Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

115results about How to "Good high temperature wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Overlaying manufacture repair technology for roll forging die

The invention discloses an overlaying manufacture repair technology for a roll forging die, belonging to the technical field of die overlaying technologies. According to the overlaying manufacture repair technology, the problems of poorer wear resistance at normal temperature and high temperature, cold-heat fatigue resistance, heat stability and high-temperature oxidation resistance due to direct use of low-heat-resistant steel 5CrMnMo and 5CrNiMo in the prior art are mainly solved. The overlaying manufacture repair technology is mainly characterized by comprising the following treatment steps of selecting the low-heat-resistant steel 5CrMnMo and 5CrNiMo die steel as substrates and enabling the heat treatment hardness HRC (Rockwell Hardness) to be 34-42, or integrally processing the surface of a die cavity to be repaired downwards or outwards for 10-15mm and preheating before welding the die; overlaying a priming coat with the thickness of 3-6mm by using an overlaying metal welding material with HRC of 34 to 42; overlaying a transition layer with the thickness of 3-6mm by using a die overlaying welding material with HRC of 42 to 48; overlaying a work layer with the thickness of 5-8mm by using an alloy overlaying material with HRC greater than 55; and carrying out tempering treatment after welding, furnace cooling to 90-190DEG C and discharging the material out of the furnace. The overlaying manufacture repair technology disclosed by the invention has the characteristics that the manufacturing period of the die is shortened, processing expenses are saved and the downtime is shortened and is mainly used for an overlaying manufacture and repair method of a hot forging rotary die.

Owner:HUBEI TRI RING AXLE

Wear resistant alloy for valve seat insert used in internal combustion engines

ActiveUS7611590B2Acceptable casting scrap rateGood heat treatment characteristicFurnace typesMachines/enginesWear resistantNiobium

This invention related to a high carbon and high molybdenum / tungsten martenisitic type iron base alloy with excellent hot hardness and wear resistance for making valve seat insert. The alloy comprises of 2.05-3.60 wt % carbon, 0.1-3.0 wt % silicon, 0-2.0 wt % manganese, 3.0-10.0 wt % chromium, 11.0-25.0 wt % molybdenum and tungsten, 0.1-6.5 wt % nickel, 0-8.0 wt % vanadium, 0-6.0 wt % niobium, 0-8.0 wt % cobalt, and the balance being iron with impurities.

Owner:WINSERT

Boracic high-speed steel with good red hardness and preparation method thereof

The invention discloses boracic high-speed steel with good red hardness, and a preparation method of the boracic high-speed steel. The boracic high-speed steel comprises the following chemical components in percentage by weight: 0.30-0.5% of C, 3.8-5.5% of Cr, 0.9-3.5% of W, 0.9-2.1% of Mo, greater than or equal to 3.5% and less than or equal to 5.0% of (W+2Mo), 0.8-1.2% of Si, 0.3-1.5% of Mn, 3.0-3.5% of B, 0.8-2.6% of Cu, 2.8-3.6% of Al, 0.5-1.0% of V, 0.8-1.6% of Ti, 0.02-0.15% of Ca, 0.03-0.25% of Ce, 0.02-0.18% of N, 0.05-0.3% of Nb, 0.12-0.25% of Mg, 0.04-0.13% of K, 0.05-0.12% of Ca, 0.06-0.15% of Ba, less than or equal to 0.03% of S, less than or equal to 0.04% of P and the balance of Fe and inevitable impurity elements. The preparation method comprises the following steps: smelting waste steel and ferrochrome, subsequently adding copper plates, silicon iron and ferromanganese iron, adjusting the component at a stokehole, after being qualified, raising the temperature to be 1,560-1,620 DEG C, adding calcium-silicon and aluminum for deoxidation, adding ferrotitanium, ferro-boron and aluminum, smelting and discharging outside a furnace, adding a rare earth magnesium alloy and a composite inoculant consisting of metal cerium, Si3N4, VN (Vanadium Nitride), Nb and K, so as to perform inoculation treatment, wherein the molten steel casting temperature is 1,400-1,450 DEG C, keeping the temperature of a cast piece at 920-1,150 DEG C for 2-4 hours, and subsequently performing air cooling.

Owner:江苏盛伟模具材料有限公司

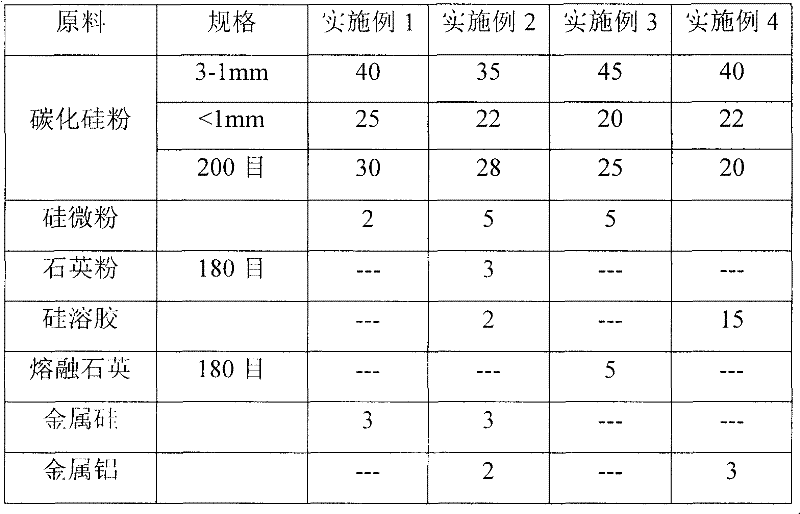

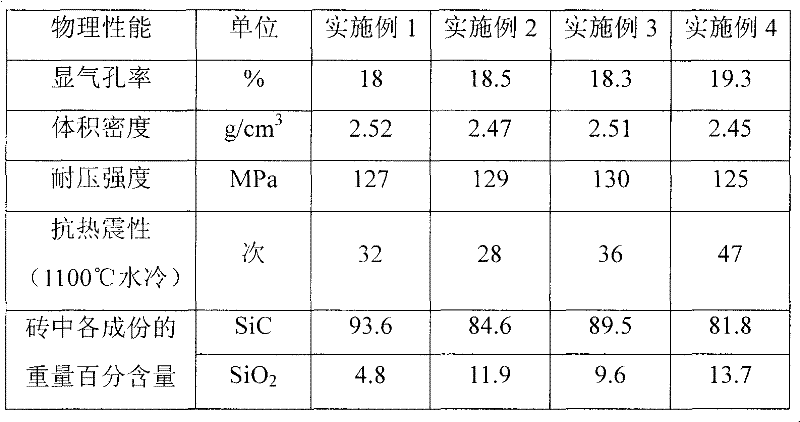

Silicon carbide brick for garbage incinerator and preparation method thereof

InactiveCN102391007AGood high temperature wear resistanceImproved thermal shock stabilityBrickCombustion chamber

The invention relates to a silicon carbide brick for a combustion chamber of a garbage incinerator and a preparation method thereof. The silicon carbide brick is combined by silicon oxide, and the content of SiC in the brick is more than or equal to 80 weight percent; the brick is formed by mixing, forming and calcining a major ingredient, a bonding agent and an antioxidant; the major ingredient is 80 to 98 weight percent of silicon carbide powder; the bonding agent is 2 to 20 weight percent of shaped or unshaped SiO2 micro powder or fine powder or solution; and the antioxidant is 0 to 5 weight percent of metal silicon powder or metal aluminum powder or mixture thereof. The preparation method comprises the following steps of: mixing raw materials in a ratio, forming under high pressure, and calcining in a kiln furnace at the high temperature of between 1,300 and 1,500 DEG C. The silicon carbide brick combined by the silicon oxide has high acid-base erosion resistant capacity, high high-temperature abrasion performance, high heat shock stability and high antioxidation performance, and meets the using requirements of environment friendliness and long service life.

Owner:TONGDA REFRACTORY TECH CO LTD +1

Deposit welding rod containing rare earth and production method

InactiveCN101190481AReduce segregationReduce subcoolingWelding/cutting media/materialsSoldering mediaRare earthRoom temperature

The invention provides a surfacing electrode containing rare earths with a welding core but without a coating. The composition of the welding core is 3.2% to 6.5% of C, 0.4% to 2.5% of Si, 0.4% to 2.0% of Mn, 0.01% to 1.0% of Re, 10% to 35% of Cr, 0.0% to 2.0% of Mo, 0.0% to 2.8% of Ni, 0.0% to 2.5% of W, 0.0% to 1.5% of V, 0.0% to 1.0% of Ti, 0.0% to 1.5% of Nb, 0.0% to 0.5% of Cu, 0.0% to 0.6% of Al, not more than 0.08% of S, not more than 0.08% of P, not more than 0.08% of , not more than 0.08% of <N>, and 59.64% to 85.99% of Fe. The welding rod is suitable for the build-up welding of burning single-roll crusher hammer; the hardness HRC of the build-up welding layer at room temperature is not less than 50 and crack is allowable for build-up welding layer.

Owner:PANZHIHUA UNIV

Guide and guard roller for guiding steel billet in high speed wire rolling machine and its making process

InactiveCN1847439AHigh hardnessGood high temperature wear resistanceFurnace typesHeat treatment process controlWaxSmelting

The present invention discloses one kind of guide and guard roller for guiding steel billet in high speed wire rolling machine and its making process. Chemically, the guide and guard roller has material comprising C 0.7-1.4 wt%, Wt% 7.0-10.0 wt%, V 0.8-1.5 wt%, Cr,5.0-10.0 wt%, B 1.2-2.5 wt%, Mo<1.5 wt%, Si<1.5 wt%, Mn<1.5 wt%, RE 0.08-0.18 wt%, Mg 0.05-0.15 wt%, Ti 0.08-0.20 wt%, S<0.05 wt%, and P<0.05 wt%, except Fe and inevitable impurity. The guide and guard roller is made through electric furnace smelting and precise wax mold casting or evanescent mold casting. It has high strength, high toughness, high wear resistance, high fatigue and oxidation resistance, high quick cooling and heating resistance, and use performance obviously higher than that of high Ni-Cr cast steel guide and guard roller.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

No-co ferrous alloy powder composition for sealing face of nuclear power valve

InactiveCN101797643AMeet the needs of the jobExtended service lifeMetallic material coating processesNuclear powerSulfur

The invention belongs to the field of alloy material, relating to no-co ferrous alloy, in particular to no-co ferrous alloy for enhancing material of the sealing face of a nuclear power valve. The no-co ferrous alloy powder composition contains the following ingredients by weight percent: 20.5%-21.5% of Cr, 3.0%-3.5% of Ni, 3.0%-3.5% of Mn, 2.0%-2.5% of Si, 0.9%-1.0% of C, 1.5%-2.0% of Mo, 0.7%-1.2% of W, 0.3%-0.5% of V, P is less than or equal to 0.02%, S is less than or equal to 0.02%, 0.5%-1.0% of Y and the balance of Fe. The no-co ferrous alloy powder composition contains no noble metal of Co, at the same time, since laser cladding technology is adopted to prepare the coating, the microhardness of the cladding layer is 1.6-1.8 times of that the stainless steel matrix. The no-co ferrous alloy powder composition has excellent high-temperature abrasion performance and high-temperature corrosion resistance, so the no-co ferrous alloy powder composition can prolong the service life of the valve.

