API oil sleeve thread sealing grease composite and preparation method thereof

A technology of thread sealing and composition, which is applied in the field of API oil casing thread sealing grease composition and its preparation, which can solve the problems of easy blockage of pipelines, difficulty in painting operation, and easy corrosion of threads, etc., and achieves good effect and good sealing effect. Excellent performance and high anti-rust performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of the above-mentioned API oil casing thread sealant composition comprises the following steps:

[0024] ① Preparation of base fat

[0025] The base grease includes 91% of low-temperature synthetic lithium complex grease and 9% of anti-rust additives by weight. The low-temperature synthetic lithium complex grease includes 12-hydroxystearic acid, 0.93% sebacic acid, 0.17% boric acid, 0.98% lithium hydroxide, and 85.15% α-olefin oil accounting for 3.77% of the base fat weight, of which saponification oil accounts for 28.39% %, thickening oil accounts for 28.39%, blending oil accounts for 28.37%, and is prepared by one-step pressurized saponification process. Add 3.77% 12-hydroxystearic acid, 0.93% sebacic acid, 0.17% boric acid, 0.98% lithium hydroxide aqueous solution and 28.39% α-olefin oil into the saponification tank, control the saponification pressure to 294kPa, and the temperature to 145-150°C. The saponification time is 2.5 to 3 hours. Ad...

Embodiment

[0034] The API oil casing thread sealant of the present invention is made of 00# base grease accounting for 42% of the sealant composition weight, 5% of 201-350# dimethyl silicone oil, 20% of 325 order flake graphite powder, and 8% 400 mesh polytetrafluoroethylene, 0.7% expanded graphite powder (expansion factor is 200 times), 1.3% 325 mesh white carbon black, 4% 325 mesh sericite powder, 4% 400 mesh light calcium carbonate, 15 % of 325 mesh tin bronze powder composition. The preparation method is as follows: as mentioned above, first add 28% of 00# base grease, 0.7% expanded graphite powder, and 5% simethicone oil, stir and mix in a mixer for 15-20 minutes, and filter through a colloid mill. Then add 20% flake graphite powder, 8% polytetrafluoroethylene, 1.3% white carbon black, 4% sericite powder, 4% light calcium carbonate, 15% tin bronze powder and 14% 00# base grease, and continue stirring 80-90 minutes. Grind and filter through a colloid mill, and pack to obtain the pr...

PUM

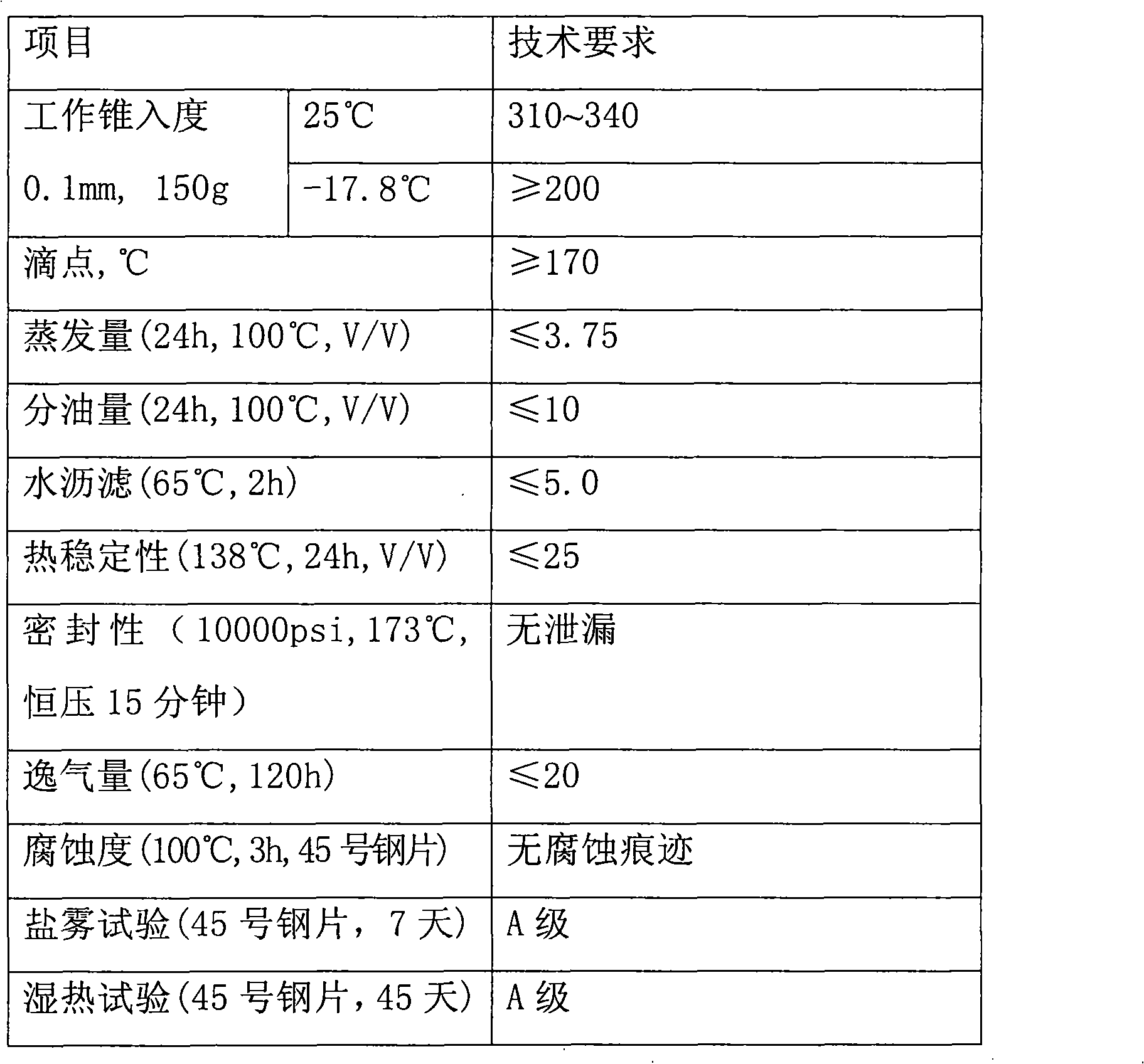

| Property | Measurement | Unit |

|---|---|---|

| cone penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com