Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

113results about How to "Eliminate casting defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

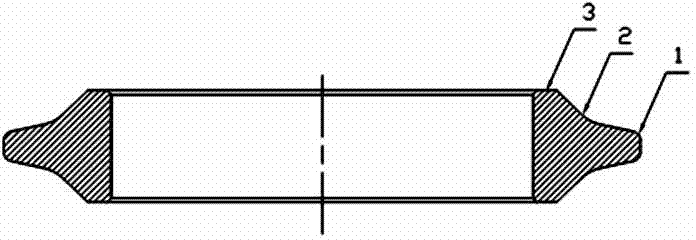

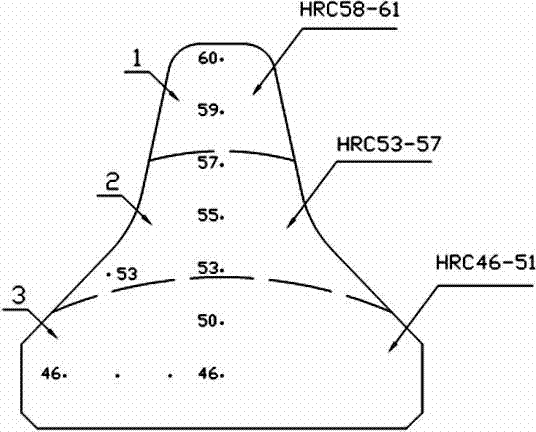

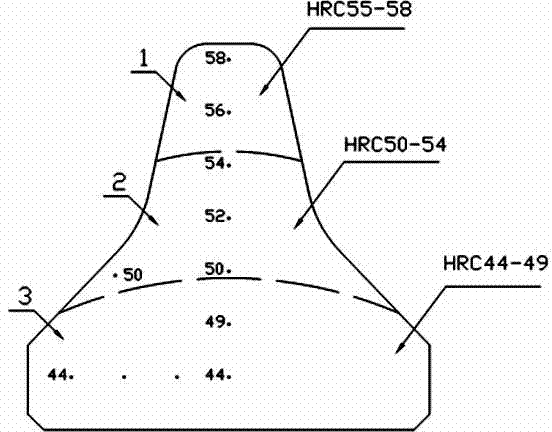

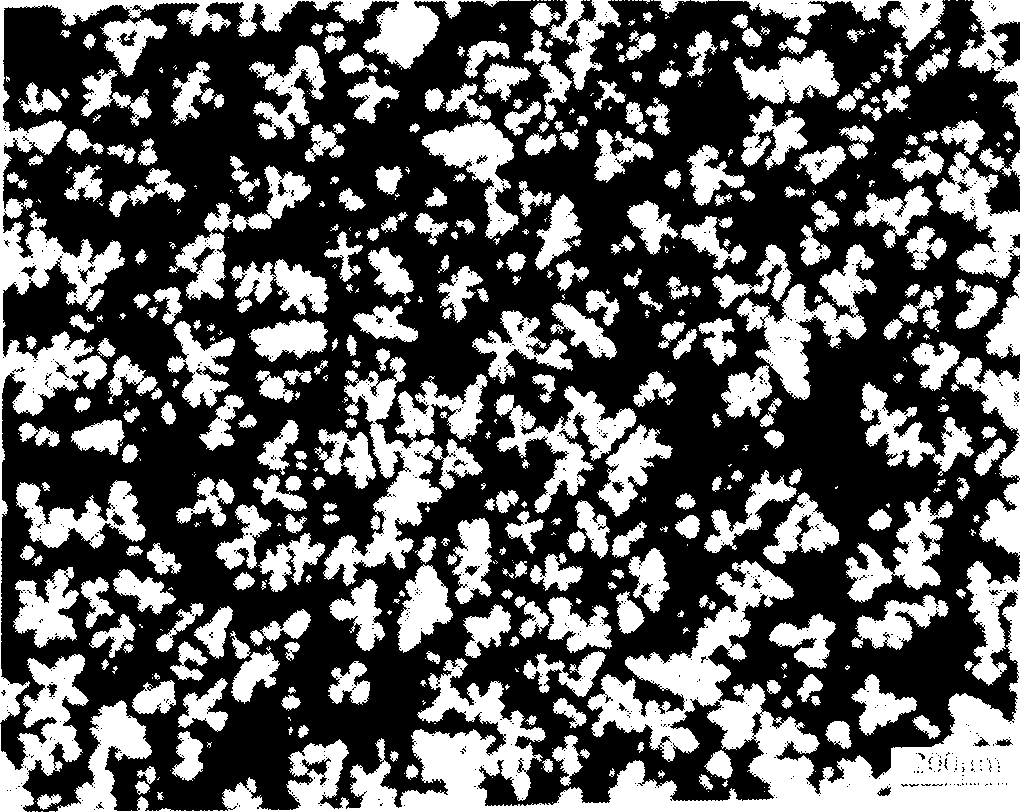

Disk-shaped roller cutter ring and manufacture method thereof

ActiveCN102517502AGuaranteed hardenabilityImprove toughnessFurnace typesHeat treatment furnacesMedium frequencyHardness

The invention discloses a disk-shaped roller cutter ring with high hardness, good toughness and excellent comprehensive performance. The disk-shaped roller cutter ring comprises the following ingredients of: 0.46-0.56% of C, 0.80-1.20% of Si, 0.20-0.65% of Mn, 5.00-5.80% of Cr, 1.15%-1.55% of Mo, 0.85-1.40% of V and the balance Fe and impurities, wherein the content of P is no more than 0.02%, and the content of S is no more than 0.01%; and the overall hardness of the cutter ring is HRC55-61 (Rockwell Hardness C55-61), or the hardness is of graded distribution, i.e. the hardness of a working edge area is HRC55-61, the hardness of a transition surface area is HRC50-57, and the hardness of a step assembly surface area and an inner ring is HRC44-51. A preparation method of the disk-shaped roller cutter ring comprises the following steps of: smelting the raw materials in an electric furnace; carrying out electroslag remelting; preforging; carrying out die forging; carrying out slow cooling; annealing; carrying out rough machining to obtain a disk-shaped roller cutter ring rough blank; carrying out high-temperature vacuum hardening and two-time high-temperature tempering on the cutter ring rough blank; carrying out low-temperature destressing treatment; carrying out fine finishing to obtain the cutter ring with the overall hardness of HRC55-61, wherein the cutter ring with the overall hardness of HRC55-61 is applicable to the tunneling of a hard rock formation by a shield tunneling machine; or carrying out medium-frequency induction tempering treatment prior to the low-temperature destressing treatment to obtain the cutter ring with graded-distribution hardness, wherein the cutter ring with the graded-distribution hardness is applicable to the tunneling of a rock formation with an upper soft part and a lower hard part.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

Casting and forging combined technique of aluminum alloy linkage rod

InactiveCN101486087AEnsure billet qualitySimplify the traditional die forging processEngine componentsRheniumRare-earth element

The invention discloses technology for casting and forging an aluminum alloy connecting rod, wherein an aluminum alloy composition of the connecting rod is adjusted by addition of rare earth element in casting technology, and the addition of the rare earth element is 2 to 5 percent of an aluminum liquid; the aluminum alloy connecting rod is guaranteed to comprise the following compositions: 88 to 94 percent of aluminum, 3.8 to 4.9 percent of copper, 0.5 to 1.5 percent of silicon, 0.4 to 1.2 percent of manganese, 0.4 to 1.0 percent of magnesium, 0.8 to 1.8 percent of rhenium and 0.4 to 0.14 percent of iron; and a casting head is not cut off and reheated in the casting technology and taken as one part or a scrapped part of a forged piece, and casting afterheat is utilized for forging. The technology simplifies the prior die forging technology, improves reasonable floatation, the streamline and mechanical properties of casting metals, improves a metallurgical structure close to the casting head on the forged piece, and has the effects of high technological utilization rate of materials, shortened technological process and energy conservation and consumption reduction. Moreover, the casting and forging technology can obviously improve the internal quality and the mechanical properties of casting blanks, and the production cost of the casting blanks is lower than that of the prior die forging.

Owner:DANYANG RONGJIA PRECISION MACHINERY

Cast Al-Si alloy

The cast Al-Si alloy consists of Si 11.0-13.5 wt%, Mg 0.15-0.55 wt%, Sr 0.015-0.080 wt%, B 0.010-0.050 wt%, Cu <0.20 wt%, Fe <0.20 wt%, Zn <0.10 wt%, Mn <0.10 wt%, Ti <0.10 wt%, each of other impurity<0.05 wt%, total impurity content<0.15 wt%, and Al the rest. The cast Al-Si alloy has Si content near the eutectic point of the alloy, and its alloy liquid has excellent flowability, powerful shrink feeding capacity, low gas absorption and less casting defaults. The cast Al-Si alloy has high toughness and lowered casting mold cost.

Owner:SOUTHEAST UNIV

Surface or local gradient reinforced wear resistant manganese steel composite material and preparing process

InactiveCN1616706AUniform and small sizeGood wettabilitySolid state diffusion coatingWear resistantHardness

The present invention relates to surface or locally gradient reinforced antiwear composite manganese steel material and its preparation process. The composite material has matrix of austenite with relatively high toughness; reinforcing layer comprising TiC with relatively high hardness, martensite and metastable austenite; and intermediate transition layer comprising gradient varying TiC, martensite and austenite. The preparation process includes the following steps: designing metastable austenite manganese steel matrix composition with C 0.8-1.3 wt% and Mn 6-13 wt%; setting Ti-Fe alloy powder as composite medium in special parts of the cast mold and casting high temperature manganese steel melt to obtain the surface or local TiC reinforcement plus metastable austenite as-cast structure; and liquid nitrogen deep cooling the surface or local to obtain phase changed gradient martensite layer. The present invention can raise comprehensive mechanical performance of manganese steel.