Owner:SUZHOU UNIV

Method of manufacturing the anti-wear sintered member, sintered valve seat, and method of manufacturing the same

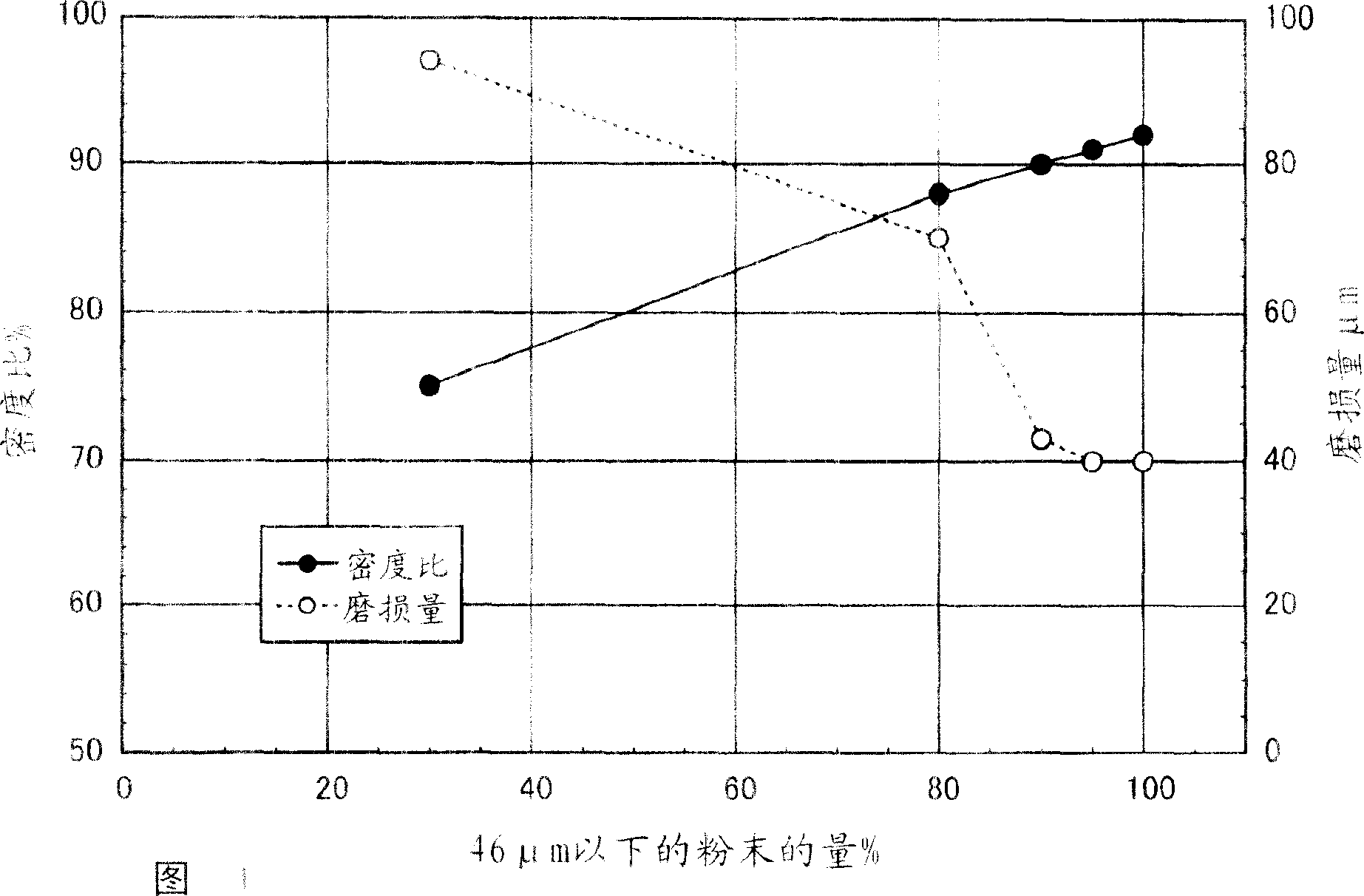

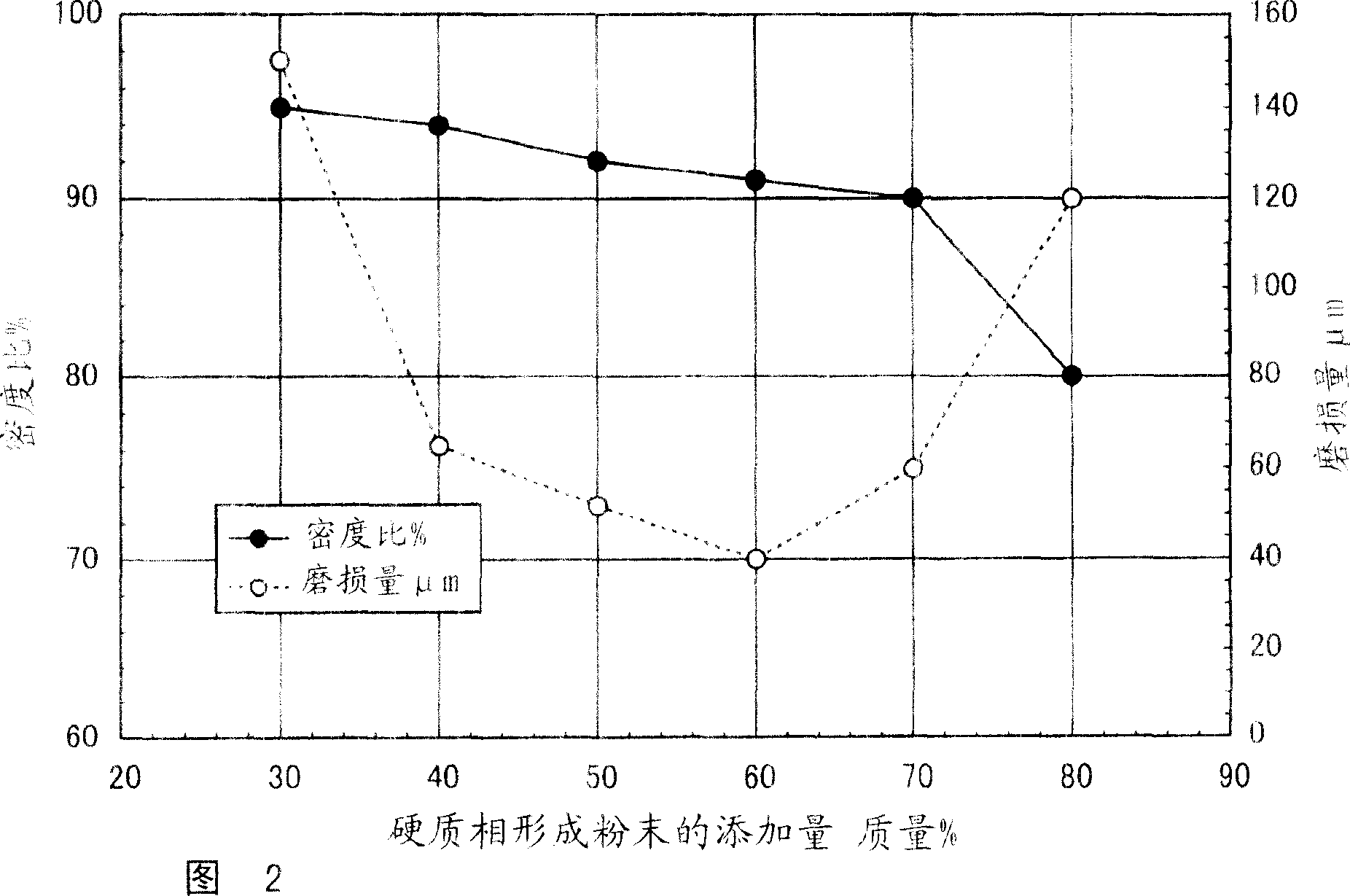

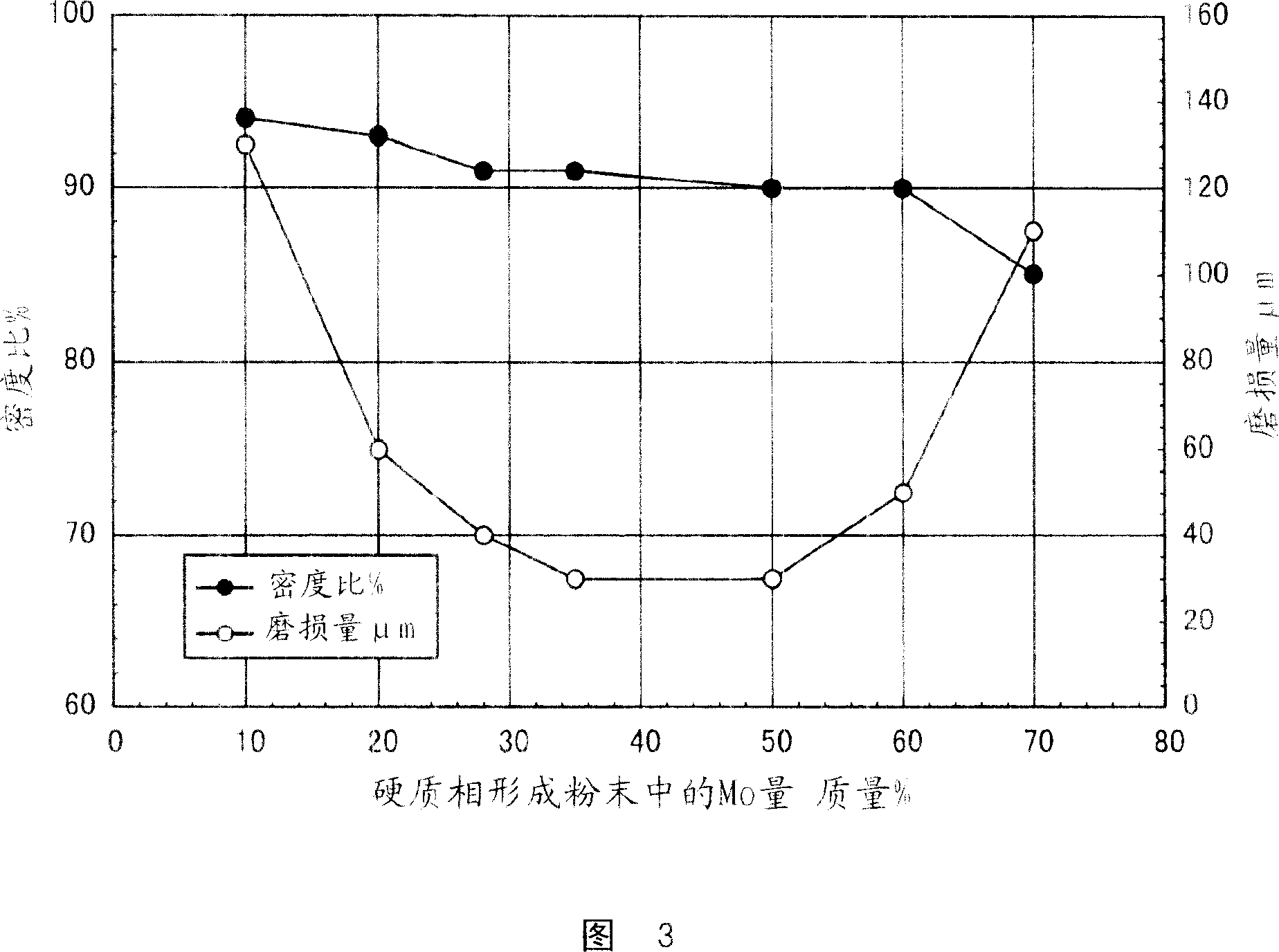

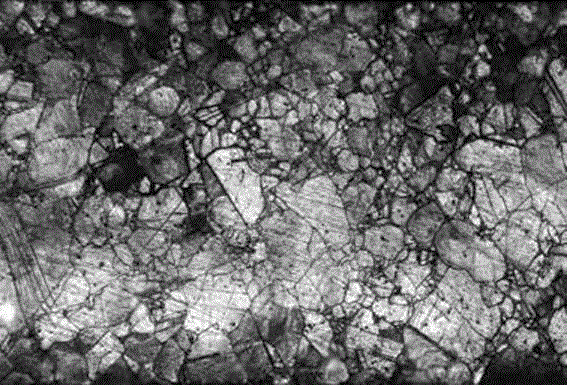

Making a wear resistant member by compacting a powder mixture containing a matrix forming powder and a hard phase forming powder, the matrix forming powder containing 90 mass % or more of particles having a maximum diameter of 46 microns, and the hard phase forming powder being 40 to 70 mass % with respect to the powder mixture.

Owner:株式会社力森诺科

Roller repairing layer and method for repairing roller by utilizing roller repairing layer

InactiveCN104651773AExtended service lifeLow costMolten spray coatingCeramic compositeMetallic materials

The invention discloses a roller repairing layer. The roller repairing layer is prepared by the following steps: thermally spraying a metal layer, a metal-ceramic composite layer and a ceramic layer on the surface of a roller matrix sequentially, wherein the metal layer is formed by thermally spraying a metal material on the surface of the matrix, and the metal material is any one of NiCr, NiCrBSi, NiAl, NiCrAl, 316L, NiCrBSiFe and NiCrBSiMoFe; the metal-ceramic composite layer is formed by thermally spraying a mixture of a metal material and a ceramic material on the surface of the metal layer, and the mixture is formed by mixing the used metal material and the ceramic material; the ceramic layer is formed by thermally spraying the ceramic material on the surface of the metal-ceramic composite layer, and the ceramic material is any one of Cr3C2, WC, Cr2O3, Al2O3, ZeO2 and TiO2. The invention also discloses a method for repairing a roller by utilizing the roller repairing layer.

