Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1030 results about "Iron based alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Iron-based alloys contain iron as the base metal. This category includes carbon steels, alloy steels, stainless steels, cast iron, maraging steel, and other specialty iron-based alloys with varying properties.

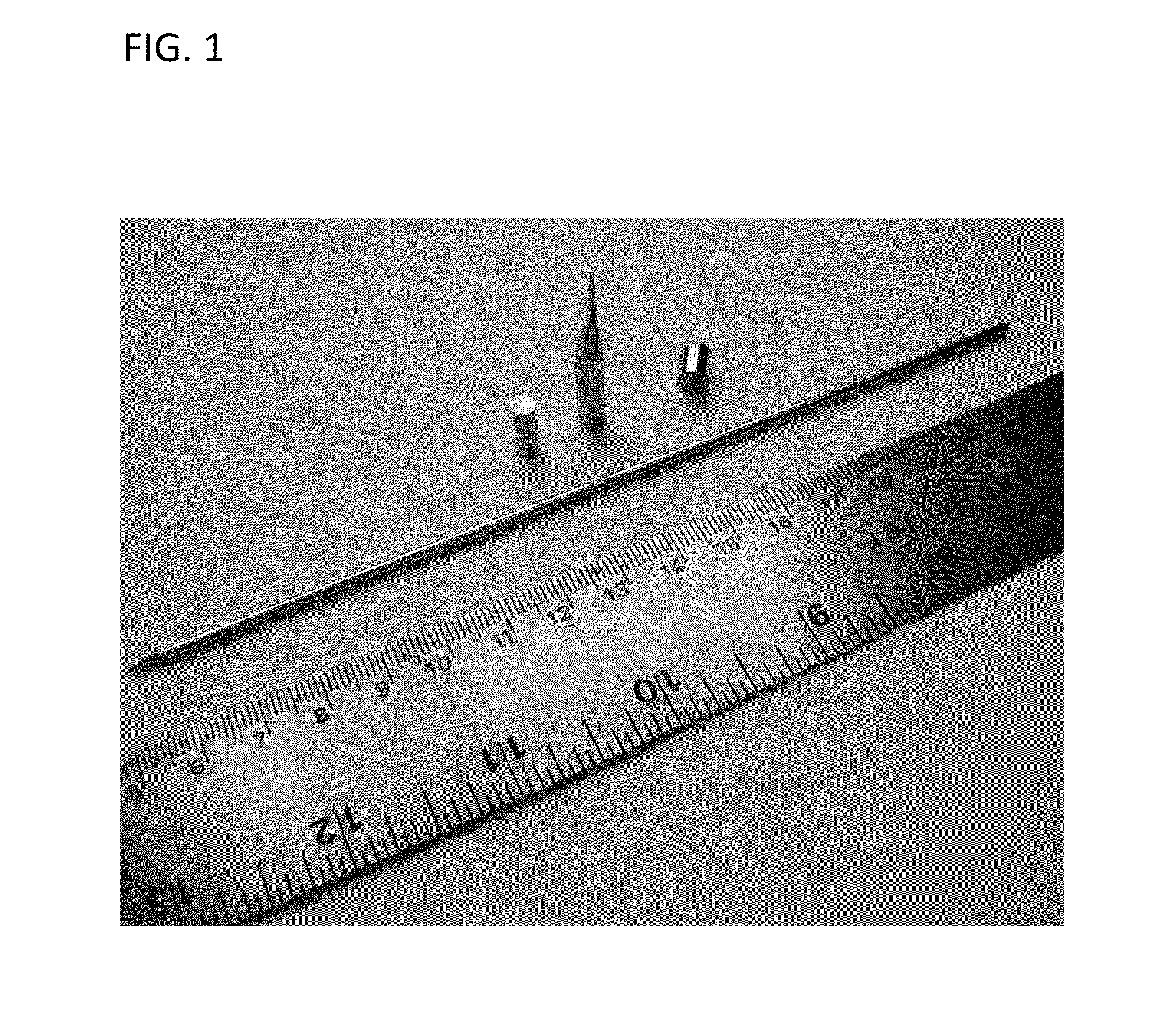

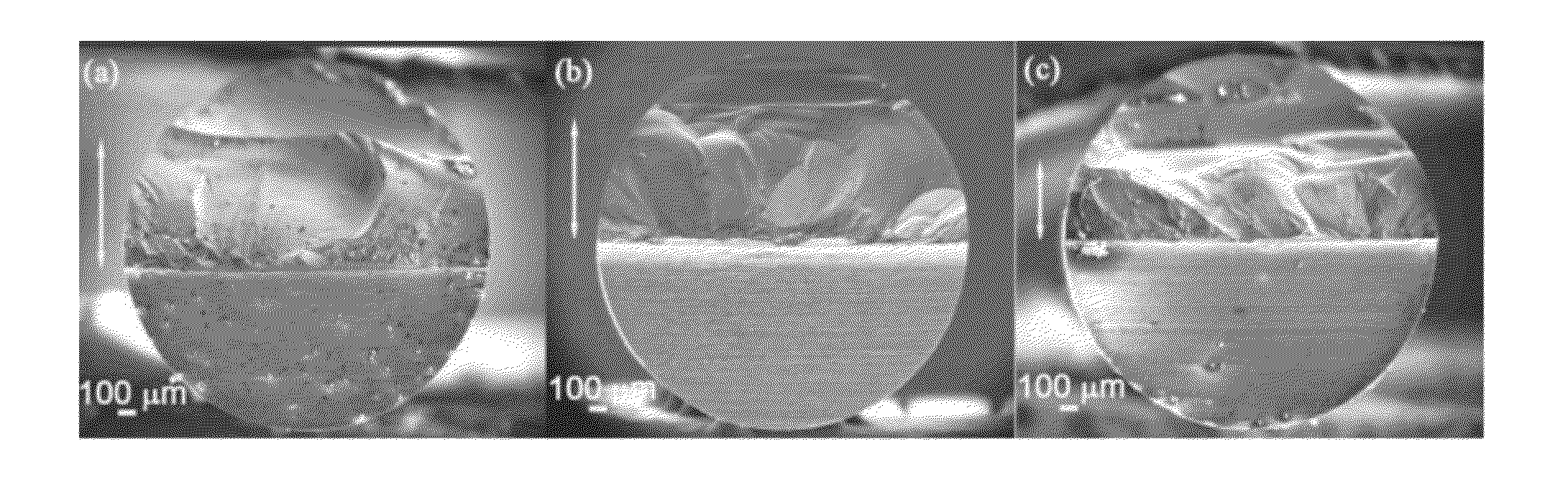

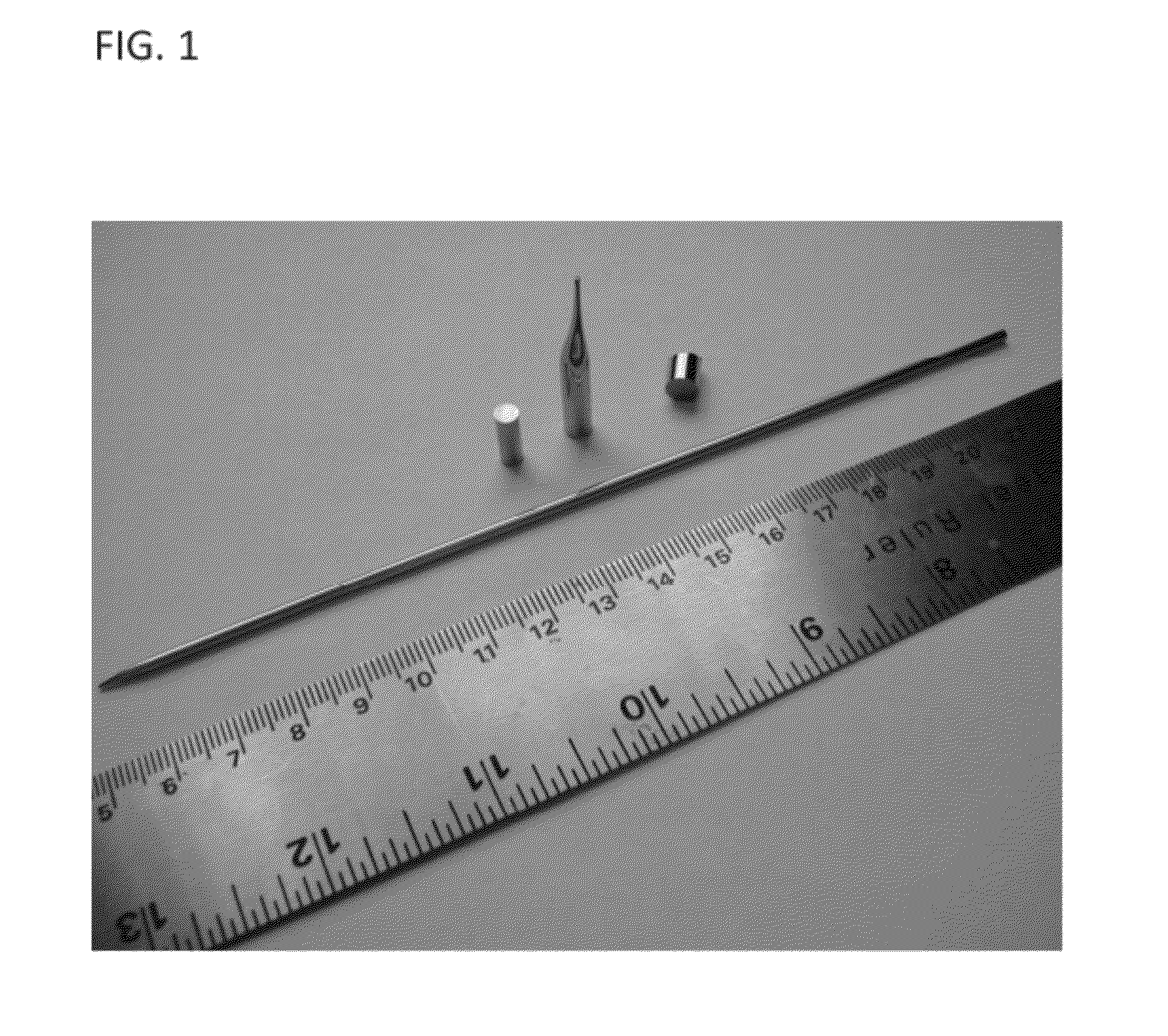

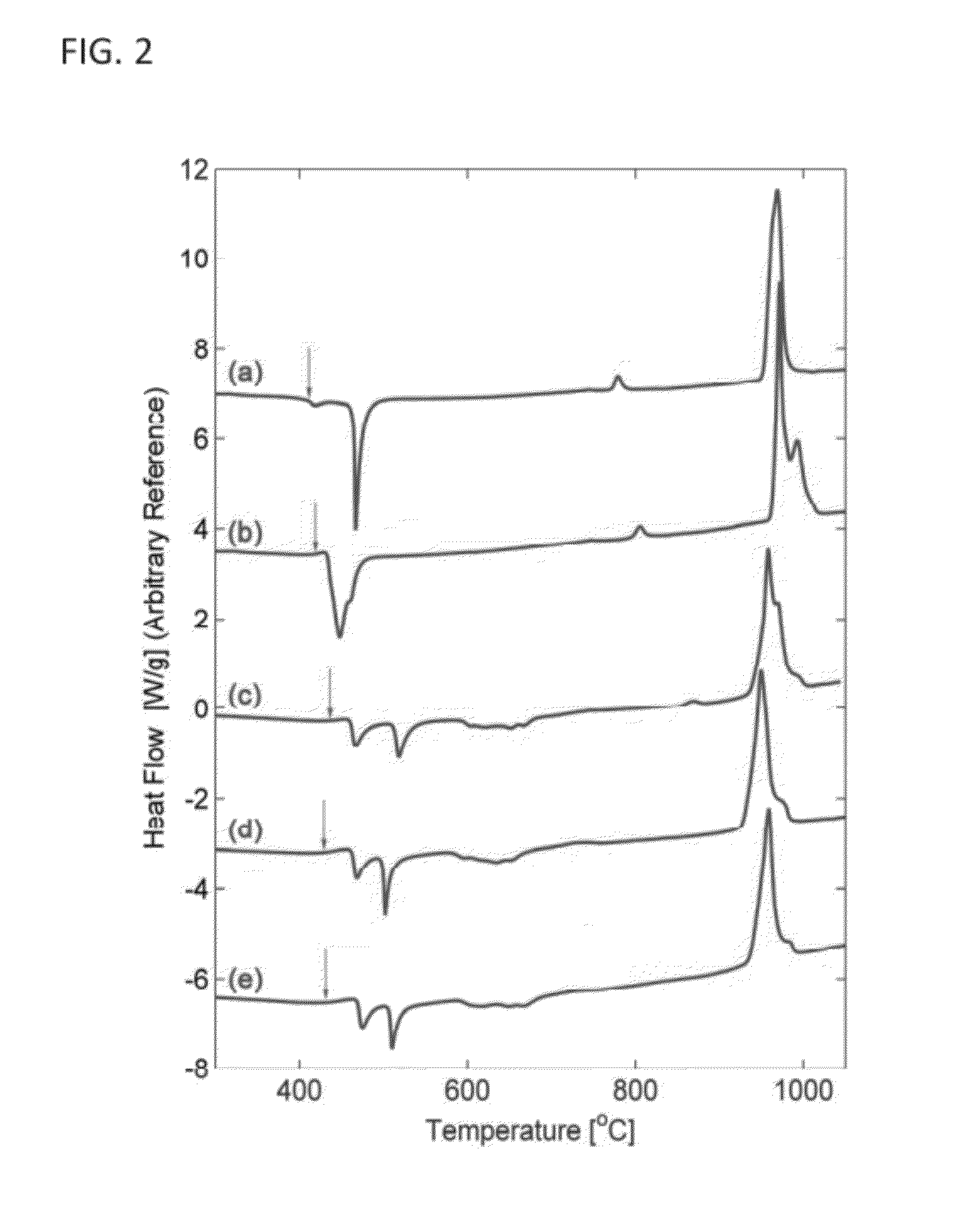

Tough iron-based bulk metallic glass alloys

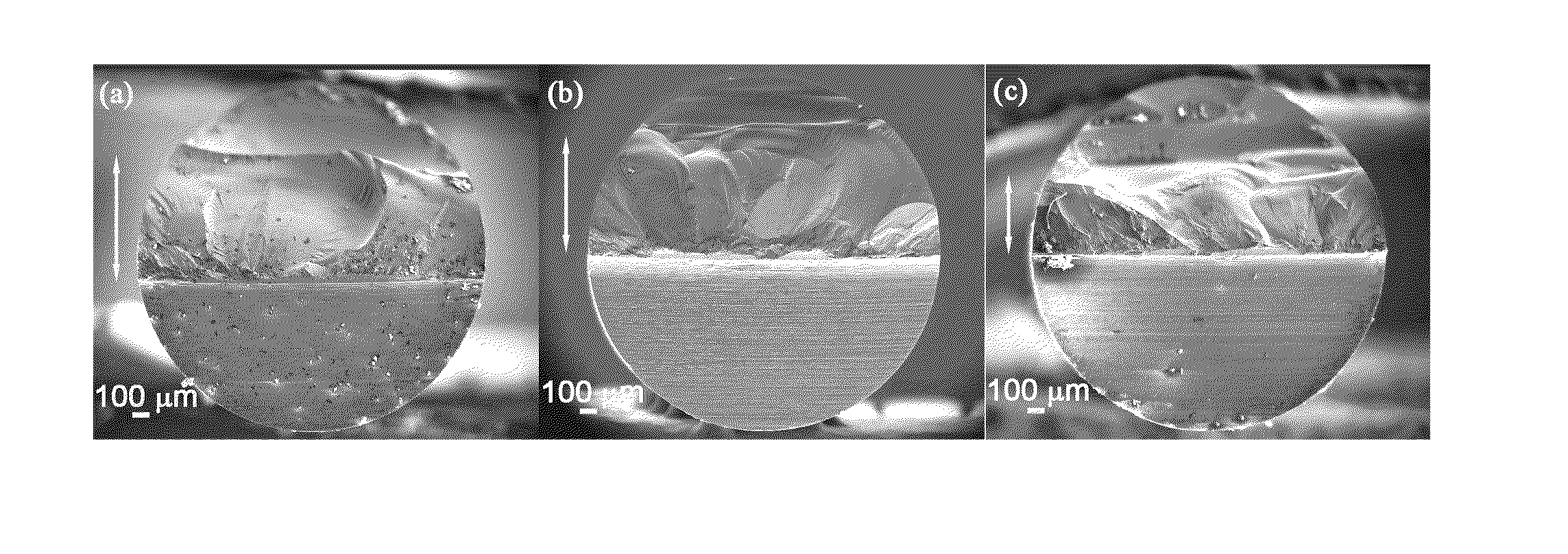

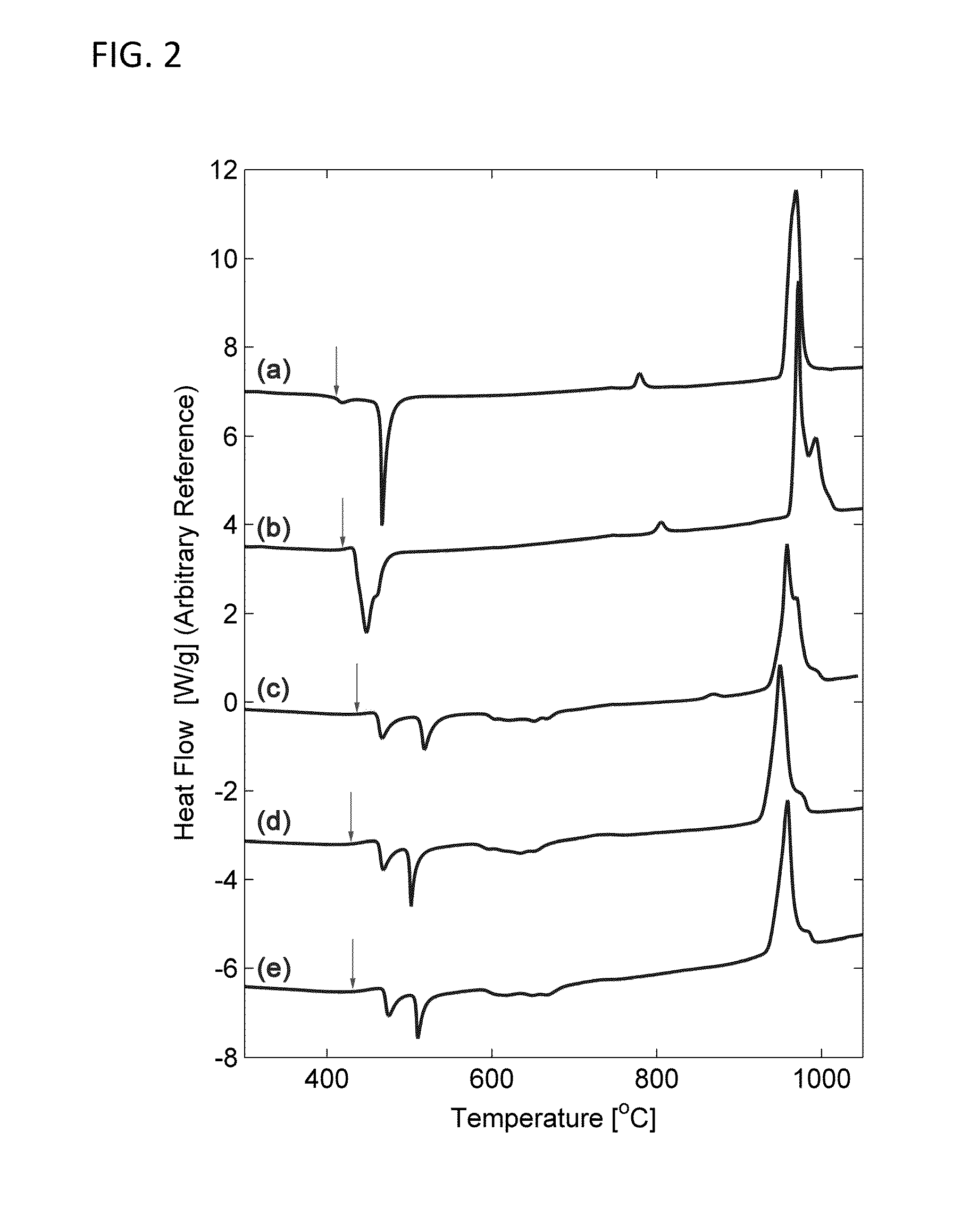

A family of iron-based, phosphor-containing bulk metallic glasses having excellent processibility and toughness, methods for forming such alloys, and processes for manufacturing articles therefrom are provided. The inventive iron-based alloy is based on the observation that by very tightly controlling the composition of the metalloid moiety of the Fe-based, P-containing bulk metallic glass alloys it is possible to obtain highly processable alloys with surprisingly low shear modulus and high toughness.

Owner:CALIFORNIA INST OF TECH

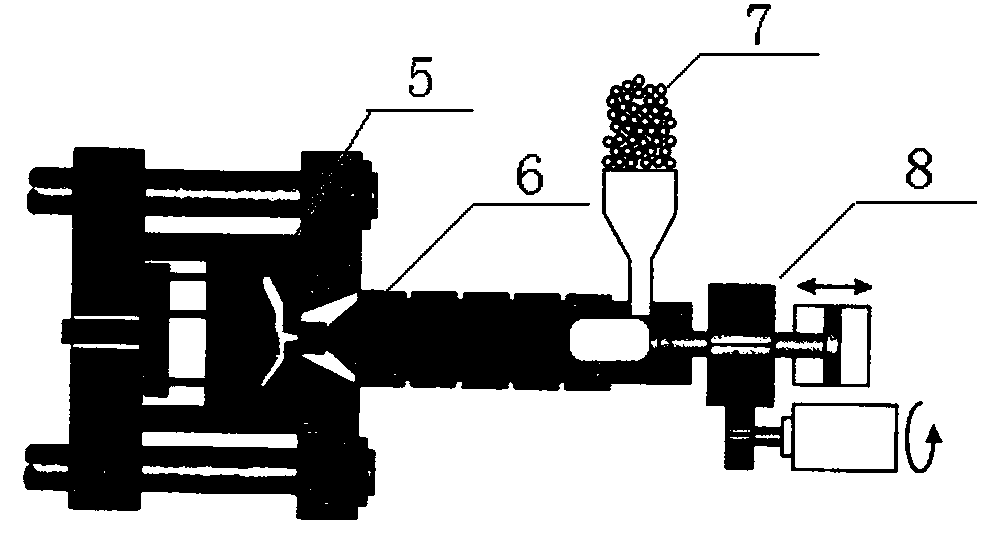

Laser fusing and coating process for wear resistant and etch-resistant coating of hydraulic support column cylinder and piston rod

ActiveCN101338427AExcellent wear resistance and corrosion resistanceImprove wear resistanceMetallic material coating processesWear resistantRoom temperature

A laser cladding process of the wear-resisting anticorrosive coating of a hydraulic pressure support pillar cylinder barrel or a piston rod cylinder barrel comprises procedures as follows: the surfaces of the standing pillar cylinder barrel and the piston rod cylinder barrel are pretreated; the surfaces of the standing pillar cylinder barrel and the piston rod cylinder barrel are decreased, de-rusted and cleaned up by alcohol under room temperature; alloying powder is chosen and an automatic powder feeder is adjusted; the iron base alloying powder with good wear-resisting anticorrosive property and sound metallurgy compatibility with a matrix is selected and the iron base alloying powder contains major constituents, including Fe, C, Cr, Ni, Mo, Si, N, Nb, Ta and B; and at last, the automatic powder feeder is adjusted. Adjusting the automatic powder feeder can lead the alloying powder from an automatic feeding end to a laser melting pool and feeding amount is adjusted so that the thickness of the alloying coating reaches 0.6mm to1.2mm. The alloying coating of the invention is even and dense and has good wear-resisting anticorrosive property. Compared with galvanization, the wear-resisting anticorrosive property and the service life of the standing pillar cylinder barrel and the piston rod manufactured by the invention are greatly improved.

