Pre-alloyed diffusion method for producing tin bronze powder

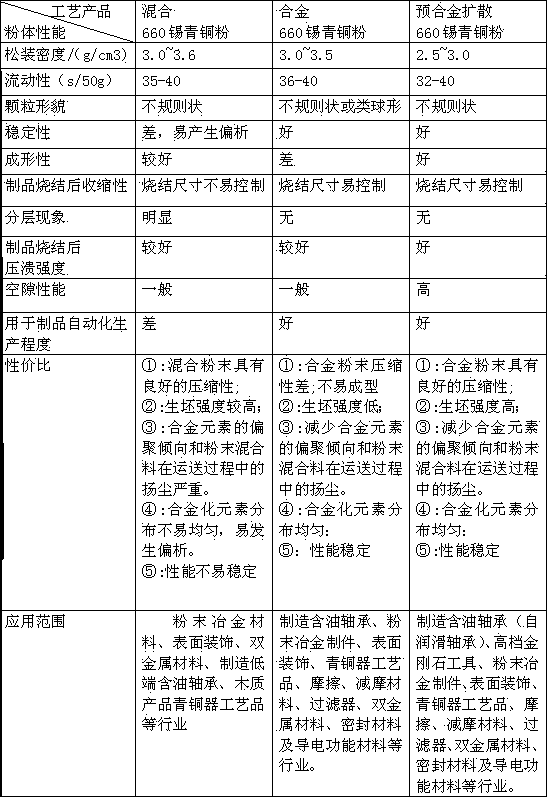

A technology of pre-alloying and tin bronze, which is applied in the field of pre-alloying diffusion method for producing 660 tin bronze powder, can solve problems such as unfavorable powder forming, and achieve the effects of easy control of sintering size, easy forming and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

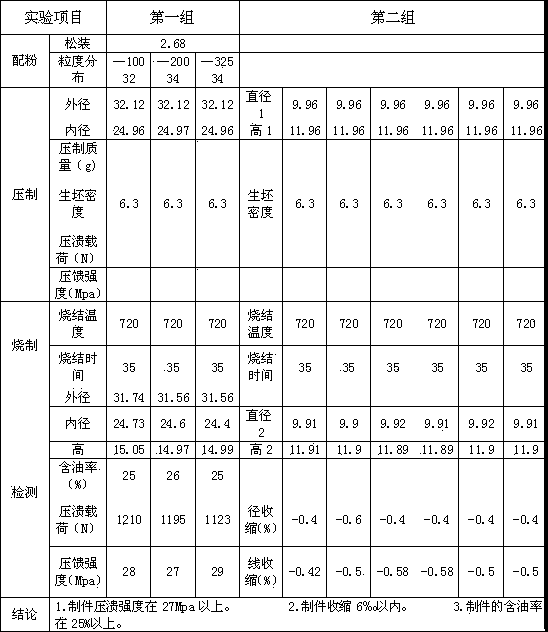

Examples

Embodiment Construction

[0007] The present invention will be further described below.

[0008] General embodiment of the present invention: the pre-alloying diffusion method of producing tin bronze powder, it comprises the steps: 90%-200 order water atomization pure copper powder, 5%-300 order zinc powder and 5%-300 order The tin powder is mixed in a V-shaped batch machine. During the mixing process, lithium stearate and 15% steel balls are added for batching for 50 minutes. After mixing, the box-type atmosphere furnace is used for diffusion sintering. The sintering temperature is 450°C and the diffusion sintering time is 30 minutes. minute.

[0009] Preferred example of the present invention: the pre-alloying diffusion method of producing tin bronze powder, it comprises the following steps: atomize pure copper powder with 88%-200 order water, 6%-300 order zinc powder and 6%-300 order tin Put the powder into a V-type batch machine for mixing. During the mixing process, add 1% lithium stearate and 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crushing strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com