Diffusion welding method for tin bronze and steel welded structures

A welding structure and diffusion welding technology, applied in welding/welding/cutting items, welding equipment, non-electric welding equipment, etc., can solve the problems of loss of components, cracking of heat-treated copper matrix, etc., to avoid intergranular cracking and eliminate casting defects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

[0025] Example. A kind of diffusion welding method of tin bronze and steel welding structure, it is characterized in that, carry out according to the following steps:

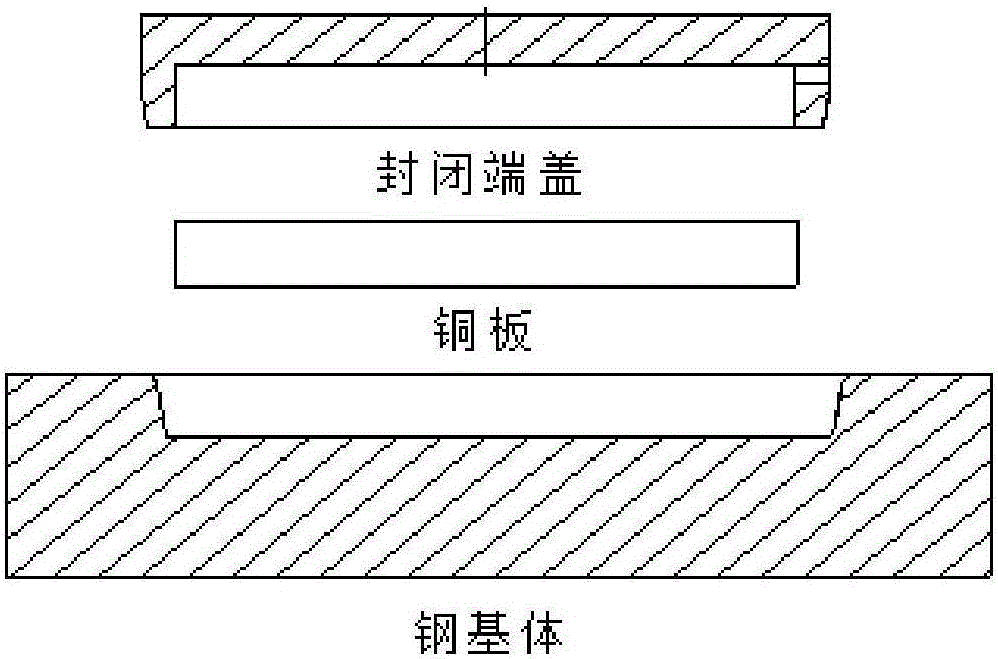

[0026] ①Multiple components are processed according to the drawings, and the welding surfaces of the multiple components are degreased and derusted, and then assembled to form a welded assembly. The multiple components include steel substrates, tin bronze plates and closed end caps;

[0027] ② Put the welding assembly into the middle of the lower support plate in the furnace of the vacuum diffusion welding equipment, and separate the welding assembly and the support plate with graphite paper;

[0028] ③ Control the vacuum degree in the vacuum diffusion welding equipment at 1.0×10 -3 ~1.0×10 -4 Pa, by heating and pressurizing;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com