Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

308results about "Preparation by alcoholysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

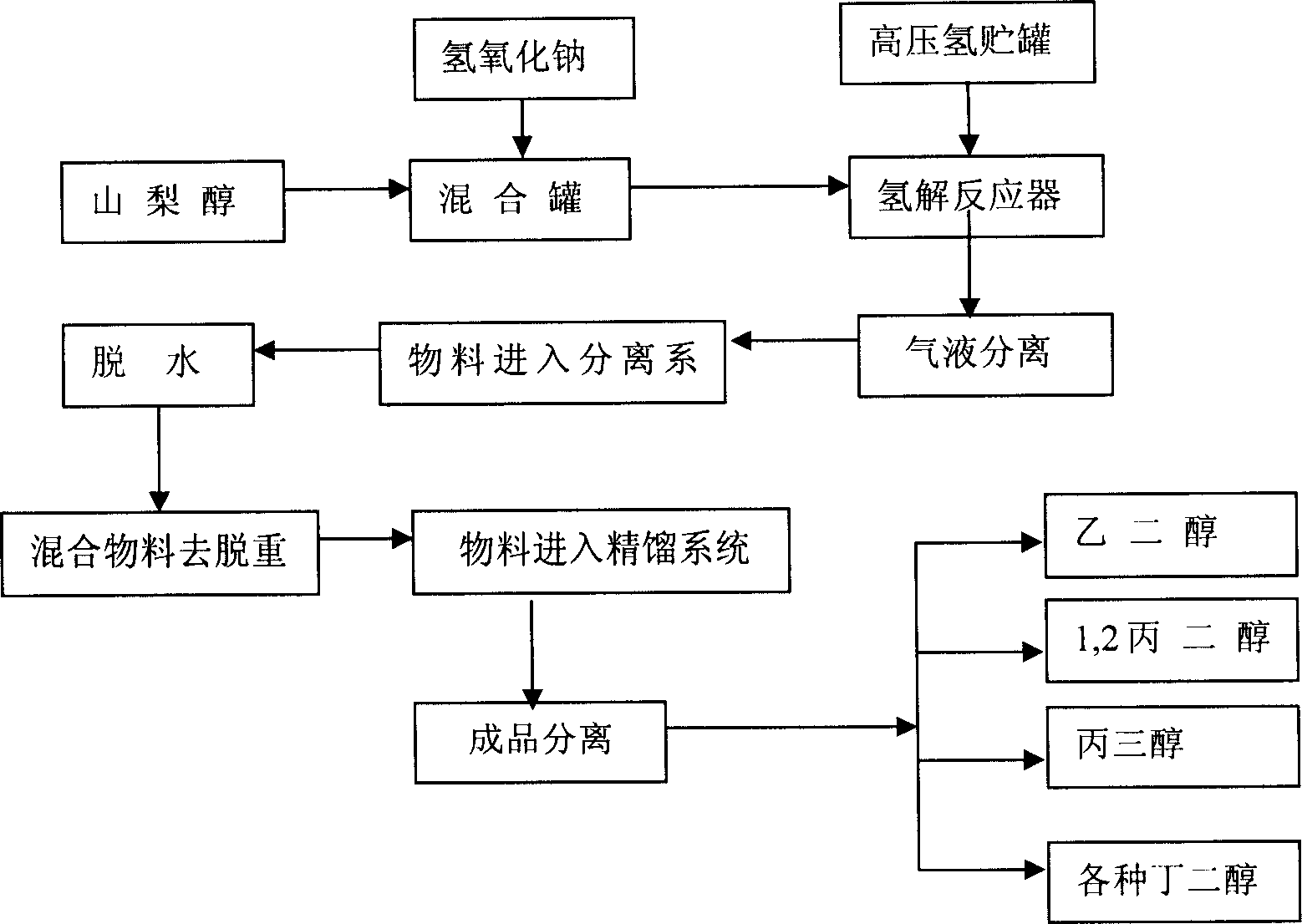

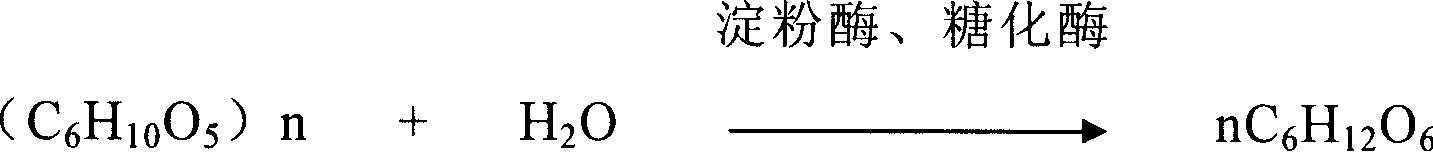

Process for producing diatomic alcohol and polyol from cracking sorbierite

InactiveCN1683293AQuality improvementIncreased production flexibilityOrganic compound preparationOrganic chemistry methodsPolyolAlcohol

The present invention relates to sorbierite cracking process to prepare C2-C4 diatomic alcohol and polyol, and is especially the process of preparing sorbierite with corn material and hydrocracking sorbierite to prepare C2-C4 diatomic alcohol and polyol. The process includes hydrocracking sorbierite to prepare the mixture of C2-C4 diatomic alcohol and polyol at high temperature and high pressure in the presence of cracking sodium hydroxide and nickel / ruthenium catalyst, separation and refining to obtain single product. The production process of the present invention has the advantages of novel production path, unique technological condition, simultaneous production of several kinds of alcohol and high product quality. In addition, using grains, such as corn, as material to replace non-regenerable resource is significant.

