Process for producing diatomic alcohol and polyol from cracking sorbierite

A technology for sorbitol and dihydric alcohol, applied in the field of dihydric alcohol and polyhydric alcohol, can solve the problem of no technical scheme and implementation scheme, etc., and achieve the effects of strong production flexibility, reduced hydrogen cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

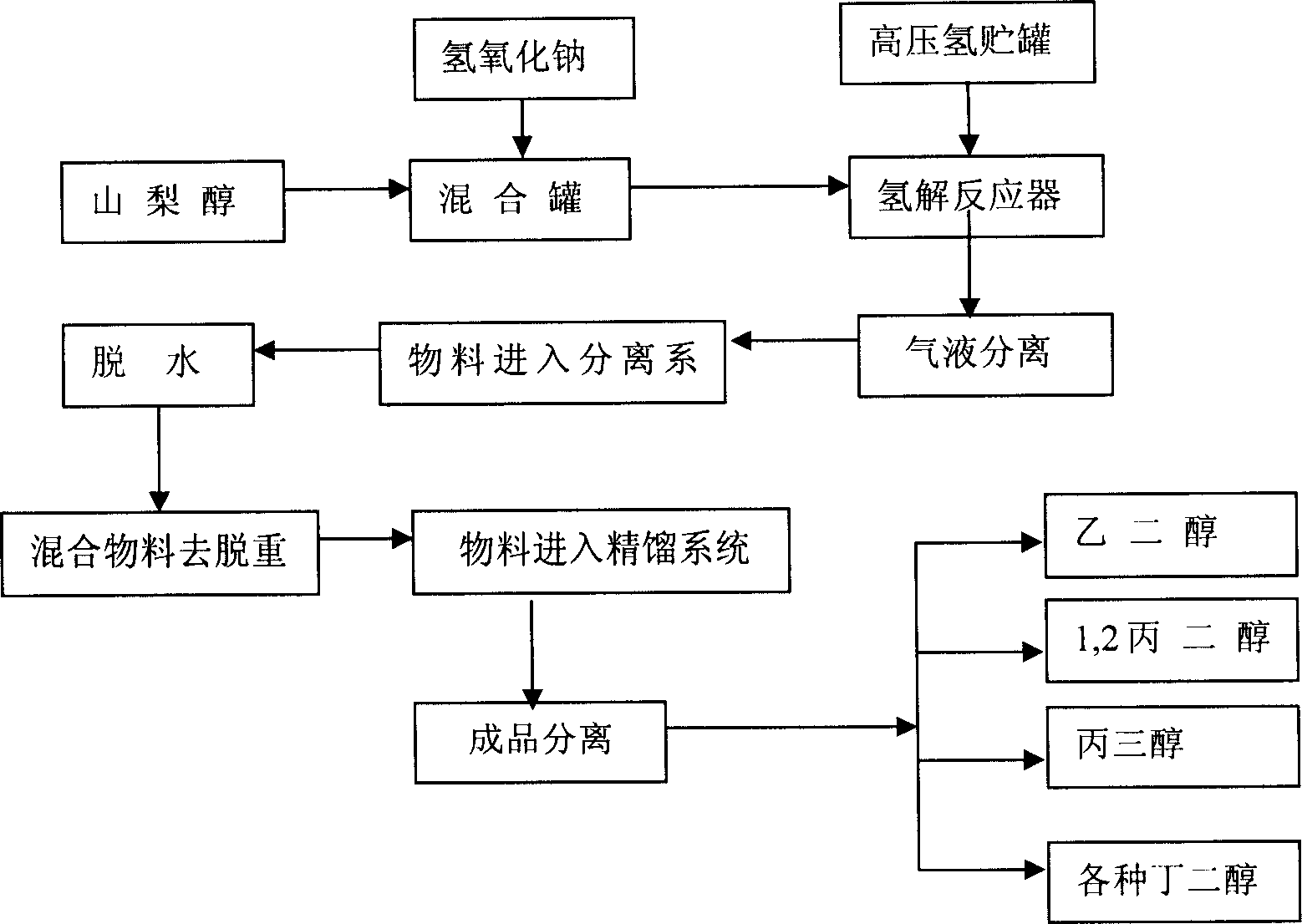

Method used

Image

Examples

Embodiment 1

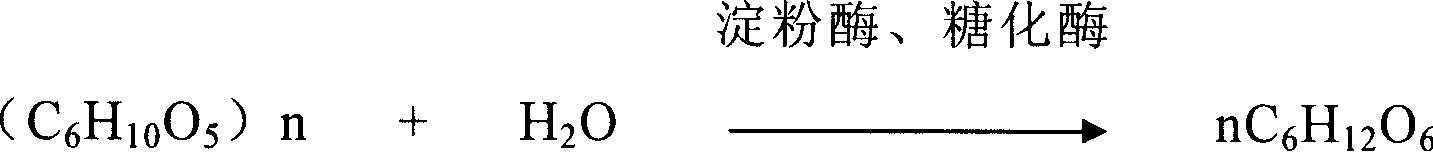

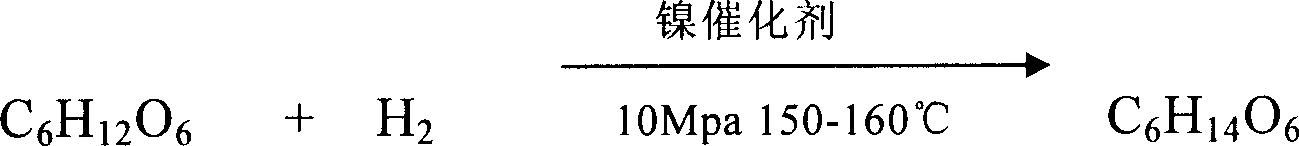

[0075] 1. Production of sorbitol:

[0076] Convert 1000 kilograms of corn into starch milk (700 kilograms on a dry basis), in the presence of amylase and glucoamylase, generate about 742 kilograms of 70% liquid glucose with water, cool and crystallize at 24 ° C, and obtain 865 kilograms of 60 after centrifugation % tidal sugar solution, then, in the presence of nickel catalyst, carry out hydrogenation reaction with hydrogen at 156 ℃ and about 10Mpa to obtain 860 kilograms of sorbitol for use.

[0077] 2. Production of Methanol:

[0078] Mix 325 kg / h of methanol and 183 kg / h of desalted water, pressurize, preheat, vaporize and overheat to a reaction temperature of 260°C, and carry out a conversion reaction at a reaction pressure of about 0.9Mpa in the presence of a catalyst to obtain about 900Nm 3 / hour reformed gas, wherein the hydrogen content is 73-74.5%. Then the high-temperature reformed gas is cooled and condensed to below 40°C, and purified by conventional methods to o...

Embodiment 2

[0084] Except adopting purchased sorbitol and hydrogen hydrogen as raw materials, other described various described alcohols are produced according to the method identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com