Electrophoretic microcapsules formed by complex coacervation of carboxyl butyronitrile/gelatin and Arabic gum and preparation method thereof

A carboxylated nitrile and gum arabic technology, applied in microcapsule preparation, microsphere preparation, optics, etc., can solve the problems of low strength of microcapsule wall materials, rough surface of microcapsules, poor transparency, etc., and achieve obvious electrophoretic display Responsive, smooth surface, good flexibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

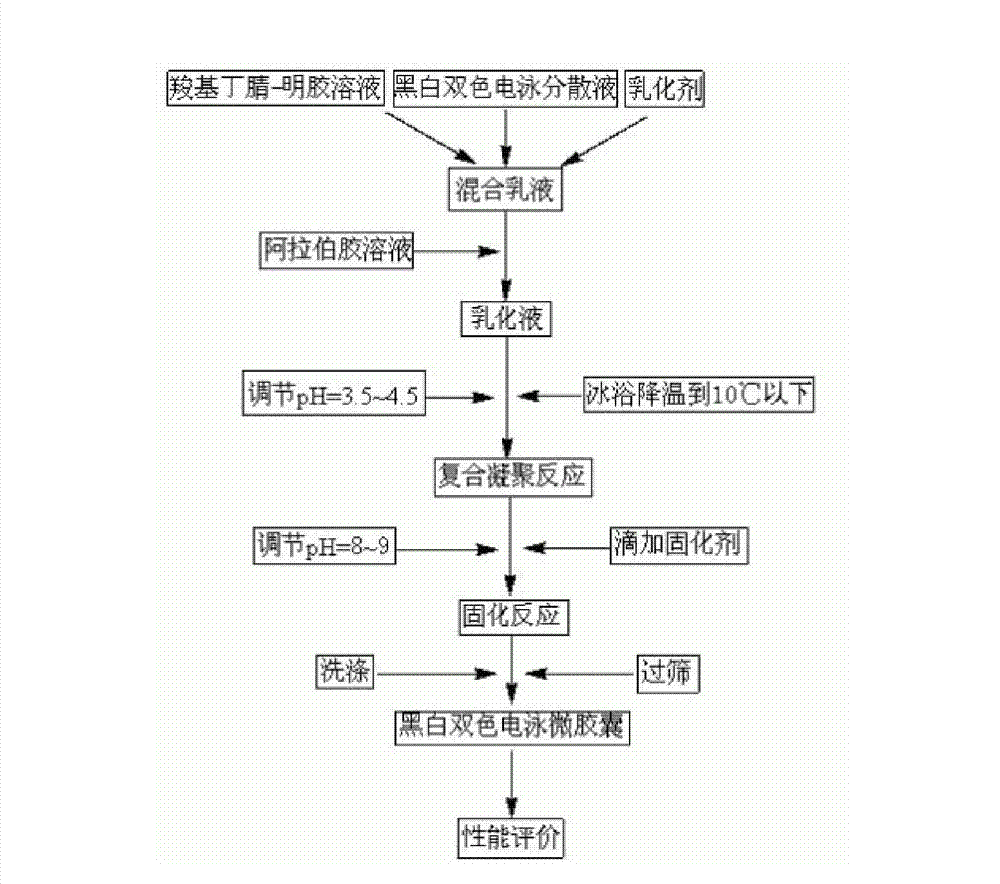

Method used

Image

Examples

example 1

[0045] 1. Preparation of carboxylated nitrile / gelatin blend material

[0046] The gelatin was formulated into an aqueous solution with a concentration of 2.5%. At 60°C, it was blended with carboxylated nitrile latex:gelatin at a ratio of 100:80, and 1% sodium tetraborate was added as an accelerator for 30 minutes of reaction. After the reaction, the blended solution was kept warm at 40°C for later use.

[0047] 2. Preparation of electrophoretic suspension

[0048] Carbon black electrophoretic particles are added to tetrachlorethylene to form a dispersion with a mass fraction of 1%, and a surfactant with a solution mass fraction of 1% is added to the dispersion, and the surfactant is sorbitan tris Oleate, add 1% charge control agent polyisobutylene monosuccinimide series to the dispersion, then add zirconium beads, grind at 300rpm for 12h, then remove the zirconium beads to obtain a stable white electrophoretic suspension Or black electrophoretic suspension, sealed for future...

example 2

[0056] 1. Preparation of carboxylated nitrile / gelatin blend material

[0057] The gelatin was formulated into an aqueous solution with a concentration of 10%. At 70°C, it was blended with carboxylated nitrile latex: gelatin at a ratio of 100:100, and 2% sodium tetraborate or citric acid was added as an accelerator, and the reaction was carried out for 20 minutes. After the reaction, the blended solution was kept warm at 30°C for later use.

[0058] 2. Preparation of electrophoretic suspension

[0059] TiO 2 The electrophoretic particles are added to tetrachlorethylene to form a dispersion with a mass fraction of 10%, and a surfactant with a solution mass fraction of 2% is added to the dispersion, and the surfactant is polyoxyethylene sorbitan mono-oil Acid, add a charge control agent polyisobutylene monosuccinimide with a solution mass fraction of 2% to the dispersion, then add zirconium beads, grind at 300rpm for 18h, and then remove the zirconium beads to obtain a stable w...

example 3

[0067] 1. Preparation of carboxylated nitrile / gelatin blend material

[0068] The gelatin was formulated into an aqueous solution with a concentration of 10%. At 80°C, it was blended with carboxylated nitrile latex:gelatin at a ratio of 100:120, and 1% sodium tetraborate was added to react for 30 minutes. After the reaction, the blended solution was kept warm at 45°C for later use.

[0069] 2. Preparation of electrophoretic suspension

[0070] Add TiO electrophoretic particles to tetrachlorethylene to prepare a dispersion with a mass fraction of 20%, and add a surfactant with a solution mass fraction of 2% to the dispersion, and the surfactant is polyoxyethylene sorbitan Monooleic acid, add polyisobutylene monosuccinimide, a charge control agent with a solution mass fraction of 2% to the dispersion, then add zirconium beads, grind at 300 rpm for 24 hours, then remove the zirconium beads to obtain a stable white electrophoretic suspension or Black electrophoretic suspension, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com