Owner:王宗国

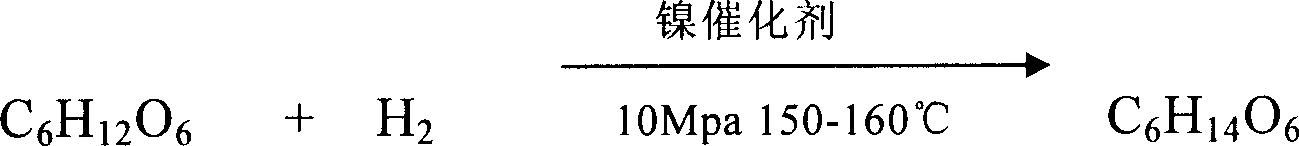

Process for co-production of dialkyl carbonate and alkanediol

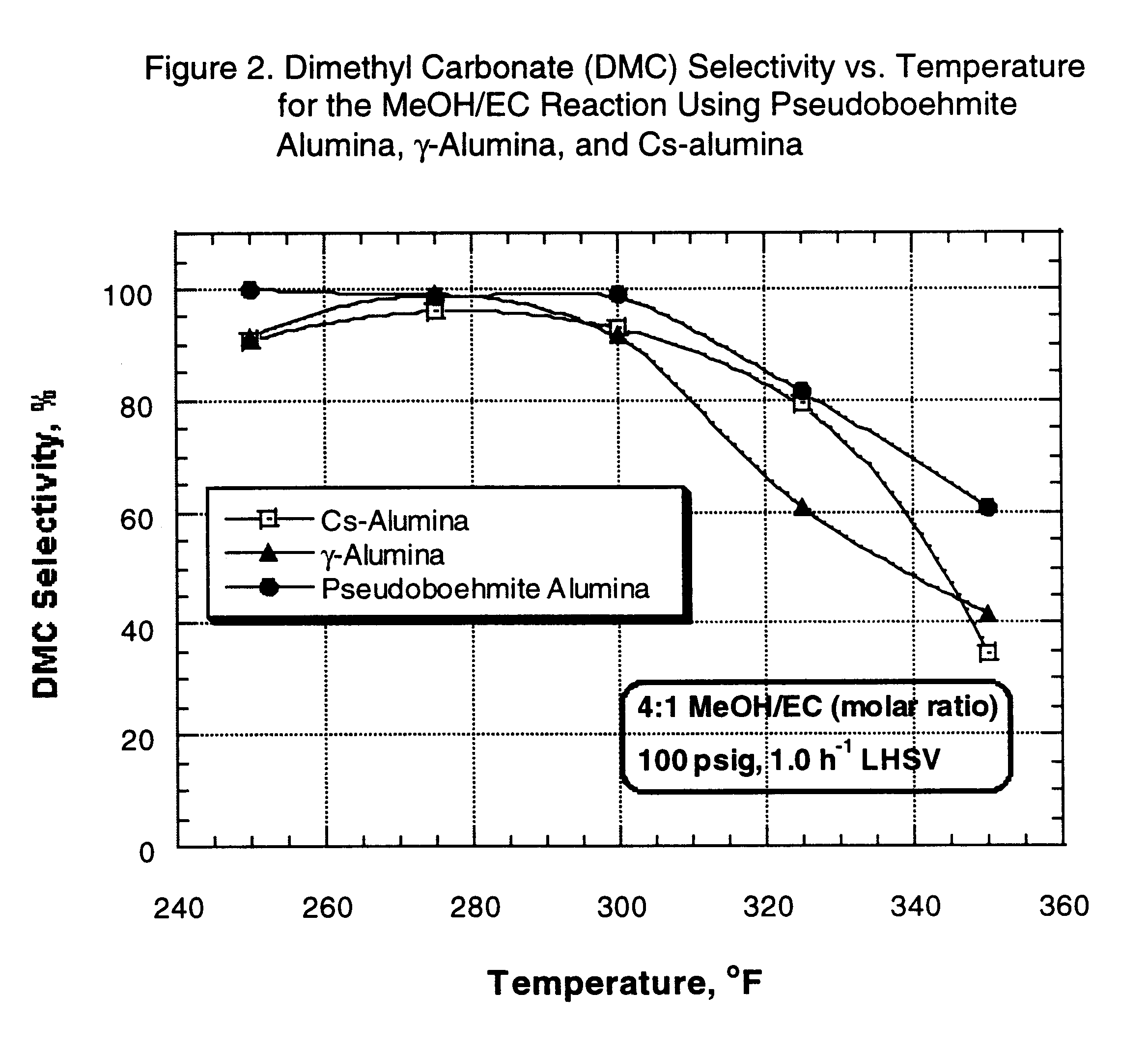

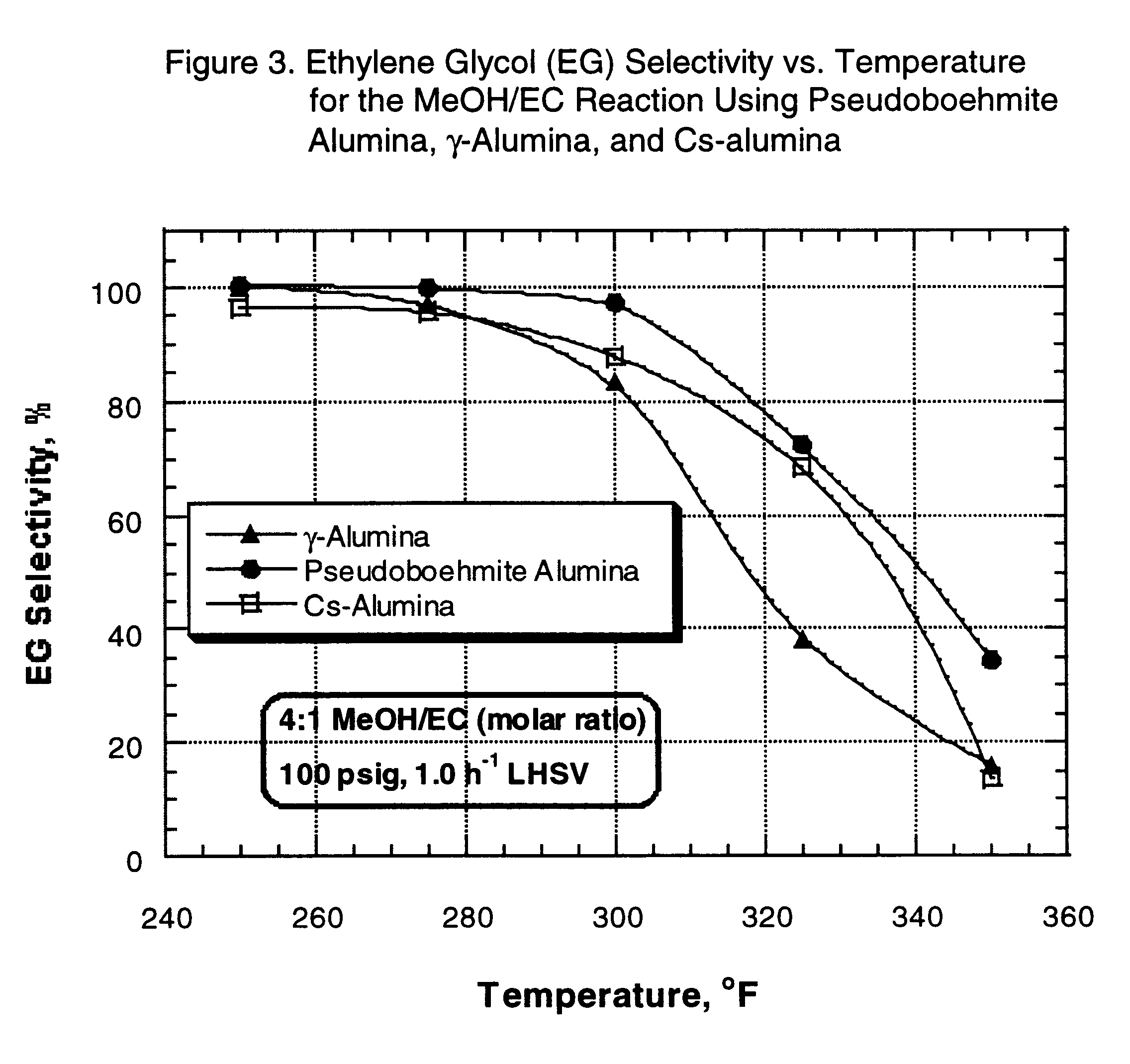

InactiveUS6207850B1Excellent regenerabilityImprove stabilityOxygen-containing compound preparationOrganic compound preparationCarbonateMetal

Owner:MOBIL OIL CORP

Rubber seed oil polyalcohol and preparation method thereof

ActiveCN101906016AReduce dependenceIncrease added valuePreparation by alcoholysisEpoxyReaction temperature

The invention relates to rubber seed oil polyalcohol and a preparation method thereof. The method comprises the following steps of: mixing rubber seed oil, hydrogen peroxide and a catalyst serving as raw materials in a weight ratio of 1:0.5-1.5:0.01-0.05, putting the mixture into a reaction kettle, stirring the mixture and raising temperature to 50 to 80 DEG C, keeping reaction temperature for 3 to 8 hours, lowering the temperature to 30 DEG C, separating acid water out, washing the mixture with aqueous solution of sodium carbonate until the pH of the mixture is between 5 and 6, washing the mixture to be neutral with saturated sodium chloride and water, and performing pressure reduction and water removal at the temperature of between 50 and 90 DEG C for 2 to 5 hours to obtain epoxy rubberseed oil; and adding the epoxy rubber seed oil, methanol, isopropanol and fluoboric acid into the reaction kettle in a weight ratio of 1:1-5:1-5:0.002-0.01, raising the temperature to 75 to 100 DEG C, performing a reaction for 0.5 to 3 hours, washing the reaction product with the aqueous solution of the sodium carbonate until the pH of the reaction product is between 5 and 6, washing the reaction product to be neutral with water, and performing vacuum pumping at the temperature of between 50 and 120 DEG C for 2 to 5 hours to obtain the rubber seed oil polyalcohol. In the method, the conventional petroleum chemical is replaced by a non-edible plant oil resource, so that the dependence of polyurethane industry on petroleum chemicals is reduced, and the added value of the rubber seed oil is increased.

Owner:SOUTHWEST FORESTRY UNIVERSITY

Process for preparing dialkyl carbonates from alkylene carbonates and alcohols

The present invention relates to a continuous process for preparing lower dialkyl carbonates as main product and alkylene glycol as by-product by catalyzed transesterification of a cyclic alkylene carbonate (e.g. ethylene carbonate or propylene carbonate) with lower alcohols, where the reaction of the alkylene carbonate is carried out with an alcohol containing dialkyl carbonate in countercurrent, characterized in that introduction of a stream containing at least 99.5% by weight of alcohol takes place below the point of introduction for the alcohol containing dialkyl carbonate in a particular spacing ratio between the abovementioned points of introduction.

Owner:COVESTRO DEUTSCHLAND AG

Method for producing epoxy fatty acid methyl ester by using illegal cooking oil

InactiveCN102161938AHigh speedEasy to control and adjust the dosageFatty acid esterificationPreparation by alcoholysisEpoxyDistillation

Owner:河北金谷增塑剂有限公司

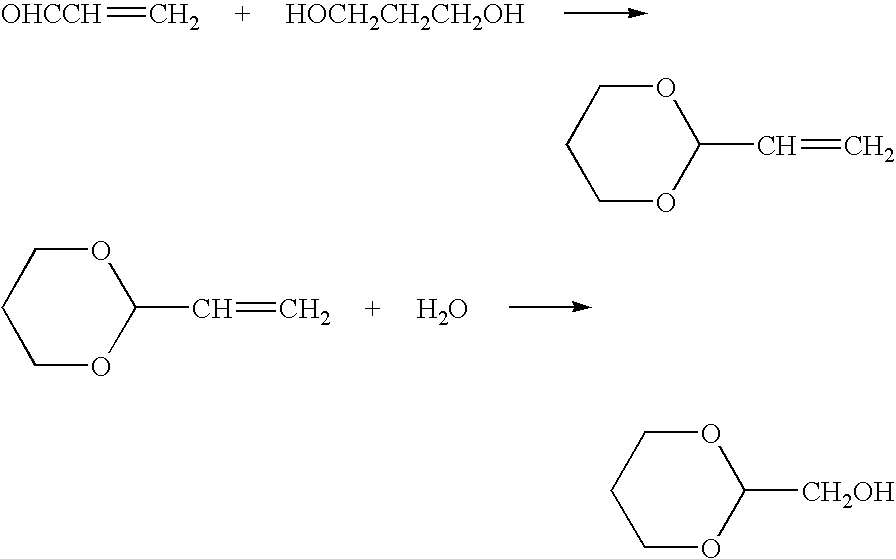

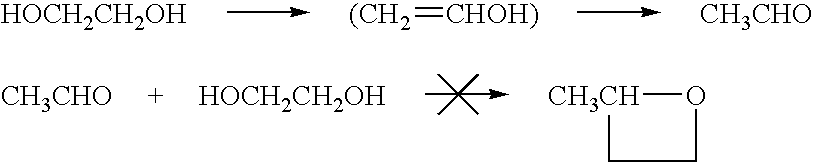

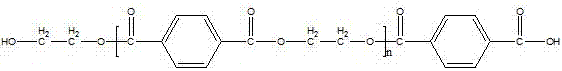

Ester-forming monomer

InactiveUS6867322B1High recovery rateEasy to separateOxygen-containing compound preparationOrganic compound preparationDepolymerizationPolymer science

An ester-forming monomer obtained by depolymerization of polytrimethylene terephthalate and having an acrolein content of no greater than 0.5 wt %. Polymers obtained using the monomer and fibers, films and molded articles comprising the polymers. The ester-forming monomer is obtained by reacting polytrimethylene terephthalate with at least one compound selected from among monoalcohols, 1,3-propanediol and water in the presence of a basic substance. When the recovered ester-forming monomer is used as the starting material for production of a polymer, it is possible to produce a molding polymer for fibers, films and the like with quality equivalent to or higher than that obtained using virgin monomer.

Owner:ASAHI KASEI KK

Method for synthesizing sec-butyl alcohol

InactiveCN102731250AIncrease reaction rateImprove conversion ratePreparation by ester-hydroxy reactionPreparation by alcoholysisButeneMethyl acetate

Owner:FUZHOU UNIV

Solid base catalyst and method for preparing biodiesel by use of solid base catalyst

InactiveCN103894170AHigh catalytic activitySmall particle sizeFatty acid esterificationBiofuelsProduction rateBiodiesel

The invention relates to a preparation method of a solid base catalyst. The preparation method comprises the following steps: weighing appropriate amount of CH3COONa solid powder and dissolving into distilled water to obtain 200g / L of a CH3COONa solution; weighing certain amount of Al2O3, and performing supersaturated impregnation on Al2O3 for 24h with the prepared CH3COONa solution; and drying the Al2O3 after supersaturated impregnation at 105 DEG C for 4h, calcining for 3h at 500 DEG C and naturally cooling to obtain Na2O / Al2O3 supported solid base catalyst. The invention also discloses a method for preparing the biodiesel with adoption of the Na2O / Al2O3 supported solid base catalyst. The supported catalyst Na2O / Al2O3 prepared by an impregnation method has good catalytic activity in a biodiesel catalytic synthesis process. The optimal process conditions for preparing the biodiesel by use of the supported catalyst are as follows: the reaction temperature is 65 DEG C, the molar ratio of methanol to oil is 9:1, the reaction time is 4h, the using amount of the catalyst is 2%, and the production rate of the biodiesel under the conditions is 85.4%.

