Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

310 results about "Tin bronze" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The High Leaded Tin Bronze (Copper-Tin-Lead) are the thermally conductive alloys with high lubrication capacity because of the high lead content. These alloys are high on performance in highly demanding environment.

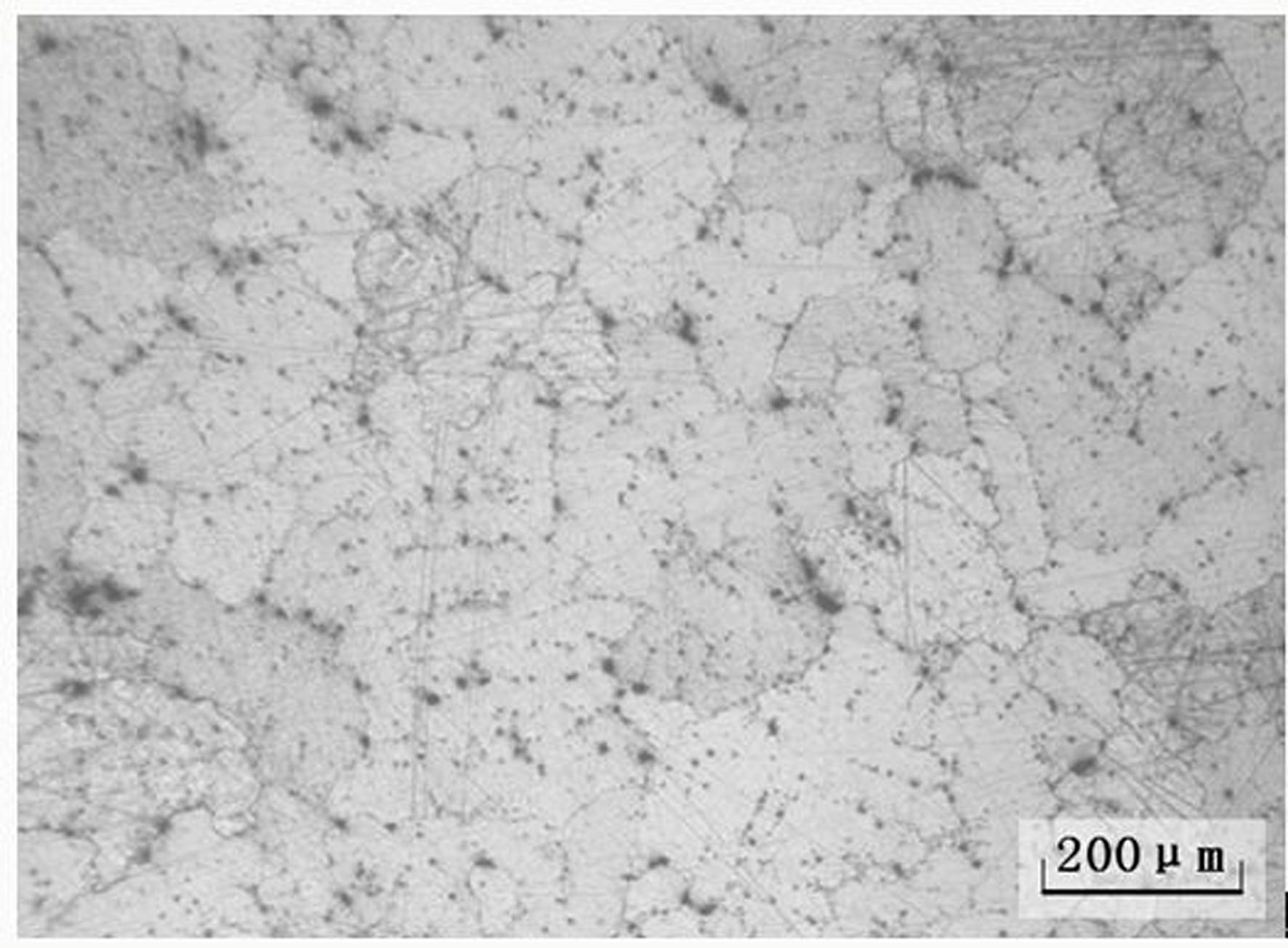

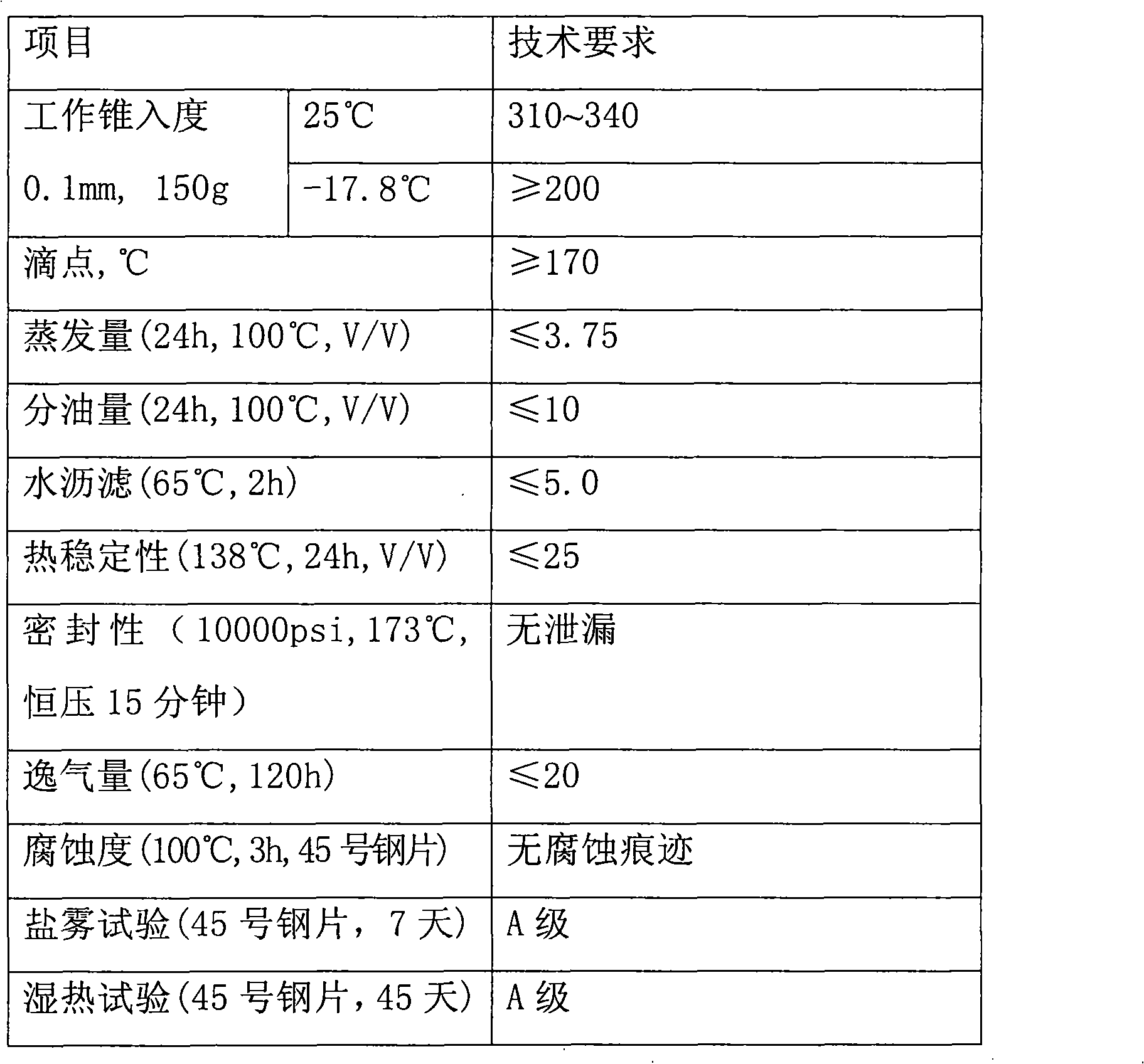

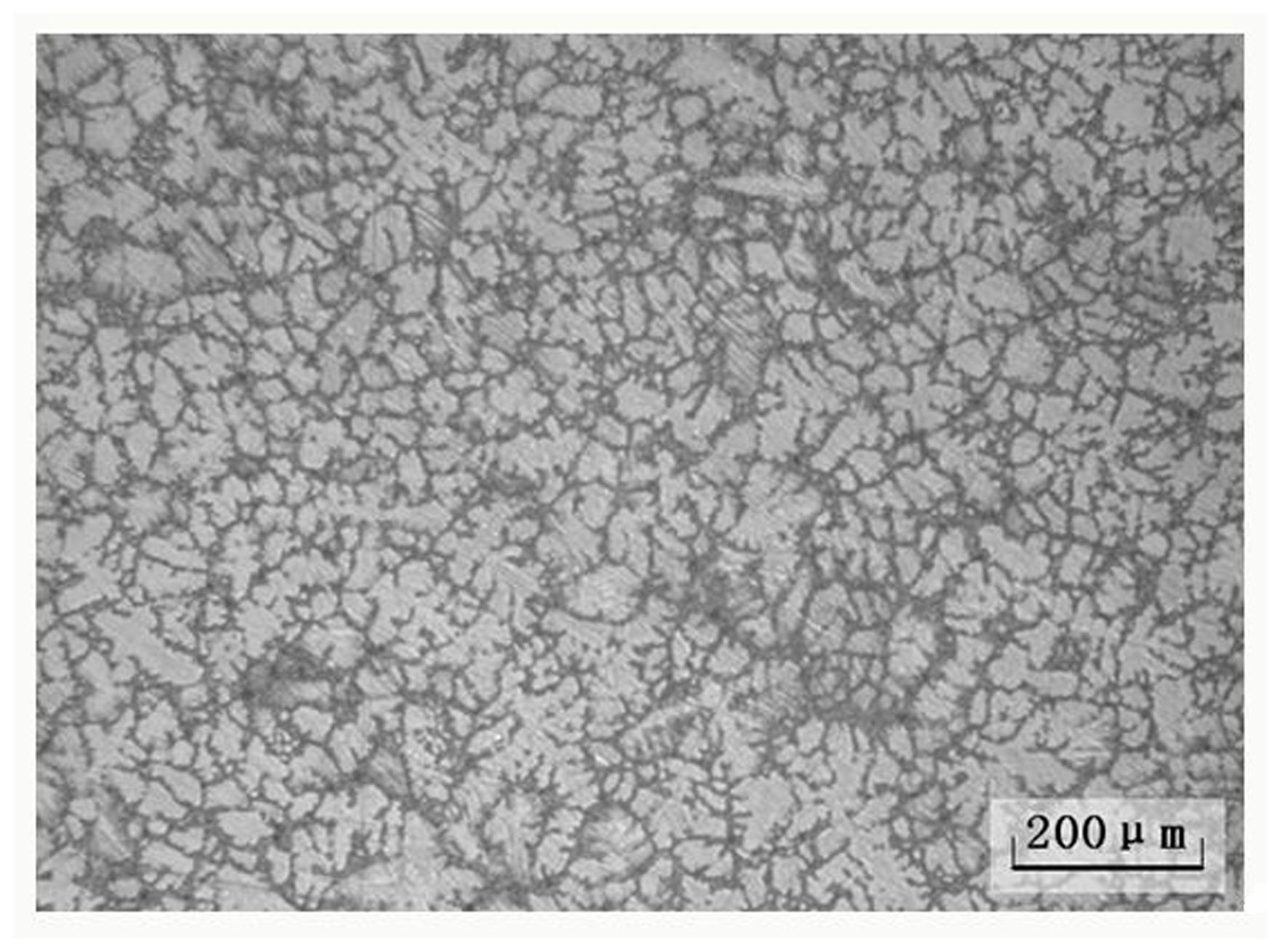

Cast wear-resistant tin bronze alloy and preparation method thereof

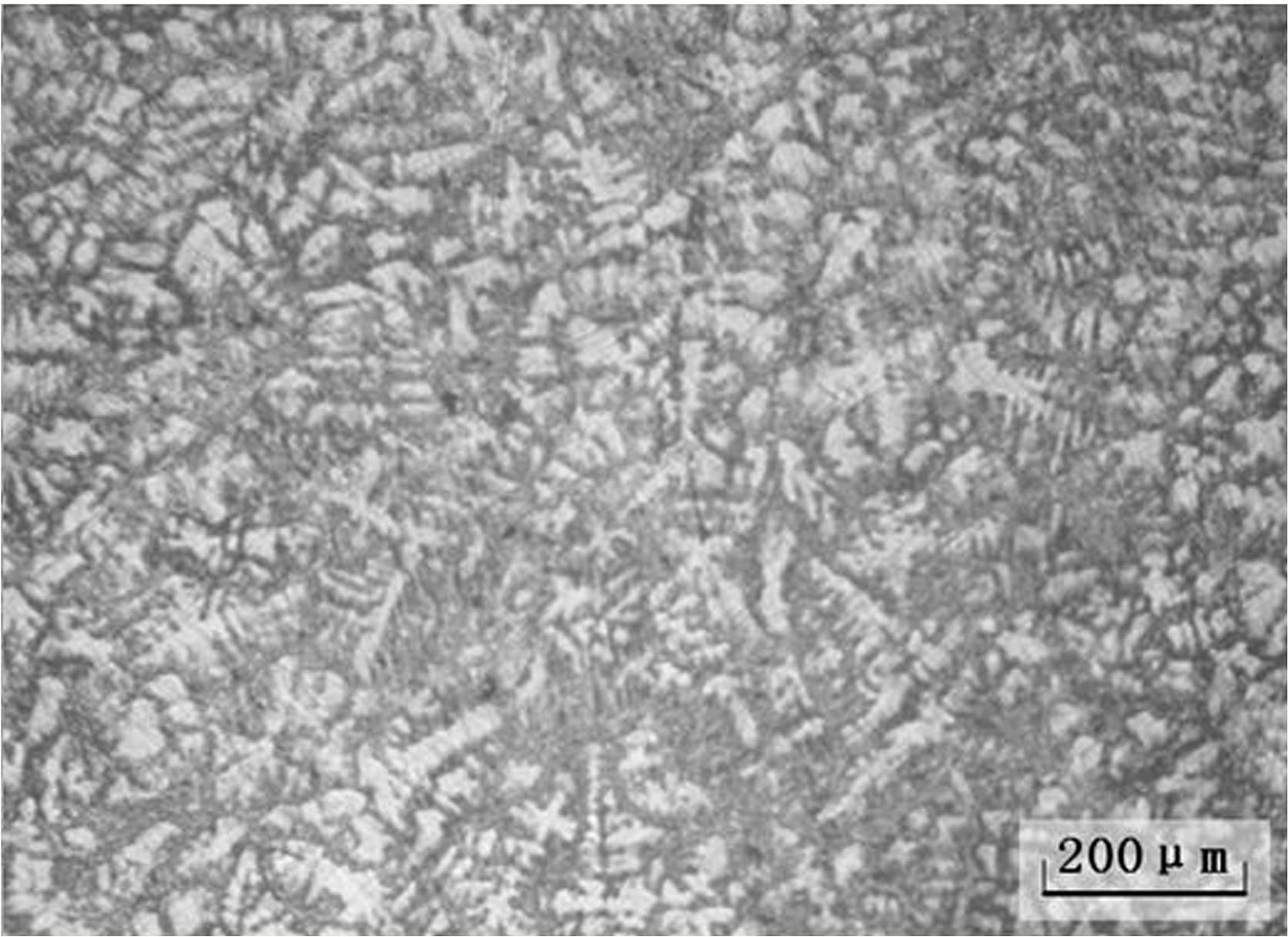

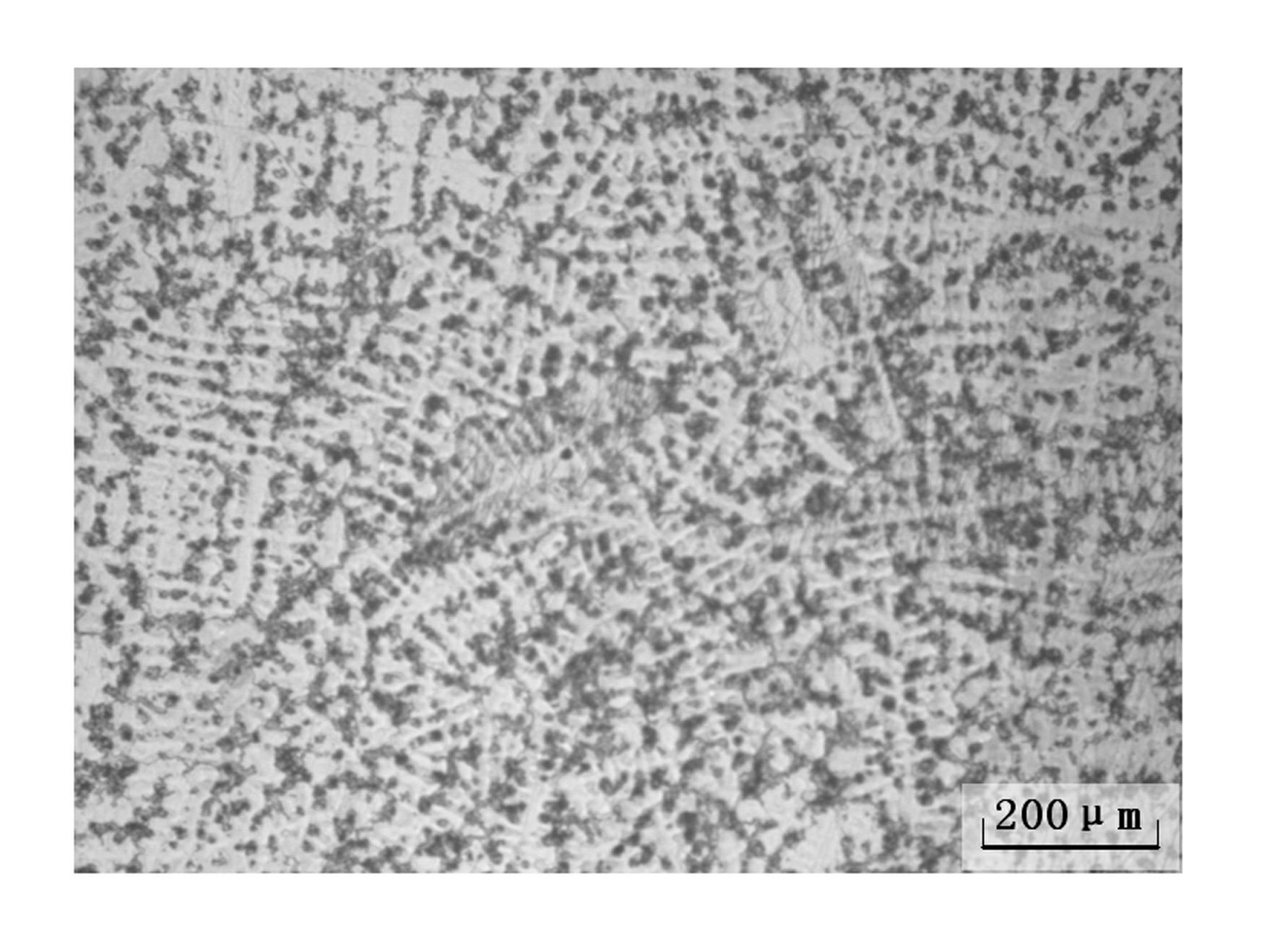

The invention discloses a cast wear-resistant tin bronze alloy and a preparation method thereof. The cast wear-resistant tin bronze alloy comprises the following components in percentage by weight: 10 to 14 percent of Sn, 2 to 5 percent of Pb, 1 to 4 percent of Ni, less than or equal to 0.25 percent of Fe, Sb, Al, Zn, P, Si and Bi which serve as impurities and the balance of Cu. The preparation method comprises the following steps of: smelting an electrolytic copper plate, a pure nickel plate, a pure tin ingot and a pure lead ingot which serve as raw materials sequentially; adding a refining agent into melting liquid, pouring, cooling, and thus obtaining a cast wear-resistant tin bronze alloy ingot; and homogenizing and annealing the alloy ingot to obtain a cast wear-resistant tin bronze alloy product. The prepared cast wear-resistant tin bronze alloy has uniform ingredients, dendritic segregation is improved obviously, a small number of cast state defects occur, the hardness of the alloy is more than or equal to 100HB, the tensile strength is more than or equal to 300MPa, the elongation is more than or equal to 10 percent, and the cast wear-resistant tin bronze alloy is particularly suitable for wear-resistant heavy load key parts in a traffic power industry.

Owner:HENAN UNIV OF SCI & TECH +1

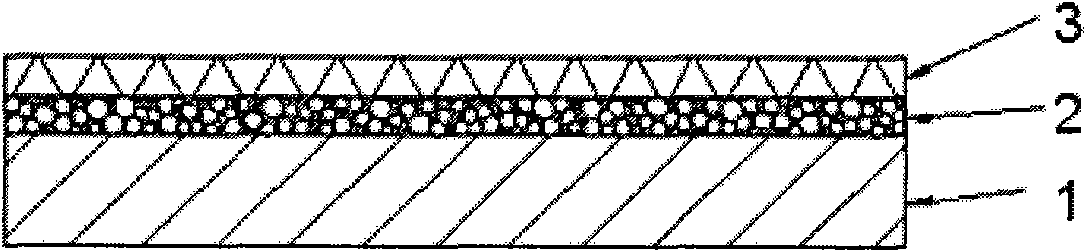

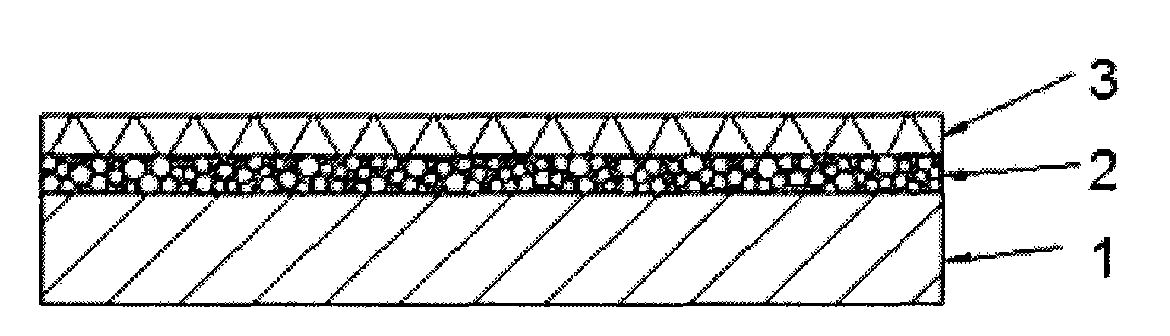

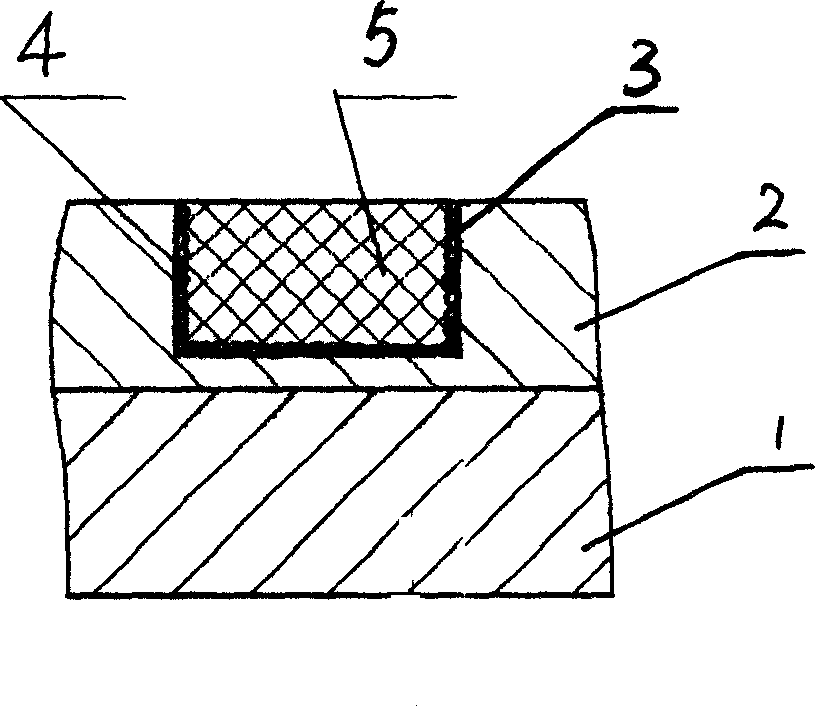

Three-layer self lubricating abrasion-resistant slide bearing material and preparation method thereof

InactiveCN101788015AReduce frictionReduce coefficient of frictionBearing componentsAviationFluoropolymer

