Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1114results about "Details of conductive cores" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

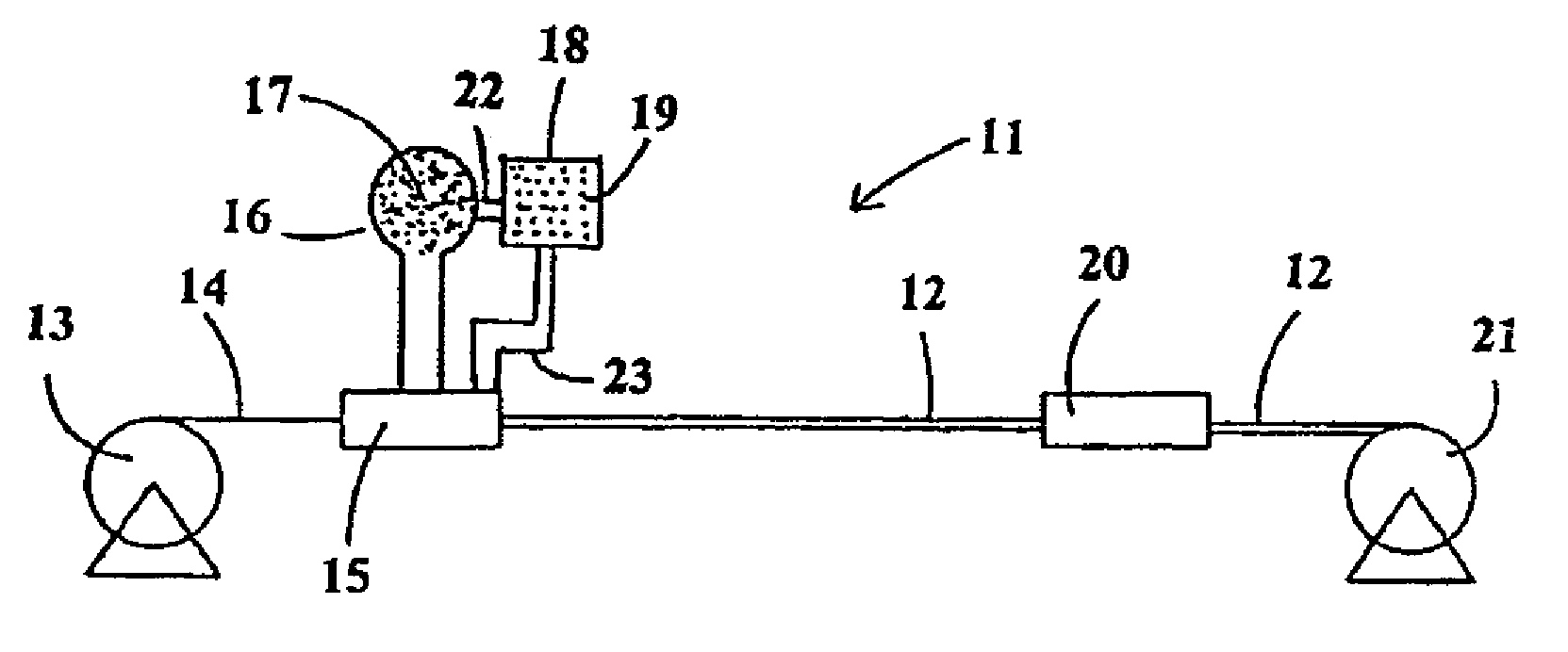

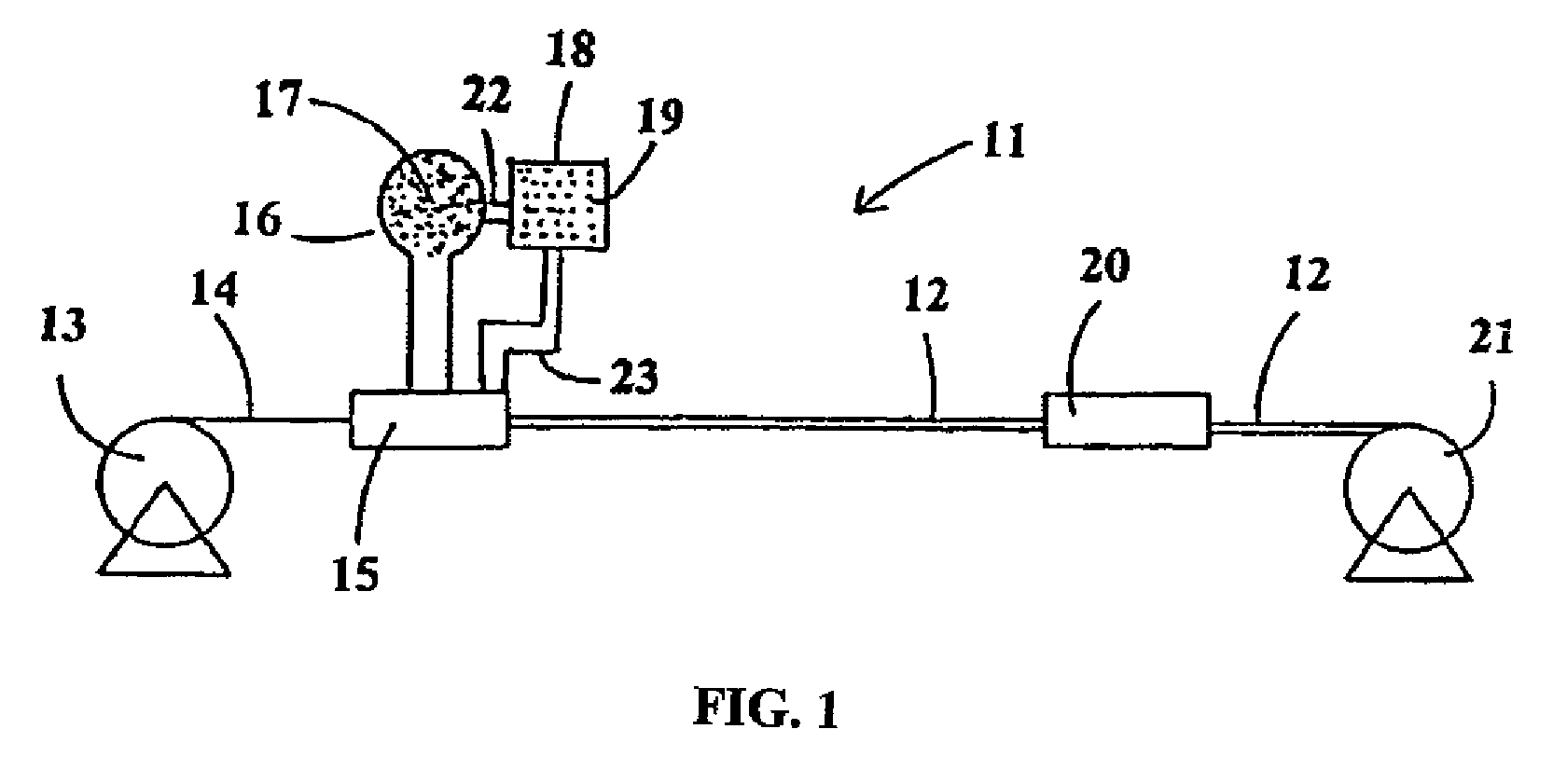

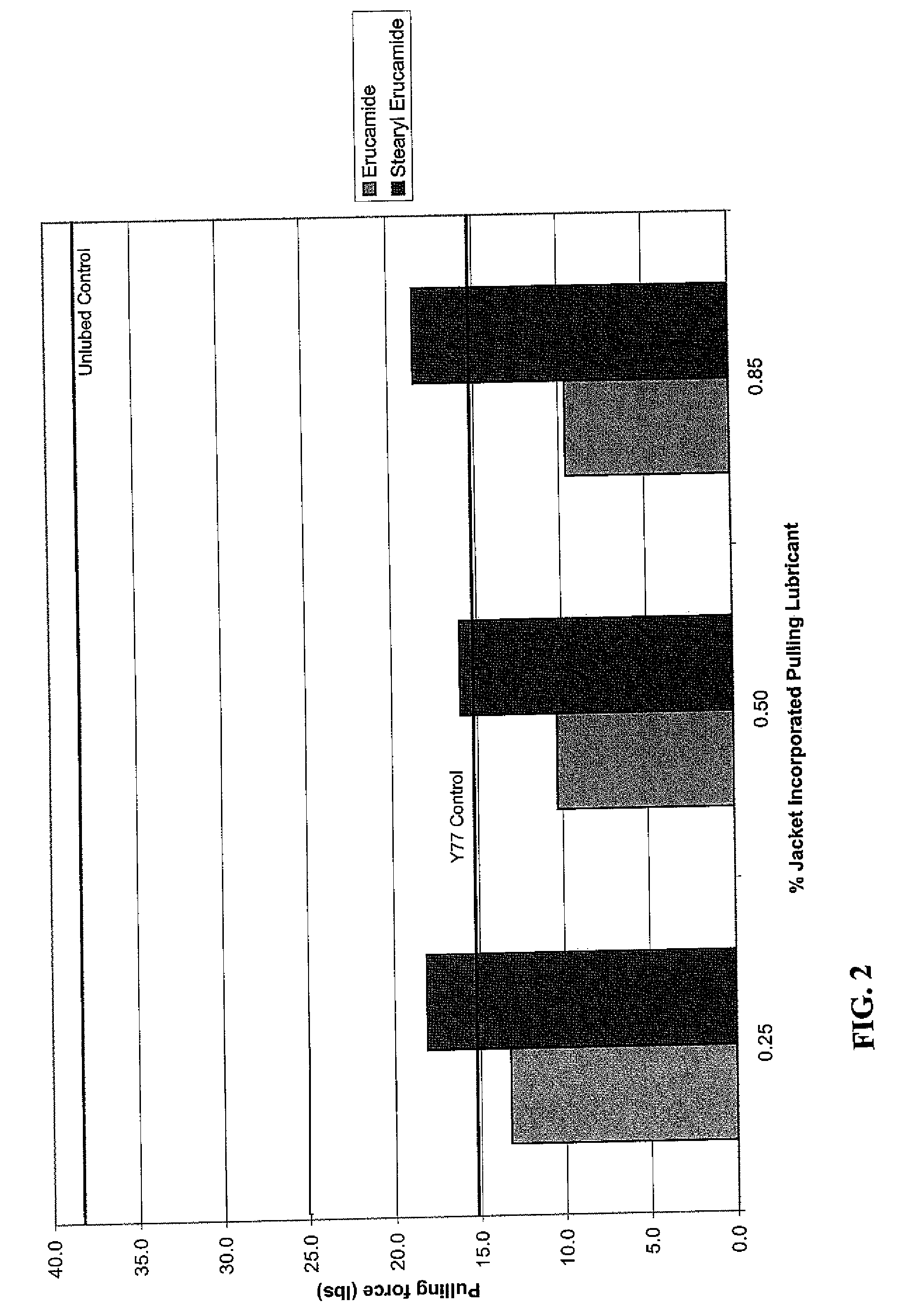

