Powder used for laser-cladding zinc corrosion resistant cobalt-based alloy and preparation technology for modified layer

A technology of laser cladding and cobalt-based alloys, which is applied in the coating process of metal materials, coatings, etc., can solve problems such as inapplicability and corrosion of common alloys, achieve good industrial application prospects and economic benefits, inhibit corrosion, improve resistance The effect of wear and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] A method for preparing an intermetallic compound-enhanced zinc-corrosion-resistant cobalt-based alloy laser cladding layer on the surface of an iron-based alloy as described above, characterized in that the steps of the method are as follows:

[0038] S1. Weigh and mix Mo, Cr, Ni, Si, Fe, C, CeO according to the above ratio 2 , Co various powders, the mixed powder is ball milled or ground for 2-5 hours, and then the mixed powder is dried in a vacuum drying oven for 5-8 hours;

[0039] S2. The surface of the iron-based alloy base material is polished, sandblasted, cleaned and dried for later use, and the dried alloy powder is placed on the surface of the iron-based alloy base material. The thickness of the alloy powder is 1.5-3mm;

[0040] S3. Use a semiconductor laser with a wavelength of 980±10nm for single-pass and multi-pass laser irradiation treatment. The thickness of the alloy powder is preset at 1.5-3mm. After optimizing the process parameters, the laser power is...