Owner:QINGDAO UNITED INNOVATION TECHN SERVICES PLATFORM

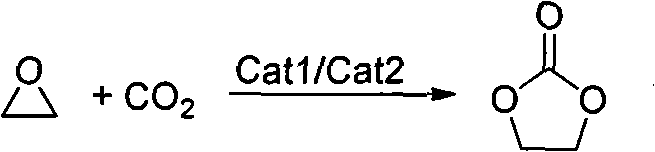

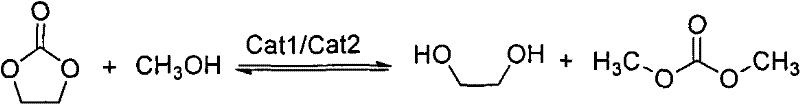

Catalytic method for preparing dimethyl cabonate along with ethylene glycol

ActiveCN102126956AOxygen-containing compound preparationOrganic compound preparationCatalytic methodEthylene oxide

The invention relates to a catalytic method for preparing dimethyl cabonate along with ethylene glycol. The invention is characterized in that ethylene oxide and carbon dioxide are used as raw materials to prepare ethylene carbonate under the catalysis of a composite catalyst; the composite catalyst and cyclic carbonate are not separated and are used to further catalyze the reaction of ethylene carbonate and methanol and prepare dimethyl cabonate and ethylene glycol. The synthesis method is characterized by high catalyst activity, low cost, long service life and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

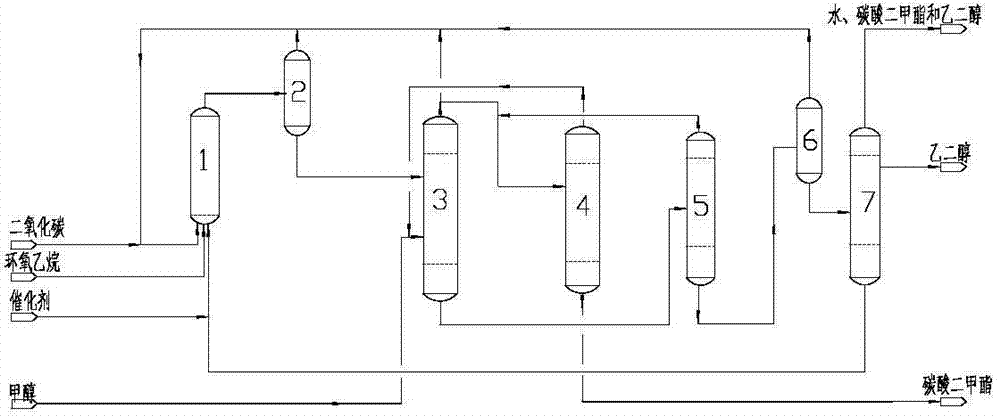

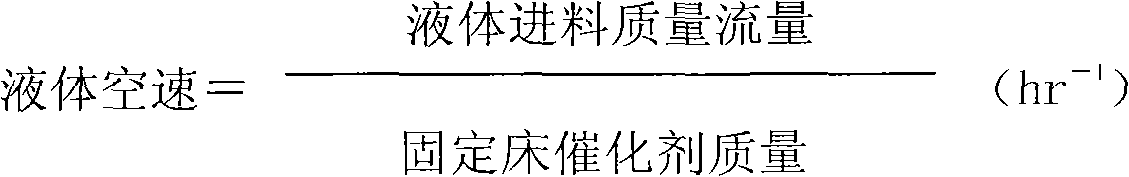

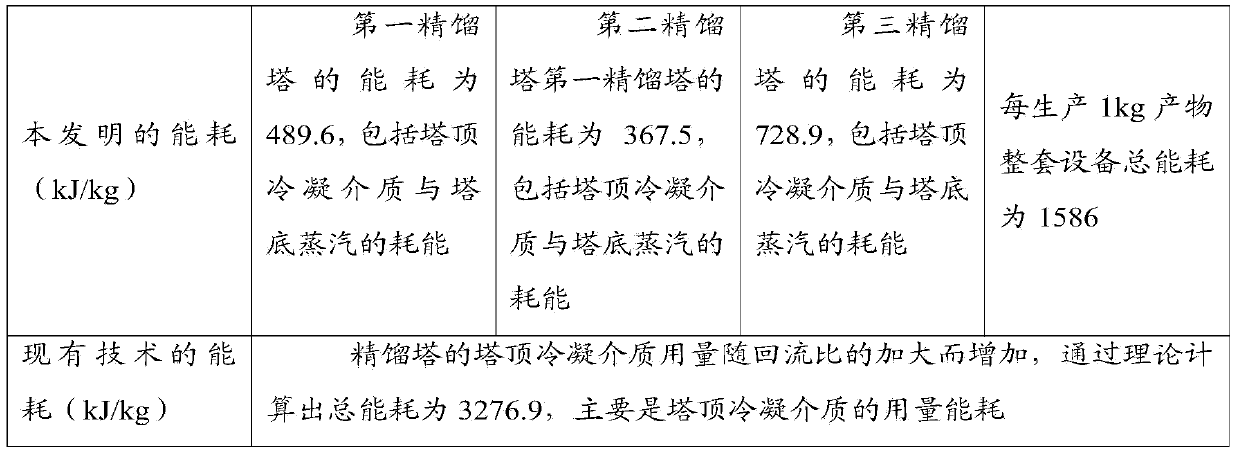

Dimethyl carbonate and ethylene glycol production process

ActiveCN104761429ALow conversion rate per passReduce energy consumptionOxygen-containing compound preparationOrganic compound preparationMethyl carbonateEthylene oxide

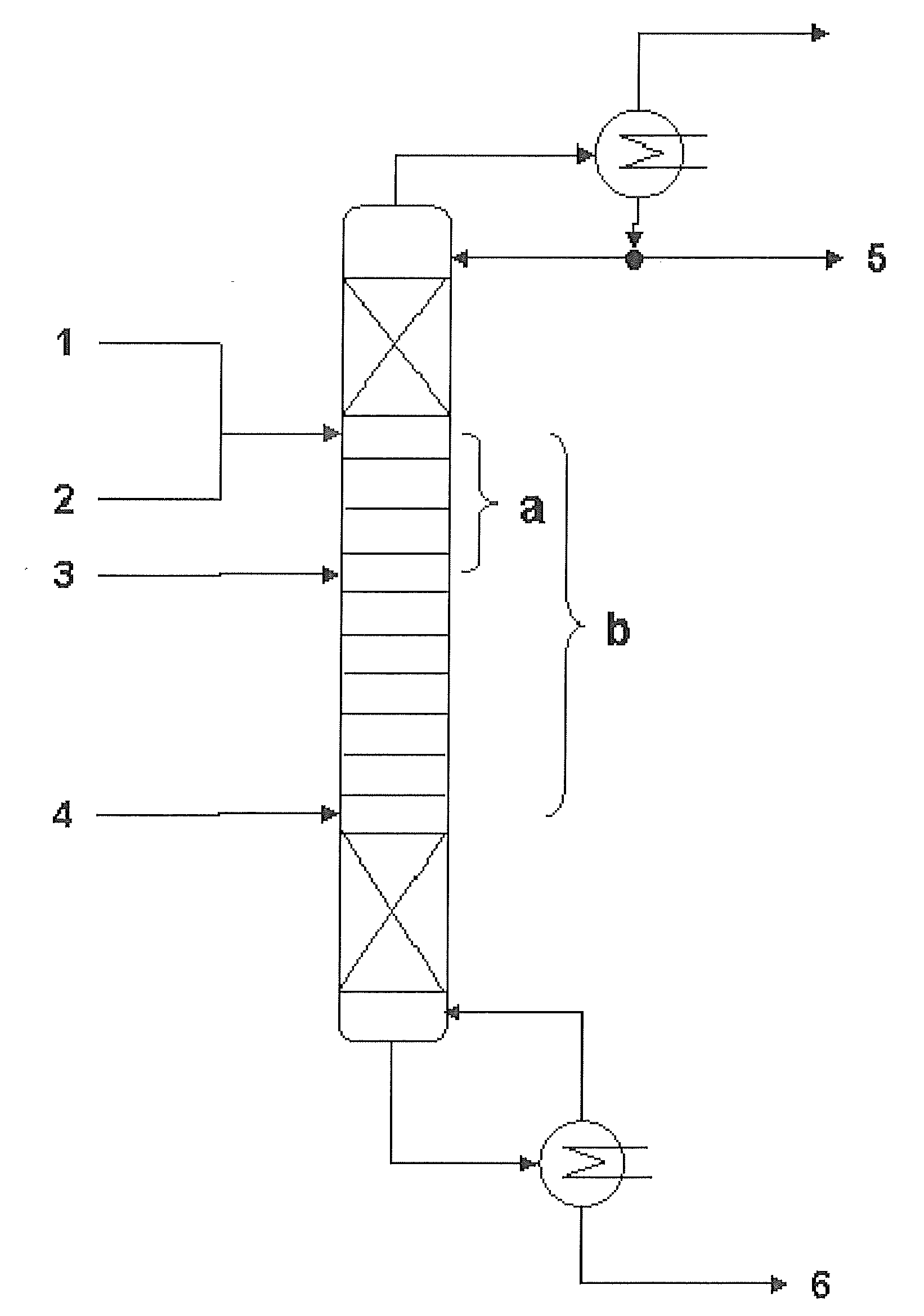

The invention relates to a dimethyl carbonate and ethylene glycol production process which is characterized in that the process comprises the following five steps: (a) the carbonylation step for production of ethylene carbonate by catalysis of reaction of ethylene oxide and carbon dioxide by use of an ionic liquid composite catalyst; (b) the step of alcoholysis for ester exchange reaction of the ionic liquid composite catalyst-containing ethylene carbonate solution of the step (a) and methanol in a reaction distillation tower and product separation; (c) the step of purification and refining of dimethyl carbonate from tower top condensate in the reaction distillation tower of the step (b); (d) the step of separation, transformation and refining of ethylene glycol from tower bottom liquid in the reaction distillation tower of the step (b); and (e) the step of circulation cycle of from the ionic liquid composite catalyst in the step (d) to the catalyst in the step (a). The process has the characteristics of high ethylene carbonate one-way conversion rate, simple process flow, small equipment investment, less waste emissions, low energy consumption and the like, and can make companies stronger in competitiveness.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Preparation method of 2-butyl alcohol

