Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

477 results about "Hexagonal crystals" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Among the primary crystal systems, the hexagonal system has the fewest substances assigned to it, including arsenic, calcite, dolomite, quartz, apatite, tourmaline, emerald, ruby, cinnabar, and graphite. All crystals in the hexagonal system are classed as optically uniaxial, meaning that light travels through...

Method for producing nitride semiconductor, crystal growth rate increasing agent, single crystal nitride, wafer and device

InactiveUS20100104495A1Improve performanceIncrease probabilityPolycrystalline material growthFrom normal temperature solutionsNitrogenCrystal structure

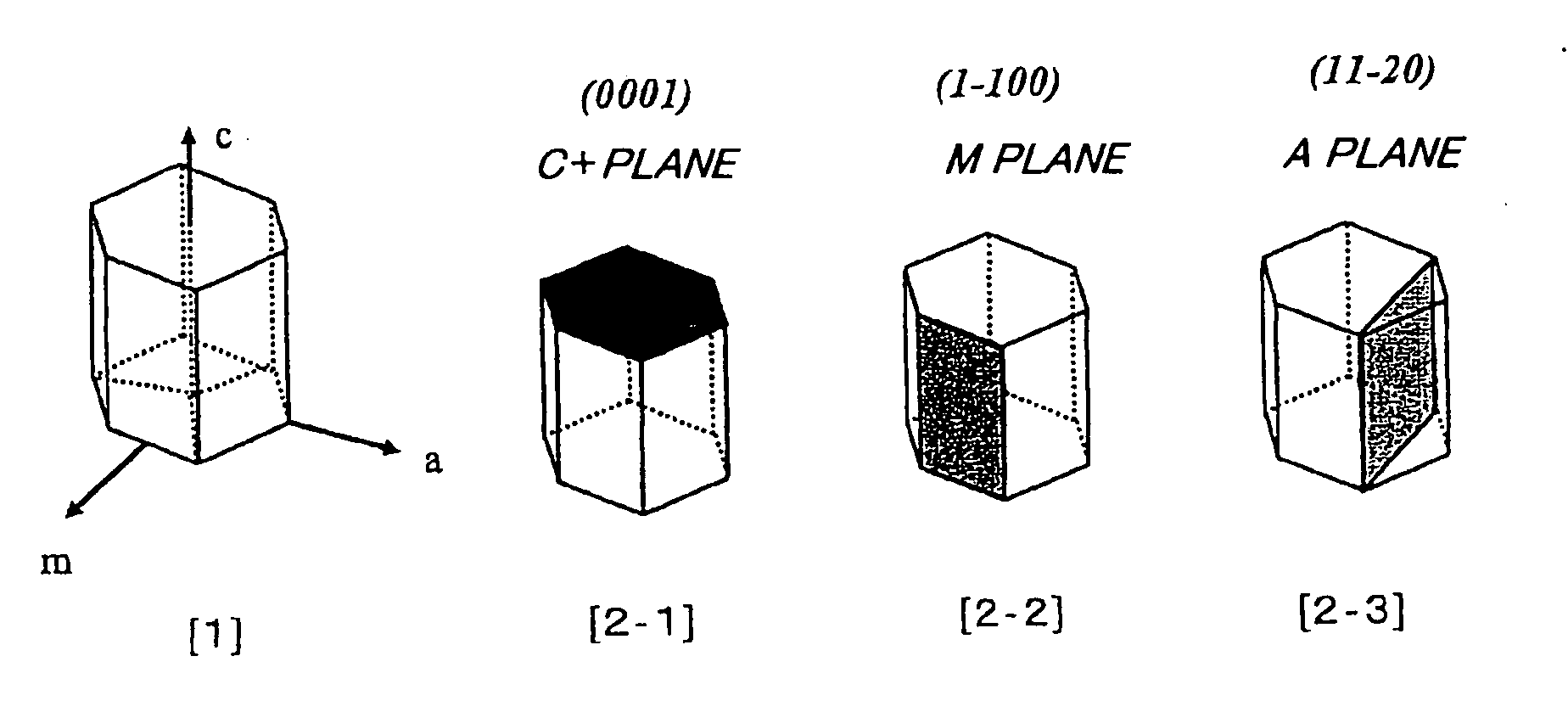

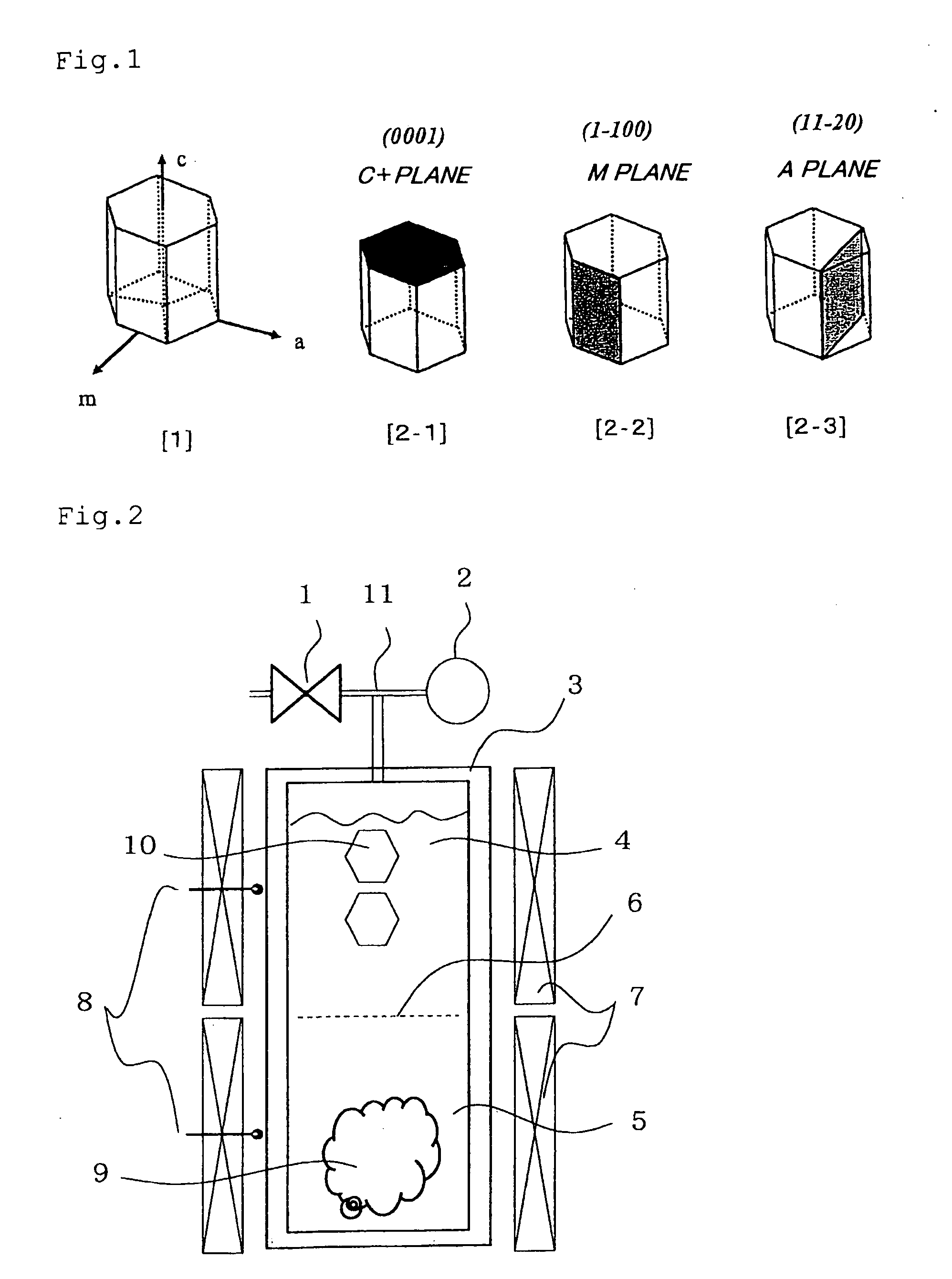

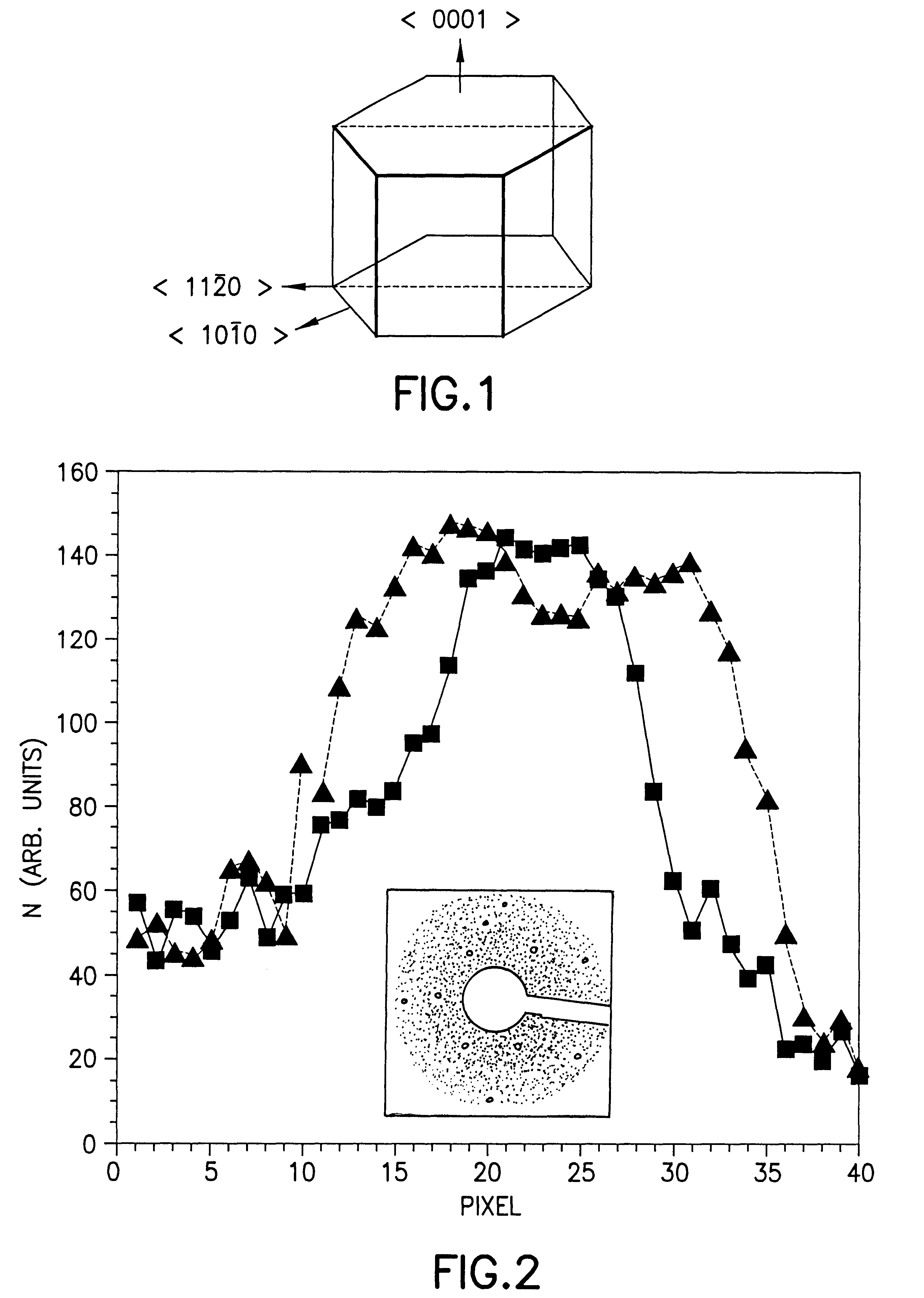

A method for producing a nitride semiconductor, comprising controlling temperature and pressure in a autoclave containing a seed having a hexagonal crystal structure, a nitrogen element-containing solvent, a raw material substance containing a metal element of Group 13 of the Periodic Table, and a mineralizer so as to put said solvent into a supercritical state and / or a subcritical state and thereby ammonothermally grow a nitride semiconductor crystal on the surface of said seed, wherein the crystal growth rate in the m-axis direction on said seed is 1.5 times or more the crystal growth rate in the c-axis direction on said seed. By the method, a nitride semiconductor having a large-diameter C plane or a nitride semiconductor thick in the m-axis direction can be efficiently and simply produced.

Owner:MITSUBISHI CHEM CORP +1

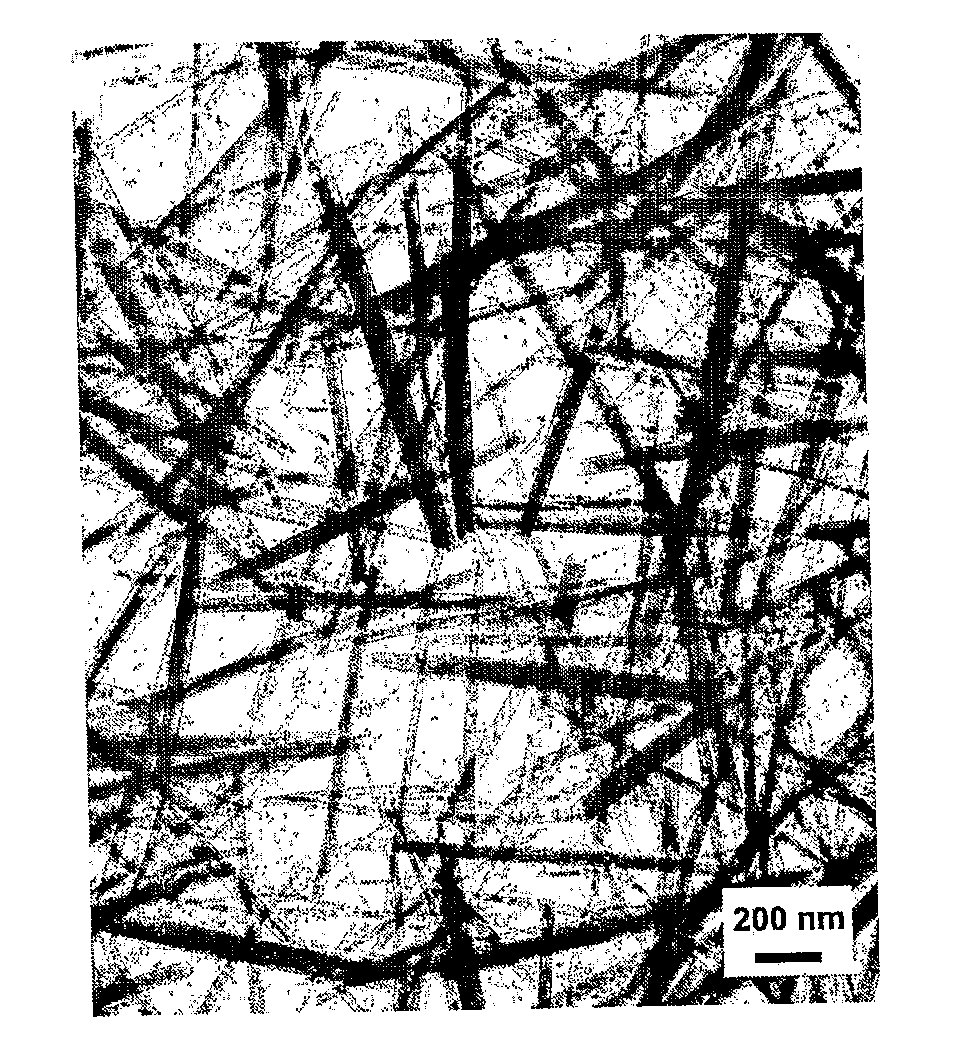

Tool with a molybdenum sulfide containing coating and method for its production

InactiveUS6528171B1Improve wear resistanceRecord information storageMagnetic recordingMetallic materialsMonolayer

The invention relates to a tool, especially a cutting insert for cutting metallic materials, which consist of a hard metal, cermet ceramics or steel base, especially of a high speed steel base, and at least one layer deposited thereon. The single layer, or in the case of several layers the outer layer or the layer underneath the outer layer, contains molybdenum sulfide. The aim of the invention is to improve the resistance to wear of the friction-reducing, molybdenum sulfide containing layer even at high pressures. To this end, the molybdenum sulfide containing layer consists of an alternating sequence of two layer that are different from one another. The first layer contains 51 to 100% by weight of metallic molybdenum and the second layer contains 21 to 100% by weight of MoS2 which substantially consists of hexagonal crystals that are at least substantially oriented in a plane parallel to the tool surface.

