Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2780 results about "Ethyl Chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A gas that condenses under slight pressure. Because of its low boiling point ethyl chloride sprayed on skin produces an intense cold by evaporation. Cold blocks nerve conduction. Ethyl chloride has been used in surgery but is primarily used to relieve local pain in sports medicine.

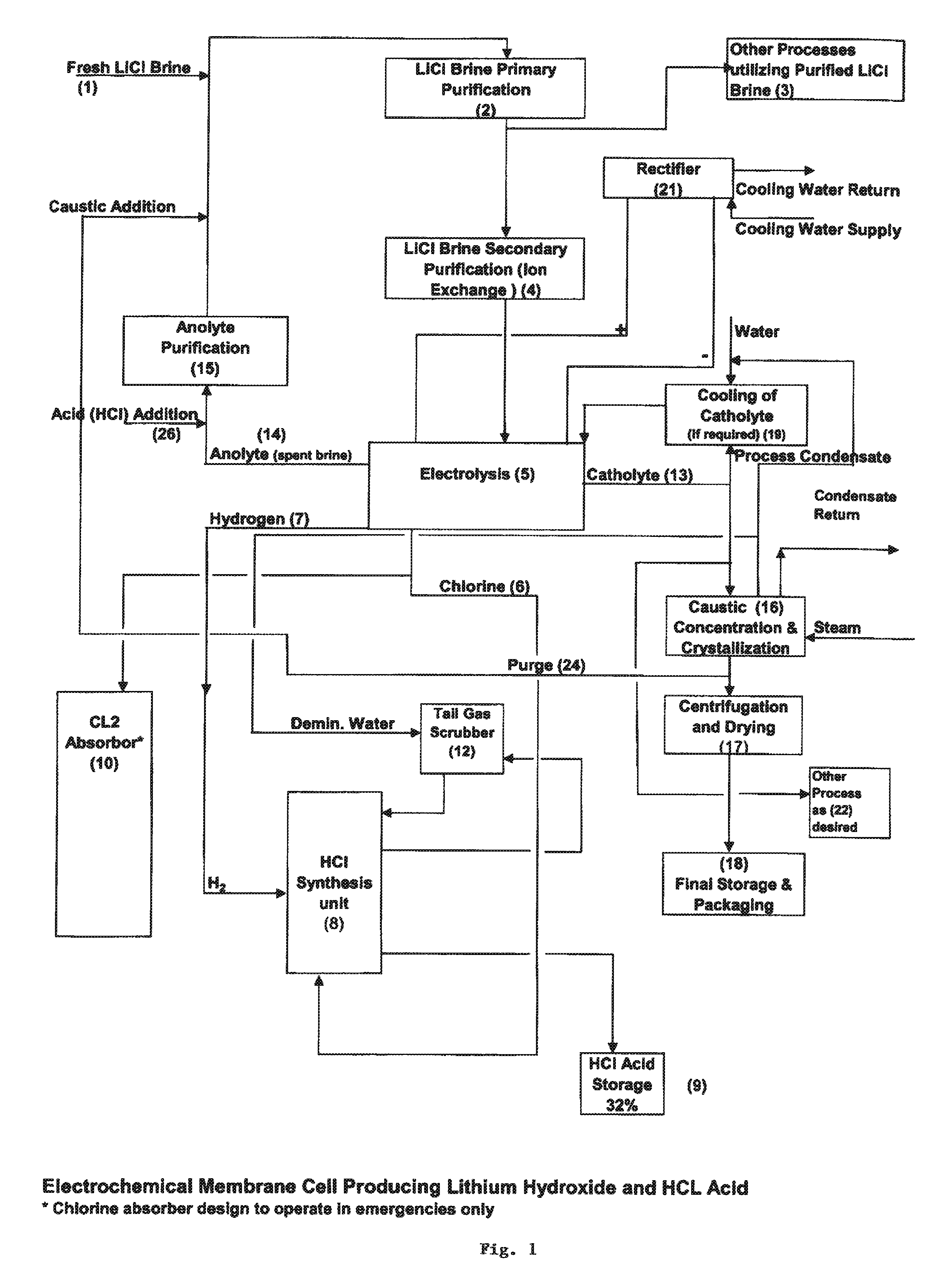

Method of making high purity lithium hydroxide and hydrochloric acid

InactiveUS20110044882A1Simple and economical processEasy to convertElectrolysis componentsEnergy inputElectrolysisIon exchange

The present invention relates to a process for producing high purity lithium hydroxide monohydrate, comprising following steps: concentrating a lithium containing brine; purifying the brine to remove or to reduce the concentrations of ions other than lithium; adjusting the pH of the brine to about 10.5 to 11 to further remove cations other than lithium, if necessary; neutralizing the brine with acid; purifying the brine to reduce the total concentration of calcium and magnesium to less than 150 ppb via ion exchange; electrolyzing the brine to generate a lithium hydroxide solution containing less than 150 ppb total calcium and magnesium, with chlorine and hydrogen gas as byproducts; producing hydrochloric acid via combustion of the chlorine gas with excess hydrogen and subsequent scrubbing of the resultant gas stream with purified water, if elected to do so; and concentrating and crystallizing the lithium hydroxide solution to produce lithium hydroxide monohydrate crystals.

Owner:ROCKWOOD LITHIUM INC

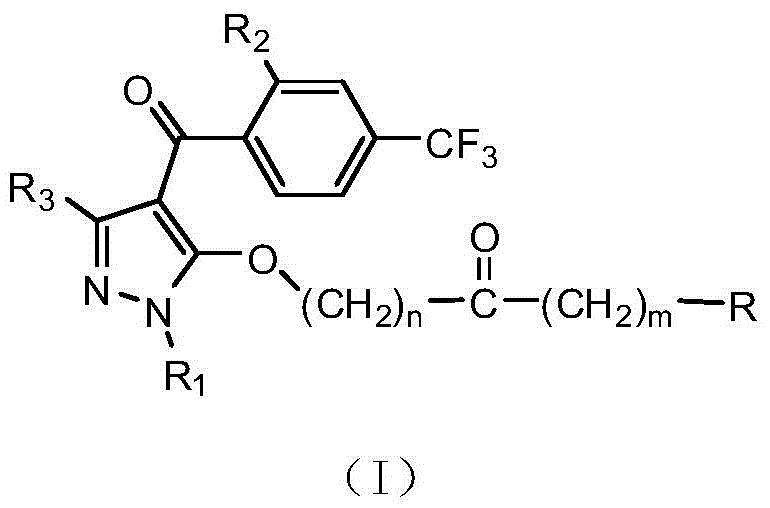

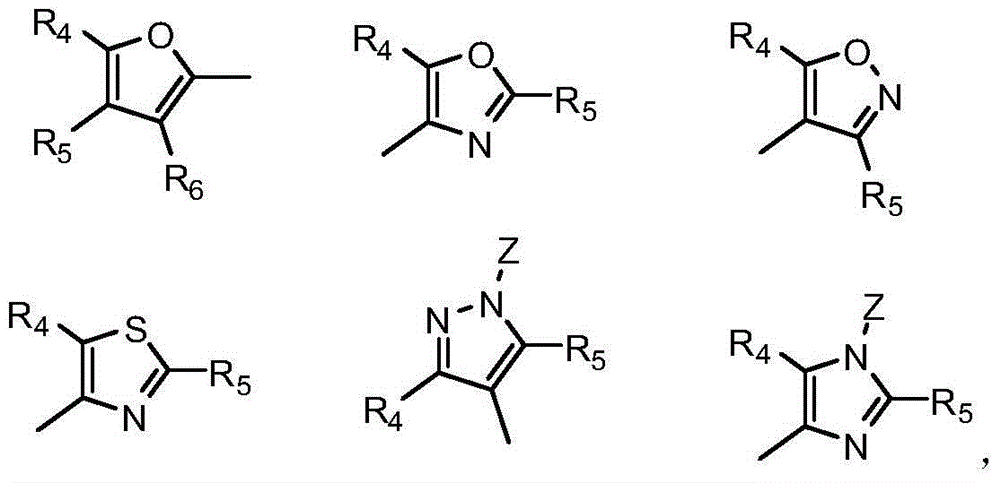

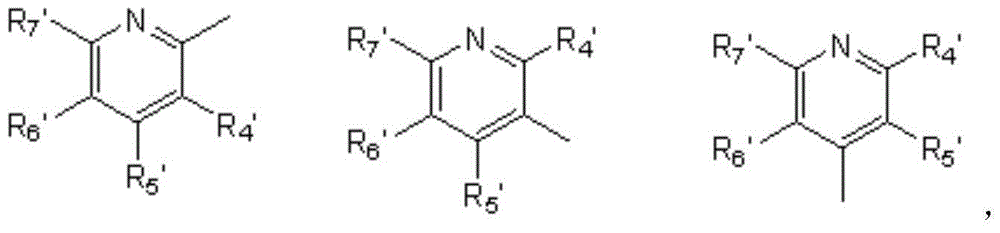

4-benzoyl pyrazole compound with herbicidal activity

ActiveCN103980202AGood choiceImprove securityBiocidePlant growth regulatorsHydrogenStructural formula

The invention relates to a 4-benzoyl pyrazole compound with herbicidal activity. The structural formula of the 4-benzoyl pyrazole compound with the herbicidal activity is as shown in specifications, wherein R1 in the structural formula is selected from hydrogen, methyl or ethyl, R2 in the structural formula is selected from methylsulfonyl, methoxyl, methylthio, fluorine, chlorine or cyan, R3 in the structural formula is selected from hydrogen, methyl, methyl fluoride, difluoromethyl or trifluoromethyl, R in the structural formula is selected from a five-membered heteroaromatic ring, a six-membered heteroaromatic ring, C1-C6 alkoxyl, aromatic hetero-oxy, six-membered aryloxy or six-membered aromatic amino, and hydrogen in the C1-C6 alkoxyl can be replaced by fluorine or chlorine; m and n are selected from 0 or 1 and cannot be 1 at the same time. A series of relatively efficient weed killers and plant growth regulators with relative good selectivity and safety are synthesized by introducing a fluorine-containing functional group to a pyrazole 3-site and chemically modifying a pyrazole 5-site.

Owner:QINGDAO KINGAGROOT CHEM COMPOUNDS CO LTD

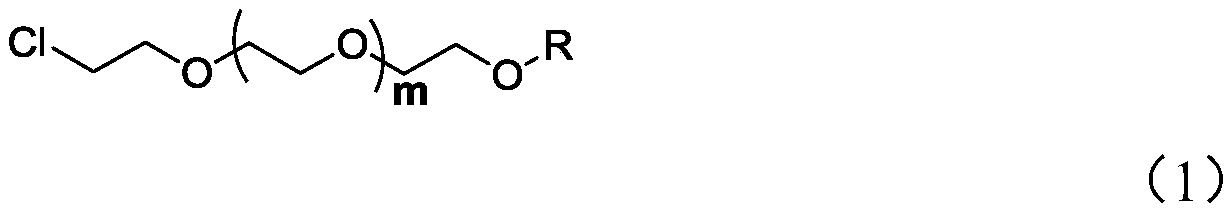

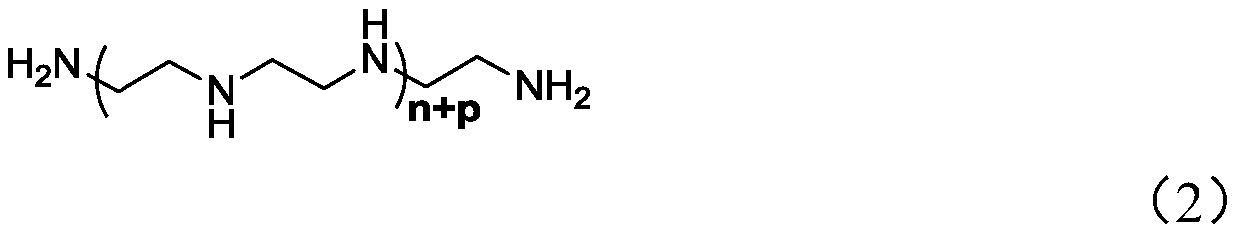

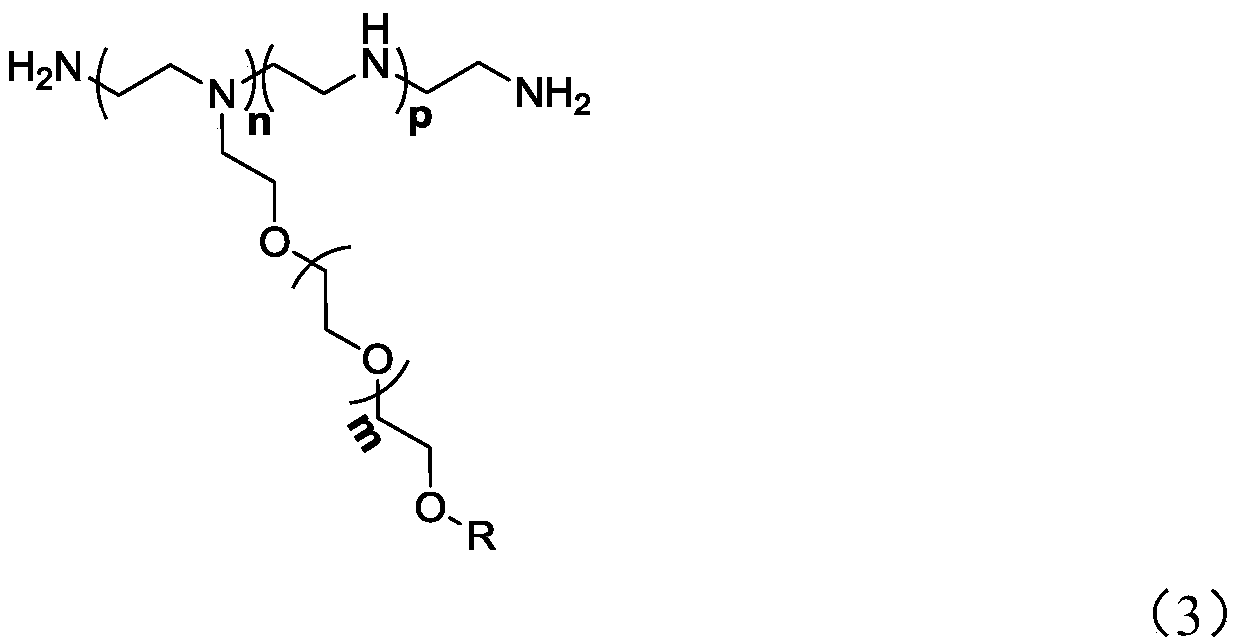

Phosphorous acid concrete super plasticizer with polyethyleneimine structure as well as preparation method and application thereof

The invention provides a new phosphorous acid concrete super plasticizer with a polyethyleneimine structure as well as a preparation method and an application thereof. The phosphorous acid concrete super plasticizer with a polyethyleneimine structure can effectively improve the concrete fluidity, and the preparation method is simple and effective. The preparation method comprises the following steps: a) making chloro-substituted polyether react with polyethyleneimine so that a part of amino groups H of the polyethyleneimine are substituted to obtain polyethyleneimine with a polyoxyethylene ether branch structure, wherein the molar ratio of the chloro-substituted polyether to the imino groups contained in the polyethyleneimine is 1:(3-8); and b) performing phosphorylation of the remaining amino groups H of the polyethyleneimine with a polyoxyethylene ether branch structure to obtain the phosphorous acid concrete super plasticizer with a polyethyleneimine structure.

Owner:JIANGSU SOBUTE NEW MATERIALS

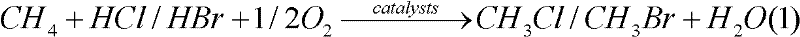

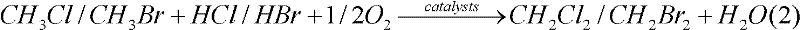

Application of cerium-based catalyst in methane oxyhalogenation methods used for preparing halogenated methane

InactiveCN102344339ARich reservesEasy to prepareCarbon monoxideHalogenated hydrocarbon preparationBromineCerium

The invention relates to a cerium-based catalyst, and relates to an application of the cerium-based catalyst in methane oxyhalogenation methods used for preparing halogenated methane. The methane oxyhalogenation methods used for preparing halogenated methane comprise a methane chlorine oxidation method used for preparing methyl chloride and a methane bromine oxidation method used for preparing methyl bromide. The cerium-based catalyst is suitable to be used in methane oxyhalogenation reactions. The cerium-based catalyst can be a CeO2 catalyst, a cerium-based bi-component composite oxide catalyst, a load-type cerium-based oxide catalyst, or the like. With the cerium-based catalyst, the methane oxyhalogenation reactions including a chlorine oxidation reaction and a bromine oxidation reaction can be effectively and stably catalyzed, and methyl chloride and methyl bromide can be prepared. With the cerium-based catalyst, reactants such as CH4, HCl and O2 can be catalytically converted with high efficiency for carrying out a chlorine oxidation reaction, such that products CH3Cl and CH2Cl2 are produced. Also, with the cerium-based catalyst, reactants such as CH4, HBr(H2O), and O2 can be converted with high efficiency for carrying out a bromine oxidation reaction, such that products CH3Br and CH2Br2 are produced.