Owner:JILIN UNIV

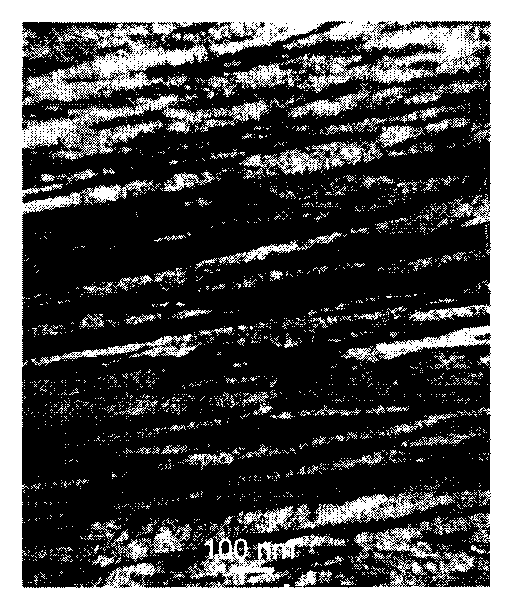

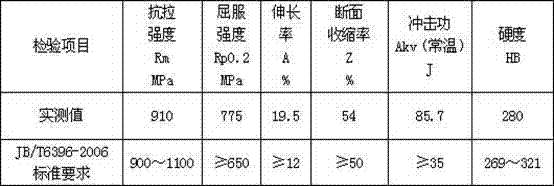

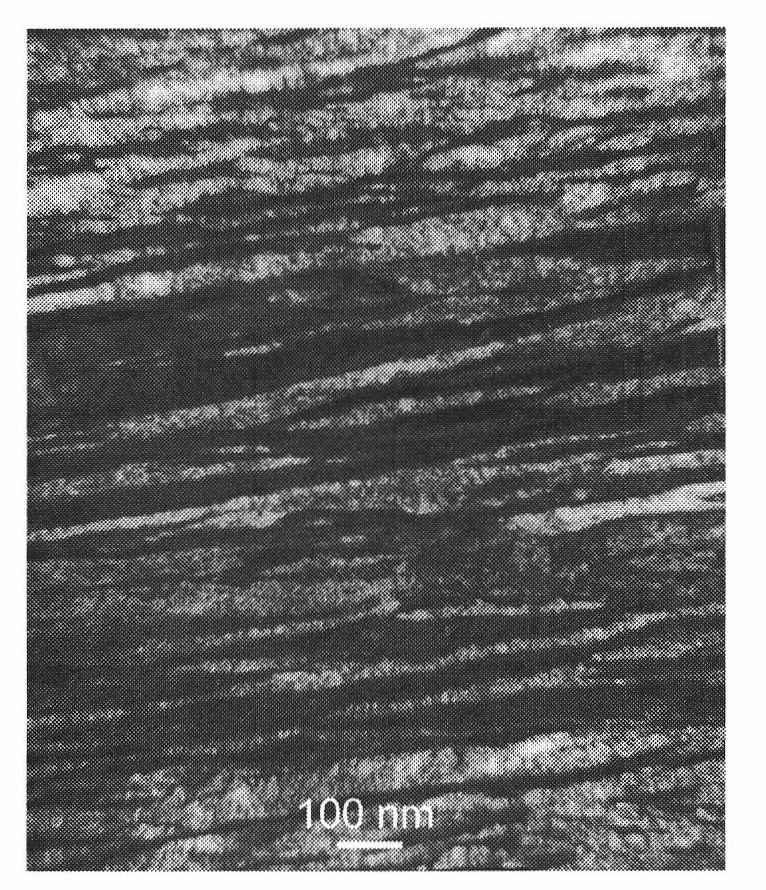

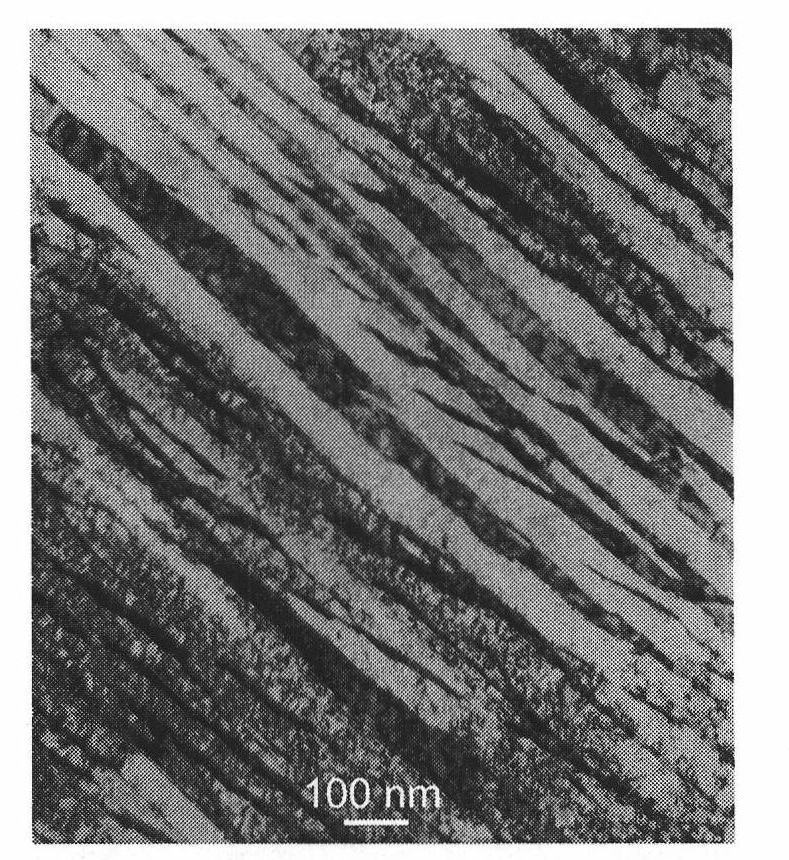

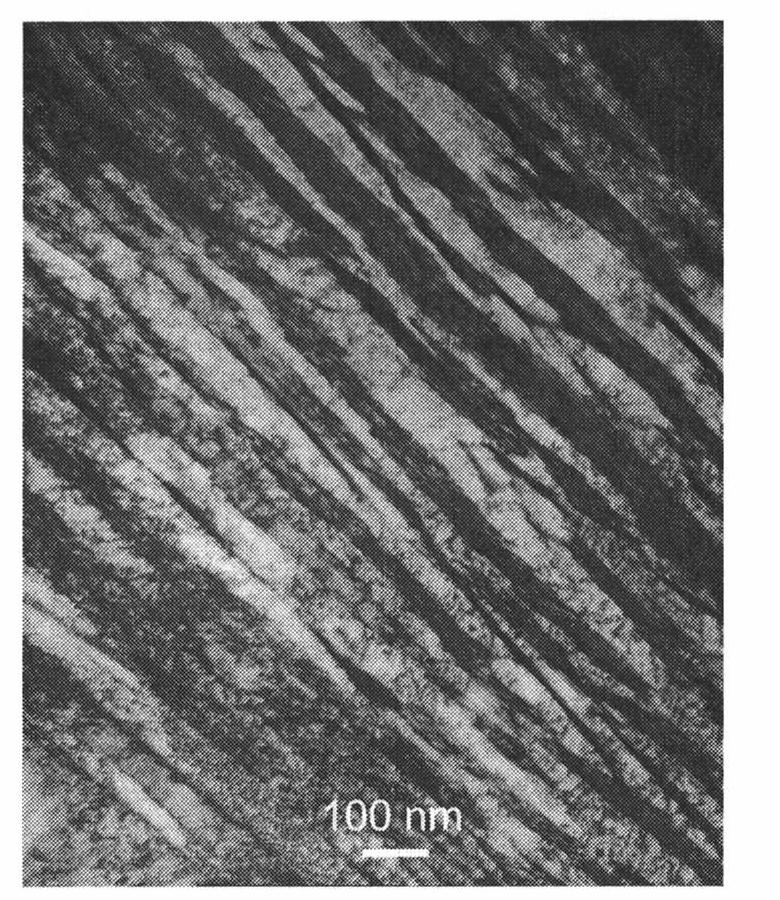

Preparation method of low-alloy high-carbon steel with high-strength and high ductility nano structure

InactiveCN101693981AHigh tensile plasticity and impact toughnessShort heat treatment cycleDuctilityChemical composition

The invention discloses a preparation method of a low-alloy high-carbon steel with a high-strength and high ductility nano structure, which is characterized in that the steel contains the following chemical components in percent by weight: 0.7-0.9 percent of C, 1.4-1.6 percent of Si, 1.2-1.4 percent of Mn, 1.4-1.6 percent of Al, 0.7-0.9 percent of Cr, 0.7-0.9 percent of W, less than 0.02 percent of P, less than 0.02 percent of S and the balance of Fe. The preparation method comprises the following steps: melting the chemical components according to the weight percent, pouring to form a steel ingot and slowly cooling to the room temperature; heating the steel ingot to 1,160-1,180 DEG C, cogging, and hot rolling to form a plate blank with the thickness being less than 25 mm, wherein the finally rolling temperature is 990-1,010 DEG C; rapidly putting the plate blank into a salt bath with the temperature of 220-260 DEG C after the rolling, and keeping the constant temperature for 4-24h, and then cooling in the air to the room temperature to obtain the low-alloy high-carbon steel with a high-strength and high ductility nano structure, wherein a microstructure comprises bainitic lath ferrites with the thickness of 60-90 nm and residual austenite and has the tensile strength of 2,000-2,300MPa, the yield strength of 1,500-1,900MPa under the condition of 0.2 percent of strain, the total elongation percentage of 6.7-7.8 percent and the uniform elongation percentage of 3.8-5.6 percent; and the Charpy measured by the ASTM:E23-02 standard, i.e. room-temperature impact work of a U-shaped notch specimen, is 7-22J. The invention has simple preparation process, direct constant temperature process in the salt bath after the hot rolling, short period of thermal treatment, low cost and easy application in production.

Owner:YANSHAN UNIV

Steel ring billet casting technique based on casting and rolling combined forming

ActiveCN104439219AReduce heating timesSave blankingMolten metal pouring equipmentsFurnace typesTemperingCasting mold

The invention discloses a steel ring billet casting technique based on casting and rolling combined forming. The steel ring billet casting technique based on casting and rolling combined forming comprises the steps that firstly, a casting mold is manufactured by means of water glass sand, the casting mold is dried and sprayed with painting, casting raw materials of a steel ring are smelted and are poured into the casting mold, and normalizing, tempering and quenching-tempering heat treatment are conducted on a steel ring billet formed through pouring; secondly, the steel ring billet is cooled to the room temperature, and polishing and machining are conducted on the cooled steel ring billet; finally, the steel ring billet which can be directly used for casting and rolling combined forming is obtained. According to the steel ring billet cast according to the technique, the defects, such as shrinkage cavities, shrinkage porosity and segregation, appearing in the steel ring billet casting process can be reduced, grains are refined to the maximum extent, and the high-quality steel ring billet capable of meeting the requirement for the ring rolling performance is manufactured; due to the fact that the processes of the casting and rolling combined forming technique are simplified, the quality and performance of the ring rolling technique and a ring workpiece are guaranteed.