Owner:WIDIA

Devices including graphene layers epitaxially grown on single crystal substrates

ActiveUS20070187694A1Semiconductor/solid-state device manufacturingSemiconductor devicesSingle crystal substrateGraphite

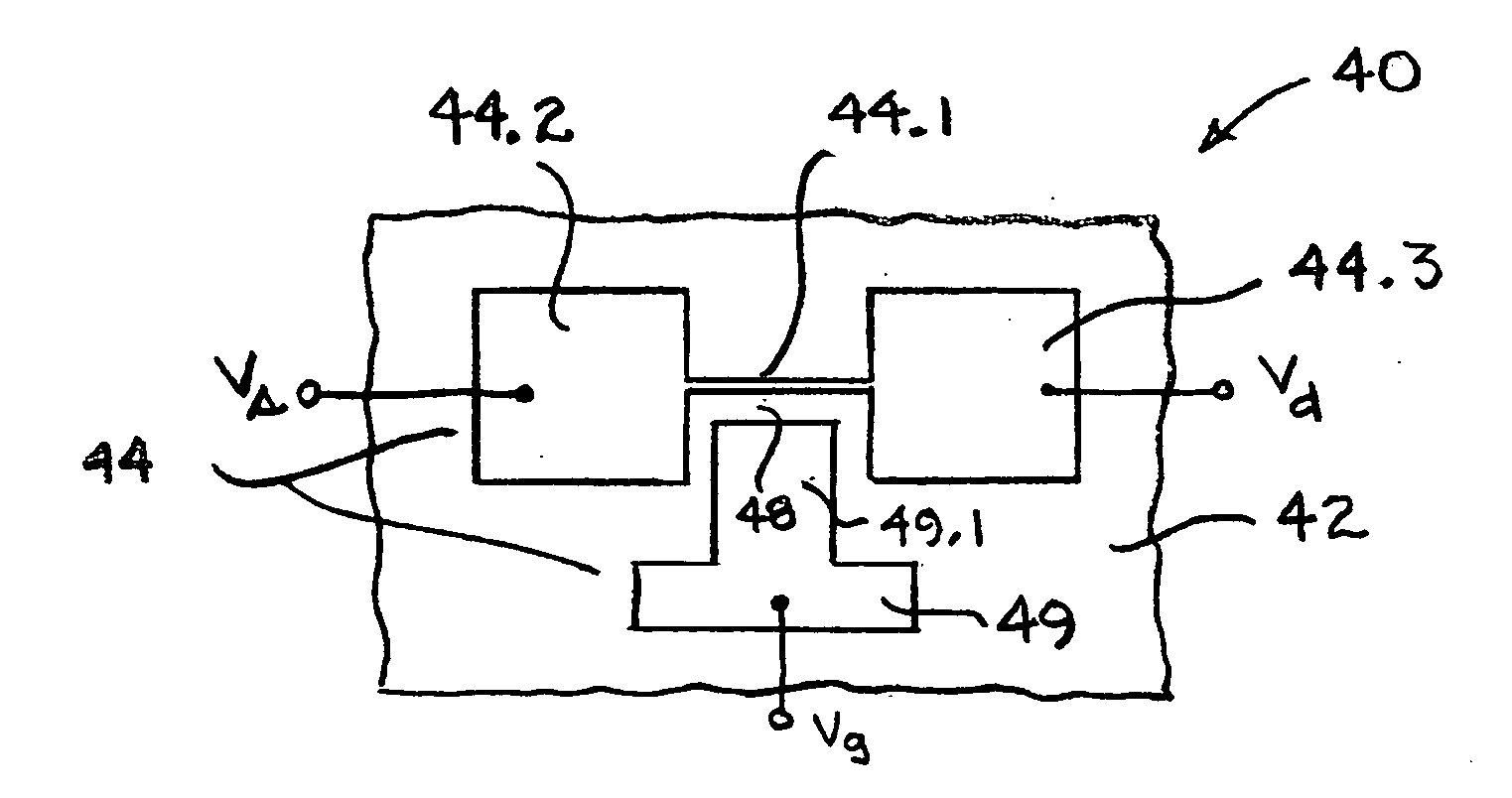

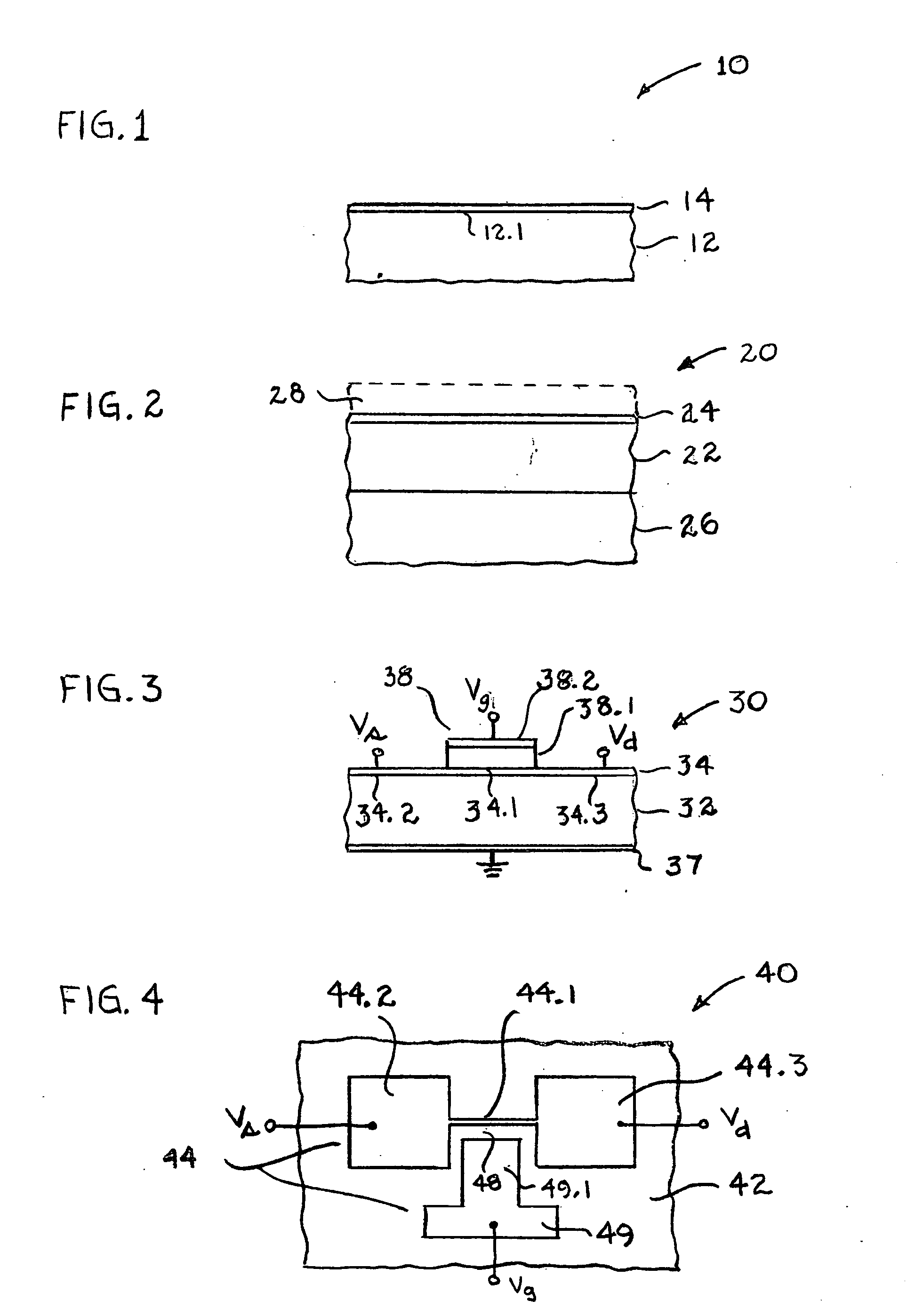

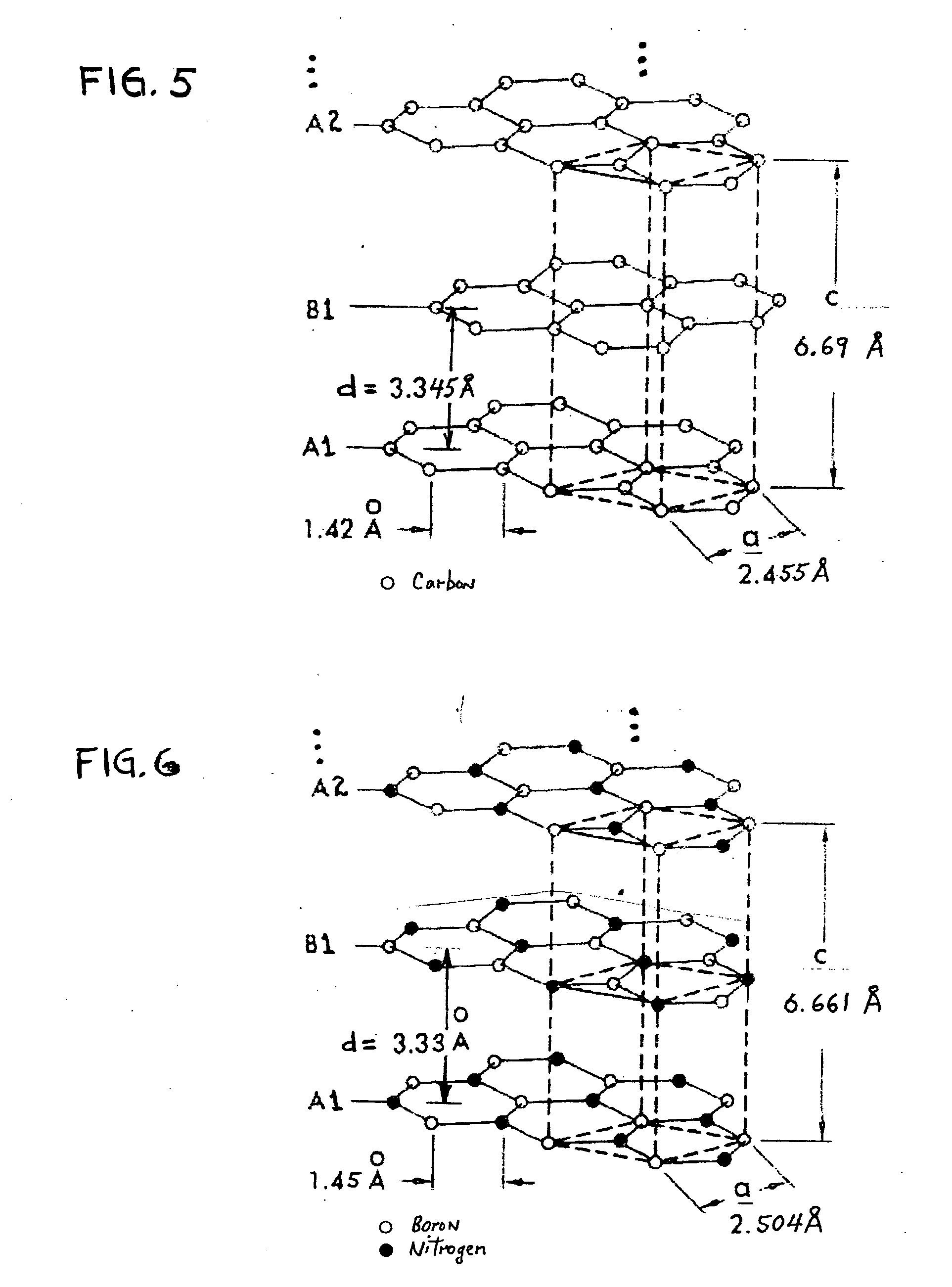

An electronic device comprises a body including a single crystal region on a major surface of the body. The single crystal region has a hexagonal crystal lattice that is substantially lattice-matched to graphene, and a at least one epitaxial layer of graphene is disposed on the single crystal region. In a currently preferred embodiment, the single crystal region comprises multilayered hexagonal BN. A method of making such an electronic device comprises the steps of: (a) providing a body including a single crystal region on a major surface of the body. The single crystal region has a hexagonal crystal lattice that is substantially lattice-matched to graphene, and (b) epitaxially forming a at least one graphene layer on that region. In a currently preferred embodiment, step (a) further includes the steps of (a1) providing a single crystal substrate of graphite and (a2) epitaxially forming multilayered single crystal hexagonal BN on the substrate. The hexagonal BN layer has a surface region substantially lattice-matched to graphene, and step (b) includes epitaxially forming at least one graphene layer on the surface region of the hexagonal BN layer. Applications to FETs are described.

