High-strength toughness lower expanding zinc base abrasion alloy and preparation process thereof

A wear-resistant alloy and low-expansion technology, applied in the field of metallurgical material manufacturing, can solve the problems of increased loss of raw materials, low melting point temperature, and large processing allowance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Take 60.8% of raw material zinc, 28.6% of aluminum, 9.8% of intermediate alloy copper and aluminum (wherein the weight ratio of copper to aluminum is 1:1), and 0.8% of cobalt and aluminum (wherein the weight ratio of cobalt to aluminum is 1:10). The intermediate alloys copper-aluminum, cobalt-aluminum and aluminum are heated together to 850°C, and then the temperature drops to about 400°C after adding zinc, and then heated to 730°C, put into the ladle, and then add dry straw or straw for anti-corrosion. Oxidation treatment, so that it can cover the surface of the molten metal, after burning out, pour the molten metal through a sink into a thin iron plate mold at a temperature of 480°C, put the mold in 80°C hot water to cool, and then cast it.

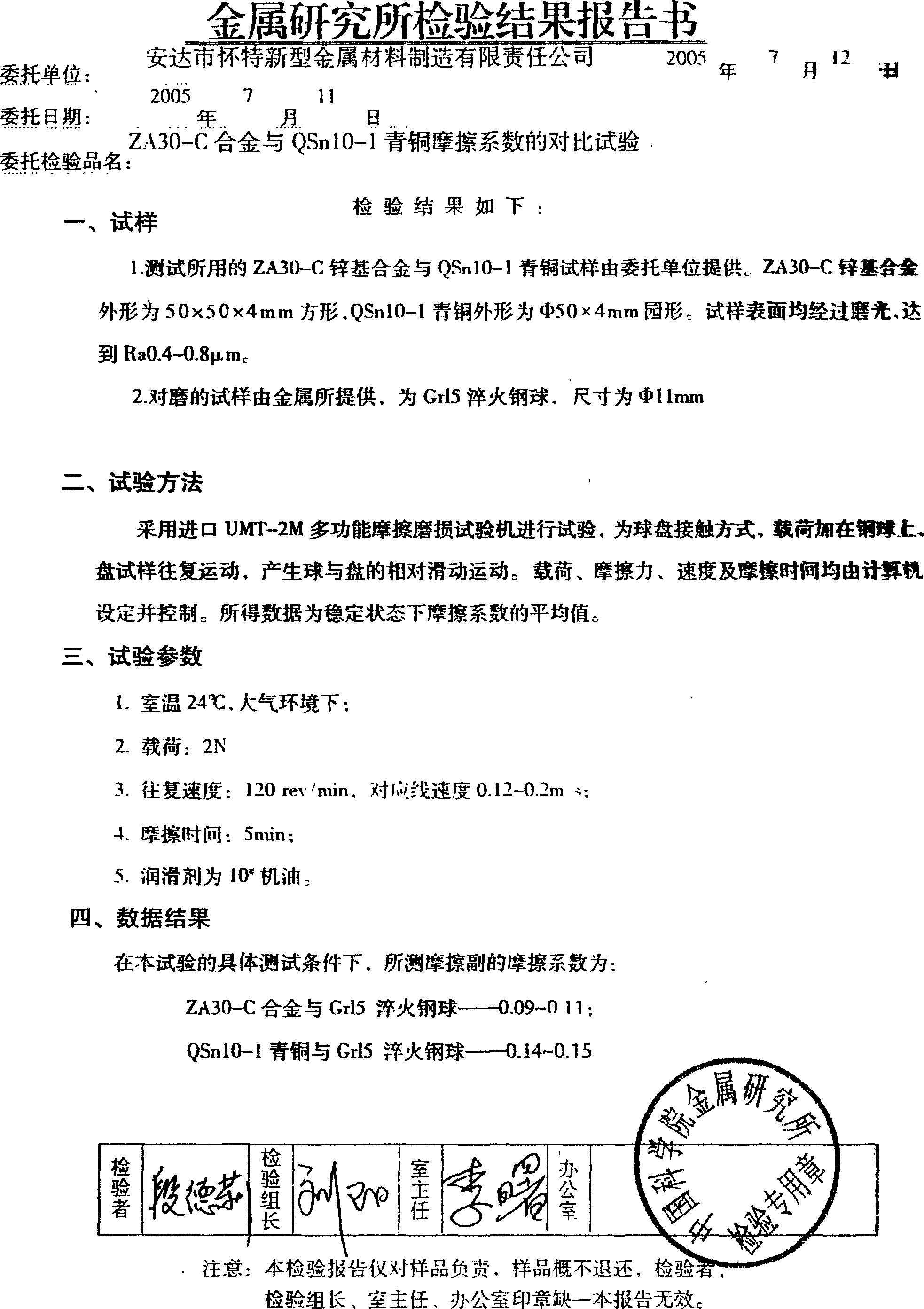

[0011] Attach the Institute of Metal Research, Chinese Academy of Sciences report on the comparative test results of the alloy (ZA30-C) of the present invention and bronze (QSn10-1) friction coefficient:

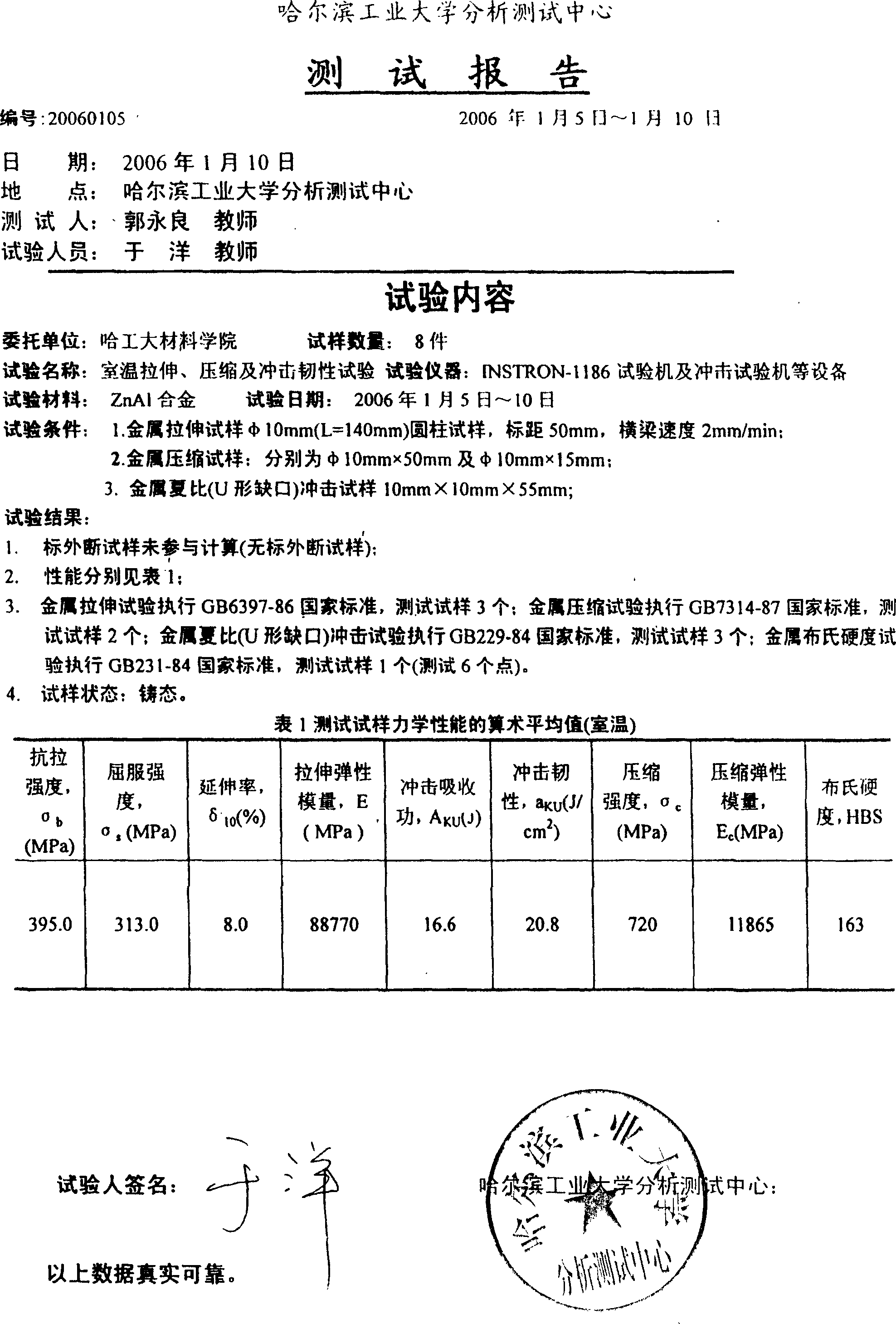

[0012] Attach Harbin In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com