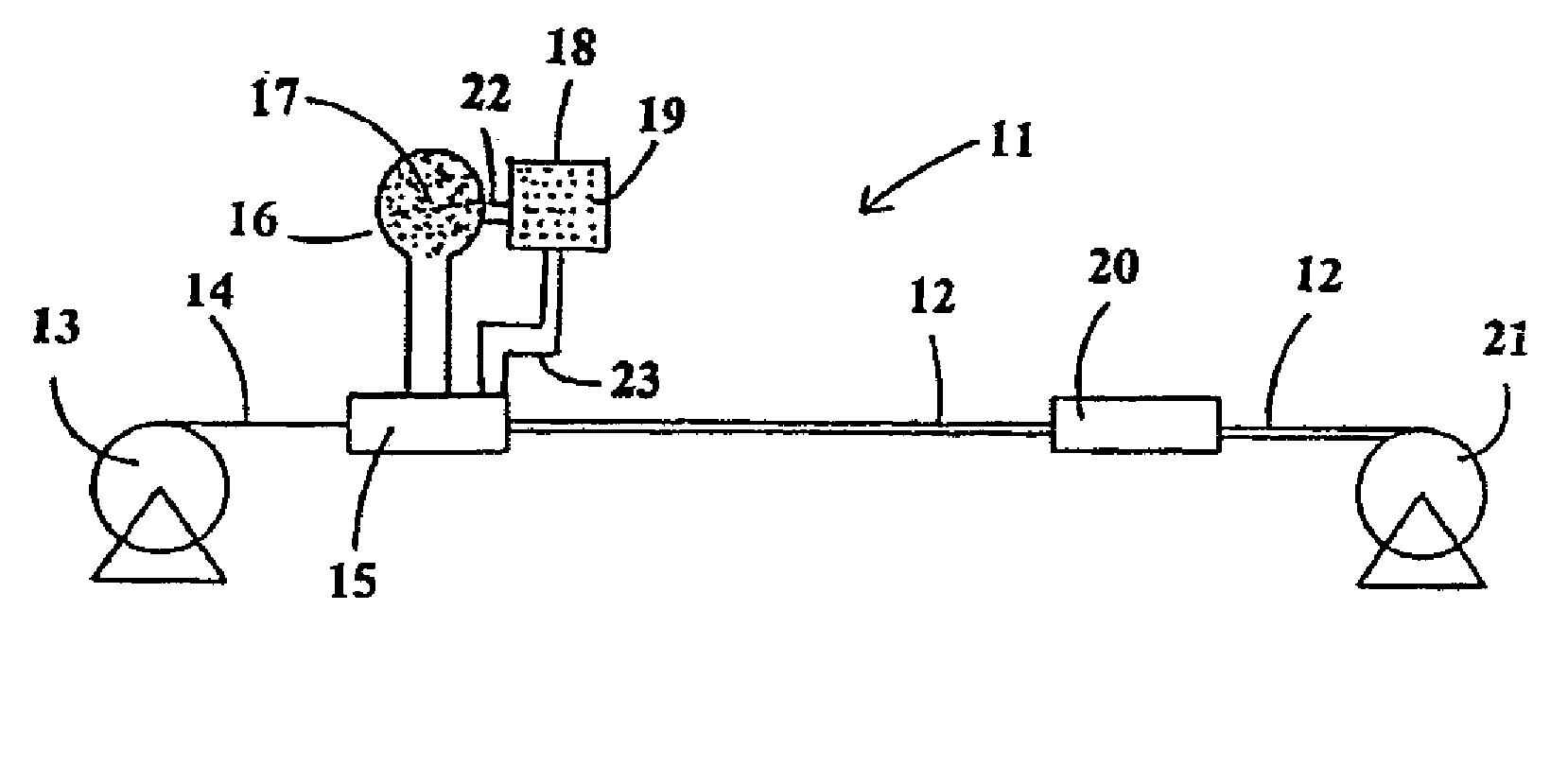

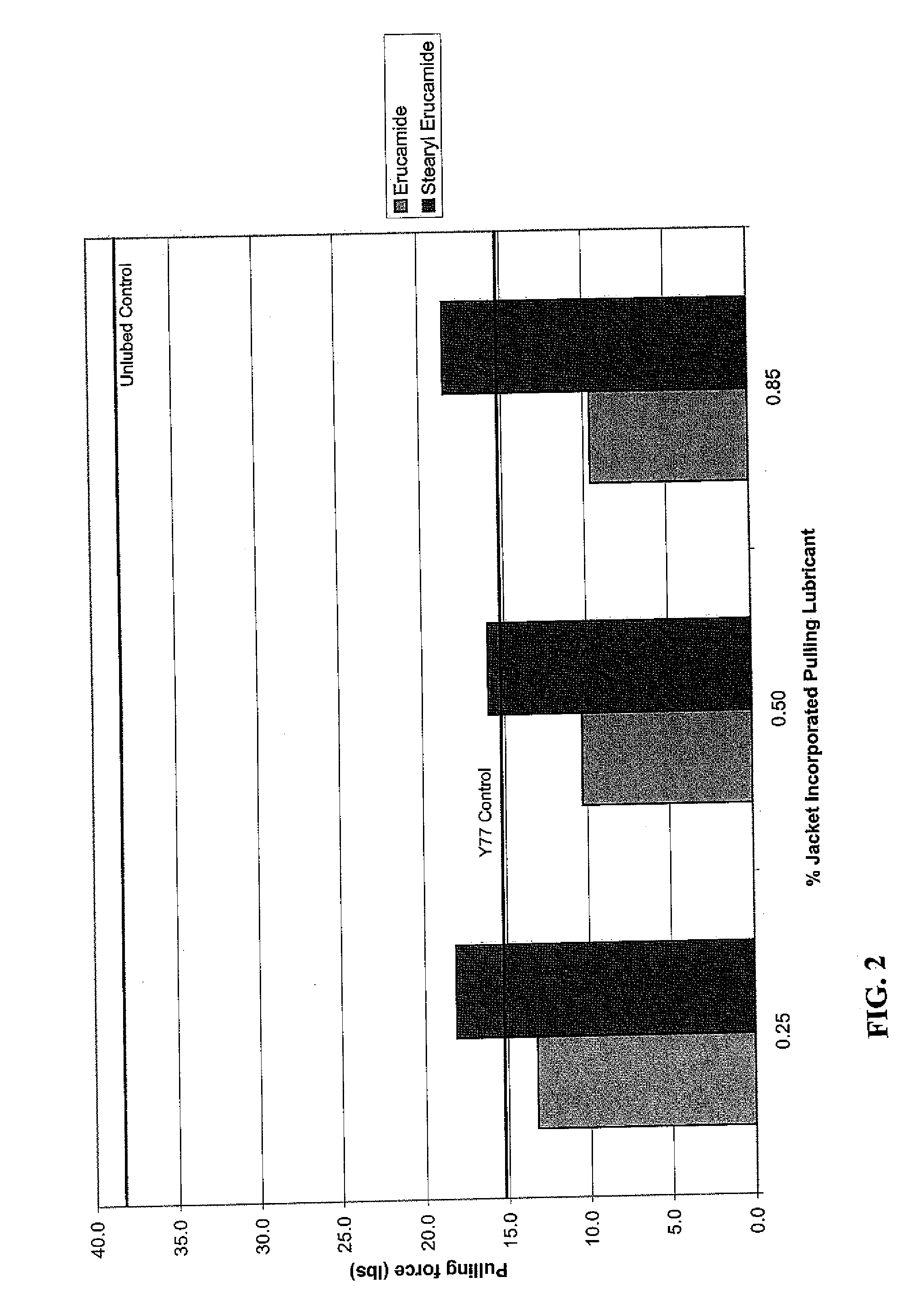

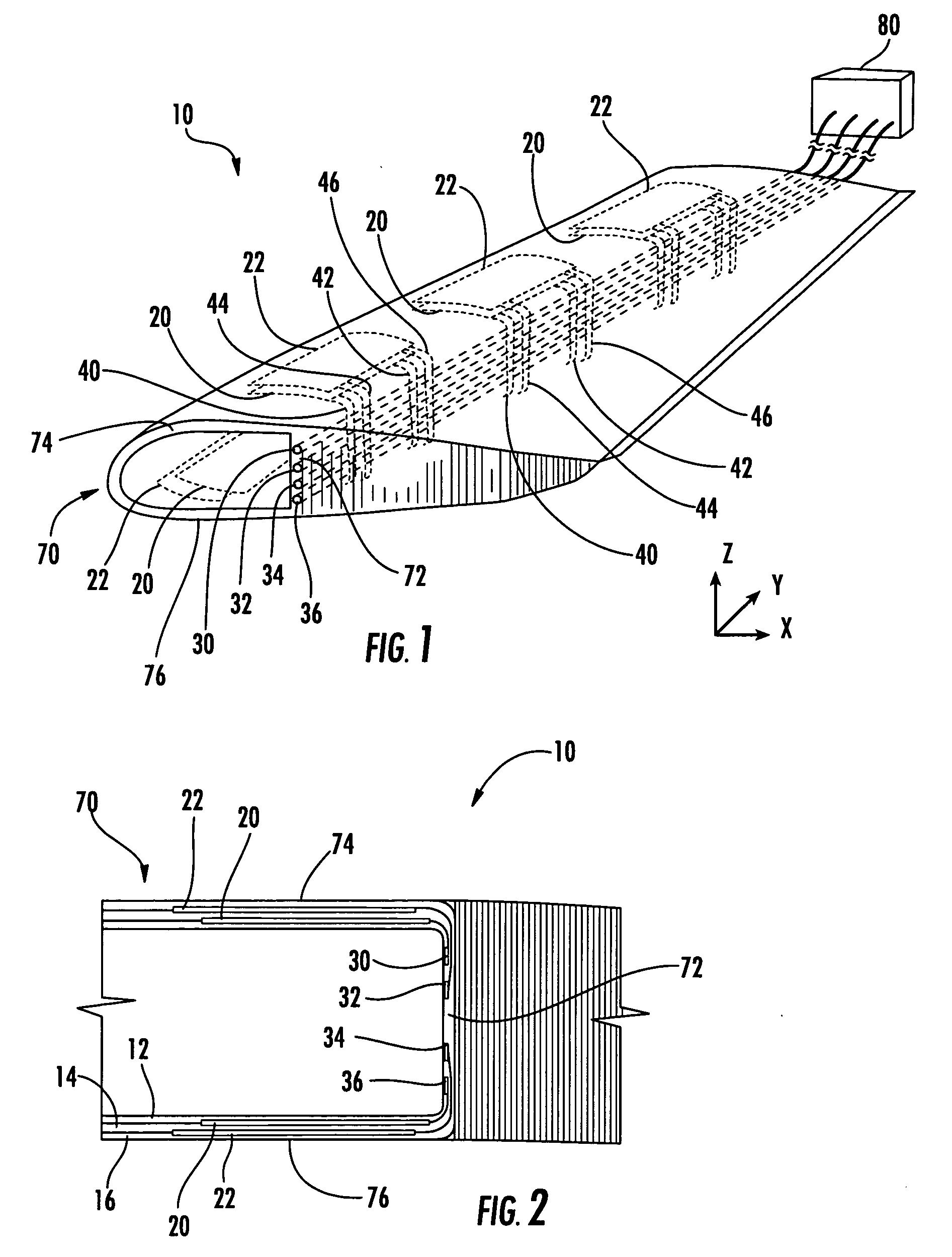

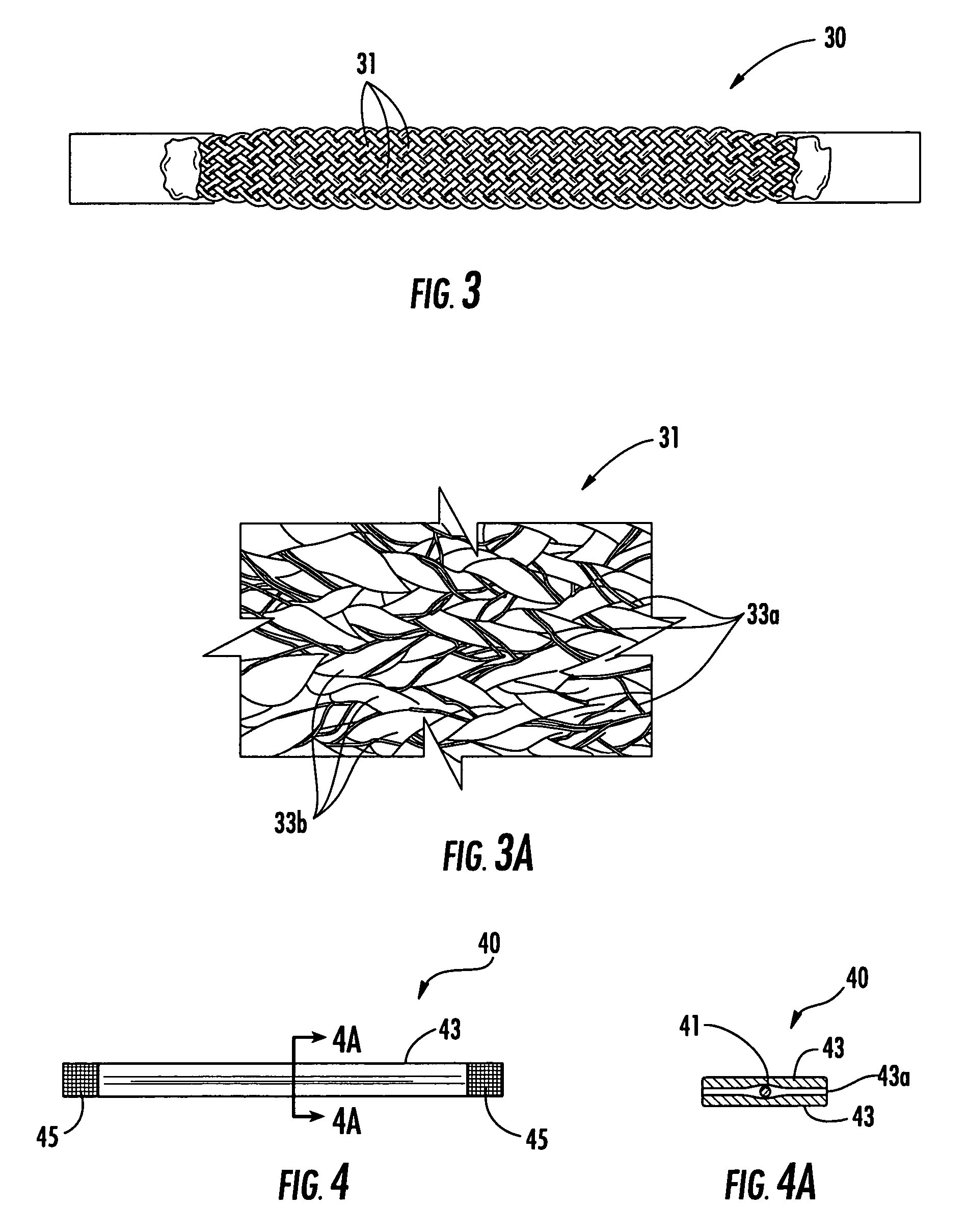

