Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

446results about "Carbonic/haloformic acid esters preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for making dialkyl carbonates

ActiveUS7074951B2Quick responseReduce separation costsOrganic compound preparationCarboxylic acid esters preparationCarbamateAlcohol

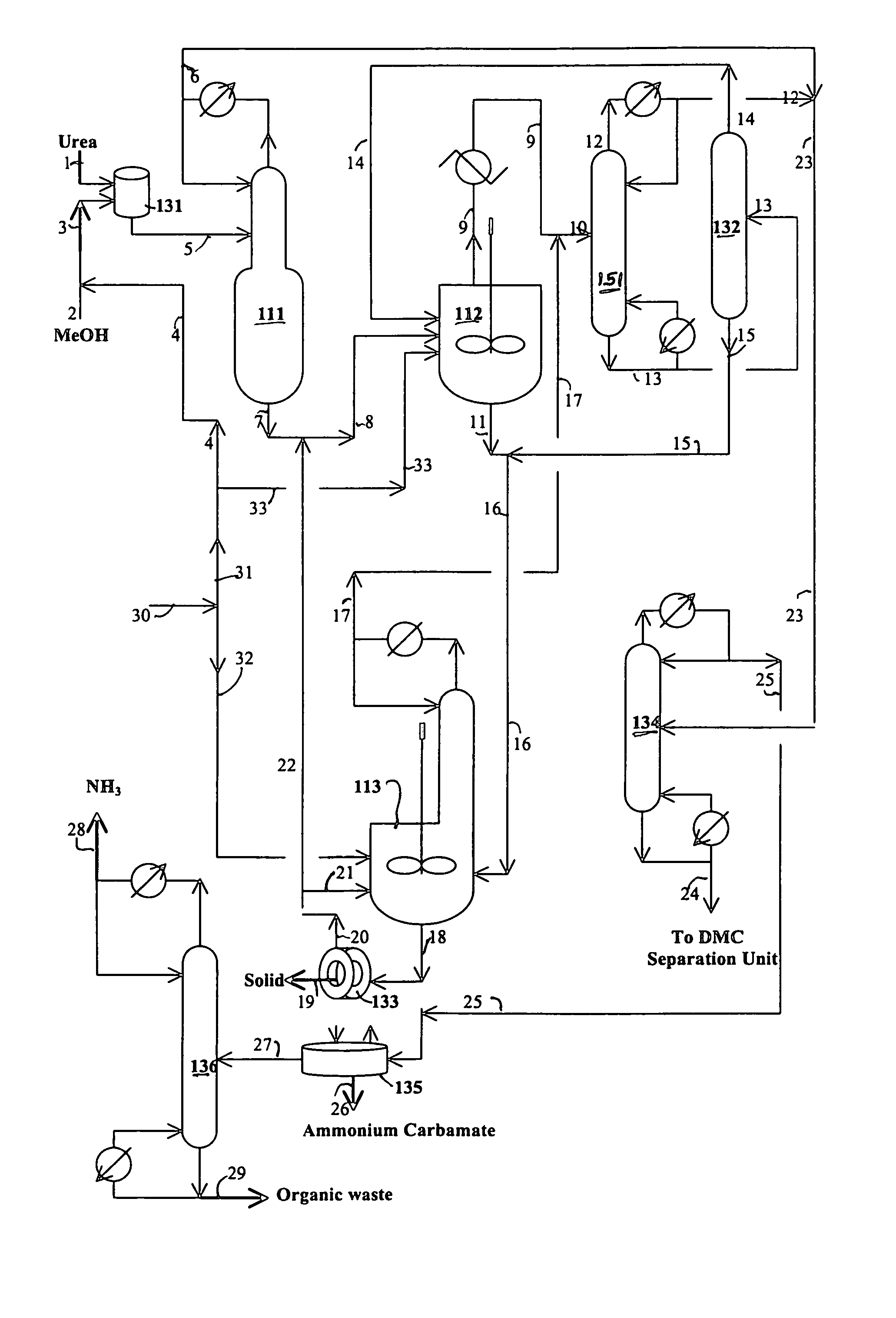

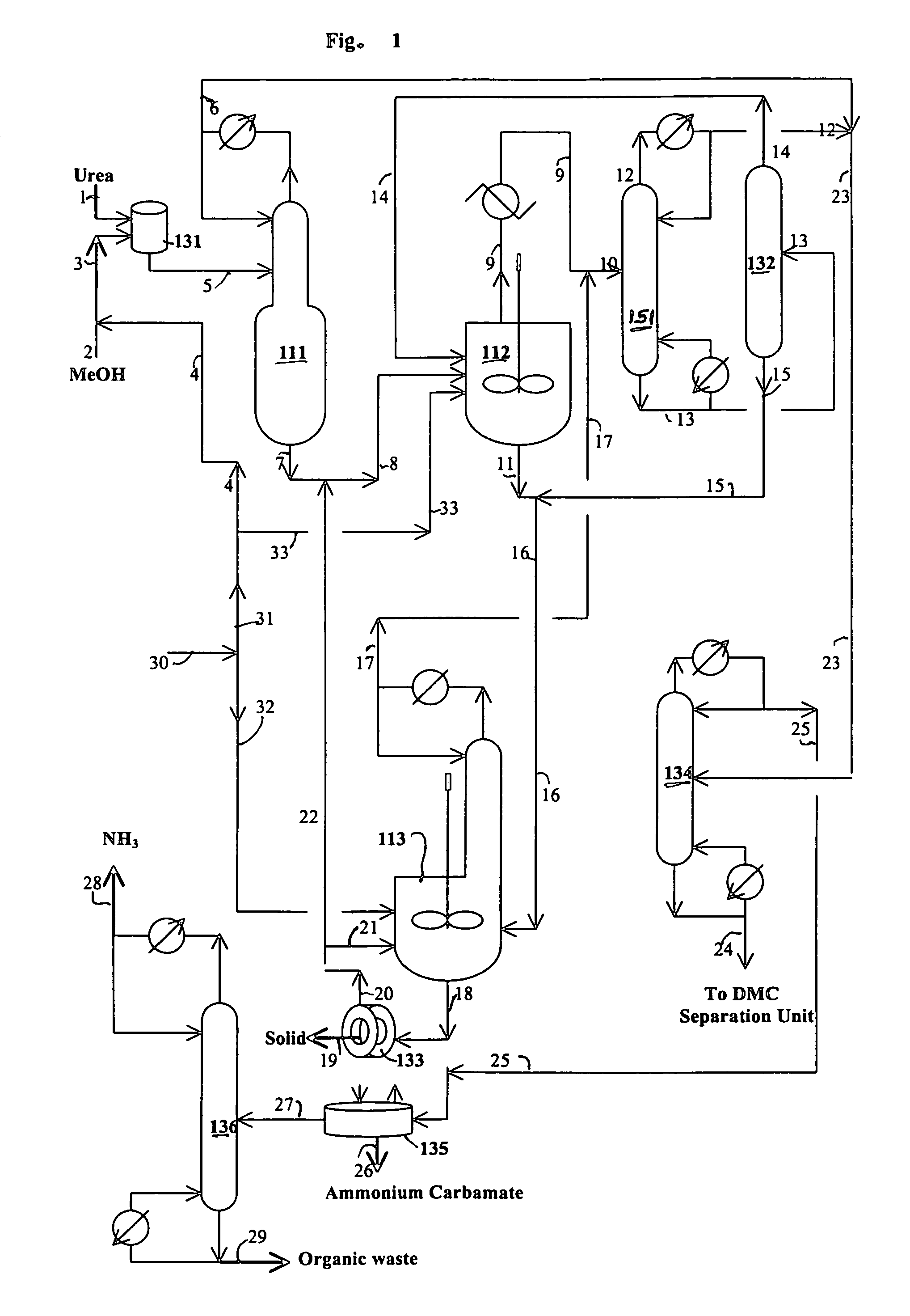

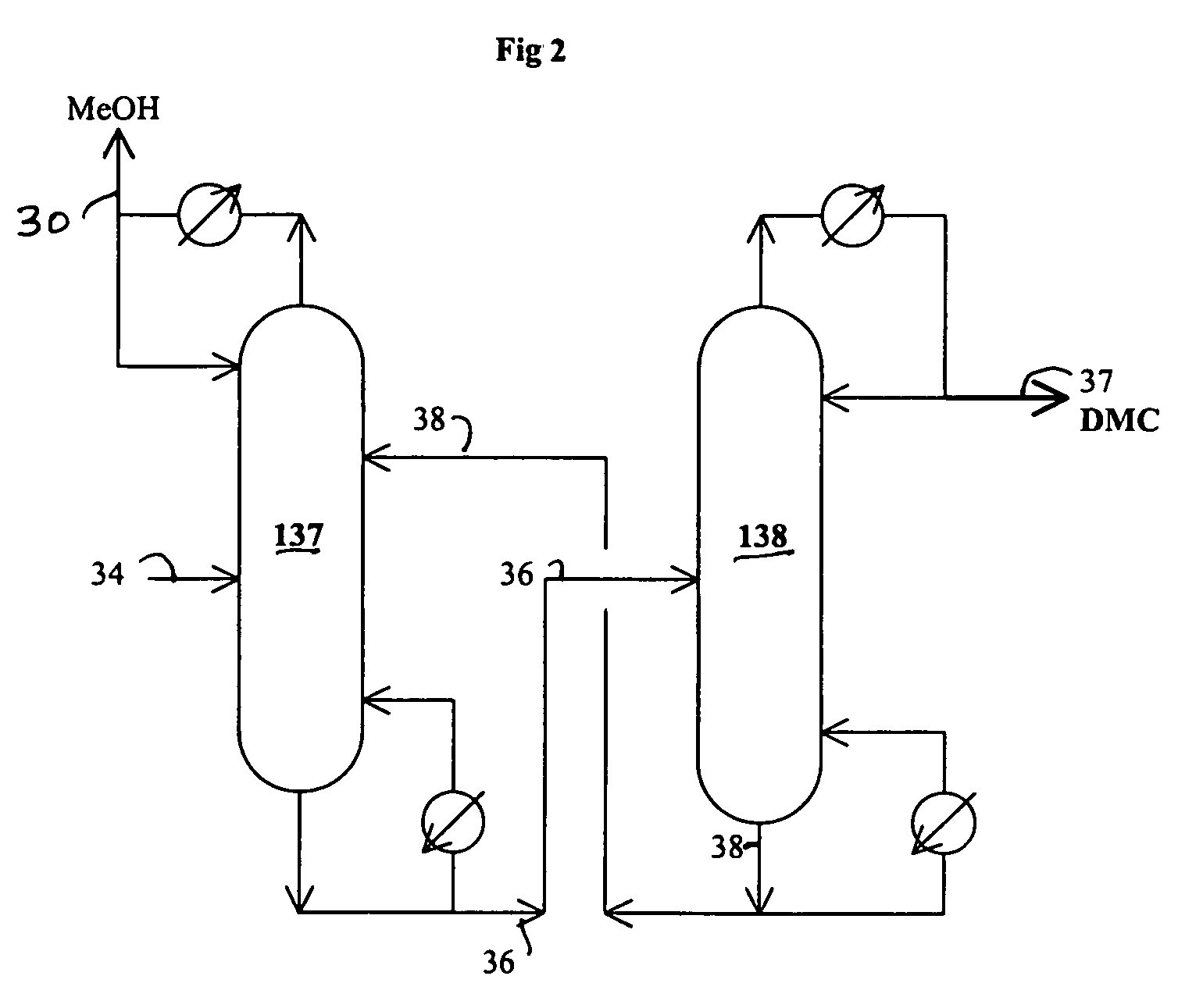

A process for the production of dialkyl carbonates from the reaction of alcohol, for example C1–C3 alcohols, with urea is disclosed wherein the water and ammonium carbamates impurities in the feed are removed in a prereactor. The water is reacted with urea in the feed to produce ammonium carbamate which is decomposed along with the ammonium carbamates originally in the feed to ammonia and carbon dioxide. In addition some of the urea is reacted with the alcohol in the first reactor to produce alkyl carbamate which is a precursor to dialkyl carbonate. Dialkyl carbonates are produced in the second reaction zone. The undesired by-product N-alkyl alkyl carbamates are continuously distilled off from the second reaction zone along with ammonia, alcohol and dialkyl carbonates under the steady state reactor operation. N-alkyl alkyl carbamates can be converted to heterocyclic compounds in a third reaction zone to remove as solids from the system.

Owner:CHEM RES & LICENSING CO

Synthesis process of propylene carbonate or vinyl carbonate

InactiveCN1421431AImprove economyGood performance repeatabilityOrganic compound preparationCarbonic/haloformic acid esters preparationReaction temperatureNitrogen

The synthesis process of propylene carbonate or vinyl carbonate includes adding urea, propylene glycol or ethylene glycol in the molar amount of 1-100 times that of urea and solid alkali in the molaramount of 0.001-10 times that of urea into the reactor and reaction at the temperature of 100-200 deg.c and vacuum degree 50-600 mmHg or nitrogen blowing in the flow rate of 1-1000 ml / ml cat. min for0.5-20 hr. The present invention has the advantages of repeatable catalyst performance, material converting rate near the theoretical number, high product selectivity, less side product, etc.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

