Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

238results about How to "Increased production flexibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

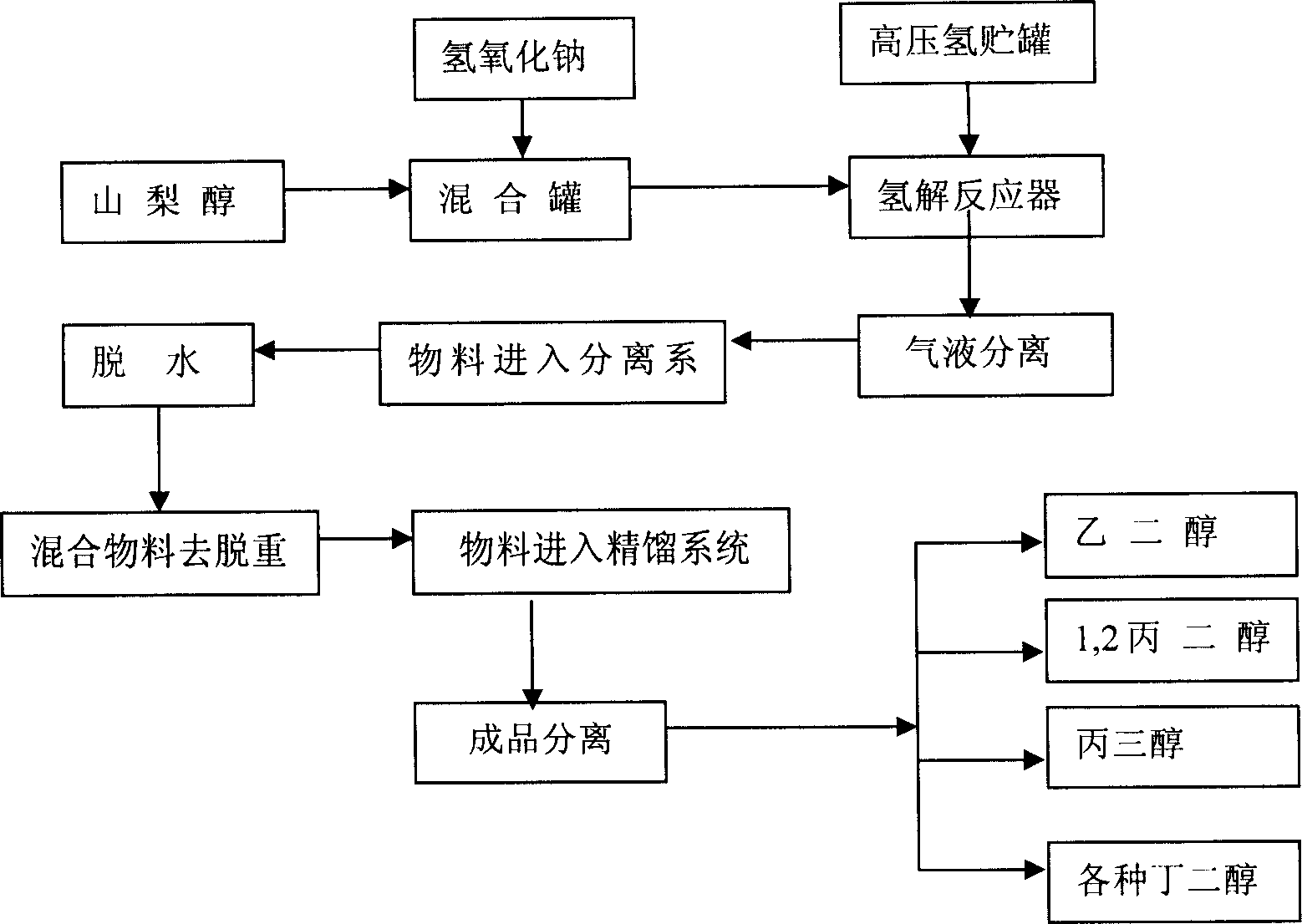

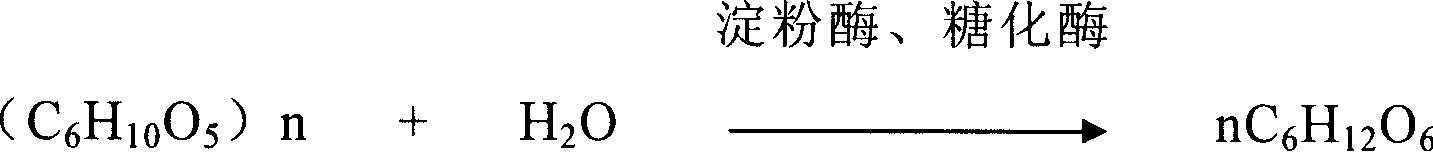

Process for producing diatomic alcohol and polyol from cracking sorbierite

InactiveCN1683293AQuality improvementIncreased production flexibilityOrganic compound preparationOrganic chemistry methodsPolyolAlcohol

The present invention relates to sorbierite cracking process to prepare C2-C4 diatomic alcohol and polyol, and is especially the process of preparing sorbierite with corn material and hydrocracking sorbierite to prepare C2-C4 diatomic alcohol and polyol. The process includes hydrocracking sorbierite to prepare the mixture of C2-C4 diatomic alcohol and polyol at high temperature and high pressure in the presence of cracking sodium hydroxide and nickel / ruthenium catalyst, separation and refining to obtain single product. The production process of the present invention has the advantages of novel production path, unique technological condition, simultaneous production of several kinds of alcohol and high product quality. In addition, using grains, such as corn, as material to replace non-regenerable resource is significant.

Owner:王宗国

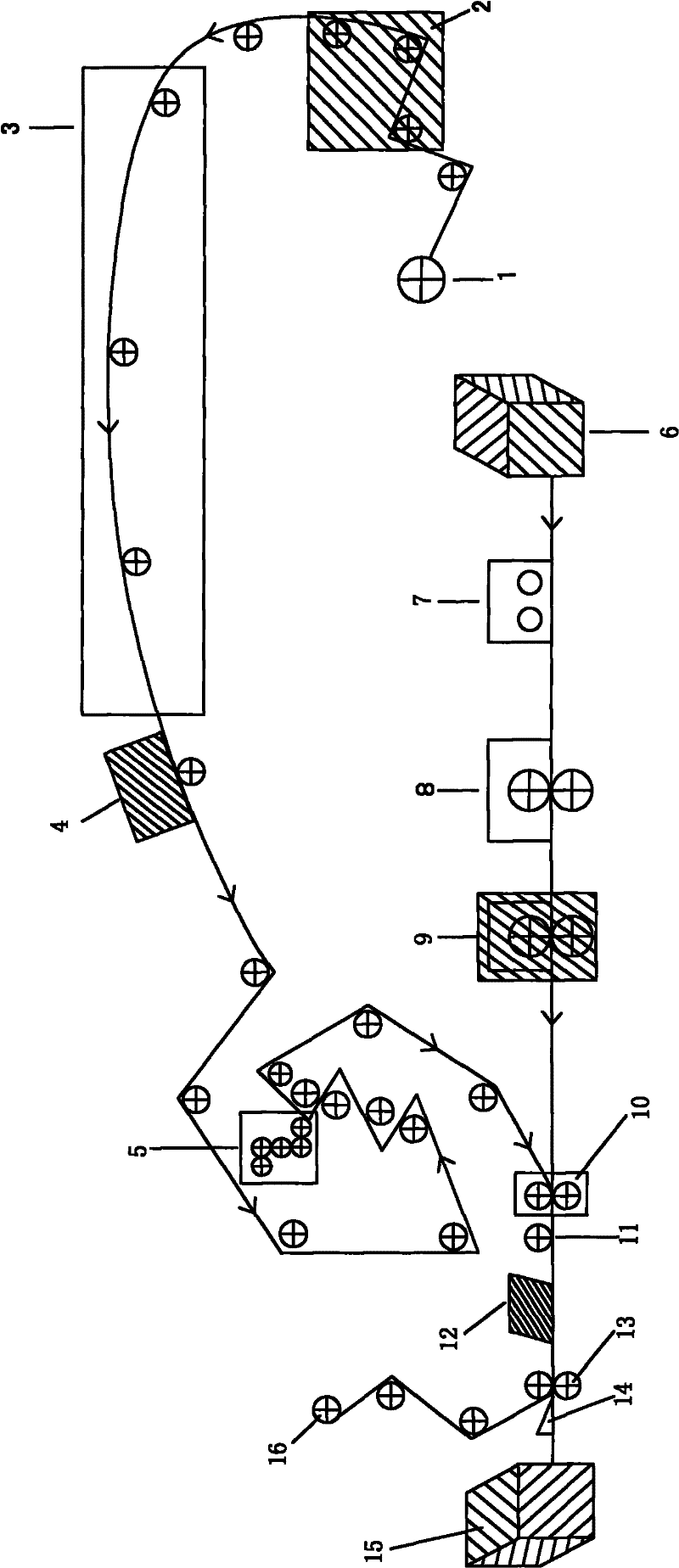

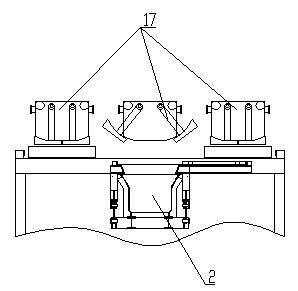

PCBA intelligent burning equipment

ActiveCN106293858ARealize automatic turnoverRealize multi-work order mixed productionConveyorsCo-operative working arrangementsControl systemAssembly line

The invention discloses PCBA intelligent burning equipment. The PCBA intelligent burning equipment comprises an equipment frame, a feeder, a robot, a plurality of burning clamps, an intelligent assembly line body and a control system, wherein the robot is used for picking, rotating and placing PCBA; the automatic burning clamp is used for positioning PCBA, burning and feeding back a burning result; the intelligent assembly line body is used for removing defective products and outputting materials; the control system is preferably but not limited to MES; the feeder, the robot, the automatic burning clamps and the intelligent assembly line body are fixed on the equipment frame and in communication connection with the control system. The PCBA intelligent burning equipment has the advantages that full-automatic operation of working procedures is achieved, manual intervention is not needed, production efficiency is increased, manpower cost can be saved, missing and misoperation of manual operation are avoided, high burning yield is achieved, production reliability is increased, production flexibility is increased, and the equipment is adaptive to a multi-specification and small-batch production manner.