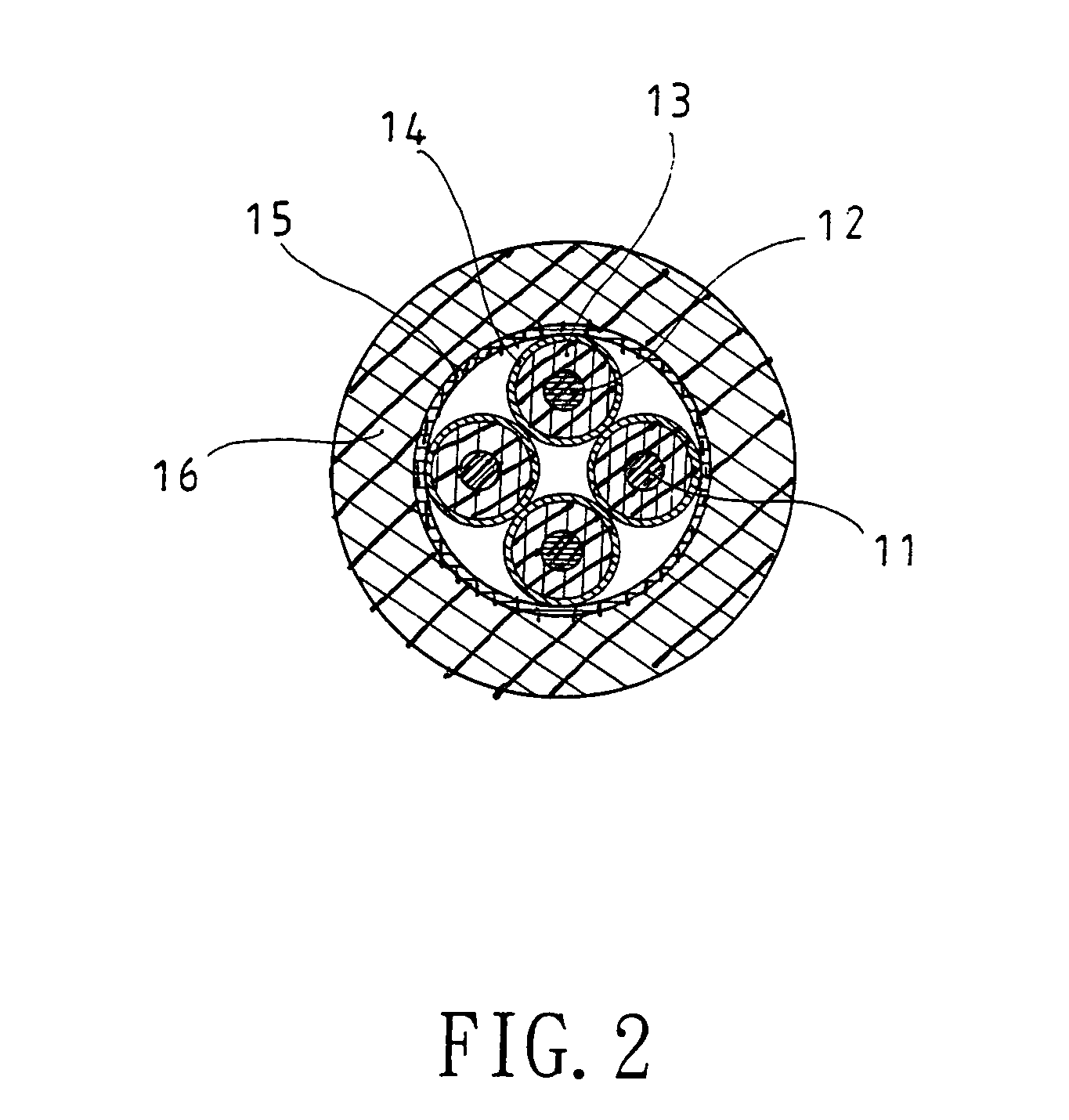

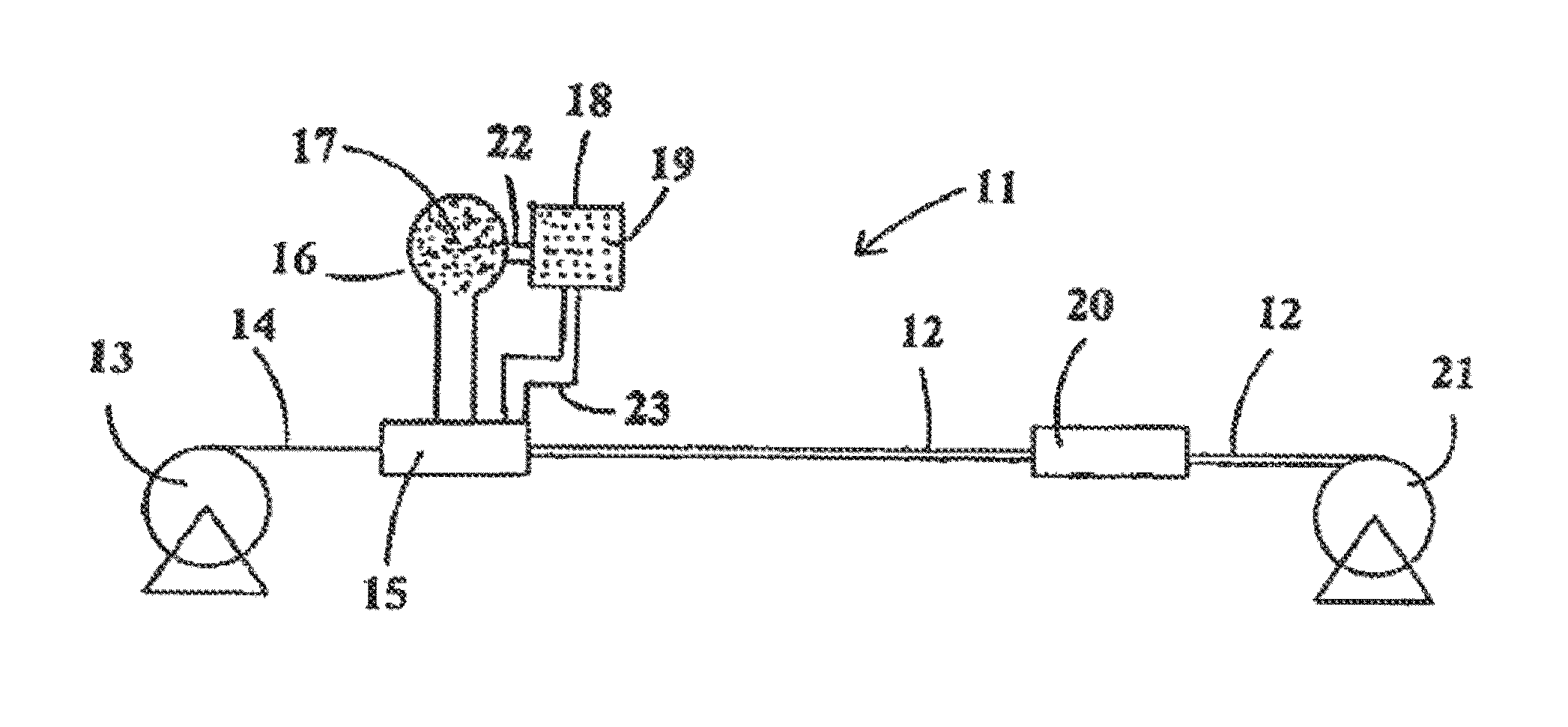

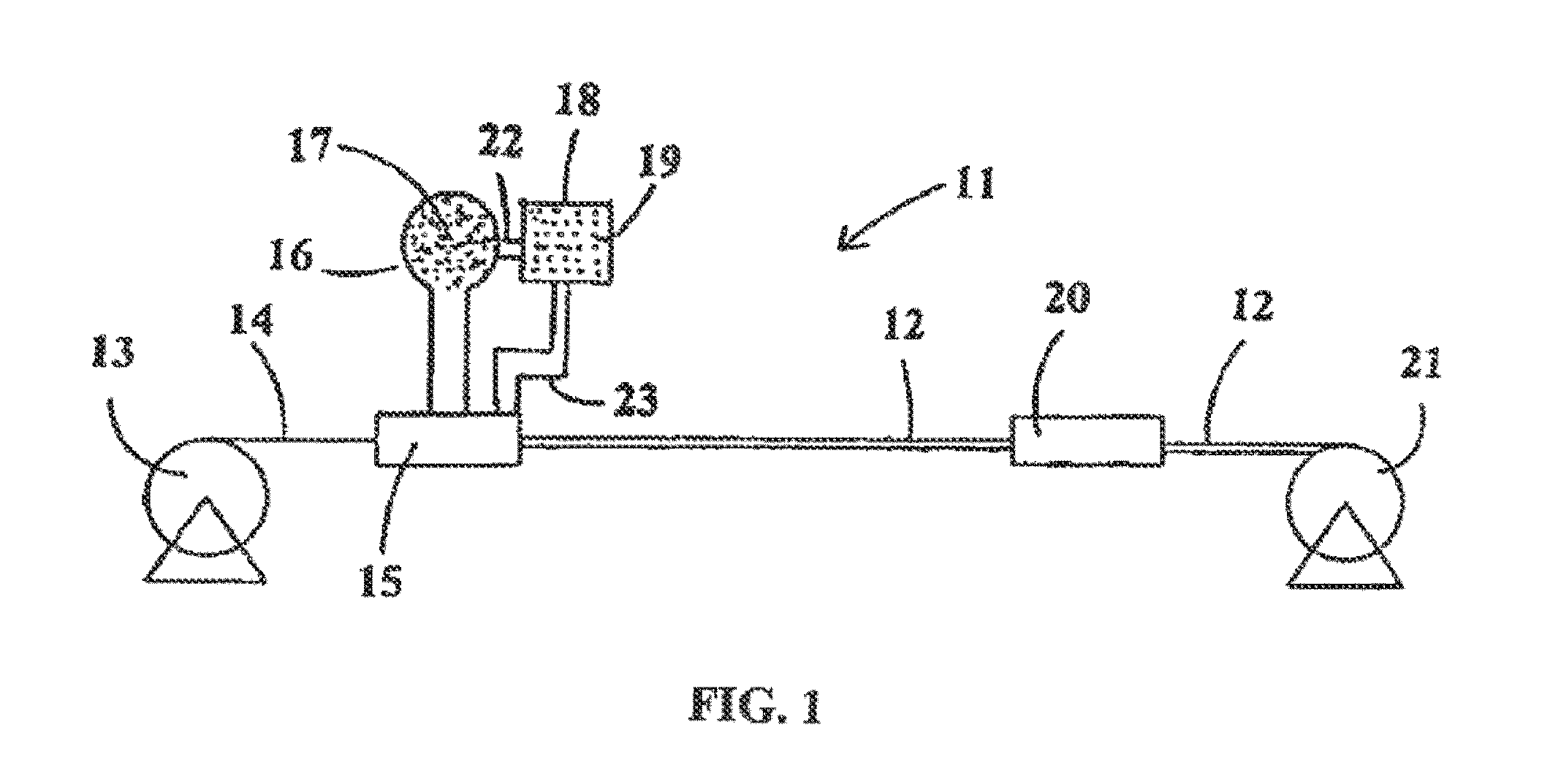

