Ceramic-phase-containing iron-based amorphous nanocrystalline composite coating and preparation thereof

A nanocrystalline composite, iron-based amorphous technology, applied in coatings, metal material coating processes, melt spraying and other directions, can solve the problems of high construction cost, high porosity, inconvenient on-site construction, etc., and achieve coating combination. The effect of high strength, improving performance and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

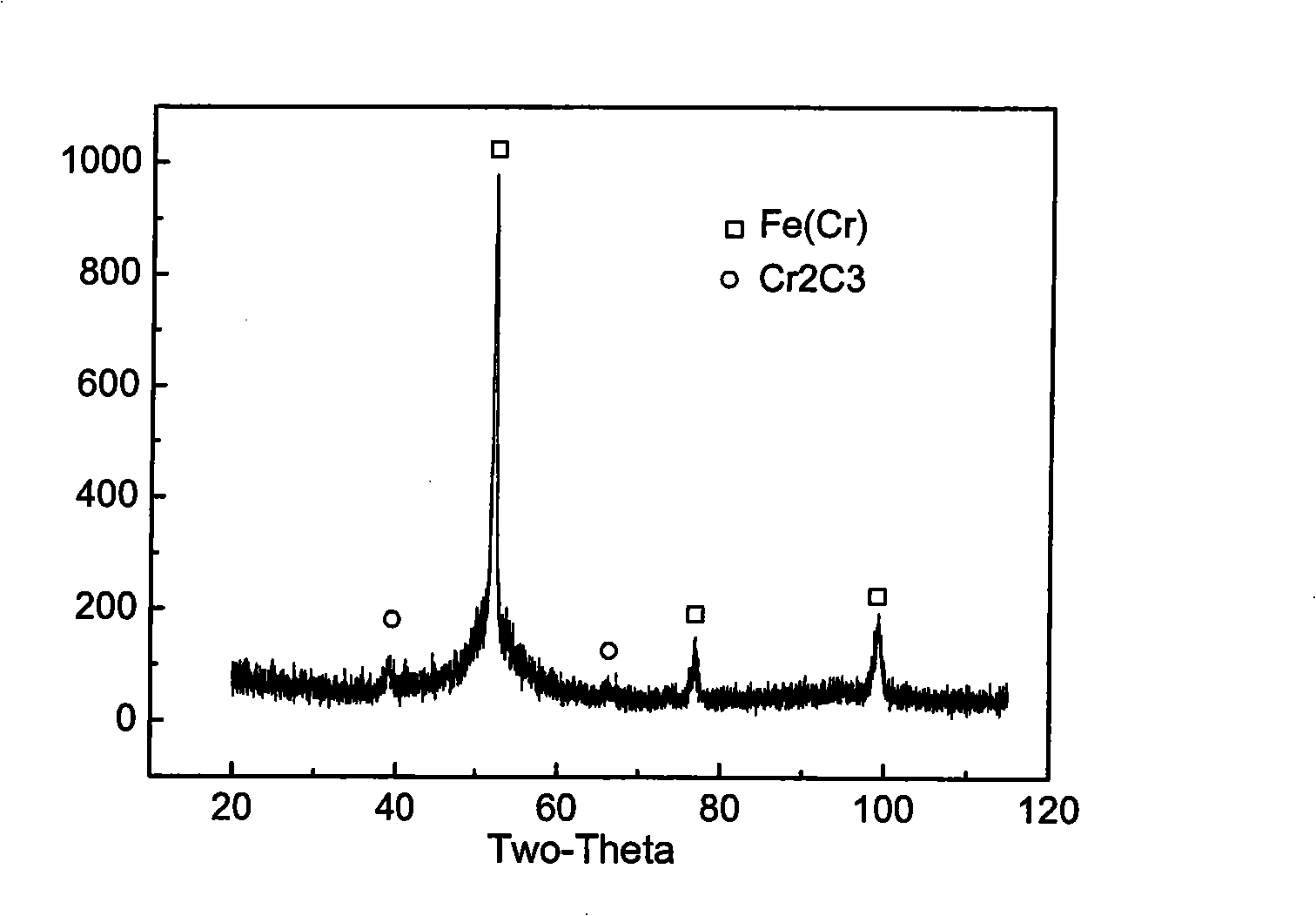