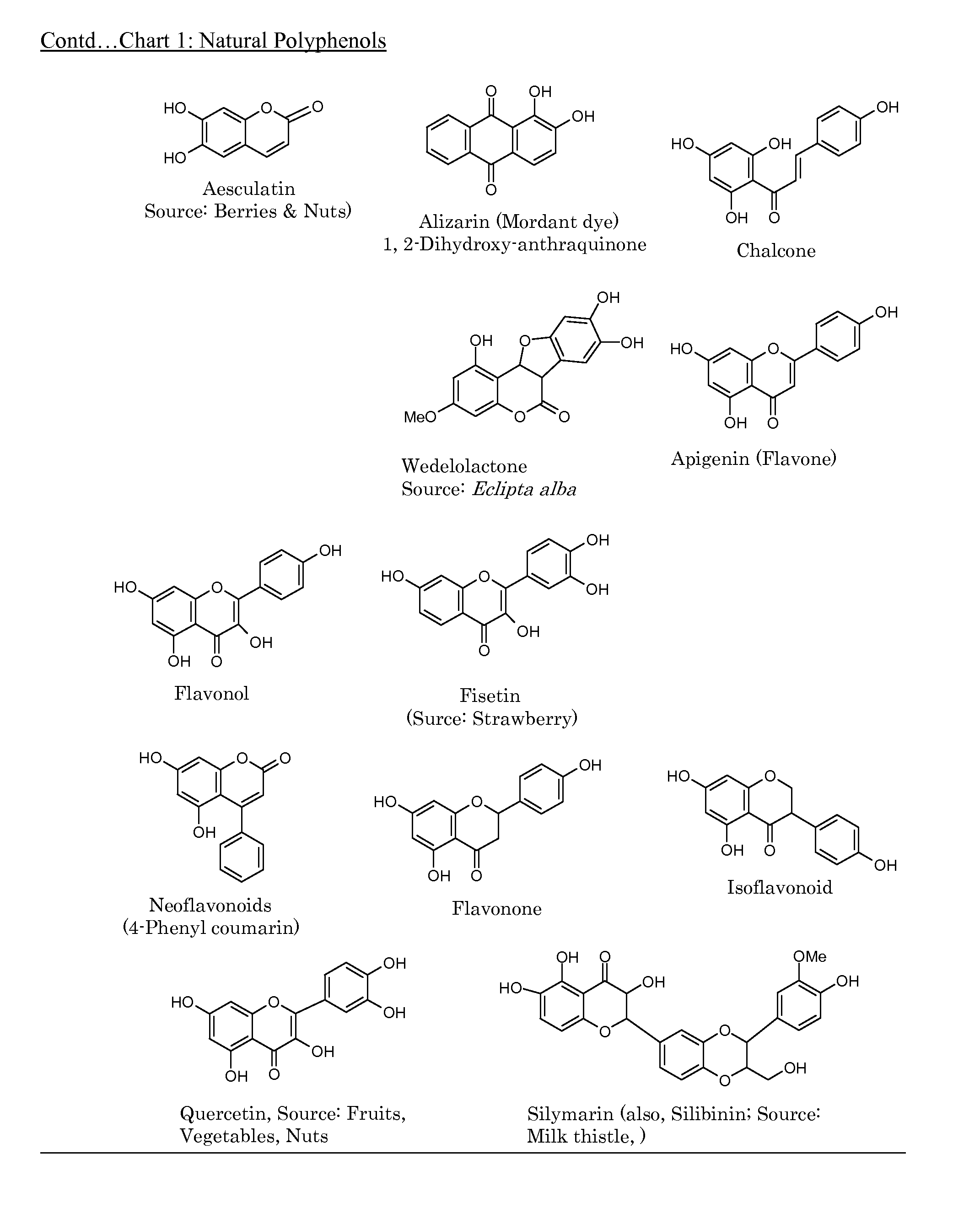

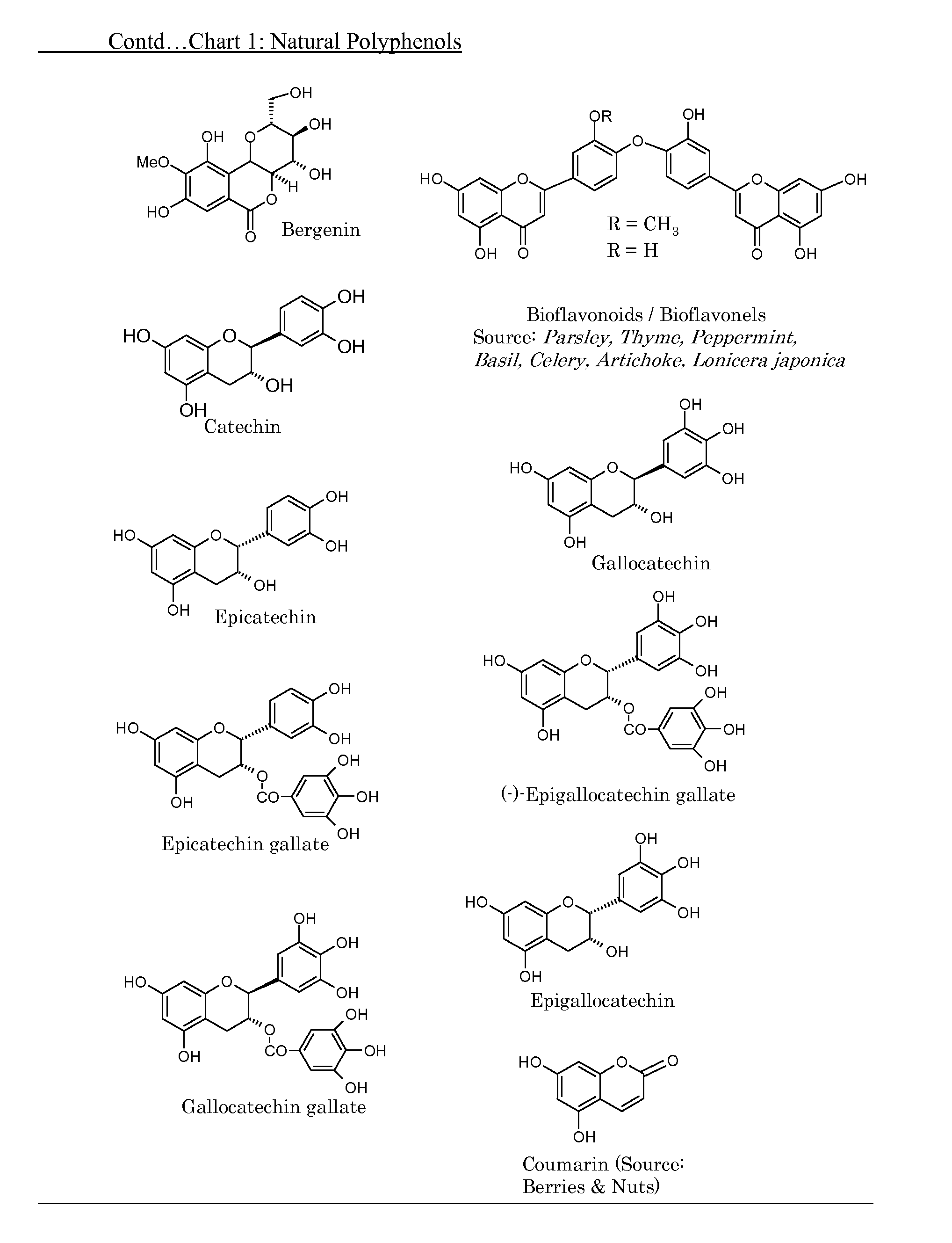

Biocompatible and biodegradable polymers from renewable natural polyphenols

ActiveUS20120184682A1Organic compound preparationCarbonyl compound preparationPolycarbonatePolyphenol

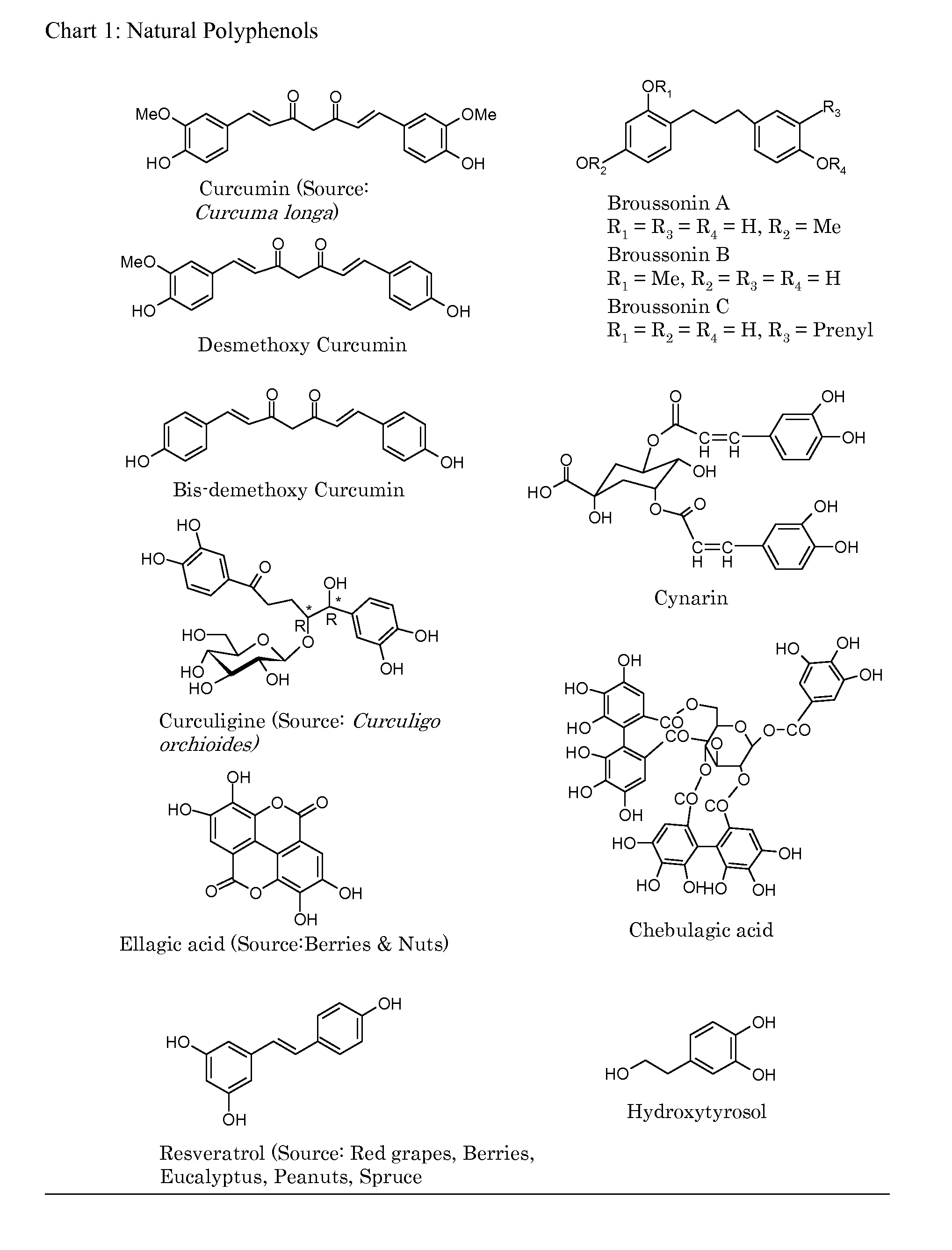

This invention describes the use of resveratrol and curcumin, representatives of naturally occurring polyphenols, in their native form, after hydrogenation, and as their respective allyl derivatives, individually, in combination with themselves and other commercial monomers, to make representative varieties of polymers, e.g., polycarbonates (PC), polyurethanes (PU), co-polymers and biodegradable polymers.

Owner:INNOVOTECH

Metal oxide catalyst for synthesizing methyl carbonate by urea process and its prepn

InactiveCN1416949ASolve key problems such as difficult separation and recyclingHigh yieldOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsMethyl carbonateCoprecipitation

The metal oxide catalyst for urea alcoholysis process of synthesizing methyl carbonate consists of 1-3 kinds oxides of Li, Mg, Ni, Zn, Pb, Al, Fe, Mo, Zr and La, and has ZnO as main component accounting for 35-95 wt%. When it consists of three kinds of metal oxide, the other two except ZnO have the same weight percentage. It is prepared through thermal decomposition process, precipitation process, or coprecipitation process. The catalyst is easy to prepare, separate, recover and regenerate, and has high catalytic activity for urea alcoholysis process of synthesizing methyl carbonate, yield up to 49.7%, no corrosion of equipment and no environmental pollution.

Owner:HEBEI UNIV OF TECH

Method for synthesizing dimethyl carbonate by using urea and methanol and adopting heterogeneous catalyst

InactiveCN1428329ALow costReact SafeOrganic compound preparationCarbonic/haloformic acid esters preparationAlkaline earth metalMethyl carbonate

The method for synthesizing dimethyl carbonate by using urea and methanol and adopting heterogeneous catalyst includes the following steps: under the condition of 600-1300 deg.c 10X10 to the power 5-1X10 to the power 5 pa and air or oxygen gas atmosphere calcining carbonate or hydroxide of alkali metal and alkaline earth metal for 1-10 hr. to obtain catalyst, adding urea and methanol into high-pressure reaction still, and adding catalyst, heating to 120-180 deg.c under the condition of magnetic stirring, low-temp. resistion time is 2 hr-10 hr. more heating to 180-240 deg.C, high-temp. reaction time 2 hr-20 hr, cooling to room temp. and making separation so as to obtain the invented roduct.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