Owner:SHENZHEN HYTERA COMM

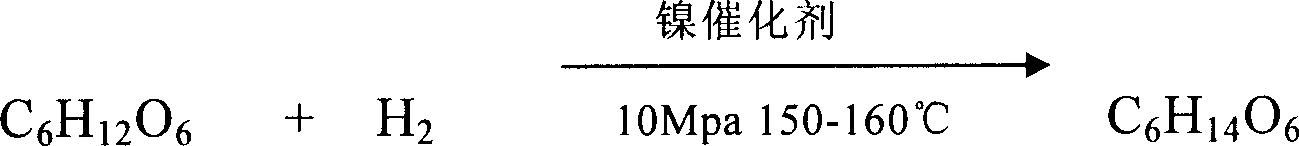

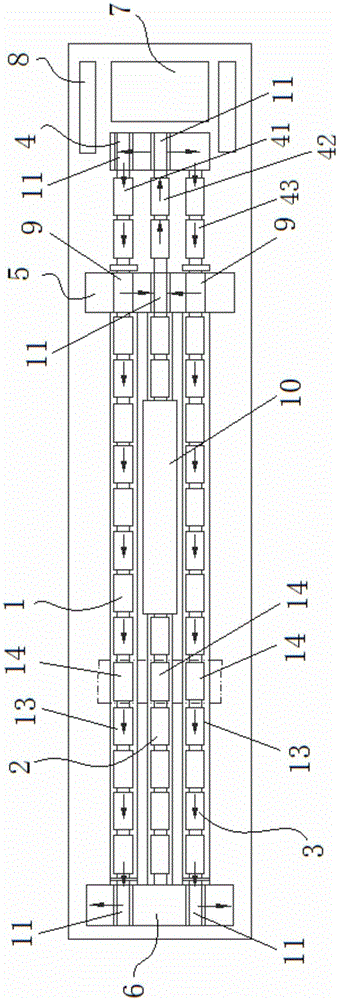

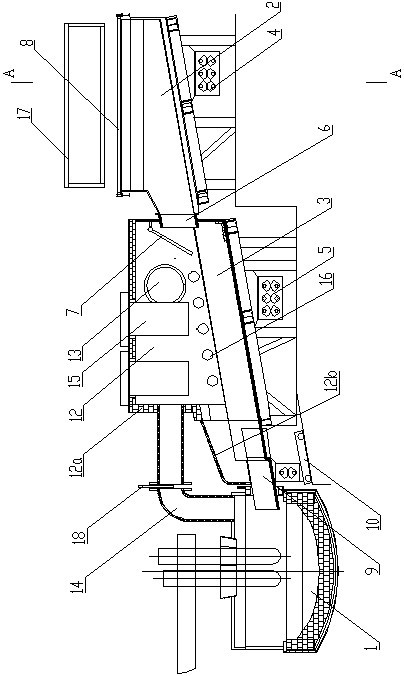

Electromagnetic-coil winding and adhesive-tape coating integrated device

ActiveCN103000366AIncrease productivityAuxiliary waiting time is shortCoils manufactureConductor CoilPaper sheet

The invention discloses an electromagnetic-coil winding and adhesive-tape coating integrated device which comprises a stand. A horizontal rotating disc which can rotate intermittently is arranged on the stand; at least the mounting station, the first winding station and the first coating station of the framework of the electromagnetic coil are arranged in sequence along the rotating direction of the rotating disc; each station of the rotating disc is at least provided with one set of clamping mechanism which can be used for vertically mounting the framework of the electromagnetic coil; the first winding station is provided with a tensioning mechanism, a three-coordinate moving mechanism, a first driving mechanism and an enameled-wire clamping and cutting mechanism, wherein the first driving mechanism is used for driving the framework of the electromagnetic coil to rotate; and the first coating station is provided with an adhesive-tape clamping mechanism, an adhesive-tape catching mechanism, an adhesive-tape ejecting mechanism, an adhesive-tape cutting mechanism, an adhesive-tape guiding mechanism, an adhesive-tape-roll mounting mechanism, an insulating-paper storing mechanism and a second driving mechanism for driving the framework of the electromagnetic coil to rotate. The electromagnetic-coil winding and adhesive-tape coating integrated device can be used for winding the electromagnetic coil and coating the adhesive tape automatically, has high production efficiency, can not generate excess waste ends of the enameled wires during winding and can finish the coating of one layer of insulating paper and one layer of adhesive tape at the same time.

Owner:XIAMEN METEOR WINDING TECH

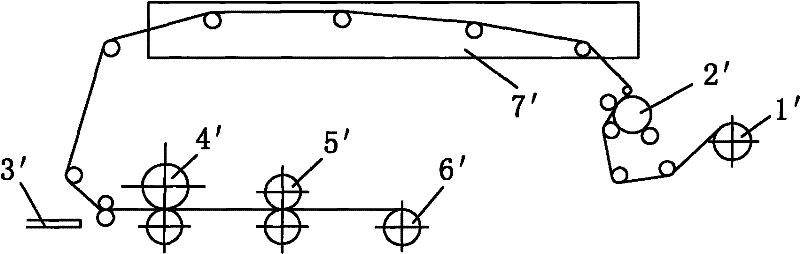

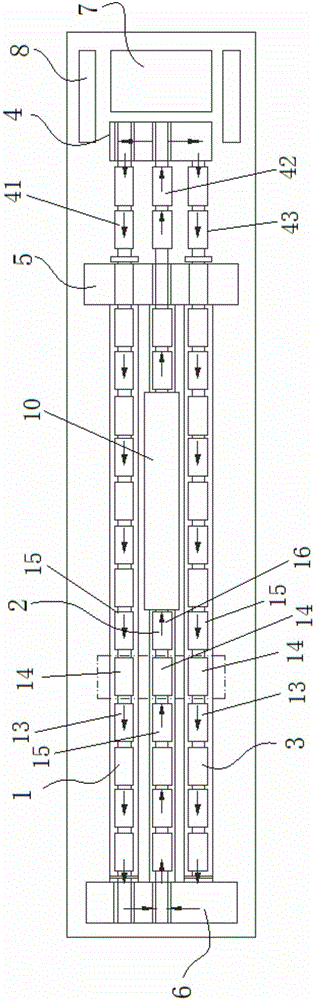

Control system and method for printing paper or coating film

InactiveCN102173193ASimplify operating proceduresImprove processing efficiencyRotary pressesPrinting press partsControl systemEngineering

The invention discloses a control system and a control method for printing paper or coating a film. The control system at least comprises a film unreeling device, a film gluing unit, a single-sheet unreeling device, a compounding unit, a film cutting device and a single-sheet delivery device. The control method at least comprises steps of feeding, gluing, compounding and reeling. The film coating, a film surface secondary pressing process, curing and cold foiling, and a laser transfer process are integrated, the operating procedures are simplified, the technological processing efficiency is improved, the additional value of a product is improved, a compound transfer process can be completed, the transferred film can be recycled, the cost is saved and the environment is protected.

Owner:东莞市博森印刷器材有限公司

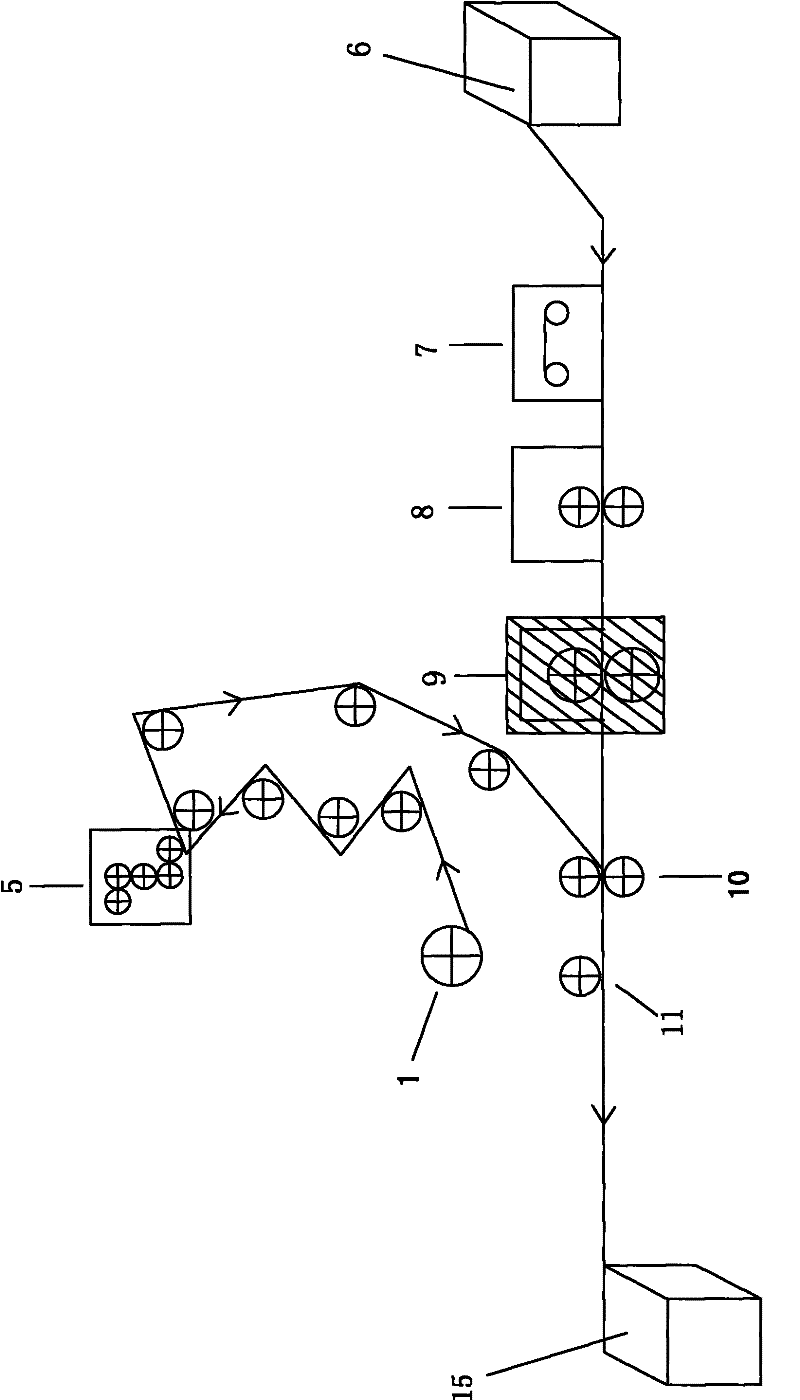

Three-dimensional production system of prefabricated components

ActiveCN105773827AIncreased production flexibilityIncrease productivityCeramic shaping plantsManufacturing engineeringKiln

The invention relates to the field of production of prefabricated components, in particular to a three-dimensional production system of the prefabricated components. The system comprises a prefabricated component production area on the upper layer, a maintenance area on the lower layer and a wheel type mold table; the prefabricated component production area includes a component prefabrication operation area, a component demolding operation area and an edge mold cleaning operation area; the maintenance area is provided with a linear maintenance kiln; the components are borne on a production line in the prefabricated component production area through the wheel type mold table, and move in the linear maintenance kiln in the maintenance area; a mold table ferry transverse moving station is arranged in the prefabricated component production area; a mold table lifting transverse moving device is arranged on the mold table ferry transverse moving station; a special production line and a production secondary line are arranged in the component prefabrication operation area; and the special production line drives the wheel type mold table to transversely move through the mold table lifting transverse moving device so as to connect with the production secondary line in parallel. The system comprehensively improves a prefabricated component production system, can realize multiple production modes, is more flexible in production, and greatly improves the production efficiency.