Owner:ALCATEL-LUCENT USA INC +1

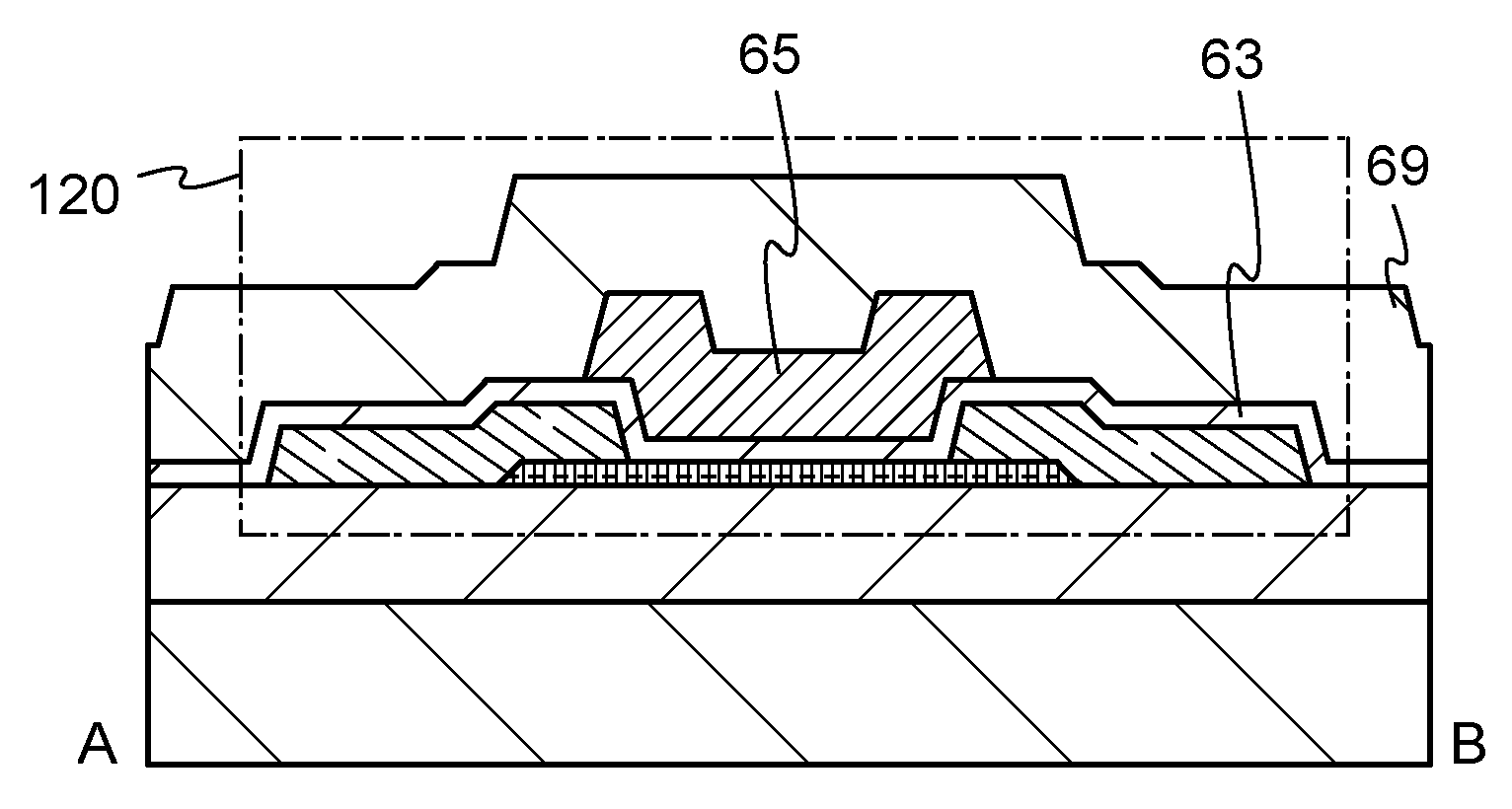

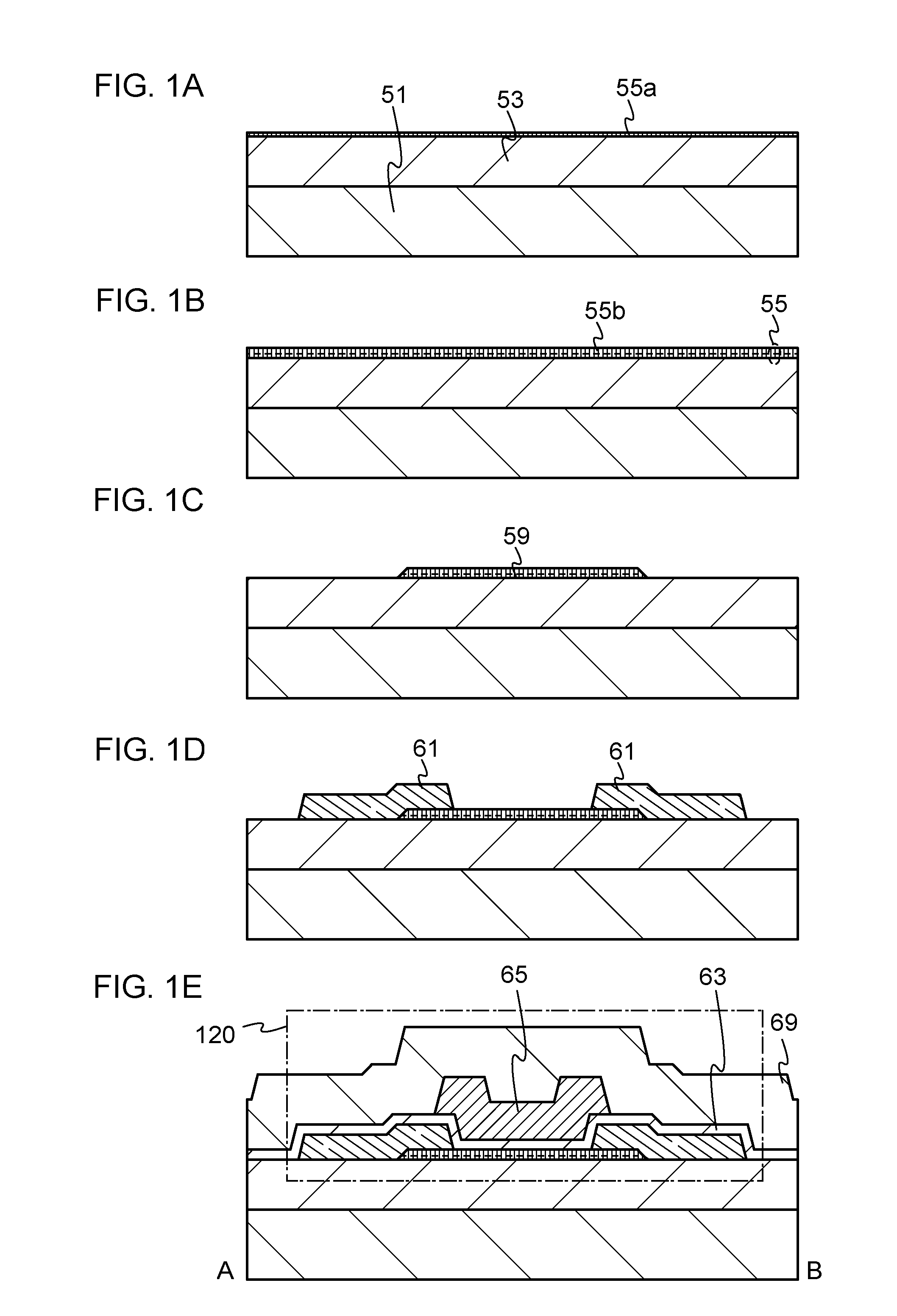

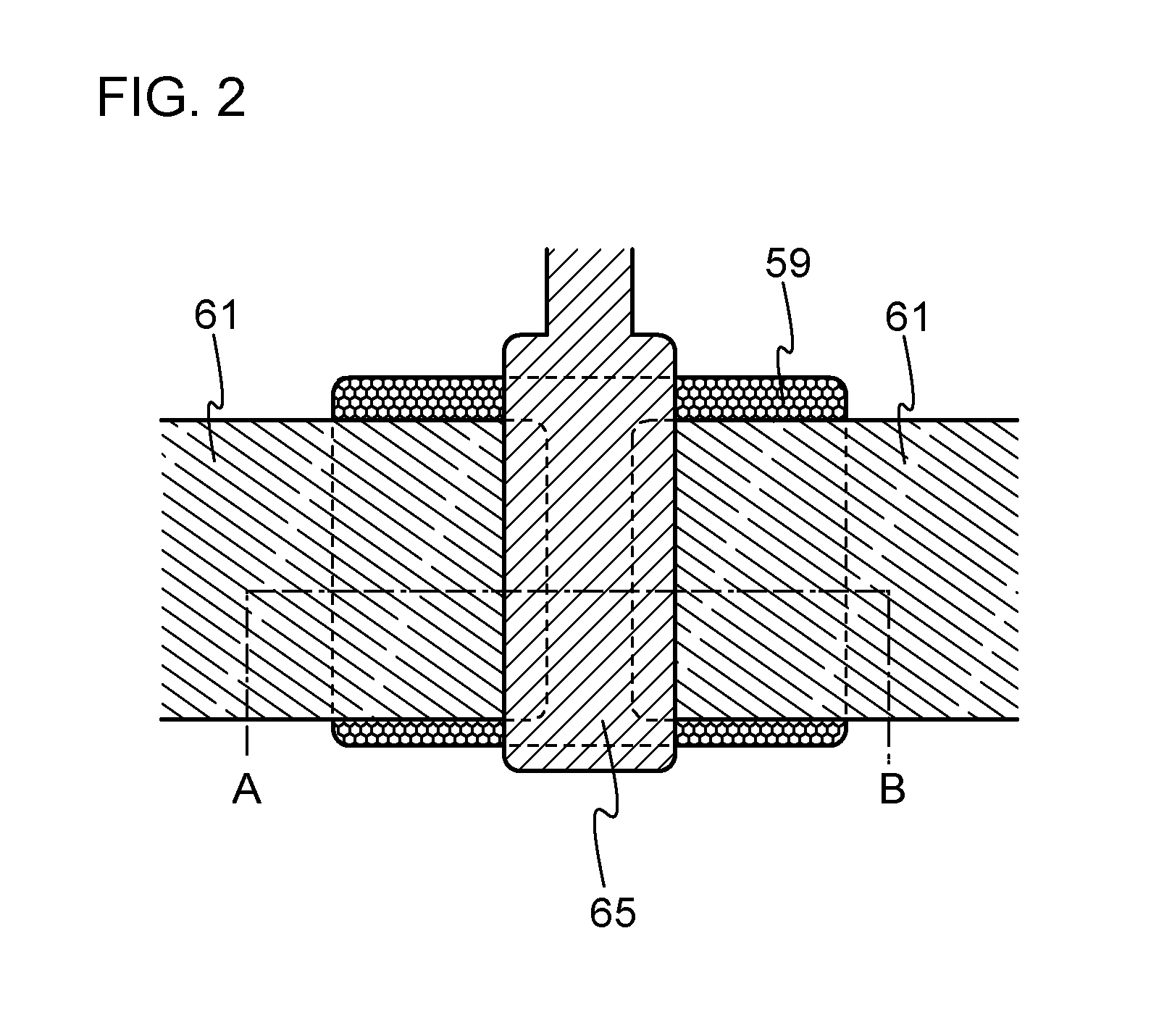

Method for manufacturing semiconductor device

ActiveUS20120064664A1Stable electrical characteristicsReduce the amount of variationSemiconductor/solid-state device detailsElectroluminescent light sourcesCrystalline oxidePower semiconductor device

An object is to manufacture a semiconductor device including an oxide semiconductor film, which has stable electric characteristics and high reliability. A crystalline oxide semiconductor film is formed, without performing a plurality of steps, as follows: by utilizing a difference in atomic weight of plural kinds of atoms included in an oxide semiconductor target, zinc with low atomic weight is preferentially deposited on an oxide insulating film to form a seed crystal including zinc; and tin, indium, or the like with high atomic weight is deposited on the seed crystal while causing crystal growth. Further, a crystalline oxide semiconductor film is formed by causing crystal growth using a seed crystal with a hexagonal crystal structure including zinc as a nucleus, whereby a single crystal oxide semiconductor film or a substantially single crystal oxide semiconductor film is formed.

Owner:SEMICON ENERGY LAB CO LTD

Nitride semiconductor light-emitting device and method for fabrication thereof

ActiveUS20060133442A1Increase heightImprove efficiencyLaser detailsNanoopticsLight emitting deviceNitride semiconductors

An adhesion layer of a hexagonal crystal is laid on a facet an optical resonator of a nitride semiconductor laser bar having a nitride-based III-V group compound semiconductor layer, and a facet coat is laid on the adhesion layer. In this way, a structure in which the facet coat is laid on the adhesion layer is obtained.

Owner:SHARP FUKUYAMA LASER CO LTD

Ferrite magnetic material, ferrite sintered magnet, and motor

InactiveUS20150170811A1Improve magnetic propertiesImprove performanceInorganic material magnetismCobalt compoundsSintered magnetsCrystal structure

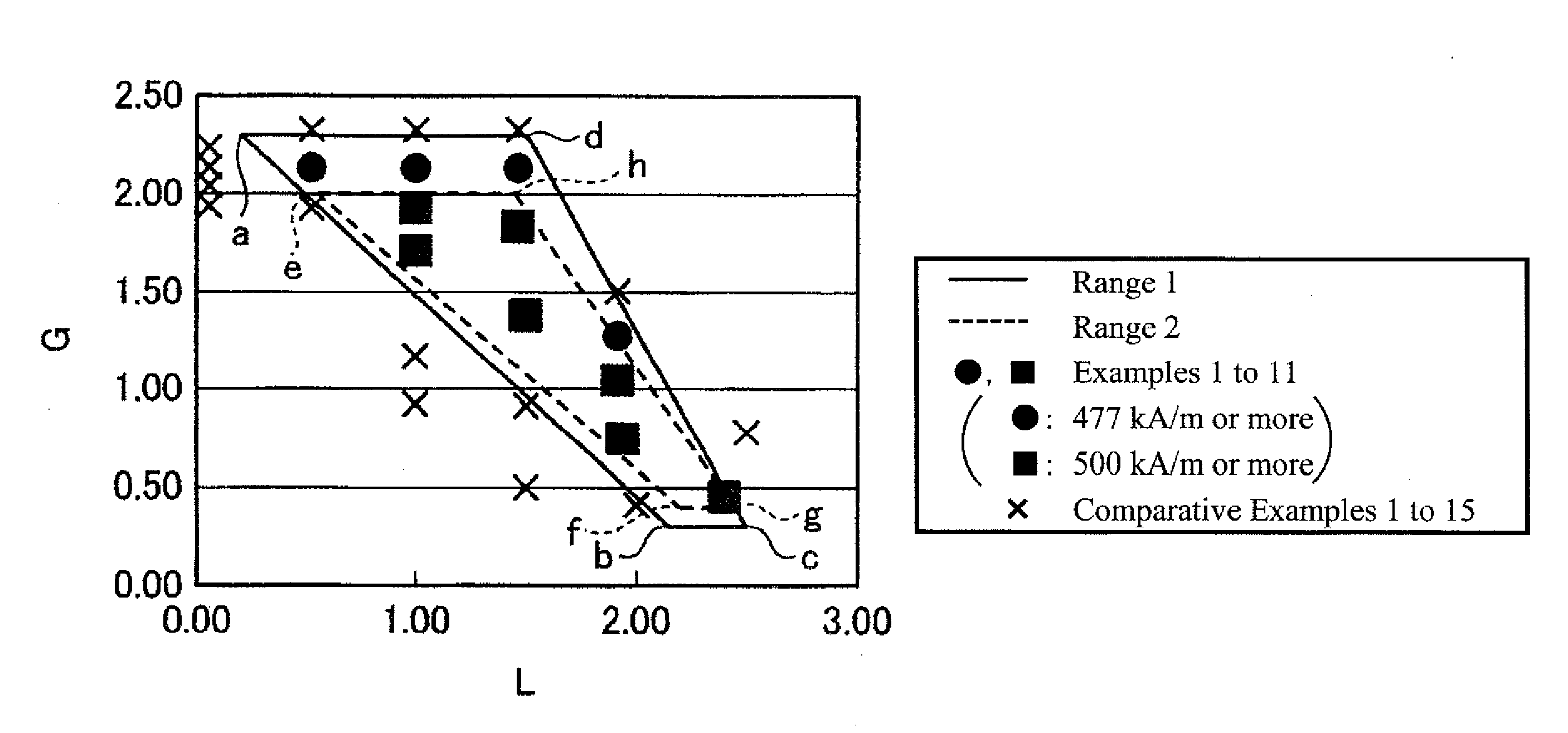

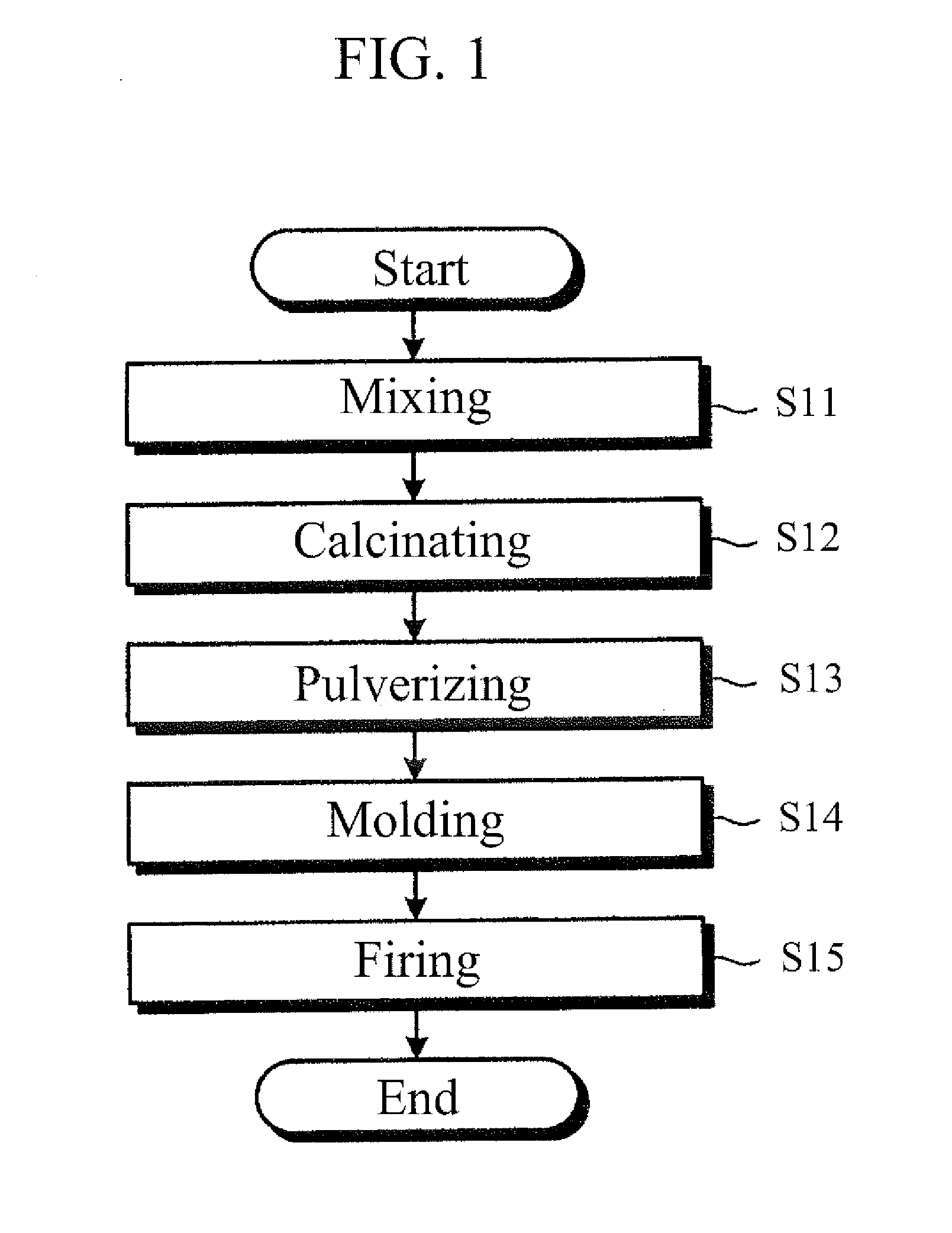

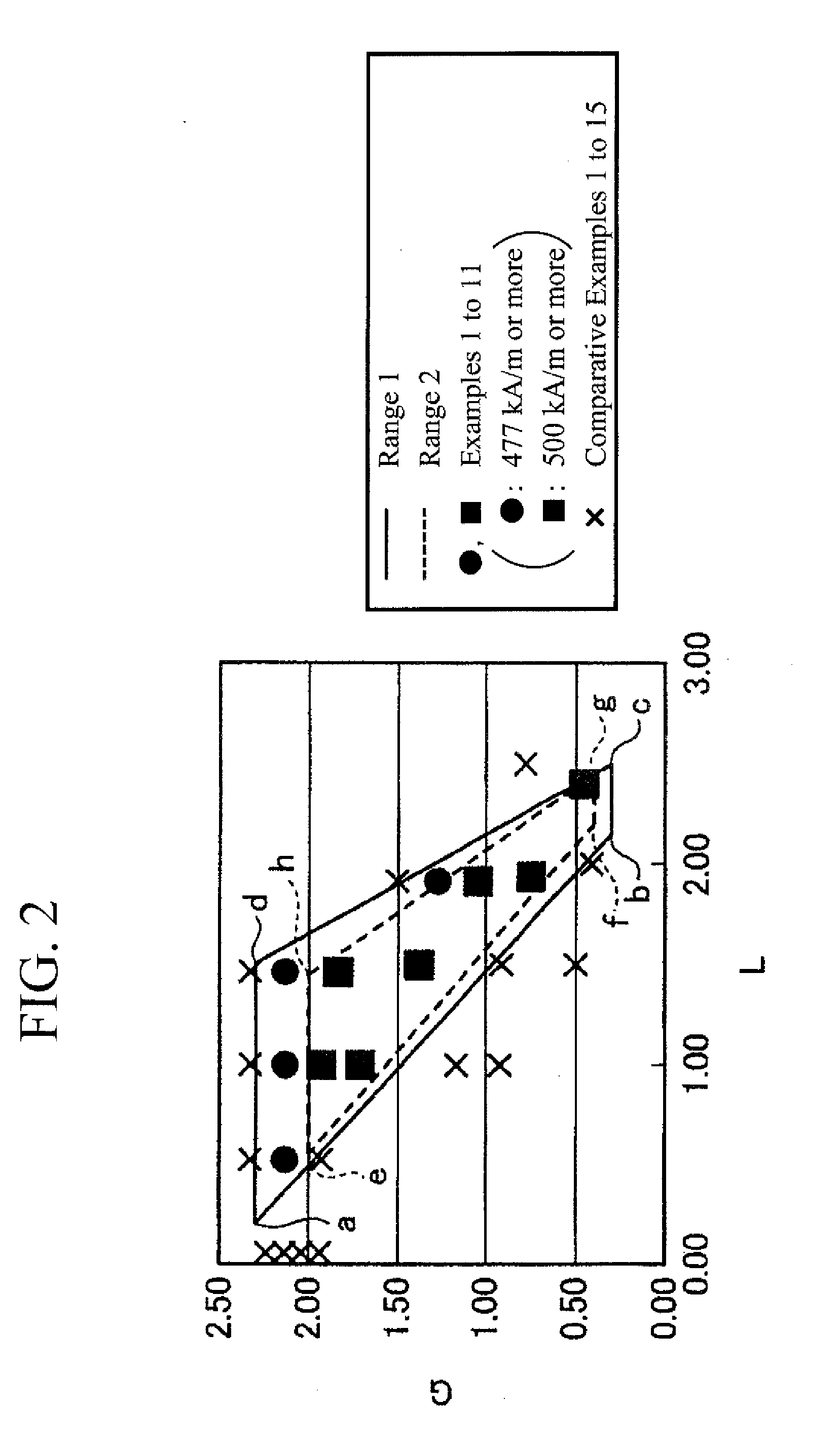

A ferrite magnetic material and ferrite sintered magnet composed thereof have a ferrite having a hexagonal crystal structure as a main component. A composition ratio of a metallic element included in the main component is represented by: RxA1-x(Fe12-yCoy)z. R is at least one element selected from La, Ce, Pr, Nd and Sm and at least includes La. A is at least two elements selected from Ca, Sr and Ba and at least includes Ca and Sr. Si component and either or both of Al component and Cr component are included as a sub-component. When a sum of Al content and a value obtained by dividing Cr content by four and a value obtained by calculating the formula [(R+A)−(Fe+Co) / 12] / Si where R, A, Fe, Co and Si indicate values of each atom % thereof are defined as L and G, respectively, L and G have to be values within a predetermined region.

