Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

627 results about "Surface engineering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surface engineering is the sub-discipline of materials science which deals with the surface of solid matter. It has applications to chemistry, mechanical engineering, and electrical engineering (particularly in relation to semiconductor manufacturing).

Reactor for plasma-based atomic layer etching of materials

ActiveUS20150162168A1Liquid surface applicatorsElectric discharge tubesSurface engineeringSurface layer

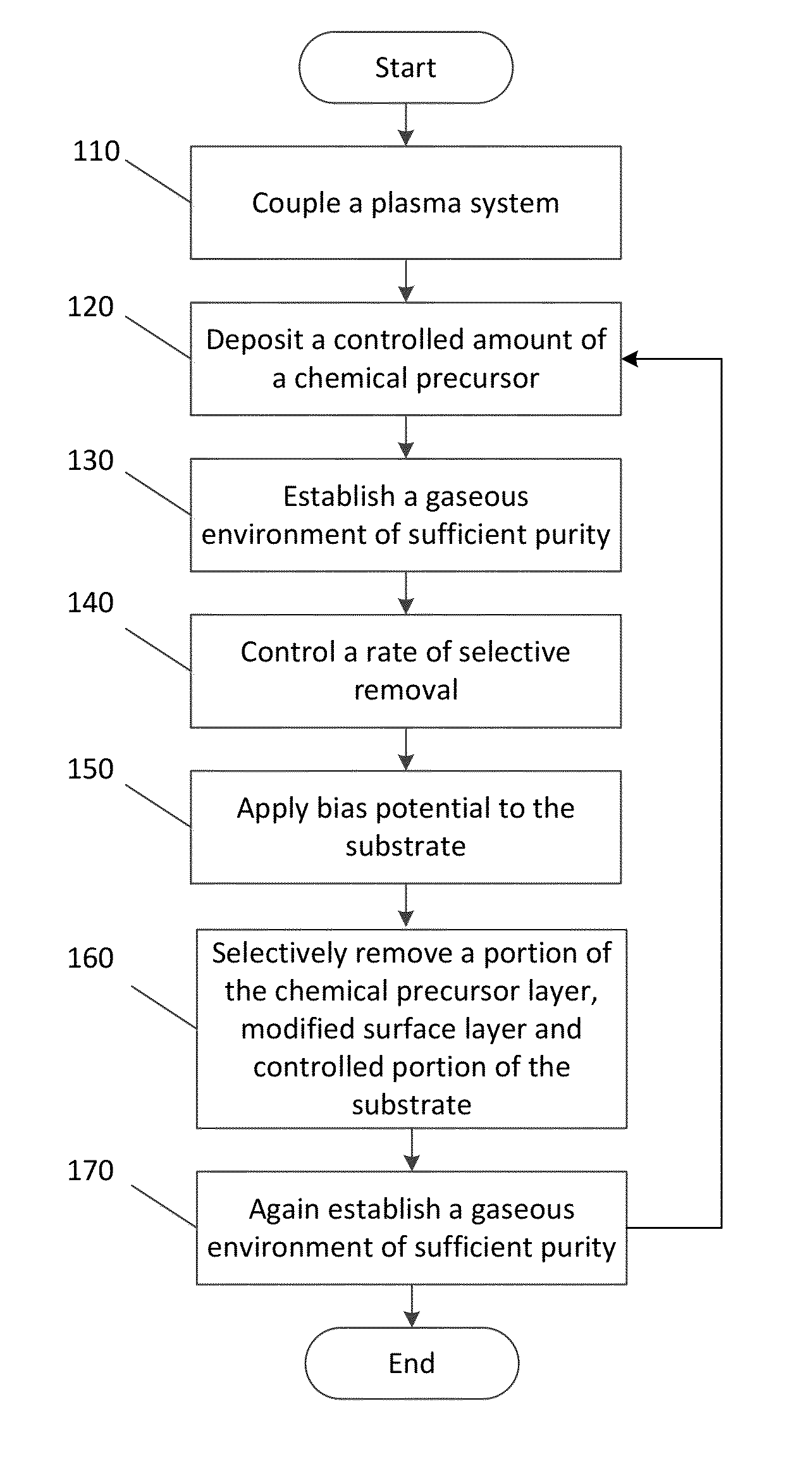

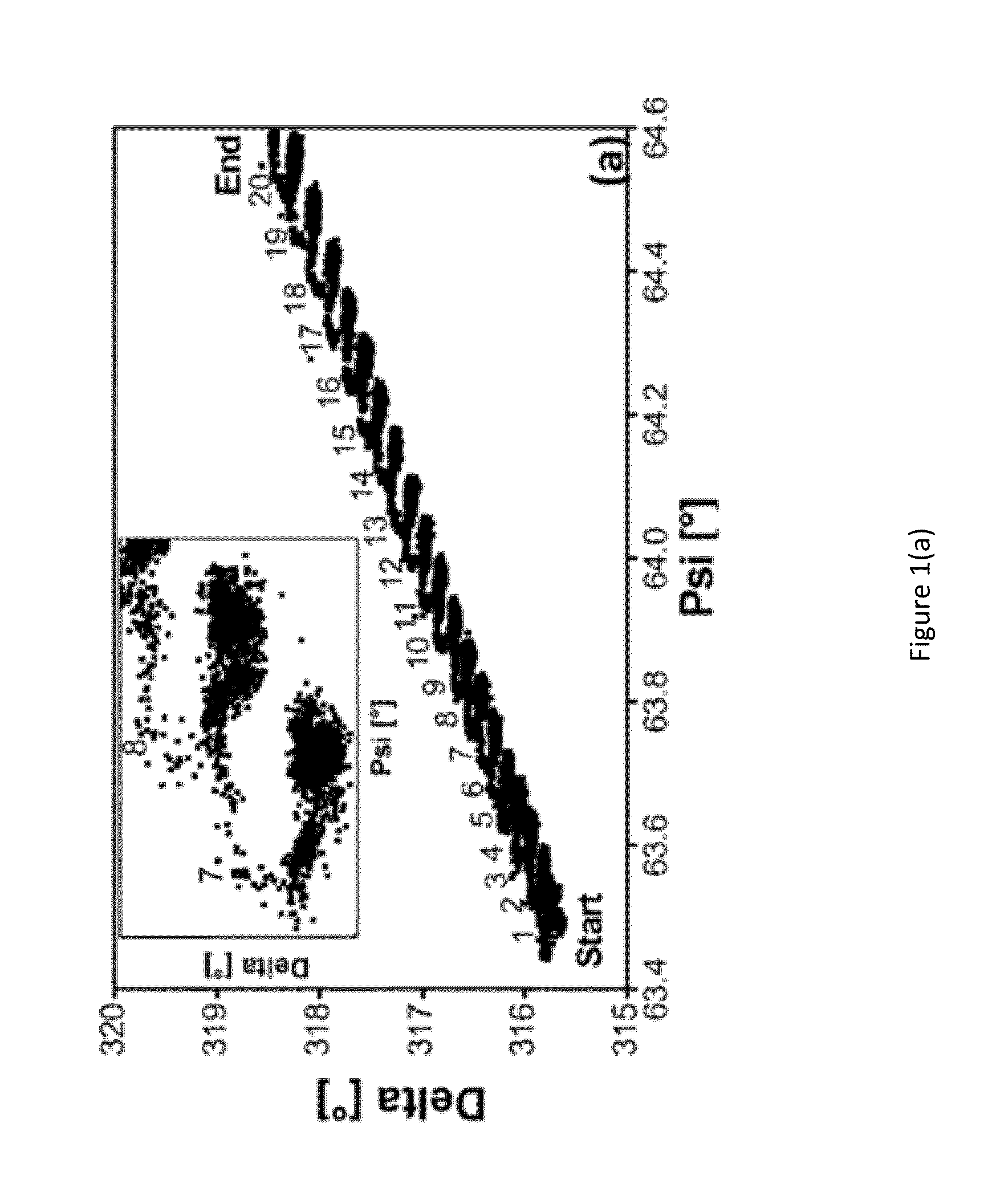

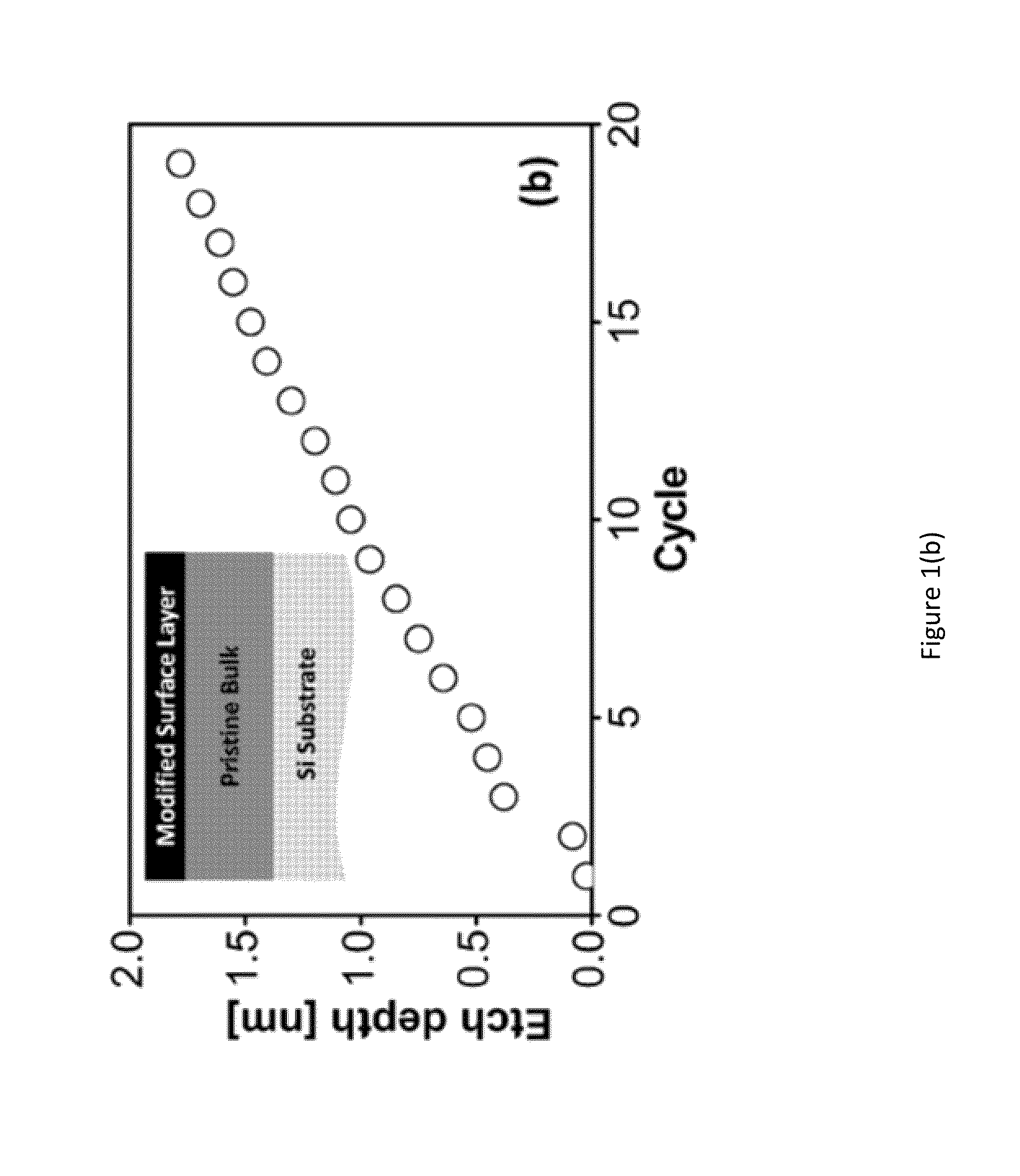

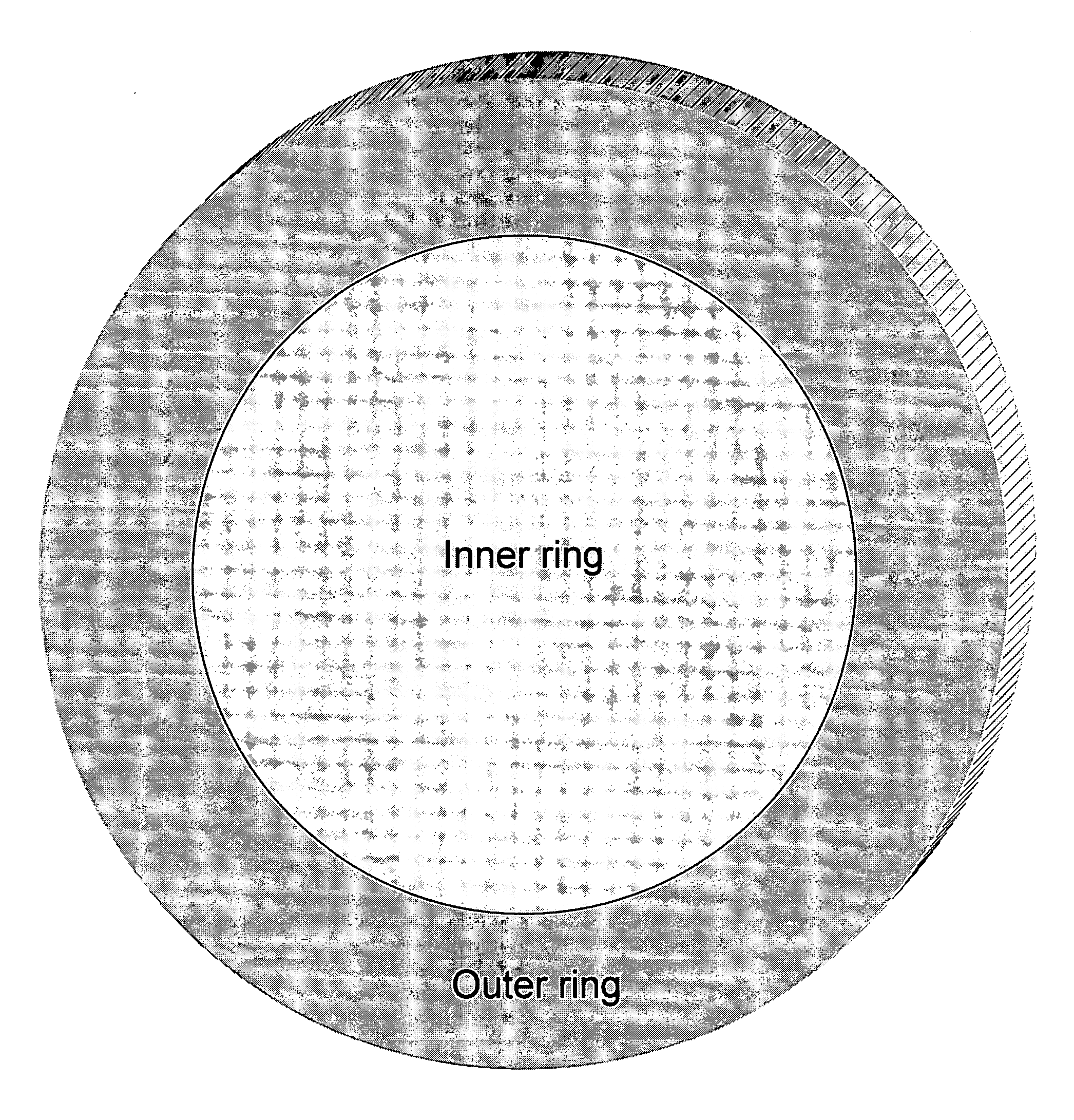

Plasma-based atomic layer etching of materials may be of benefit to various semiconductor manufacturing and related technologies. For example, plasma-based atomic layer etching of materials may be beneficial for adding and / or removing angstrom thick layers from a surface in advanced semiconductor manufacturing and related technologies that increasingly demand atomistic surface engineering. A method may include depositing a controlled amount of a chemical precursor on an unmodified surface layer of a substrate to create a chemical precursor layer and a modified surface layer. The method may also include selectively removing a portion of the chemical precursor layer, a portion of the modified surface layer and a controlled portion of the substrate. Further, the controlled portion may be removed to a depth ranging from about 1 / 10 of an angstrom to about 1 nm. Additionally, the deposition and selective removal may be performed under a plasma environment.

Owner:UNIV OF MARYLAND

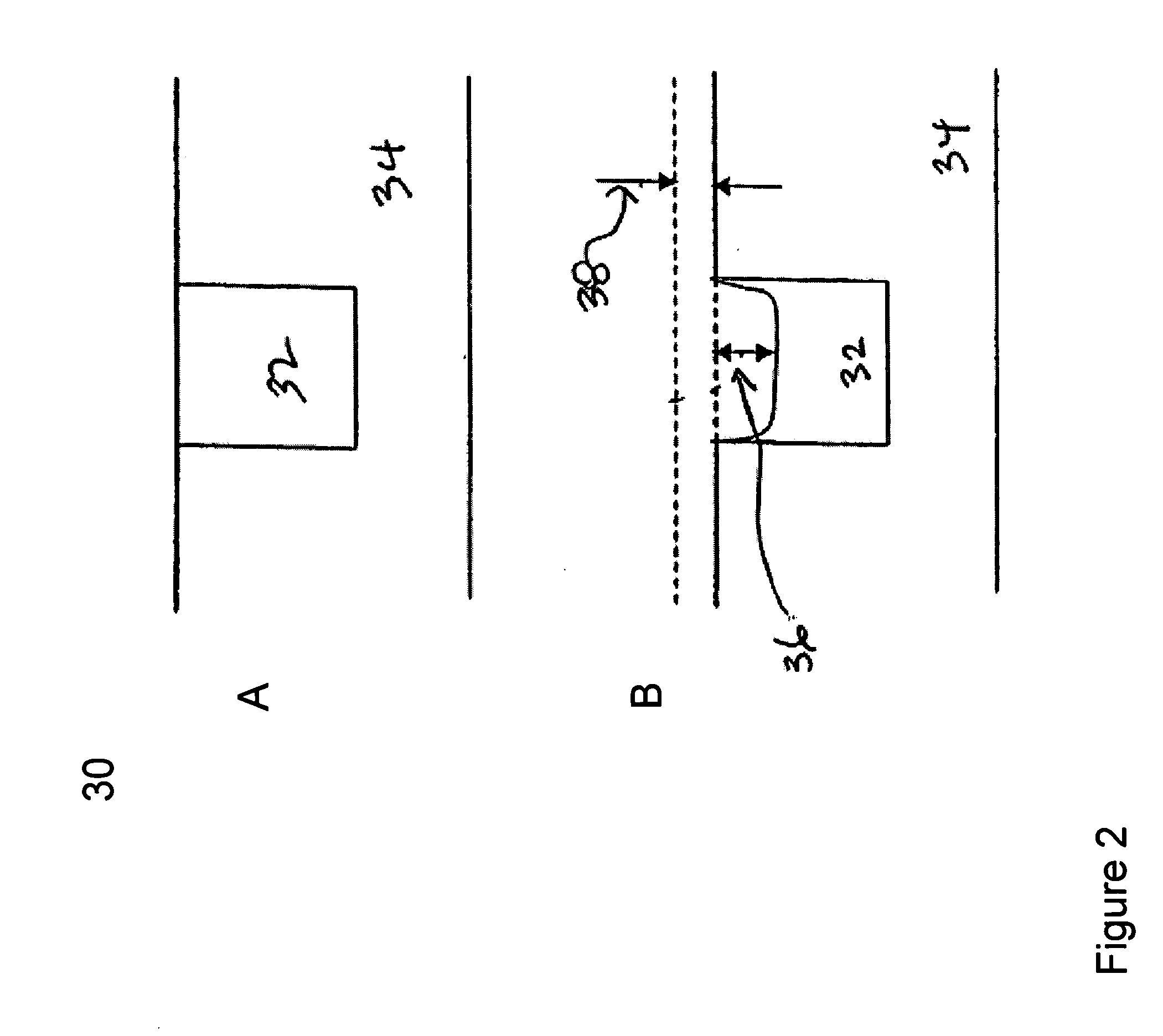

Customized polishing pads for CMP and methods of fabrication and use thereof

ActiveUS20060276109A1Easy to controlImpact on polishing propertyAdditive manufacturing apparatusLapping machinesPorositySurface engineering

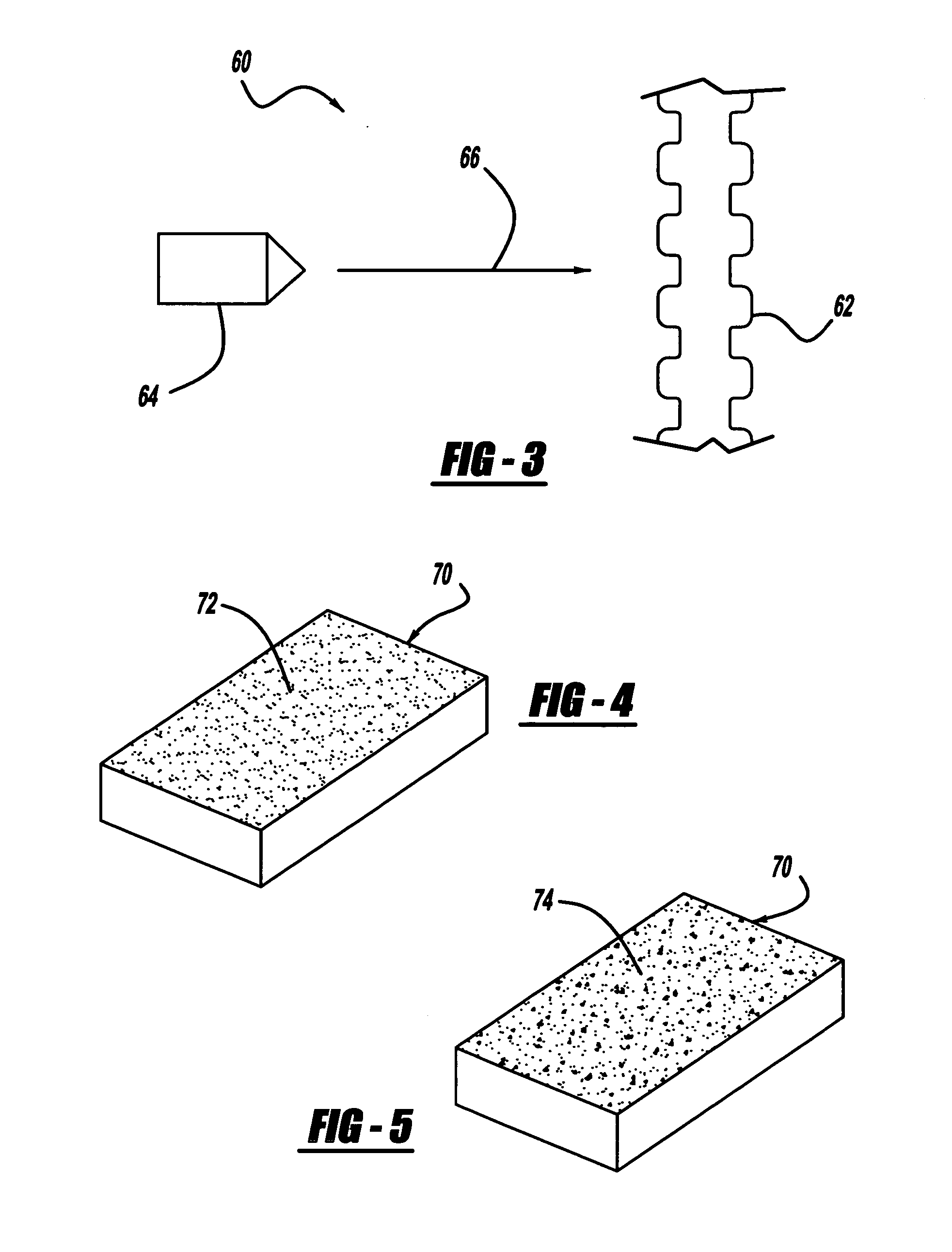

The present application relates to polishing pads for chemical mechanical planarization (CMP) of substrates, and methods of fabrication and use thereof. The pads described in this invention are customized to polishing specifications where specifications include (but not limited to) to the material being polished, chip design and architecture, chip density and pattern density, equipment platform and type of slurry used. These pads can be designed with a specialized polymeric nano-structure with a long or short range order which allows for molecular level tuning achieving superior themo-mechanical characteristics. More particularly, the pads can be designed and fabricated so that there is both uniform and nonuniform spatial distribution of chemical and physical properties within the pads. In addition, these pads can be designed to tune the coefficient of friction by surface engineering, through the addition of solid lubricants, and creating low shear integral pads having multiple layers of polymeric material which form an interface parallel to the polishing surface. The pads can also have controlled porosity, embedded abrasive, novel grooves on the polishing surface, for slurry transport, which are produced in situ, and a transparent region for endpoint detection.