InactiveCN102992956AHigh selectivityImprove conversion rateChemical industryPreparation by alcoholysisAlcoholN-Butyl acetate

The invention relates to a preparation method of 2-butyl alcohol. The method comprises the following steps: carrying out an ester exchange reaction of 2-butyl acetate and low-carbon alcohol in a catalytic rectifying tower in the presence of an ester exchange catalyst, and collecting the 2-butyl alcohol from tower bottoms, wherein the low-carbon alcohol is C1-C3 alcohol. The method has the advantages of high 2-butyl acetate conversion rate and high 2-butyl alcohol selectivity.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

Method for producing polyol by using polyurethane waste

The invention relates to a method for producing polyol by using polyurethane waste. In the scheme adopted by the invention, the method for producing the polyol is characterized by sequentially comprising the following steps of: 1. fully mixing polyurethane waste grains, a polyester polyol alcoholysis agent with molecular weight of 200-2000, and an antioxidant, and then injecting into a reaction kettle; 2. injecting a micro-molecular polyol alcoholysis agent with molecular weight of less than 200 into the reaction kettle, controlling the temperature of the reaction kettle to be between 180 DEGC and 240 DEG C, performing alcoholysis reaction for 30-120 min under the protection of nitrogen; and 3. removing micro-molecular alcohol with molecular weight of less than 200 in vacuum, and reducing temperature and discharging when a hydroxyl value and an acid value reach set values. By adopting the scheme, the invention overcomes the defects of the prior art and provides a preparation method, which is favorable for effectively utilizing resources, reducing or eliminating the source of environment pollution caused by human, and obtaining polyol products with stable quantity.

Owner:ZHEJIANG HUAFON NEW MATERIALS CO LTD

Method for catalyzing synthesizing sec-butyl alcohol through cation exchange resin

InactiveCN102838450AHigh catalytic activityGood choicePreparation by ester-hydroxy reactionPreparation by alcoholysisSec-Butyl acetateSec-butyl alcohol

The invention discloses a method for catalyzing synthesizing sec-butyl alcohol through cation exchange resin. The method comprises the step of carrying out ester exchange under the effect of the cation exchange resin with the sec-butyl acetate and the carbinol serving as the raw materials, so as to synthesize to obtain the sec-butyl alcohol. The sec-butyl acetate provided by the invention has the conversion rate up to 35 to 50%; and the method has the advantages that the reaction condition is mild, the corrosion to equipment is low, the selectivity and the activity of a catalyst are high, and repeated use is realized.

Owner:FUZHOU UNIV

Method for preparing fatty acid methyl ester and glycerol from kitchen waste oil by utilizing acid-base two-step method

InactiveCN102021082AReduce dosageEasy to prepareFatty acid esterificationBiofuelsProcess systemsAlcohol

The invention relates to an acid-base two-step process system which comprises a preprocessing system and is used for preparing fatty acid methyl ester and glycerol from kitchen waste oil. The system comprises a kitchen waste oil preprocessing unit, an acid-base two-step esterlysis reaction unit, a glycerol separation and recovery unit, a rinsing and dehydrating unit and a decoloration filtering unit and the like. The processes are as follows: step I: after impurity removal, dehydration and deodorization are carried out on the kitchen waste oil, 40% concentrated sulfuric acid the weight of which is 1-5% of that of the waste oil is added, absolute methanol is added based on the alcohol-oil ratio of (6:1)-(9:1), heating is carried out until the temperature is 60-65 DEG C, the mixture is stirred for 1-3 hours at a revolving speed of 200-400r / min, and then rinsing separation and dehydration are carried out, thus obtaining the fatty acid methyl ester and crude glycerol; and step II: solid base catalyst the mass percent concentration of which is 0.5-5% is added in the rinsed fatty acid methyl ester mixture, absolute methanol is added based on the alcohol-oil ratio of (3:1)-(6:1), reaction is carried out for 1-3 hours at 20-50 DEG C, and then distillation is carried out under reduced pressure, thus obtaining the fatty acid methyl ester.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

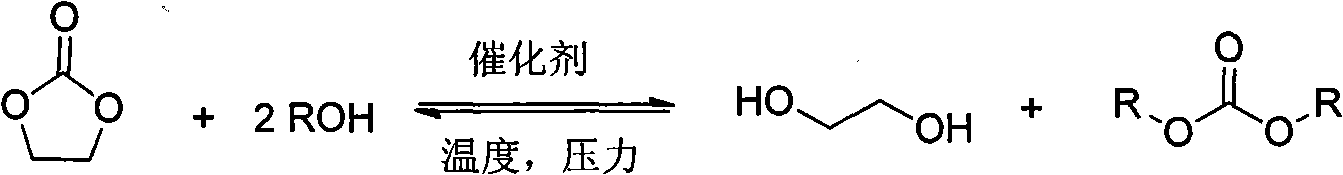

Method for simultaneously preparing glycol and carbonate by catalysis

ActiveCN102093164AOxygen-containing compound preparationOrganic compound preparationCarbonate esterFatty alcohol

The invention relates to a method for simultaneously preparing glycol and carbonate by catalysis, which is characterized in that ethylene carbonate and fatty alcohol are used as raw materials; and in the reaction process, a basic catalyst is used, the reaction pressure is 0.1-1.0 MPa, the temperature is 333-433K, the reaction time is 0.25-6 hours, and the mol ratio of the ethylene carbonate to the fatty alcohol is 1:4-1:32, so that glycol and carbonate can be selectively synthesized at high conversion rate.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

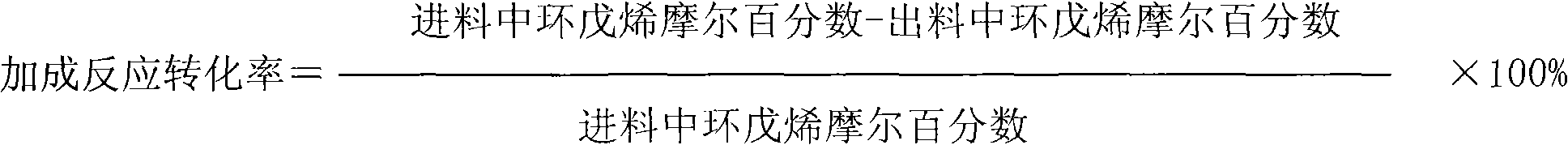

Method for preparing cyclopentanol from cyclopentene through indirect hydration method

ActiveCN102399133AEasy to recycleNo pollution in the processPreparation by alcoholysisProcess systemsCyclopentene

The invention relates to a method for preparing cyclopentanol from cyclopentene through an indirect hydration method. The method comprises steps that: liquid phase cyclopentene and acetic acid are subject to an addition reaction with a fixed-bed catalyst, such that cyclopentyl acetate is obtained, wherein the catalyst is sulfonic cation exchange resin with a mass exchange capacity of 3-5.5mmol / g;the product of the addition reaction is processed through rectification separation, such that refined cyclopentyl acetate is obtained; the refined cyclopentyl acetate is subject to an ester exchange reaction with methanol under the existence of a catalyst CaO, such that cyclopentanol and methyl acetate are produced; the produced methyl acetate is removed during the reaction process; the product of the ester exchange reaction is filtered, such that the catalyst is removed; and the obtained product is processed through rectification separation, such that the product cyclopentanol is obtained. The method provided by the invention provides substantial positive effects. The addition reaction and the ester exchange reaction have relatively high conversion rate and selectivity, and an average overall yield reaches approximately 80%. More importantly, no substance with high acidity and corrosivity is appeared in the reaction system during the whole reaction process. The raw materials which are not reacted can easily be recovered and reused, and almost no environment pollution is caused.

Owner:CHINA PETROLEUM & CHEM CORP +1

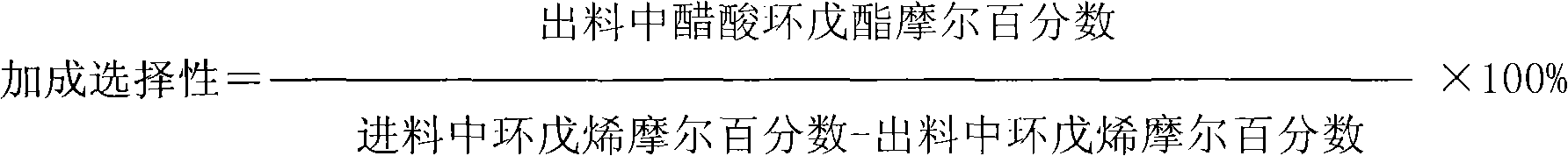

Low corrosive integrated process for preparing dialkyl carbonates

An integrated process for the production of a dialkyl carbonate and a diol from an alkylene oxide, carbon dioxide and an aliphatic monohydric alcohol is described in which an alkylene oxide is first reacted with carbon dioxide in the presence of a halogen-free carbonation catalyst to provide a corresponding cyclic carbonate and the cyclic carbonate is then reacted with an aliphatic monohydric alcohol in the presence of the carbonation catalyst and / or a transesterification catalyst and recycling the carbonation catalyst to provide a corresponding dialkyl carbonate and diol, wherein the dialkyl carbonate product exhibits a halogen concentration of about 5 ppm or less.