Owner:XIAMEN UNIV

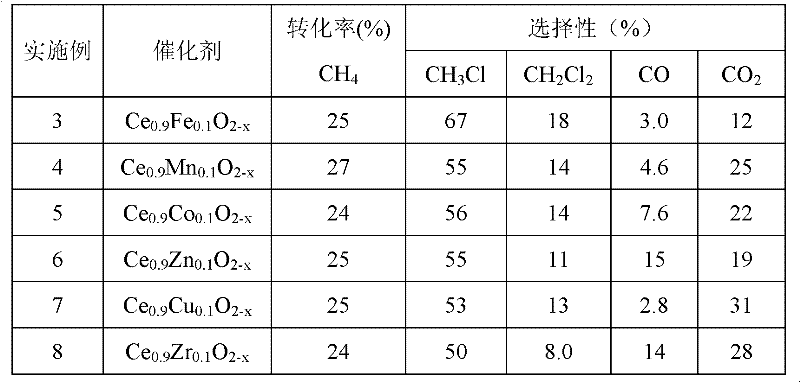

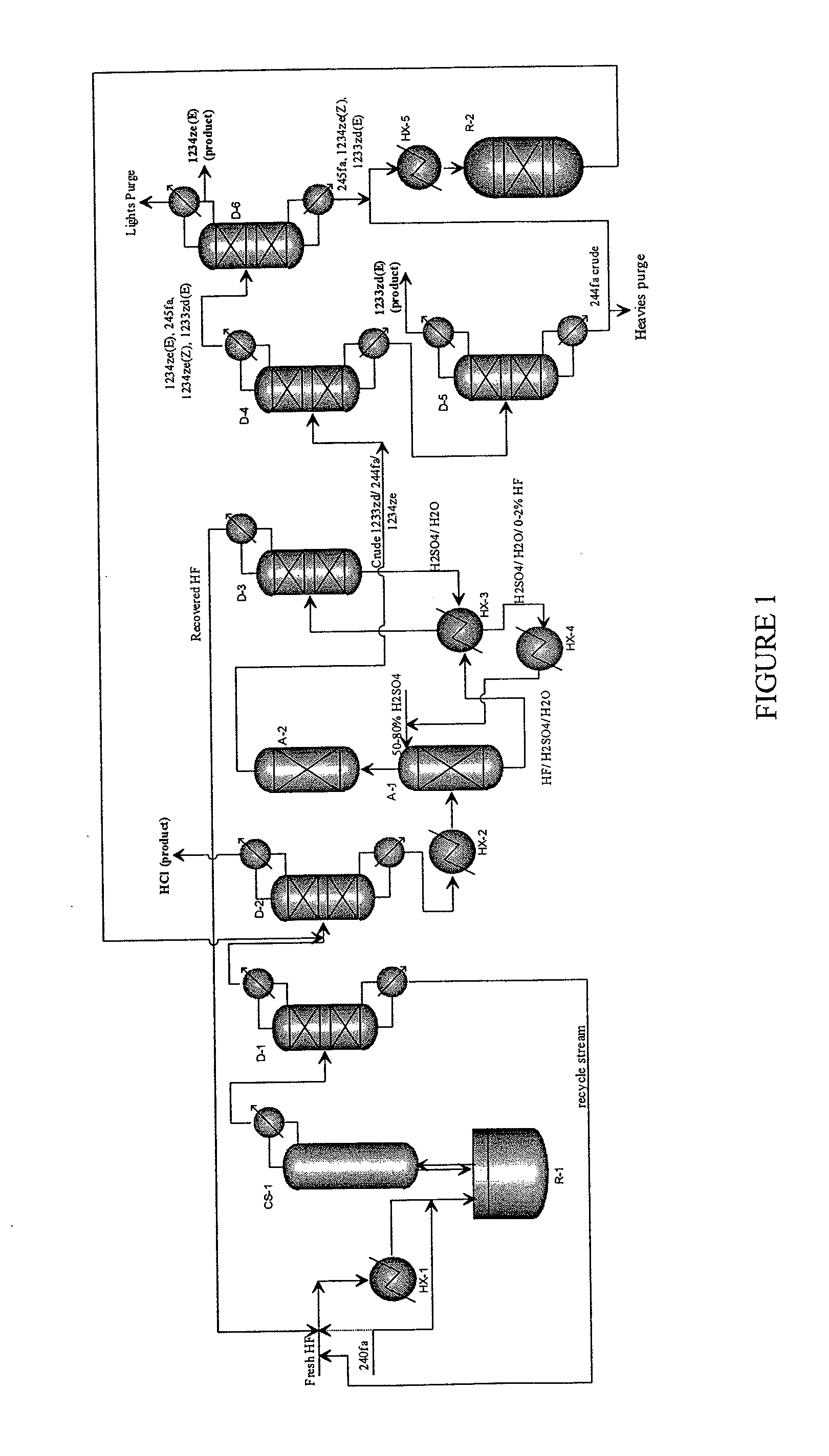

Integrated Process to Co-Produce Trans-1-Chloro-3,3,3-Trifluoropropene and Trans-1,3,3,3-Tetrafluoropropene

ActiveUS20110245549A1Low costPreparation by dehalogenationPreparation by hydrogen halide split-offDistillation1,3,3,3-Tetrafluoropropene

The disclosed integrated manufacturing process includes a combined liquid phase reaction and purification operation which directly produces trans-1-chloro-3,3,3-trifluoropropene and 3-chloro-1,1,1,3-tetrafluoropropane which is a precursor to the manufacture of trans-1,3,3,3-tetrafluoropropene. The mixture of co-products is easily separated by conventional distillation and 3-chloro-1,1,1,3-tetrafluoropropane is then dehydrochlorinated to produce trans-1,3,3,3-tetrafluoropropene by contacting in the liquid phase with a caustic solution or in the vapor phase using a dehydrochlorination catalyst.

Owner:HONEYWELL INT INC

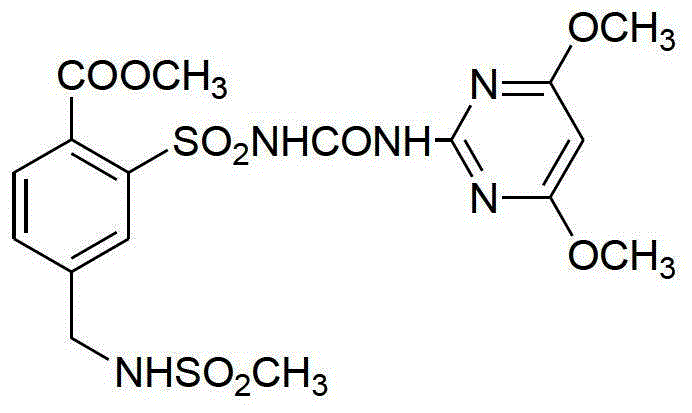

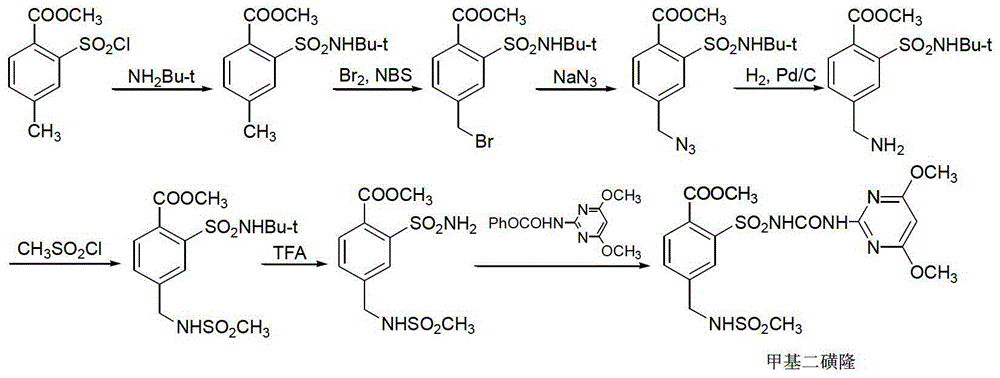

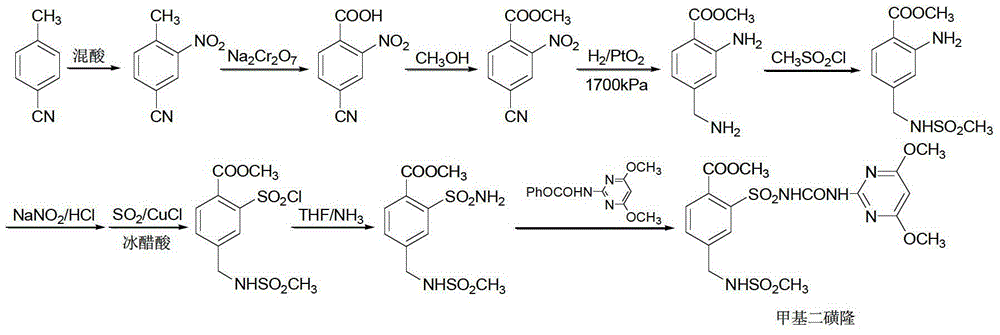

Mesosulfuron-methyl synthetic method

ActiveCN103333120ARaw materials are cheap and easy to getEasy to operateOrganic chemistryMesosulfuron-methylChloride

The invention discloses a mesosulfuron-methyl synthetic method. The mesosulfuron-methyl synthetic method is characterized in that mesosulfuron-methyl is prepared from raw materials such as paratoluic acid by adopting the seven steps of chlorosulfonation-ammonolysis, oxidation, dehydration, reduction, alcoholysis, methyl sulfone chloride acylation and condensation. The mesosulfuron-methyl synthetic method provided by the invention has the advantages of being low in cost of the raw materials, easy in availability of the raw materials, simple in operation and mild in conditions, having low requirements on equipment, high yield and strong practicability and being suitable for industrial production.

Owner:JIANGSU REPONT PESTICIDE FACTORY

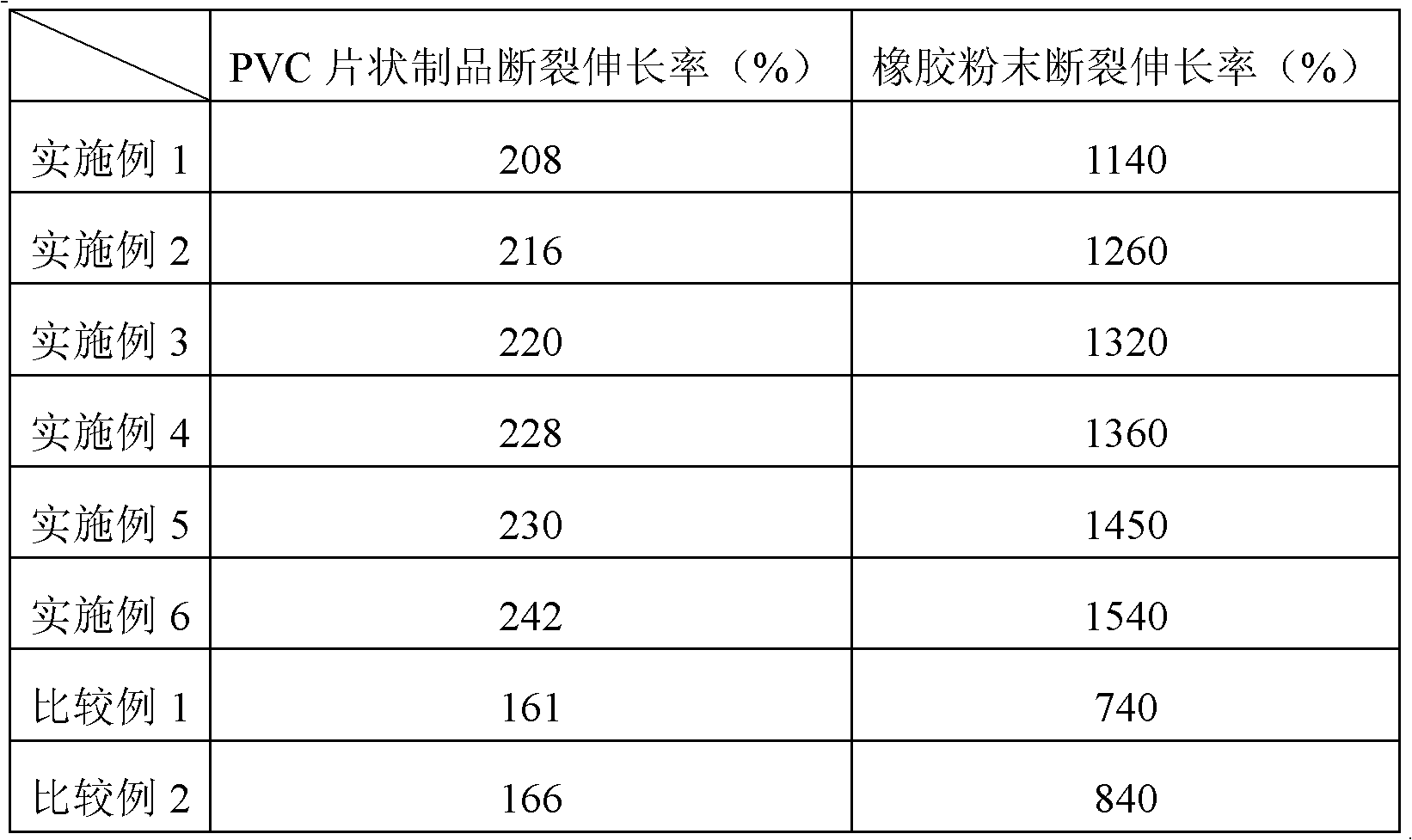

Polyvinyl chloride (PVC) mixture with high elongation at break

The invention provides a polyvinyl chloride (PVC) mixture which comprises the following components in parts by weight: (a) 100 parts of PVC resin, (b) 5-30 parts of low-temperature toughening modifier, (c) 0.5-5 parts of stabilizer, (d) 0-50 parts of filler, (e) 0-50 parts of wood meal, (f) 0-10 parts of acrylic polymer, (g) 0-20 parts of anti-shock modifier, (h) 0-5 parts of lubricant and (i) 0-10 parts of pigment. The low-temperature toughening modifier is rubber powder of which the elongation at break is 1000-1600% and the weight percent of chlorine is at least 10%. The elongation at break of the PVC mixture is greatly enhanced, thereby basically overcoming the defect of low elongation at break of the PVC product, greatly widening the application range of PVC and enhancing the industrial competitive power of PVC.

Owner:SHANDONG RIKE CHEM

Carbonyl reductase, gene and mutant and application thereof to asymmetrical reduced carbonyl compound

ActiveCN102618513AHigh optical purityMild reaction conditionsBacteriaMicroorganism based processesHigh concentrationMethyl o-chloromandelate

The invention discloses a novel carbonyl reductase, a gene, a mutant thereof, a recombinant expression vector containing the gene and the mutant, a recombinant expression transformant, a recombinase preparation method, and applications of the carbonyl reductase and recombinase to preparation of active chiral alcohols with a chiral carbonyl compound before asymmetrical reduction. The carbonyl reductase is derived from candida glabrata, is applied to preparation of a plurality of optically-active chiral alcohols such as (R)-chloromandelic acid methyl ester, (R)-2-hydroxy-4-phenyl ethyl butyrate, (R)-4-chlorin-3-phenyl ethyl butyrate and the like. Compared with other preparation methods, a product prepared through the method has high concentration, does not require additionally or slightly adding any expensive coenzyme, has high optical purity, and has the advantages of mild reaction conditions, easiness and convenience for operating, easiness for amplifying and the like, and has a good industrial application prospect in the production of clopidogrel, L-carnitine and perindopril antihypertensive medicinal intermediates.

Owner:EAST CHINA UNIV OF SCI & TECH

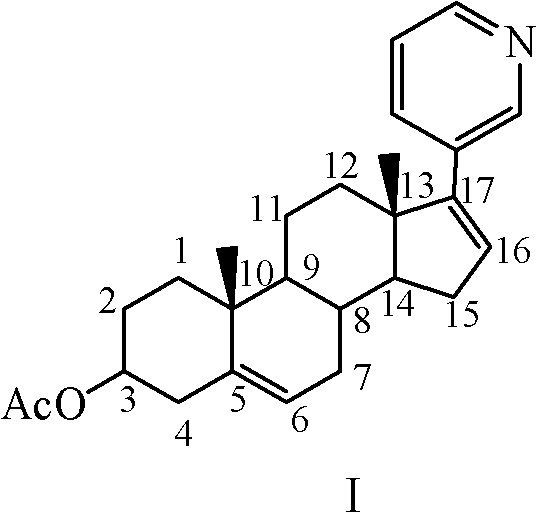

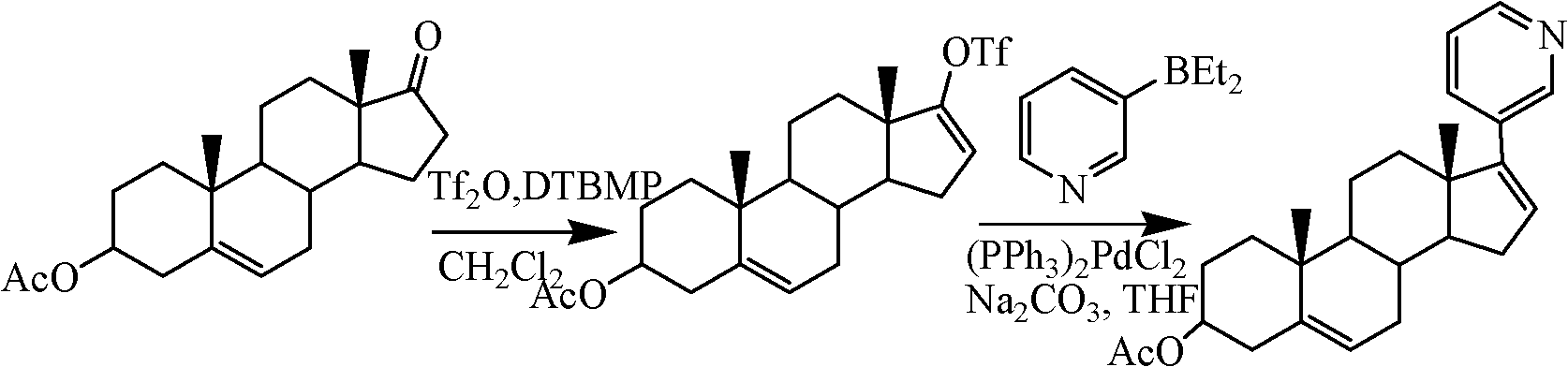

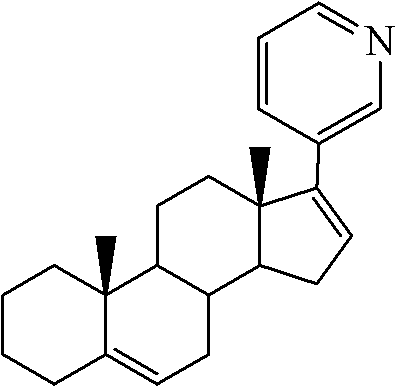

Preparation method of abiraterone acetate

ActiveCN102627681AReduce usageAvoid separation and purificationSteroidsAcetic anhydrideEthyl Chloride

The invention relates to a preparation method of abiraterone acetate. The method comprises: taking dehydroepiandrosterone as the raw material, which successively reacts with hydrazine hydrate and idoine so as to obtain 17-iodo-adrost-5, 16-diene-3beta-ol, which then undergoes a Negishi coupling reaction with 3-pyridine zinc halide to obtain abiraterone, and finally conducting esterification with acetyl chloride or acetic anhydride, thus obtaining the target product abiraterone acetate.