Owner:郴州市泰益表面涂层技术有限公司

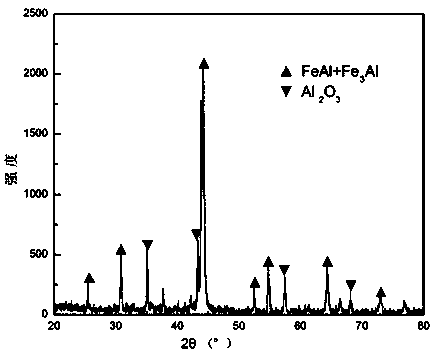

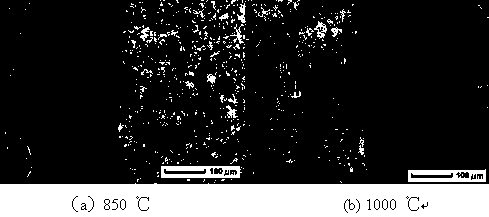

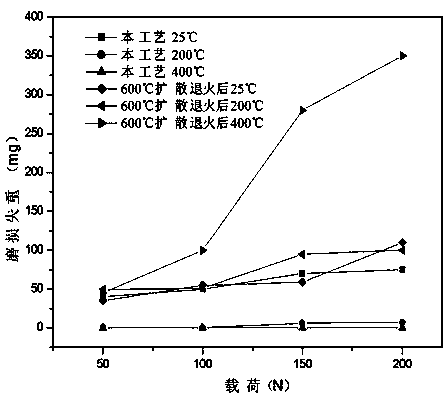

Preparation method of high-temperature wear-resistant coating on surface of steel piece

ActiveCN103628013AImprove corrosion resistanceImprove high temperature resistanceHot-dipping/immersion processesWear resistantWear resistance

The invention relates to the technical field of steel piece surface treatment, and in particular relates to a preparation method of a high-temperature wear-resistant coating on the surface of a steel piece. According to the preparation method, a composite coating of a Fe-Al intermetallic compound and a little Al2O3 is obtained through liquid dip aluminum plating and subsequent compound dispersion treatment. The process flow of the preparation method comprises pretreatment (alkali cleaning, acid pickling and assisted plating), dip aluminum plating and dispersion treatment, wherein the dip aluminum plating is carried out for 1-10 minutes in liquid aluminum at a temperature ranging from 720 DEG C to 800 DEG C; and compound dispersion annealing which is carried out in a protective atmosphere or in vacuum at a temperature ranging from 850 DEG C to 1100 DEG C for 1-5 hours, and in air at a temperature ranging from 400 DEG C to 600 DEG C for 20-30 minutes. The temperature and the time of the dispersion treatment are adjusted so that composite wear-resistant coatings containing the intermetallic compound and a little Al2O3 and are different in thickness can be obtained. The preparation method has the characteristics of simple and convenient process, low cost, high coating binding force, excellent high-temperature wear resistance and the like, and thus can be widely applied to surface strengthening of high-temperature wear resisting steel pieces.

Owner:东台市溱东科技发展有限公司 +1

Preparation method of self-propagating synthesis TiB2 particle-reinforced copper-based surface composite material and composite copper casting

InactiveCN103302266AGood high temperature stabilityGood high temperature wear resistanceWear resistantCopper metal

The invention relates to the technical field of metal-based composite material preparation and provides a preparation method of a self-propagating synthesis TiB2 particle-reinforced copper-based surface composite material and a composite copper casting. The preparation method comprises the following steps: mixing metal powder such as B2O3 powder, Ti powder, Al powder and Cu powder by a vacuum lost foam casting process and an SHS (Self-propagating High-temperature Synthesis) technology, adding a bonding agent for preparing into SHS powder paste, applying the SHS powder paste onto the work surface of the casting, producing a self-propagating synthesis reaction due to a high temperature of a copper metal solution in a pouring process to generate a TiB2 particle hard phase, and finally obtaining the surface self-propagating synthesis TiB2 particle-reinforced copper-based surface composite casting. The composite copper casting has the advantages that the compactness of a particle-reinforced alloy layer of the composite copper casting is high, and the composite copper casting is metallurgically bonded with a basic body and is high in strength, good in heat conductivity and high-temperature frictional wear resistance and suitable for various wear-resistant copper alloy parts working in high-temperature wear-resistant work conditions.

Owner:JIANGSU LANRI ULTRA HARD MATERIAL

Wear resistant alloy for valve seat insert used in internal combustion engines

ActiveUS20060283526A1Acceptable casting scrap rateGood heat treatment characteristicMachines/enginesLift valveNiobiumWear resistant

This invention related to a high carbon and high molybdenum / tungsten martenisitic type iron base alloy with excellent hot hardness and wear resistance for making valve seat insert. The alloy comprises of 2.05-3.60 wt % carbon, 0.1-3.0 wt % silicon, 0-2.0 wt % manganese, 3.0-10.0 wt % chromium, 11.0-25.0 wt % molybdenum and tungsten, 0.1-6.5 wt % nickel, 0-8.0 wt % vanadium, 0-6.0 wt % niobium, 0-8.0 wt % cobalt, and the balance being iron with impurities.

Owner:WINSERT

High-temperature oxidation and wear resistant molybdenum alloy and preparation method thereof

The invention discloses a high-temperature oxidation and wear resistant molybdenum alloy and a preparation method thereof. The molybdenum alloy comprises the following components by weight percent: 5-15% of Cr, 1.0-5.0% of Ti, 1.0-5.0%of Nb, 0.25-1.90% of C and the balance of molybdenum and inevitable impurities. Concerning the molybdenum alloy, the recrystallization temperature reaches 1200-1300 DEG C, the high-temperature creep resistance is 1.2-1.5 times that of the TZM molybdenum alloy, the high-temperature strength and hardness are 1.5-2.0 times those of the TZM molybdenum alloy and the wear resistance at 500-800 DEG C in the air is 1.5-2.0 times that of the TZM molybdenum alloy. The problem of poor wear resistance and oxidability of the traditional molybdenum alloy is simultaneously solved by adopting the molybdenum alloy formula, the preparation process is simple and is easily controlled, and the molybdenum alloy is prepared through conventional powder metallurgy; and therefore the molybdenum alloy has extensive application prospect.

