Copper alloy base self-lubricating composite material and preparation method thereof

A composite material and copper alloy technology, applied in the field of materials, can solve the problems of reducing the mechanical properties of materials, crushing strength, density and hardness, and wear resistance of materials, and achieve good self-lubricating properties and high wear resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

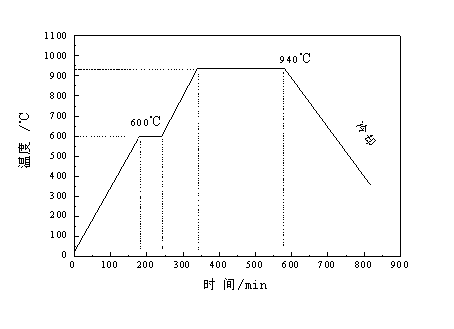

Embodiment 1

[0035] Prepare a copper alloy-based self-lubricating composite material, its chemical composition is Ni10%, Sm 2 o 3 1%, MoS 2 1%, Ag1%, CaF 2 1%, Al 2 o 3 2%, W3%, nickel-plated graphite 3%, ZQSn663 tin bronze powder (the chemical composition in ZQSn663 tin bronze powder is Zn5%, Sn5%, Pb2%, copper 88% by mass percentage) 78%, its properties are shown in Table 1 Shown, the preparation method is as follows:

[0036] (1) Mixing: Use a barrel to mix the powder on the mixer. The speed of the mixer is 400r / min. Steel balls and springs are added to the barrel to form the abrasive, so that the volume ratio of the abrasive to the metallurgical composite powder is 7. : 1, it is conducive to stirring and uniform mixing; wherein the compound powder mixing for metallurgy is carried out according to the following steps:

[0037] (a) Weigh Ni and Sm respectively 2 o 3 、MoS 2 , Ag, CaF 2 、Al 2 o 3 , W, nickel-plated graphite and ZQSn663 tin bronze powder for use, the weighing am...

