High magnetic induction nitrogen-coupled iron-based amorphous nanocrystalline alloy and preparation method thereof

A technology of iron-based amorphous alloys and nanocrystalline alloys, applied in magnetic materials, magnetic objects, electrical components, etc., can solve problems such as uneven distribution of nitrogen elements and difficulty in doping iron-based amorphous alloys with nitrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Preparation of nitrogen-coupled iron-based amorphous alloy strips, the chemical formula is (Fe 90 Zr 7 B 3 ) 99.75 N 0.25 .

[0075] (1) Elemental Fe, Zr, B, and ZrN are uniformly mixed according to the above stoichiometric ratio, and a nitrogen-coupled iron-based alloy ingot with uniform composition is prepared by using an electric arc melting furnace. First evacuate until the air pressure is lower than 2.0×10 -2 Pa, and then filled with argon until the pressure is 0.05MPa for multiple smelting, after smelting, the molten alloy ingot is cooled for 30 minutes to obtain a nitrogen-coupled iron-based alloy ingot with uniform composition.

[0076] (2) The obtained nitrogen-coupled iron-based alloy ingot is ground with a grinding wheel to remove surface impurities, crushed and remelted, and packed into a quartz tube with a nozzle at the bottom. The width of the nozzle is 0.8mm, and the gas pressure in the furnace chamber is adjusted to be low. At the standard atmosphe...

