Lead-free environment-friendly copper base alloy bar and preparation method thereof

A technology of copper-based alloys and manufacturing methods, applied in the manufacture of alloy rods, the field of lead-free and environmentally friendly copper-based alloy rods, can solve the problems of reducing the machinability of alloy rods, lead hazards, etc., shorten the production cycle, improve production efficiency, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

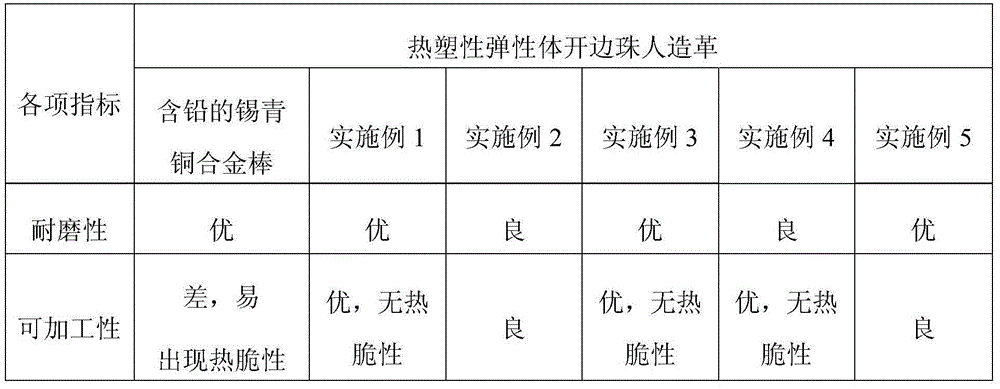

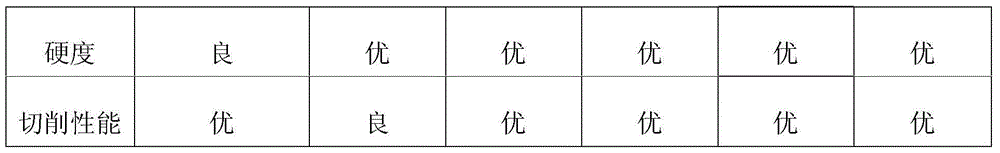

Embodiment 1

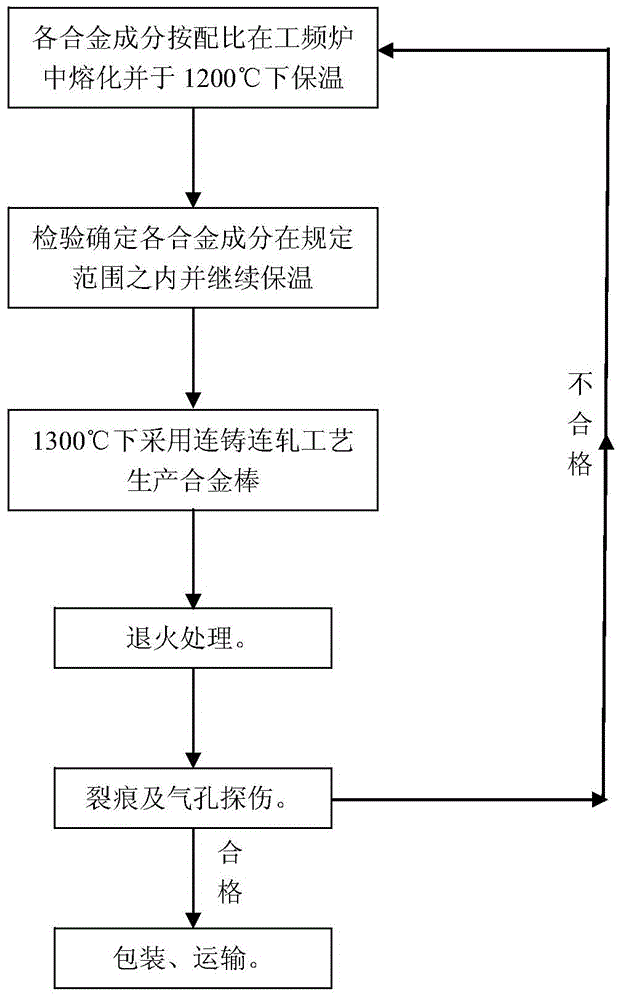

[0024] Example 1, a lead-free environmentally friendly copper-based alloy rod, composed of the following components in weight percentage: zinc: 2%, tin: 0.5%, silicon: 4.5%, phosphorus: 0.25%, manganese: 0.01%, the balance for copper. Its manufacturing process is as figure 1 As shown, perform the following steps in sequence:

[0025] Weigh each component according to the proportion, put it in a power frequency electric furnace, heat it to 1250°C and melt it, stir it evenly with a graphite rod, and cover it with 12cm thick high-purity scaly graphite powder to prevent oxidation, and keep it warm for 1 hour , to detect whether the alloy composition is within the specified range. After the inspection is completed and qualified, continue to keep warm for about 40 minutes, then raise the temperature to 1300°C again, and turn on the vibration device of the industrial frequency electric furnace. The vibration frequency is 1 time / second. Continuous casting and rolling The method is t...

Embodiment 2

[0027] Example 2, a lead-free environmentally friendly copper-based alloy rod, consisting of the following components in weight percentage: zinc: 1%, tin: 7%, silicon: 1.5%, phosphorus: 0.1%, manganese: 0.1%, and the balance for copper. Its manufacturing process is as figure 1 As shown, perform the following steps in sequence:

[0028] Weigh each component according to the proportion, put it in a power frequency electric furnace, heat it to 1290°C and melt it, stir it evenly with a graphite rod, and cover it with 11cm thick high-purity scaly graphite powder to prevent oxidation, and keep it warm for 1.3 hours , to detect whether the alloy composition is within the specified range. After the inspection is completed and qualified, continue to keep warm for about 50 minutes, then raise the temperature to 1300°C again, and turn on the vibration device of the industrial frequency electric furnace. The vibration frequency is 1 time / second. Continuous casting and rolling The method...

Embodiment 3

[0030] Example 3, a lead-free environmentally friendly copper-based alloy rod, consisting of the following components in weight percentage: zinc: 4.5%, tin: 4%, silicon: 3%, phosphorus: 0.2%, manganese: 0.08%, and the balance for copper. Its manufacturing process is as figure 1 As shown, perform the following steps in sequence:

[0031] Weigh each component according to the proportion, put it in a power frequency electric furnace and heat it to 1300°C to melt, then stir it evenly with a graphite rod, and cover it with 13cm thick high-purity scaly graphite powder to prevent oxidation, and keep it warm for 1.5 hours , to detect whether the alloy composition is within the specified range, after the detection is completed and qualified, continue to keep warm for about 60 minutes, then raise the temperature to 1300°C again, turn on the vibration device of the industrial frequency electric furnace, the vibration frequency is 1 time per second, and adopts continuous casting and roll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com