Technique for processing tin bronze valve body and tube union

A processing technology, tin bronze technology, applied in the direction of metal processing equipment, manufacturing tools, metal extrusion control equipment, etc., can solve the performance, reliability, yield, material utilization and equipment capacity limitations of die-casting products, which cannot meet the requirements Requirements for high-performance structural parts, difficulty in obtaining compactness and other problems, to achieve the effect of solving air-tightness problems, improving ductility and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

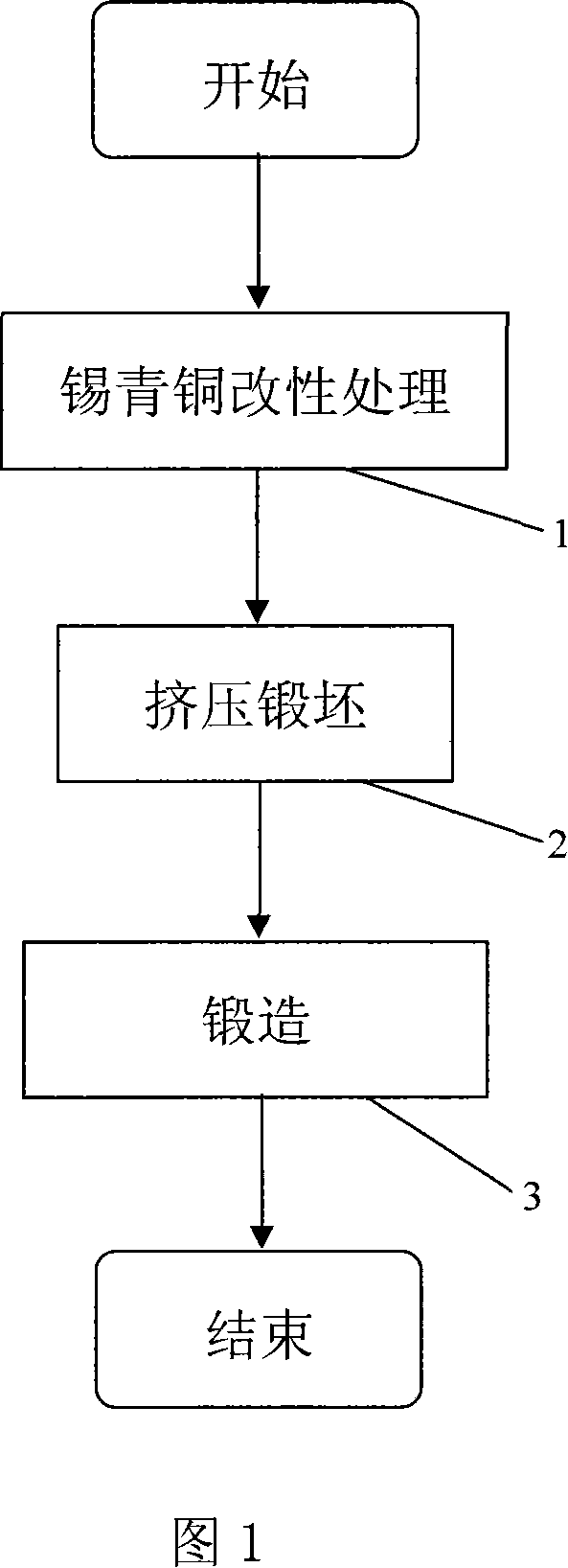

[0020] As shown in Figure 1, the processing technology of high-strength and high-ductility magnesium alloy parts sequentially includes three steps of tin bronze modification treatment 1, extrusion forging billet 2, and forging 3.

[0021] The copper is used as the raw material and the alloy composition is proportioned for batching. When the alloy is smelted, the raw material is first added to the furnace, and then the calcined charcoal is added as a protective agent to isolate the alloy from the air. Among them, the thickness of the charcoal covering layer is 50-70mm. Then heat the alloy material to 600°C, keep it in the furnace for 30 minutes, then continue to heat up to 900°C, and finally heat the alloy to 1150°C, remove the slag and charcoal on the liquid surface, and add about 0.1% phosphor copper, Stir the molten pool with a graphite rod, add charcoal to raise the temperature to 1200°C, keep it warm for 30 minutes, and prepare for continuous casting.

[0022] When the fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com