Owner:CMC MATERIALS INC

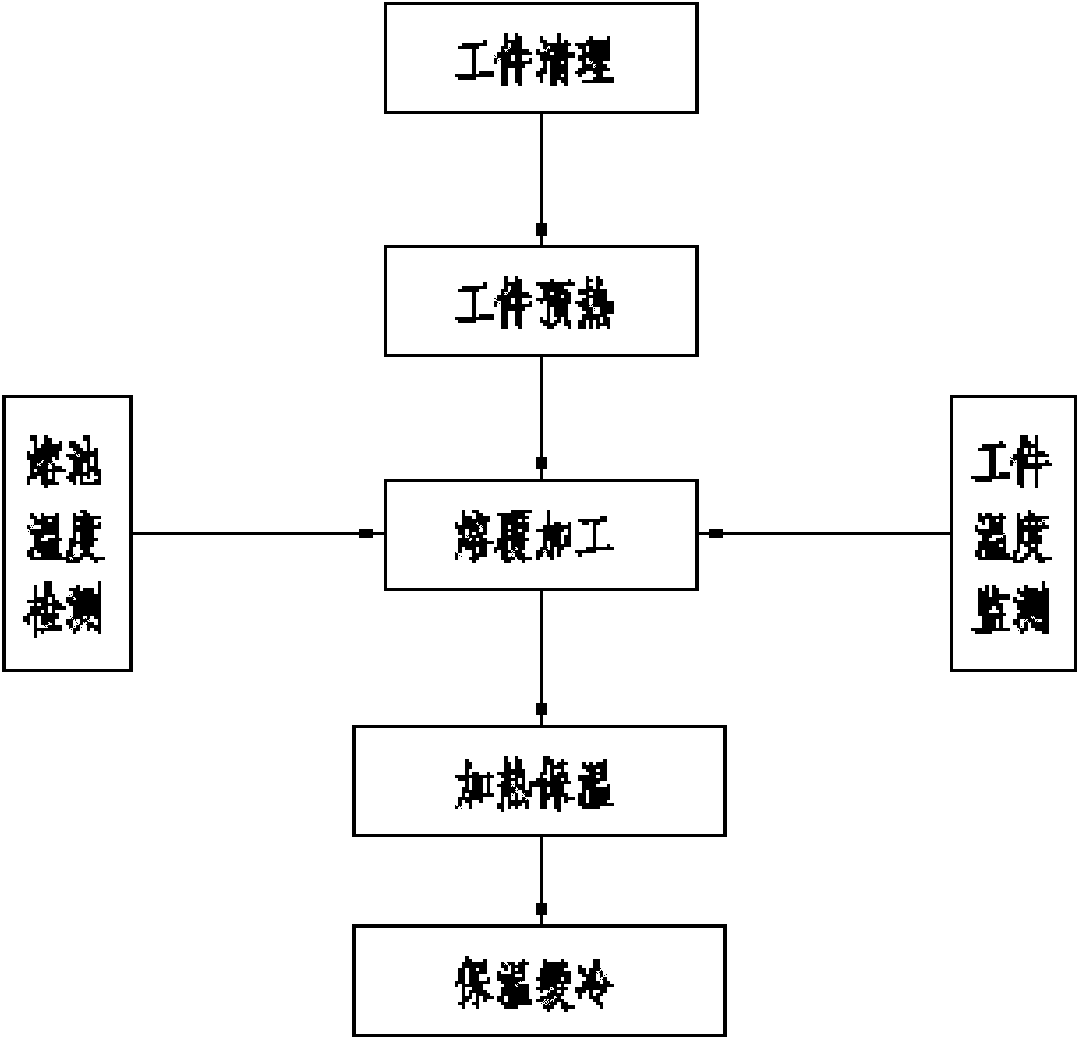

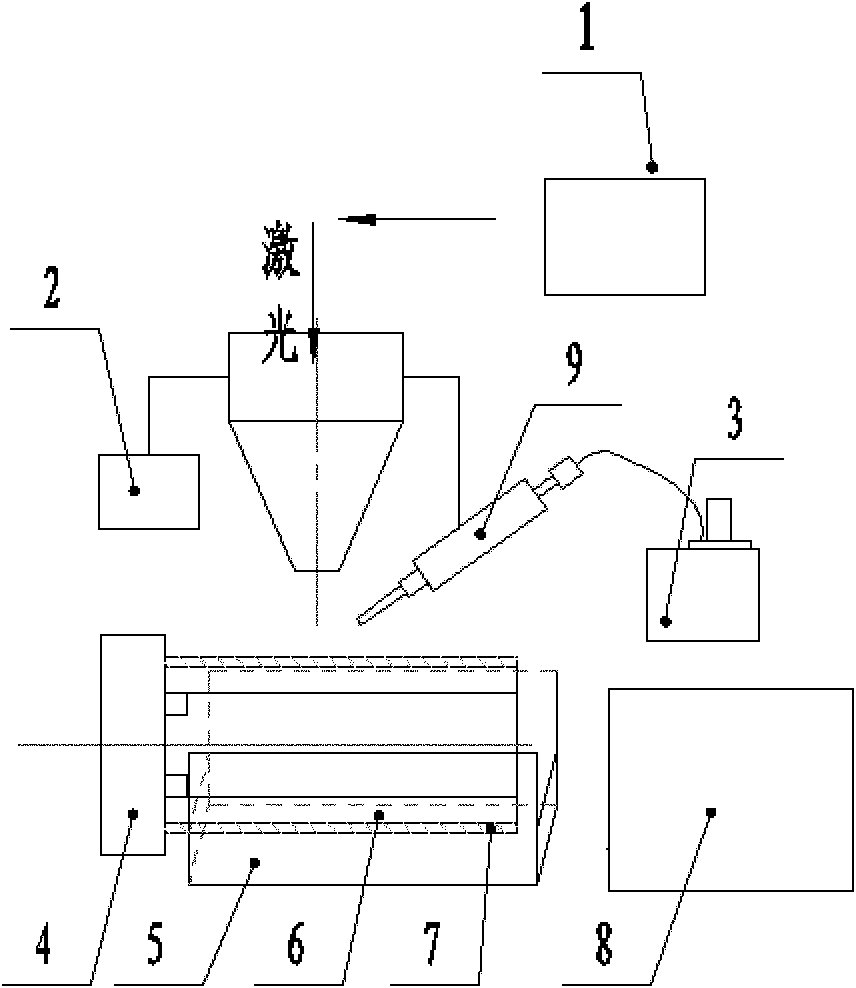

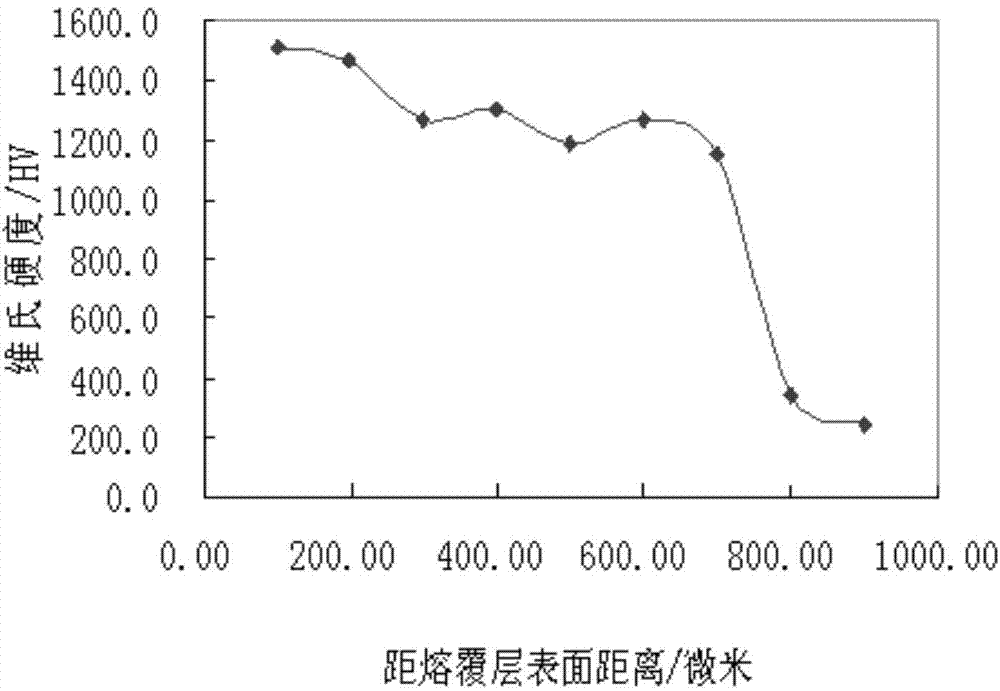

Method for carrying out laser-cladding on high-hardness nickel-based alloy material in large area

ActiveCN102465294AImprove wear and corrosion resistanceDense tissueMetallic material coating processesLaser beam welding apparatusSurface engineeringHeat-affected zone

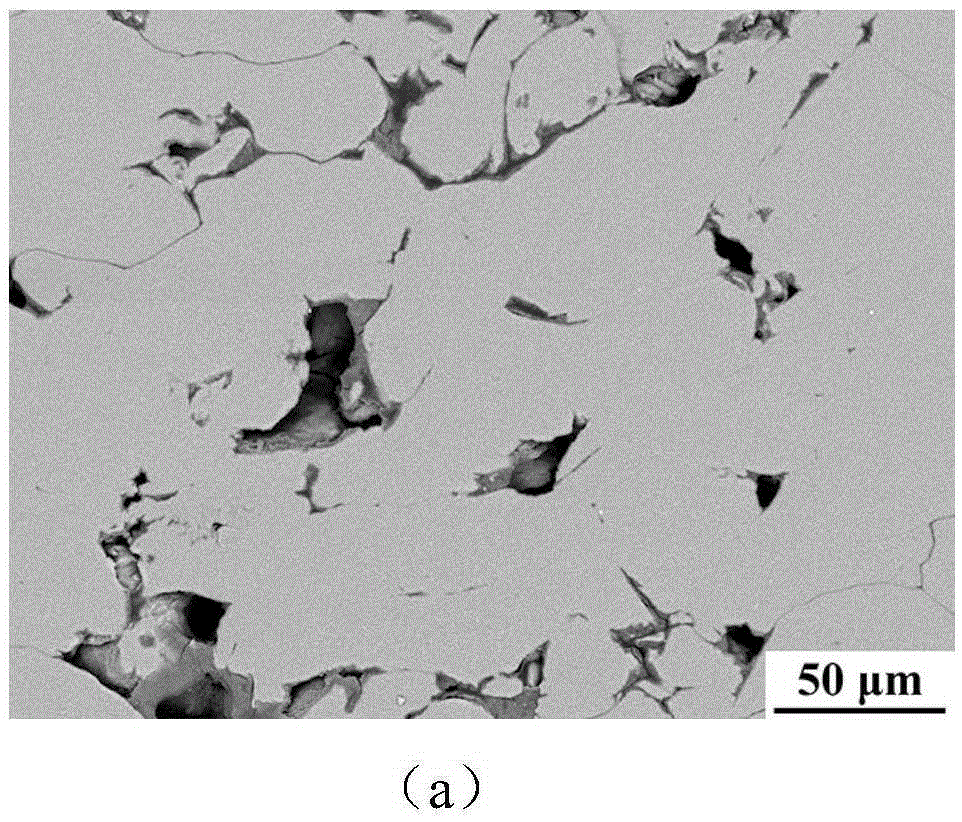

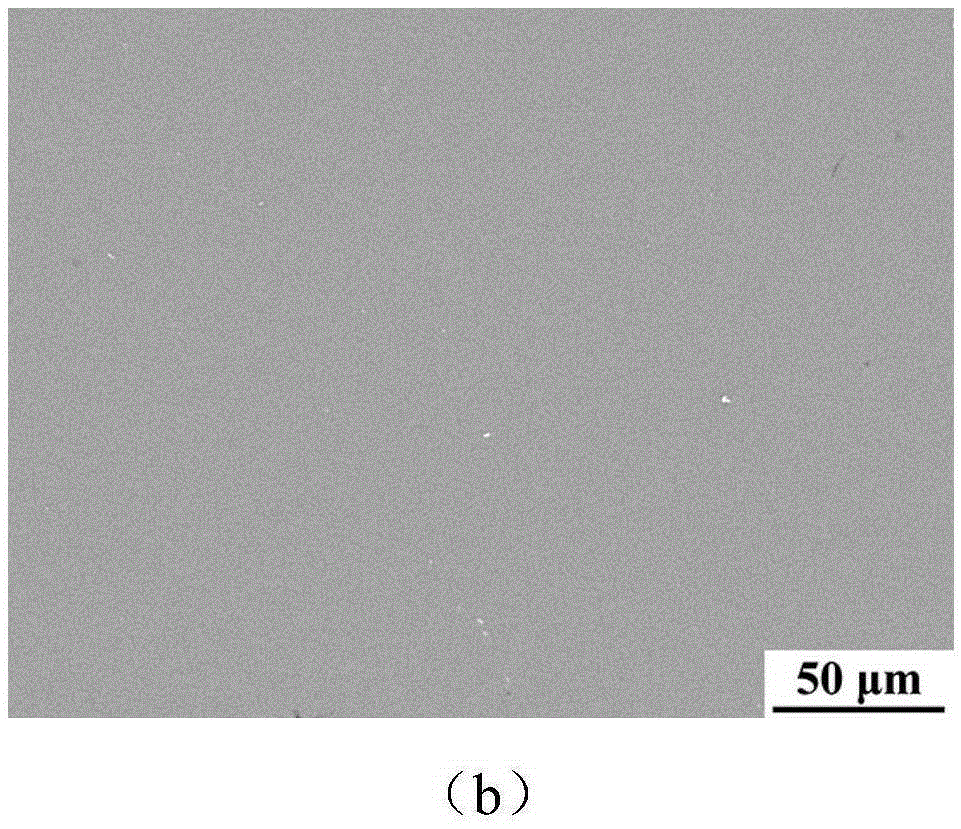

The invention belongs to the field of material surface engineering and more particularly relates to a method for carrying out cladding on a high-hardness wear-resistant anti-corrosion nickel-based alloy material on a metal substrate E in a large area by applying a laser cladding technology, solving the problem of cracks generated in the laser cladding process of the high-hardness wear-resistant nickel-based alloy, in particular the cladding defects, such as cracks with the thickness of more than 1mm, pores and the like during large-area cladding. According to the invention, the high-hardness nickel-based alloy powder material is cladded on the surface of the metal substrate in the large area to form a high-hardness wear-resistant anti-corrosion nickel-based alloy coating by applying the laser cladding technology and adopting a scientific and reasonable process method. According to the method disclosed by the invention, stability and consistency of laser cladding are foundationally ensured, defects, such as cracks, pores, impurities can be prevented from generating, heat affected regions of the substrate are reduced, dilution rate is reduced, the high-wear-resistance anticorrosion nickel-based alloy coating with firm metallurgical bonding and fine and compact grains is obtained and has the hardness reaching 58-63HRC, and the service life of the processed workpiece can be prolonged by more than 1-2 times.

Owner:NINGBO SIASUN ROBOT TECH CO LTD

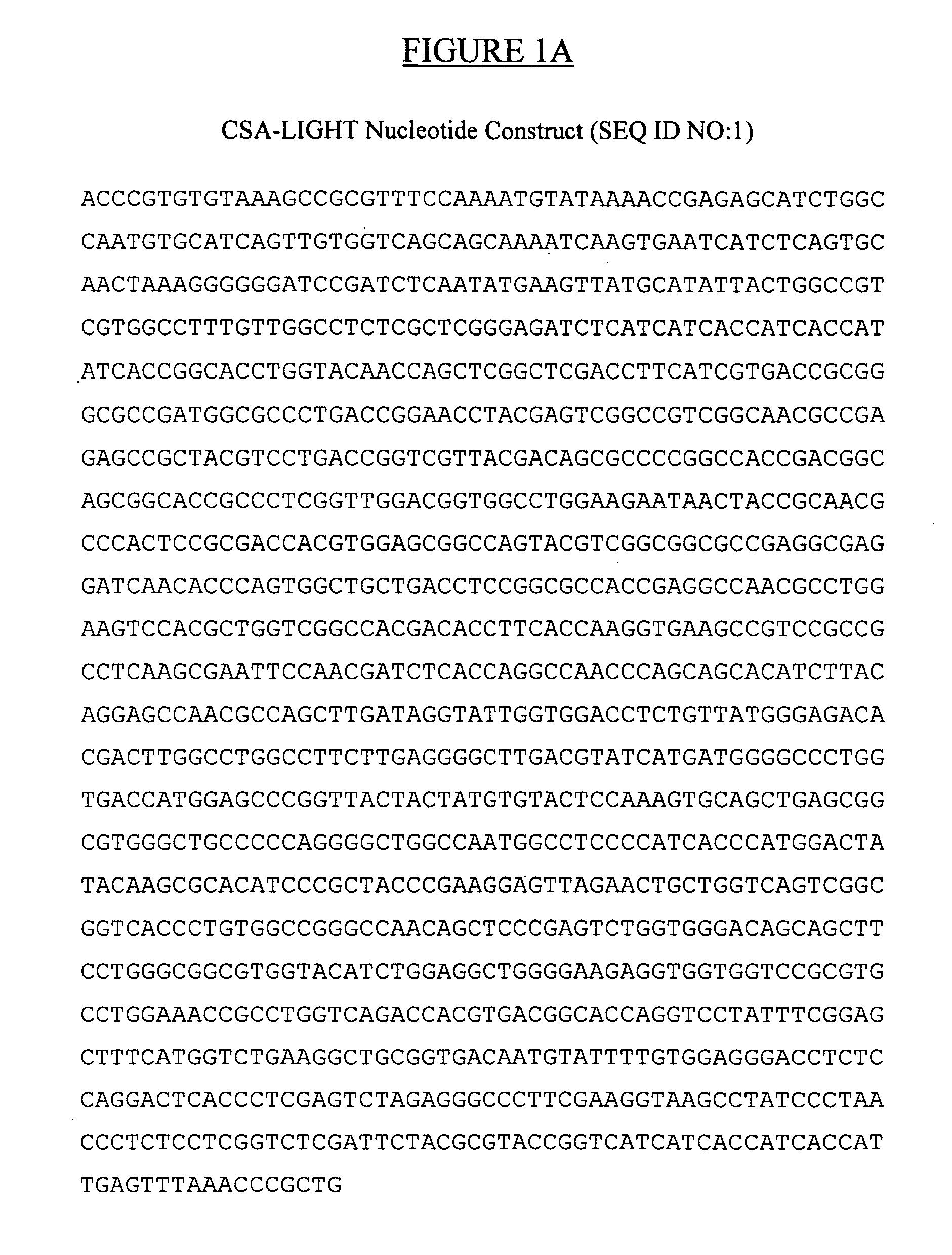

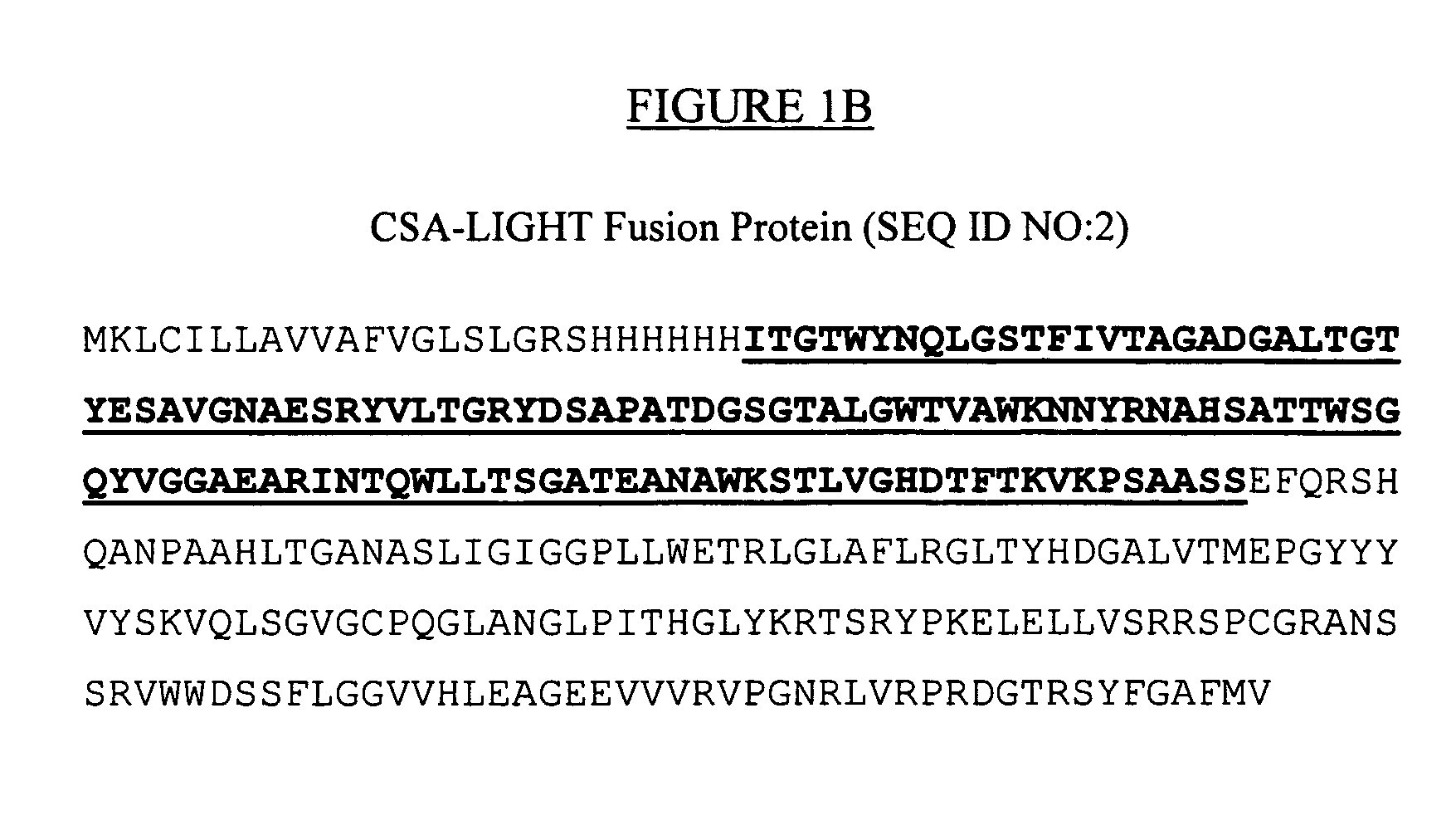

In vivo cell surface engineering

The present invention provides methods and compositions for the in vivo engineering of cell surfaces, such as tumor cell surfaces, with one or more immune co-stimulatory polypeptides. The methods, compositions and engineered cells are useful, for example, to stimulate an immune response against the cells. When the engineered cell surfaces are tumor cell surfaces, the methods, compositions and engineered cells are useful for improving a patient's immune response against the cancer and for reducing tumor size and inhibiting tumor growth.

