Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

73results about How to "Guaranteed oil resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

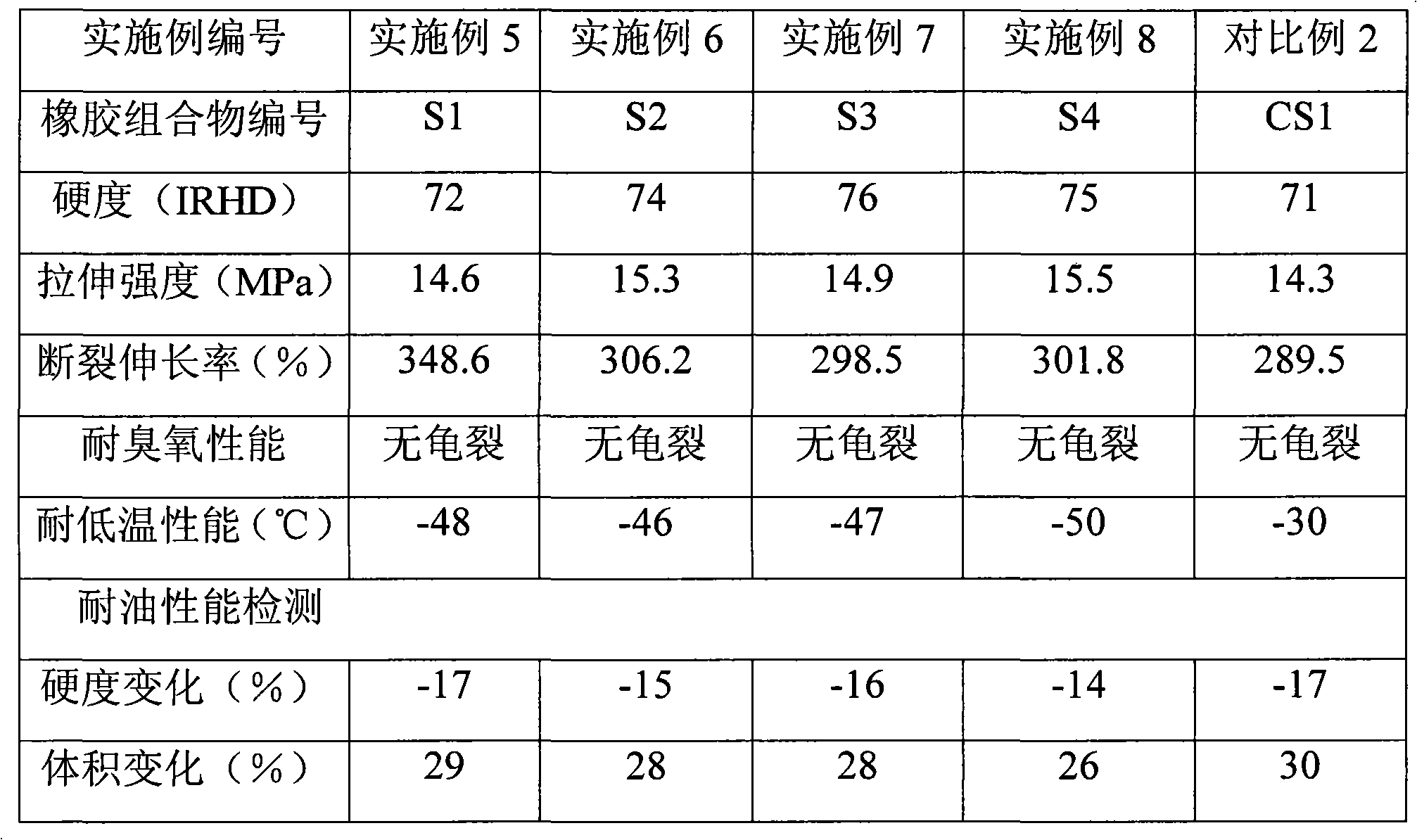

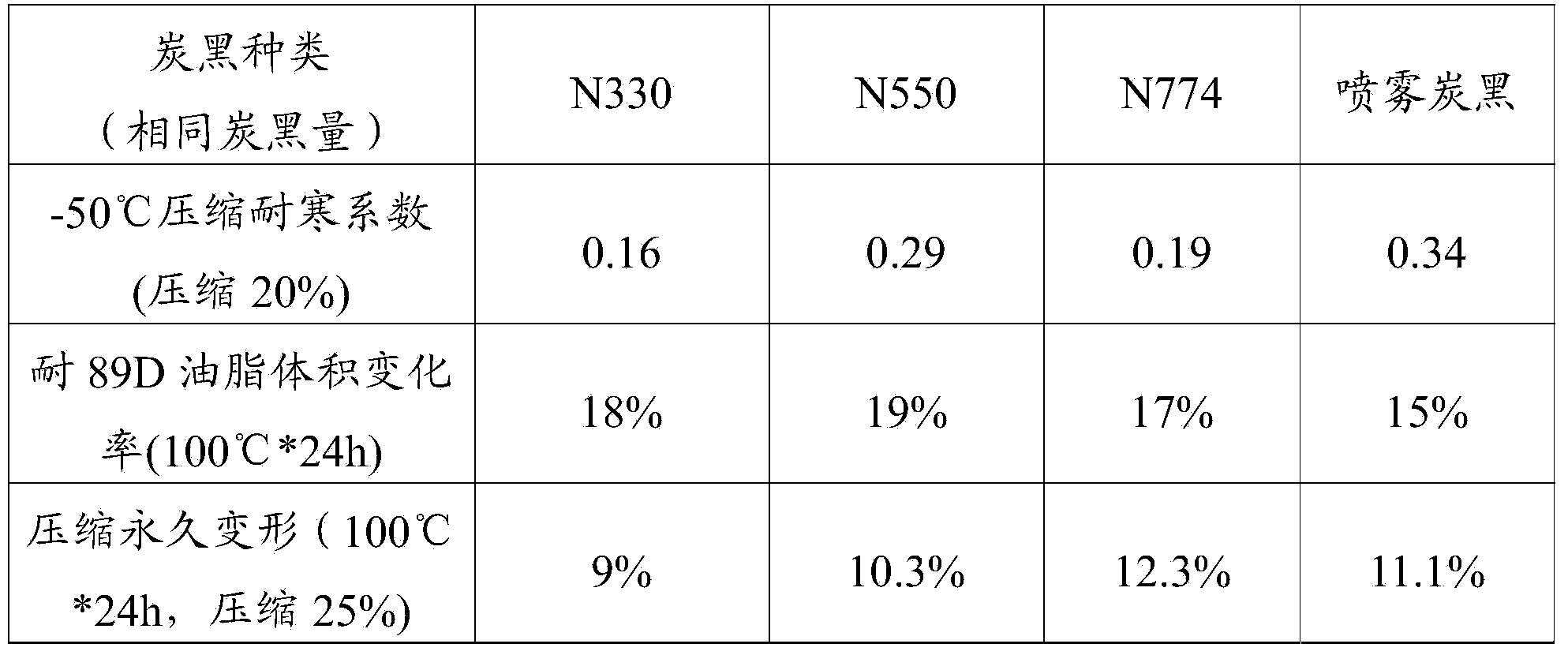

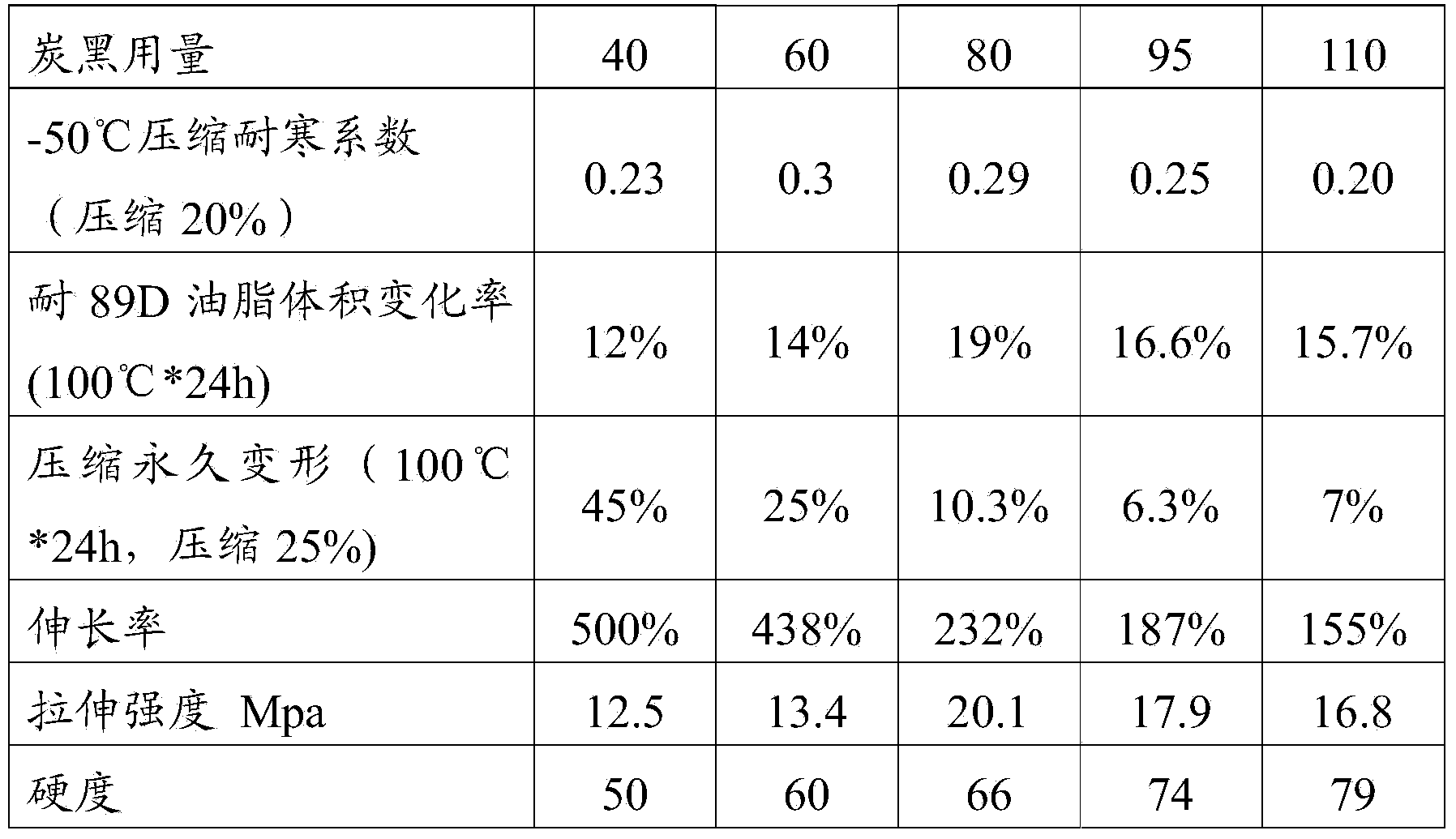

Oil resistant low temperature resistant rubber composition

InactiveCN101353451AGuaranteed oil resistanceGuaranteed ozone resistancePolymer scienceNitrile rubber

The invention relates to a rubber composite, comprising nitrile rubber, polyvinyl chloride, carbon soot, activator, vulcanizator, age inhibitor, antiscorcher, accelerant and plasticizer, wherein, the plasticizer is ethylhexyl sebacate and adipate. The rubber composite of the invention obviously improves the anti-low temperature performance of the rubber composite while ensuring the anti-oil performance, anti-ozone performance, tensile strength and elongation at break.