Owner:国新德

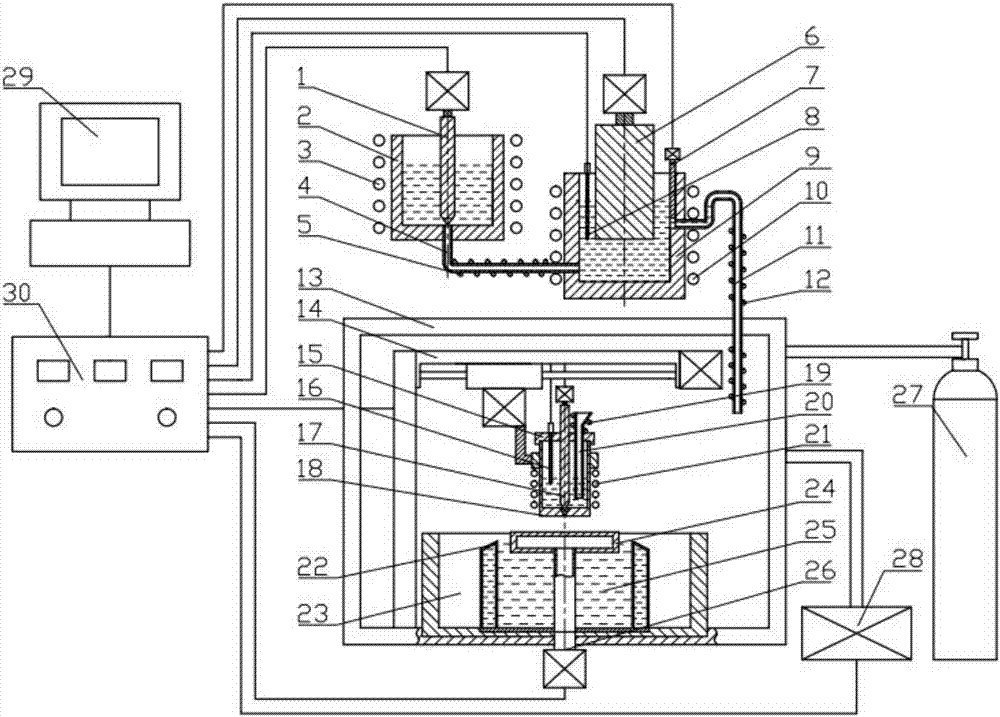

High-efficiency metal 3D printing equipment and method

ActiveCN106925783AHigh precisionLow costAdditive manufacturing apparatusIncreasing energy efficiencySpray nozzleEngineering

The invention discloses high-efficiency metal 3D printing equipment and a method, and belongs to the technical field of 3D printing. Through such measures as separation of a supply system of metal 3D printing equipment from a discharge system, separation of a printing forming area from a cooling medium, positioning of the supply system out of a forming room and capability of controlling the size of a discharge port of a nozzle according to sizes of products, based on direct melt supply and cooling medium cooling, the high-efficiency metal 3D printing equipment and method adopt 3D printing to form high-quality metal products with high efficiency and low cost, and in particular, are suitable for high-efficiency formation of large metal products. The 3D printing equipment is flexible in mechanism actions, fast in operating speed, high in flexibility, high in sensitivity and low in manufacturing cost; the 3D printing forming process is high in efficiency; process parameters are liable to control; and the metal products formed by printing are excellent in quality and repeatability and low in production cost.

Owner:UNIV OF SCI & TECH BEIJING

Differential motion airtight feeding electric furnace smelting device and feeding method thereof

ActiveCN102181601AShorten the lengthIncrease the feeding speedCharge manipulationElectric furnaceEngineeringHeat losses

The invention discloses a differential motion airtight feeding electric furnace smelting device and a feeding method thereof. The device comprises an electric furnace and a charging device, wherein the charging device comprises a cold receiving conveying trough and a heat conveying trough; the lower sides of the cold receiving conveying trough and the heat conveying trough are provided with an independently-controlled excitation device respectively; the outlet of the cold receiving conveying trough is provided with a conveying throat opening which is extended into the heat conveying trough; and the distance between the conveying throat opening and the bottom of the heat conveying trough is greater than or equal to the depth of the heat conveying trough. By the feeding method, shock excitation at different frequencies is applied to the two conveying troughs to realize the differential motion conveying of raw materials, so that a thicker material layer can be laid on the cold receiving conveying trough, and the material loading speed is increased; simultaneously, a shorter cold receiving conveying trough and a shorter material-conveying bottom elongated slot can be designed, so that the device and the method make project implementation convenient. In addition, due to the adoption of the throat opening and a sealed door structure, the possibility of material blocking and the air leakage rate are greatly reduced, and the device has low heat loss and a good dedusting effect, and is high-efficient, energy-saving and environment-friendly during smelting.

Owner:CISDI ENG CO LTD

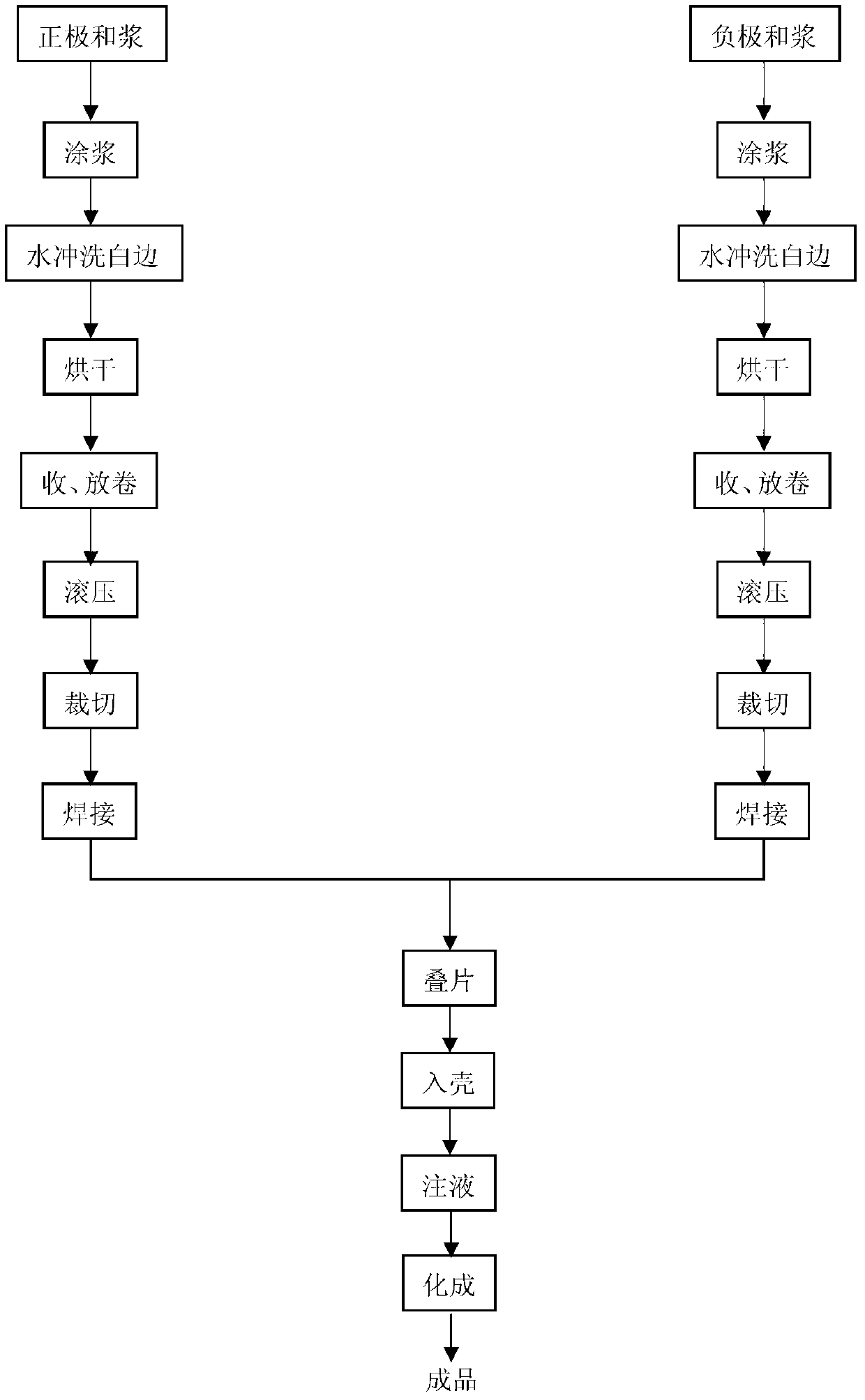

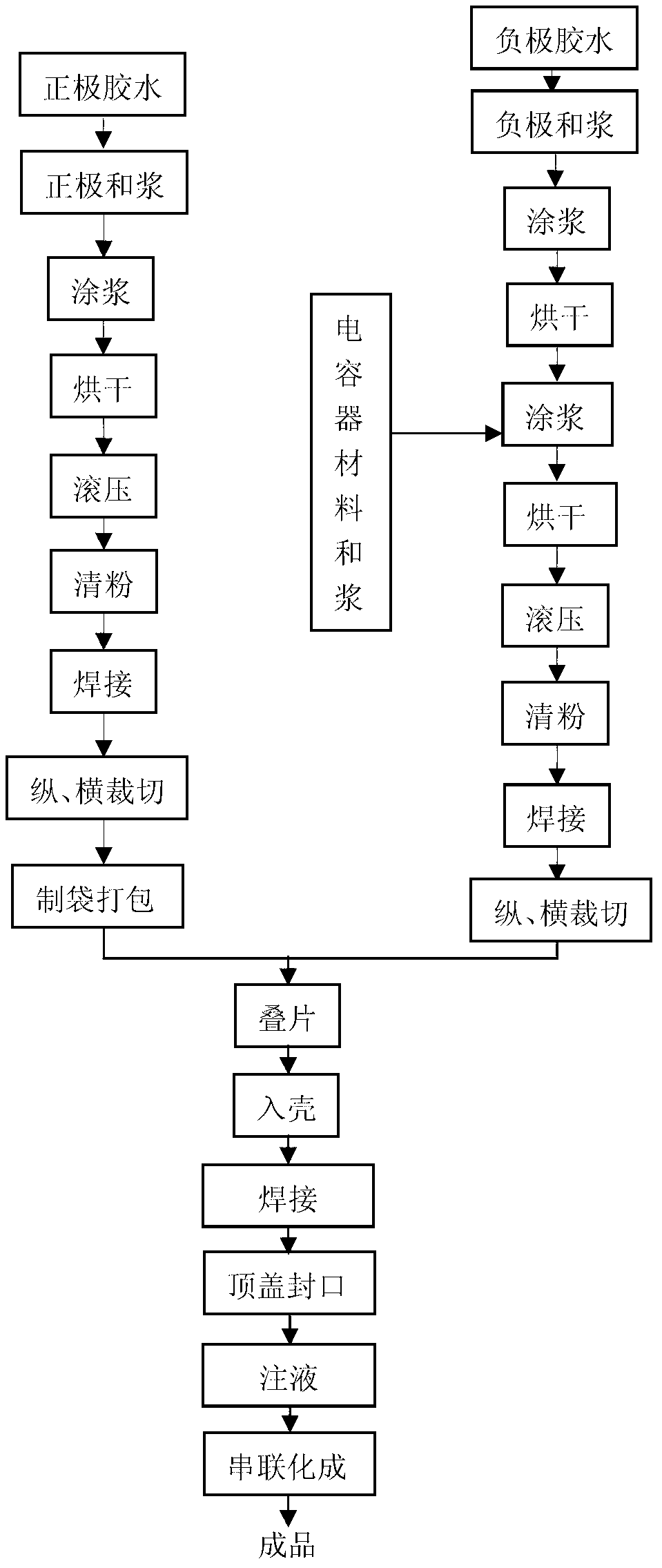

Preparation method of asymmetric rare earth capacitor battery

ActiveCN103138030AReduce turnover processHigh dimensional accuracyElectrochemical generatorsElectricity cogenerationCapacitanceElectrical battery

The invention relates to a preparation method of an asymmetric rare earth capacitor battery, and belongs to the field of water power battery. The method comprises the steps that: positive electrode and negative electrode battery slurries and a capacitor slurry are prepared; the positive electrode slurry is coated on foamed nickel, such that a positive electrode is prepared; bake-drying, rolling, powder removing, welding, and longitudinal and transverse cutting are carried out, such that a positive electrode sheet is prepared; the positive electrode sheet is packaged by using a separation film bag; the negative electrode slurry is coated on foamed nickel, and the materials are bake-dried; the capacitor slurry is coated on the material, and secondary bake-drying, rolling, powder removing, welding, and longitudinal and transverse cutting are carried out, such that a negative electrode sheet is prepared; the positive and negative electrode sheets are stacked, such that a battery core is prepared; the battery core is placed in a housing, and welding, top cover sealing, and liquid injection are carried out; and series connection formation is carried out, such that the battery is prepared. According to the invention, laminated coating is adopted in preparing the negative electrode sheet, such that the capacitor material is completely effectively combined with the battery material, and the integration of the positive and negative electrode sheets and the conductive lugs is realized. The battery has the advantages of high safety, environment friendliness, and low cost. The battery has both the energy density advantage of a nickel-metal hydride battery and the power density advantage of an asymmetric supercapacitor, such that operation conditions for electric vehicle and the like can be achieved.