Owner:BADGE LICENSING LLC

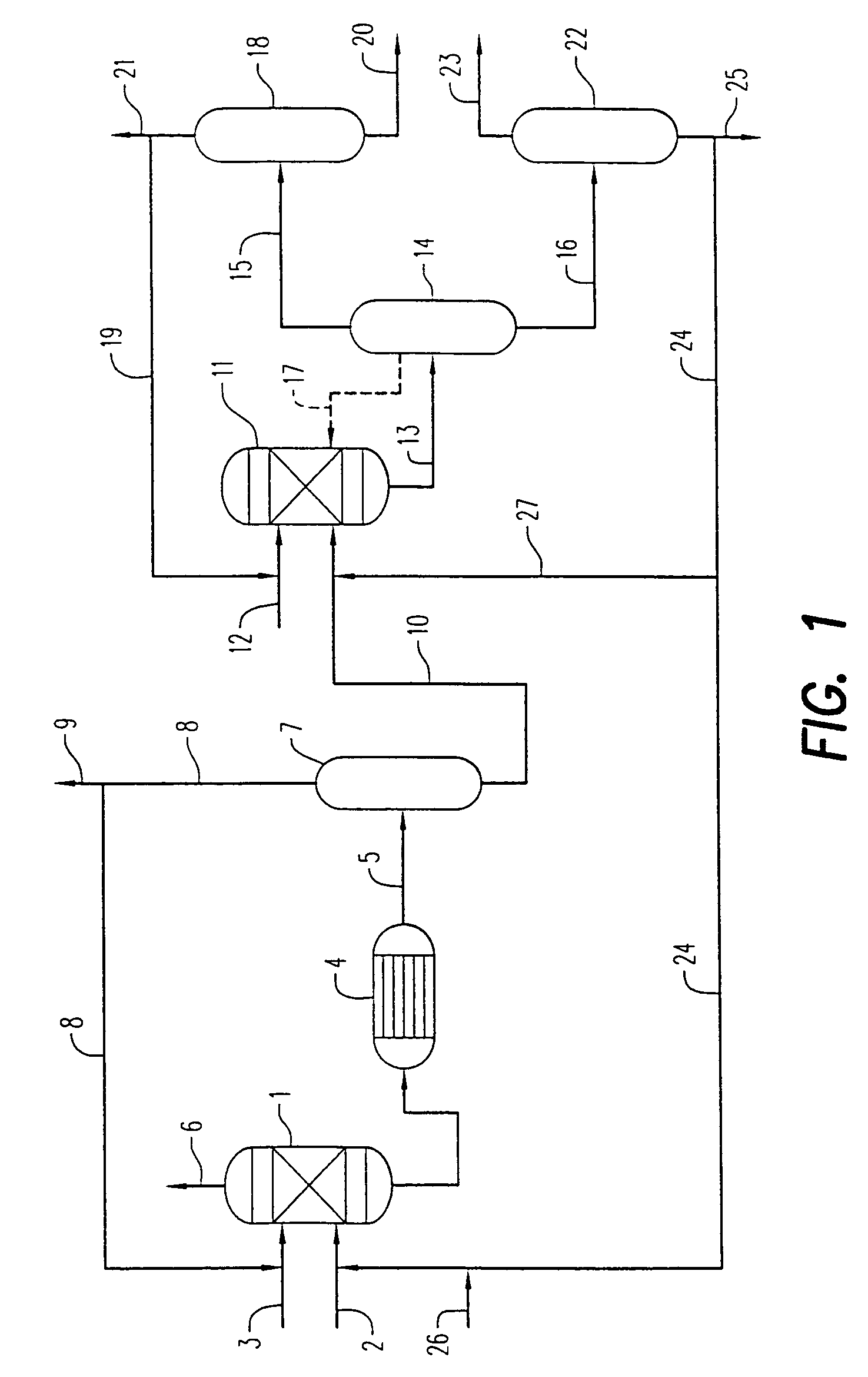

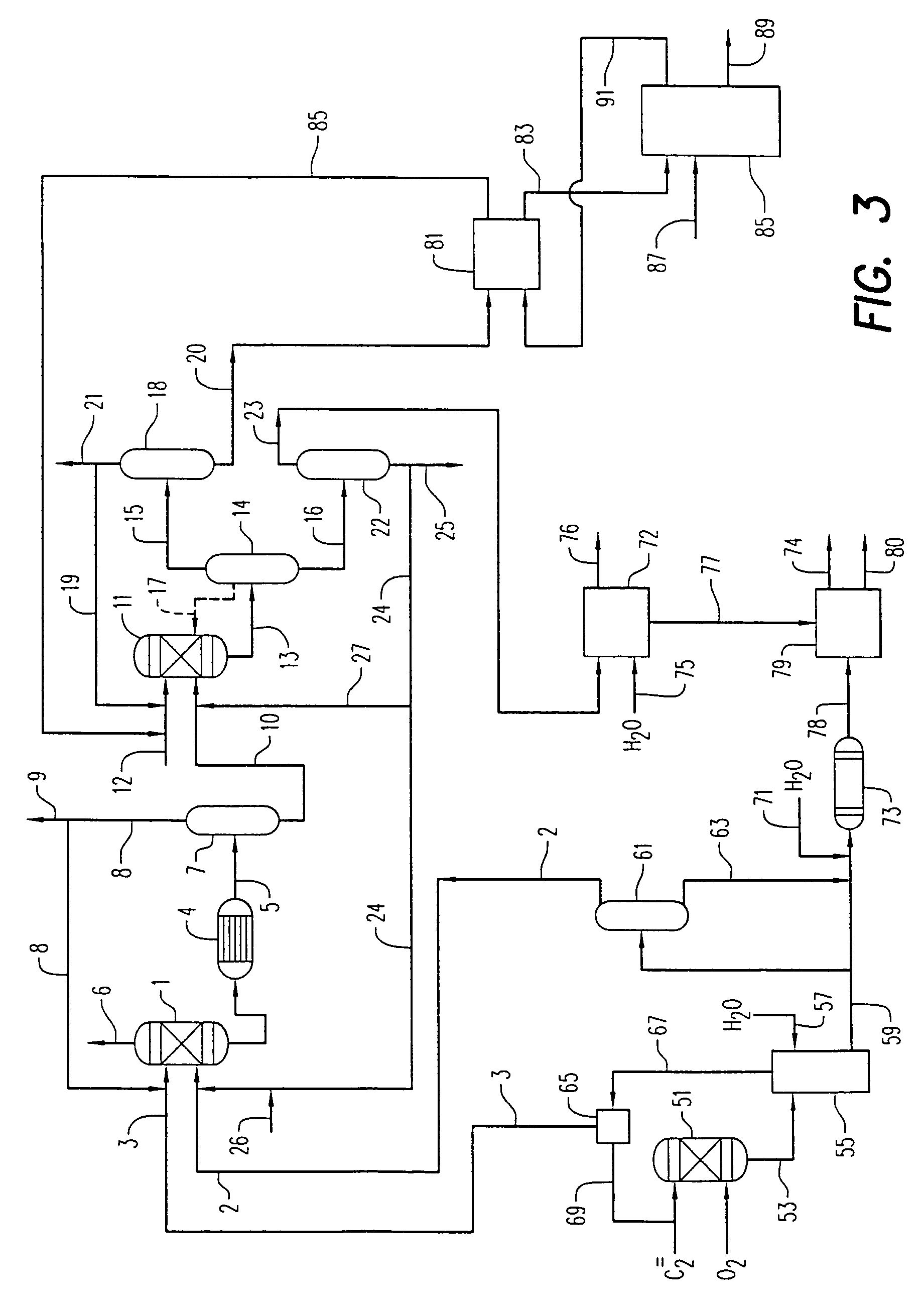

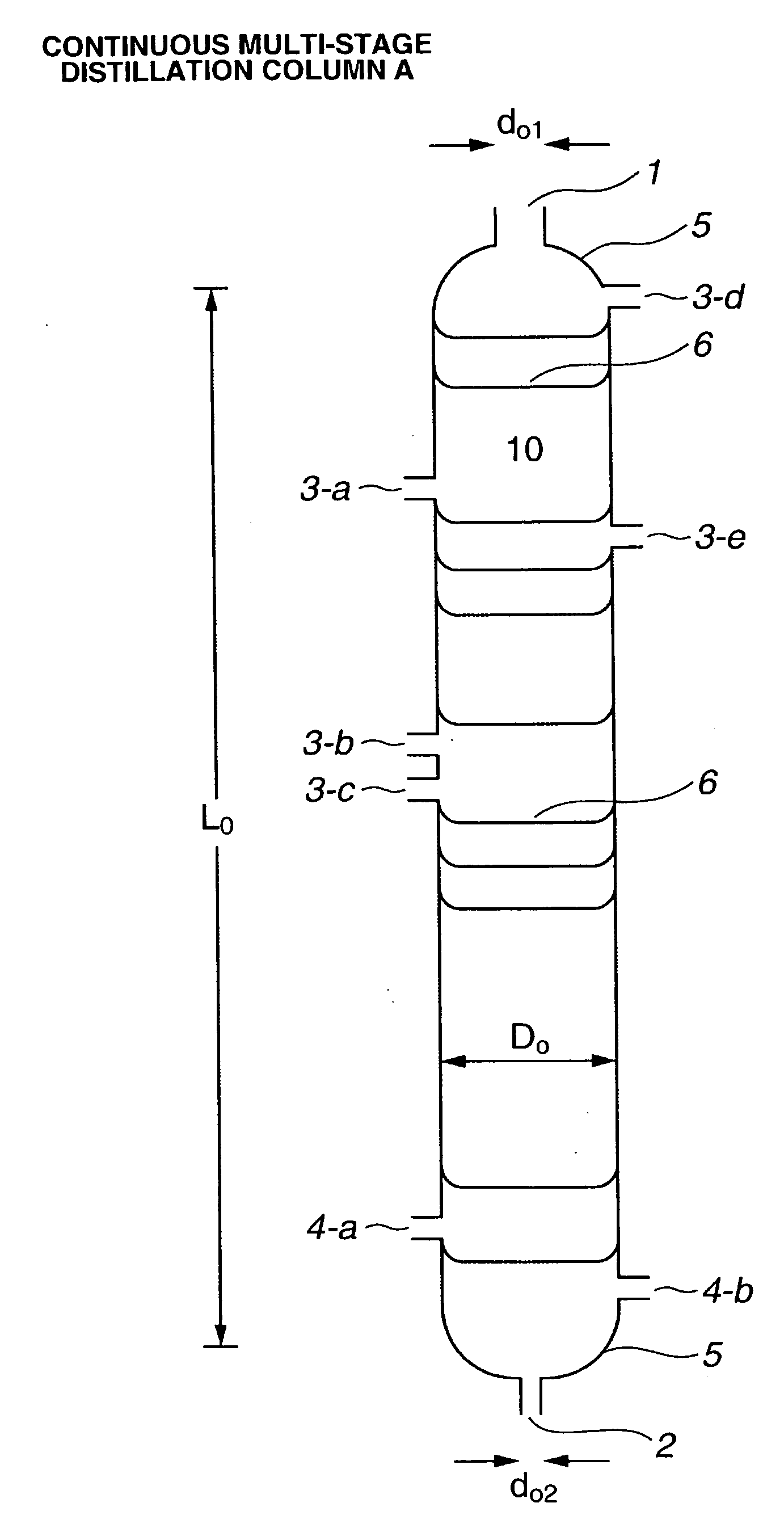

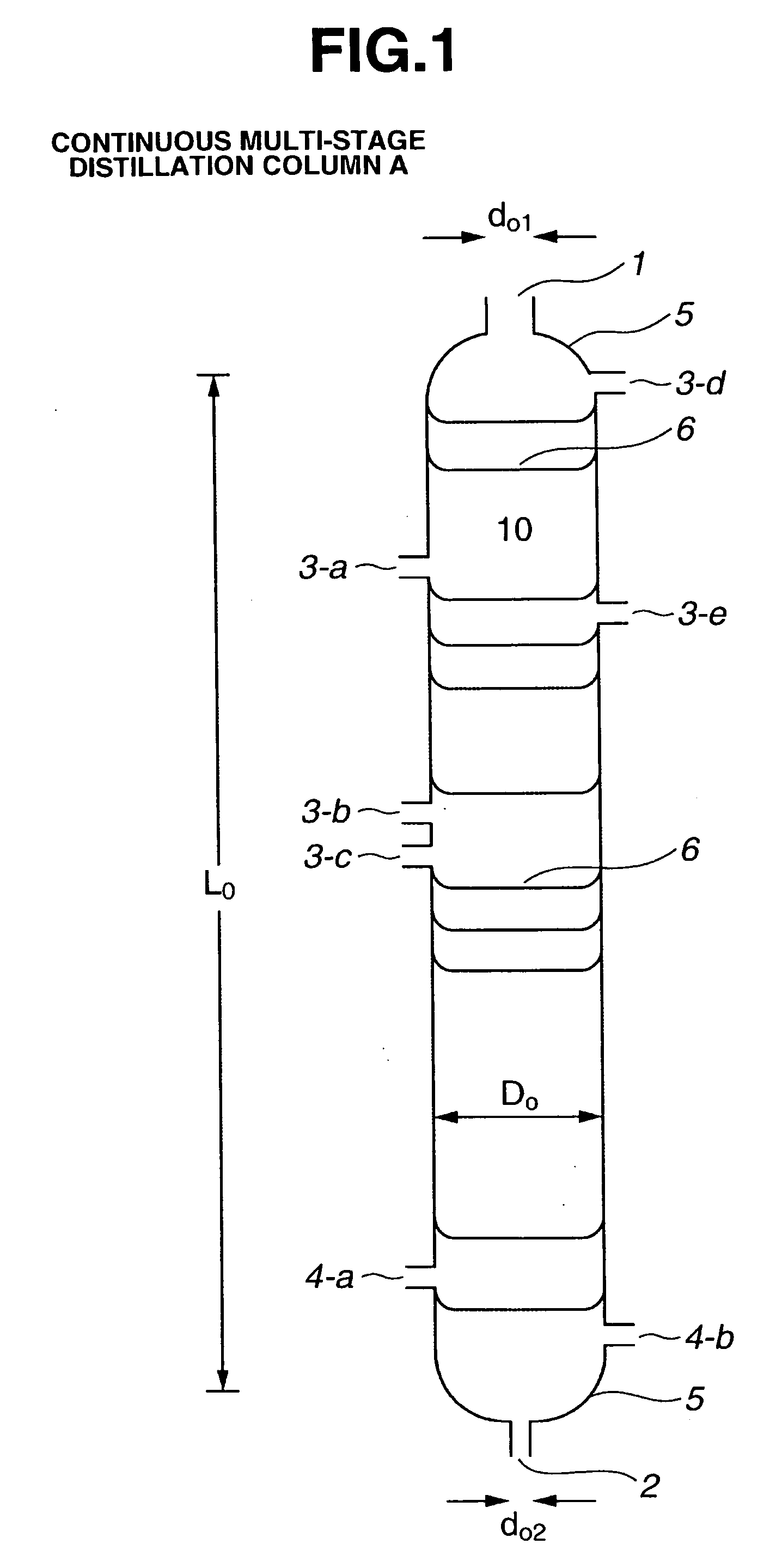

Industrial Process for Producing High-Purity Diol

InactiveUS20090270656A1High yieldHigh selectivityOxygen-containing compound preparationOrganic compounds purification/separation/stabilisationAlcoholDistillation

It is an object of the present invention to provide a specific apparatus and process for industrially producing a high-purity diol by taking a cyclic carbonate and an aliphatic monohydric alcohol as starting materials. Moreover, it is an object to thus provide a specific industrial apparatus and industrial production process that are inexpensive and, for example, enable the high-purity diol to be produced in an amount of not less than 1 ton / hr, preferably not less than 2 tons / hr, more preferably not less than 3 tons / hr, stably for a prolonged period of time (e.g. not less than 1000 hours, preferably not less than 3000 hours, more preferably not less than 5000 hours). According to the present invention, the above objects can be attained by using a continuous multi-stage distillation column A, a continuous multi-stage distillation column C, and a continuous multi-stage distillation column E, which have a specified structure, and withdrawing a liquid component from the side cut outlet, which is installed at the bottom of a chimney tray having a specified structure installed in an enrichment section of the continuous multi-stage distillation column E.

Owner:ASAHI KASEI CHEM CORP

Conversion of sugar, sugar alcohol, or glycerol to valuable chemicals using a promoted zirconium oxide supported catalyst

A process for converting a sugar, sugar alcohol, or glycerol to a valuable chemical is described. The process may use a support comprising zirconium oxide promoted by a polyacid or promoter material. A catalytically active metal may be impregnated on the polyacid-promoted zirconium oxide support and the catalyst may then be introduced the sugar, sugar alcohol, or glycerol a source of hydrogen under reaction conditions. At least 40 wt % of the sugar, sugar alcohol or glycerol may be converted to a polyol and / or a shorter carbon-chain alcohol that may include at least one of propylene glycol, ethylene glycol, glycerin, methanol, ethanol, propanol and butandiols. Specific processes for converting glycerin having a selectivity for propylene glycol and for converting sorbitol with a selectivity for propylene glycol, ethylene glycol, and / or glycerin are also described.

Owner:CLARIANT INT LTD

Method for synthesizing diethyl carbonate and coproducing diol by using carbon dioxide

ActiveCN104418701ARapid responseEasy to optimizeProductsOxygen-containing compound preparationEpoxyReaction temperature

The invention discloses a method for synthesizing diethyl carbonate and coproducing diol by using carbon dioxide, belonging to the field of synthesis of organic chemicals. An epoxy compound, the carbon dioxide and ethanol are used as raw materials and directly esterified in the presence of a catalyst to prepare the diethyl carbonate, and the diol is also coproduced; and the catalyst is characterized by consisting of an alkali metal halide and an alkali catalyst which are used as active ingredients, wherein the weight ratio of the epoxy compound to the catalyst is 100: (1-5), the reaction temperature is 80-230 DEG C, the reaction pressure is 0.5-15MPa, and the reaction time is 0.01-5h. The diethyl carbonate is synthesized by directly using the CO2, the epoxy compound and the ethanol, so the yield and selectivity of the target product are relatively high, the production cost of the diethyl carbonate can be reduced, and the diethyl carbonate has good industrial application value.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