Owner:BYD CO LTD

Anticorrosion and antistatic method for oil filling pipe assembly and its mating paint

InactiveCN1357581AAnti-corrosion and anti-staticImprove conductivityEpoxy resin coatingsProduction lineEpoxy

The present invention relates to anticorrosion and antistatic method for oil filling pipe assembly and its mating paint. To the surface of iron and steel base of oil filling pipe assembly, single component epoxy zinc-riched primer to form anticorrosion layer and single component epoxy antistatic finish paint to form antistatic layer are painted successively. The two kinds of paint have the same base material and crosslinking agent and the crosslinking agent will crosslink with epoxy resin only at the cure temperature of 120-250 deg.c with short cure time. The two coatings are well matched. The method of the present invention may be used in production line.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST

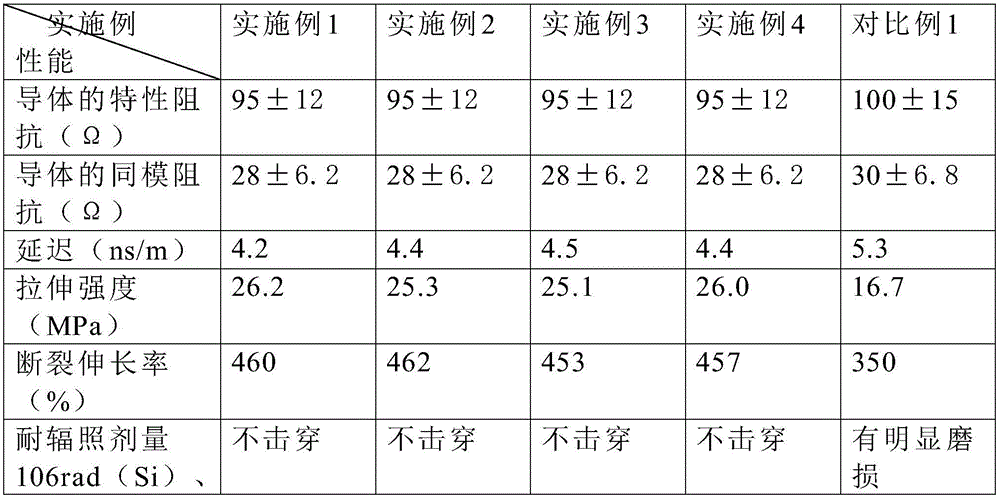

Irradiation crosslinking slurry-resistant halogen-free flame-retardant cable material used for petroleum platform and preparation method thereof

ActiveCN104927176AGood compatibilityImprove mechanical propertiesPlastic/resin/waxes insulatorsAntioxidantSlurry

The invention provides an irradiation crosslinking slurry-resistant halogen-free flame-retardant cable material used for a petroleum platform and a preparation method thereof. The material is composed of the following raw materials by weight: 25 to 55 parts of ethylene vinyl acetate copolymer, 10 to 20 parts of ethylene-vinyl acetate-carbon monoxide terpolymer, 25 to 45 parts of polyethylene, 5 to 15 parts of copolymer polyethylene grafted maleic anhydride, 8 to 10 parts of carbon black, 120 to 160 parts of a halogen-free flame retardant, 0.7 to 1.8 parts of a coupling agent, 1.5 to 3 parts of a crosslinking sensitizer, 1.4 to 2.4 parts of an antioxidant, 2 to 4 parts of silicone and 0.5 to 1.2 parts of a lubricant, wherein the ethylene vinyl acetate copolymer has a vinyl acetate VA content of 33% and a melt index of 0.2 g / 10min. According to the invention, the irradiation crosslinking slurry-resistant halogen-free flame-retardant cable material with low smoke, no toxicity, simple and convenient custom irradiation processing and low investment cost used for a petroleum platform and a preparation method thereof are provided; meanwhile, a halogen-free flame-retardant slurry-resistant sheathing material which meets the standards of halogen-free / anti-slurry cables used for a Norway NEK606 offshore platform can be produced.

Owner:中广核三角洲(江苏)塑化有限公司

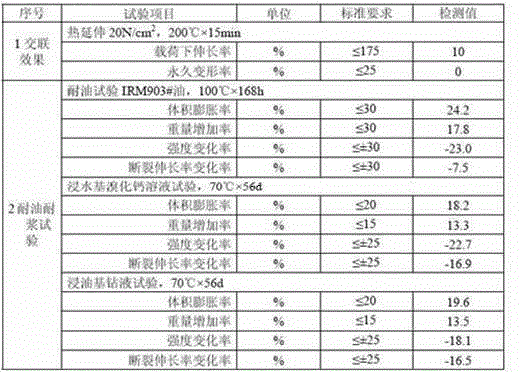

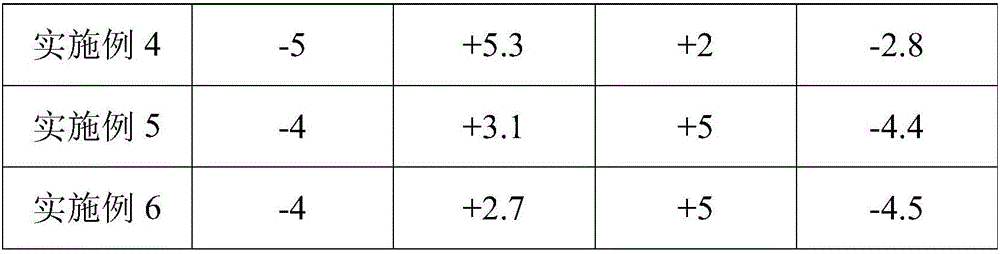

Rubber sealing composite with excellent comprehensive performance and preparation method thereof

InactiveCN101955600AConvenient sourceGuaranteed oil resistanceOther chemical processesActive agentAntioxidant

The invention provides a rubber sealing composite with the excellent comprehensive performance. The composite is characterized in that the composite comprises the following components in parts by weight: 60-65 parts of butadiene-nitrile rubber, 35-40 parts of ethylene methyl acrylate (EMA), 1.5-3 parts of keto-amine reaction product antiager, 1-3 parts of p-phenylene diamine antiager, 1.5-2.5 parts of physical antioxidant, 0.5-1.0 part of stearic acid, 6-10 parts of activator, 35-60 parts of reinforcing agent, 2-6 parts of plasticizer, 1.5-3 parts of vulcanizing agent and 2-5 parts of promoting agent. The invention also provides a preparation method of the rubber sealing composite and the method is to perform mixing with a mixer or an open mill. The preparation method is simple and clear. The whole production process is convenient to operate, the raw materials are easy to purchase, and the prepared oil-resistant sealing material integrates the advantages of butadiene-nitrile rubber and EMA rubber.

Owner:SHANGHAI ZHONGLI AUTO PARTS

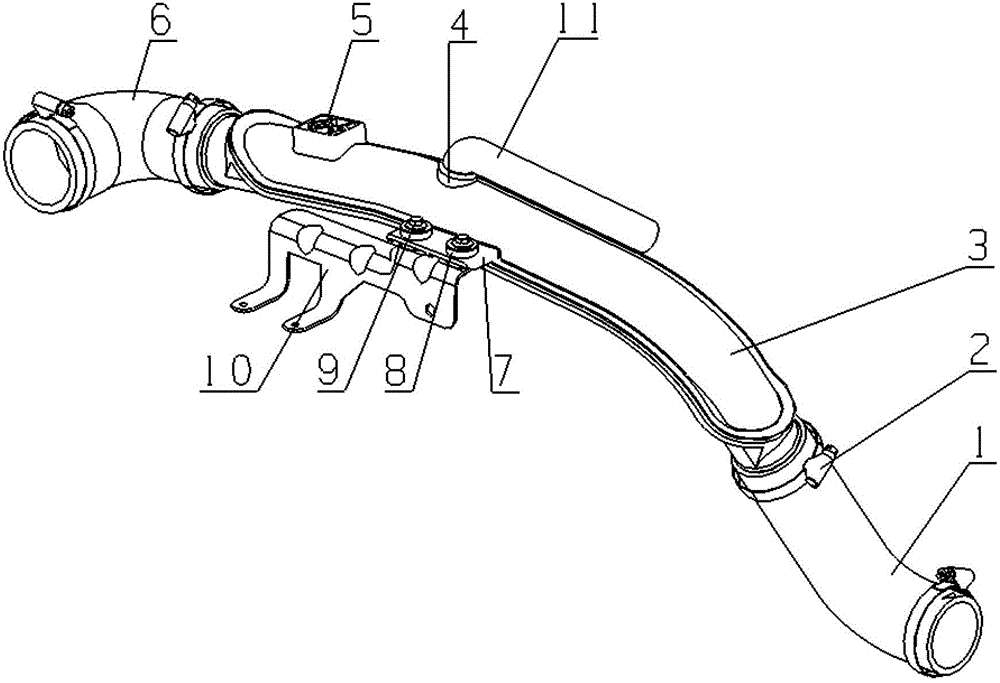

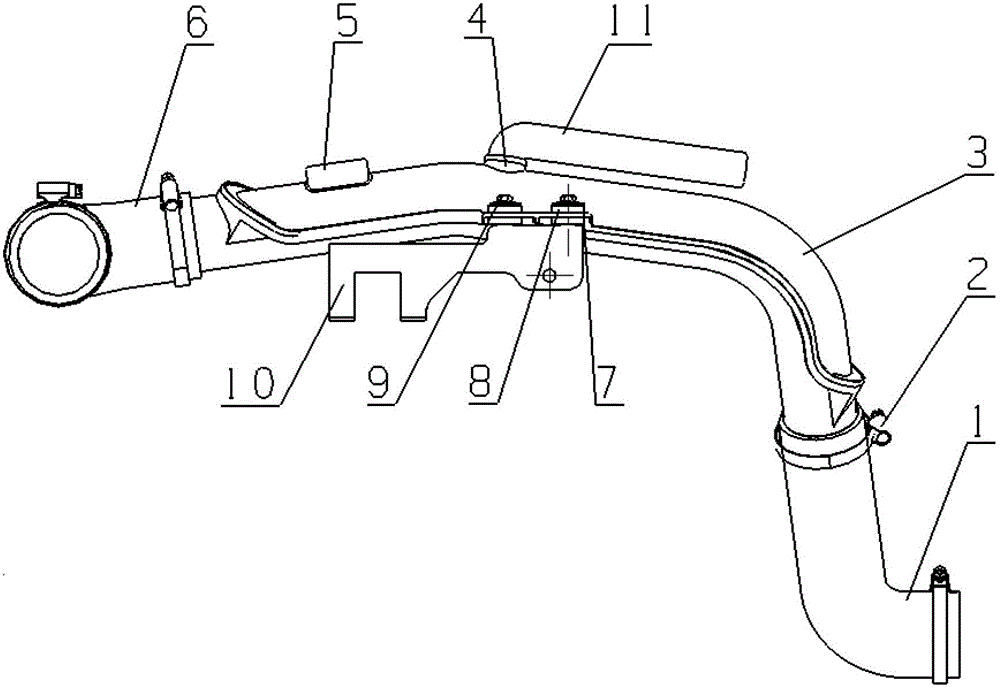

Gas outlet pipe for intercooler

ActiveCN103147841AImprove NVH performanceEliminate Noise PeaksPipe supportsInternal combustion piston enginesEngineeringIntercooler

The invention discloses a gas outlet pipe for an intercooler, which comprises a hard gas outlet pipe, flexible gas outlet pipes used for connecting a intercooler and connected with the two ends of the hard gas outlet pipe respectively, and a flexible gas outlet pipe b connected with a throttle valve of an engine, wherein a sensor interface is formed in the hard gas outlet pipe, and the hard gas outlet pipe and the sensor interface are subjected to integral injection moulding. The gas outlet pipe for the intercooler is in a flexible gas outlet pipe plus hard gas outlet pipe plus flexible gas outlet pipe structure, the hard gas outlet pipe is in an injection moulding structure, and multiple required parts can be integrated, so that the problems that the quality of welding joints at the sensor interface and a fixed bracket welded on the traditional aluminum pipe cannot be controlled easily, gas can leak, and an appearance is not attractive are solved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