Owner:SHANDONG NEWTIME PHARMA

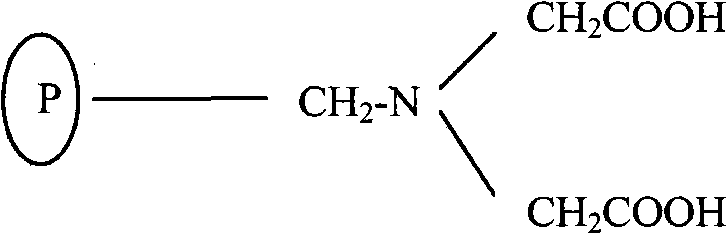

Novel chelate resin and production method and application thereof

ActiveCN101735372AHigh removal rateSimple process controlOther chemical processesMetal impuritiesChloroacetic acids

The invention provides a chelate resin and a production method and the application thereof, and the novel chelate resin can effectively remove impurities in trichlorosilane; the preparation method provided by the invention comprises the following steps: (1) zinc chloride is used as catalyzer, a white ball and chloromethyl ether are reacted to obtain chloromethylate white ball; (2) the chloromethylate white ball and hexamine are reacted, and then concentrated hydrochloric acid-ethanol mixing solution is used for decomposing, so as to obtain primary amine resin; (3) the primary amine resin is added in the chloroacetic acid aqueous solution, and the reaction is carried out for 10-30 hours at 55-70 DEG C to obtain the chelate resin; the chelate resin can effectively remove the metal impurities such as boron, phosphorus, calcium, magnesium, copper, ferrum and other impurities in trichlorosilane, the removal rate can reach more than 99 percent; the chelate resin has high processing capacity with 200t per cube and is the optimal choice for improving the product quality.

Owner:SUNRESIN NEW METERIALS CO LTD XIAN

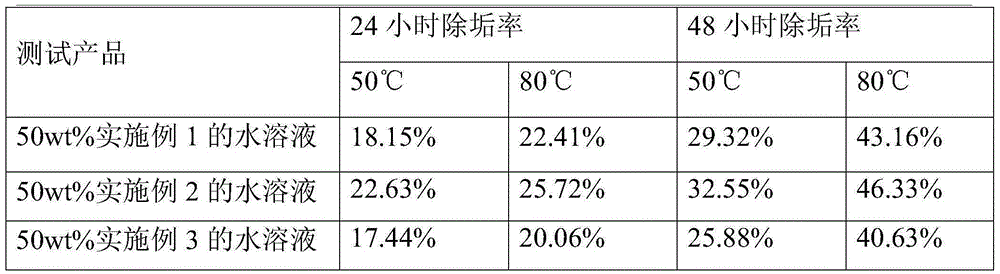

Barium-strontium-calcium descaling and blockage removing agent for near-well area and preparing method of barium-strontium-calcium descaling and blockage removing agent

ActiveCN105112036APrevents accumulation of scaleReduce secondary damageDrilling compositionCarboxylic saltChloroacetic acids

The invention discloses a barium-strontium-calcium descaling and blockage removing agent for a near-well area and a preparing method of the barium-strontium-calcium descaling and blockage removing agent. The barium-strontium-calcium descaling and blockage removing agent comprises a polyamine carboxylate solution, nonionic surfactant accounting for 3%-10% of the total mass of the polyamine carboxylate solution and an emulsion breaker accounting for 2%-8% of the total mass of the polyamine carboxylate solution. The polyamine carboxylate solution is prepared from polyamine midbody and chloroacetic acid salt through a reaction, wherein the polyamine midbody is prepared through organic amine and epoxy chloropropane with the mole ratio of 1.05-1.5:1 through a reaction, and the chloroacetic acid salt is prepared from chloroacetic acid and alkali with the same mole ratio through a reaction. The barium-strontium-calcium descaling and blockage removing agent for the near-well area has a good removing effect on indissolvable salt such as barium sulfate, strontium sulfate and calcium sulfate, and the descaling rate is higher than 40%. Meanwhile, the barium-strontium-calcium descaling and blockage removing agent has the expansion preventing and inhibiting performance, the clay expansion reducing rate is higher than 80%, corrosion to equipment is slight, and water locking can be avoided. Blockage removing can be effectively achieved on a reservoir stratum near a well, the permeability of the reservoir stratum is improved, and thus the recovery ratio of oil and gas resources is increased.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

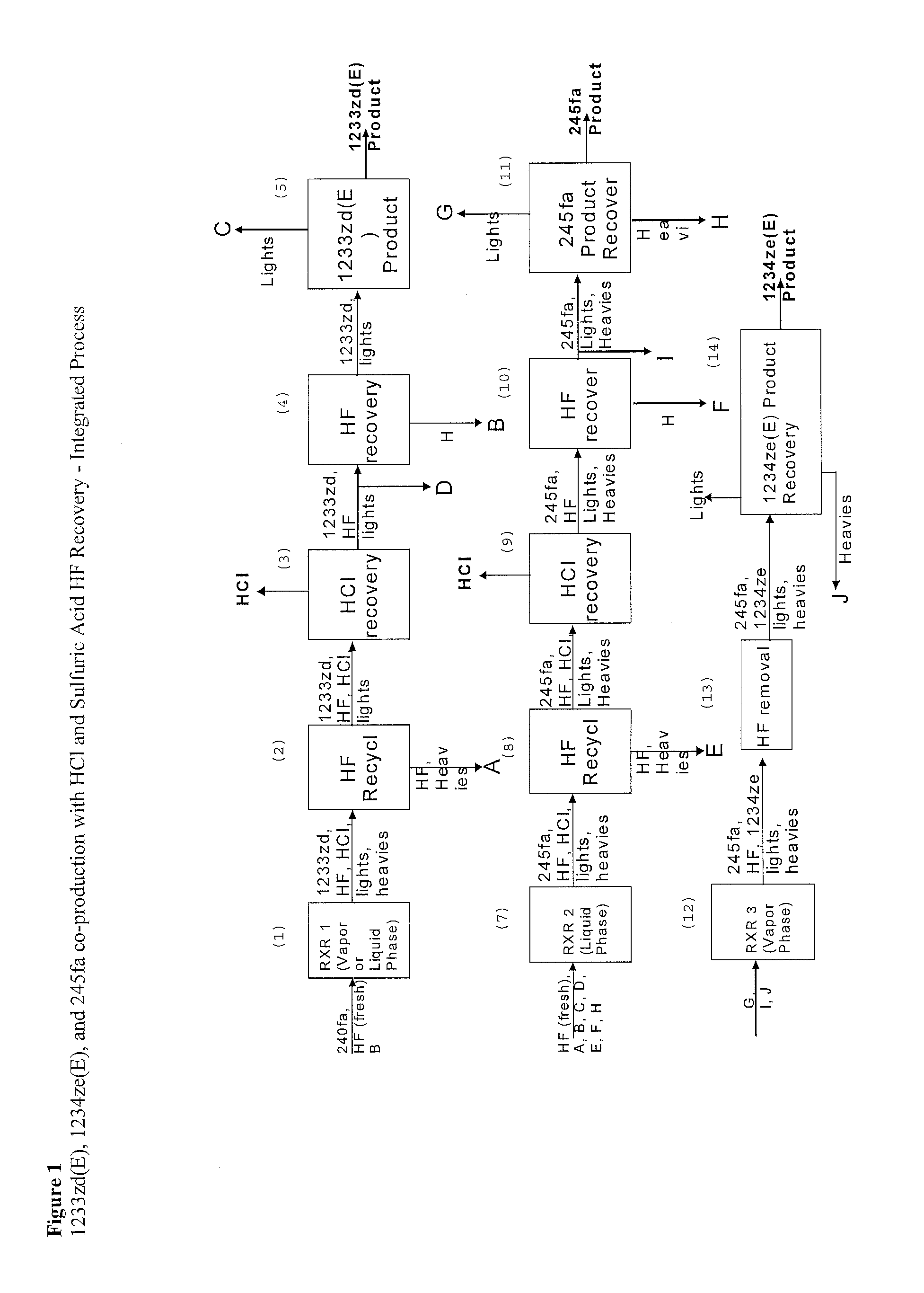

Integrated Process to Coproduce Trans-1-Chloro-3,3,3-Trifluoropropene, Trans-1,3,3,3-Tetrafluoropropene, and 1,1,1,3,3-Pentafluoropropane

ActiveUS20120059200A1High selectivityImprove production yieldPreparation by dehalogenationHydrocarbon from carbon oxidesGas phase1,3,3,3-Tetrafluoropropene

Disclosed is an integrated manufacturing process to co-produce (E)1-chloro-3,3,3-trifluoropropene, (E)1,3,3,3-tetrafluoropropene, and 1,1,1,3,3-pentafluoro-propane starting from a single chlorinated hydrocarbon feed stock, 240fa. The process includes a combined liquid or vapor phase reaction / purification operation which directly produces (E)1-chloro-3,3,3-trifluoropropene (1233zd(E)) from 240fa. In the second liquid phase fluorination reactor 1233zd(E) is contacted with HF in the presence of catalyst to produce 1,1,1,3,3-pentafluoropropane (245fa) with high conversion and selectivity. A third reactor is used for dehydrofluorination of 245fa to produce (E)1,3,3,3-tetrafluoropropene (1234ze(E)) by contacting in the liquid phase with a caustic solution or in the vapor phase using a dehydrofluorination catalyst. This operation may be followed by one or more purification processes to recover the 1234ze(E) product.