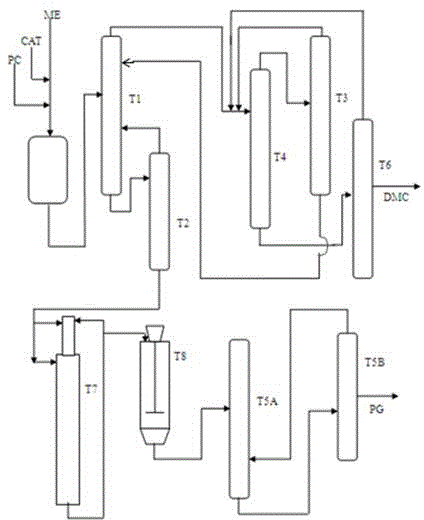

Method for continuously producing dimethyl carbonate and co-producing 1, 2-propylene glycol by virtue of transesterification method

InactiveCN104557554AEmission reductionReduce labor intensityOrganic compound preparationPreparation from organic carbonatesMetal catalystTransesterification

The invention relates to a method for continuously producing dimethyl carbonate and co-producing 1, 2-propylene glycol by virtue of a transesterification method. The method comprises the following steps: (1) reacting and rectifying; (2) recovering dimethyl carbonate; (3) recovering methanol; (4) separating methanol and 1, 2-propylene glycol; (5) carbonizing; (6) filtering; (7) separating 1, 2-propylene glycol; and (8) refining 1, 2-propylene glycol. The method provided by the invention is used for solving the problem in the prior art that 1, 2-propylene glycol is low in yield and low in purity and cannot be continuously produced as a methanol alkaline metal catalyst is hard to be separated from 1, 2-propylene glycol. The purity of 1, 2-propylene glycol produced by the invention reaches 99.99%, so that the pharmaceutical grade production requirement is realized. The method is safe in operating process, energy-saving and high in yield, the discharge of kettle bottom slurry is reduced by 50% or over, and continuous production is realized.

Owner:SHANDONG SHIDA SHENGHUA CHEM GROUP +1

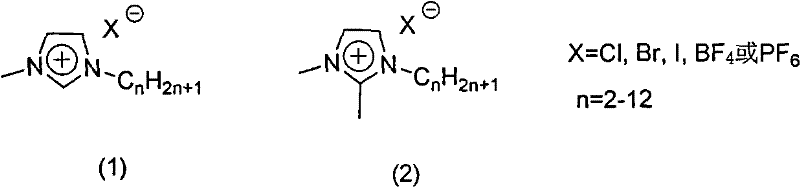

Synthetic method of ionic liquid catalyzed propylene carbonate to synthesize dimethyl carbonate

InactiveCN103980124BSimple processReduce dosageOrganic compound preparationChemical industryMethyl carbonatePropylene carbonate

The invention relates to a synthetic method of diphenyl carbonate from propylene carbonate by catalysis of an ionic liquid. The method comprises steps of reaction rectification, separation and purification of dimethyl carbonate, and separation and purification of propylene glycol. Methanol, propylene carbonate and an ionic liquid catalyst react in a reactive rectifying tower, and the reaction products are separated; dimethyl carbonate and methanol azeotrope is distilled from the tower top, and, a mixture of propylene glycol, methanol, the catalyst and a small amount of dimethyl carbonate is obtained in the tower kettle; separation of the methanol and methyl carbonate azeotrope from the tower top is achieved by a dimethyl carbonate pressurized rectification tower, a dimethyl carbonate atmospheric rectification and a dimethyl carbonate product tower; separation and purification of propylene glycol in the tower kettle is achieved by a lightness-removing tower, a propylene glycol product tower and a methanol recovery tower; and the separated catalyst returns to the reaction rectifying system for reuse. The usage of the ionic liquid catalyst simplifies the process for dimethyl carbonate synthesis from propylene carbonate and methanol and combined production of propylene glycol, and the method has the advantages of low energy consumption, catalyst reuse and good combined production effect.

