shaped or pentagonal) conductive areas in a second orientation. Each sense (or drive) line in the first orientation can be coupled to a separate metal trace in the border area of the touch sensor panel, and each polygonal area in the second orientation can also be coupled to a metal trace in the border area of the touch sensor panel. The metal traces can allow both the row and column lines to be routed to the same edge of the substrate for flex circuit attachment.

Owner:APPLE INC

Capacitive array

ActiveUS20060270145A1Average distributionImprove distributionTransistorMultiple fixed capacitorsCapacitanceEngineering

Owner:STMICROELECTRONICS SRL

High voltage pulsed power supply using solid state switches with droop compensation

ActiveUS7554221B2Reduce stray capacitanceShortened fall timeElectronic switchingApparatus without intermediate ac conversionCapacitanceBalancing network

Systems and methods for generating a high voltage pulse. A series of voltage cells are connected such that charging capacitors can be charged in parallel and discharged in series. Each cell includes a main switch and a return switch. When the main switches are turned on, the capacitors in the cells are in series and discharge. When the main switches are turned off and the return switches are turned on, the capacitors charge in parallel. One or more of the cells can be inactive without preventing a pulse from being generated. The amplitude, duration, rise time, and fall time can be controlled with the voltage cells. Each voltage cell may also includes a balance network to match the stray capacitance seen by each voltage cell. Droop compensation is also enabled.

Owner:STANGENES IND INC

Semiconductor device

ActiveUS20140048797A1Increase manufacture rangeIncrease channel widthTransistorSolid-state devicesContact holeSemiconductor

There is provided a semiconductor device including a first conductive layer, an insulating layer, a second conductive layer, a channel layer, a passivation layer and a third conductive layer. The insulating layer covers the first conductive layer. The second conductive layer is formed on the insulating layer and has an inner opening. The channel layer is formed on the inner opening of the second conductive layer to fully cover the inner opening. The passivation layer is formed upon the channel layer to cover the channel layer and has a contact hole inside the inner opening of the second conductive layer. The third conductive layer is formed in the contact hole.

Owner:HANNSTAR DISPLAY CORPORATION

High voltage pulsed power supply using solid state switches with droop compensation

ActiveUS20070146092A1Accurate compensationEffective isolationTransmission control/equlisationApparatus without intermediate ac conversionCapacitanceBalancing network

Systems and methods for generating a high voltage pulse. A series of voltage cells are connected such that charging capacitors can be charged in parallel and discharged in series. Each cell includes a main switch and a return switch. When the main switches are turned on, the capacitors in the cells are in series and discharge. When the main switches are turned off and the return switches are turned on, the capacitors charge in parallel. One or more of the cells can be inactive without preventing a pulse from being generated. The amplitude, duration, rise time, and fall time can be controlled with the voltage cells. Each voltage cell may also includes a balance network to match the stray capacitance seen by each voltage cell. Droop compensation is also enabled.