Owner:HONEYWELL INT INC

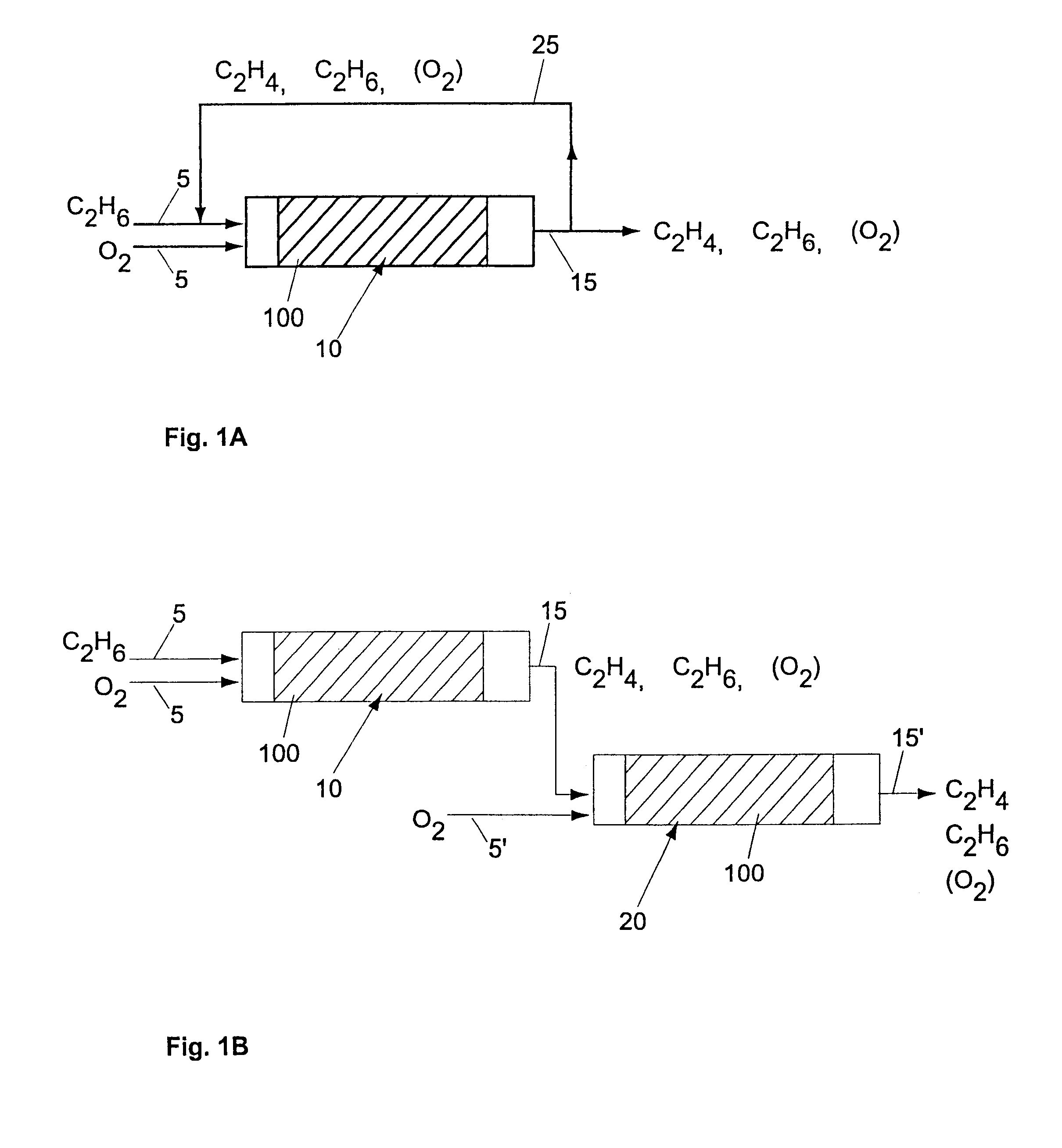

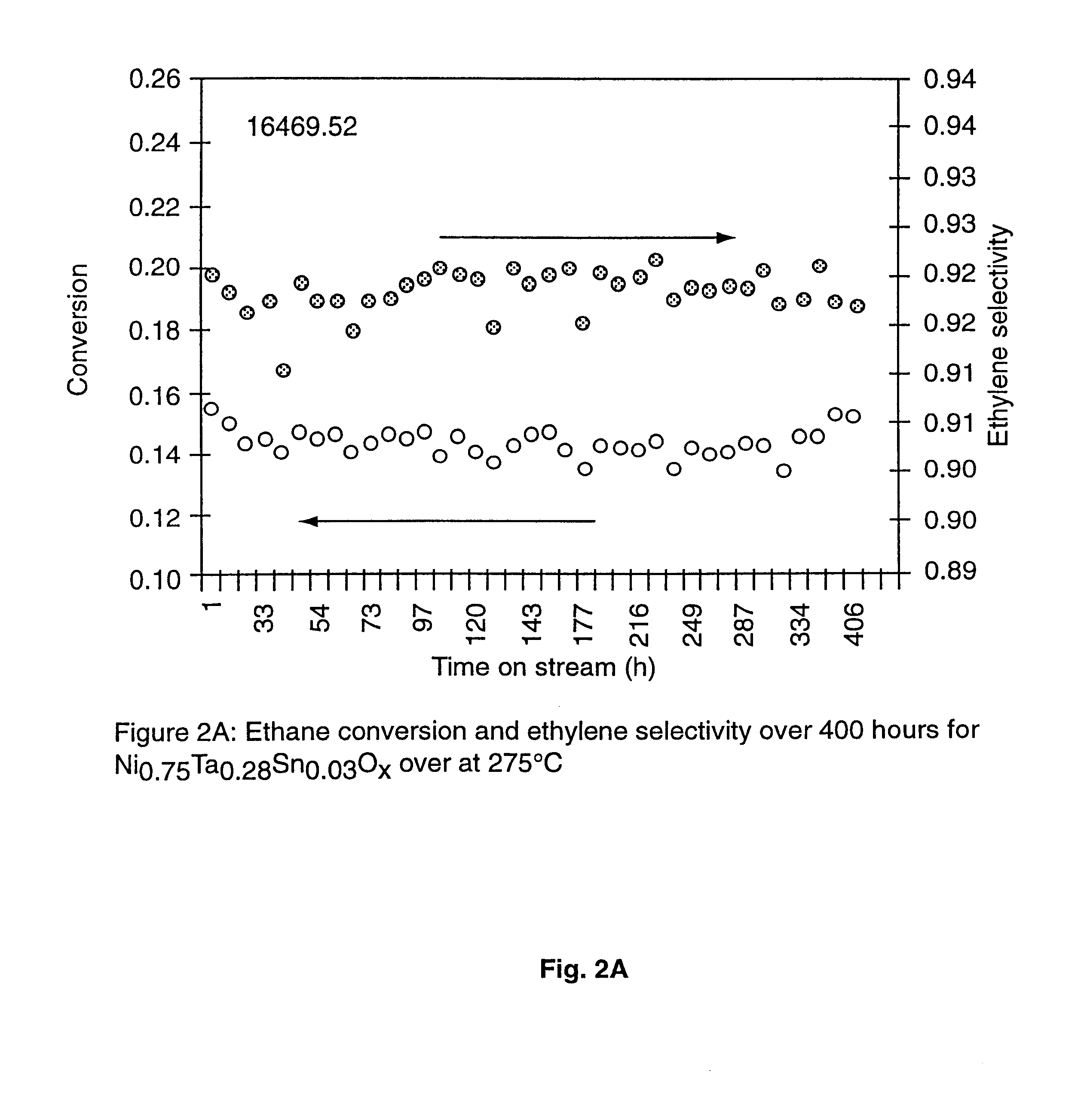

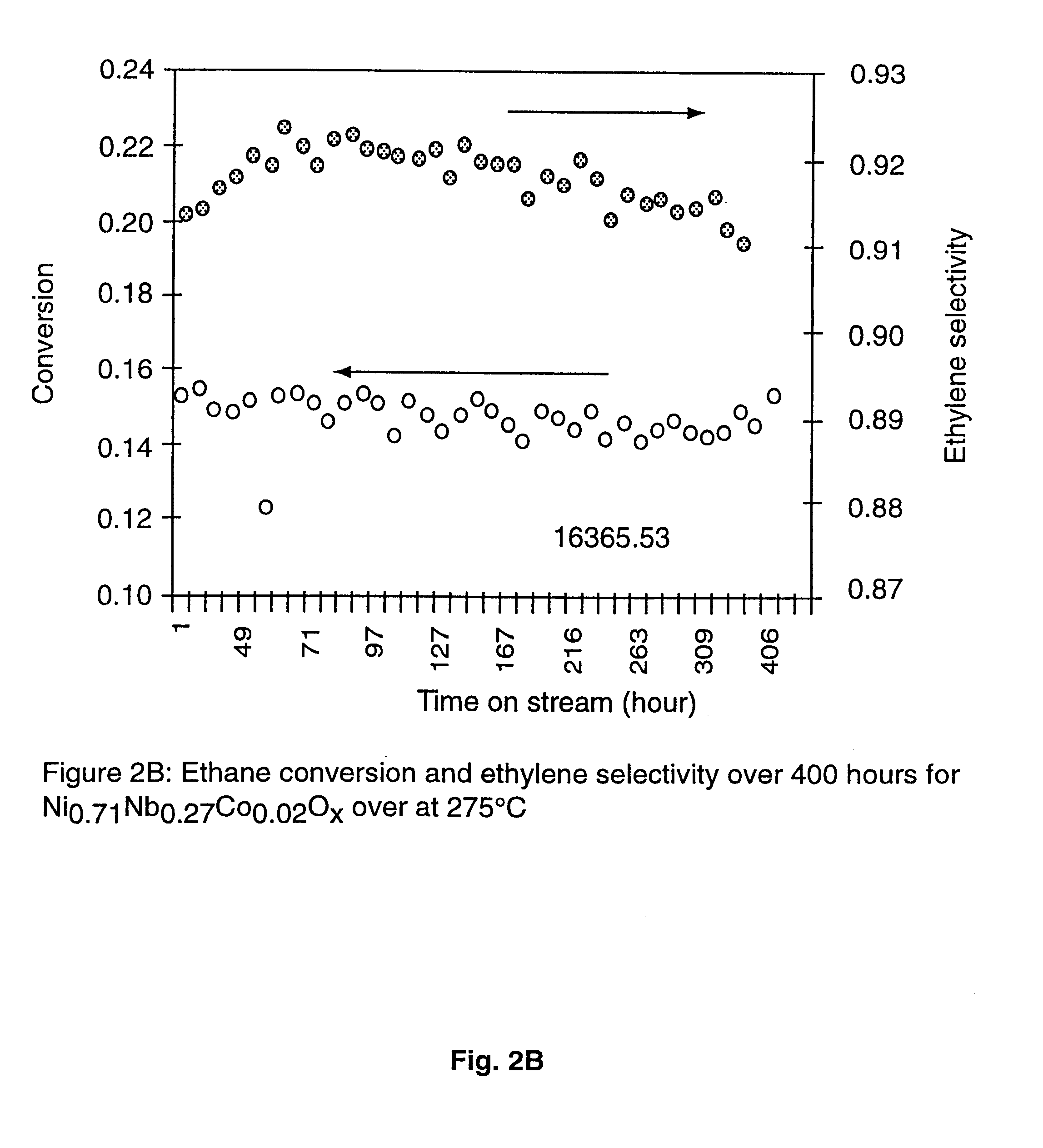

Ni catalysts and methods for alkane dehydrogenation

Owner:CELANESE INT CORP

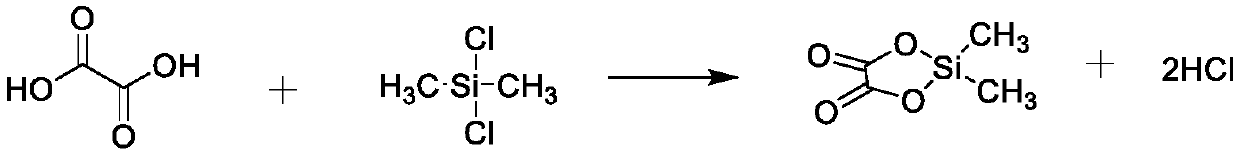

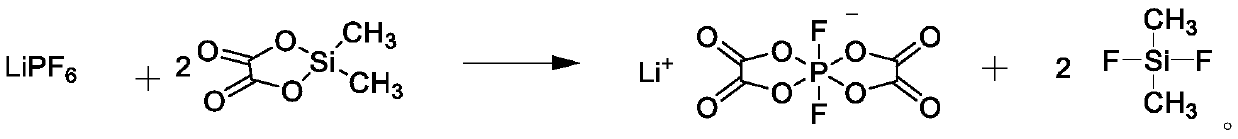

Preparation method of lithium difluorobisoxalate phosphate solution

The invention provides a preparation method of a lithium difluorobisoxalate phosphate solution. The preparation method of the lithium difluorobisoxalate phosphate solution comprises the following steps that (1) dichlorodimethylsilane and oxalic acid are reacted in the presence of a non-aqueous solvent to generate dimethyl silicon-based oxalate; and (2) lithium hexafluorophosphate is added into thereaction solution in the step (1), and reacting is carried out to obtain the lithium difluorobisoxalate phosphate solution. The preparation method is simple and practical, and industrial production can be achieved; the prepared lithium difluorobisoxalate phosphate solution can be directly used as an additive of a non-aqueous electrolyte battery; and the prepared lithium difluorobisoxalate phosphate solution has few chlorine compounds and free acids, wherein the chlorine compounds in terms of chlorine concentration are less than 5 mass ppm, and the free acids in terms of acid concentration converted from hydrofluoric acid are less than 200 mass ppm.

Owner:JIANGSU GUOTAI SUPER POWER NEW MATERIALS

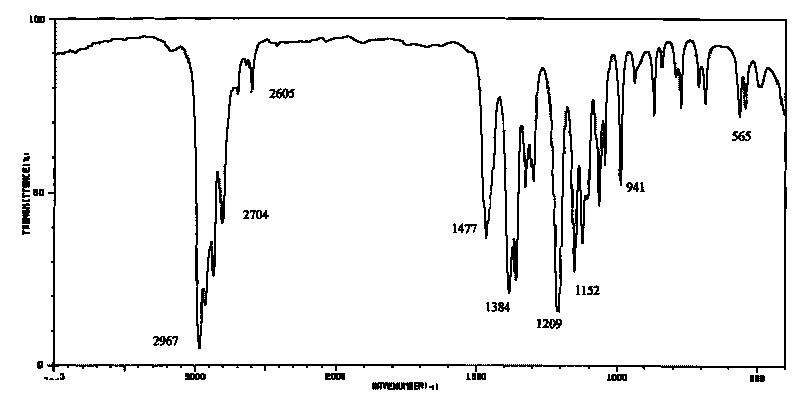

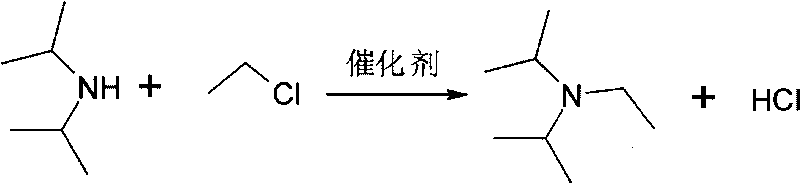

Preparation method of N,N-diisopropylethylamine

InactiveCN101759571AIncrease profitLow costAmino preparation by functional substitutionDiisopropylamineReaction temperature

The invention discloses a preparation method of N,N-diisopropylethylamine, which comprises the following steps of: reacting diisopropylamine and ethyl chloride as raw materials in a high-pressure autoclave by adopting an MIX type catalyst, wherein the mol ratio of the diisopropylamine to the ethyl chloride is 2-4:1, the mass ratio of the MIX type catalyst to the ethyl chloride is 1:20-10, the reaction temperature is 130-230 DEG C, the reaction pressure is 0.8-2.5MPa, and the reaction time is 4-10 hours; and adding a strongly alkaline solution into the obtained reaction liquid until the pH is 12.5-13.5, and then carrying out liquid separation and rectification to obtain the N,N-diisopropylethylamine. The preparation method of the N,N-diisopropylethylamine has the characteristics of simple process, high yield, low cost and little discharge of the three wastes.

Owner:ZHEJIANG UNIV

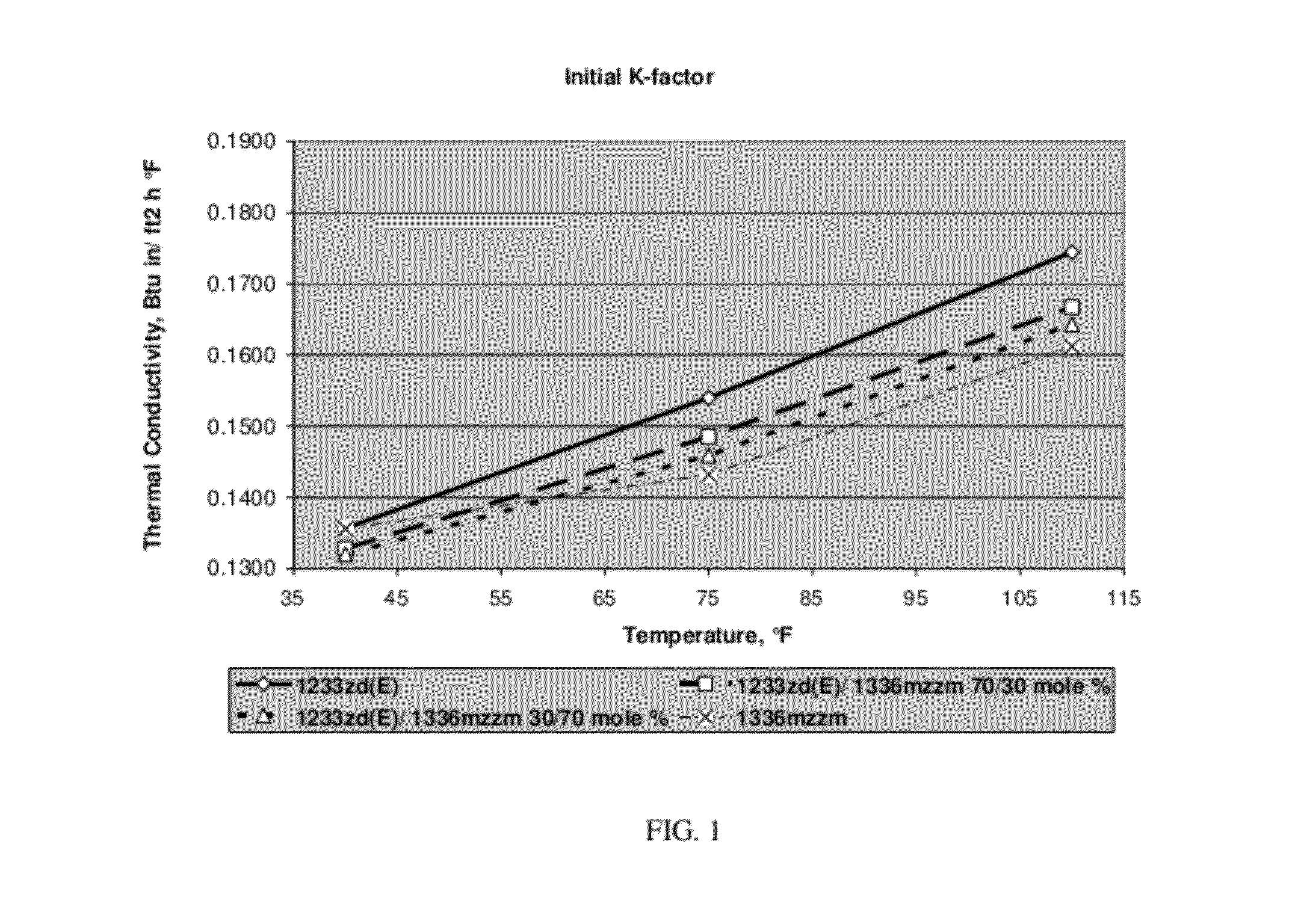

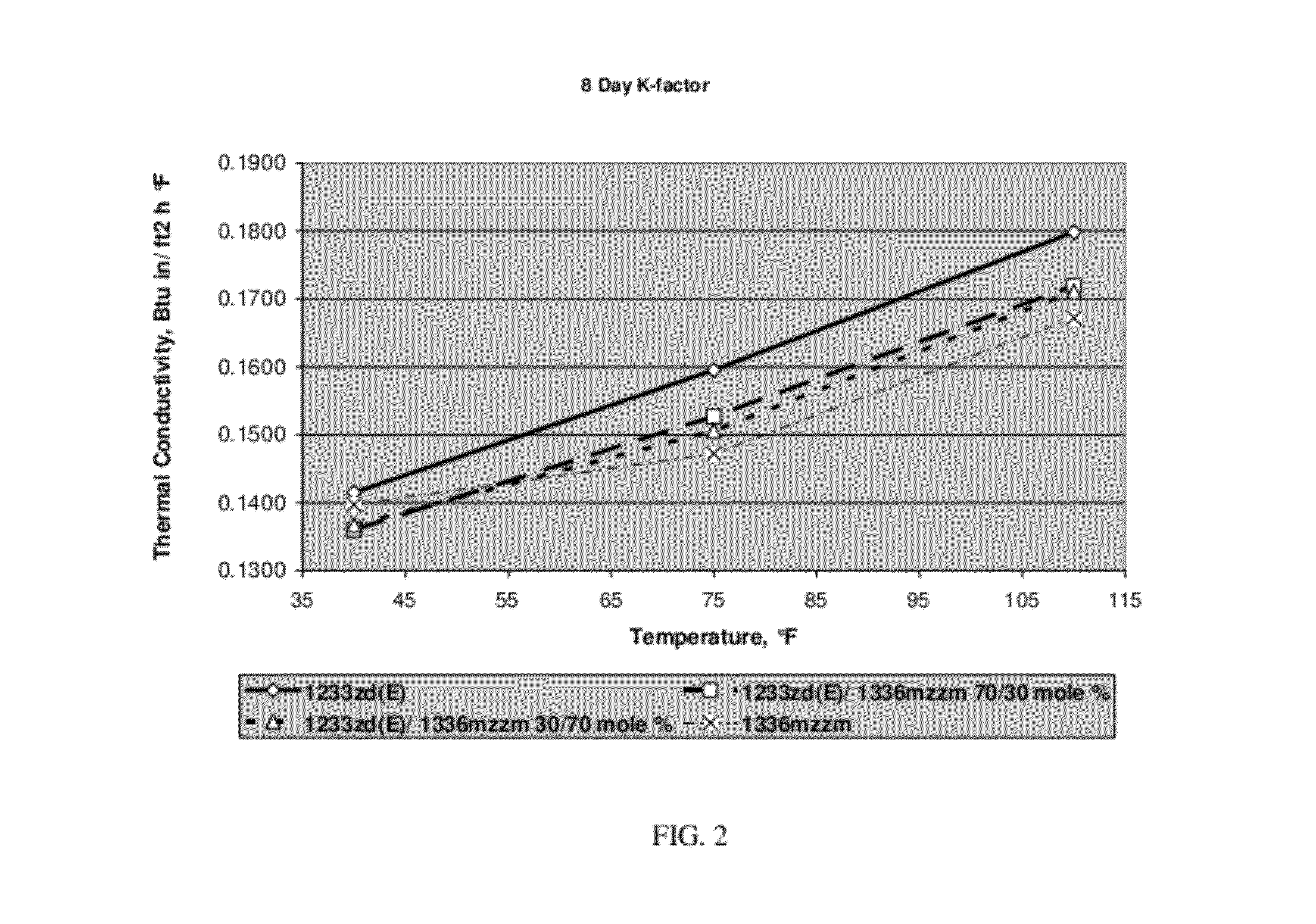

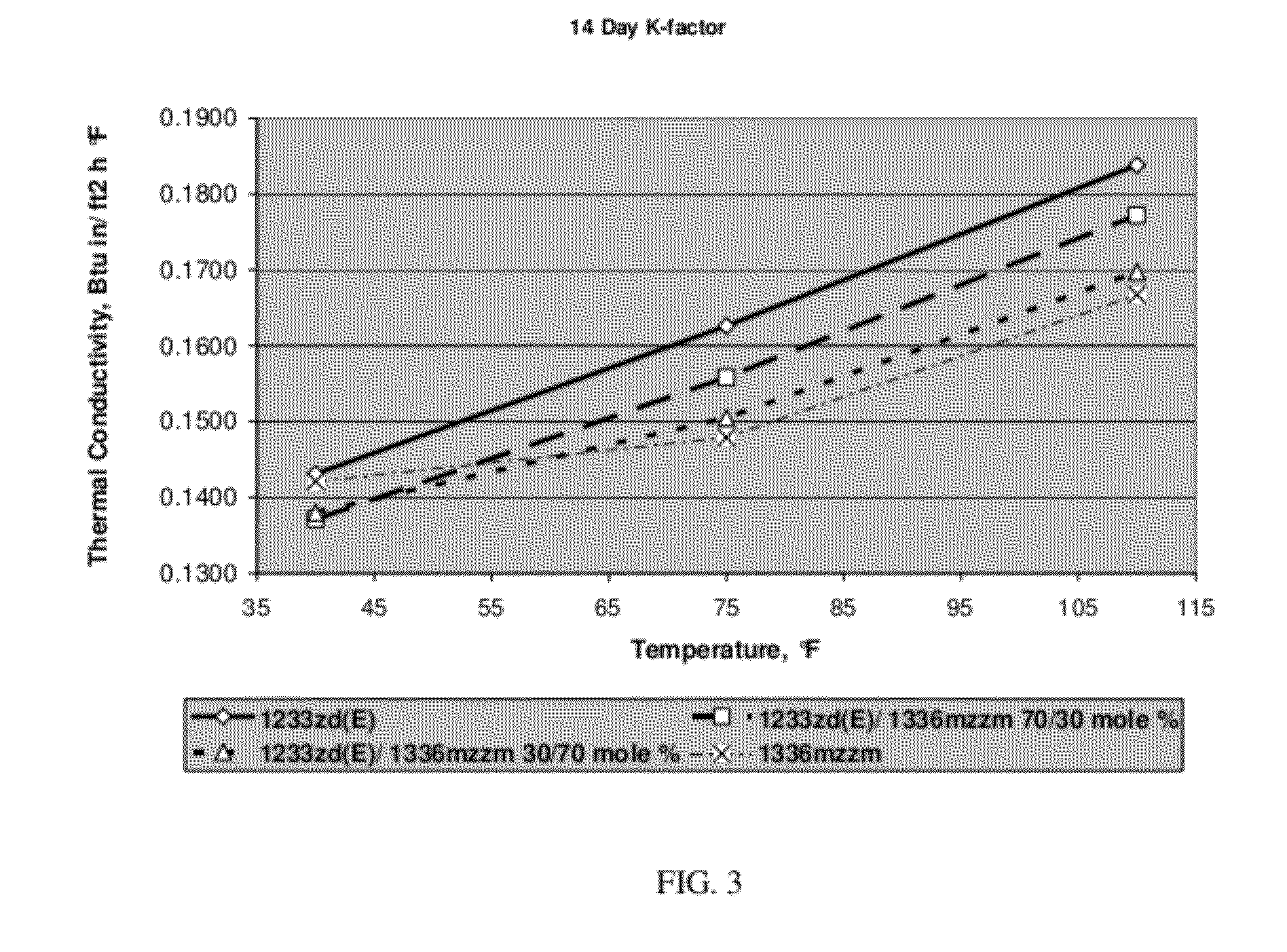

Mixtures containing 1,1,1,3,3,3-hexafluorobutene and 1-chloro-3,3,3-trifluoropropene