Owner:淄博国利新电源科技有限公司

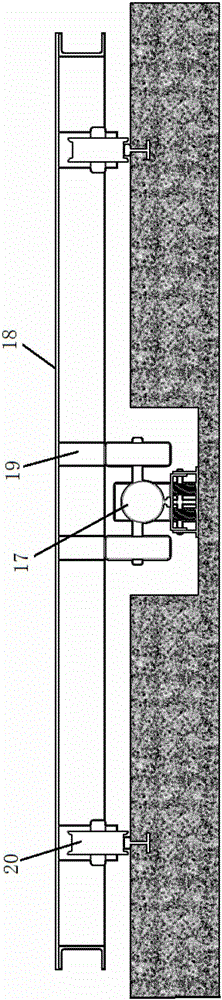

Double-tower constant-melting-rate protective atmosphere electro slag furnace available for three-station alternate smelting

The invention relates to a double-tower constant-melting-rate protective atmosphere electro slag furnace available for three-station alternate smelting. The double-tower constant-melting-rate protective atmosphere electro slag furnace available for three-station alternate smelting comprises two rotatable tower furnace ends, a mobile smelting station, two auxiliary stations, an electrical system and a PLC (programmable logic controller) and computer control system. The rotatable furnace ends are arranged between the mobile smelting station and the auxiliary stations. Smelting powder main circuits of the rotatable furnace ends are respectively positioned on the mobile smelting station through coaxial positioning cylinders on the upper portions of crystallizer electrodes. The ends of cylinder piston rods of the positioning cylinders are connected with a coaxial return circuit of an electro slag power source. The cylinder piston rods are inserted into four vertical posts below the crystallizer electrodes. The double-tower constant-melting-rate protective atmosphere electro slag furnace available for three-station alternate smelting has the advantages that two small electro slag ingots are obtained in by resmelting on the two smelting stations through two support arms, effective utilization rate of the electro slag furnace and production flexibility are improved, production efficiency is improved, and the difficulty in production of high-tonnage large-diameter long metal electrodes can be overcome.

Owner:SUZHOU ZHENWU ELECTRIC FURNACE +1

Method for catalytic synthesis of L-pyrroldone carboxylic acid and salt thereof

InactiveCN101698656AShort reaction timeHigh yieldOrganic chemistryWhite oilPyrrolidonecarboxylic Acid

The invention provides a method for producing pyrroldone carboxylic acid and salt thereof. The method comprises the following steps of: adding glutamic acid or univalent salt of glutamic acid and a catalyst in silicone oil or white oil, heating the mixture to the temperature of between 150 and 250 DEG C for cyclized dehydration to obtain the L-pyrroldone carboxylic acid with high yield and high optical purity or univalent salt thereof, wherein the whole process is carried out at the normal pressure; after the reaction lasts for 30 minutes to 6 hours, adding deionized water to dissolve the L-pyrroldone carboxylic acid in the reaction solution, and separating the mixed solution to obtain the target product; and adding corresponding alkali solution to neutrally react with the L-pyrroldone carboxylic acid, and separating the mixed solution to obtain the corresponding solution of L-pyrroldone carboxylic acid salt. In the method, the catalyst is used in the reaction system and the reaction is carried out at the normal pressure, so that the yield and optical purity of the product are improved, and the reaction time is shortened; and the white oil or silicone oil is introduced as a thermal conduction medium, so that the reaction solution can transfer heat more evenly and the reaction temperature is controlled more easily. The invention provides a method for effectively producing the pyrroldone carboxylic acid and the salt of pyrroldone carboxylic acid from the L-glutamic acid and the univalent salt of L-glutamic acid.