Owner:TIANJIN UNIV

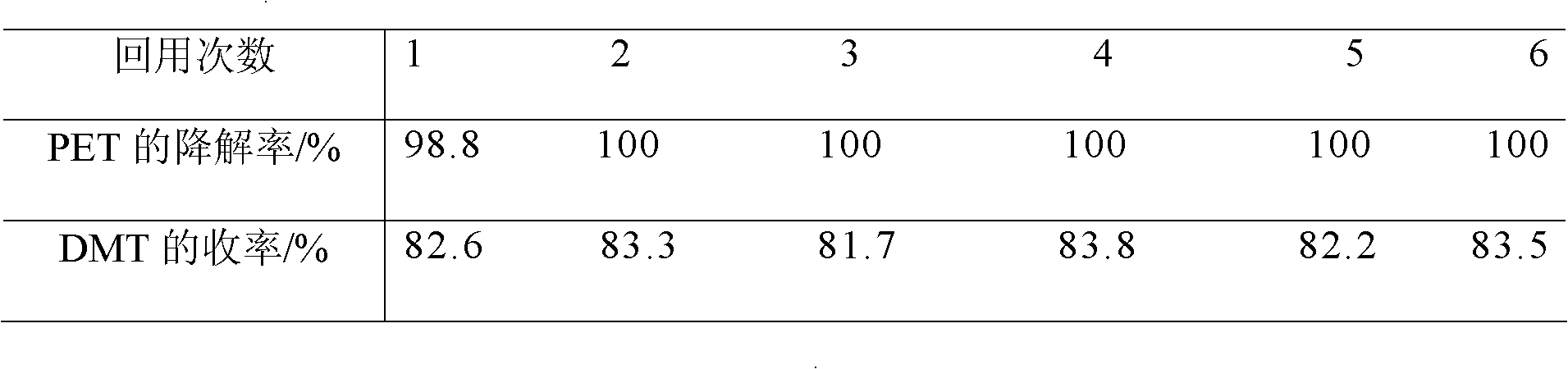

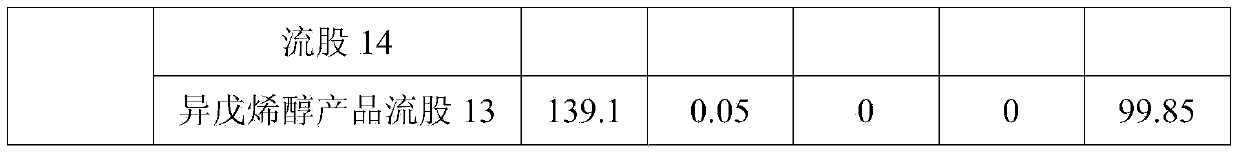

Method for degrading polyethylene terephthalate

InactiveCN102153443AOvercome concentrationOvercome strong baseOxygen-containing compound preparationOrganic compound preparationHigh concentrationDimethyl terephthalate

The invention discloses a method for degrading polyethylene terephthalate. The method comprises the following steps: carrying out alcoholysis reaction on the polyethylene terephthalate in the presence of a catalyst by utilizing a brominated 1-butyl-3-ehtyl imidazole ionic liquid and methanol as solvents; and filtering and separating so as to obtain glycol and dimethyl terephthalate, and simultaneously recovering the brominated 1-butyl-3-ehtyl imidazole ionic liquid. By using the method, the characteristic that used high-concentration inorganic strong acid or strong alkaline can not be recycled is overcome, reaction conditions are mild, and the high requirement on equipment is improved.

Owner:HEFEI UNIV OF TECH

Methyl ethyl ketone preparation method

InactiveCN102992984AImprove conversion rateHigh selectivityOrganic compound preparationCarbonyl compound preparationDehydrogenationSec-Butyl acetate

The invention relates to a methyl ethyl ketone preparation method. The method comprises the following steps: 1, carrying out an ester exchange reaction of sec-butyl acetate and low carbon alcohol in a catalytic rectifying tower in the presence of an ester exchange catalyst, wherein the low carbon alcohol is C1-C3 alcohol; and 2, carrying out a dehydrogenation reaction of the tower bottoms obtained in step 1 or sec-butyl alcohol separated from the tower bottoms obtained in the step 1 in the presence of a dehydrogenation catalyst. The method which allows sec-butyl alcohol to be prepared through using the sec-butyl acetate and the low carbon alcohol has the advantages of high raw material conversion rate and high sec-butyl alcohol selectivity.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

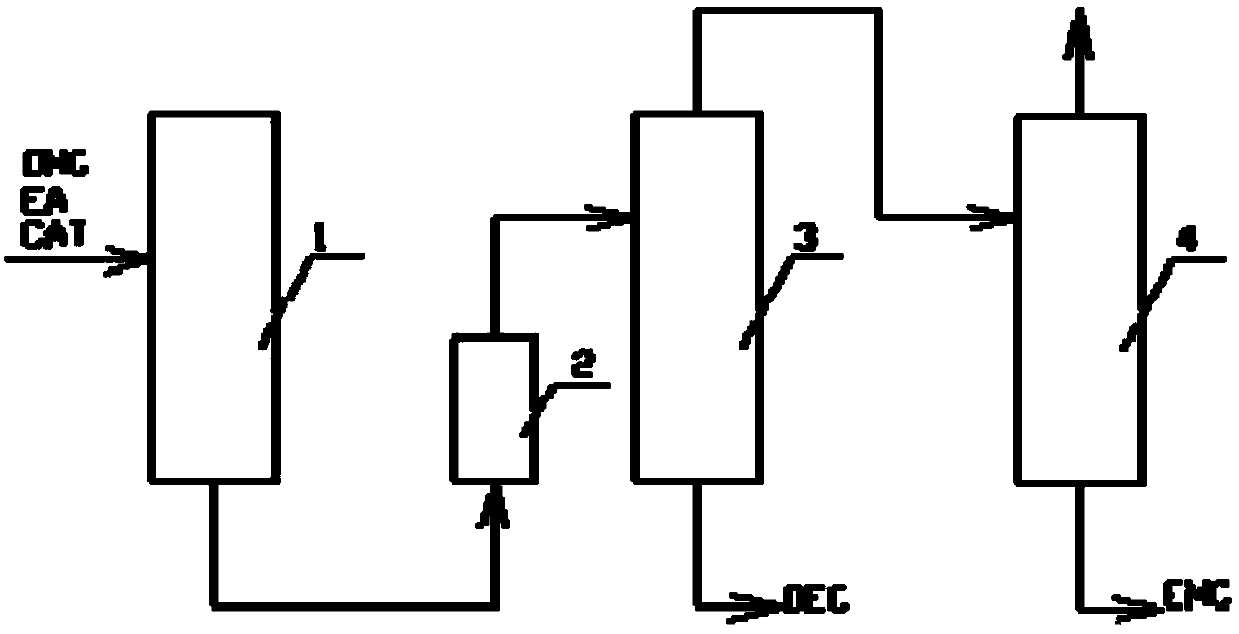

Preparation method of diethyl carbonate and methylethyl carbonate

ActiveCN103804124AReduce energy consumptionOxygen-containing compound preparationOrganic compound preparationAnhydrous ethanolReflux

The invention relates to the field of production of chemical products, and particularly relates to a preparation method of diethyl carbonate and methylethyl carbonate. The preparation method comprises the following steps: continuously adding the raw materials including dimethyl carbonate, absolute ethyl alcohol and a catalyst into a first rectifying tower for reactive rectification, wherein the temperature of a tower kettle is controlled to be 80-100 DEG C; adding a substance discharged from the tower kettle of the first rectifying tower into a second rectifying tower for reactive rectification to obtain a diethyl carbonate product, wherein the temperature of the tower kettle is controlled to be 115-130 DEG C; adding the substance discharged from the top of the second rectifying tower into a third rectifying tower for reactive rectification to obtain a methylethyl carbonate (EMC) product, wherein the temperature of the tower kettle is controlled to be 100-115 DEG C. The preparation method provided by the invention is used for preparing diethyl carbonate and methylethyl carbonate by adopting a continuous reactive rectification process, and the parameters such as the operation ratio, the reflux ratio and the like of the rectifying tower need not to be changed after being determined during the whole operation process as long as the feeding process is well controlled, therefore, the energy consumption is relatively low.