Owner:HENAN UNIV OF SCI & TECH

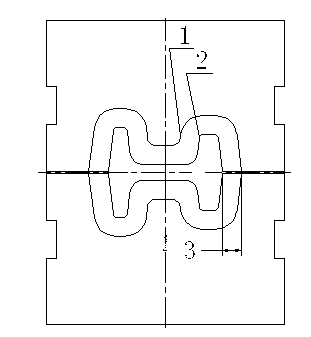

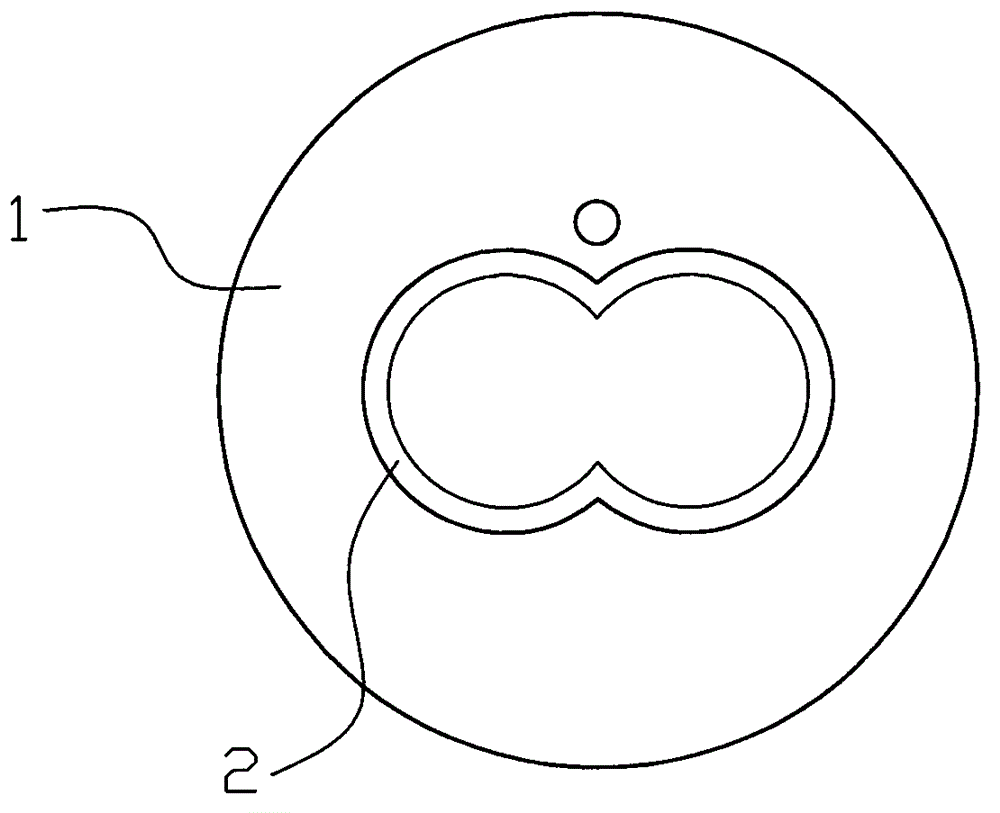

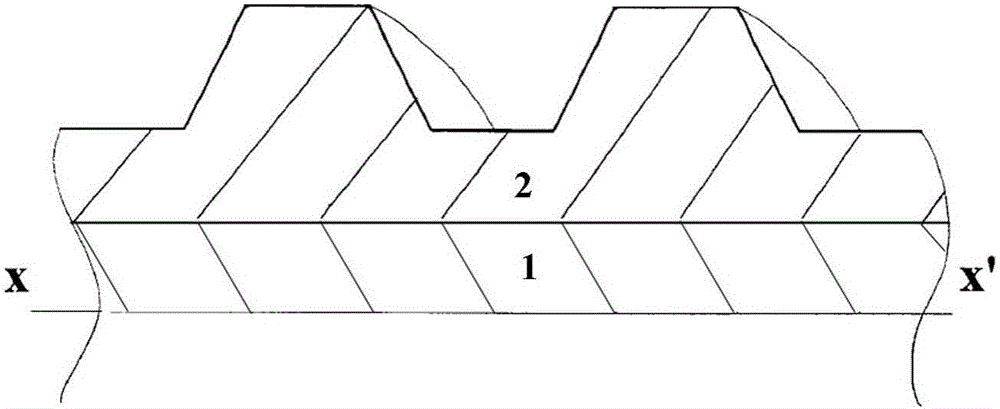

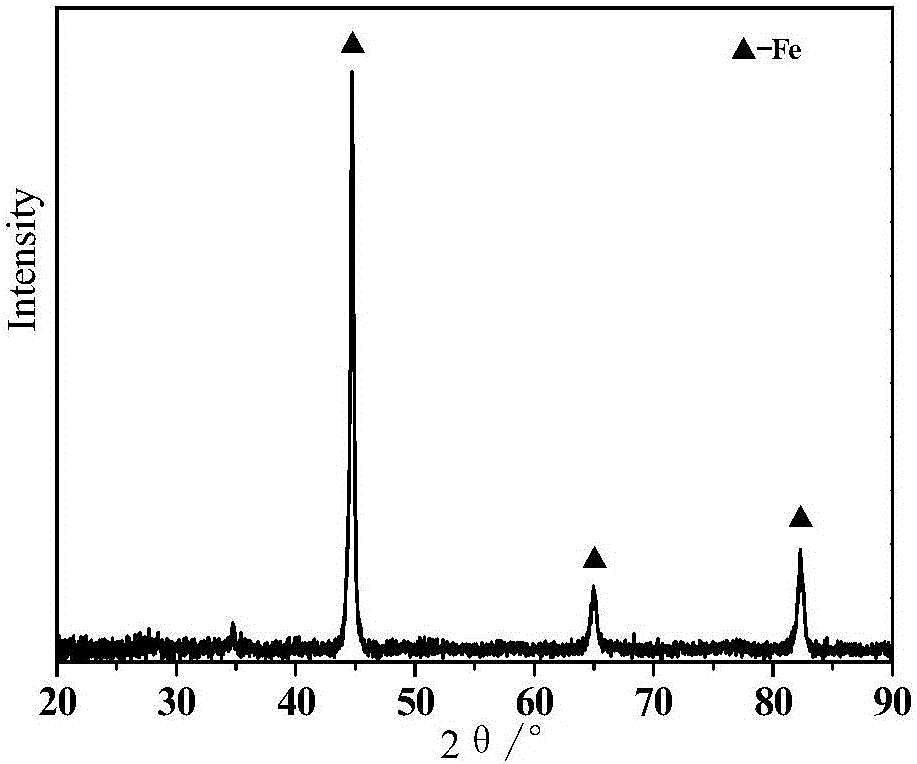

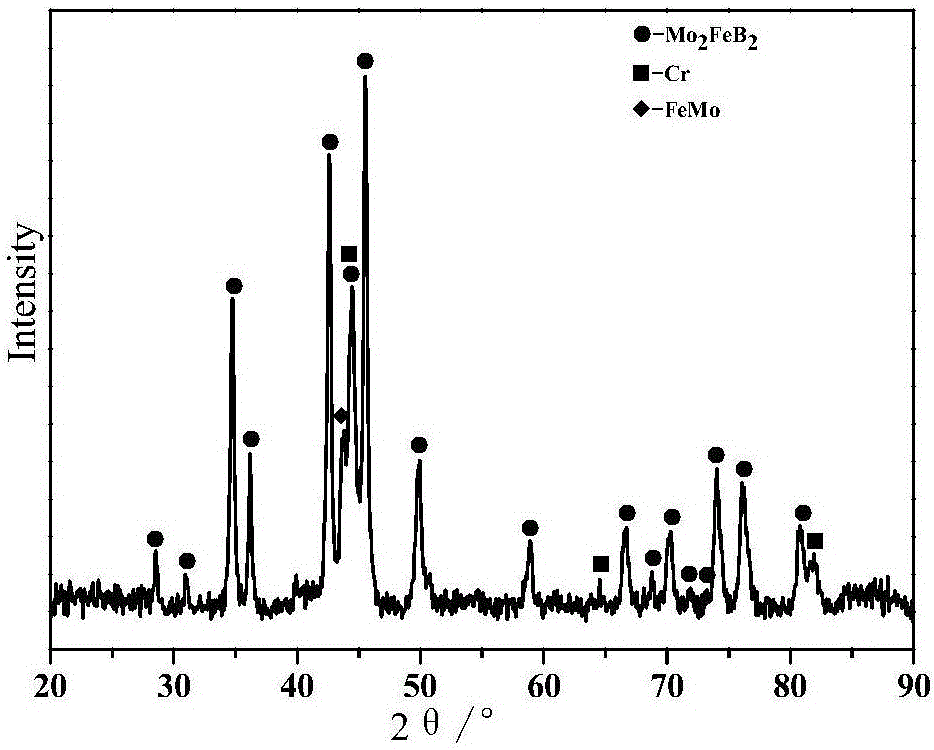

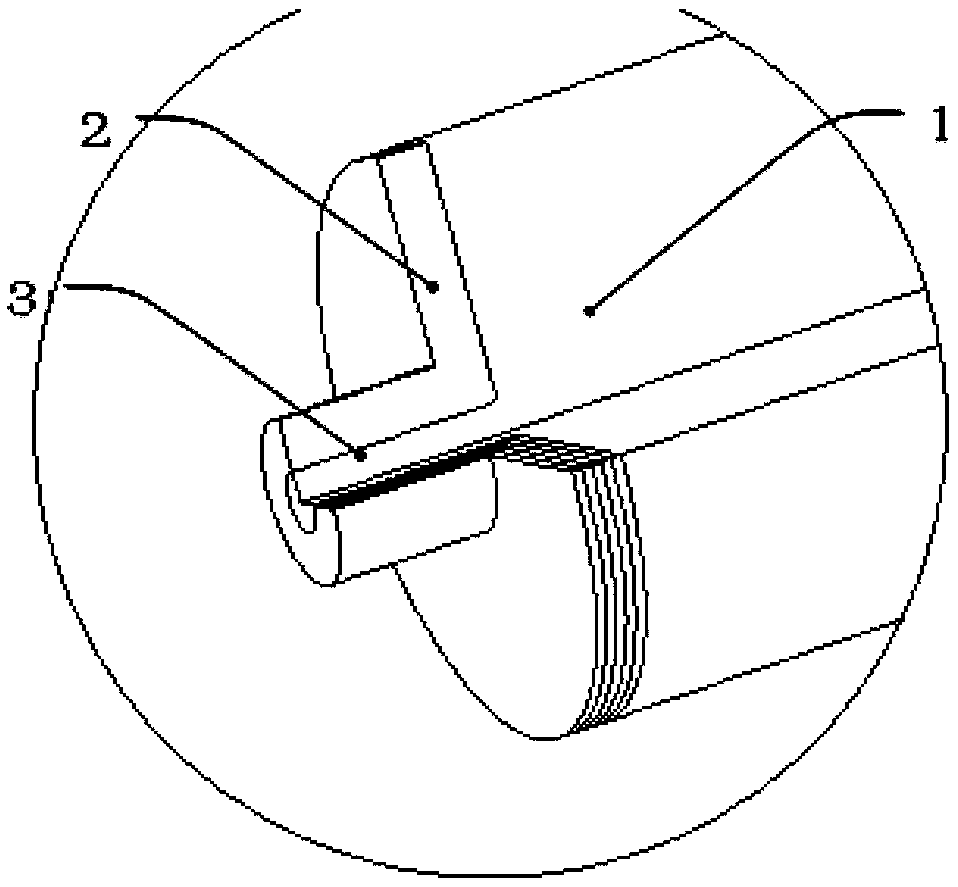

Metal cylinder and manufacturing method thereof

The invention discloses a metal cylinder and a manufacturing method thereof. According to the metal cylinder, an alloy steel rod containing chrome molybdenum is used as a cylinder material (1); the periphery of the cylinder material (1) is wrapped by a polybasic boride base metal ceramic layer (2) through a sintering method; and the polybasic boride base metal ceramic layer (2) is a Mo2FeB2-Fe base metal ceramic layer, a Mo2NiB2-Ni base metal ceramic layer or a WCoB-Co base metal ceramic layer. The manufacturing method of the metal cylinder comprises the following steps of: placing the cylinder material in a sheath; filling proportioned raw material powder in a gap of the cylinder material and the sheath; integrally placing the sheath in a sealed container and vacuuming; sintering in the sealed container; and finishing the polybasic boride base metal ceramic layer to prepare the metal cylinder. The polybasic boride base super-hard bimetal cylinder or metal cylinder has the advantages of low comprehensive cost, simple manufacturing process, long service life, suitability for industrialization and the like, and can be used for replacing currently and widely used cylinders subjected to treatment such as nitriding, spray welding and casting.

Owner:浙江华业塑料机械股份有限公司

Iron-storage type casting material for iron tapping channel, and preparation method thereof

The invention discloses an iron-storage type casting material for an iron tapping channel. The casting material is composed of brown corundum, dense corundum, silicon carbide, ball asphalt, alpha-Al2O3, pure calcium aluminate cement, silica micropowder, silicon metal powder, Guangxi white mud, aluminium metal powder, an explosion-proof fiber and FDN. The invention also provides a preparation method of the iron-storage type casting material for the iron tapping channel. The method comprises the steps of mixing the above-mentioned raw materials according to a proportion; stirring the mixture for 10 minutes in a stirring machine; discharging the mixture and packaging. Compared with a conventional technology, the method has the beneficial effects that the casting material is manufactured by employing Al2O3-SiC-C material and a carbon-containing polymer, and has good high-temperature wear resistance, good slag-resistant chemical corrosion performance, high and good oxidation resistance, good thermal shock-resistant stability, good high-temperature volume stability, good explosion resistance, high iron content, high safety coefficient and high slag resistance, sticks no slag iron, is convenient for production, and reduces labor intensity.

Owner:王振江

Fire-resisting lining body crack repairing material

The invention discloses a fire-resisting lining body crack repairing material, which is prepared from the following raw materials in parts by mass: 60 to 62 parts of brown aluminum oxide particles, 5 to 6 parts of active alpha-Al2O3, 25 to 30 parts of Al-80 special alumina homogenizing material fine powder, 3 to 5 parts of high-quality silicon dioxide micro powder, 5 to 6 parts of plasticizers and 1.5 to 2.5 parts of storing agents. 14.5 to 15.5 parts of bonding agents are added into the raw materials; first mechanical stirring mixing is performed; after the uniform mixing, the material ageing is performed for more than 24 hours; then, the secondary mechanical stirring is performed; finally, the crack repairing material is prepared after the extrusion treatment by an extrusion machine; the crack repairing material is in a paste shape with good plasticity; finally, a 5.0-10kg plastic bag is used for sealing and packaging. The fire-resisting lining body crack repairing material has the advantages that the intensity is high; the high-temperature etching resistance is high; the high-temperature wear-resistance is high; the construction is convenient; the adhesion performance is high; the fire-resisting lining body crack repairing material can be firmly combined with the original lining body; the safe period operation of a thermal kiln furnace is met; the fire-resisting lining body crack repairing material is particularly suitable for the CFB boiler lining body crack fast rush repair.

Owner:郑州耐都热陶瓷有限公司

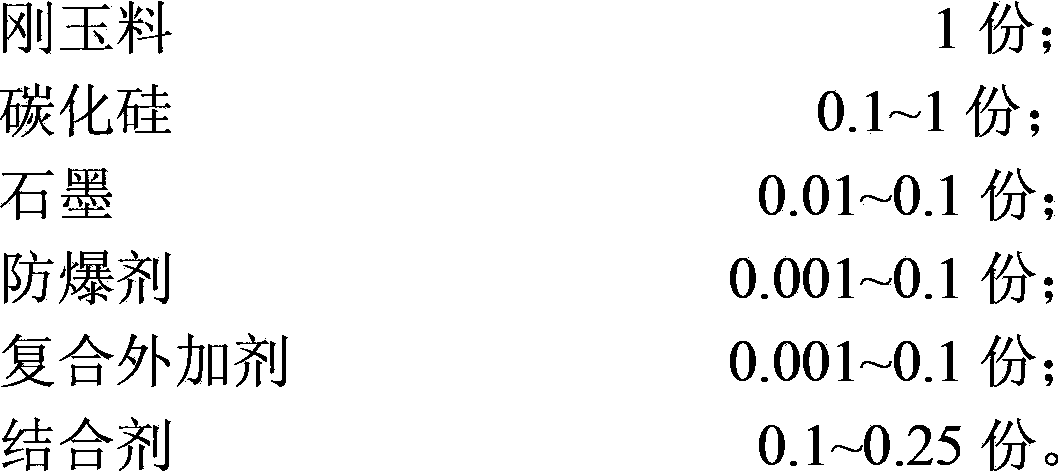

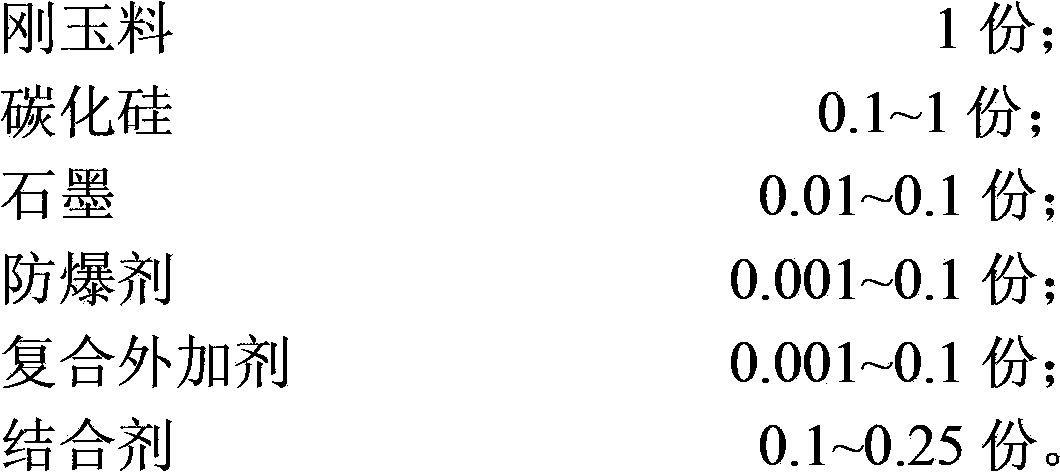

Wear resistance casting material for ladle

The present invention relates to a wear resistance casting material for ladle. The wear resistance casting material comprises, by weight, 1 part of a corundum material, 0.1-1 part of silicon carbide, 0.01-0.1 part of graphite, 0.001-0.1 part of an explosion-proof agent, 0.001-0.1 part of a composite additive, and 0.1-0.25 part of a binding agent. According to the present invention, the cement component-free inorganic nanometer binding agent is adopted, good quality electrofusion or sintering corundum or special grade alumina clinker is adopted as the main material, silicon carbide, graphite, an explosion-proof agent and the like are added, and variety and the number of a composite additive are optimized to prepare the wear resistance casting material with characteristics of rapid baking, high high-temperature strength, good high-temperature wear resistance, excellent thermal shock stability and good construction performance; and ladle bottom of the bottom washing type ladle with a capacity of one ton is used in gray iron casting, wherein the service life can be more than 3000 times and is more than two times the service life of the conventional material, and slag removing is easy.