Owner:盐城市大丰区生产力促进中心

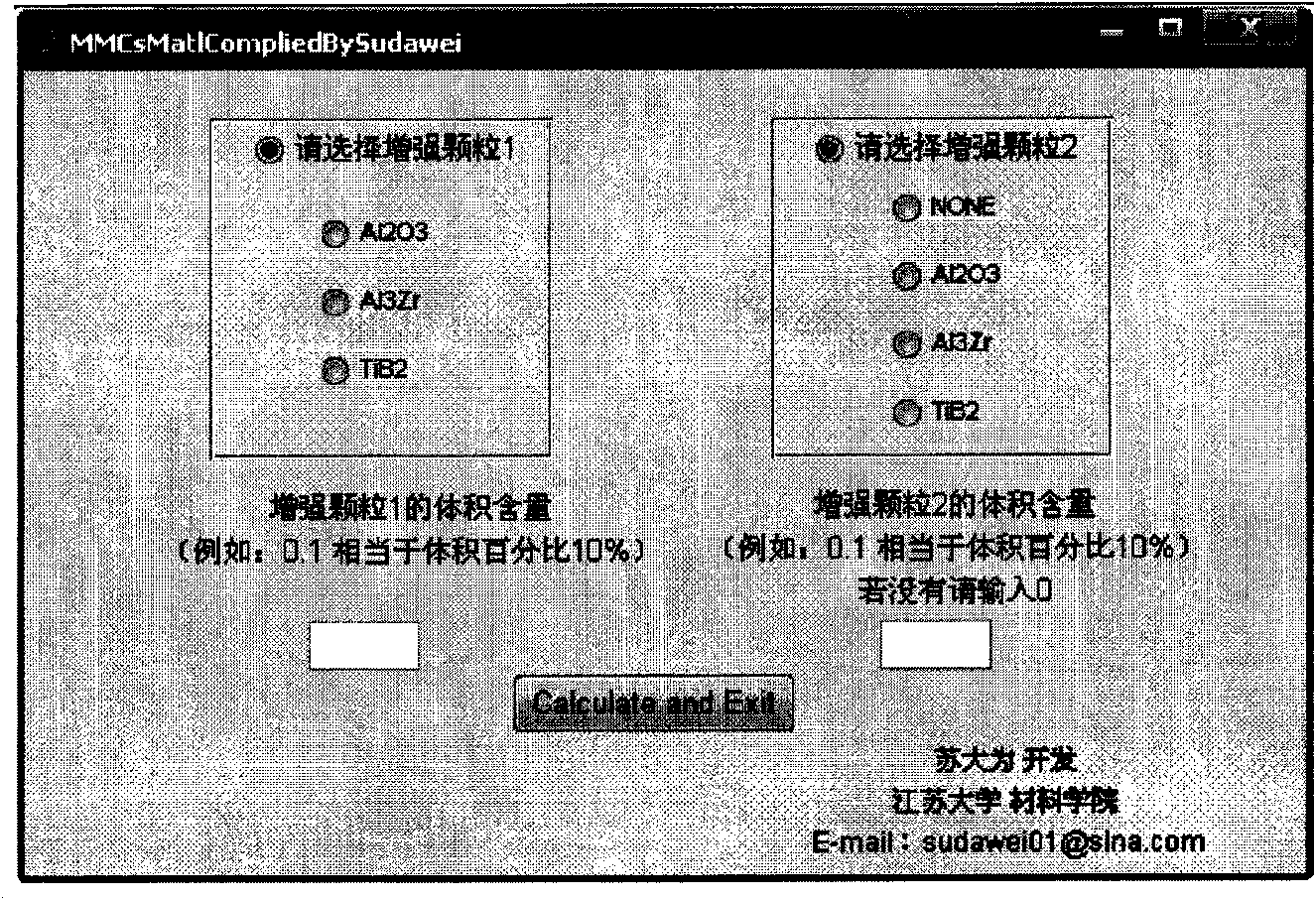

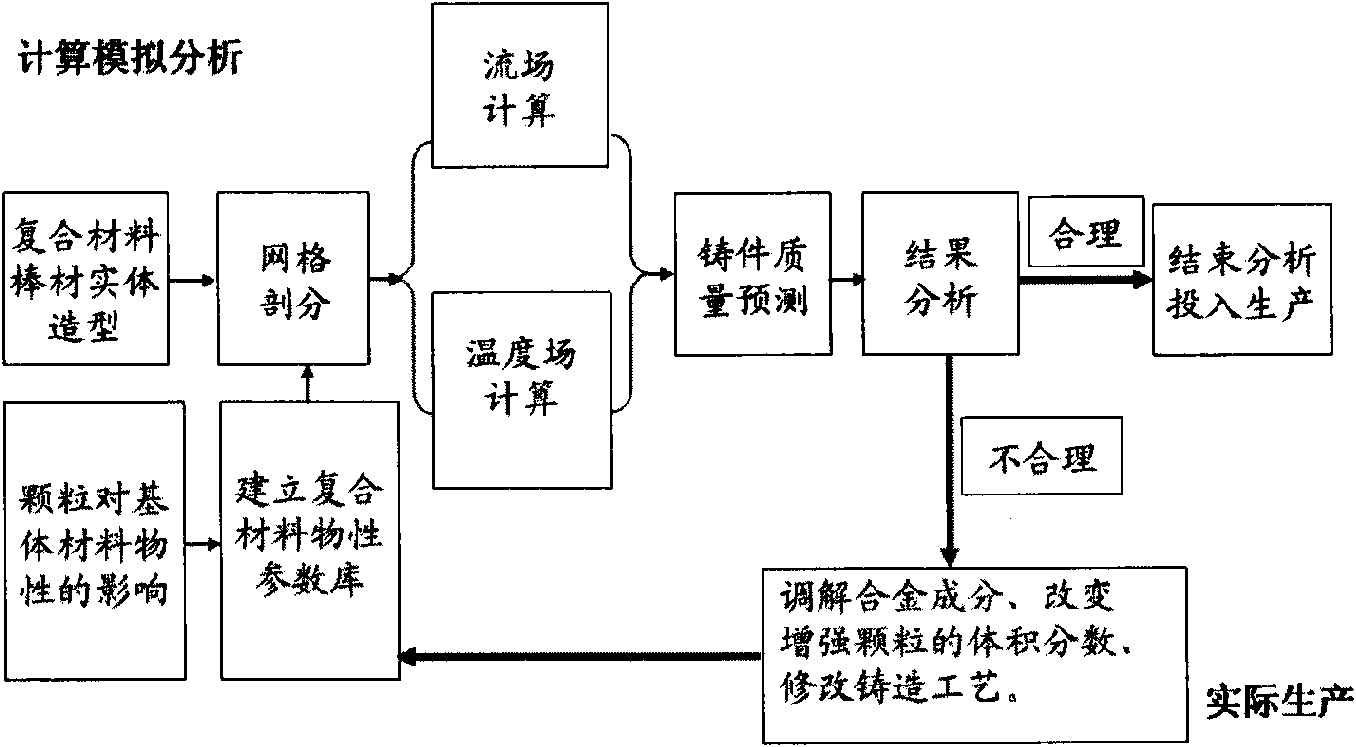

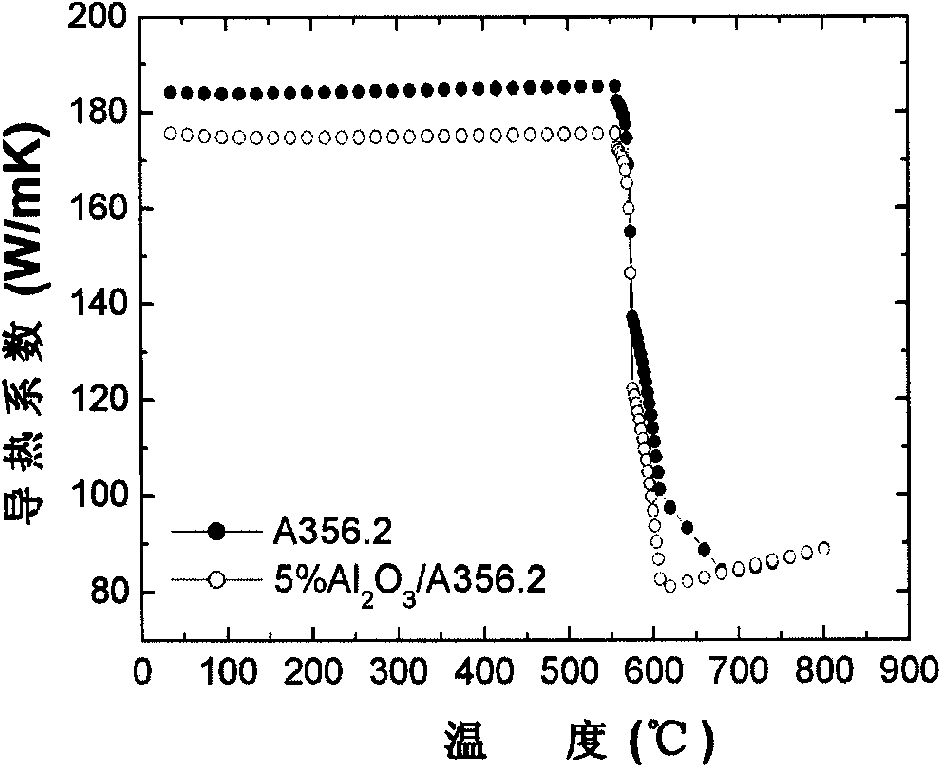

Computer simulation method for casting property of particle-reinforced aluminum matrix composite

InactiveCN101567019AGood casting processEliminate casting defectsSpecial data processing applicationsBoundary valuesSpatial structure

The invention relates to a computer simulation method for the casting property of a particle-reinforced aluminum matrix composite, which comprises the following steps: acquiring volume fraction or mass fraction of a reinforcement particle of an aluminum matrix composite to be analyzed input into a computer and mass fraction of a matrix composition; calculating and determining physical parameters of a metallic matrix composite by using the data through a performance calculation program of the metallic matrix composite; dividing a space structure grid of a component to be cast, and determining boundary value conditions of the casting process; calculating a flow field, a temperature field and a stress field of the boundary value conditions and cooling parameter added value; analyzing the casting property of the composite according to the calculation result; and if the casting performance is not satisfied, recalculating until a satisfied product is obtained by adjusting the casting process or the addition of the reinforcement particles or adjusting the alloy content in the range of an allowable alloy content. The computer simulation method has the advantages of improving the yield, shortening a new product development cycle, and reducing the cost.

Owner:JIANGSU UNIV

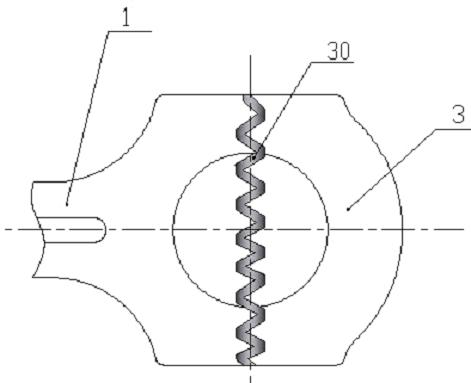

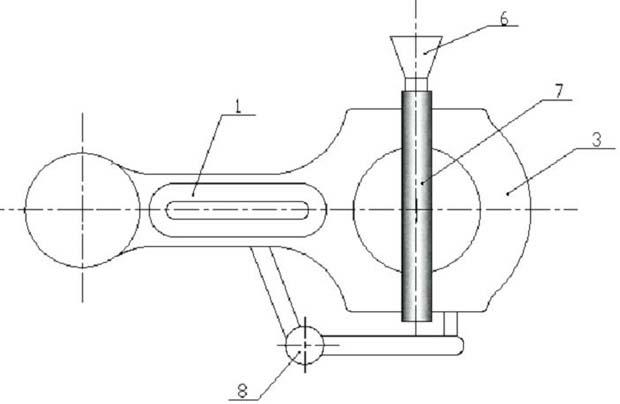

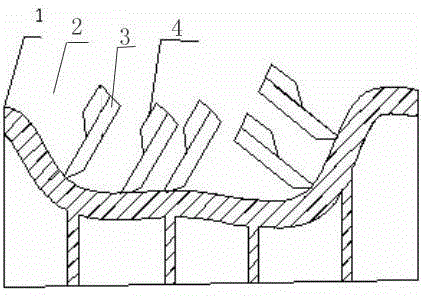

Manufacturing method of composite double-metal cracking connecting rod

InactiveCN102626777ABroaden your optionsGuarantee the performance of the main bodyConnecting rodsShaftsHigh loadMechanical engineering

The invention relates to a manufacturing method of a composite double-metal cracking connecting rod. The method disclosed by the embodiment of the invention comprises the following steps of: arranging a movable isolating plate at a big head part of a connecting rod cavity; dividing the mold cavity into two independent parts; firstly casting a connecting rod body and a connecting rod cover by adopting materials of a connecting rod main body; when large parts of the connecting rod body and the connecting rod cover are solidified, pulling out the isolating plate from the mold cavity, then injecting materials for cracking areas into the cavity formed after the isolating plate is pulled, and forming a composite double-metal casting piece by combining two materials in a metallurgical manner; and then finishing cracking separation for the connecting rod body and the connecting rod cover along preset cracking surfaces by adopting cracking equipment, and carrying out positioning and accurate assembly by utilizing a meshed intertongue structure on the two cracking surfaces. The manufacturing method of the composite double-metal cracking connecting rod has the advantages that the material selection range of the cracking connecting rod is expanded, the process is simple and feasible, the cost is low, and the assembling accuracy of the connecting rod is high; the technology is also suitable for manufacture of high-power engine connecting rods so as to meet the requirement for bearing high-load and large-torque connecting rods; and the process method has a wide application prospect.

Owner:JIANGSU UNIV

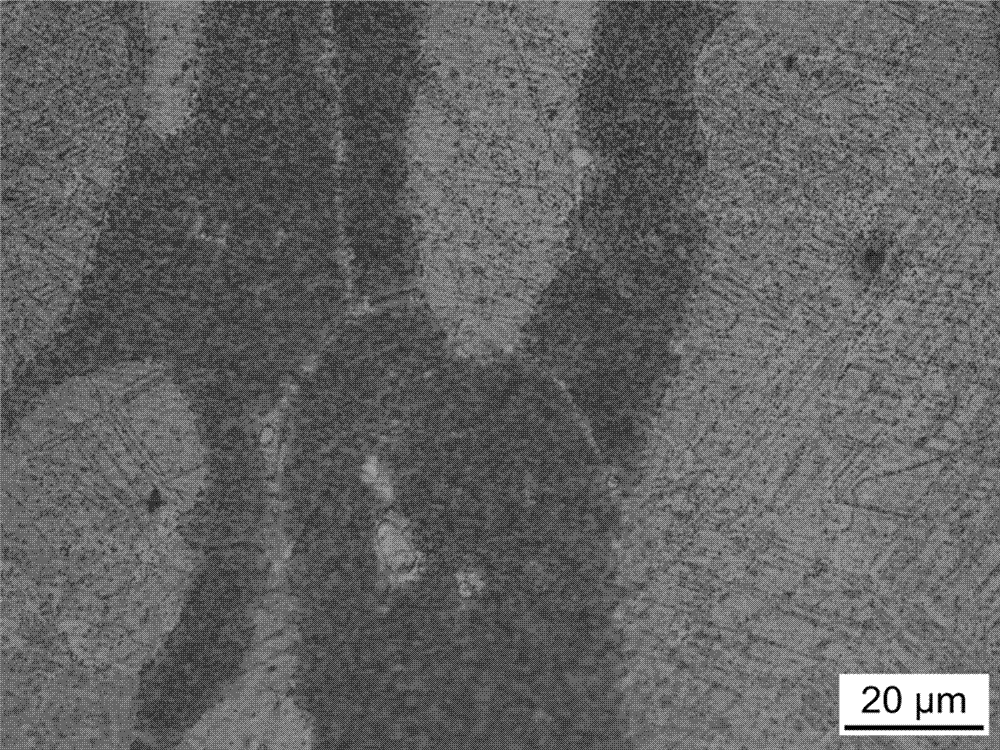

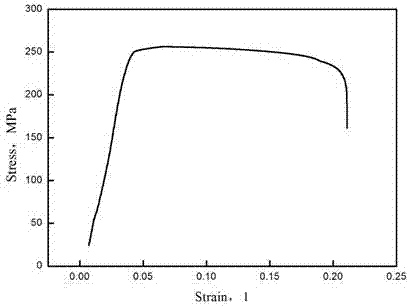

Low-Li high-plasticity high-strength Mg-Li alloy and preparation method of Mg-Li alloy plate

The invention discloses a low-lithium high-plasticity high-strength Mg-Li alloy prepared from the following components in percentage by mass: 4-7% of Li, 2-6% of Al, 0.5-3% of Zn, 0.2-1% of Mn, 0.1-1% of RE, 0-0.05% of Ti+B, less than 0.3% of impurities and the balance of Mg. The invention also discloses a preparation method of an Mg-Li alloy plate. The preparation method comprises the following steps: proportioning, smelting, casting, homogenizing, extruding, rolling and annealing. The Mg-Li alloy related to the invention is relatively low in Li content and relatively high in strength and corrosion resistance; meanwhile, due to the addition of Li, a close-packed hexagonal crystal structure of Mg is changed, the alloy has relatively high plasticity and can be subjected to cold-rolling deformation; and the adopted extrusion rolling process is simple in operation, the finished product rate is relatively high, and the obtained plate has favorable overall performances.

Owner:郑州轻研合金科技有限公司

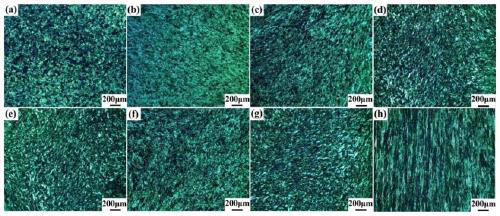

Composite technique for rolling semi-solid state copper-lead bearing alloy/steel bi-metal

InactiveCN101244430ASolve the problem of lead segregationPromote interdiffusionTemperature control deviceWork treatment devicesRare earthComposite plate

The invention relates to a roll-bonding process for semisolid copper-lead bearing alloys / steel bimetals. The weight content percentage of the lead in the copper-lead bearing alloy is 10.0 to 30.0%. In order to refine the crystalline grain of the lead and improve the mechanical property of the alloy, sulfur, tin, nickel, manganese, rare earth and other the third alloy elements can be added in the copper-lead alloy. The process comprises four steps: pretreatment of steel plates, preparation of semisolid sizing agent, roll bounding and water cooling. The detailed process comprises the following steps: performing mechanical agitation to the melted copper-lead bearing alloys at 930 to 1050 DEG C to obtain the semisolid sizing agent; pouring the semisolid sizing agent on the pretreated steel plates; synchronously feeding the semisolid copper-lead bearing alloys and solid steel plates in to a mill for rolling; spraying water for cooling to obtain the bimetallic composite plate. The invention effectively overcomes the defect of lead segregation in the production of the copper-lead bearing alloys in the prior art, therefore, metallographic structure with fine lead particle and even distribution is obtained. According to mechanical test results, the interfacial shear strength of the copper-lead bearing alloys / steel bimetallic slabs prepared using the process is more than 60Mpa, increased by about 10Mpa.

Owner:UNIV OF SCI & TECH BEIJING

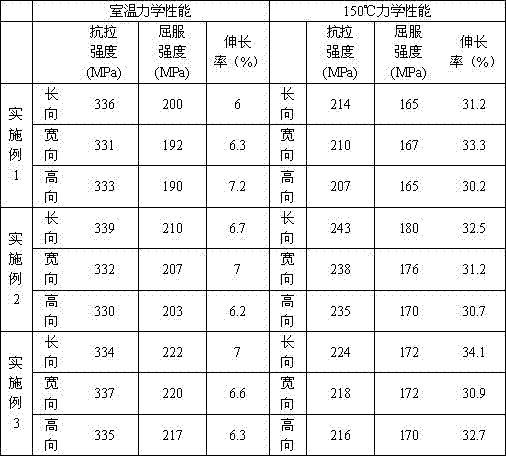

Forging process for eliminating anisotropism of large-sized AQ80M magnesium alloy bearing member

The invention relates to a forging process for eliminating anisotropism of a large-sized AQ80M magnesium alloy bearing member and belongs to the technical field of magnesium alloy material machining. The process specifically includes the steps that an ingot blank is prepared; extrusion blooming is performed with the low extrusion ratio, specifically, extrusion is performed on an extruding machine with the extrusion ratio being 3-4 and the extrusion speed being 0.3-2.8 mm / s; cooperating with intermediate annealing, multiple passes of direction-changing heading are performed on a hydraulic press so that the blank can be forged into a large-sized magnesium alloy bearing member; and the magnesium alloy bearing member is subjected to aging treatment. By means of the forging process, preparation of magnesium alloy bearing members with the size being larger than 470*390*170 mm<3> can be achieved; after aging treatment is finished, the yield strength difference among the length direction, the width direction and the height direction is smaller than or equal to 10 MPa at both the room temperature and the temperature of 150 DEG C; and the problem of anisotropism of large-sized magnesium alloy parts is solved.