Owner:青岛成功精细化工有限公司 +3

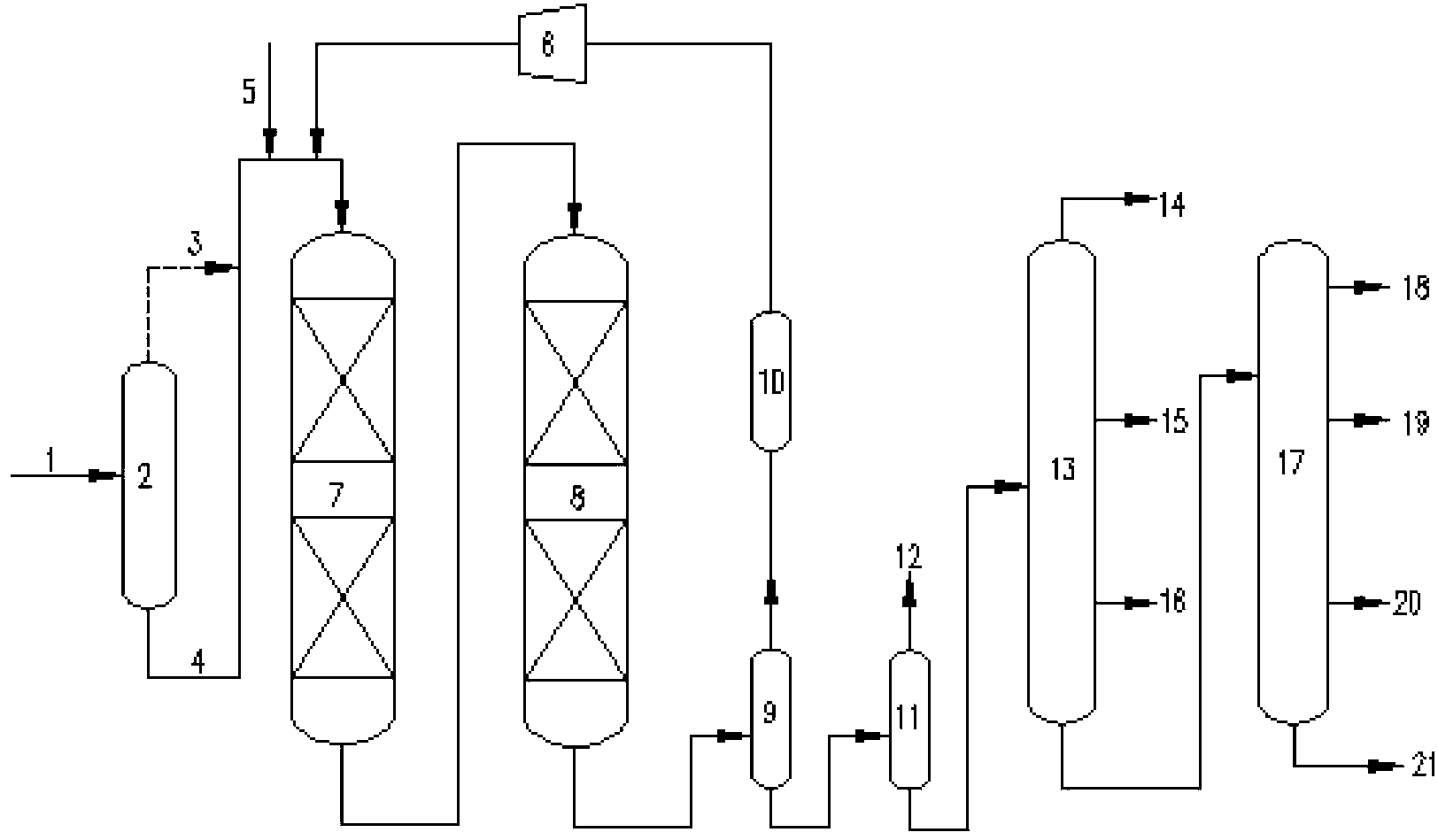

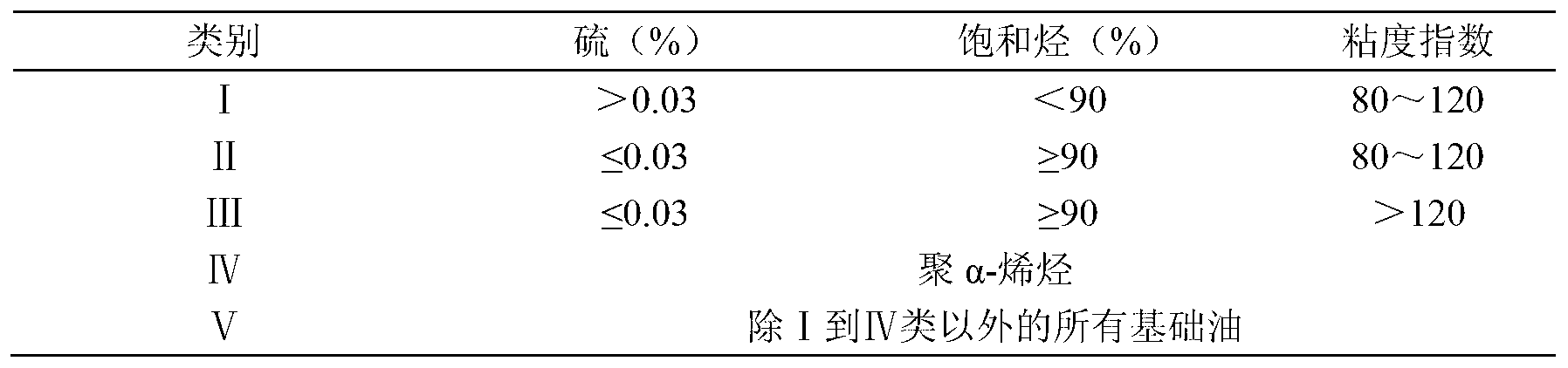

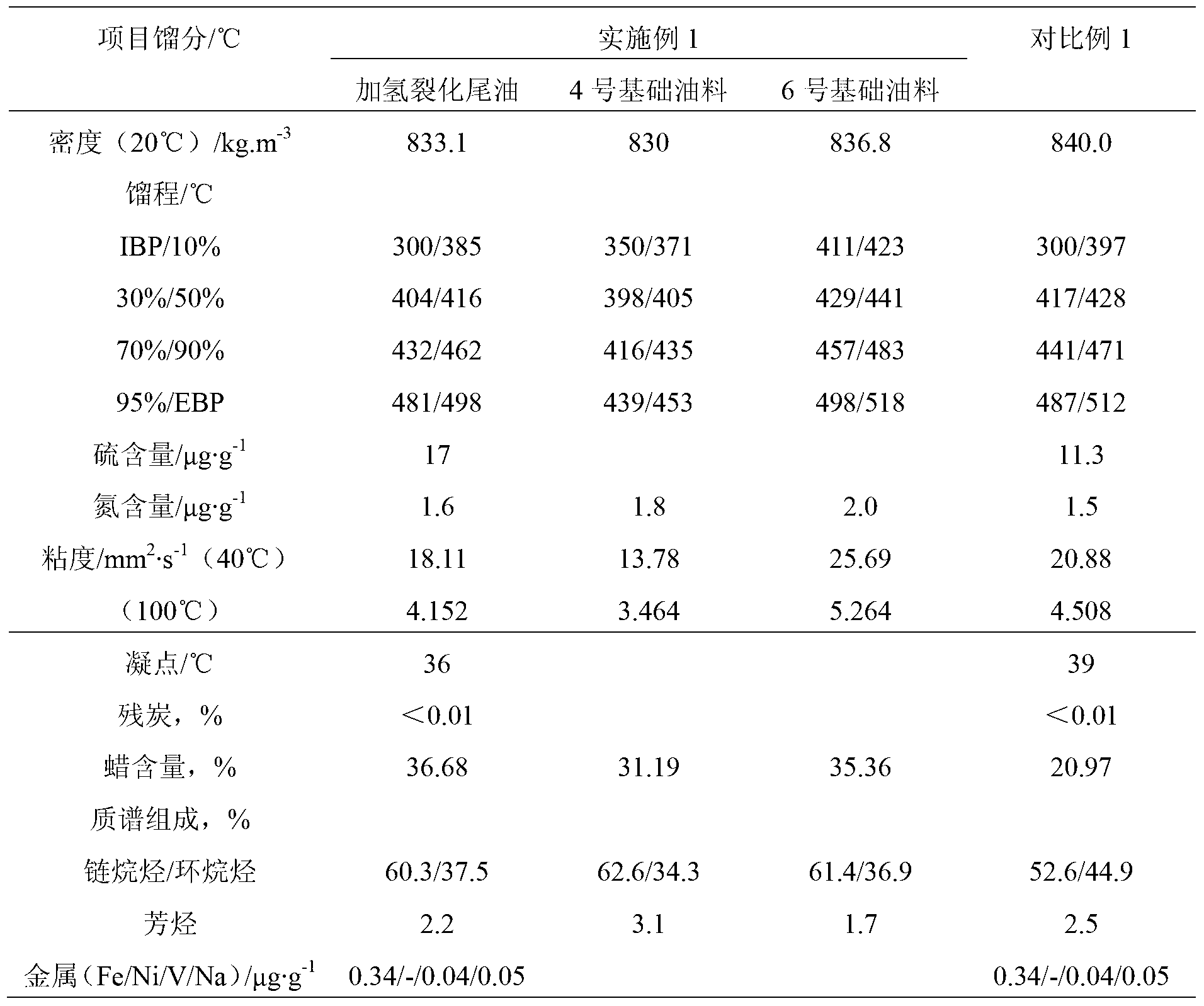

Method for producing high-grade lubricant base oil through hydrogenating of hydrocracking tail oil

ActiveCN103305267AHigh selectivityIncreased production flexibilityTreatment with hydrotreatment processesMixed feedingHydrogen

The invention discloses a method for producing high-grade lubricant base oil through hydrogenating of hydrocracking tail oil. The method comprises the steps of: by taking the hydrocracking tail oil as a raw material, firstly carrying out decompression pre-fractionation to obtain NO.4 base oil stock with final boiling point of less than or equal to 430 DEG C and NO.6 base oil stock with initial boiling point of more than 430 DEG C; leading in the NO.4 base oil stock and NO.6 base oil stock into an isodewaxing reactor and a supplementary refining reactor together with hydrogen by adopting a feeding switching mode or respective feeding mode, so as to carry out hydrogenation isodewaxing reaction and supplementary refining reaction, wherein the isodewaxing reactor and the supplementary refining reactor are connected in series; after reaction is finished, separating out gas from liquor to obtain a liquor phase, and fractionating the liquor phase to obtain the high-grade lubricant base oil. By adopting a method of switching or independently feeding plus mixed feeding, the selectivity of raw materials and the flexibility of production can be improved. The base oil produced can achieve the requirement of API II type and III type lubricant base oil, and the yield of the obtained API III base oil is high.

Owner:SINOPEC NANJING ENG & CONSTR +1

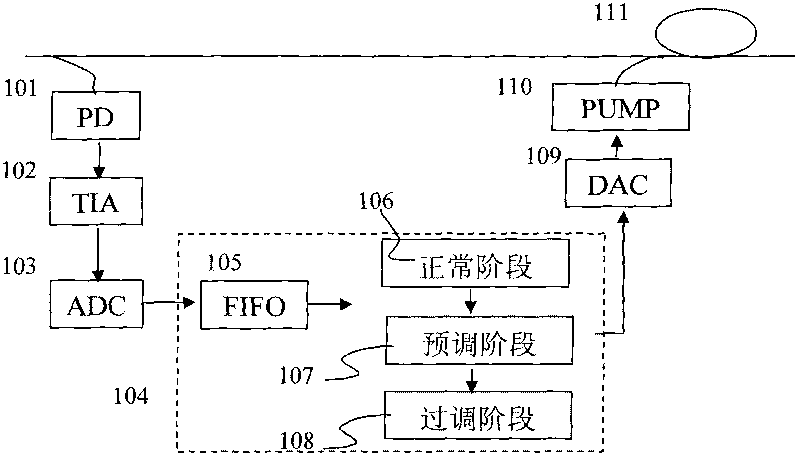

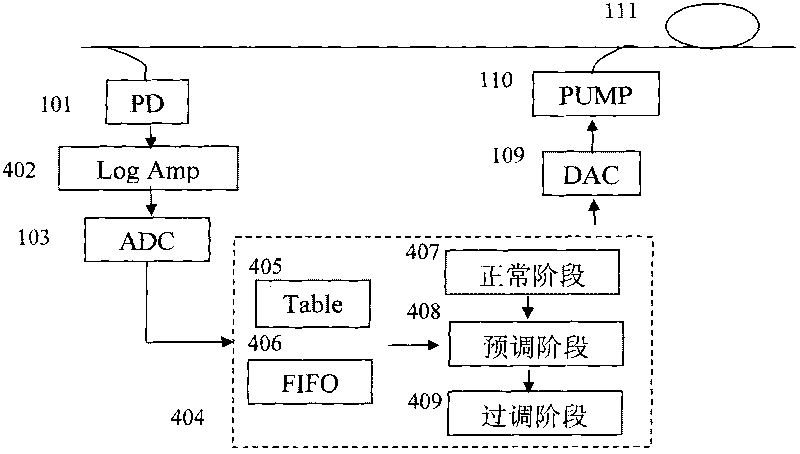

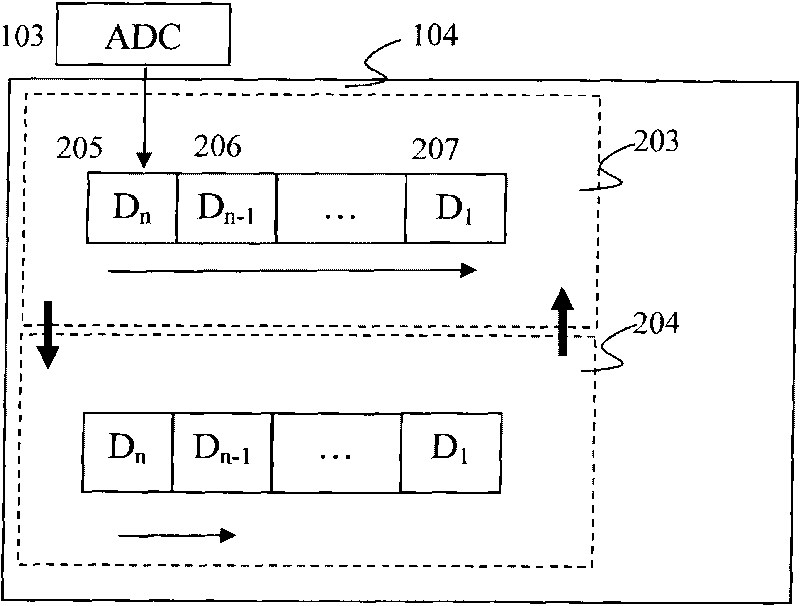

Device and method for controlling transient effect in erbium-doped fiber amplifier (EDFA)

ActiveCN101729186AExcellent transient suppression effectFlexible working styleWavelength-division multiplex systemsElectromagnetic transmissionPhotodetectionType number

The invention discloses a device and a method for controlling the transient effect in an erbium-doped fiber amplifier (EDFA). The device comprises a photoelectric detection diode, a transconductance circuit, an analog to digital converter, a digital processor and a pump laser which are connected in sequence, wherein the pump laser is used for the analog to digital converter, and the photoelectricdetection diode is used for receiving the optical fiber inputted by the EDFA. The method comprises the following steps: making the digital signals obtained by the conversion of the analog to digital converter enter a first in first out (FIFO) data queue to capture the change of optical intensity; comparing the data on the head and the tail of the FIFO data queue under the normal stage model and making the FIFO data queue be in the pre-regulation stage mode if the change of the optical intensity being more than a set proportion; locking the data on the head of the FIFO data queue, continuouslycomparing the data on the head of the FIFO data queue and the data on the tail of the FIFO data queue and making the FIFO data queue be in the over-regulation stage model if the change of the opticalintensity being more than a preset proportion; and finally adjusting the control current of the pump laser of the EDFA rapidly when the optical intensity changing suddenly so as to control the transient effect. The invention can be used for adjusting the EDFA of any type and any requirement without changing the hardware, thus the production efficiency and the flexibility are improved.

Owner:GUANGXUN SCI & TECH WUHAN

Method for remanufacturing photosensitive drum into another photosensitive drum

ActiveCN101620404AIncreased production flexibilityAvoid wastingSolid waste disposalElectrographic process apparatusAgricultural engineering

The invention discloses a method for remanufacturing a photosensitive drum into another photosensitive drum, which comprises the following steps: A, disassembling a first drum gear arranged at one end of a drum body of the photosensitive drum and a first component arranged at the other end of the drum body of the photosensitive drum; and B, respectively assembling a second drum gear suitable for anther photosensitive drum and a second component at two ends of the drum body. The method can improve the flexibility of production of consumables regeneration enterprises and avoid resource waste.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

Combination method for producing high-grade lubricant base oil by hydrogenating hydrocracking tail oil

ActiveCN103289738AHigh selectivityIncreased production flexibilityTreatment with hydrotreatment processesDistillationProcess engineering

The invention discloses a combination method for producing high-grade lubricant base oil by hydrogenating hydrocracking tail oil. The combination method comprises the steps of: carrying out decompression and fractional distillation on the hydrocracking tail oil to obtain NO.4 base oil stock with end distillation point of less than or equal to 430 DEG C and NO.6 base oil stock with end distillation point of more than 430 DEG C; then by adopting a mode of switching feeding or a mode of respectively feeding, carrying out hydrogenated isodewaxing reaction and complement refining reaction together with hydrogen; firstly carrying out gas-liquid separation on the reaction product to obtain hydrogen-rich gas and low-distillate oil; feeding the low-distillate oil into an atmospheric and vacuum distillation device to obtain dry gas and high-grade lubricant base oil; mixing and feeding the hydrogen-rich gas and dry gas into a PSA (Pressure Swing Adsorption) purification unit for purifying and then recycling. The combination method is flexible in process flow, strong in raw material adaptability, good in product quality, and low in energy consumption, the produced base oil can achieve the requirement of API (American Petroleum Institute) II type and III type high-grade lubricant base oil, and the yield of the obtained API III type base oil is higher.