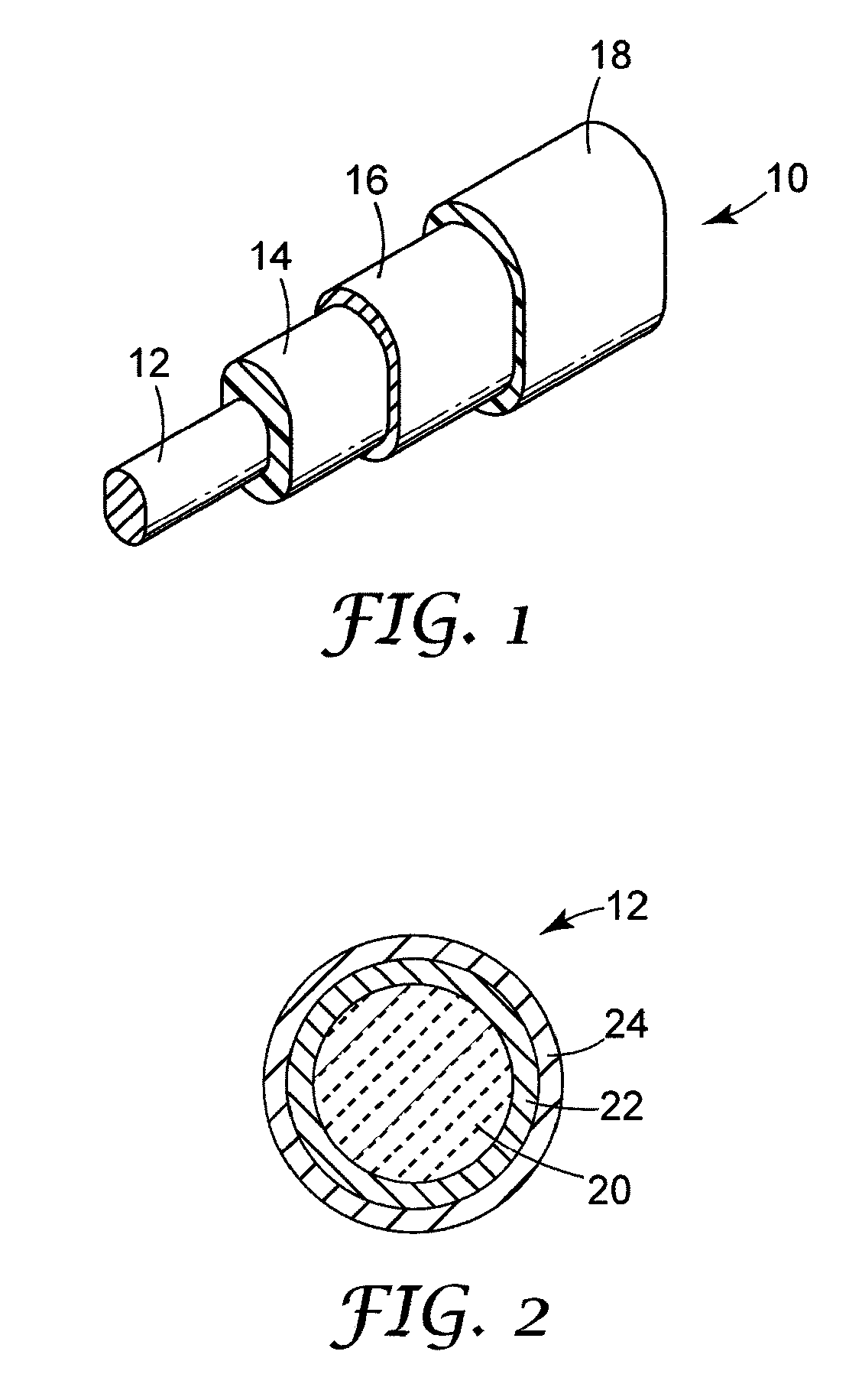

Method of manufacturing THHN electrical cable, and resulting product, with reduced required installation pulling force

