Polyvinyl chloride (PVC) mixture with high elongation at break

A technology of elongation at break and polyvinyl chloride, which is applied in the fields of polyvinyl chloride mixture with excellent weather resistance, processing performance, high elongation and toughness, can solve the problem that PVC products are prone to nail cracking, poor processing performance, low temperature toughness Problems not solved, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

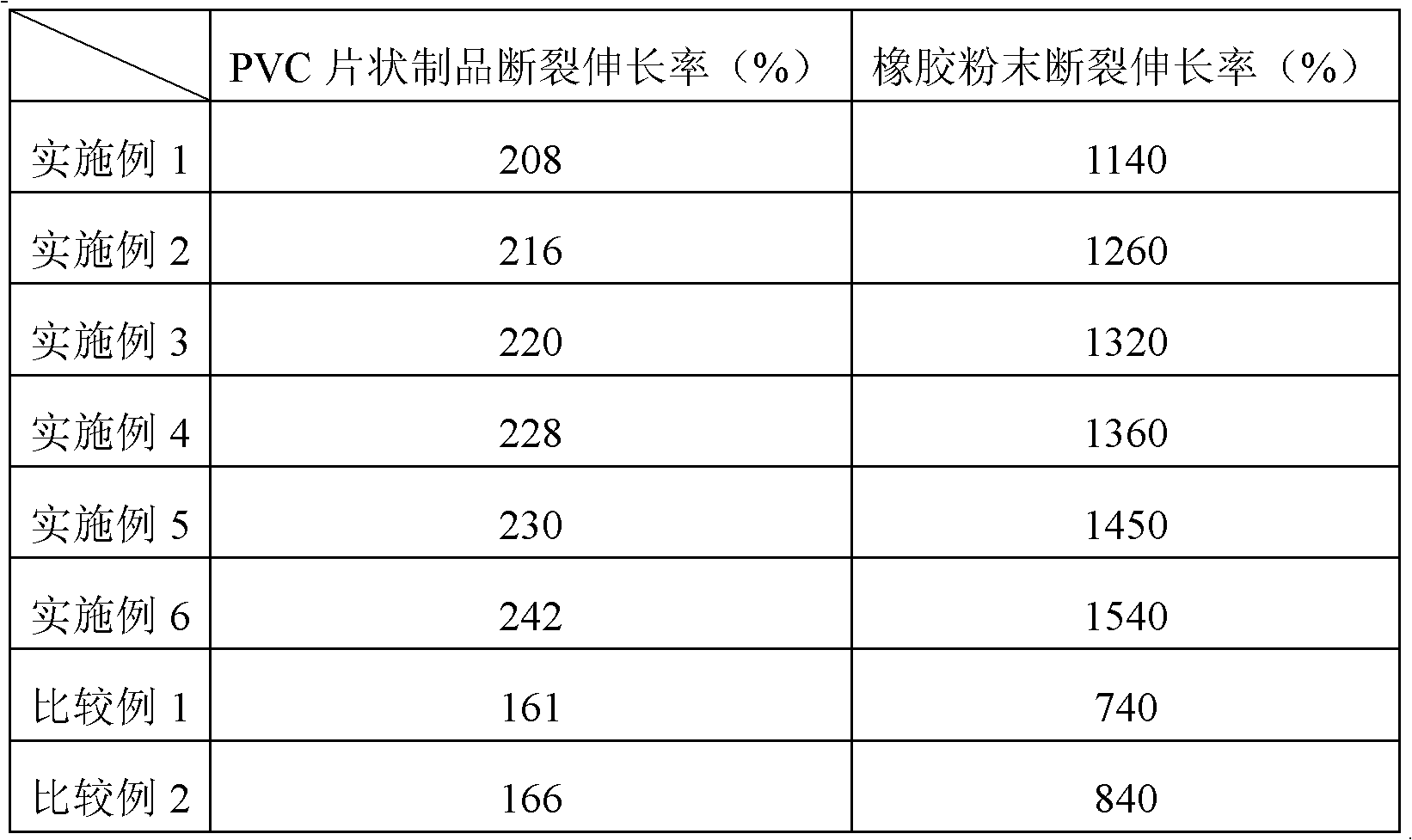

Embodiment 1

[0045] In the reactor of 30 liters that stirring paddle is equipped with, add 0.25 parts of methyl methacrylate / acrylic acid copolymers that dissolve into water as dispersant, add the polyoxyethylene lauryl ether of 0.24 parts as emulsifier, Then add water, so that the total water consumption and all auxiliary raw materials are 250 parts, then add 30 parts of high-density polyethylene, after stirring the temperature of the reaction material rises to 80 ° C, start to feed 18 parts of chlorine gas, The speed is kept at 18 parts / hour, and then the temperature is raised to 135°C while the chlorine gas is passed, and the heating time is one hour. The temperature rises and the chlorine gas is carried out at the same time. Parts of speed is passed into remaining 18 parts of chlorine. Then keep the temperature between 135-138 DEG C and react for 3 hours, cool to below 40 DEG C, centrifuge and dry to obtain rubber powder (sample 1) with elongation at break of 1140%.

[0046] The conve...

Embodiment 2

[0049] Add water, 0.1 part of polymethyl methacrylate / acrylic acid copolymer dispersant, 0.05 part of initiator in a 30-liter reactor equipped with a stirring paddle, and use the total water consumption and all auxiliary raw materials to be 250 parts , and then add 30 parts of sample (1), after stirring the temperature of the reaction material to 80 ° C, then add 5 parts of butyl acrylate and 1 part of methyl methacrylate, keep the temperature at 80 to 85 ° C, and react After 3 hours, it was cooled to below 40° C., centrifuged, and dried to obtain a rubber powder (sample 2) with an elongation at break of 1260%.

[0050] The conversion rate of the reaction was 99.3%, and the particle size of the powder was 310 microns.

[0051] The preparation method of PVC mixture and PVC sheet product is the same as embodiment 1.

Embodiment 3

[0053] In the reactor of 30 liters that stirring paddle is equipped with, add 0.25 parts of methyl methacrylate / acrylic acid copolymers that dissolve into water as dispersant, add the polyoxyethylene lauryl ether of 0.24 parts as emulsifier, Then add water, so that the total water consumption and all auxiliary raw materials are 250 parts, then add 30 parts of high-density polyethylene, after stirring the temperature of the reaction material rises to 90 ° C, start to feed 18 parts of chlorine gas, The speed is kept at 18 parts / hour, and then the temperature is raised to 140°C while passing chlorine gas, and the heating time is 1 hour. Parts of speed is passed into remaining 18 parts of chlorine. Then keep the temperature between 138-142° C. and react for 3 hours, cool to below 40° C., centrifuge, and dry to obtain rubber powder (sample 3) with an elongation at break of 1320%.

[0054] The conversion rate of the reaction was 99.2%, and the particle size of the powder was 340 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com