Owner:TDK CORPARATION

Silicon carbide epitaxial layers grown on substrates offcut towards <1{overscore (1)}00>

InactiveUS6329088B1Polycrystalline material growthSemiconductor/solid-state device manufacturingOptoelectronicsHexagonal crystals

A silicon carbide epitaxial film, grown on an offcut surface of a SiC crystalline substrate of hexagonal crystal form, having an offcut angle of from about 6 to about 10 degrees, toward the <1{overscore (1)}00> crystalline direction of the substrate. The resultant silicon carbide epitaxial film has superior morphological and material properties.

Owner:CREE INC

Devices including graphene layers epitaxially grown on single crystal substrates

ActiveUS7619257B2Semiconductor/solid-state device manufacturingSemiconductor devicesSingle crystal substrateGraphite

An electronic device comprises a body including a single crystal region on a major surface of the body. The single crystal region has a hexagonal crystal lattice that is substantially lattice-matched to graphene, and a at least one epitaxial layer of graphene is disposed on the single crystal region. In a currently preferred embodiment, the single crystal region comprises multilayered hexagonal BN. A method of making such an electronic device comprises the steps of: (a) providing a body including a single crystal region on a major surface of the body. The single crystal region has a hexagonal crystal lattice that is substantially lattice-matched to graphene, and (b) epitaxially forming a at least one graphene layer on that region. In a currently preferred embodiment, step (a) further includes the steps of (a1) providing a single crystal substrate of graphite and (a2) epitaxially forming multilayered single crystal hexagonal BN on the substrate. The hexagonal BN layer has a surface region substantially lattice-matched to graphene, and step (b) includes epitaxially forming at least one graphene layer on the surface region of the hexagonal BN layer. Applications to FETs are described.

Owner:ALCATEL-LUCENT USA INC +1

Metal gradient doped lithium battery positive electrode material

InactiveCN105870402AReduced responseImprove operational efficiencyCell electrodesHigh concentrationManganese

A metal gradient doped lithium battery positive electrode material containing a hexagonal crystal positive electrode material body and modified metal. An active unit of the positive electrode material powder body is composed of oxides of single metal of nickel and cobalt, or two metals of nickel and cobalt, nickel and manganese, and cobalt and manganese, or three metals of nickel, cobalt and manganese; and the modified metal is an active metal element different from nickel, cobalt or manganese, in particular, the modified metal is concentrated on the surface of the positive electrode material powder and shows continuous decline towards the core, thereby forming a continuous concentration gradient doping distribution; and the powder material has no interface or stratification. Since the modified metal has higher concentration on the surface of the positive electrode material powder, the reactivity of surface of positive electrode material to the electrolyte can be reduced, thereby enhancing stability and security of the lithium battery, lowing the dose, and increasing energy density and service life.

Owner:JEN CATHOLIC UNIV

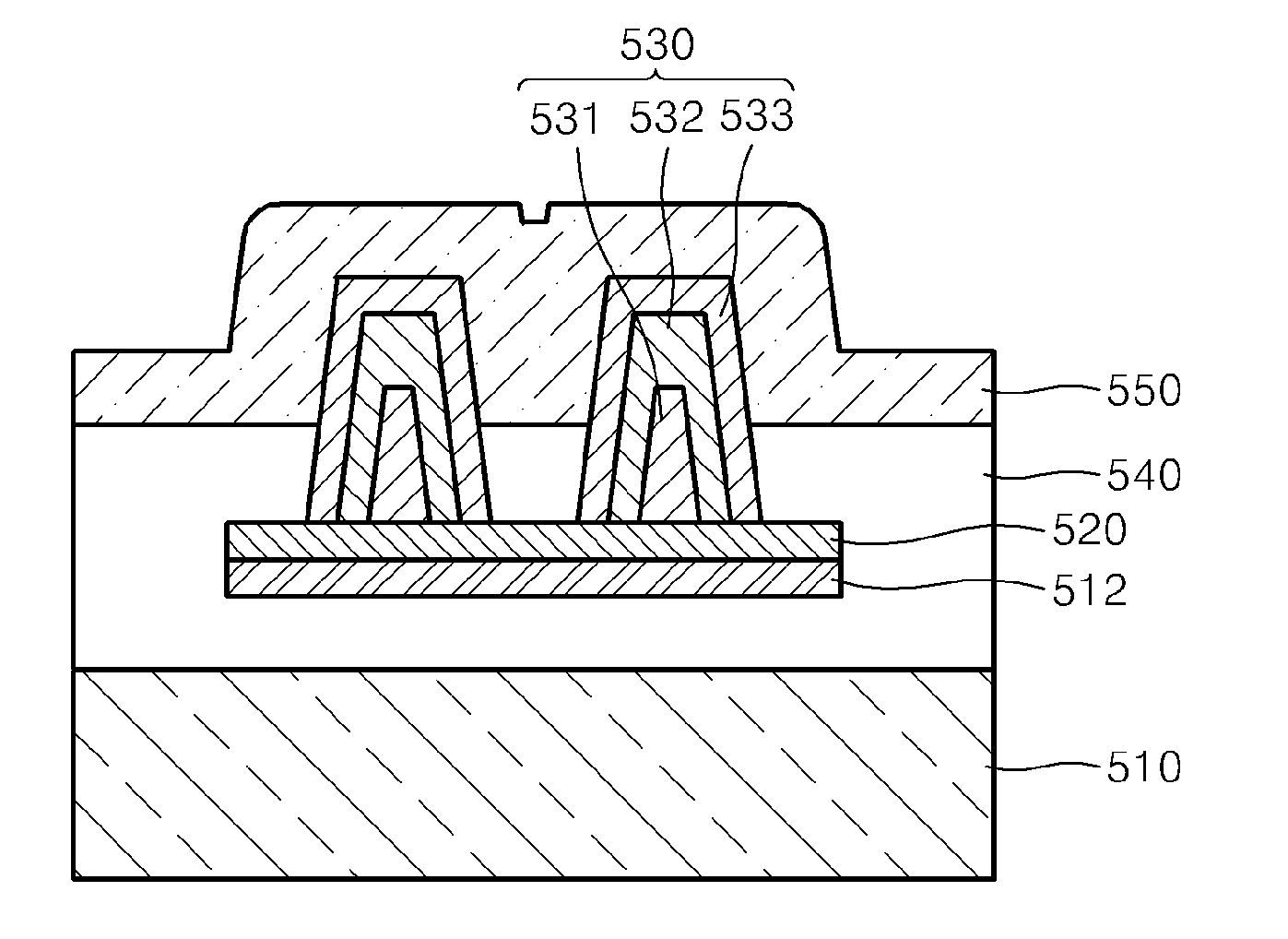

Semiconductor compound structure and method of fabricating the same using graphene or carbon nanotubes, and semiconductor device including the semiconductor compound structure

ActiveUS20120056237A1Easy to depositSemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialCarbon nanotube

A semiconductor compound structure and a method of fabricating the semiconductor compound structure using graphene or carbon nanotubes, and a semiconductor device including the semiconductor compound structure. The semiconductor compound structure includes a substrate; a buffer layer disposed on the substrate, and formed of a material including carbons having hexagonal crystal structures; and a semiconductor compound layer grown and formed on the buffer layer.

Owner:SAMSUNG ELECTRONICS CO LTD

Magnesium hydroxide particles, process for producing the same, and resin composition containing the particles

InactiveUS6676920B1Maintain good propertiesOxide/hydroxide preparationSilicaShell moldingSingle crystal

Owner:KYOWA CHEM IND

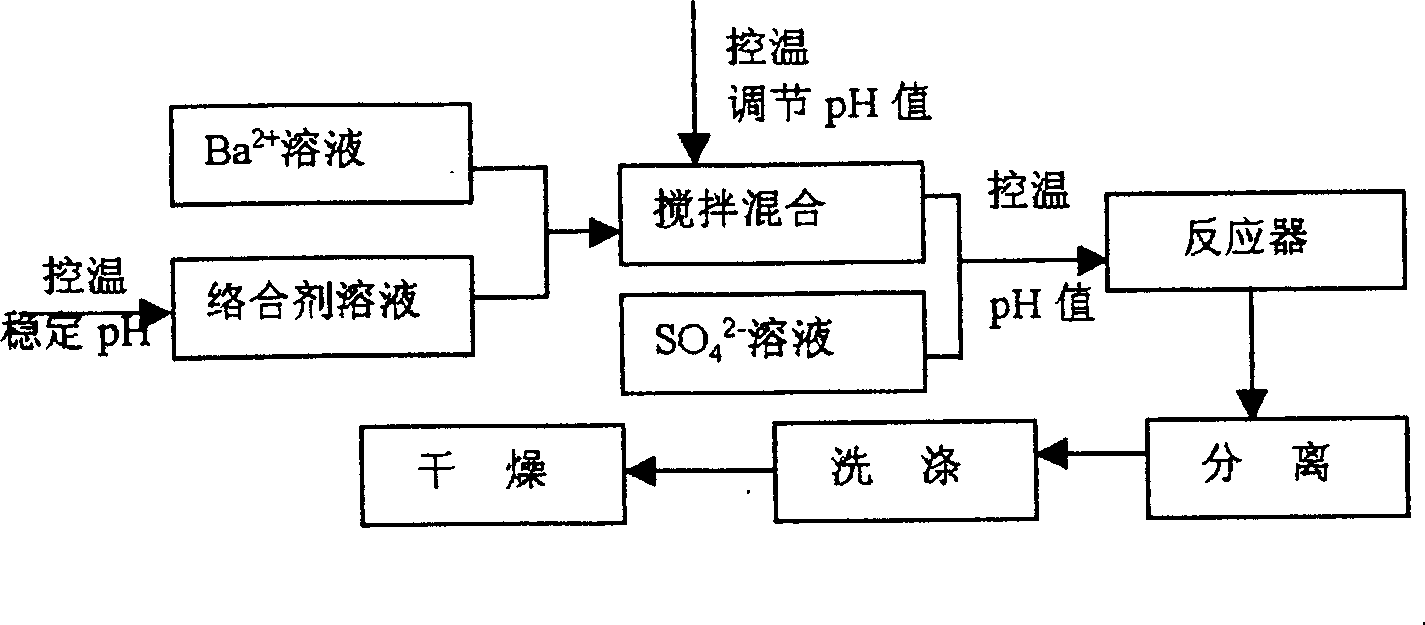

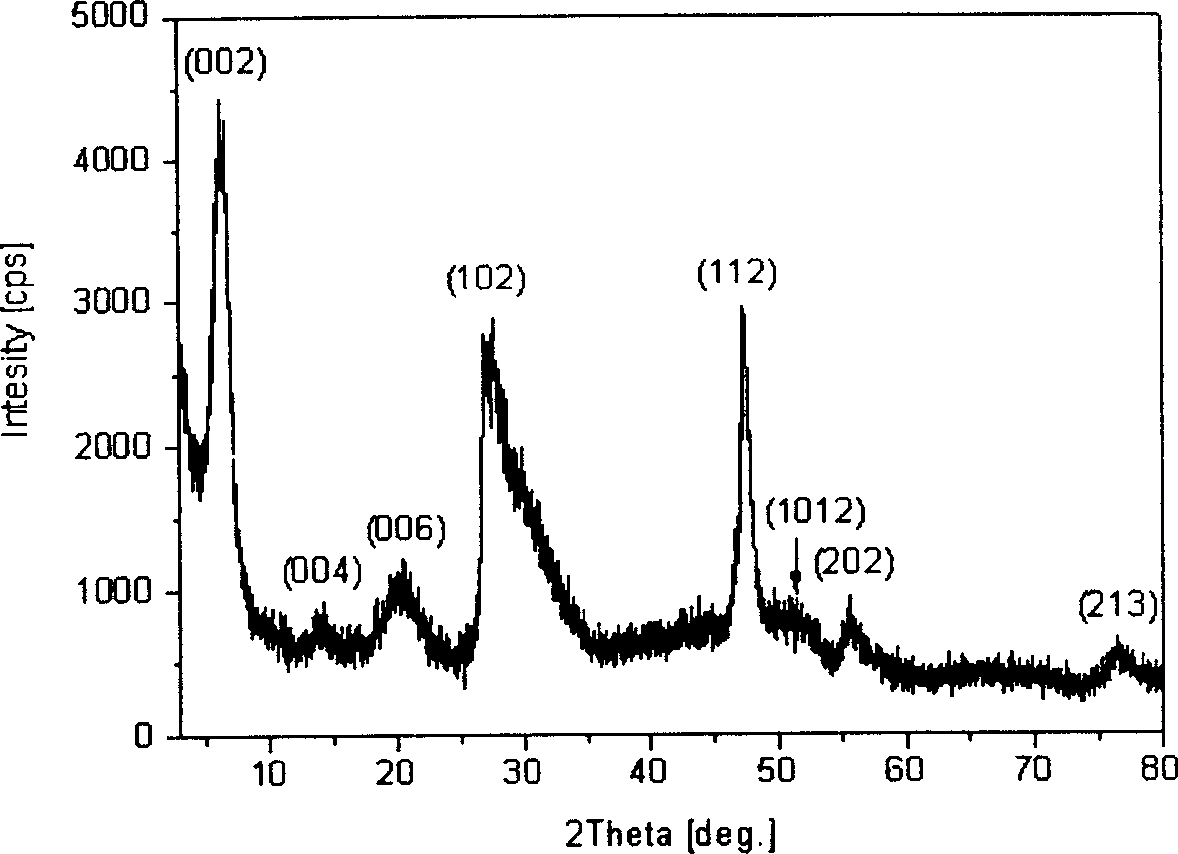

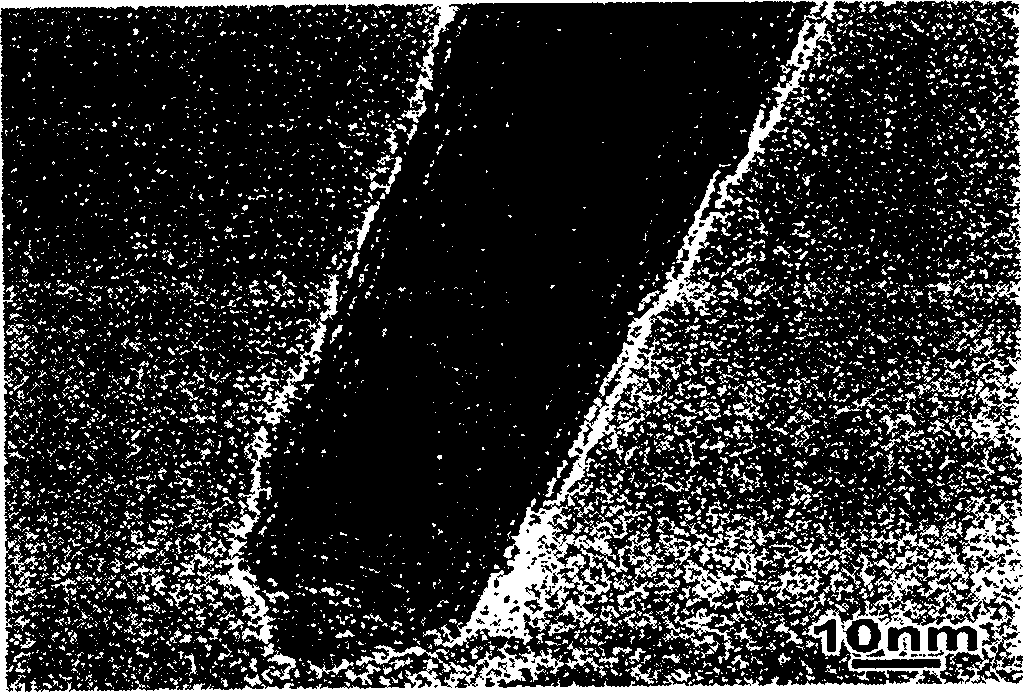

Prepn of nano barium sulfate

InactiveCN1398789AStable operating conditionsGood resolubility and dispersibilityMaterial nanotechnologyCalcium/strontium/barium sulfatesSal ammoniacSulfate radicals

The present invention belongs to the field of chemical technology and is especially a complexing process of preparing nanometer BaSO4. The process includes two main steps of complexing reaction and deposition reaction. Specifically. Ba2+ ion solution and EDTA complexing agent solution produce complexing reaction in a reactor to produce complex solution with certain stability and ammonia water being used for regulating system pH value. The complex solution is made to react with sulfate radical solution while stirring to prepare nanometer level BaSO4 particles as precipitate. The nanometer level BaSO4 product is hexagonal crystal and blue in color, and has grain size of 20-40 nm and average grain size of 25 nm. The process is stable in operation, and the product has high quality and dispersivity.