ActiveUS20120104307A1Readily apparentOther chemical processesTransportation and packagingSolventEthyl Chloride

The present invention relates to mixtures of 1,1,1,3,3,3-hexafluorobutene (1336mzzm) and 1-chloro-3,3,3-trifluoropropene (1233zd). The blends are useful as blowing agents for polymer foam, solvents, aerosol propellants and heat transfer media.

Owner:HONEYWELL INT INC

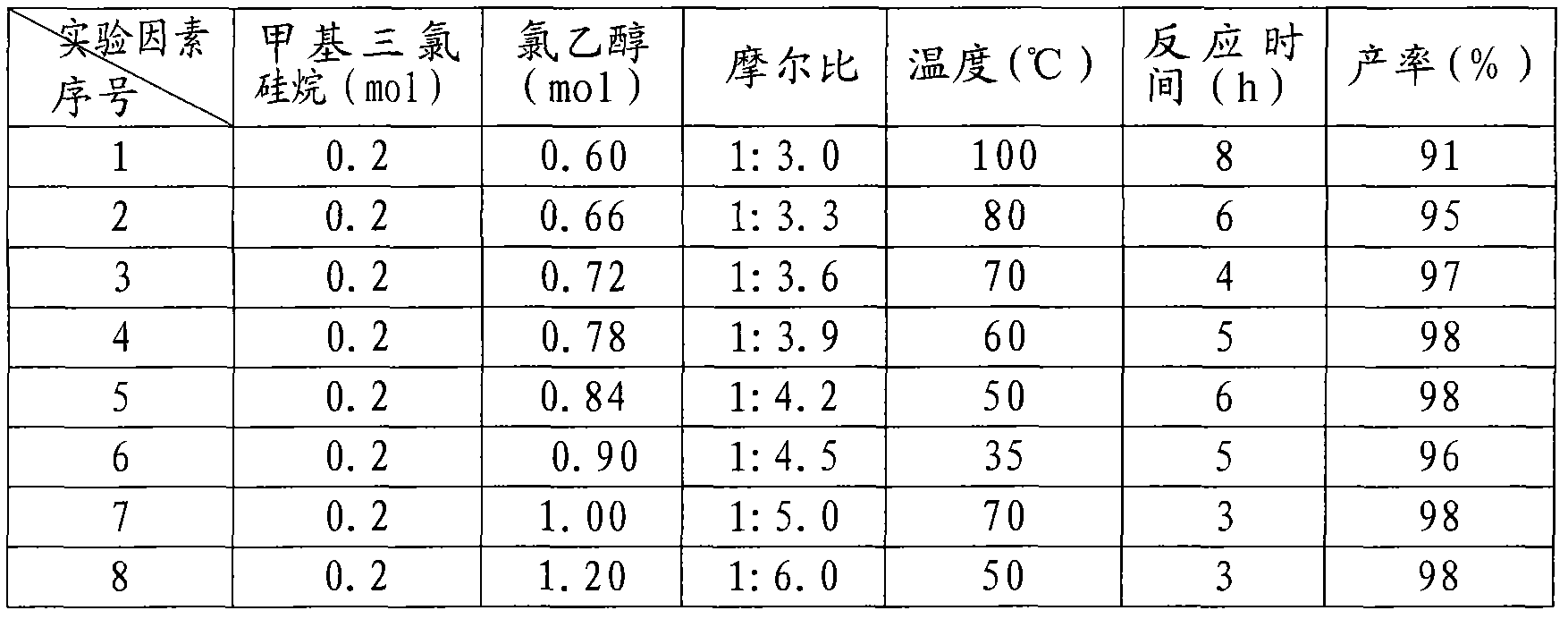

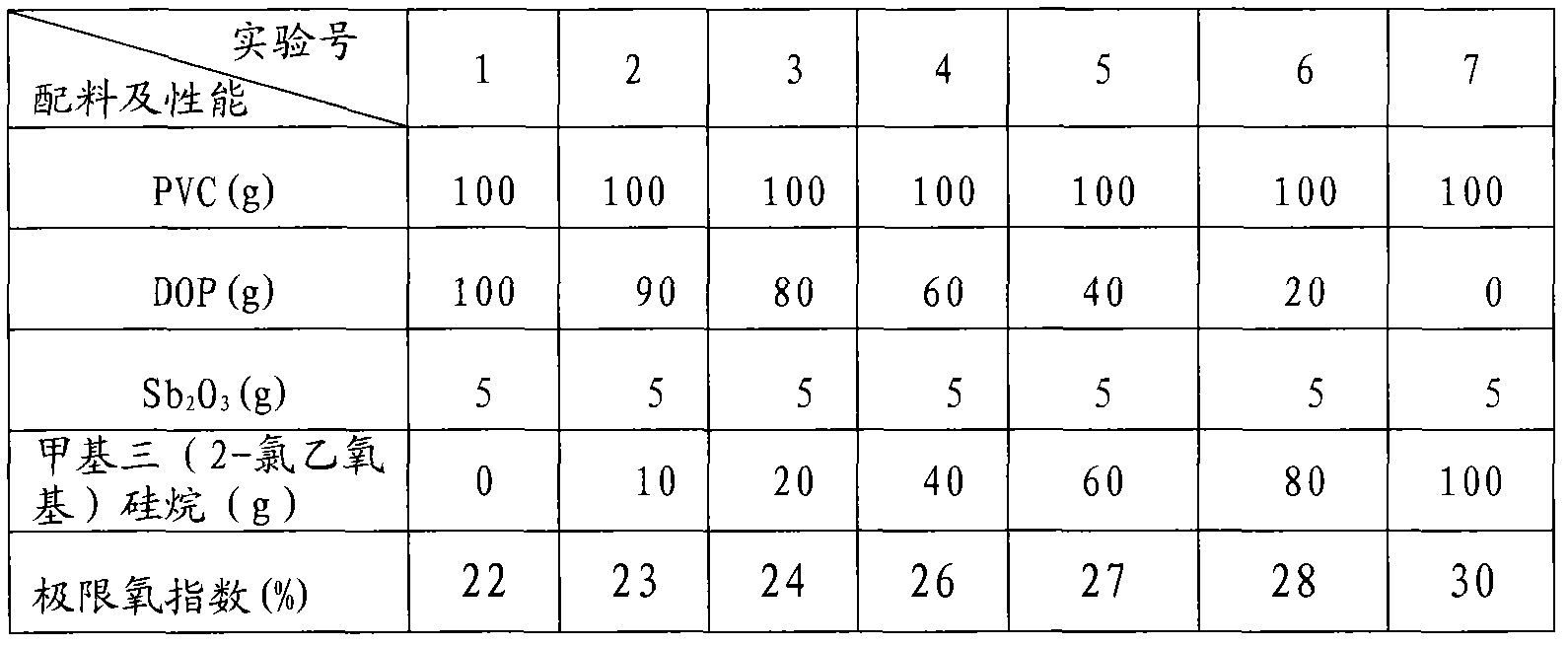

Methyl tri(2-chloroethoxy) silane compound and preparation method thereof

ActiveCN102174055AStabilize the C-Si bond structureSymmetrical ester structureGroup 4/14 element organic compoundsSilane compoundsHalogen

The invention relates to a methyl tri(2-chloroethoxy) silane compound which is used as a silicon-halogen synergistic flame-retardant plasticizer and a preparation method thereof. The methyl tri(2-chloroethoxy) silane compound has the following structural formula: CH3Si(OCH2CH2Cl)3. The preparation method of the methyl tri(2-chloroethoxy) silane compound comprises the following steps: dropwise adding and stirring chloroethanol at a certain molar ratio to methyl trichlorosilane, carrying out a reaction on the chloroethanol and the methyl trichlorosilane for a certain time at a certain temperature, and purifying after finishing hydrogen chloride release and reaction to obtain methyl tri(2-chloroethoxy) silane. The methyl tri(2-chloroethoxy) silane can be used as the good flame-retardant plasticizer, and the process for producing the methyl tri(2-chloroethoxy) silane is simple, has low equipment investment and cost and is easy to realize industrial production.

Owner:河南森远科技有限公司

Gold-containing catalyst for preparing vinyl chloride by using acetylene method as well as preparation method and application of catalyst

InactiveCN102327777ANo pollution in the processThere will be no deactivationMolecular sieve catalystsPreparation by halogen halide additionMicro structureEthyl Chloride

The invention discloses a gold-containing catalyst for preparing vinyl chloride by using an acetylene method as well as a preparation method and application of the catalyst. The catalyst contains a gold element, a lanthanum element, a cobalt element, a co-catalytic metal element and a carrier with a porous micro-structure. The gold accounts for 0.3%-2% by mass of the catalyst; the gold element in the catalyst comes from gold chlorides or gold nitrates; the cobalt element comes from chlorides of the cobalt or cobalt nitrates; and the lanthanum element comes from lanthanum chlorides or lanthanum nitrates. The catalyst disclosed by the invention in use is free from inactivation phenomenon caused by sublimation of industrial catalyst mercury chloride, has no pollution to the environment, overcomes defects of high toxicity and high pollution of the conventional industrial catalyst mercury chloride, has the characteristics of simple preparation method, high conversion rate of the acetylene and selectivity of the vinyl chloride, long service life up to 1000 hours or more, high temperature resistance, and high intensity and is renewable, and the conversion rate of the acetylene and selectivity of the vinyl chloride approximate to or exceed the technical indexes of the mercury chloride catalyst.