Owner:湖南镁宇科技有限公司

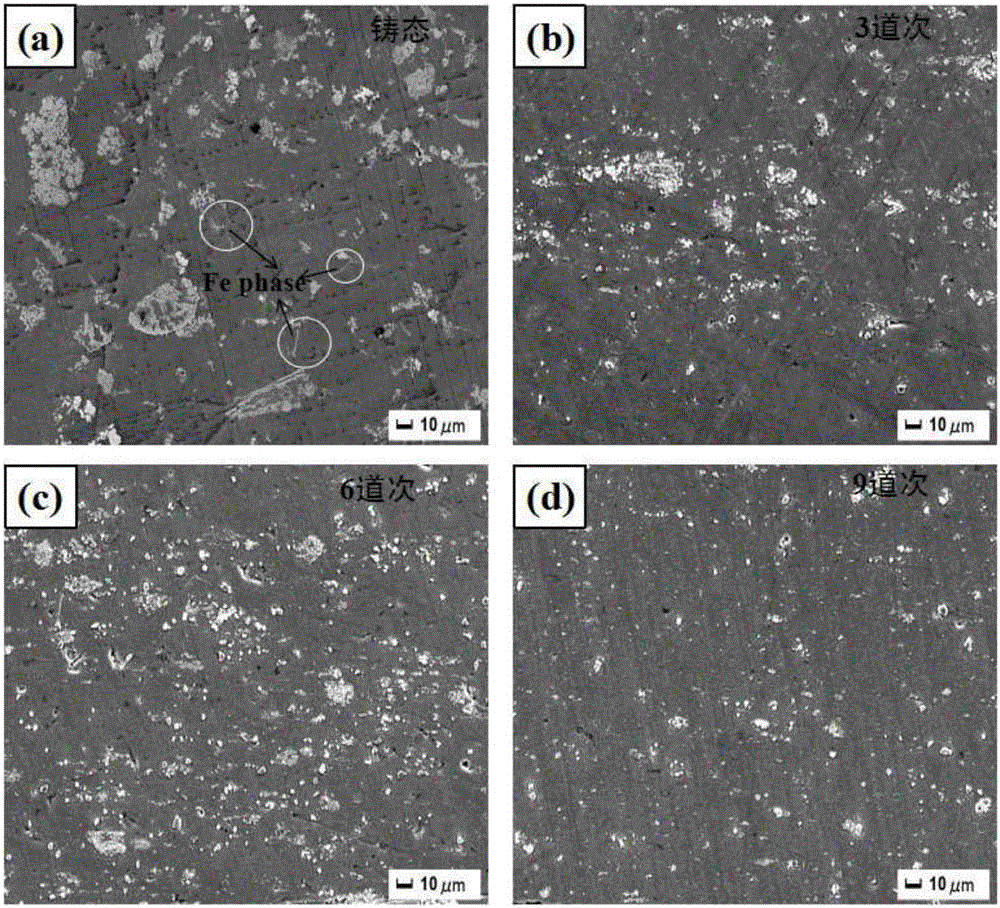

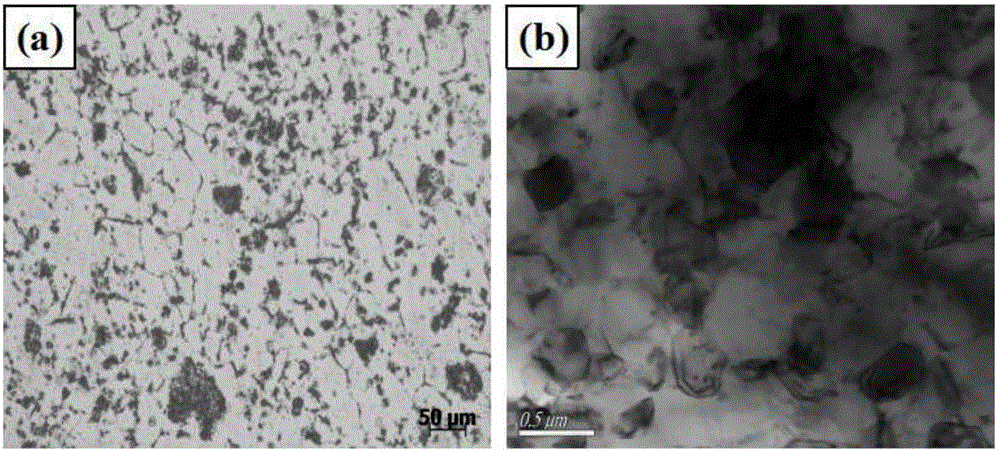

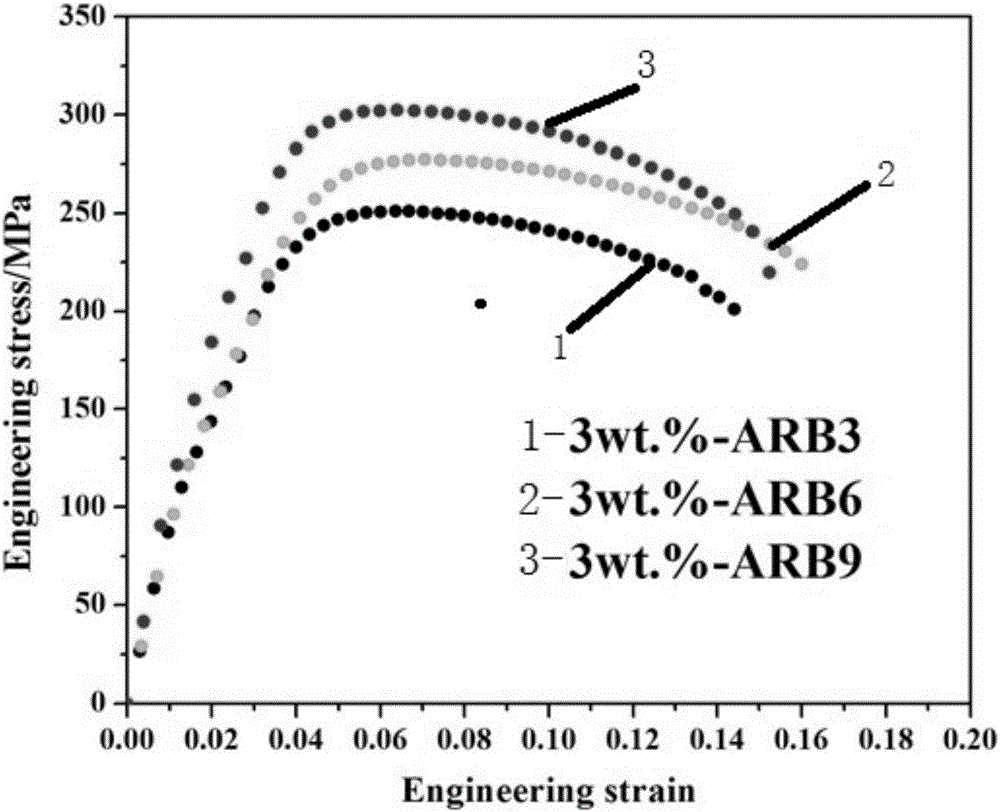

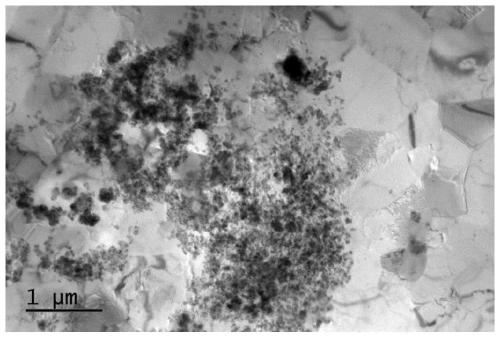

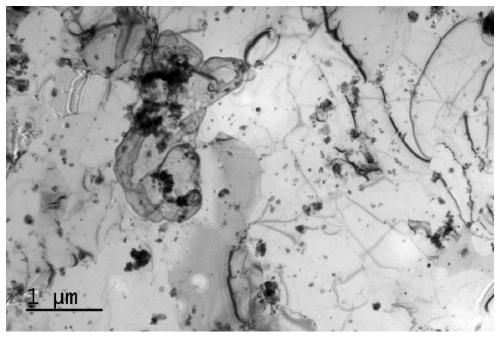

Preparation method of high-toughness aluminum base nanometer composite material

The invention relates to the field of preparation of aluminum base nanometer composite materials, in particular to a preparation method of a high-toughness aluminum base nanometer composite material. Firstly, an in-situ synthesis method is adopted to prepare a nanometer particle reinforced aluminum base composite material; then, a prepared cast composite material is cut to plates with a certain thickness and regular shapes, and the surface degreasing treatment is performed; and finally, the degreased plates are stacked and fixed, and multiple times of ply rolling deformation treatment are performed to obtain the composite material with uniformly dispersed nanometer reinforced bodies and fine matrix grains. In the prepared aluminum base nanometer composite material, because of dispersibility improvement of the nanometer reinforced particles, refining of the matrix grains and reduction of casting defects, the toughness of the composite material is greatly improved.