The invention belongs to the technical field of a polymer composite material, in particular to a three-layer self lubricating abrasion-resistant slide bearing material and a preparation method thereof. The composite material consists of three layers, wherein the bottom layer is a steel plate or other metal plates, the middle layer is a porous sintered tin bronze powder layer, fluoropolymers are soaked in holes, and the surface layer is a textile / fluoropolymer composite material. The textile / fluoropolymer composite material is prepared through an emulsion soaking method, and is then glued on the surface of a base material through a hot press forming method. Compared with the prior art, the material of the invention obtains good self lubricating performance, abrasion-resistant performance and temperature-resistant performance through completely introducing the fluoropolymers to be used as gluing resin, and at the same time, the textile / fluoropolymer composite material is perfectly glued on the surface of the base material through the hot press forming method. The material of the invention is applicable to self lubricating bearings in the fields such as aviation, aerospace, machinery, automobiles and the like.

Owner:FUDAN UNIV

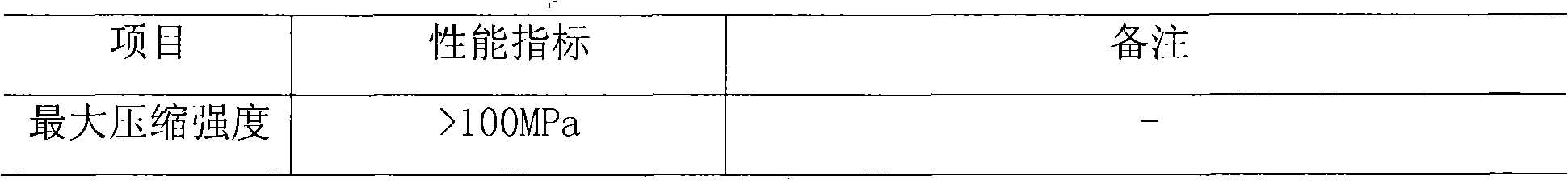

API oil sleeve thread sealing grease composite and preparation method thereof

ActiveCN101565648AImprove low temperature fluidityMechanical automatic spraying effect is goodOther chemical processesAdditivesWear resistantPetroleum

The invention provides an API oil sleeve thread sealing grease composite. The components of the composite include 40-50 percent of basic grease, 5-10 percent of dimethyl silicon oil, 16.5-20 percent of crystalline graphite powder, 6-9 percent of polyfluortetraethylene, 0.5-1.0 percent of expansion graphite powder, 1-2 percent of white carbon black, 3-4 percent of sericite in powder, 3-4 percent oflight calcium carbonate and 10-15 percent of tin bronze powder according to the percentage accounting for in the weight of the sealing grease composite. The invention also provides a preparation method of the API oil sleeve thread sealing grease composite. The invention has the beneficial effects that among the components of the sealing grease composite, synthetic oil is taken as a substitute formineral oil, and therefore the low temperature fluidity of the basic grease is improved to facilitate the brush application in winter. The addition of high performance antirust to the basic grease ensures that pipe threading does not rust when oil sleeves and pipes are stored outside in long term. Without zinc powder added but with the consumption of copper powder increased and other wear-resistant materials added, the high temperature lubricity of the grease is guaranteed and the pipe threading of the oil sleeves and pipes is prevented from thread gluing when screwing together. With novel high efficiency sealing materials added in the components of the sealing grease composite, the leak tightness of the grease is guaranteed.