Owner:TIANJIN UNIV +1

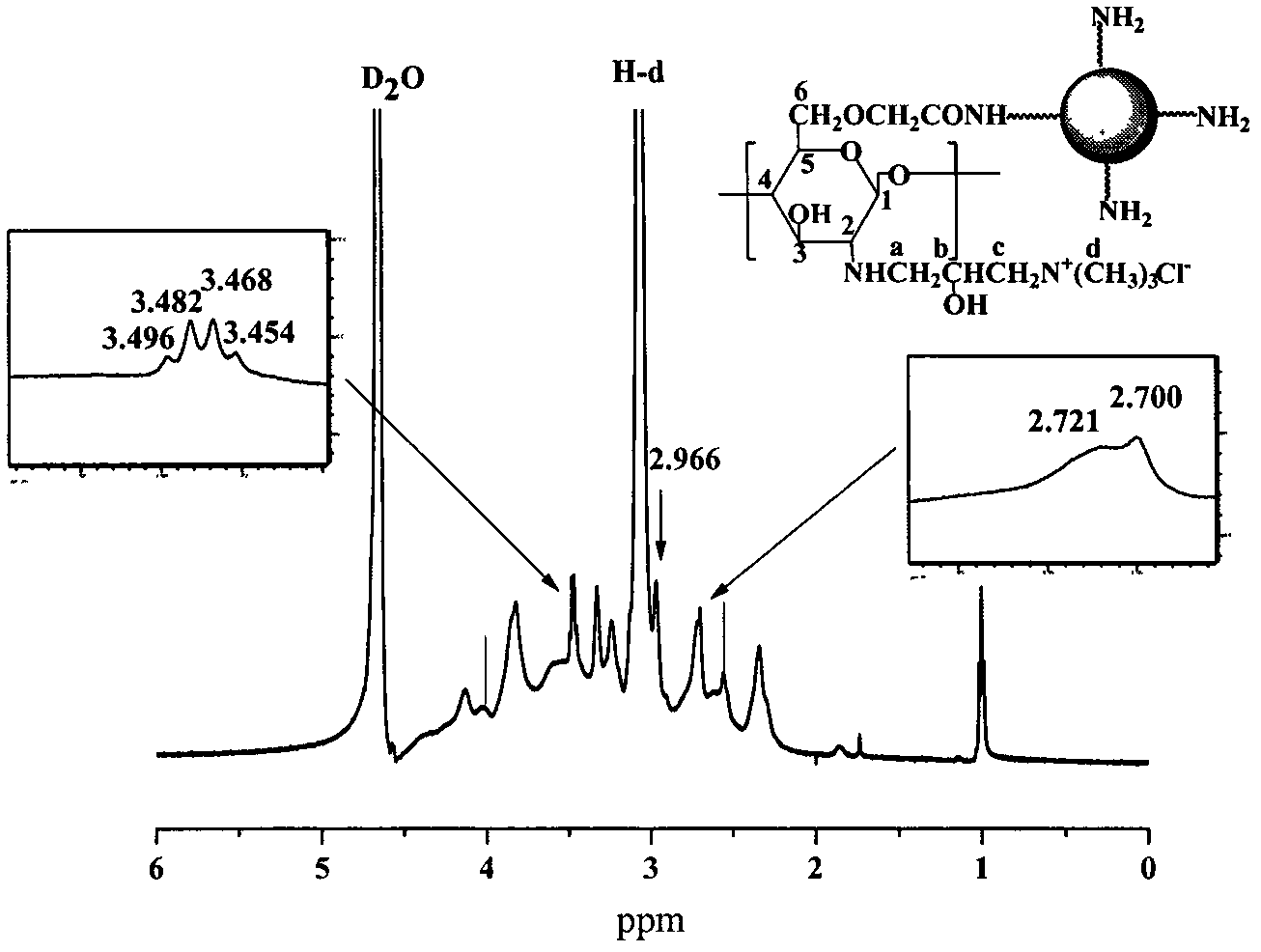

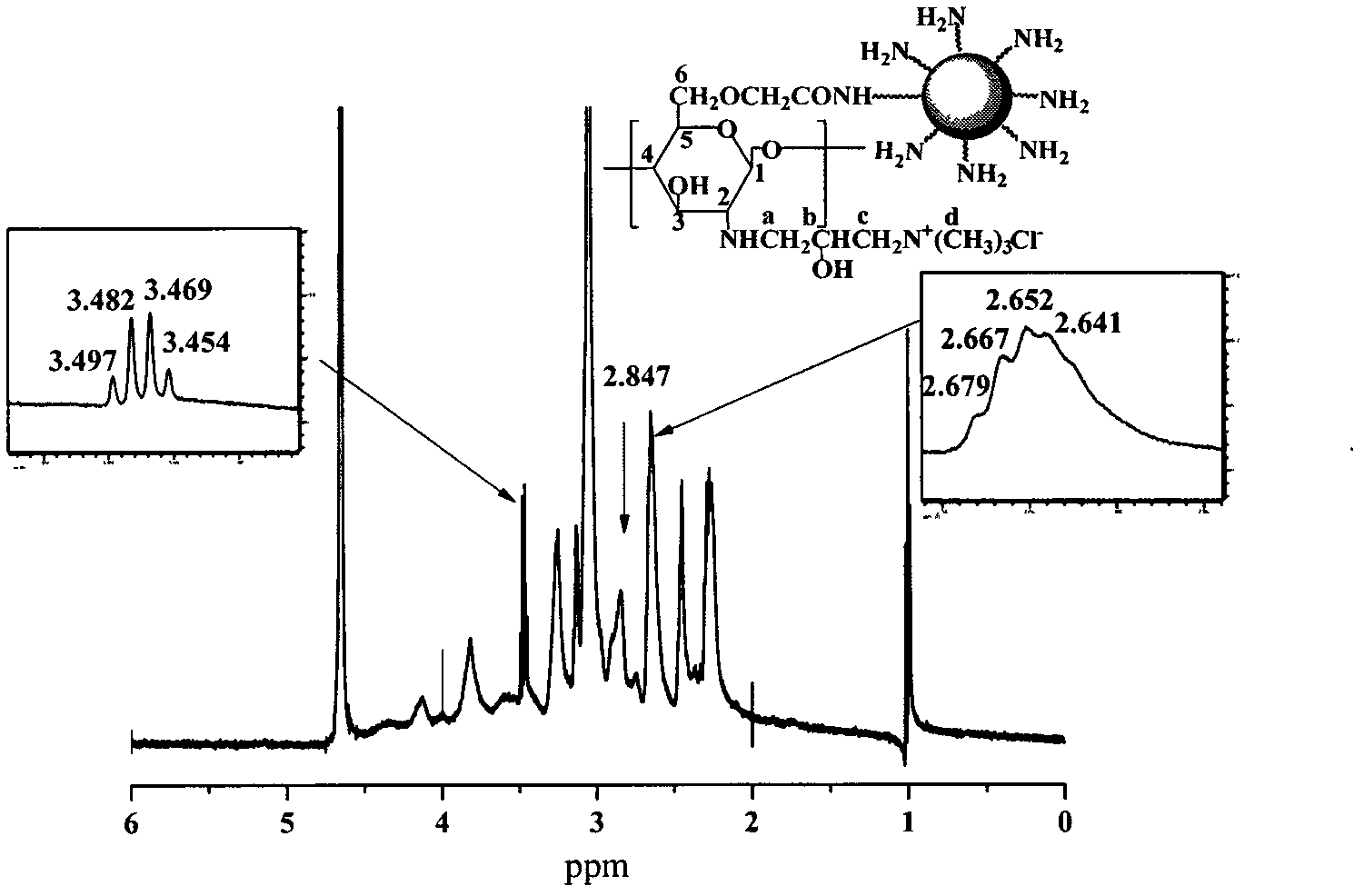

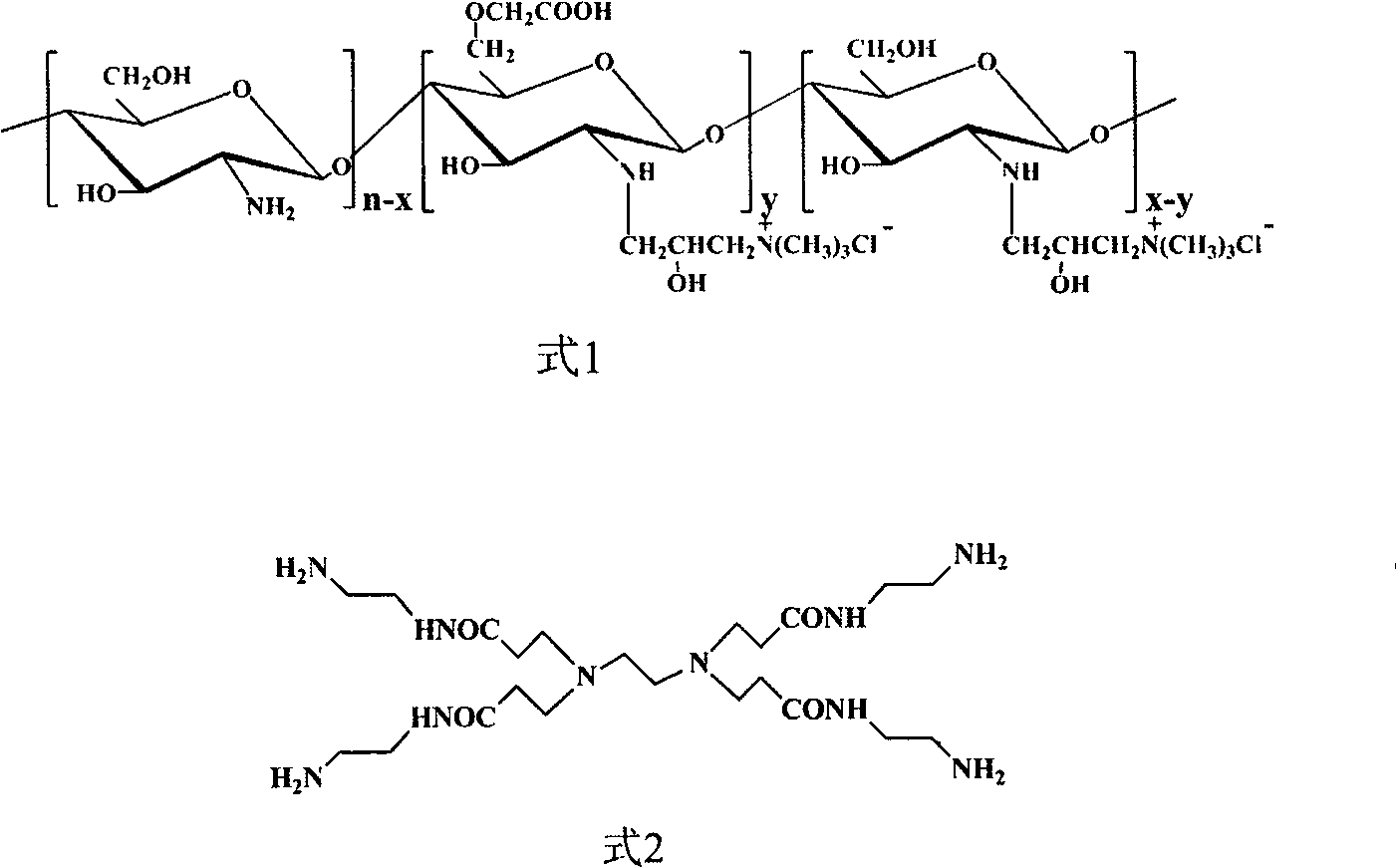

Carboxymethyl chitosan quaternary ammonium salt/PAMAM(Polyamidoamine) core-shell nanoparticles and preparation method

The invention discloses carboxymethyl chitosan quaternary ammonium salt / PAMAM(Polyamidoamine) core-shell nanoparticles and a preparation method. The nanoparticles are chitosan derivatives which are formed in a way that amino-terminated polyamidoamine dendritic macromolecule is grafted with carboxymethyl chitosan quaternary ammonium salt, and the chitosan derivatives are self-aggregated to form core-shell nanoparticles in water solution. The preparation method comprises the following steps: performing quaterisation decoration to amino at a second position of chitosan by CTA (3-Chloro-2-hydroxypropyltrimethyl ammonium chloride); performing carboxymethyl decoration to hydroxy at a sixth position of chitosan quaternary ammonium salt to synthetize carboxymethyl chitosan quaternary ammonium salt; activating carboxyl of the carboxymethyl chitosan quaternary ammonium salt by using NHS(N-Hydroxysuccinimide) / EDC(carbodiimide) to link the amino-terminated polyamidoamine dendritic macromolecule to synthetize the dendritic chitosan derivatives. The preparation process condition is simple and mild, and the product is easy to purify; and the core-shell nanoparticles of the prepared dendritic chitosan derivatives have the advantages of excellent water-solubility and functionality and has the attractive application prospect in the fields of antibiosis, gene transfer and drug controlled release.

Owner:TIANJIN UNIV

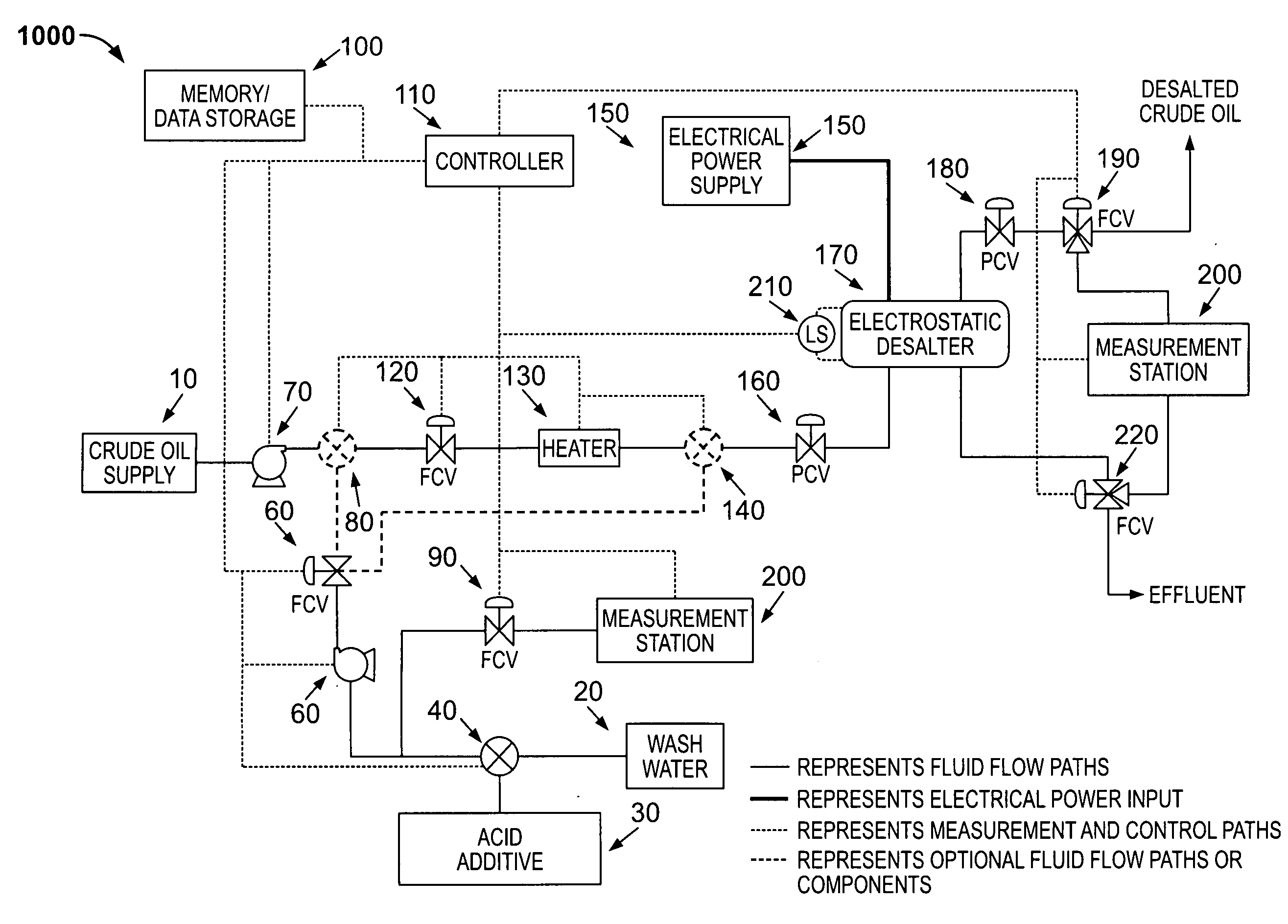

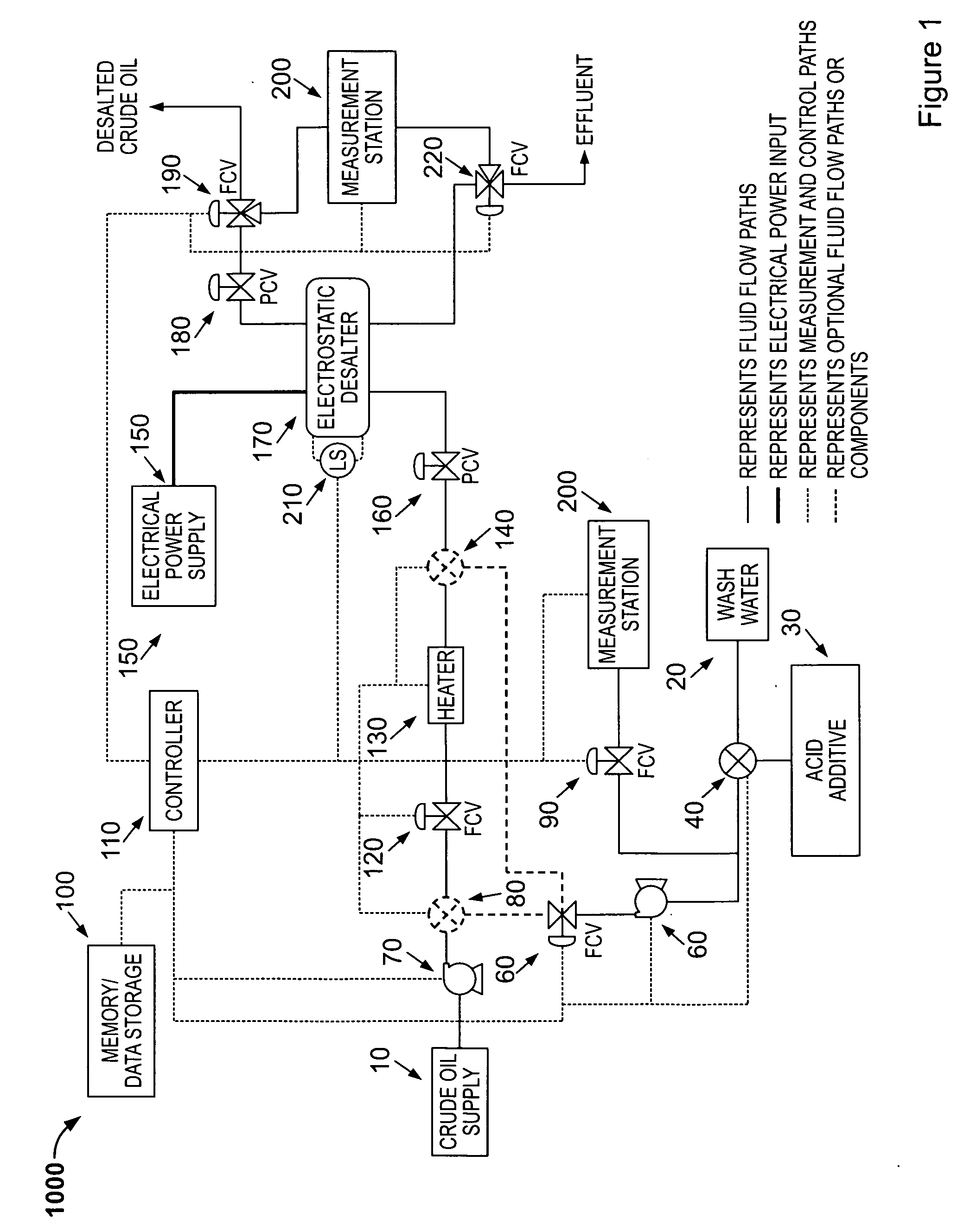

Method and device for electrostatic desalter optimization for enhanced metal and amine removal from crude oil

InactiveUS20110120913A1Working-up pitch/asphalt/bitumen by selective extractionSolvent extractionChloroacetic acidsAlpha hydroxy acid

A method for removing calcium, iron, other metals, and amines from crude oil in a refinery desalting process includes the steps of: running a plurality of tests to determine at least one statistically significant processing characteristic of the refinery desalting process; adding a wash water to the crude oil; adding the wash water to the crude oil to create an emulsion; adding to the wash water, the crude oil or the emulsion an acid additive consisting of at least one of the following: oxalic acid, citric acid, water-soluble hydroxyacid selected from the group consisting of glycolic acid, gluconic acid, C.sub.2-C.sub.4 alpha-hydroxy acids, malic acid, lactic acid, poly-hydroxy carboxylic acids, thioglycolic acid, chloroacetic acid, polymeric forms of the above hydroxyacids, poly-glycolic esters, glycolate ethers, and ammonium salt and alkali metal salts of these hydroxyacids, and mixtures thereof; resolving the emulsion containing the acid additive into a hydrocarbon phase and an aqueous phase; and adjusting a control setting of the processing characteristic as a function of the tests.

