Oil-resistant low-smoke halogen-free flame-retardant polyolefin cable material and preparation method thereof

A technology of polyolefin cable material and low-smoke halogen-free plastic, which is applied to insulated cables, cables, circuits, etc., can solve the problems of poor low temperature performance and low tensile strength, and achieves improved flame retardant performance, reduced production costs, and reduced production costs. The effect of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific examples.

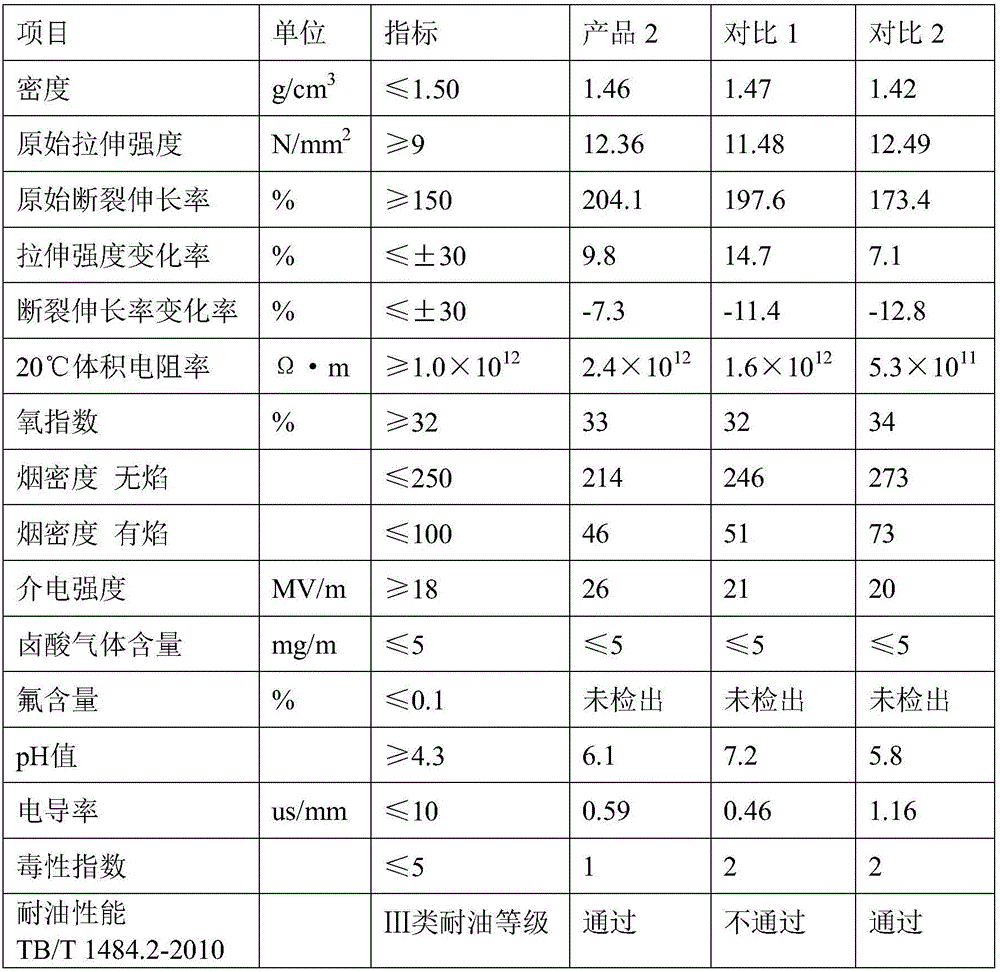

[0015] An oil-resistant, low-smoke, halogen-free, flame-retardant polyolefin cable material, the composition of which is shown in Table 1.

[0016] Table 1 Composition of oil-resistant, low-smoke, halogen-free, flame-retardant polyolefin cable materials

[0017] Element

Product 1

Product 2

Product 3

Product 4

Contrast 1

Contrast 2

Regenerated low-smoke and halogen-free cable material particles

90 copies

88 copies

86 copies

80 copies

0 copies

100 copies

Silicone grafted polyethylene

10 copies

9 servings

6 servings

5 copies

6 servings

15 copies

Ethylene vinyl acetate copolymer

10 copies

9 servings

9 servings

8 servings

9 servings

5 copies

Inorganic flame retardant

30 copies

26 copies

24 copies

20 copies

24 copies

35 copies ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com