Owner:TIANJIN PIPE GROUP CORP

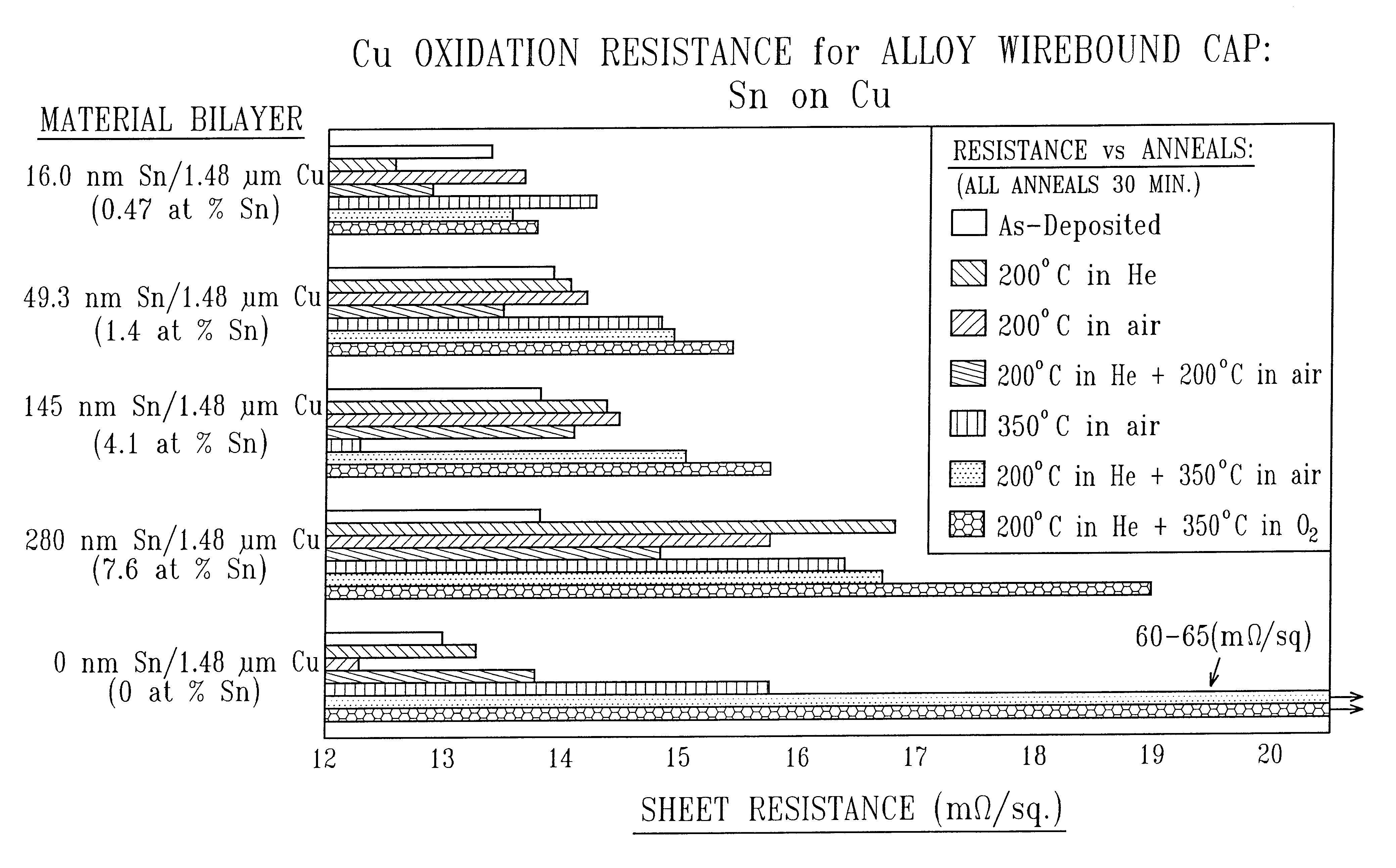

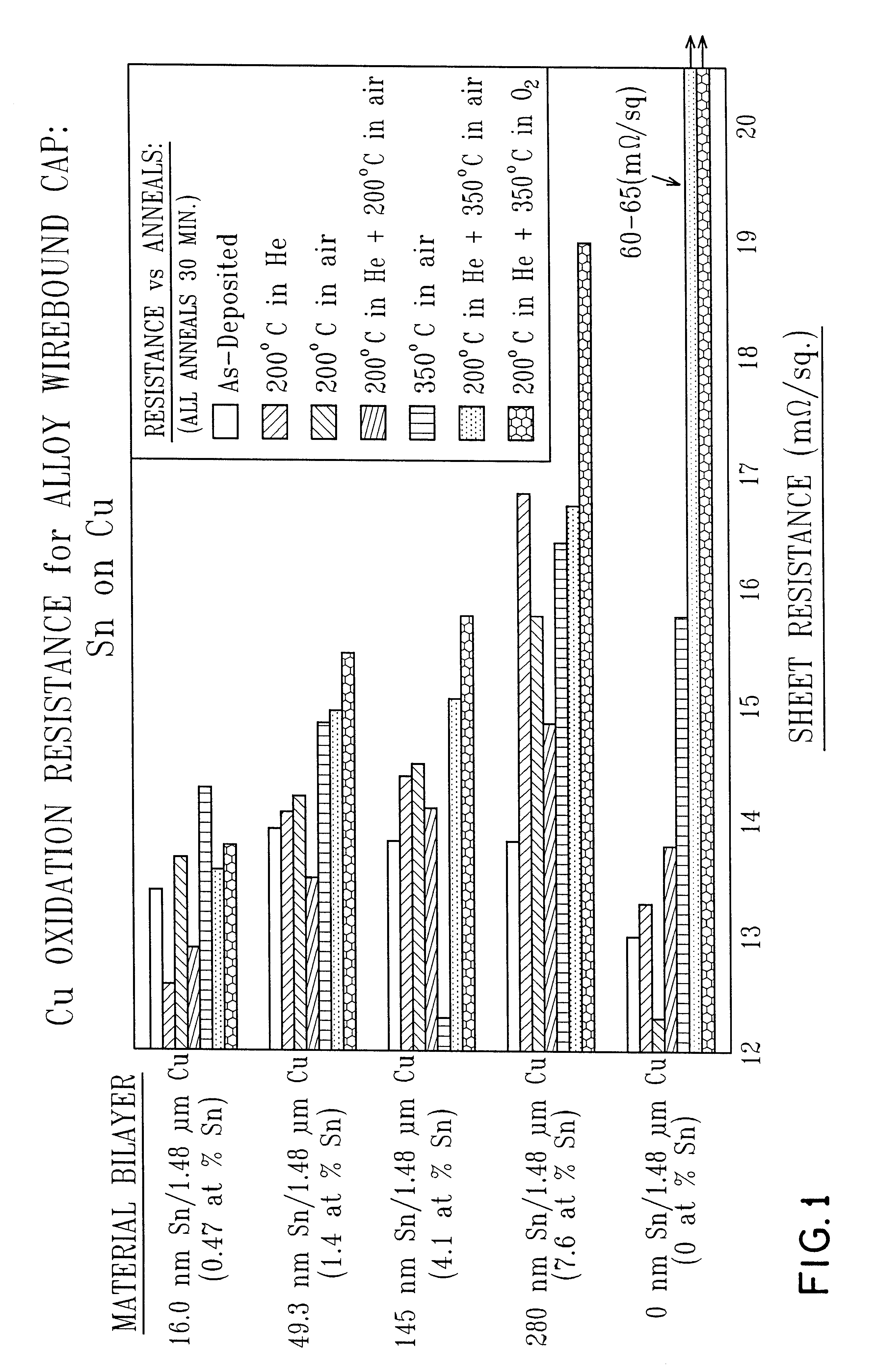

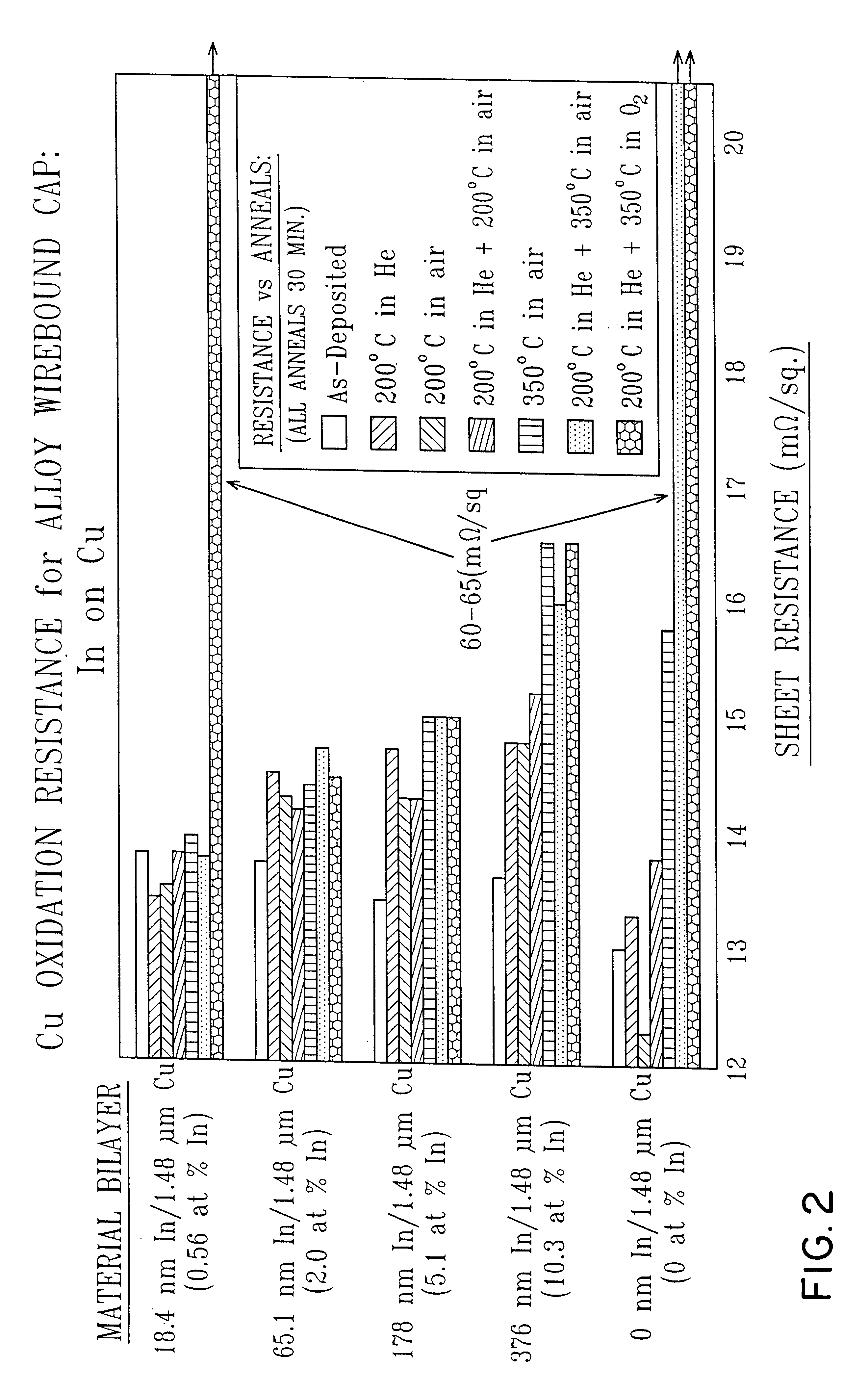

Method to selectively cap interconnects with indium or tin bronzes and/or oxides thereof and the interconnect so capped

InactiveUS6551931B1Prevent uncontrolled growthSemiconductor/solid-state device detailsSolid-state devicesIndiumCopper oxide

Owner:GLOBALFOUNDRIES INC

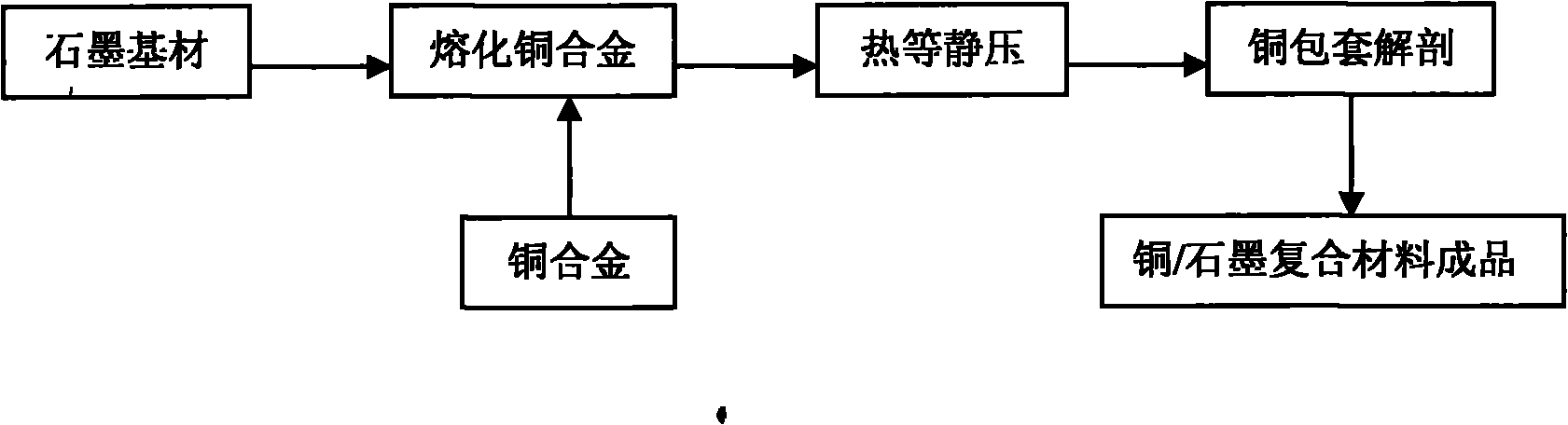

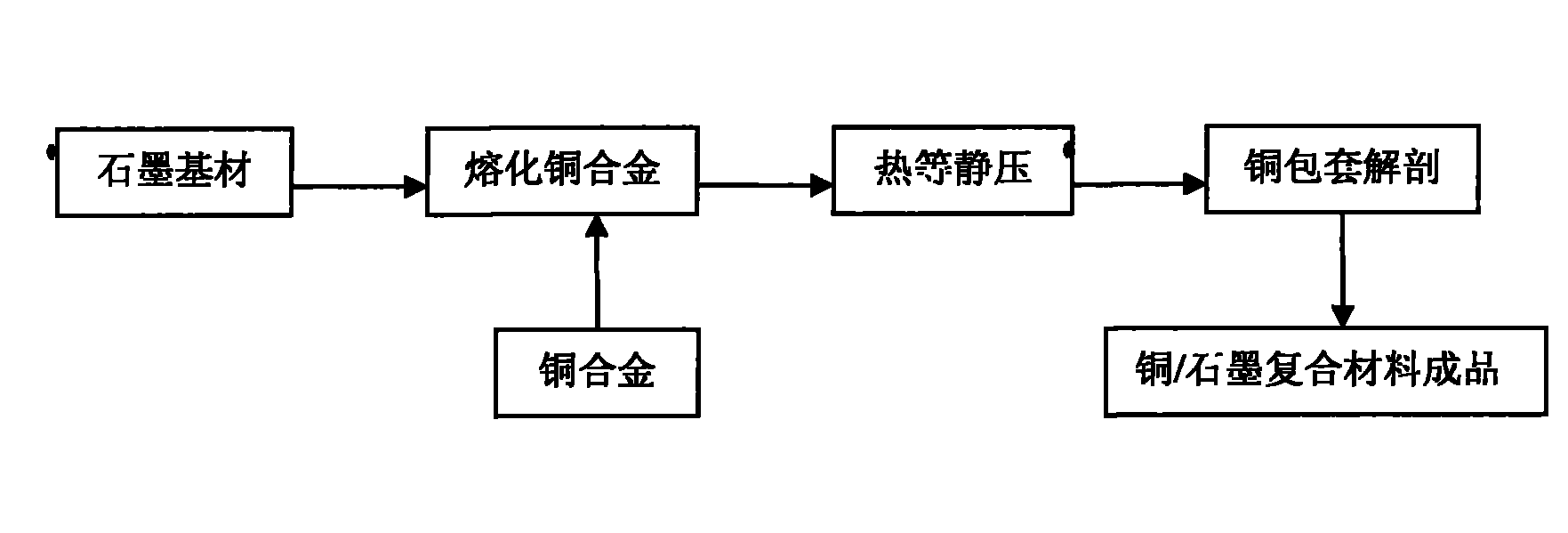

Copper/graphite compound material and preparation method thereof

ActiveCN102146552AHigh mechanical strengthIncreased mechanical toughnessHot-dipping/immersion processesThermal insulationCarbon graphite

The invention relates to a copper / graphite compound material and a preparation method thereof. In the compound material, carbon graphite is used as a substrate material, and a tin bronze alloy is used as a dipping metal. The preparation method comprises the following steps: (1) melting the tin bronze alloy to meltwater in a heat treatment furnace, immersing carbon graphite material blocks, and cooling so as to form a copper clad wrap coated by the graphite material blocks; (2) putting the copper clad wrap obtained in the step (1) in a hot isostatic press for hot isostatic press dipping at the temperature of 1100-1300 DEG C under the pressure of 60-80MPa at the atmosphere of argon, carrying out thermal insulation and pressure preservation for 60-120 minutes, and then carrying out belt pressure cooling; and (3) taking out the copper clad wrap obtained in the step (2) and then dissecting the copper clad wrap by using a machining method. The copper / graphite compound material is applied to machinery motive seal or bearings with high parameters (the temperature changes between minus 253 to 350 DEG C and the rotate speed is over 10000 rpm).

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

High wear resistant/friction reducing tin bronze base composite material

The present invention relates to one copper-base composite material comprising multiple wall carbon nanotube 0.2-4.5 wt%, TiB2 0.1-1.3 wt%, except Cu-Sn alloy containing Sn in 0.35-12.0 wt%. It has excellent wear resistance, low friction coifficient, relatively high compression and tensile strength, moderate hardness, excellent electric conductivity and heat conductivity. It may be used in productino transmission bush, current collecting slid board for electric train and electric contact material.

