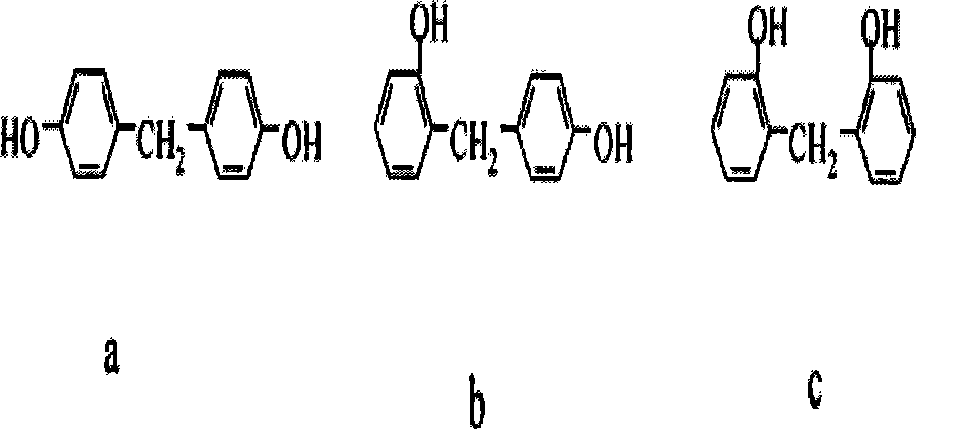

Process for producing wind electricity grade of bisphenol F epoxy resin

A technology of epoxy resin and wind power, which is applied in the field of preparation of wind power grade bisphenol F epoxy resin, can solve the problems of low para-isomer content, low product purity, and difficulty in control, and achieve simple synthesis method and high efficiency. Epoxy value, moisture reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

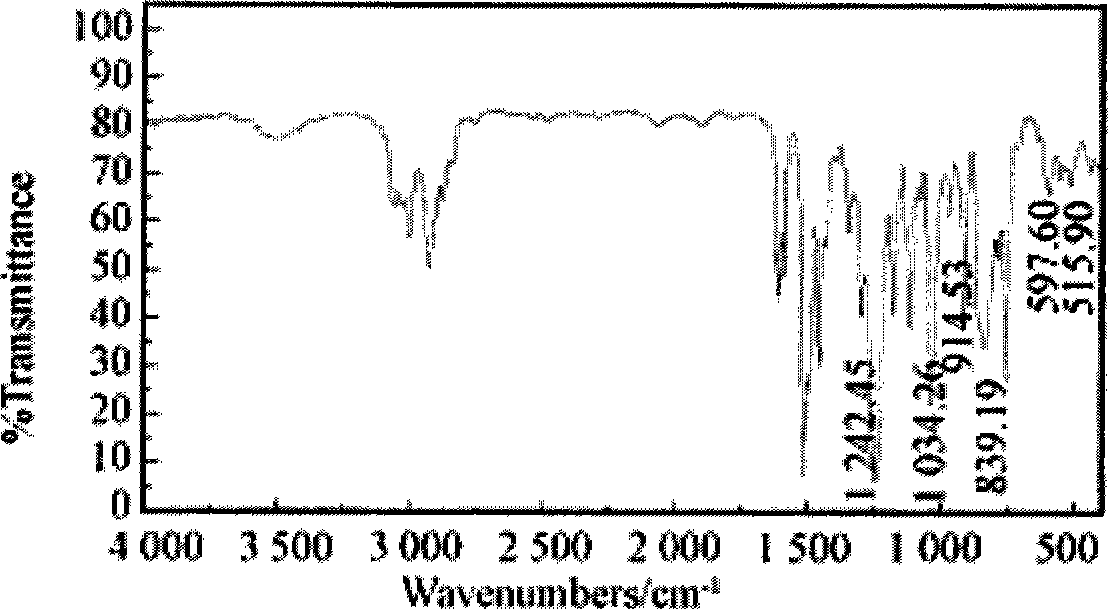

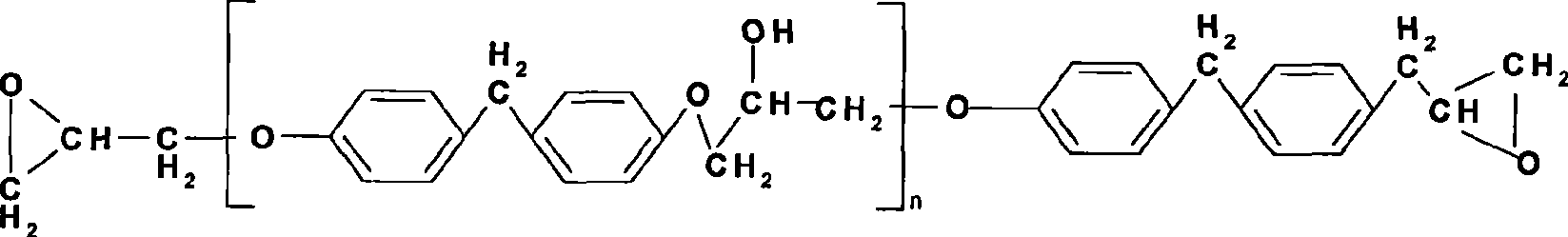

Method used

Image

Examples

Embodiment 1

[0031]Step 1: Add 188.5g of raw material phenol and 35g of methanol into a 1000mL three-necked flask equipped with an electric stirrer, a thermometer and a reflux condenser, heat in a water bath, and after the phenol is fully melted, add 76.5g of phosphoric acid with a mass fraction of 85% , water 32g, and through strong stirring, the system is mixed evenly, and then 32.5g of formaldehyde solution with a mass fraction of 37% is added dropwise at a certain speed, and the stirring speed is fixed. Reduce the stirring speed by half, stop after 30 minutes, then separate the inorganic phase and the organic phase (bisphenol F isomer mixture), most of the phosphoric acid is recovered in the form of 70% aqueous solution, and can be used as a catalyst after concentration, and the organic phase Use solid sodium bicarbonate to neutralize to a pH value of about 5.0, and the generated carbon dioxide is discharged into the atmosphere, and the sodium phosphate precipitate is removed by filtrat...

Embodiment 2

[0037] Step 1: Add 188.5g of raw material phenol and 50g of methanol into a 1000mL three-neck flask equipped with an electric stirrer, a thermometer and a reflux condenser, heat in a water bath, and after the phenol is fully melted, add 76.5g of phosphoric acid with a mass fraction of 85% , 35g of water, and through strong stirring, the system is mixed evenly, and then 40.6g of formaldehyde solution with a mass fraction of 37% is added dropwise at a certain speed, and the stirring speed is fixed. Reduce the stirring speed by half, stop after 30 minutes, then separate the inorganic phase and the organic phase (bisphenol F isomer mixture), most of the phosphoric acid is recovered in the form of 70% aqueous solution, and can be used as a catalyst after concentration, and the organic phase Use solid sodium bicarbonate to neutralize to a pH value of about 5.0, and the generated carbon dioxide is discharged into the atmosphere, and the sodium phosphate precipitate is removed by filtr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com