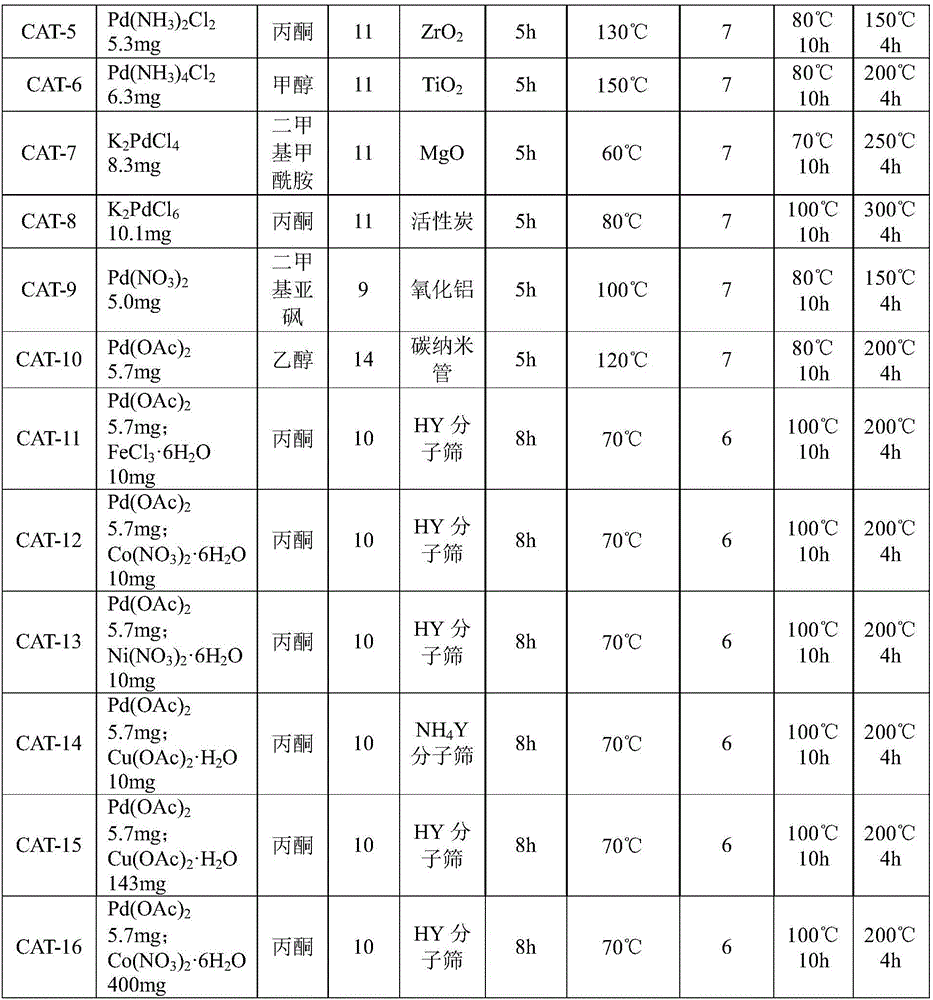

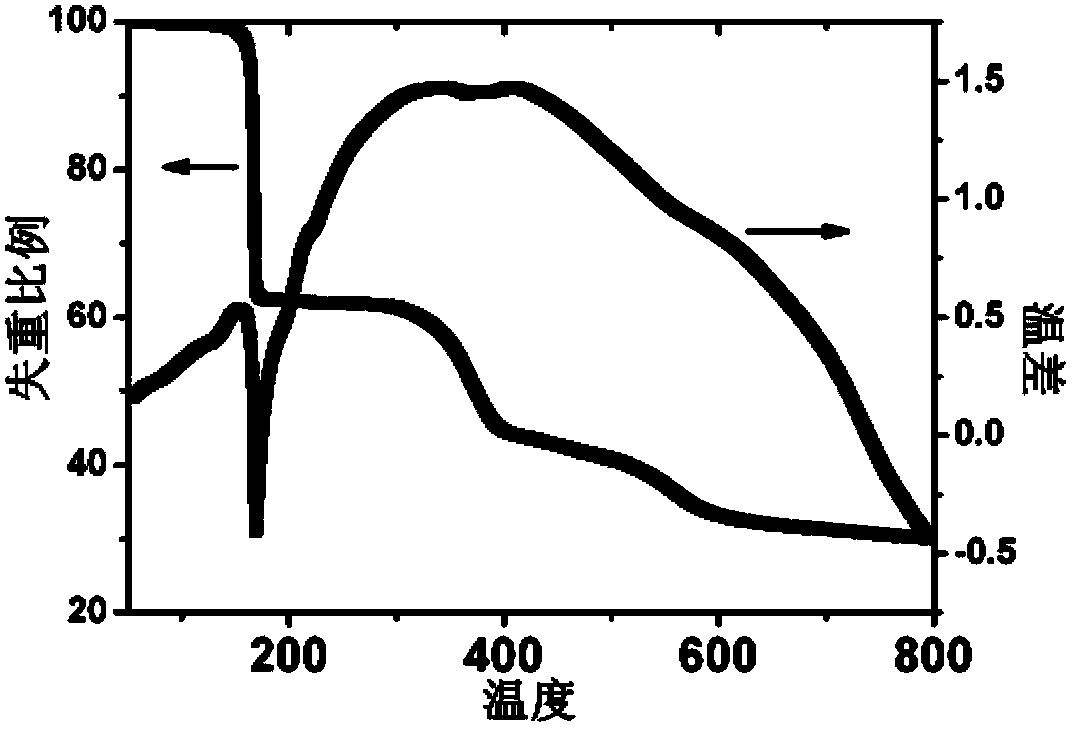

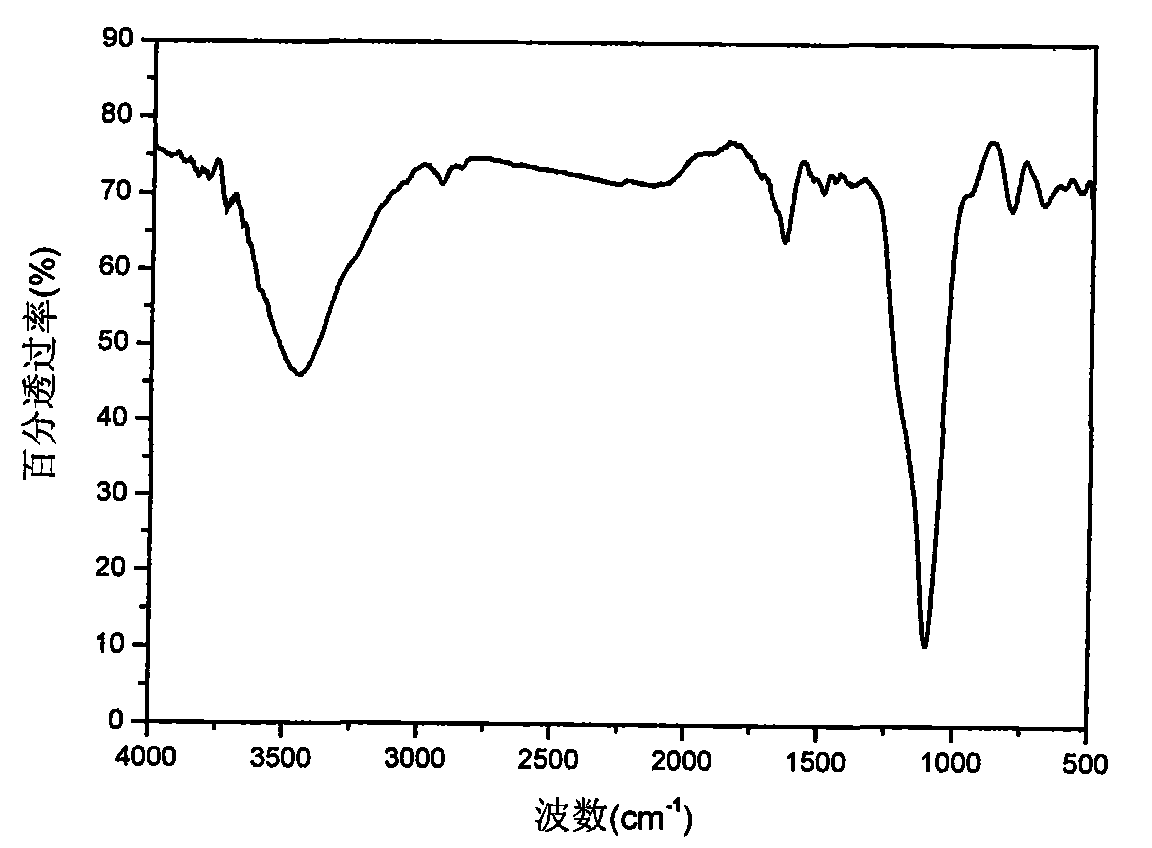

Supported palladium-based catalyst and preparation method and application thereof

ActiveCN106179506APromote generationHigh activityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsGas phaseCarbon nanotube

The invention provides a supported palladium-based catalyst and a preparation method and an application thereof. The supported palladium-based catalyst comprises an active ingredient and a carrier, wherein the active ingredient is a palladium-based compound; the carrier is selected from at least one of aluminum oxide, silicon oxide, magnesium oxide, zinc oxide, zirconium oxide, titanium dioxide, metal organic framework compound, activated carbon, molecular sieve, carbon nanotube, and graphene. The supported palladium-based catalyst is applied to the reaction of methyl nitrite vapor-phase carbonylation preparing dimethyl carbonate, and has the advantages that the catalytic activity is high, the product selectivity is high, and the service life is long.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Process for synthesizing methyl carbonate by alcoholysis of urea with aliphatic diol as cyclic agent

InactiveCN1569810AEasy to separateNo pollutionOrganic compound preparationCarbonic/haloformic acid esters preparationAlcoholMethyl carbonate

The invention discloses a process for synthesizing methyl carbonate by alcoholysis of urea with aliphatic diol as cyclic agent consisting two steps, (1) reacting urea with aliphatic diatomic alcohol (ethylene glycol or 1,2-methyl ethylene glycol) to synthesize ethylene carbonate ester or propylene carbonate ester, (2) subjecting ethylene carbonate ester or propylene carbonate ester with methanol ester to synthesize methylcarbonate.

Owner:HEBEI UNIV OF TECH

Process for synthesizing methyl carbonate by alcoholysis of methanol and urea

InactiveCN1569809AThe reaction process is simpleEasy to operateOrganic compound preparationCarbonic/haloformic acid esters preparationChemical synthesisAlcohol

The invention discloses a process for synthesizing methyl carbonate from alcoholysis of methanol and urea in a high pressure reactor, wherein the catalyst is a amine salt type ionic liquid having a molecular formula of R1R2R3NHX-MaXb, the raw material methanol and urea are subject to alcoholysis reaction and methyl carbonate is synthesized in one step.