Owner:ZHEJIANG UNIV

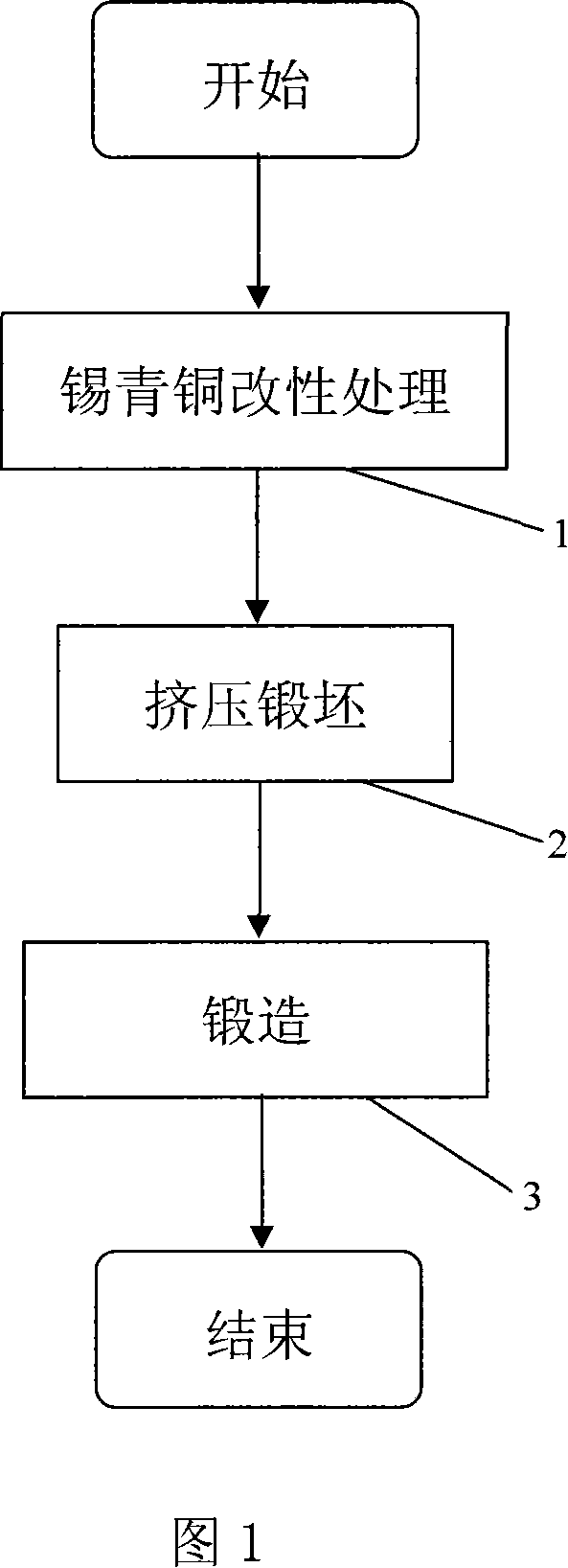

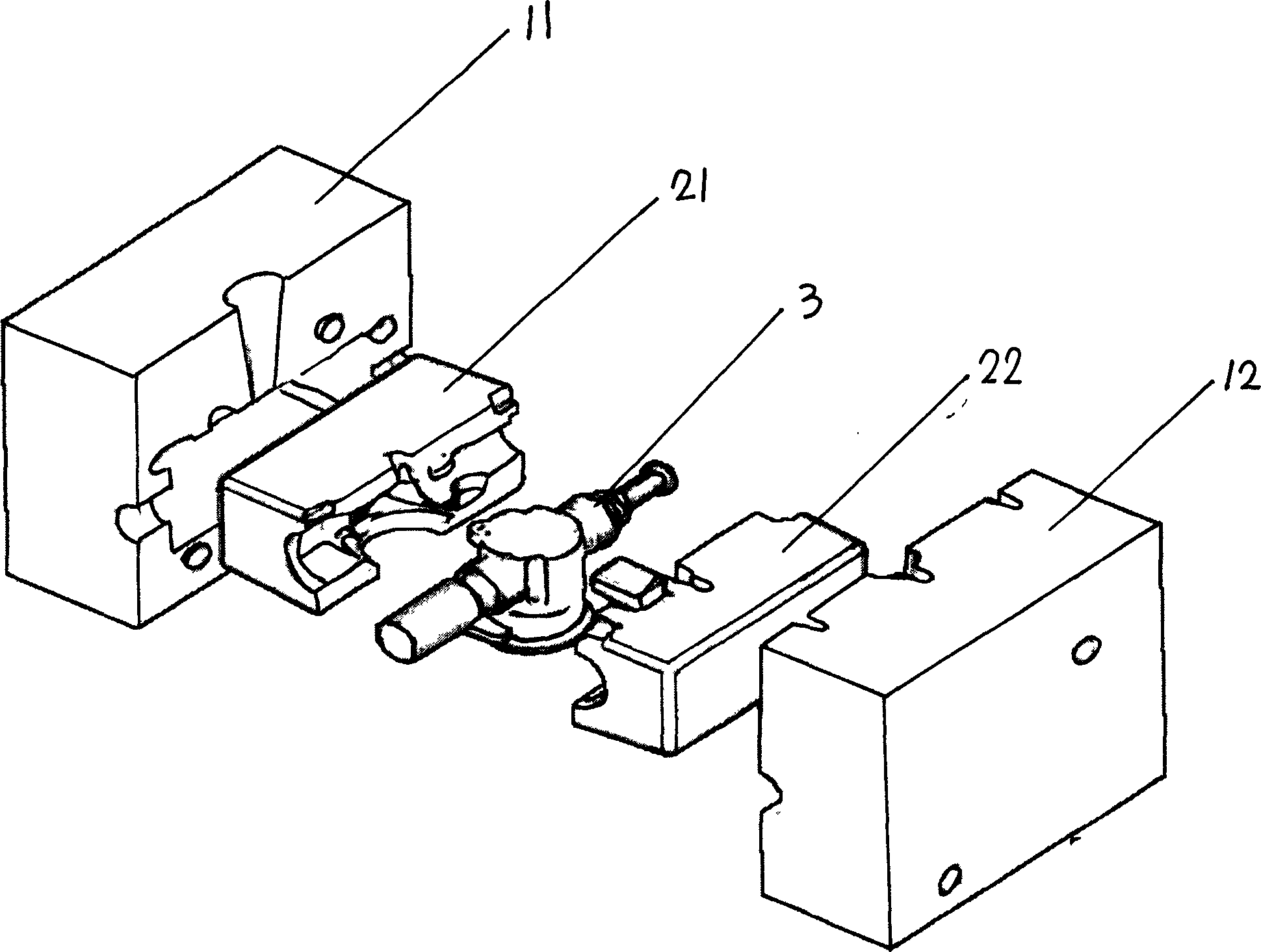

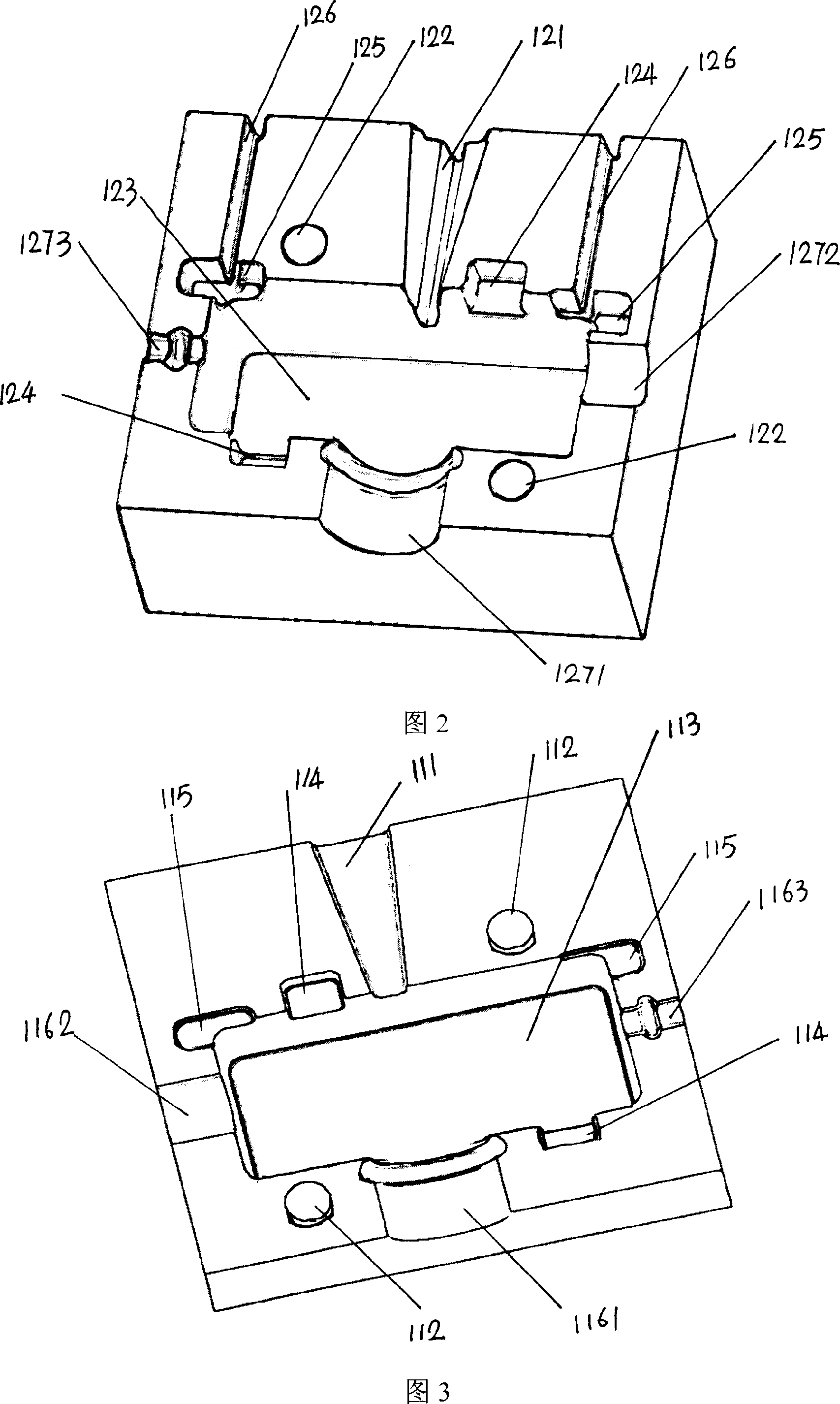

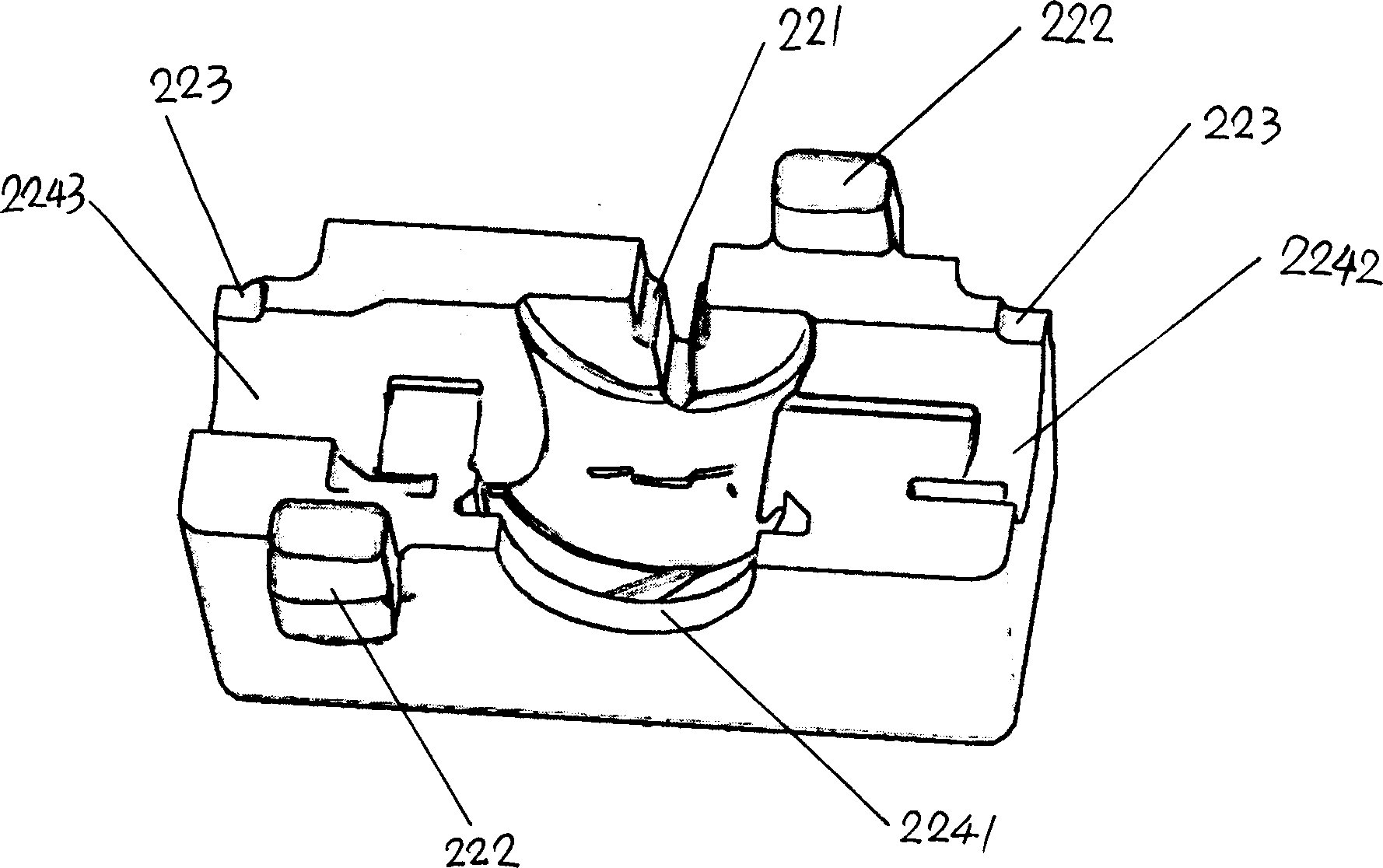

Technique for processing tin bronze valve body and tube union

InactiveCN101152692AImprove ductilitySolve the problem of airtightnessExtrusion control devicesRare earthAlloy composite

The present invention discloses a processing technique of a tin bronze valve body and a pipe joint which comprises a modification processing of tin bronze, extruding and forging of the unburnt earthenware, forging and so on. The tin bronze is metamorphosed and modified by the present invention by adding rare earth to purify and RE-Li-Bi alloy composite modifier to refine the crystal grain and improves the scalability of bronze and addresses the tin bronze sealing problem. The forging of an unburnt earthenware piece is a technique which is light and fast at the beginning, heavy and slow in the middle and is formed by tapping in the brittle region. The processes of forging the original unburnt earthenware, extruding the unburnt earthenware, forging the tin bronze valve body and producing a pipe joint are integrated; the work which needed a plurality of months at the beginning is capable of being integrated and finished in a production cycle, so the processing accuracy is increased; the process is simplified; the production efficiency is improved and the production cost is reduced. The present invention is mainly used for the bronze valve which is provided with the dimension of 3 / 8 inches to 4 inches and the series components for forging the pipe joint.

Owner:王仁辉

Metal mold type gravity casting die for cast of tin bronze, and casting method

InactiveCN1915559ASolve the problem that is not suitable for gravity casting of metal moldResolve integrityMolten metal supplying equipmentsFoundry mouldsMetal moldTin bronze

A gravitationally casting metal mould set for casting the tin-bronze workpiece is composed of a metal mould consisting of upper and lower moulds, external sand core consisting of upper and lower cores and inlaid in the recess of metal mould, and internal sand core. Its casting method includes such steps as assembling the mould set, pouring molten tin-bronze, and cooling.

Owner:SHANGHAI TIANSHEN COPPER GRP CO LTD

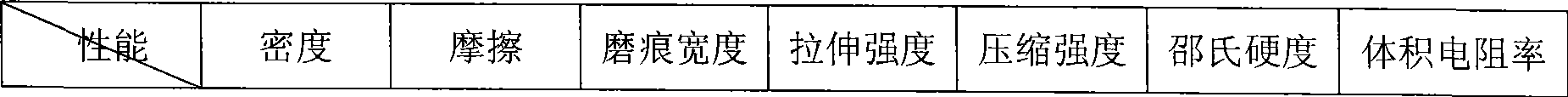

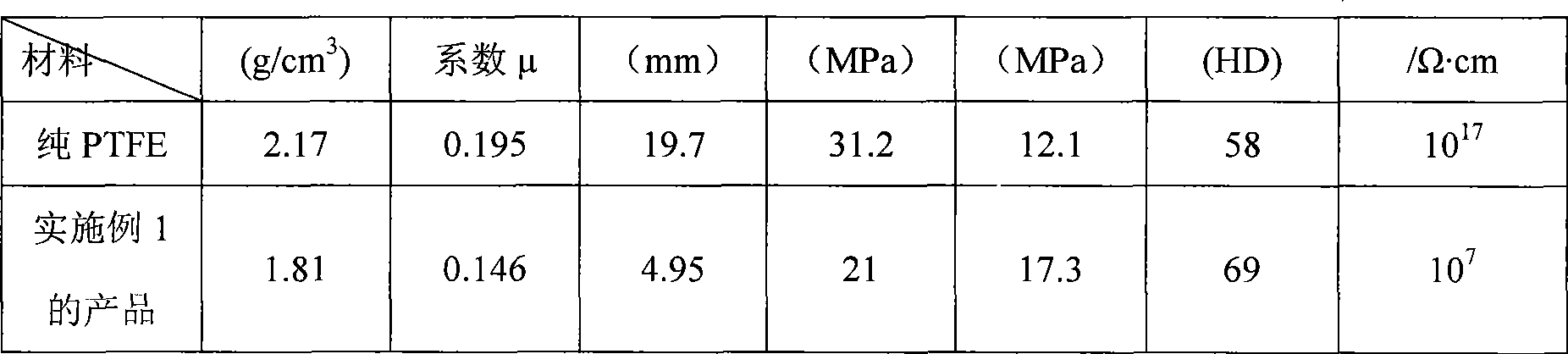

Preparation method of reinforced polytetrafluoroethylene for high/medium-pressure valve sealing element

ActiveCN103467896AImprove wear resistanceImprove the lubrication effectCarbon fibersCarbon nanofiber

The invention relates to a preparation method of a reinforced polytetrafluoroethylene for a high / medium-pressure valve sealing element. The method comprises the following steps of material preparation, drying, material mixing, die filling for compaction molding, sintering, mechanical machining and inspection for warehouse entering. The reinforced polytetrafluoroethylene comprises the following components in parts by mass: 0.5 to 1.5 parts of high-strength carbon nanofibers, 3 to 5 parts of molybdenum disulfide powder, 20 to 25 parts of tin bronze powder and 65 to 75 parts of polytetrafluoroethylene powder, wherein one or more of 5 to 10 parts of reinforced glass fibers being from 3mm to 5mm in length, 10 to 15 parts of silicon dioxide powder, 1 to 2 parts of graphite powder, 1 to 3 parts of white corundum powder and 1 to 3 parts of green silicon carbide powder can be added into the reinforced polytetrafluoroethylene; the reinforced polytetrafluoroethylene further comprises a dispersant 5040, the weight of which accounts or 1% of the total weight of all raw materials. The polytetrafluoroethylene taken as a base material is easy to available and low in cost; the mass percent of copper in the reinforced polytetrafluoroethylene is less than one fourth, so that the copper consumption is greatly reduced and the machining quantity is also reduced, namely, more importantly, the quantity of machining wastes is reduced. The abrasion resistance and the self-lubrication of a blank are improved by adding the molybdenum disulfide into the reinforced polytetrafluoroethylene, so that the sealing ability of a workpiece is greatly improved while the service life of the workpiece is prolonged. The workpiece has the performance of corrosion resistance and aging resistance and has no conductivity. Thus, the reinforced polytetrafluoroethylene is very suitable for the workpiece with a certain insulation requirement.

Owner:CHANGDE XIANGYU EQUIP MFG

Abrasion-proof self-lubricating composite material and its preparation

The invention relates to an abrasion resistant self-lubricating composite material and a preparation method thereof. The material comprises the following raw materials in weight percentage: 5 to 30 percent of polyphenyl ester fine powder, 10 to 45 percent of tin bronze fiber, 2 to 15 percent of glass microballoons, spherical SiO2 or Al2O3 particles, and the balance being suspended PTFE resin moulding powder. The material can be applied to an oil bath dynamic seal of an engine and the manufacture of a dynamic seal of a high pressure water pump. In addition, in some working occasions with comparatively heavy dust or volatile solvents, the material can also be used as a sliding element or a dynamic sealing element with antistatic requirements, such as in a coal mine, a chemical industrial workshop. Moreover, the material is also suitable for oil forbidden high abrasion resistant self-lubricating parts at ultralow temperature and ultrahigh temperature, such as ultralow temperature refrigerating machines, liquid fuel pumps, oxygen generating devices, high temperature driers, conveyor belts inside furnaces, medicines, foods and so on.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