Owner:CHONGQING JIANGLU LASER TECH

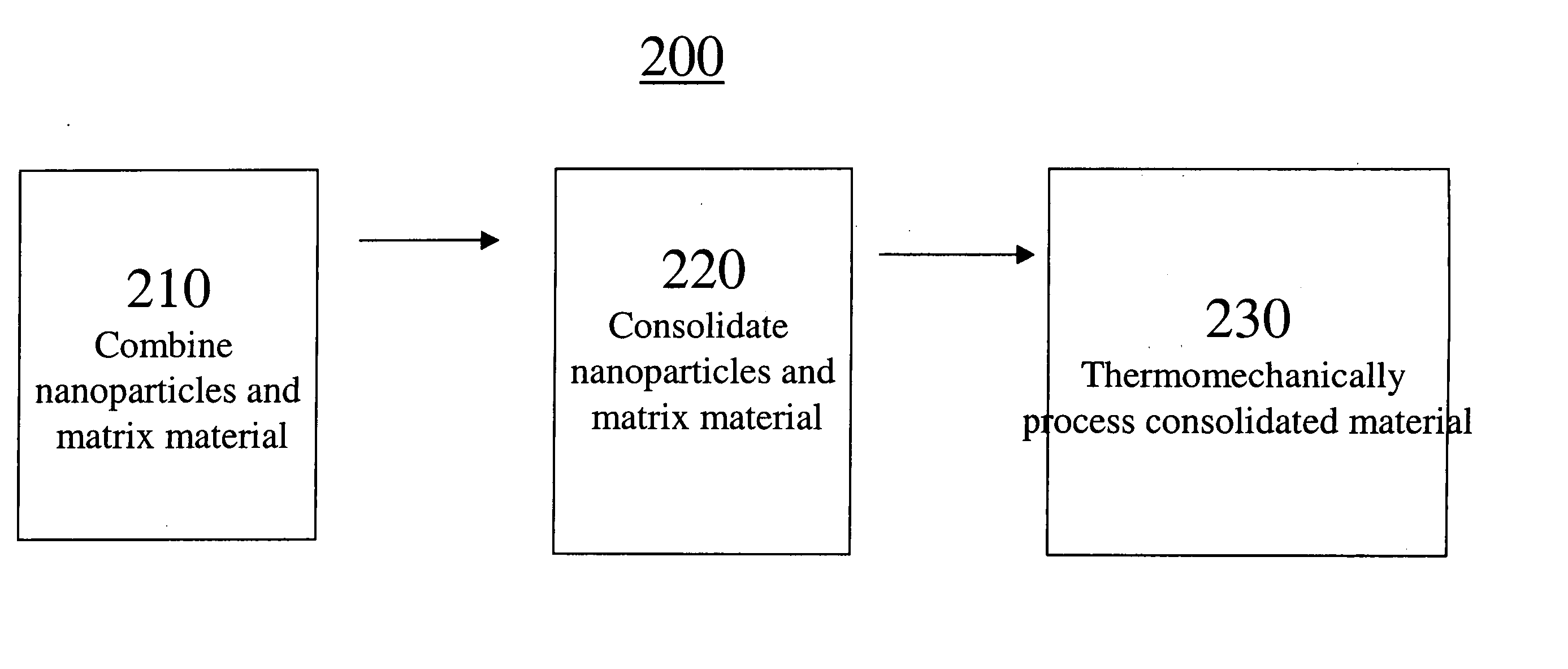

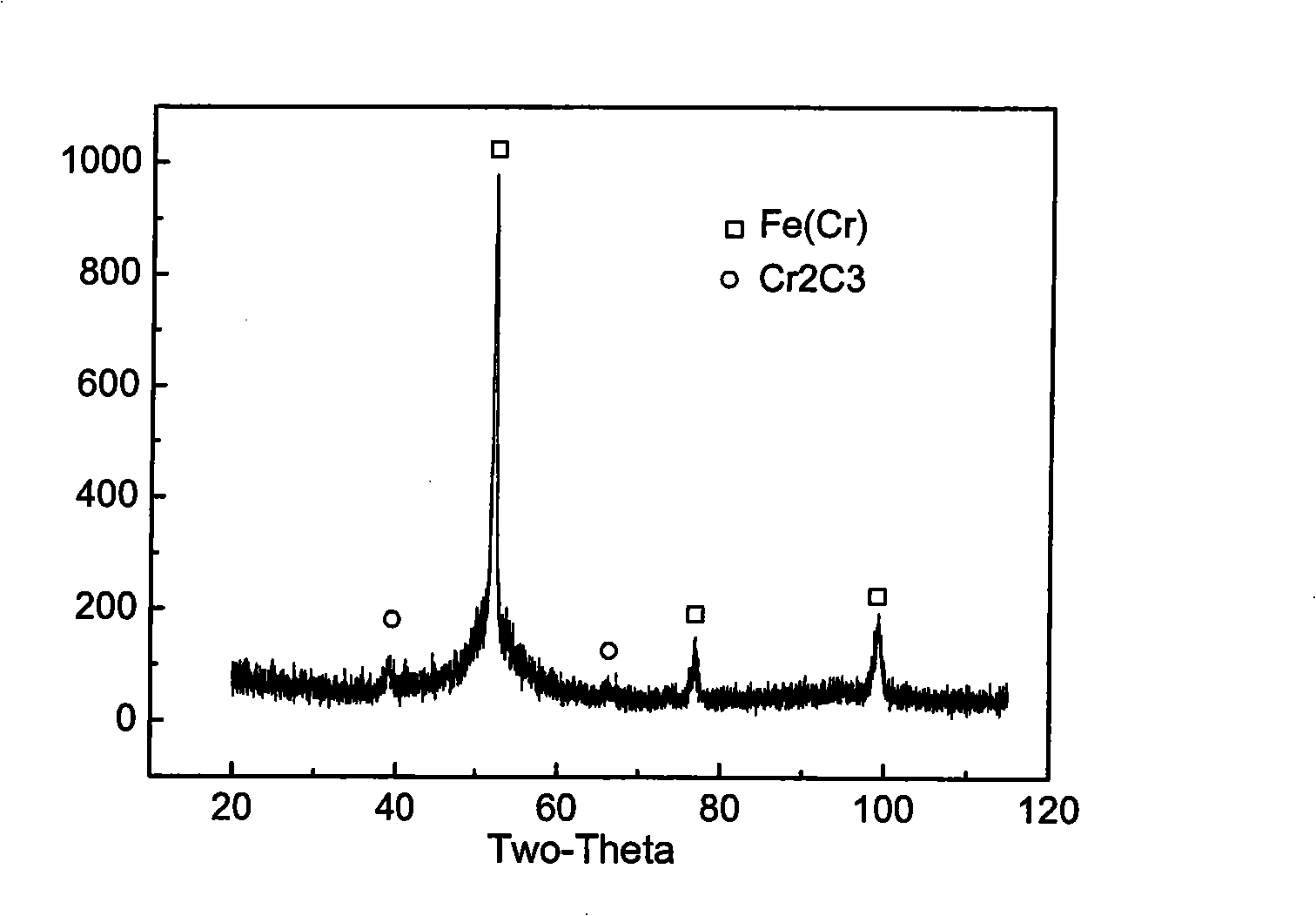

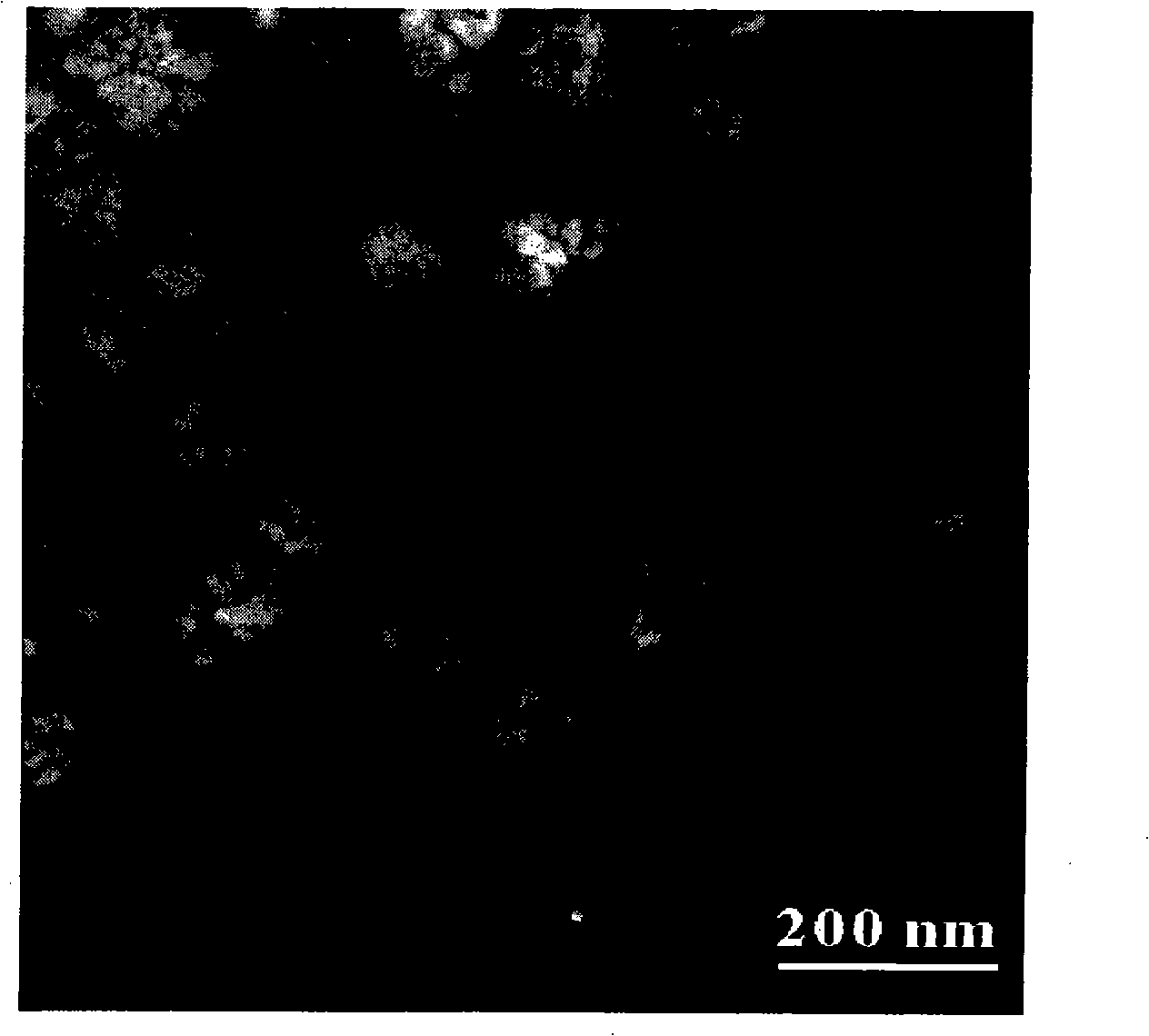

Metallic alloy nanocomposite for high-temperature structural components and methods of making

InactiveUS20050133121A1Increase volume fractionTransportation and packagingMetal-working apparatusNanocompositeAirplane

A nanocomposite comprising a plurality of nanoparticles dispersed in a metallic alloy matrix, and a structural component formed from such a nanocomposite. The metallic matrix comprises at least one of a nickel-based alloy and an iron-based alloy. The nanocomposite contains a higher volume fraction of nanoparticle dispersoids than those presently available. The structural component include those used in hot gas path assemblies, such as steam turbines, gas turbines, and aircraft turbine. A method of making such nanocomposites is also disclosed.

Owner:GENERAL ELECTRIC CO

Tough iron-based bulk metallic glass alloys

A family of iron-based, phosphor-containing bulk metallic glasses having excellent processability and toughness, methods for forming such alloys, and processes for manufacturing articles therefrom are provided. The inventive iron-based alloy is based on the observation that by very tightly controlling the composition of the metalloid moiety of the Fe-based, P-containing bulk metallic glass alloys it is possible to obtain highly processable alloys with surprisingly low shear modulus and high toughness. Further, by incorporating small fractions of silicon (Si) and cobalt (Co) into the Fe—Ni—Mo—P—C—B system, alloys of 3 and 4 mm have been synthesized with high saturation magnetization and low switching losses.

Owner:CALIFORNIA INST OF TECH

Iron-based alloy powder for high strength and toughness laser deposited coating

InactiveCN101974724AGood workmanshipMetallic material coating processesLaser beam welding apparatusHardnessAlloy coating

The invention discloses iron-based alloy powder for a high strength and toughness laser deposited coating in the technical field of alloy materials. The iron-based alloy powder comprises the following components: 0.60 to 1.00 percent of C, 0.35 to 0.70 percent of Si, 0.30 to 0.60 percent of Mn, 5.00 to 7.00 percent of Cr, 2.50 to 4.00 percent of Ni, 1.50 to 2.50 percent of Mo, 1.00 to 1.50 percent of W, 0.70 to 1.00 percent of V, 0.20 to 0.40 percent of Ti, 0.50 to 0.70 percent of B, 0.20 to 0.40 percent of Nb, 0.10 to 0.30 percent of Ce and the balance of Fe. The iron-based laser deposited alloy coating without cracks in large area can be obtained without pre-heating and post thermal treatment, the deposited alloy coating has high hardness which reaches 62 to 67HRC, and the yield strength reaches 1,700 to 2,000MPa.

Owner:SHANGHAI JIAO TONG UNIV

Alloy powder special for laser-remelted high hardness crackless iron-base alloy

InactiveCN101381869AHigh strengthHigh hardnessMetallic material coating processesThermal sprayingNiobium

The invention belongs to the technical field of alloy material, and relates to an improvement on the prior art, in particular to special alloy powder for laser cladding of high-hardness crack-free iron-based alloy. The formula of the alloy powder comprises the following compositions in weight percentage: 0.3 to 0.5 of C, 1.2 to 2.0 of Si, 0.4 to 1.0 of B, 1.5 to 2.5 of Ni, 1.0 to 1.5 of Cr, 1.0 to 1.5 of Mn, 1.5 to 2.5 of Mo, 0.15 to 0.7 of V, and 0.15 to 0.7 of Nb, the balance being Fe; and the total weight of the compositions is 100 percent. The special alloy powder can obtain the iron-based alloy with large area, large thickness and no crakes for laser cladding without preheating and subsequent heat treatment, has high strength, hardness and wear resistance and good plastic toughness of a cladding layer, and has lower cost compared with most of hot spraying self melting alloy powder and the prior laser cladding special iron-based alloy powder.

Owner:东莞市豪恩新材料技术有限公司

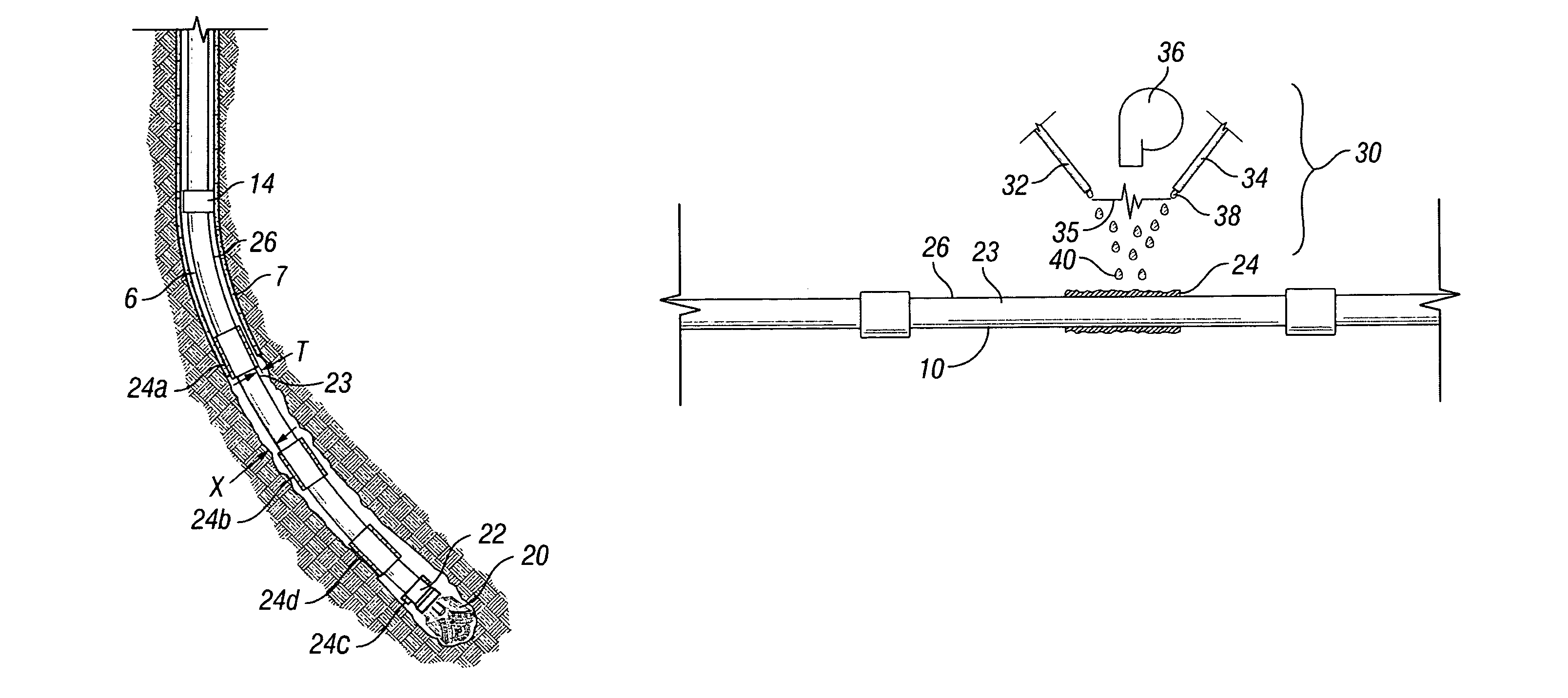

Wear resistant layer for downhole well equipment

ActiveUS7487840B2Improve wear resistanceReduce coefficient of frictionDrill bitsMolten spray coatingThermal sprayingWear resistant

Owner:INNOVEX DOWNHOLE SOLUTIONS INC

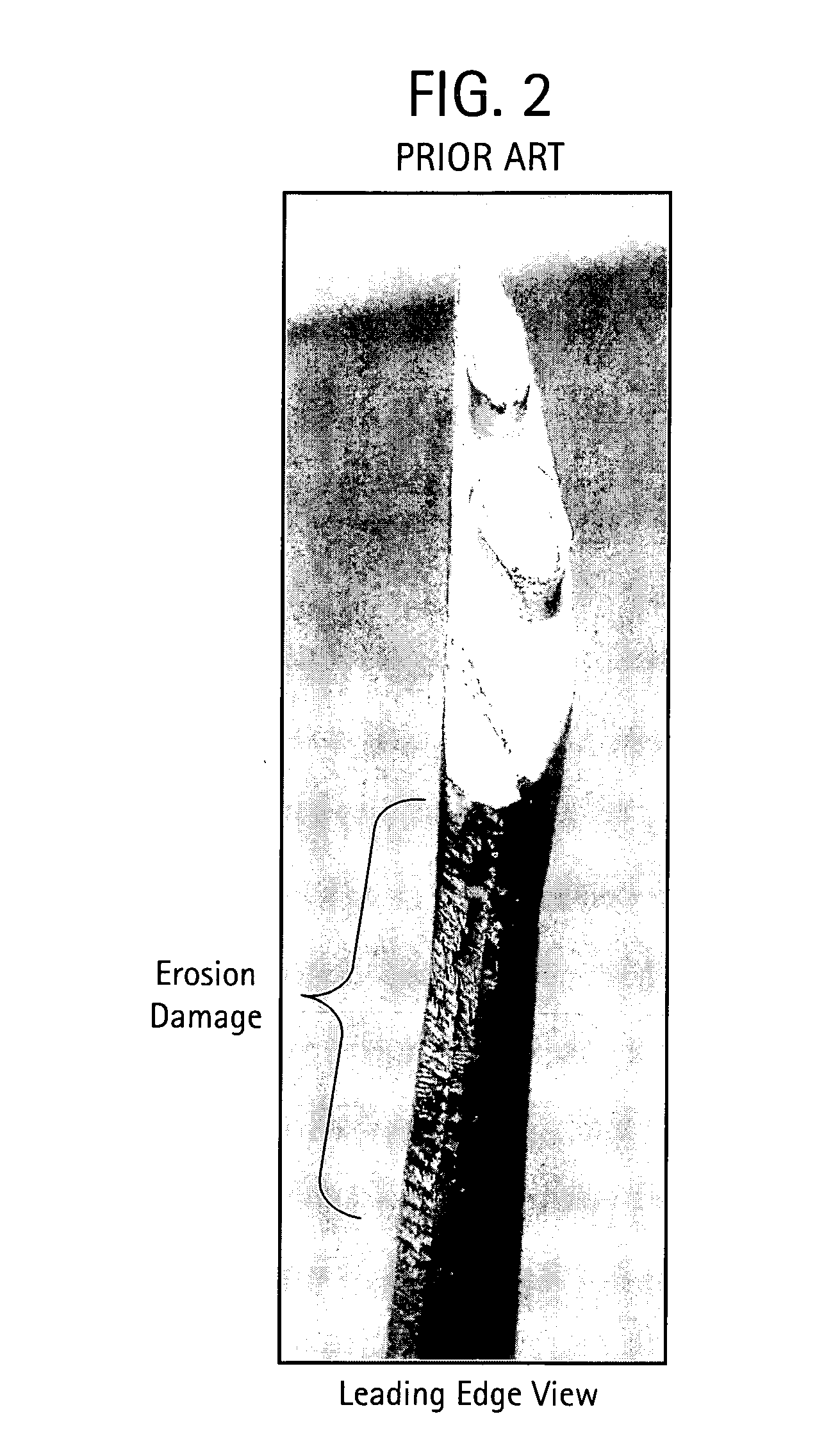

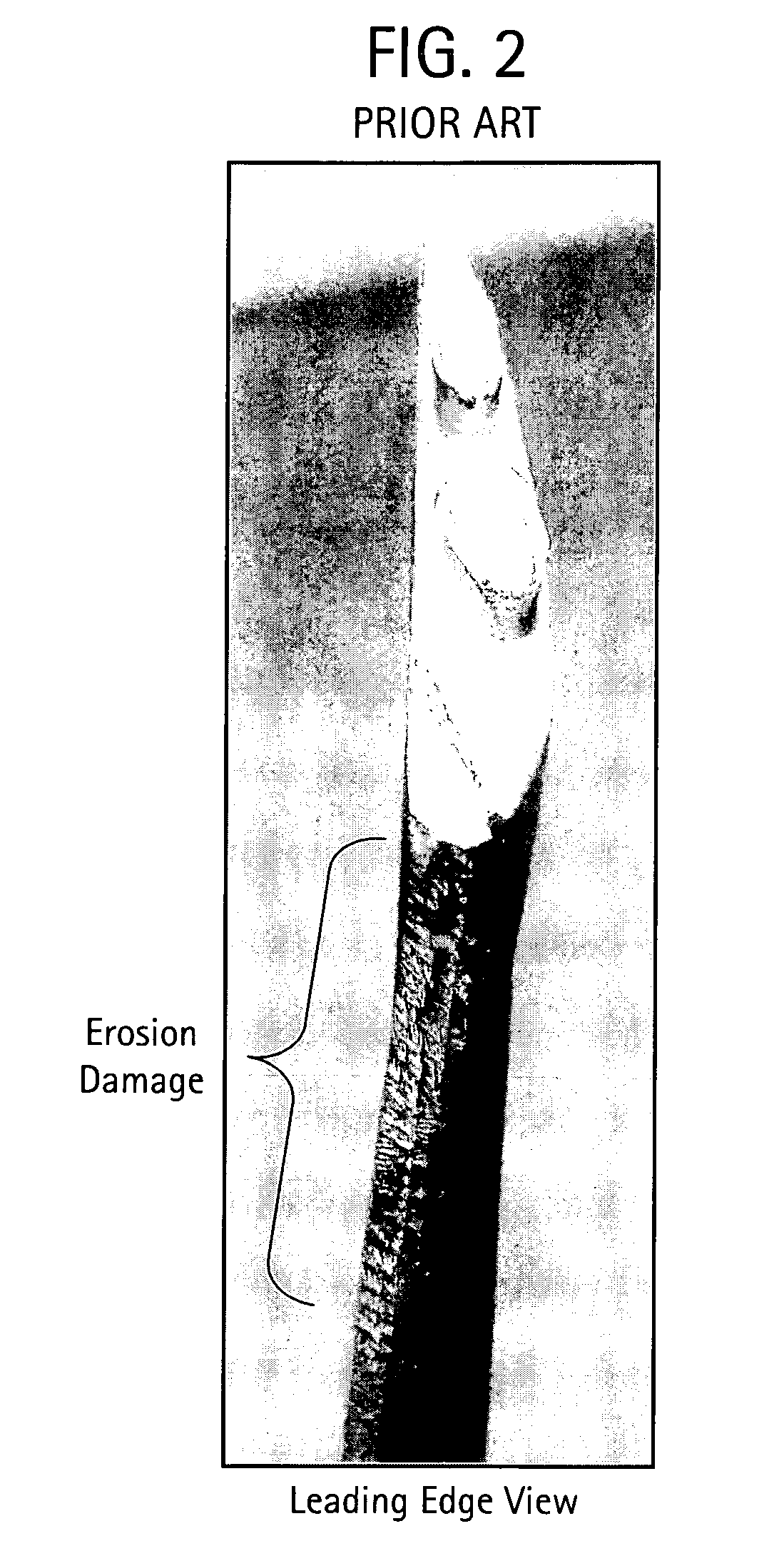

Erosion and wear resistant protective structures for turbine engine components

An erosion resistant protective structure for a turbine engine component comprises a shape memory alloy. The shape memory alloy includes nickel-titanium based alloys, indium-titanium based alloys, nickel-aluminum based alloys, nickel-gallium based alloys, copper based alloys, gold-cadmium based alloys, iron-platinum based alloys, iron-palladium based alloys, silver-cadmium based alloys, indium-cadmium based alloys, manganese-copper based alloys, ruthenium-niobium based alloys, ruthenium-tantalum based alloys, titanium based alloys, iron-based alloys, or combinations comprising at least one of the foregoing alloys. Also, disclosed herein are methods for forming the shape memory alloy onto turbine component.