Owner:ZHONGBEI UNIV

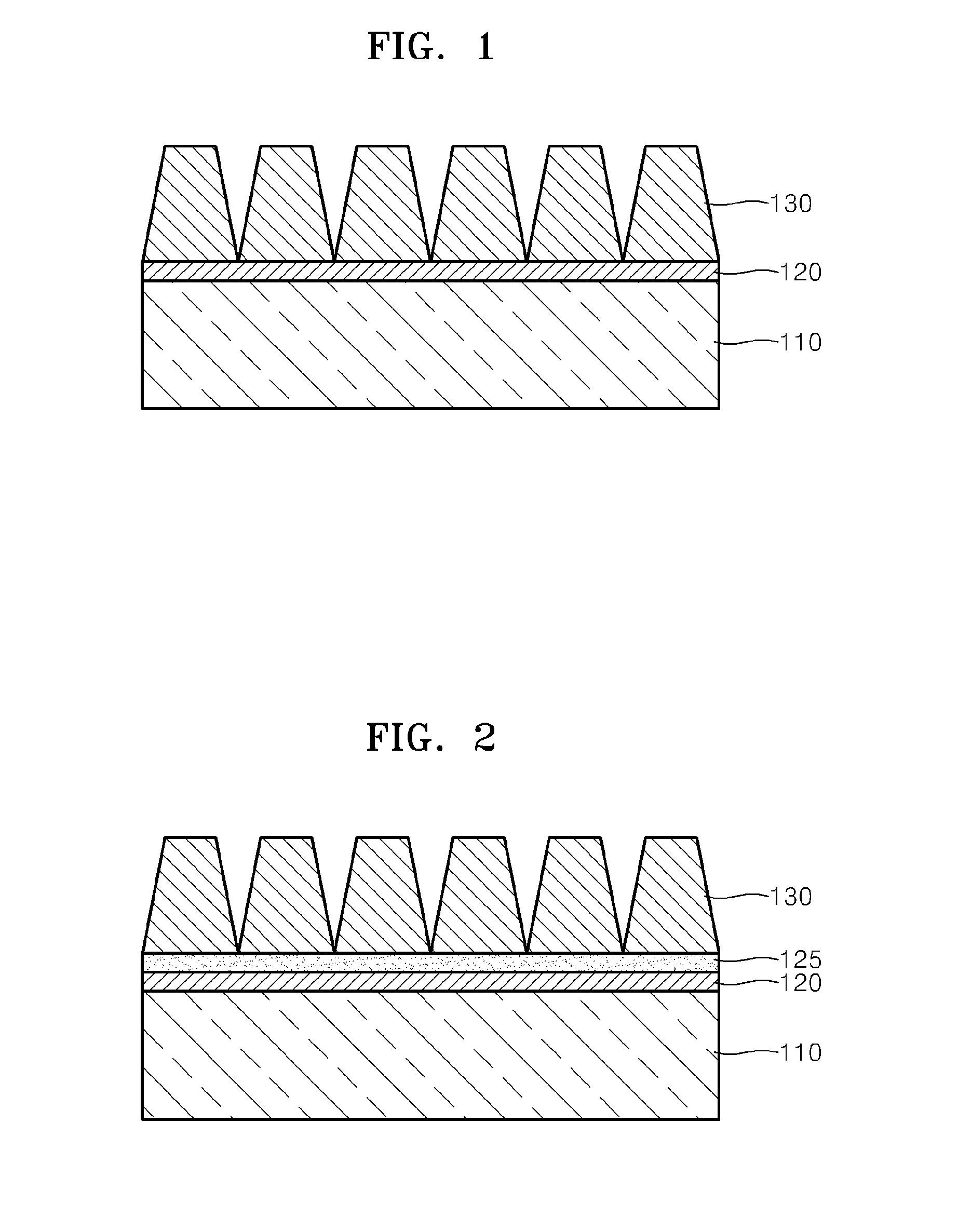

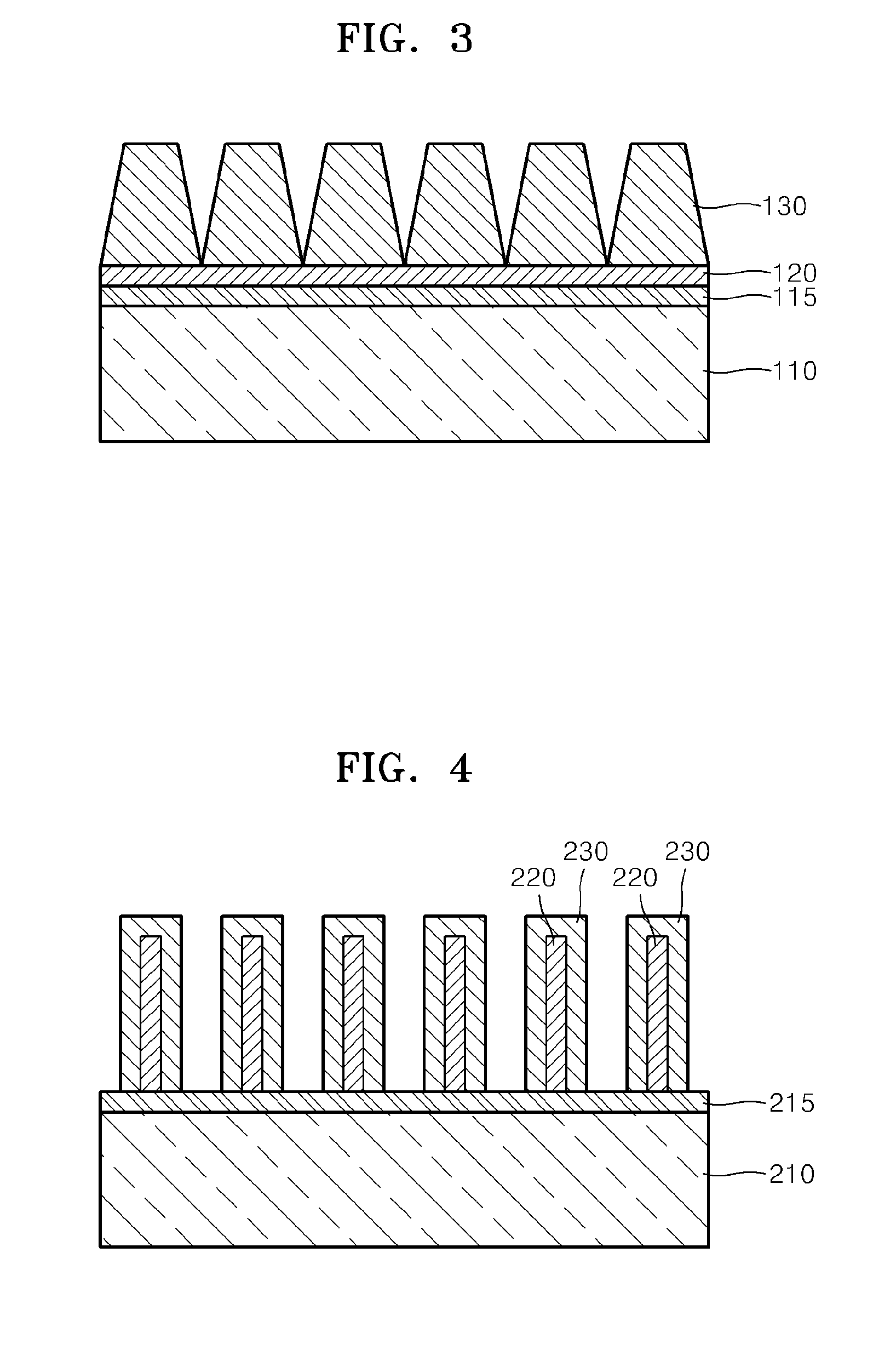

Nitride semiconductor light emitting device with surface texture and its manufacture

ActiveUS20100006876A1Improved external emission efficiencySemiconductor/solid-state device manufacturingSemiconductor devicesCrystal structureActive layer

A nitride semiconductor light emitting device includes: a substrate for growing nitride semiconductor of a hexagonal crystal structure; a first nitride semiconductor layer of a first conductivity type formed above the substrate; an active layer formed on the first nitride semiconductor layer for emitting light when current flows; a second nitride semiconductor layer of a second conductivity type opposite to the first conductivity type formed on the active layer; texture formed above at least a partial area of the second nitride semiconductor layer and having a plurality of protrusions of a pyramid shape, each of the protrusions including a lower layer made of nitride semiconductor doped with impurities of the second conductivity type and an upper layer made of nitride semiconductor not intentionally doped with impurities; and a transparent electrode covering surfaces of the second nitride semiconductor layer and the texture.

Owner:STANLEY ELECTRIC CO LTD

Silicon carbide epitaxial layers grown on substrates offcut towards <1100>

InactiveUS20020059898A1Polycrystalline material growthFrom solid stateOptoelectronicsHexagonal crystals

A silicon carbide epitaxial film, grown on an offcut surface of a SiC crystalline substrate of hexagonal crystal form, having an offcut angle of from about 6 to about 10 degrees, toward the <1{overscore (1)}00> crystalline direction of the substrate. The resultant silicon carbide epitaxial film has superior morphological and material properties.

Owner:CREE INC

Method for growing semiconductor layer, method for producing semiconductor light-emitting element, semiconductor light-emitting element, and electronic device

InactiveUS20080283846A1Suppressed piezoelectric fieldImprove crystal qualityPolycrystalline material growthSolid-state devicesCrystal structureSemiconductor

Disclosed herein is a method for growing a semiconductor layer which includes the step of growing a semiconductor layer of hexagonal crystal structure having the (11-22) or (10-13) plane direction on the (1-100) plane of a substrate of hexagonal crystal structure.

Owner:SONY CORP

ZnIn2S4 nano materials and their synthesis method and application

InactiveCN1884090AImprove photoelectric performanceSimple methodGallium/indium/thallium compoundsZinc compoundsOrganic sulfide compoundIndium

The invention discloses a Znln2S4 nanometer material and synthesizing method and application, which is characterized by the following: adopting bivalent zinc salt, trivalent indium salt and organic sulfide as raw material; proceeding solvent heating or water heating reaction at 100-220 deg.c in the sealing reactor; setting surface activist as addictive; synthesizing Znln2S4 nanometer pipe, nanometer band and nanometer line selectively through controlling solvent kind, reacting temperature and reacting time. The invention belongs to layer-shaped hexagonal crystal phase with kind's direction of specific property, which is fit for relative domains of solar battery, optical catalyst, high-energy battery, and heat-conversion.

Owner:NANKAI UNIV

Oxide semiconductor film and semiconductor device

ActiveUS20120241735A1Stable electrical characteristicsStable characteristicsSemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialCrystal structure

Provided is an oxide semiconductor film which has more stable electric characteristics and essentially consists of indium zinc oxide. In addition, provided is a highly reliable semiconductor device which has stable electric characteristics by using the oxide semiconductor film. The oxide semiconductor film essentially consisting of indium zinc oxide has a hexagonal crystal structure in which the a-b plane is substantially parallel to a surface of the oxide semiconductor film and a rhombohedral crystal structure in which the a-b plane is substantially parallel to the surface of the oxide semiconductor film.