Owner:ASSATEAGUE OIL

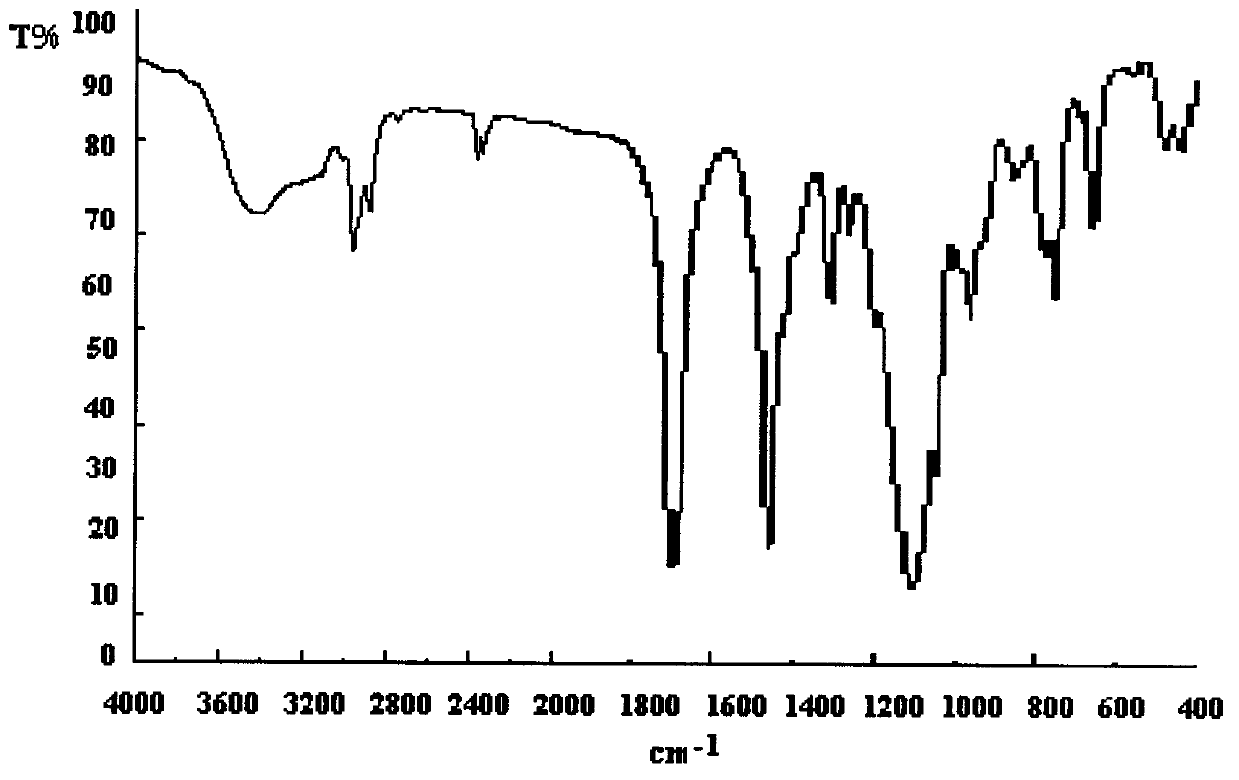

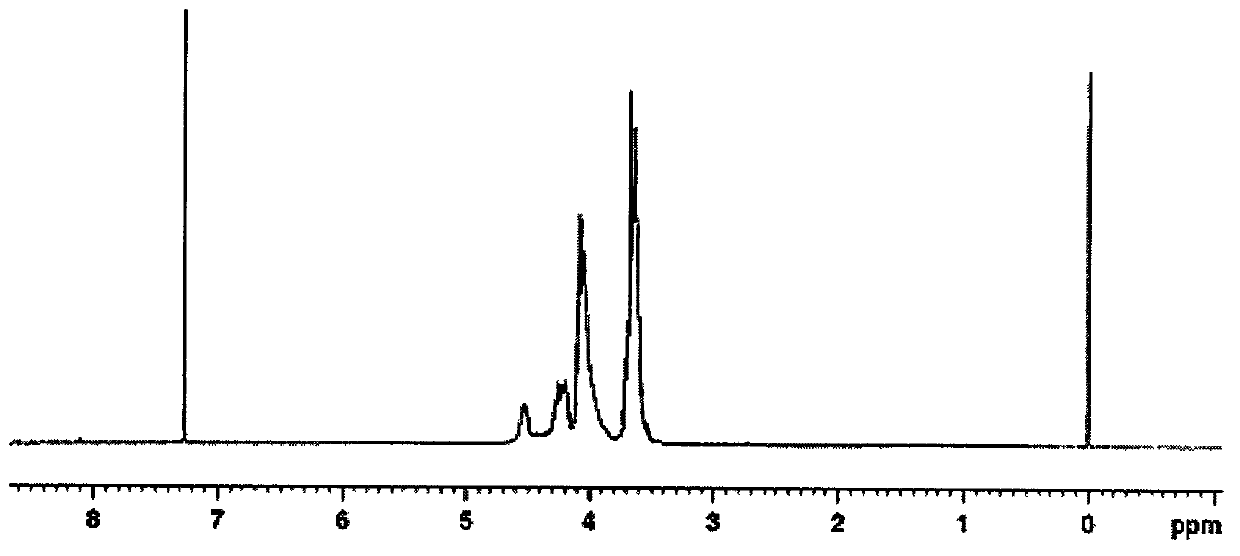

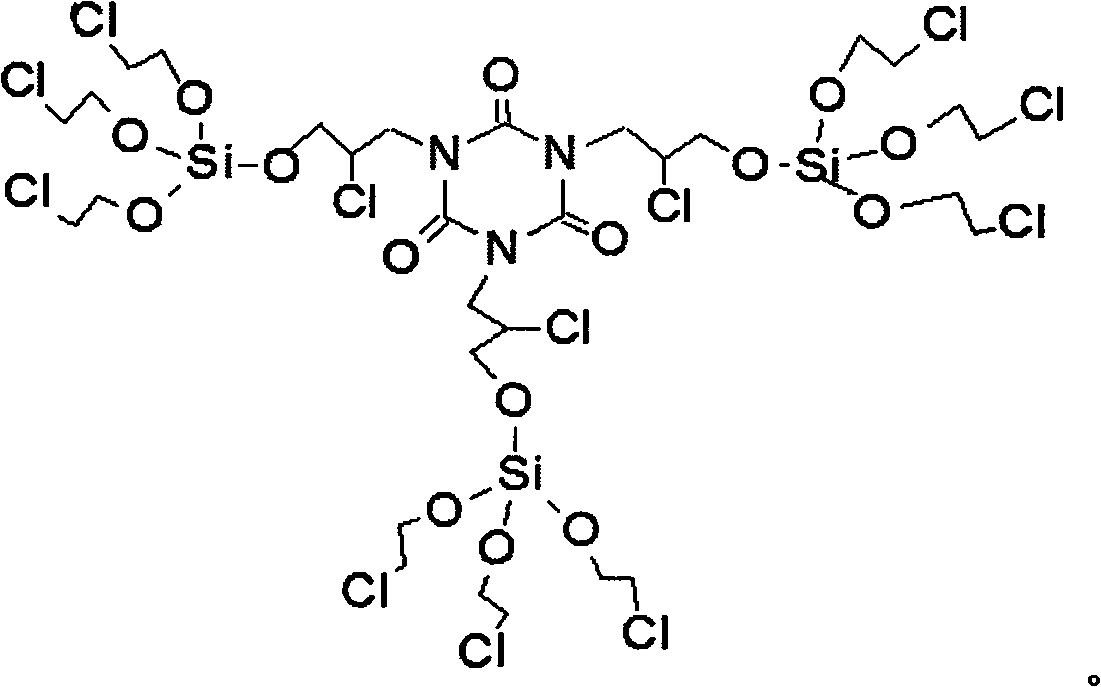

Isocyanurate chloropropyl chloroethyl silicate and preparation method thereof

ActiveCN102731545AGood compatibilityHigh synergistic flame retardant performanceSilicon organic compoundsEpoxyPolyvinyl chloride

The invention relates to a nitrogen, silicon and chlorine thee-element synergic flame retardant tri{2-chloro-3-[tri(chloroethoxy)silicon acyloxy]propyl}isocyanurate compound and a preparation method thereof. The structure of the compound is shown as a formula in the specification. The preparation method comprises the following steps: dripping organic solvent solution of triglycidyl Isocyanurate into silicon tetrachloride, and reacting for 4 to 6 hours at a temperature of between 50 and 70 DEG C; and cooling to 30 DEG C, introducing ethylene oxide under the liquid surface, reacting for 2 to 3 hours at a temperature of between 45 and 55 DEG C, and purifying to obtain the tri{2-chlor-3-[tri(chloroethoxy)silicon acyloxy]propyl}isocyanurate. The compound has good flame retardant plasticization, and is suitable for flame retardant plasticizer such as polyvinyl chloride, polyurethane, epoxy resin, unsaturated resin and the like; and the method has simple production process and low cost, and is easy for industrial production.

Owner:SUZHOU UNIV OF SCI & TECH

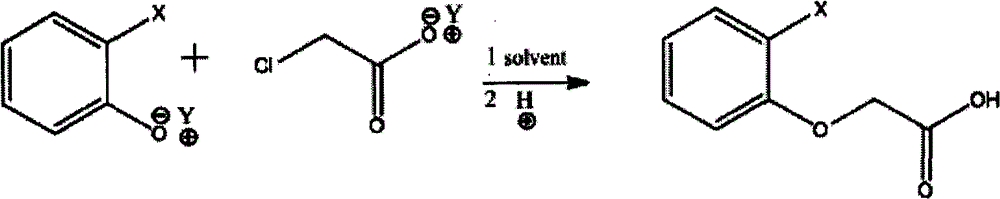

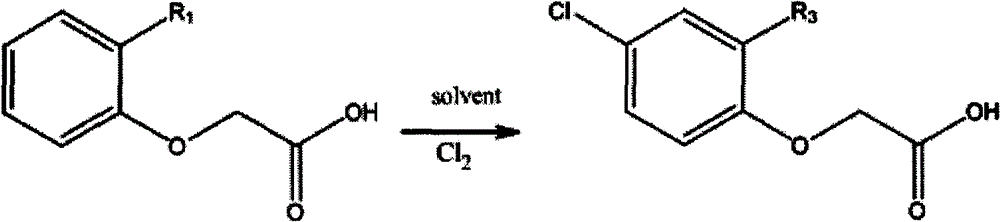

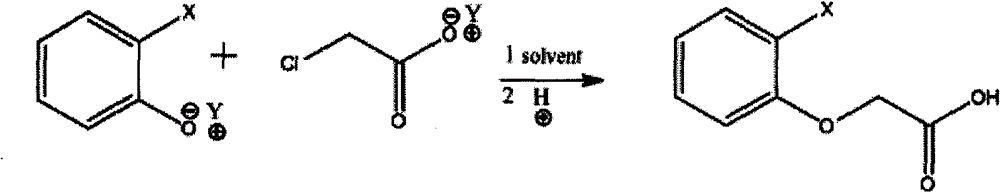

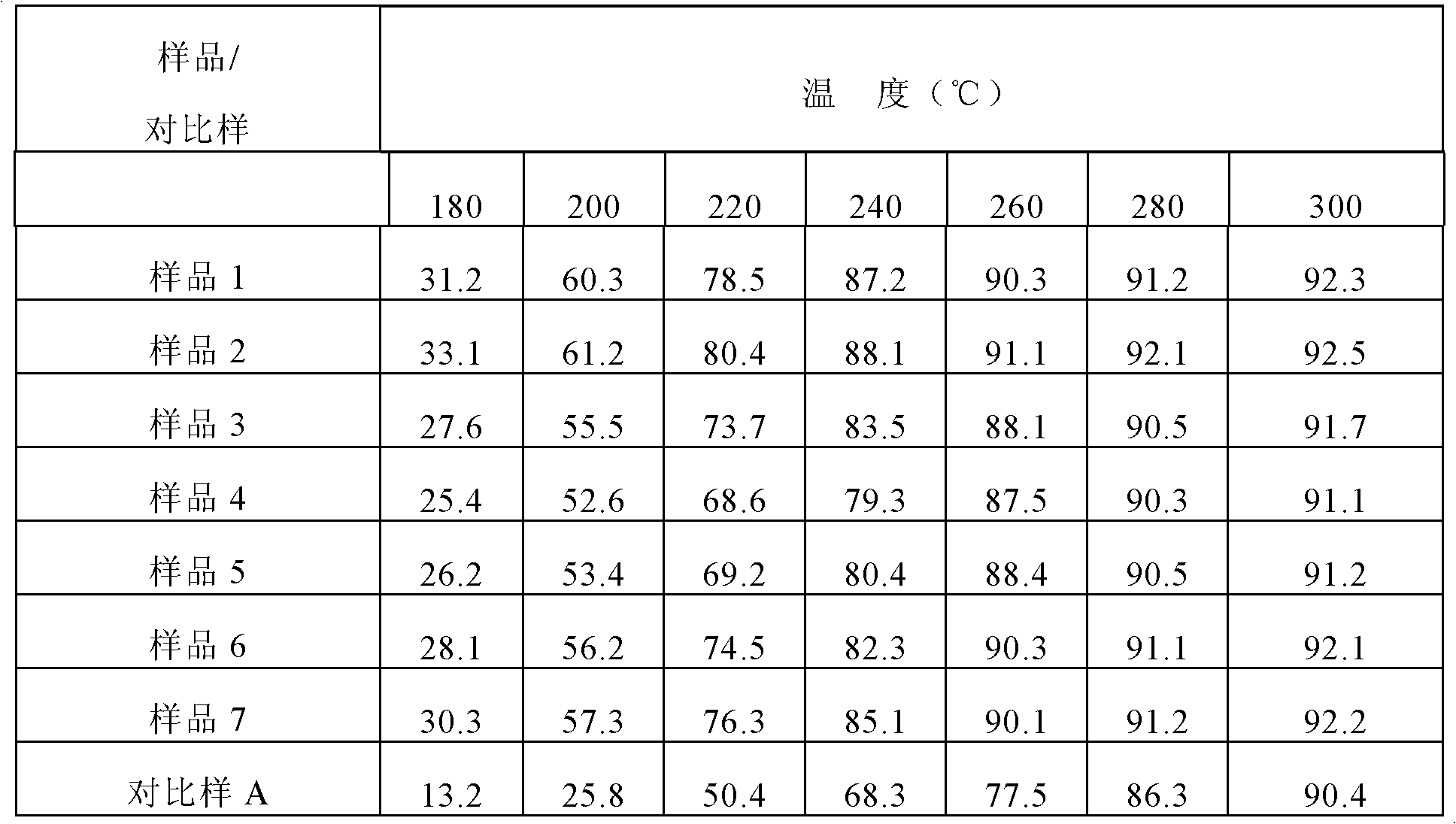

Method for synthesizing phenoxyacetic acid derivative

ActiveCN103058855AAvoid external dischargeMeet production balanceOrganic compound preparationCarboxylic compound preparationChloroacetic acidsEthyl Chloride

The invention relates to a method for synthesizing a phenoxyacetic acid derivative. The method comprises the steps of mixing a salt compound of phenol or methyl phenol and a salt compound of chloroacetic acid, putting the mixture in a solvent to carry out a heating reaction, acidifying with an inorganic acid to obtain phenoxyacetic acid, dissolving the phenoxyacetic acid in a solvent, adding a catalyst to the solvent, passing chlorine in the solvent and carrying out a heating chlorination, cooling and crystallizing to obtain a chlorinated phenoxyacetic acid derivative or a methyl phenoxyacetic acid derivative. Compared with a conventional method, the method provided by the invention can recycle the solvent of the reaction system and wastewater for cycle use during the reaction process, can meet self-production balance and realize recycle and reuse of a sealed system, and has a yield higher than 95%, a content larger than 98%, the recycle and reuse utilization rate of the solvent higher than 95% and emission reduction of the waste water in the whole production process higher than 95%.

Owner:JIANGXI TIANYU CHEM CO LTD

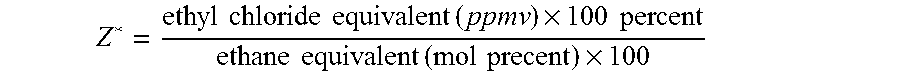

Process for the production of alkylene oxide using a gas-phase promoter system

ActiveUS20070032670A1Improve performanceImprove efficiencyOrganic chemistryChemical recyclingGas phaseNitric oxide

An improved process for the manufacture of ethylene oxide through the epoxidation of ethylene using a catalyst comprising silver and at least one efficiency-enhancing salt of a member of a redox-half reaction pair. Added to the epoxidation reaction is a two-component gas-phase promoter system comprising a chlorine-containing component (for example ethyl chloride, methyl chloride, vinyl chloride and ethylene dichloride), and a nitrogen-containing component of nitric oxide and other compounds capable of generating under reaction conditions at least one gaseous efficiency-enhancing member of a redox-half reaction pair comprising NO, NO2, N2O3 or N2O4. The amount of each component of said gaseous promoter is adjusted to maintain the ration of N* to Z* less than or equal to 1 wherein, N* is the nitric oxide equivalent in ppmv, ranging from 1 to 20 ppmv and Z*=ethyl chloride equivalent (ppmv)*100 percent / ethane equivalent (mol percent)*100 ranging from 5 to 40 ppmv.

Owner:DOW TECH INVESTMENTS

Composite modified starch as hematite reverse flotation inhibitor and preparation method thereof

The invention discloses composite modified starch as a hematite reverse flotation inhibitor and a preparation method thereof. The composite modified starch comprises 100 weight portions of raw material starch, 0.5-10 weight portions of sodium hypochlorite as an oxidizing agent, 1.2-7.0 weight portions of sodium hydrosulphite, 0.2-1.2 weight portions of sodium nitrite as esterification reagents, 0.5-3.5 weight portions of 3-chloro-2-hydroxypropyl-trimethyl quaternary ammonium salt as a cationic reagent, 3.0-7.0 weight portions of caustic alkali, and 25-40 weight portions of water. The composite modified starch contains carboxylic groups, sulfonic anions, and quaternary ammonium cations, and has the advantages of cold water solubility and low viscosity, and has the advantages of increasing the yield of hematite concentrate, improving the filtering conditions of iron ore pulp, and the like.

Owner:GUANGXI UNIV +1

Non-mercury catalyst for production of vinyl chloride and preparation method thereof

InactiveCN102069000AAvoid pollutionEase of mass productionPhysical/chemical process catalystsPreparation by halogen halide additionBarium dichlorideCopper chloride

The invention discloses a non-mercury catalyst for the production of vinyl chloride and a preparation method thereof, belonging to the fields of chemical catalyst and the preparation thereof. The non-mercury catalyst of the invention uses cocoanut active charcoal as carrier and stannous chloride as main active substance, wherein the weight percentage of stannous chloride is 15%-30%; and at least one additive of barium chloride, zinc chloride and copper chloride is added and the total additive weight percentage is 0.5-2%. By using the non-mercury catalyst, the environmental pollution caused by the mercury-containing catalyst can be avoided; the large-scale production can be benefited, the conversion rate and selectivity of the catalyst can be increased, the yield of the product can be increased; by increasing the quality of the carrier, technical guarantee can be provided for the large-scale production device of vinyl chloride, the loss of the active matter can be slowed down, the service life of the catalyst can be prolonged; and the use efficiency of the catalyst can be increased by 500%.

Owner:YIBIN TIANYUAN GRP CO LTD

Preparation method of medium-viscosity poly alpha-olefin base oil

ActiveCN103666552AEasy to separateReduce pollutionTreatment with polymerisationOligomerDistilled water

The invention relates to a preparation method of medium-viscosity poly alpha-olefin base oil. The preparation method comprises the following steps: under conditions with a temperature of 20 DEG C-120 DEG C, reaction pressure of 0.1 MPa-1.4 MPa and a volume ratio of alpha-olefin / a solvent of (1:0)-(1:3), catalyzing 1-decene or 1-decene and alpha-olefin of C8-C12 for oligomerization for 2 hours-12 hours by using an alkaline-modified AlCl3 / Al2O3 immobilized catalyst; and filtering the catalyst after stopping reaction, washing by distilled water, distilling under the normal pressure to remove the solvent, distilling under reduced pressure to remove un-reacted alpha-olefin to obtain alpha-olefin oligomer base oil, wherein the yield of the poly alpha-olefin is greater than 60 omega%, the movement viscosity of the oligomer at 100 DEG C is 10.0mm<2> / s-25.0mm<2> / s, and the chlorine content of the oligomer is less than 2.0 omega%.