Owner:东营石大胜华新材料有限公司 +1

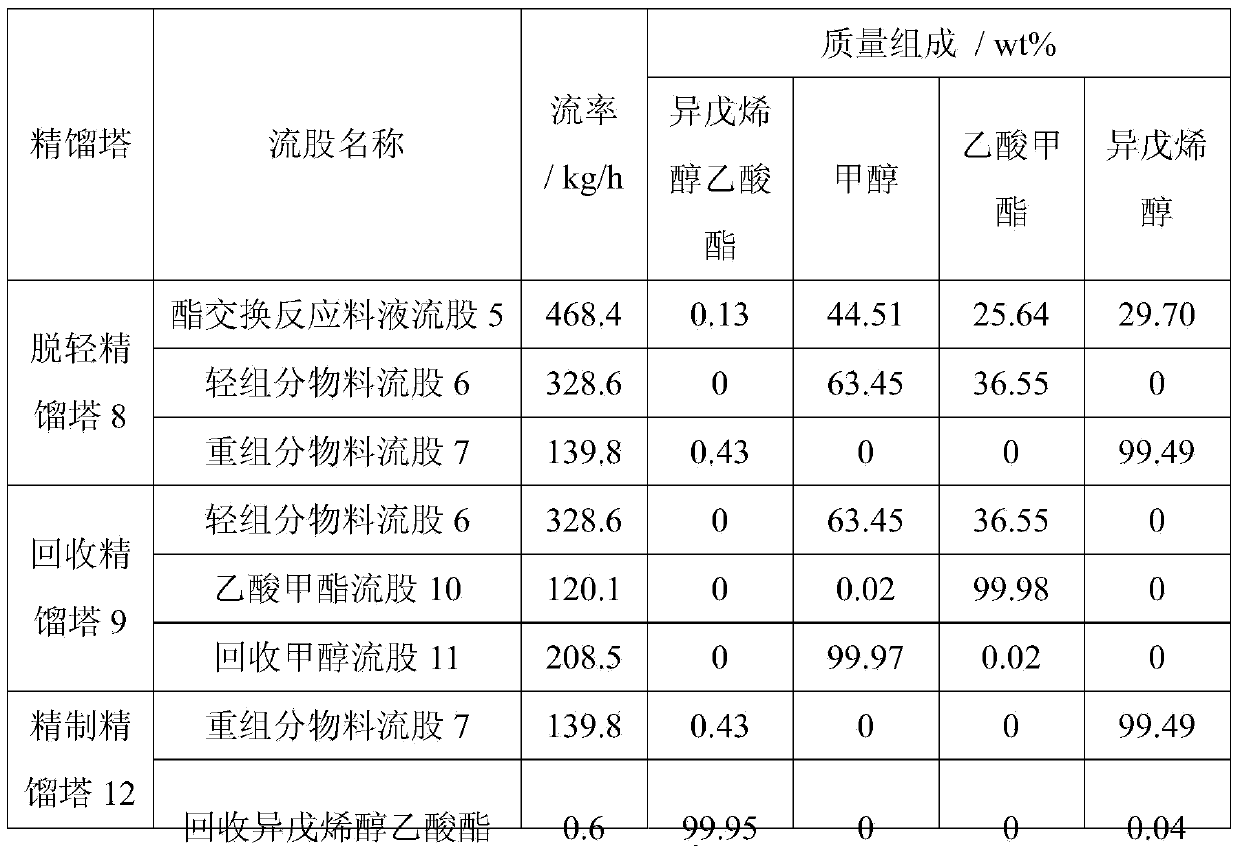

Method and system for preparing 3-methyl-2-buten-1-ol through ester exchange

ActiveCN103992206AEasy to separate and recycleEasy to recycleOxygen-containing compound preparationPreparation by ester-hydroxy reaction3-methyl-2-buten-1-olSolvent free

The invention relates to a method and a system for preparing 3-methyl-2-buten-1-ol through ester exchange. According to the method, solvent-free heterogeneous catalysis ester exchange reaction is carried out on 3-methyl-2-buten-1-ol acetic acid ester and methyl alcohol used as raw materials under the catalytic action of solid alkali or strongly alkaline anion exchange resin so as to obtain 3-methyl-2-buten-1-ol and methyl acetate, and after purification, the unreacted methyl alcohol and the unreacted 3-methyl-2-buten-1-ol acetic acid ester can be recycled. The method has the characteristics that the catalyst is easy to separate, recycle and reuse, no three wastes (waste gas, industrial wastewater and industrial residue) are generated, the yield of the 3-methyl-2-buten-1-ol product is high, and the like.

Owner:NANJING UNIV OF TECH

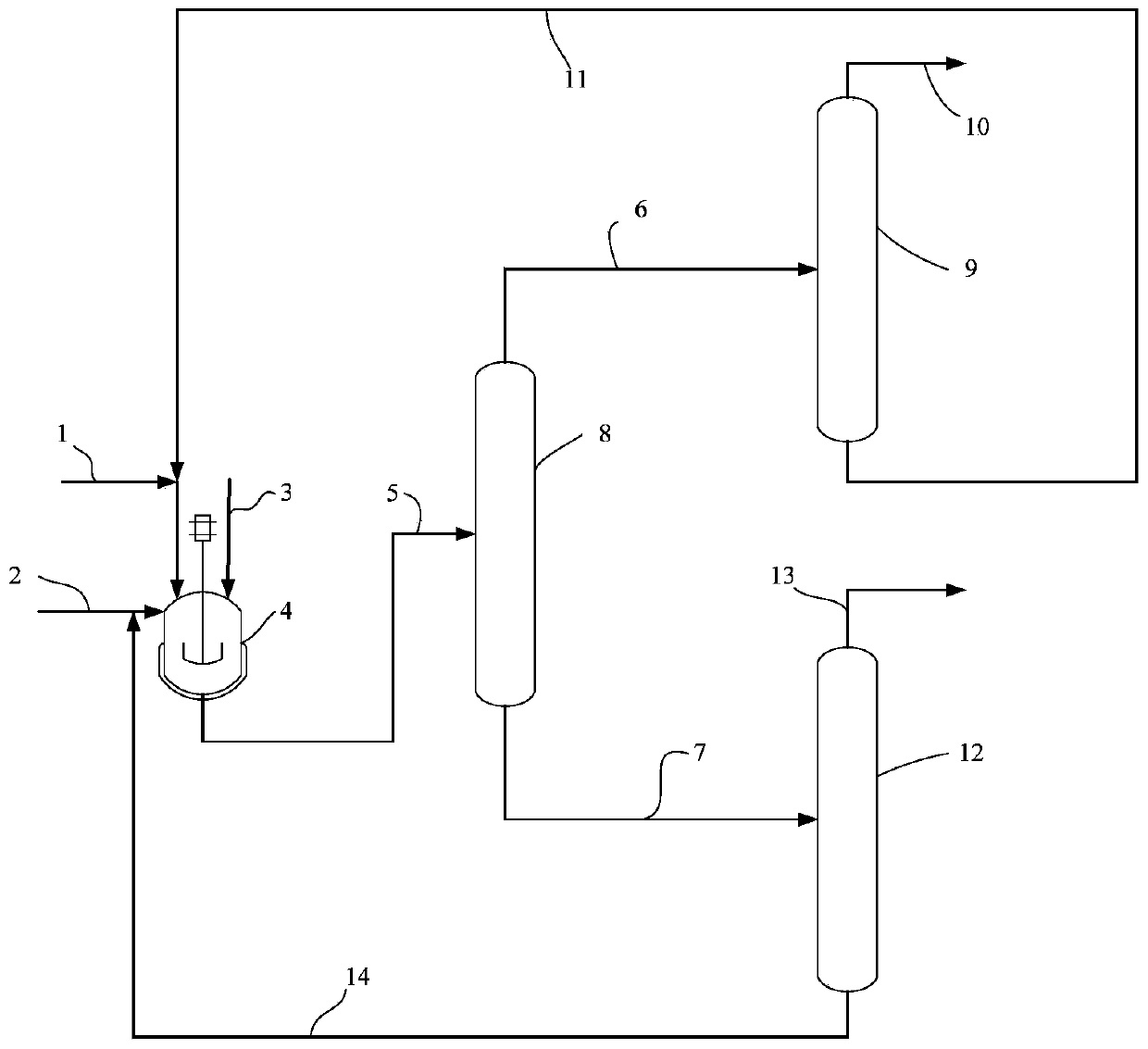

Method for controlled degradation and recovery of polyethylene terephthalate material

InactiveCN107417492AGood choiceMild reaction conditionsOxygen-containing compound preparationOrganic compound preparationLiquid productPolyethylene terephthalate glycol

The invention provides a method for controlled degradation and recovery of a polyethylene terephthalate material. The method comprises the following steps: preparing a degradation solution composed of a metal salt and a solvent; dipping the polyethylene terephthalate material in the degradation solution according to a mass ratio of the polyethylene terephthalate material to the degradation solution of 1: 1-100, and sealing the polyethylene terephthalate material to the degradation solution in a reaction vessel; carrying out a degradation reaction at a temperature of 100-260 DEG C for 10 min to 48 h; after completion of the degradation reaction, carrying out cooling to room temperature, and then adding a diluent, wherein a mass ratio of the addition amount of the diluent and a degradation product mixture is 1-5: 1; and carrying out filtering and separating so as to obtain a solid product terephthalic acid or its derivative, and subjecting the liquid product to vacuum distillation so as to obtain ethylene glycol or its derivative. The method provided by the invention has the advantages of mild degradation reaction conditions, low cost and easy separation of degradation products.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Technology for continuous co-production of ethylene carbonate, ethylene glycol and dimethyl carbonate from by-product CO2

InactiveCN103360361ASave raw materialsReduce labor costsPreparation from organic carbonatesBulk chemical productionMethyl carbonateEthylene oxide

The invention discloses a technology for continuous co-production of ethylene carbonate, ethylene glycol and dimethyl carbonate from ethylene oxide and CO2. The technology includes: adding a catalyst into a fixed bed tubular reactor and conducting heating, passing the ethylene oxide and CO2 through a first fixed bed tubular reactor continuously to generate ethylene carbonate, vaporizing the ethylene carbonate and methanol, then passing them through a second fixed bed tubular reactor continuously, thus generating ethylene glycol and dimethyl carbonate. The technology has the characteristics of raw material saving, labor cost saving, continuous production, high production efficiency, and change of the by-product CO2 into things of value, and environmental protection.

Owner:山东日新复合材料有限公司

Method for producing cyclohexanol

ActiveCN106349010AIncrease reaction rateImprove conversion rateOxygen-containing compound preparationLactams preparationAlcoholReaction rate

The invention provides a method for preparing cyclohexanol from cyclohexyl carboxylate serving as raw material by performing an ester exchange reaction under a near critical or supercritical condition. According to the method, a catalyst is not used, reaction products do not need to be separated in the reaction process, and low alcohol-to-ester ratio can be adopted; furthermore, the method has the characteristics of high reaction rate, high conversion rate, high selectivity and simple aftertreatment.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for preparing alkanediols and alkanetriols having a vicinal diol group

InactiveUS7385092B2Short reaction timeIncreased space-time yieldCosmetic preparationsOxygen-containing compound preparationFormateDistillation

A process for preparing diols or triols made up ofa1) reacting at least one monoolefin having 4 to 20 carbon atoms with hydrogen peroxide and formic acid in the presence of water to form a mixture ora2) reacting at least one monoolefin alcohol having 4 to 20 carbon atoms first with formic acid, and then reacting the product formed thereby with hydrogen peroxide in the presence of water to form a mixture,b) removing, by distillation, the water and formic acid from the mixture obtained in a1) or a2),c) reacting the mixture obtained from b) with an aliphatic alcohol in the presence of a sulfonic acid to form the diol or triol and at least one formic ester by-product, andd) optionally removing, by distillation, the at least one formic ester by-product formed together with any residual at least one aliphatic C1-C4-alcohol to isolate the diol or triol.

Owner:EVONIK DEGUSSA GMBH

Popular searches

Distillation separation Synthetic resin layered products Carboxylic acid esters separation/purification Monocomponent polyesters artificial filament Preparation by hydrolysis Metal/metal-oxides/metal-hydroxide catalysts Organic-compounds/hydrides/coordination-complexes catalysts Liquid-gas reaction processes Fractional distillation Carbonic/haloformic acid esters preparation

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com