Owner:JIANGSU UNIV

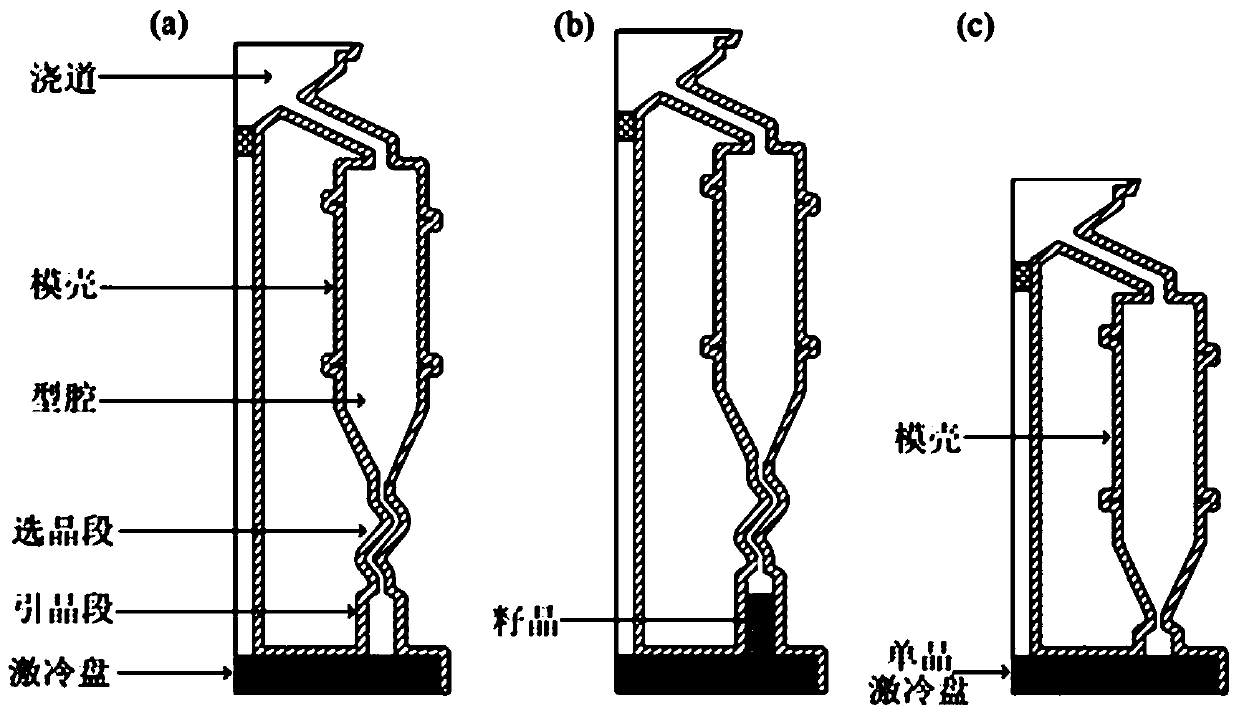

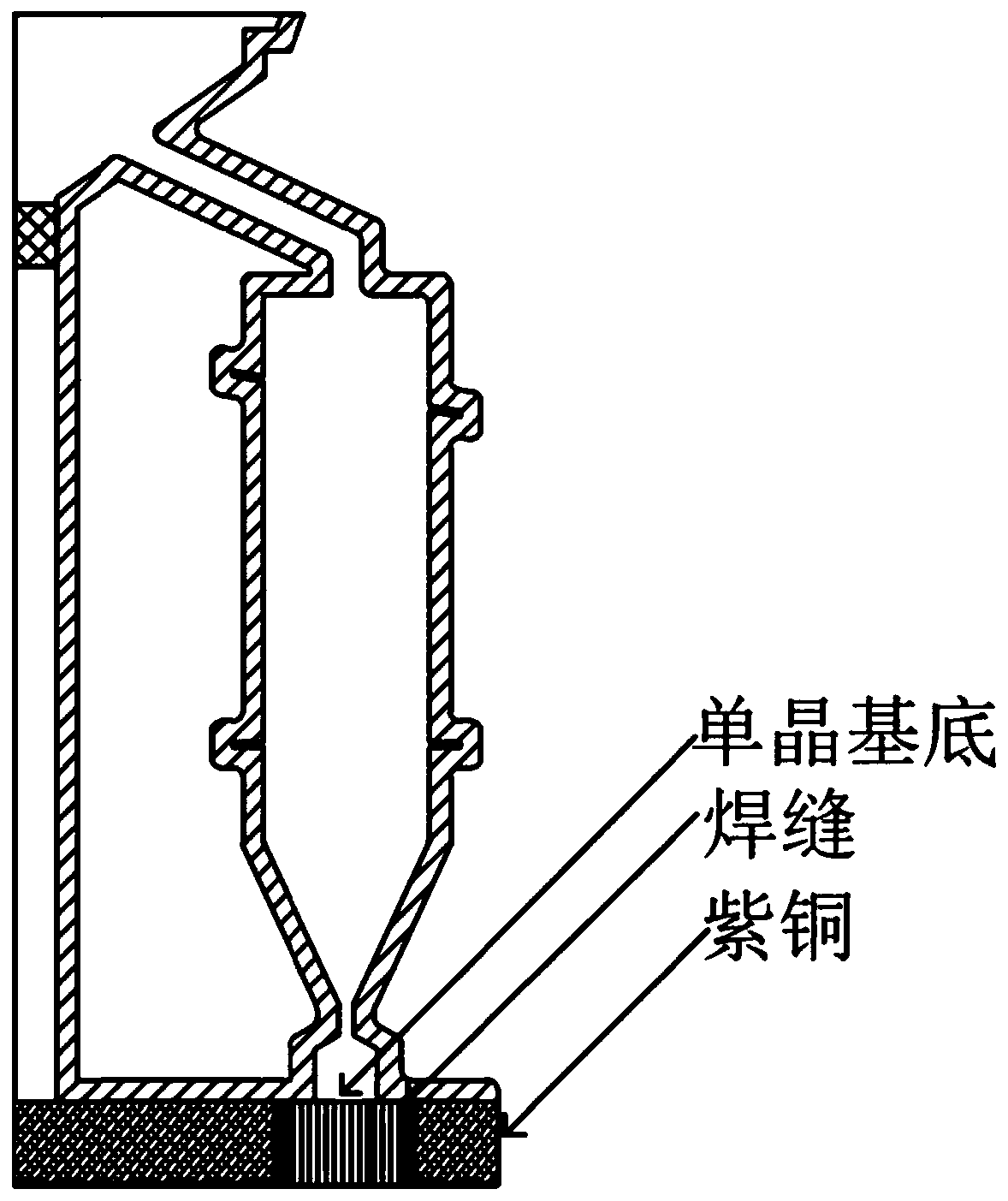

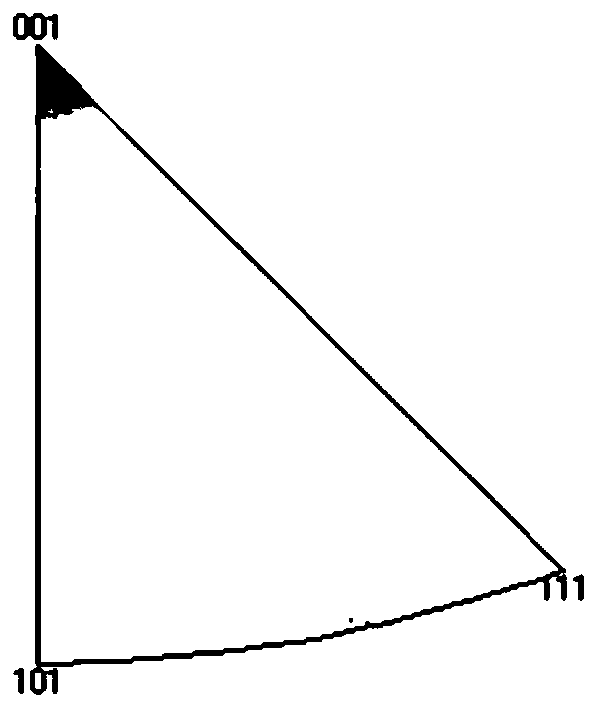

Substrate triggered single crystal high temperature alloy directional solidification technology

ActiveCN111364096AExpected crystallographic orientationEliminate casting defectsPolycrystalline material growthFrom frozen solutionsMetallurgySingle crystal superalloy

The invention relates to a substrate triggered single crystal high temperature alloy directional solidification technology. The technology comprises the following steps: (1) preparing a single crystalsubstrate material matched with the crystallographic characteristics of a single crystal high temperature alloy; (2) preparing a single crystal substrate chilling plate from the obtained single crystal substrate material; and (3) applying the obtained single crystal substrate chilling plate to directional solidification equipment, and carrying out high temperature alloy smelting and directional solidification preparation to obtain a single crystal high temperature alloy product. Compared with a crystal selection method and a seed crystal + crystal selection method, on the basis of accuratelycontrolling the orientation of the single crystal high-temperature alloy, the overall height of a casting is reduced by eliminating a spiral crystal selector, and the purposes of enhancing axial heatdissipation, improving the temperature gradient of a pasty region and eliminating freckles and mixed crystals near an edge plate are achieved. By means of successful implementation of the technology,the blade preparation quality and the preparation success rate are greatly improved, and the preparation cost of a single crystal high temperature alloy blade is reduced.

Owner:SHANGHAI JIAO TONG UNIV

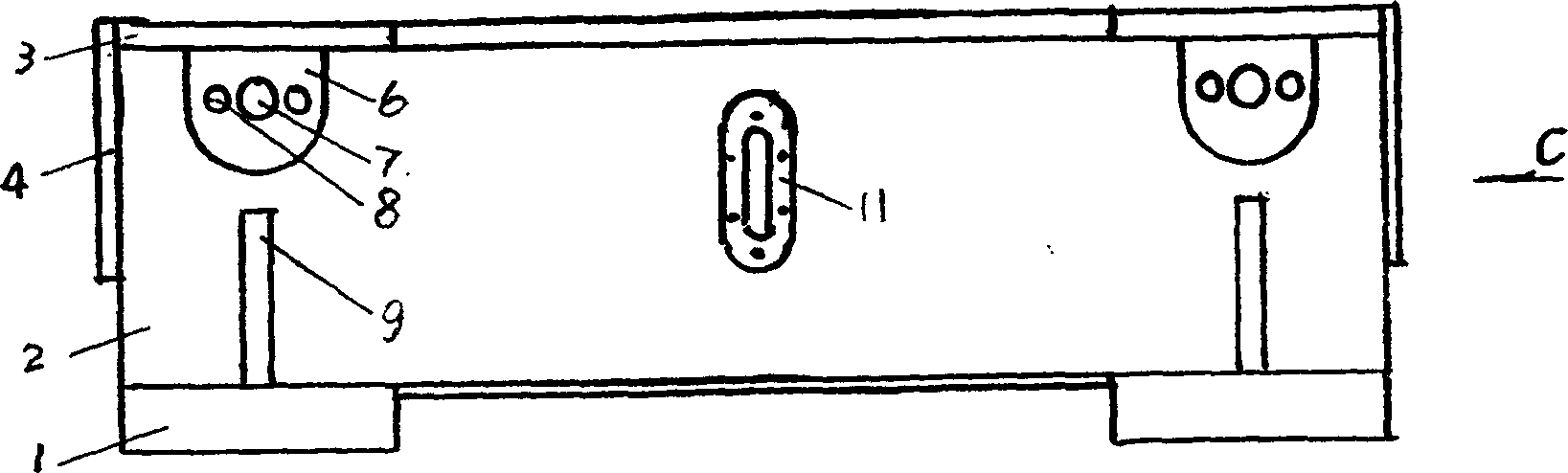

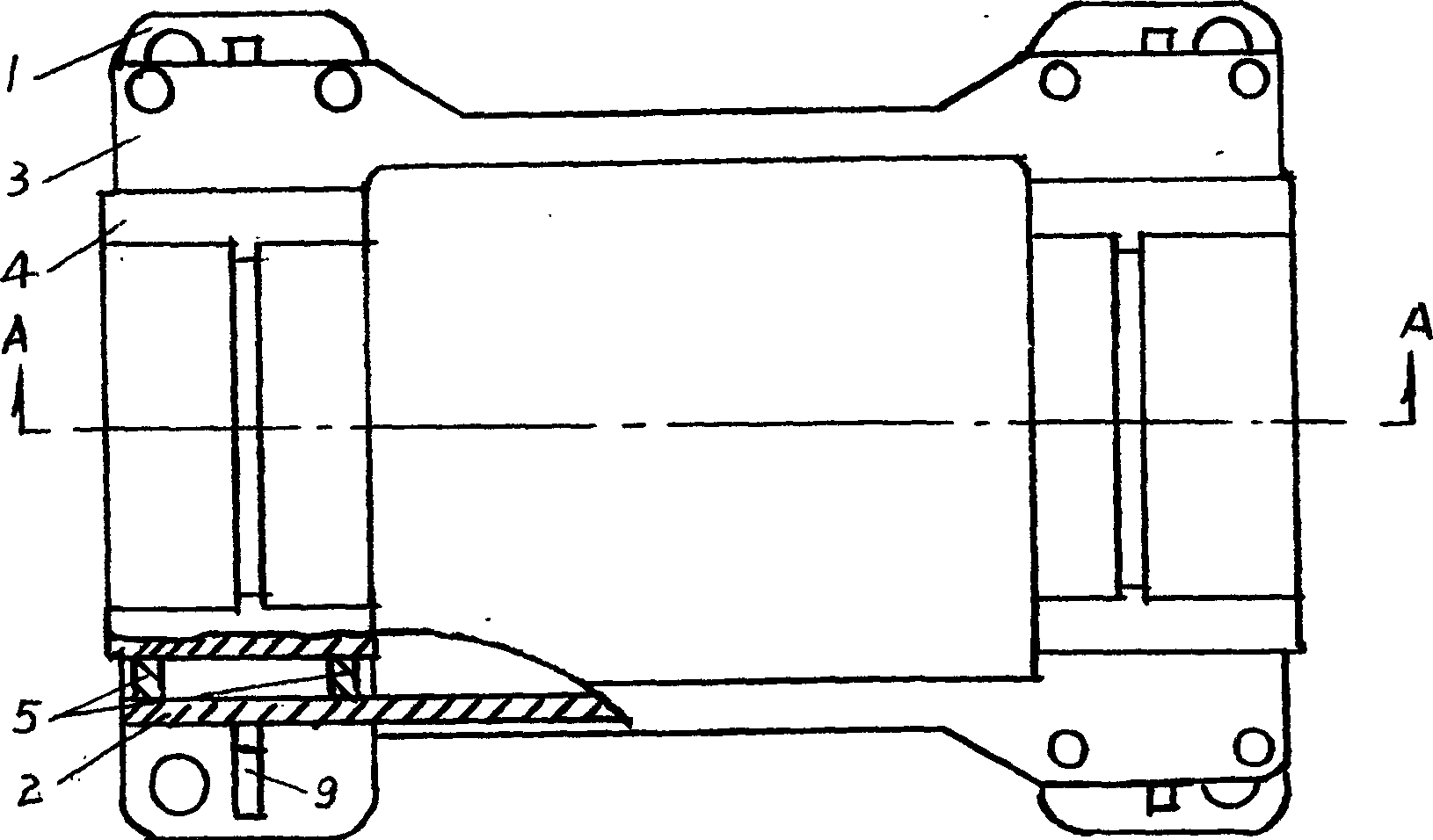

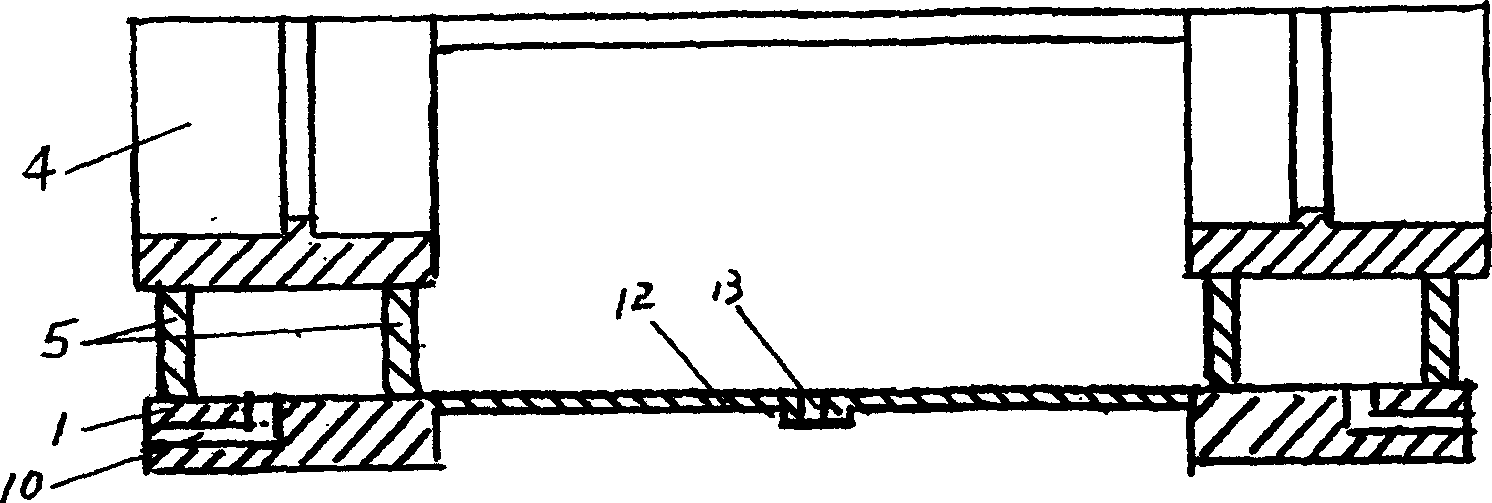

All welded steel structured bearing seat of blower fan water-cooling type in large-scale power station, and manufacturing method thereof

InactiveCN1687600AStress reliefMeet the design requirementsPump componentsPumpsPower stationWater channel

The invention discloses a fan water-cooled bearing base of the large power station with full steel welded structure and its manufacturing method. It is characterized in that it adopts the Q235A swage with good welding capability to process the separating parts and assembly the parts, adopts CO2 to protectively weld to form the upper cover and the base of the bearing base. The bearing base has cooling water channel, the lubrication oil tank and the temperature detecting channel; the raw metal roughing after the annealing, and anneal again after the roughing, metal refine and the cooling water channel and the lubricating oil channel detect the water pressure.