InactiveUS7749024B2Reduce coefficient of frictionLower surfaceRelieving strain on wire connectionLiquid organic insulatorsElectrical conductorPull force

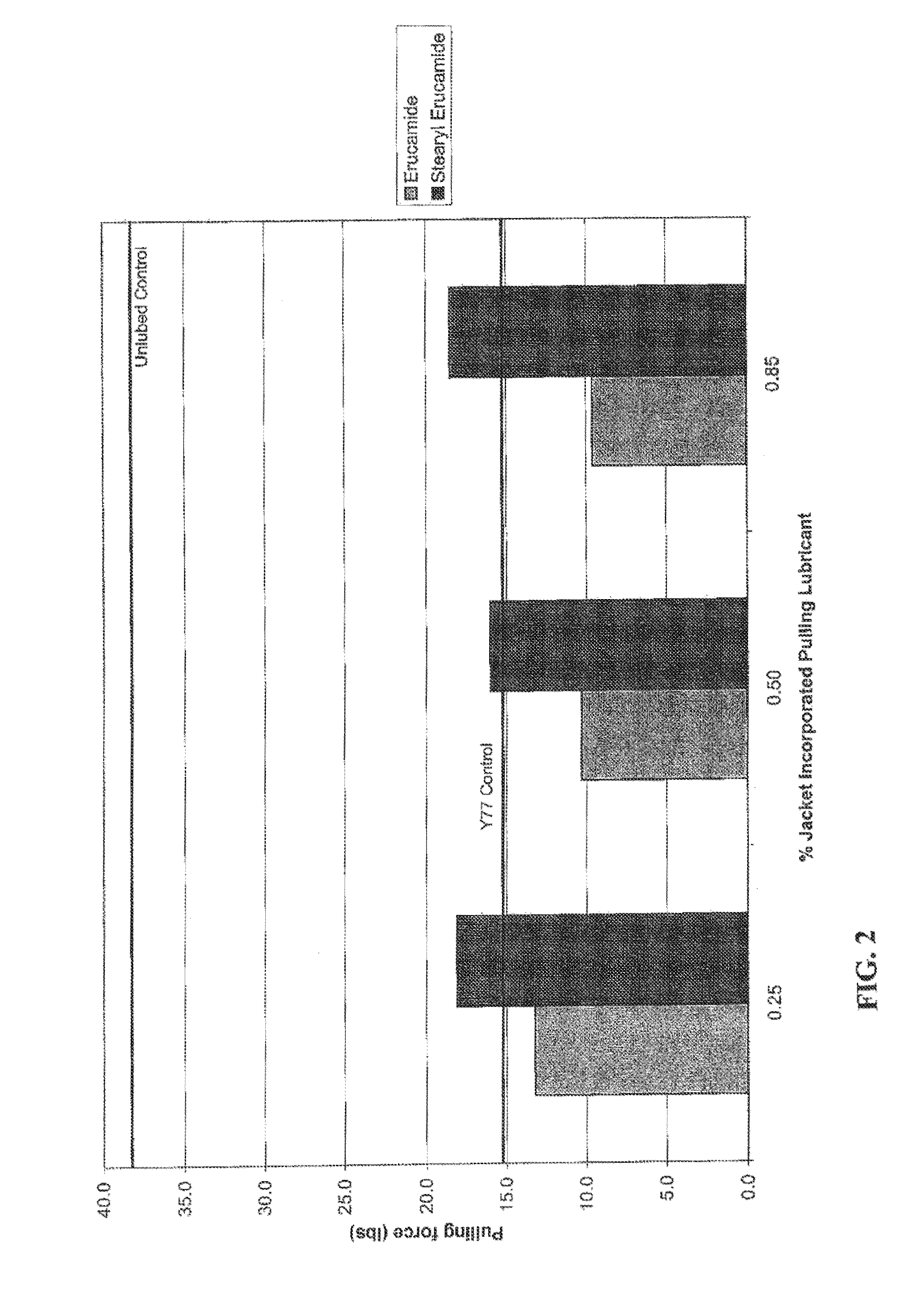

Disclosed is type THHN cable having a reduced surface coefficient of friction, and the method of manufacture thereof, in which the central conductor core and insulating layer are surrounded by a nylon sheath. A high viscosity, high molecular weight silicone based pulling lubricant for THHN cable, or alternatively, erucamide or stearyl erucamide for small THHN gauge wire, is incorporated, by alternate methods, with the nylon material from which the outer sheath is extruded, and is effective to reduce the required pulling force on the cable during installation.