Embodiment 2

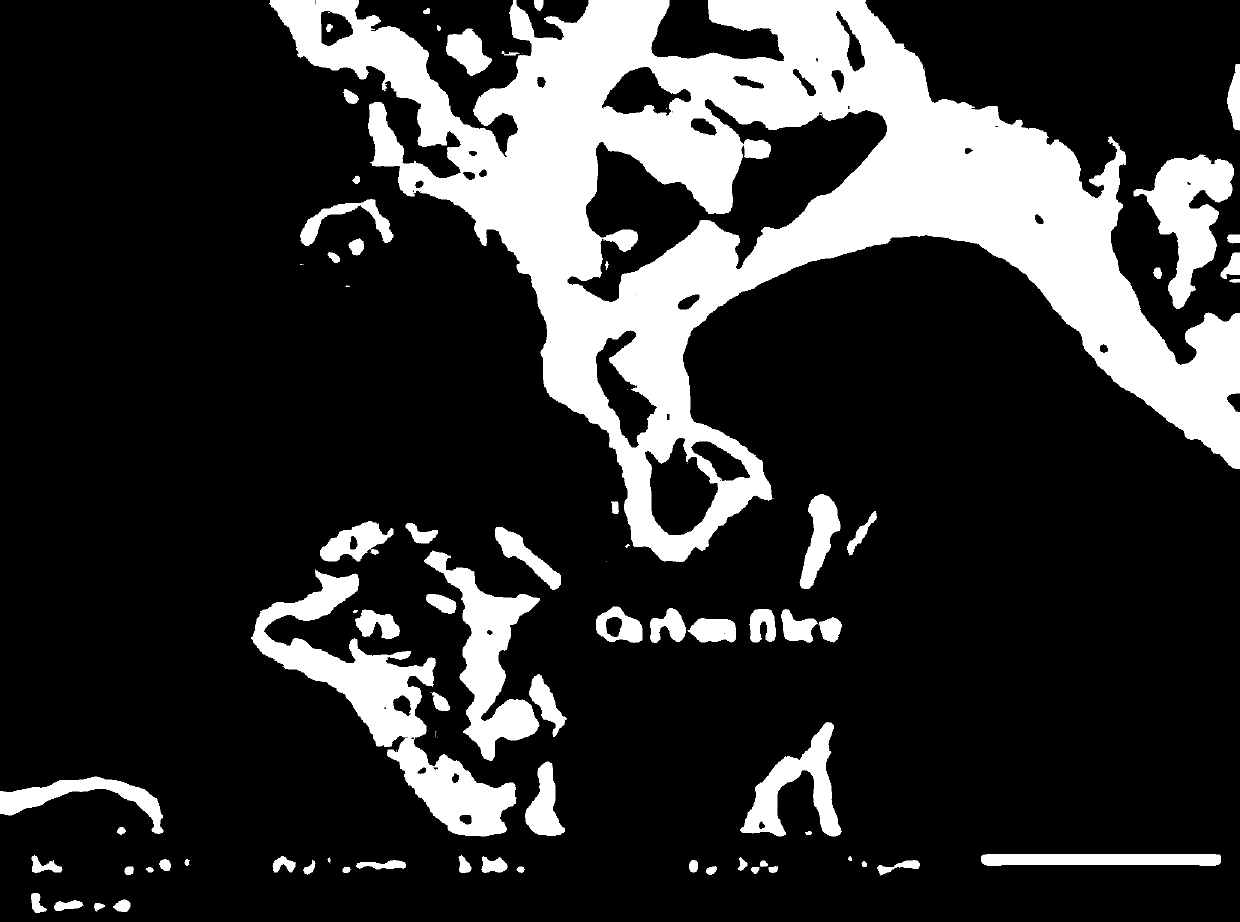

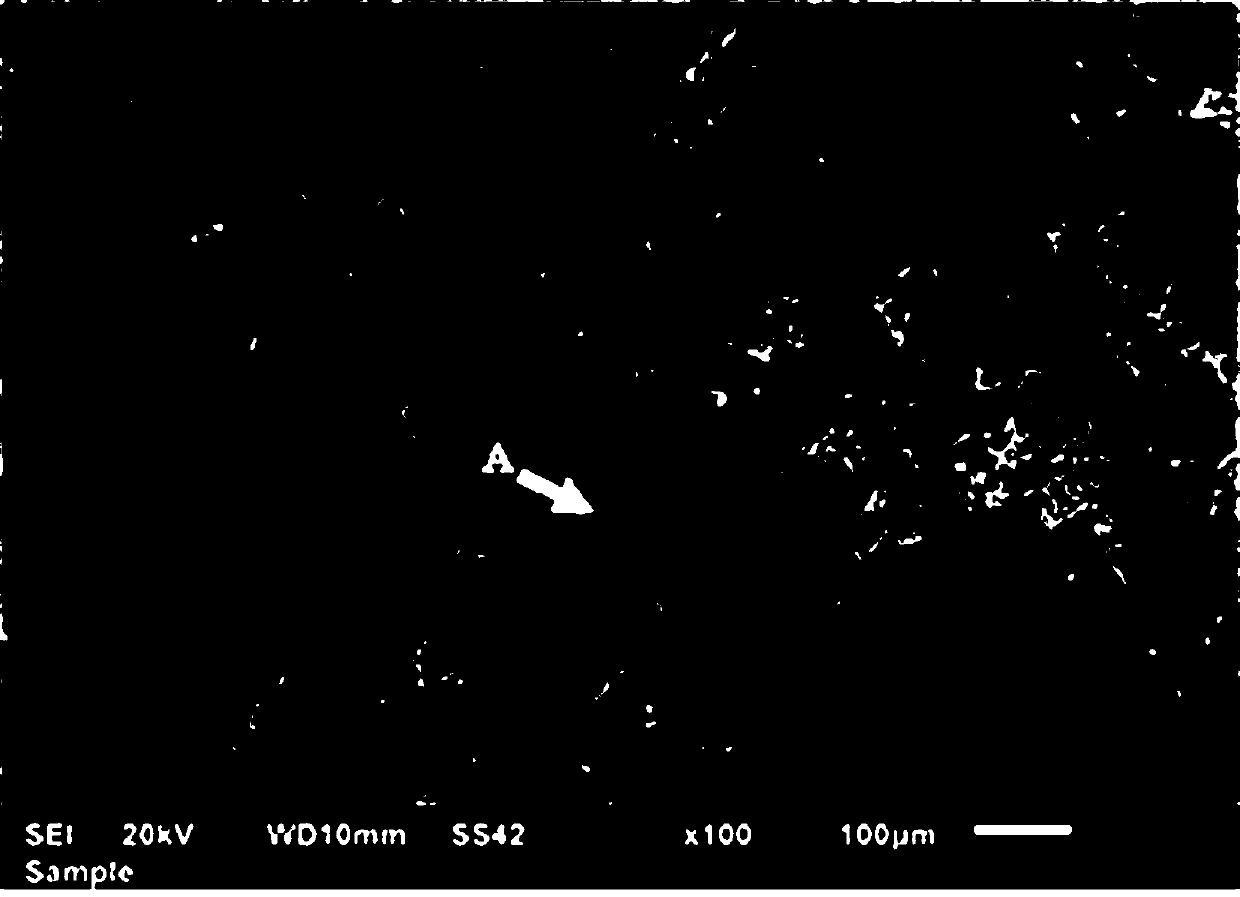

[0044] Prepare a copper alloy-based self-lubricating composite material, its chemical composition is Ni10%, Sm 2 o 3 1%, MoS 2 1%, Ag1%, CaF 2 1%, Al 2 o 3 2%, W 3%, nickel-plated graphite 3%, copper-plated carbon fiber (diameter 1μm) 1.1%, ZQSn663 tin bronze powder (the chemical composition in ZQSn663 tin bronze powder is Zn5%, Sn5%, Pb2%, copper 88%) 76.9%, its properties are shown in Table 1, and its preparation method is as follows:

[0045] (1) Mixing: Use a barrel to mix the powder on the mixer. The speed of the mixer is 400r / min. Steel balls and springs are added to the barrel to form the abrasive, so that the volume ratio of the abrasive to the metallurgical composite powder is 7. : 1, it is conducive to stirring and uniform mixing; wherein the compound powder mixing for metallurgy is carried out according to the following steps:

[0046] (a) Weigh Ni and Sm respectively 2 o 3 、MoS 2 , Ag, CaF 2 、Al 2 o 3 , W, nickel-plated graphite, copper-plated carbon fi...

Embodiment 3

[0054] Prepare a copper alloy-based self-lubricating composite material, its chemical composition is Ni10%, Sm 2 o 3 1%, MoS 2 1%, Ag1%, CaF 2 1%, Al 2 o 3 2%, W 3%, nickel-plated graphite 3%, copper-plated carbon fiber (diameter 1μm) 1.6%, ZQSn663 tin bronze powder (the chemical composition in ZQSn663 tin bronze powder is Zn5%, Sn5%, Pb2%, copper 88%) 76.4%, its properties are shown in Table 1, and the preparation method is as follows:

[0055] (1) Mixing: Use a barrel to mix the powder on the mixer. The speed of the mixer is 400r / min. Steel balls and springs are added to the barrel to form the abrasive, so that the volume ratio of the abrasive to the metallurgical composite powder is 7. : 1, it is conducive to stirring and uniform mixing; wherein the compound powder mixing for metallurgy is carried out according to the following steps:

[0056] (a) Weigh Ni and Sm respectively 2 o 3 、MoS 2 , Ag, CaF 2 、Al2 o 3 , W, nickel-plated graphite, copper-plated carbon fibe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com