Owner:GENERAL ELECTRIC CO

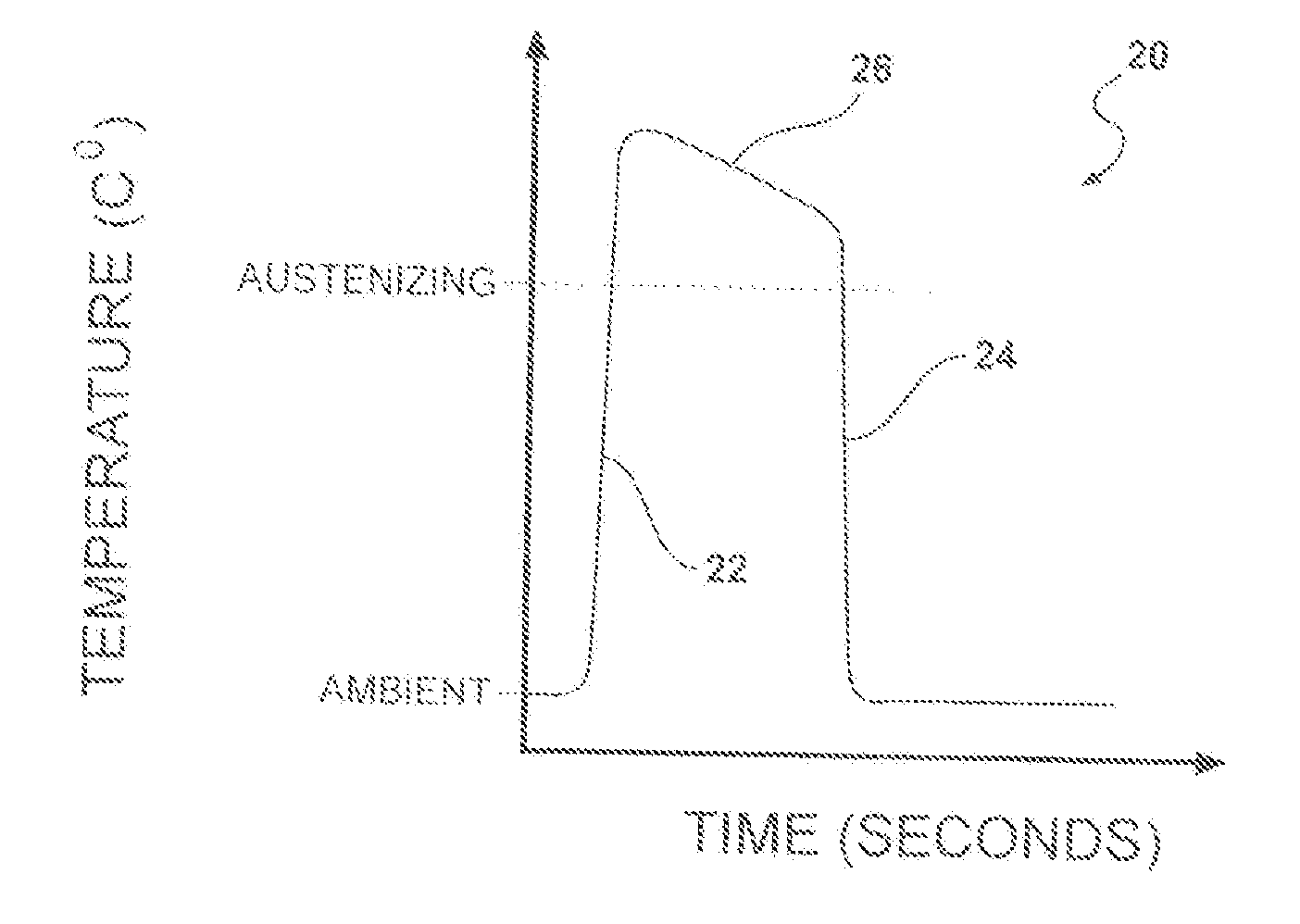

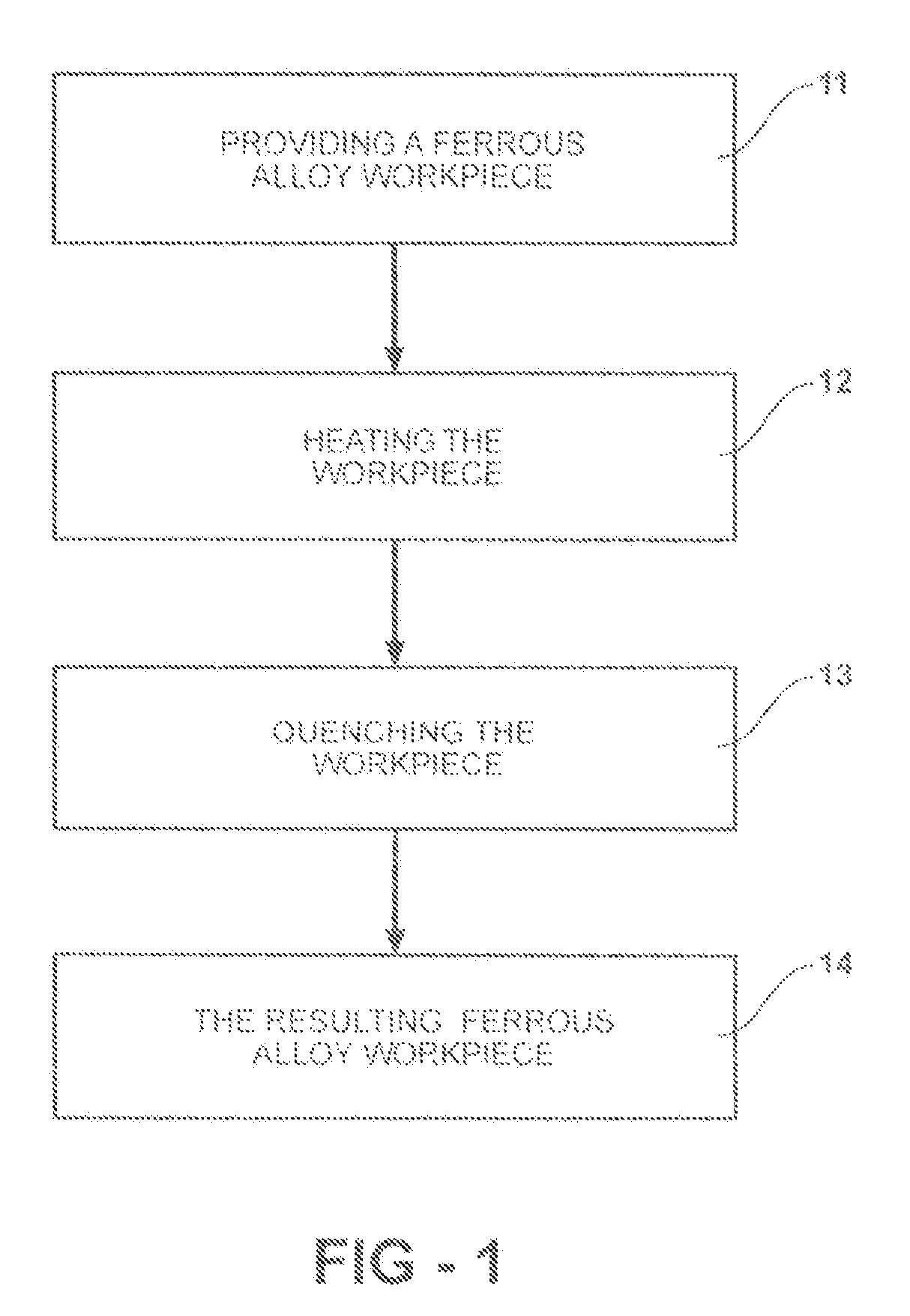

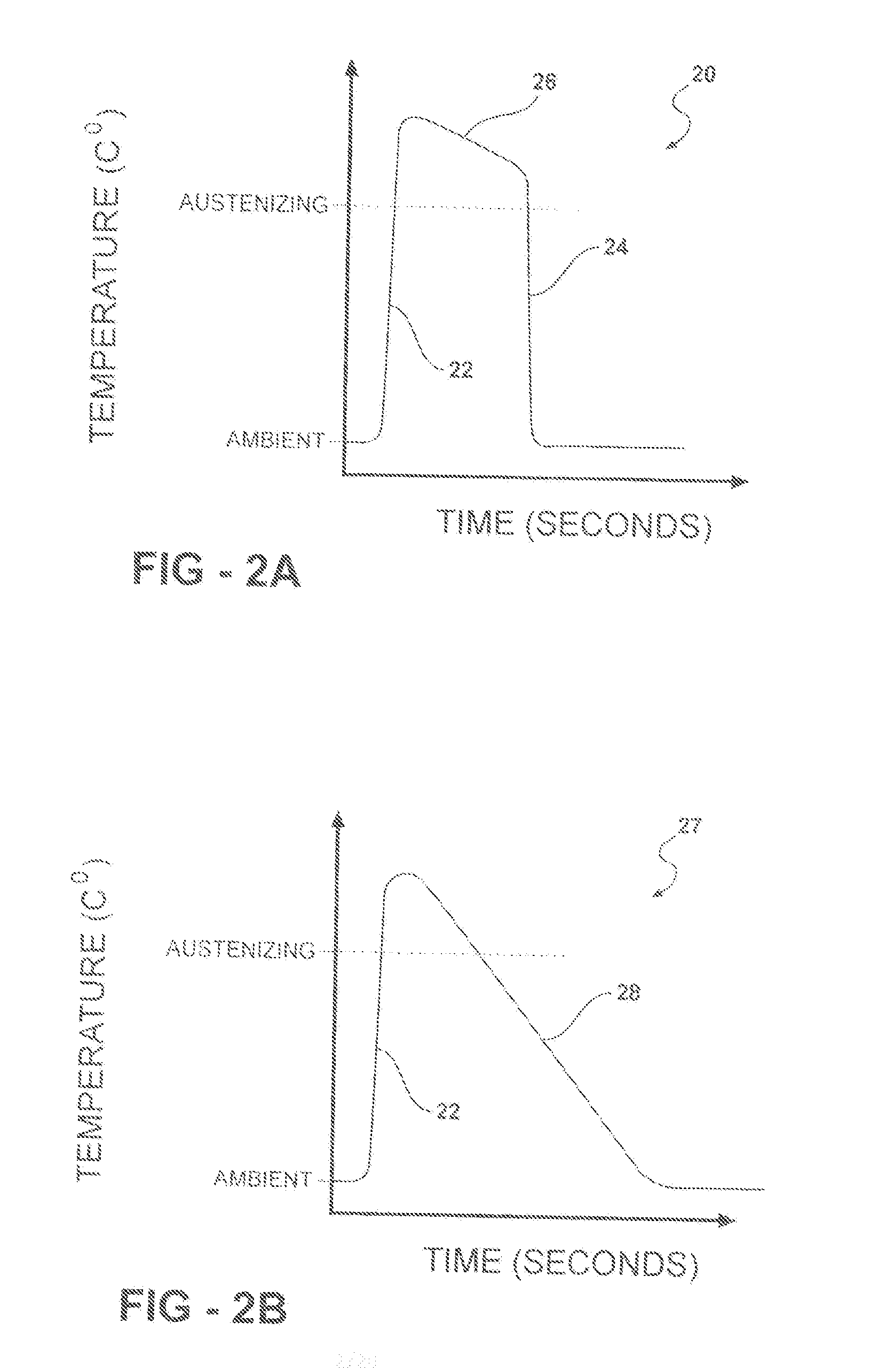

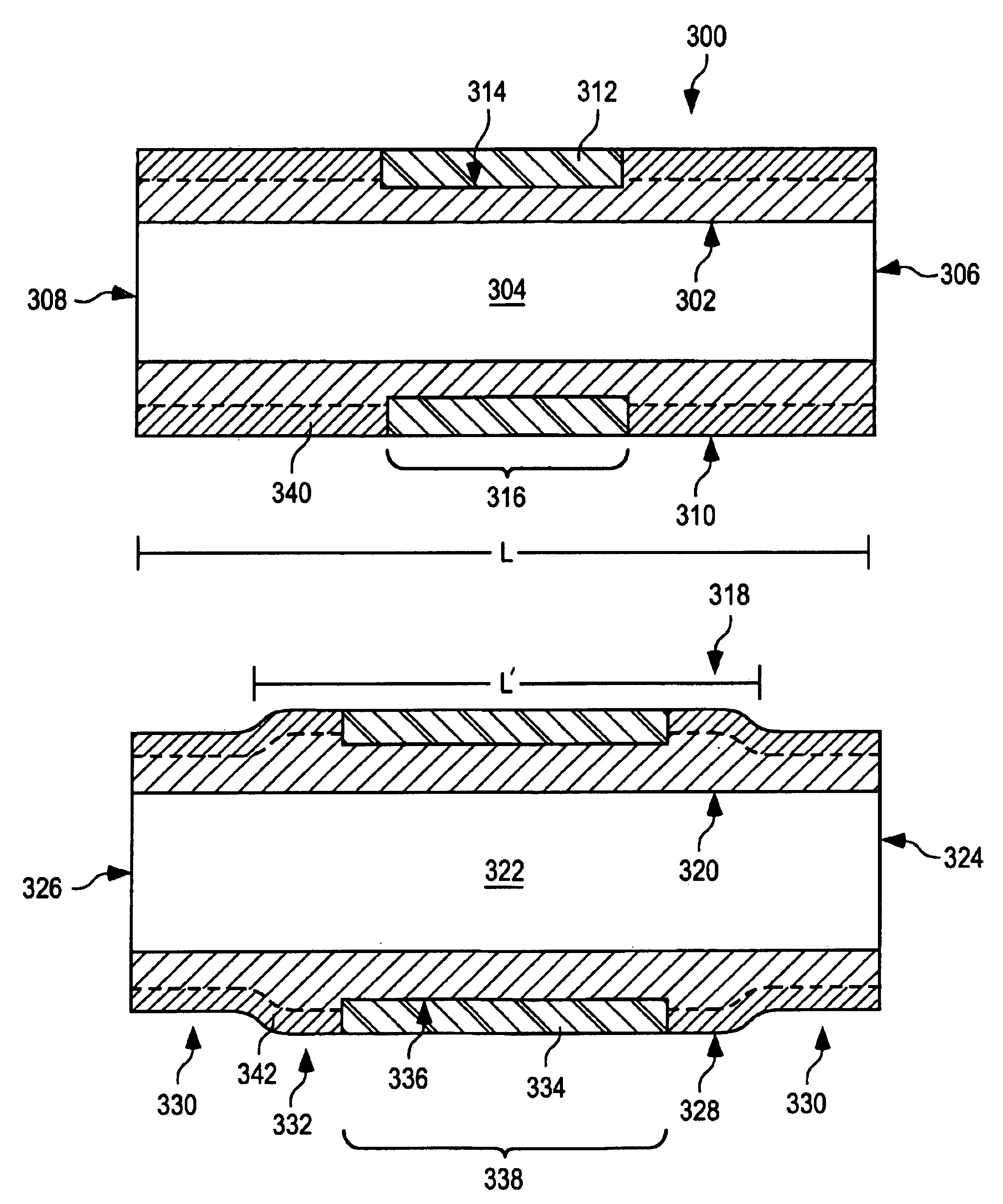

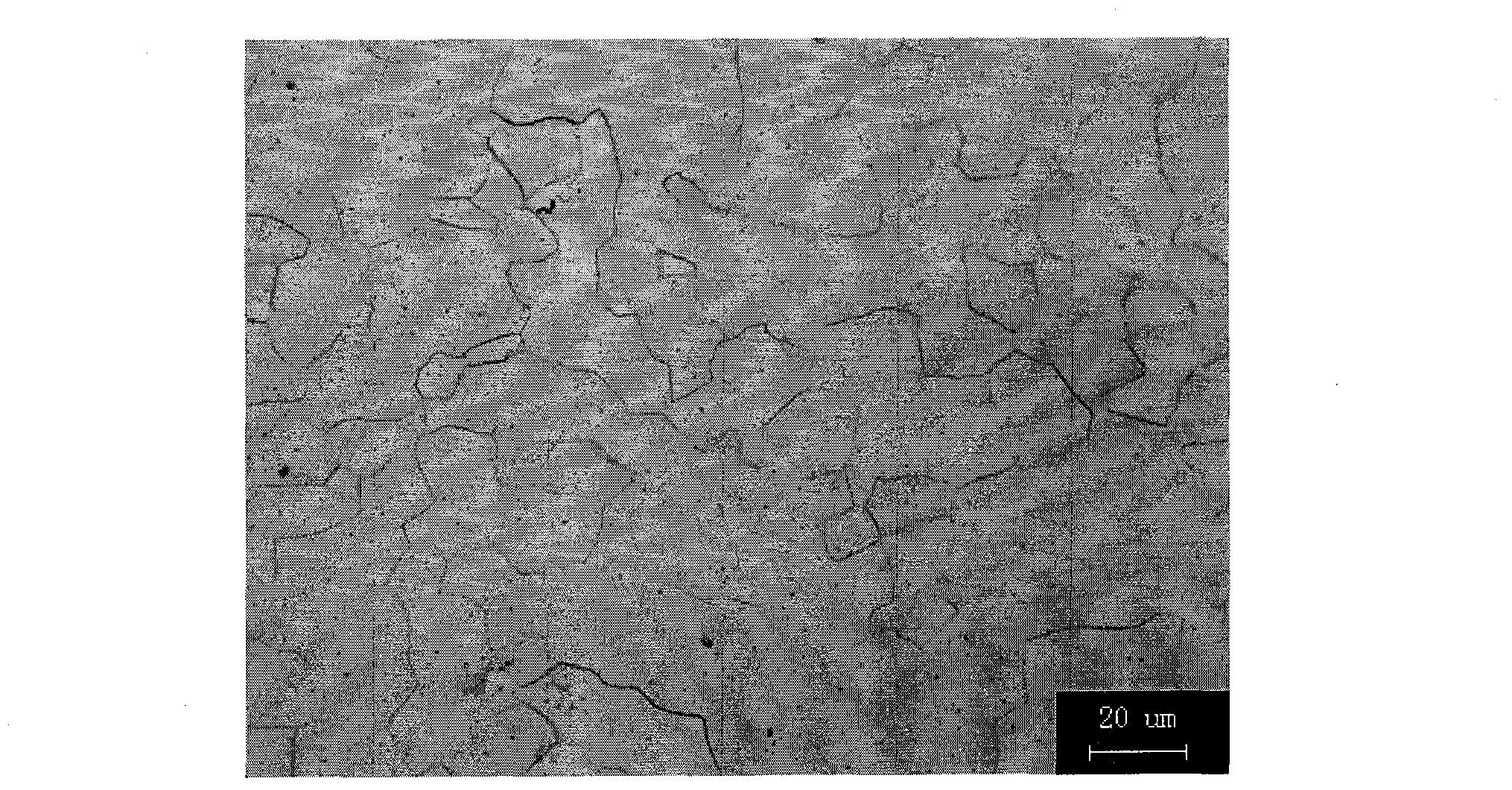

Microtreatment of Iron-Based Alloy, Apparatus and Method Therefor, and Articles Resulting Therefrom

ActiveUS20100132854A1Minimum of costMinimum of timeFurnace typesIncreasing energy efficiencyHigh carbonQuenching

Iron-based alloys and articles in strips, sheets, workpieces and the like are converted into high strength steel with a minimum of cost, time and effort, including producing dual phase materials. This is achievable by extremely rapid micro-treating of low, medium, and high carbon iron-based alloys and articles by rapid heating and rapid cooling at least a portion of the alloy / article. This heating step involves nearly immediately heating the iron-based alloy to a selected temperature above its austenite conversion temperature. Then, the alloy is immediately quenched, also at an extremely fast rate, on at least a portion of the iron-based alloy in a quenching unit adjacent the heating unit. This procedure forms high strength alloy in a desired area, depending upon where the treatment was performed.