Owner:天津振普筑炉衬里工程有限公司

High strength wear-resisting cast medium carbon steel and preparation method thereof

The invention discloses high strength wear-resisting cast medium carbon steel and a preparation method thereof. The high strength wear-resisting cast medium carbon steel comprises the following chemical components in percentage by mass: 0.32-0.45% of carbon, 0.45-0.60% of silicon, 0.80-1.15% of manganese, 0.80-1.20% of chrome, 0.06-0.12% of boron, 0.06-0.12% of titanium, 0.10-0.20% of N, less than or equal to 0.01% of P, less than or equal to 0.01% of S and the balance of iron. The preparation method comprises the steps of: (1) smelting; (2) when the temperature of molten steel reaches 1600-1650 DEG C, sequentially adding 1.6-1.8% of metallic aluminum, 1.2-1.4% of ferrosilicon, 4.5-5.5% of ferroboron and 0.2- 0.4% of ferrotitanium according to the mass percentage of molten steel, heating the molten steel to 1700-1750 DEG C, discharging from a furnace after preserving heat for 3-4 hours, and pouring into a casting ladle; (3) carrying out micro-alloying treatment on the molten steel; (4) drossing, and pouring into a casting mold; and (5) carrying out thermal treatment. According to the preparation method disclosed by the invention, precious alloying elements such as nickel, molybdenum and vanadium are not added by reasonably setting the components in the steel, and the prepared cast medium carbon steel has the characteristics of high hardness and good high-temperature abrasion performance and is relatively low in production cost.

Owner:伟成金属制品有限公司

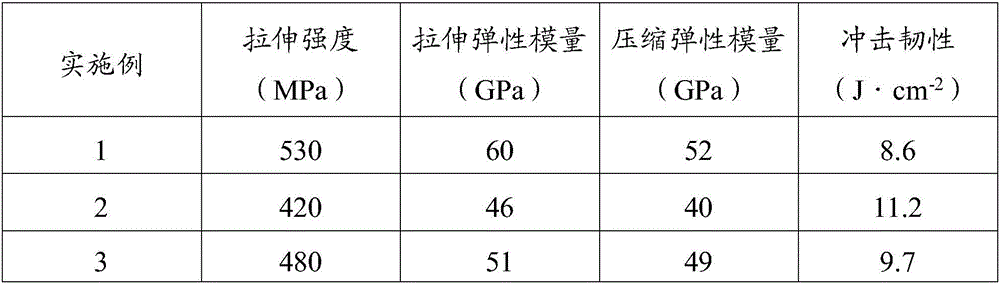

Hybrid fiber reinforced polypropylene composite material

InactiveCN106397973AIncrease surface tensionImprove interface compatibilityGlass fiberPolypropylene composites

The invention discloses a hybrid fiber reinforced polypropylene composite material. The hybrid fiber reinforced polypropylene composite material comprises, by mass, 10 to 30% of glass fiber, 10 to 50% of carbon fiber, 2 to 5% of aramid fiber, 5 to 15% of bamboo fiber, 5 to 25% of basic magnesium sulfate whisker, 10 to 30% of polypropylene, 2 to 5% of a functional polypropylene copolymer, 3 to 6% of epoxy resin, 2 to 8% of a binder, and 5 to 30% of a filler. According to a preparation method, the self-made functional polypropylene copolymer is added as a high molecular surfactant, so that the surface tension of the hybrid fiber reinforced polypropylene composite material is increased obviously, and interfacial compatibility of polypropylene resin with glass fiber is improved; the hybrid fiber reinforced polypropylene composite material possesses relatively high elasticity modulus, tensile strength, and toughness; and material application range is widened.

Owner:JIANGSU SHENXIANG ELECTROMECHANICAL

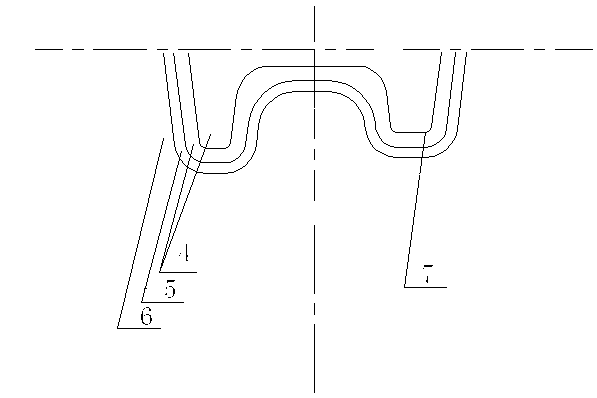

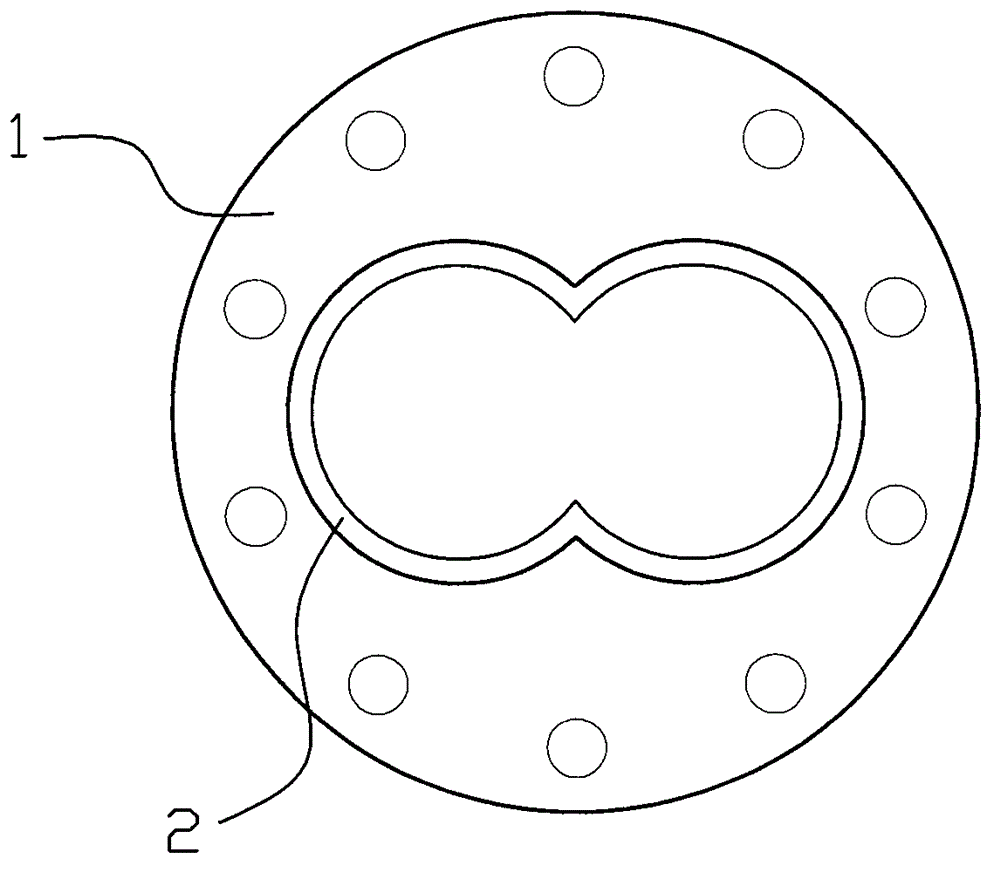

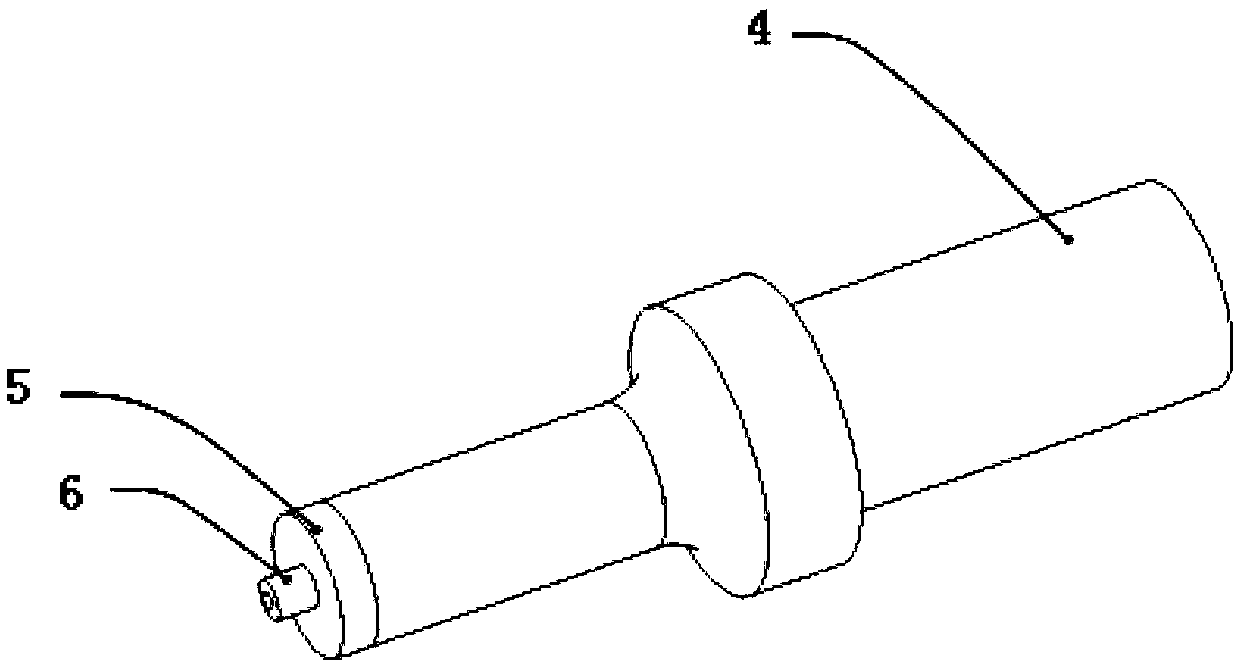

Multiple-boride-based superhard bimetal screw and preparation method thereof

The invention discloses a multiple-boride-based superhard bimetal screw and a preparation method thereof. According to the bimetal screw, an alloy structure steel bar containing chromium and molybdenum serves as a mandrel, the surface of the mandrel is wrapped by a multiple-boride-based metal ceramic layer, and then the finished screw is prepared through finish machining. Multiple-boride-based metal ceramic is high in fracture toughness and good in machinability, the thermal expansion coefficient of the screw is similar to that of steel, the screw can be well combined with the chromium-molybdenum alloy structure steel, friction abrasion performance, high temperature resistance and corrosion resistance are excellent, use performance of the screw can be greatly improved, and the service life of the screw is prolonged. Compared with a screw which is widely used at present and subjected to nitriding, spray welding and the like, the bimetal screw has good application prospects and economic benefits.