Embodiment 1

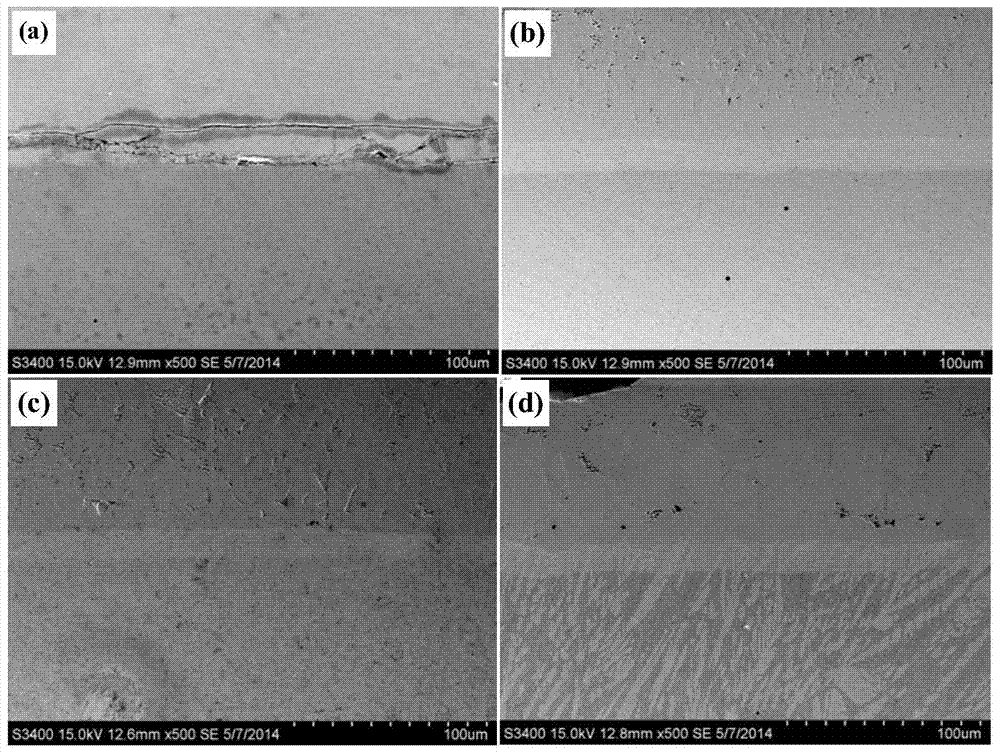

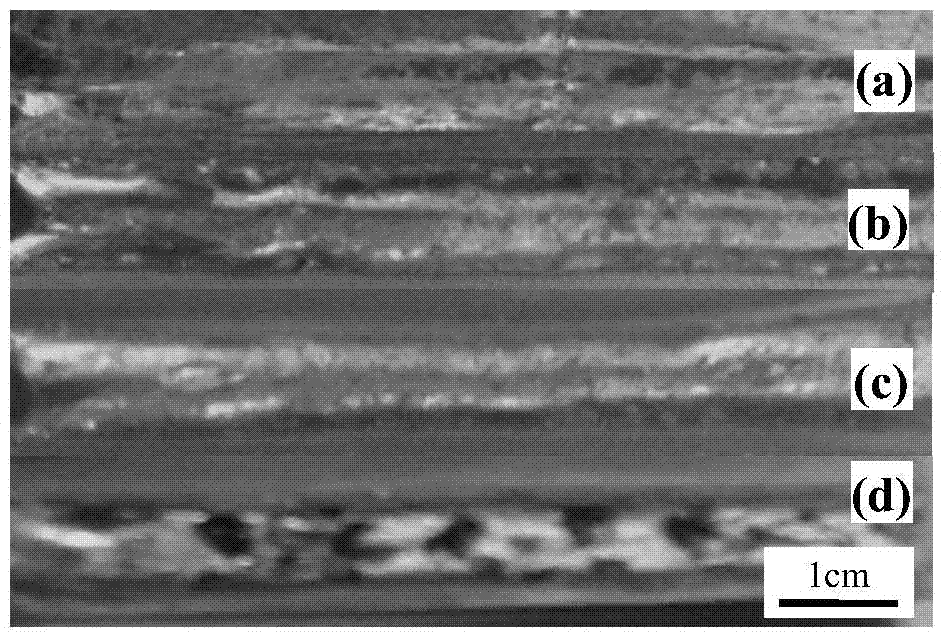

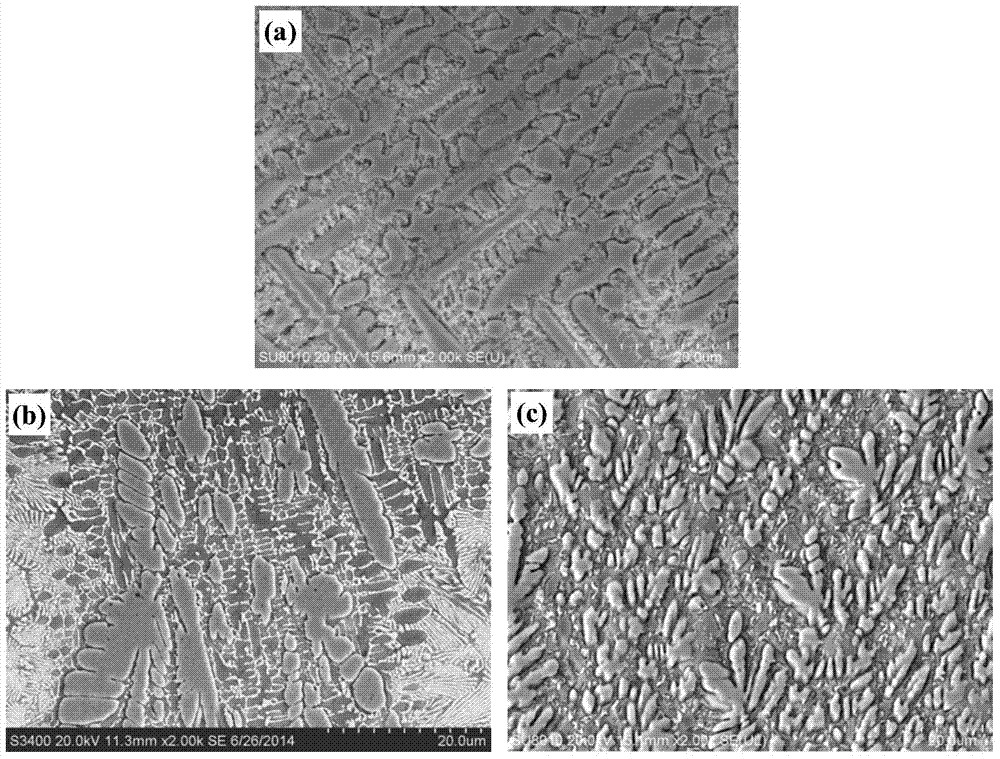

[0042] Co-based alloy (2.5% Si) laser cladding layer enhanced by intermetallic compounds on the surface of 316L stainless steel.

[0043] According to the weight percentage, the powder adopts Mo 28.5, Cr 8.5, Ni 1.5, Fe 1.5, C 0.08, CeO 2 0.5, Si 2.5, the balance is a mixed powder of Co. The purity of various powders of the coating material is not lower than 99.9%, and the particle size of the coating alloy powder is 50-120 microns. The coated alloy powder needs to be ground and mixed in a planetary ball mill or a mortar for 2 to 5 hours, and then the uniformly mixed powder is dried in a vacuum drying oven for 2 to 8 hours.

[0044] The 316L stainless steel is processed into the required sample size by using a CNC wire cutting machine, and the surface to be laser treated is polished to 600 SiC metallographic sandpaper in turn, then sandblasted, ultrasonically cleaned with alcohol or acetone, and dried for later use.

[0045] The dried alloy powder is pre-placed on the surfac...

Embodiment 2

[0047] Co-based alloy (3.5% Si) laser cladding layer enhanced by intermetallic compounds on the surface of 316L stainless steel.

[0048] According to the weight percentage, the powder adopts Mo 28, Cr 8, Ni 1.4, Fe 1.4, C 0.07, CeO 2 0.5, Si 3.5, the balance is a mixed powder of Co. The purity of various powders of the coating material is not lower than 99.9%, and the particle size of the coating alloy powder is 50-120 microns. The coated alloy powder needs to be ground and mixed in a planetary ball mill or a mortar for 2 to 5 hours, and then the uniformly mixed powder is dried in a vacuum drying oven for 2 to 8 hours.

[0049] The 316L stainless steel is processed into the required sample size by using a CNC wire cutting machine, and the surface to be laser treated is sequentially polished to No. 600 SiC metallographic sandpaper, then sandblasted, ultrasonically cleaned with alcohol or acetone, and dried for later use.

[0050] The dried alloy powder is pre-placed on the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com