Owner:STANGENES IND INC

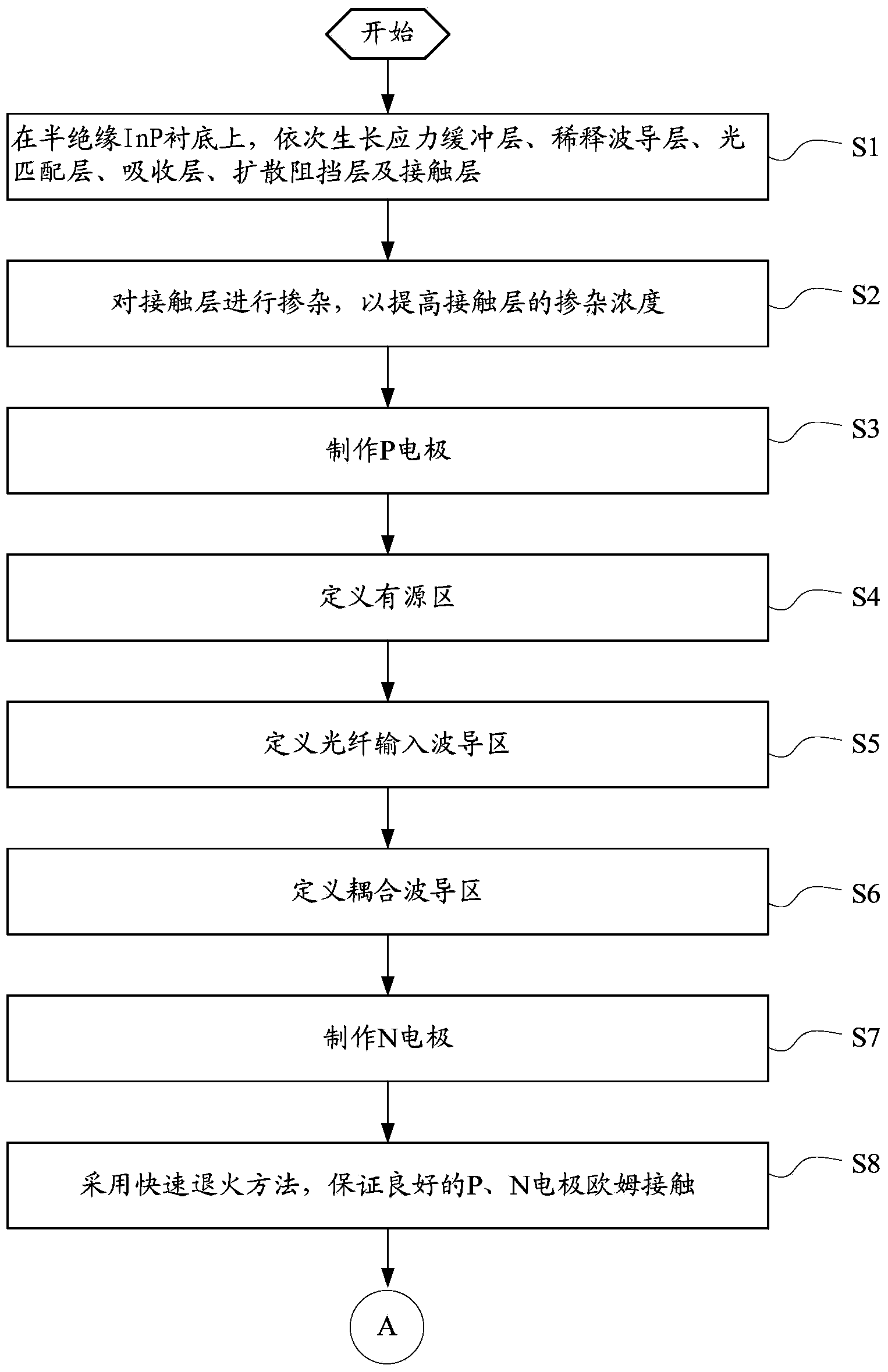

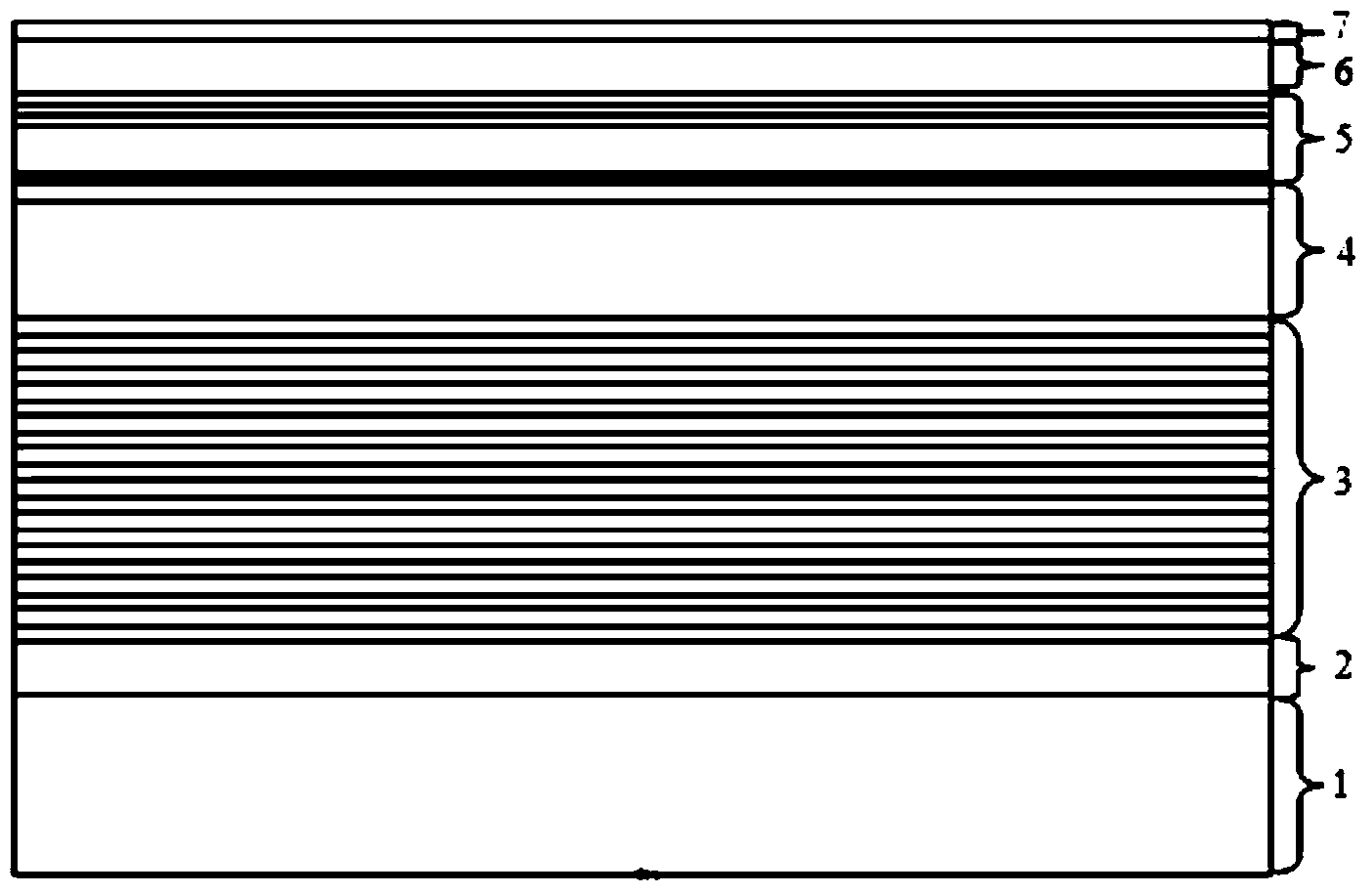

Manufacturing method of evanescent wave coupling high-speed high-power photoelectric detector

ActiveCN103646997AIncrease contactReduce the difficulty of cleavage processFinal product manufactureSemiconductor devicesOhmic contactCoplanar waveguide

The invention comprises a manufacturing method of an evanescent wave coupling high-speed high-power photoelectric detector. The method comprises a, sequentially growing an InP stress buffering layer, ten cycle-alternating InP / InGaAsP diluted waveguide layers, two InGaAsP light matching layers, three InGaAs absorbing layers, an InP diffusion barrier layer and an InGaAs contact layer; b, doping the InGaAs contact layer through a Zn3As2 source; c, fabricating a P electrode; d, defining an active area; e, defining an optical fiber input waveguide area; f, defining a coupling waveguide area; g, fabricating an N electrode; h, guaranteeing good ohmic contact between the P electrode and the N electrode through a rapid annealing method; i, planarizing the whole table board through benzocylobutene materials to the same plane with the P electrode; j, fabricating coplanar waveguide electrodes; k, thinning epitaxial wafers to 110 mu m and cleaving the epitaxial wafers to strip array chips; l, coating film on the waveguide end surfaces of the strip array chips; m, cleaving the array chips into unit chips.

Owner:THE 44TH INST OF CHINA ELECTRONICS TECH GROUP CORP

Semiconductor storage device

ActiveUS7545663B2Increase speedReduce stray capacitanceSemiconductor/solid-state device detailsSolid-state devicesComputer architectureSemiconductor storage devices

Data transfer speed is increased in a semiconductor storage device in which the core unit and the interface unit are separate chips. The device has a plurality of core chips through in which a memory cell is formed, and an interface chip in which a peripheral circuit is formed for the memory cell. The plurality of core chips through have latch circuit units through for temporarily storing data to be outputted by the memory cell, and latch circuit units through for temporarily storing data to be inputted to the memory cell, respectively, and these latch circuit units through and latch circuit units through are connected in a cascade to the interface chip. Since the plurality of latch circuit units connected in a cascade can thereby perform a pipeline operation, it becomes possible to achieve high-speed data transfer.