Owner:COLA JR GARY M

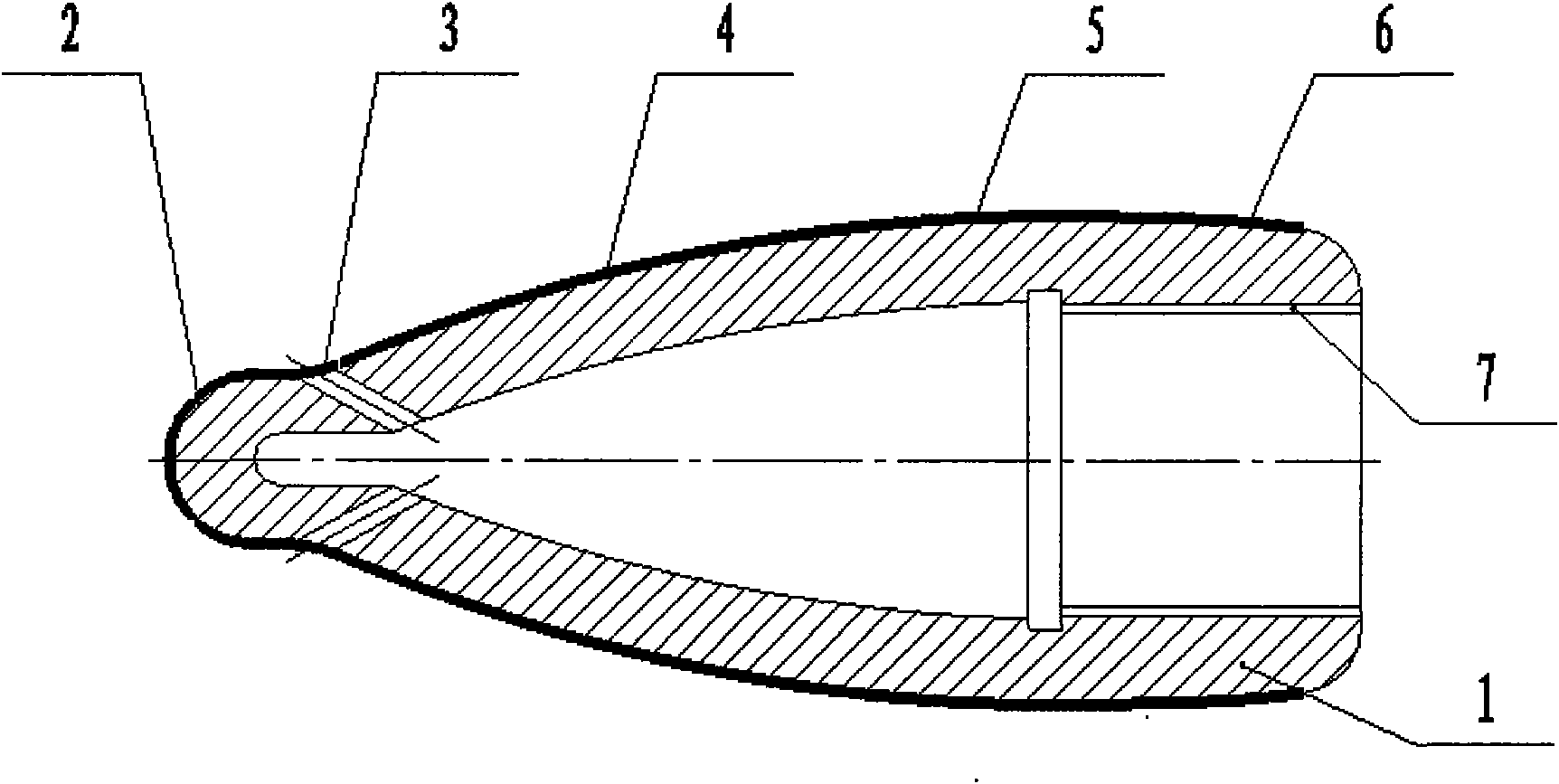

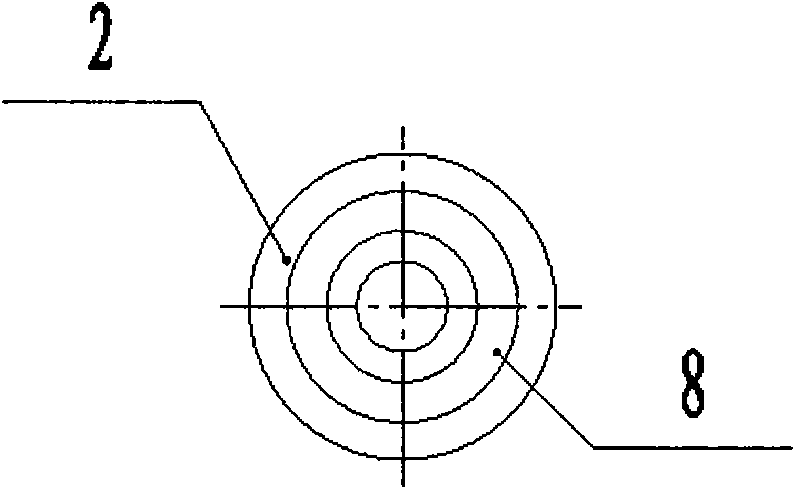

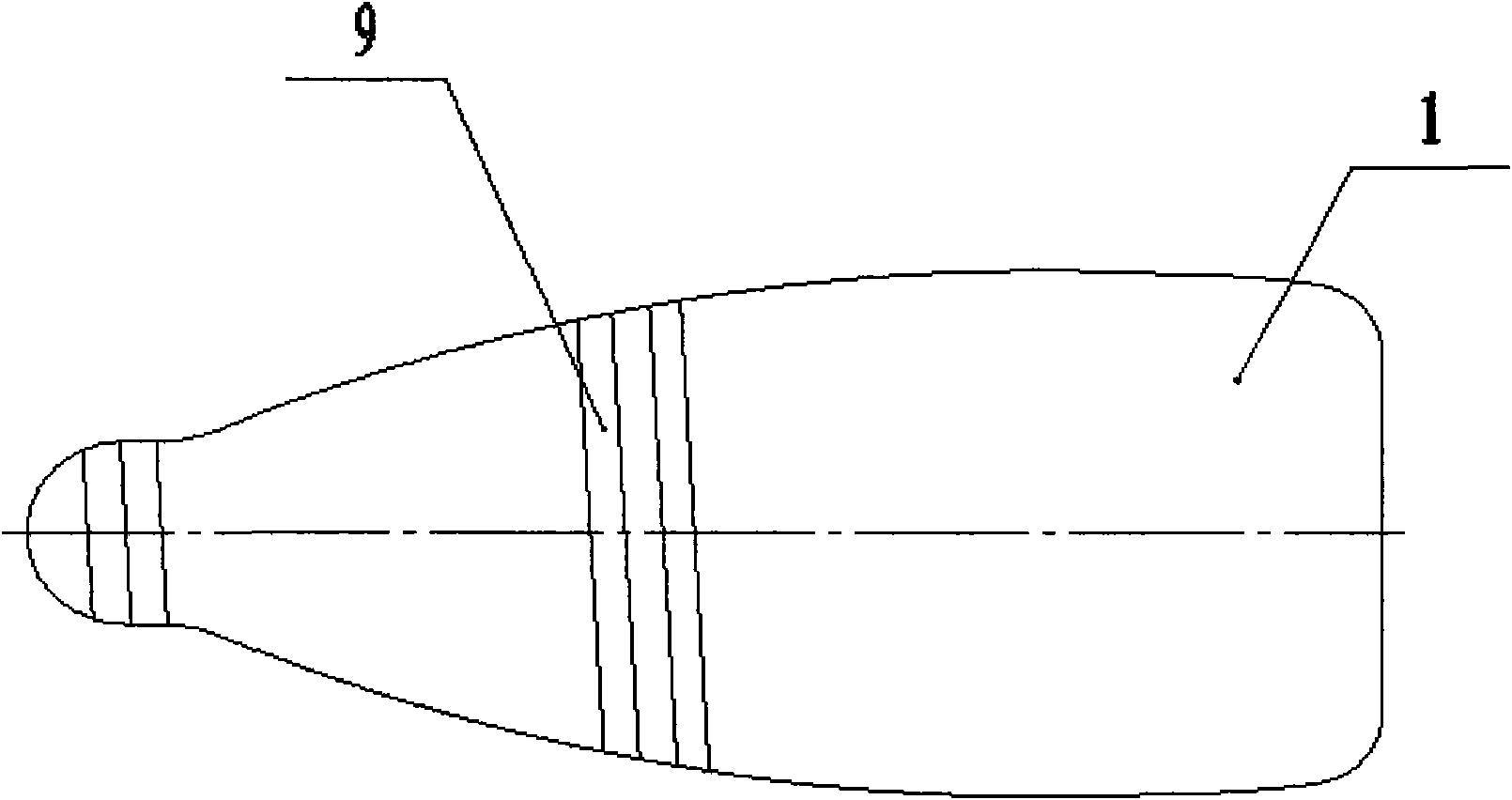

Binary alloy coating seamless steel tube top and manufacture method thereof

InactiveCN101596551AReduce stress concentrationEliminates crack-prone problemsMandrelsFurnace typesBinary alloyLaser coating

A binary alloy coating seamless steel tube top and a manufacture method belong to the field of laser processing. Aiming at solving the easy peel-off of molybdenum alloy of a molybdenum alloy top, prolonging service life and reducing cost, the invention melts and coats nickel-base or cobalt-base alloy coating at the nose or working part of the top, melts and coats iron-base alloy coating at the straightening part and the parallel part to obtain a binary alloy coating seamless steel tube top; the preparation of the top has the following steps of manufacturing the top by adopting a casting manner, performing mechanical processing on the cast top and reserving melt thickness of 1.0-3.0mm on the external surface of the top for laser melt process; using nickel-base or cobalt-base alloy to perform laser melt on the top end of the nose part; performing laser melt on the lateral of the nose part as well as the working part with nickel-base or cobalt-base alloy as melt powder, finishing laser melt on the straightening part and the parallel part with iron-base alloy incessantly; performing strain-removal treatment, namely performing mechanical processing of top nose spiracle and finishing laser coating polishing and grinding.

Owner:BEIJING UNIV OF TECH

Electric power generator, steam turbine rotor spindle repaired by laser and repairing method thereof

InactiveCN1674408AMeet working conditionsHigh creep limitMagnetic circuit rotating partsPump componentsOptoelectronicsCobalt

The present invention provides a laser repaired power generator and turbine rotor shaft, on its matrix surface on alloy covering layer which can be mutually merged with matrix surface and is different from matrix completely in components is formed, and on the surface where the matrix and alloy layer are connected a micromolten layer whose thickness is 0.05-0.1 mm is formed, and said alloy covering layer is nickel base, cobalt base or iron base alloy. Said invention also provides a laser repairing method of the described power generator and turbine rotor shaft. It adopts a pre-set laser melt-covering mode, and its technological parameters are: laser power 1200-2000 W, spot diameter 2-6 mm and spot moving speed 2-20 mm / s.

Owner:SHENYANG DALU LASER TECH

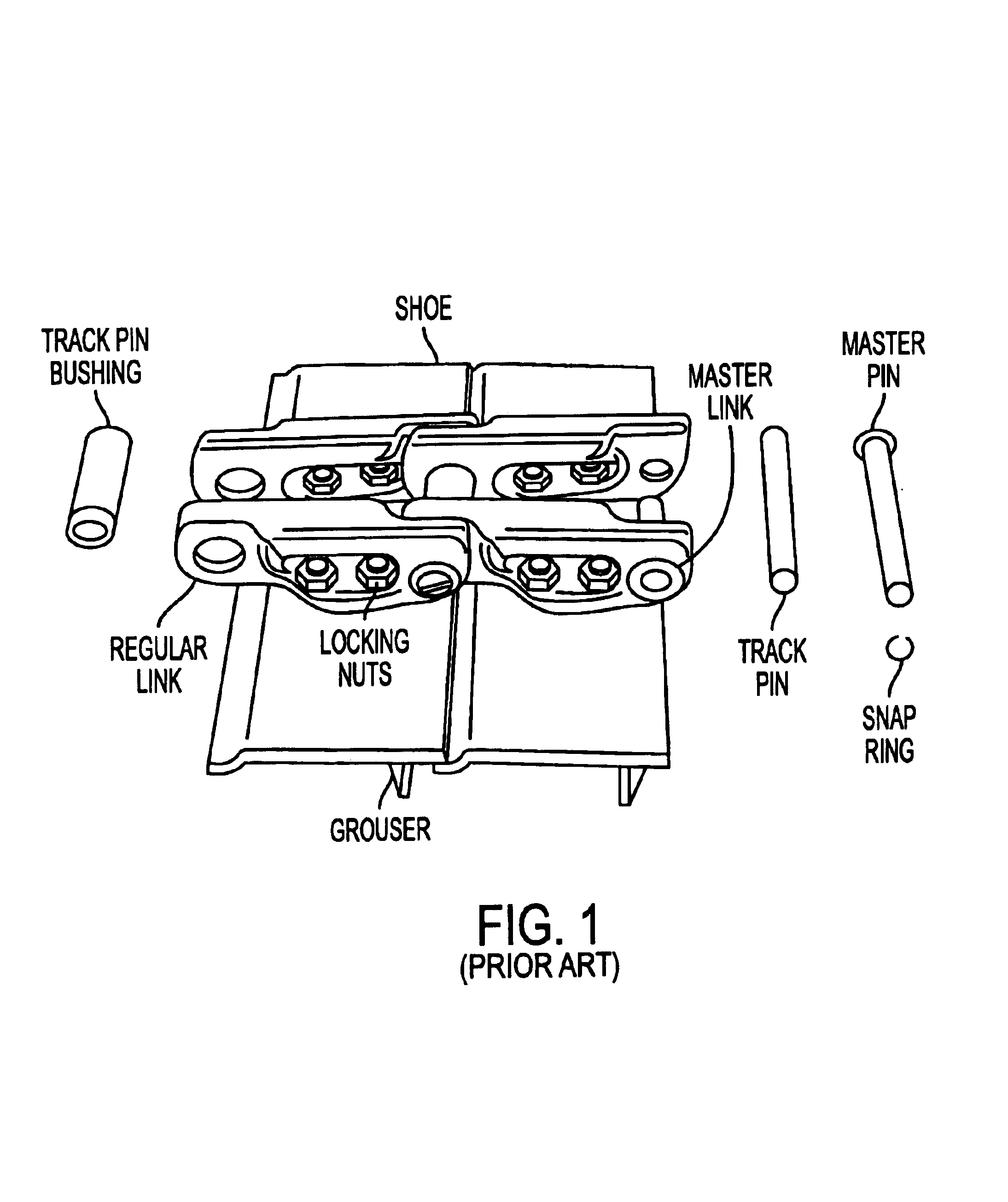

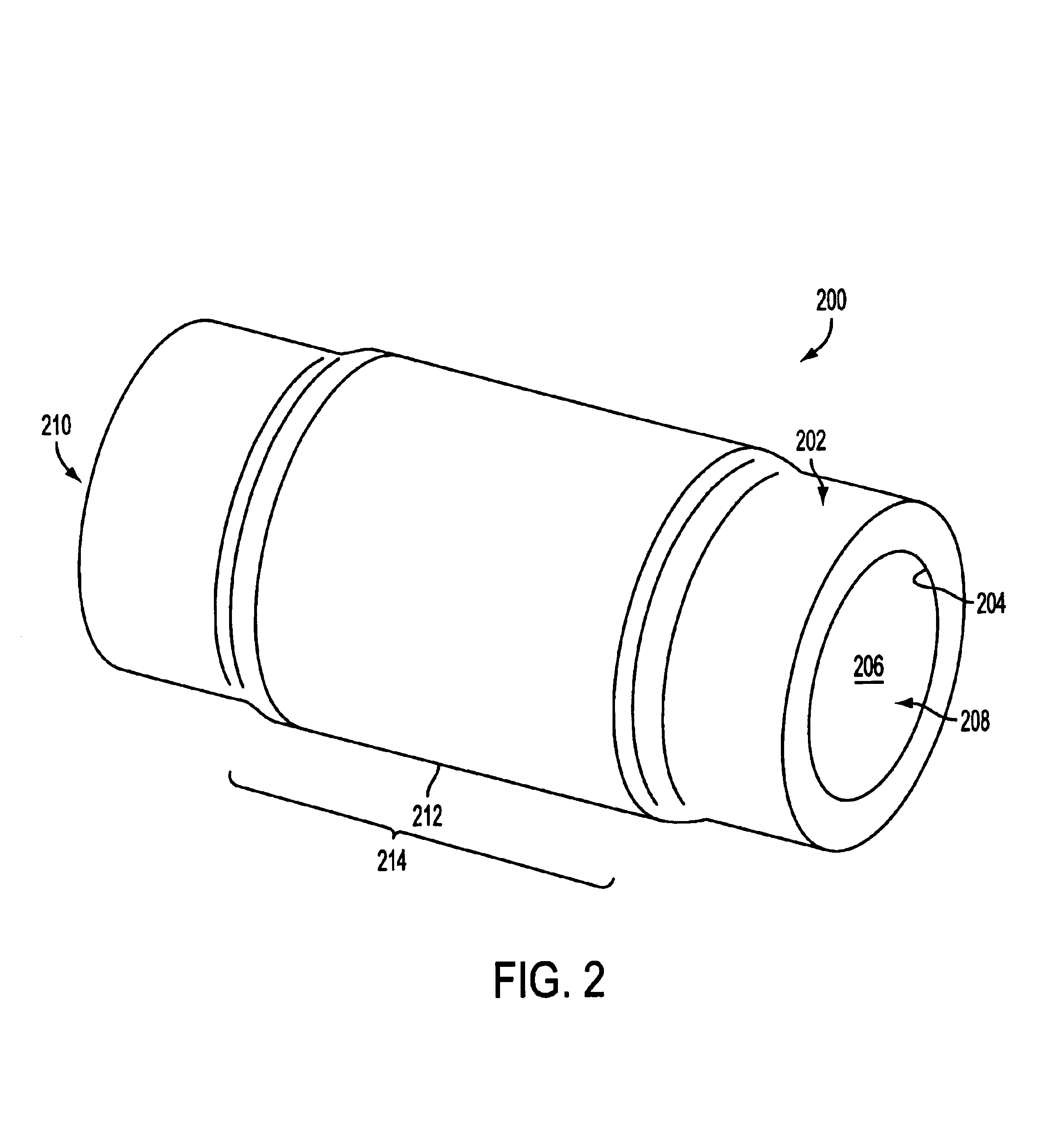

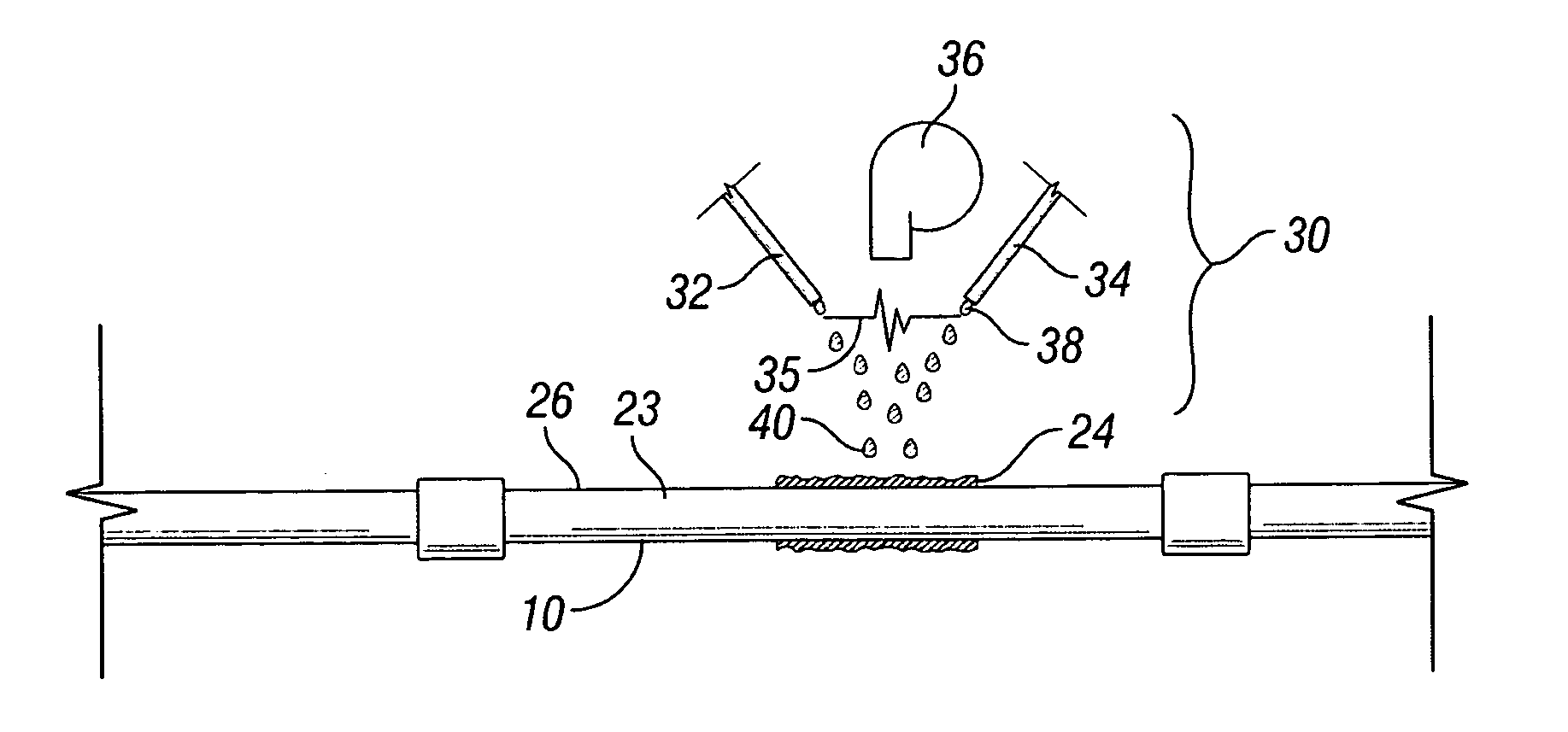

Track pin bushing having a metallurgically bonded coating

A track pin bushing for cooperating with a track pin in an endless track has a tubular body with a metallurgically bonded wear-resistant coating and a method for forming such a coated track pin bushing is taught herein. The tubular body, formed of an iron-based alloy, has an outer surface that is carburized and quenched, i.e., case-hardened, in at least a section thereof. At least a portion of the case hardened section has been removed to a depth sufficient to expose a non-carburized layer of the iron-based alloy. A hard metal alloy slurry is disposed on the non-carburized layer and forms a metallurgical bond between the non-carburized layer and the coated unfused slurry by fusing the hard metal alloy. The thickness of the unfused slurry is adjusted to be from 1.67 to 2.0 times a final thickness of the wear-resistant coating. The wear-resistant coating comprises a fused, metal alloy comprising at least 60% iron, cobalt, nickel, or alloys thereof. The portion of the outer surface with the wear-resistant coating corresponds to a contact surface adapted to engage with a drive sprocket in the endless track of the track-type vehicle.

