Semisynthetic metal cutting fluid with trimethylolpropane oleate serving as base oil and preparation method of semisynthetic metal cutting fluid

A technology of trimethylolpropane oleate and metal cutting fluid, which is applied in the field of semi-synthetic metal cutting fluid and its preparation, can solve the problems of large amount of surfactant, viscosity of cutting fluid system, etc., and achieves simple and convenient preparation method, The effect of low price and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

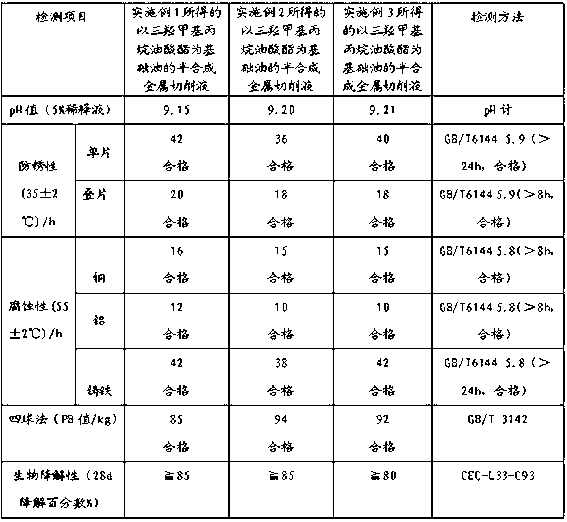

Examples

Embodiment 1

[0046] A semi-synthetic metal cutting fluid based on trimethylolpropane oleate, calculated by weight percentage, its raw material composition and content are as follows:

[0047] Trimethylolpropane Oleate 20%

[0048] Non-ionic surfactant 15%

[0049] Anionic surfactant 3%

[0050] Rust inhibitor 15%

[0051] Co-solvent 5%

[0052] Extreme pressure agent 3%

[0053] Defoamer 0.5%

[0054] Fungicide 1%

[0055] Water 37.5%

[0056] Wherein said nonionic surfactant is polyoxyethylene lauryl ether;

[0057] Described anionic surfactant is sodium ricinoleate sulfate;

[0058] The rust inhibitor is a mixture of sodium benzoate and tall oil, wherein sodium benzoate and tall oil are calculated by mass ratio, i.e. sodium benzoate: tall oil is 2:13;

[0059] Described auxiliary solvent is n-butanol;

[0060] Described extreme pressure agent is sulfurized castor oil;

[0061] Described defoamer is 1000X;

[0062] Described bactericide is pyrithione.

[0063] Its preparation...

Embodiment 2

[0068] A semi-synthetic metal cutting fluid based on trimethylolpropane oleate, calculated by weight percentage, its raw material composition and content are as follows:

[0069] Trimethylolpropane Oleate 25%

[0070] Non-ionic surfactant 20%

[0071] Anionic surfactant 4%

[0072] Rust inhibitor 12%

[0073] Co-solvent 6%

[0074] Extreme pressure agent 3%

[0075] Defoamer 0.5%

[0076] Fungicide 0.5%

[0077] water 29%

[0078] Wherein said nonionic surfactant is EL-40;

[0079] Described anionic surfactant is sodium petroleum sulfonate;

[0080] The antirust agent is a mixture of monoethanolamine borate and tall oil, wherein monoethanolamine borate and tall oil are calculated by mass ratio: monoethanolamine borate: tall oil is 5:7;

[0081] Described auxiliary solvent is n-butanol;

[0082] The extreme pressure agent is sulfurized castor oil;

[0083] The defoamer is 1000X;

[0084] The fungicide is pyrithione.

[0085] Its preparation method of the semi-synth...

Embodiment 3

[0090] A semi-synthetic metal cutting fluid based on trimethylolpropane oleate, calculated by weight percentage, its raw material composition and content are as follows:

[0091] Trimethylolpropane Oleate 30%

[0092] Non-ionic surfactant 25%

[0093] Anionic surfactant 5%

[0094] Rust inhibitor 12%

[0095] Co-solvent 10%

[0096] Extreme pressure agent 2%

[0097] Defoamer 0.2%

[0098] Fungicide 0.8%

[0099] water 15 %

[0100] Wherein said nonionic surfactant is Tween 80;

[0101] Described anionic surfactant is sodium petroleum sulfonate;

[0102] Described antirust agent is tall oil acid;

[0103] Described auxiliary solvent is n-butanol;

[0104] The extreme pressure agent is sulfurized castor oil;

[0105] The defoamer is 1000X;

[0106] The fungicide is pyrithione.

[0107] Above-mentioned a kind of preparation method that takes trimethylolpropane oleate as base oil semi-synthetic metal cutting fluid specifically comprises the following steps:

[0108]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com