Embodiment 2

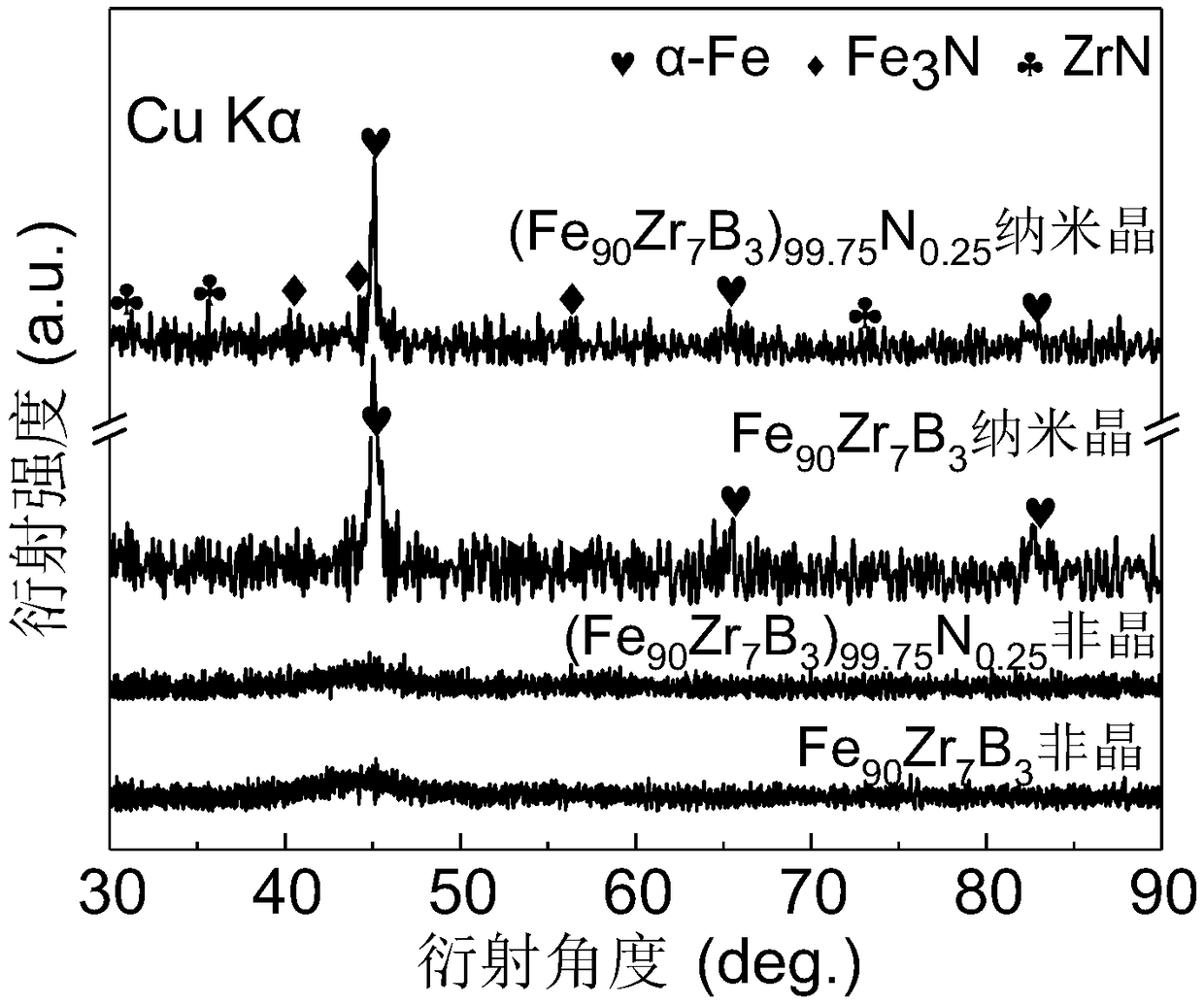

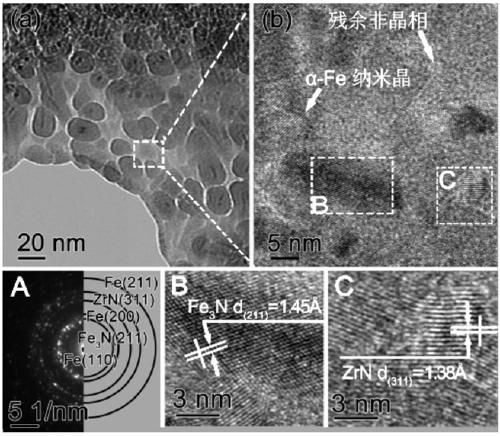

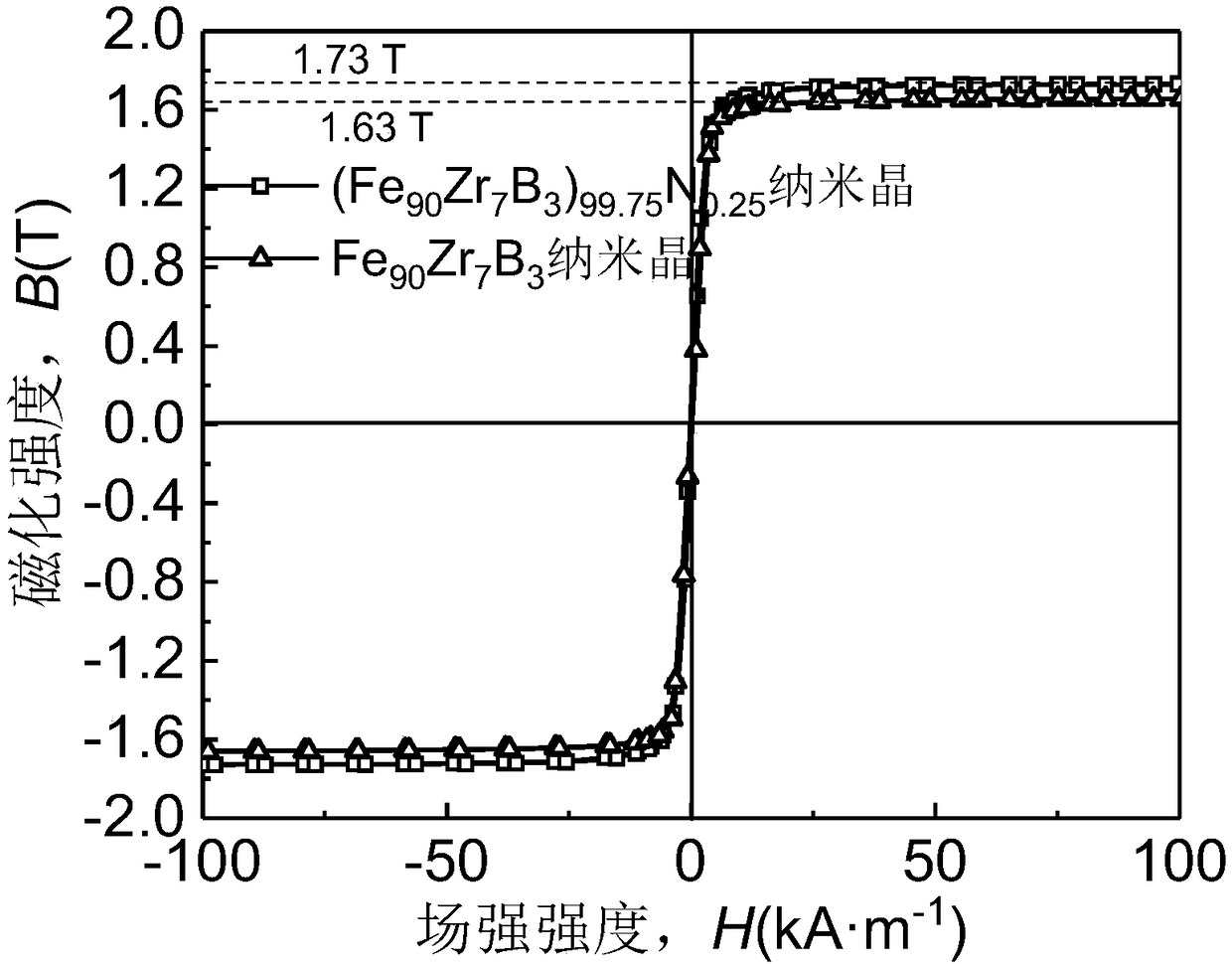

[0081] The nitrogen-coupled iron-based amorphous alloy strip prepared in Example 1 is subjected to high vacuum heat treatment to obtain a high magnetic induction nitrogen-coupled iron-based amorphous nanocrystalline alloy strip, and the chemical molecular formula is (Fe 90 Zr 7 B 3 ) 99.75 N 0.25 .

[0082] The obtained completely amorphous nitrogen-coupled iron-based amorphous alloy strips were placed in a quartz tube and evacuated to 5.0×10 -3 Pa, place the quartz tube in a heat treatment furnace, raise the temperature to 510 °C at a rate of about 2 °C / s, keep it warm for 15 minutes, then heat it up to 630 °C, keep it for 1 hour, then quickly take out the quartz tube and place it in water to quench to room temperature. Then high-vacuum tempering was carried out at 200°C for 90 minutes to obtain a high magnetic induction nitrogen-coupled iron-based amorphous nanocrystalline alloy ribbon.

[0083] The nitrogen content of the obtained high magnetic induction nitrogen-coupl...

Embodiment 3

[0086] Preparation of high magnetic induction nitrogen-coupled iron-based amorphous nanocrystalline alloy strips, the chemical formula is Fe 76.5 Si 12.7 B 8 Cu 1 (Nb 0.75 Mo 0.75 )N 0.3 .

[0087] (1) Put elemental Fe, Si, B, Cu, Nb, Mo, and NbN into the alumina crucible in the induction melting furnace after mixing uniformly according to the above stoichiometric ratio, and evacuate until the air pressure is lower than 2.0×10 -2 Pa, and then filled with argon to a pressure of 0.05MPa for smelting, heat preservation for 25 minutes after melting, and then pour the molten alloy ingot into a copper mold to cool for 30 minutes to obtain a nitrogen-coupled iron-based alloy ingot with uniform composition.

[0088] (2) The obtained nitrogen-coupled iron-based alloy ingot is ground with a grinding wheel to remove surface impurities, crushed and remelted, and then packed into a quartz tube with a nozzle at the bottom. The width of the nozzle is 0.8mm, and the furnace chamber pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com