Low-Li high-plasticity high-strength Mg-Li alloy and preparation method of Mg-Li alloy plate

A magnesium-lithium alloy and high plasticity technology, which is applied in the field of preparation of low-lithium, high-plasticity, and high-strength magnesium-lithium alloys and their sheets, can solve problems that are not conducive to controlling the surface quality and shape of sheets, cannot balance high strength and high plasticity, and are Poor corrosion resistance and other problems, to eliminate casting defects, high yield, and improve corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

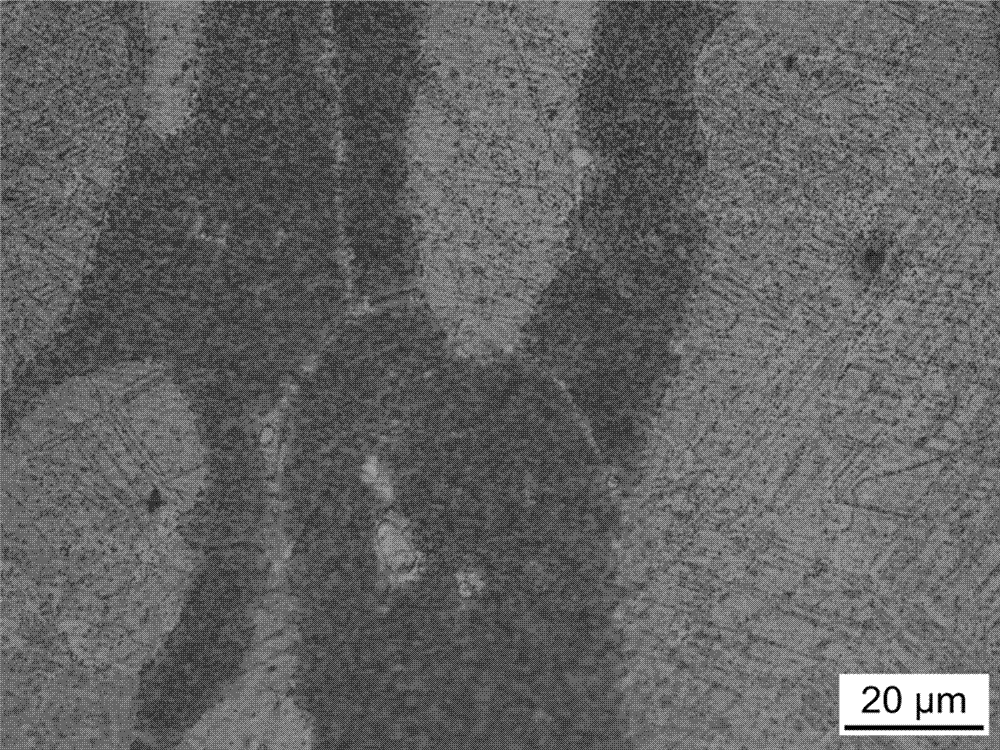

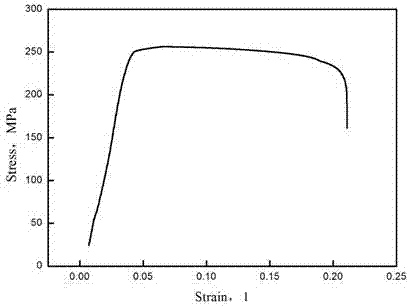

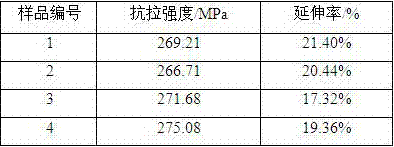

Image

Examples

Embodiment 1

[0030] A low-lithium, high-plasticity, high-strength magnesium-lithium alloy is composed of the following components by mass percentage: Li 6%, Al 3%, Zn 1%, Mn 0.5%, RE 0.3%, Ti+B 0.02%, and the balance is Mg and other impurity elements, and the total content of impurity elements is less than 0.3%.

[0031] The preparation method of the above-mentioned low-lithium high-plastic high-strength magnesium-lithium alloy plate comprises the following steps:

[0032] (1) Dosing according to the mass percentage of each component in the alloy, in which, Mg, Li, Al, Zn are added in the form of pure metal ingots; Mn is added in the form of AlMn10 master alloy; RE is lanthanum-rich mixed rare earth; MgRE20 Add in form; Ti+B is added in the form of AlTi5B1; add the prepared raw materials into the vacuum induction melting furnace, vacuumize, under the protection of argon, adopt the method of gradually increasing the power and heating, and melt at 760-770°C to obtain metal liquid;

[0033]...

Embodiment 2

[0043] A low-lithium, high-plasticity, high-strength magnesium-lithium alloy consisting of the following components by mass percentage: Li 6%, Al 3%, Zn 1%, Mn 0.5%, RE 0.5%, Ti+B 0.0005%, and the balance is Mg and other impurity elements, and the total content of impurity elements is less than 0.3%.

[0044]The preparation method of the above-mentioned low-lithium high-plastic high-strength magnesium-lithium alloy plate comprises the following steps:

[0045] (1) Dosing according to the mass percentage of each component in the alloy, in which, Mg, Li, Al, Zn are added in the form of pure metal ingots; Mn is added in the form of AlMn10 master alloy; RE is lanthanum-rich mixed rare earth; MgRE20 Add in form; Ti+B is added in the form of AlTi5B1; add the prepared raw materials into the vacuum induction melting furnace, vacuumize, under the protection of argon, adopt the method of gradually increasing the power and heating, and melt at 760-770°C to obtain metal liquid;

[0046]...

Embodiment 3

[0052] A low-lithium, high-plasticity, high-strength magnesium-lithium alloy consisting of the following components by mass percentage: Li 4%, Al 2%, Zn 0.5%, Mn 0.2%, RE 0.1%, Ti+B 0.0005%, the balance It is Mg and other impurity elements, and the total content of impurity elements is less than 0.3%.

[0053] The preparation method of the above-mentioned low-lithium high-plastic high-strength magnesium-lithium alloy plate comprises the following steps:

[0054] (1) Dosing according to the mass percentage of each component in the alloy, in which, Mg, Li, Al, Zn are added in the form of pure metal ingots; Mn is added in the form of AlMn10 master alloy; RE is lanthanum-rich mixed rare earth; MgRE20 Add in form; Ti+B is added in the form of AlTi5B1; add the prepared raw materials into the vacuum induction melting furnace, vacuumize, under the protection of argon, adopt the method of gradually increasing the power and heating, and melt at 780-790°C to obtain metal liquid;

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com