Owner:HIROSHIMA UNIVERSITY +1

Coil component

ActiveUS7369028B2Reduce stray capacitanceIncrease inductanceUnwanted magnetic/electric effect reduction/preventionCoilsCapacitanceOuter coil

A coil component includes a first coil block and a second coil block that are sandwiched between magnetic substrates so as to form a chip body, and external electrodes that are attached to the chip body. The first coil block includes a coil body and an insulating body. The coil body includes an outer coil portion and an inner coil portion. The outer coil portion includes a first pattern group and a second pattern group, which are connected helically vertically in an alternating fashion. The inner coil portion includes a first spiral pattern and a second spiral pattern, which are connected to each other in series. In other words, low stray capacitance is achieved by the outer coil portion, while high inductance is achieved by the inner coil portion.

Owner:MURATA MFG CO LTD

High voltage pulsed power supply using solid state switches with voltage cell isolation

ActiveUS7550876B2Reduce stray capacitanceShortened fall timeApparatus without intermediate ac conversionPulse generation by energy-accumulating elementBalancing networkCells isolation

Systems and methods for generating a high voltage pulse. A series of voltage cells are connected such that charging capacitors can be charged in parallel and discharged in series. Each cell includes a main switch and a return switch. When the main switches are turned on, the capacitors in the cells are in series and discharge. When the main switches are turned off and the return switches are turned on, the capacitors charge in parallel. One or more of the cells can be inactive without preventing a pulse from being generated. The amplitude, duration, rise time, and fall time can be controlled with the voltage cells. Each voltage cell may also include a balance network to match the stray capacitance seen by each voltage cell. Droop compensation is also enabled. Isolation diodes ensure that a discharge current can bypass inoperable voltage cells.