Owner:DEERE & CO

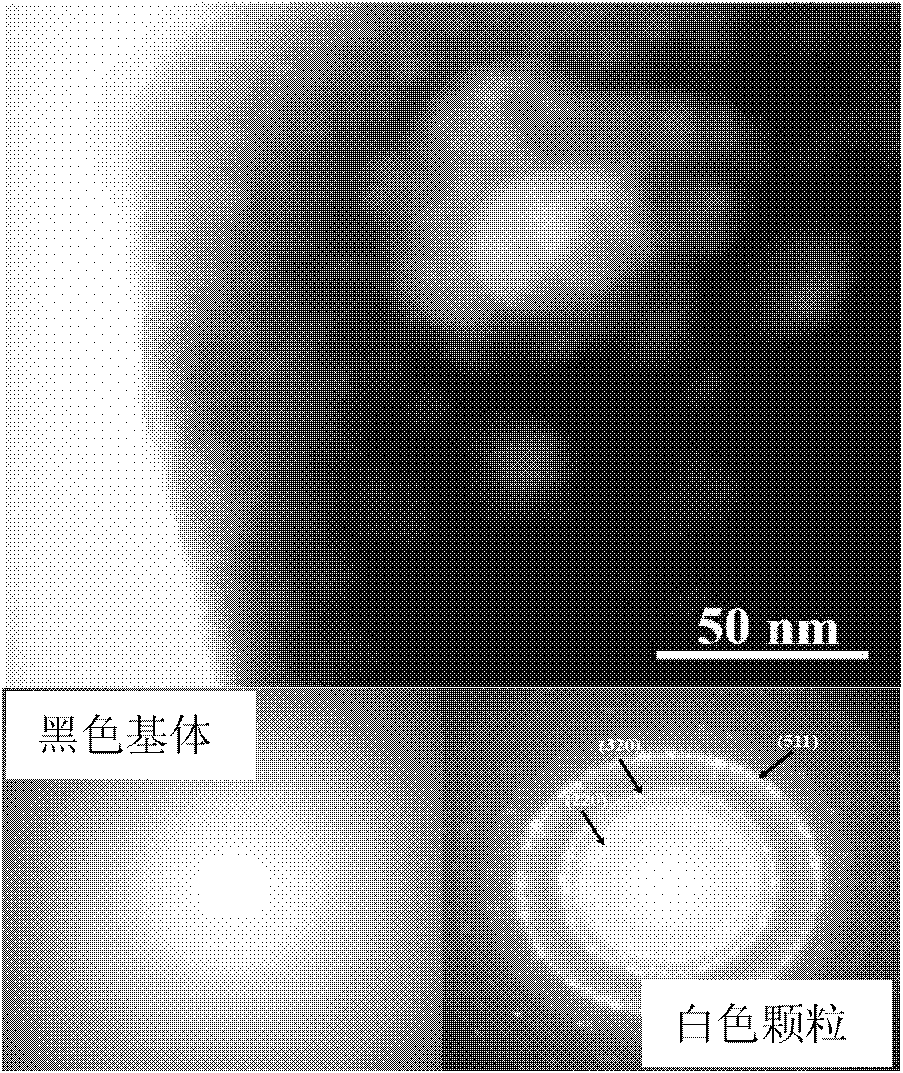

Ceramic-phase-containing iron-based amorphous nanocrystalline composite coating and preparation thereof

ActiveCN101298654AEasy to useExtended service lifeMolten spray coatingOxide ceramicsThermal spraying

The invention belongs to the field of thermal spraying and particularly relates to a composite amorphous and nano-crystalline coating layer with ceramic phase and ferrum base and a preparation method thereof. Carbide or oxide ceramics of Co or Ni ladles are firstly added into a flux core, a flux-cored wire is prepared together with the flux core and a ferrum-base alloy with amorphous ingredients and used as a spraying material, and the electric arc spraying method is adopted for leading the flux-cored wire to be melted, atomized into fused drops and finally deposited on a substrate, thus preparing the composite amorphous and nano-crystalline coating layer with ceramic-phase structure and ferrum base, which has the performance of high bond strength, good wear resistance, corrosion resistance and oxidation resistance as well as remarkably prolonged service life of the substrate, and the composite amorphous and nano-crystalline coating layer with ceramic phase and ferrum base can be widely applied to the restoration and the protection of device parts in the fields of metallurgy, electric power and petroleum, etc.

Owner:CENT IRON & STEEL RES INST

Non-Carburized Components of Track-Type Machines Having A Metallurgically Bonded Coating

Undercarriage assembly components of track-type machines having a metallurgically bonded wear-resistant coating and methods for forming such coated undercarriage assembly components is taught herein. The bodies of the undercarriage assembly components, formed of an iron-based alloy, have a hard metal alloy slurry disposed on a surface or into an undercut or channel and then fused to form a metallurgical bond with the iron-based alloy. The wear-resistant coating comprises a fused, metal alloy comprising at least 60% iron, cobalt, nickel, or alloys thereof. The portion of the outer surface of the undercarriage assembly components having the wear-resistant coating corresponds to a wear surface of the component during operation of the endless track of the track-type vehicle.

Owner:DEERE & CO

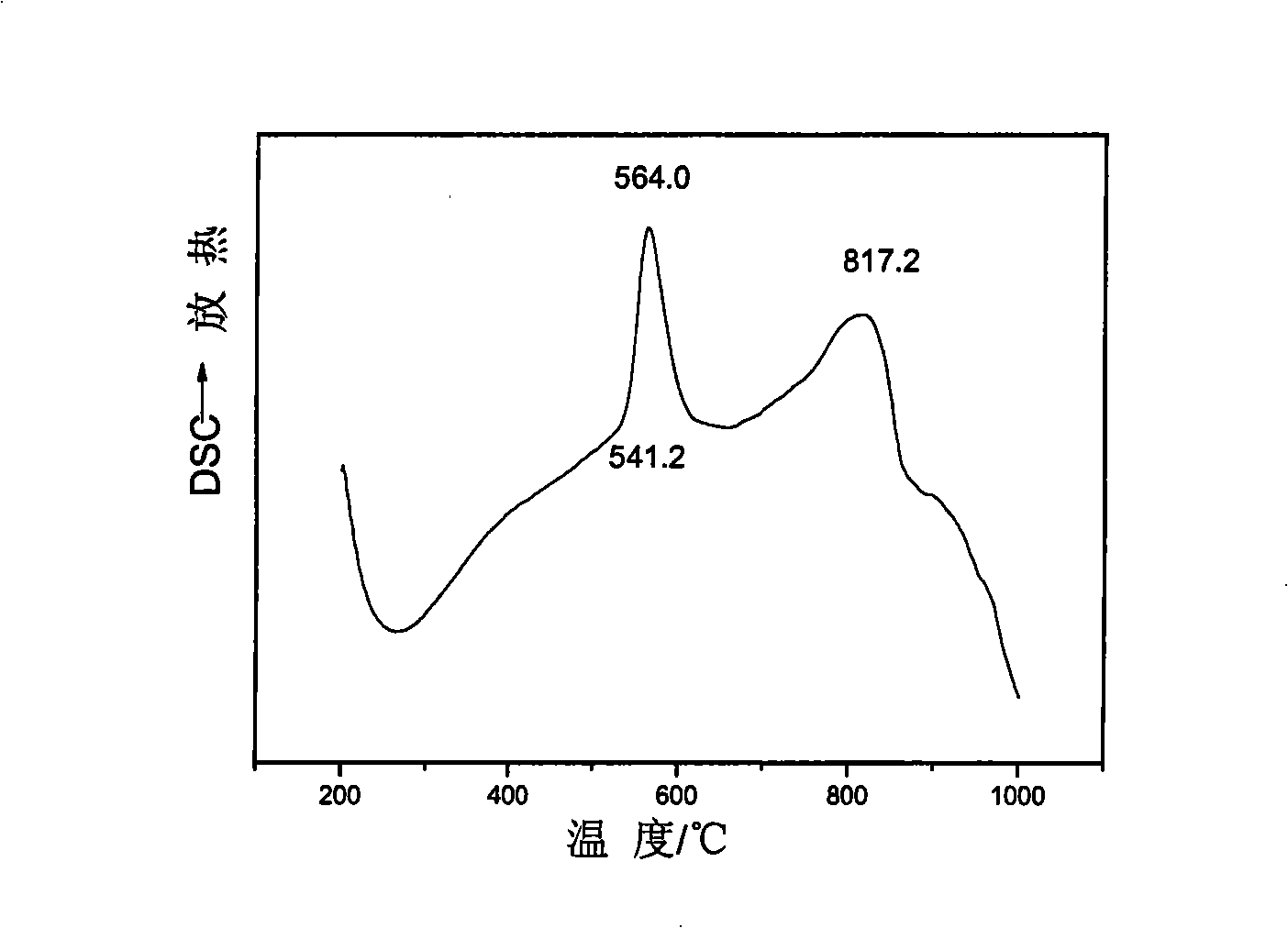

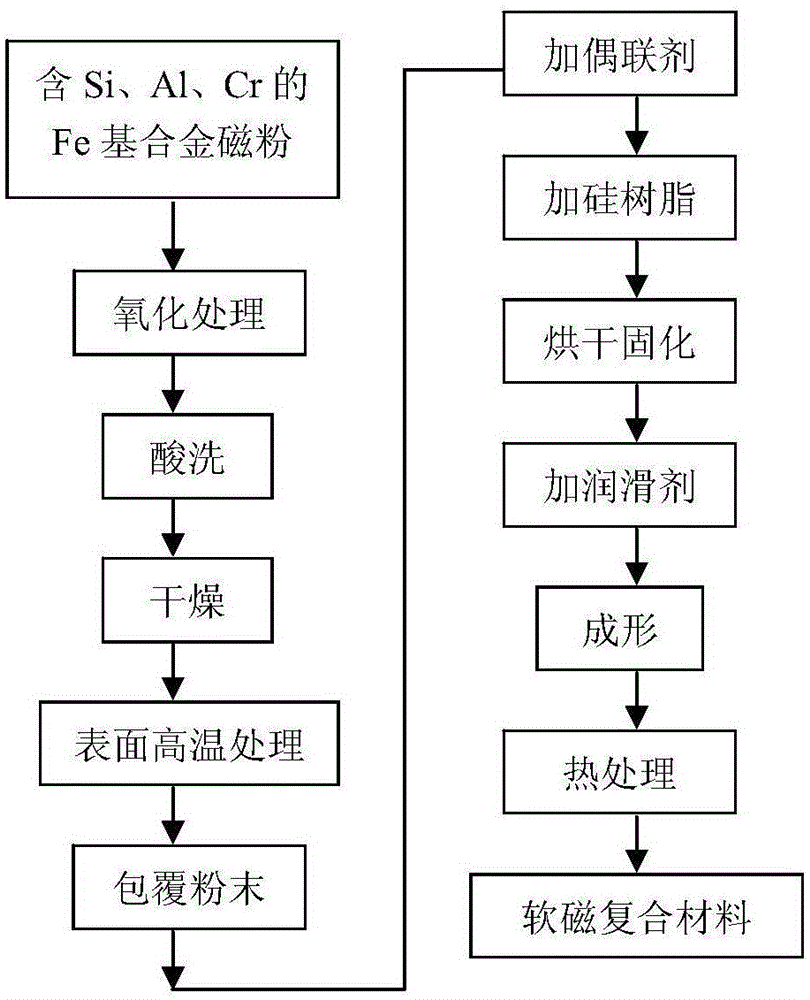

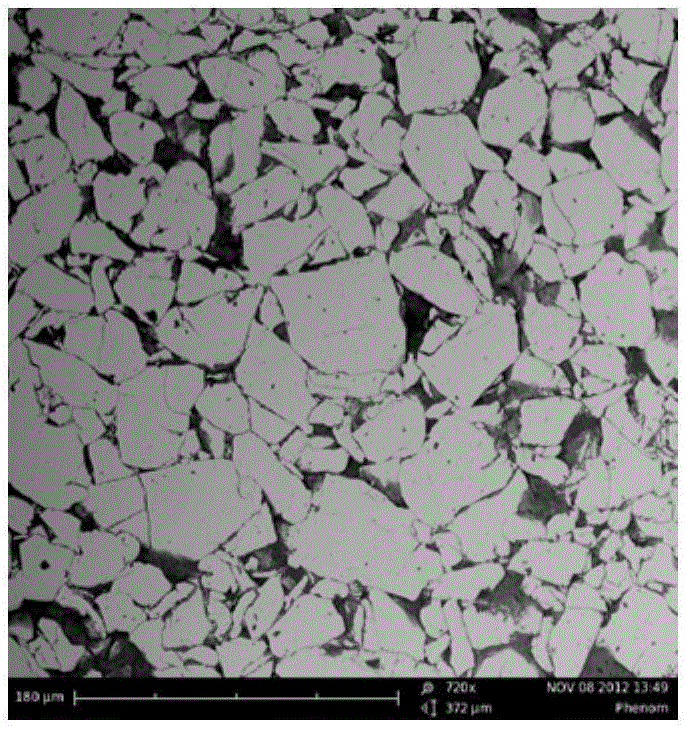

Coating method iron-based magnetically soft alloy powder and preparation method of soft magnet composite material

ActiveCN105149574AHigh resistivityImprove compactnessInorganic material magnetismMagnetic powderOxide

The invention relates to a coating method for iron-based magnetically soft alloy powder and a preparation method of soft magnet composite material. The coating method for iron-based magnetically soft alloy powder comprises the following steps: carrying out accelerated oxidation on iron-based magnetic metal powder at high temperature, forming an oxide layer on the surface of the powder and then carrying out acid pickling, thus obtaining powder with surface coated with SiO2, Al2O3 and Cr2O3 oxides. The preparation method of the soft magnet composite material comprises the following steps: adding coupling agent, silicon resin and lubricating agent to the coated powder, carrying out pressing forming, and then carrying out annealing heat treatment, thus obtaining the soft magnet composite material. According to the invention, the advantage that an oxide produced in reaction of elements including Si, Al and Cr contained in the iron-based magnetically soft alloy powder with oxygen is high in electrical resistivity, small in thermal expansion coefficient and steady in chemical performance and can resist high temperature is fully utilized; the adopted coating technology is to produce a coating layer in situ on the surface of the alloy magnetic powder, and is simple in process, easy to operate and low in cost; the metal soft magnet composite material prepared by adopting the method disclosed by the invention has good magnetic property and frequency stability.

Owner:CENT SOUTH UNIV

Particle reinforced iron-based metal powder for ultra-high speed laser cladding

ActiveCN108103499AImprove surface wear resistanceExtended service lifeTransportation and packagingMetal-working apparatusUltra high speedChemical composition

The invention provides particle reinforced iron-based alloy powder for ultra-high speed laser cladding. The iron-based alloy powder is composed of iron matrix metal powder and oxide particles or carbide particles and comprises 50-98% of iron matrix metal powder and 2-50% of oxide particles or carbide particles, wherein an iron matrix is composed of, by mass, 0.03-2% of C, 0.50-2.80% of Si, 0.30-1.60% of Mn, 2-12% of Cr, 0.5-3% of V, 0.5-4% of Mo, 0.3-1% of Nb, less than or equal to 0.030% of P, less than or equal to 0.030% of S, 0.05-3.0% of B and the balance Fe and inevitable impurities. Theparticle size of the metal power is 10-100 microns, and the flowability of the metal power is 32-45 s / 100 g. By adopting the particle reinforced iron-based metal powder, the laser cladding technologyis adopted and matched with different processes for reinforcing and repairing matrix surfaces.

Owner:中机新材料研究院(郑州)有限公司

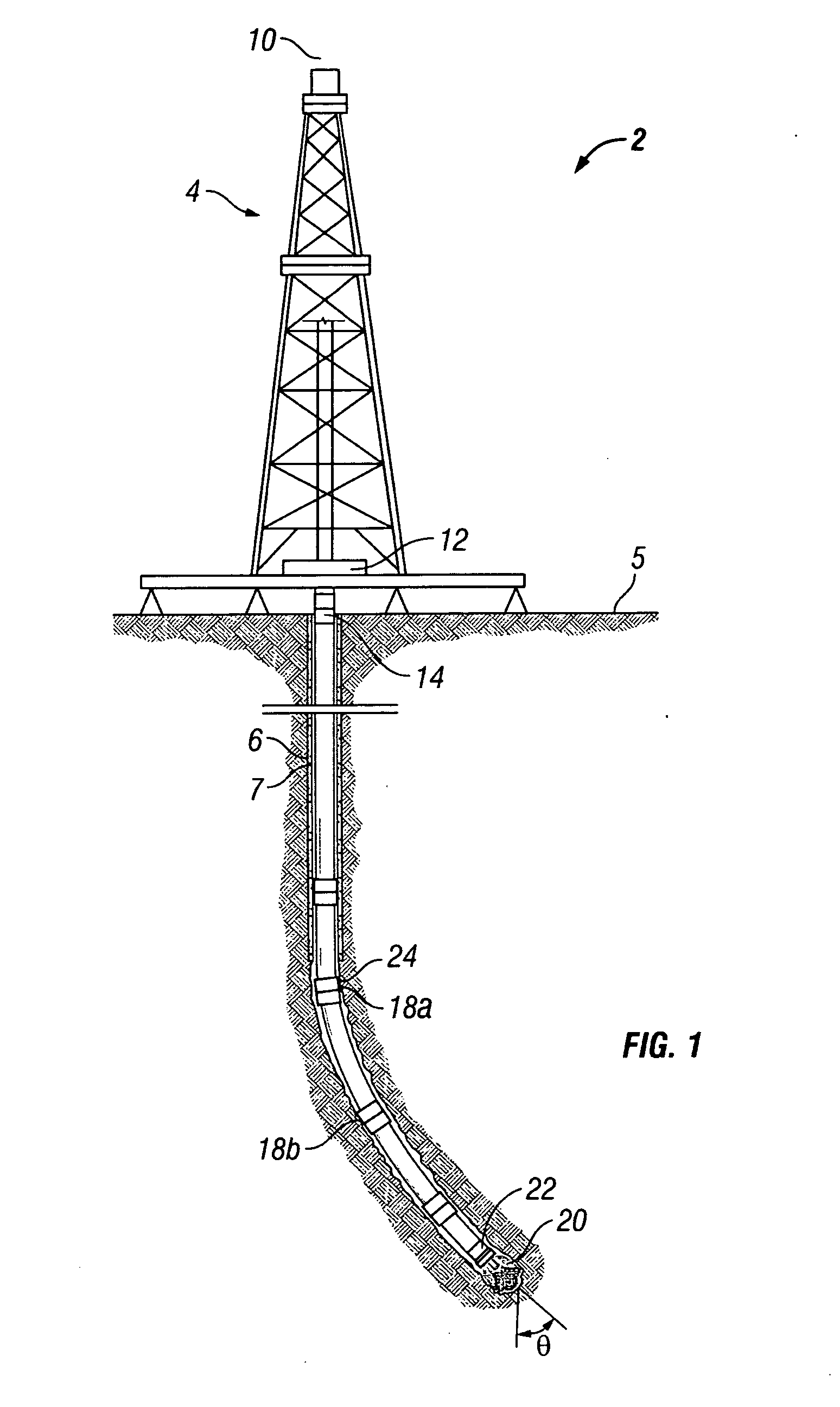

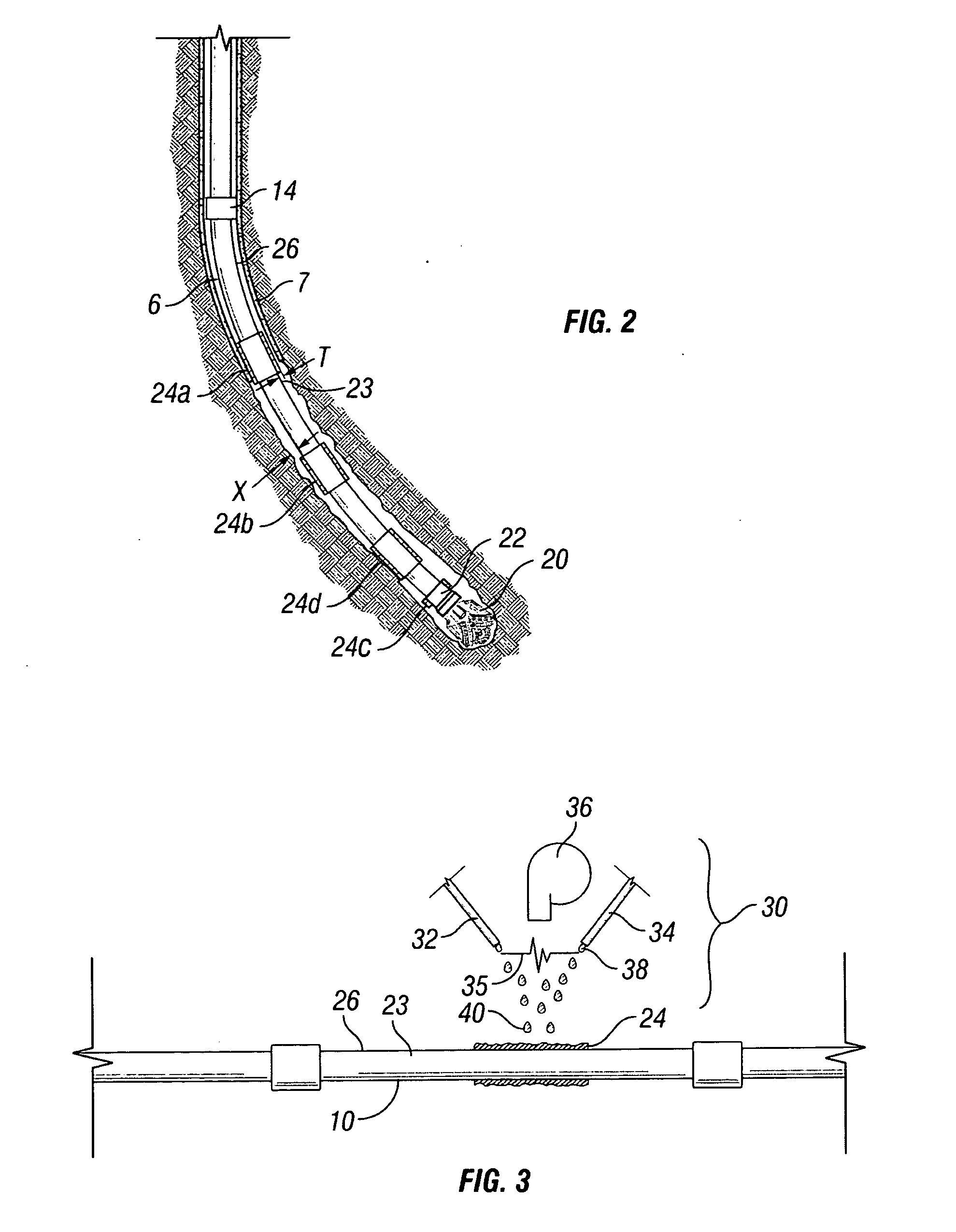

Wear resistant layer for downhole well equipment

ActiveUS20060102354A1Reduce coefficient of frictionImprove wear resistanceDrill bitsMolten spray coatingThermal sprayingWear resistant

The present disclosure provides a method, system, apparatus, and related alloy to provide a protective wear coating on a downhole component for a well through a synergistic use of a thermal spraying process in combination with a novel iron-based alloy. The thermal spraying process melts the material to be deposited while a pressurized air stream sprays the molten material onto the downhole component. The coating operation takes place at low temperatures without fusion or thermal deterioration to the base material. The wear resistance is increased while providing a lower coefficient of friction by the wear resistant layer relative to a coefficient of friction of the downhole equipment without the wear resistant layer. In at least one embodiment, the disclosed process using the iron-based alloy can apply a much thicker coating than heretofore has been able to be applied without spatting and without necessitating an intermediate buffer layer.

