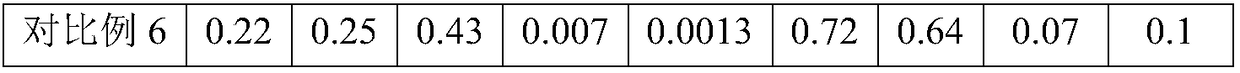

Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

142results about How to "Improve temper stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

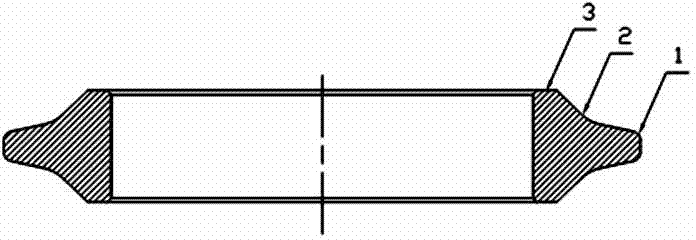

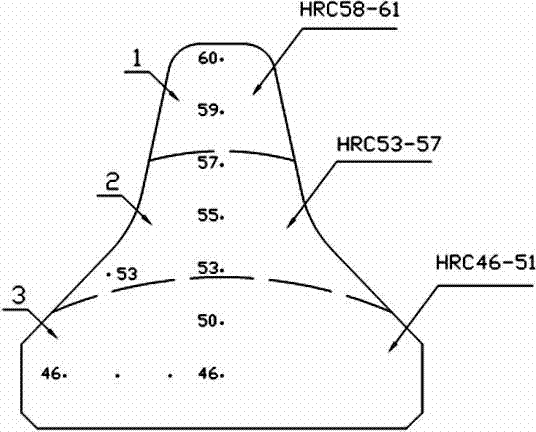

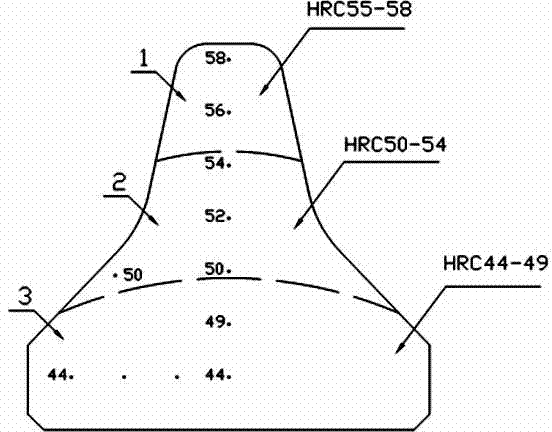

Disk-shaped roller cutter ring and manufacture method thereof

ActiveCN102517502AGuaranteed hardenabilityImprove toughnessFurnace typesHeat treatment furnacesMedium frequencyHardness

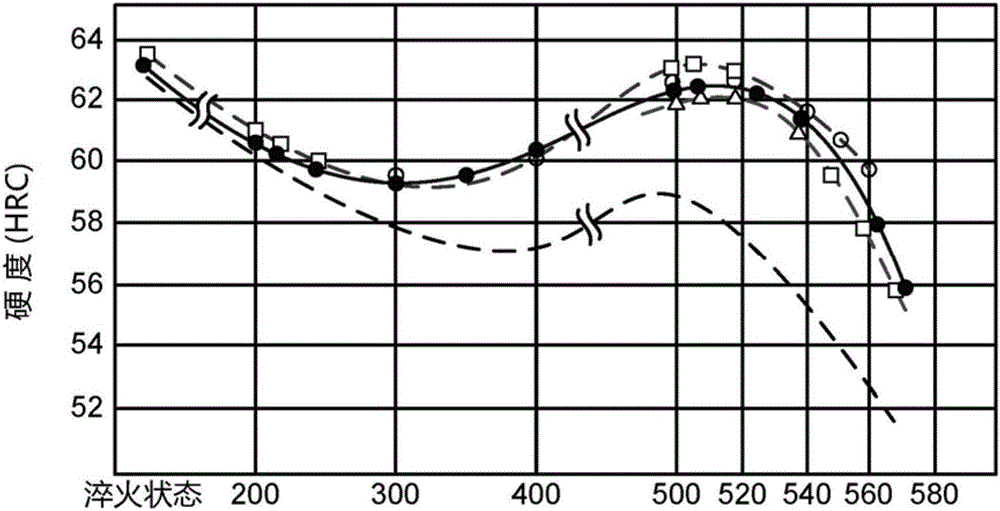

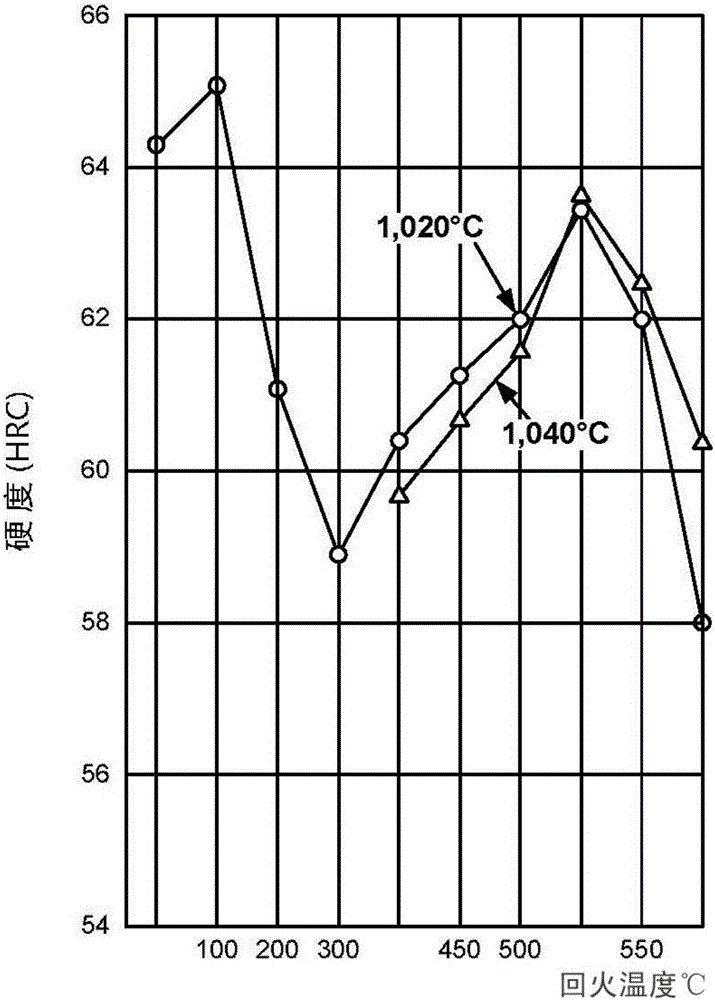

The invention discloses a disk-shaped roller cutter ring with high hardness, good toughness and excellent comprehensive performance. The disk-shaped roller cutter ring comprises the following ingredients of: 0.46-0.56% of C, 0.80-1.20% of Si, 0.20-0.65% of Mn, 5.00-5.80% of Cr, 1.15%-1.55% of Mo, 0.85-1.40% of V and the balance Fe and impurities, wherein the content of P is no more than 0.02%, and the content of S is no more than 0.01%; and the overall hardness of the cutter ring is HRC55-61 (Rockwell Hardness C55-61), or the hardness is of graded distribution, i.e. the hardness of a working edge area is HRC55-61, the hardness of a transition surface area is HRC50-57, and the hardness of a step assembly surface area and an inner ring is HRC44-51. A preparation method of the disk-shaped roller cutter ring comprises the following steps of: smelting the raw materials in an electric furnace; carrying out electroslag remelting; preforging; carrying out die forging; carrying out slow cooling; annealing; carrying out rough machining to obtain a disk-shaped roller cutter ring rough blank; carrying out high-temperature vacuum hardening and two-time high-temperature tempering on the cutter ring rough blank; carrying out low-temperature destressing treatment; carrying out fine finishing to obtain the cutter ring with the overall hardness of HRC55-61, wherein the cutter ring with the overall hardness of HRC55-61 is applicable to the tunneling of a hard rock formation by a shield tunneling machine; or carrying out medium-frequency induction tempering treatment prior to the low-temperature destressing treatment to obtain the cutter ring with graded-distribution hardness, wherein the cutter ring with the graded-distribution hardness is applicable to the tunneling of a rock formation with an upper soft part and a lower hard part.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

42CrMoE thermal treatment technique

ActiveCN101368275AHigh surface hardnessImprove surface wear resistanceSolid state diffusion coatingFurnace typesMiddle frequencyCase hardening

The invention belongs to a heat processing technique of 42CrMoE material used for a reciprocating compressor. The technique is suitable for the heat processing technique for the 42CrMoE piston rods used for all the reciprocating compressors and can also be applied to the mechanical devices which require high rigidity, wear resistance and corrosion resistance. The invention can solve the problems of cracks, low surface hardening rigidity as well as poor wear resistance, poor acid resistance and poor corrosion resistance generated when the traditional surface heating processing technique is applied to the 42CrMoE piston rod, and the like. The invention includes the forging and shaping, hardening and tempering, stabilizing, nitriding, middle frequency or high frequency quenching as well as low temperature annealing of the 42CrMoE material; a surface compounded heat processing technology combined with nitriding and middle frequency or high frequency quenching is adopted: the 42CrMoE material is arranged in a nitriding furnace; ammonia gas is pumped in after the treatments of temperature rising and pro-oxidation to carry out nitriding treatment; then the middle frequency or high frequency quenching on the surface is carried out. The heat processing technique can be adopted to completely prevent the quenching cracks generated during the traditional high frequency quenching, improve the surface rigidity to be more than HRC60, improve the wear resistance by 34 percent and improve the acid and corrosion resistance by 40 percent.