Owner:UNIV OF LOUISVILLE RES FOUND INC

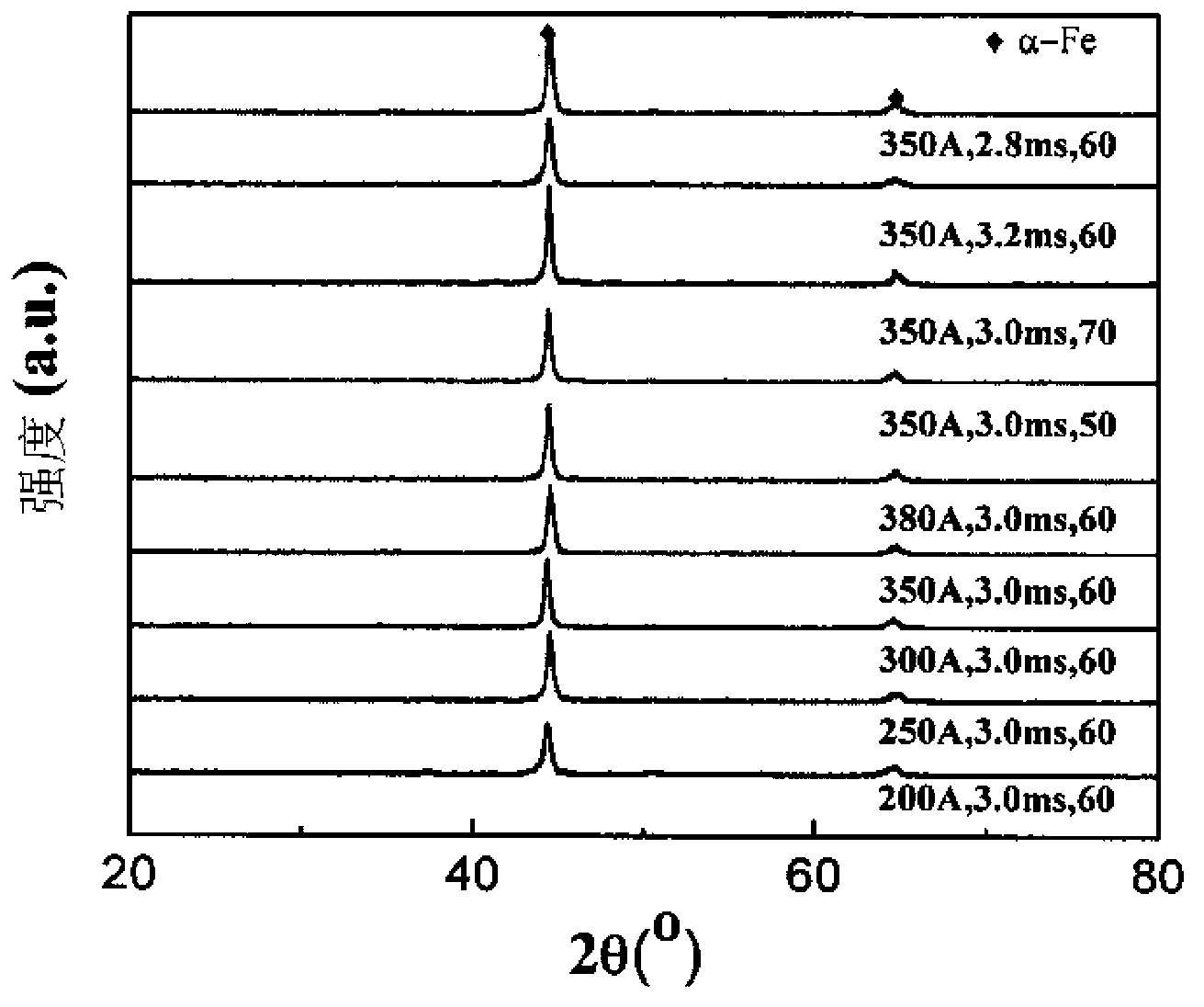

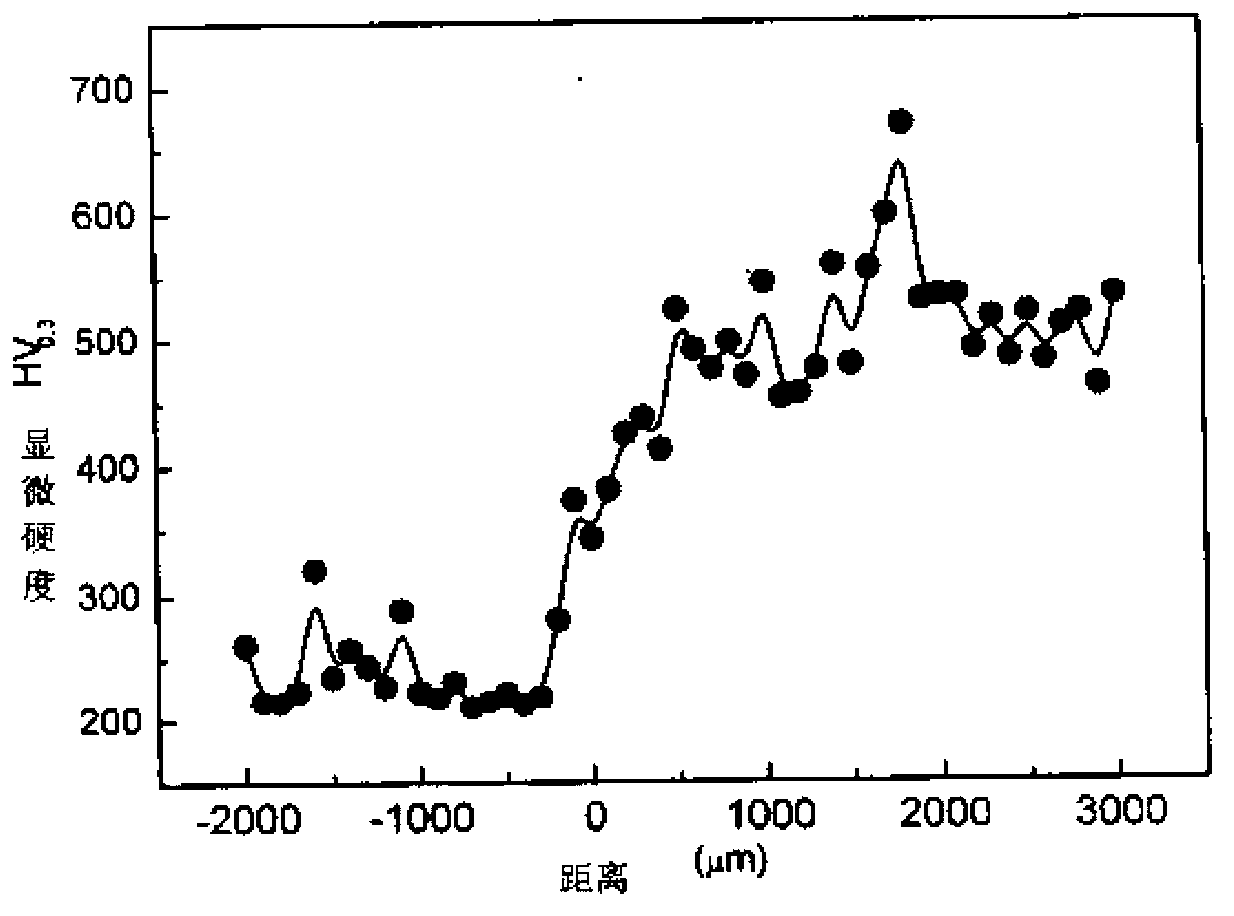

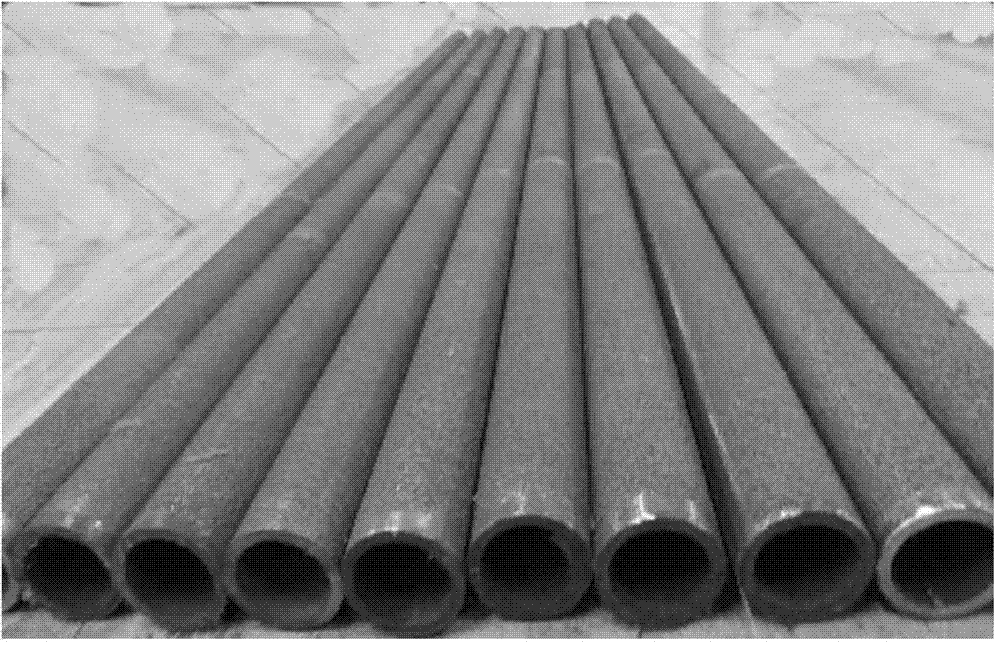

Iron-based amorphous powder for wear-resisting and corrosion-resisting coating and preparation method thereof

InactiveCN103302287AImprove wear and corrosion resistanceWear and corrosion resistance and long service lifeMetallic material coating processesSurface engineeringThermal spraying

The invention discloses iron-based amorphous powder for wear-resisting and corrosion-resisting coating and a preparation method thereof, and belongs to the technical field of surface engineering. Iron-based amorphous alloy coating adopts iron as a main component, and also comprises amorphous phase (in at least 30 percent by volume), and the representation formula of all elements in percentage by weight is FeaCrbNicSidBeMnfCgMohNbiCujCokRel. The powder is prepared through direct ball-milling mixing in proportion of all components according to the required weight ratio. The powder can be used for not only laser cladding but also thermal spraying technology, mixed powder is melt by high-energy density laser beams, an iron-based amorphous or amorphous composite cladding layer is formed on the outer surface of a matrix, the cladding layer has the characteristics of higher wear and collision resistance, the dilution rate is low, the wear-resisting and collision-resisting service lives of a petroleum drill rod, an air compressor screw rod, a roller, a water-cooled wall pipe and an economizer pipe are remarkably prolonged, the process is simpler, and the manufacturing cost is low.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

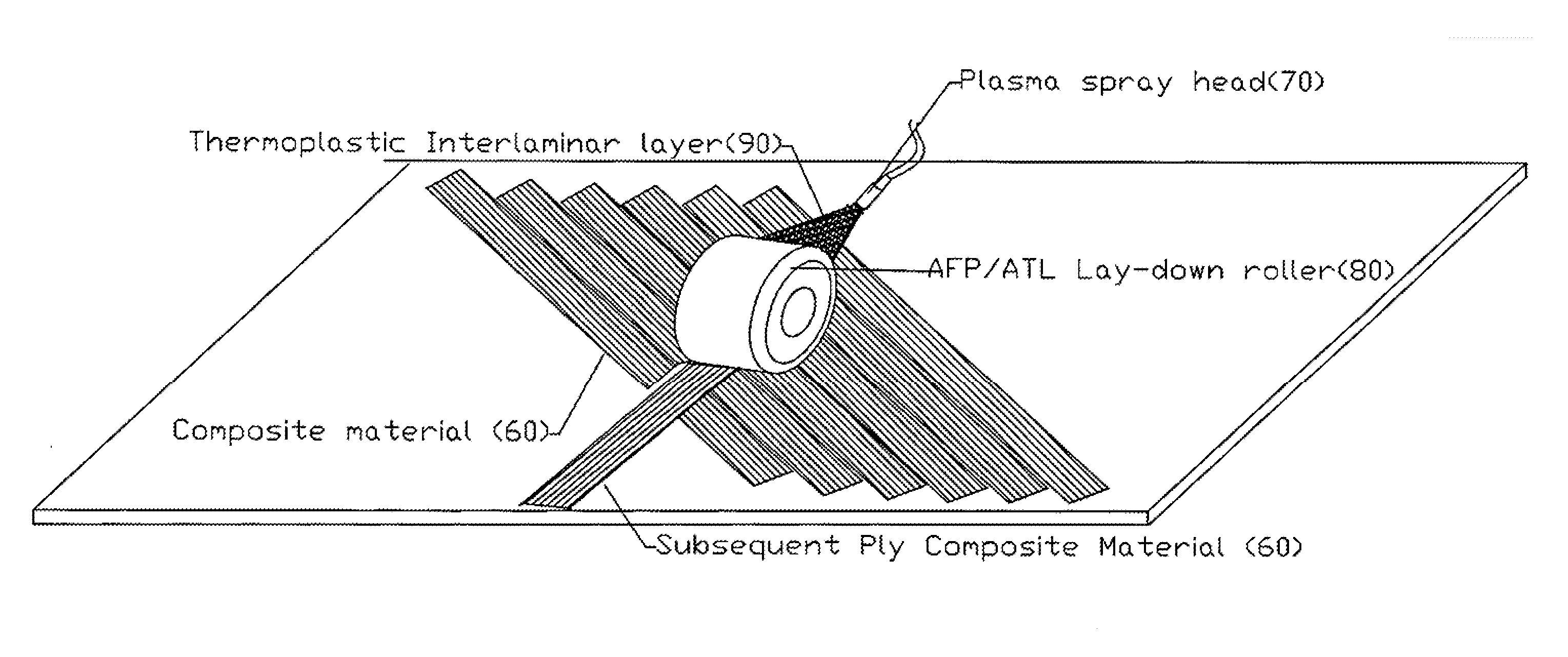

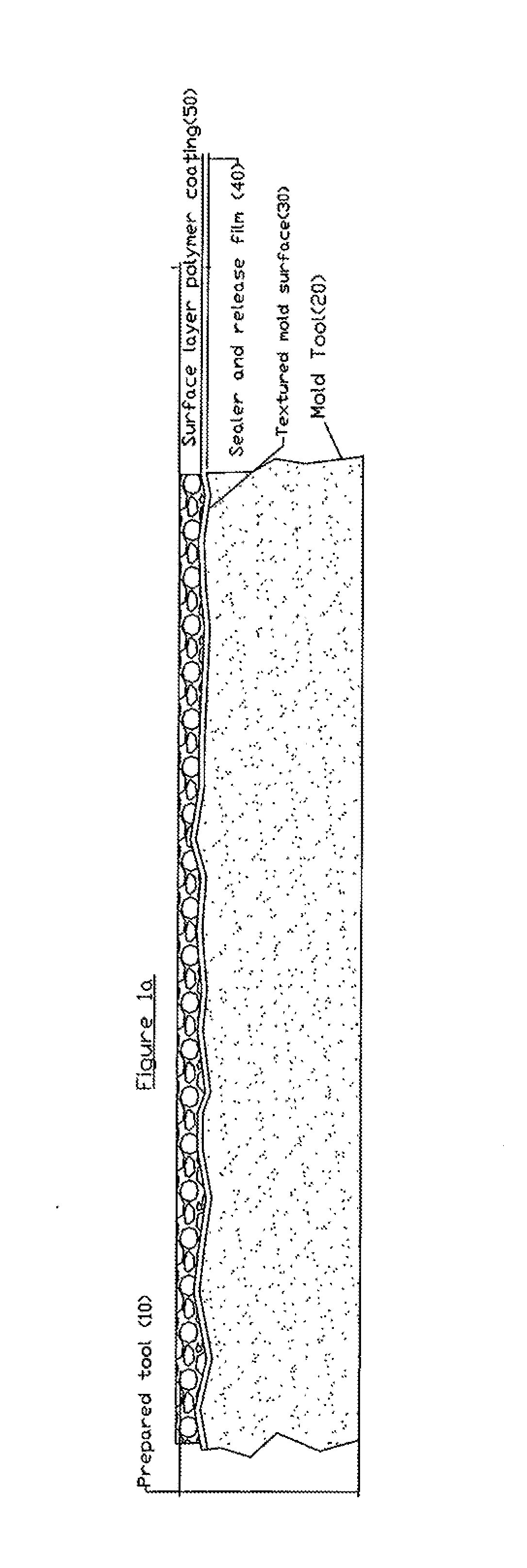

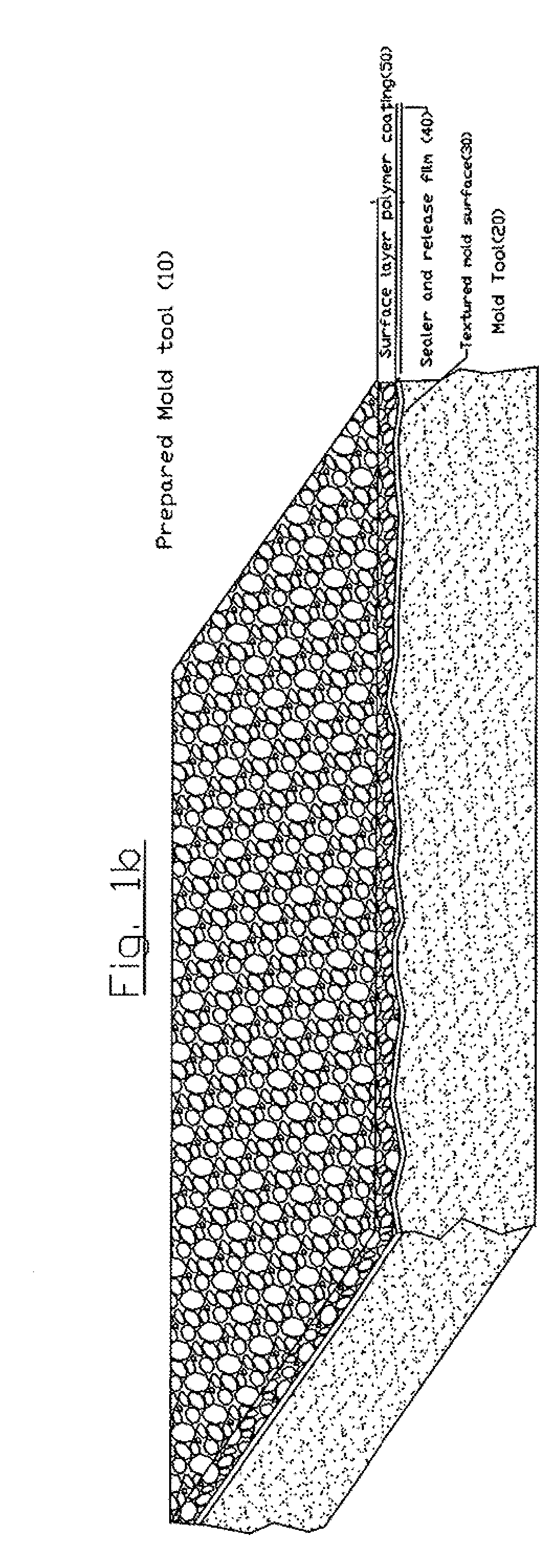

Surface Engineering of Thermoplastic Materials and Tooling

InactiveUS20140110633A1Improve propertiesEasy to separateLiquid surface applicatorsMechanical working/deformationSurface engineeringSurface layer

A prepared mold tool having a thermoplastic surface layer polymer coating on the mold surface of the mold tool or prepared prepreg having a thermoplastic surface layer polymer coating on the surface of the thermoplastic fiber reinforced prepreg are described that enhance first ply laydown of thermoplastic fiber reinforced composite prepregs onto mold tools for prepreg forming or in situ tape placement. Resulting thermoplastic fiber reinforced composite parts from a thermoplastic fiber reinforced thermoplastic composite material having structural reinforcement fibers with one or more high performance polymers, and a thermoplastic surface layer polymer coating which forms a polymer blend with the high performance polymers of the thermoplastic fiber reinforced composite material thereby imparting improved properties, and methods for making and using same, are provided herein.