Owner:INNOVEX DOWNHOLE SOLUTIONS INC

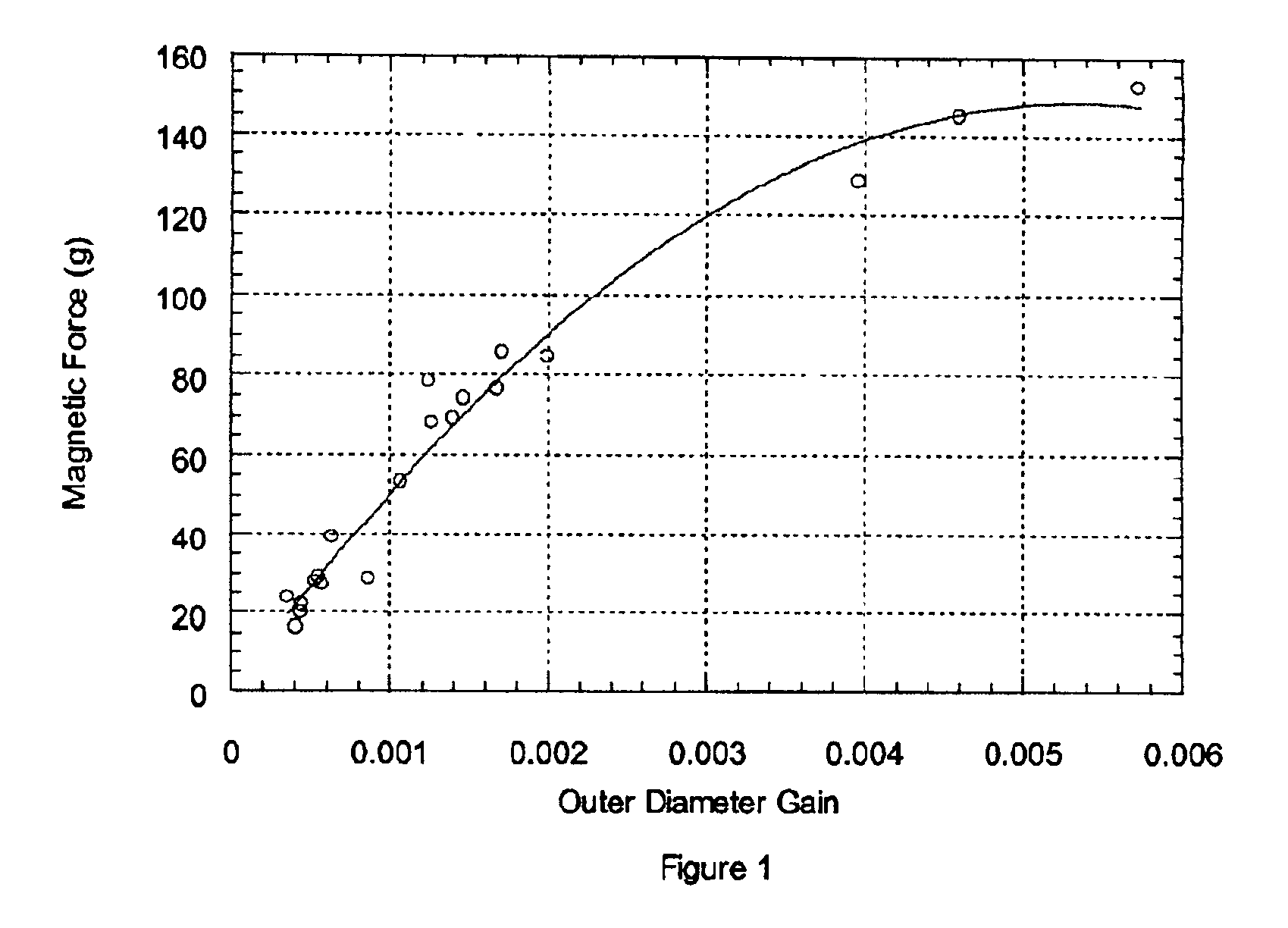

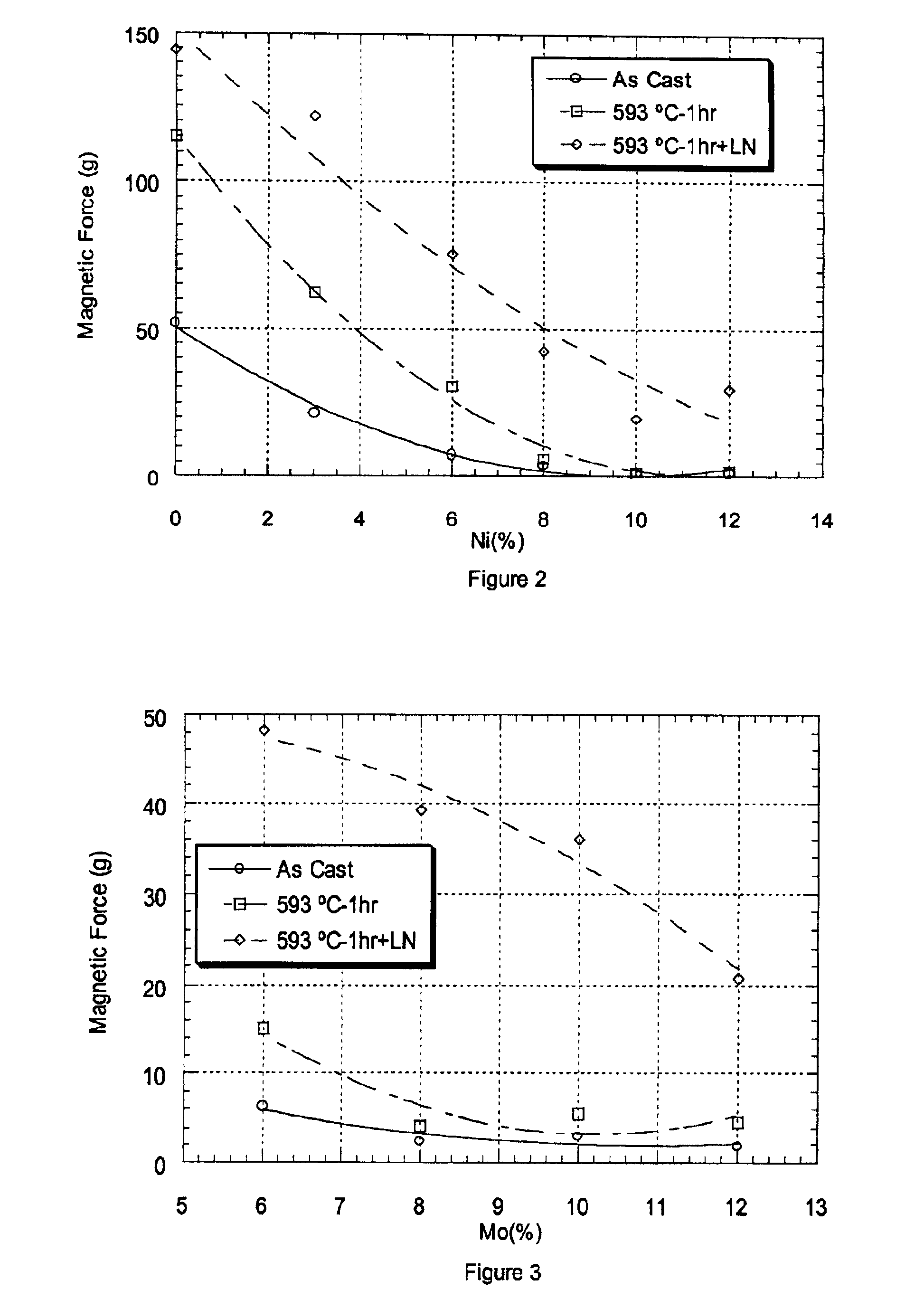

Wear resistant alloy containing residual austenite for valve seat insert

InactiveUS6916444B1Good compatibilityImprove wear resistancePiston ringsMachines/enginesNiobiumWear resistant

This invention related to a novel iron base alloy using residual austenite to improve wear resistance for valve seat insert material for internal combustion engines. The residual austenite is stable even after heat treatment and liquid nitrogen chilling. The alloy comprises of 2.0-4.0 wt % carbon, 1.0-3.0 wt % silicon, 0-4.0 wt % manganese, 3.0-9.0 wt % chromium, 5.0-15.0 wt % molybdenum, 3.0-15.0 wt % nickel, 0-6.0 wt % vanadium, 0-4.0 wt % niobium, 0-6.0 wt % cobalt, and the balance being iron with impurities.

Owner:WINSERT

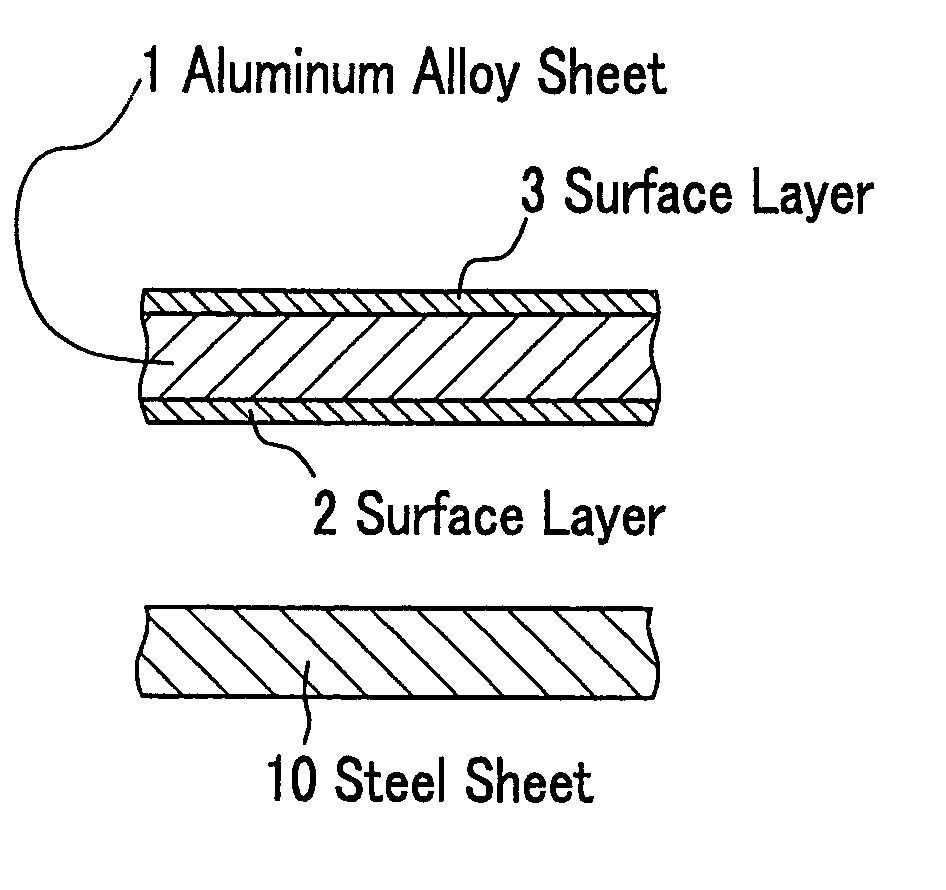

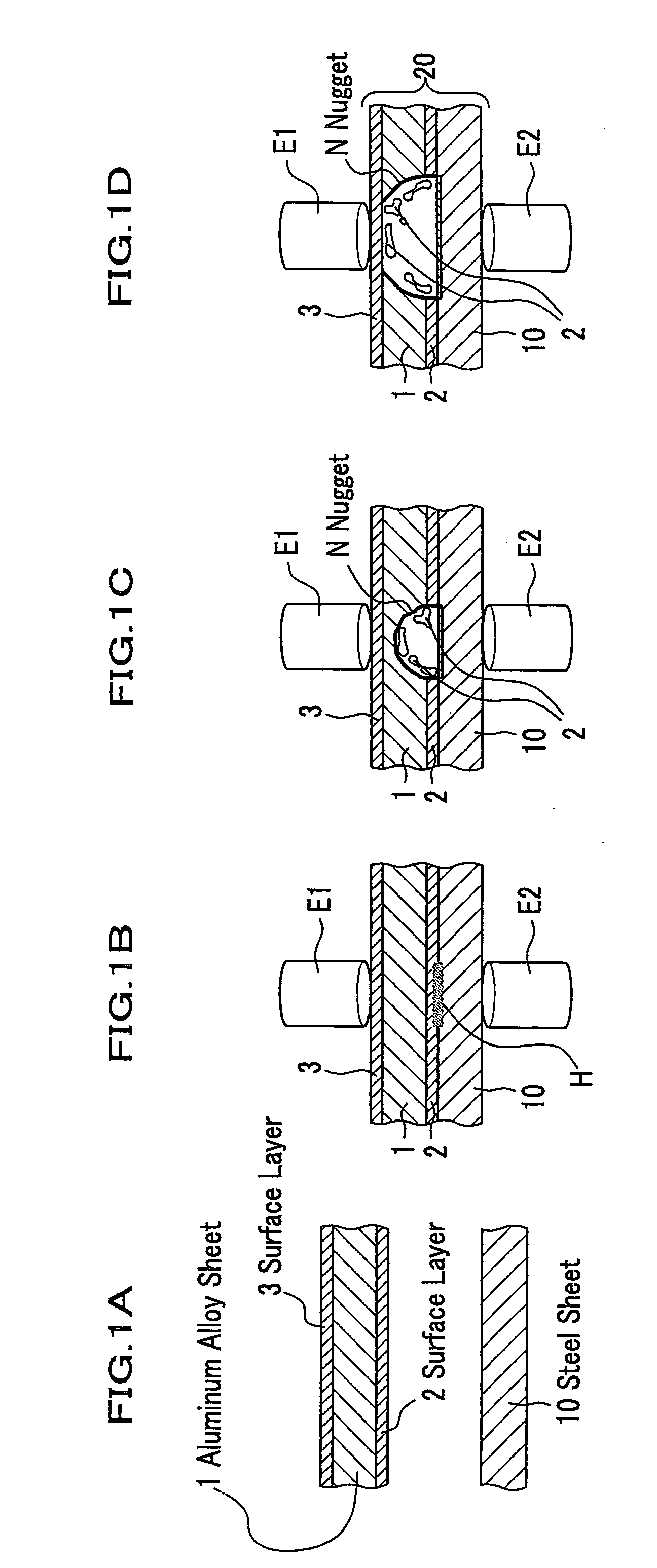

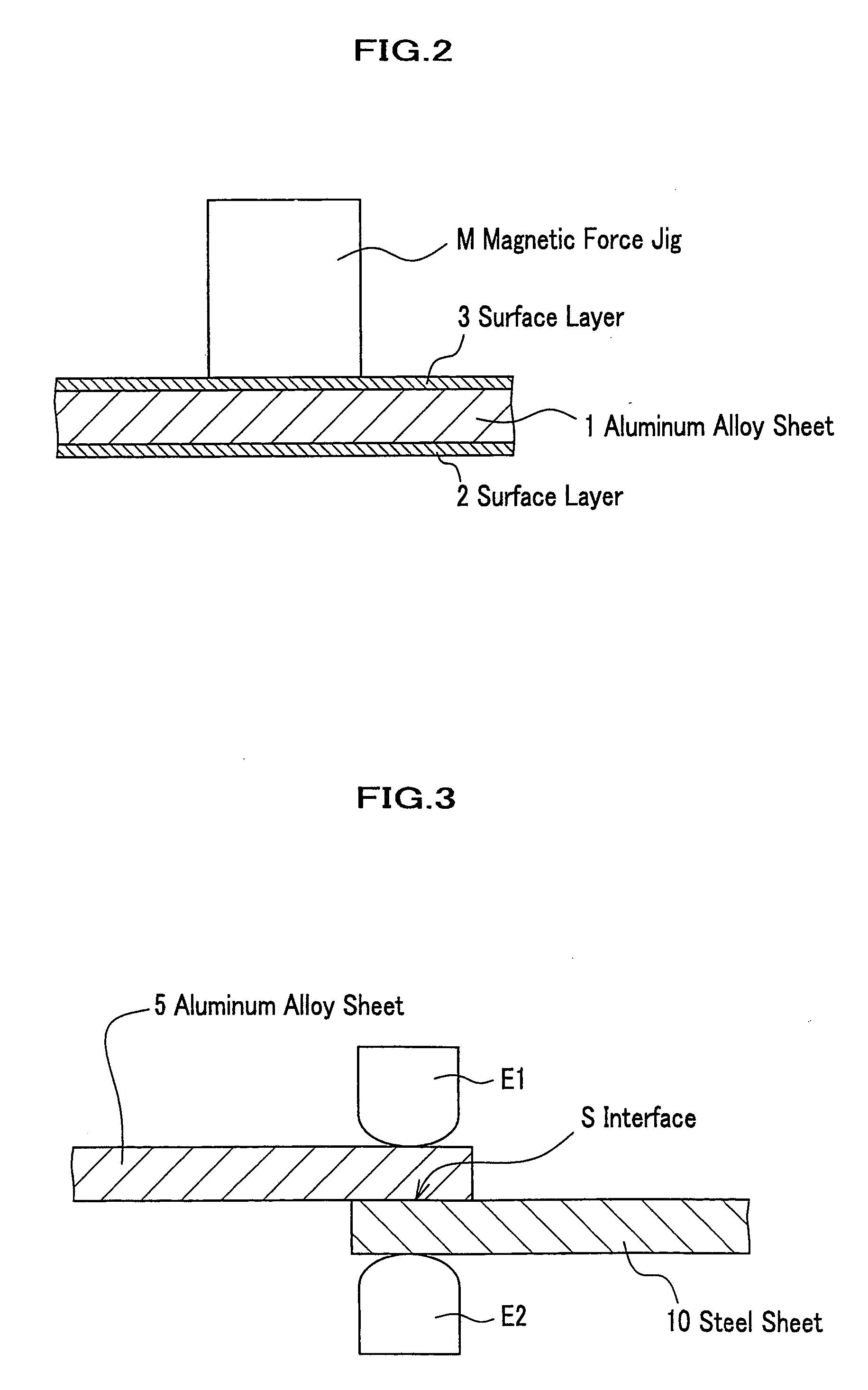

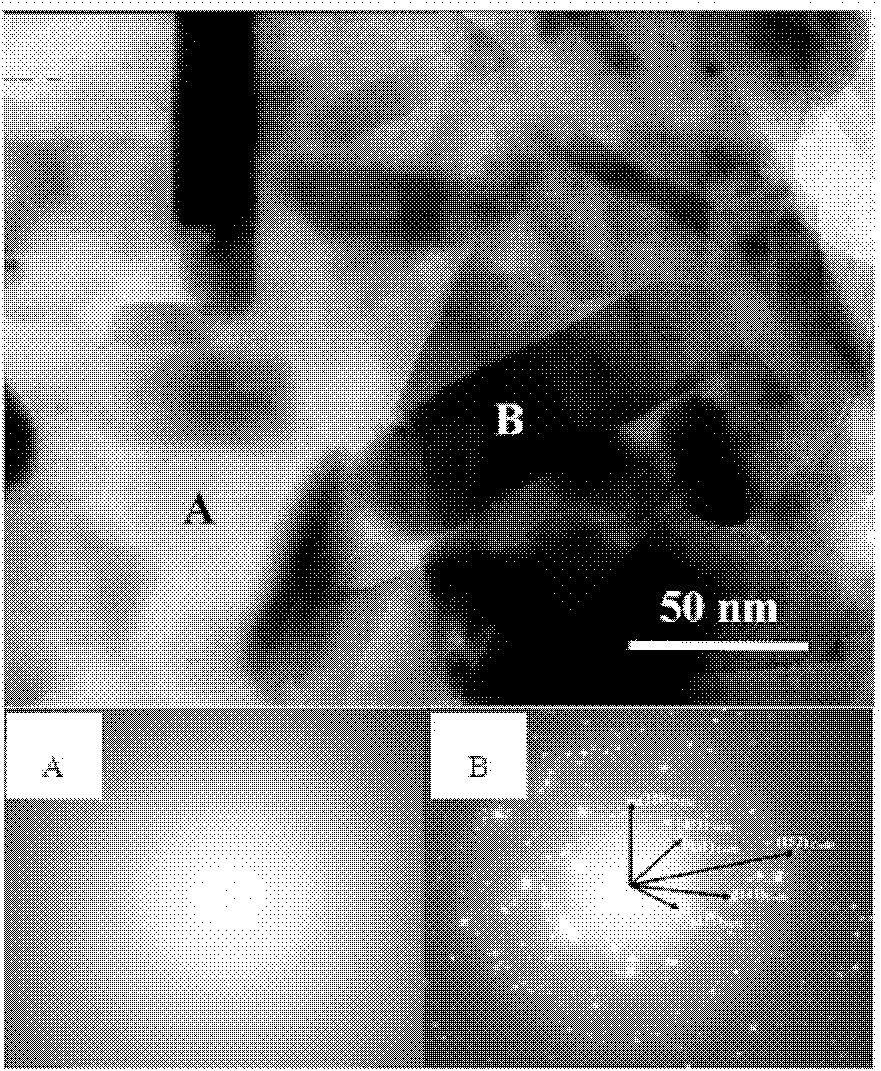

Resistance welding method of different kinds of materials, and resistance welding member of aluminum alloy material and different kind of material

InactiveUS20050218121A1Improve solderabilityEfficiency of manufacturing can not be realizedHot-dipping/immersion processesArc welding apparatusSurface layerSpot welding

The resistance welding method of different kinds of materials is the method for welding an iron material and an aluminum alloy material, and comprises the steps of: performing in advance a coating treatment at least to a portion of the aluminum alloy material, where resistance welding is performed, with any of iron and iron-base alloy and forming a surface layer; and performing resistance welding of the iron material and the aluminum alloy material through the surface layer, and the resistance welding may be any of spot welding and projection welding.

Owner:HONDA MOTOR CO LTD +1

Metal powder material for 3D printing, preparation method of metal powder material and 3D printing method

The invention discloses a metal powder material for 3D printing, a preparation method of the metal powder material and a 3D printing method. The preparation method of the metal powder material for 3D printing comprises the following steps that iron-base alloy powder with the grain sizes ranging from 20 micrometers to 60 micrometers is used as a base body, iron oxide powder and carbon powder with the grain sizes ranging from 50 nanometers to 2 micrometers are used as additives, the powder is evenly mixed, and the metal powder material is obtained; the mass ratio of the iron oxide powder and the carbon powder is within the range of 4.4:1-8.8:1, and the ratio of the sum of the mass of the iron oxide powder and the mass of the carbon powder to the mass of the iron-base alloy powder is within the range of 1:100-1:400. After the metal powder material is prepared, the metal powder material is printed to be a three-dimensional blank through a micro-jetting bonding 3D printing method; the three-dimensional blank is subjected to degreasing sintering, the sintering temperature is no lower than 900 DEG C, and a 3D printing product is obtained. The metal powder material is used in the 3D printing method, and therefore the obtained printing product is high in compactness.