Owner:SEMICON ENERGY LAB CO LTD

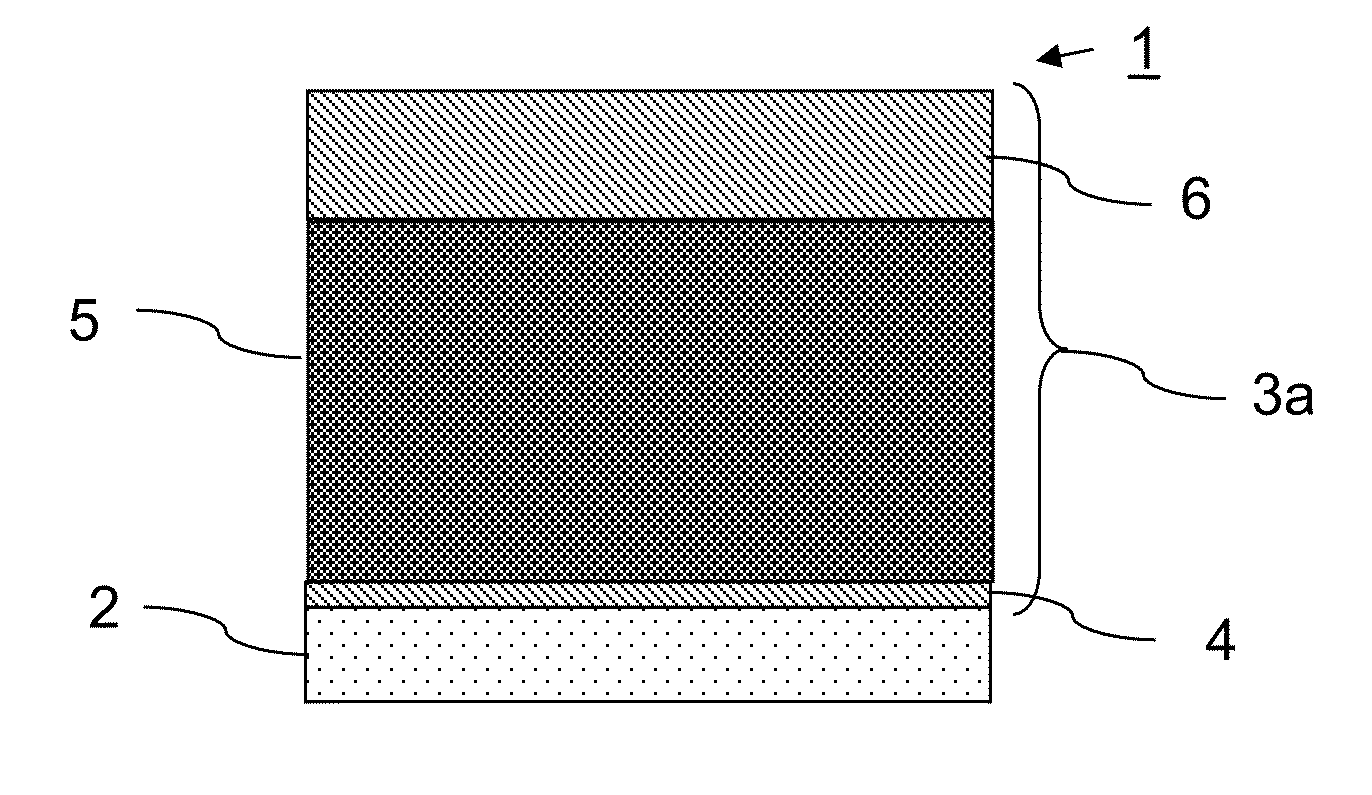

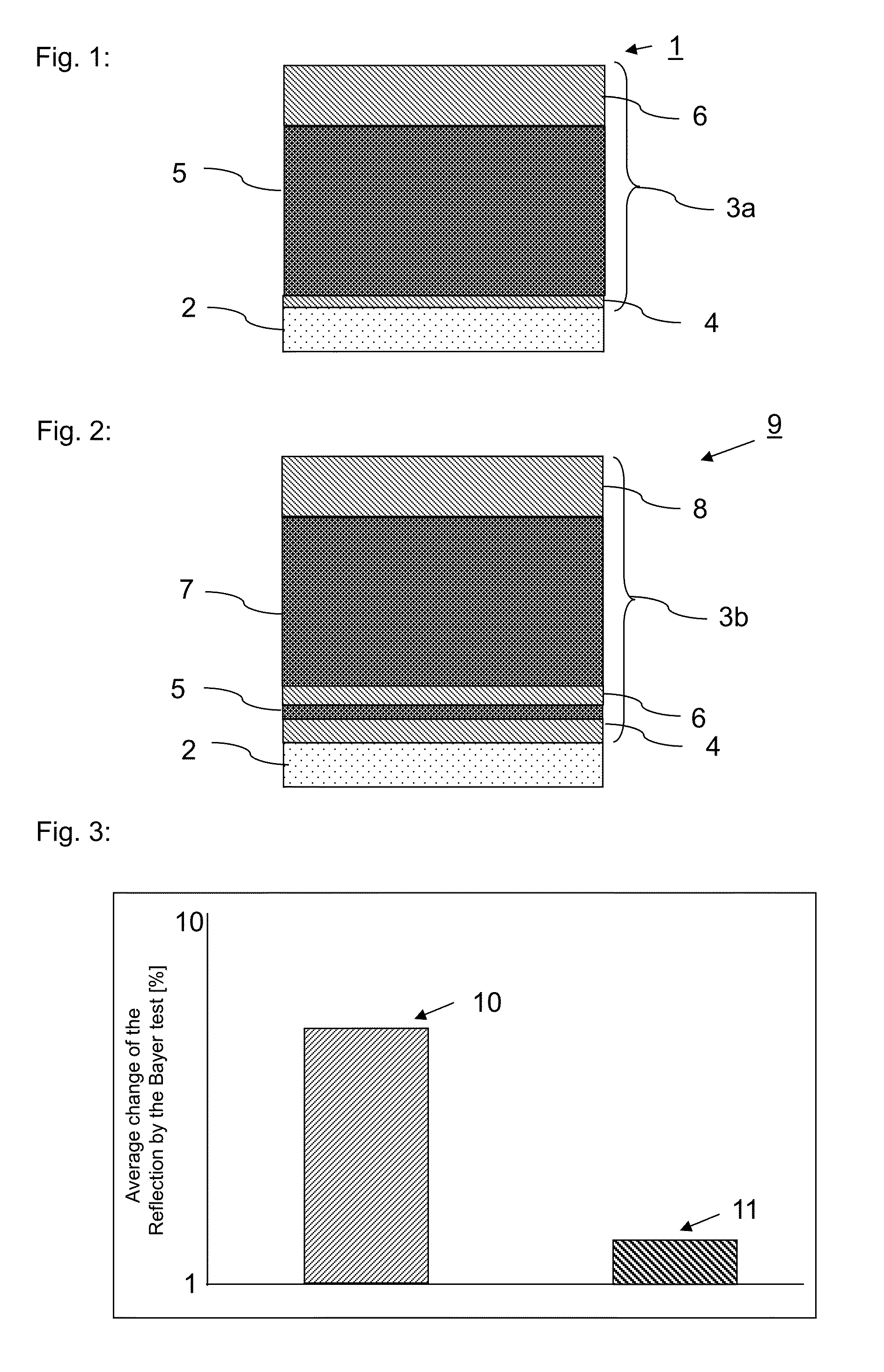

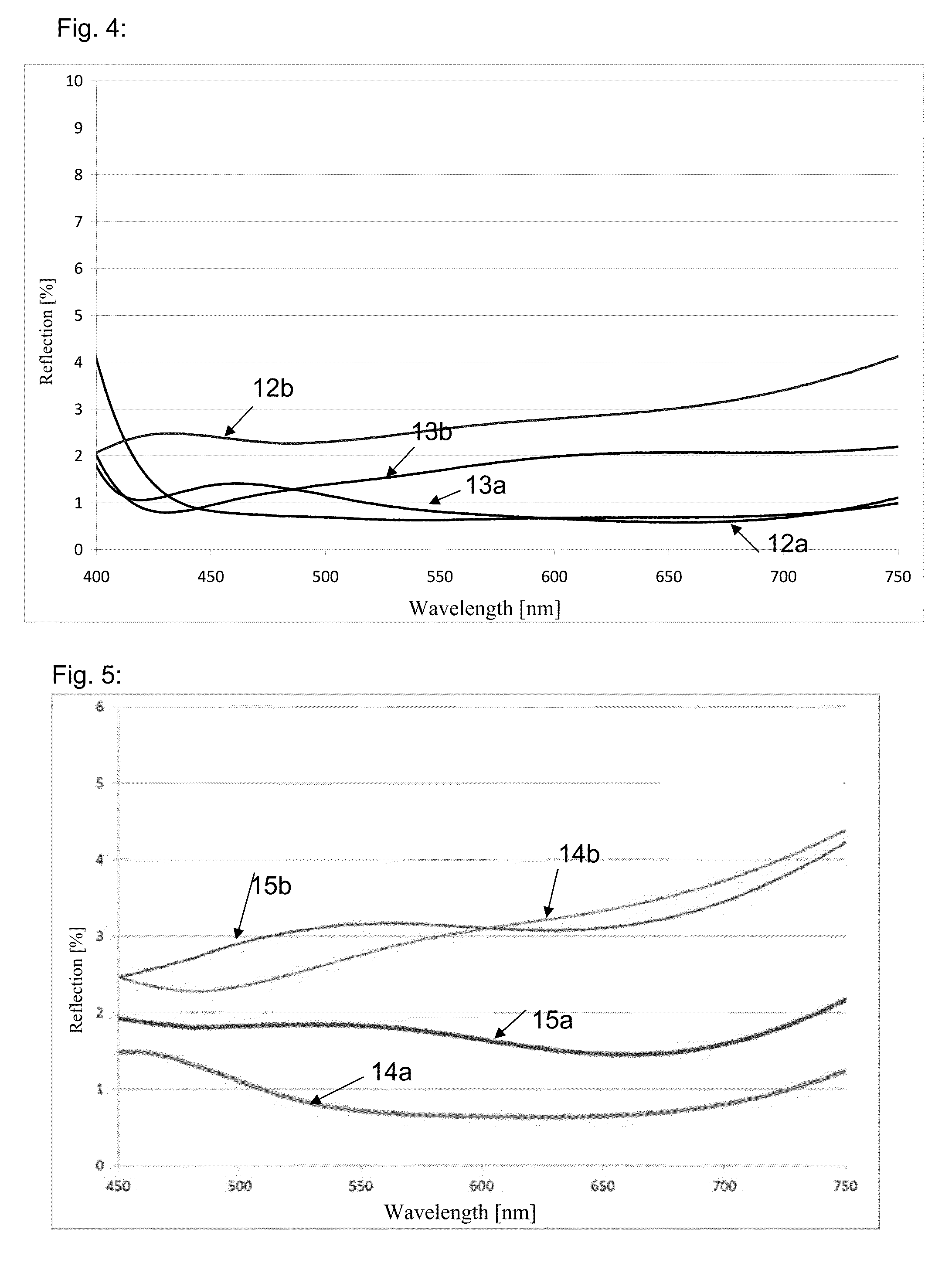

Hard Anti-reflective coatings and manufacturing and use thereof

InactiveUS20150355382A1Crystal formation can be enhancedImprove mechanical propertiesLayered productsVacuum evaporation coatingAnti-reflective coatingCrystal structure

A coated substrate is provided with a scratch-resistant anti-reflective coating. The anti-reflective coating is designed as an optical interference coating that has at least two low refractive index layers and at least one high refractive index layer. The high refractive index layer is a transparent hard material layer and includes crystalline aluminum nitride with a hexagonal crystal structure with a (001) preferred orientation. The low refractive index layers include SiO2. The low refractive index layers and high refractive index layers are arranged alternately.

Owner:SCHOTT AG

Cerium oxide abrasive and slurry containing the same

InactiveUS20060162260A1Dispersion force can be reducedSlow polishing rateMaterial nanotechnologyPigmenting treatmentCeriumCrystal structure

Disclosed are a cerium oxide abrasive for selectively polishing various SiO2 films and SiO2—Si3N4 films; and a slurry containing the same. The cerium oxide abrasive and the polishing slurry of the present invention have a high polishing rate and are also free from microscratches in a polished surface upon polishing since polycrystalline cerium oxide having a mean crystalline particle size of 5 nm or less is synthesized by using hexagonal cerium carbonate having a hexagonal crystal structure as a raw material of cerium.

Owner:LG CHEM LTD

Wafer producing method

ActiveUS20160228985A1Improve productivitySufficient amountPolycrystalline material growthAfter-treatment detailsOptoelectronicsIngot

A crystal wafer is produced from a hexagonal crystal ingot. A separation start point is formed by setting the focal point of a laser beam inside the ingot at a predetermined depth, which depth corresponds to the thickness of the wafer to be produced. The laser beam is applied to the upper surface of the ingot while relatively moving the focal point and the ingot to form a modified layer parallel to the upper surface of the ingot and cracks extending from the modified layer along a c-plane in the ingot, thus forming the separation start point. First the laser beam is scanned from a scanning start point to a scanning end point on the ingot. Then the laser beam is scanned from the scanning end point to the scanning start point. The first and second steps are alternately repeated to separate the cracks from the modified layer.

Owner:DISCO CORP

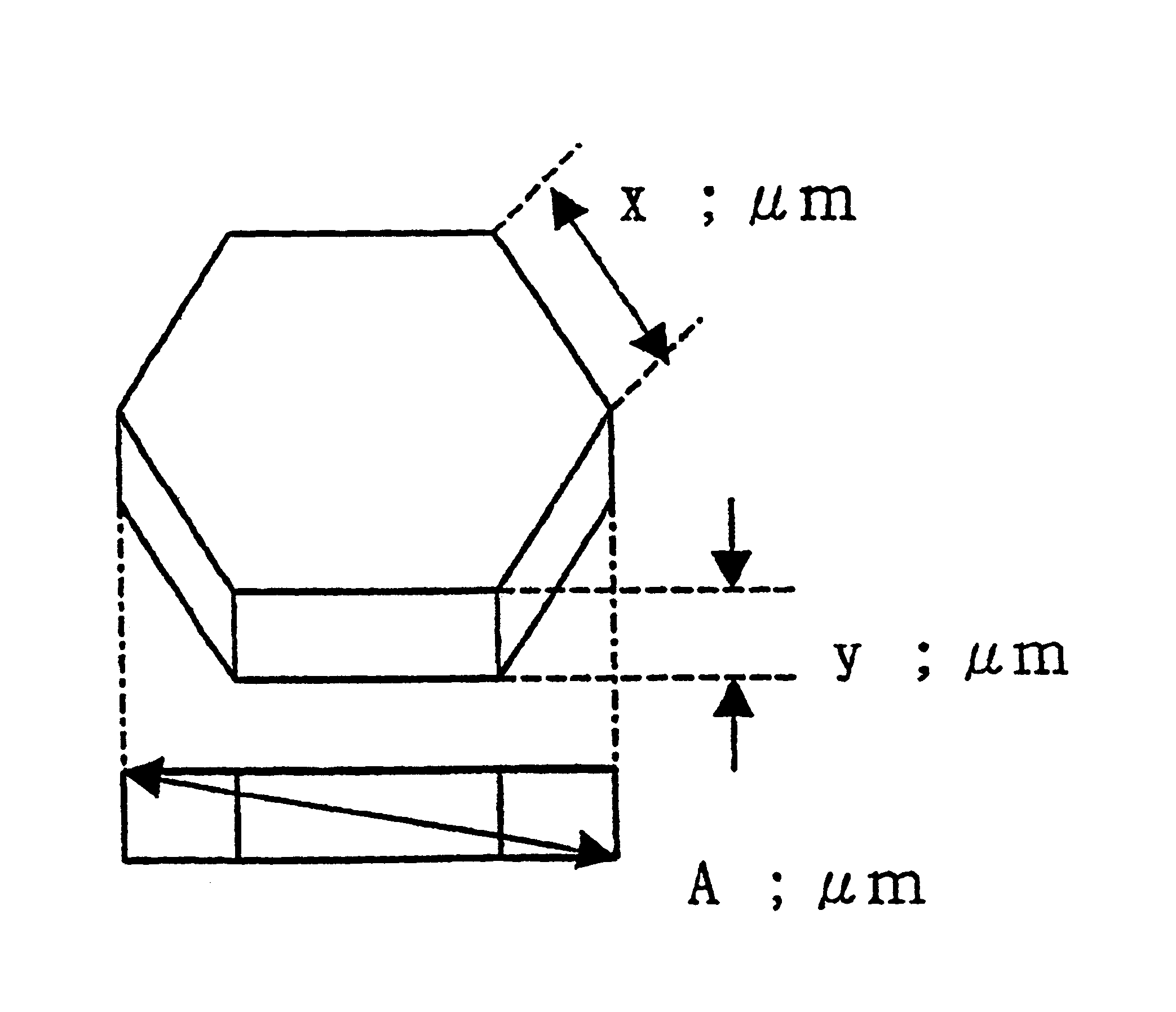

Magnesium hydroxide particles, method of the production thereof, and resin composition containing the same

InactiveUS20030235693A1Improve thermal stabilityLow mechanical strengthSynthetic resin layered productsDomestic articlesSingle crystalSynthetic resin

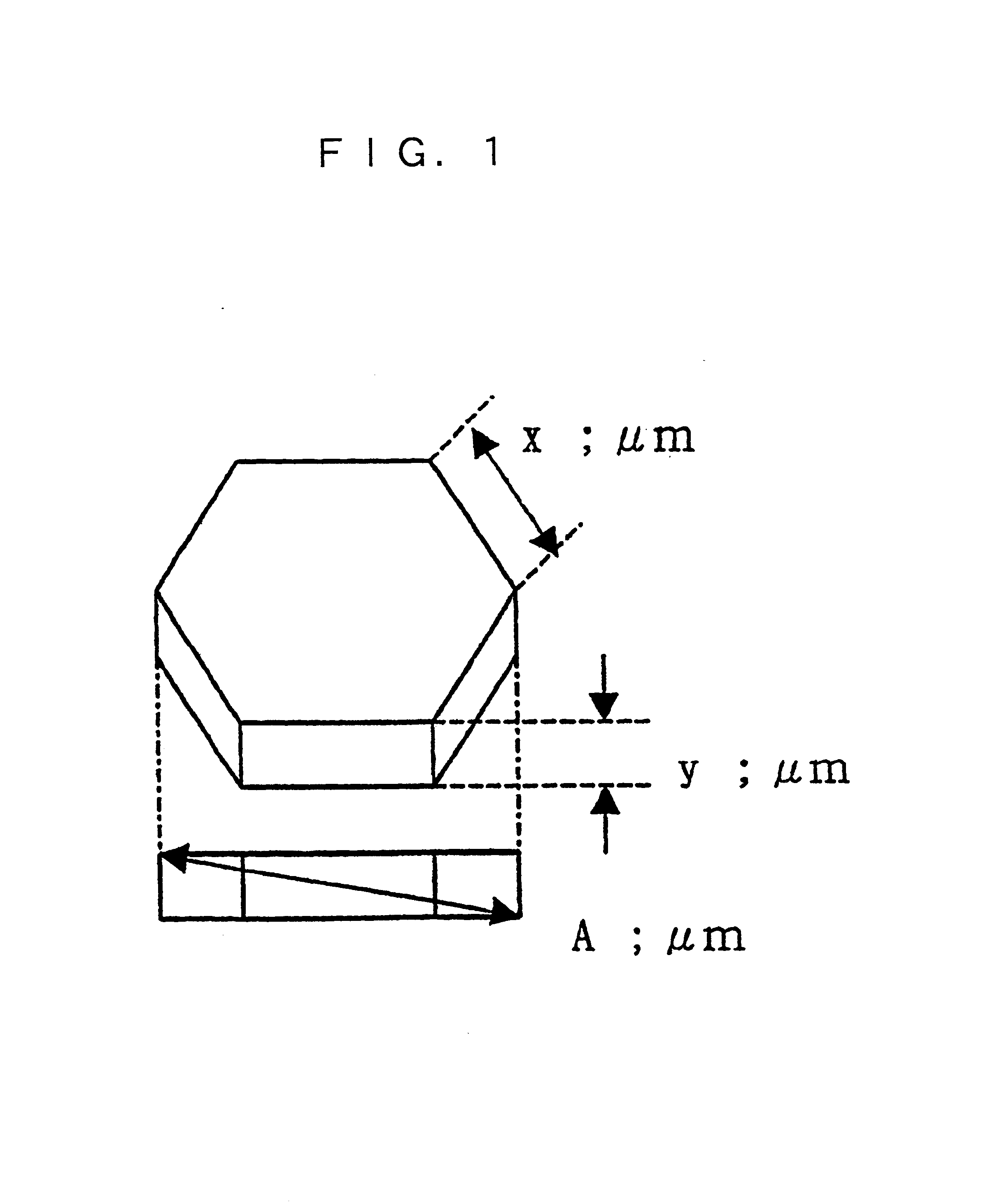

Provided are magnesium hydroxide particles having a hexagonal crystal form and having an aspect ratio (H) which satisfies the following expression (I),0.45.A.B<H<1.1.A.B (I)(wherein H is an aspect ratio, A is an average secondary particle diameter (mum) of all of the particles measured by a laser diffraction scattering method and B is a specific surface area (m<2> / g) of all of the particles measured by a BET method), a flame-retardant comprising the particles, a flame-retardant resin composition comprising 100 parts by weight of a synthetic resin and a 5 to 300 parts by weight of the magnesium hydroxide particles, and a molded article therefrom. The magnesium hydroxide particles are hexagonal single crystals, the hexagonal form thereof are not necessarily required to be regular hexagonal, and the size thereof are not necessarily constant. However, the aspect ratio thereof has a specific value in relation to the specific surface area and the average particle diameter, and the magnesium hydroxide particles have excellent properties as a flame retardant for synthetic resins.