Owner:EAST CHINA NORMAL UNIVERSITY

Starlike tetraphenylethylene derivative molecular glass, positive photoresist, positive photoresist coating and application thereof

ActiveCN104557552AGood rigid structureHigh glass transition temperatureOrganic compound preparationCarboxylic acid esters preparationSolubilityVitrification

The invention discloses starlike tetraphenylethylene derivative molecular glass, a positive photoresist, a positive photoresist coating and application thereof. The starlike tetraphenylethylene derivative molecular glass has the molecular structure shown in the description. The molecular glass is simple in synthesis process and suitable for industrial production; the tetraphenylethylene has a spatial solid geometrical skeleton adopting a rigid structure, can effectively inhibit molecular crystallization and is easy for film formation; the molecular glass has good solubility in various polar solvents, and has the characteristics of high glass transition temperature and high thermal stability, and can better meet requirements of a photoetching process; by adopting a spin coating method, a good film can be obtained, and the molecular glass can be used as the photoresist and can be prepared into the positive photoresist for photoetching through cooperation with other additives.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Catalyst for the synthesis of dimethyl carbonate from urea and methanol, preparation and use thereof

InactiveUS7271120B2Speed up the conversion processHigh selectivityHeat treatmentsOrganic compound preparationActive componentMethyl carbonate

A catalyst for the preparation of dimethyl carbonate from urea and methanol having a composition on weight base of: active component of from 20 to 50 wt %, and carrier of from 80 to 50 wt %, and prepared by equal-volume spraying and impregnating method is disclosed. The method for the synthesis of dimethyl carbonate can be carried out in a catalytic rectification reactor, said method comprising: (1) dissolving urea in methanol to form a methanol solution of urea; and (2) feeding the methanol solution of urea and methanol counter-currently into the reaction zone, wherein the reaction is carried out at conditions including reaction temperature of from 120° C. to 250° C., reaction pressure of from 0.1 MPa to 5 MPa, kettle bottom temperature of from 70° C. to 210° C., stripping section temperature of from 70° C. to 250° C., rectifying section temperature of from 70° C. to 280° C., and reflux ratio of from 1:1 to 20:1. The preparation of the catalyst according to the present invention is simple and has good repeatability, and the catalyst could further enhance the yield of DMC as well as conversion of urea in the catalytic rectification reactor.

Owner:INST OF COAL CHEM +1

Star-shaped adamantane derivative molecular glasses, and preparation method and application thereof

ActiveCN103804196AEasy to synthesizeAchieve separationOrganic compound preparationCarboxylic acid esters preparationAlkoxy groupPerylene derivatives

The invention discloses star-shaped adamantane derivative molecular glasses having the following structure shown in the description, wherein substituents R1-R12 are respectively hydrogen, hydroxy, alkoxy or acid sensitivity substituents; the substituents R1-R12 can be different or the same, but the substituents at a same benzene ring cannot both be hydrogen. The invention also discloses a preparation method of the star-shaped adamantane derivative molecular glasses. The method is simple in synthesis process, products of the steps of a reaction all can be separated from the system through a recrystallization or precipitation method. The molecular glasses can be used as photoresist main body materials made into thin films, and also can be used for photoetching.

Owner:国科天骥(北京)新材料技术有限责任公司

Urea alcoholizing process of synthesizing dimethyl carbonate

InactiveCN1421430AImprove economyMild reaction conditionsOrganic compound preparationCarbonic/haloformic acid esters preparationReactions stressUrea

The urea alcoholizing process for synthesizing dimethyl carbonate includes adding solid alkali into reactor, adding urea solution comprising urea and methanol in the molar ratio of 0.01-100 and the material feeding rate radio of 0.01-100 into the reactor, and reaction at 150-250 deg.c and 0.1-10 MPa in the conditions of reactor bottom temperature 70-200 deg.c, stripping section temperature 70-200deg.c, rectifying section temperature 70-200 deg.c and reflux ratio of 1-20. The present invention has the advantages of continuous process, mild reaction condition, etc.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

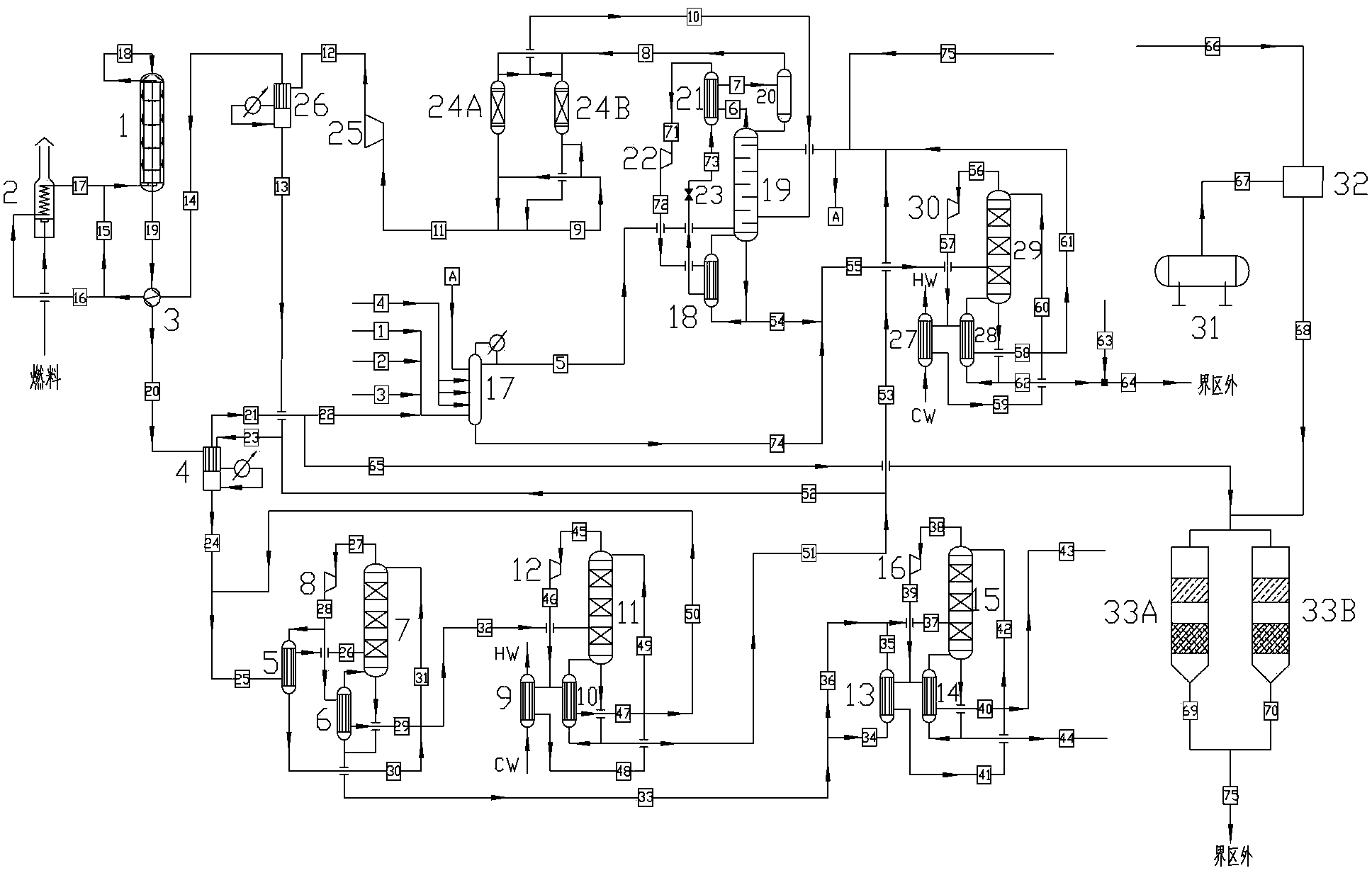

Process for producing dimethyl carbonate from industrial synthetic gas

ActiveCN103408428ANo overheating phenomenonDoes not affect safe operationOrganic compound preparationChemical industryMethyl carbonateGas phase

The invention relates to a process for producing dimethyl carbonate from industrial synthetic gas. According to the invention, O2, CO, N2, NO, and methanol are delivered into an esterification system for esterification; heavy component drawn from the esterification system is subjected to recovery treatment in a wastewater tower; light component drawn from the esterification system passes a compressor II and is subjected to a carbonylation reaction in a carbonylation reactor; the carbonylation reaction product is delivered into a second condensation separation tower, and is subjected to gas-liquid separation; separated liquid phase is refined in a pressurized rectification tower; part of non condensable gas is discharged from the separated gas phase, and the gas phase is continued to be subjected to a reaction in the esterification system; the discharged non-condensable gas is delivered into a denitration reactor; light component at a top of the pressurized rectification tower is subjected to further recovery treatment in a methanol recovery tower; heavy component from the pressurized rectification tower is delivered into a product tower; dimethyl carbonate is drawn from the top of the product tower, and dimethyl oxalate is drawn from the bottom of the product tower. The process has the economical and practical characteristics of low equipment investment, environment friendliness, energy saving, high catalyst efficiency, high raw material utilization rate, and the like.