Owner:SOUTHWIRE CO LLC

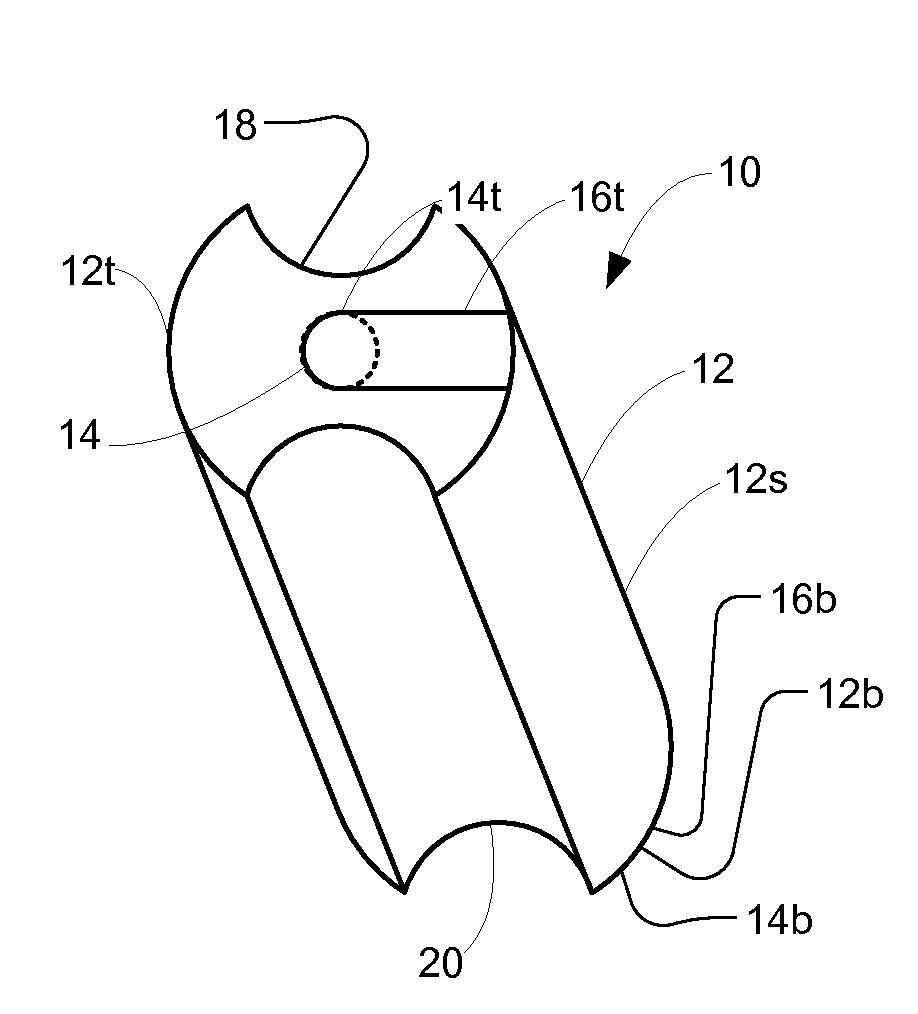

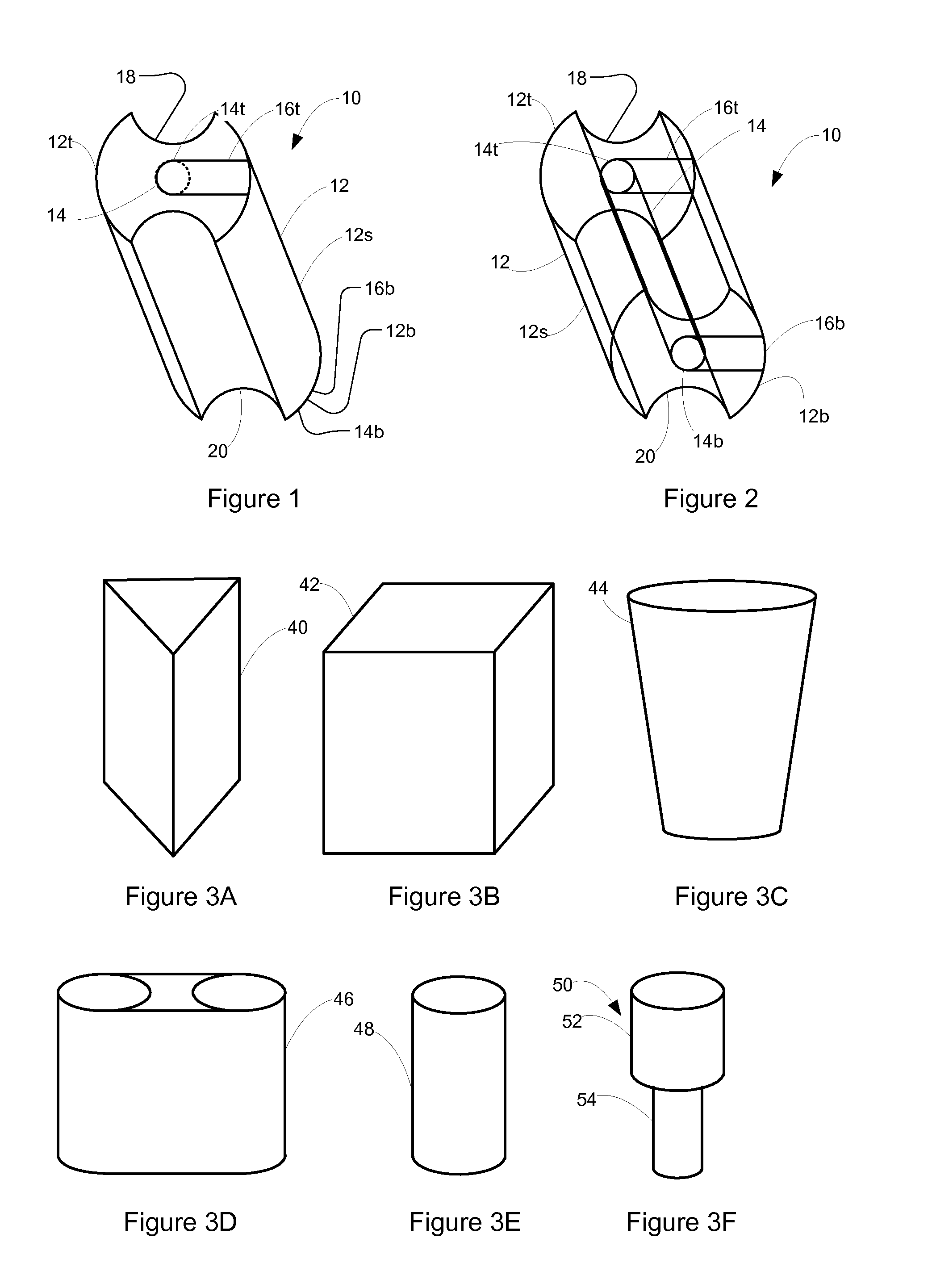

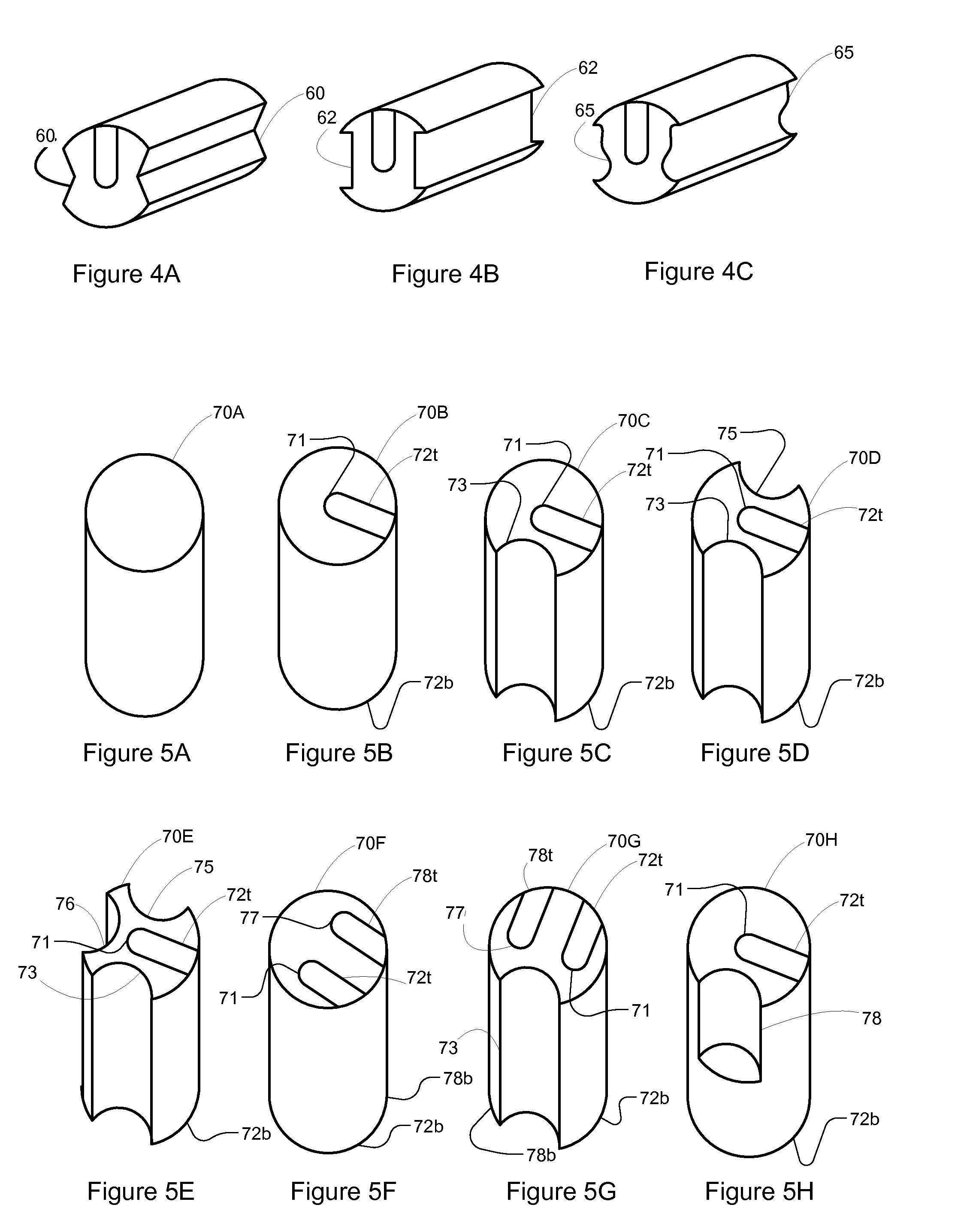

Z-Directed Delay Line Components for Printed Circuit Boards

ActiveUS20110019374A1Printed circuit aspectsDetails of conductive coresElectricityElectrical conductor

A Z-directed signal delay line component for insertion into a printed circuit board while allowing electrical connection to internal conductive planes contained with the PCB. In one embodiment the Z-directed delay line component is housed within the thickness of the PCB allowing other components to be mounted over it. The delay line embodiments include a W-like line and a plurality of spaced apart, semi-circular line segment connected such that current flow direction alternates in direction between adjacent semi-circular line segments, each of which in other embodiments can be varied by use of shorting bars. Several Z-directed delay line components may be mounted into a PCB and serially connected to provide for longer delays. The body may contain one or more conductors and may include one or more surface channels or wells extending along at least a portion of the length of the body. Methods for mounting Z-directed components are also provided.