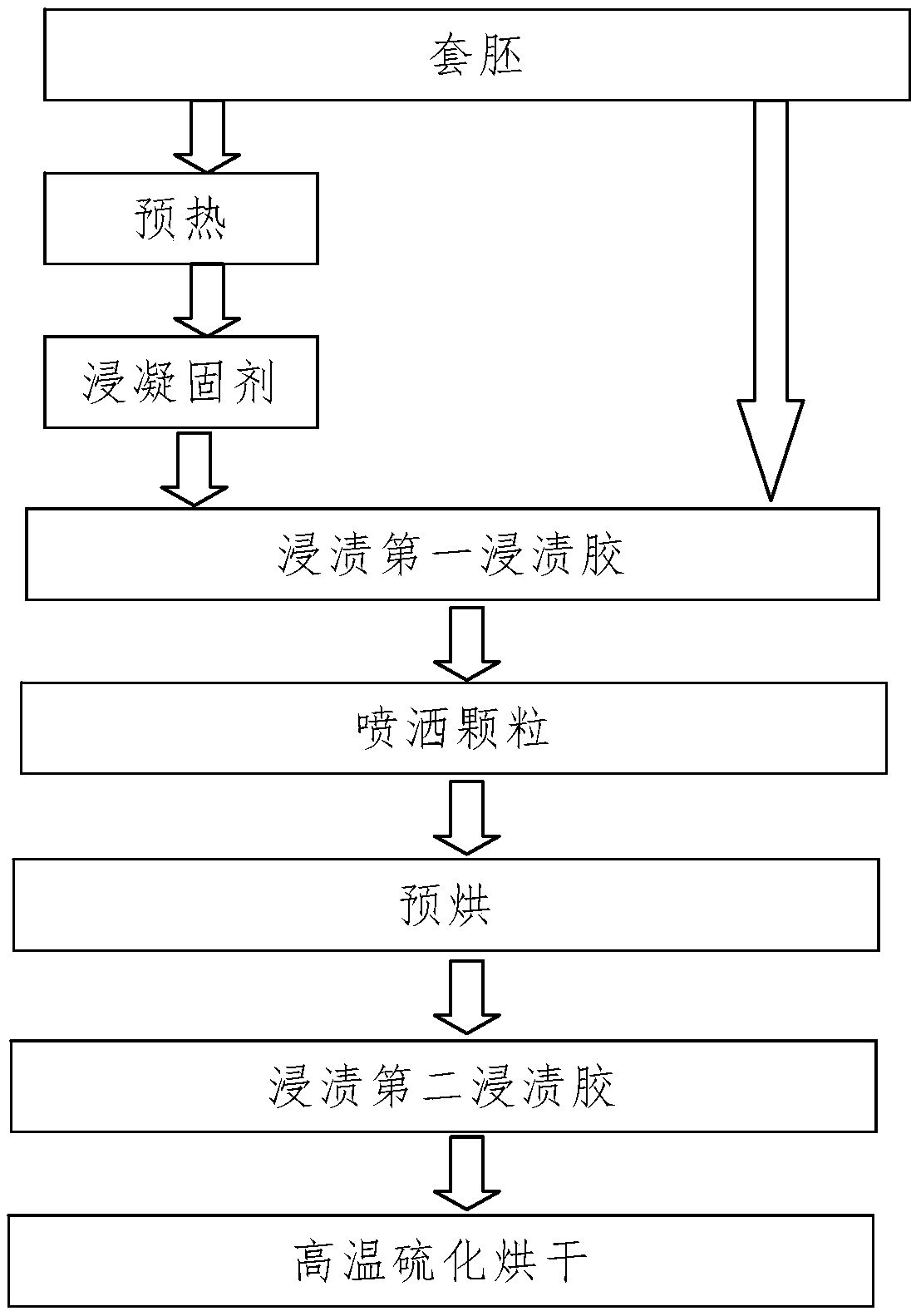

Preparing method for butyronitrile-particle anti-sliding glove

The invention relates to a preparing method for a butyronitrile-particle anti-sliding glove. The preparing method includes the steps that S1, first soaking gum with the first viscosity and second soaking gum with the second viscosity are provided, wherein the first soaking gum and the second soaking gum are obtained through hbutadiene-acrylonitrile latex by adjusting the viscosity, and the first viscosity is larger than the second viscosity; S2, a glove blank sleeves a hand mold, and the product is soaked into the first soaking gum in the step S1; S3, particles are evenly sprayed on the glovesoaked in the step S2, and then pre-drying is carried out; S4, the glove obtained in the step S3 is soaked into the second soaking gum, and the soaked glove is obtained after soaking; S5, the soaked glove obtained in the step S4 is heated and vulcanized, and the butyronitrile-particle anti-sliding glove is obtained. According to the preparing method for the butyronitrile-particle anti-sliding glove, particles outside the glove are increased, coating is carried out after particles, the original wear resistance and oil resistance of a product are guaranteed, the friction force of the surface ofthe glove is improved, the glove also has the anti-sliding effect after meeting liquid such as water or oil, and the operability is improved.

Owner:SHANDONG XINGYU GLOVES

Oil-resisting and cold-resisting nitrile butadiene rubber composition and preparation method thereof

The invention relates to oil-resisting and cold-resisting nitrile butadiene rubber composition and a preparation method thereof. The oil-resisting and cold-resisting nitrile butadiene rubber composition comprises components in parts as follows: nitrile butadiene rubber, a reinforcing system, a vulcanization system and a plastification system. The nitrile butadiene rubber composition uses single nitrile butadiene rubber and has good oil resistance and oil resistance.

Owner:CHINA ACADEMY OF RAILWAY SCI CORP LTD +1

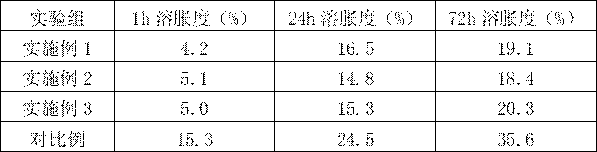

Oil-resistant silicone rubber compound and preparation method thereof

The invention discloses an oil-resistant silicone rubber compound. The oil-resistant silicone rubber compound is prepared from the following raw materials in parts by mass: 100 parts of methyl vinyl silicone rubber, 3-10 parts of fluorine-containing silicone oil, 30-50 parts of polytetrafluoroethylene, 10-30 parts of diatomite, 40-75 parts of white carbon black, 2-8 pars of a coupling agent, 5-20parts of a structural treatment agent and 1-5 parts of a heat resistant agent. The rubber compound is prepared by mixing methyl vinyl silicone rubber, fluorine-containing silicone oil, polytetrafluoroethylene, diatomite and the like as a matrix. By introducing fluorine in the silicone oil to a methyl vinyl silicone rubber chain segment, the oil resistant effect is improved. The volume change of the silicone rubber soaked in engine oil is reduced by blending porous filler such as polytetrafluoroethylene and diatomite. The heat resistant agent repairs damage of the engine oil to main chains of the silicone rubber in the soaking process of the silicone rubber in the engine oil, so that the oil resistance of the silicone rubber is guaranteed. The invention also discloses a preparation method of the oil-resistant silicone rubber compound.

Owner:镇江亿维硅材料科技有限公司

Low pressure power steering tube rubber composition with chlorinated polyethylene rubber as main component

InactiveCN102417666AImprove mechanical propertiesImprove heat resistanceFlexible pipesEpoxyPolymer science

The invention relates to a rubber composition for low pressure power steering tubes. The rubber composition comprises the following components by mass: chlorinated polyethylene rubber 100 parts, fast extruding carbon black 40 to 60 parts, medium thermal carbon black 0 to 20 parts, calcium hydrate 10 parts, dioctyl ester 20 to 30 parts, magnesium oxide 7 to 15 parts, epoxy resin 3 to 5 parts, the antioxidant NBC 1 part, diallyl phthalate 6 to 10 parts, and 1,4-bis(tert-butylperoxyisopropyl)benzene 6 to 8 parts. According to the invention, chlorinated polyethylene is utilized to substitute chlorosulfonated polyethylene in the low pressure power steering tubes, which guarantees heat resistance and oil resistance of the low pressure power steering tubes and enables a low price to be obtained;a production process for the rubber composition is simple, and the product of the rubber composition has widely available sources and better practical application.

Owner:TIANJIN PENGYI GRP CO LTD

Nano antibacterial preservative film for fruits/vegetables and preparation method thereof

The invention discloses a nano antibacterial preservative film for fruits / vegetables, and belongs to the technical field of preservative films. The nano antibacterial preservative film comprises the following raw materials in parts by weight: 20-25 parts of linear low-density polyethylene, 6-10 parts of low-density polyethylene, 8-11 parts of polyvinylidene chloride, 3-5 parts of acetic acid, 5-7 parts of gelatin, 3-5 parts of nano silicon dioxide, 6-8 parts of nano molecular sieve, 1-2 parts of silver powder, 1-2 parts of titanium white powder, 2-4 parts of zinc oxide, 0.5-0.8 part of carboxymethyl cellulose, 0.5-1.5 parts of paraffin, 1-2 parts of antifogging agent, 0.1-0.7 part of antimicrobial agent, 3-4 parts of plasticizer and 1-3 parts of coupling agent. The invention also discloses a preparation method of the nano antibacterial preservative film for fruits / vegetables. The nano antibacterial preservative film is environmentally friendly, excellent in mechanical property and favorable in air and moisture permeability, causes less pollution, and has excellent antibacterial and preservative capabilities.

Owner:HEFEI ZHENXUN LOW TEMPERATURE TECH CO LTD

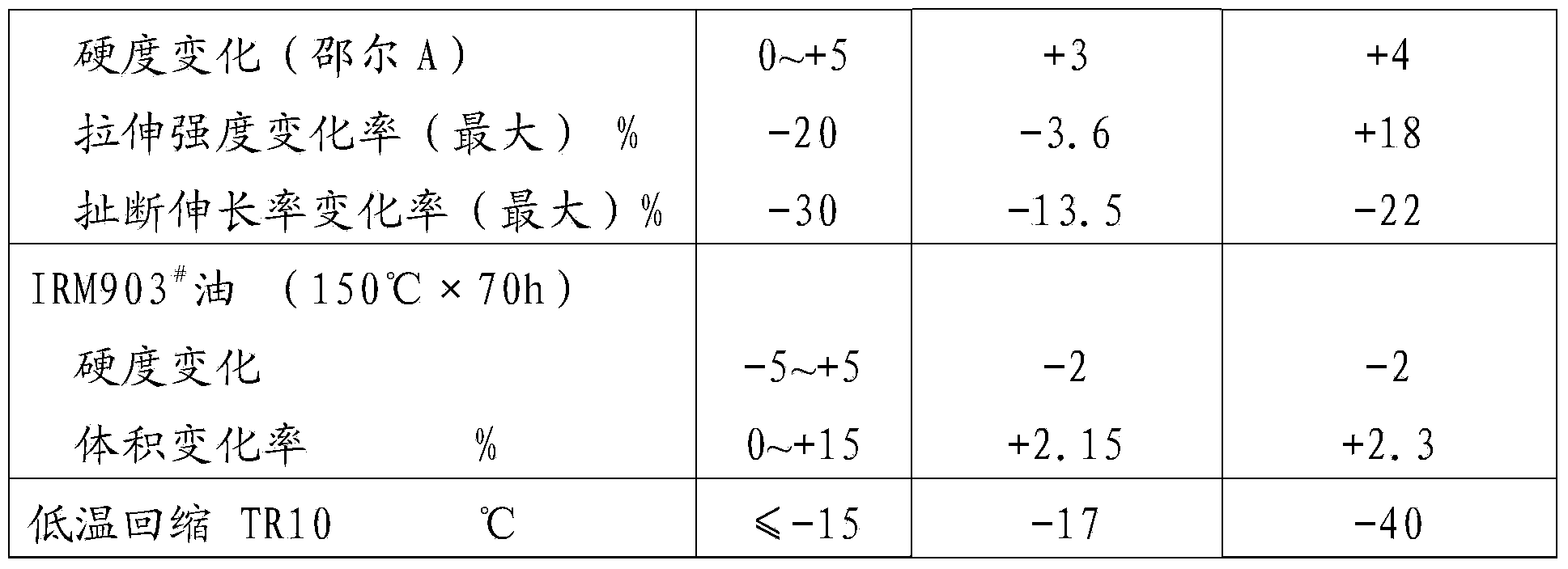

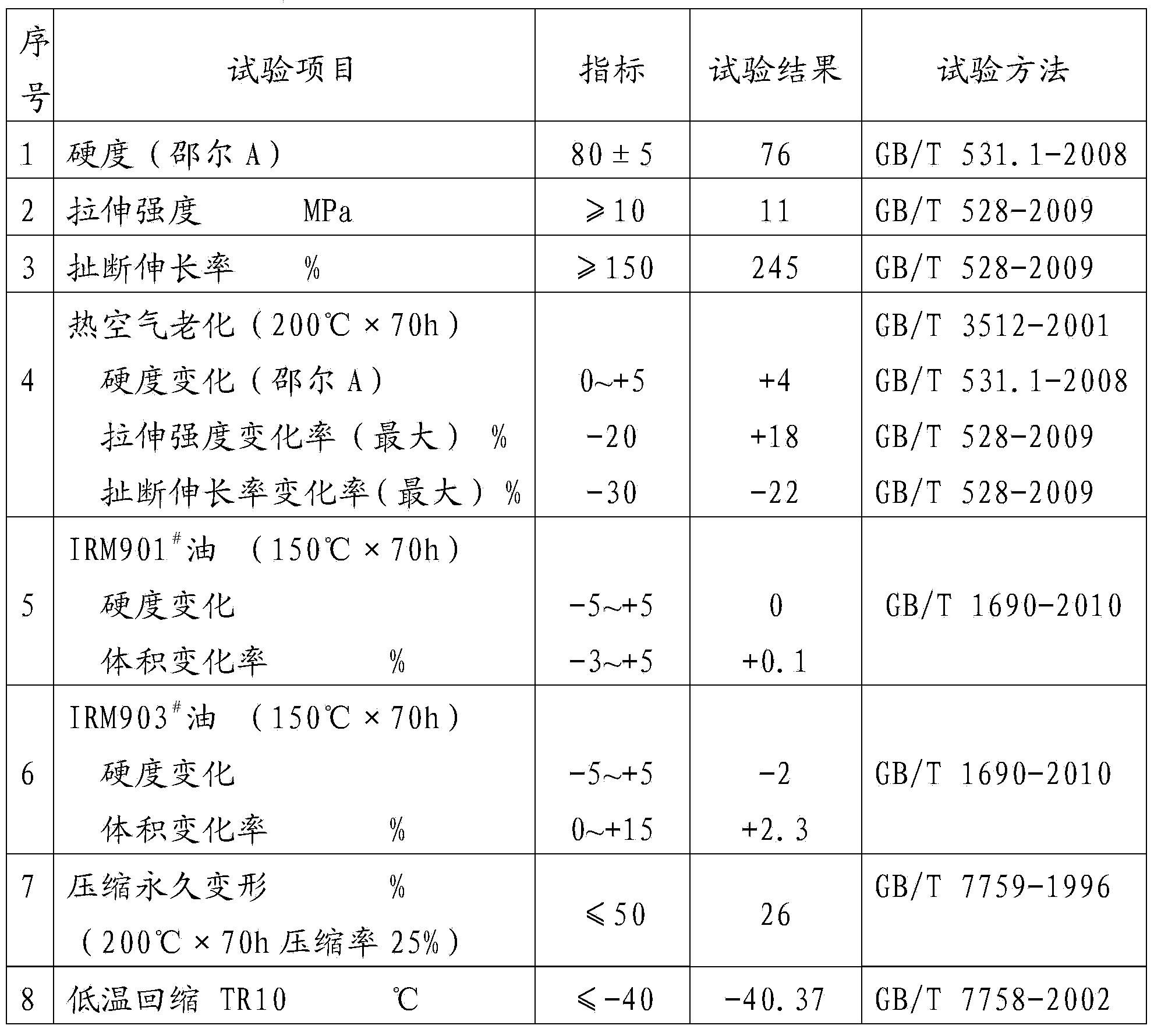

Low-temperature resistant fluororubber for oil seal

The invention belongs to the technical field of rubber, and particularly relates to low-temperature resistant fluororubber for an oil seal. The low-temperature resistant fluororubber comprises the following components in parts by weight: 0-100 parts of fluororubber VPL85540, 0-100 parts of fluororubber LTFE6400, 0.5-1.5 parts of HT290, 10-40 parts of 10WC10222, 0-40 parts of N990, 0-10 parts of N774, 3-4 parts of TAIC-70 and 1.2-2 parts of 2,5-Dimethyl-2,5-di(tert-butylperoxy)hexane-45. The fluororubber provided by the invention has excellent low-temperature resistance while guaranteeing resistance to high temperature and oil; the low-temperature retraction temperature TR10 can reach minus 40 DEG C; by adopting the rubber provided by the invention to manufacture an oil seal of a damper, the oil seal can be used for a long time at (-40)-(+200) DEG C.