Owner:SHANGHAI WUZHENG ENG TECH CO LTD

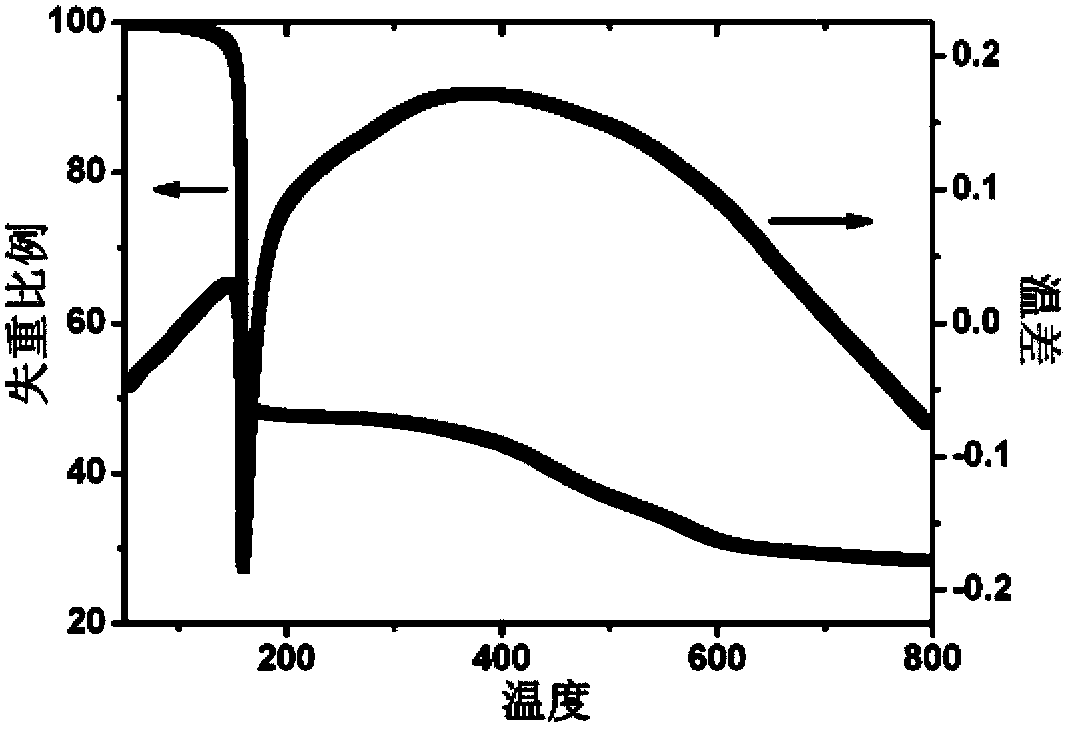

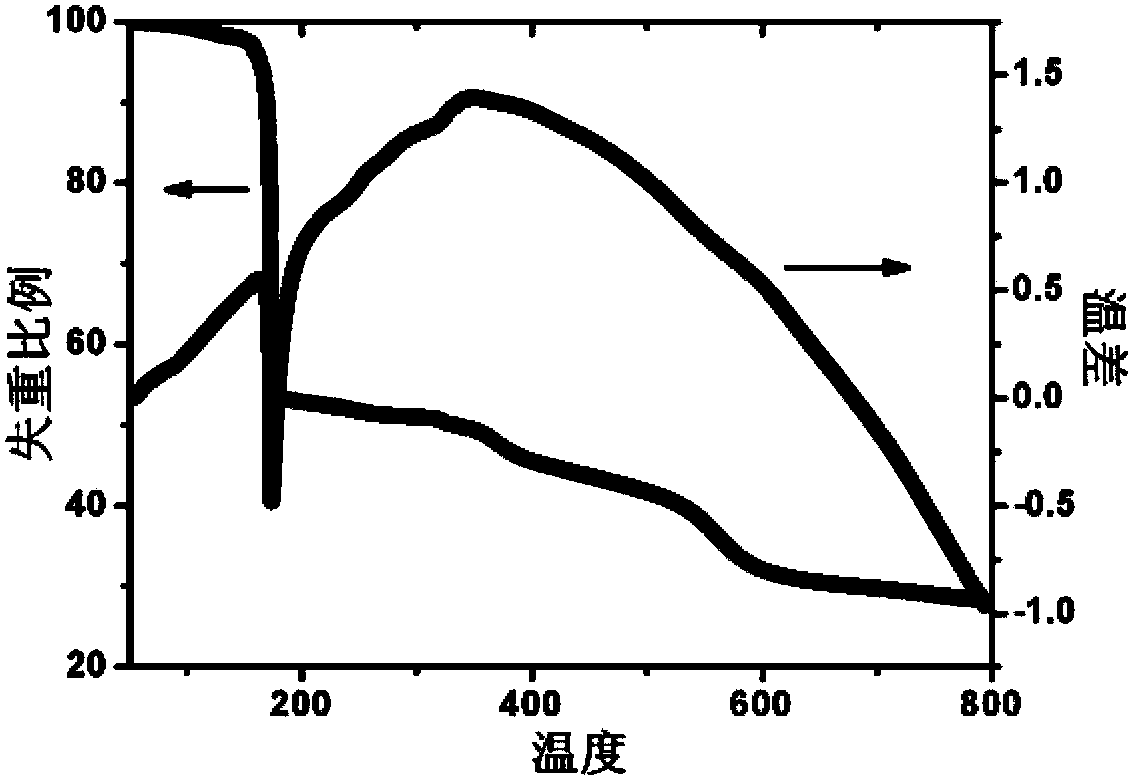

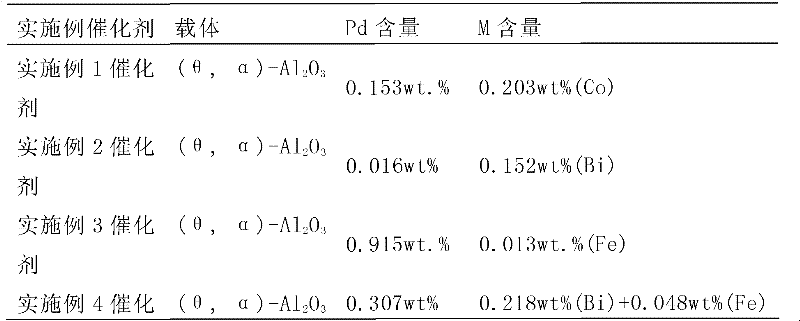

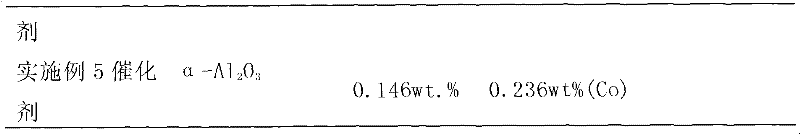

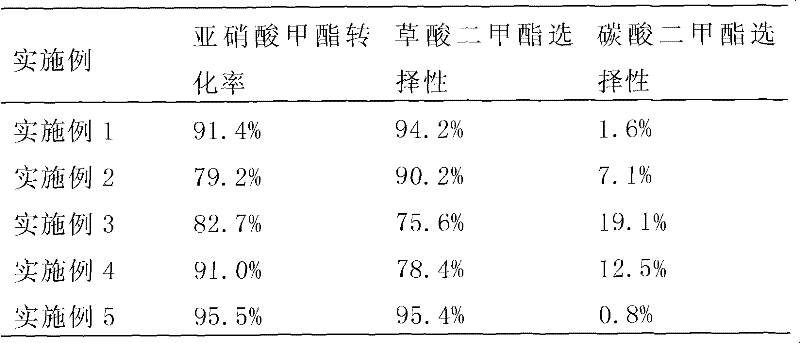

Supported catalyst used in selective synthesis, and preparation method and purpose thereof

ActiveCN102218330AExpand the scope of selectionTo achieve selective regulationOrganic compound preparationPreparation by carbon monoxide or formate reactionActive componentCatalyst support

The invention relates to a supported catalyst used in selective synthesis. The catalyst comprises a main active component, an auxiliary active component, and a catalyst carrier. The main active component is Pd and / or its oxide, wherein the weight percentage content of the main active component is 0.01% to 1.0%. The auxiliary active component is at least one of the metals of Fe, Ni, Co, and Bi, and / or at least one of the oxides of the metals of Fe, Ni, Co, and Bi, wherein the weight percentage content of the auxiliary active component is 0.01% to 0.5%. The left component is Al2O3, which is thecatalyst carrier. The invention also relates to a preparation method and a purpose of the catalyst. As an experiment result, with the adding of the catalyst, relative selectivity of mesoxalic dimethyl ester and dimethyl carbonate in reaction products can be modulated.