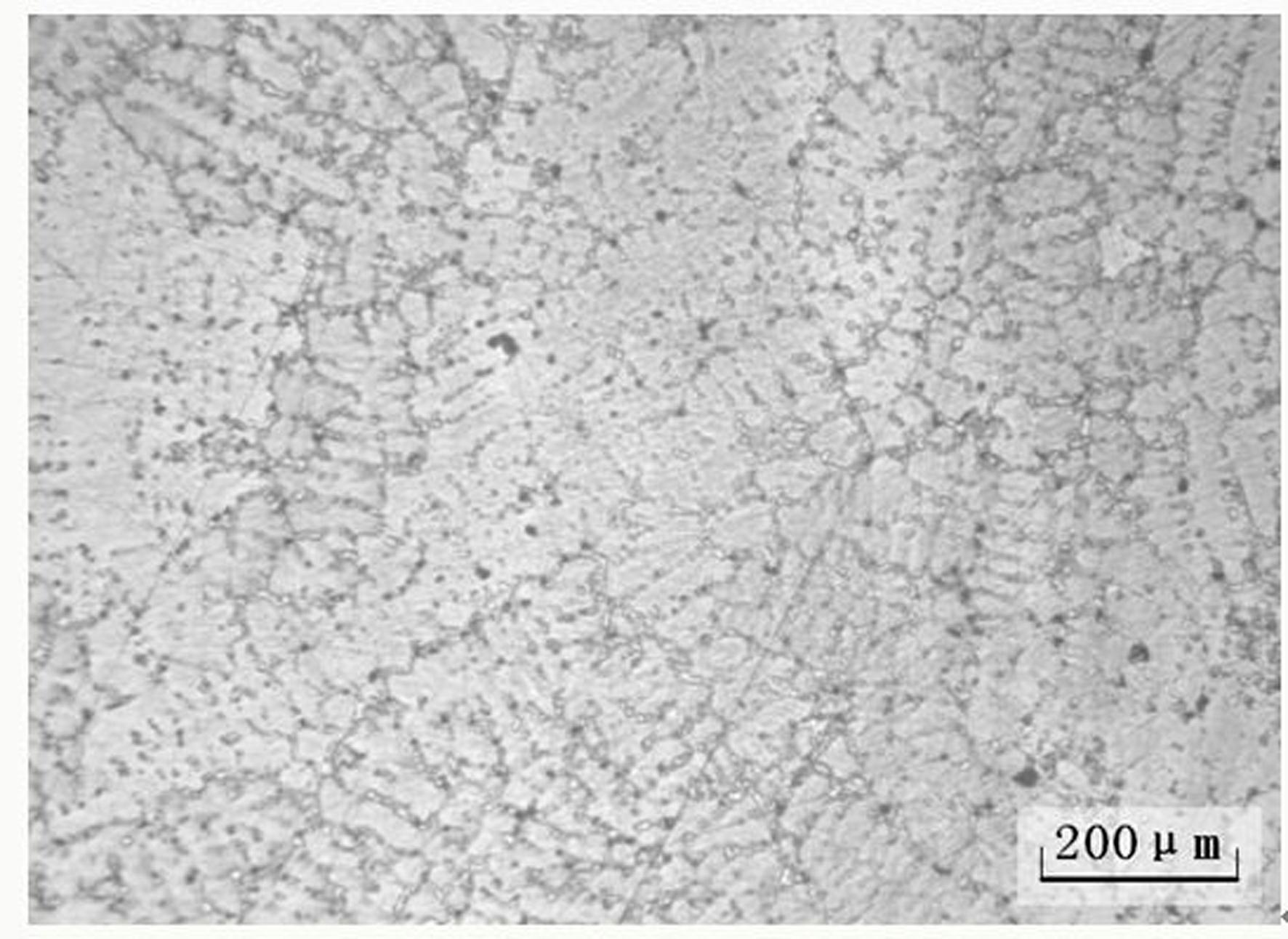

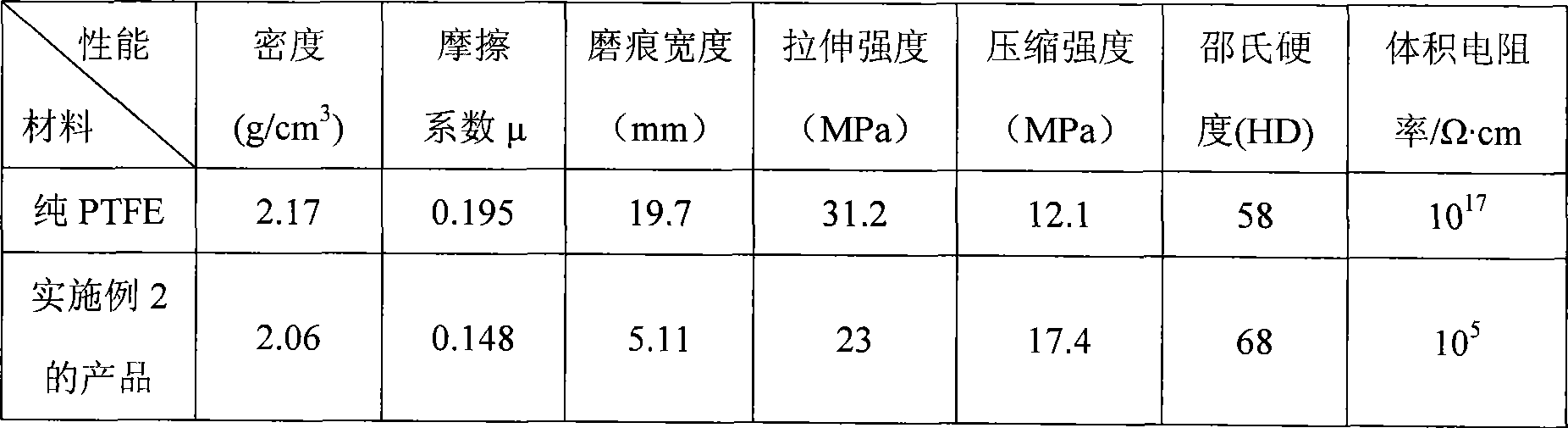

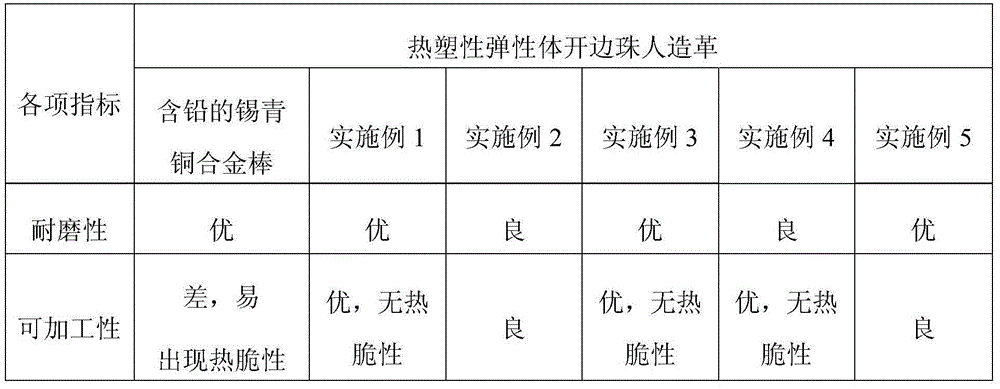

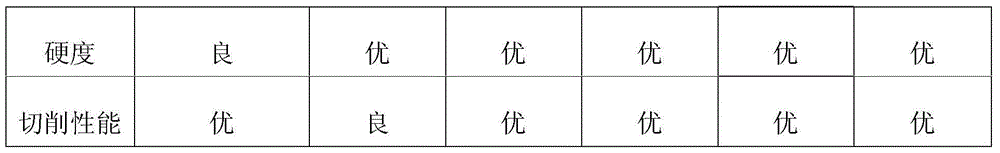

Antimony-added high-tin bronze alloy rod for high-speed railway equipment and manufacturing method thereof

ActiveCN102628120AHigh hardnessImprove environmental performanceFoundry mouldsFoundry coresWear resistanceTin bronze

The invention provides an antimony-added high-tin bronze alloy for high-speed railway equipment and an antimony-added high-tin bronze alloy rod manufactured by the alloy. The alloy components comprise antimony, tin and copper, wherein the components of the alloy are as follows by weight percentage: 1-3% of the antimony, 8-10% of the tin and 87-91% of the copper. According to the antimony-added high-tin bronze alloy for high-speed railway equipment and the alloy rod manufactured by the alloy, disclosed by the invention, the traditional lead element is replaced by the antimony element, so that not only can the environment-friendly performance of the alloy and the alloy rod be improved, but also the hardness of the alloy and the alloy rod can be greatly improved; and the alloy harness can be improved to 110-120 HBS from the previous 70-80 HBS and the wear resistance can be obviously improved.

Owner:SUZHOU JINCANG ALLOY NEW MATERIAL

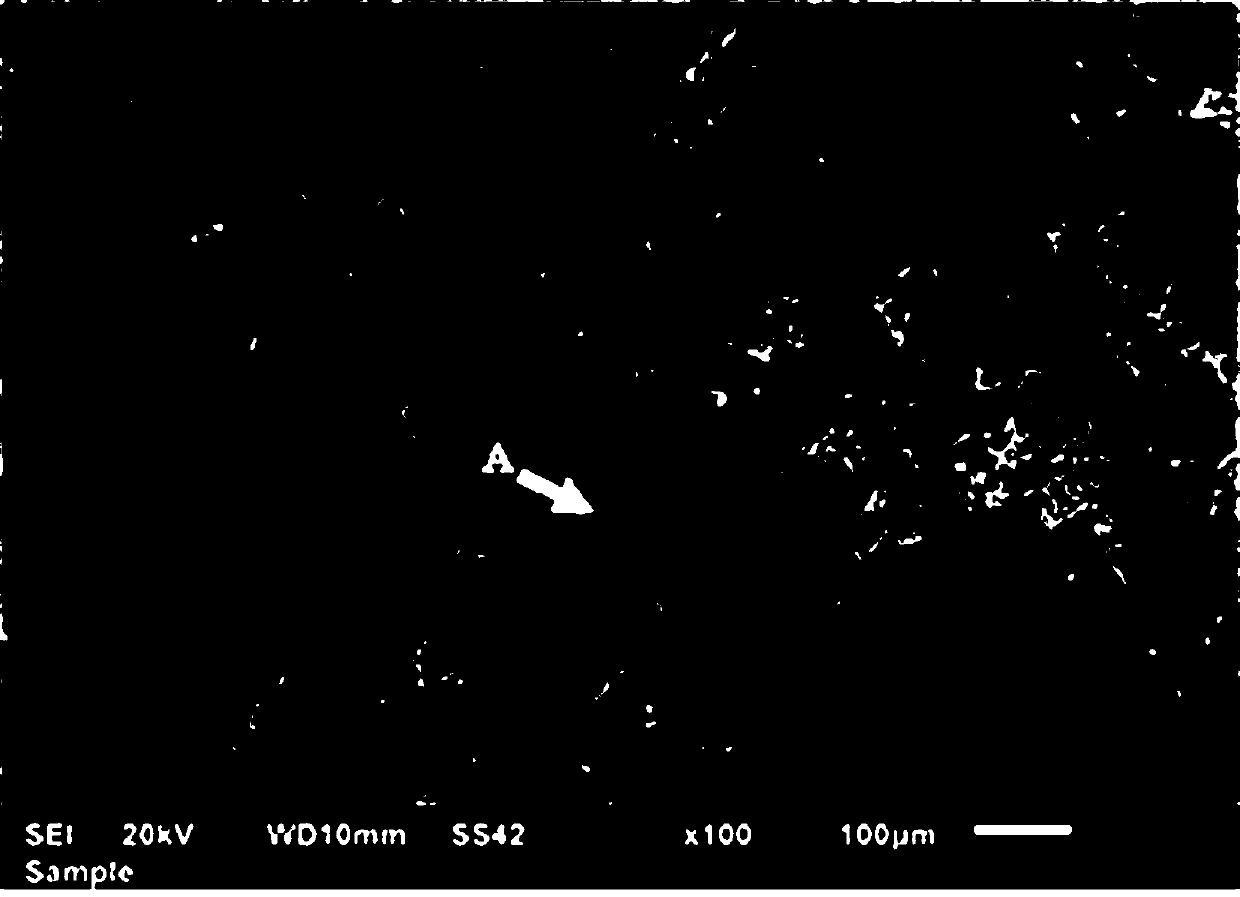

Copper alloy base self-lubricating composite material and preparation method thereof

The invention belongs to the technical field of materials, and particularly relates to a copper alloy base self-lubricating composite material and a preparation method thereof. The composite material comprises the following chemical components in percentage by mass: 9-10% of Ni, 0.5-1% of Sm2O3, 0.5-1% of MoS2, 0-1% of Ag, 0-2% of CaF2, 1-2% of Al2O3, 0-3% of W, 1-3% of nickel-plated graphite, 1.1-3.0% of copper-plated carbon fiber, 0-2.8% of pore forming agent NH4HCO3 and the balance of ZQSn663 tin bronze powder. The preparation method comprises the following steps: mixing the components, pressing to obtain a sample, sintering, performing hot dipping with composite PTFE (polytetrafluoroethylene), and drying to prepare the composite material. Through a method combining powder metallurgy sintering and composite hot dipping and hole sealing technologies, the novel copper alloy base composite self-lubricating material which has high strength, high wear resistance and self-lubricating property can be prepared in an environment-friendly and low-cost way. By regulating and controlling the components and technologies, the density of the prepared copper alloy base composite self-lubricating material is 4.71-6.54 g / cm<3>, the hardness is 30-58 HV, the crushing strength is 99-222 MPa, and the friction coefficient is 0.15-0.06, thereby meeting the requirements for self-lubricating materials of friction bushings under different working conditions.

Owner:NORTHEASTERN UNIV

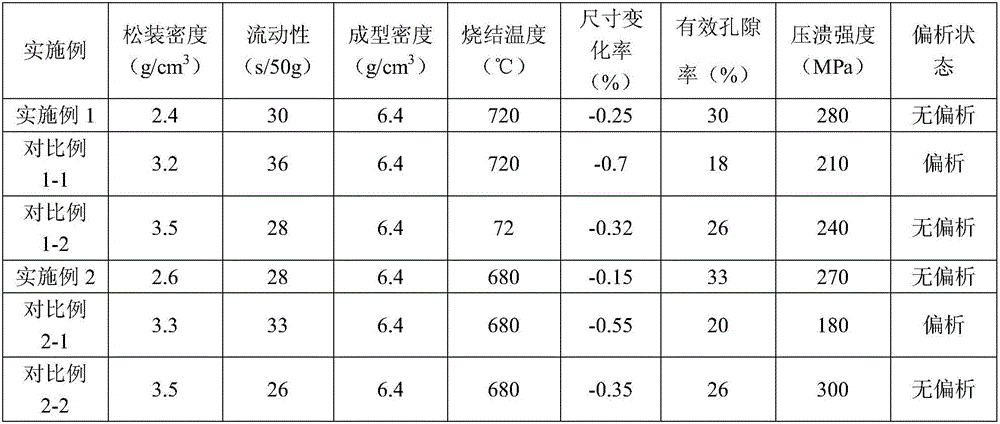

Tin bronze alloy powder and preparation method thereof

The invention discloses a tin bronze alloy powder and a preparation method thereof and relates to the technical field of metal alloy. The tin bronze alloy powder is prepared from the following raw materials in percentage by weight: 5-40 percent of copper oxide powder, 60-90 percent of copper-tin alloy powder and 0-20 percent of zinc powder. According to the tin bronze alloy powder and the preparation method, by selecting the copper oxide powder, the copper-tin alloy powder and the zinc powder as the raw materials and regulating the proportion of the raw materials, the prepared tin bronze alloy powder is low in apparent density and good in formability; by carrying out pre-oxidation and crushing on copper powder, the using ratio of the copper powder is greatly increased, and the production cost is lowered; and meanwhile, as active diffusion sintering is carried out in the diffusion sintering process in a reducing atmosphere after copper is oxidized, the active diffusion sintering is easier than direct diffusion sintering of the copper powder and the copper-tin alloy powder, and the alloying process is more easily carried out. The preparation method is simple in process; and the prepared tin bronze alloy powder is low in apparent density and good in formability.

Owner:KUN SHAN DOTOP METAL TECH CO LTD

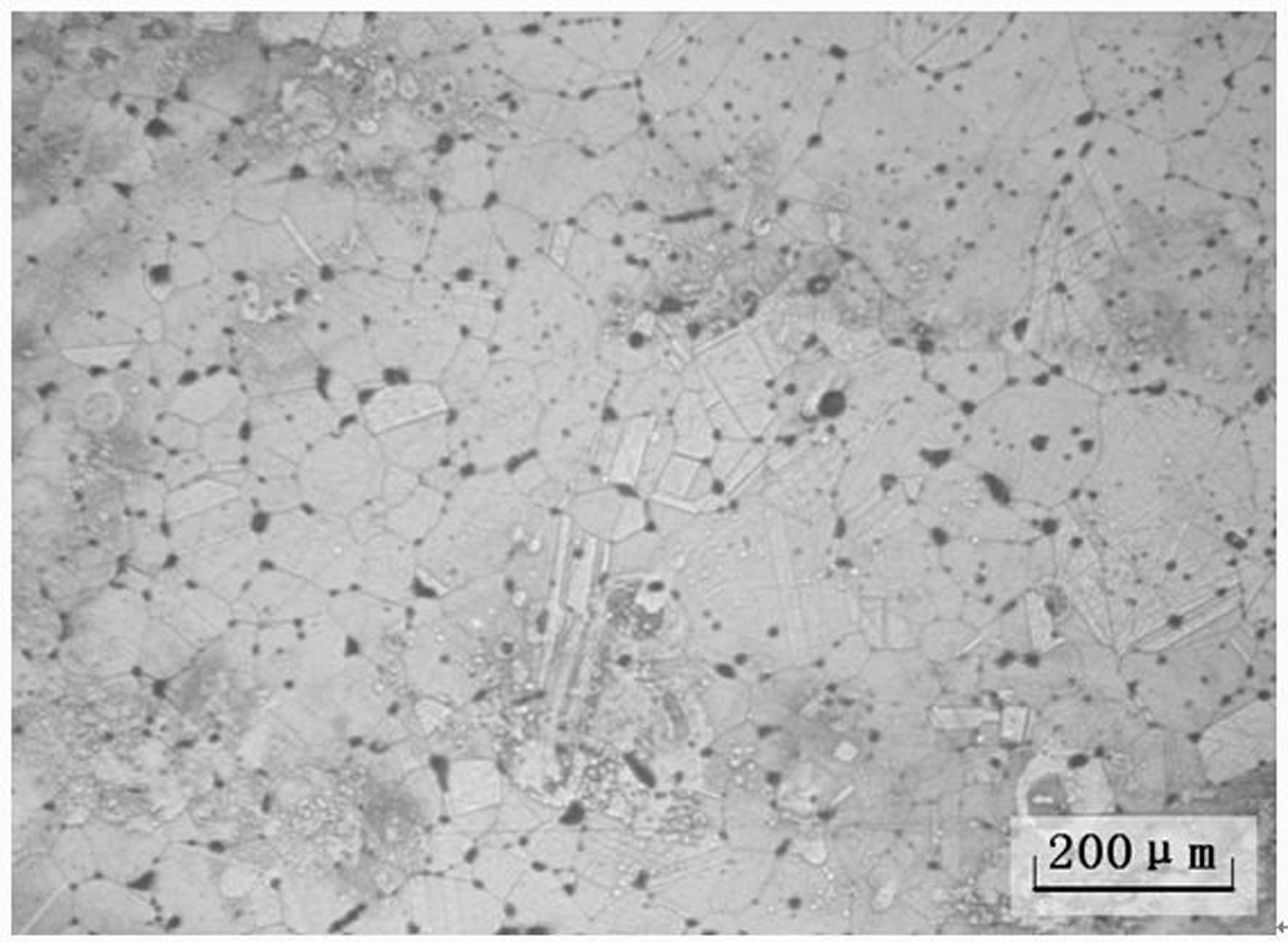

Production method of microalloyed tin bronze alloy

The invention discloses a production method of microalloyed tin bronze alloy. The production method of the microalloyed tin bronze alloy includes the steps of firstly, subjecting alloy to smelting, thermal insulation, degassing, deslagging and refining in a smelting furnace; secondly, adding refiner to refined melt for microalloying; thirdly, performing alloy casting, namely subjecting the microalloyed melt to ingot casting; and fourthly, performing cold rolling and cogging, namely subjecting the alloy subjected to alloy casting to cold rolling so as to obtain deformed tin bronze alloy. Casting grain of the microalloyed tin bronze alloy produced by the production method is small in size, segregation degree of Sn in the alloy can be lowered, brittle cracking in rolling can be eliminated, and the alloy is highly plastic. Especially, the microalloyed castings can be directly subjected to cold rolling, and accordingly a homogenizing step in the existing production method is omitted, energy resources are economized, process flow is shortened, production efficiency is improved, and production cost is reduced.