Owner:SHENYANG BLOWER WORKS GROUP CORP

Boracic high-speed steel with good red hardness and preparation method thereof

The invention discloses boracic high-speed steel with good red hardness, and a preparation method of the boracic high-speed steel. The boracic high-speed steel comprises the following chemical components in percentage by weight: 0.30-0.5% of C, 3.8-5.5% of Cr, 0.9-3.5% of W, 0.9-2.1% of Mo, greater than or equal to 3.5% and less than or equal to 5.0% of (W+2Mo), 0.8-1.2% of Si, 0.3-1.5% of Mn, 3.0-3.5% of B, 0.8-2.6% of Cu, 2.8-3.6% of Al, 0.5-1.0% of V, 0.8-1.6% of Ti, 0.02-0.15% of Ca, 0.03-0.25% of Ce, 0.02-0.18% of N, 0.05-0.3% of Nb, 0.12-0.25% of Mg, 0.04-0.13% of K, 0.05-0.12% of Ca, 0.06-0.15% of Ba, less than or equal to 0.03% of S, less than or equal to 0.04% of P and the balance of Fe and inevitable impurity elements. The preparation method comprises the following steps: smelting waste steel and ferrochrome, subsequently adding copper plates, silicon iron and ferromanganese iron, adjusting the component at a stokehole, after being qualified, raising the temperature to be 1,560-1,620 DEG C, adding calcium-silicon and aluminum for deoxidation, adding ferrotitanium, ferro-boron and aluminum, smelting and discharging outside a furnace, adding a rare earth magnesium alloy and a composite inoculant consisting of metal cerium, Si3N4, VN (Vanadium Nitride), Nb and K, so as to perform inoculation treatment, wherein the molten steel casting temperature is 1,400-1,450 DEG C, keeping the temperature of a cast piece at 920-1,150 DEG C for 2-4 hours, and subsequently performing air cooling.

Owner:江苏盛伟模具材料有限公司

Hot rolling roller for rolling nonferrous metal, and manufacturing method thereof

The present invention discloses a hot rolling roller for rolling a nonferrous metal, and a manufacturing method thereof. Chemical components of the roller comprise, by weight, 0.50-0.80% of C, 0.30-1.20% of Si, 0.20-1.00% of Mn, less than or equal to 0.025% of P, less than or equal to 0.020% of S, 4.50-6.00% of Cr, 0.20-0.80% of Ni, 0.20-1.00% of Mo, 0.10-0.50% of V, and the balance of Fe and unavoidable impurities. The manufacturing method of the roller comprises the following process steps: a, refining a steel ingot; b, forging a roller blank; c, carrying out quenching and tempering, and carrying out mechanical processing; d, carrying out a quenching heat treatment; and e, carrying out a tempering treatment. The hot rolling roller has characteristics of high wear resistance, good thermal cracking resistance and good electrochemical corrosion resistance, and a service life of the hot rolling roller can be increased by more than 50% compared with the ordinary Cr3 roller.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

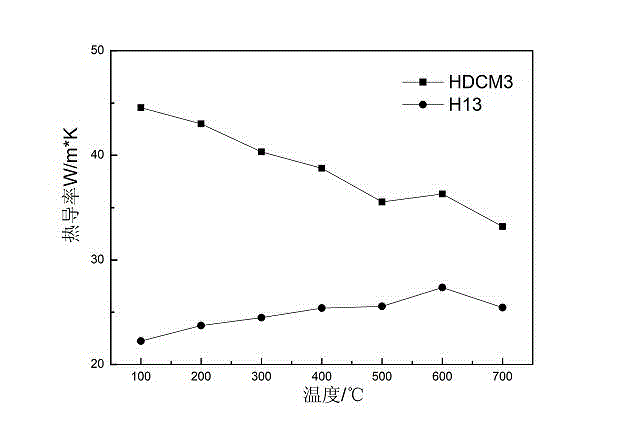

High-thermal conductivity high-abrasion resistance hot stamping die steel and preparation method thereof

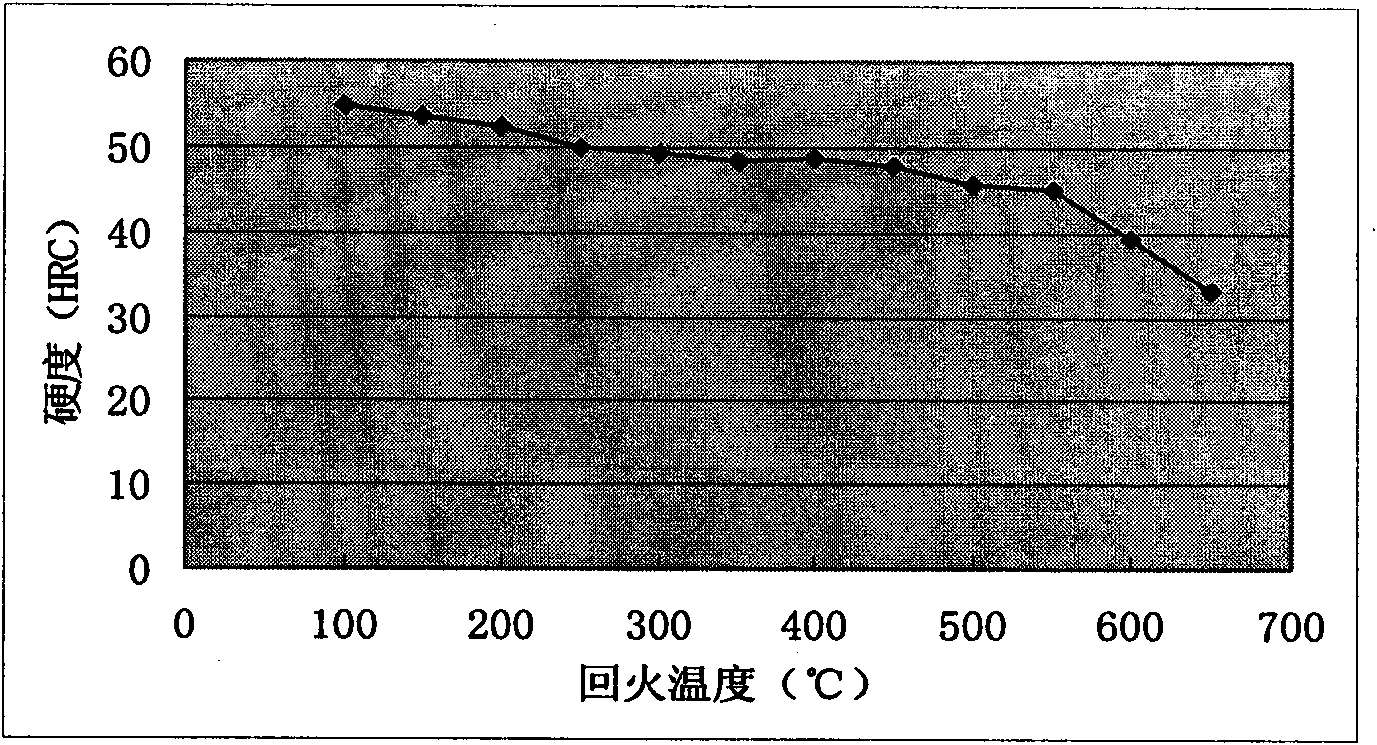

The invention relates to a novel high-thermal conductivity high-abrasion resistance hot stamping die material. The current hot stamping die steels on the market are mainly various improved high alloy steels such as H13 steel, H11 steel and the like. The steel disclosed by the invention comprises the following components in percentage by mass: 0.45-0.5% of C, less than 0.2% of Si, less than 0.20% of Mn, 1.0-2.0% of W, 2.0-3.5% of Mo, less than 0.30% of Cr and the balance of Fe and other unavoidable impurity elements, wherein the S content is less than or equal to 0.03% and the P content is less than or equal to 0.03% in the impurity elements. The steel has the characteristics that simple C, Mo and W elements are taken as the main components and the proportion of carbide is coordinated; low Mn content, low Cr content and super low Si content are kept; the material has good machinability after being subjected to electric-furnace smelting, electroslag remelting, annealing, high-temperature homogenizing, forging and annealing; after being subjected to heat treatment (quenching at the temperature of 1060-1100 DEG C and repeatedly high-temperature tempering), the steel has the toughness of general hot stamping die steels such as H13 steel and is better in hardness, tempering stability and thermal fatigue property; and the steel is more suitable for hot stamping due to the advantages of lower thermal expansion coefficient, high thermal conduction ability and high abrasion resistance particularly.

Owner:SHANGHAI UNIV

Low temperature resistant wind power flange steel with high welding performance and high strength

The invention discloses a low temperature resistant wind power flange steel with high welding performance and high strength, comprising the following chemical components in percentage by weight: 0.13-0.18% of C, 0.17-0.40% of Si, 1.30-1.45% of Mn, 0.035-0.060 of V, 0.03-0.05% of Nb, 0.015-0.030% of Al, 0.010-0.020% of Ti, not more than 0.005% of S, not more than 0.015% of P, not more than 0.04% of As, not more than 0.0020% of [O], 0.0060-0.0110% of [N], not more than 0.0002% of [H] and the balance of Fe; meanwhile, the required carbon equivalent (CEV) of the material is 0.40-0.43%. After the normalizing treatment, a flange made of the steel of the invention has the following performances: 500-570 MPa of tensile strength Rm, 325-360 MPa of yield strength Re1, 28-39% of elongation A5 and 76-85% of reduction rate of cross section; at the temperature of -50 DEG C, the impact energy AKv of the V-shaped nick is 110-180 Joules. The invention has the advantages of good welding performance, stable low temperature impact performance and higher strength.