Owner:郴州市泰益表面涂层技术有限公司

Surfacing repairing method for coiled side guide plate

ActiveCN109877418AExcellent high temperature wear performanceGood high temperature wear resistanceArc welding apparatusWelding/cutting media/materialsSlagAlloy

The invention discloses a surfacing repairing method for a coiled side guide plate. By reasonably matching an abrasion-resistant alloy surfacing material and a welding process, the hardness of surfaced metal can reach HRC42-HRC48, thus, the areas, close to the roller bed surface and in contact with the edge of strip steel, of the coiled side guide plate have good high-temperature abrasion resistance, and the defects such as strip steel edge damage and scabbing are reduced. After the 718 material coiled side guide plate is subjected to surfacing repairing, surfaced metal is well combined with base metal, welding defects such as cracks, slag inclusions, pores and incomplete fusion are avoided, preheating does not need to be conducted or low-temperature preheating is conducted before welding,a surfacing transition layer is not needed, heat treatment does not need to be conducted after welding, the manufacturing process is simple, surfacing procedures are few, the repairing efficiency ishigh, the production cost can be reduced through many times of repairing, and the coiled side guide plate is recycled.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

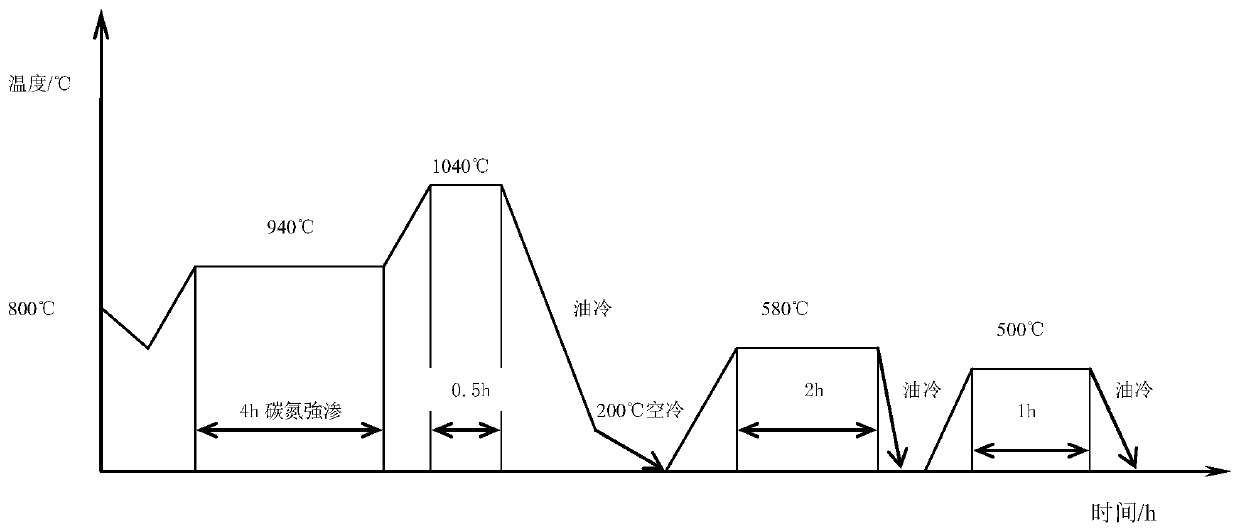

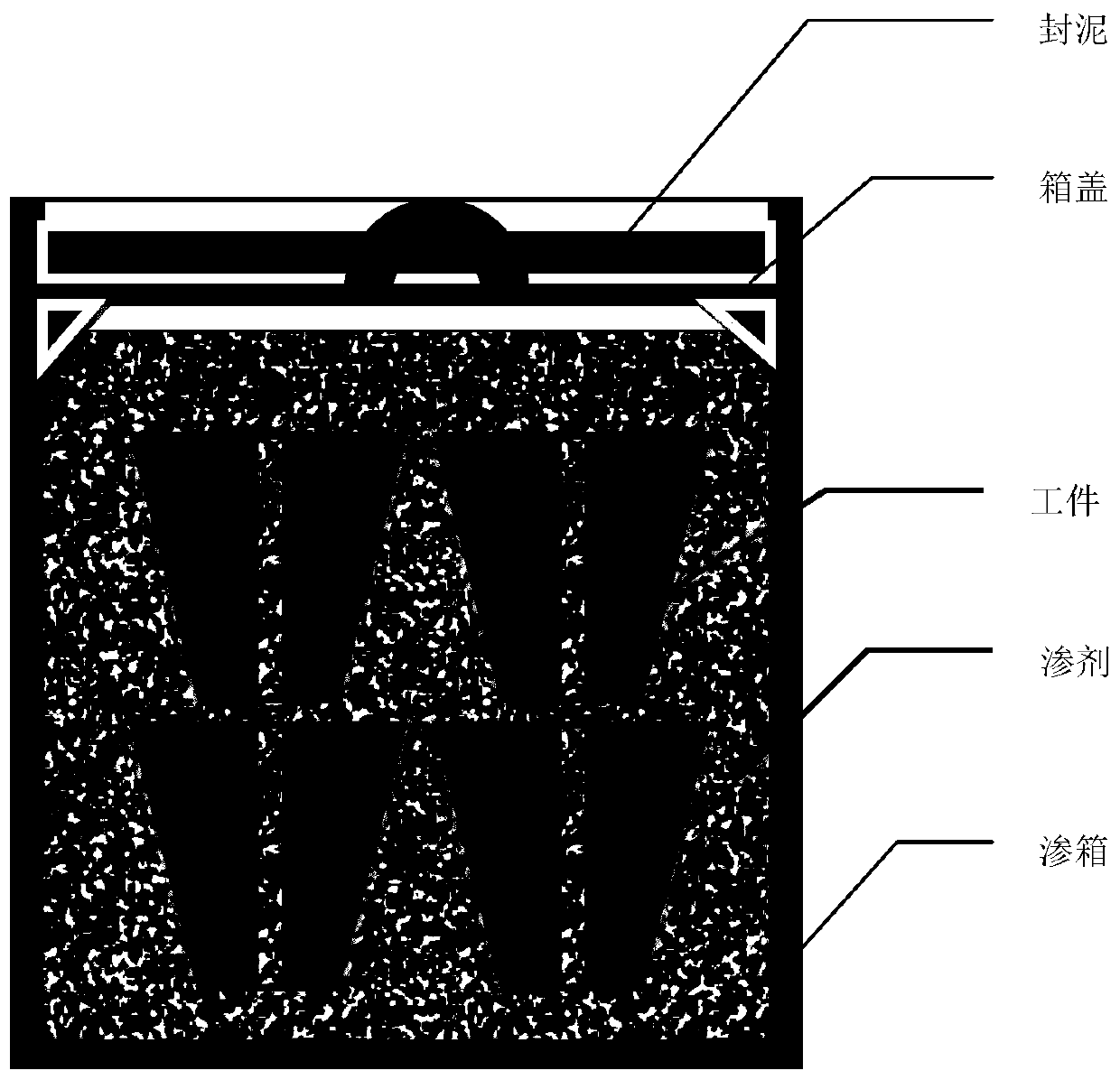

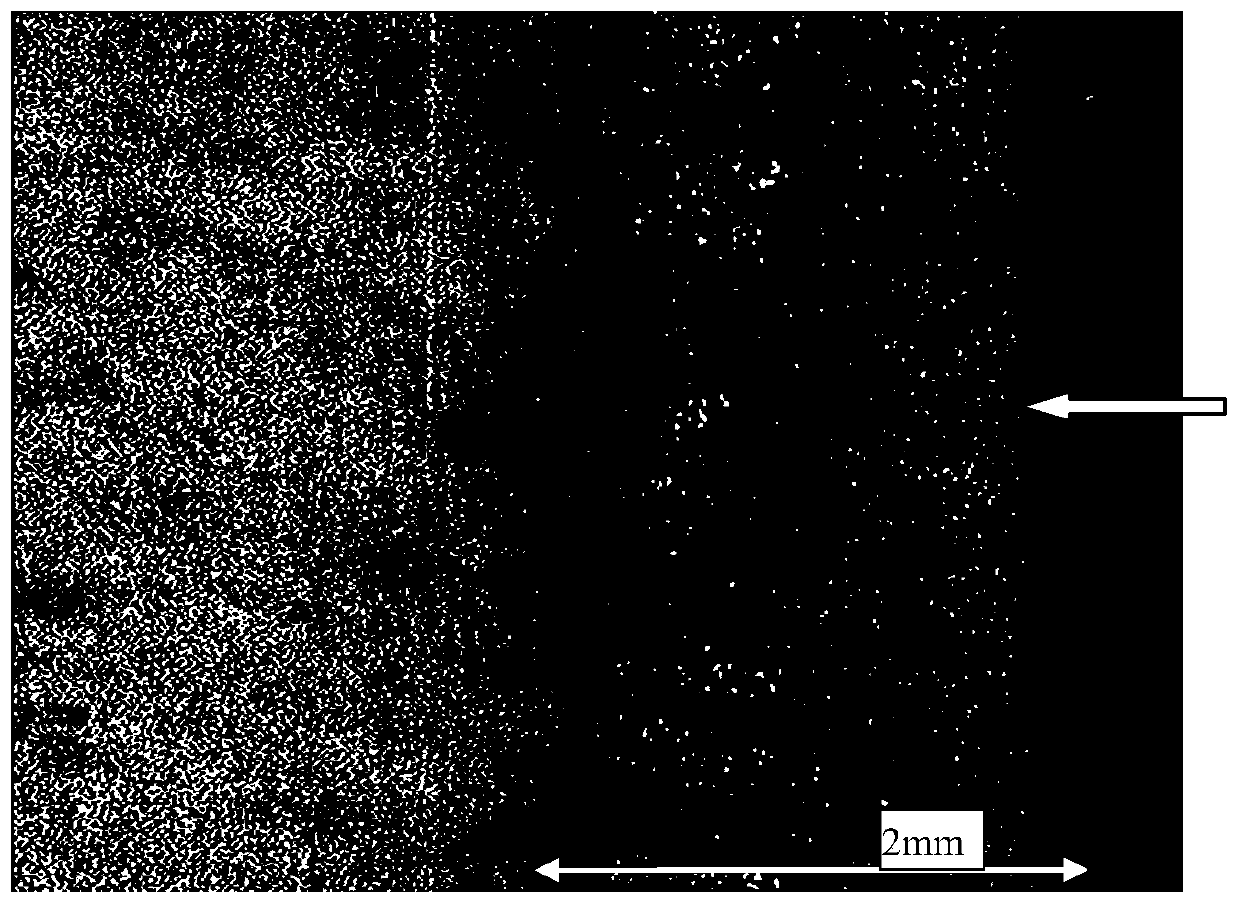

Heat treatment process improving hot hardness and high temperature abrasion resisting performance of hot mold steel

ActiveCN110565048AExtend high temperature service lifeSimple methodSolid state diffusion coatingHigh-temperature corrosionHeat treated

The invention provides a heat treatment process improving the hot hardness and the high temperature abrasion resisting performance of hot mold steel. Charcoal, urea particles, sodium carbonate powderand chromic anhydride are mixed to obtain a carbon-nitrogen strong permeating mixture; a hot mold steel workpiece and the carbon-nitrogen strong permeating mixture are installed in a permeating box atthe same time, and a box cover of the permeating box is sealed; the permeating box is placed into a crucible type electric furnace to be subjected to constant temperature carbon-nitrogen strong permeating at 850-950 DEG C; after quenching treatment, the hot mold steel workpiece is directly immersed into quenching oil to be cooled; and after air cooling, placing into a box type intermediate temperature tempering furnace for tempering twice is performed, and the hot mold steel workpiece high in hot hardness and high in high temperature abrasion resisting performance is obtained. The heat treatment process has the advantages of being easy and convenient to operate, low in cost and obvious in effect, the surface hardness of the obtained hot mold steel can reach 62 HRC or above, the high temperature abrasion resisting performance under the temperature of 600 DEG C exceeds that of a same hot mold steel conventional heat treatment piece twice or above, and the service life of a hot working mold can be effectively prolonged.