Owner:PUJING CHEM IND SHA +1

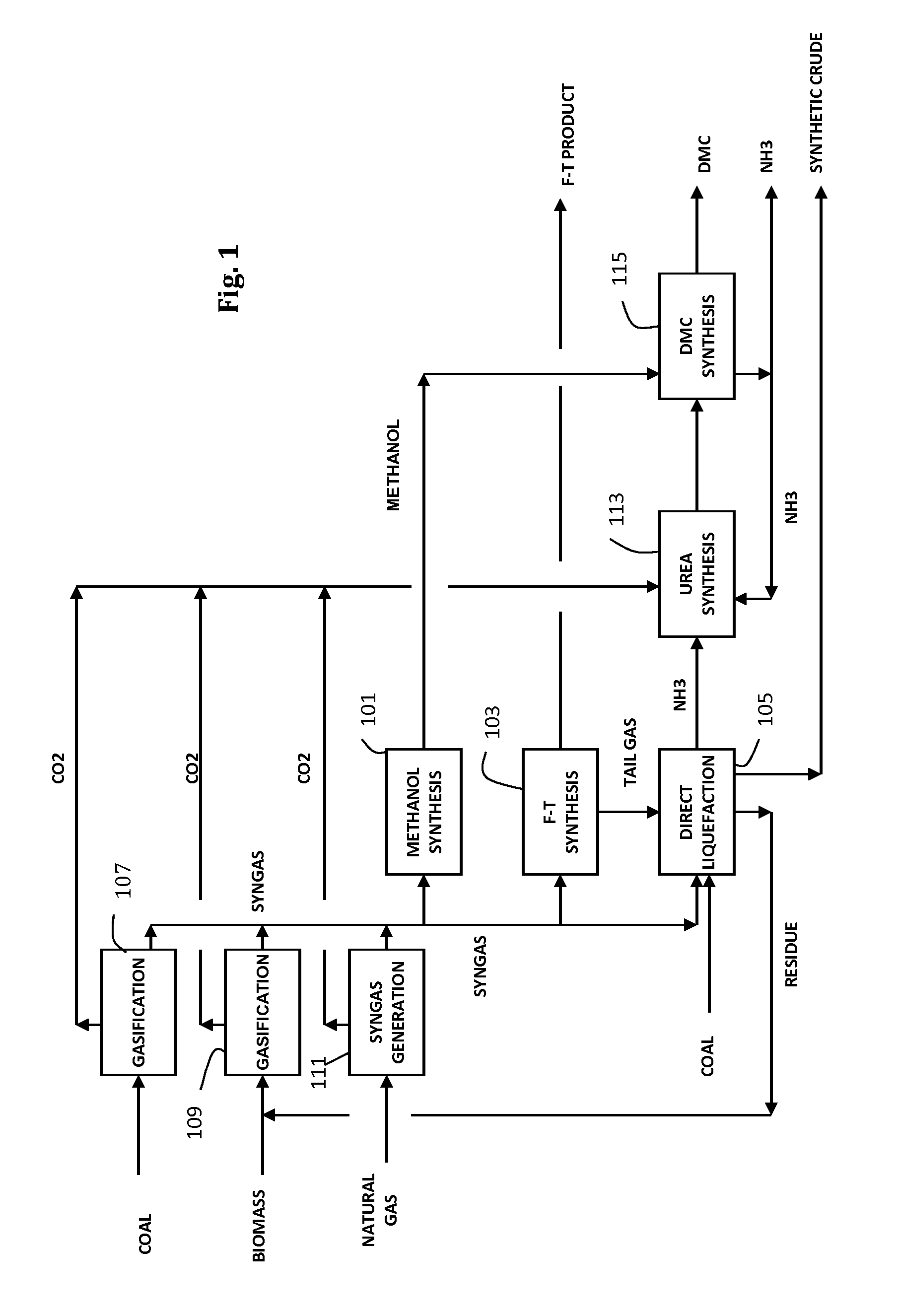

Integrated coal to liquids process and system

InactiveUS20090286889A1Efficient use ofMinimize carbon dioxide emissionUrea derivatives preparationProductsNegative carbon dioxide emissionCarbonylation

An integrated coal-to-liquids process is provided to minimize carbon dioxide emissions and efficiently make use of carbon resources, by recovering carbon dioxide emissions from Coal-to-Liquids (CTL) facilities, using the recovered carbon dioxide in at least one carbonylation reaction step for converting ammonia to urea and then converting urea into dimethyl carbonate.

Owner:ACCELERGY CORP

Complex catalyst for synthesizing carbonate ester by using homogeneous oxidation carbonylation of alcohol (S), its prepn. tech. and use

InactiveCN1792453ASimple preparation processHigh activityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsQuaternary ammonium cationProtein carbonyl

A complex catalyst for preparing carbonate from alcohol by homogeneous oxidizing-carbonylating reaction has a chemical formula MXnLm, where M is metal, X is chosen from halogen, SO4 (or HSO4) radical, CO3 (or HCO3) radical, etc, L is chosen from RN4 ion, RP4 ion, pyridine, etc, and m=1-12. It is prepared through complex reaction between quaternary ammonium (or phosphorus) salt and metal salt. Its application method is also disclosed.

Owner:NANJING UNIV OF TECH

Technology of preparing diethyl carbonate by urea alcoholysis method

ActiveCN101659616AThe preparation process has no special requirementsEasy to prepareOrganic compound preparationCatalyst activation/preparationFiltrationHigh pressure

The invention belongs to the synthesis of organic carbonates and relates to a technology of synthesizing diethyl carbonate by a urea alcoholysis method. The technology comprises the steps of: adding anhydrous ethyl alcohol, ethyl carbamate and a catalyst into a high pressure reaction kettle, wherein the mole ratio of the anhydrous ethyl alcohol to the ethyl carbamate is 2 to 25, and the catalyst is combined metal oxide, and accounts for 0.5 to 10 percent of the whole system by mass percent; raising the temperature to 150 to 200 DEG C by stirring so as to carry out reaction for 1 to 15 hours; and taking out the reaction liquid after the reaction, and realizing the separation of the catalyst and the reaction liquid by simple filtration. The combined metal oxide is prepared by 2 to 3 metal oxide precursors among Li, Na, K, Ca, Mg, Ba, Sr, Al, Sn, Pb, La, Ti, W, Zr, Fe, Co, Ni, Cu and Zn through thermal decomposition method or coprecipitation method. The preparation method of the technology is simple, the catalyst activity is high, the stability is good, and the separation and recycling are easy.

Owner:HEBEI UNIV OF TECH

Solid borne ionic liquid Cu salt catalyst as well as preparation method thereof and application in synthesis of dimethyl carbonate

InactiveCN101559385AHinder dissolutionHigh catalytic activityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsMolecular sievePtru catalyst

The invention provides a compound, the constitutional formula is shown as (1), in formula (1) the carrier is one of B type silicon gel and SBA-15 molecular sieve, n is 1-3, R is any one of CH3 and CH2CH3, X is any one of Cl, Br, I, Ac, NO3. The preparation method of the compound comprises the steps of preparing pyridine ionic liquid, preparing solid borne ionic liquid matrix and preparing solid borne ionic liquid Cu salt catalyst. The application of the solid borne ionic liquid Cu salt catalyst in the synthesis of dimethyl carbonate is further provided in the invention. The catalytic activity of the catalyst of the invention is improved, and the loss of the active center Cu ion and corrosion of equipment are reduced; with the catalyst prepared by the invention adopted in the synthesis of dimethyl carbonate, the conversion rate of the methyl alcohol achieves 17%, and the selectivity of the dimethyl carbonate achieves 97.6%.

Owner:SHAANXI NORMAL UNIV

Chlorine-free bimetallic catalyst for gas phase synthesis of dimethyl carbonate and preparation and application

InactiveCN102872879AEvenly dispersedNot easy to agglomerate and sinterOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsActivated carbonMethyl carbonate

A chlorine-free bimetallic catalyst for gas phase synthesis of dimethyl carbonate is characterized in that the catalyst comprises an active component of copper, an additive, and active carbon; on a metal basis, the catalyst comprises 10.0-25.0 wt% of Cu, 1.0-10.0 wt% of the additive, and 65-85 wt% of active carbon. The catalyst of the invention has the advantages of high conversion rate and good selectivity.

Owner:TAIYUAN UNIV OF TECH

Process for the preparation of dialkyl carbonate

ActiveUS20070083062A1High selectivityHigh yieldPhysical/chemical process catalystsOrganic compound preparationAlcoholCyanide

The present invention provides a process for the preparation of dialkyl carbonates of general formula (1) wherein R=alkyl (C1-C8) or C6H5CH2 the said process comprises a reaction in between cyclic carbonate and alcohol, in the presence of a solid, double metal cyanide complex catalyst, at a temperature in the range of 140-180° C., for a period of 4-10 hrs, followed by the separation of catalyst from the above said reaction mixture by known methods to obtain the desired product.

Owner:COUNCIL OF SCI & IND RES

Methods for enhancing the efficiency of rhenium-promoted epoxidation catalysts and epoxidation methods utilizing these

ActiveUS20100267973A1Improve efficiencyReduce raw material consumptionOxygen-containing compound preparationOrganic compound preparationRheniumEther

A method for enhancing the efficiency of a rhenium-promoted epoxidation catalyst is provided. Advantageously, the method may be carried out in situ, i.e., within the epoxidation process, and in fact, may be carried out during production of the desired epoxide. As such, a method for the epoxidation of alkylenes incorporating the efficiency-enhancing method is also provided, as is a method for using the alkylene oxides so produced for the production of 1,2-diols, 1,2-carbonates, 1,2-diol ethers, or alkanolamines.

Owner:THE DOW CHEM CO +1

Catalyst of synthetic propylene and application thereof

InactiveCN1424141ALow costEasy to manufactureMolecular sieve catalystsOrganic compound preparationMolecular sieveActivated carbon

A catalyst for synthesizing the propylene carbonate is composed of potassium salt (10-20 wt%), and activated carbon, metal oxide, or molecular sieve (80-90 wt%). The propylene carbonate is prepared through reaction between potassium salt, epoxy propane and iodomethane at 120-180 deg.C and 2-6 MPa for 0.5-2 hr. Its advantages are high catalytic activity, low cost and cyclic use.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Preparation method of Cu nanoparticle-loaded ordered mesoporous carbon catalyst

InactiveCN104888779AImprove surface activityImprove stabilityMaterial nanotechnologyOrganic compound preparationGas phaseNanoparticle

The invention discloses a preparation method of a Cu nanoparticle-loaded ordered mesoporous carbon catalyst. A carbon source precursor, a template and a copper salt are co-assembled in a solvent so that the Cu nanoparticle-loaded ordered mesoporous carbon catalyst is prepared. The Cu nanoparticle-loaded ordered mesoporous carbon catalyst is a nanoscale catalyst. Copper particles with the sizes of 5-25nm are inlaid in channels and surfaces of the ordered mesoporous carbon so that migration and agglomeration in the reaction process are not produced easily. The Cu nanoparticle-loaded ordered mesoporous carbon catalyst has high stability in normal pressure continuous fixed bed gas phase methanol oxidation carbonylation synthesis of dimethyl carbonate, has good reaction activity and has a good industrial application prospect.