Owner:JIANGSU SHAGANG GROUP HUAIGANG SPECIAL STEEL CO LTD

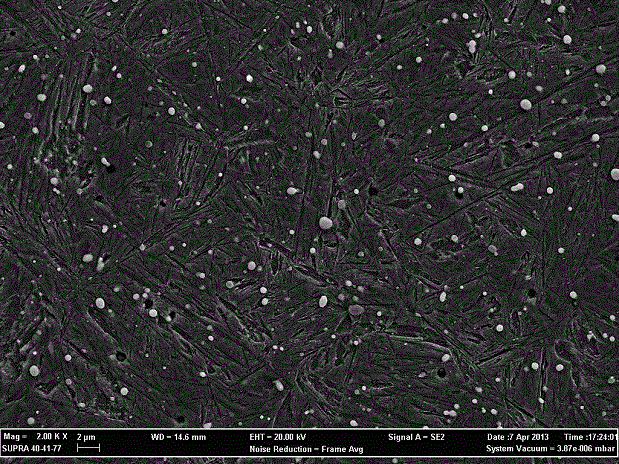

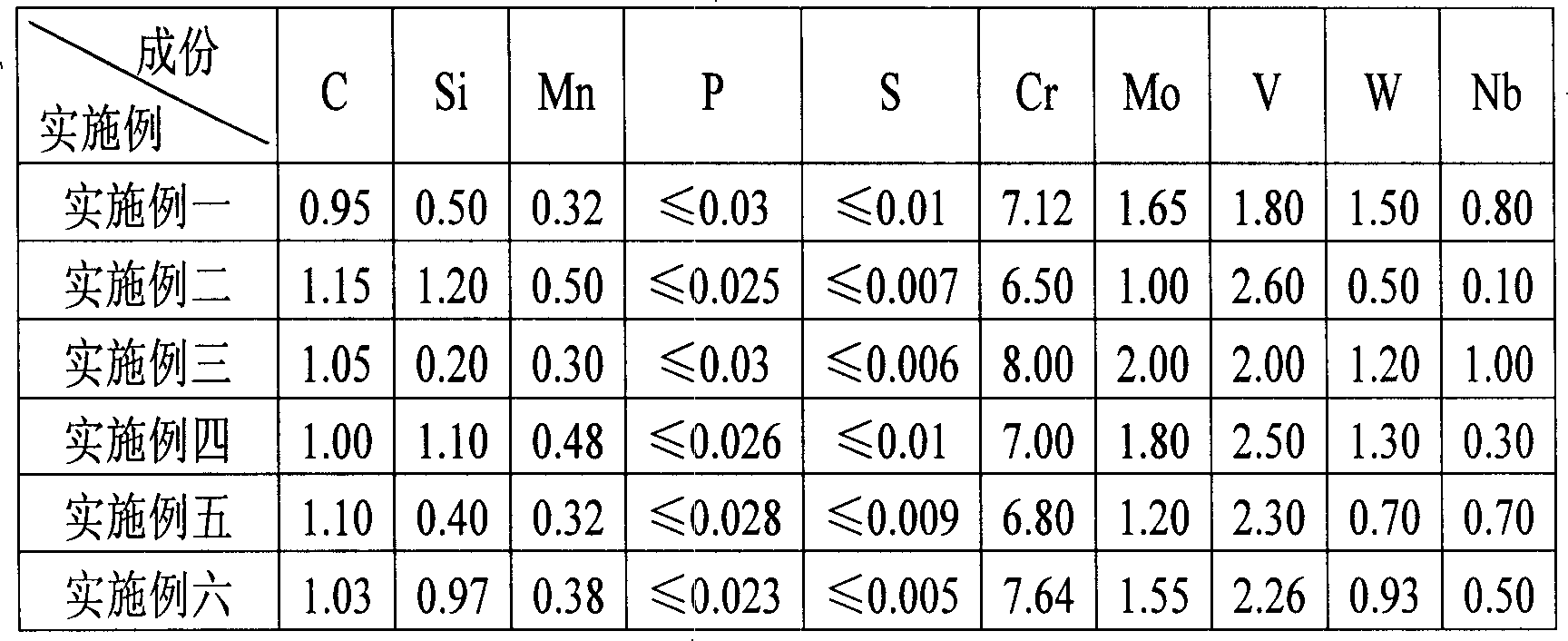

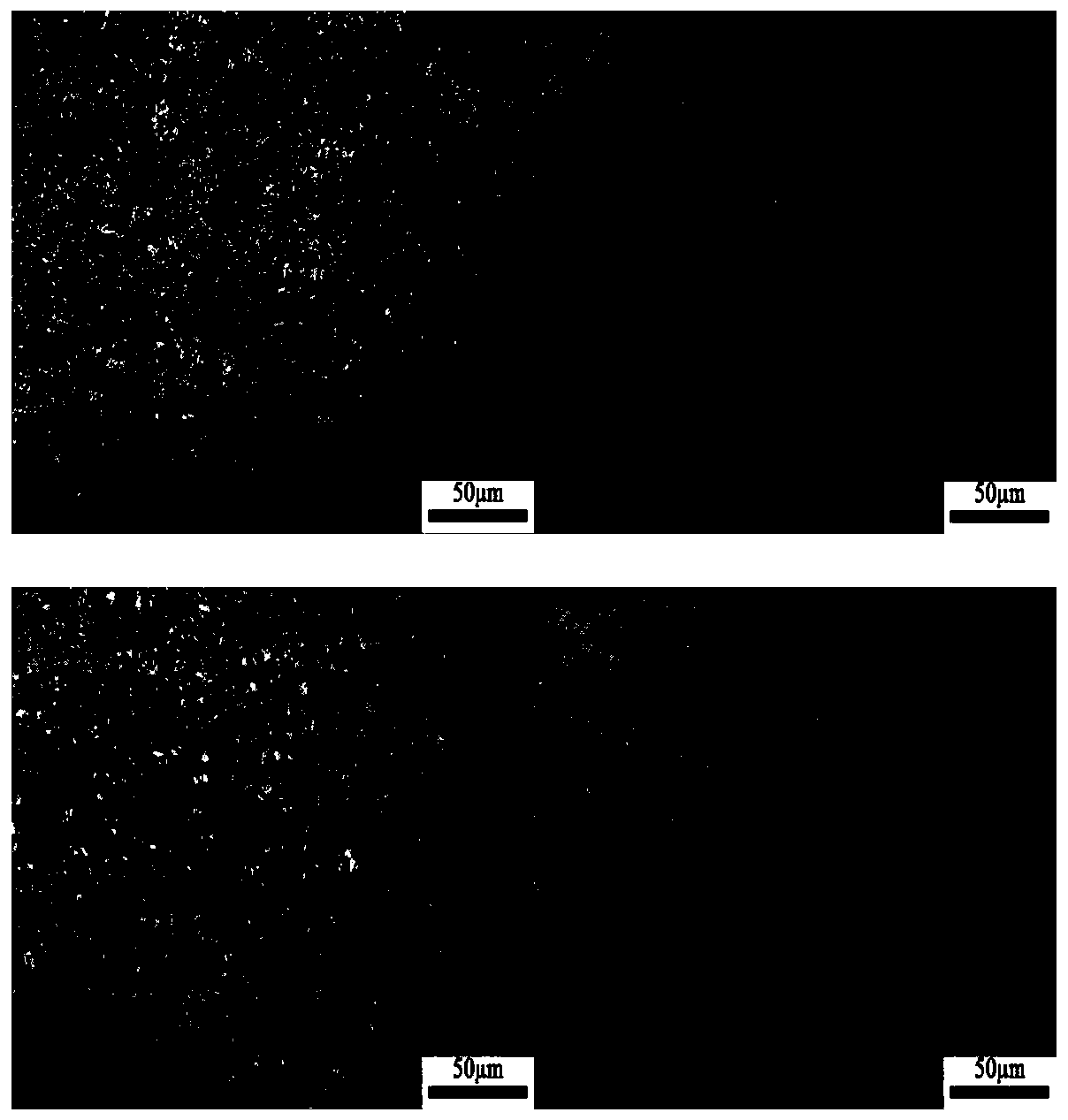

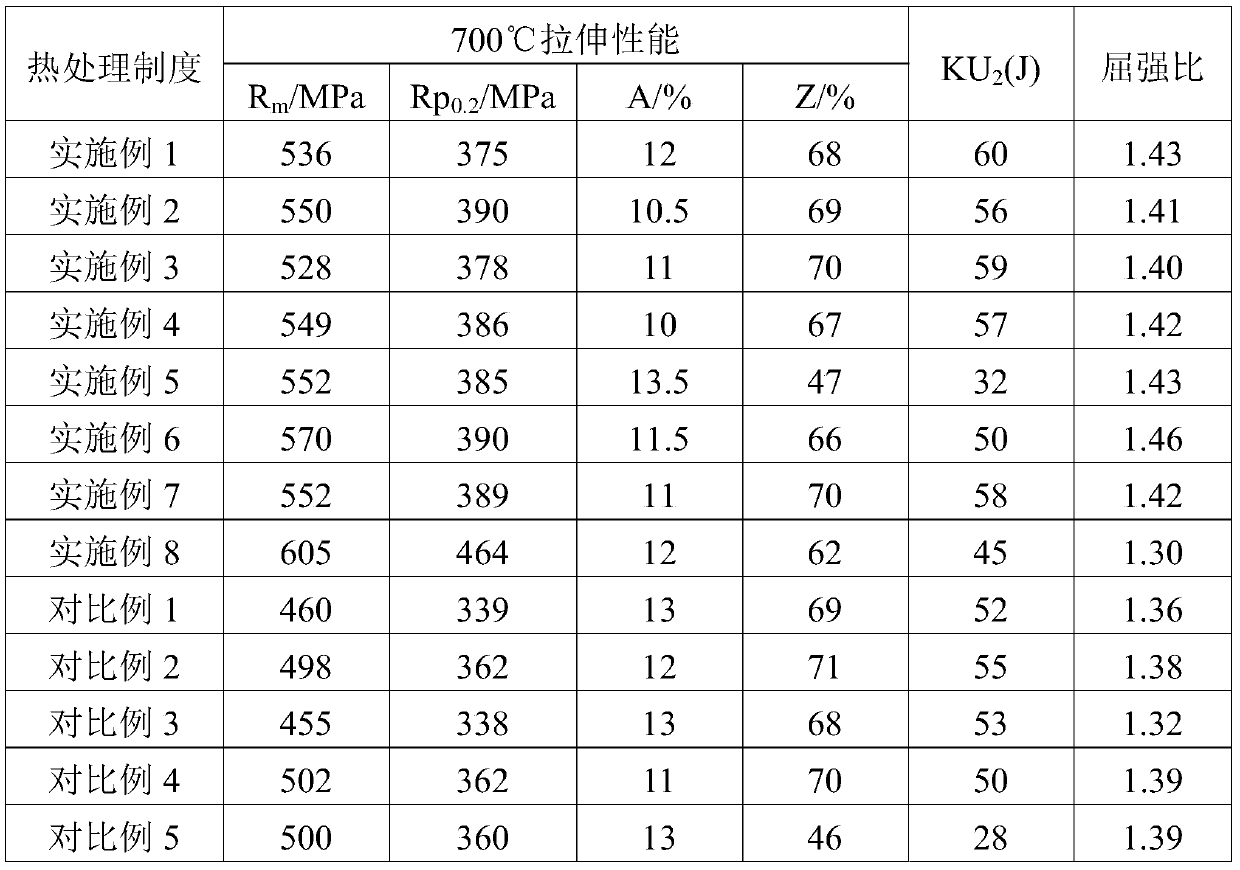

High malleable high wear-resisting cold process mould steel

The present invention relates to one kind of high toughness and high wear resistance cold-work die steel, which includes C 0.95-1.15 wt%, Si 0.20-1.20 wt%, Cr 6.50-8.00 wt%, Mo 1.00-2.00 wt%, V 1.80-2.60 wt%, W 0.50-1.50 wt%, Nb 0.10-1.00 wt%, Mn 0.20-0.50 wt%, and Fe and impurity for the rest. The cold-work die steel has high wear resistance, high strength, high toughness, high hardness, high tempering stability and other features, and may be used in replacing M2 high speed die steel for lowering cost.

Owner:HEYE SPECIAL STEEL

Hot-work die steel and heat treatment method thereof

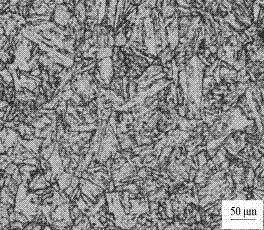

ActiveCN110438310AShort austenitizing timeFine austenite grainsIncreasing energy efficiencyQuenchingHot work

The invention relates to the field of metal material heat treatment, in particular to hot-work die steel and a heat treatment method thereof. The heat treatment method comprises the following steps of1), heating the die steel at rate of 80-180 DEG C / min to 1100D EG C-1300 DEG C, and carrying out heat preservation for 3-10 minutes; 2), quenching the die steel after heat preservation in a quenchingmedium; and 3), tempering the quenched die steel. According to the method, the obtained hot-work die steel grains are not coarsening, the carbides are more dispersed and distributed, the tempering stability is good, the high temperature strength at the same hardness after processing is greatly improved, the thermal fatigue performance of the die steel is improved, after the heat treatment is performed to the same hardness, the impact toughness of the die steel after the new process is slightly higher than that of the traditional process, the method greatly shortens the heating and heat preservation time in the quenching process, and can achieve the effects of saving time and cost for small-batch and small-sized products.