Owner:SINOPEC NANJING ENG & CONSTR +1

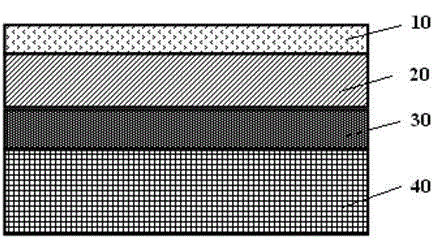

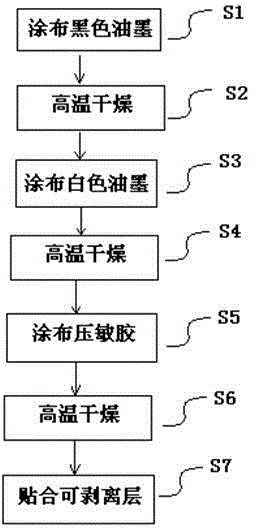

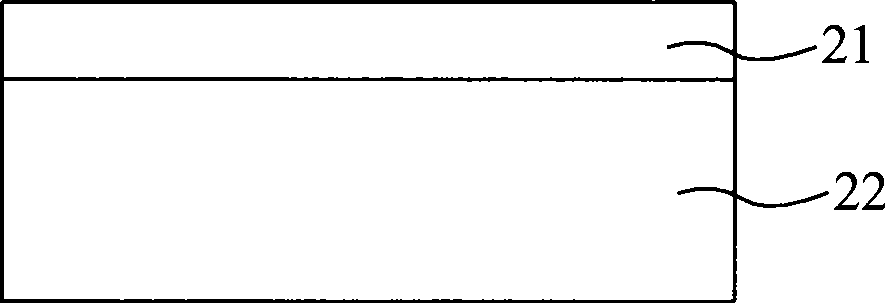

Self-adhesion label for laser etching and preparation method thereof

InactiveCN104464509AGood high and low temperature resistanceGood solvent resistanceStampsFilm/foil adhesivesLaser etchingWeather resistance

The invention discloses a self-adhesion label for laser etching and a preparation method of the self-adhesion label for laser etching. The label comprises a black face layer, a white bottom layer, a transparent adhesive layer and a strippable layer, wherein laser etching is conducted on the surface of the black face layer; the white bottom layer is bonded under the black face layer tightly in a face-to-face mode; the transparent adhesive layer is coated to the lower surface of the white bottom layer; the strippable layer is laminated to the lower surface of the transparent adhesive layer. The black face layer is formed by coating and drying black oil ink paste, wherein the black oil ink paste comprises, by weight, 40-60 parts of polyurethane resin, 15-30 parts of black color paste, 8-20 parts of amino resin and 10-25 parts of solvents. According to the self-adhesion label for laser etching and the preparation method, resin and cross-linking agents are screened and react with each other in a high-temperature cross-linking film forming mode to form a film coating, the film coating has the advantages of being excellent in high-low temperature resistance, solvent resistance, weather resistance, wear resistance and scraping resistance and good in bonding performance, necessarily destroyed when being stripped and capable of achieving the anti-fake function and being used for laser etching, and the preparation method is low in preparation cost and high in production flexibility.

Owner:SHANGHAI SUNTREE PAPER PROD CO LTD

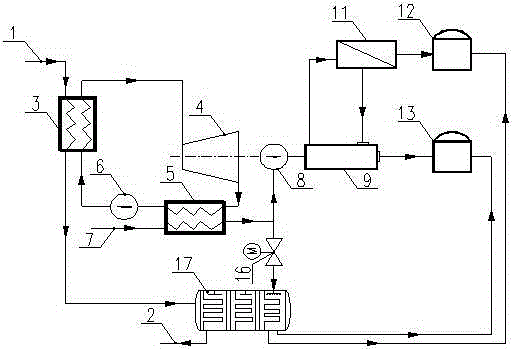

Hot-film-coupling seawater desalination device driven by low-temperature waste heat

ActiveCN105174589AImprove efficient useImprove comprehensive utilization efficiencyGeneral water supply conservationSeawater treatmentOrganic Rankine cycleIndustrial waste

The invention discloses a hot-film-coupling seawater desalination device driven by low-temperature waste heat, belonging to the field of industrial energy saving. The hot-film-coupling seawater desalination device comprises an organic Rankine cycle system, a reverse-osmosis seawater desalination system, a low-temperature multi-effect distillation system and a temperature regulation system, wherein the organic Rankine cycle system is used for driving the reverse-osmosis seawater desalination system to produce fresh water, and a heat source is provided by the waste heat discharged by the organic Rankine cycle system to the low-temperature multi-effect distillation system so as to fresh water; the temperature regulation system is used for regulating the temperature of raw material seawater entering the reverse-osmosis seawater desalination system. According to the hot-film-coupling seawater desalination device, the organic Rankine cycle system, the reverse-osmosis seawater desalination system and the low-temperature multi-effect distillation system are combined, so that the efficient utilization and the deep utilization of the industrial waste heat are improved, and the requirements of different seawater desalination users on the water quality and the water yield are met.

Owner:POWERCHINA HEBEI ELECTRIC POWER SURVEY & DESIGN INST CO LTD

Large and medium chinaware manufacturing method

ActiveCN108582416ARich Applicable TypesReduce manufacturing costCeramic shaping apparatusClaywaresTime spaceCeramic

The invention discloses a large and medium chinaware manufacturing method. Compared with a traditional method, such subsequent treatment processes as outer surface finishing, finish carving treatmentand / or colored drawing treatment and glazing of large and medium chinaware ceramic blanks and production of chinaware outer profile surfaces belong to simultaneous asynchronous treatment spaced by specific space-time intervals, so that the problem of performing subsequent processes one by one after completion of previous treatment procedures in the traditional method is overcome, and saving of a lot of time and delication of the artistic effect can be both considered. In addition, the method can finish complex shapes, is more suitable for manufacturing of large and medium artistic shape chinaware, meanwhile, greatly enriches the shaping range of large and medium chinaware, and greatly reduces the manufacturing cost of large artistic porcelains.

Owner:湖南筑巢智能科技有限公司

Resonater

InactiveUS20160201621A1Reduce tooling costsEasy and cost-effectivePipe elementsMachines/enginesEngineeringResonator

A resonator (1) has at least first and second annular chambers (2, 3, 17) arranged between inlet and outlet pieces (22, 21). An inner pipe (4) extends between the inlet piece (22) and the outlet piece (21) and has wall holes (23) that connect to the annular chambers (2, 3, 17). The first annular chamber (2) has a U-shaped circumferential wall (6) coaxial to the resonator longitudinal axis (5) and transitions at both ends to engage the inner pipe (4). The second annular chamber (3) has an L-shaped circumferential wall (12) coaxial to the resonator longitudinal axis (5). An end of the L-shaped circumferential wall remote from the first annular chamber (2) transitions into a cylindrical end piece (13), and an opposite end of the L-shaped circumferential wall lies on part of the outer wall (9) of the first annular chamber (2) extending parallel to the resonator longitudinal axis (5).

Owner:UMFOTEC +1

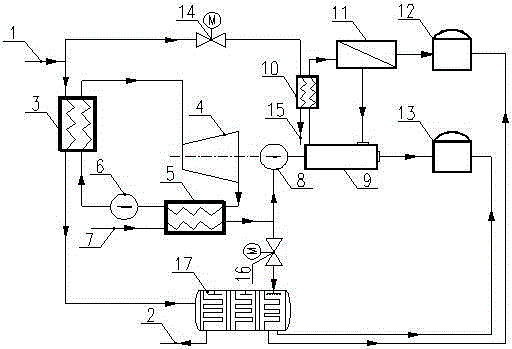

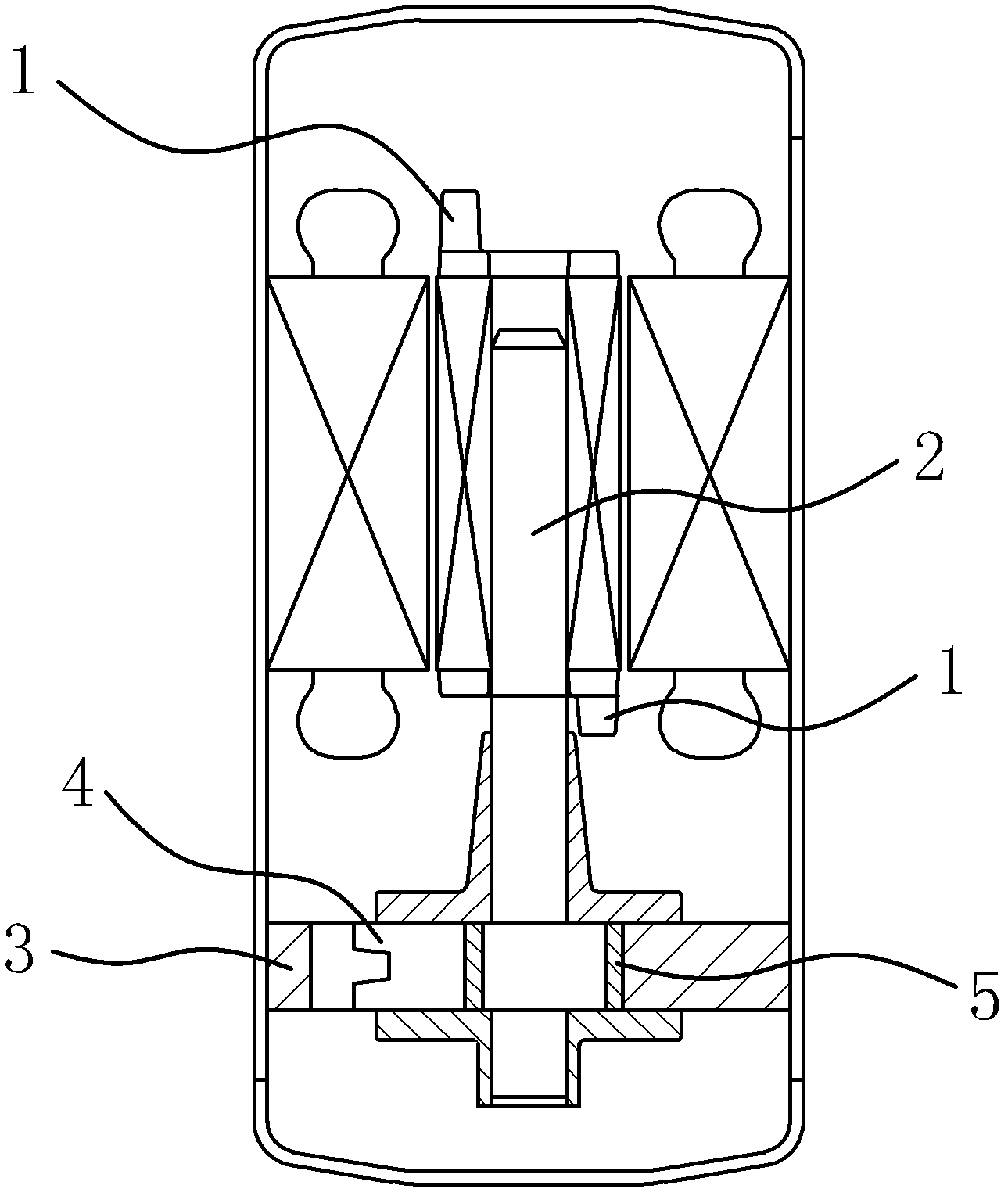

Method for manufacturing air condition compressor balance block

ActiveCN102248373ALow costIncreased production flexibilityMechanical engineering technologyWork in process

The invention provides a method for manufacturing an air condition compressor balance block, belonging to the technical field of mechanical engineering. By means of the method, the technical problems that the production efficiency is low, the reject rate is high and the like when high manganese steel is adopted to manufacture the air condition compressor balance block in a conventional method for manufacturing the air condition compressor balance block are solved. The method for manufacturing the air condition compressor balance block comprises the following steps of: A, blanking: cutting a section made from high manganese steel materials into blanks with a length corresponding to a required length; B, pre-pressing forming: putting the blanks in a mould and extruding into process products with shapes similar to the shapes of finished products; C, softening and lubricating treatments: carrying out the softening treatment and the phosphorization and saponification lubricating treatment on the process products; D, coining forming: putting the process products subjected to softening and the lubricating treatments in the mould to carry out extrusion forming to obtain semi-finished products; and E, machining: clamping the semi-finished products on a machine tool and machining to obtain the finished products. The method provided by the invention has the advantages of low production cost, high production efficiency and the like.