Owner:YANTAI RUNFUXIANG OIL SEAL

Computer mouse cell material and preparation method thereof

The invention discloses a computer mouse cell material, and belongs to the technical field of a mouse material. The material comprises the following raw materials, by weight part, 25-30 parts of polycarbonate, 15-18 parts of fluorosilicone rubber, 40-50 parts of an acrylonitrile-butadiene-styrene copolymer, 12-14 parts of glass fiber, 4-8 parts of diatomite, 18-20 parts of cast stone powder, 6-8 parts of silicon nitride, 3-5 parts of silicone oil, 5-7 parts of paraffin, 10-14 parts of phosphate, 8-10 parts of zinc oxide, 2-4 parts of essence, 16-18 parts of a plasticizer, 1-3 parts of a stabilizer and 1-3 parts of an antistatic agent. The invention further discloses a preparation method of the material. The material is small in environmental pollution and excellent in wear resistance and high temperature resistance and gives off fragrance.

Owner:HEFEI SIBOT SOFTWARE DEV CO LTD

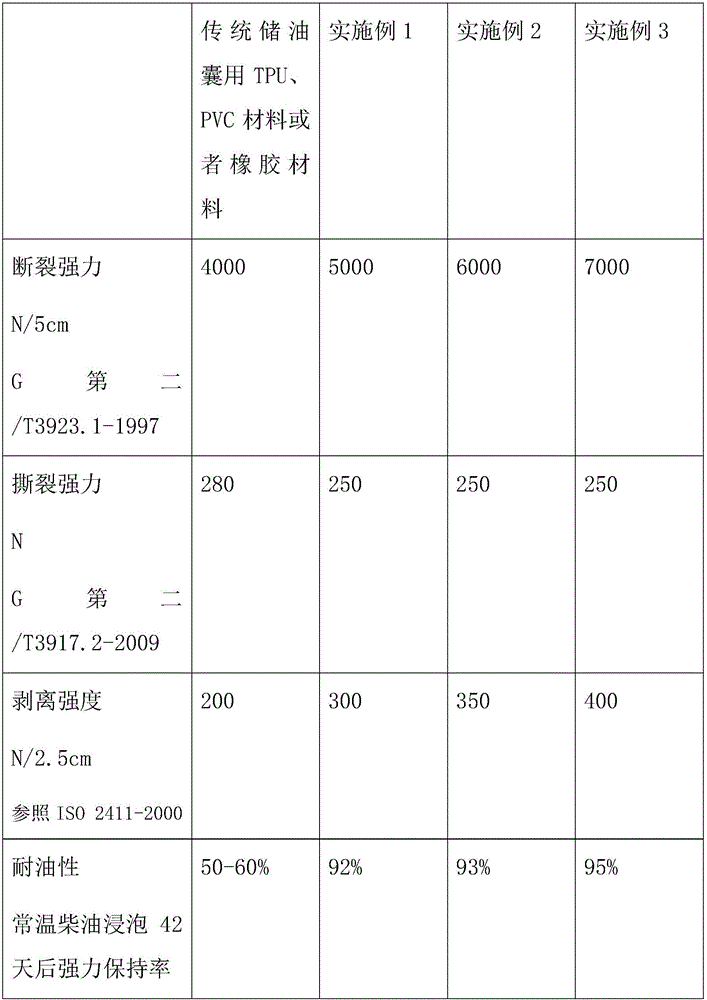

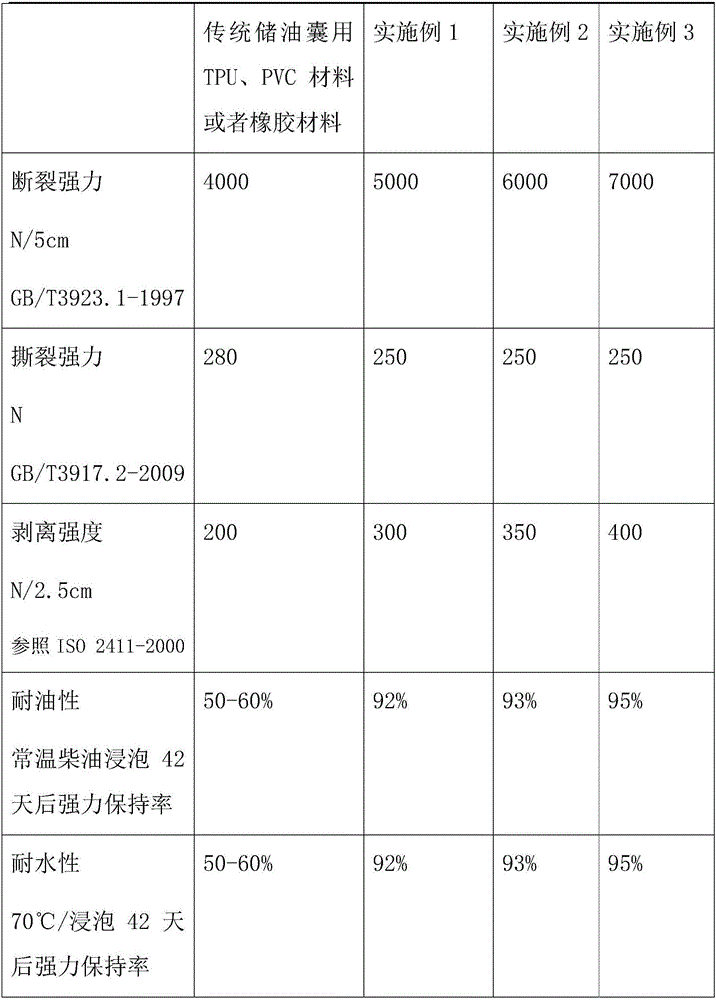

TPU composite material for oil storage bag

ActiveCN106218045AGood oil resistanceImprove water resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesWeather resistanceHydrolysis

The invention provides a TPU composite material for an oil storage bag. The TPU composite material is characterized by comprising a first face, a binding layer, a framework layer, a binding layer and a second face in sequence from top to bottom. Defects in the prior art are overcome, oil resistance, water resistance and weather resistance of the product are better, and hydrolysis resistance of the product is improved while the oil resistance is ensured.

Owner:CTA HI TECH TEXTILES

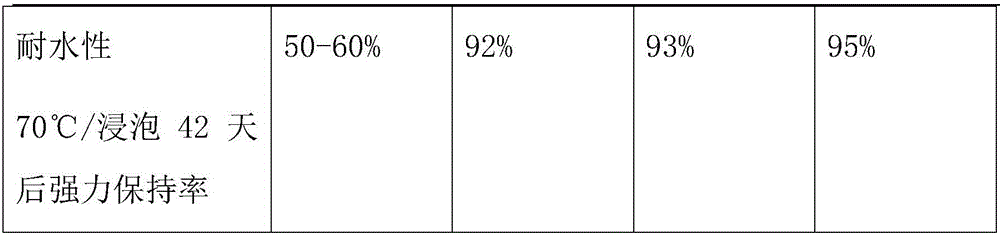

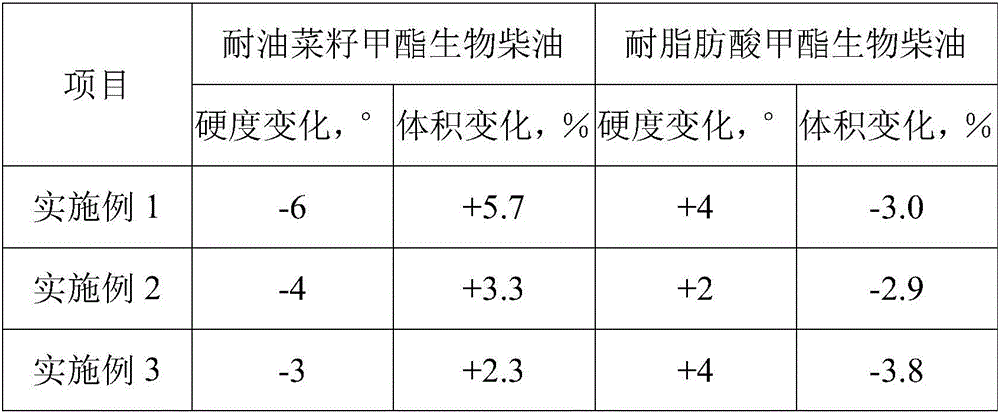

Biological fuel oil-resistant rubber sealing element material and preparation method thereof

ActiveCN106832463AResists expansion and corrosionResistance to extraction corrosionPolyesterPolyvinyl chloride

The invention discloses a biological fuel oil-resistant rubber sealing element material, which is prepared from the following raw materials in parts by weight: 100 parts of a mixture of nitrile rubber and polyvinyl chloride, 50-70 parts of fast extruded carbon black, 3-8 parts of an indirect zinc oxide, 1-2 parts of stearic acid, 1-3 parts of 2,2,4-trimethyl-1,2-dihydroquinoline polymer, 1-3 parts of 4,4-bis(a,a-dimethyl benzyl)-diphenylamine, 5-10 parts of a polyester plasticizer, 3-8 parts of calcium hydroxide, 3-5 parts of ultra high molecular weight polyethylene, 1-3 parts of paraffin, 1-2 parts of sulphur, 0.5-1.5 parts of an accelerant TMTD and 1-3 parts of an accelerant CBS. The invention further discloses a preparation method of the biological fuel oil-resistant rubber sealing element material. The biological fuel oil-resistant rubber sealing element material is capable of effectively resisting expanding corrosion of biological fuel oil and preventing extracting corrosion of biological fuel oil, and has good biological fuel oil resistance.

Owner:ANHUI ZHONGDING SEALING PARTS

Double-density fast-curing rubber compound and production method thereof

InactiveCN104479180AGuaranteed physical propertiesGuaranteed oil resistancePolymer sciencePhysical property

The invention relates to a double-density fast-curing rubber compound which is composed of the following compact compounds and foaming compounds in parts by weight. The invention also relates to a production method of the double-density fast-curing rubber compound, which comprises a compact compound production process and a foaming compound production process. When being used for leather shoe production, the compound produced according to the double-density bicolor die-pressing leather shoe quick-curing compound formula and production method implements fast-curing production, and ensures various physical properties, oil resistance and flame retardancy of the leather shoes.