Owner:UNIV OF SCI & TECH BEIJING

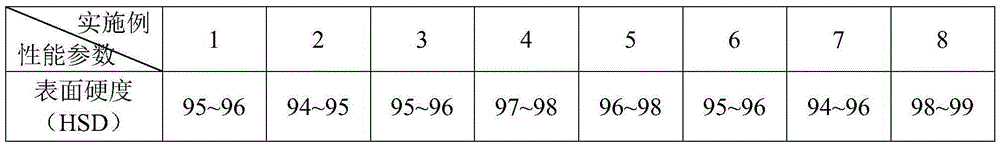

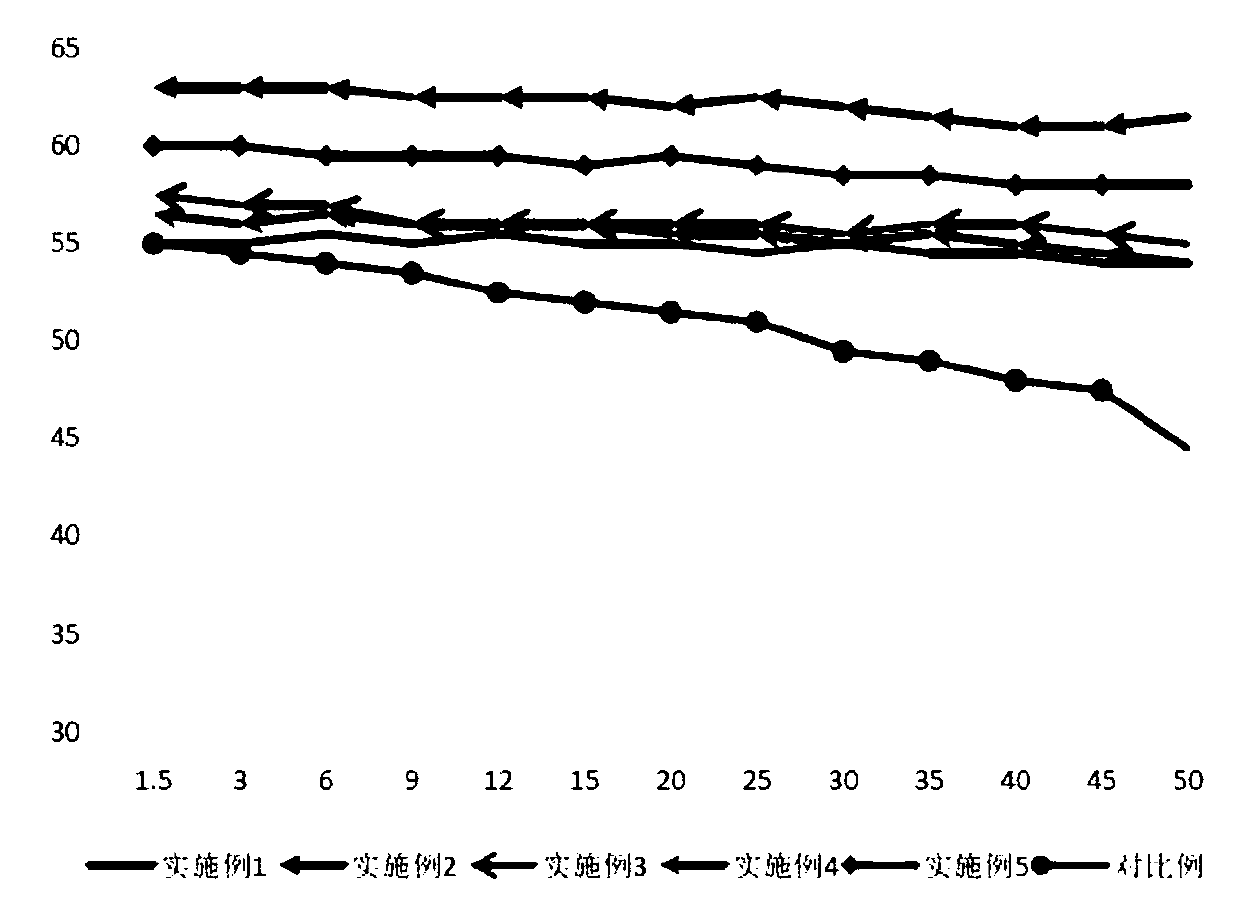

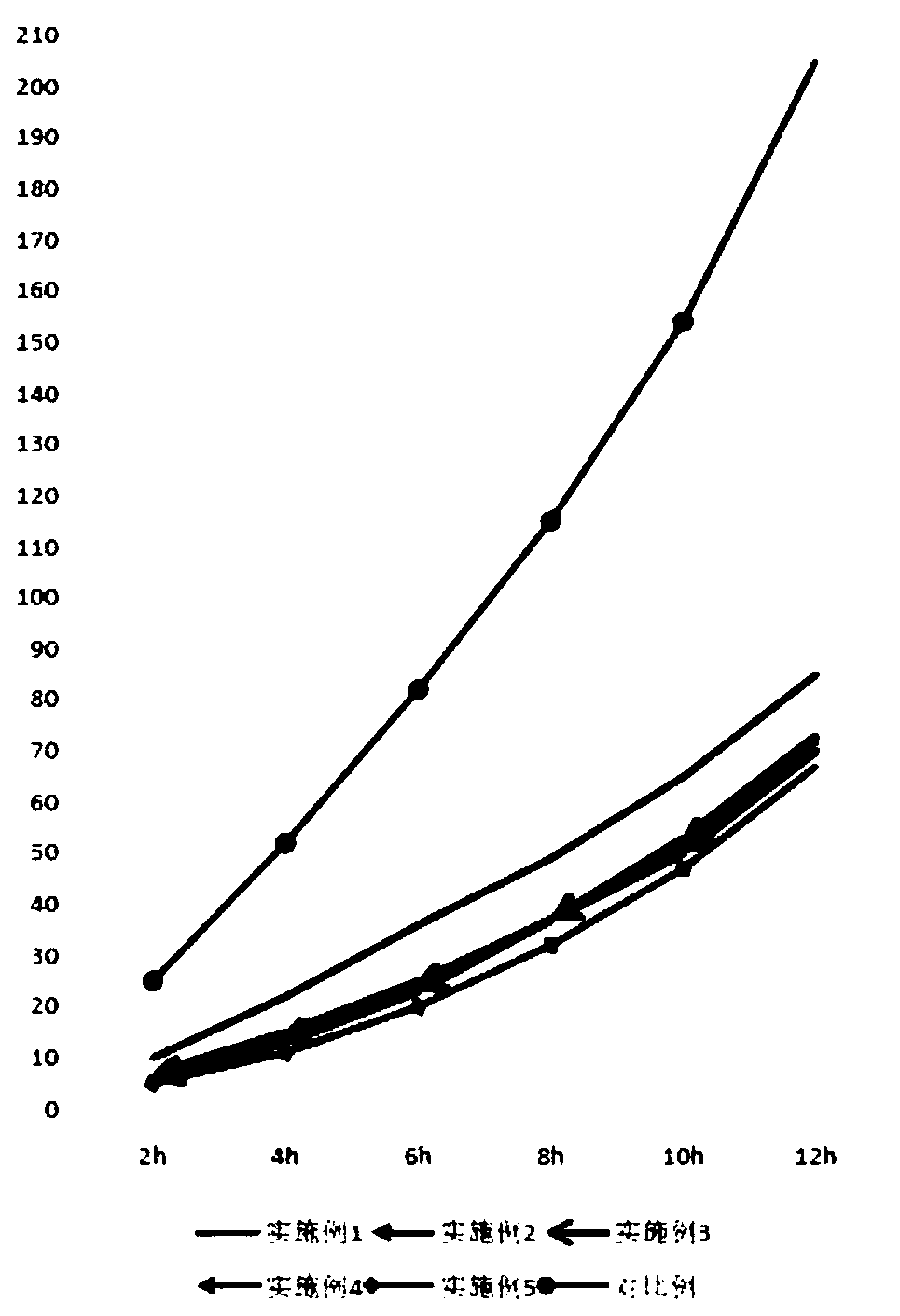

High-wear-resisting cold roll and manufacturing method thereof

ActiveCN105385959AManufacturing Process Step ImprovementsImprove purityMetallurgyHigh wear resistance

The invention relates to a high-wear-resisting cold roll. Chemical components in the cold roll comprise, by weight percentage, 0.80%-1.20% of C, 0.4%-1.20% of Si, 0.20%-0.50% of Mn, 7.50%-9.00% of Cr, 0.20%-1.00% of Mo, 0.05%-0.50% of V, less than or equal to 0.40% of Ni, less than or equal to 0.015% of S, less than or equal to 0.015% of P and the balance Fe and inevitable impurities. The high-wear-resisting cold roll has the high wear resistance; and under the same using condition, the service life of the roll is prolonged by more than one time than a roll made of original common chrome steel system materials.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

High-temperature wear-resisting and corrosion-resisting steel powder for additive manufacturing and additive manufacturing method

ActiveCN105886923AExcellent high temperature wear resistanceImprove temper stabilityAdditive manufacturing apparatusIncreasing energy efficiencyAdditive layer manufacturingLaser

The invention discloses high-temperature wear-resisting and corrosion-resisting steel powder for additive manufacturing. The high-temperature wear-resisting and corrosion-resisting steel powder is prepared from the following elements in percentage by weight: 0.1 to 0.3 weight percent of C, 1.0 to 1.5 weight percent of Mn, 0.2 to 0.6 weight percent of Si, 5 to 9 weight percent of Cr, 2.0 to 6.0 weight percent of Ni, 1.0 to 1.5 weight percent of Mo, 0.2 to 0.4 weight percent of V, 0.3 to 0.7 weight percent of Nb, and the balance of Fe, wherein the sum of mass percent of all the elements is 100 percent. A method for additive manufacturing by using the steel powder comprises the following steps of putting the steel powder into additive manufacturing equipment; partitioning a part to be manufactured and setting laser process parameters: output power is 200 to 400W, the spot diameter is 0.06 to 0.1mm, the scanning speed is 960 to 1500mm / s, and track pitch is 0.06 to 1.2mm; then importing partitioned programs into the additive manufacturing equipment; filling the additive manufacturing equipment with high-purity argon; finally, printing layer by layer, and obtaining a high-temperature wear-resisting and corrosion-resisting steel part at last.

Owner:XIAN BRIGHT ADDTIVE TECH CO LTD

Build-up welding rod for repairing Cr3 roller and build-up welding method

InactiveCN101658986AImprove wear resistanceMeet repair requirementsRolling equipment maintainenceArc welding apparatusCrack resistanceHigh carbon

The invention relates to a build-up welding rod for repairing a Cr3 roller and a build-up welding method, which belong to the technical field of welding materials and welding. The build-up welding rodcomprises a welding core and a coating, the welding core is H08A steel and the coating of the welding rod comprises, by mass percent, 36 to 42 marble, 20 to 26 fluorite, 1.5 to 4 low-carbon ferromanganese, 1 to 4 ferromolybdenum, 13 to 17 high carbon ferro-chrome, 0 to 1.5 calcined soda, 1 to 4 rare earth alloy, 4 to 8 titanium dioxide, 0.5 to 1.5 graphite, 3 to 5 No,45 silicoferrite and 4 to 7 silicon dioxide. The build-up metal has no crack, good crack resistance, good wear resistance, high hardness and plasticity and good tempering stability. The welding method is simple and convenient, and the connection of the melt-applying metal and the roller is firm to excellently satisfy the repairing requirement of the Cr3 support roller.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

Mineral high-strength wear-resistant material and preparation method thereof