Owner:JIANGXI UNIV OF SCI & TECH

Metal self-lubricating composite material

The present invention discloses a metal self-lubricaitng compound material and its preparation method. Its preparation process includes the following steps: uniformly mixing tin bronze, copper-platedgraphite, tin powder and lead oxide powder according to a certain proportion, then sintering a layer of self-lubricating layer on the copper-plated steel back. The said material is applicable to high-load long-life use in aqueous vapour, water and gas at -200-400 deg.C, and mainly is used for making bearing material in the dry friction or the low-viscosity fluid of chemical solution, etc.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Tin bronze-steel backing self-lubricating wear-resisting bi-metal material and preparation method thereof

ActiveCN105290407AHigh tensile strengthPromote interdiffusionCopper platingUltimate tensile strength

The invention discloses a tin bronze-steel backing self-lubricating wear-resisting bi-metal material. The surface of a steel backing of the material is plated with copper. Tin bronze comprises, by weight, 5%-20% of Ni, 0.5%-1% of Cr, 0.5%-1% of Ti, and the balance copper-tin alloy. The invention further discloses a preparation method of the material. The material has the advantages that the anti-dry-grinding self-lubricating performance is achieved, the interface bonding strength is high, working procedures are easy and convenient, and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

High tin bronze plating solution for chemical plating of surface of tempered bead wire, and its chemical dip plating method

InactiveCN103924225AEasy to operateEasy to controlLiquid/solution decomposition chemical coatingChemical platingTurbidity

The invention discloses a high tin bronze plating solution for chemical plating of the surface of a tempered bead wire, and its chemical dip plating method. The plating solution comprises a main salt, a stabilizer with the concentration of 15-65g / L, a complexing agent with the concentration of 0.01-10g / L, and a solvent. The chemical dip plating solution is prepared by using the above components according to the proportions of the components, and after the tempered bead wire is plated through the chemical dip plating method, the method allows the thickness of a chemical plated high tin bronze layer of the tempered bead wire to be controlled in a range of 1.2-2.5mum, a mass ratio of the plated layer to the tempered bead wire to be stably controlled in a range of 0.15-0.80g / kg and the tin content of the plated layer to reach 8-12%. The method has the advantages of no electoplating, simple operation, easy control and low cost, and the plating solution has the advantages of certain oxidation resistance, unlikely turbidity, no acid mist, reduction of the maintenance cost, and good plating effect.

Owner:JIANGSU XINGDA STEEL TYPE CORD

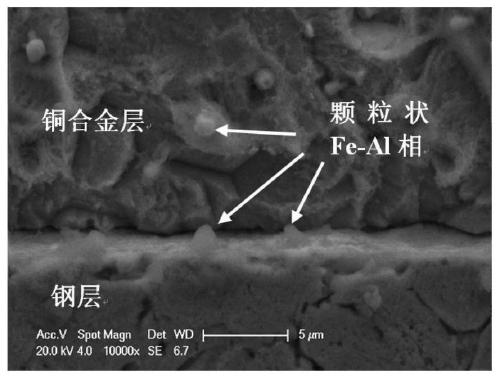

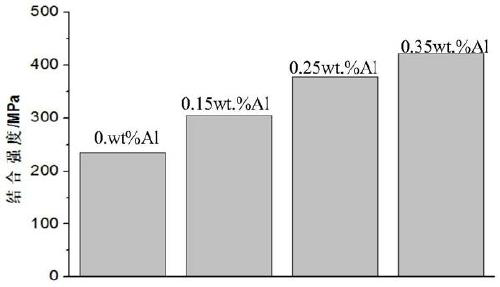

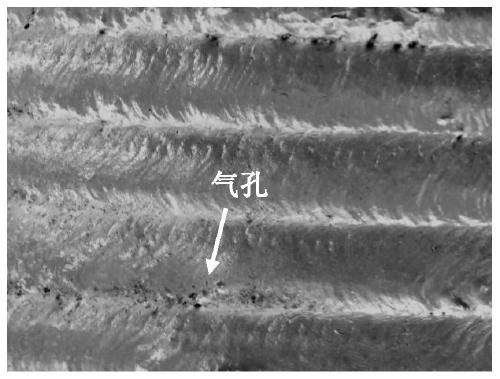

Copper steel composite material, arc additive preparing method and application of copper steel composite material and tin bronze alloy

ActiveCN110039154AHigh bonding strengthImprove wear resistanceAdditive manufacturing apparatusArc welding apparatusSheet steelUltimate tensile strength

The invention discloses a copper steel composite material, an arc additive preparing method and application of the copper steel composite material and a tin bronze alloy. The composite material is composed of a copper alloy layer and a steel layer. The copper alloy layer is novel tin bronze and comprises the following components including, by weight percent, 5%-10% of Sn, 0.15%-0.35% of Al, 0.05%-0.2% of Si, smaller than 0.01% of Pb, smaller than 0.01% of Ni and the balance Cu. A preparing technology of the composite material includes the steps that firstly, casting of a novel tin bronze alloybar is conducted; secondly, the alloy bar is subjected to extruding and drawing technologies, and a wire with the diameter being 0.8 mm to 1.6 mm is prepared; and thirdly, the wire is arranged on thesurface of a steel plate in an arc additive manner, and the copper / steel composite material is obtained. The copper steel composite material is high in combination strength and has dendrite tissue which is compact, uniform and fine, and the wear reducing and resisting performance and the bearing performance are high.

Owner:SOUTHEAST UNIV

Method for preparing micro-grain tin bronze alloy

InactiveCN1789451AImprove performanceImprove flow uniformityHeat treatment process controlGraphiteHeating furnace

The invention relates the method for preparation of microcrystal tin bronze alloy, comprising the following steps: melting the 93.5-96.5wt% Cu, 2.0-4.0wt% Se and 1.5-2.5% Pb at the condition of vacuum, making the tin bronze alloy casting blank, after surface treating the casting blank, forging it at 650-800Deg.C to make tin bronze bar, cutting the aluminum-bronze plate to lump blank and carrying out surface preparation and coating graphite lubricant, heating the blank and die, squeezing the blank with die and getting the tin bronze alloy plate. The invention improves the mechanical property and frictional behavior of tin bronze alloy, expanding the application area of alloy and meeting the product requirement.

Owner:SHANGHAI JIAO TONG UNIV

New environment-friendly lead-free silicon-containing alloy material and preparation method thereof

The invention discloses a new environment-friendly lead-free silicon-containing alloy material. The new environment-friendly lead-free silicon-containing alloy material comprises the following components in percentage by weight: 6-8 percent of zinc, 6-8 percent of tin, 1-3 percent of silicon and the balance of copper. By the new material, the traditional lead element is replaced by a silicon element; under the condition that cost is not increased, the chip cutting performance of the existing tin bronze is preserved, and the environment protection performance of the alloy is improved; and phosphorus and aluminium elements are properly added, based on the advantages, the mechanical performance of the alloy also can be greatly improved, such as tensile strength, yield strength and elongation rate, and the new material has a wide application prospect.

Owner:SUZHOU JINCANG ALLOY NEW MATERIAL

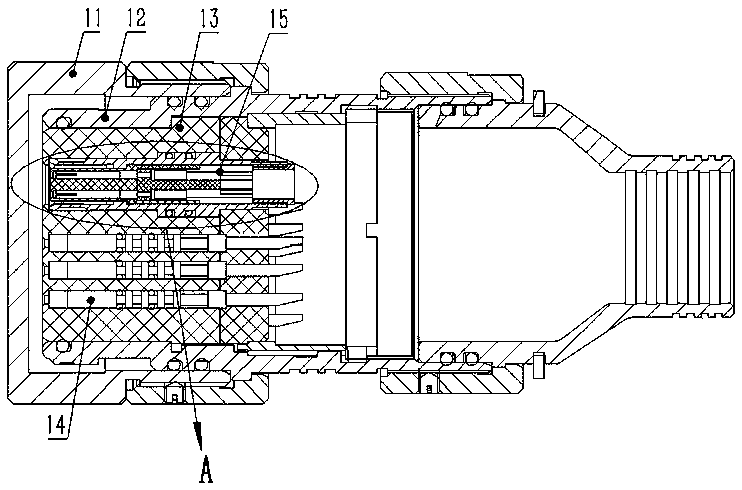

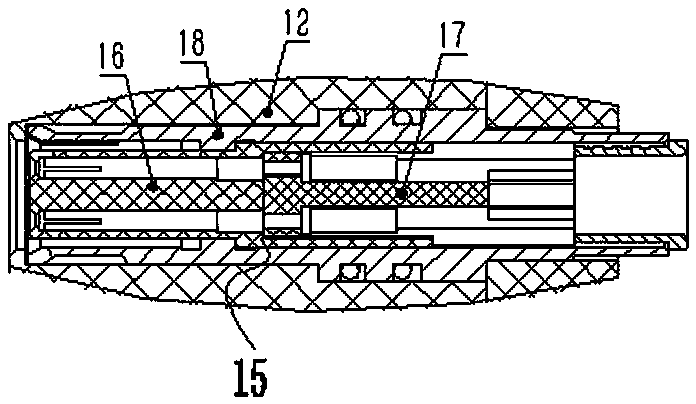

Connector and contact component thereof

ActiveCN105375159AImprove sealingSecuring/insulating coupling contact membersCoupling contact membersMetallic materialsEngineering

The invention discloses a connector and a contact component thereof. The front contact member of the contact component is assembled in a front sleeve by adopting an insulator spacing and fixing mode, and the rear contact member is fixed in a rear sleeve in a spacing way by adopting a glass sintering sealing mode. Meanwhile, butt plugging of the front contact member and the contact member of another connector is realized, and conductive connection of a rear insulator and a conductive wire is realized so that a beryllium copper alloy or a tin bronze alloy can be adopted to act as the front contact member. Metal material suitable for glass sintering sealing is adopted to act as the rear contact member and the rear sleeve so that flowing and burning-resistant capacity of the plugging contact part of the contact members in the plugging process of the plug and the socket of the whole contact component can be guaranteed by the front contact member, and sealing performance between the contact members and the fixing sleeves of the contact component can be enhanced by glass sintering sealing as for the rear contact member. Therefore, sealing performance between the contact members and the fixing sleeves can be enhanced in the contact component under the premise of guaranteeing basic plugging and flowing performance.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

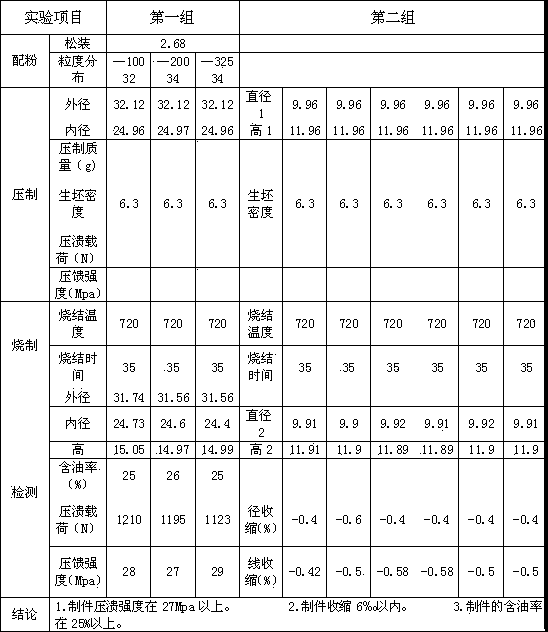

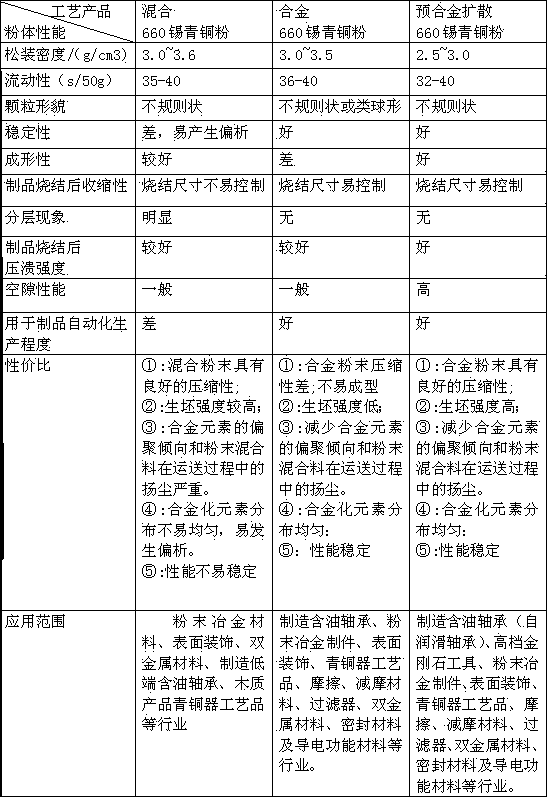

Pre-alloyed diffusion method for producing tin bronze powder

The invention discloses a pre-alloyed diffusion method for producing tin bronze powder. The method comprises the steps as follows: 86%-90% of water atomized pure copper powder smaller than 200 meshes, 5%-7% of zinc powder smaller than 300 meshes and 5%-7% of tin powder smaller than 300 meshes are placed in a V-shaped blending machine for mixing; during a mixing process, lithium stearate and 15%-25% of steel balls are added and blended for 50-70 minutes; and after the mixing is performed, a box type atmosphere furnace is adopted for diffusion sintering at the temperature of 450 DEG C for 30 minutes. With the adoption of the method, during a production process, the stability is good, the forming is easy, the sintering size is easy to control, the layering phenomenon is prevented, the crushing strength of the sintered product is good, and the application range of the finished product is wide.

Owner:安徽明月新铜粉体新材料高科技有限公司

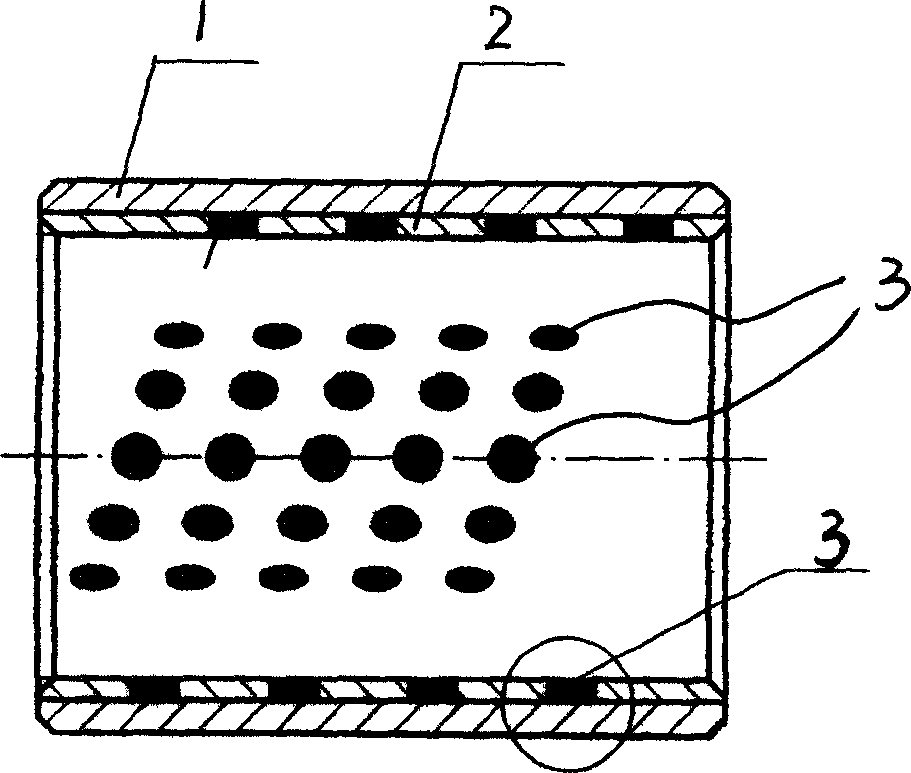

Thin-wall bimetal self-lubricating bearing and manufacturing method

The invention discloses a thin wall bimetal self-lubricating bear that is compound by steel board or corrosion resistant plate and copper alloy layer. Blind hole is distributed on the copper alloy layer. Tin bronze powder layer is on the inner surface of blind hole and solid lubrication is contained in the tin bronze powder layer. The manufacture method includes the following steps: compound copper alloy layer on the steel board or corrosion resistant plate, processing blind holes on the copper alloy layer and spraying ammonium chloride solution on the surface of blind hole and spreading tin bronze powder onto the ammonium chloride solution; taking copper powder sintering to make the powder layer combining on the surface of blind hole; embedding the solid lubrication into blind hole, sintering at 365-395 degree centigrade to make board material; taking cutting, rolling and finishing to make the product. It has the feature of low cost and high intention.