Owner:CYTEC IND INC

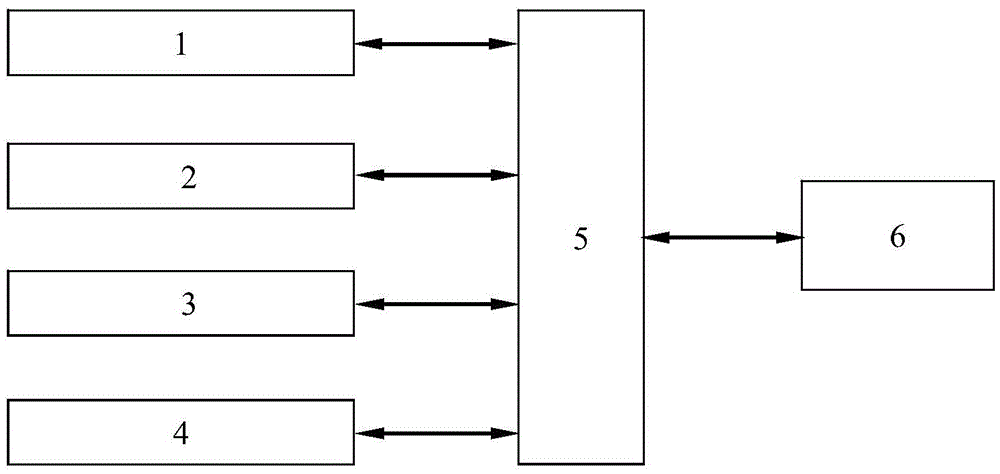

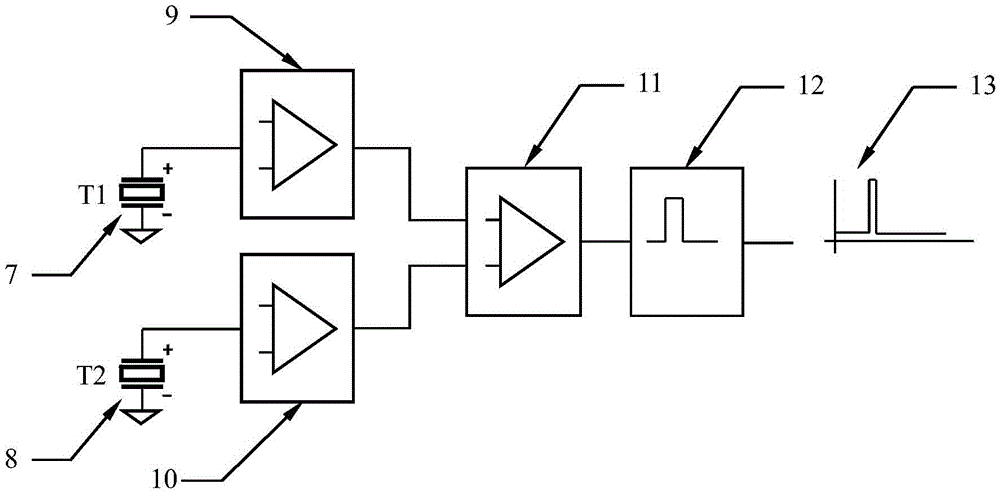

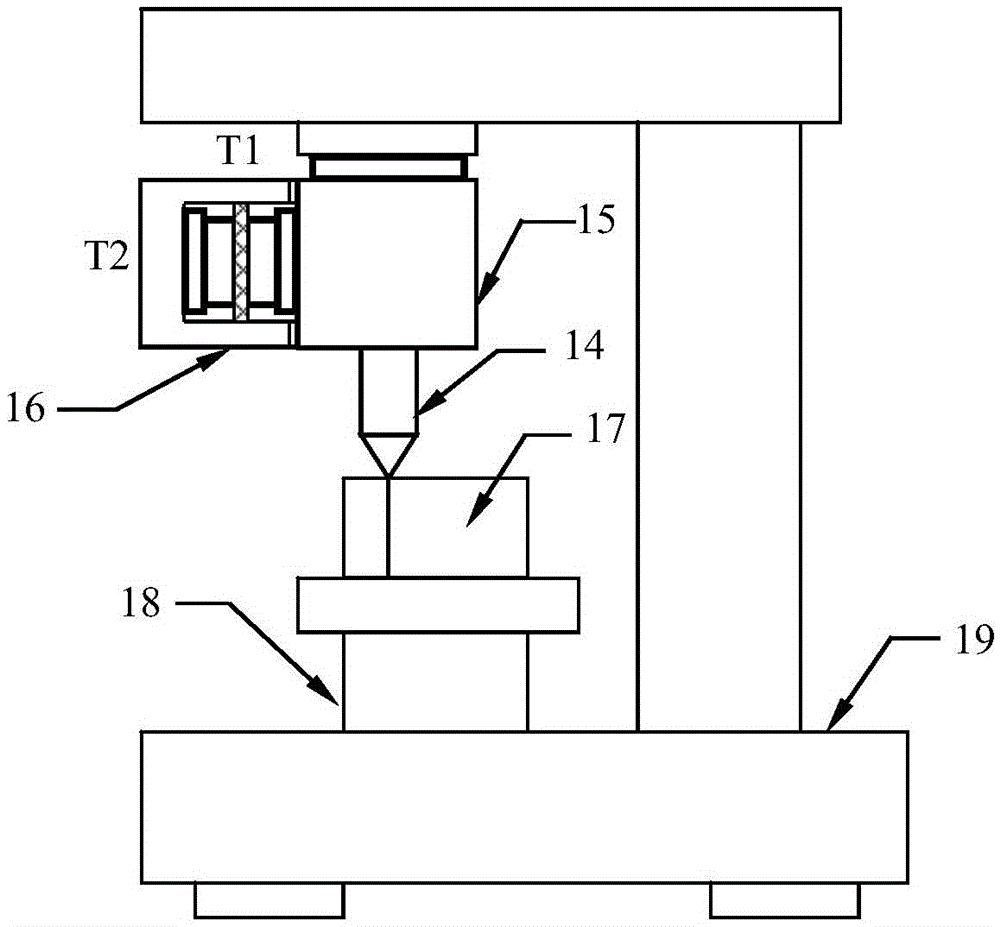

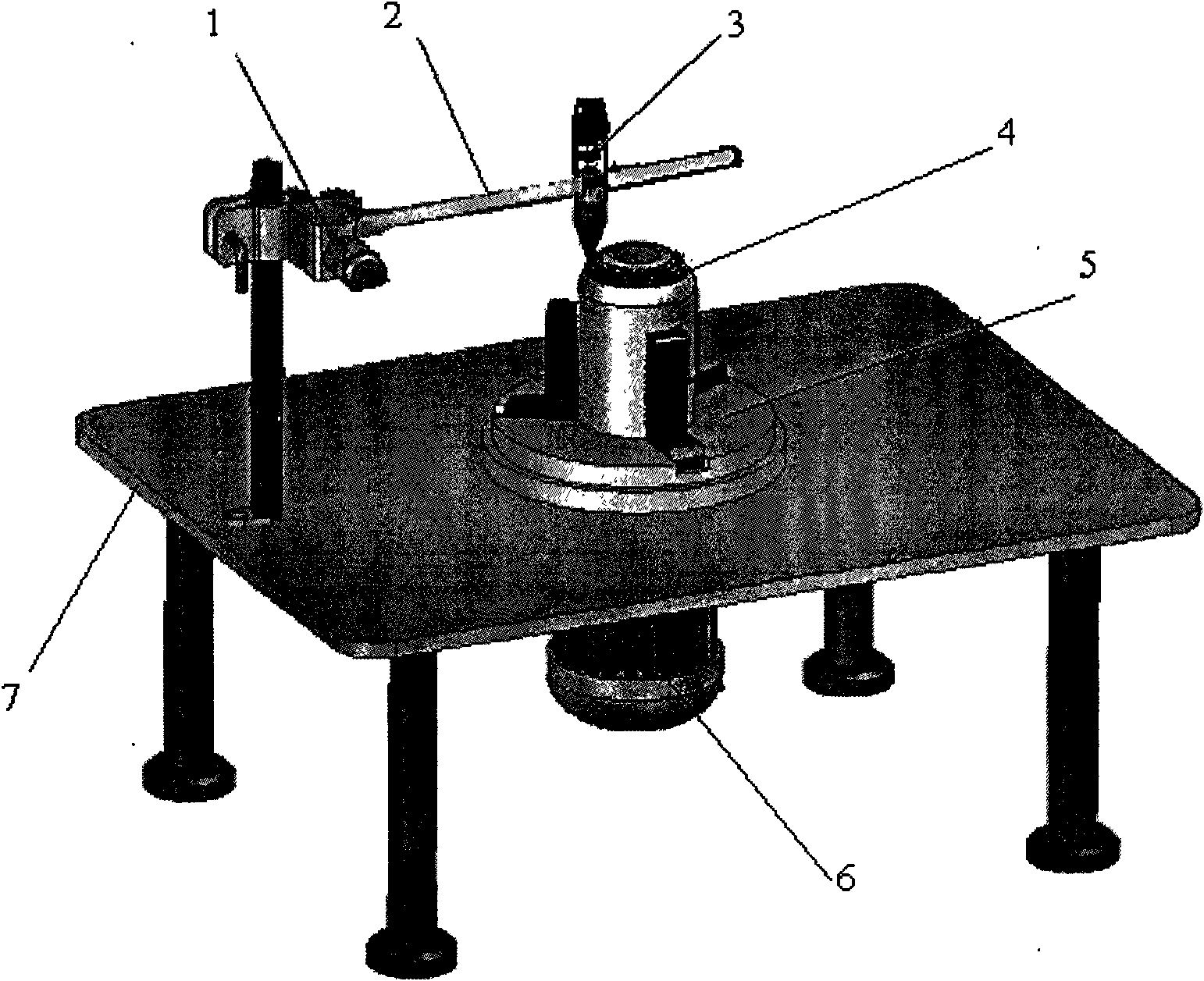

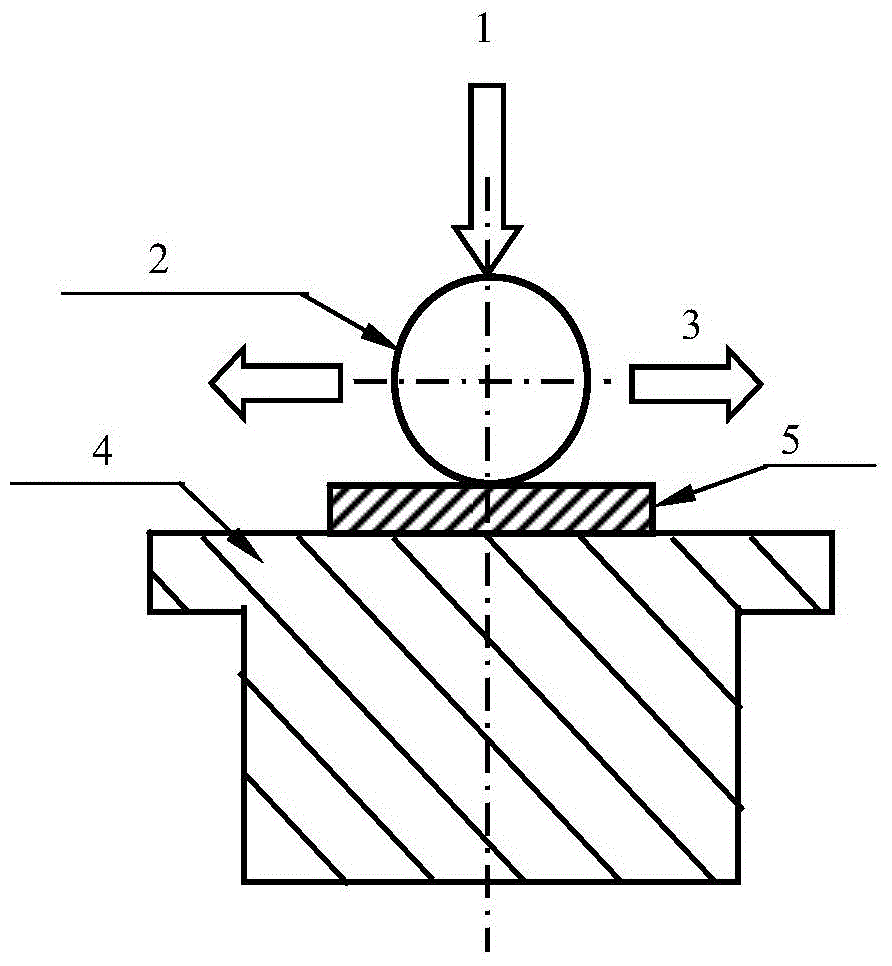

Integration equipment and detection method for evaluating coating bonding strength based on interface fracture toughness

ActiveCN105628610AWith upgrade and extension functionMeet updateAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial strength using tensile/compressive forcesInteractive softwareData display

The invention discloses integration equipment and a detection method for evaluating coating bonding strength based on interface fracture toughness, belonging to the technical field of material surface engineering. With the equipment, a computer is used for controlling operation of four functional modules, including an ultrasonic detection module, a hardness testing module, a continuous press-in testing module and an interface crack detecting module; a man-machine interactive software system is used for processing acquisition and transmission of data of the functional modules and analysis operation and data display and output of an interface press-in mechanical model in an integrated manner; and through ultrasonic nondestructive measurement on elasticity modulus of a coating and a matrix and continuous press-in testing on a coating-matrix interface, quantitative detection on all parameters of an interface fracture toughness formula is completed in one equipment, and the critical load PC of coating-matrix interface fracture and the corresponding interface fracture toughness Kca are obtained. The equipment and the detection principle are clear, the modular design is beneficial to updating and expanding of a mechanical model library, and a detection sample is simple and convenient to prepare.

Owner:DALIAN UNIV OF TECH

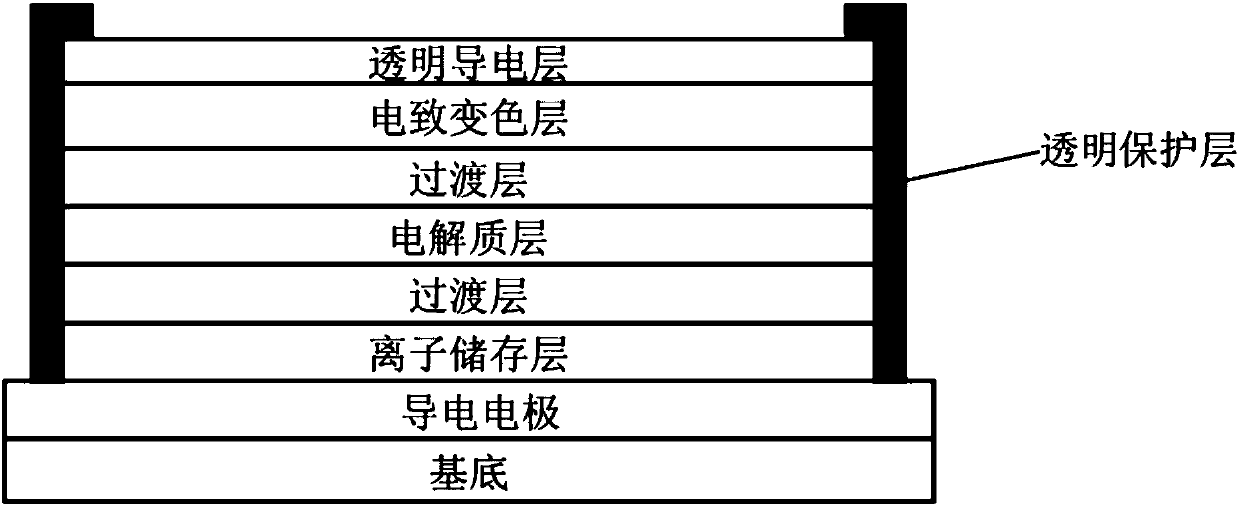

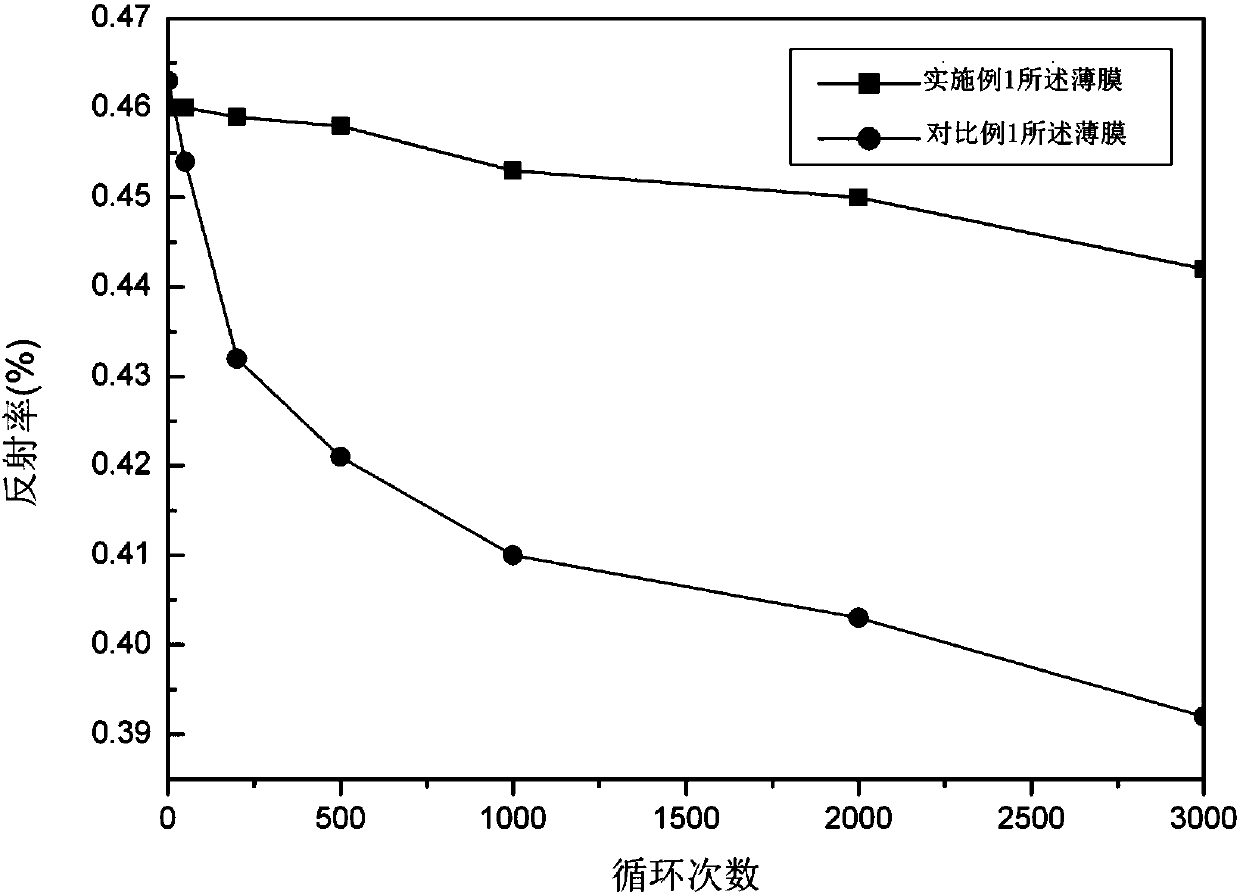

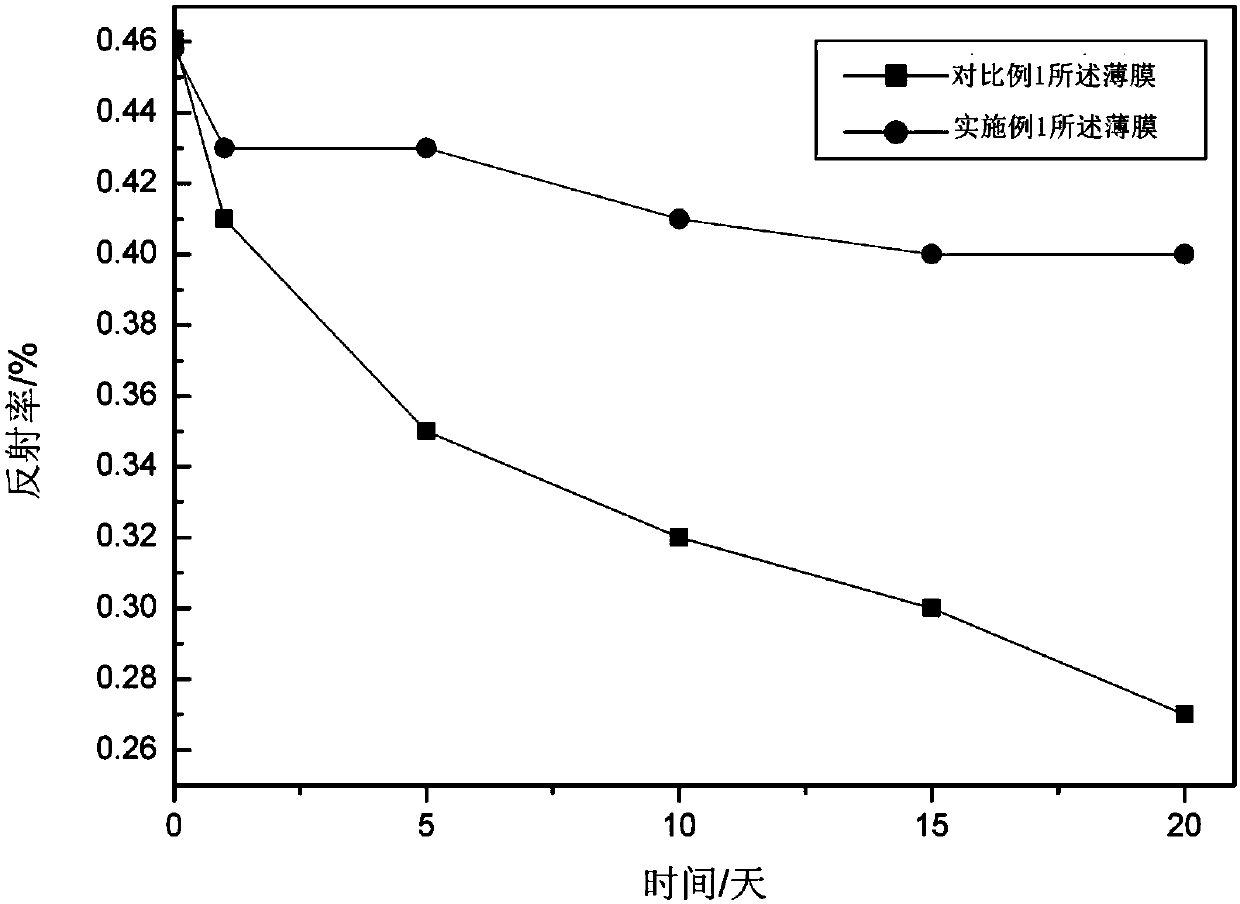

Electrochromism film with stable performance and preparation method thereof

InactiveCN108037628AImprove color changing performanceImprove performanceNon-linear opticsSurface engineeringElectrochromism

The invention belongs to the technical field of surface engineering, and particularly relates to an electrochromism film with the stable performance and a preparation method thereof. The film system structure of the film sequentially comprises a substrate, a conductive electrode, an ion storage layer, a transition layer, an electrolyte layer, a transition layer, an electrochromism layer and a transparent conductive layer from bottom to top, and the section of the film system is the transparent protective layer. According to the electrochromism film with the stable performance, the interface and the environment are blocked by depositing a protective layer on the section of the film system of the electrochromism film, the electrochromism film has the stable color change performance in the ground environment and the space environment, performance degradation cannot happen, and the good circular stability and environment stability are achieved. According to the electrochromism film, the transition layer is additionally arranged between the coloring layer and the electrolyte layer, on one hand, leakage current is lowered when the transition layer is adopted as an electron barrier layer,and the coloring memory effect is improved; on the other hand, the voltage value needed by electrochromism is lowered, and the circular stability is improved.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

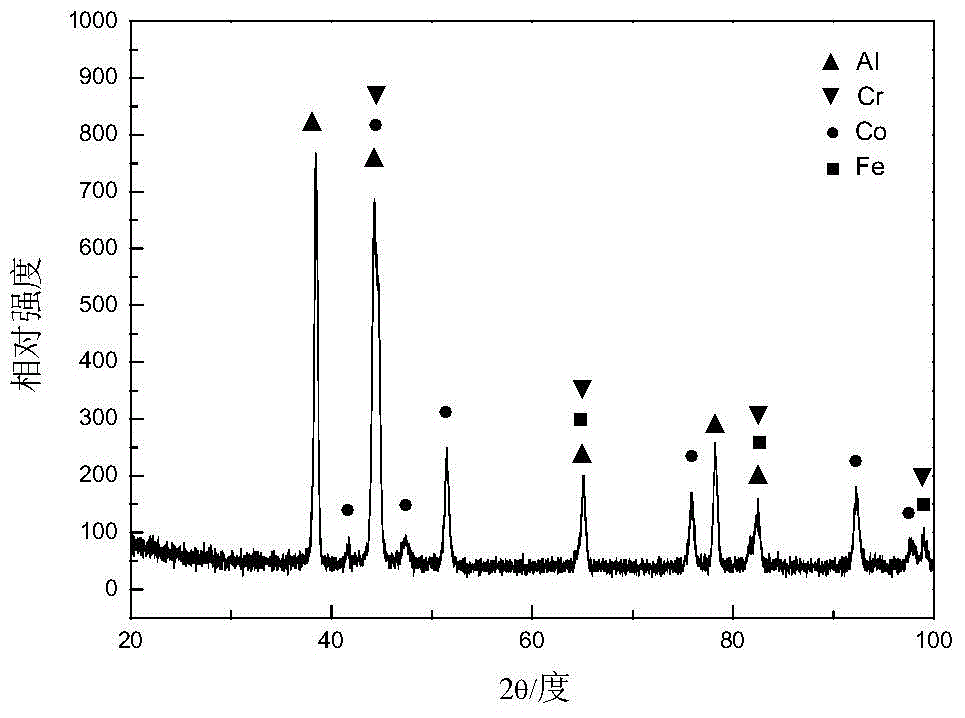

Cavitation erosion-resistant laser high-entropy alloying powder on stainless steel surface and preparation process thereof

ActiveCN104561990ASolve crackingSolve associativityHeat inorganic powder coatingHigh entropy alloysSurface engineering

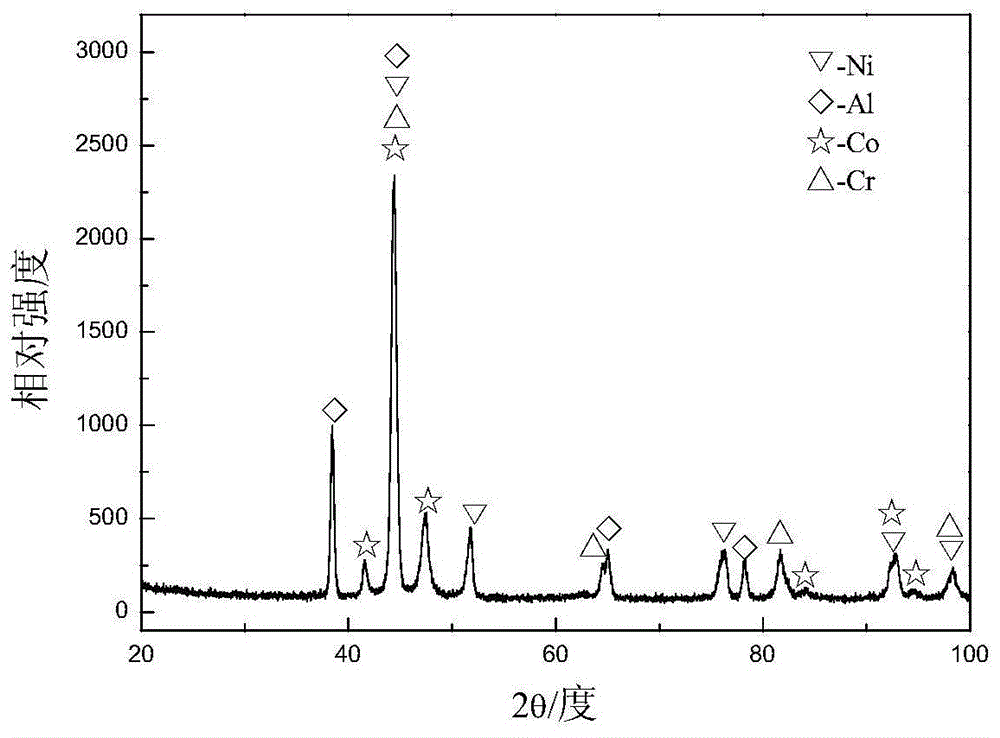

The invention provides a cavitation erosion-resistant laser high-entropy alloying powder on a stainless steel surface and a preparation process thereof and belongs to the technical field of surface engineering. The component of the high-entropy alloying powder comprises four metal elements, namely Co, Cr, Al and Ni and a non-metal element B; the additive amounts of the metal elements in the powder are equal in molar ratio and the molar number of the non-metal element B is x times that of other component powder, wherein x is greater than or equal to 0 but less than or equal to 1. By adopting a proper laser radiation process parameter, a high-entropy alloy coating which is combined with a stainless steel base material and is uniform and fine in tissue, free of cracks and excellent in cavitation erosion resistance can be prepared by virtue of a surface alloying technology of laser reaction synthesis.