Owner:CHINA UNIV OF MINING & TECH

Technology of producing dimethyl carbonate by alcoholysis of urea

InactiveCN1903828AReduce consumptionSave energyOrganic compound preparationCarbonic/haloformic acid esters preparationAlcoholPtru catalyst

The present invention relates to a process for producing dimethyl carbonate by using urea alcoholysis method. Said process includes the following several steps: making urea solution and methyl alcohol be backwards fed into reaction zone of reaction rectification tower according to the mole ratio of 8-12:1 to make contact reaction, under the action of catalyst producing crude dimethyl carbonate solution, then making said crude dimethyl carbonate solution undergo the processes of normal pressure distillation, pressure distillation, secondary normal pressure distillation and fine purification so as to obtain the invented product dimethyl carbonate.

Owner:PETROCHINA CO LTD

Process for the preparation of aromatic polycarbonate

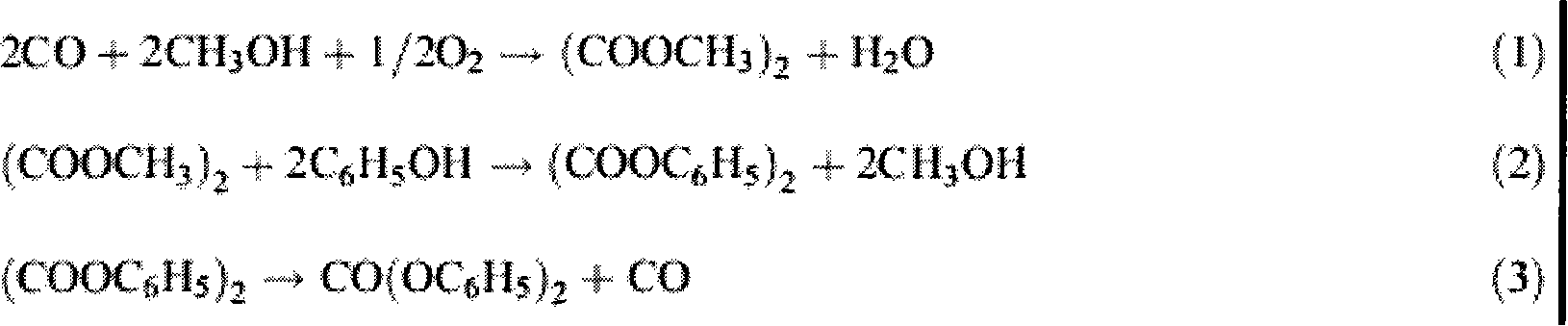

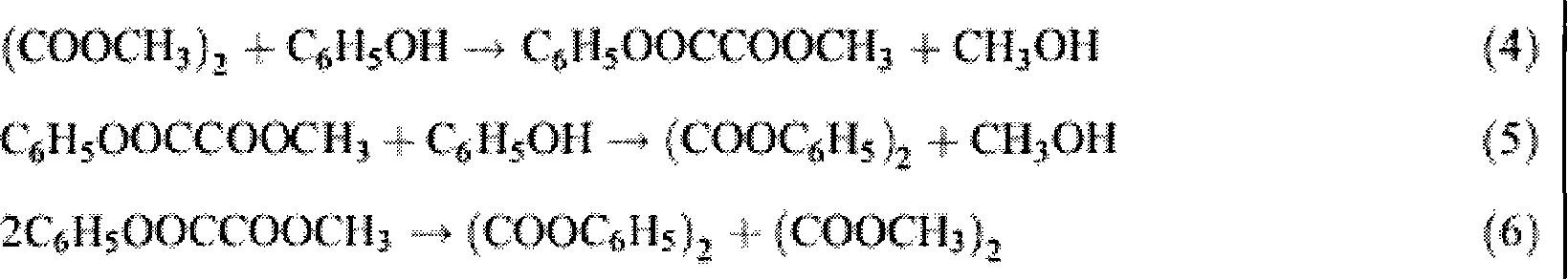

InactiveUS6265524B1Impairing ester interchange reactivityHigh molecular weightOrganic compound preparationCarbonic/haloformic acid esters preparationHalogenAromatic hydrocarbon

A process for producing an aromatic polycarbonate through an ester interchange reaction between an aromatic carbonic acid diester and an aromatic dihydroxy compound, wherein the aromatic carbonic acid diester is obtained through the decarbonylation reaction of an aromatic oxalic acid diester represented by the following general formula (1):wherein two Ar's are the same or different aromatic hydrocarbon groups having 6 to 14 carbon atoms, and has a hydrolyzable halogen content of 5 ppm or less.According to the present invention, an aromatic polycarbonate having a high molecular weight and excellent color can be easily produced without impairing ester interchange reactivity for the production of the aromatic polycarbonate by using an aromatic carbonic acid diester obtained through the decarbonylation of an aromatic oxalic acid diester and controlling the amount of hydrolyzable halogen contained in the aromatic carbonic acid diester to a value smaller than a predetermined value.

Owner:TEIJIN LTD +1

Double component carried catalyst for synthesizing diphenyl carbonate and its preparing method

InactiveCN1391986AHigh catalytic activityGood repeatabilityMolecular sieve catalystsOrganic compound preparationPhenolOxidative carbonylation

The present invention relates to double-component carried catalyst PdCl2-Cu(OAc)2 / zeolite for synthesizing diphenyl carbonate and its preparation. The catalyst consists of zeolite in 50-100 weight portions, PdCl2 in 0.1-10 weight portions and Cu(OAc)2 in 0.1-30 weight protions. It is prepared through equi-volume soaking and roasting at 250-750 deg.c. The catalyst system has also metal acetate as inorganic oxidation-reduction assistant, hydroquinone as organic oxidation-reduction assistant, and tetrabutyl ammonium bride as surfactant. The catalyst has very high catalytic activity and excellent selectivity to liquid phenol in synthesizing diphenyl carbonate. The catalyst is easy to separate from product, easy to recover and regenerate and has simple preparation process.

Owner:HEBEI UNIV OF TECH

Non-noble metal homogeneous catalysis system for alcohol oxidation carbonylation and using method thereof

InactiveCN101856625AHigh activityHigh selectivityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsChemical industryPtru catalyst

The invention belongs to the field of chemical industry and discloses a non-noble metal homogeneous catalysis system for alcohol oxidation carbonylation and a using method thereof. The system consists of a composite catalyst MNC and a solvent NS (IV) which dissolves the composite catalyst, wherein the composite catalyst MNC is compounded by a metal complex MXn-Lm (I), a metal salt synergistic aid N (II) and / or an alkaline aid C (III). The general formula of the system is I+II+III+IV, I+II+IV, or I+III+IV. The catalyst has the advantages of simple process, mild reaction, high catalytic activity, good selectivity and stability, and low corrosion on production equipment. Meanwhile, the homogeneous system formed by the composite catalyst and the solvent can perform liquid phase circulation and has industrial application prospects.

Owner:NANJING UNIV OF TECH

Organic acid base catalyst for synthesizing aryl ester carboxylic acid by interesterification

InactiveCN101195095AImprove performanceEasy to separateOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsOrganic baseCarboxylic acid

The invention belongs to the technical fields of organic chemistry and catalytic chemistry, and relates to an organic acid-base catalyst which is used for carboxylic acid aryl-ester groups which are compounded by ester exchanges. The organic base in the organic acid-base catalyst refers to an organic compound which contains nitrogen, phosphorus and halogen elements and solid-carrying organic base of the organic base, while the organic acid mainly refers to organic sulfonic acid, organic phosphorus acid, organic carboxyl acid, urea and the like and solid-carrying organic acid of the organic acid. The invention can be used as organic matters such as amino acid and the like which has double functions of organic acid and base and as catalysts which can be used to solid support the organic acid base on a same carrier. The catalyst of the invention has good catalytic performance and is easy to be separated from reaction systems, ester exchange conditions are temperate, the invention is convenient to continue, the conversion rate of oxalic dim-ethyl ester can reach over 90%, the selectivity to phenyloxalate can reach over 70%, and the invention is suitable for industry applications.

Owner:JILIN UNIV

Copper-based catalyst prepared by ammonia distillation method and application of copper-based catalyst in oxidation carbonylation synthesis of alkyl carbonate

ActiveCN103084201AImprove stabilityReduced activityMolecular sieve catalystsOrganic compound preparationEthyl ChlorideProtein carbonyl

The invention discloses a copper-based catalyst prepared by an ammonia distillation method and an application of the copper-based catalyst in a reaction system for oxidation carbonylation synthesis of alkyl carbonate. The use of a chlorine-containing compound is completely avoided in the preparation process of the catalyst, so that the problems of equipment corrosion and deactivation caused by chlorine loss are completely solved; and the catalyst prepared by the ammonia distillation method is high in selectivity, long in service life, low in preparation cost and relatively simple in process.

Owner:TIANJIN UNIV

Catalyst for preparing dimethyl carbonate by using urea alcoholysis and preparation method thereof

ActiveCN101596452AImprove stabilityEvenly dispersedOrganic compound preparationChemical recyclingAlcoholHomogeneous catalysis

The invention provides a catalyst for preparing dimethyl carbonate by using urea alcoholysis and a preparation method thereof. The catalyst has a specific surface area of 150-350 m / g, a specific pore volume of 0.5-2.0 cm / L and the pore-size distribution of 50-150, gamma-Al2O3 as a carrier accounts for 50-80 percentage of the catalyst by weight, and the balance comprises active constituents. The main active constituent comprises at least one of ZnO, CaO and PbO, and an active constituent oxide and an alumina carrier can form a stable spinelle structure. The catalyst has good stability, can achieve the stable operation service life longer than 500 hours, reacts with a urea methanol solution to synthesize the dimethyl carbonate with higher catalytic activity, has the simple preparation method, can finish load without special equipment, is beneficial to industrialized amplification, is a fixedly-carrier catalyst and solves the problem that the prior homogeneous catalyst is difficult to recycle.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com