Owner:天津市富华皮革制品有限公司

Flexible grease-proof paper-based friction plate and manufacturing method thereof

InactiveCN110118234AGuaranteed oil resistanceConsistent frictionOther chemical processesFriction liningNitrile rubberAdhesive

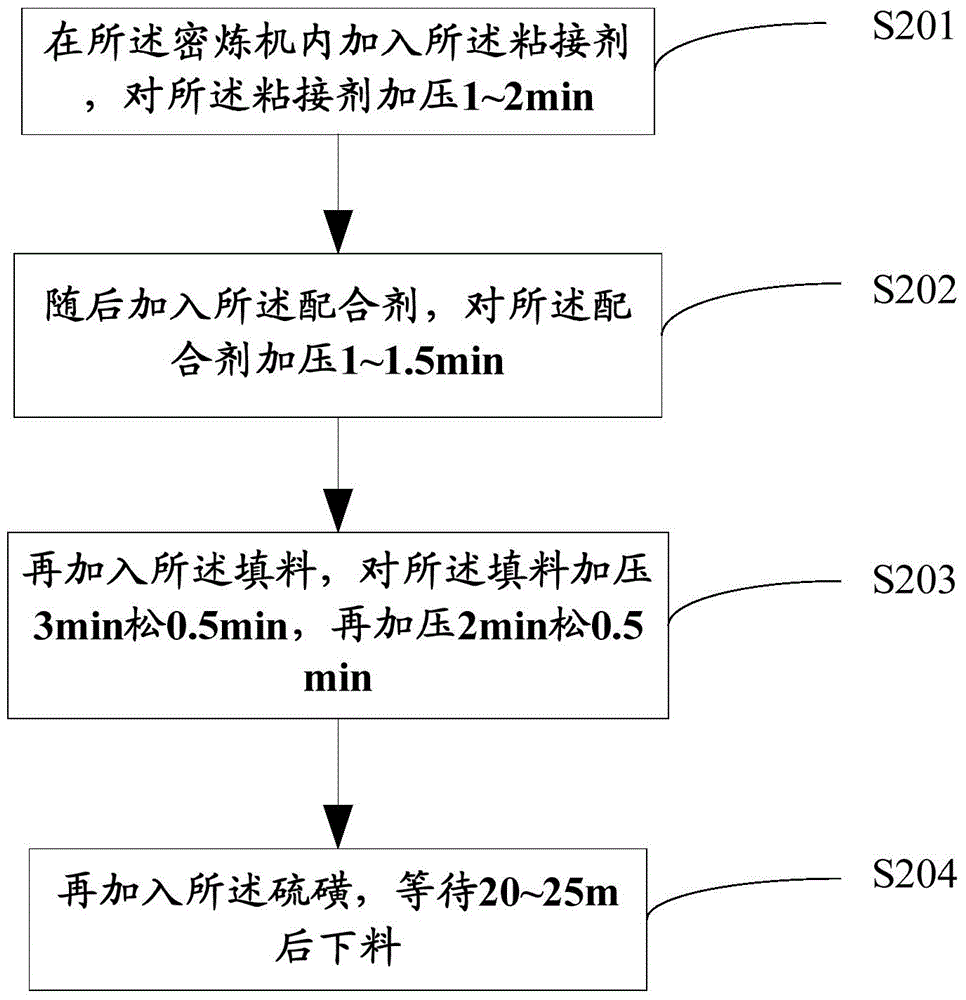

The invention provides a flexible grease-proof paper-based friction plate and a manufacturing method of the flexible grease-proof paper-based friction plate. The flexible grease-proof paper-based friction plate comprises, by mass, 0.8-1.2 parts of compounding agent; 2.5-5.5 parts of sulfur; 44-73 parts of filler; 8-12 parts of flexible adhesive; 10-20 parts of brittle adhesive; 10-14 parts of nitrile rubber; 0.3-1 part of flexible reinforcing fiber and 0.5-2 parts of carbon fiber. By the adoption of the flexible grease-proof paper-based friction plate and the manufacturing method of the flexible grease-proof paper-based friction plate, the grease resistance of a friction material can be guaranteed, the friction performance existing after oil immersion of the friction plate is identical with that of the friction plate without oil immersion, and a stable friction performance and a high friction coefficient of the paper-based friction plate can be guaranteed; the flexible reinforcing fiber and the carbon fiber with good friction performance are used as reinforcing fiber, the flexible adhesive and the brittle adhesive are used as adhesive, the flexible reinforcing fiber and the carbonfiber are complementary in performance, so that the flexibility of the paper-based friction material is improved, and the friction wear resistance of the paper-based friction material is also improved.

Owner:NANTONG WANDA FRICTION MATERIAL

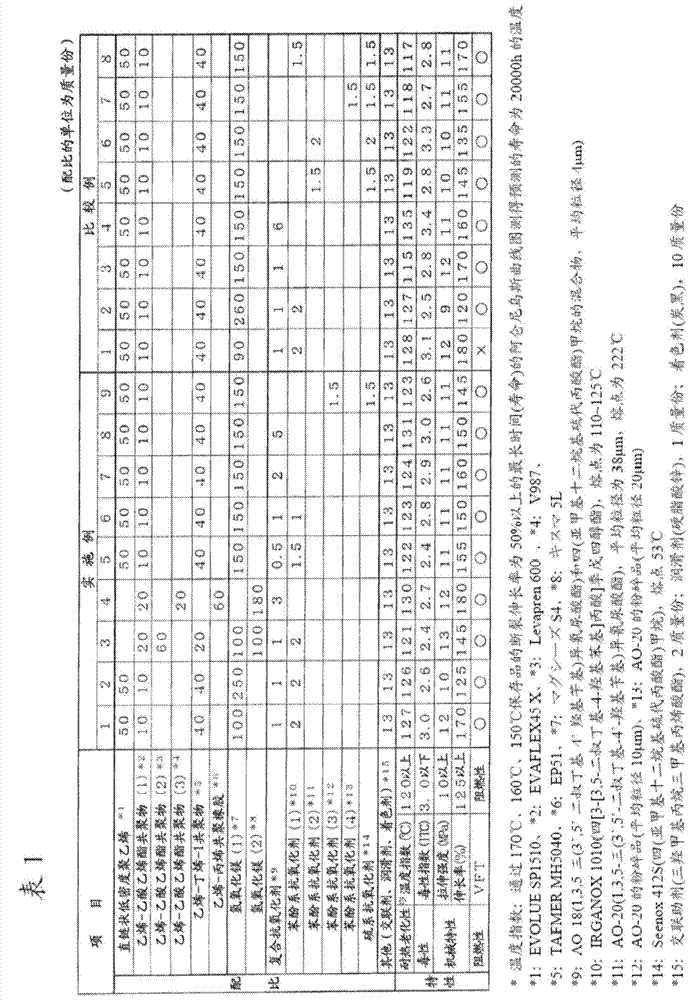

Halogen-free heat aging-resistant flame-retardant resin compound and wire and cable using the same

ActiveCN103834079AImprove securityImprove flame retardant performanceInsulated cablesInsulatorsCross-linkCelsius Degree

A halogen-free heat aging-resistant flame-retardant resin compound includes a mixture of 100 parts by mass of polyolefin-based resin, 100 to 250 parts by mass of metal hydroxide, and 2 to 5 parts by mass of an antioxidant including a first antioxidant having a melting point of not less than 200 degrees Celsius and a mean particle diameter of not greater than 10 [mu]m solely or a combination with a second antioxidant, and the mixture is cross-linked.

Owner:HITACHI METALS LTD

Oil-resistant and mud-resistant irradiation-crosslinking flame-retardant cable material

ActiveCN107236182AImprove mechanical propertiesGood compatibilityPlastic/resin/waxes insulatorsFire retardantMechanical property

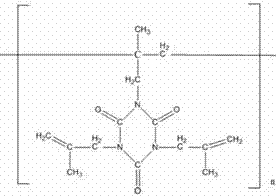

The invention relates to an oil-resistant and mud-resistant irradiation-crosslinking flame-retardant cable material. The cable material contains the following components in parts by weight: an ethylene-vinyl acetate copolymer, an ethylene-vinyl acetate-carbon monoxide terpolymer, high-density polyethylene, a polyethylene grafted maleic anhydride copolymer, carbon black, an aluminum hydroxide flame retardant, a magnesium hydroxide flame retardant, a coupling agent, a crosslinking sensitizer, an antioxidant, silicone and a lubricant, wherein the content of vinyl acetate VA in the ethylene-vinyl acetate copolymer is 33%, and the melt index of the ethylene-vinyl acetate copolymer is 0.2g / min; and the crosslinking sensitizer is a trimethyl allyl isocyanate TMAIC prepolymer, the polymerization degree n is 2-10, a monomer of the prepolymer is trimethyl allyl isocyanate TMAIC, and the molecular weight is 291.35. The cable material is low in smoke and toxic-free, the commissioned irradiation processing is simple and convenient, and the consistency of a filling and a base material in a blended material is improved, and the mechanical property of the material is improved.

Owner:中广核高新核材科技(苏州)有限公司

Oil-resistant low-smoke halogen-free flame-retardant polyolefin cable material and preparation method thereof

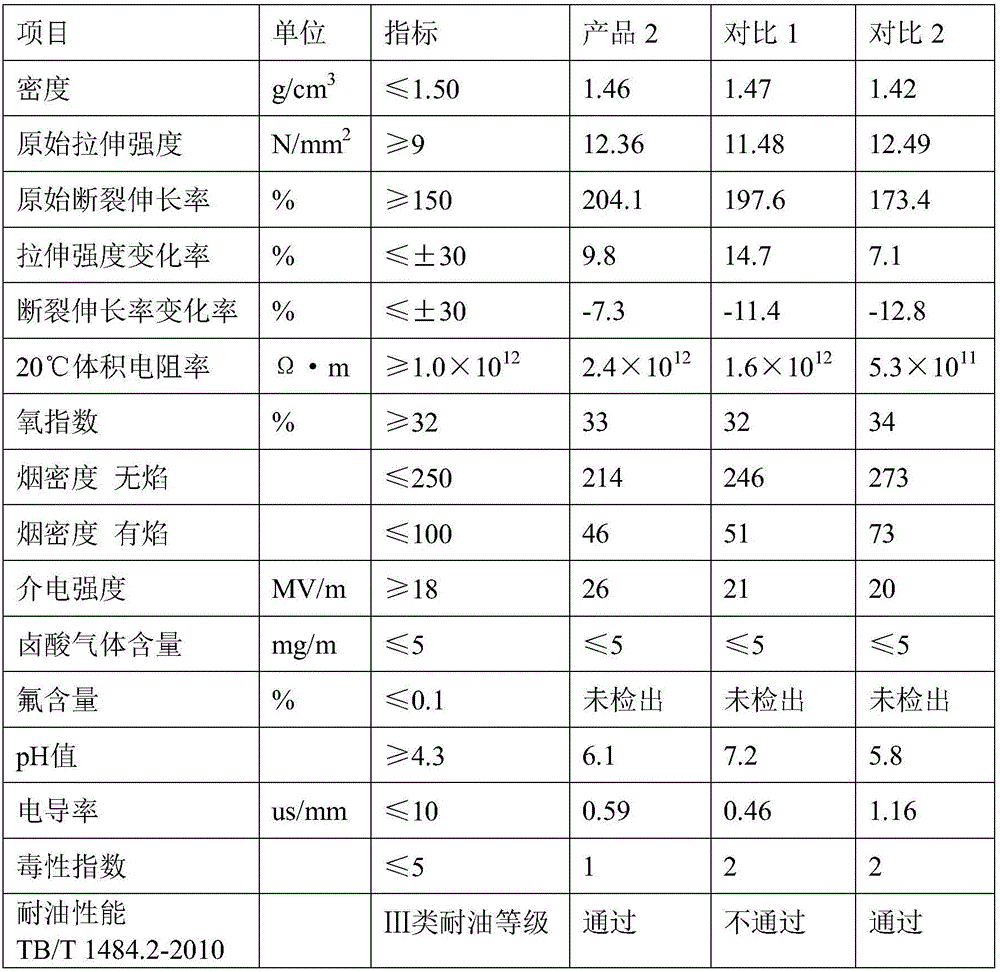

ActiveCN105820405AGuaranteed oil resistanceEfficient preparationPlastic/resin/waxes insulatorsInsulated cablesPolyolefinArray data structure

The invention discloses an oil-resistant low-smoke halogen-free flame-retardant polyolefin cable material and a preparation method thereof. The cable material comprises the following components in parts by weight: 80-90 parts of recycled low-smoke halogen-free plastic alloy, 5-10 parts of organic silicon grafted polyethylene, 8-10 parts of an ethylene-vinylacetate copolymer, 20-30 parts of an inorganic flame retardant, 1-3 parts of a modifying agent, 2-5 parts of an interface compatibilizer, 1-1.5 parts of an irradiation cross-linking agent, 0.3-0.5 parts of an anti-oxidant, 0.5-1 part of a lubricating agent and 3-5 parts of a color masterbatch. The oil-resistant low-smoke halogen-free flame-retardant polyolefin cable material and the preparation method thereof disclosed by the invention have the benefits that the oil resistance of products can reach the class-III oil resistance grade regulated in TB / T 1484.2-2010; through the modified inorganic flame retardant, the flame retardance of the cable material is greatly improved; the organic silicon grafted polyethylene ensures the oil resistance of the cable material. Through performing compound modification on the recycled plastic alloy, the oil-resistant low-smoke halogen-free flame-retardant polyolefin cable material is efficiently prepared, so that not only is the production cost reduced, but also wastes are re-utilized, and sources are saved.