Owner:孙承玉 +2

Novel lead-free environmentally-friendly high-strength wearable copper-based alloy rod and preparation method thereof

The invention relates to a novel lead-free environment-friendly high-strength wearable copper-based alloy rod. The alloy rod comprises the following components in percentage by weight based on the total weight of the alloy rod: 0.05-7% of manganese, 2-11.5% of tin, 0.01-3% of phosphor, 1.5-10% of zinc and the balance of copper. By virtue of the alloy rod provided by the invention, the performances of the traditional lead-containing tin-bronze alloy rod are kept, and the manganese element is adopted to replace the lead element so as to meet environmental-friendly requirement.

Owner:SUZHOU JINCANG ALLOY NEW MATERIAL

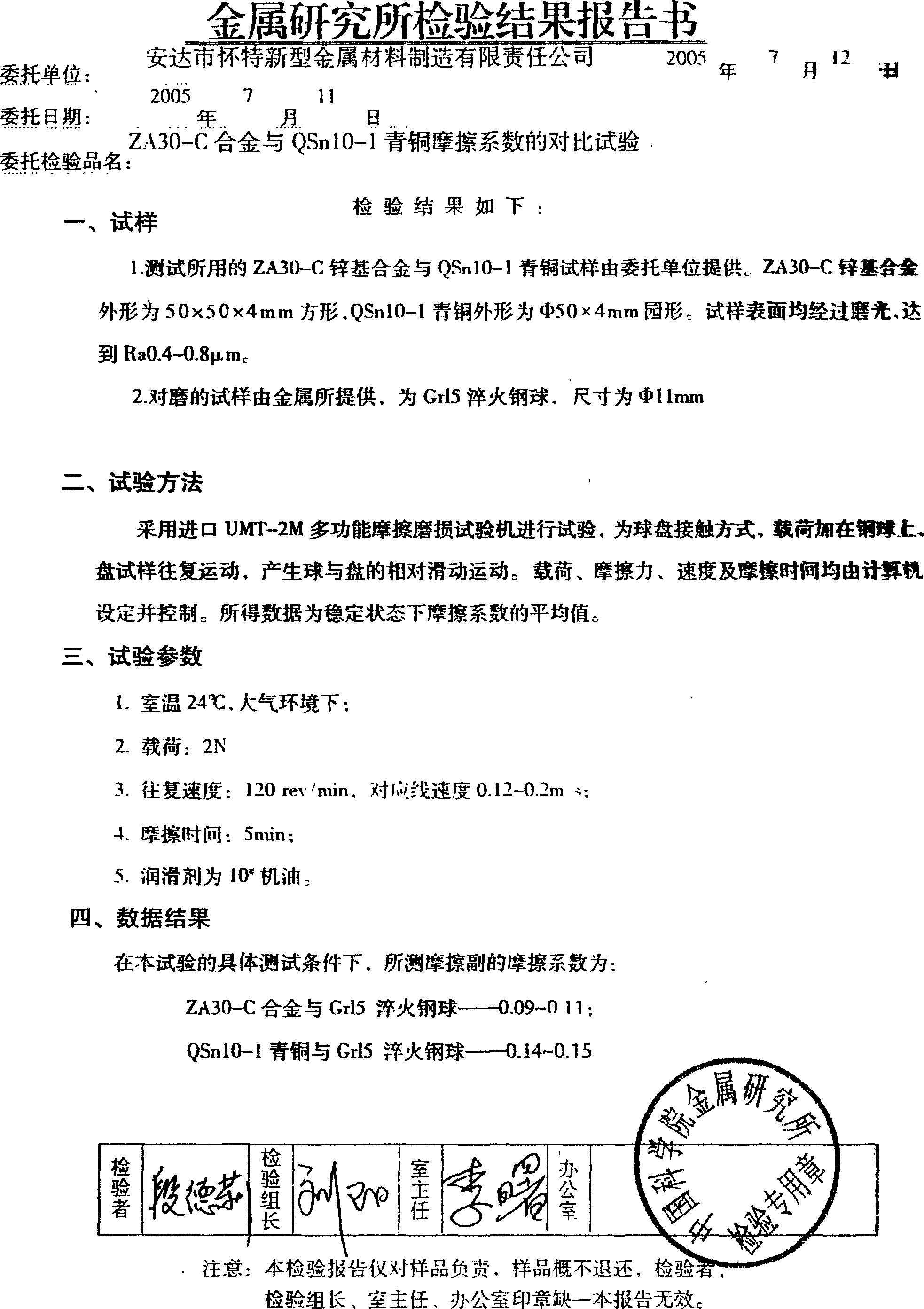

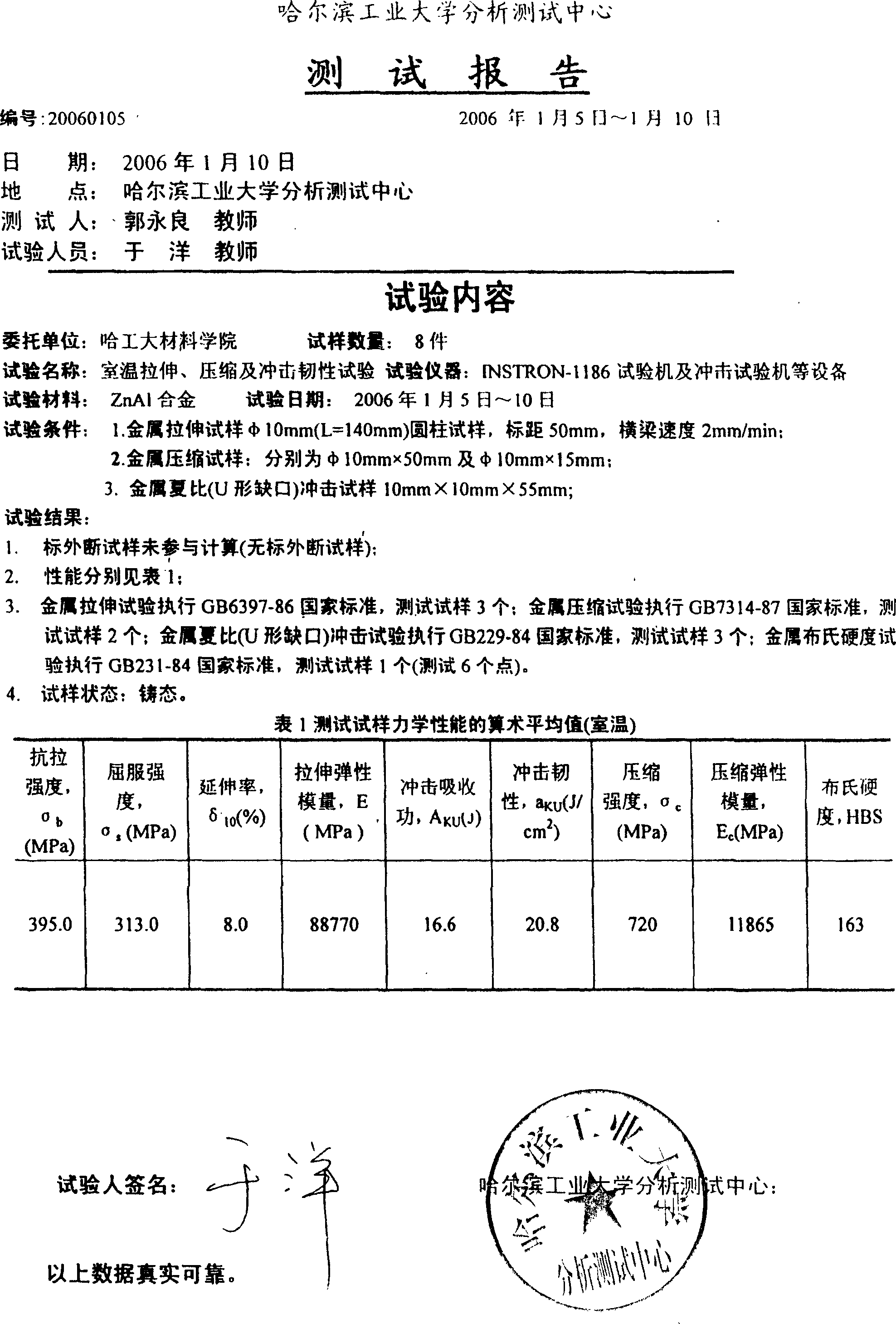

High-strength toughness lower expanding zinc base abrasion alloy and preparation process thereof

This invention discloses a method to produce a high strength of extension, low coefficient of friction, strong toughness, low expansion zinc alloy. The weight of ingredients is as follows: zinc is 55-65%, aluminum is 20-30%, intermediate alloy Al-Cu is 10-15%, and Co-Al is 1-2%. Heating the intermediate alloy and aluminum to 800-850 deg.C, after adding into zinc, the temperature of the mixture reaches 700-750 deg.C, then putting the mixture into the burning box and doing antioxidation, decanting it into the model with the temperature of 480-550 deg.C, putting the model into the water with the temperature of 40-80 deg.C to cool, at last we can get the alloy. The strength extension of this zinc alloy is 395-410Mpa, linear expansion factor is 17a*10-6, the hardness is 140-165HB, each physical index of it exceeds the characteristic of tin bronze, it can be as the succedaneum of tin bronze. It can be applied to axletree, axile bush, wormgear, nut and guide rail plate of numerical control machine, and it is a perfect wear resistant material.

Owner:HEILONGJIANG HUAITE NEW MATERIALS

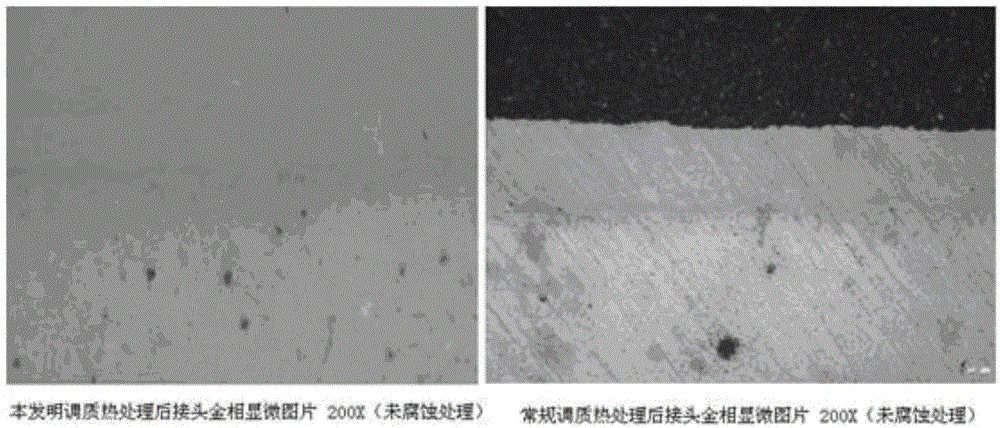

Diffusion welding method for tin bronze and steel welded structures

ActiveCN106271033ARealize no lossEliminate casting defectsWelding/soldering/cutting articlesNon-electric welding apparatusEngineeringGraphite

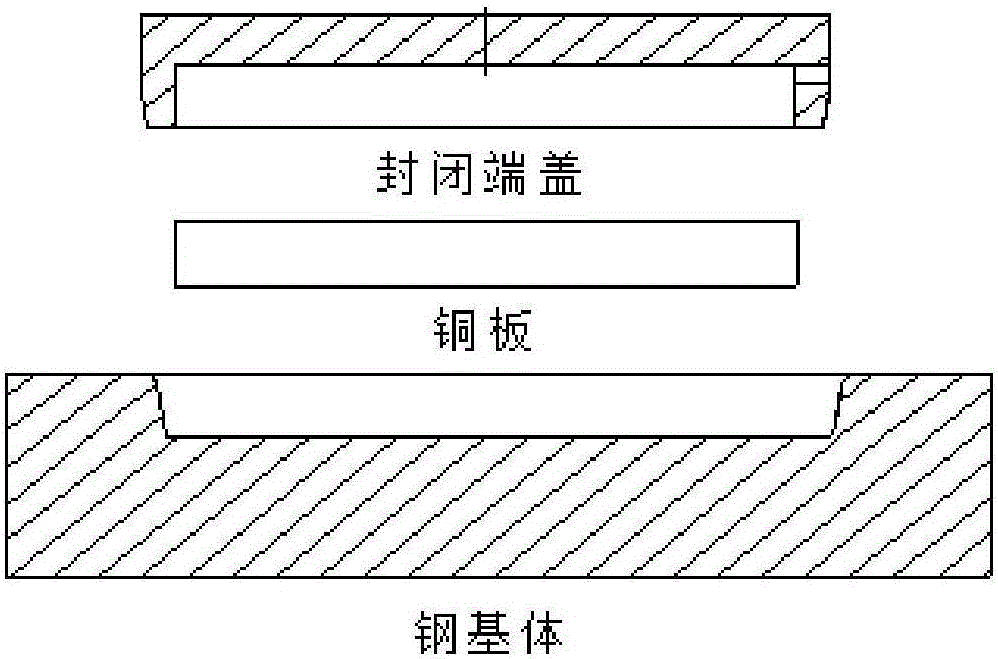

The invention discloses a diffusion welding method for tin bronze and steel welded structures. The diffusion welding method is characterized by comprising steps of 1, machining a plurality of components according to drawings, carrying out oil and rust removal treatment on welded surfaces of the multiple components and then assembling the components to obtain welded assemblies; 2, placing the welded assemblies between lower support plates in furnaces of vacuum diffusion welding equipment and separating the welded assemblies from the support plates by graphite paper; 3, allowing the internal vacuum degree of the vacuum diffusion welding equipment to range from 1.0*10<-3> to 1.0*10<-4> Pa under the control and carrying out heating and pressurizing treatment on the welded assemblies; 4, cooling the welded assemblies and fetching weldments. The components comprise steel matrixes, tin bronze plates and closed end covers. The diffusion welding method has the advantages that loss of tin bronze compositions QSn10-2-3 can be prevented, and the material stability can be guaranteed; casting defects of tin bronze QSn10-2-3 can be eliminated to a certain extent, and copper matrixes can be guaranteed against cracking after heat treatment is carried out on the weldments.

Owner:AVIC LIYUAN HYDRAULIC

Extruded high-tin bronze alloy and preparation method thereof

The invention discloses extruded high-tin bronze alloy and a preparation method thereof. The extruded high-tin bronze alloy comprises the following components by weight percent: 8-12% of Sn, 1-4% of Pb, 2-5% of Ni, less than or equal to 0.28% of Fe, Sb, Al, Zn, P, Si and Bi impurities, and the balance of Cu. The extruded high-tin bronze alloy is prepared by a solidification crystallization molding process under pressure. The extruded high-tin bronze alloy provided by the invention has the following advantages: (1) the components of the alloy are uniform, and are directly molded by extrusion in a liquid state, so that the segregation is improved, the cracks and are reduced and the like; and (2) the density of the alloy is high and is more than or equal to 9.0g / cm<3>, the hardness of the alloy is more than or equal to 125HB, the tensile strength is more than or equal to 350MPa, and the elongation is more than or equal to 15%.

Owner:HENAN UNIV OF SCI & TECH +1

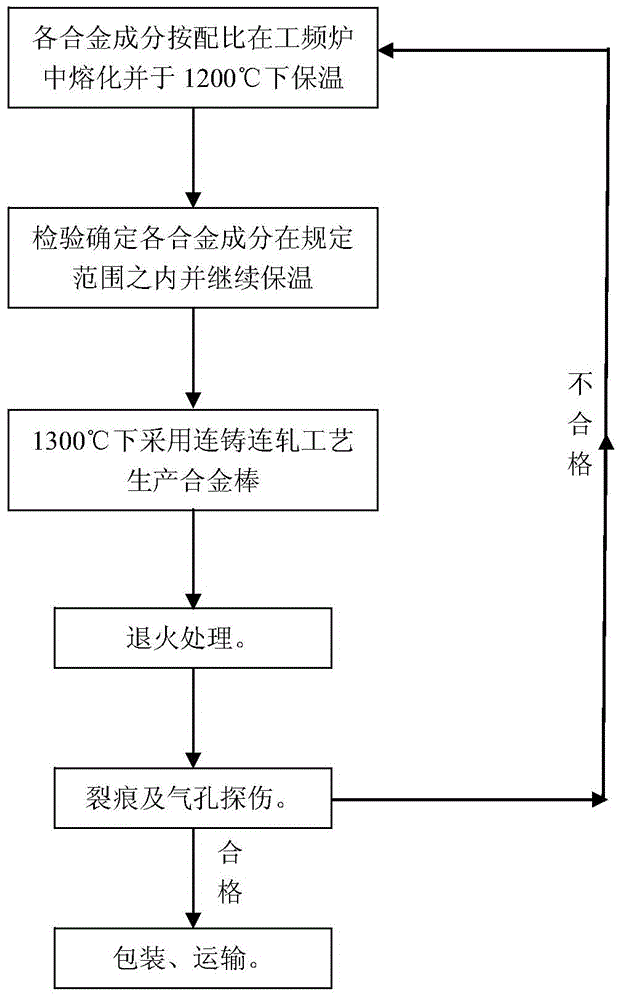

Lead-free environment-friendly copper base alloy bar and preparation method thereof

The invention provides a lead-free environment-friendly copper base alloy bar and a preparation method thereof. The lead-free environment-friendly copper base alloy bar comprises the following components by weight percent: 1-7% of zinc, 0.5-7% of tin, 0.5-6% of silicon, 0.05-0.25% of phosphorus, 0.01-0.15% of manganese and the balance of copper. The lead-free environment-friendly copper base alloy bar and the preparation method have the beneficial effects that the production process of continuous casting and rolling is adopted, thus omitting the steps of billet treatment and annealing extrusion in the traditional production process, shortening the production cycle, improving the production efficiency and greatly reducing the production cost; the alloy bar adopts silicon instead of lead in the traditional copper alloys and is lead-free, thus avoiding environmental pollution caused by using lead and being beneficial to environmental protection; the lead-free environment-friendly copper base alloy bar provided by the invention absolutely can replace tin bronze bars containing lead.