Owner:SICHUAN ENG TECHN COLLEGE

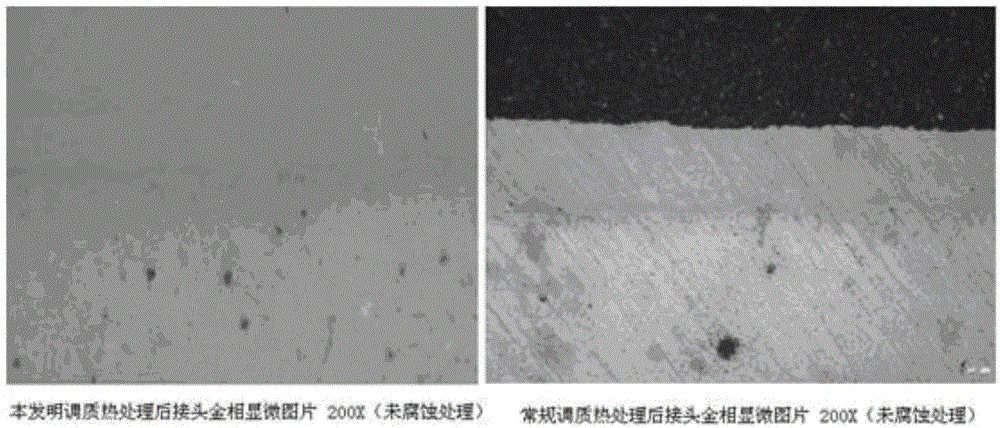

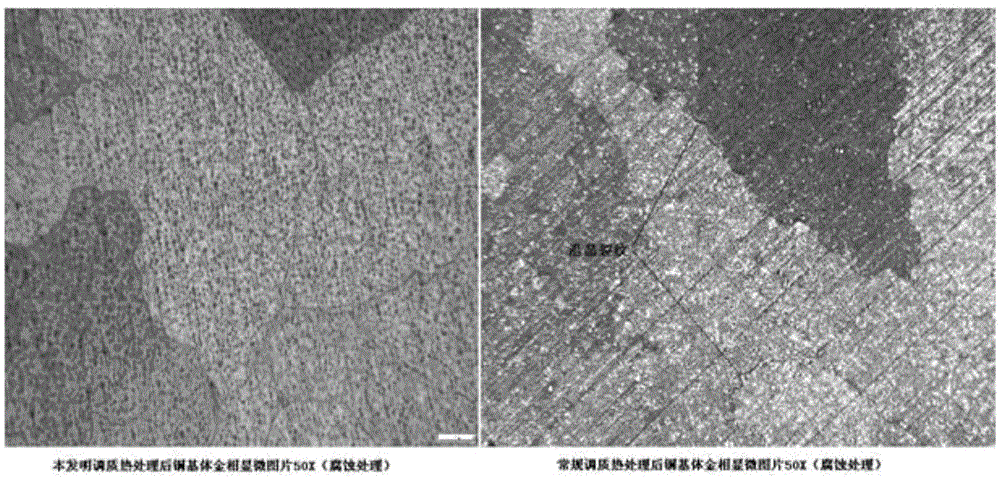

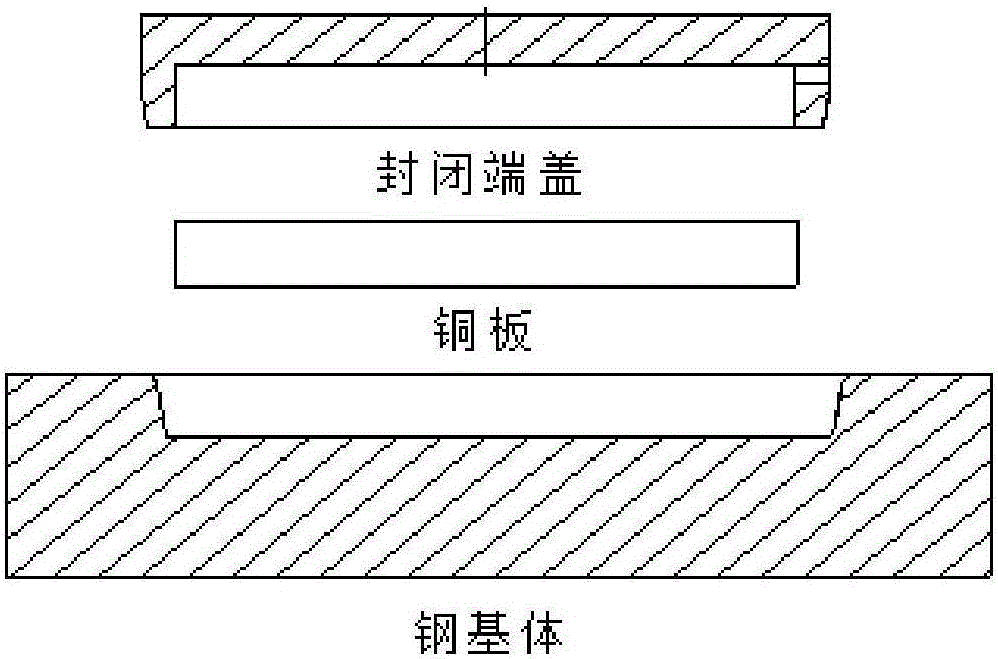

Diffusion welding method for tin bronze and steel welded structures

ActiveCN106271033ARealize no lossEliminate casting defectsWelding/soldering/cutting articlesNon-electric welding apparatusEngineeringGraphite

The invention discloses a diffusion welding method for tin bronze and steel welded structures. The diffusion welding method is characterized by comprising steps of 1, machining a plurality of components according to drawings, carrying out oil and rust removal treatment on welded surfaces of the multiple components and then assembling the components to obtain welded assemblies; 2, placing the welded assemblies between lower support plates in furnaces of vacuum diffusion welding equipment and separating the welded assemblies from the support plates by graphite paper; 3, allowing the internal vacuum degree of the vacuum diffusion welding equipment to range from 1.0*10<-3> to 1.0*10<-4> Pa under the control and carrying out heating and pressurizing treatment on the welded assemblies; 4, cooling the welded assemblies and fetching weldments. The components comprise steel matrixes, tin bronze plates and closed end covers. The diffusion welding method has the advantages that loss of tin bronze compositions QSn10-2-3 can be prevented, and the material stability can be guaranteed; casting defects of tin bronze QSn10-2-3 can be eliminated to a certain extent, and copper matrixes can be guaranteed against cracking after heat treatment is carried out on the weldments.

Owner:AVIC LIYUAN HYDRAULIC

Swaging integrated forming process for large-diameter AQ80M magnesium alloy cake material

ActiveCN106890865AGuaranteed forming effectGuaranteed mechanical propertiesExtrusion control devicesPre deformationRoom temperature

The invention relates to a swaging integrated forming process for a large-diameter AQ80M magnesium alloy cake material, and belongs to the technical field of processing of a magnesium alloy material. The process comprises the following specific steps: preparing an AQ80M magnesium alloy ingot blank by semi-continuous casting; heating an extrusion die and an extrusion barrel; carrying out extrusion pre-deformation at low extrusion ratio; straightening and cutting the blank; carrying out multi-directional forging forming; and carrying out aging treatment. By the swaging integrated forming process for the large-diameter AQ80M magnesium alloy cake material, the large-diameter magnesium alloy cake material of which the diameter is phi 690 mm to phi 700 mm, the thickness is 100-110 mm, the tensile strength is greater than or equal to 330 MPa, the yield strength is greater than or equal to 190 MPa and the ductility is greater than or equal to 6% at room temperature, and the tensile strength is greater than or equal to 200 MPa, the yield strength is greater than or equal to 160 MPa and the ductility is greater than or equal to 30% at the temperature of 150 DEG C. The prepared large-size magnesium alloy cake material completely meets requirements of a large magnesium alloy part.