Owner:YANGZHOU HAONIANHUA POLYMER MATERIALS CO LTD

Oil-resistant paper-base friction plate and production method thereof

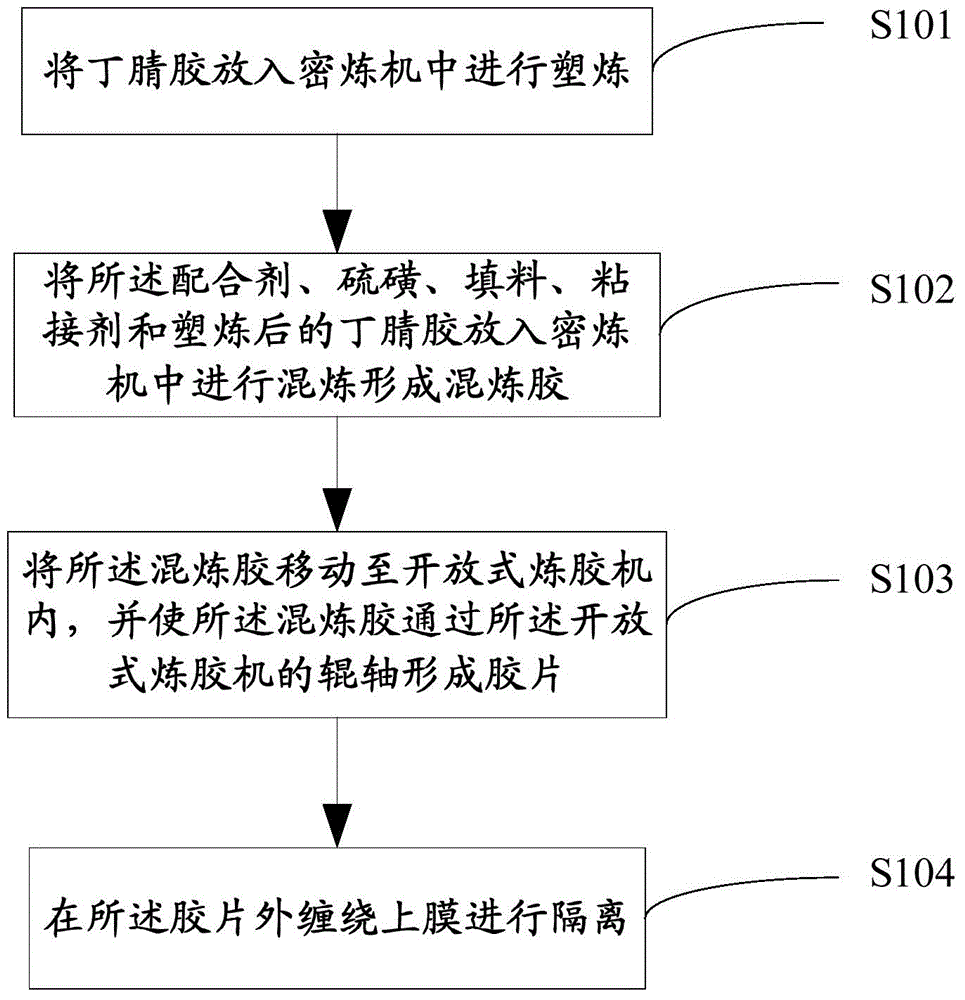

The invention relates to an oil-resistant paper-base friction plate and a production method thereof. The oil-resistant paper-base friction plate comprises the following materials in parts by weight: 0.8-1.2 parts of compounding agent, 2.5-5.5 parts of sulfur, 44-73 parts of filler, 20-28 parts of adhesive and 10-14 parts of butadiene-acrylonitrile rubber. The method comprises the following steps: S101: plastifying the butadiene-acrylonitrile rubber in a Banbury mixer; S102: adding the compounding agent, sulfur, filler, adhesive and plastified butadiene-acrylonitrile rubber into the Banbury mixer, and compounding to form the compounded rubber; S103: moving the compounded rubber into an open rubber mixing mill to form a rubber plate; and S104: winding a film outside the rubber plate for isolation. The production method can ensure the oil resistance of the friction material. The frictional property of the friction plate subjected to oil impregnation is the same as before oil impregnation, thereby simultaneously ensuring the stable frictional property and higher friction factor of the paper-base friction plate.

Owner:NANTONG WANDA FRICTION MATERIAL

Preparation method of TPU composite material for oil storage bag

ActiveCN106142796ASimple preparation processReasonable selection of parametersLayered product treatmentSynthetic resin layered productsWater resistantHydrolysis

The invention provides a preparation method of a TPU composite material for an oil storage bag. The method comprises the following steps of (1) respectively coating a binding layer in a scraping way or a rolling way on two sides of a framework layer; then, performing drying at the drying temperature being 160 to 180 DEG C for 1 to 3 minutes; (2) performing pre-drying at the temperature being 140 to 160 DEG C for 5 to 10s; then, performing extrusion casting of the first surface and the second surface at the two sides of the material obtained in the first step, wherein the extrusion casting temperature is 190 to 200 DEG C; (3) pasting the material obtained in the second step by a laminating roller; (4) heating and baking the material obtained in the third step. The method overcomes the detects in the prior art, the production and preparation process is simple; the prepared product has better oil resistant performance, water resistant performance and weather resistant performance; the oil resistant performance is ensured; meanwhile, the hydrolysis resistant performance of products is improved.

Owner:CTA HI TECH TEXTILES

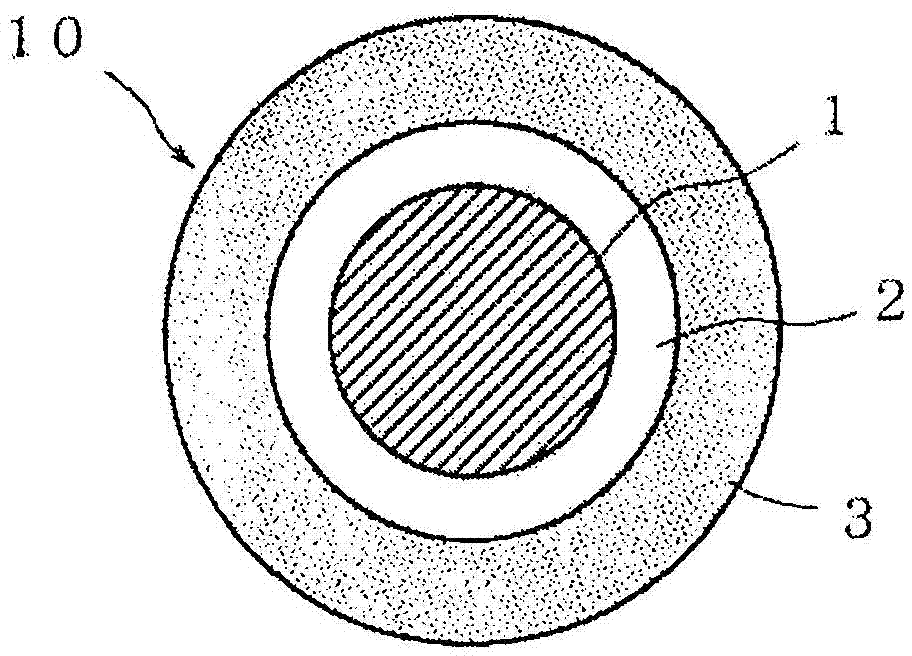

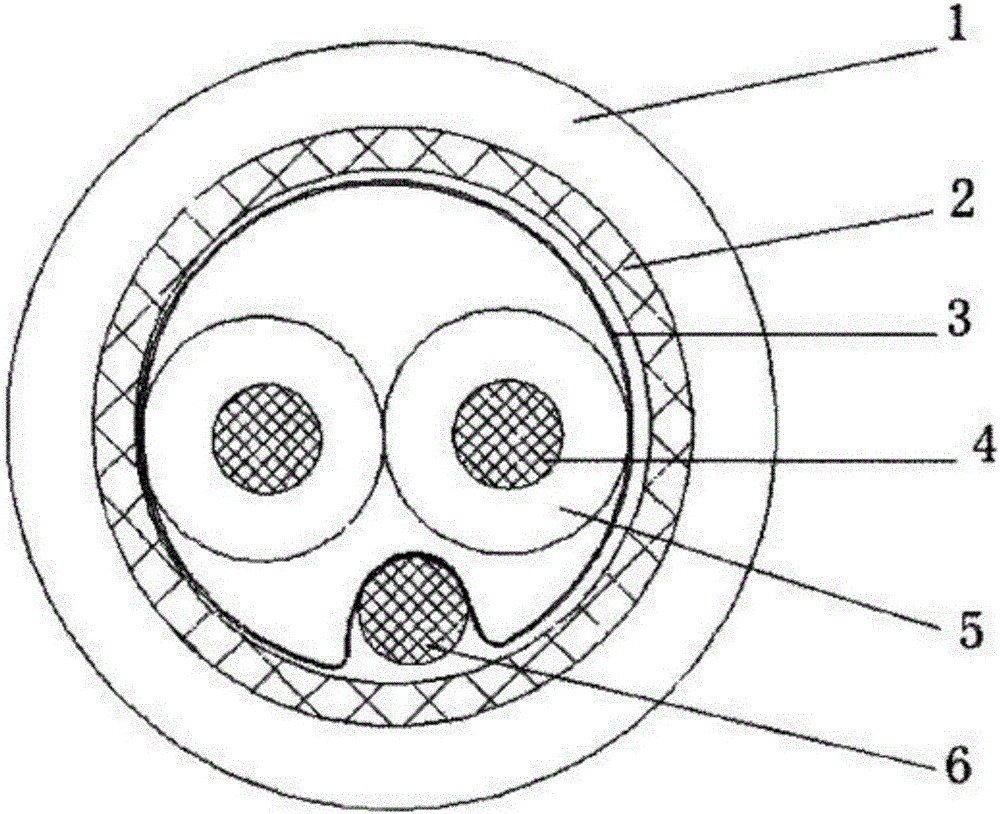

LVDS cable for automobile wire

InactiveCN105845262AGuaranteed to be roundNot easily deformedInsulated cablesCommunication cablesEngineeringElectrical conductor

The invention relates to an LVDS cable for an automobile wire. The LVDS cable comprises a sheath layer, a braided fabric layer, an aluminum foil layer, a conductor and a ground wire, wherein the conductor is wrapped by using an insulating layer, the aluminum foil layer wraps the insulation layer, the ground wire is clamped between the aluminum foil layer and the braided fabric layer, and the sheath layer wraps the braided fabric layer; the thickness of the sheath layer ranges from 0.6 to 0.8mm, the thickness of the braided fabric layer from 0.3 to 0.5mm, and the thickness of the insulating layer ranges from 0.4 to 0.7mm; and the aluminum foil material of the aluminum foil layer comprises the following components by weight percentage: 0.05-0.20% of Si, 0.02-0.08% of Fe, 0.10-0.30% of Cu, 0.70-1.20% of Mn, 0.02-0.04% of Mg, 0.002-0.008% of Zn, 0.02-0.05% of Ti, 0.001-0.05% of B, 0.02-0.05% of Y, 0.02-0.05% of Ce, and the balance being Al and inevitable impurities. The layers in the LVDS cable for the automobile wire are manufactured by adopting specific materials reasonable in compatibility, comprehensive performance of the cable is further improved, especially the strength of the cable is increased, thus loss in signal transmission is low, and anti-interference capability is high.

Owner:NINGBO KBE ELECTRICAL TECH

Formula for low-smoke environment-friendly oil-resistant insulating cable

InactiveCN105566806AStop burningImprove bending resistancePlastic/resin/waxes insulatorsEnvironmental resistanceAntioxidant

The invention discloses a formula for a low-smoke environment-friendly oil-resistant insulating cable. The low-smoke environment-friendly oil-resistant insulating cable is prepared from, by weight, 40-50 parts of SG-1 type resin, 30-38 parts of plasticizer, 35-40 parts of an antioxidant, 20-30 parts of hydrous zinc borate, 40-60 parts of magnesium hydrate, 9-20 parts of TCP, 1.9-2.6 parts of an antioxidant, 33-39 parts of a stabilizer, 40-46 parts of DOP, 30-60 parts of chlorinated paraffin, 38-40 parts of dioctyl phthalate, 20.6-30.9 parts of dioctyl terephthalate, 28-32 parts of epoxidized soybean oil, 10.8-26 parts of vinyl acetate, 20-36 parts of light calcium carbonate and 30-50 parts of heavy calcium carbonate. The formula is reasonable and scientific, the cable is good in radiation resistance, good in waterproofness and excellent in mechanical property, mechanical physical performance of the produced finished product cable is higher than that of a common rubber cable, and the cable has flame resistance and abrasion resistance and is high in use safety and long in service life.

Owner:安徽天龙电器线缆集团有限公司

Hydrogenated epoxy vinyl resin-modified nitrile butadiene rubber material and preparation method thereof

The invention discloses a hydrogenated epoxy vinyl resin-modified nitrile butadiene rubber material and a preparation method thereof. The hydrogenated epoxy vinyl resin-modified nitrile butadiene rubber material is prepared from the following raw materials in parts by weight: 40 to 70 parts of nitrile butadiene rubber; 10 to 25 parts of styrene butadiene rubber; 10 to 25 parts of epichlorohydrin rubber; 0.1 to 3 parts of vulcanizing agent; 4 to 12 parts of silicon powder; 4 to 10 parts of hydrogenated epoxy vinyl resin; 2 to 5 parts of anti-aging agent; 2 to 5 parts of plasticizer; and 15 to 45 parts of organic solvent. According to the hydrogenated epoxy vinyl resin-modified nitrile butadiene rubber material and the preparation method thereof provided by the invention, the preparation process is simple, not only are the oil resistance and leak tightness of the nitrile butadiene rubber ensured, but also the elasticity, tensile strength and low temperature resistance of the nitrile butadiene rubber are increased, and application to multiple aspects is met.