Owner:锦州捷通铁路机械股份有限公司

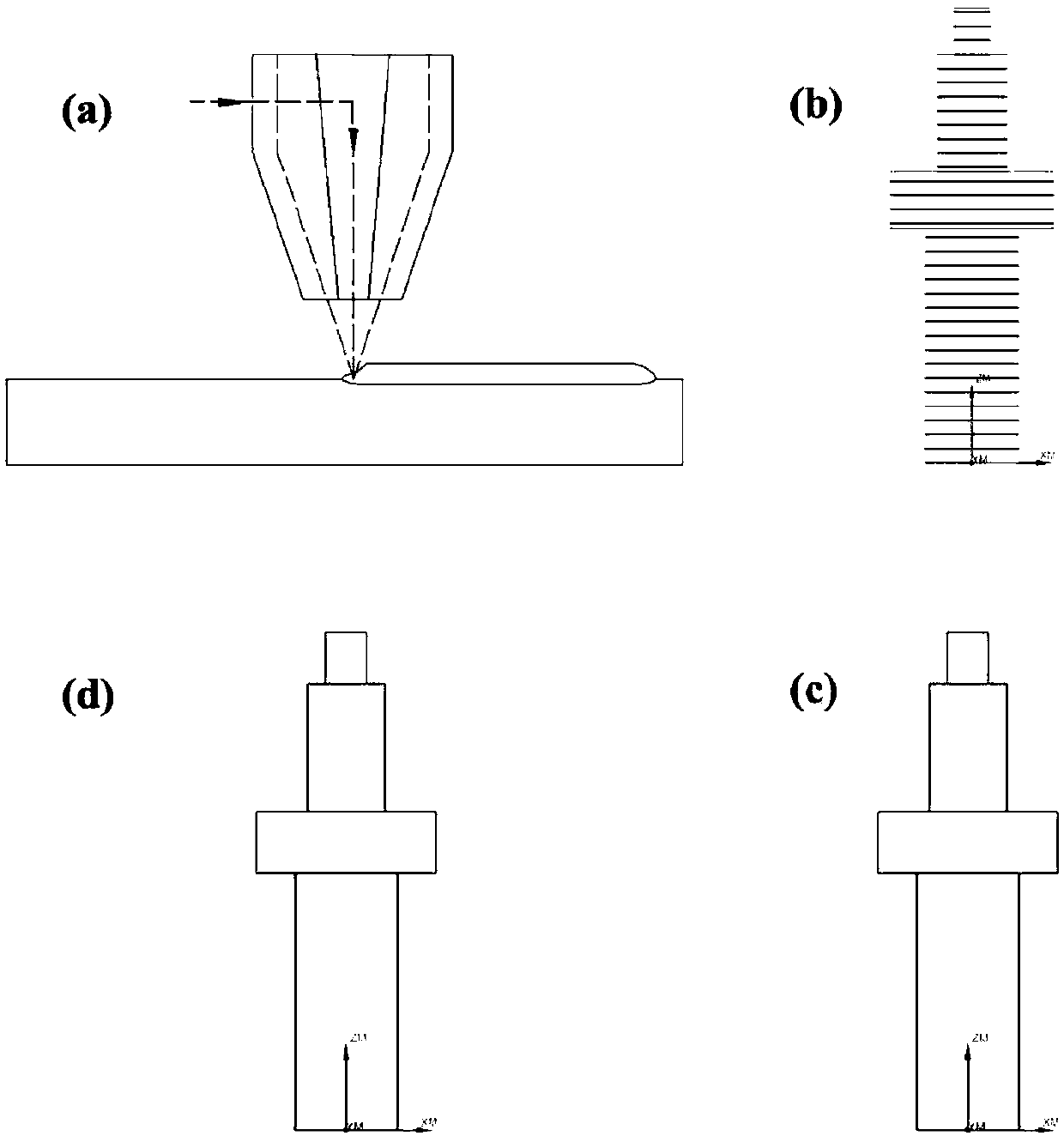

Laser near net forming method of functional graded friction stir welding stirring head

ActiveCN109514075AGood binding performanceEnhanced high temperature wear resistanceLaser beam welding apparatusNon-electric welding apparatusTungstenBoron nitride

The invention provides a preparation method of a functional graded friction stir welding stirring head. According to the preparation method, high-temperature wear resistant materials are adopted in friction positions with workpieces, i.e. the surfaces of a stirring pin and a shaft shoulder; materials with good toughness, high strength and good economy are adopted in non-contact positions of the center of the stirring pin and the end surface of the shaft shoulder, and finally, a laser near net forming mode is adopted so as to realize graded transition of the two materials and near net forming of the stirring head. According to the laser near net forming method of the functional graded friction stir welding stirring head, the stirring pin and the shaft shoulder which make direct contact withmetal when the stirring head is operated can have good high-temperature wear resistant performance, and the whole stirring head has the advantages of good toughness, high strength and good economy. Compared with traditional tool steel and die steel, the laser near net forming method has the advantages that the application range of a stirring tool is enlarged, and the service life is prolonged; compared with a tungsten-based stirring head and a polycrystalline cubic boron nitride stirring head, the laser near net forming method has the advantage that the whole fracture toughness and the manufacturing economy of the stirring head are greatly increased.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

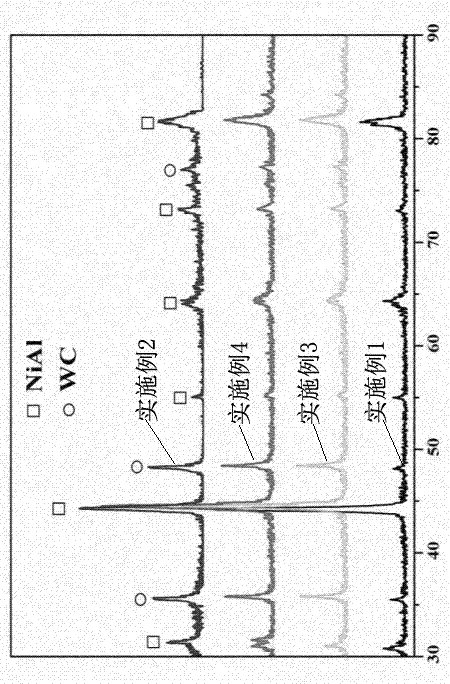

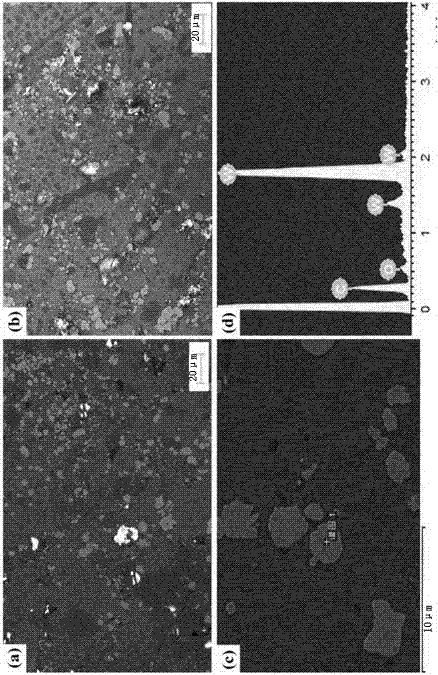

Preparation method of NiAl/WC composite with high-temperature wear resistance

The invention provides a NiAl / WC composite with the high-temperature wear resistance and a preparation method of the composite. The composite is prepared from raw materials including Ni powder, Al powder and WC powder; the mole ratio of the Ni powder to the Al powder is 1:1; the mass of the WC powder accounts for 5wt%-40wt% of the total mass of Ni-Al-WC mixed powder; the Ni powder has the particle size ranging from 100 meshes to 300 meshes and the purity ranging from 95%-99.5%; the Al powder has the particle size ranging from 100 meshes to 300 meshes and the purity ranging from 95%-99.5%; and the WC powder has the particle size ranging from 100 meshes to 300 meshes and the purity ranging from 95%-99.5%. With the preparation method, high-temperature sintering is not required, so that the obtained composite is uniform in structure, free of pores and high in stability.

Owner:SHANDONG UNIV OF SCI & TECH

Method for preparing high-temperature wear resistant lining plate by plasma arc cladding

InactiveCN102912339AImprove performance and lifeExcellent high hardnessMetallic material coating processesEmulsionCeramic particle

The invention discloses a method for preparing a high-temperature wear resistant lining plate by plasma arc cladding. The method comprises the steps as follows: removing rust, greasy dirt and oxide skin on the surface of a metal base; preparing metal-based ceramic particle reinforced alloy powder according to the metal base and the work requirement; mixing mixed alloy powder with white emulsion; uniformly coating the mixed alloy powder onto the surface of the metal base; controlling the thickness of a precoating layer to be 0.8-2 mm; naturally drying; fixing the metal base with the precoating layer to a machine tool of plasma arc cladding equipment; conducting single-pass scan on the precoating layer on the surface of the metal base by plasma arc; and uniformly cladding the surface of the metal base along with the movement of the plasma arc so as to obtain a cladding layer with the cladding thickness of 0.3-1.5 mm. The high temperature resistant compound lining plate prepared by the method is low in cost and stable in quality, is suitable for large-scale production, can meet the requirements of field high-temperature wear condition and can be effectively prolonged in service life.

Owner:QINHUANGDAO GERUIDE ENERGY SAVING TECH SERVICE

Method for preparing nozzle bricks for metallurgical casting

The invention discloses a method for preparing nozzle bricks for metallurgical casting, and belongs to the field of technologies for preparing nozzle bricks. The method includes carrying out mixed-milling and sieving on zircon, bauxite and anthracite and then carrying out heat-insulation calcination treatment on the zircon, the bauxite and the anthracite; grinding and sieving the zircon, the bauxite and the anthracite to obtain zirconium nitride-based ceramics, grinding white corundum, carrying out vibration screening on the white corundum to obtain gradation white corundum, then mixing the gradation white corundum, fused magnesia, the zirconium nitrate-based ceramics and the like with one another to obtain mixtures, then placing the mixtures in a hydraulic press and then compressing the mixtures to obtain rough nozzle brick bodies; carrying out forced-air drying on the rough nozzle brick bodies, then transferring the rough nozzle brick bodies into a rotary kiln and firing the rough nozzle brick bodies to obtain multi-phase fireproof materials; cooling the multi-phase fireproof materials to obtain the nozzle bricks for metallurgical casting. The method has the advantages that the nozzle bricks prepared by the aid of the method are high in structural strength and excellent in oxidation resistance, corrosion resistance, thermal shock resistance and high-temperature abrasion resistance; crack can be prevented in service procedures, the nozzle bricks are safe and durable, and the service lives of the nozzle bricks can be effectively prolonged.

Owner:石磊

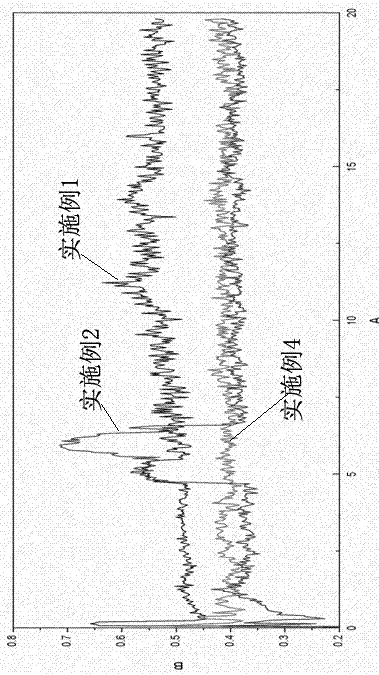

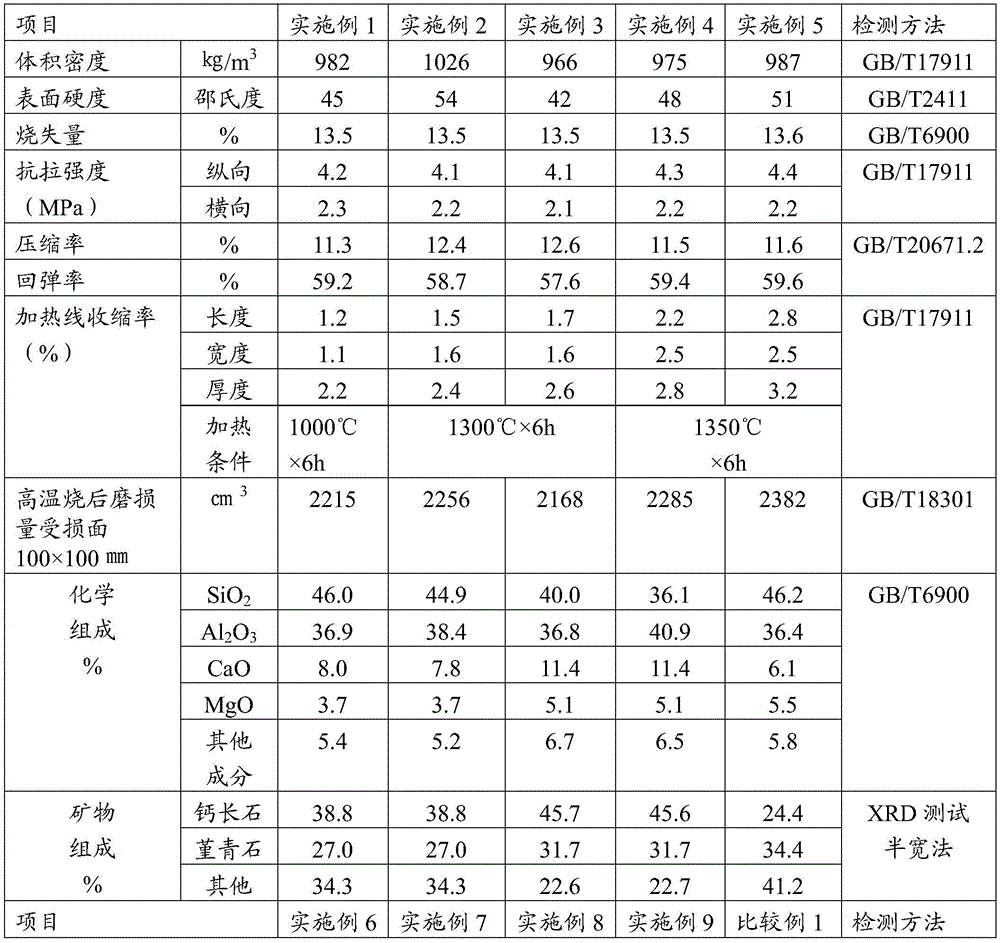

Ceramic fiber sealing pad plate and preparation method thereof

ActiveCN105622080AImprove high temperature wear resistanceExtended service lifeEngine sealsFiberChemical composition