Owner:湖南镁宇科技有限公司

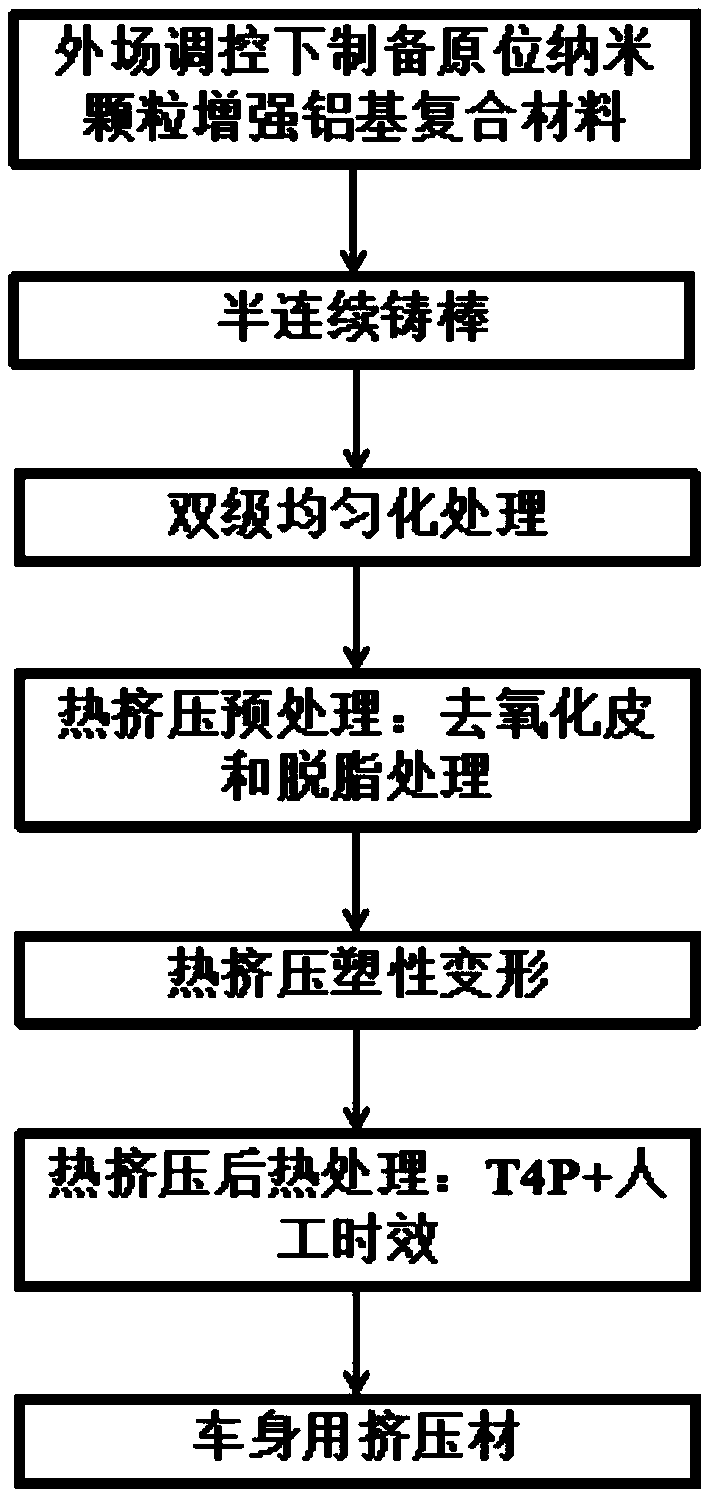

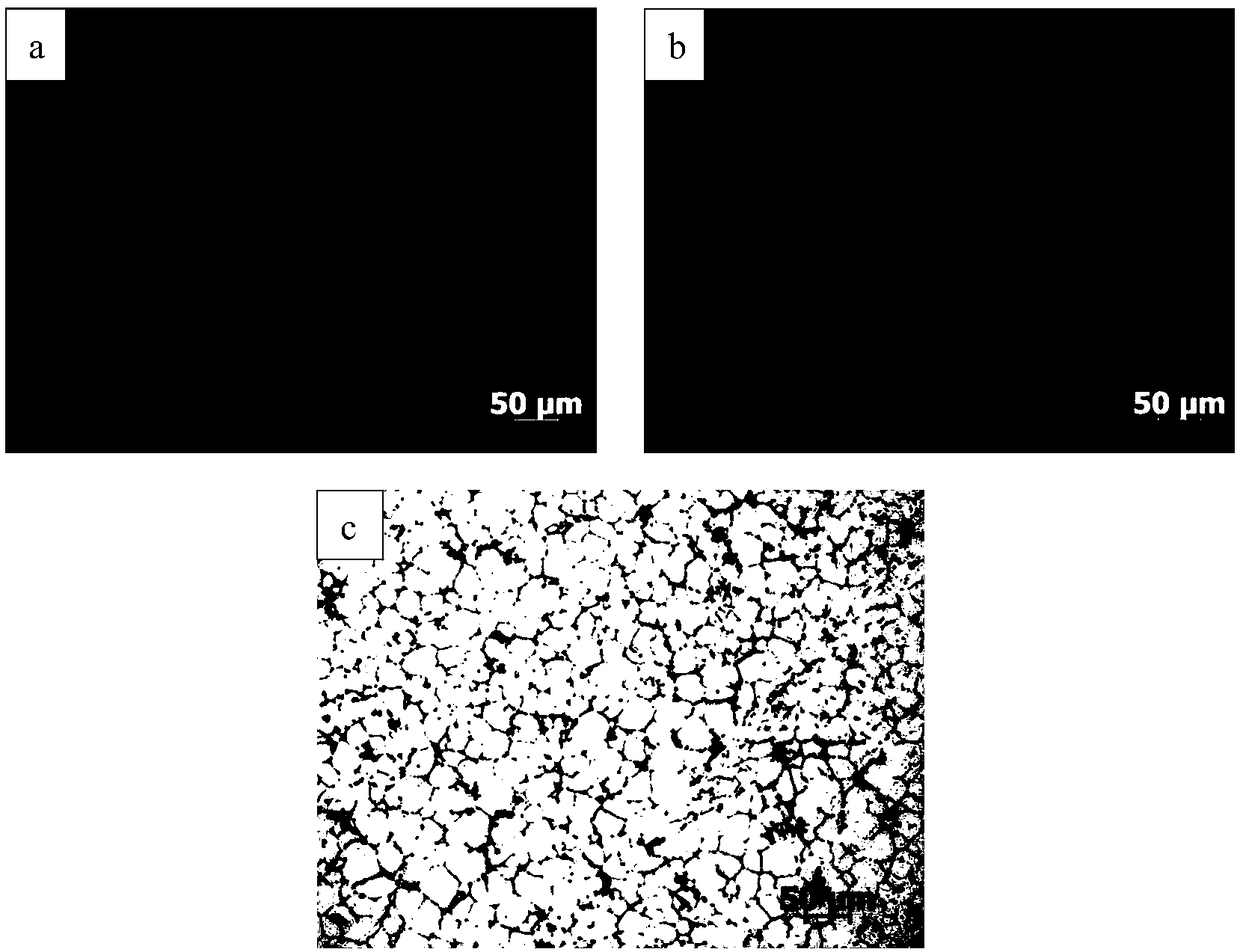

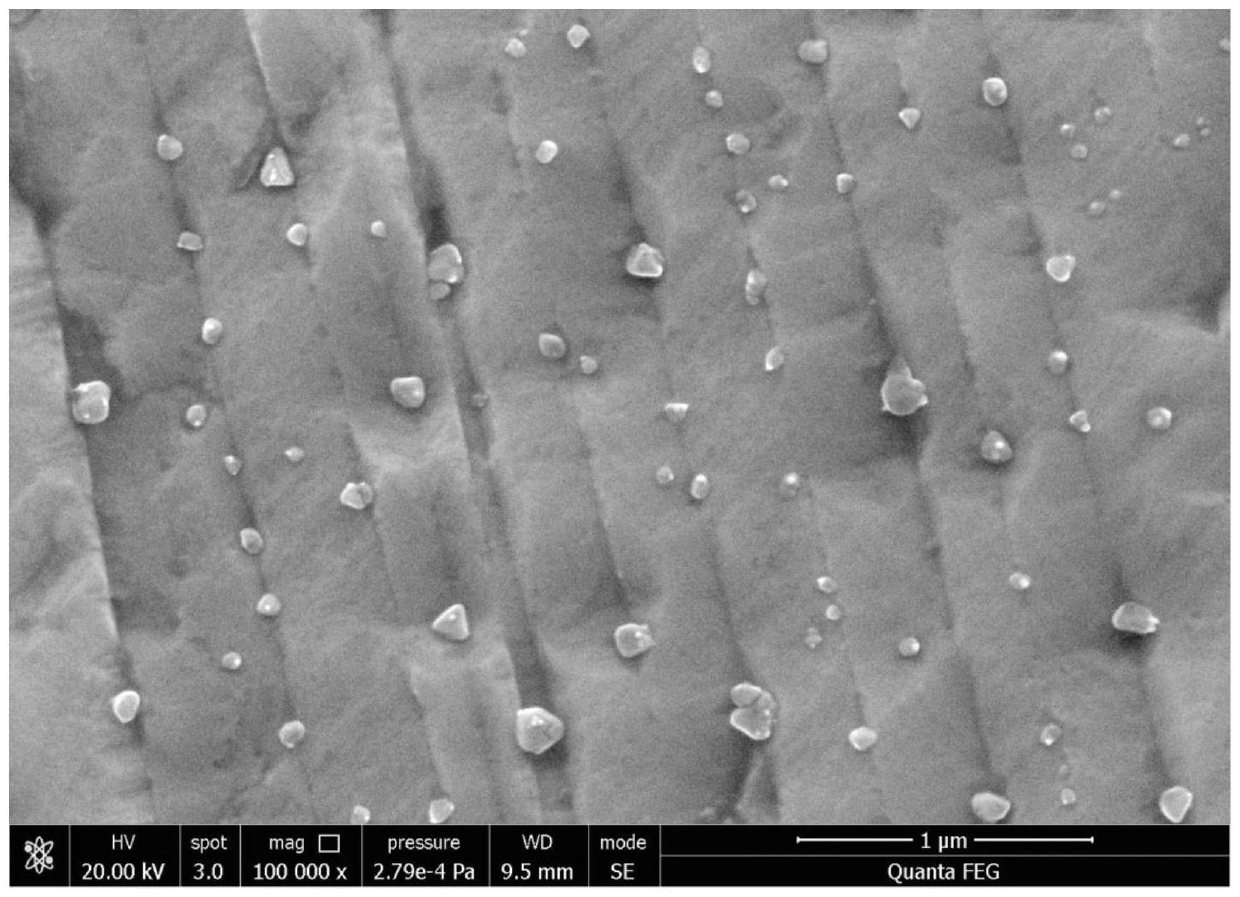

Extrusion process for vehicle body in-situ nanoparticles enhancing aluminum base composite material

ActiveCN108796404AImprove tissue performance uniformityImprove strong plasticityResearch ObjectThermal expansion

The invention relates to the field of aluminum base composite material processing, in particular to an extrusion process for a vehicle body in-situ nanoparticles enhancing aluminum base composite material. The vehicle body in-situ nanoparticles enhancing aluminum base composite material synthesized in situ under the outer field control is used as a research object, the casting defects such as holes and loosening are eliminated by adopting the hot extrusion plasticity, so that the texture is refined and dense, the extruded grains are uniform and small, and the mechanical properties are obviously improved; meanwhile, under the action of the extrusion pressure, the agglomeration particles are dispersed and dispersed in a matrix, the bonding force with the matrix is higher, a lot of dislocation is generated, a high-density dislocation mesh is formed, and dislocation enhancement is produced accordingly. The T4P+ artificial aging heat treatment of the follow-up extrusion material can eliminate the thermal residual stress caused by the different thermal expansion coefficients of nanoparticles and matrix in the process of the hot extrusion, the plasticity of the vehicle body extrusion material is further improved, and the vehicle body in-situ nanoparticles enhancing aluminum base composite material extrusion material which can replace the steel plate is obtained.

Owner:JIANGSU UNIV

Short-flow processing technology of ferrule roughcast used for turntable bearing

InactiveCN102886660AMinor casting defectsEliminate casting defectsFurnace typesHeat treatment furnacesTemperingPunching

The invention discloses a short-flow processing technology of ferrule roughcast used for a turntable bearing. The short-flow processing technology comprises the processing steps of carrying out smelting, casting to form an annular casting, cutting a feed head, heating the annular casting, and rolling the annular ferrule roughcast; and then carrying out normalizing and tempering heat treatment on the rolled annular ferrule roughcast. Compared with the existing processing technology, the short-flow processing technology omits the processes of primarily heating an ingot casting, forging (or milling) bar stock, sawing (or carrying hot cutting) the stock, carrying out stock heating for a second time, and carrying out forging, punching and the like, thereby greatly reducing the production cost. Ferrule parts of the turntable bearing, which can meet the technical requirements, can be obtained through the subsequent normalizing and tempering heat treatment. The short-flow processing technology is applied to the ferrule roughcast used for the turntable bearing, and the external diameter of which is within the scope of 500mm-1500mm.

Owner:LUOYANG LYC BEARING

Full mold casting molten iron introducing type chill

InactiveCN104942225AReduce manufacturing costEliminate casting defectsFoundry mouldsFoundry coresPolystyreneCasting defect

The invention provides a full mold casting molten iron introducing type chill. The full mold casting molten iron introducing type chill comprises a casting full mold, wherein mold sand of an inner cambered surface of the casting full mold is provided with a plurality of polystyrene foam bars; pig iron is pressed on the middle upper parts of the polystyrene foam bars; the foam bars and a casting model body are in seamless connection, and the foam bars can form iron casting bars after pouring; the polystyrene foam bars have the length of 200-400mm, have the width of 30-100mm, have the thickness of 10-30mm, and are distributed in the mold sand with an oblique array interval of 30-150mm, and the installation oblique angle is 5-45 degrees; the included angle of the inner cambered surface of the casting full mold is 15-120 degrees. By utilizing the full mold casting molten iron introducing type chill, the manufacturing cost of the chill is reduced; the casting defect that a thermal joint of a casting is probably easy to shrink is eliminated; the quality of a casting is ensured. The full mold casting molten iron introducing type chill has the characteristics of low manufacturing cost, simple structure, convenience and reliability in clamping, and good effects.

Owner:SHIYAN LONGGANG CASTING

Preparation method of ultra-fine-crystal high-toughness heat-resistant aluminum alloy lead

ActiveCN111057978AReduced service lifeReduce weightCable/conductor manufactureZirconium alloyInduction furnace

The invention relates to a preparation method of an ultra-fine-crystal high-toughness heat-resistant aluminum alloy lead. The preparation method comprises the following steps: (1) performing proportioning, wherein the aluminum alloy lead consists of the following components in parts by weight: 100 parts of industrial pure aluminum, 0.7 part of aluminum-zirconium alloy, 0.4 part of aluminum-copperalloy, 0.4 part of aluminum-erbium alloy, 0.0015 part of a refiner Al-5Ti-B, 0.06 part of a modifier Sr and 0.5 part of a refining agent hexachloroethane; (2) performing smelting: adding pure aluminuminto a coreless medium-frequency induction furnace, increasing the furnace temperature to 740 DEG C, starting ultrasonic vibration for 20 seconds when the temperature reaches 720 DEG C, adding intermediate alloy, a modifying agent and a refining agent by a bell pressing method after the metal is completely melted, wherein electromagnetic stirring is carried out during the adding process, and thenperforming refining and slagging off; and (3) casting prepared alloy liquid into ingots, then performing multi-directional forging on the alloy ingots, and performing homogenization treatment, rolling, stress removal annealing, low-temperature continuous equal channel angular processing (ECAP), precipitation strengthening, drawing and twisting.

Owner:甘肃西北之光电缆有限公司

Preparation method of low-alloy high-carbon steel with high-strength and high ductility nano structure

The invention discloses a preparation method of a low-alloy high-carbon steel with a high-strength and high ductility nano structure, which is characterized in that the steel contains the following chemical components in percent by weight: 0.7-0.9 percent of C, 1.4-1.6 percent of Si, 1.2-1.4 percent of Mn, 1.4-1.6 percent of Al, 0.7-0.9 percent of Cr, 0.7-0.9 percent of W, less than 0.02 percent of P, less than 0.02 percent of S and the balance of Fe. The preparation method comprises the following steps: melting the chemical components according to the weight percent, pouring to form a steel ingot and slowly cooling to the room temperature; heating the steel ingot to 1,160-1,180 DEG C, cogging, and hot rolling to form a plate blank with the thickness being less than 25 mm, wherein the finally rolling temperature is 990-1,010 DEG C; rapidly putting the plate blank into a salt bath with the temperature of 220-260 DEG C after the rolling, and keeping the constant temperature for 4-24h, and then cooling in the air to the room temperature to obtain the low-alloy high-carbon steel with a high-strength and high ductility nano structure, wherein a microstructure comprises bainitic lath ferrites with the thickness of 60-90 nm and residual austenite and has the tensile strength of 2,000-2,300MPa, the yield strength of 1,500-1,900MPa under the condition of 0.2 percent of strain, the total elongation percentage of 6.7-7.8 percent and the uniform elongation percentage of 3.8-5.6 percent; and the Charpy measured by the ASTM:E23-02 standard, i.e. room-temperature impact work of a U-shaped notch specimen, is 7-22J. The invention has simple preparation process, direct constant temperature process in the salt bath after the hot rolling, short period of thermal treatment, low cost and easy application in production.

Owner:YANSHAN UNIV

Homogenization treatment and subsequent processing method suitable for magnesium alloy ingots

The invention discloses a homogenization treatment and subsequent processing method suitable for magnesium alloy ingots. The method comprises the following steps: (1) analyzing components of a magnesium alloy and number of low melting point phases; (2) performing the following steps according to the number of low melting point phases: preheating at a temperature which is 10-20 DEG C lower than an initial melting temperature of the low melting point phase change, performing deformation comprising one or a combination of optional two in forging, extruding and rolling on the alloy, and performing long-term homogenization on the deformed alloy; (3) performing subsequent alloy treatment, comprising the following sub-steps: performing direct ageing, continuously deforming and performing ageing, raising the temperature to 10-20 DEG C below the initial melting temperature of the next low melting point phase change, deforming, homogenizing, repeating until the low melting point phases are completely eliminated, and directly deforming and ageing without cooling after the homogenization is finished finally.

Owner:GRIMAT ENG INST CO LTD

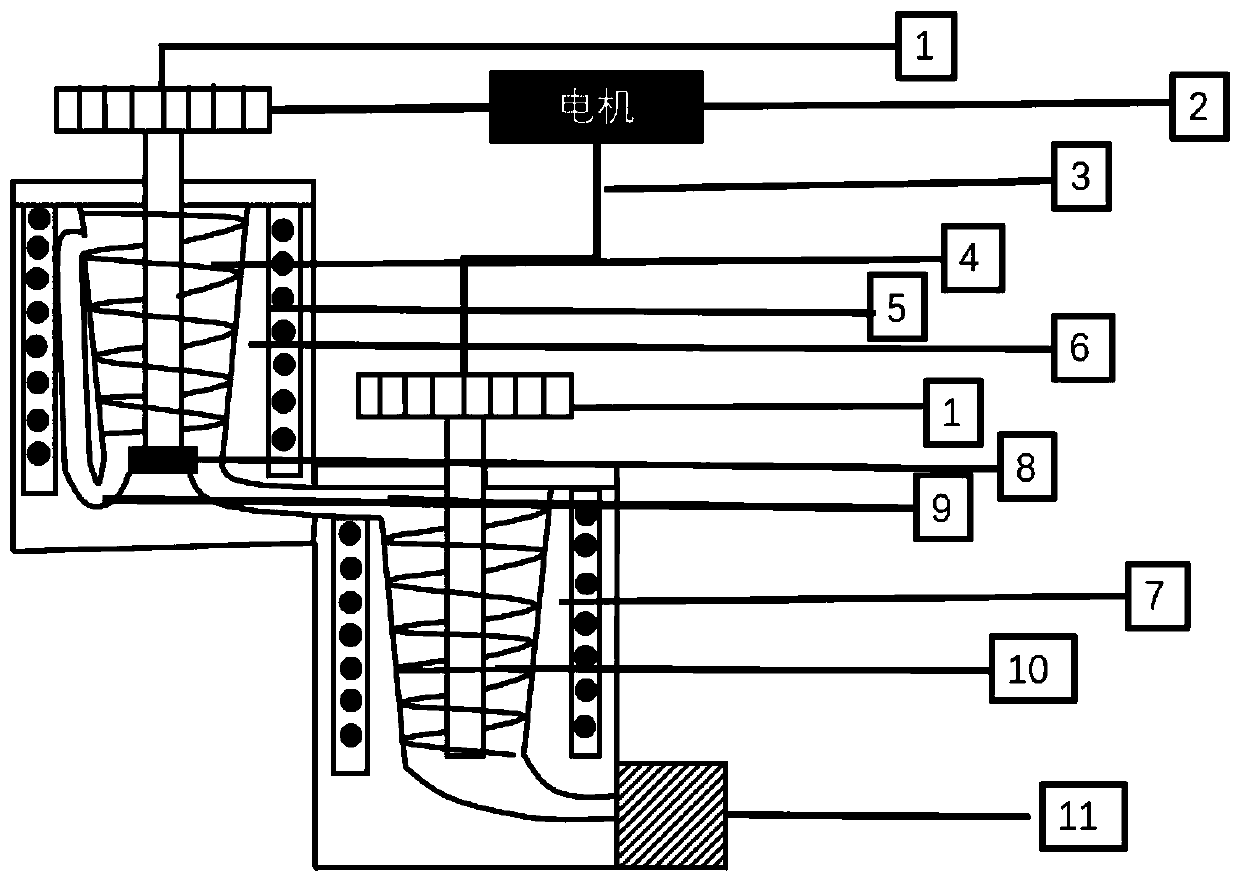

Manufacturing device and method for high-tenacity nano-particle-reinforced aluminum matrix composite material