Owner:常州市五洲化工有限公司

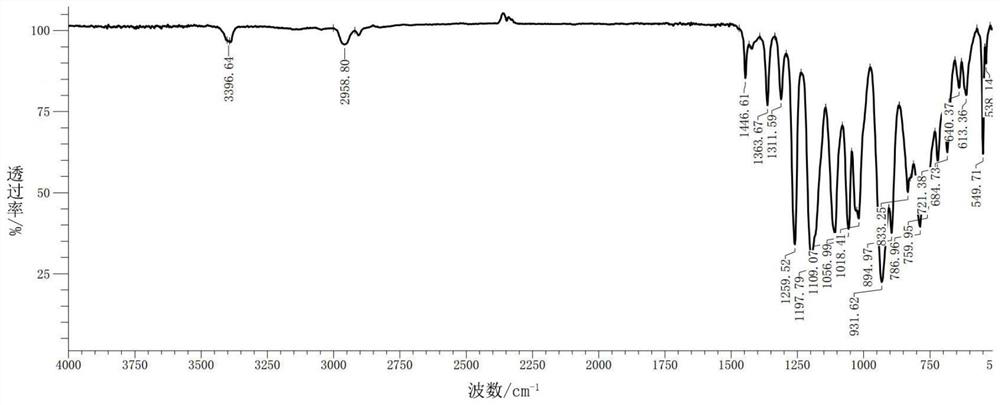

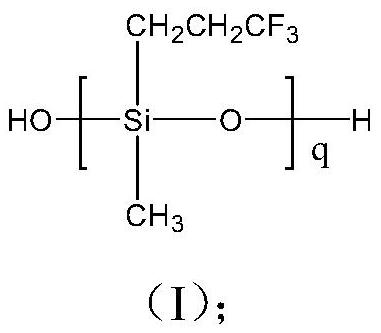

Engine oil-resistant low-pressure-change addition type liquid fluorinated silicone rubber and preparation method thereof

The invention relates to engine oil-resistant low-pressure-change addition type liquid fluorosilicone rubber and a preparation method thereof. The engine oil-resistant low-pressure-change addition type liquid fluorosilicone rubber comprises the following components in parts by weight: 100 parts of fluorosilicone base rubber; 10 to 20 parts of fumed silica; 10-20 parts of precipitated white carbon black; 1-3 parts of hydroxyl fluorosilicone oil; 2 to 5 parts of trifluoropropyl methyl cyclosilazane; 0.1 to 0.3 part of divinyl tetramethyl disilazane; 1-3 parts of distilled water; 0.1 to 0.3 part of a heat-resistant additive; 1.3 to 2.9 parts of a cross-linking agent; 0.3 to 0.6 part of a platinum catalyst; and 0.05 to 0.2 part of an inhibitor. According to the preparation method, fluorosilicone treating agents such as low-molecular-weight hydroxyl fluorosilicone oil and trifluoropropyl methyl cyclosilazane are used, the fumed silica and the precipitated silica are compounded to achieve a synergistic effect, and the specific cross-linking agent and the preparation method are matched, so that the compression set of the addition type liquid fluorosilicone rubber is greatly reduced, and the service life of the addition type liquid fluorosilicone rubber is prolonged. Even if the lubricating oil is soaked in high-temperature engine oil for a long time, the system cannot be damaged, the lower deformation rate can still be kept, and the oil pressure change resistance is very excellent.

Owner:新元化学(山东)股份有限公司 +1

Cigarette holder adhesive and preparation method thereof

InactiveCN104059560AStrong coagulationExcellent laminationPolysaccharide adhesivesChemical additionAqueous solution

The invention discloses a cigarette holder adhesive and a preparation method thereof. The cigarette holder adhesive consists of an aqueous solution of Pullulan and levan, wherein the mass concentration of the Pullulan is 0.1-10 percent (W / V), and the mass concentration of the levan is 0.01-1 percent (W / V). The product does not contain any chemical additive, is combusted into carbon dioxide and water vapor, has slight burnt flavor, is safe to human body, non-toxic and harmless, high in initial adhesion and high in drying speed, does not have monomer residues and can be suitable for performing holder adhesion for a high-speed cigarette making machine at the speed of 10000-12000 cigarettes per minute.

Owner:SHANDONG JINMEI BIOTECH

Highly wear-resistant oil-resistant fireproof coating and preparation method thereof

InactiveCN107201098AStrong adhesionImprove wetting abilityFireproof paintsAntifouling/underwater paintsFiberWear resistant

The invention discloses a highly wear-resistant oil-resistant fireproof coating and belongs to the technical field of coatings. The highly wear-resistant oil-resistant fireproof coating comprises the following raw materials in parts by weight: 45-55 parts of styrene modified acrylic emulsion, 15-18 parts of styrene-acrylic emulsion, 7-11 parts of asbestos fibers, 3-5 parts of graphite fibers, 5-7 parts of emery powder, 8-12 parts of expanded vermiculite powder, 2-8 parts of brominated polystyrene, 3-7 parts of melamine cyanurate, 6-8 parts of ammonium polyphosphate, 1-3 parts of antimony oxides, 3-5 parts of a boron-containing flame retardant, 0.5-1 part of a light stabilizer, 1-2 parts of an antifoaming agent, 0.1-0.5 part of an antibacterial agent and 10-25 parts of water. The invention further discloses a preparation method of the highly wear-resistant oil-resistant fireproof coating. The highly wear-resistant oil-resistant fireproof coating disclosed by the invention is simple in preparation and high in adhesive ability and has excellent wear resistance, oil resistance and fire resistance.

Owner:HEFEI MINGYOU HIGH TEMPERATURE TECH CO LTD

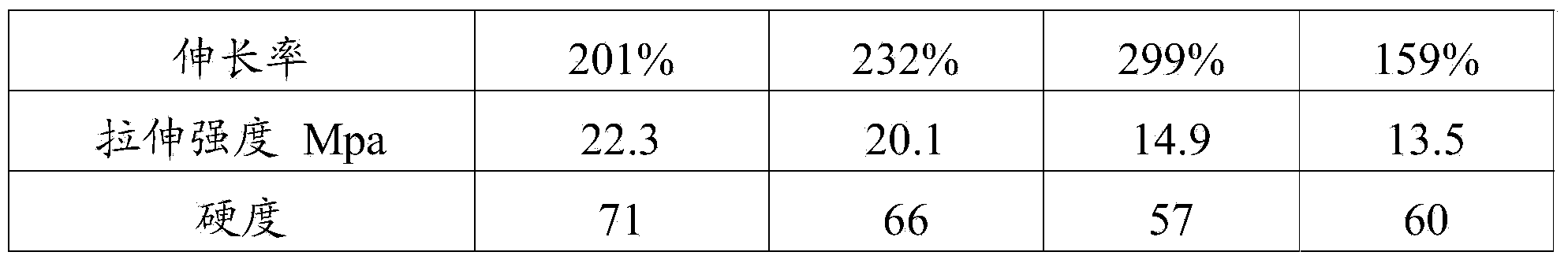

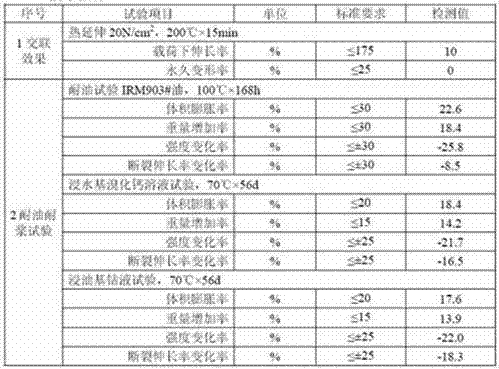

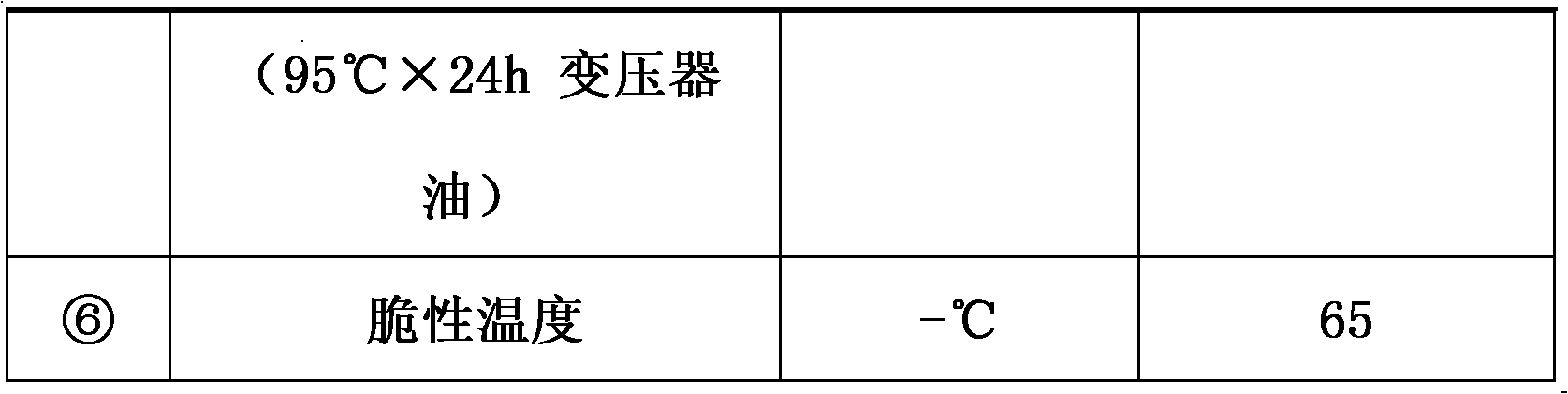

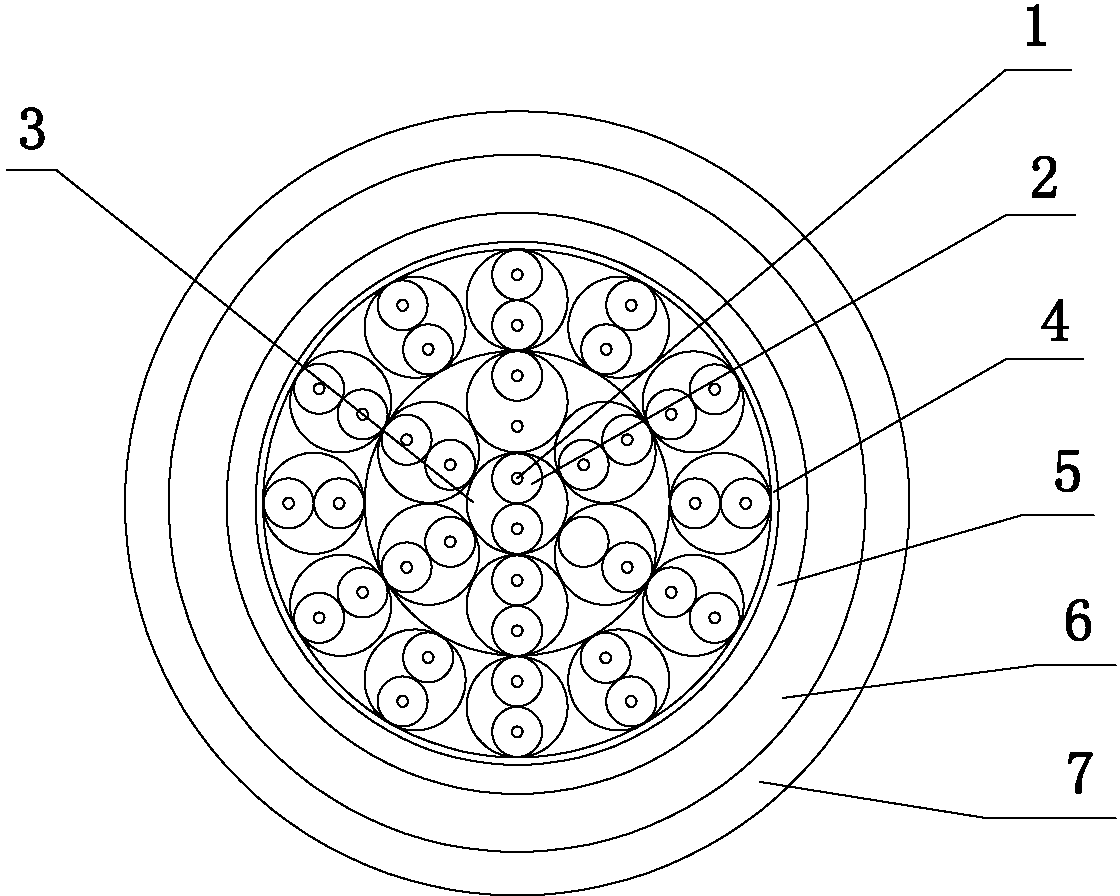

Low temperature rubber capsule used in oil conservator for transformer and preparation process