Owner:SHENYANG POLYTECHNIC UNIV

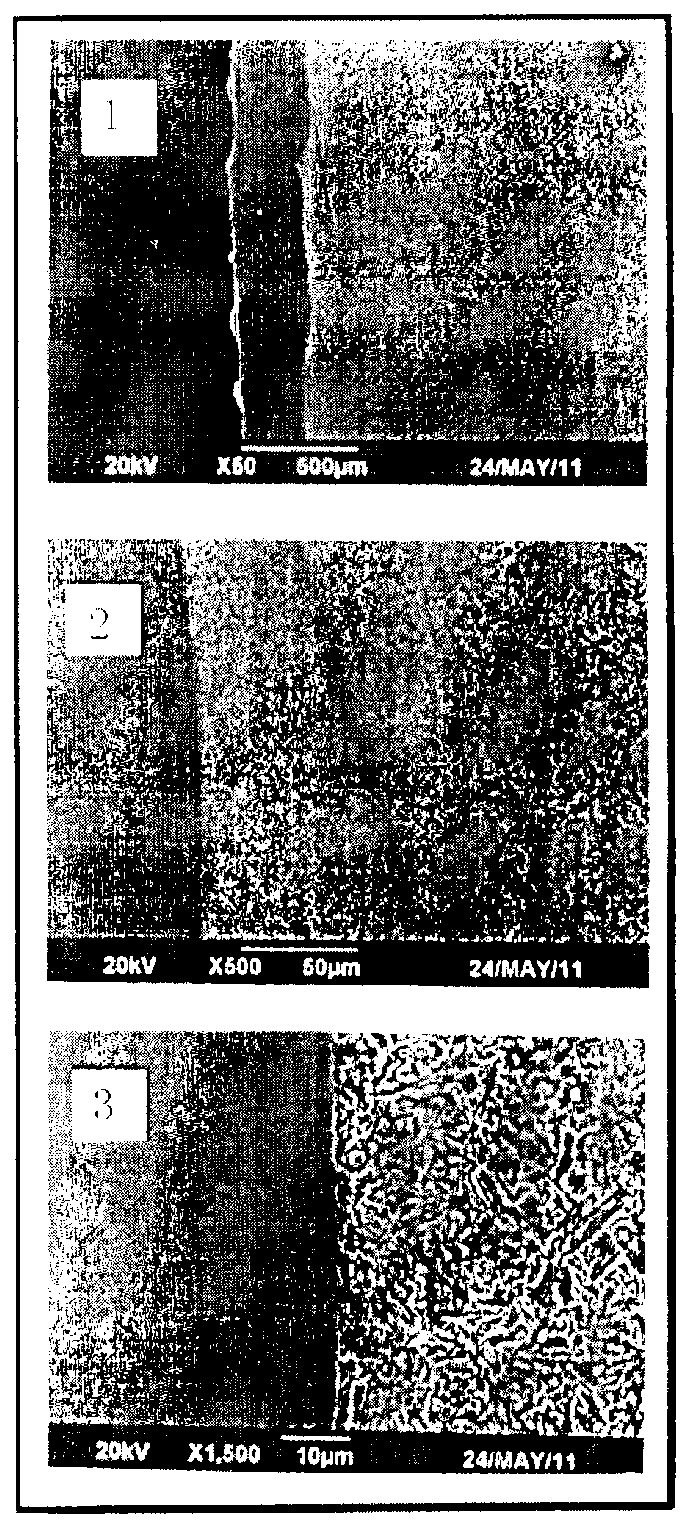

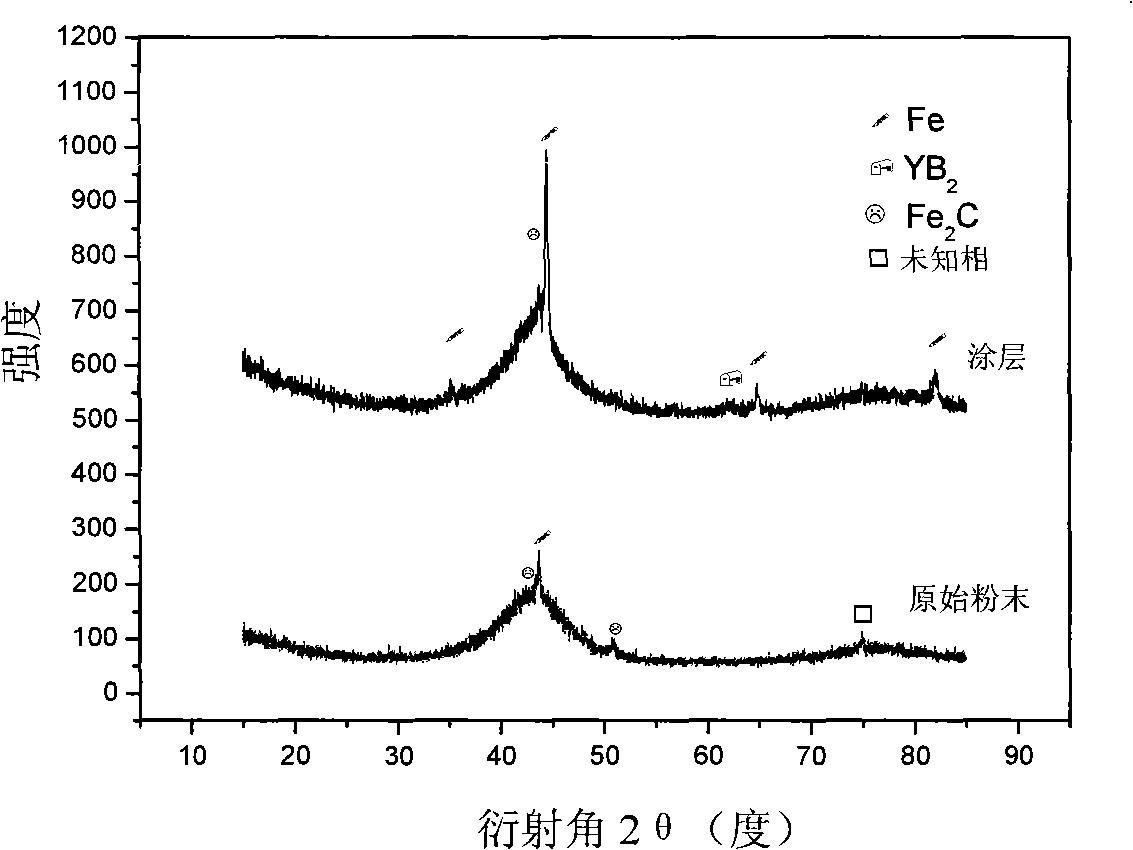

Preparation of non-magnetic high corrosion resistant amorphous steel coating

InactiveCN101323951AImprove mechanical propertiesGood physical propertiesMolten spray coatingHeat inorganic powder coatingSurface engineeringVoid ratio

The invention relates to a ferrous alloy with strong performance of glass formation and a technique method for preparing the coating of the amorphous alloy, in particular to a preparation method of non-magnetic amorphous steel coating with the performance of high anticorrosion and wearing resistance. The method of the invention solves the problem that large brittleness is existed in Fe-based large bulk of amorphous alloy and is a restriction as the structural material to go to engineering application, while the invention causes the application of bulk amorphous alloy to surface engineering field (especially amorphous alloy coating) to be possible. By adopting the Fe-based bulk amorphous alloy to prepare Fe-based amorphous alloy coating, firstly, mater alloy is produced by a method of vacuum induction melting according to needed components; then gas atomization technology is adopted to prepare amorphous alloy powder; supersonic thermal spray technology is adopted to prepare Fe-based amorphous alloy coating. The non-magnetic amorphous steel coating with high anticorrosion performance and wearing resistance produced by the invention is uniform, has low void ratio (less than 0.1 percent), is non-magnetic and has the performance of high anticorrosion and wearing resistance as well as vast application prospect to shell material of ships.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Preparation method of alumina film

InactiveCN102409293AFast preparationAvoid damageVacuum evaporation coatingSputtering coatingSurface engineeringIon bombardment

The invention relates to a preparation method of an alumina film and belongs to the technical field of surface engineering. The method comprises the following steps: putting a flexible polymer film base in a vacuum chamber, and vacuumizing the vacuum chamber till pressure in the vacuum chamber is less than or equal to 2.0*10<-3> Pa; carrying out argon ion bombardment on the base with an ion source, thereby improving the adhesion of a plated film layer, wherein the flow of argon is 15sccm, the discharge voltage of an ion beam is 280V, and the current of the ion beam is 1A; and depositing an alumina film by using an oxygen ion beam aided impulse reaction magnetron sputtering technology, wherein a target source is an aluminum target. In the preparation process, the base is always maintained at room temperature, thus the damage of high temperature to the flexible polymer film base can be avoided; and the rapid deposition of the high-quality alumina film can be realized on the flexible polymer base.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

Induction-cladded gradient hard composite material coating technique

ActiveCN104894558AOvercome limitationsImprove thermal shock resistanceMolten spray coatingSurface engineeringCrack free

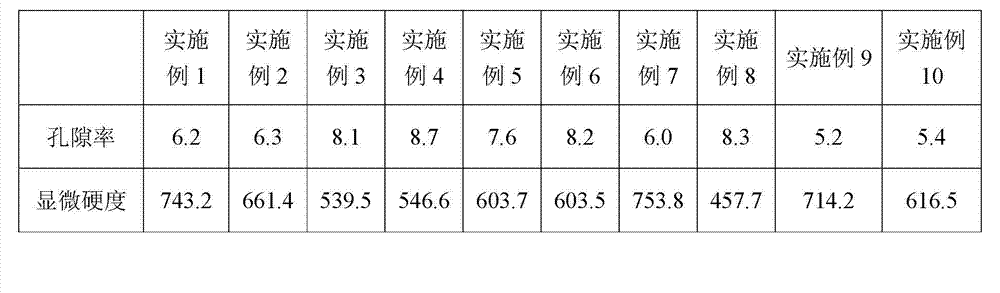

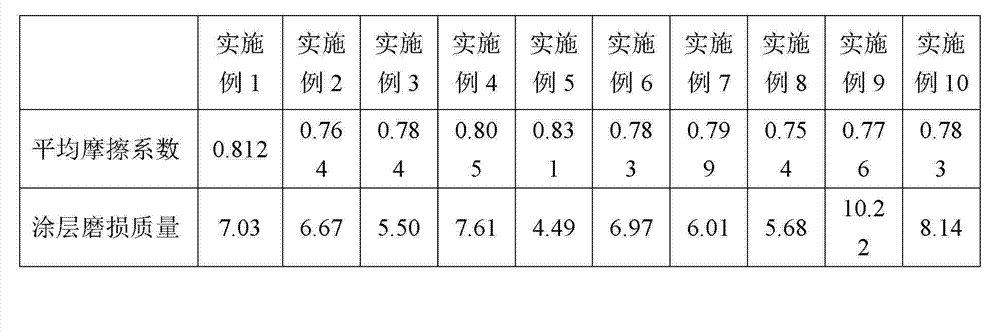

The invention discloses an induction-cladded gradient hard composite material coating technique, and belongs to the technical field of material surface engineering. The surface of a metal part is pre-coated with a gradient coating, a hard phase and a metal phase of the gradient coating are composited, the pre-coating has element gradient distribution that the content of the hard phase increases gradually from an inner layer to an outer layer, the volume percent of the hard phase ranges from 0% to 90%, the pre-coating is inductively heated and re-melted in a protective atmosphere, and a continuous gradient hard composite material coating, which is combined with the base body interface of the metal part and is compact and flawless, is formed through mutual diffusion of the layers. By the gradient hard composite material pre-coating, the problems such as overhigh heat stress caused by conventional metallurgical bonding of induction-cladded hard coatings, concentrated coating impact heat stress caused by cladding of laser beams, electron beams and plasma beams and base body structure degradation caused by overall coating heating, brazing and sintering of the part are solved; the continuous gradient hard composite material coating meets requirements on high performance such as wear, corrosion and impact resistance of the part.

Owner:DALIAN UNIV OF TECH

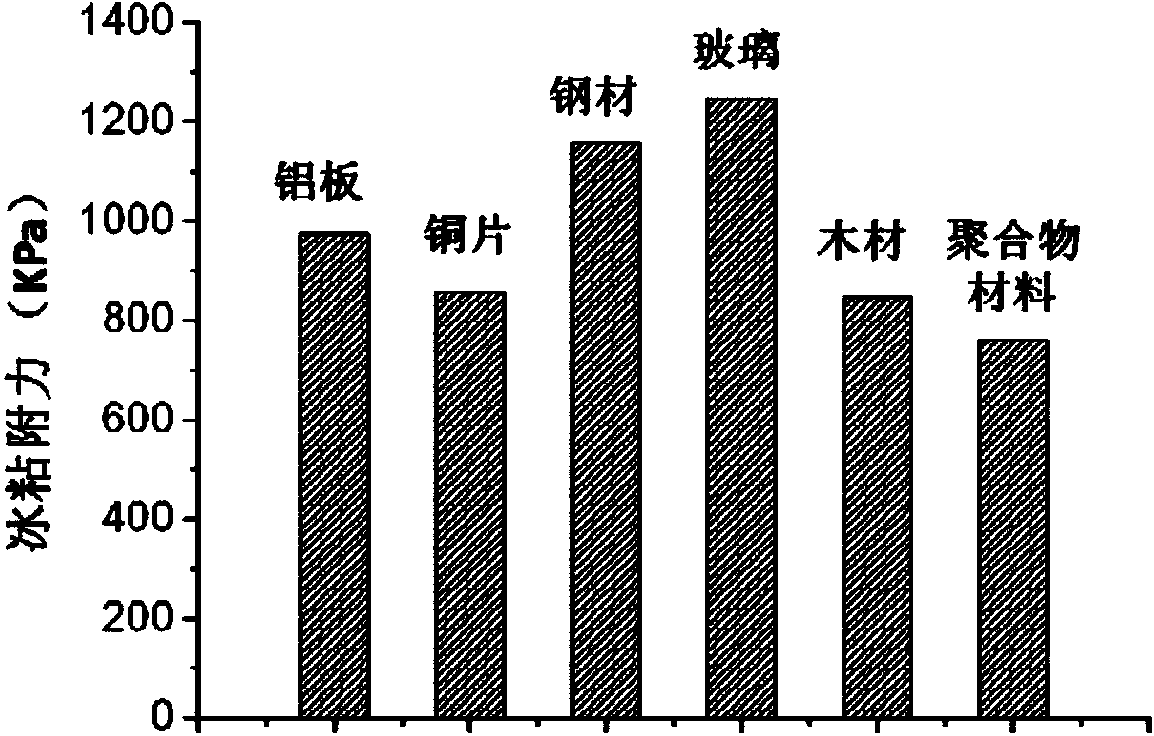

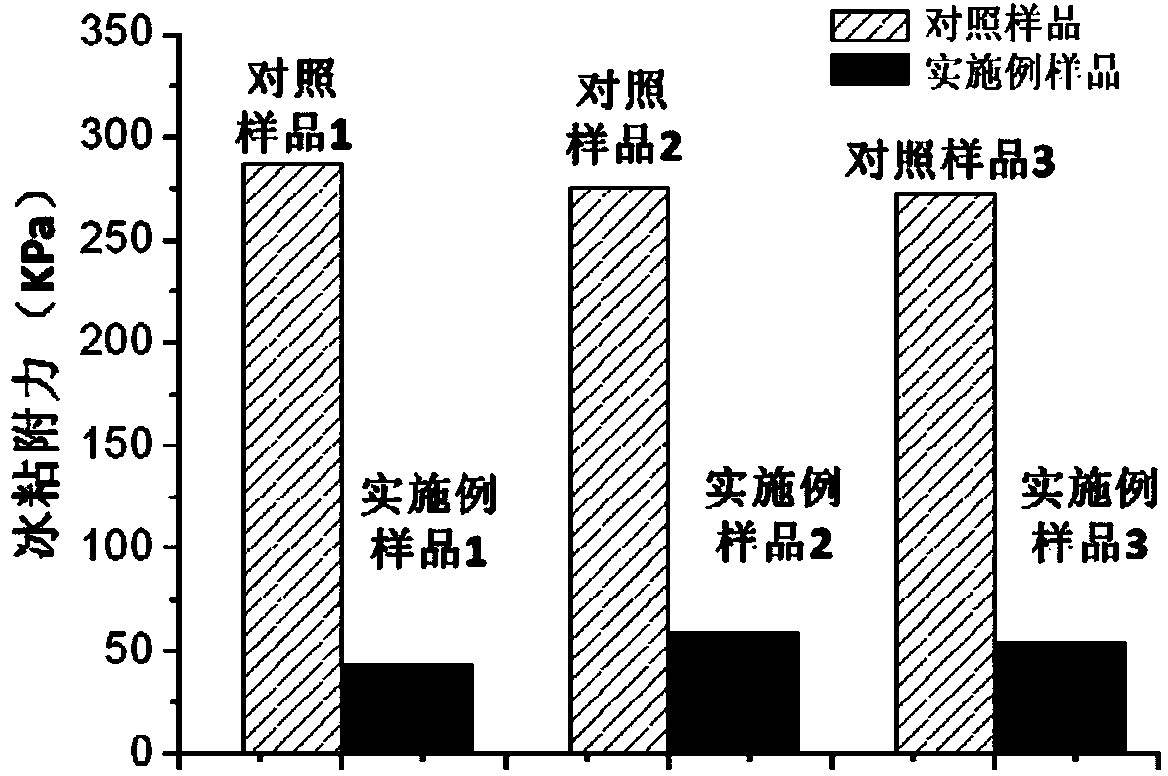

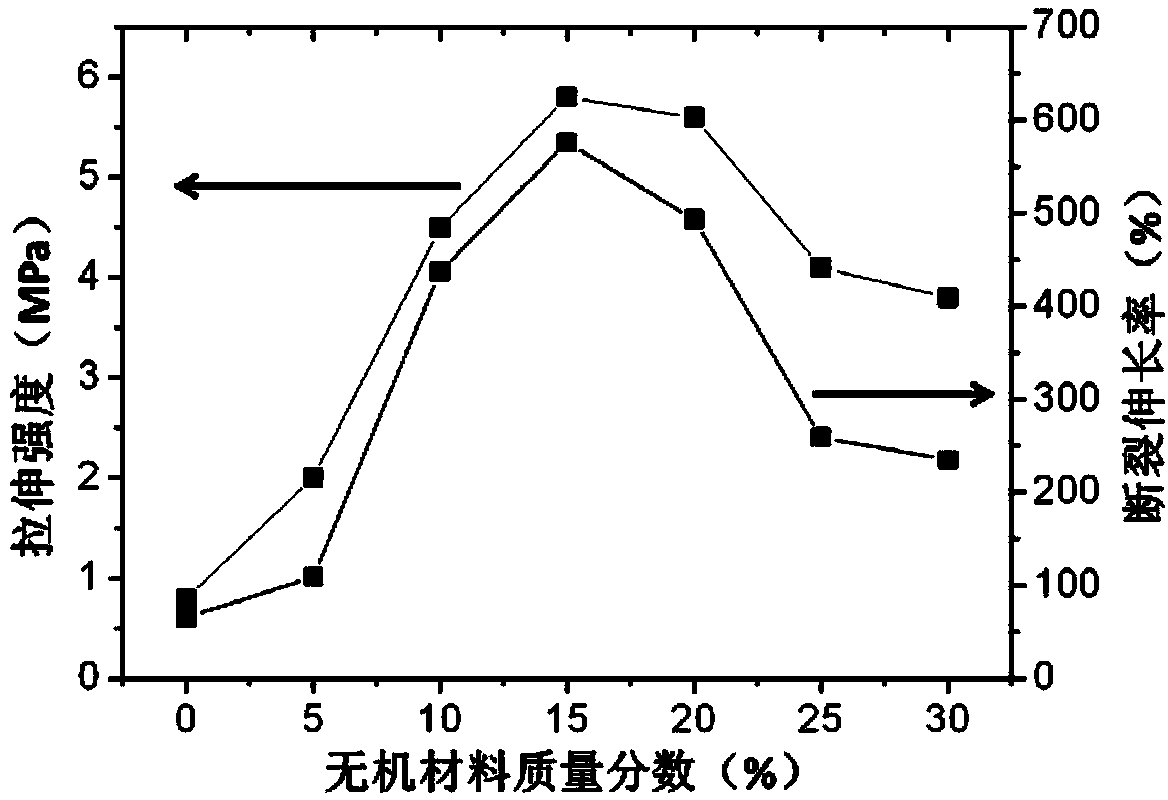

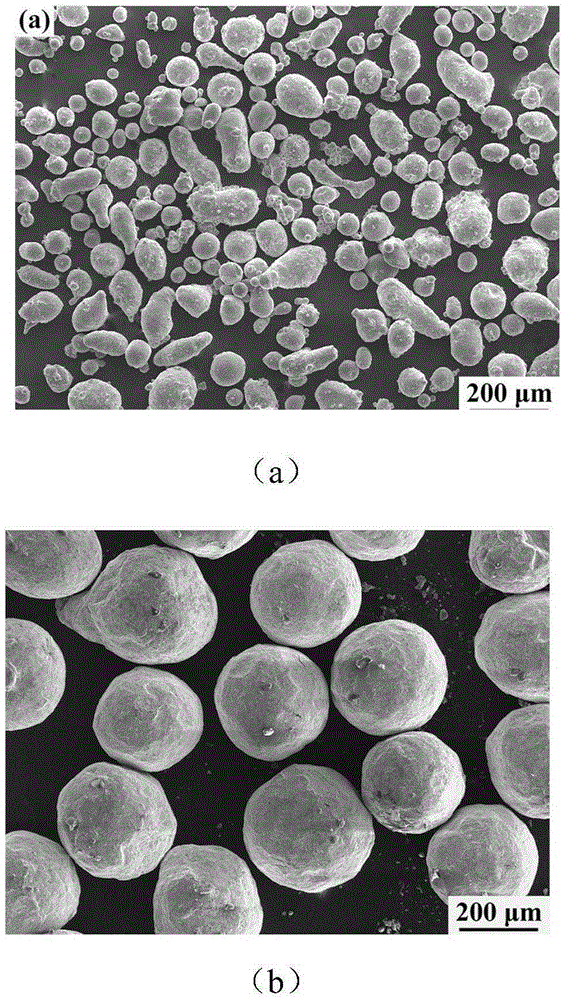

Organic silicon gel anti-ice-covering coating as well as preparation method and application thereof

InactiveCN104212339ALow ice adhesionReduce adhesionOther chemical processesCoatingsSurface engineeringSilicon rubber

The invention belongs to the technical field of material surface engineering, and in particular relates to an organic silicon gel anti-ice-covering coating, and a preparation method and application of the organic silicon gel anti-ice-covering coating. The low-ice-adhesion organic silicon gel anti-ice-covering coating consists of crosslinkable polysiloxane, a crosslinking agent, a catalyst, a promoter, non-volatile hydrophobic liquid and an inorganic material. The preparation method comprises the following steps: performing mixing and uniform ball-milling on polysiloxane, the crosslinking agent, the catalyst, the promoter, the non-volatile hydrophobic liquid and the inorganic material, then coating on a base material, and curing to obtain an anti-ice-covering coating, wherein crosslinkable polysiloxane, the crosslinking agent, the catalyst and the promoter form an organic silicon rubber network by virtue of reaction, and the non-volatile hydrophobic liquid is effectively fixed in the anti-ice-covering coating; gel formed by the non-volatile hydrophobic liquid and the crosslinkable organic silicon rubber network is a main anti-icing functional layer which can delay the surface icing of water and reduce the binding force between an ice layer and a substrate material so as to ensure that the coating surface achieves an anti-ice-covering effect, and the mechanical performance of the anti-ice-covering coating also can be effectively improved.

Owner:STATE GRID CORP OF CHINA +2

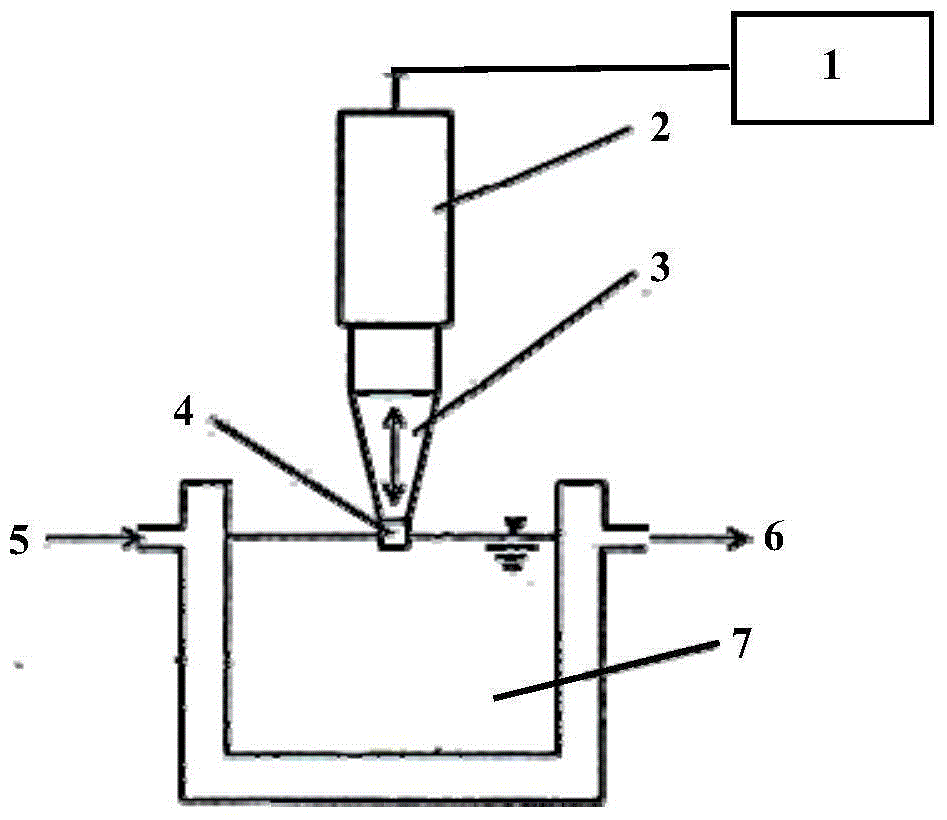

Cold spraying manufacturing method for anticorrosive aluminum base or zinc-aluminum base metal coating on magnesium alloy surface

ActiveCN105256307ADeposition will notImprove corrosion resistanceMolten spray coatingPressure inorganic powder coatingSurface engineeringDeposition temperature

The invention discloses a cold spraying manufacturing method for an anticorrosive aluminum base or a zinc-aluminum base metal coating on a magnesium alloy surface and belongs to the field of the material surface engineering technology and mechanical manufacturing. The method includes the following steps that firstly, aluminum base or zinc-aluminum base metal powder is mixed with hard metal powder so as to manufacture mixed powder for cold spraying; and secondly, a cold spraying process is adopted, the mixed powder is sprayed to a pretreated magnesium alloy matrix, and the anticorrosive aluminum base or zinc-aluminum base metal coating is manufactured on the surface of the magnesium alloy matrix. By the adoption of the method, the grain speed and the deposition temperature do not need to be remarkably improved, operation is easy, a sedimentary body manufactured through the method is more excellent in electric conductivity and thermal conductivity and higher in corrosion resistance, abrasion resistance and mechanical performance, and therefore the method can be widely applied for manufacturing coatings with high electric conductivity, thermal conductivity, corrosion resistance and abrasion resistance or workpieces with the high mechanical performance.