The invention discloses a mineral high-strength wear-resistant material which is prepared from the following raw materials in percentage by weight: 0.30-0.50% of C, 0.10-0.65% of Si, less than or equal to 1.0% of Mn, 1.0-4.5% of Cr, 0.05-3% of Ni, 0.15-1.5% of Mo, 0.05-0.5% of V, 0.010-0.5% of Nb, 0.01-0.5% of Al, less than or equal to 0.025% of P, less than or equal to 0.015% of S and the balanceof Fe. A chain wheel manufactured from the mineral high-strength wear-resistant material is excellent in alloy element proportion, is pure in steel, is uniform in structure, has excellent comprehensive performance, is high in chain gear hardness, is uniform in hardness and is good in wear resistance; and meanwhile, a base body part has good impact toughness and strength. The defects that a commonChinese chain wheel is poor in comprehensive performance and is low in coal passing amount are solved. The mineral high-strength wear-resistant material greatly improves the coal passing amount of the chain wheel, reduces chain wheel use cost, and improves economic benefits.

Owner:YINGKOU SPECIAL STEEL FORGING

Boro-carburizing microalloying method of shearer cutter

InactiveCN101323944ADense tissueHigh strengthSolid state diffusion coatingProcess efficiency improvementManganeseRoom temperature

The invention relates to a borocarbon diffusion micro alloying method for the pick of a coal mining machine. Alloy steel 35CrMo is adopted as pick material, and the method comprises the following processing steps that: step 1, acid cleaning; step 2, carburization, titanizing and manganizing treatment: carburizer and lanthana powder are carried out and evenly stirred and sent into an infiltration box; titanium powder and manganese power are adopted to coat on the cutting part at the tooth tops of the pick that is then vertically put into the infiltration box which is compacted and sealed; then the infiltration box is sent into a heating furnace, the temperature is rised to 650 DEG C + / - 10 DEG C, is kept for 1.5 to 2.5 hours, then continuously rised to 910 DEG C + / - 10 DEG C and is kept for 8 to 10 hours; then the temperature is lowered to 850 DEG C + / - 10 DEG C and is kept for 1.5 to 2.5 hours and continuously lowered to less than 800 DEG C and taken out of the furnace; the taken-out infiltration box is cooled to room temperature and opened; step3, boronizing, tungstenizing and chromizing treatment; step 4, salt-bath treatment; step 5, annealing treatment; step 6, tempering treatment; step 7, shot-peening treatment. The method of the invention is capable of improving the intensity, hardness and high-temperature abrasion resistance at the tooth tops of the pick of the coal mining machine and causes the handle of the pick to be difficult to break.

Owner:JIANGYIN XINHONG SCI & TECH

690 MPa-grade hydrogen sulfide corrosion resisting steel plate and production method thereof

The invention discloses a 690 MPa-grade hydrogen sulfide corrosion resisting steel plate. The steel plate comprises the following chemical components in percentage by mass: 0.14-0.16% of C, 0.20-0.40% of Si, 1.05-1.10% of Mn, 0.40-0.45% of Ni, P not more than 0.012%, S not more than 0.003%, 0.020-0.040% of Al, 0.020-0.030% of Nb, 0.035-0.040% of V, 0.01-0.02% of Ti, 0.30-0.35% of Cr, 0.25-0.30% of Mo, 0.0015-0.0020% of B, N not more than 0.010%, Cu not more than 0.20%, and the balance of Fe and inevitable impurities. A production method of the 690 MPa-grade hydrogen sulfide corrosion resisting steel plate comprises the procedures of heating, rolling and heat treatment. The 690 MPa-grade hydrogen sulfide corrosion resisting steel plate has such characteristics as high compactness, higher strength grade, excellent low-temperature impact toughness, excellent lamellar tearing resistance and excellent hydrogen sulfide corrosion resistance, can satisfy the requirements of hydrogen sulfide corrosion resisting steel for ship storage tanks, is excellent in comprehensive performance and welding performance, and is lower in cost.