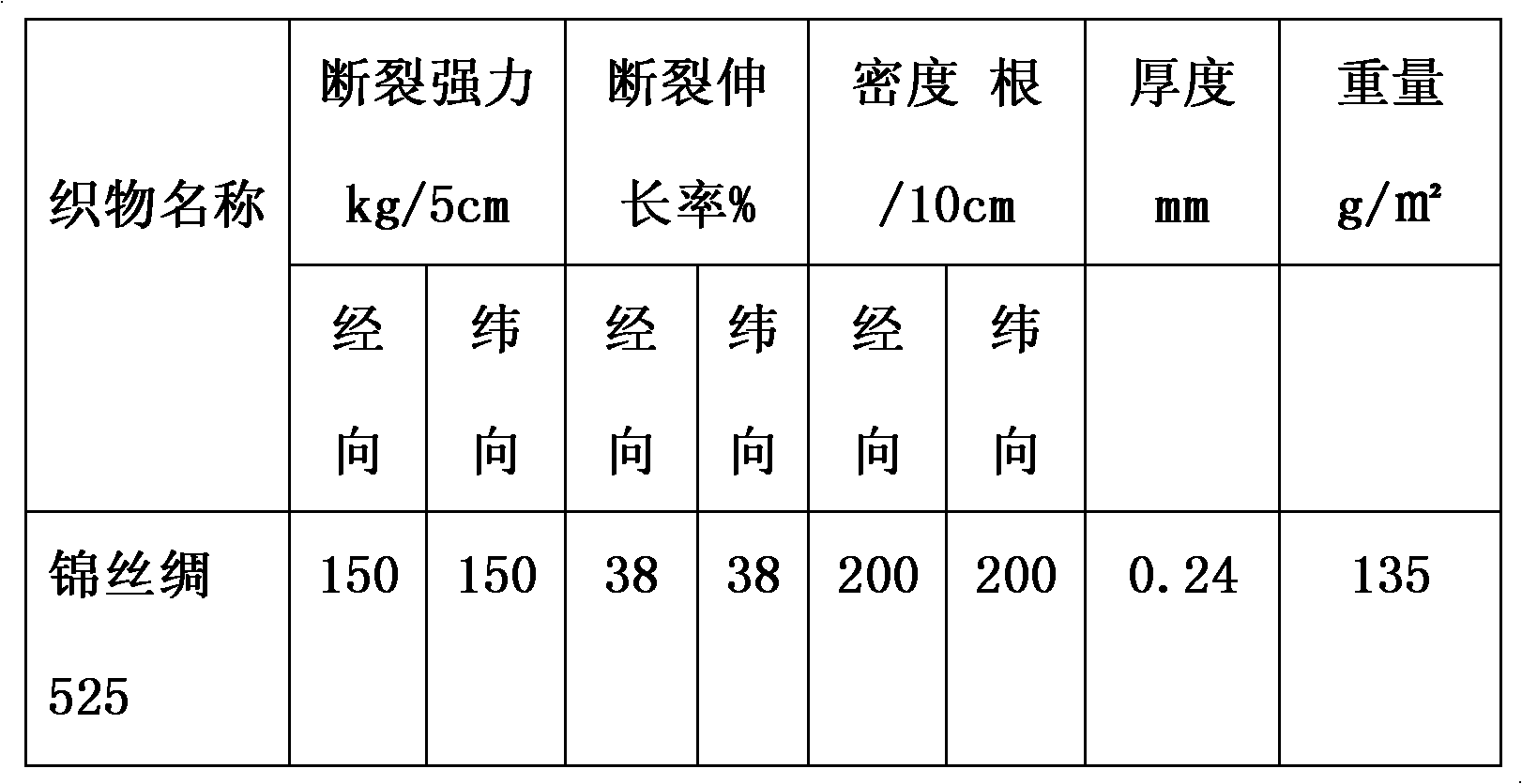

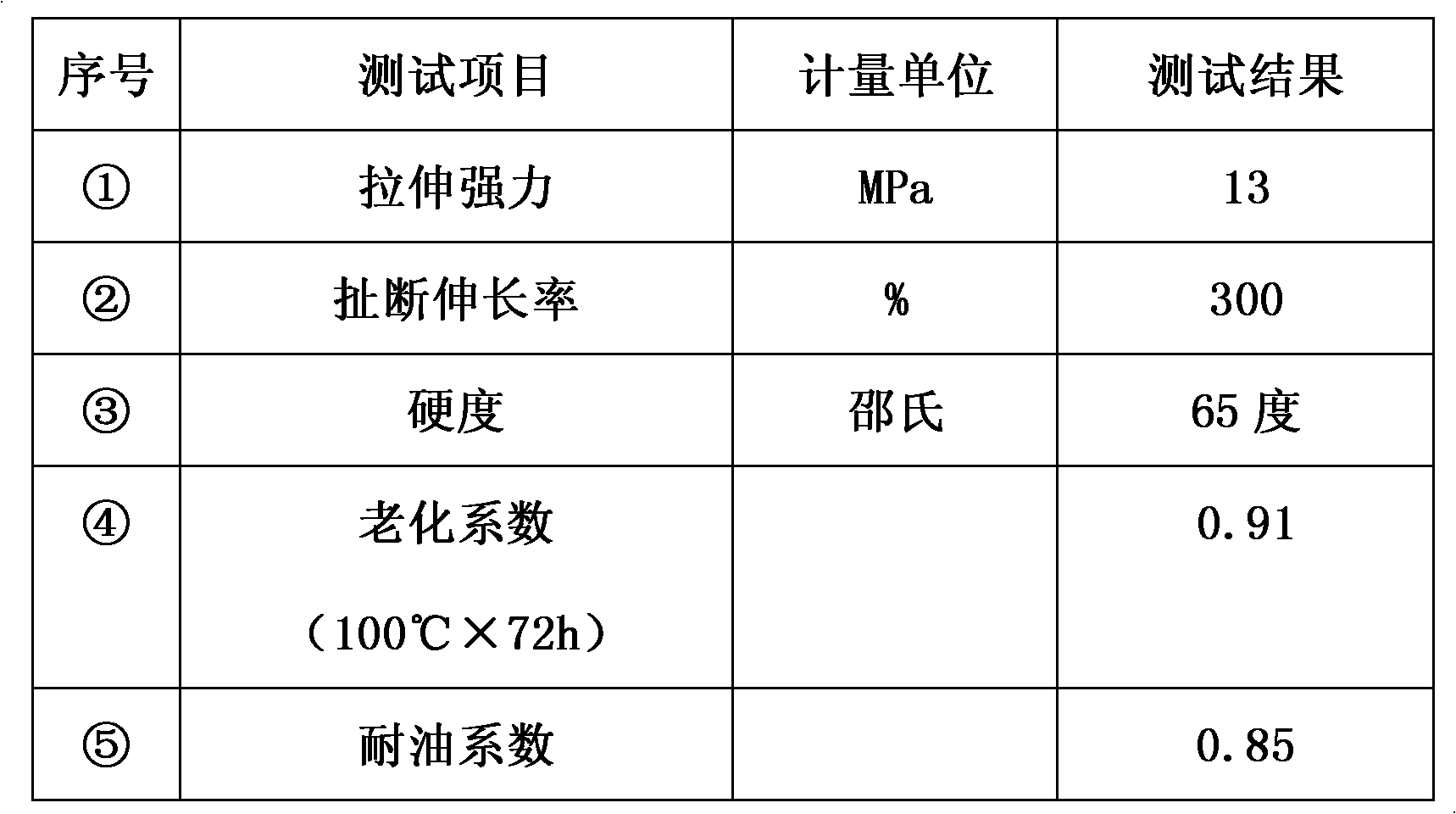

ActiveCN102486011AGuaranteed oil resistanceGuaranteed cold resistanceTransformers/inductances coolingTextiles and paperFiberVulcanization

The invention provides a low temperature rubber capsule used in an oil conservator for a transformer and a preparation process. The invention is characterized in that: the fabric, nylon silk 525, is used as a framework material of the low temperature rubber capsule, and the surface of the nylon silk 525 is coated with a sizing material which has good oil resistance, heat resistance and cold resistance and comprises butyronityile-26, butyronityile-18, a strengthening agent and a plasticizer; the preparation process comprises a step of filtering slurry of the sizing material with a 100-mesh screen and applying the sizing material on each surface of the nylon silk 525 at least three times, a step of calendering an obtained rubberized fabric by using a pressure rubberizing method and carrying out double-surface rubberizing on the rubberized fabric with a three-roll calender after rubber coating, a step of severing and molding the calendered rubberized fabric according to requirements of a drawing, a step of spreading talcum powder on the surface of formed capsules and putting the capsules into a vulcanizing tank for vulcanization and a step of carrying out visual and dimensional inspection and pressure test on the vulcanized capsules, packaging qualified capsules and putting the packaged qualified capsules in a warehouse. According to the invention, the problem that conventional rubber capsules used in an oil conservator for a transformer can not be normally used under a low temperature of -60 DEG C is thoroughly overcome.

Owner:SHENYANG HONGDA RUBBER & PLASTIC CO LTD

Environment-friendly cable for automobile charging pile

InactiveCN105761787AGood softnessImprove stress resistanceConductive materialDetails of conductive coresCopper wireEngineering

The invention discloses an environment-friendly cable for an automobile charging pile. A cable core is formed by regularly twisting a plurality of power core wires and a control core wire, flexibility of the cable and roundness of the cable core are guaranteed, and both a first conductor and a second conductor are formed by stranding tinned copper wires, thereby enabling the conductors to achieve excellent flexibility and roundness, and improving an anti-pressure capability of the cable; a first insulating layer, a second insulating layer, a main sheath layer and a sub sheath layer adopt irradiation insulating materials, thereby ensuring that the cable has the characteristics of flexibility, oil resistance, alkali resistance, ultraviolet resistance, wear resistance, cracking resistance and the like; and the sheath is extruded outside the cable core, thereby ensuring compactness of a cross section of the cable, and enabling the cable to have excellent anti-rolling performance.

Owner:安徽华海特种电缆集团有限公司

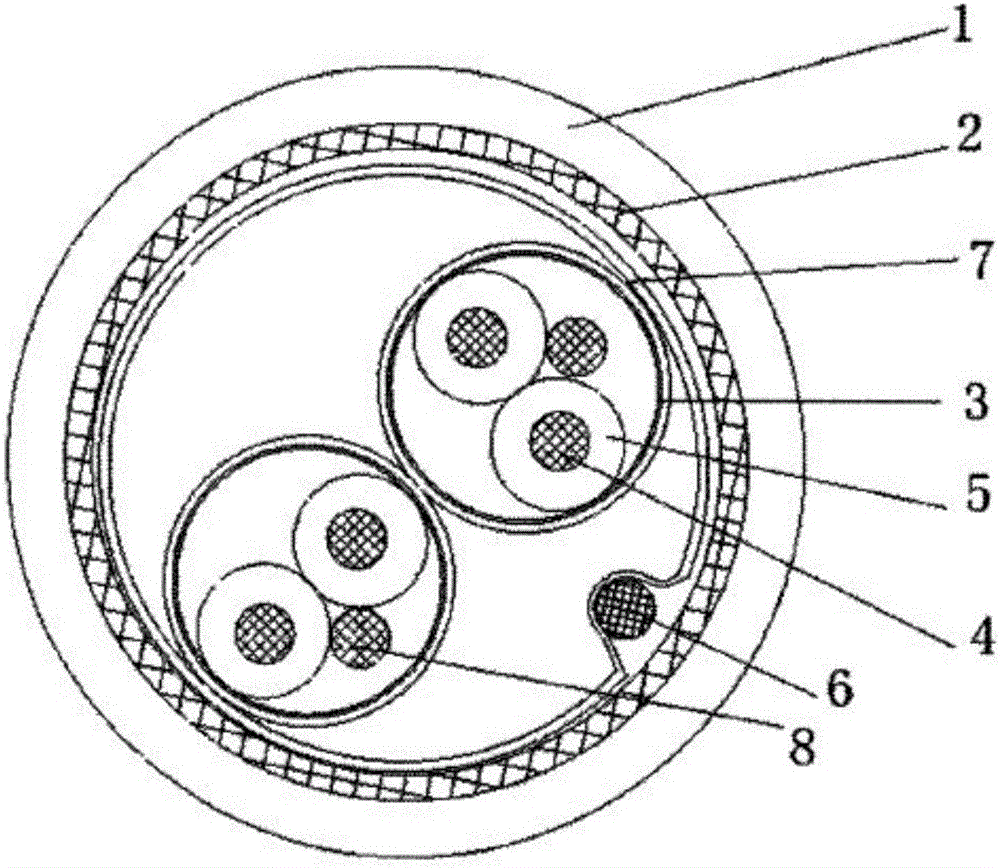

Sonar signal control flexile cable with high electromagnetic-interference resistance

InactiveCN102915811AReasonable structureLow densityPlastic/resin/waxes insulatorsFlexible cablesCopper wireFlexible cable

The invention discloses a sonar signal control flexible cable with high electromagnetic-interference resistance. The sonar signal control flexible cable is characterized by comprising conductor cores having flexible tinned copper wire structures. Each conductor core is covered with an insulating layer made of a non-polar high-polymer composite material, each two conductor cores covered with the insulating layers form a stranded pair, each stranded pair is covered with a shield layer, and two layers of stranded pairs are arranged along a circumference direction of the stranded pair in the center as a lining core. The cable formed of the multiple stranded pairs is covered with a braided shield layer, the braided shield layer is covered with a copper-plastic composite belt shield layer, the copper-plastic composite belt shield layer is covered with an outer braided shield layer, and the outer braided shield layer is provided with sheath. The sonar signal control flexible cable is reasonable in structure, low in density, light, flame-retardant and environment-friendly. Performance of environmental protection, convenience in installation and the like of the cable is improved, effective transmission of the cable is guaranteed, and the cable can work normally even in strong electromagnetic fields.

Owner:SINOSTAR CABLE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com