Owner:DONGGUAN HUAJING POWDER METALLURGY

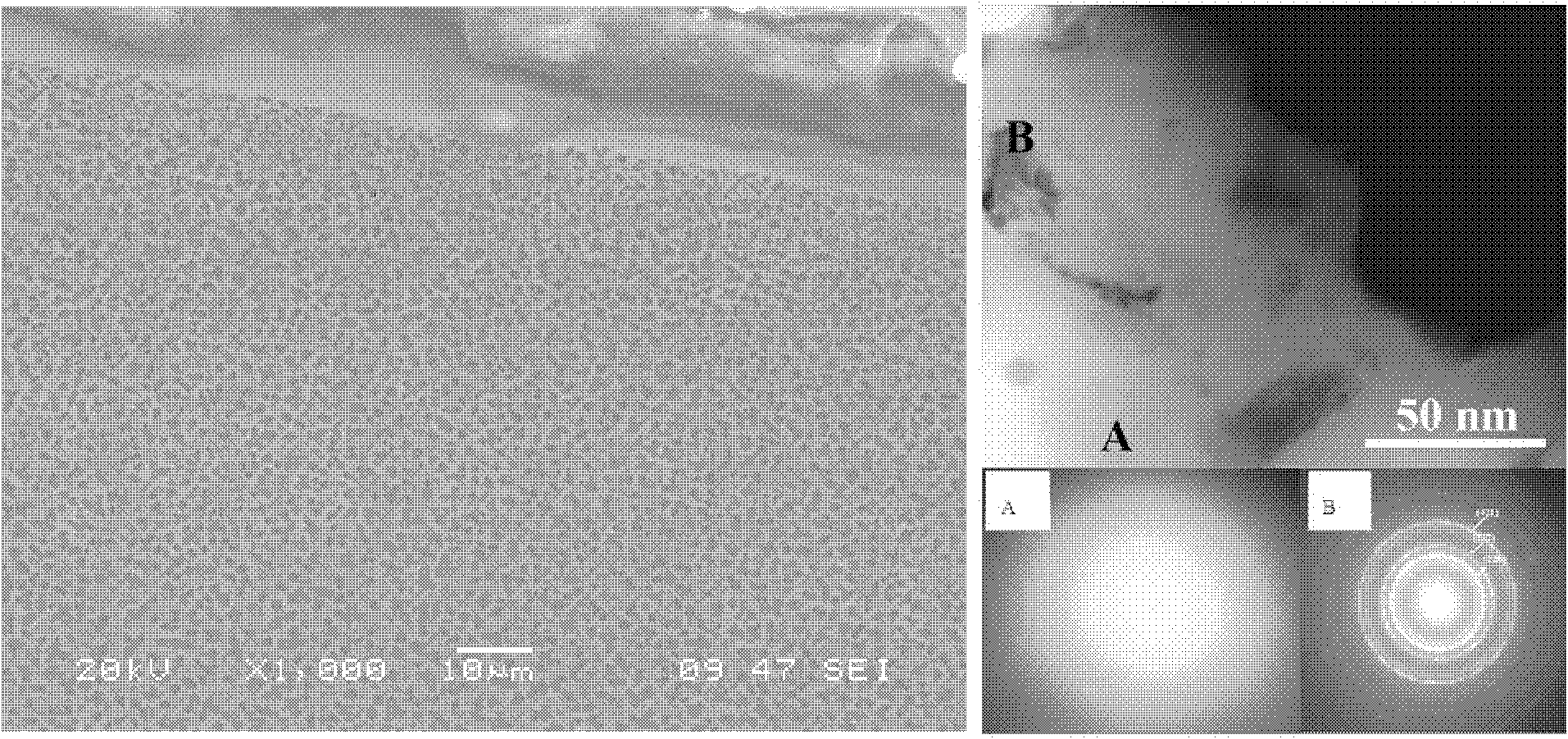

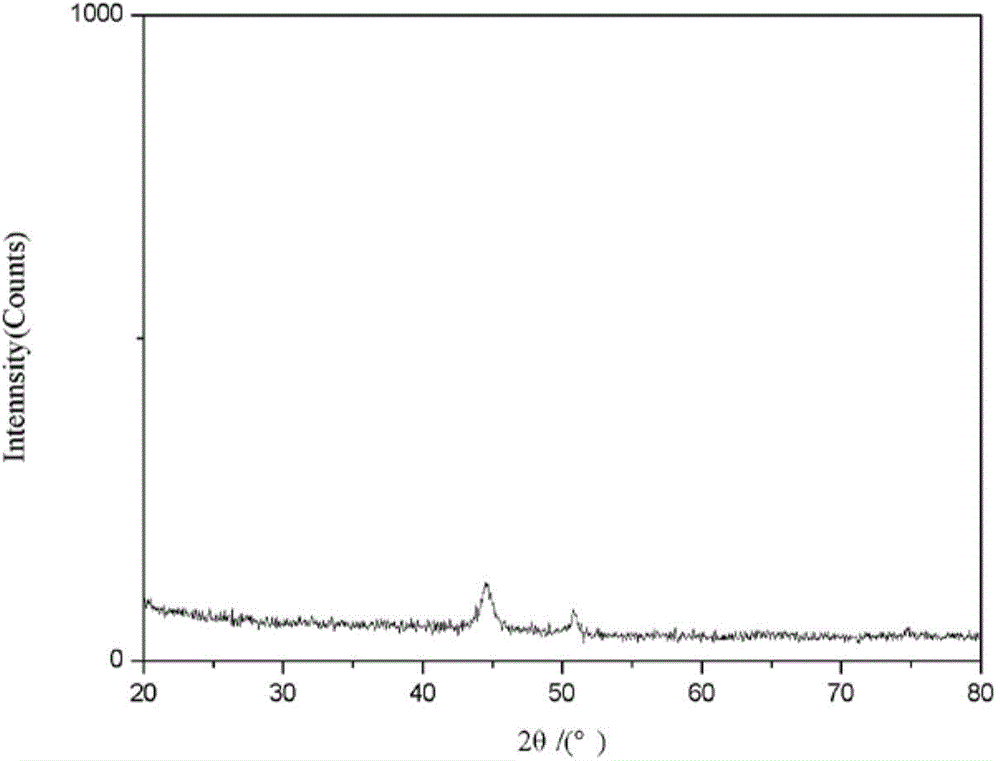

Laser preparation method of iron-based amorphous nanometer crystalline coat

The invention provides a laser preparation method of an iron-based amorphous nanometer crystalline coat, belonging to the technical field of coating a surface. The method comprises the following steps of: transporting laser melted and coated metal powder by means of side shaft synchronous powder transportation; melting and coating under the argon protection atmosphere to be formed into an iron-based alloy coat; and remelting by means of laser into the iron-based amorphous nanometer crystalline coat. The laser preparation method leads the coat to have smaller element segregation and even component distribution in fine equiaxial structure, leads a melting pond and a melting body to have higher glass forming capability, and is good for forming the amorphous nanometer crystalline tissue.

Owner:SHANGHAI JIAO TONG UNIV

Iron-based amorphous coating and laser preparation method thereof

ActiveCN104480462ALow costImprove corrosion resistanceMetallic material coating processesAtmosphereIron based alloy

The invention discloses a laser preparation method of an iron-based amorphous coating. A formula formed by all the elements of the iron-based amorphous coating according to the weight percent is FeaCrbNicSidBeCf, wherein the sum of b, c, d, e and f is not more than 50. Powder can be used after the components are uniformly mixed in proportion according to a required weight ratio. Powder is fed by synchronous powder feeding and is cladded in an argon protection atmosphere to prepare an iron-based alloy coating and the iron-based alloy coating is subjected to laser remelting to prepare the iron-based amorphous coating. The prepared coating has few defects and higher corrosion resistance and has a whole amorphous structure.

Owner:NANJING UNIV OF SCI & TECH

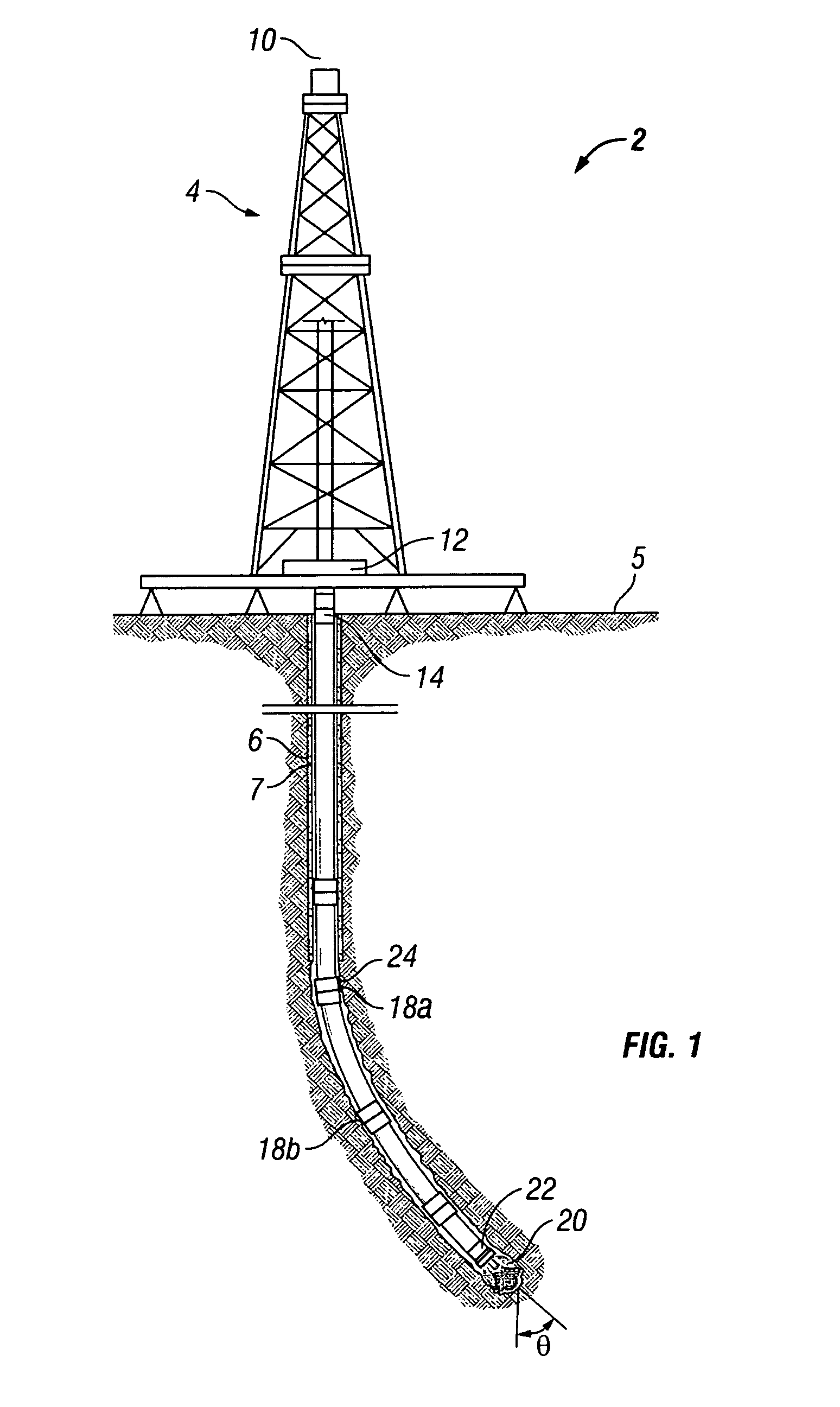

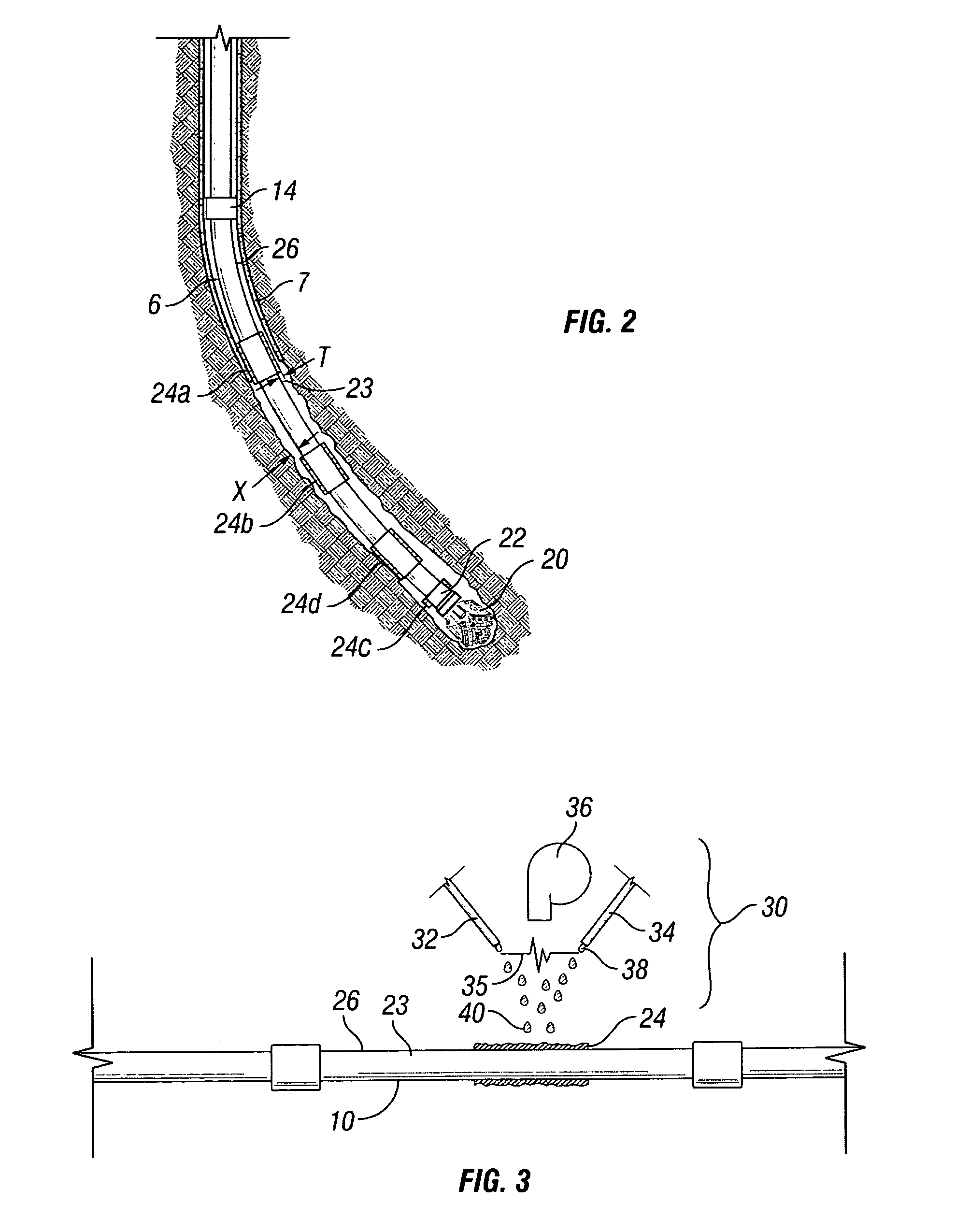

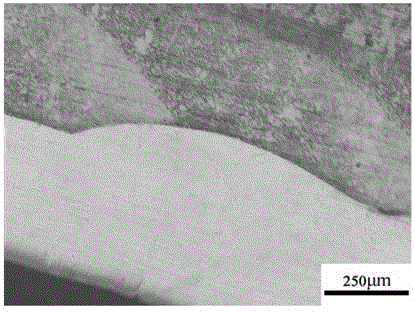

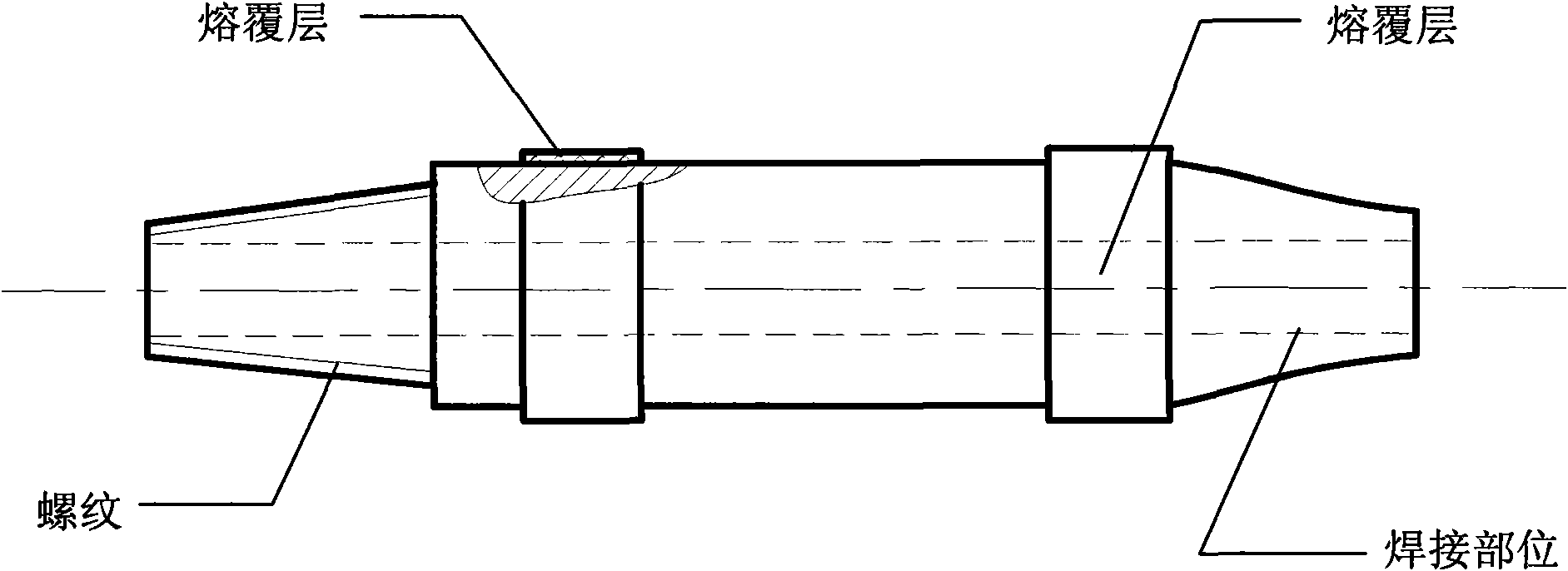

Wear and corrosion resistant iron-based alloy laser-cladding petroleum drill stem joint

ActiveCN102619477AHigh energy density of laserLittle thermal impactDrilling rodsMetallic material coating processesPetroleumDrill

The invention relates to a wear and corrosion resistant iron-based alloy laser-cladding petroleum drill stem joint. A layer of laser-cladding wear and corrosion resistant iron-based alloy coating is arranged on the surface of the drill stem joint and has the advantages of favorability in forming, compact tissue, uniformity in components and no crack; and the thickness of the laser-cladding wear and corrosion resistant iron-based alloy coating can be accurately controlled within 0.3 to 1.5mm. Cladding layers are not needed to completely cover the surface of the whole drill stem joint and are only required to respectively clad easily-abrasive belts at two ends of a joint cylinder for 30-50mm. The iron-based alloy powder comprises the following components in percentage by weight: 0.1-1.5 percent of C, 10-30 percent of Cr, 1-10 percent of Ni, 0.2-3.0 percent of Mn, 0.1-3.0 percent of Mo, 1.0-2.5 percent of Si, 0.1-3.5 percent of B and the balance of Fe, wherein the total weight percentage is 100 percent. According to the wear and corrosion resistant iron-based alloy laser-cladding petroleum drill stem joint, the problem that the drill stem joint is high in failing speed in an oil field is solved; the automation of a manufacturing and processing process of the drill stem joint is easily realized; and the drill stem joint has the advantages of high work efficiency, great advantages in economy and broad popularization prospect.

Owner:青岛麒特新材料科技有限公司

Acid resistant austenitic alloy for valve seat insert

InactiveUS20070086910A1Improve wear resistanceImprove corrosion resistanceMachines/enginesLift valveNiobiumManganese

A high carbon austenitic iron base alloy for wear and corrosion resistant applications is developed for valve seat insert applications when corrosion resistance is required. The alloy comprises 1.8-2.8 wt % carbon, 0.5-3.5 wt % silicon, 10.0-25.0 wt % chromium, less than 1.5 wt % manganese, 2.0-10.0 wt % molybdenum and tungsten combined, 1.0-4.0 wt % niobium and vanadium combined, 0-1.0 wt % titanium, 0.01-0.2 wt % aluminum, 12-25 wt % nickel, 0.5-3.0 wt % copper, and the balance being iron and a small amount of impurities.

Owner:WINSERT

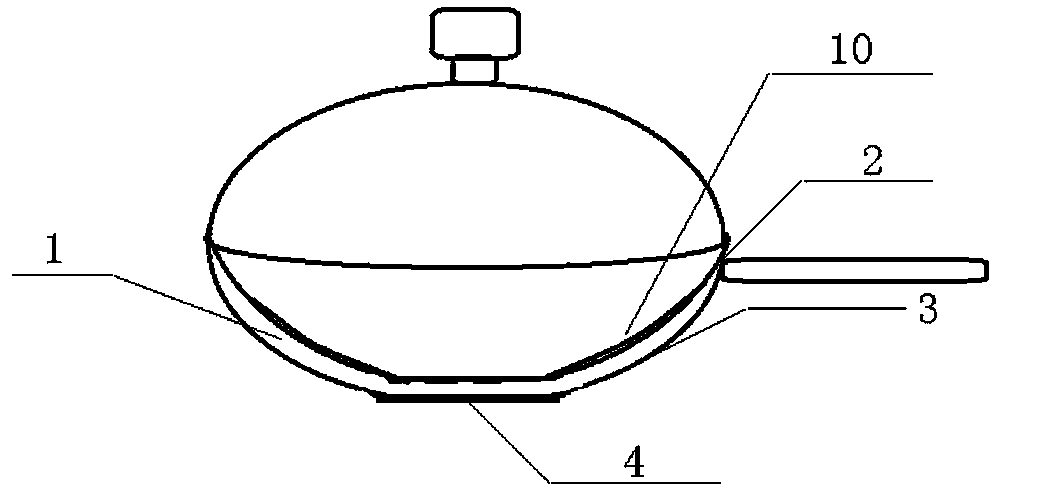

Novel composite cooker and manufacturing method thereof

The invention provides a novel composite cooker which comprises a cooker body with the thickness of 1.5 mm-5.0 mm. The thickness of the cooker wall is successively and progressively decreased by the 2 mm-3 mm space from the upper portion of the plane of a cooker bottom to the edge of the cooker wall. The cooker body comprises an inner layer cooker body and an outer layer cooker body, the inner layer cooker body is made of one of iron, iron-base alloy, stainless steel, titanium and titanium alloy, the outer layer cooker body is made of aluminum alloy or pure aluminum or AZ31B magnesium alloy or magnesium alloy, and a magnetic conduction energy storage layer is pressed on the outer surface of the outer layer cooker body. The materials of the inner surface of the cooker is healthful and sanitary, the heat conduction performance of the outer surface of the cooker is good, the outer surface is light in material, the magnetic conduction energy storage layer is arranged on the outer portion of the cooker bottom, the heat collection effect of the cooker bottom is increased, cooking energy consumption is reduced, and the application range of the cooker is expanded. The invention further provides a manufacturing method of the novel composite cooker. The method is easy to operate, saves materials, reduces cost, and is convenient to implement and beneficial to industrialization of the novel composite cooker.

Owner:WUYI RUIPU KITCHENWARE CO LTD

Abrasion-resistant steel for low-alloy ultra-high strength engineering machine and preparation method thereof

The invention belongs to the technical field of iron-base alloy and particularly relates to abrasion-resistant steel for a low-alloy ultra-high strength engineering machine and a preparation method thereof. The abrasion-resistant steel comprises, by mass, 0.20-0.40% of C, 0.40-0.90% of Si, 0.8-2.0% of Mn, 1.00-2.50% of Cr, 0.30-0.60% of Mo, V<=0.08%, Ti<=0.04%, S<=0.004%, 0.004-0.008% of P, B<=0.002%, 0.002-0.005% of N and the balance Fe and inevitable impurities. The abrasion-resistant steel combines reasonable chemical components and a large deformation rolling process, has the advantages of being low in alloy element content, strong in strength, good in toughness, low in cost, good in abrasive resistance and the like, and is suitable for engineering machines, mining equipment, cement equipment and the like.