Owner:WUYANG IRON & STEEL

Hot roll for rolling titanium plate and manufacturing method of hot roll

The invention discloses a hot roll for rolling a titanium plate, and a manufacturing method of the hot roll. The hot roll comprises the following chemical constituents in percentage by weight: 0.30-0.50% of C, 0.60-2.00% of Si, 0.20-1.00% of Mn, 4.50-6.00% of Cr, 0.05-0.65% of Ni, 1.00-2.00% of Mo, 0.50-1.50% of V, less than or equal to 0.025% of P, less than or equal to 0.020% of S, and the balance of Fe and unavoidable impurities. The manufacturing method of the hot roll for rolling the titanium plate comprises the processing steps of steel ingot refining, roll blank forging, thermal refining, induction quenching treatment, tempering treatment and the like. Compared with the traditional hot roll made of a Cr3 material, the hot roll is good in abrasive resistance, corrosion resistance and thermal crack resistance, and the service life of the hot roll can be prolonged by above 70%.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Alloy for producing cold rolled working roll and method for producing same

The invention relates to an alloy for cold-rolling worker rollers and its preparing process, wherein the alloy comprises the main chemical constituents of: C 0.9-1.2%, Si 0.85-1.25%, Mn 0.40-0.60%, Cr 2.50-5.50%, Ni 0.25-0.45%, Mo 0.25-0.45%, V 0.05-0.155 and balancing Fe.

Owner:BAOSTEEL ROLL SCI & TECH

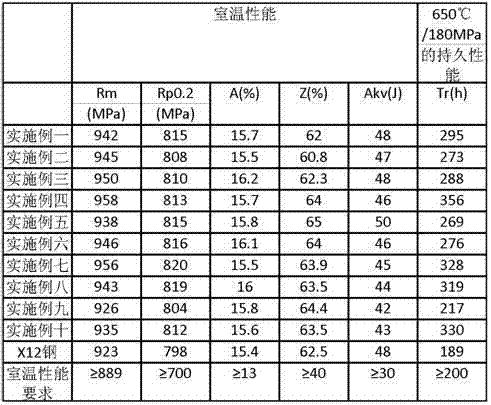

Heat-resistant steel for ultra-supercritical steam turbine rotor

The invention provides heat-resistant steel for an ultra-supercritical steam turbine rotor, which can solve the problem that an ultra-supercritical steam turbine rotor manufactured by adopting X12CrMoWVNbN10-1-1 ferrite heat-resistant steel can not satisfy the demand of an ultra-supercritical steam turbine unit with the temperature of 620 DEG C, and is characterized by comprising the following elements by mass percent: 0.1-0.15 percent of carbon (C), 0.15-0.25 percent of manganese (Mn), 10.00-11.00 percent of chromium (Cr), 2.0-4.0 percent of cobalt (Co), 0.6-1.1 percent of molybdenum (Mo), 1.0-3.0 percent of wolfram (W), 0.15-0.25 percent of nickel (Ni), 0.15-0.25 percent of vanadium (V), 0.07-0.09 percent of niobium (Nb), 0.02-0.04 percent of nitrogen (N), and the balance of Fe and impurity elements.

Owner:WUXI TURBINE BLADE

Wide and thin specification NM450 wear-resistant steel plate and fabrication method

InactiveCN109182666ASimple rolling and heat treatment processWide controllable range of heat treatment parametersSteel platesWear resistant

The invention discloses a wide and thin specification NM450 wear-resistant steel plate and relates to the technical field of metallurgy. The wide and thin specification NM450 wear-resistant steel plate comprises the following chemical ingredients of, in percentage by mass, 0.18-0.22% of C, 0.20-0.60% of Si, 0.8-1.2% of Mn, less than or equal to 0.012% of P, less than or equal to 0.003% of S, 0.30-0.50% of Cr, 0.008-0.030% of Ti, 0.0008-0.0025% of B and the balance Fe and unavoidable impurities. According to the wide and thin specification NM450 wear-resistant steel plate and a fabrication method, the designed wear-resistant steel reaches the 450 HB grade in brinell hardness and has a chemical ingredient system of good toughness and high strength, a related rolling and heat treating processis simple, the controllable range of heat treating parameters is wide, the comprehensive performance of products is good, and the wide and thin specification NM450 wear-resistant steel plate and thefabrication method have good development value and market prospects.

Owner:NANJING IRON & STEEL CO LTD

Corrosion resistant metal coating for gear box inner surface

ActiveCN106498291AStable austenite phaseImprove hardenabilityNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveCorrosion resistantMetal coating

The invention discloses a corrosion resistant metal coating for a gear box inner surface. The corrosion resistant metal coating comprises the following components by mass percentage: 0.03-0.05% of C, 0.45-0.48% of Mn, 12.76-12.79% of Cr, 6.12-6.15% of Ni, 0.16-0.18% of Mg, 0.22-0.25% of Mo, 0.27-0.29% of Co, 0.26-0.28% of V, 0.22-0.24% of Ti, 0.21-0.23% of Na, 0.12-0.15% of Ga, 0.32-0.35% of Eu, 0.12-0.14% of Lu, 0.62-0.68% of La, and the balance Fe.

Owner:南京创贝高速传动机械有限公司

Hot work die steel material and preparation method thereof

ActiveCN103911556AImprove temper stabilityImprove thermal fatigue resistanceChemical compositionThermal fatigue

The invention provides a hot work die steel material and a production process thereof. The hot work die steel material is characterized by comprising the following chemical components in percentage by weight: 0.36-0.44% of C, 0.10-0.25% of Ti, 0.10-0.50% of Mn, 0.15-0.20% of Nb, 5.0-5.5% of Cr, 0.20-0.25% of Mo, 1.0-1.5% of V, 0.10-0.15% of B, 1.50-2.00% of W, 0.50-0.70% of Si, less than or equal to 0.025% of S, less than or equal to 0.020% of P and the balance of Fe. The hot work die steel material has the characteristics of high tempering resistance and high thermal fatigue resistance.

Owner:JIANGSU LIANFENG ENERGY EQUIP

High-performance and high-speed-stamping cold work die steel and preparation method thereof

The invention relates to high-speed-stamping cold work die steel and a preparation method thereof. The high-speed-stamping cold work die steel is characterized by primarily comprising, by mass, 0.85%-0.95% of C, 0.80%-1.20% of Si, 0.30%-0.60% of Mn, 0.025% or less of P, 0.015% or less of S, 7.90%-8.40% of Cr, 1.40%-1.70% of Mo, 1.90%-2.20% of W, 2.20%-2.50% of V, 0.90%-1.20% of Al, 0.20% or less of Cu, 0.25% or less of Ni, and the balance Fe. By adding the alloy element, namely Al, the hardness, red hardness and the surface hardness and heat stability after nitriding of the steel are further improved; through addition of Mo, the hardenability, heat resistance, temper embrittlement resistance and temper softening resistance of the steel can be improved; and the high-speed-stamping cold work die steel has the remarkable beneficial effects of having high hardness, heat hardness and heat stability, meeting the development demand of modern industry, reducing consumption and increasing social benefits.

Owner:GUANGDONG STRONG METAL TECH

Corrosion-resistant metal coating used for outer surface of gear box

ActiveCN106498290AImprove corrosion resistanceImprove antistatic performanceNon-macromolecular adhesive additivesFilm/foil adhesivesMetal coatingCorrosion resistant

The invention discloses a corrosion-resistant metal coating used for the outer surface of a gear box. The corrosion-resistant metal coating comprises, by mass, 0.06%-0.08% of C, 0.15%-0.18% of Mn, 10.76%-10.79% of Cr, 2.12%-2.15% of Ni, 0.13%-0.15% of Mg, 0.21%-0.23% of Mo, 0.25%-0.27% of Co, 0.06%-0.08% of V, 0.42%-0.44% of Ti, 0.22%-0.25% of Na, 0.17%-0.19% of Ga, 0.22%-0.25% of Ce, 0.16%-0.18% of Nd, 0.32%-0.38% of La and the balance Fe.

Owner:南京创贝高速传动机械有限公司

Producing process of large-diameter core rod for rolling of mandrel pipe mill

The invention discloses a producing process of a large-diameter core rod for the rolling of a mandrel pipe mill, which has the advantage of prolonging the service life of the core rod. The producing process comprises the following steps of: steel raw material selecting, steel ingot smelting, core rod blank forging, primary aligning, surface rough turning, quenching and tempering, secondary aligning, and finish turning. After the rough turning is completed, the oxidization black scale on the depressed position of the core rod surface is removed before quenching and tempering. As the oxidization black scale is removed, the quality of the subsequent quenching and tempering can be ensured, the influence of oxidization black scale on the core rod quality is prevented, and the service life of the produced core rod is greatly prolonged; by restoring the cracks on the surface of the core rod by supplementary welding, the finished rate of the core rod is enhanced; as the secondary hardening treatment is adopted in the quenching and tempering process, the tempering stability of the core rod is increased, the friction resistance of the steel pipe in rolling is decreased, and the invention is especially suitable for producing large-diameter core rods.