Owner:SUZHOU JINCANG ALLOY NEW MATERIAL

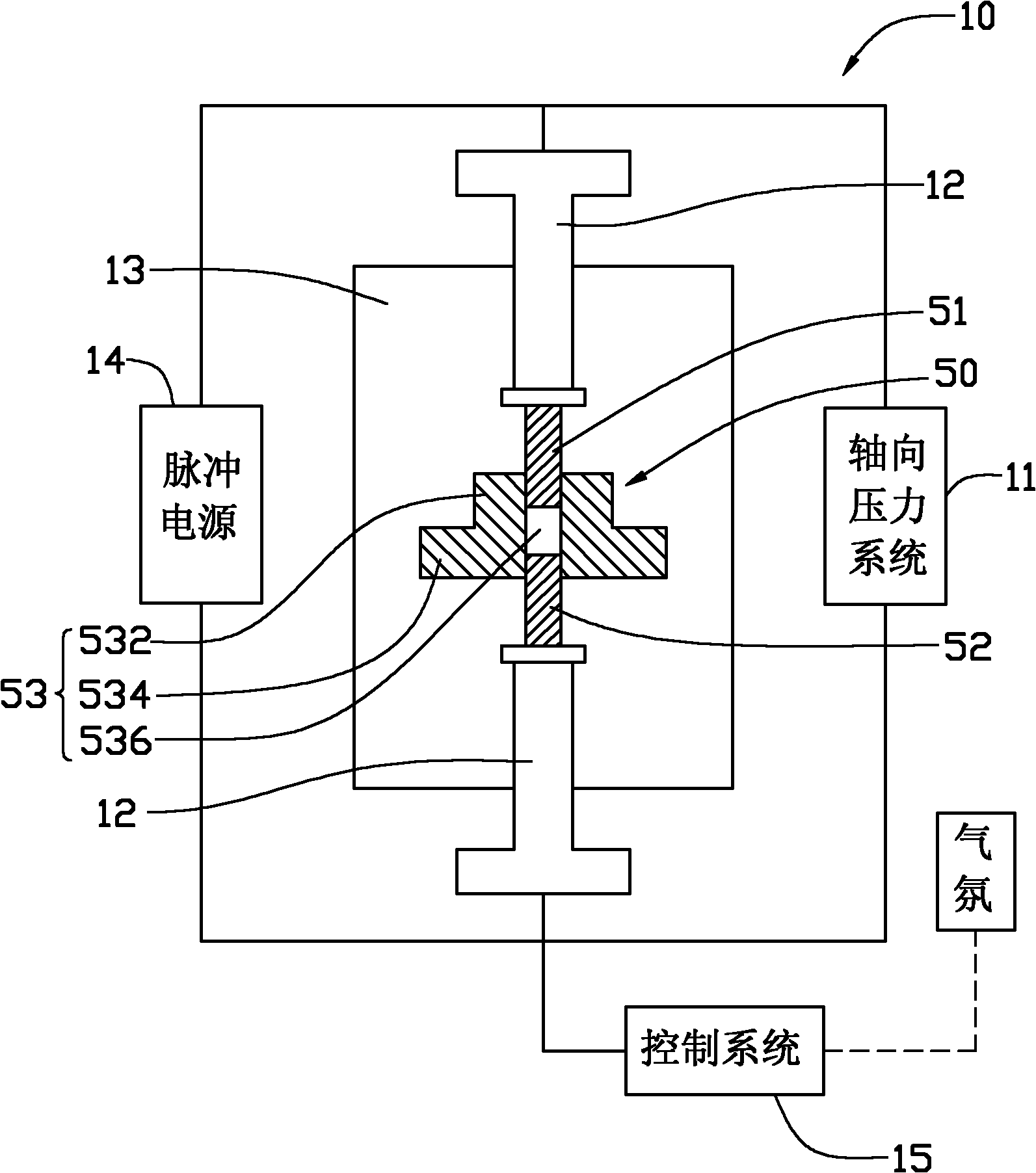

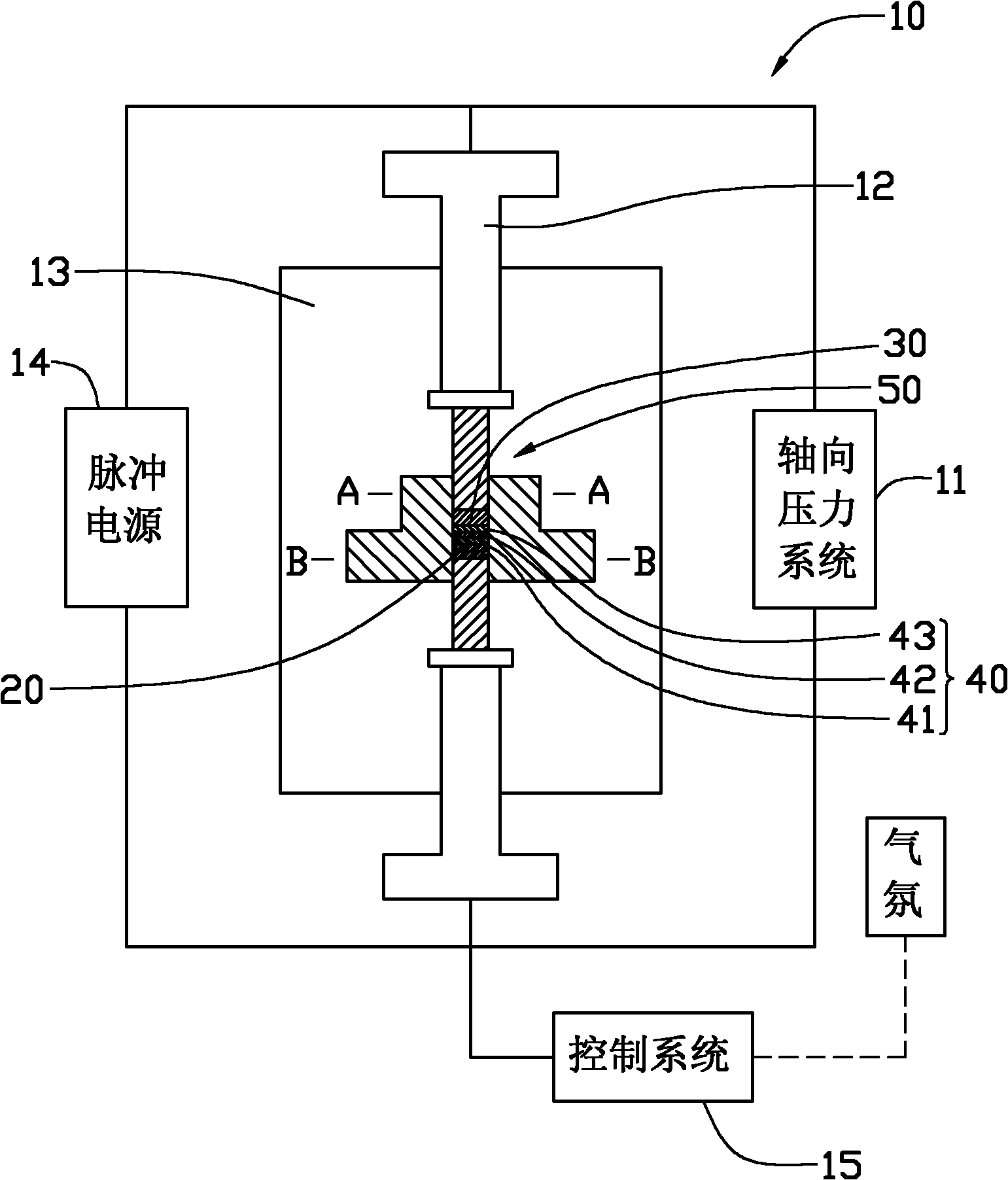

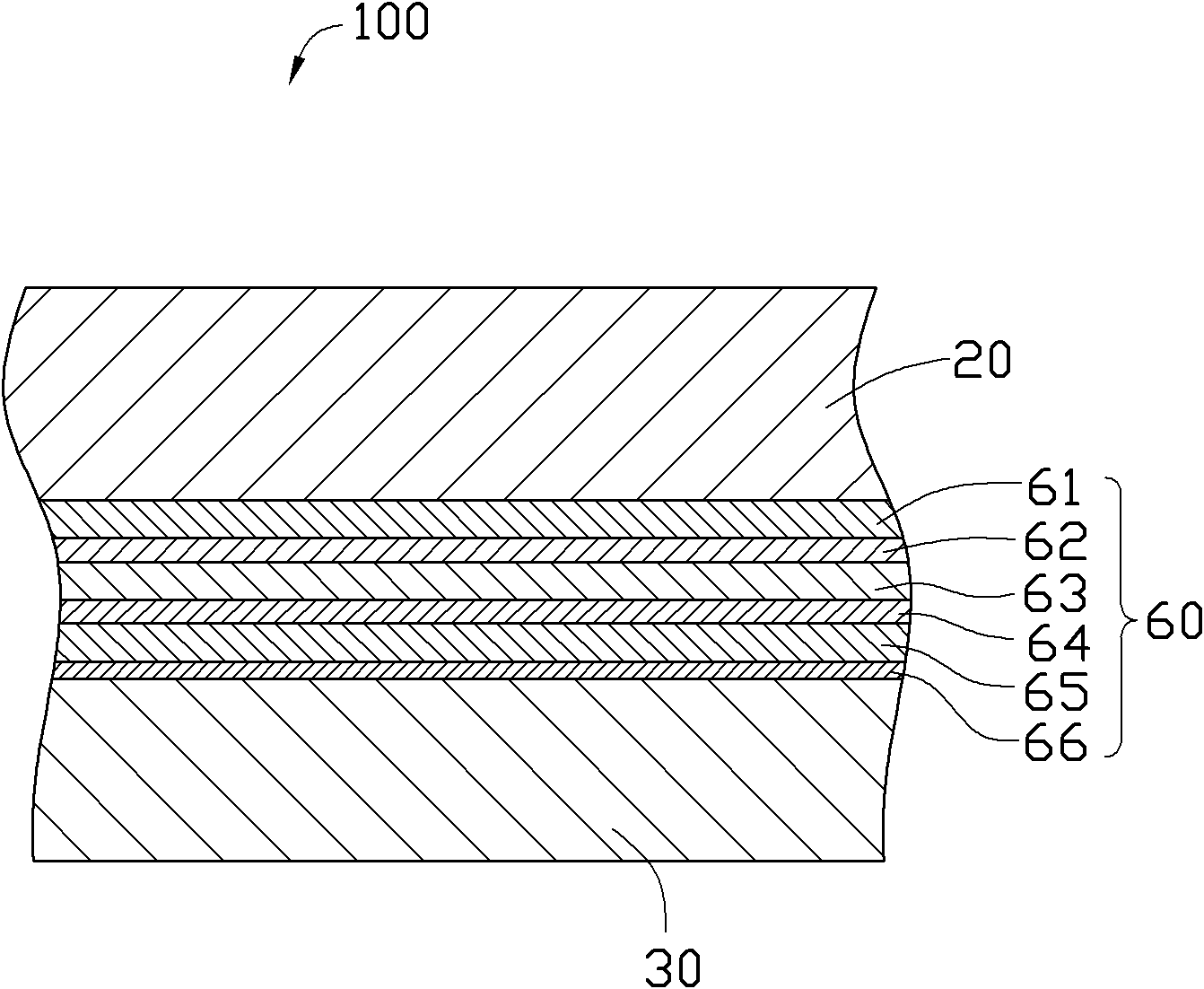

Connection method for tin bronze and alumina ceramic and prepared connecting piece

The invention provides a connection method for tin bronze and alumina ceramic. According to the connection method, discharge plasma sintering equipment is mainly used for applying a pulse current on tin bronze, alumina ceramic and a metal interface layer to realize discharge plasma connection; a connecting die is designed to have different sectional areas perpendicular to the direction of the current at an upper part and a lower part; an alumina ceramic member with a high melting point is located at the upper part, a tin bronze member with a low melting point is located at the lower part, and a current applied on the alumina ceramic member is greater than a current applied on the tin bronze member, thereby enabling the two members to be simultaneously softened for connection. The invention also provides a connecting piece for tin bronze and alumina ceramic prepared by the above-mentioned connection method.

Owner:HONGFUJIN PRECISION ELECTRONICS (ZHENGZHOU) CO LTD +1

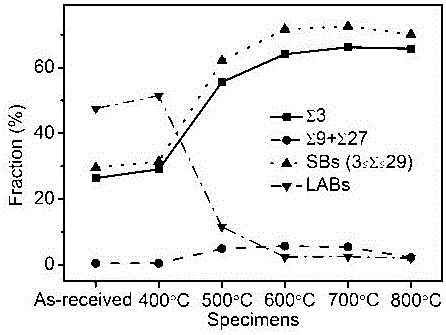

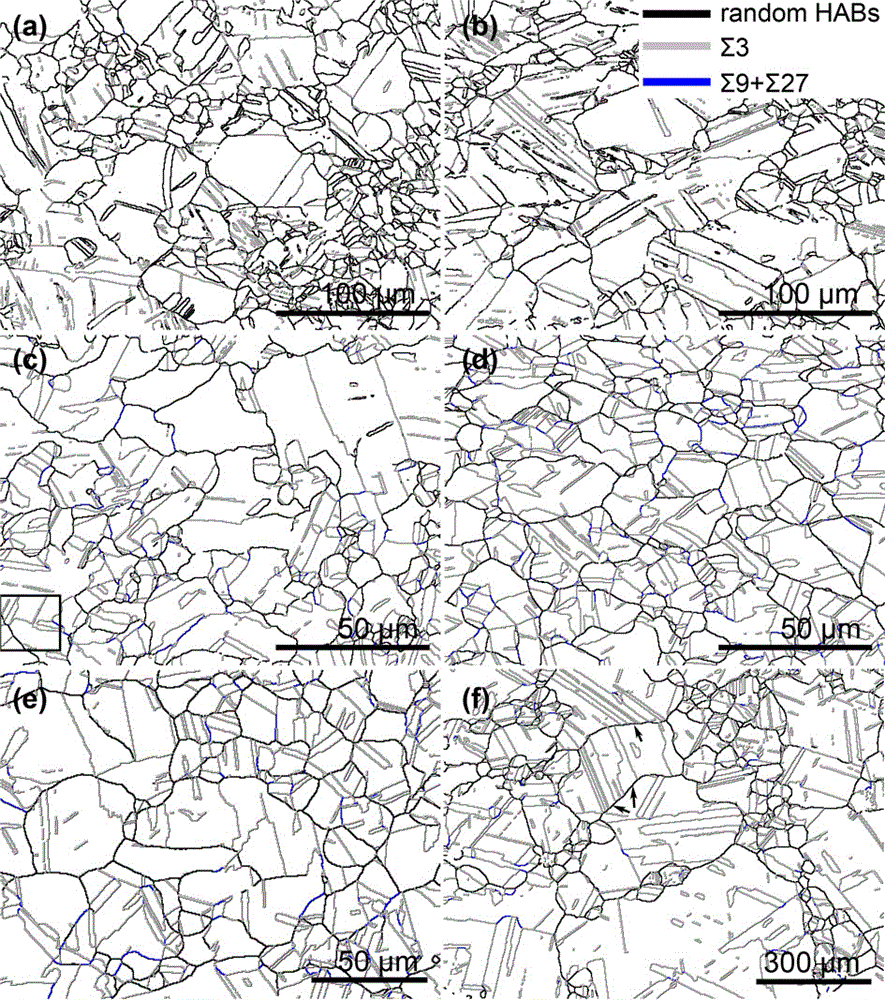

Processing method for obtaining high-proportion special grain boundary from tin bronze

The invention discloses a processing method for obtaining a high-proportion special grain boundary from tin bronze. The processing method for obtaining the high-proportion special grain boundary from tin bronze comprises the steps that firstly, a plurality of workpieces with the dimension being 20 mm, a plurality of workpieces with the dimension being 9 mm and a plurality of workpieces with the dimension being 3 mm are obtained by cutting the tin bronze in the rolling direction, the transverse direction and the normal direction correspondingly through a linear cutting tool, then the workpieces are placed in the environment at the temperature of 400-800 DEG C for heat preservation for 0.5-5 hours, and then the workpieces are subjected to water quenching to the room temperature; secondly, polishing is conducted stage by stage with 200-2500# metallographic abrasive paper, and then mechanical polishing is conducted; and thirdly, electrochemical polishing is conducted in a polishing solution, the polishing temperature is 20-30 DEG C, the polishing voltage is 9 V, and the polishing time is 90 s. According to the processing method, it is proved through test analysis that the proportion of the special grain boundary is remarkably increased before the recrystallization annealing temperature is reached completely along with the rise of the annealing temperature; the structure obtained through the heat treatment process is stable, the change rule is obvious, and the experiment repeatability is good; and operation of the heat treatment process is simple, the technique is reliable, and the efficiency is high.

Owner:CHONGQING UNIV OF TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com