Owner:STANGENES IND INC

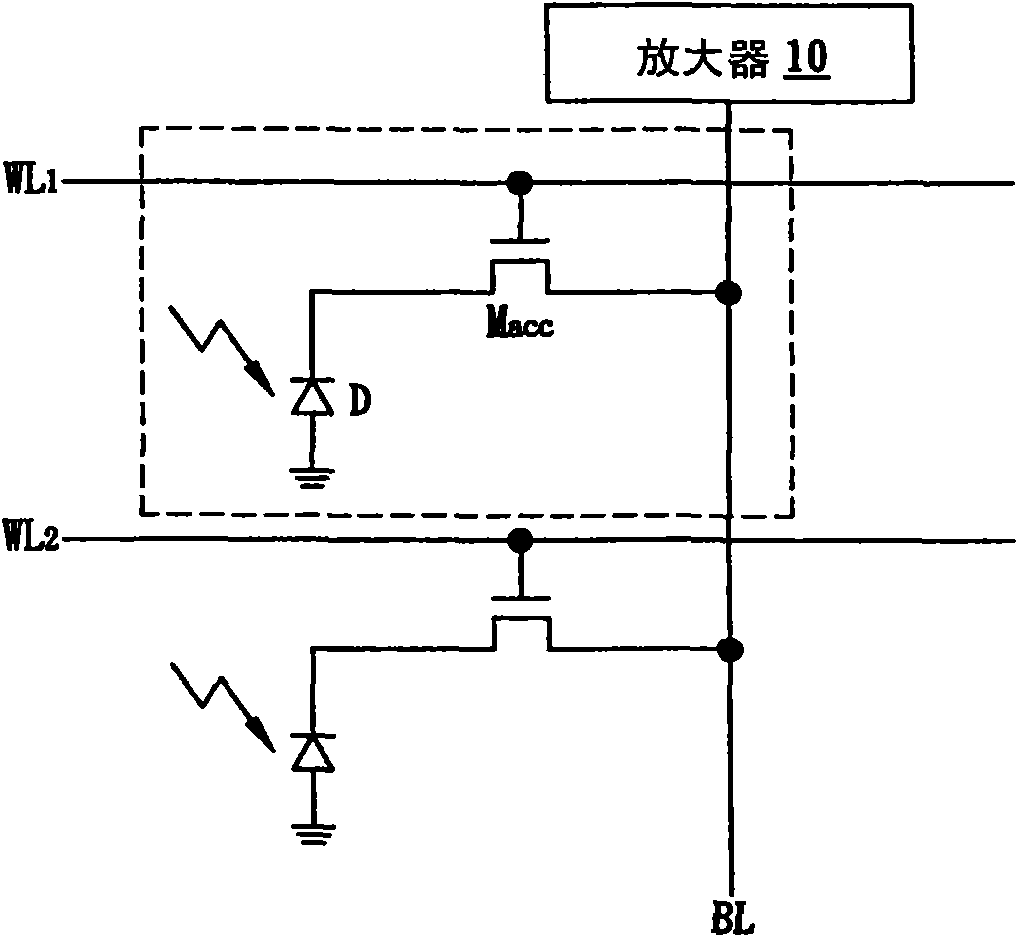

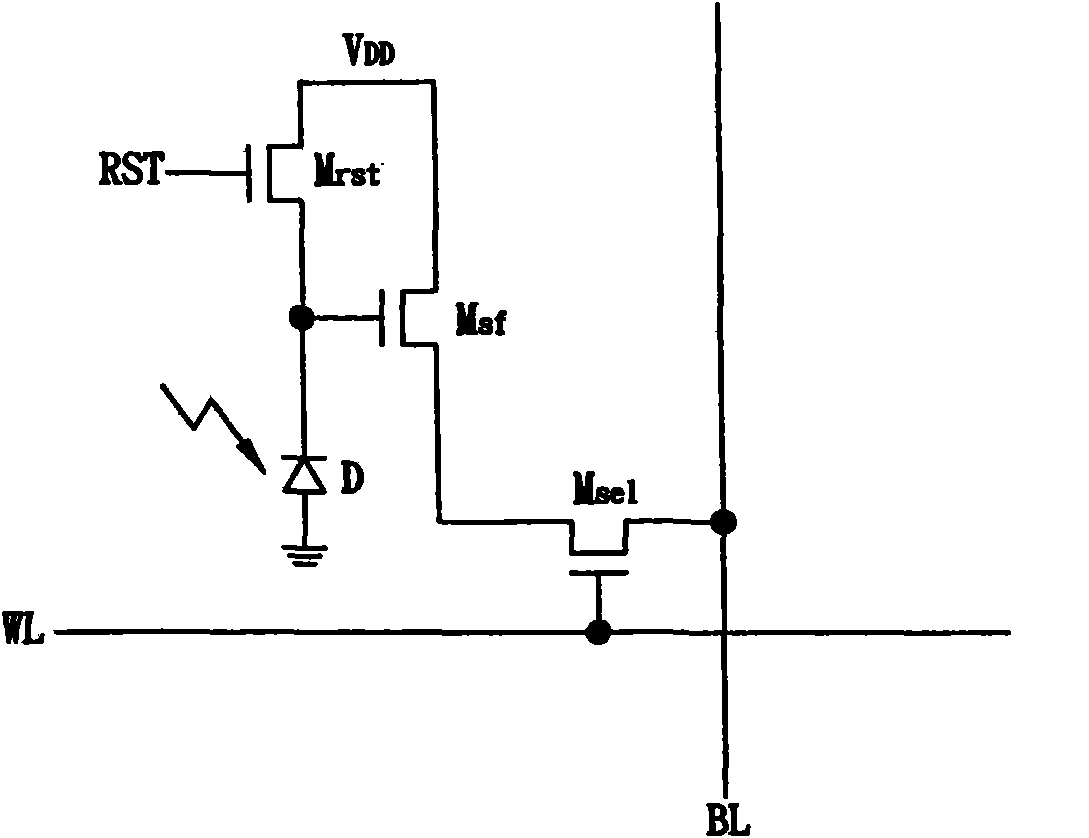

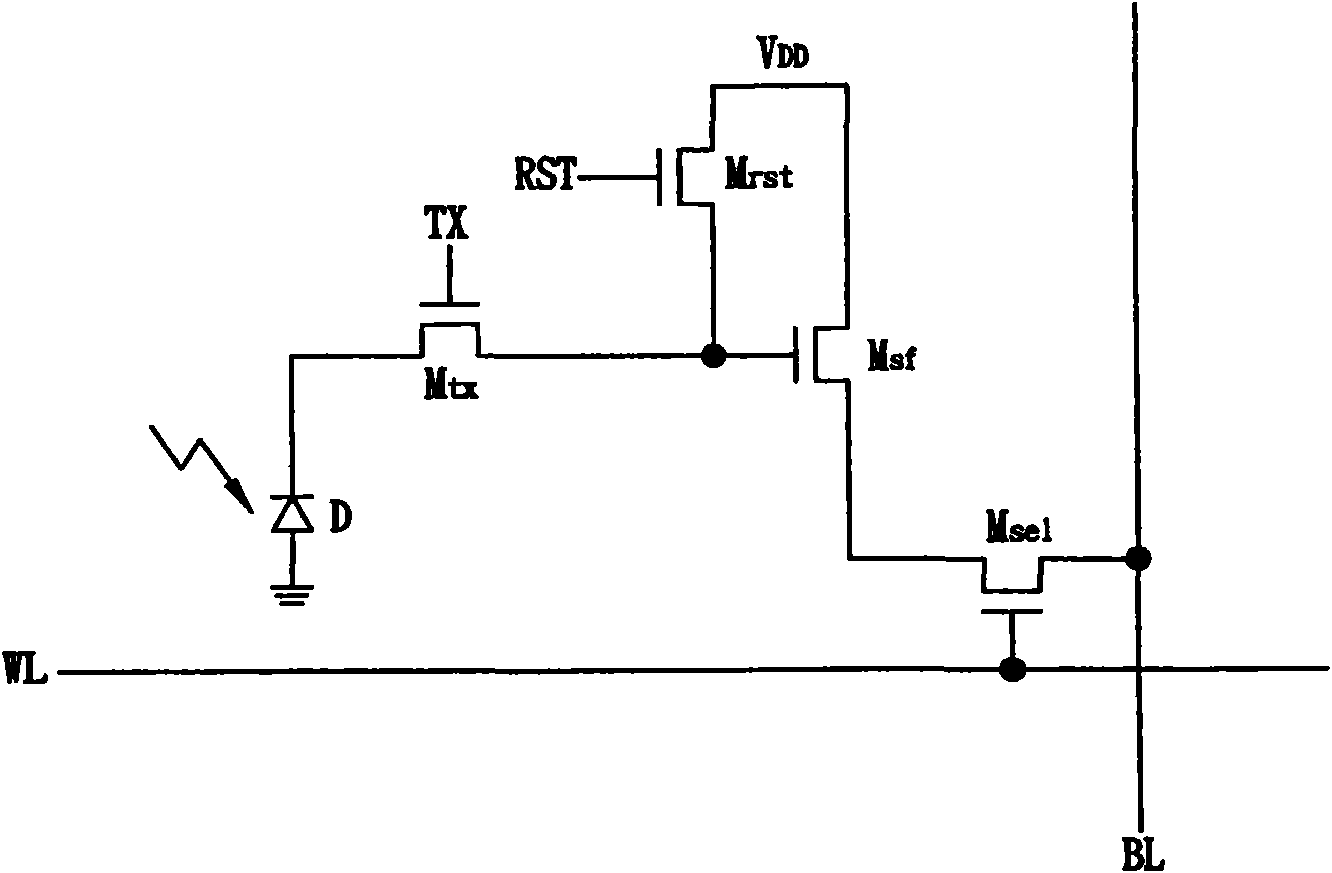

Image sensor and high-conversion-gain and low-noise pixel readout circuit

InactiveCN101902583AWithout sacrificing pixel countReduce stray capacitanceTelevision system detailsTelevision system scanning detailsCapacitanceLow noise

The invention provides a pixel circuit of a CMOS (complementary metal oxide semiconductor) image sensor, which is characterized by using at least two transferring transistors for respectively transferring the accumulated optical signals of corresponding photodetectors to a first node, using a resetting transistor for resetting the voltage of the first node as the preset resetting voltage of a second node, and using a source follower for buffering the integrated optical signals. In the embodiment of the invention, a capacitor is connected between the first node and the second node, so as to reduce the impact of the effective capacitance comprising the capacitance in the floating diffusion areas and the stray capacitance in the photodetectors and transferring transistors.