Owner:XUZHEN NEW ENERGY TECH (SHANGHAI) CO LTD

Ni-based coating with abrasion-resistance corrosion-resistance nanometer structure and preparation method

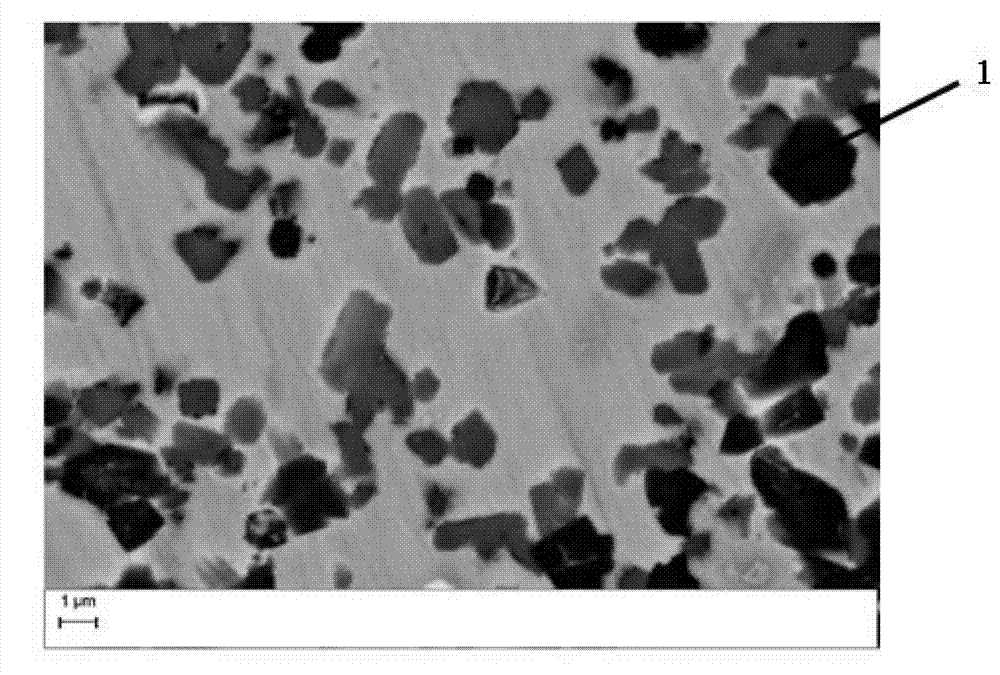

ActiveCN101591482AReduce porosityEasy to manufactureMolten spray coatingAnti-corrosive paintsSurface engineeringCombustion

The invention provides a Ni-based coating with an abrasion-resistance corrosion-resistance nanometer structure and a preparation method thereof, which belong to the technical field of surface engineering. The Ni-based coating and the preparation method aim to solve the problems of poor corrosion resistance, high cost and the like of the coating of the prior nanometer structure. Spray powder of the coating comprises the following compositions by weight: 0.5 to 1.5 weight percent of C, 3.0 to 5.0 weight percent of B, 2.5 to 6.0 weight percent of Si, 4.0 to 9.0 weight percent of Fe, 12.0 to 25 weight percent of Cr, and the balance of Ni, wherein the granularity of the spray powder is between 5 and 55 micrometers. The method comprises the steps of preparing spray powder by adopting a gas atomization method; then spraying the spray powder onto a substrate by active combustion high-speed gas spray technology, and preparing the Ni-based coating with the nanometer structure. The coating has high comprehensive performance in abrasion resistance and corrosion resistance, and low preparation cost, and is applicable for industrial production.

Owner:CHINA ELECTRIC POWER RES INST +1

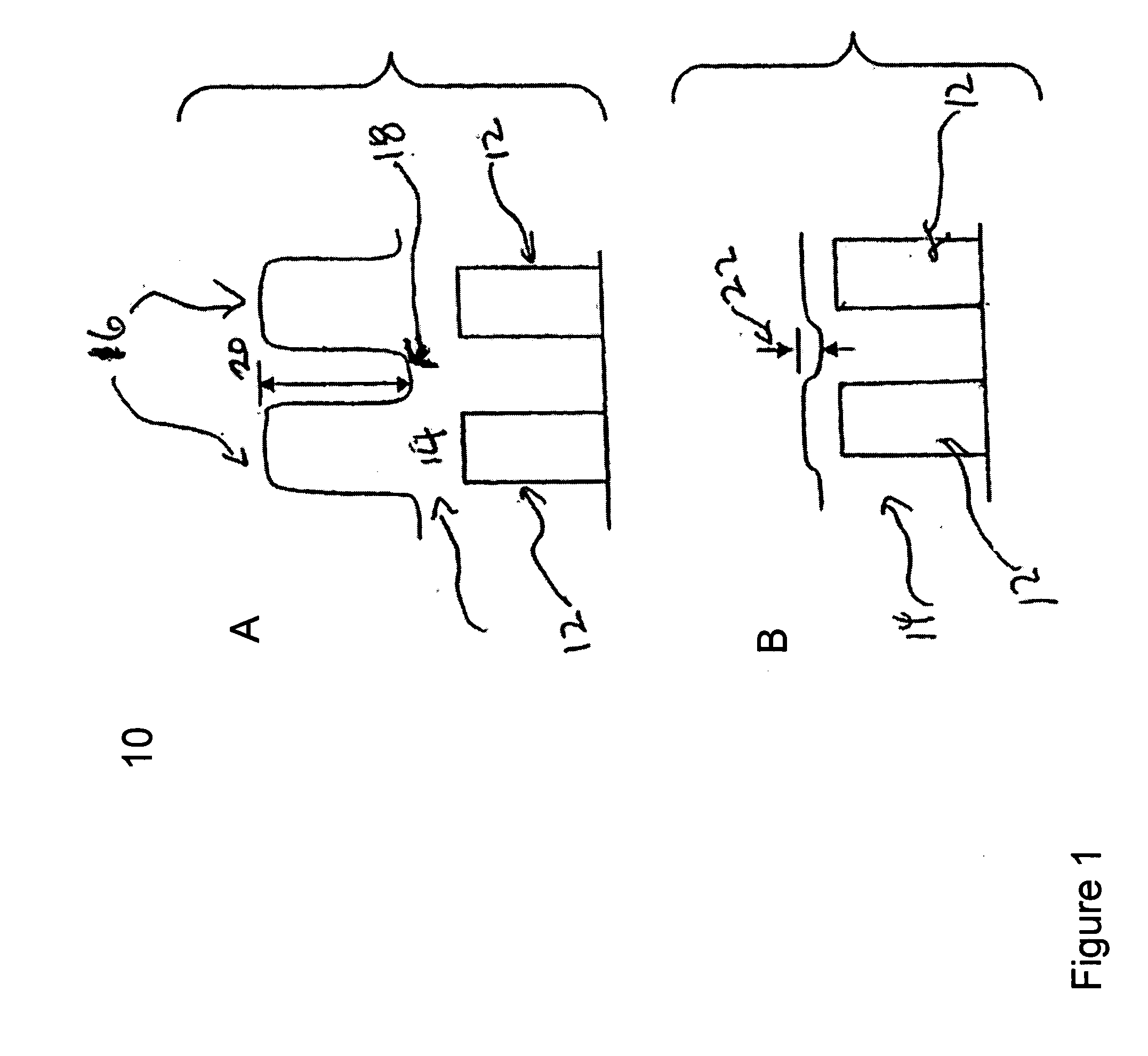

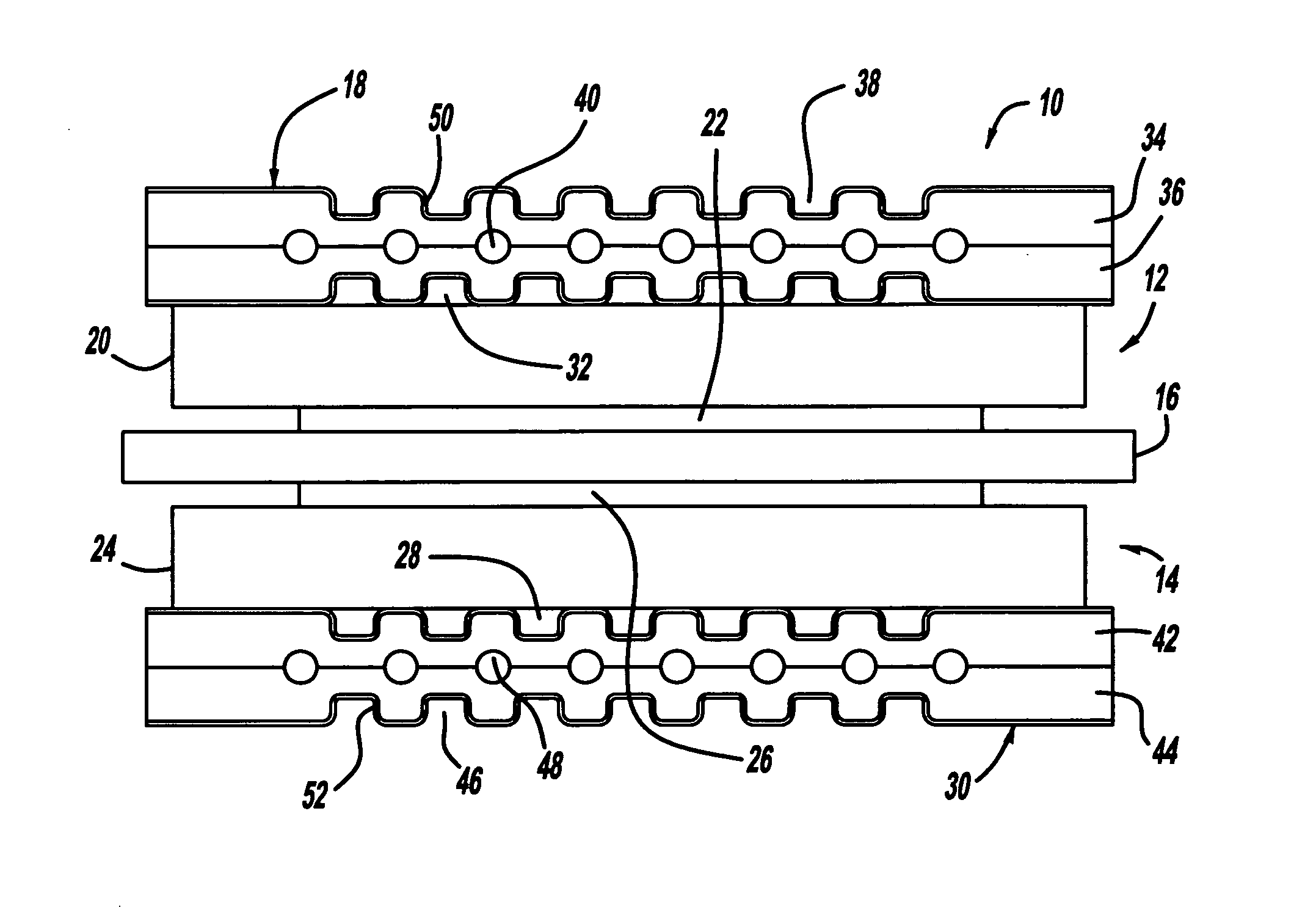

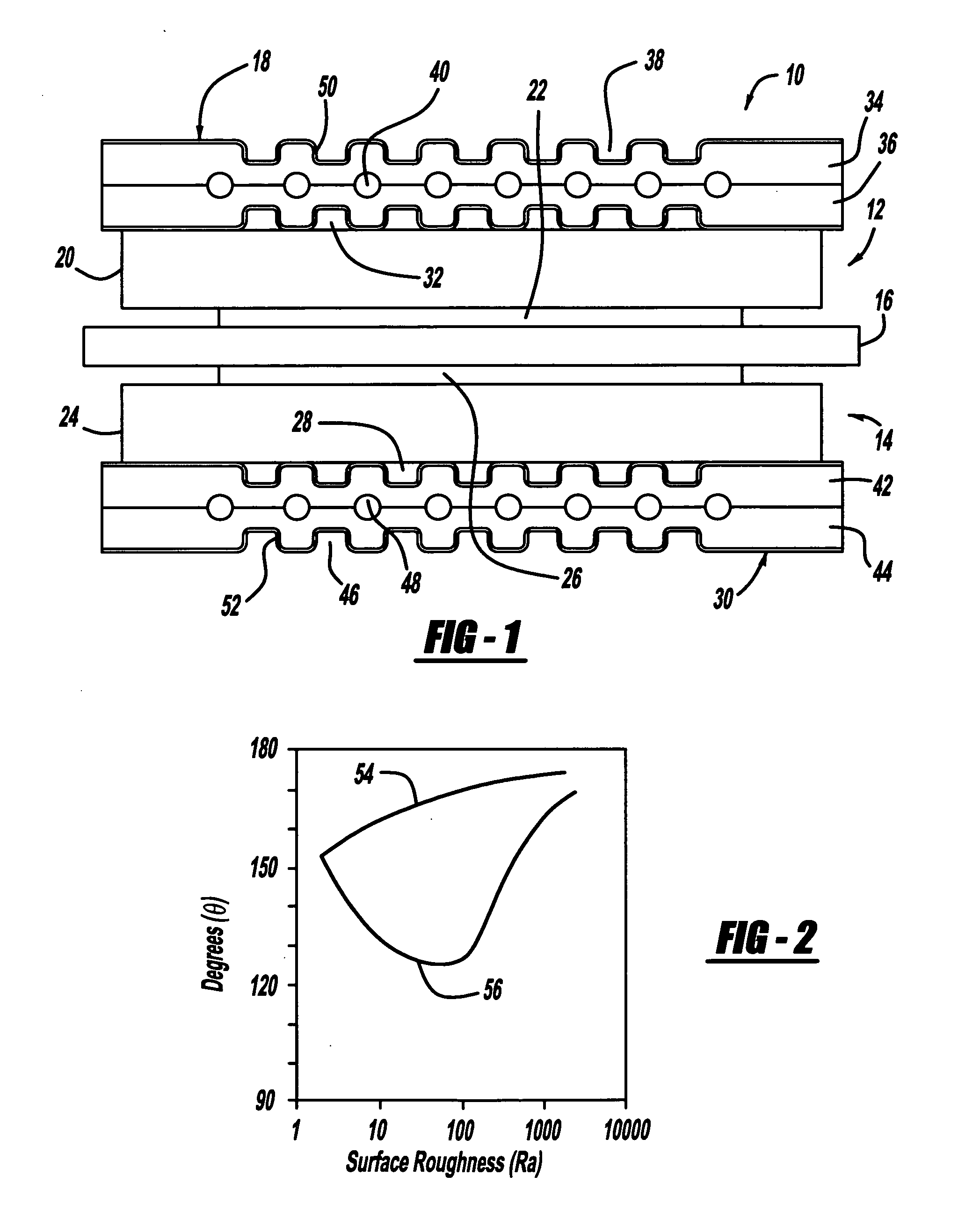

Surface engineering of bipolar plate materials for better water management

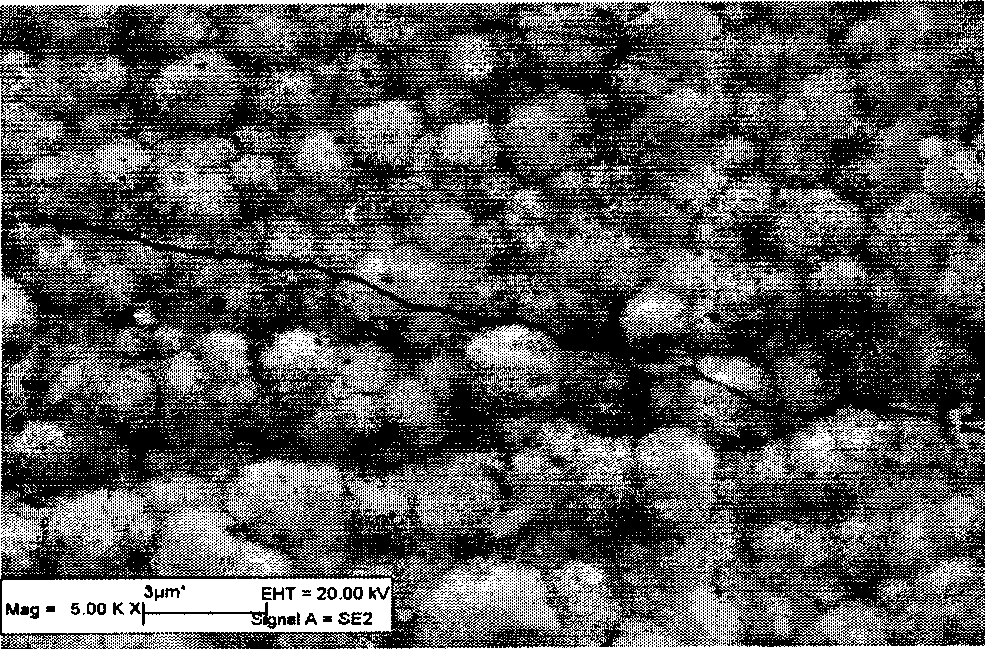

InactiveUS20070141439A1Improve hydrophilicityLess hydrophilicFuel cells groupingWater management in fuel cellsSurface engineeringRough surface

A flow field plate or bipolar plate for a fuel cell, where a surface of the flow field plate is textured or roughened to change the surface morphology of the plate. A conductive coating is deposited on the roughened surface where the roughness of the surface of the plate increases the hydrophilic nature of the coating. Therefore, if the coating is naturally hydrophobic, the surface roughness makes the coating hydrophilic to wick water away. If the coating is a conductive hydrophilic coating, then the surface roughness makes the coating super-hydrophilic, and may counter the effects of surface contamination that would act to make the hydrophilic coating less hydrophilic.

Owner:GM GLOBAL TECH OPERATIONS LLC

Method for electrodepositing chromium and chromium alloy composite coating through ultrasound-pulse for trivalent chromium plating liquid system

InactiveCN101392394AImprove current efficiencyReduce pollutionElectrolytic coatingsSurface engineeringAlloy composite

The invention relates to a method for ultrasound-pulse electrodepositing of chromium and chromium alloy composite plating layer in a tervalent chromium plating bath system, pertaining to the technology of surface engineering and surface processing. The method comprises the pretreatment of to be plated articles and the ultrasound-pulse electrodepositing. By using the method, a Cr / SiC or Cr / SiO2 composite plating layer with 0 to 5.5 percent of composite particles, a Cr-Ni / SiC or Cr-Ni / SiO2 alloy composite plating layer with 0 to 3.9 percent of composite particles, and a Cr-Ni-Fe / SiC or Cr-Ni-Fe / SiO2 composite plating layer with 0 to 4.4 percent of composite particles can be obtained. The thickness of the composite plating layer can be thickened with the electrodepositing time, with the largest thickness of 18.26Mum. The composite plating layer is compact and smooth and can be well combined with the substrate, and has good wearing resistance and corrosion resistance.

Owner:CENT SOUTH UNIV

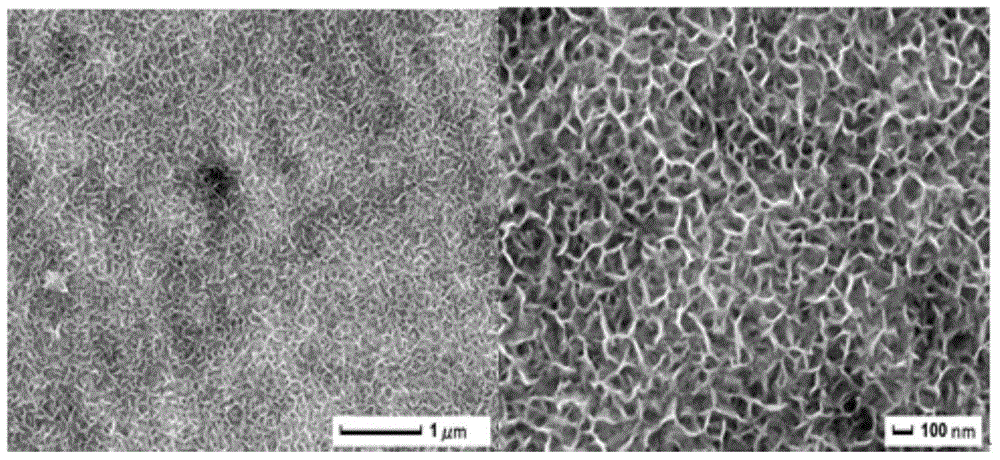

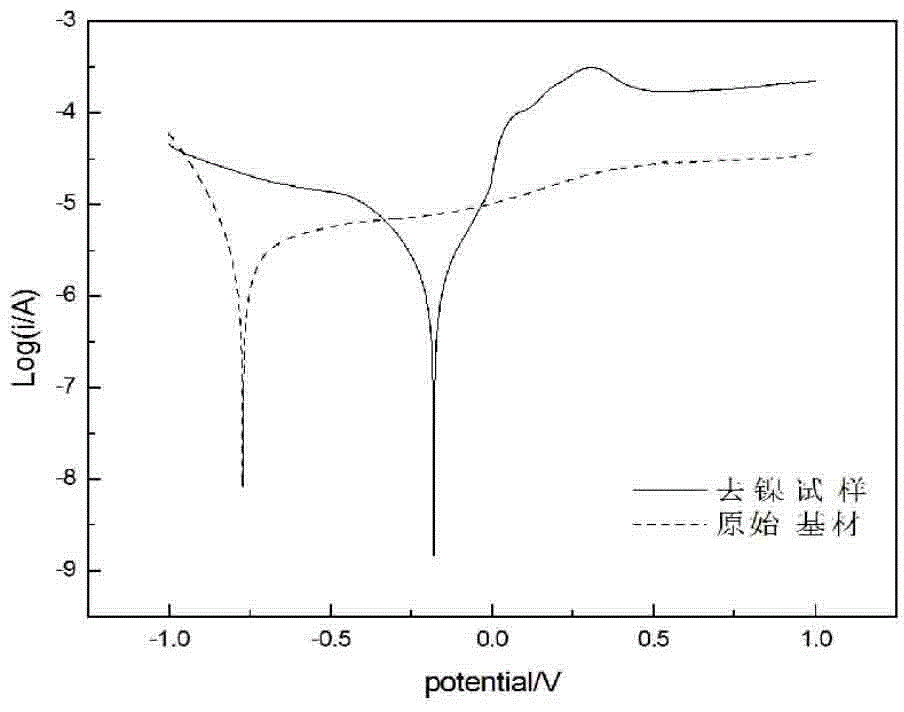

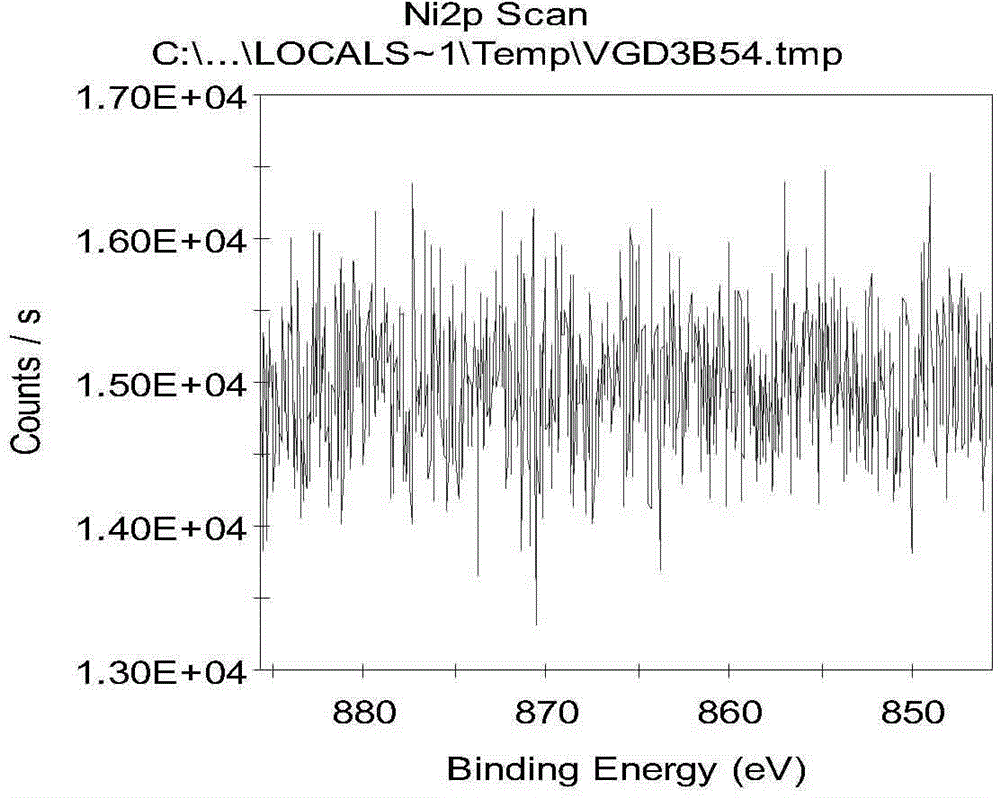

Production method of nickel-titanium alloy surface nickel-free layer

The invention provides a production method of a nickel-titanium alloy surface nickel-free layer, and relates to the fields of surface engineering technologies and biomaterials. The method comprises the following steps: pre-treating nickel-titanium alloy, and placing the nickel-titanium alloy in an alloy removal treatment fluid to carry out a reaction in order to obtain nickel-titanium alloy with the surface being a nickel-free layer. The nickel-titanium alloy with the surface being the nickel-free layer has high corrosion and blood coagulation resistance to meet special demands of intravascular stents, cardiac valves and other human body intervention materials.