Owner:PETROCHINA CO LTD +1

Catalyst used for vinyl chloride preparation, its preparation method and application

ActiveCN102441407AImprove catalytic performanceExtend your lifePreparation by hydrogen halide split-offPreparation by halogen halide additionActivated carbonEmulsion

The invention discloses a catalyst used for vinyl chloride preparation, its preparation method and application. The catalyst used for vinyl chloride preparation adopts activated carbon as a carrier, which is loaded with a barium compound and a phosphorus compound. By mass, the barium compound accounts for 0.2%-20% of the total mass of the catalyst, and the phosphorus compound accounts for 0%-10% of the total mass of the catalyst. The preparation method of the catalyst comprises: adding water into a water-soluble barium compound, a water-soluble phosphorus compound and an aqueous polymer monomer so as to prepare a solution or emulsion A; adding activated carbon into the solution or emulsion A for immersion; taking the well immersed activated carbon out and subjecting it to spin drying, then making monomer polymerization; heating the well polymerized activated carbon, dehydrating it, and decomposing and carbonizing the polymer; activating the carbonized catalyst, thus obtaining the catalyst used for vinyl chloride preparation.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI +1

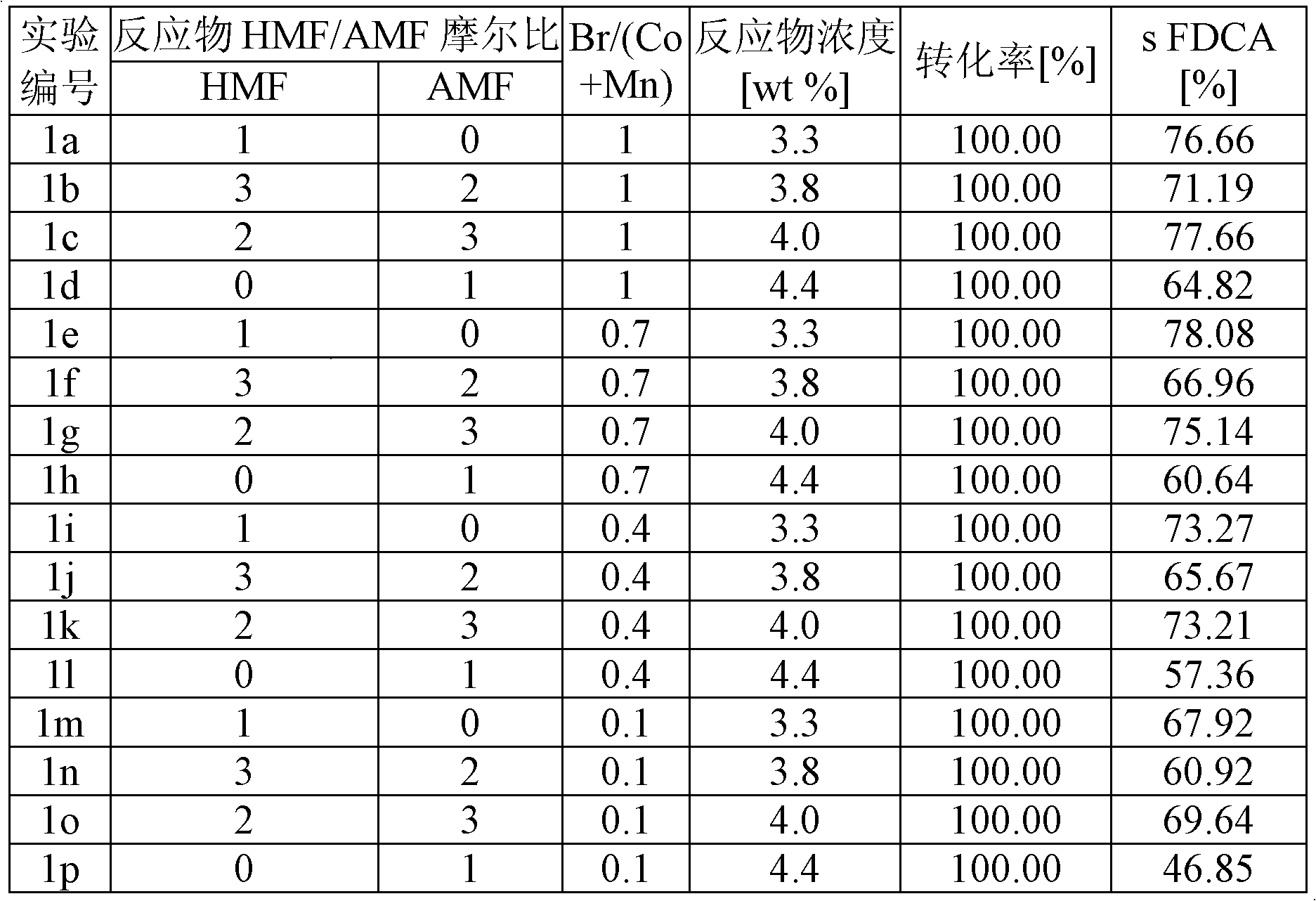

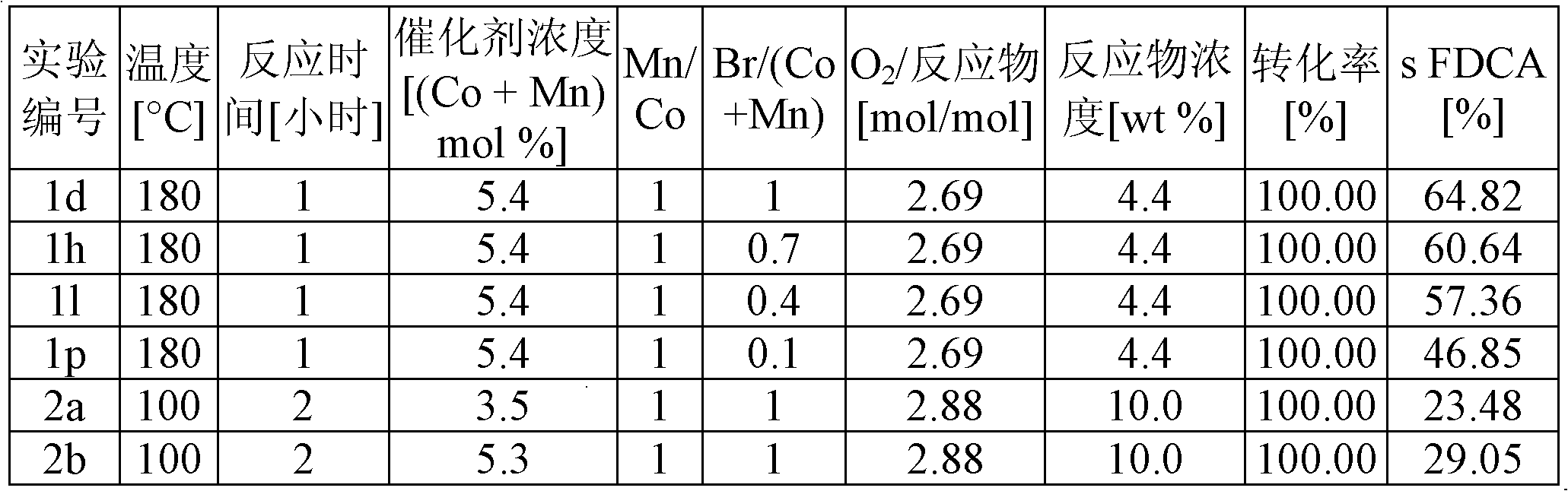

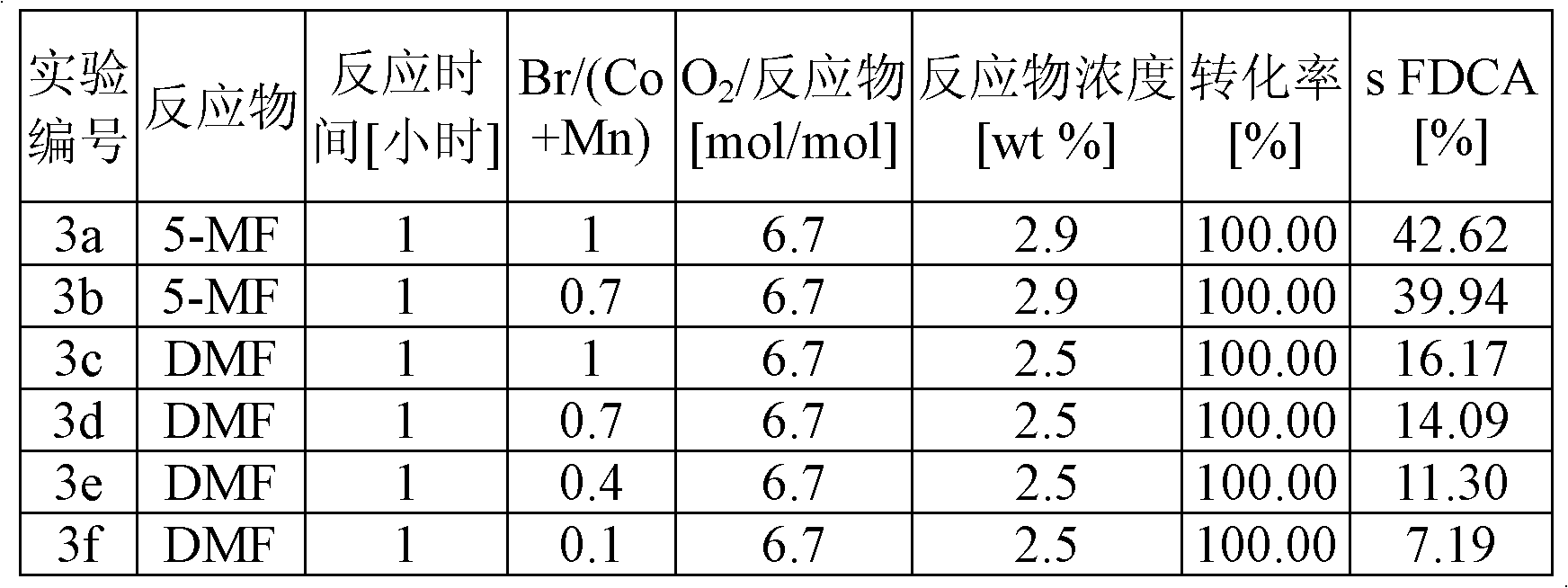

Method for the preparation of 2,5-furandicarboxylic acid and for the preparation of the dialkyl ester of 2,5-furandicarboxylic acid

ActiveCN102666521AOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsFuranDicarboxylic acid

The invention describes a method for the preparation of 2,5-furan dicarboxylic acid comprising the step of contacting a feed comprising a compound selected from the group consisting of 5-hydroxymethylfurfural ("HMF"), an ester of 5-hydroxymethyl-furfural, 5-methylfurfural, 5-(chloromethyl)furfural, 5-methylfuroic acid, 5-(chloromethyl)furoic acid, 2,5- dimethylfuran and a mixture of two or more of these compounds with an oxidant in the presence of an oxidation catalyst at a temperature higher than 140 DEG C.

Owner:FURANIX TECH BV

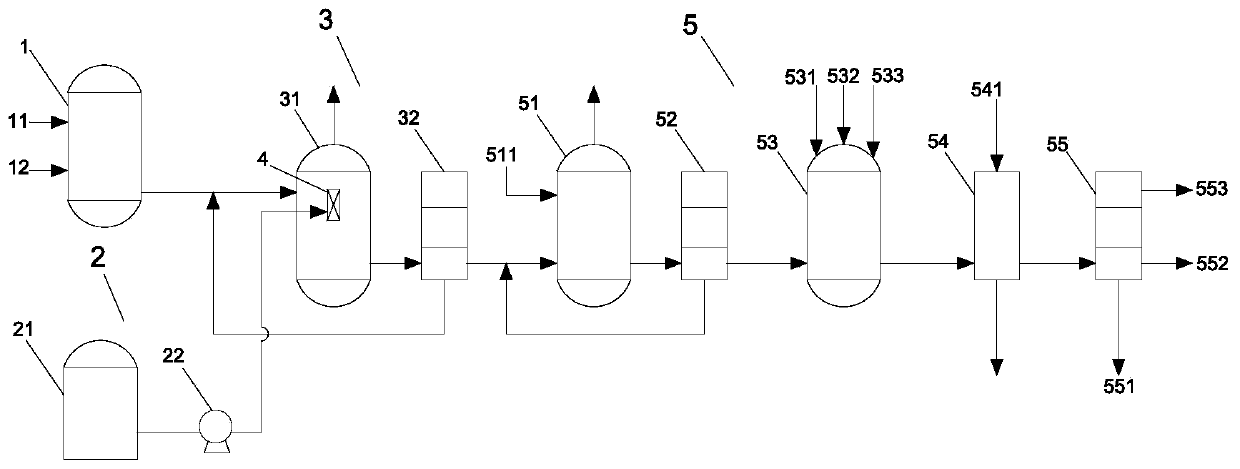

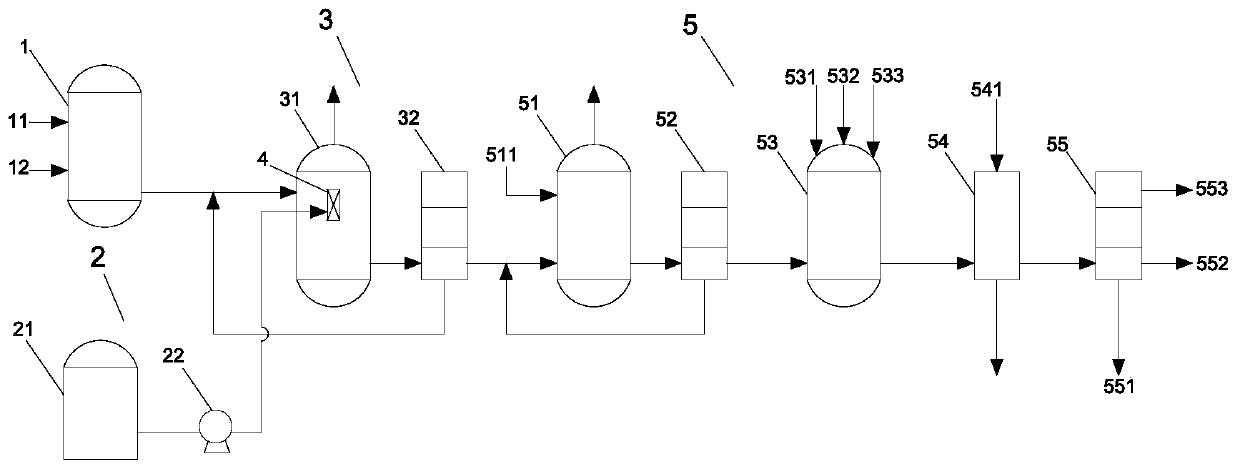

Synthetic system of 3-cyanomethylbenzoic acid methyl ester and method thereof

InactiveCN110002993AIncrease the mass transfer area of the phase boundaryImprove mass transfer efficiencyOrganic compound preparationPreparation by cyanide reactionChlorideMethyl benzoate

The invention provides a synthetic system of 3-cyanomethylbenzoic acid methyl ester and a method thereof. The system comprises an acylation reaction vessel used for preparation of m-Toluoyl chloride;a liquid chlorine feeding unit used for storing and conveying liquid chlorine; a chlorination reaction unit which is connected with the acylation reaction vessel and used as a chlorination reaction chamber of m-Toluoyl chloride; a micro-interface generator which is respectively connected with the liquid chlorine feeding unit and the chlorination reaction unit and used for receiving liquid chlorineconveyed by the liquid chlorine feeding unit, crushing the liquid chlorine into micro-droplets with the diameter being micron level and conveying the micro-droplets to the chlorination reaction unitafter the crushing; and an esterification and cyanation reaction unit which is connected with the chlorination reaction unit. In the prior art, m-Toluoyl chloride and liquid chlorine cannot be fully mixed when m-Toluoyl chloride and liquid chlorine react such that yield of 3-cyanomethylbenzoic acid methyl ester is reduced. The above problem is solved by the synthetic system and the method of the invention.

Owner:NANJING UNIV

Inorganic chloride ion remover and application method

InactiveCN103420469AReduce dosageLow running costWater/sewage treatmentAluminateIndustrial waste water

Provided is inorganic chloride ion remover. The inorganic chloride ion remover comprises one or both of calcium oxide and calcium carbonate, and meta-aluminate, wherein one or both of the calcium oxide and the calcium carbonate are mixed to form a mixture, and the mixture and the meta-aluminate are mixed to form the inorganic chloride ion remover according to the ratio. According to the total mass of calcium oxide inorganic chloride ion remover, the calcium oxide accounts for 70-80% of the calcium oxide inorganic chloride ion remover, and the meta-aluminate accounts for 30-20% of the calcium oxide inorganic chloride ion remover; according to the total mass of calcium carbonate inorganic chloride ion remover, the calcium carbonate accounts for 75-85% of the calcium carbonate inorganic chloride ion remover, and sodium metaaluminate accounts for 15-25% of the calcium carbonate inorganic chloride ion remover; according to the total mass of mixed inorganic chloride ion remover, the calcium oxide and the calcium carbonate account for 70-85% of the mixed inorganic chloride ion remover, and the meta-aluminate accounts for 15-30% of the mixed inorganic chloride ion remover. An application method of the inorganic chloride ion remover comprises the steps of adding the inorganic chloride ion remover to chloric waste water, setting the addition mass ratio to be 1-5%, continuously stirring the mixture for 10-30 minutes, standing to carry out layering, and carrying out separation, wherein the supernatant is waste water without chloride ions. The inorganic chloride ion remover has the advantages of being low in price, easy to obtain, low in addition amount, simple in removal technology, small in investment, low in operation cost and the like, and the removal rate of chloride ions in industrial waste water with the chloride ion content of 50% can reach 99.9%.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com