Owner:HIMAX IMAGING LIMITED

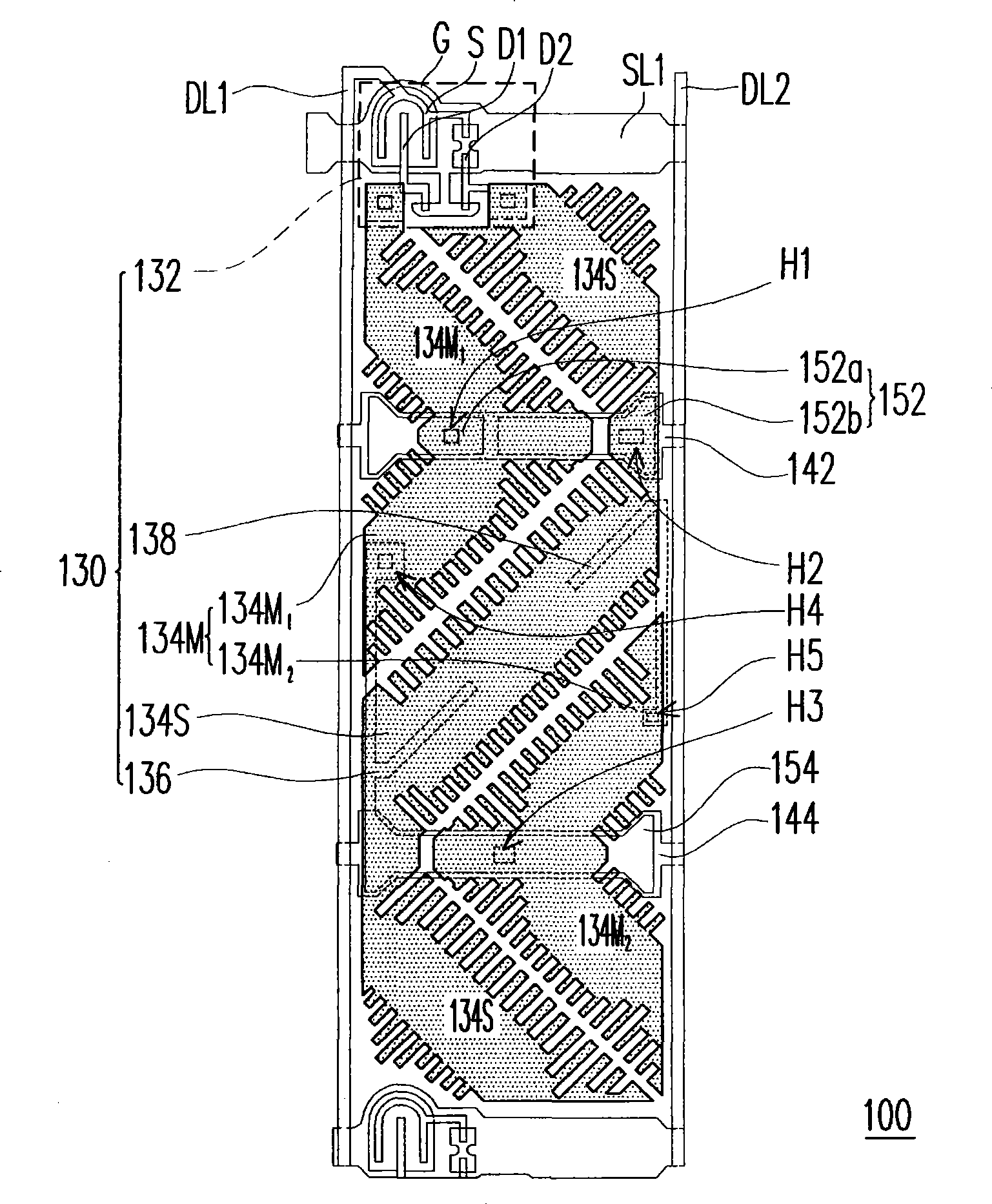

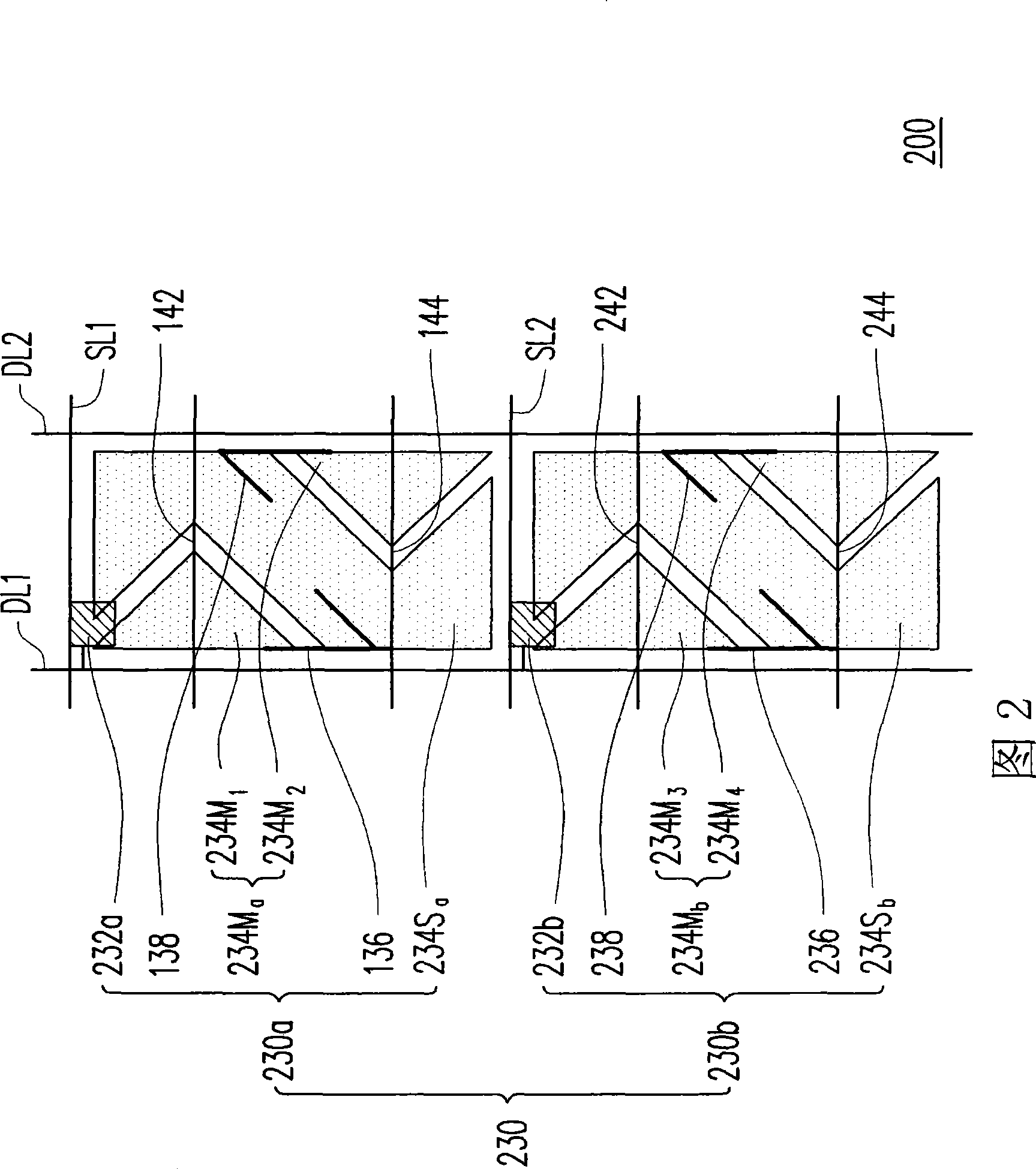

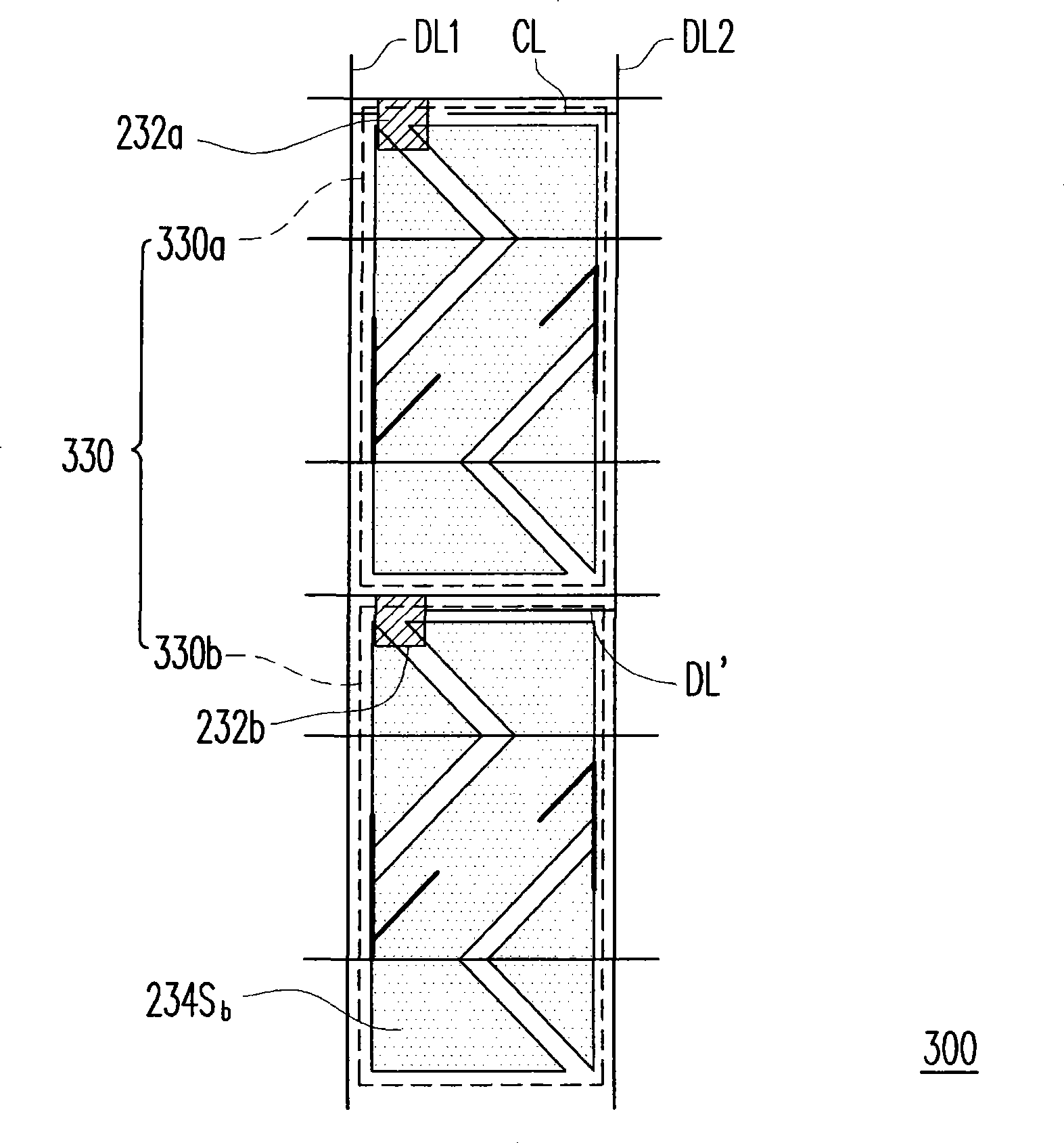

Pixel array of LCD

ActiveCN101387803AImprove crosstalkReduce stray capacitanceNon-linear opticsCapacitanceLiquid-crystal display

The invention discloses a pixel array of liquid crystal display devices, comprising M data lines, N scan lines and a plurality of pixel structures electrically connected with the data lines and the scan lines and arranged in an array, wherein each pixel structure comprises a switch component, at least one main pixel electrode, at least one pixel electrode, a first capacity coupling electrode pattern and a second coupling electrode pattern, the switch component is electrically connected with the first scan line and the first data line, at least one main pixel electrode and at least one pixel electrode are electrically connected with the switch component, the first and the second capacitor coupling electrode patterns are electrically connected with at least one main pixel electrode and are coupled with at least one pixel electrode in a capacitor type, the first capacitor coupling electrode pattern is adjacent to the first data line and the second capacitor coupling electrode pattern is adjacent to the second data line.

Owner:AU OPTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com