Owner:WUXI SHENKANG MECHANICAL EQUIP

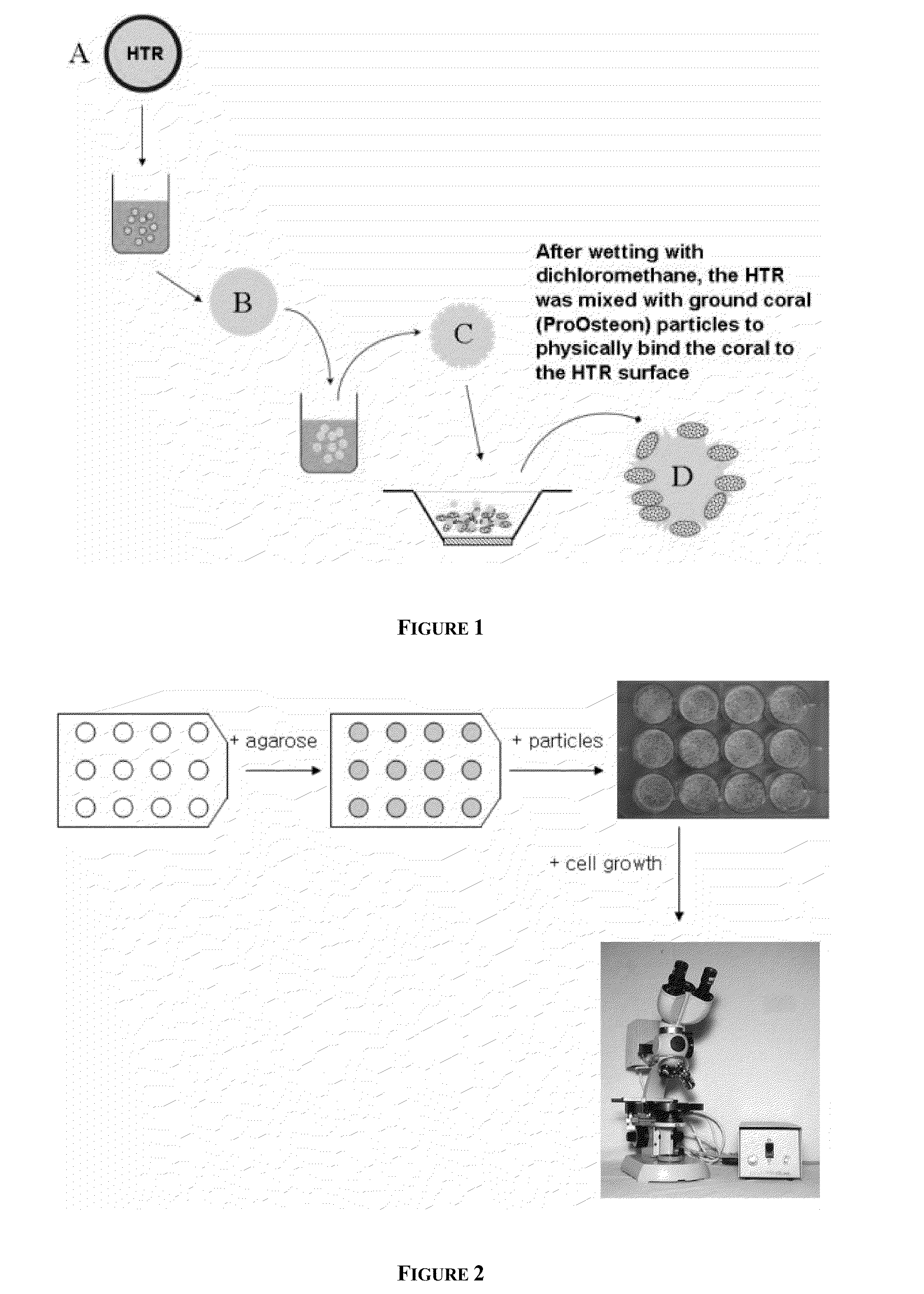

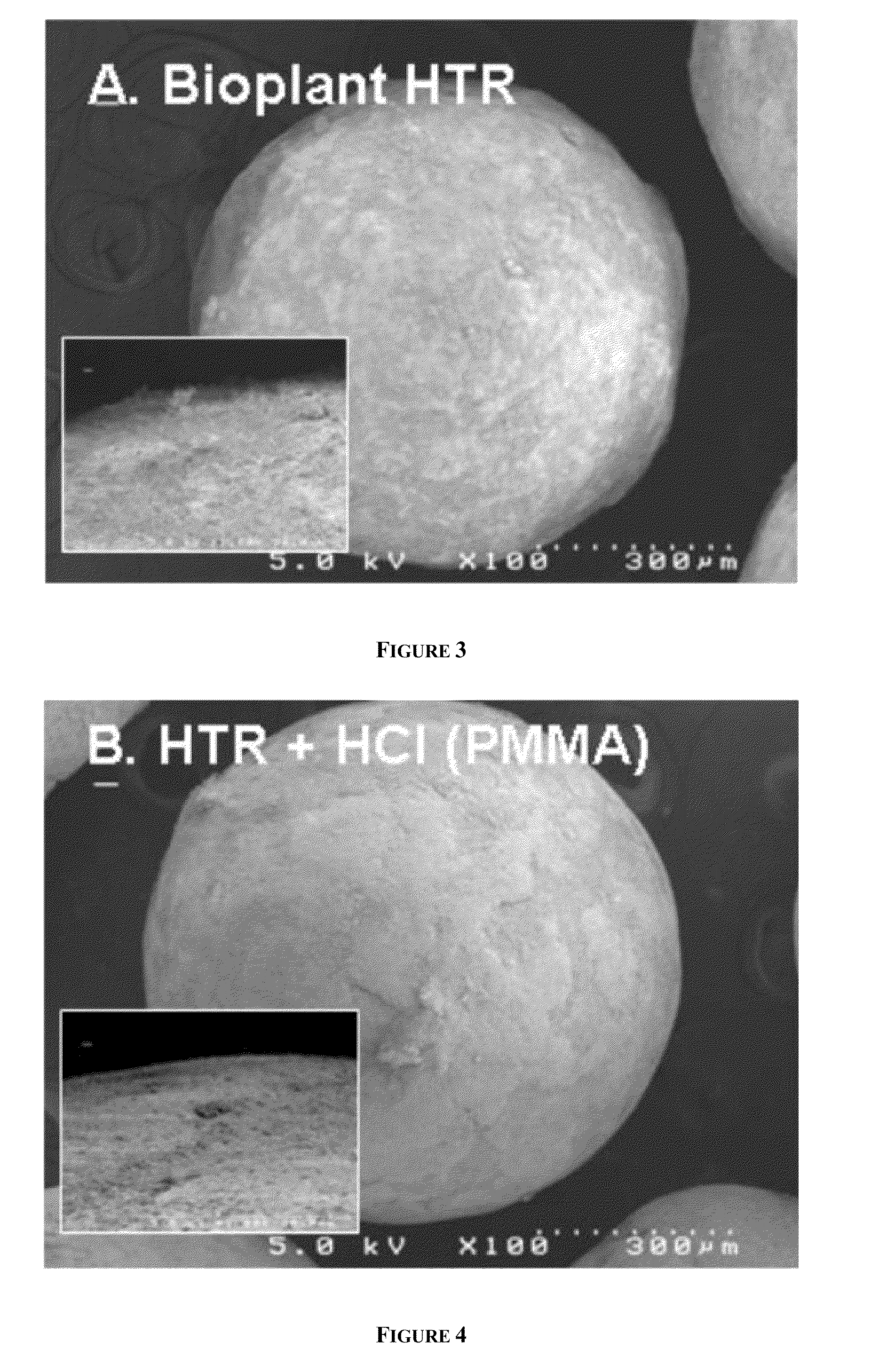

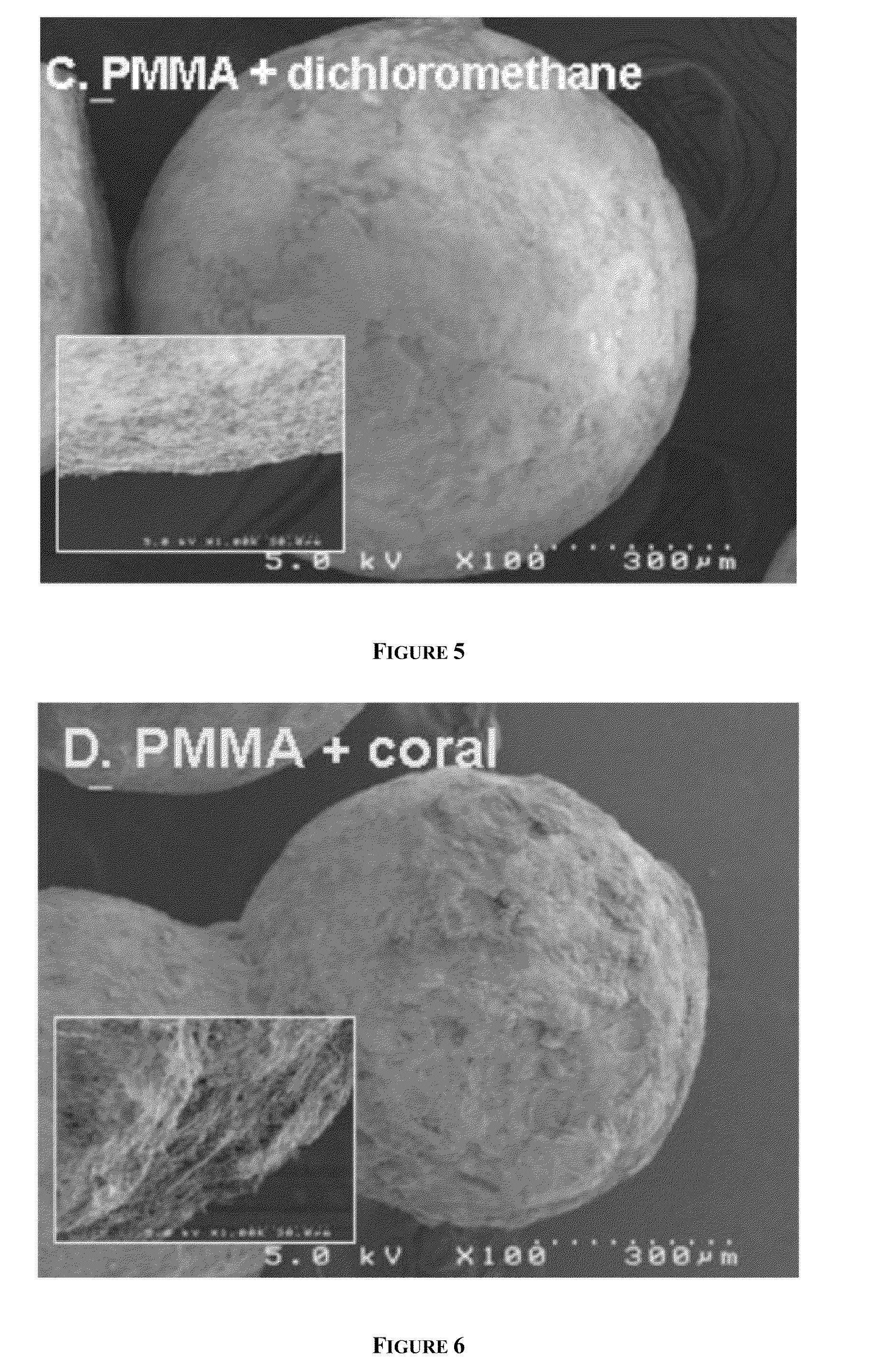

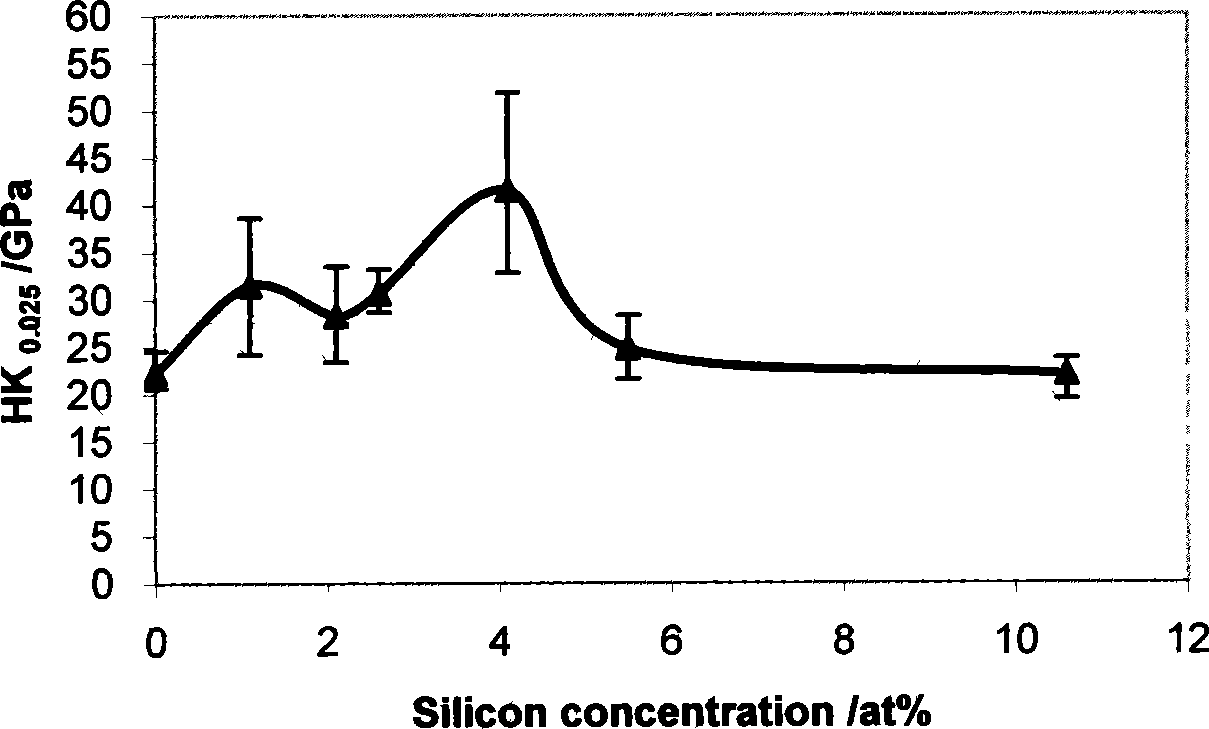

Surface engineering of tissue graft materials for enhanced porosity and cell adhesion

In one aspect, the invention relates to providing enhanced application tissue graft materials in regenerative medicine through improved cellular interactions. Biocompatible implant materials, methods for preparing biocompatible implant materials, methods for using same, and methods for treating tissue injury are disclosed. This abstract is intended as a scanning tool for purposes of searching in the particular art and is not intended to be limiting of the present invention.

Owner:VANDERBILT UNIV

Glass-hard low-frictional coefficient nano-multi-layer amplitude modulation structure coating and preparation method thereof

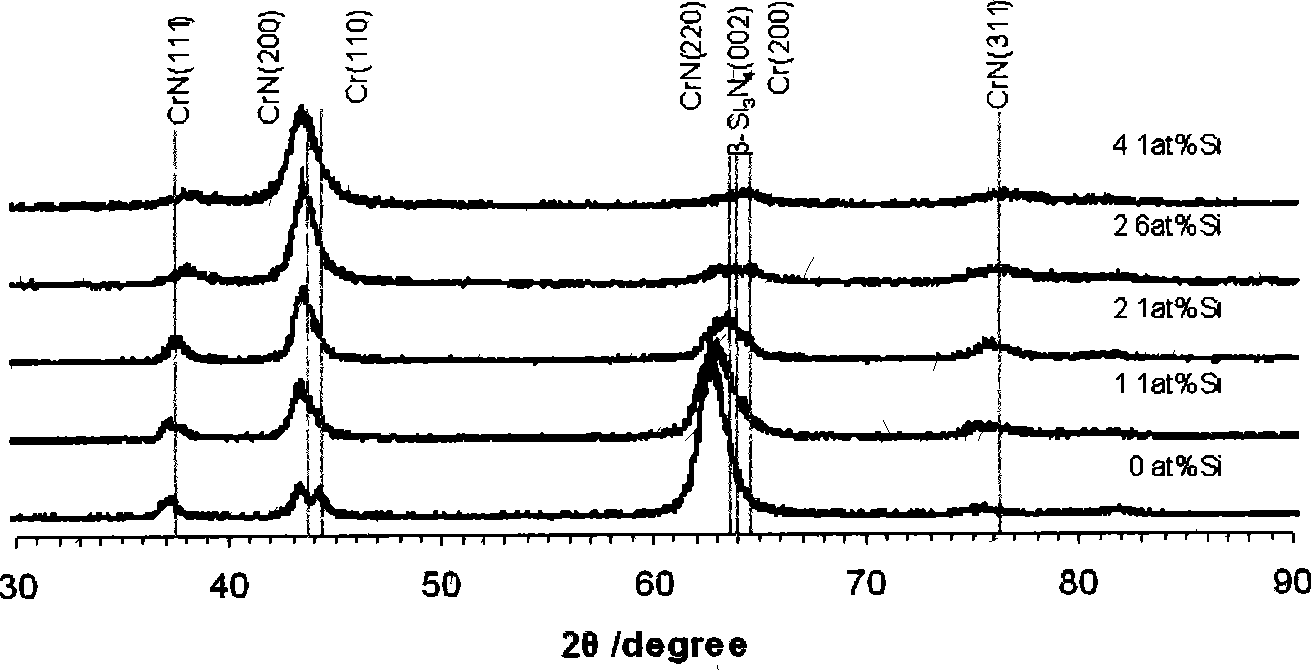

InactiveCN101367286AHigh hardnessReduce coefficient of frictionLayered productsVacuum evaporation coatingCritical loadNitrogen gas

The invention belongs to a surface engineering technology and in particular relates to a high-hardness and low-friction coefficient plating layer with a nanometer multilayered amplitude modulation structure and a method for preparing the same. A Cr-Si-N plating layer is plated by an unbalance magnetron sputtering ion plating method in a closed magnetic field. In preparation, the input power of Cr target current is 2 kilowatts; and the input power of Si target current is changed within the range between 0.3 and 0.7 kilowatt so as to adjust the content of silicon in the plating layer. When a CrN transition layer and the Cr-Si-N plating layer are deposited, the flow of the introduced argon gas is 10 sccm; and the bias voltage of direct current pulse is 60 volt below zero. When the CrN transition layer and the Cr-Si-N plating layer are deposited, the flow of nitrogen gas is used and positioned in a light emission spectrum device on the near surface of the Cr target for carrying out the closed-loop control so as to accurately modulate the compositions of the plating layer. The plating layer has the nanometer multilayered amplitude modulation structure which in turn consists of a base layer, a Cr interface layer, a CrN transition layer and a Cr-Si-N amplitude modulation structural layer with CrN and Si3N4 arranged outwards at intervals; the outermost layer is the Cr-Si-N amplitude modulation structural layer, wherein the amplitude modulation wavelength of the Cr-Si-N amplitude modulation structural layer is less than 50 nanometers; the hardness is larger than 20 GPa; the highest hardness exceeds 20 GPa; and the Cr-Si-N amplitude modulation structural layer has excellent film-based binding strength (a scuffing method determines that the critical load is larger than 85 newtons) and has friction coefficient of less than 0.5 between WC balls. A plating layer material can be used for mechanical parts under the condition of high-load service and cutters.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Method for preparing seawater corrosion resistant cladding layer on steel matrix

ActiveCN102181857ALong corrosion lifeSolving Manufacturing ChallengesMetallic material coating processesSurface engineeringHigh energy

The invention discloses a method for preparing a seawater corrosion resistant cladding layer on a steel matrix, which belongs to the technical field of surface engineering. The method comprises a process of preparing mixed powder for cladding, wherein the mixed powder comprises the following raw material components in percentage by weight: 23 to 32 percent of Cr powder, 12 to 17 percent of Mo powder, 1 to 4 percent of W powder, 0.3 to 1 percent of Nb powder and the balance of Ni powder. The method for preparing the cladding layer comprises the following steps of: cladding the mixed powder to form a pre-cladding layer; and performing multilayer cladding. The method has the advantages that: Ni-Cr-Mo alloyed powder is not required to be prepared by processes such as a gas atomization method or a water atomization method and the like, powder raw materials required to be subjected to cladding are mixed by a mechanical material mixing method, a high-energy density laser beam is used for melting the mixed powder, an alloyed Ni-Cr-Mo anti-corrosion cladding layer is formed on the surface of the steel matrix in situ, the cladding layer is combined with the matrix in a metallurgy mode, and the dilution rate is low; preparation cost is relatively low, the cladding layer is resistant to seawater corrosion and has long service life, and the process is relatively simple; and the problem of preparation of the Ni-Cr-Mo anti-corrosion cladding layer is solved.

Owner:JIANGSU KEHUAN INNOVATIVE MATERIAL CO LTD

Powdered material used for preparing high-temperature wear-resistant cladding layer and preparation method thereof

InactiveCN102965665AImprove wear lifeLow dilution rateMetallic material coating processesSurface engineeringImpeller

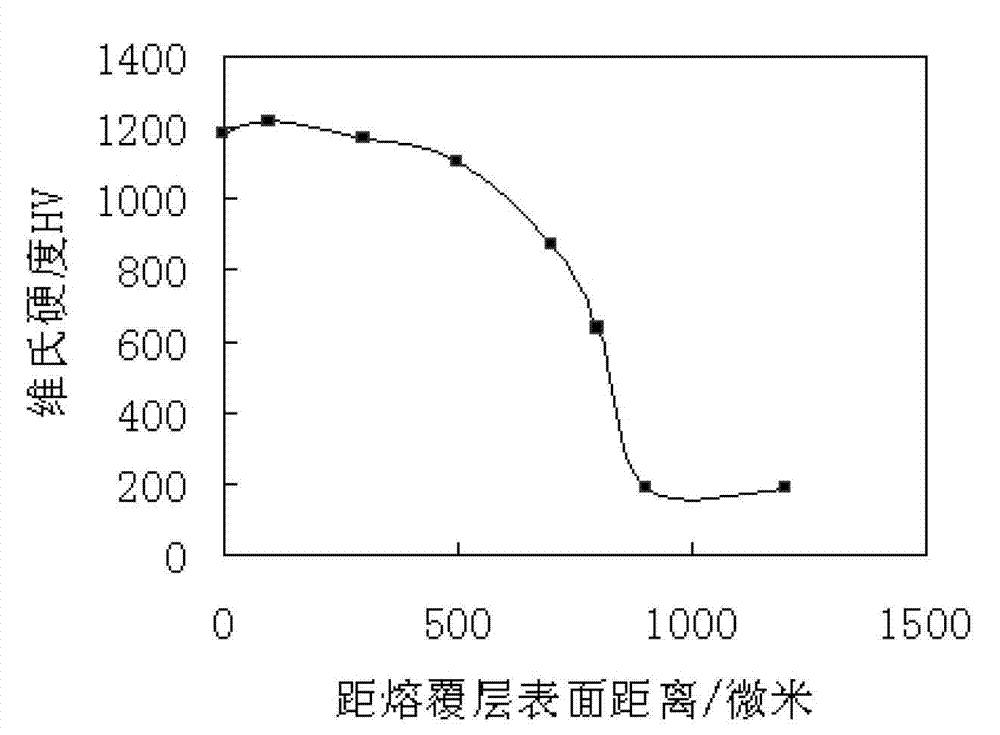

The invention discloses a powdered material used for preparing a high-temperature wear-resistant cladding layer and a preparation method thereof, belonging to the technical field of surface engineering. The powdered material comprises the following components by weight percent: 6-28% of TiB2, and the balance of Ni-Cr-Mo-Fe-Nb-B-Si-C alloy powder, wherein the Ni-Cr-Mo-Fe-Nb-B-Si-C alloy powder comprises the following ingredients by weight percent: 23-28% of Cr, 1-3% of Mo, 2-4% of Fe, 0.5-1% of Nb, 3-4.5% of B, 3.5-4.5% of Si, 0.5-1.3% of C and the balance of Ni. The preparation method comprises the steps of preparing powdered raw materials and mixed powder, and preparing the mixed powder to be the cladding layer used for the anti-abrasion treatment of a water cooling wall tube of a circulating fluidized bed boiler, or used for the anti-abrasion treatment of mill exhausters in a thermal power plant or an impeller of an induced draft fan. A TiB2 ceramic particle reinforced wear-resistant cladding layer is prepared by adopting a laser cladding technology, the surface microhardness ranges from 1000-1200HV, the technical requirements of high temperature and wear resistance of the water cooling wall tube of the circulating fluidized bed boiler are met, and the service life of the water cooling wall tube can be prolonged obviously.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Thermal spraying composite coating material for piston ring and preparation method of thermal spraying composite coating material

ActiveCN103205667AHigh hardnessImprove wear resistanceMolten spray coatingSurface engineeringThermal spraying

The invention discloses a thermal spraying composite coating material for a piston ring and a preparation method of the thermal spraying composite coating material, belonging to the field of material surface engineering. The composite coating material is mainly formed by mechanically mixing four different powders in percentage by mass: 20-60wt.% of TiO2 as a ceramic material with the powder diameter of 20-120mum, 0-30wt.% of NiCrBSiFe as a self-melting alloy with the powder diameter of 30-130mum, 20-40wt.% of Cr2O3 as a ceramic reinforced material with the powder diameter of 10-70mum and 0-20wt.% of nickel-coated graphite C-Ni as an antifriction material with the powder diameter of 20-120mum. A wear-resistant coating for the piston ring is prepared by using an atmosphere plasma spraying technology, and the prepared coating has excellent wear resistance.