Owner:KYOWA CHEM IND

Scratch-resistant coatings, substrates having scratch-resistant coatings and methods for producing same

ActiveUS20150284840A1Increase resistanceImprove stress conditionVacuum evaporation coatingSputtering coatingCrystal structureRefractive index

A substrate having a coating for enhanced scratch resistance is provided. The coating includes at least one high refractive index transparent hard material layer. The hard material layer includes crystalline aluminum nitride having a hexagonal crystal structure that exhibits a predominant (001) preferred orientation of the hexagonal symmetry.

Owner:SCHOTT AG

Vertical heterostructure field effect transistor and associated method

A vertical heterostructure field effect transistor including a first layer having a first material, and the first material having a hexagonal crystal lattice structure defining a first bandgap and one or more non-polar planes is provided. The transistor further includes a second layer that is adjacent to the first layer having a second material. Further, the second layer has a first surface and a second surface, and a portion of the second layer first surface is coupled to the surface of the first layer to form a two dimensional charge gas and to define a first region. The second material may have a second bandgap that is different than the first bandgap. Furthermore, the transistor may include a conductive layer that is disposed in the trench and is interposed between the first region and a second region that is not in electrical communication with the first region if no electrical potential is applied to the conductive layer, and an electrical potential applied to the conductive layer allows electrical communication from the first region to the second region.

Owner:GENERAL ELECTRIC CO

Sintered polycrystalline yttrium aluminum garnet and use thereof in optical devices

InactiveUS20100048378A1Improve the level ofControl loadMaterial nanotechnologyRare earth metal compoundsCelsius DegreeYttrium

A transparent yttrium aluminum garnet precursor composition is provided that includes a plurality of calcined particles of yttrium aluminum oxide having a mean particle domain size of between 10 and 200 nanometers and a predominant hexagonal crystal structure. High levels of YAG transparency are obtained for large YAG articles through control of the aluminum:yttrium atomic ratio to 1:06±0.001 and limiting impurity loadings to less than 100 ppm. The composition is calcined at a temperature between 700° Celsius and 900° Celsius to remove organic additives to yield a predominant metastable hexagonal phase yttrium aluminum oxide nanoparticulate having an atomic ratio of aluminum: yttrium of 1:0.6±0.001. With dispersion in an organic binder and a translucent YAG article is formed having a transmittance at a wavelength of 1064 nanometers of greater than 75%. The translucent YAG article is characterized by an average domain size of less than 1 micron and having a density of at least 99% and inclusions present at less than 2 surface area percent. The ability of a batch of yttrium aluminum oxide nanoparticles to serve as a transparent YAG precursor includes collecting an X-ray fluorescence spectrum from a plurality of aluminum oxide nanoparticles having a predominant crystal structure other than garnet to yield an A1:Y raw integrated peak intensity ratio. The nanoparticles are sintered to yield a predominant garnet phase and a secondary phase and optionally isostatic pressing during sintering. By using only precursor nanoparticles with a standard deviation of ±0.003 in the peak ratio exceptionally high transparency YAG is reproducibly produced.

Owner:NANOCEROX

Rare Earth Nanorods

ActiveUS20080279744A1Reduce expenditureMaterial nanotechnologyPolycrystalline material growthNanoparticleRare earth

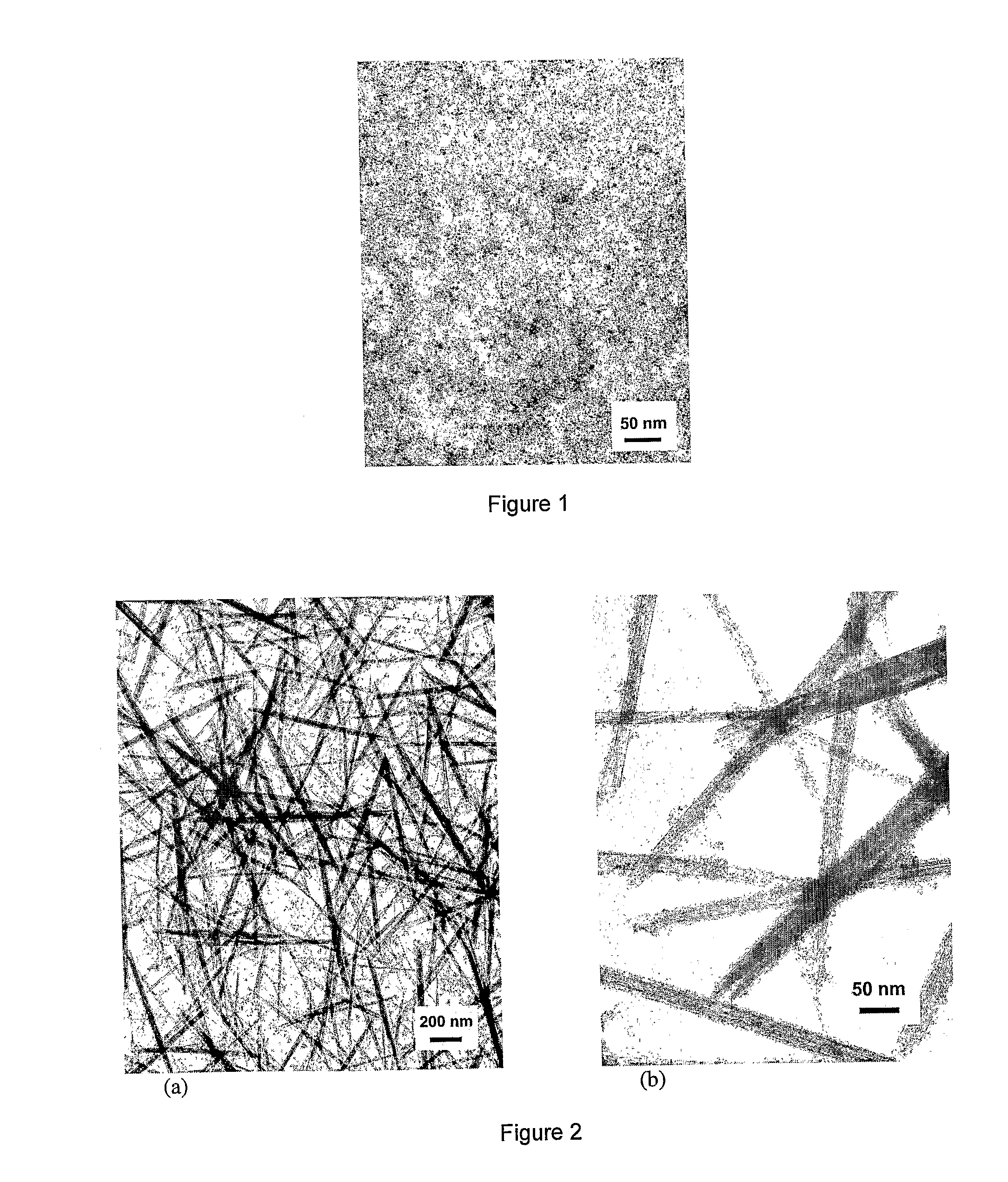

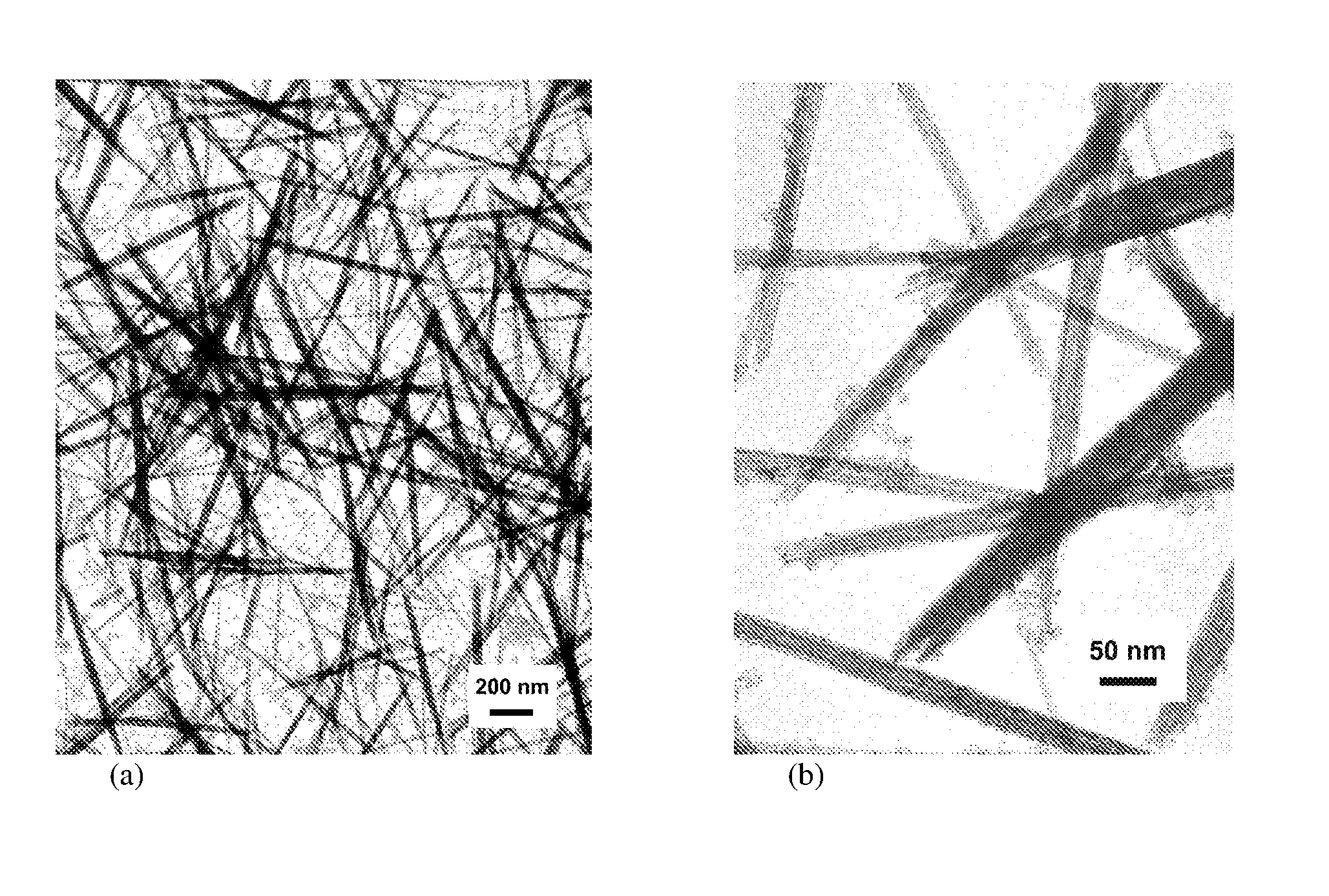

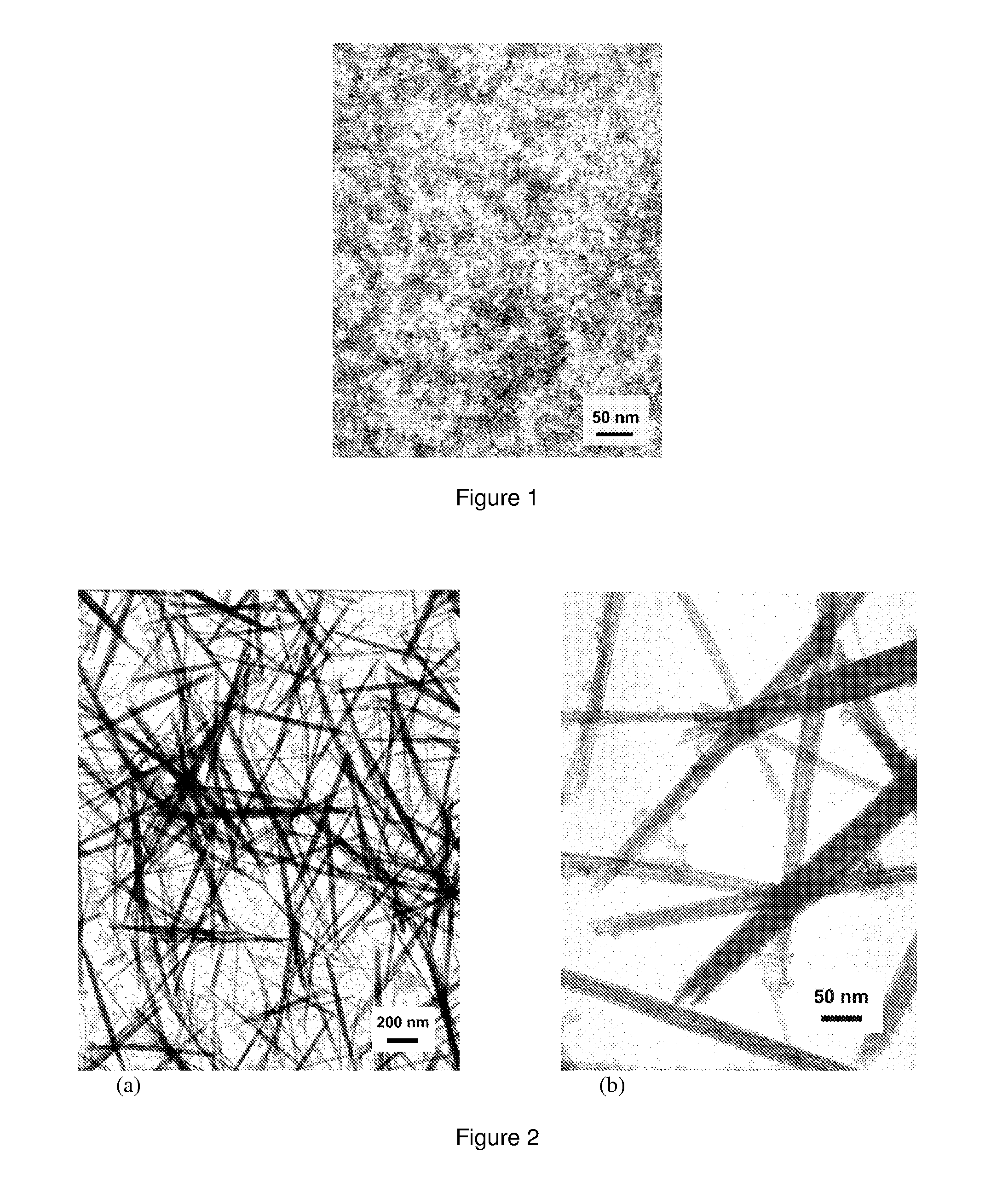

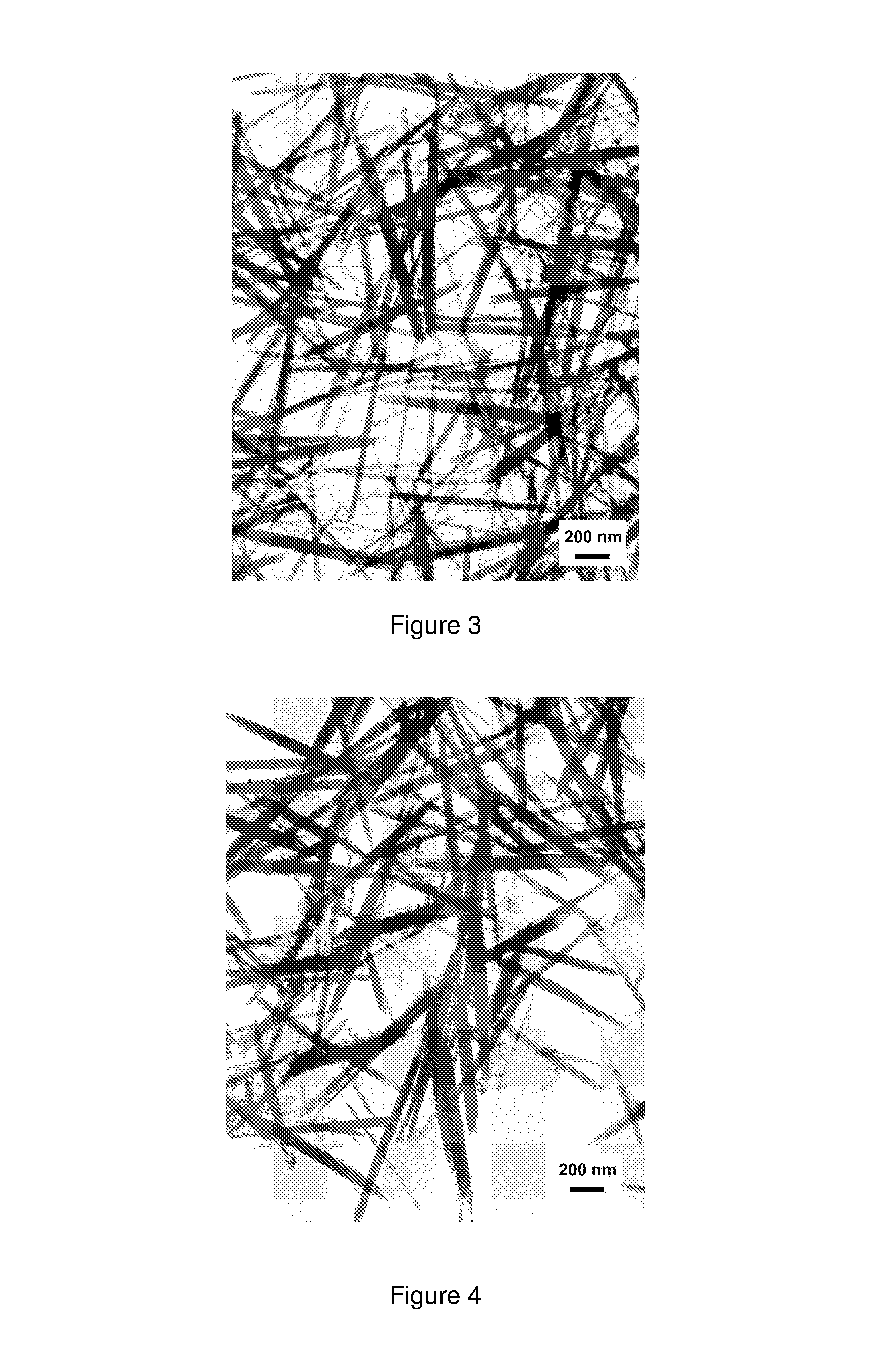

A process for the production of nanorods containing a rare earth metal is disclosed. The process comprises the steps of: (a) increasing the pH of an aqueous solution of the formula MX3, where M is a trivalent rare earth metal cation and X is a monovalent anion so as to produce a reaction product containing X anions in solution and a precipitate in the form of trivalent rare earth hydroxide nanoparticles of the formula M(OH)3, the nanoparticles having a hexagonal crystal structure; and, (b) ageing the nanoparticles of step (a) in the presence of the reaction product containing X anions in solution so as to cause rod-like anisotropic growth of the nanoparticles and form rare earth hydroxide nanorods.