Owner:浙江百达精工股份有限公司

Resource recycling method and system for steelmaking tailings

The invention discloses a resource recycling method and system for steelmaking tailings. Through reasonable design, a jaw crusher, an impact crusher and a vibrating screen can be used for producing tailings with the grain diameters being of three specifications. The tailings with the grain diameters being 10mm-15mm and the tailings with the grain diameters being 4.75mm-10mm can be used as coarse aggregate in a concrete mixture. The tailings with the grain diameters being 0-4.75mm can be used as fine aggregate in the concrete mixture. The tailings with the three types of grain diameters can be further mixed into cement clinker. Steel slag fine powder is obtained through magnetic-separation with a dry separator to be returned to an iron and steel smelting system for secondary smelting and recovery of the metal iron. Grain steel is produced through a de-ironing separator, and further, products with higher economic value are produced through resource recycling of the tailings. According to the resource recycling method and system for the steelmaking tailings, waste is turned into wealth, and both the problem of environment pollution and the problem of resource waste are solved.

Owner:杨立武

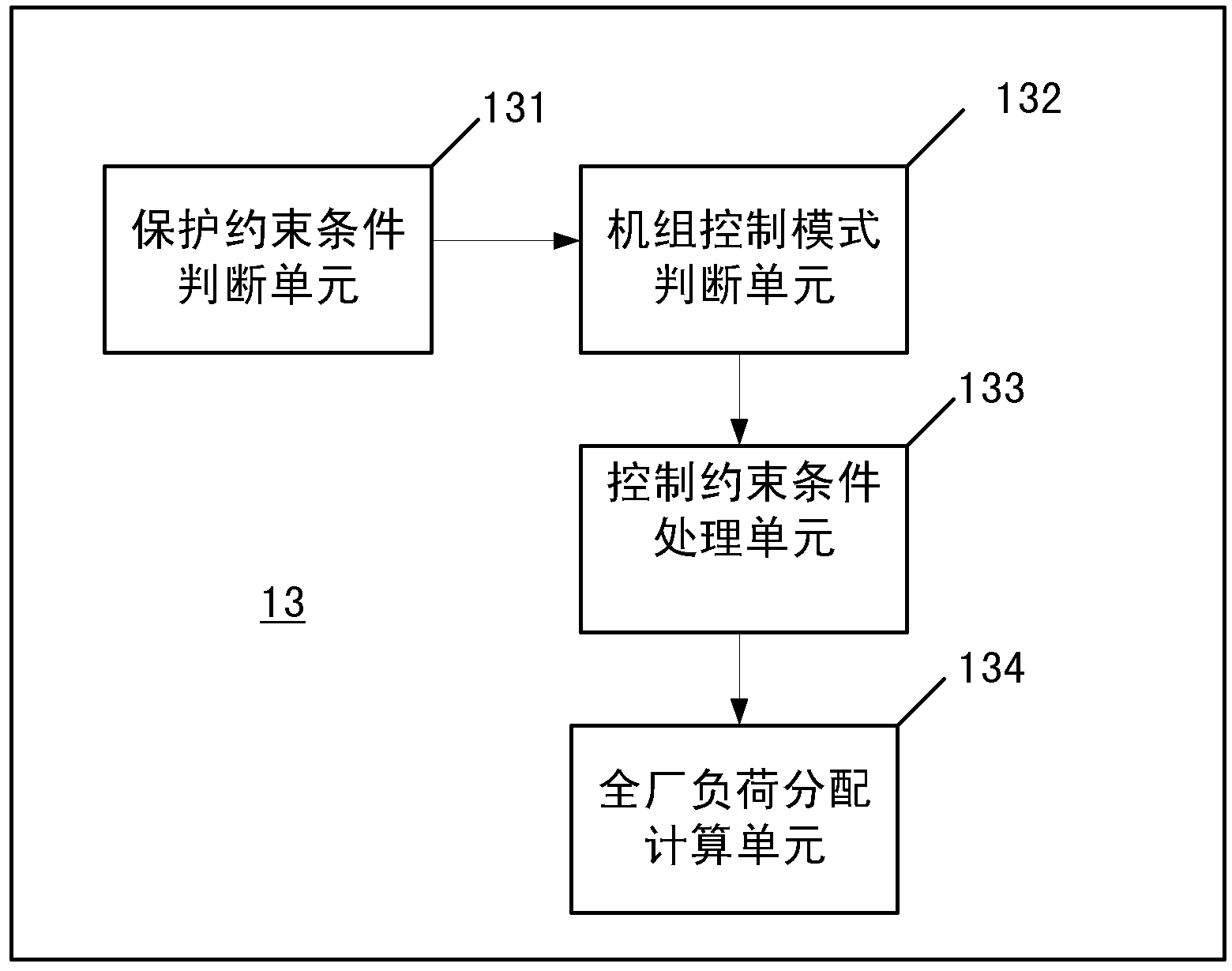

Electrical telemechanical host with plant-level automatic power generation function

InactiveCN102222914AEnsure consistencyGuaranteed operating accuracyAc networks with different sources same frequencyInformation technology support systemControl signalEngineering

The invention provides an electrical telemechanical host with a plant-level automatic power generation function. The electrical telemechanical host is connected with a remote signaling module, a remote measuring module, a remote invoking module, a remote control module and an invoking EMS / SCADA main station. The electrical telemechanical host specifically comprises a communication sub-module, a database sub-module, and a full-plant load distribution sub-module, wherein the communication sub-module is used for realizing data communication between the invoking EMS / SCADA main station and the database sub-module and the data communication among the remote signaling module, the remote measuring module, the remote invoking module, the remote control module and the database sub-module; the database sub-model is used for memorizing data required for plant-level AGC (automatic gain control) and carrying out data interaction respectively with the communication sub-module and the full-plant load distribution sub-module; and the full-plant load distribution sub-module generates a control signal of a generator unit active power output based on the data memorized in the database sub-module and sends the control signal to the remote invoking module in sequence through the database sub-module and the communication sub-module. In the electrical telemechanical host, on the basis of sufficiently playing the function of the existing electrical telemechanical host, the quantity of field hardware equipment is reduced, and the operation precision of the data is improved during the unit active adjustment process.

Owner:上海惠安系统控制有限公司

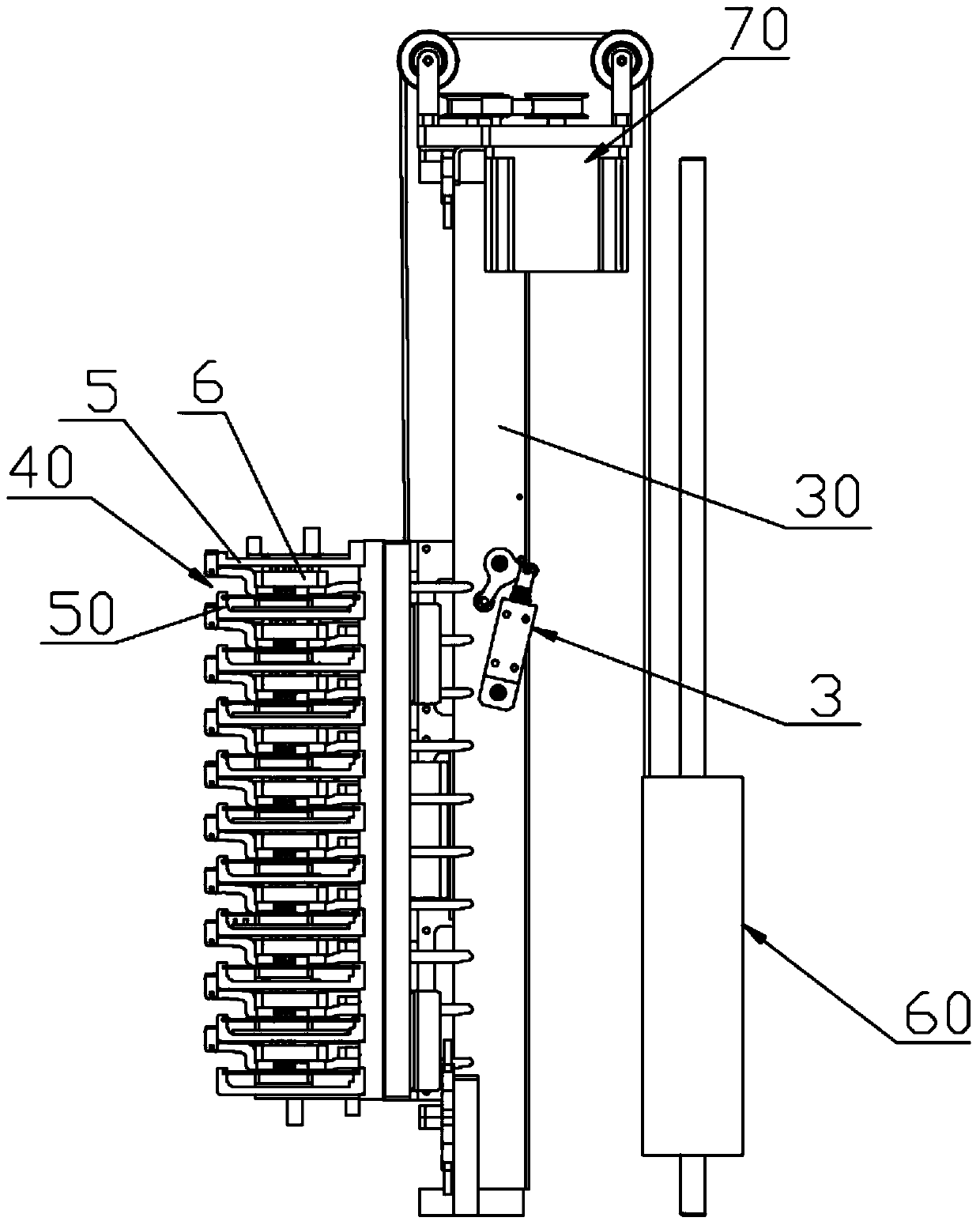

Intelligent card tower type chip writing device and chip writing method

ActiveCN104200254AIncreased production flexibilityLow costCo-operative working arrangementsRecord carriers used with machinesSmart cardContact type

The invention discloses an intelligent card tower type chip writing device and a chip writing method. The chip writing device comprises a tower type chip writing module and a driving mechanism driving the tower type chip writing module to move in the vertical direction, wherein the tower type chip writing module comprises multiple chip writing units arranged in the vertical direction. A contact type chip writing module is arranged on each chip writing unit, non-contact type chip writing modules are further arranged on a part or all of chip writing units, the contact type chip writing modules comprise probes and contact type card readers, and the non-contact type chip writing modules comprise antenna plates and non-contact type card readers. Probe connecting mechanism for lifting up and putting down the probes are connected onto the probes, and a shielding layer made of a wave-absorbing material is arranged between every two adjacent chip writing units provided with the non-contact type chip writing modules. The chip writing device can perform chip writing on contact type smart cards and can also perform chip writing on non-contact type smart cards.