The invention provides a ceramic fiber sealing pad plate, which has the chemical composition of 30 to 48 parts by mass of SiO2, 30 to 42 parts by mass of Al2O3, 5 to 13 parts by mass of CaO and 3 to 8 parts by mass of MgO. Through the chemical composition of the ceramic fiber sealing pad plate provided by the invention, anorthite and dichroite mineral facies in a specific proportion range can be formed, wherein the anorthite and dichroite mineral facies can greatly improve the high-temperature wear-resistant performance of the sealing pad plate and can prolong the service life. The result shows that the long-time use temperature of the ceramic fiber sealing pad plate reaches 900 DEG C or higher than 900 DEG C; the highest use temperature can reach 1200 DEG C or higher than 1200 DEG C; a heatproof roller of the assembled ceramic fiber sealing pad plate has good high temperature wear resistance; the service life at least reaches 20 days or more, and can reach 60 days or more to the highest degree.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

High-temperature wear-resistant surfacing alloy material based on ultralow-carbon high-boron and preparation method and application thereof

ActiveCN108817730AImprove thermal stabilityEnhanced high temperature wear performanceArc welding apparatusWelding/cutting media/materialsWear resistantNiobium

The invention discloses a high-temperature wear-resistant surfacing alloy material based on ultralow-carbon high-boron. The alloy material comprises a 304L stainless steel strip and a metal powder core; and the alloy material comprises the following chemical components of, by mass, less than 0.02% of carbon, 13.2-15.2% of chromium, 0.2-0.5% of silicon, 1.2-1.5% of manganese, 0.19-2.02% of niobium,4.0-5.0% of boron, 4.1-5.2% of nickel, 0.2-2.9% of molybdenum, 0.84-1.44% of tungsten, 0.19-2.88% of vanadium and the balance iron. The invention further discloses a preparation method of the high-temperature wear-resistant surfacing alloy material based on the ultralow-carbon high-boron, a coupling arc hot wire TIG welding is utilized, the vanadium, the molybdenum and the tungsten alloy elementsare introduced into the surfacing alloy material, different types of multi-element composite metal boride is formed in the surfacing alloy, so that the ultralow-carbon high-boron iron-based surfacingalloy material has high hardness and good high-temperature wear resistance, and good thermal stability can be achieved; and the high-temperature wear resistance and the thermal stability which cannotbe obtained by the high-carbon high-chromium-chromium iron-based surfacing alloy material can be obtained, and the service life of worn parts in a high-temperature environment can be prolonged.

Owner:威海三盾焊接材料工程有限公司

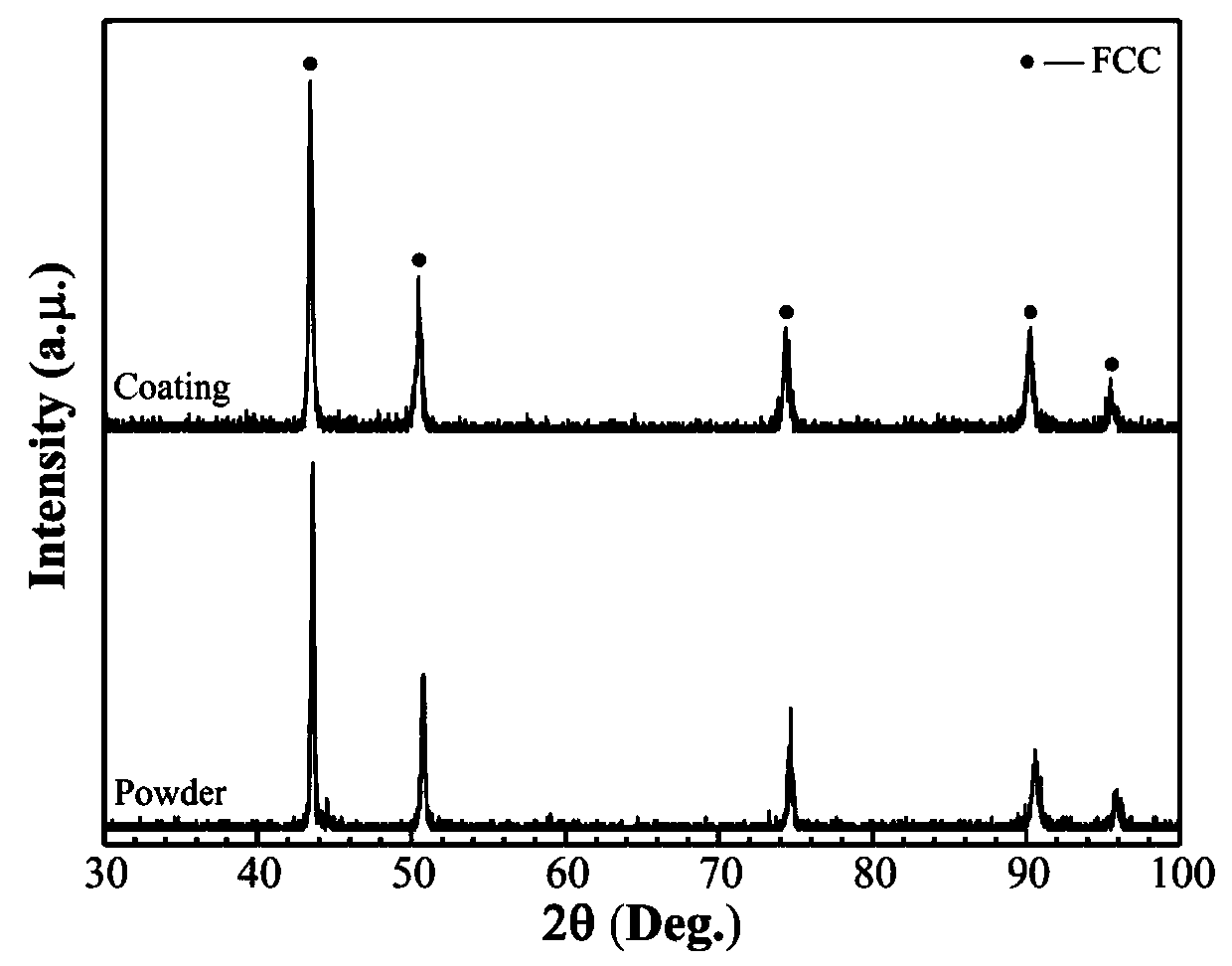

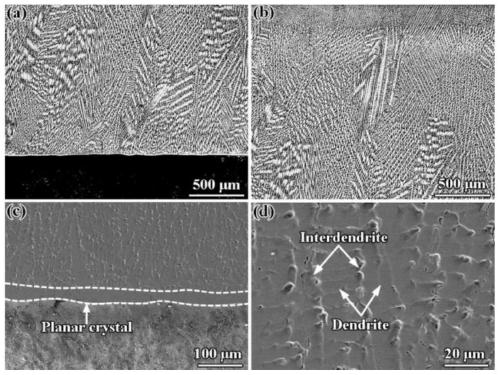

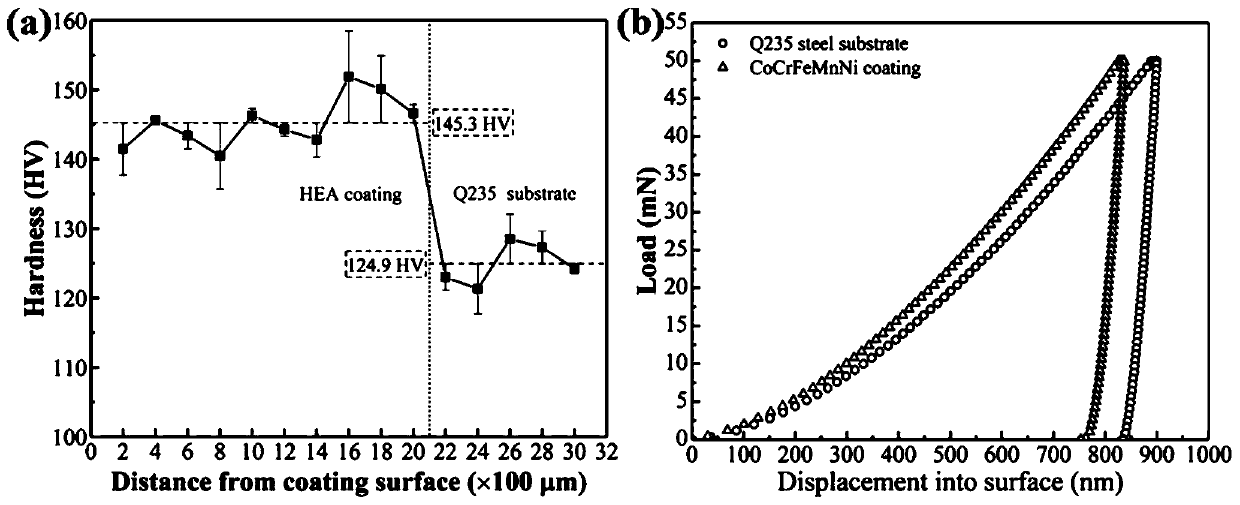

High-hardness high-entropy alloy coating and preparation method and application thereof

ActiveCN111364040ALow wear resistanceSmall volume wear rateMetallic material coating processesHigh entropy alloysMilling cutter

The invention discloses a high-hardness high-entropy alloy coating and a preparation method and application thereof. The high-entropy alloy coating comprises the following components and atoms of CoCrFeMnNiTixVy, wherein x = 0.3-1, y = 0.1-1. The high-entropy alloy coating can be applied to a high-temperature-resistant frictional wear material, and particularly can be applied to a milling cutter coating, a high-temperature rotating shaft coating or a high-temperature friction disc coating. The preparation method of the high-entropy alloy coating comprises the steps of powder mixing, drying, pretreatment of a base material and cladding of the coating. The plasma cladding CoCrFeMnNiTiV high-entropy alloy coating prepared through the method is composed of a V-rich BCC1 phase and a Ti-rich BCC2 phase, and the solidification structure of the plasma cladding CoCrFeMnNiTiV high-entropy alloy coating is of a cellular dendritic crystal structure. The average hardness of the CoCrFeMnNiTiV high-entropy alloy coating reaches 942.8 HV0. 3, and is 7.5 times that of matrix Q235 steel.

Owner:NANJING INST OF TECH +2

High-carbon martensitic stainless steel for mill guide roller and heat treatment method of mill guide roller

InactiveCN106086702AGood high temperature wear resistanceImprove thermal stabilityFurnace typesHeat treatment furnacesStrip millMartensitic stainless steel

The invention discloses high-carbon martensitic stainless steel for a mill guide roller and a heat treatment method of the mill guide roller. The high-carbon martensitic stainless steel is prepared from the following components according to mass percent: 1.3% to 1.6% of C, 18% to 22% of Cr, 0.5% to 0.8% of Ni, 0.2% to 0.3% of V, 1.0% to 1.3% of Si, 0.4% to 0.8% of Mn and 71% to 80% of Fe. The invention further discloses the heat treatment method of the mill guide roller. The heat treatment method is characterized in that the mill guide roller is prepared from the high-carbon martensitic stainless steel, and the heat treatment method comprises the following steps of annealing treatment, quenching treatment and low-temperature tempering treatment. According to the high-carbon martensitic stainless steel and the heat treatment method, the toughness, wear resistance and corrosion resistance of the high-carbon martensitic stainless steel can be increased, so that the service life of the prepared mill guide roller is greatly prolonged.

Owner:HEFEI ORIENT METALLURGICAL EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com