Owner:CENT IRON & STEEL RES INST

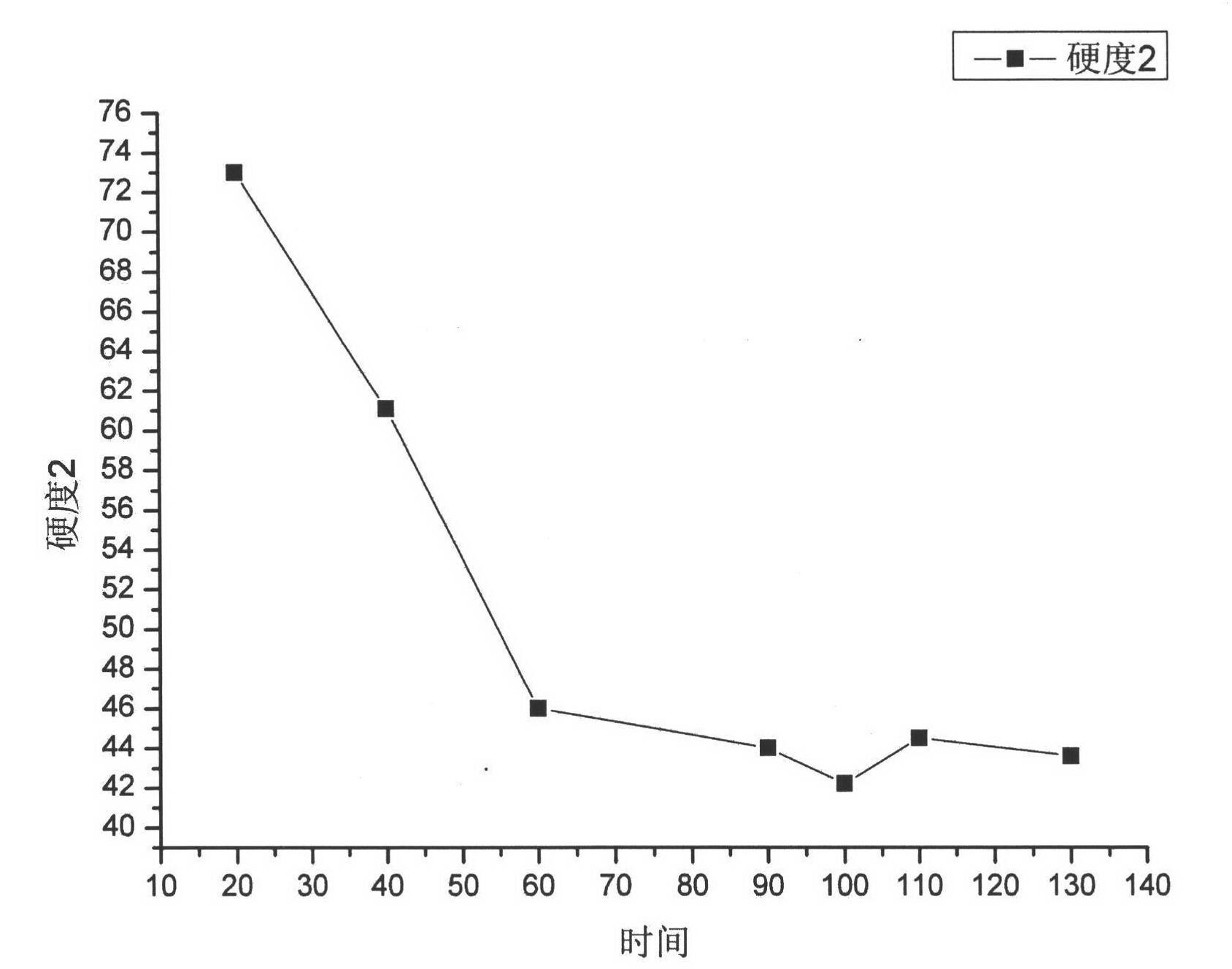

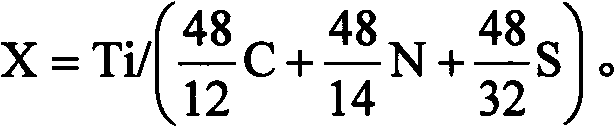

Gapless atom cold-rolled hot-galvanized steel plate and production method thereof

ActiveCN103510002AReduce manufacturing costFully recrystallized structureChemical compositionGranularity

The invention relates to a gapless atom cold-rolled hot galvanized steel plate and a production method thereof, which belongs to the technical field of iron-base alloys and solves the technical problem that the product performance can not reach the standard when a horizontal continuous annealing furnace is adopted for annealing to produce the gapless atom hot-galvanized steel plate in the prior art. The technical scheme is as follows: the gapless atom cold-rolled hot galvanized steel plate comprises the following chemical components in percentage by weight: 0.0005%-0.0028% of C, at most 0.03% of Si, 0.08%-0.20% of Mn, 0.02%-0.065% of Ti, at most 0.0030% of N, at most 0.015% of P, at most 0.010% of S, and the balance of Fe and inevitable impurity elements. The microscopic structure grain fineness of the cold-rolled steel plate is Grade I6.5-I8.0, the yield strength is 165-200 MPa, the tensile strength is 270-330 MPa, the percentage elongation after fracture A80mm is 38-44%, and the plastic strain ratio r is greater than or equal to 1.9. The method lowers the production cost of the gapless atom cold-rolled hot-galvanized steel plate. The product is mainly used for home appliance products, hardware structures and the like.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Erosion and wear resistant protective structures for turbine engine components

An erosion resistant protective structure for a turbine engine component comprises a shape memory alloy. The shape memory alloy includes nickel-titanium based alloys, indium-titanium based alloys, nickel-aluminum based alloys, nickel-gallium based alloys, copper based alloys, gold-cadmium based alloys, iron-platinum based alloys, iron-palladium based alloys, silver-cadmium based alloys, indium-cadmium based alloys, manganese-copper based alloys, ruthenium-niobium based alloys, ruthenium-tantalum based alloys, titanium based alloys, iron-based alloys, or combinations comprising at least one of the foregoing alloys. Also, disclosed herein are methods for forming the shape memory alloy onto turbine component.

Owner:GENERAL ELECTRIC CO

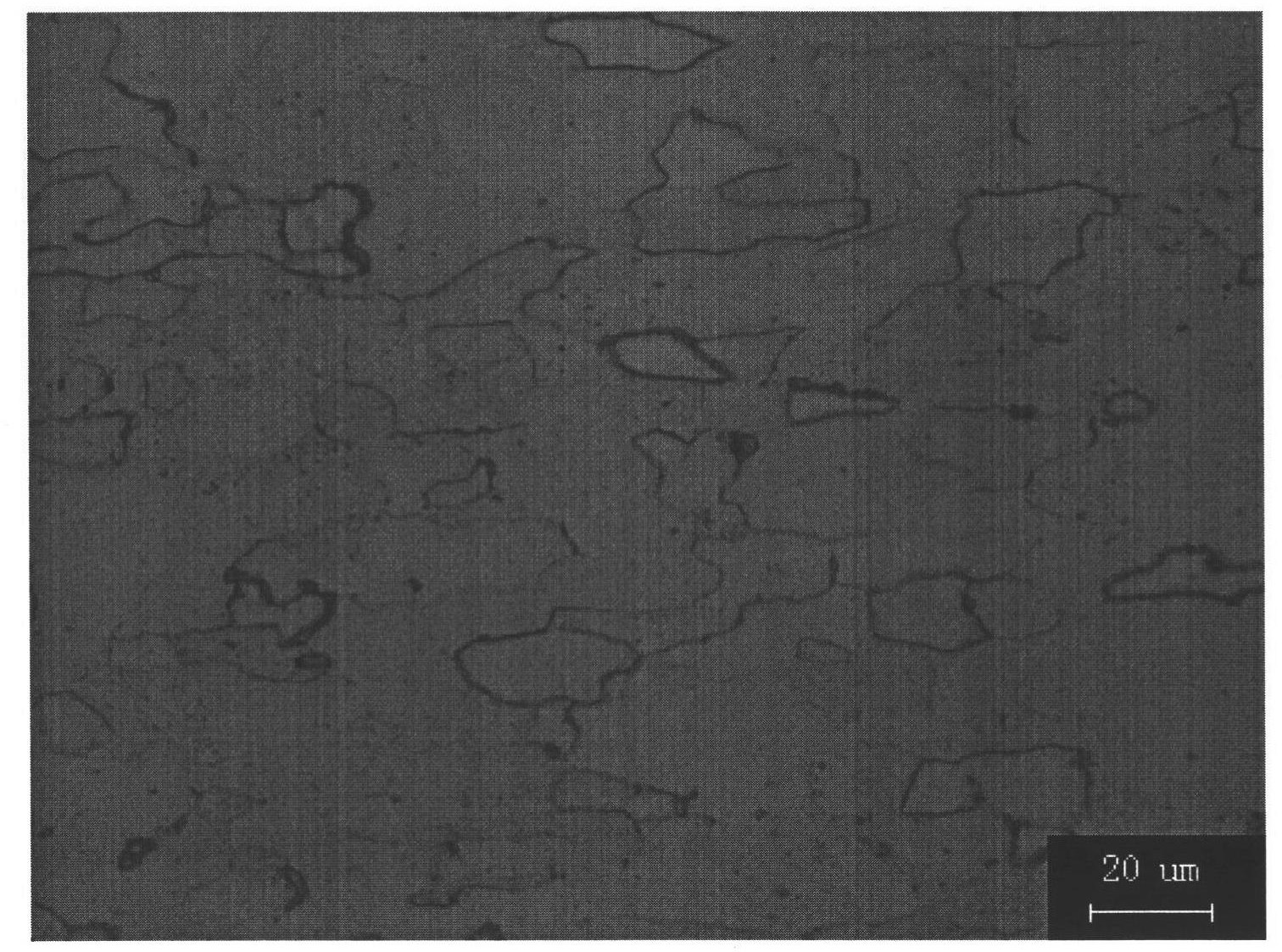

Low-temperature continuous-annealing interstitial-free atom cold-rolled steel plate and production method thereof

ActiveCN102653839ALower recrystallization temperatureRealize the structureChemical compositionReduction ratio

The invention relates to a low-temperature continuous-annealing interstitial-free atom cold-rolled steel plate and a production method thereof and belongs to the technical field of iron-based alloys. The production method of the cold-rolled steel plate comprises the following steps of: controlling the components of the cold-rolled steel plate in percentage by mass: 0.0005-0.0025% of C, less than or equal to 0.03% of Si, 0.05-0.15% of Mn, less than or equal to 0.015% of P, less than or equal to 0.01% of S, less than or equal to 0.0025% of O, less than or equal to 0.0025% of N, 0.015-0.050% of Al, 0.03-0.07% of Ti, and the balance of Fe and inevitable mixed elements; and meanwhile, controlling the continuous-annealing temperature of the cold-rolled steel plate to be 710-740 DEG C, and controlling the cold-rolling reduction ratio to be not less than 80%. According to the cold-rolled steel plate and the production method thereof, the reasonable chemical components and the suitable control of cold-rolling reduction are adopted, the recrystallization temperature is lowered, full-old-rolled microstructures are formed, and a lower continuous-annealing temperature can be adapted, so that the equipment cost and energy consumption are reduced, the control difficulty of a production process is reduced, the product defects and production accidents are avoided.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

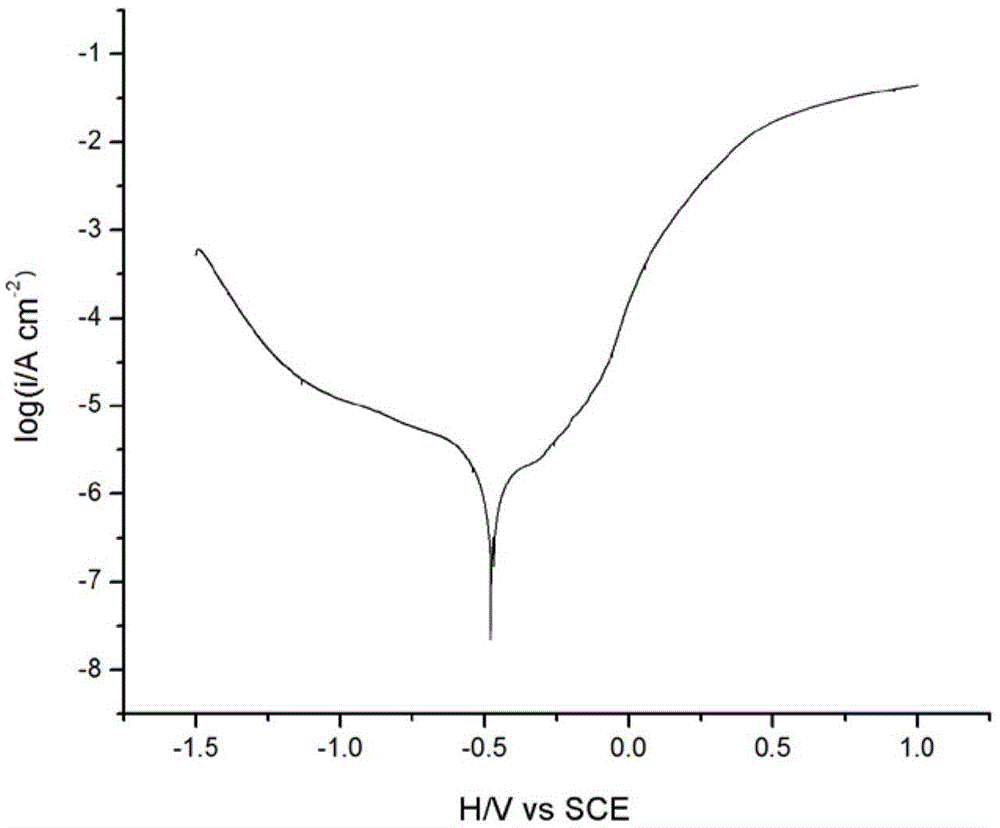

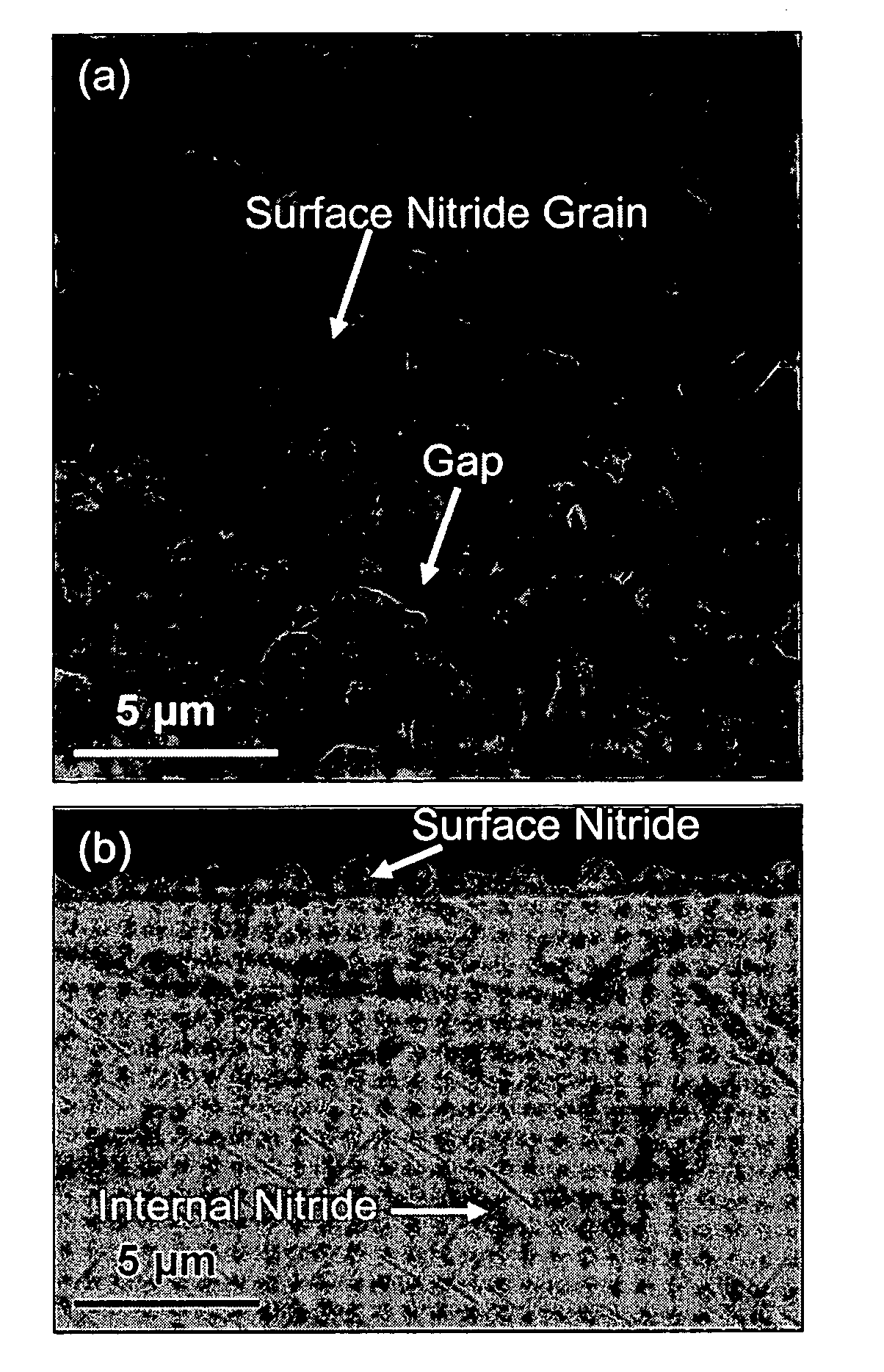

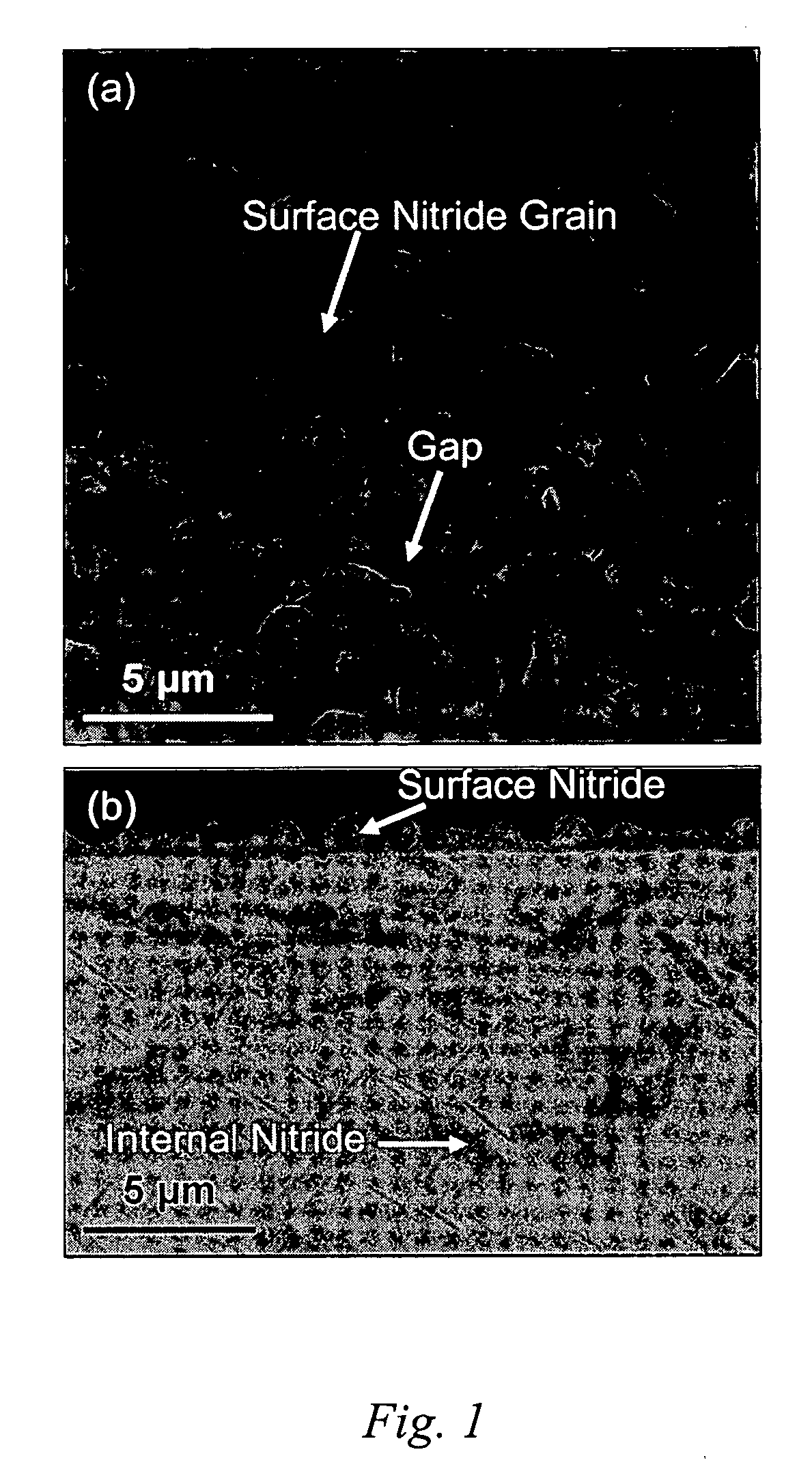

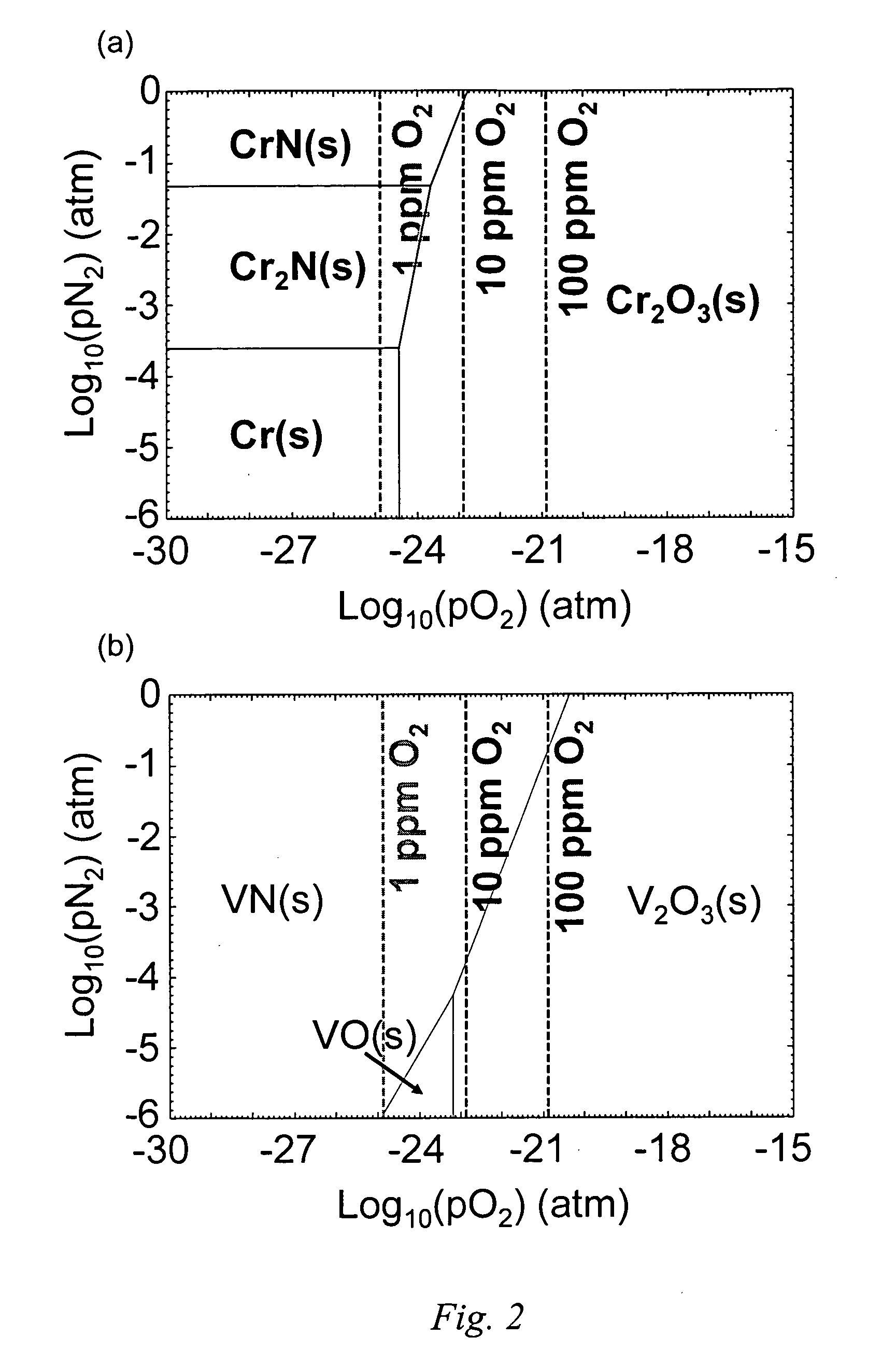

Iron-based alloy and nitridation treatment for PEM fuel cell bipolar plates

A corrosion resistant electrically conductive component that can be used as a bipolar plate in a PEM fuel cell application is composed of an alloy substrate which has 10-30 wt. % Cr, 0.5 to 7 wt. % V, and base metal being Fe, and a continuous surface layer of chromium nitride and vanadium nitride essentially free of base metal. A oxide layer of chromium vanadium oxide can be disposed between the alloy substrate and the continuous surface nitride layer. A method to prepare the corrosion resistant electrically conductive component involves a two-step nitridization sequence by exposing the alloy to a oxygen containing gas at an elevated temperature, and subsequently exposing the alloy to an oxygen free nitrogen containing gas at an elevated temperature to yield a component where a continuous chromium nitride layer free of iron has formed at the surface.

Owner:UT BATTELLE LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com