Owner:攀钢集团成都钢铁有限责任公司 +1

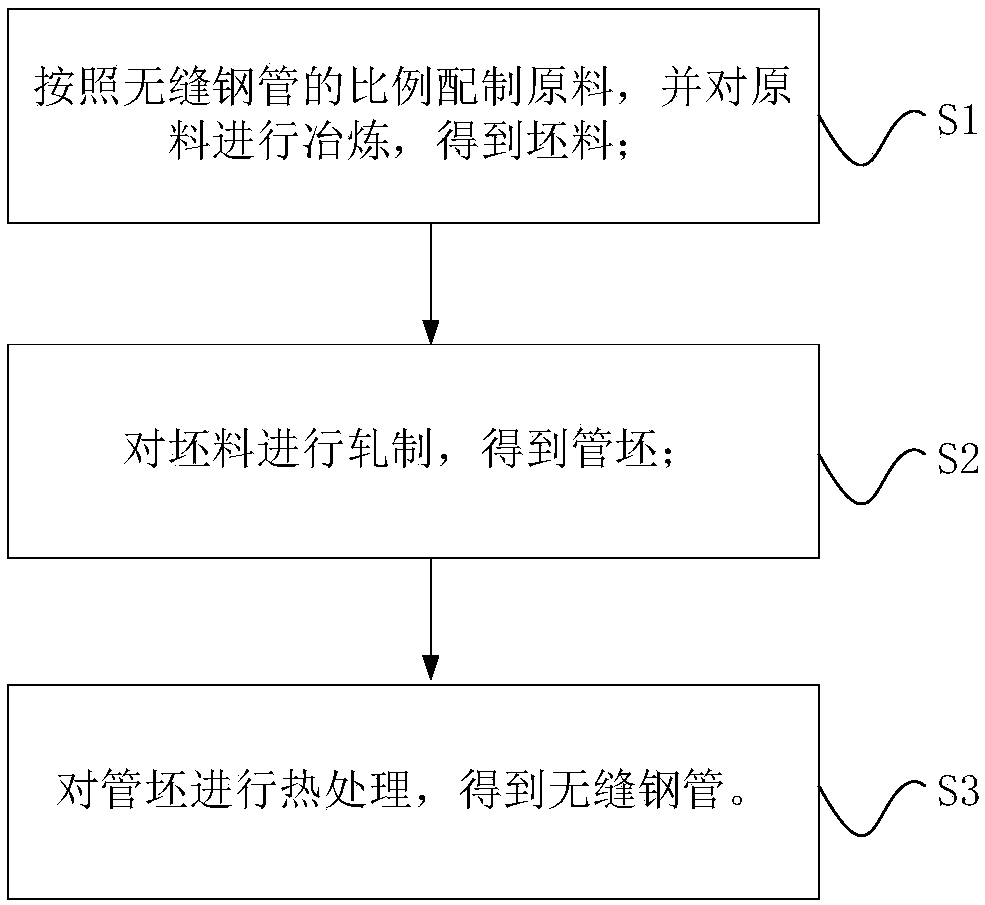

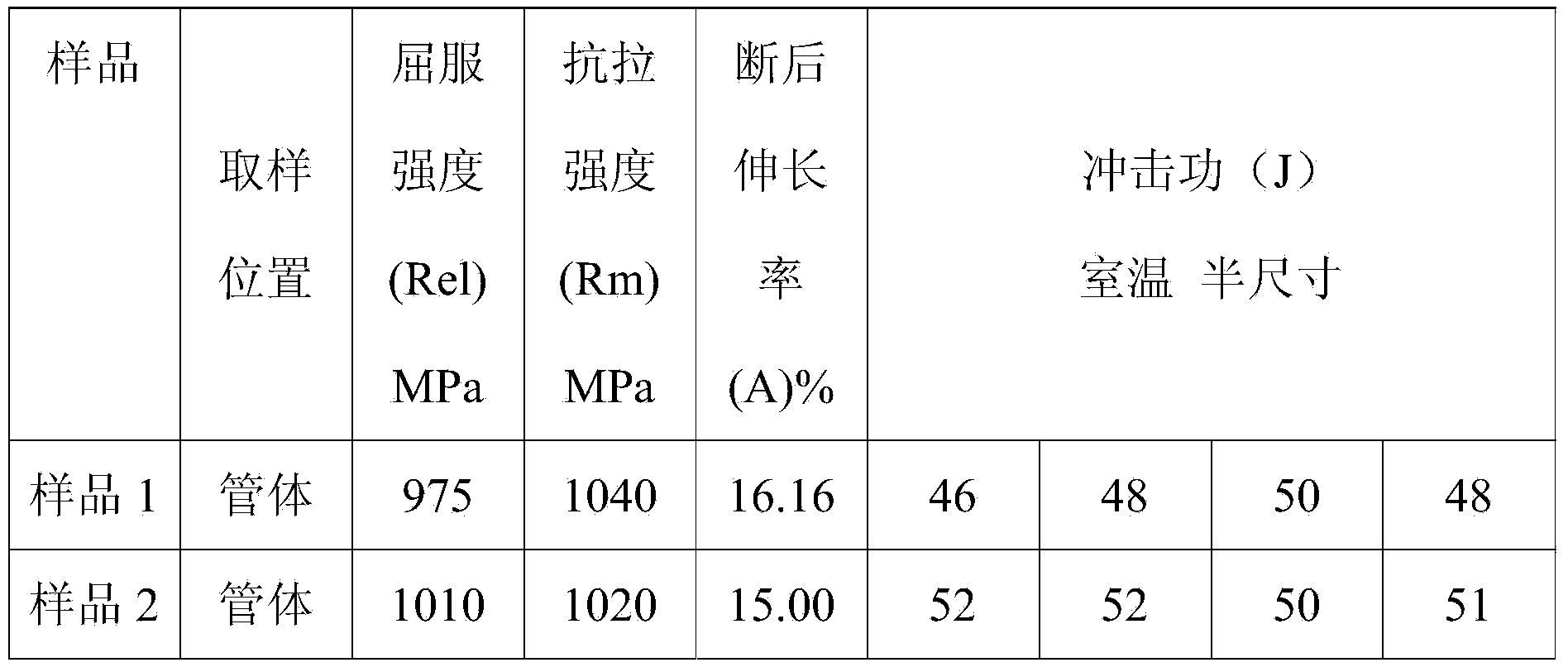

Seamless steel tube and preparation method of seamless steel tube

InactiveCN108660377AImprove toughnessHigh strengthProcess efficiency improvementRigid pipesHigh pressureUltimate tensile strength