Owner:ADVANCED NANO TECH

Rare earth nanorods

ActiveUS7943106B2Reduce expenditureMaterial nanotechnologyPolycrystalline material growthRare-earth elementAnisotropic growth

A process for the production of nanorods containing a rare earth metal is disclosed. The process comprises the steps of: (a) increasing the pH of an aqueous solution of the formula MX3, where M is a trivalent rare earth metal cation and X is a monovalent anion so as to produce a reaction product containing X anions in solution and a precipitate in the form of trivalent rare earth hydroxide nanoparticles of the formula M(OH)3, the nanoparticles having a hexagonal crystal structure; and, (b) ageing the nanoparticles of step (a) in the presence of the reaction product containing X anions in solution so as to cause rod-like anisotropic growth of the nanoparticles and form rare earth hydroxide nanorods.

Owner:ADVANCED NANO TECH

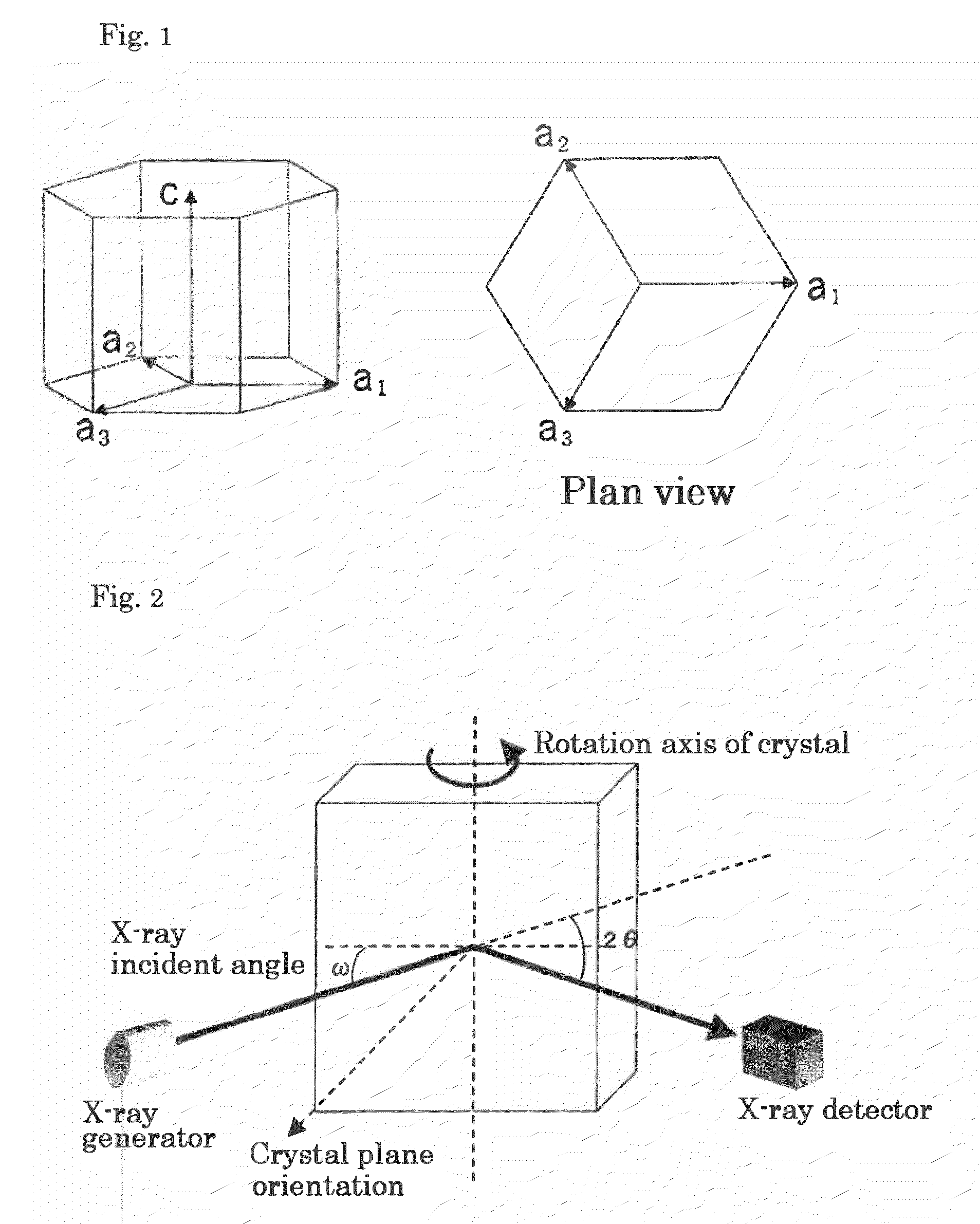

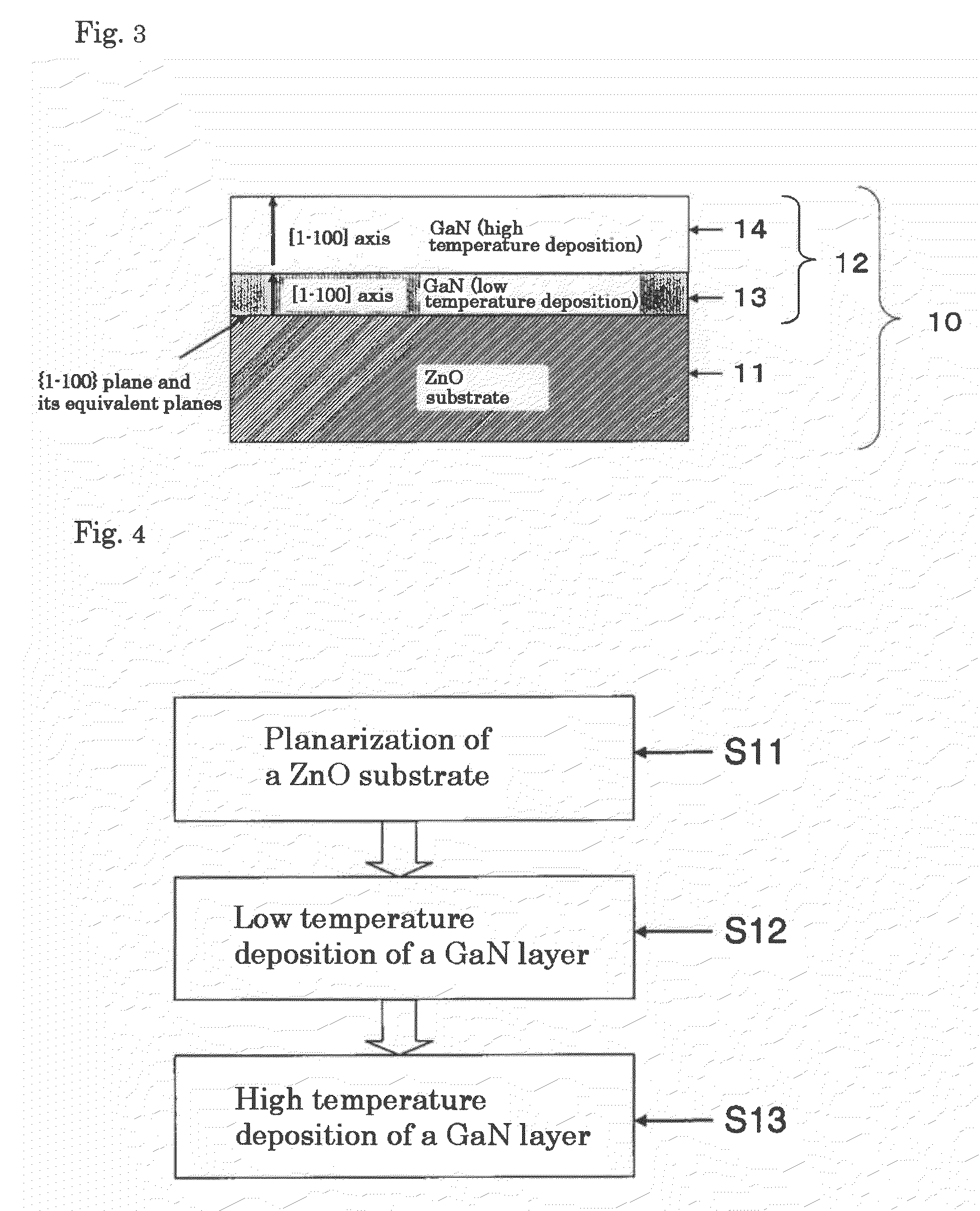

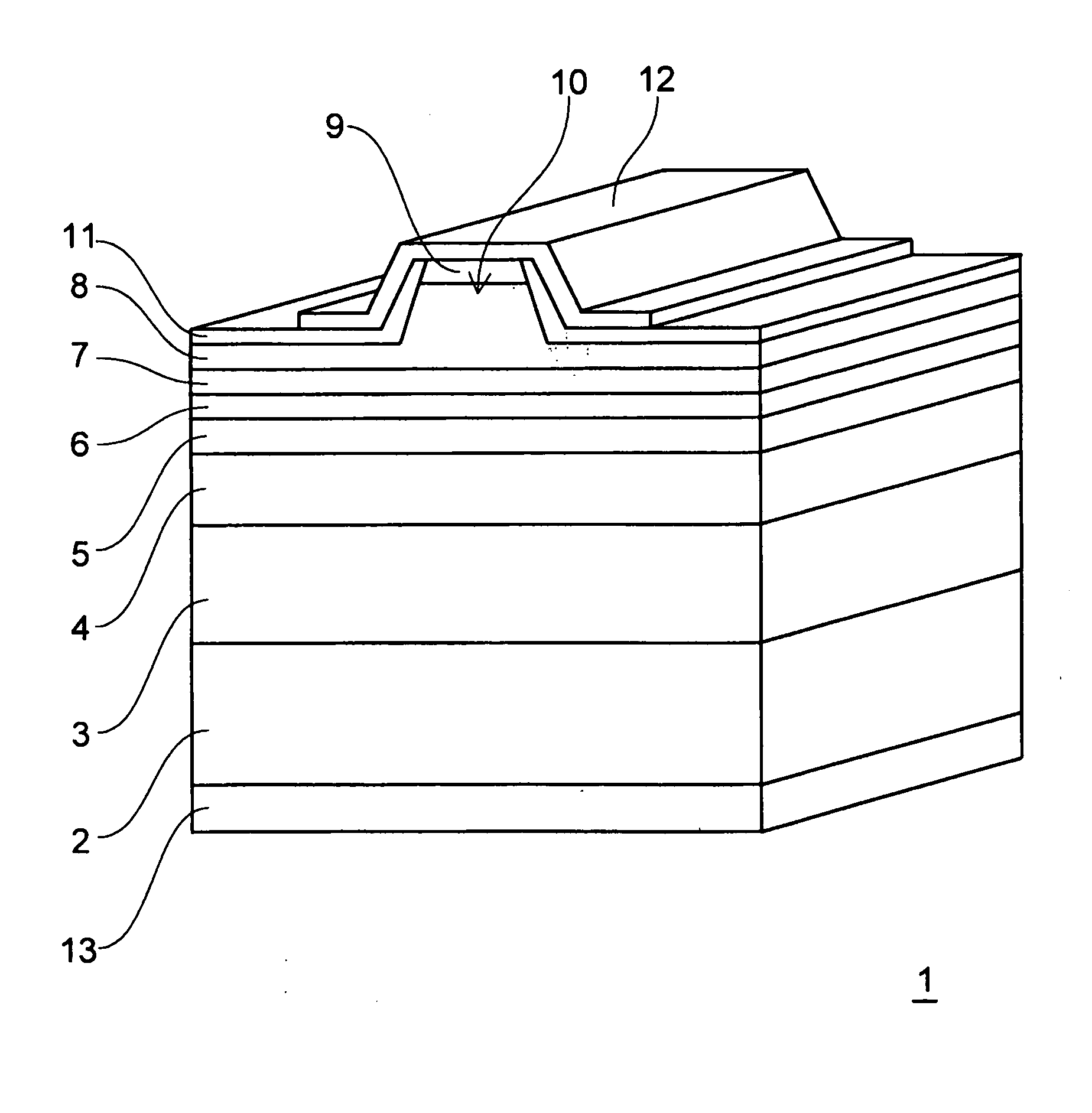

Group iii-v nitride layer and method for producing the same

InactiveUS20100163931A1Improve propertiesHigh crystallinityPolycrystalline material growthVacuum evaporation coatingAngle dependenceFull width at half maximum

There is disclosed a hexagonal Group III-V nitride layer exhibiting high quality crystallinity capable of improving the properties of a semiconductor device such as a light emitting element. This nitride layer is a Group III-V nitride layer belonging to hexagonal crystal formed by growth on a substrate having a different lattice constant, which has a growth-plane orientation of {1-100} and in which a full width at half maximum b1 of angle dependence of X-ray diffraction intensity in a {1-210} plane perpendicular to the growth-plane upon X-ray incident angle from a direction parallel to the growth-plane satisfies the condition of 0.01°≦b1≦0.5°, or the full width at half maximum b2 of angle dependence of X-ray diffraction intensity in a {0001} plane upon X-ray incident angle from a direction parallel to the growth-plane satisfies the condition of 0.01°≦b2≦0.5°.

Owner:KANAGAWA ACADEMY SCI & TECH +2

Light emitting element and manufacturing method thereof

InactiveUS20090200573A1Improve responseDecreased oxygen diffusionOptical wave guidanceLaser detailsCrystal structureNitride semiconductors

In a laser chip 1 using a nitride semiconductor having a hexagonal crystal structure, the −c plane is used as a first resonator facet A, which is the side of the laser chip 1 through which light is emitted. On the first resonator facet A, that is, on the −c plane, a facet protection film 14 is formed. This ensures firm joint between the first resonator facet A and the facet protection film 14 and alleviates deterioration of the first resonator facet A.

Owner:SHARP FUKUYAMA LASER CO LTD

Method for manufacturing semiconductor device

ActiveUS8871565B2Stable electrical characteristicsImprove reliabilityTransistorSemiconductor/solid-state device detailsCrystalline oxideIndium

Owner:SEMICON ENERGY LAB CO LTD

Magnetically supported titanium dioxide photocatalyst and preparation method thereof

InactiveCN102350354AEasy to separateThe synthesis method is simpleWater/sewage treatment by irradiationMetal/metal-oxides/metal-hydroxide catalystsMaterials preparationReaction temperature

The invention discloses a magnetically supported titanium dioxide photocatalyst and a preparation method thereof, belonging to the technical field of material preparation. A solvothermal process is used for obtaining a dimension-adjustable ferroferric oxide spherical particles, and the pH value, reaction temperature, reaction time and other experimental parameters are regulated to control the hydrolysis of tetrabutyl titanate, so that the tetrabutyl titanate is uniformly supported on the surface of the ferroferric oxide magnetic nucleus, thereby preparing the hexagonal crystal form magnetically supported titanium dioxide photocatalyst. The magnetically supported titanium dioxide photocatalyst has the advantages of controllable preparation technique, high safety and reliability and high yield, can be used for quickly catalyzing the degradation of pollutants, and can be easy in industrialization production.

Owner:SHAOXING UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com