ActiveCN110144478AImprove compactnessImprove uniformityTransportation and packagingRotary stirring mixersNanoparticleCompression device

The invention relates to an aluminum matrix composite material, in particular to a manufacturing device and method for a high-tenacity nano-particle-reinforced aluminum matrix composite material. Themanufacturing device and method is characterized in that based on a designed spiral circulation stirring combination and compression integrated device, firstly an aluminum alloy matrix is placed in aspiral circulation stirring combination device and is heated to certain temperature and molten; an in-situ reactant; in-situ nano-combination is realized by virtue of the effect of spiral circulationstirring; then an in-situ combination melt is directly introduced into a spiral compression device, and is cooled to lower temperature in the spiral compression device; nano-particle cluster breakingand matrix crystal grain refining in the in-situ combined nano-particle-reinforced aluminum matrix combination material are realized by utilizing a large deformation shearing effect which is generatedby movement of a lead screw in the spiral compression device; and finally the material is formed through an extrusion end mould to obtain the high-tenacity nano-particle-reinforced aluminum matrix composite material of a required shape.

Owner:JIANGSU UNIV

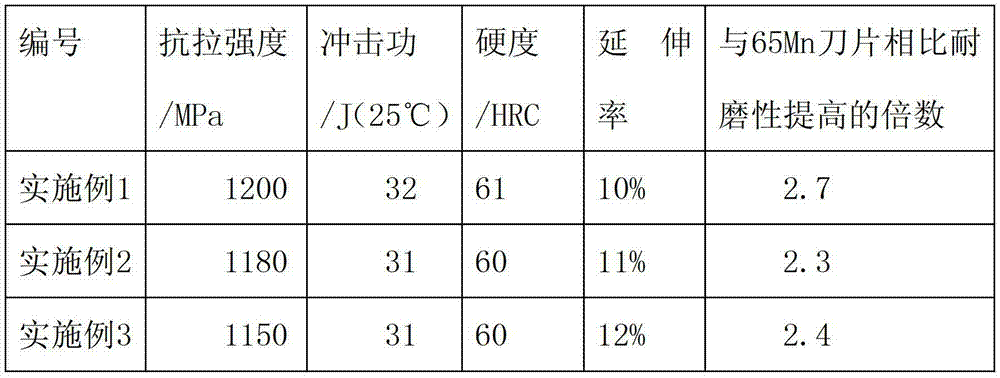

High-wear-resisting land leveler blade and production method

ActiveCN103205633AHigh hardnessHigh strengthFoundry mouldsFoundry coresElemental compositionSteelmaking

The invention relates to a high-wear-resisting land leveler blade and a production method. The elementary composition of the high-wear-resisting land leveler blade includes, by weight, 0.25-0.27% of C (carbon), 0.4-0.6% of AL (aluminum), 0.8-1% of Mn (manganese), 1.5-2% of W (wolfram), 0.5-0.7% of Si-B-C-N (silicon-boron-carbon-nitrogen) nano amorphous particles, no more than 0.0032% of B (boron), no more than 0.015% of P (phosphorus), no more than 0.015% of S (sulfur) and the balance being Fe (iron). The production method includes performing electric steelmaking, molten iron desulphurization and dephosphorization, performing converter top-bottom combined blowing and vacuum degassing processing, pressing in the Si-B-C-N nano amorphous particles by the pour-over process, casting a blade plate blank, cooling the blade plate blank to 1250-1270 DEG C to preserve heat for 1-2 hours, cooling the blade plate blank to 960-980 DEG C to be quenched with oil, tempering at 300 DEG C and then cooling sharply, and finally obtaining the land leveler blade. The blade has good match of strength, toughness and hardness, abrasive resistance of the blade is increased by more than twice as compared with that of a 65Mn blade, the production method is convenient, cost is low and production efficiency is high.

Owner:西安翱翔新材料科技有限公司

Copper alloy conductor for railway electric power transmission line and preparation method thereof

InactiveCN108265194AGas element content is smallImprove corrosion resistanceConductive materialMetal/alloy conductorsElectric power transmissionMicro structure

The invention relates to a copper alloy conductor for a railway electric power transmission line and a preparation method thereof and belongs to the technical field of non-ferrous metal conductor processing, copper alloy preparation and cable manufacture. The copper alloy is a copper-silver two-component alloy having silver content of 0.05% to 0.12%. Through a vacuum self-consuming melting-vacuumelectron beam melting combined technology, a molten copper-silver rod is cleaned and purified and harmful gas such as oxygen, hydrogen and nitrogen and harmful impurities are eliminated so that the high purity and high clarity of the copper-silver alloy are realized. Through large extrusion ratio deformation, casting defects are eliminated, the micro-structure is refined and the plasticity of thealloy is improved. The later drawing process is free of annealing and the total deformation of drawing is 50% to 75%. The preparation method can produce the high purity and high clarity copper-silverconductor, has gas element content of less than 10ppm, oxygen content of less than 3ppm and conductivity of 100.5% to 102.5% IACS and can be used for preparation of wear-resistant and corrosion-resistant railway power transmission line.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG +2

Magnesium alloy thick plate and preparation method thereof

ActiveCN112481536ASolve rolling difficultiesSolve the mechanical propertiesThick plateMagnesium alloy

The invention aims to provide a preparation method of a novel magnesium alloy thick plate. The alloy comprises, by mass, 3.5-5.0% of Al, 2.0-3.5% of Zn, 0.1-0.8% of Mn, 0.01-0.80% of RE, 0.001-0.090%of Ca, less than or equal to 0.005% of Fe, less than or equal to 0.05% of Si, less than or equal to 0.005% of Cu, less than or equal to 0.005% of Ni and the balance Mg, and the total content of impurities does not exceed 0.1%, wherein the sum of the Al content and the Zn content satisfies the condition that Al+Zn is greater than or equal to 6% and less than or equal to 8%. Aiming at a novel Mg-Al-Zn alloy system, a forming process for preparing the large-size magnesium alloy thick plate with low anisotropy and high strength is developed to satisfy urgent demands of such fields as aerospace, weaponry and automobiles on the magnesium alloy thick plate with low cost and high performance.

Owner:CHANGSHA ADVANCED MATERIALS IND RES INST CO LTD

Method for producing sand coated iron mould of steel casting

InactiveCN107042284AFine granularityHigh dimensional accuracyFoundry mouldsFoundry coresSurface finishFoundry

The invention discloses a method for producing a sand coated iron mould of a steel casting. The method is used for manufacturing of the complex steel casting. The method comprises the steps of manufacturing a coated sand core and upper and lower sand coated iron mould models for casting casting; putting internal chillers in the coated sand core and the upper and lower sand coated iron mould models; putting the coated sand core into the upper and lower sand coated iron mould models; carrying out model assembly and pouring; and turning a box to take out the casting. According to the method, the characteristic that a sand shell does not separate from the iron mould models is applied, chilling points are manually controlled through controlling thickness of the iron mould and the sand shell, the sand shell does not deform, a pouring system can be simplified, shrinkage cavities, heat cracks and other casting defects of the multi-hot spot complex steel casting are eliminated, inherent quality of the casting is dense, size precision of the casting is high, surface finish is close to that of precision casting, the casting is uniform and consistent and free of flash and burr, the deformation amount is low, the qualification rate of a casting product is greatly increased, the utilization amount of coated sand can be greatly decreased, the method has the obvious advantages that less casting sand is utilized and energy consumption is low, energy consumption during the mould manufacturing process and exhaust and waste residue discharge during the casting process are reduced, the working environment can be greatly improved, and labor intensity is reduced.

Owner:襄阳金德合金磨料有限公司

Casting and forging combined technique of aluminum alloy linkage rod

InactiveCN101486087BEnsure billet qualitySimplify the traditional die forging processEngine componentsRare-earth elementRhenium

The invention discloses technology for casting and forging an aluminum alloy connecting rod, wherein an aluminum alloy composition of the connecting rod is adjusted by addition of rare earth element in casting technology, and the addition of the rare earth element is 2 to 5 percent of an aluminum liquid; the aluminum alloy connecting rod is guaranteed to comprise the following compositions: 88 to94 percent of aluminum, 3.8 to 4.9 percent of copper, 0.5 to 1.5 percent of silicon, 0.4 to 1.2 percent of manganese, 0.4 to 1.0 percent of magnesium, 0.8 to 1.8 percent of rhenium and 0.4 to 0.14 percent of iron; and a casting head is not cut off and reheated in the casting technology and taken as one part or a scrapped part of a forged piece, and casting afterheat is utilized for forging. The technology simplifies the prior die forging technology, improves reasonable floatation, the streamline and mechanical properties of casting metals, improves a metallurgical structure close to the casting head on the forged piece, and has the effects of high technological utilization rate of materials, shortened technological process and energy conservation and consumption reduction. Moreover, the casting and forging technology can obviously improve the internal quality and the mechanical properties of casting blanks, and the production cost of the casting blanks is lower than that of the prior die forging.

Owner:DANYANG RONGJIA PRECISION MACHINERY

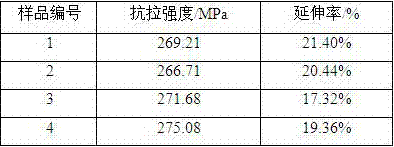

A kind of preparation method of high strength and high damping cualmn shape memory alloy

ActiveCN110527934BHigh densitySmall tissueMetal rolling arrangementsElongation control deviceSolution treatmentMetal alloy

The invention discloses a preparation method of a high-strength and high-damping CuAlMn shape memory alloy. The invention relates to a method for preparing a non-ferrous metal alloy by using a mother(intermediate) alloy through a smelting method, in particular to a groove type rolling process, which comprises the following steps: putting a CuAlMn shape memory alloy raw material prepared from CN105568019B into a box type furnace with the temperature of 830-880 DEG C, and carrying out solution treatment for 12-17 minutes; then feeding into a space between rollers of a groove-shaped rolling machine; carrying out the 1-8 passes of groove rolling along the length direction of the alloy; after the last pass of rolling is finished, carrying out primary groove rolling in the same rolling groove;and then putting the alloy sample into water at the temperature of 0-27 DEG C for quenching treatment, so that the high-strength and high-damping Cu-11.9Al-2.5 Mn shape memory alloy is prepared, and the casting defects of micro-area looseness, holes and segregation of the CuAlMn shape memory alloy prepared in the prior art are overcome.

Owner:HEBEI UNIV OF TECH

Cast titanium alloy material suitable for high temperature of 650-750 DEG C and preparation method thereof

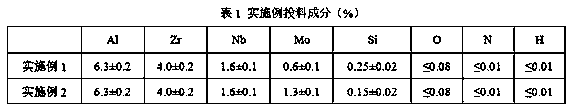

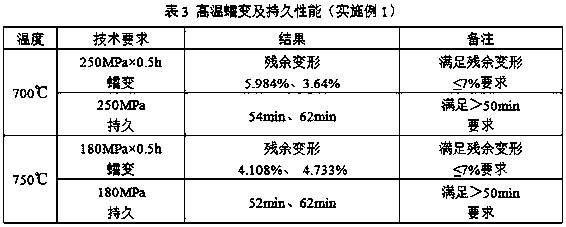

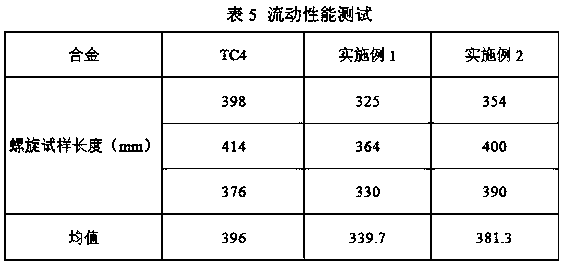

The invention relates to a cast titanium alloy material suitable for the high temperature of 650-750 DEG C and a preparation method thereof. The cast titanium alloy material is prepared from the alloycomponents in specific chemical percentage by mass: 5.0-7.5% of Al, 3.0-5.5% of Zr, 0.5-3.0% of Nb, 0.2-2.0% of Mo, 0.1-0.6% of Si, less than or equal to 0.15% of O, and the balance of Ti and unavoidable impurity elements. During preparation, raw materials are selected from ultra 0A grade-0A grade small particle titanium sponge, and the alloy elements Nb, Mo and Si are added in the form of intermediate alloys; Zr is added in the form of zirconium sponge; a part of Al is brought in by the intermediate alloys, and the insufficient part is added by pure aluminum; the intermediate alloys and thetitanium sponge are compounded, mixed, and then compressed into electrodes; the electrodes are assembled, welded and then made into an alloy ingot by smelting, then the alloy ingot is cast into an alloy casting, and after heat isostatic pressure treatment, internal shrinkage holes are removed to produce a finished product. The cast titanium alloy material has the good room temperature and the high-temperature mechanical performance of 650-750 DEG C, the high-temperature creep performance of 650-750 DEG C and the endurance performance can also meet the design requirements, the good casting andwelding properties are achieved, and the using requirements of key structural parts of airspace engines are met.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com