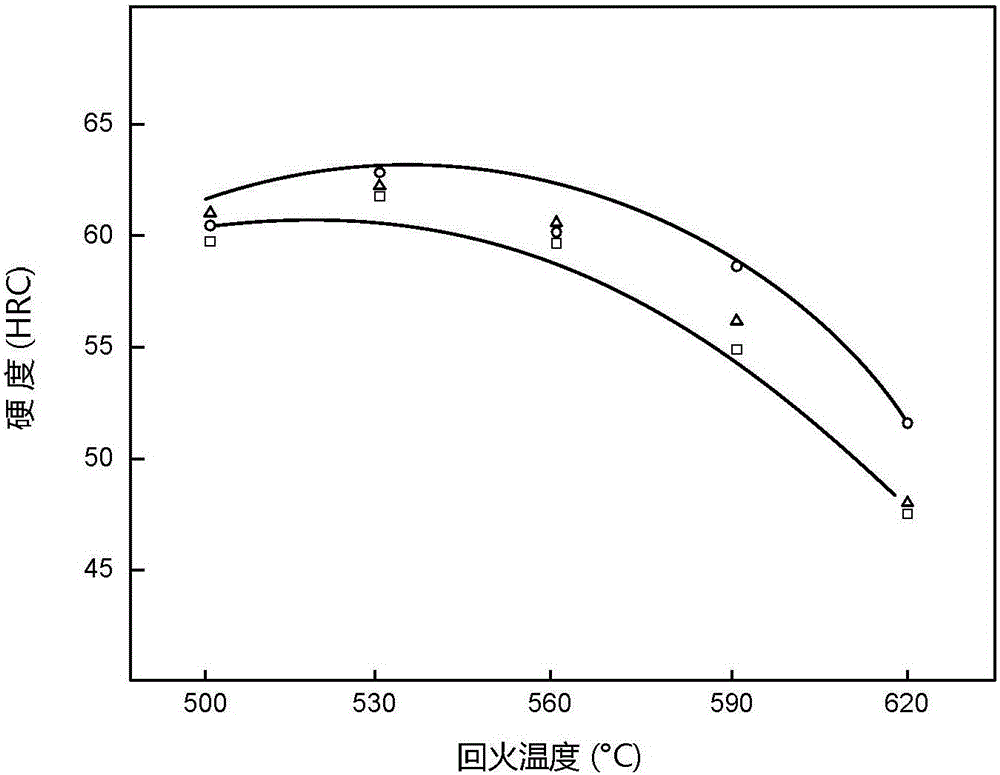

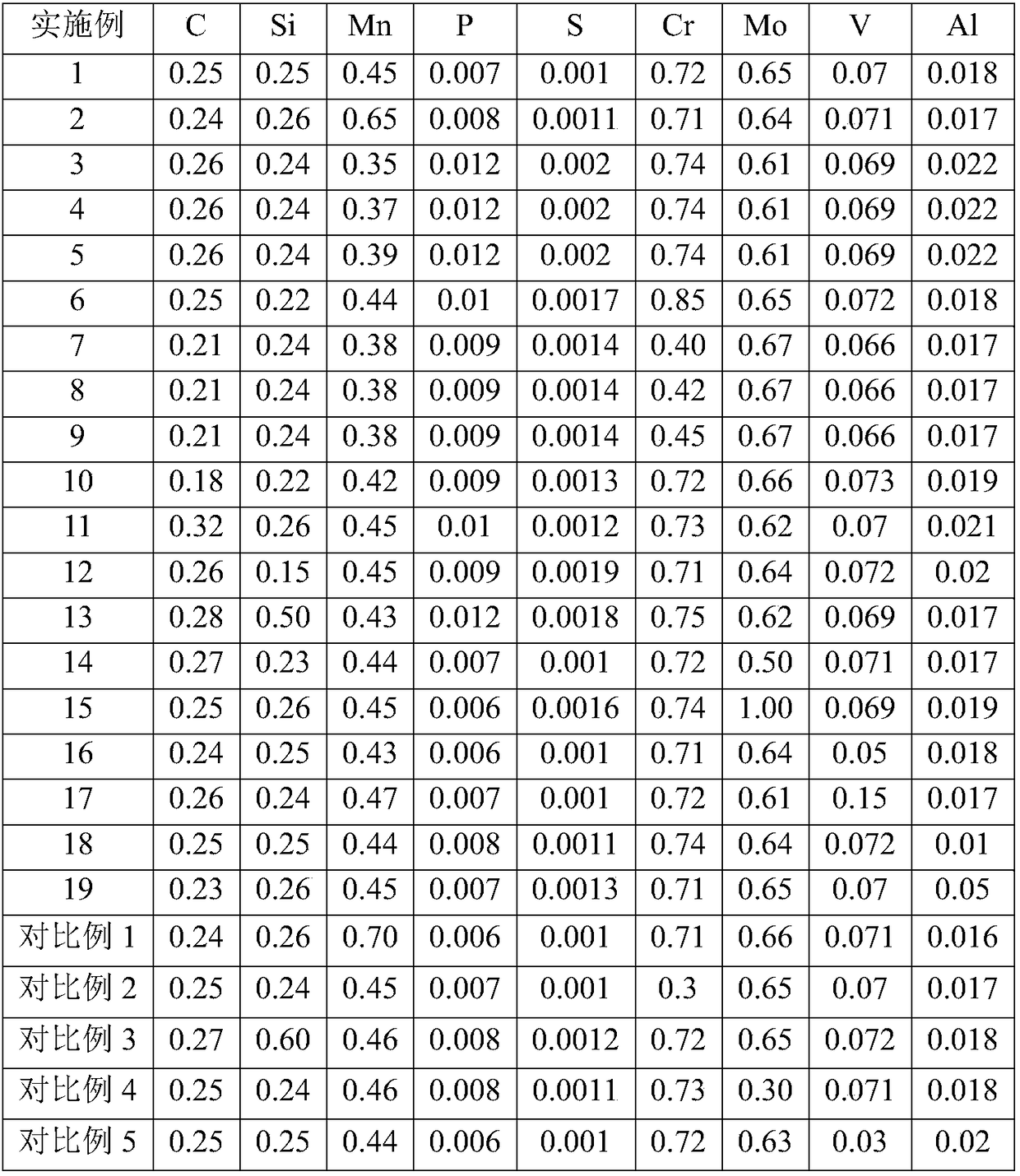

The invention provides a seamless steel tube and a preparation method of the seamless steel tube. Relative to the total weight of the seamless steel tube, the seamless steel tube is prepared from thefollowing components in percent by weight: 0.18-0.32% of C, 0.15-0.50% of Si, 0.35-0.65% of Mn, 0.40-0.85% of Cr, 0.50-1.00% of Mo, 0.05-0.15% of V, 0.01-0.05% of Al, less than 0.015% of P, less than0.003% of S and the balance Fe and inevitable impurities. By strictly controlling the chemical constituent contents of raw materials, the chemical components are reasonably proportioned, so that the strength, toughness and hydrogen sulfide stress corrosion resistance of the obtained seamless steel tube can meet the exploiting demands on high-pressure and high-temperature oil and gas fields in severe corrosive environments.

Owner:HENGYANG VALIN STEEL TUBE

Manufacturing method of high wearproof gear steel

ActiveCN111394639AIncrease contentImprove toughnessFurnace typesHeat treatment furnacesTemperingGear wheel

The invention relates to a manufacturing method of high wearproof gear steel. The manufacturing method comprises the following steps: 1, smelting, wherein molten steel comprises the following components: 0.15-0.60% of C, 0.50-1.3% of Si, 0.50-1.2% of Mn, 0.60-1.5% of Cr, equal to or less than 0.030% of P, equal to or less than 0.035% of S, 0.010-0.050% of Al, 0.008-0.025% of N and the balance of Fe; 2, pouring: pouring molten steel into steel billets; 3, rolling: after heating the steel billets, rolling the steel billets in a single-phase region at the initial rolling temperature of 980-1100 DEG C, sequentially carrying out intermediate rolling, pre finish rolling and finish rolling, during the rolling process, controlling cooling, after intermediate rolling, carrying out spraying coolingon the steel billets, after pre finish rolling, carrying out spraying cooling on the steel billets once more, then, carrying out KOCKS finish rolling, and controlling the finishing temperature to be 780-900 DEG C to obtain an unstable austenite; and 4, cooling: carrying out blast cooling the steel billets on a cooling bed, controlling the average cooling rate to be 40-80 DEG C / min and the final cooling temperature to be 300-480 DEG C, after final cooling, carrying out air cooling on the material to the room temperature, and in the cooling process, converting the austenite into ferrite and pearlite. After carburizing, quenching and tempering, the rolled steel has excellent wear resistance.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

High-alloy steel pipe piercing plugand manufacturing method thereof

InactiveCN104988416AHigh temperature strengthImprove toughnessMandrelsSolid state diffusion coatingUltimate tensile strengthToughness

The invention discloses a high-alloy steel pipe piercing plug. The high-alloy steel pipe piercing plug comprises the following chemical elements in percentage by mass: 0.25-0.35% of C, 0.35-1.5% of Si, 0.35-1.0% of Mn, 1.0-3.0% of Cr, 2.0-3.0% of Mo, 1.0-2.0% of Ni, 1.5-2.5% of W, 0.2-1.0% of V, and the balance of Fe and inevitable impurities; the surface of the high-alloy steel pipe piercing plug has an oxide film; and the outer surface of the high-alloy steel pipe piercing plug has a screw way. The invention further discloses a manufacturing method of the piercing plug; and the manufacturing method comprises the step of: manufacturing of a plug blank; annealing; machining of the steel pipe piercing plug and machining of the screw way on the surface of the plug; and formation of the oxide film through the surface high-temperature oxidation treatment. The piercing plug is higher in high-temperature strength and better in toughness. The oxide film on the surface of the piercing plug is excellent in adhesive force.

Owner:BAOSHAN IRON & STEEL CO LTD

Low-chromium wear-resisting steel ball

InactiveCN105331902AImprove temper stabilityAvoid grain coarseningFurnace typesHeat treatment furnacesChromiumCorrosion

The invention discloses a low-chromium wear-resisting steel ball. The low-chromium wear-resisting steel ball comprises, by weight, 0.7%-0.9% of C, 0.3%-0.5% of S, 0.8%-1% of Mn, 0.9%-1.1% of Cr, 0.07%-0.09% of Ni, 0.07%-0.09% of Mo, 0.03%-0.04% of Al, 0.3%-0.5% of Cu, 0.0005%-0.002% of B, 0.19%-0.21% of V, 0.01%-0.014% of P, 0.001%-0.0012% of S and the balance Fe. The low-chromium wear-resisting steel ball is high in wear resistance, good in toughness, high in impact resistance, resistant to corrosion and low in cost.

Owner:NINGGUO SOUTHERN WEAR RESISTANT MATERIALS

High-chromium wear-resistant steel ball and preparation method thereof

InactiveCN106191703AIncrease temperatureToughness to avoidFurnace typesHeat treatment furnacesWear resistantSteel ball

The invention discloses a high-chromium wear-resistant steel ball. The high-chromium wear-resistant steel ball comprises, by weight percentage, 1-1.5% of C, 0.5-0.7% of Si, 1.2-1.4% of Mn, 12-14% of Cr, 0.03-0.05% of Ni, 0.1-0.12% of Mo, 0.1-0.3% of W, 0.08-0.1% of Al, 0.1-0.2% of Cu, 0.003-0.004% of B, 0.02-0.03% of Ti, 0.2-0.3% of Nb, 0.15-0.2% of V, not larger than 0.2% of P, not larger than 0.01% of S and the balance Fe, wherein the expression of Nb+10.3(C / Cr)<1.55% is met. The invention further discloses a preparation method of the high-chromium wear-resistant steel ball. The high-chromium wear-resistant steel ball and the preparation method have the beneficial effects that wear resistance is good and toughness is high.

Owner:ANHUI RUITAI NEW MATERIALS TECH

High-toughness austenite type high-manganese steel plate and production method thereof

InactiveCN107858602AAvoid or reduce low temperature brittle phenomenonGuaranteed yieldSheet steelChemical composition

The invention discloses a high-toughness austenite type high-manganese steel plate and a production method thereof. The steel plate consists of the following chemical components in percentage by massof 0.30-0.40% of C, 0.20-0.40% of Si, 23.50-25.50% of Mn, 7.0-7.5% of Cr, 0.020-0.040% of Al, 0.020-0.040% of Nb, less than or equal to 0.008% of P, less than or equal to 0.003% of S and the balance Fe and inevitable impurities. The production method for the steel plate comprises processes of steel-making, continuous casting, heating, rolling and thermal treatment. The chemical components of the steel plate adopt C, Mn and Cr solid solution strengthening; and the obtained steel plate has the characteristics of being high in compactness, relatively high in strength grade, high in ductility, lowin yield ratio, excellent in low-temperature impact toughness and the like, can meet requirements of the high-toughness austenite type high-manganese steel plate, has relatively good comprehensive performances and welding performances, and is relatively low in cost.

Owner:WUYANG IRON & STEEL

Trenchless drill rod steel

The invention discloses a trenchless drill rod steel. The trenchless drill rod steel comprises, by mass, 0.26-0.29% of C, 0.17-0.37% of Si, 1.05-1.30% of Mn, 0.010% or less of S, 0.015% or less of P, 0.80-1.10% of Cr, 0.20-0.25% of Mo, 0.10% or less of Ni, 0.07-0.15% of V, 0.1% or less of Cu, 0.015% or less of As, 0.010% or less of Sn, 0.003% or less of Pb, 0.010% or less of Sb, and the balance Fe and inevitable impurities. The steel is hardened and tempered, so the performances of the hardened and tempered steel accord with S135 steel grade standards; the nitridation temperature does not influence the performances of hardened and tempered steel pipes in a subsequent nitridation process; and added alloy elements have a high cost performance, so the obtained steel can be used as trenchless drill rod steel.

Owner:WUXI DOUBLE HORSE DRILLING TOOLS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com