Owner:BEIJING UNIV OF TECH

Method for preparing powder-cored welding wire and cladding layer used for cladding surface of hot working die

InactiveCN101602132AExtended service lifeQuality improvementArc welding apparatusWelding/cutting media/materialsSurface engineeringHot working

The invention discloses a method for preparing a powder-cored welding wire and a cladding layer used for cladding the surface of a hot working die, and belongs to the technical field of surface engineering. The preparation process comprises the following steps: preparing the powder-cored welding wire of a ceramic-metal composite material cladding layer, selecting the hot working die with the outline size achieving the design requirement, preparing the cladding layer, and grinding the die with the prepared cladding layer. The method has the advantages that the surface of the hot working die is prepared with the ceramic-metal composite material cladding layer of which effective thickness reaches 1 to 2 millimeters so as to effectively prolong the service life of the hot working die and improve the quality of a processed product; and the method has simple operation and low cost.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

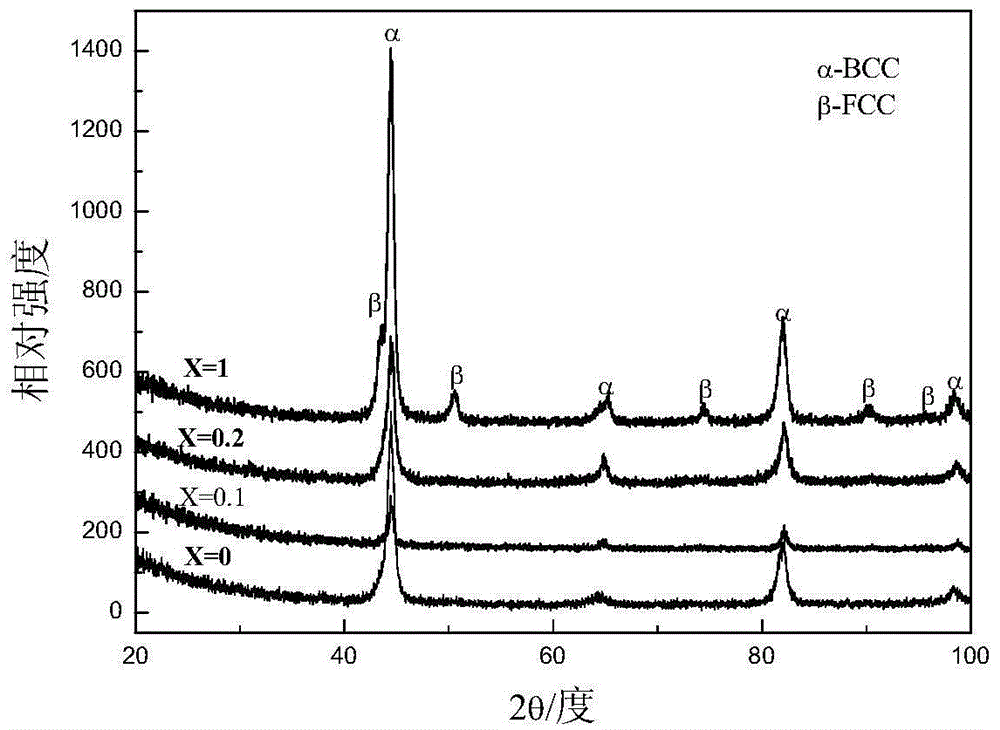

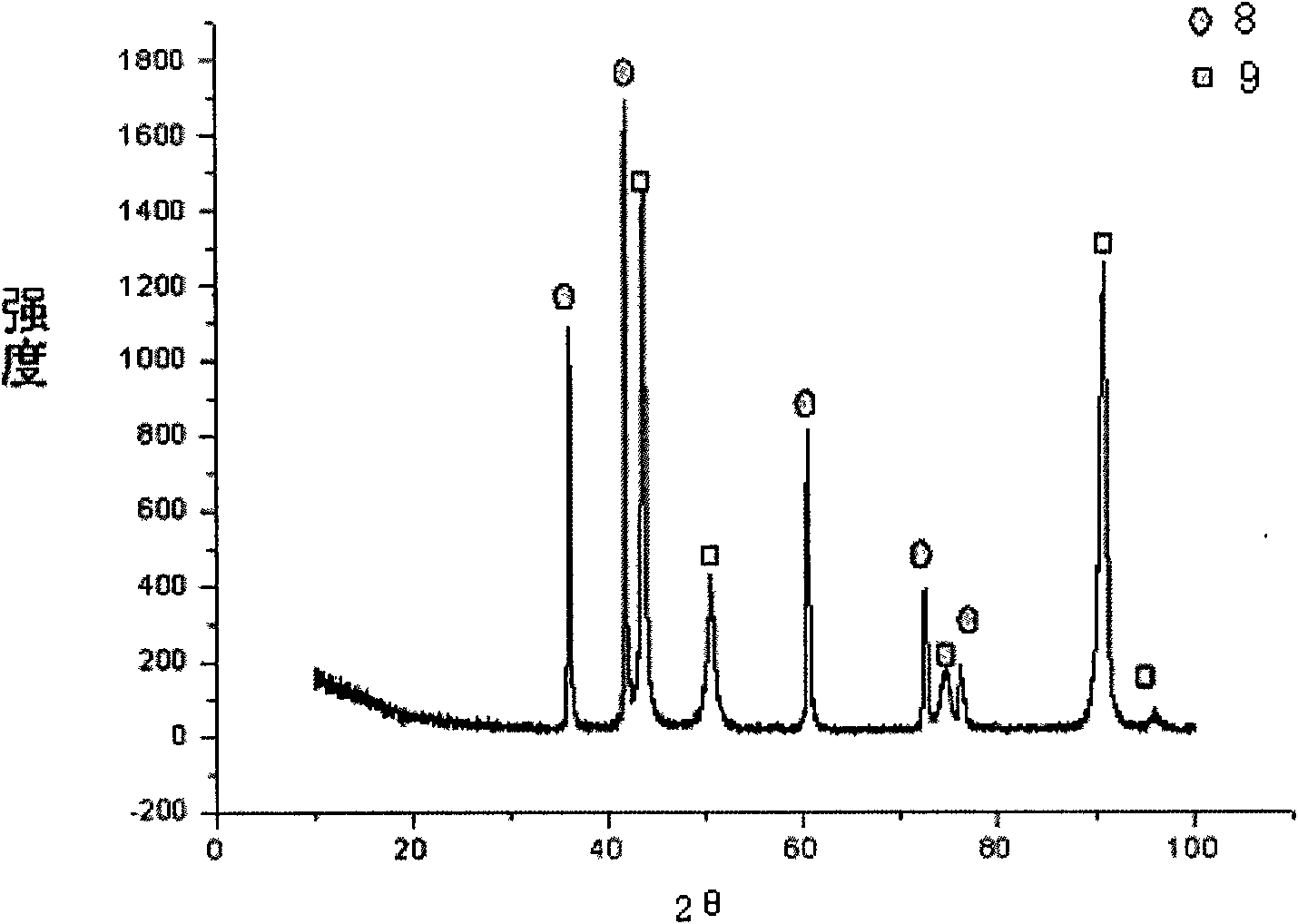

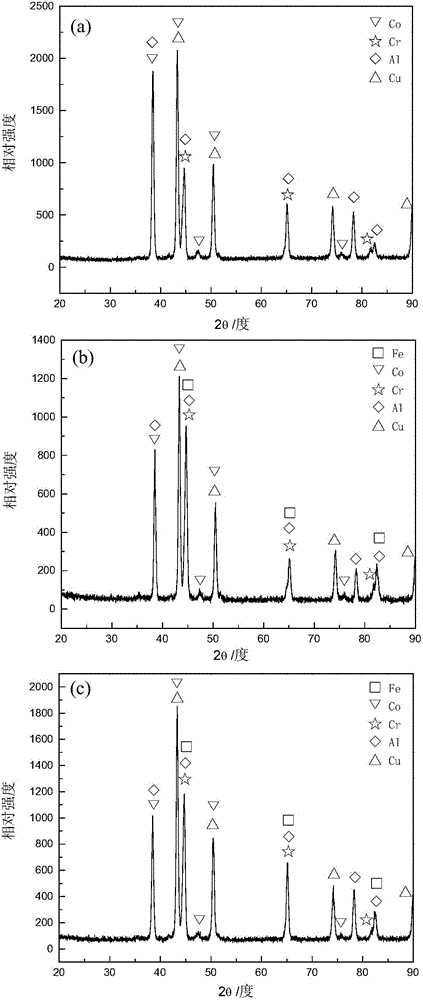

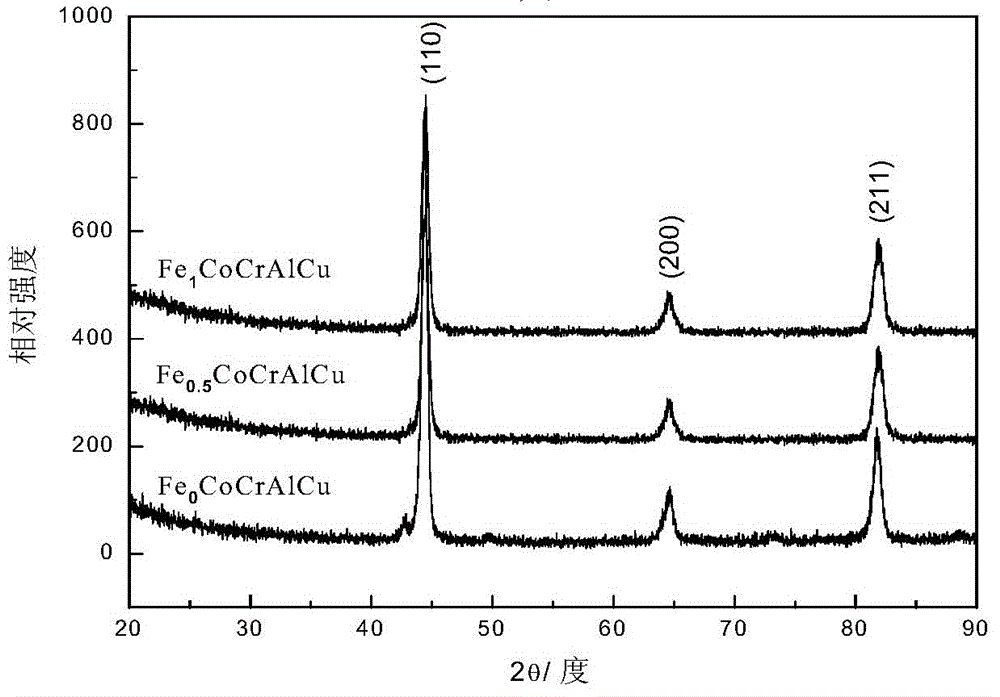

Powder for used in nickel single-element-based alloy surface laser high-entropy alloying and preparation process

ActiveCN104550901ASimple crystal structureImprove surface propertiesMetallic material coating processesSurface engineeringHigh entropy alloys

The invention discloses powder for use in nickel single-element-based alloy surface laser high-entropy alloying and a preparation process, and belongs to the technical field of surface engineering. The high-entropy alloy powder consists of four metal elements of Fe, Co, Cr and Al in an equal molar ratio of 1:1:1:1. Appropriate process parameters are selected by adopting a laser alloying method, so that a FeCoCrAlNi high-entropy alloyed layer which has the advantages of flat surface, metallurgical bonding and superior performance is successfully prepared a Ni-based alloy surface. According to the prepared high-entropy alloyed layer, the defect of generation of a large quantity of intermetallic compounds in the conventional multi-element alloy condensing process is overcome due to the existence of a high-mixed-entropy effect, and the phase composition of the alloyed layer is of a simple solid solution structure, so that the brittleness of the alloyed layer is lowered, and a coating has the superior performance of high hardness, wear resistance and the like; the powder and the preparation process can be applied to the technical field of surface engineering, and have wide application prospects.

Owner:SHENYANG POLYTECHNIC UNIV

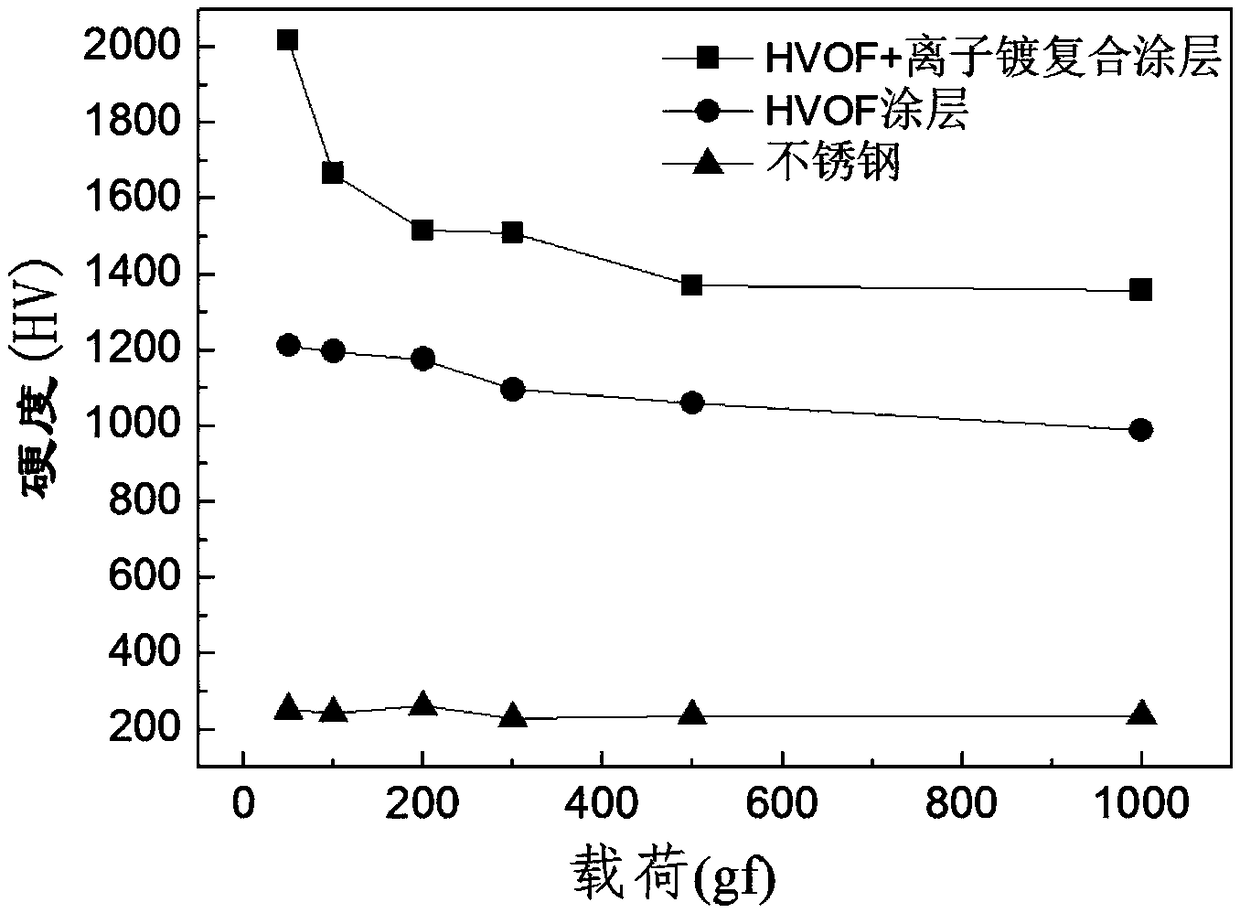

Hard-seal ball valve with high wear resistance and corrosion resistance and preparation method

InactiveCN108130533AHigh hardnessImprove wear resistanceMolten spray coatingVacuum evaporation coatingSurface engineeringHigh resistance

The invention discloses a hard-seal ball valve with high wear resistance and corrosion resistance and a preparation method of the hard-seal ball valve with high wear resistance and corrosion resistance and belongs to the technical field of metal surface engineering. The hard-seal ball valve comprises a steel ball valve base body. A carbide cermet coating of the hundreds-of-micron order and a nitride ceramic coating of the micro-nano order are sequentially synthesized on the steel ball valve base body, and the carbide cermet coating is a WC-Co-based or high-temperature-resistant Cr3C2-NiCr-based coating. The nitride ceramic coating is a dense Cr, Ti, AlCr or other binary or polybasic nitride multi-layer coating. The preparation method of the hard-seal ball valve comprises the steps that a metal ceramic hardened layer and a nitride multi-layer hole sealing layer are sequentially synthesized on the surface of the ball valve by the adoption of supersonic flame spraying and vacuum ion plating methods. The surface-modified hard-seal ball valve with high wear resistance and corrosion resistance has the high hardness, low friction coefficient, wear resistance, corrosion resistance and other compound properties, the surface microhardness reaches 1,800-3,000 HV, and the resistance standard salt spray test is performed for more than 240 hours, and the service life of the hard-seal ball valve is prolonged remarkably.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

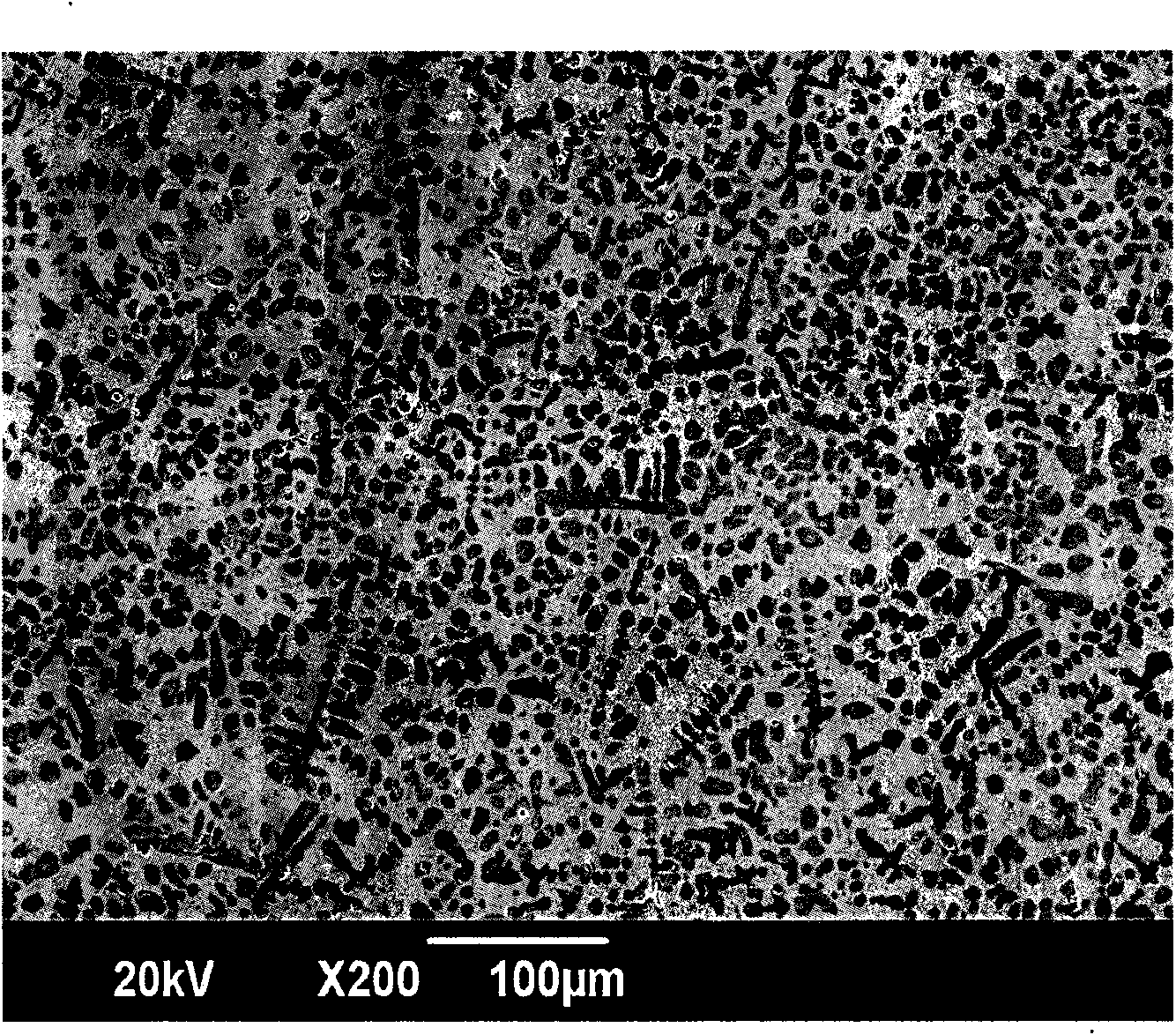

Powder material for laser high entropy alloying of iron single element base alloy surface

ActiveCN104646660ASolve the disadvantages of poor combinationSolve crackingMetallic material coating processesSurface engineeringHigh entropy alloys

The invention discloses a powder material for laser high entropy alloying of an iron single element base alloy surface, belongs to the surface engineering technology field, and provides a new power material for preparation of a high entropy alloy coating. The powder material for the laser high entropy alloying of the iron single element base alloy surface consists of five types or more than five types of metallic elements. Constituent elements of the powder material for the laser high entropy alloying of the iron single element base alloy surface contain single element base alloy base material principal element iron, wherein content of the confirmed single element base alloy base material principal element iron is 0-30% of the total molar fraction of the coating alloy power material, and adding content of other types of the constituent elements in the coating alloy power material is 5-35% 0f the total molar fraction of the coating alloy power material. The powder material for the laser high entropy alloying of the iron single element base alloy surface is prepared by using appropriate laser irradiation technological parameters, and can prepare the high entropy alloy coating in metallurgical bonding with an iron base alloy base material, uniform and fine in texture, flawless and excellent in performance.

Owner:SHENYANG POLYTECHNIC UNIV

Powder material for boiler tube high temperature resistance and wear resistance protecting and preparation method thereof

InactiveCN103878363AHigh hardnessImprove wear resistanceMetallic material coating processesSurface engineeringWear resistant

The invention relates to powder material for boiler tube high temperature resistance and wear resistance protecting and a preparation method thereof, and belongs to the technical field of surface engineering. The power material comprises the following components, by weight percentage, 10-20% of titanium-nickel alloy powder, 1.5-3.5% of graphite powder, 0.5-1% of silica powder, 8-25% of nickel-chromium alloy powder Ni80Cr20, 5-10% of iron boride powder and the balance of tri-chromium dicarbide powder. The preparation method comprises the following steps that power material is prepared, mix powder is formed, liquid-containing binders are prepared, sizing agents are prepared from the mix powder, prilling is completed through spray drying, and finished product powder is prepared from screening the prilling powder and is used for preparing a cladding layer. The metal cladding layer with high wear resistant duplex ceramic is formed through laser cladding, and the hardness ranges from 1100 HV to 1600 HV, so that the powder material for boiler tube high temperature resistance and wear resistance protecting and the preparation method thereof has the advantages that efficiency of the laser cladding is higher, loss of powder spattering is low, grain of the cladding layer is tiny, wear resistance of the cladding layer is high and the like.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Powder used for laser-cladding zinc corrosion resistant cobalt-based alloy and preparation technology for modified layer

ActiveCN104493152AAvoid erosionStrongly corrosiveMetallic material coating processesSurface engineeringTemperature resistance

The invention discloses powder used for enhancing a zinc corrosion resistant cobalt-based alloy laser-cladding layer by preparing an intermetallic compound on surface of iron-base alloy and a preparation technology, belongs to the technical field of surface engineering, and provides a novel protection coating material and a preparation technology thereof to further improve high-temperature resistance abrasion and zinc corrosion performance of key components on a hot galvanizing production line of sink rolls, shaft sleeves, and the like, and prolong the service life of the components. The alloy powder is good in forming capacity, and high in bonding intensity with iron-base alloy base body; the laser-cladding layer is high in cost performance, excellent in abrasion resistant and zinc corrosion resistant performance, and suitable for preparation and re-preparation of laser surface protection coatings on components of the sink rolls, the shaft sleeves, and the like, and has a favorable application prospect and economic benefits.

Owner:SHENYANG POLYTECHNIC UNIV

Method for preparing metallic matrix composite coating reinforced by alumina ceramics particles

InactiveCN101580938AReduce manufacturing costHigh hardnessMolten spray coatingHeat inorganic powder coatingSurface engineeringMetal matrix composite

The invention relates to a method for preparing metallic matrix composite coating reinforced with alumina ceramics particles in the technical fields such as materials, electric power, metallurgy, machinery and the like, belonging to surface engineering techniques. The metallic matrix composite coating reinforced by alumina ceramics particles (AL2O3P / NiCrBSi) is prepared on the surface of the mild steel base material based on the characteristics of high wear and erosion resistance, low cost of the alumina materials, fine self-fluxing nature, wettability and plasma spraying technology of the NiCrBSi alloy, and the property of wearing and erosion resistance is improved. The technique process of preparing WCP / NiCrBSi composite material coating is as follows: coating design; sifting dusty spray; mixing the powder according to certain ratio; superficial treatment of base material; controlling plasma spraying parameter; and preparing WCP / NiCrBSi coating.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com