Owner:GUANGZHOU MINGSEN TECH CO LTD

Isothermal-isobaric multipurpose thermal tempering equipment for ultra-thin glass

ActiveCN106865964AVersatileComplete specificationsGlass reforming apparatusGlass tempering apparatusElectrical controlEngineering

The invention discloses isothermal-isobaric multipurpose thermal tempering equipment for ultra-thin glass. The equipment comprises an upper piece platform, a heating furnace, a tempering section, a lower piece platform, a draught fan, a draught fan pipeline system and an electrical control system, wherein the draught fan is connected with the tempering section through the draught fan pipeline system and is used for continuously and uniformly supplying wind to the tempering section, a glass preheating region, a glass softening region and a glass stabilizing region are respectively arranged in the heating furnace, and the tempering section is divided into a glass shaping region and a glass tempering region. The isothermal-isobaric multipurpose thermal tempering equipment is provided with the glass preheating region and the glass stabilizing region, so that the adequate and uniform heating of glass is guaranteed; by utilizing an upper-lower duel roller bed, the glass deformation in the heating process can be furthest reduce; and furthermore, the upper-lower duel roller bed type glass shaping region is arranged at the tempering section, so that the softened glass can be shaped before being tempered, and the flatness of the softened glass reaches the standard requirement of tempered glass. The isothermal-isobaric multipurpose thermal tempering equipment has multiple purposes of flattening and bending and can be used for producing flat and bent tempered glass of various specifications and shapes.

Owner:侯维绪

Manufacturing device of antique furniture and manufacturing method thereof

ActiveCN104742213AImprove manufacturing precisionVarious shapesWood working apparatusMilling cutterSharp angle

The invention provides a manufacturing device of an antique furniture. The manufacturing device comprises a frame, a workbench, a cutter, a wooden tenon processing device, a mortise processing device, a polishing device, a shaping device and a round angle modifying and milling device. The workbench is arranged on the frame, and a through hole is arranged on the workbench; the through hole comprises a first through hole and a second through hole. The cutter is used for cutting a wood into wooden blocks, the mortise processing device is used for processing the wooden blocks into mortises corresponding to matched tenons, the polishing device is used for polishing an assembled body of the tenons and the mortises, and the shaping device is used for shaping the assembled body. As for the wooden tenon processing device, the round angle modifying and milling device, the wooden tenon processing device is used for processing the wooden blocks into tenons, and the round angle modifying and milling device is used for modifying a sharp angle part of the wood. The invention further provides a manufacturing method of the antique furniture. The manufacturing device has the advantages of high manufacturing precision, variable manufacturing shapes, material-saving, high manufacturing flexibility, fast manufacturing speed and high production efficiency.

Owner:JINGDE HUIHONG ANTIQUE FURNITURE

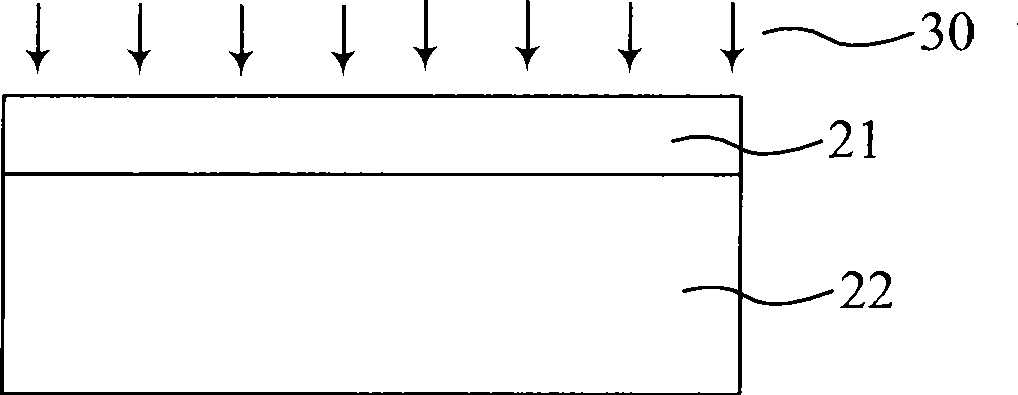

Method for removing silicon oxide layer on surface of silicon substrate and contact hole forming

InactiveCN101459071AAvoid damageQuality improvementSemiconductor/solid-state device manufacturingSurface oxidationAmmonium fluorosilicate

A method for removing silicon oxide layers from the surfaces of silicon substrates includes steps of disposing a silicon substrate with a silicon oxide layer into an etching device, wherein the silicon oxide layer is formed on the surface of the silicon substrate while NH4F atom groups formed in the etching device react with the silicon oxide layer on the surface of the silicon substrate to generate solid (NH4)2SiF6, and heating the silicon substrate to gasify the (NH4)2SiF6 on the silicon substrate, and exhausting the (NH4)2SiF6 gas from a heating device. Correspondingly, the invention further provides a method of forming contact holes. The method for removing silicon oxide layers from the bottom surfaces of silicon substrates prevents damages to the surfaces of the silicon substrates in the prior art by steps of transforming the natural silicon oxide layer on the surface of the silicon substrate into ammonium fluorosilicate which passivates the surface of the silicon substrate, then heating to gasify the ammonium fluorosilicate, exhausting the ammonium fluorosilicate gas and removing the silicon oxide layer from the surface of the silicon substrate.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Process for producing fuel oil

InactiveCN100348702CWide variety of sourcesEasy to handleTreatment with hydrotreatment processesTarFuel oil

A process for preparing fuel oil from tar fraction includes such steps as hydrogenating reaction between tar fraction, H2 and hydrorefining catalyst Mo-Ni / Al2O3 for removing S and N, the arylhydrocarbon saturation reaction on hydromodifying catalyst W-Mo-Ni / Al2O3 for further removing S and N, and separating out H2, dry gas, H2S, NH4 and liquefied gas to obtain fuel oil.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP

Method for preparing modification aluminoxane

InactiveCN102190678AHigh reaction yieldIncrease productivityOrganic-compounds/hydrides/coordination-complexes catalystsGroup 3/13 element organic compoundsAluminoxaneAluminium alkyl

The invention discloses a preparation method for modification aluminoxane, comprising the following steps: a) preparing an inertia solvent solution of aluminium alkyl under the protection of an inert gas; b) mixing water, a modifier and an inertia solvent to prepare a hydrolysis agent under the protection of an inert gas; c) mixing the inertia solvent solution of aluminium alkyl and the hydrolysis agent in a T-type pipe reactor at a temperature of between -10 DEG C and -50 DEG C, flowing the mixture into a kettle reactor, heating the mixture to a temperature of between 10 to 100 DEG C and reacting for 1 to 10 hours; d) obtaining a reaction solution by filtering, reducing pressure to remove the solvent to obtain alkylauminoxane. According to the method of the invention, the interacting effect of the modifier and water is utilized to control the local concentration of water and the composition and concentration of the modifier are used to influence the composition of the generated aluminoxane so as to improve the storage stability and usage effect of the alkylauminoxane.

Owner:NORTHEAST GASOLINEEUM UNIV

Loading device used for board composite welding

PendingCN111152461AFlexible movementSo as not to damageFlat articlesStructural engineeringWaste material

The invention discloses a loading device used for board composite welding. The loading device comprises a rack, a loading conveying channel perpendicularly mounted on the rack and a welding conveyingchannel provided with a composite welding machining station, a connecting station is mounted at the connecting position of the loading conveying channel and the welding conveying channel, a discharging station is mounted on the welding conveying channel, a worktable and a power mechanism are mounted on the welding conveying channel, a surface material placing platform, a bottom material placing platform, a waste material placing platform, a finished product placing platform and a carrying mechanism are mounted on the loading conveying channel, the carrying mechanism comprises a carrying moduleand a horizontal driving mechanism, the carrying module comprises a mounting plate, a suction cup assembly and a vertical power mechanism, and the suction cup assembly comprises multiple suction cups. According to the device, two or more boards are subjected to composite welding, production flexibility is high, the upper and the lower of a middle material are covered, the middle material can be effectively protected against damage in the subsequent procedure, and production quality is improved.

Owner:广州明森合兴科技有限公司

Cloth laser printing machine

PendingCN110171209ARealize automatic unwindingImprove efficiencyPrintingWebs handlingFree stateAutomation

The invention provides a cloth laser printing machine. The machine comprises two symmetrically arranged cloth winding / unwinding devices, a vacuumizing conveying device and a laser printing device, wherein the cloth winding / unwinding devices comprise winding / unwinding rollers arranged on a winding / unwinding rack, a plurality of cloth winding / unwinding guide rollers arranged behind the winding / unwinding rollers, tension adjusting rollers arranged between the cloth winding / unwinding guide rollers correspondingly, cloth winding / unwinding tension adjusting mechanisms which are arranged on one side of the tension adjusting rollers correspondingly and are used for adjusting the tension of the tension adjusting rollers, and center deviation correcting mechanisms which are arranged on one side of the tension adjusting rollers correspondingly; the vacuumizing conveying device is arranged between the cloth winding / unwinding devices which are symmetrically arranged; and the laser printingdevice is arranged on the vacuumizing conveying device. The cloth laser printing machine is flexible in production and high in automation degree, the longitudinal tension of cloth in the moving process can be reduced and eliminated, accurate laser printing can be carried out on various types of cloth in a tension-free state or a micro-tension state, and the printing precision and efficiency are improved.

Owner:广州市森特自动化控制技术有限公司

Automatic assembling device for flexible shaft holes applied to large precision equipment

InactiveCN105598658APrevents chafing or even damageAvoid damageMetal working apparatusHydraulic cylinderBall screw

The invention relates to an automatic assembling device for flexible shaft holes applied to large precision equipment. The automatic assembling device comprises a platform, a sleeve positioning and clamping device, a shaft supporting and positioning device, a flexible feeding moving device, two shaft hole assembling detection device and an auxiliary device. Positions of all the devices are adjusted through mechanisms such as hydraulic cylinders, sliding blocks and ball screws, the real-time positions of the devices are monitored through multiple laser sensors, and assembling of multiple types of the shaft holes of the precision equipment can be met. The flexibility of the assembling process is achieved through multiple elastic elements and force sensors, and the assembly force is monitored in real time. All the devices are installed on the same platform, the layout is ordered, the reliability is good, the operability is high, the detection precision is high, and the assembling quality and efficiency for assembling of the shaft holes for the large precision equipment are effectively improved.

Owner:SHANGHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com