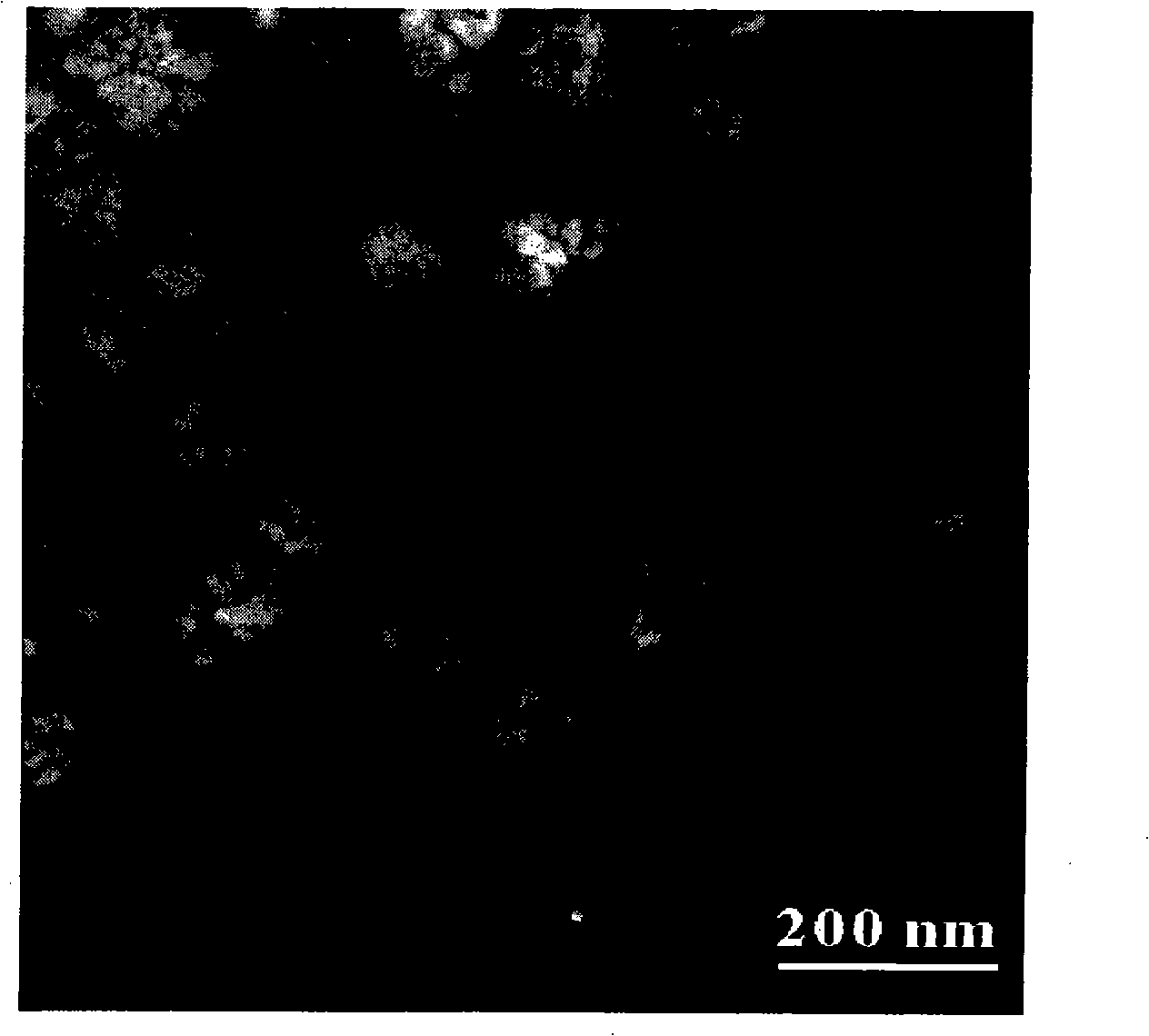

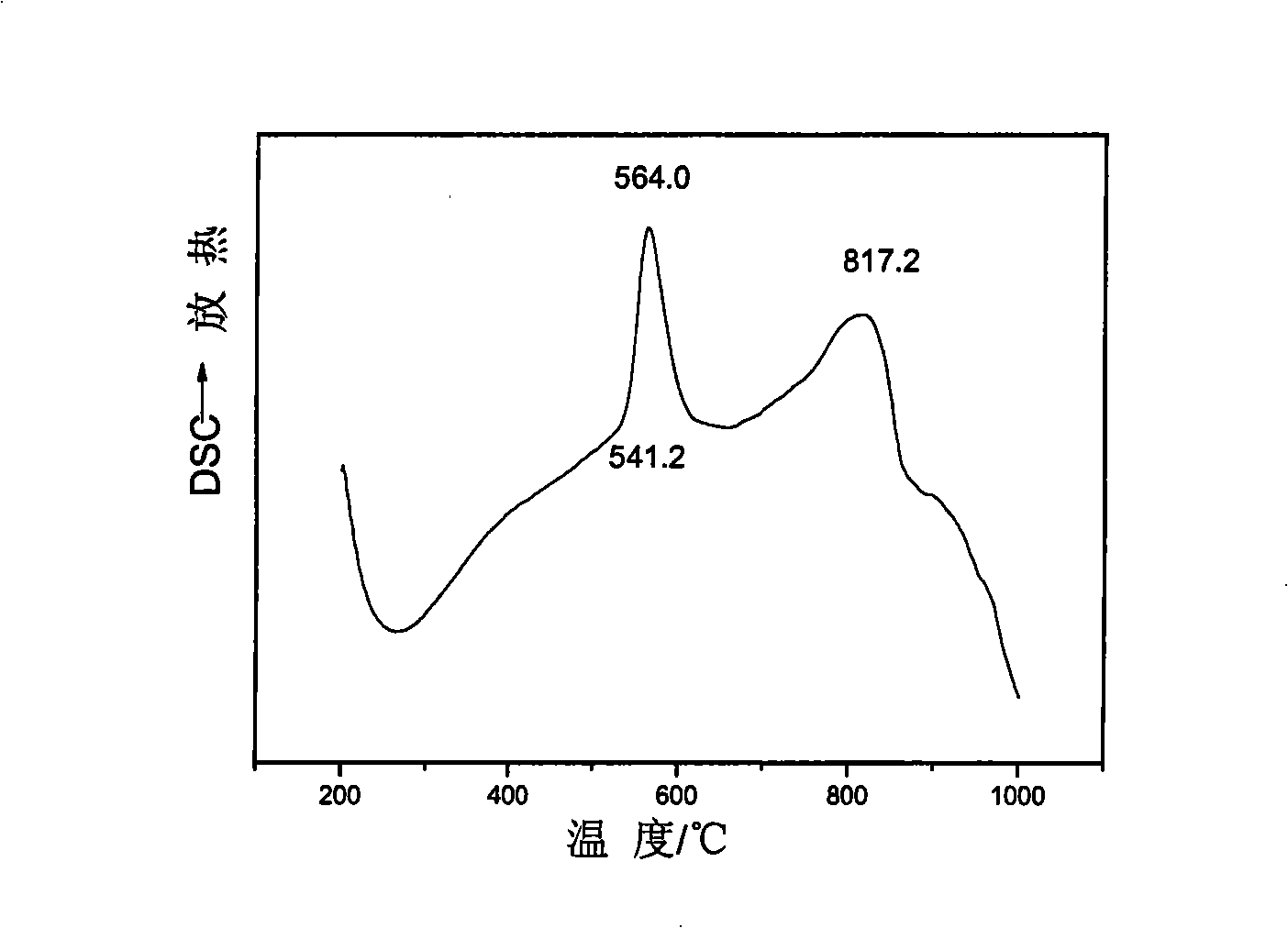

[0024] 1. The weight percentage of selected ingredients is Cr 16.99%, Mo 1.98%, W 3.80%, Mn 0.38%, B 3.10%, C 0.80%, Si 0.43%, and the weight of Co-wrapped WC powder in the drug core accounts for 5.20% of the total weight, The balance is Fe, and the above ingredients are prepared into drug core filaments. The total composition of the drug skin and drug core meets the above ingredients. The particle size of Co-coated WC powder in the drug core is 44 μm to 124 μm, and the particle size of other powders is between 26 μm and 150 μm. , The drug core weight accounts for 37.07%. The arc spraying process parameters are: arc voltage 34V, working current about 200A, atomizing gas pressure 0.7MPa, and spraying distance 200mm. The bonding strength between the sprayed coating and the substrate is above 46MPa, and the micro-Vickers hardness is greater than 900HV0.3kg. It has the characteristics of high hardness, good wear resistance, and good erosion resistance. It is suitable for high-tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com