Owner:LEXMARK INT INC

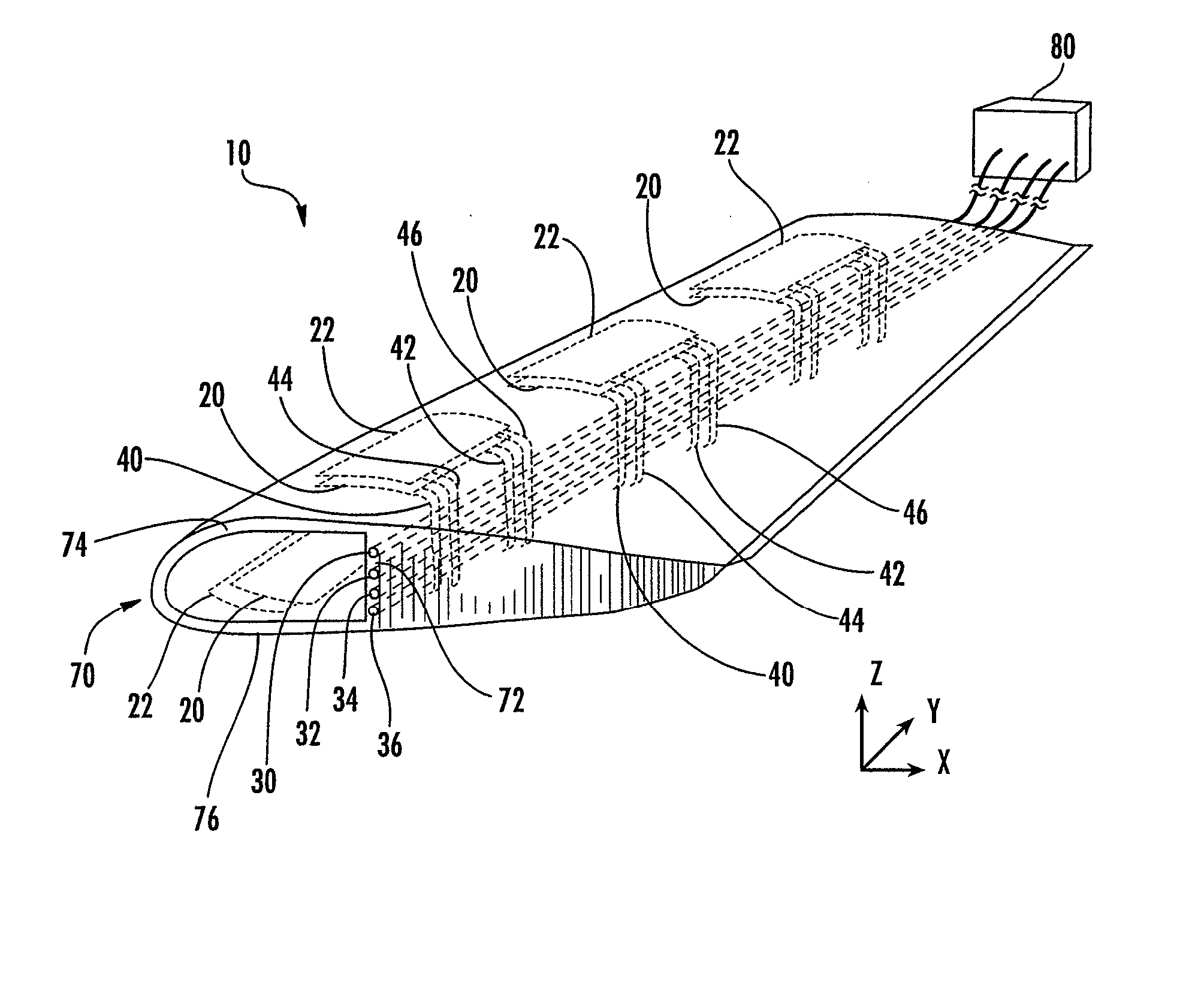

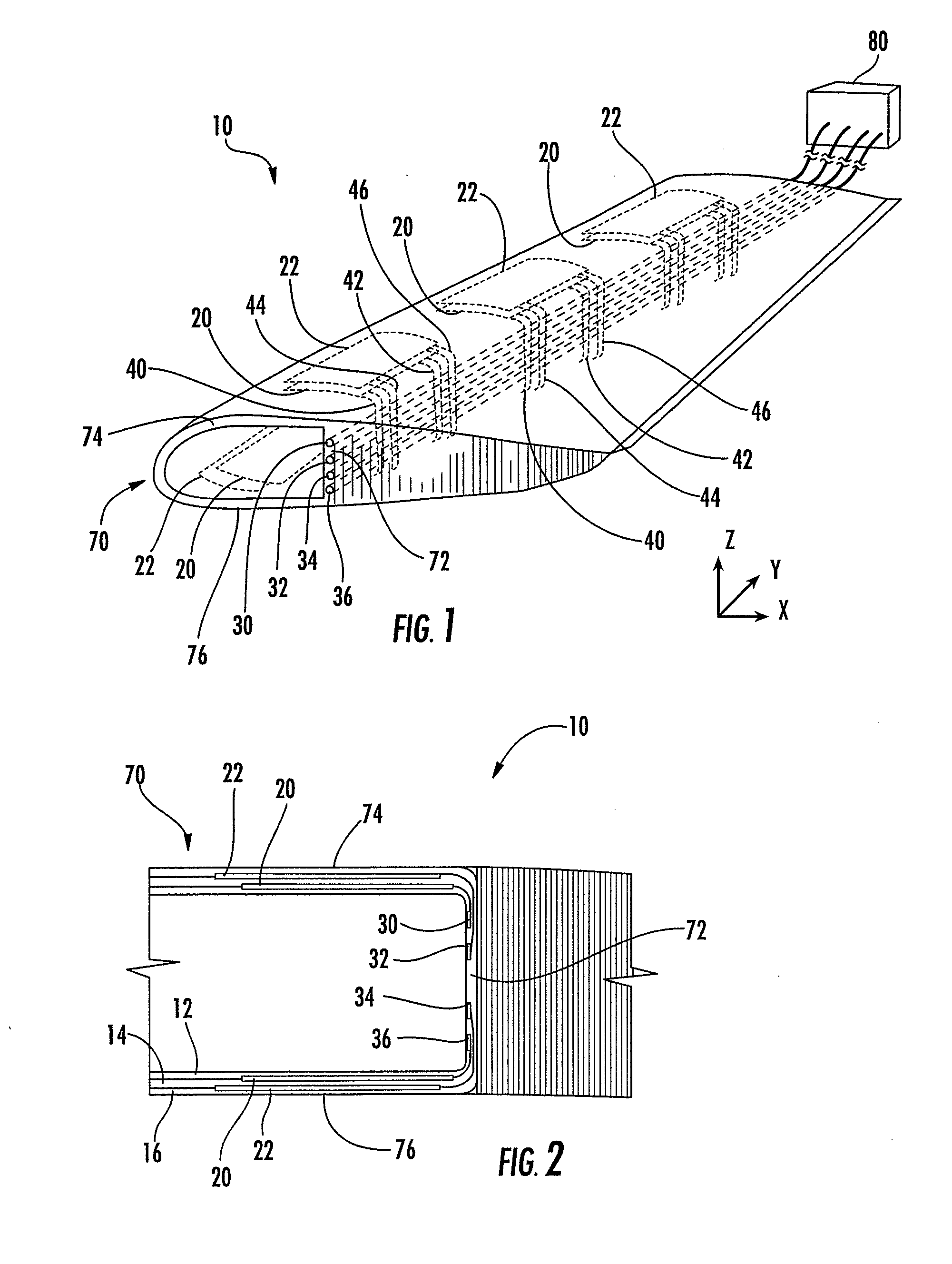

Method of manufacturing electrical cable, and resulting product, with reduced required installation pulling force

ActiveUS20100230134A1Reduce coefficient of frictionLower surfaceLine/current collector detailsLiquid organic insulatorsNylon materialElectrical conductor

Disclosed is type THHN cable having a reduced surface coefficient of friction, and the method of manufacture thereof, in which the central conductor core and insulating layer are surrounded by a nylon sheath. A high viscosity, high molecular weight silicone based pulling lubricant for THHN cable, or alternatively, erucamide or stearyl erucamide for small THHN gauge wire, is incorporated, by alternate methods, with the nylon material from which the outer sheath is extruded, and is effective to reduce the required pulling force on the cable during installation.

Owner:SOUTHWIRE CO LLC

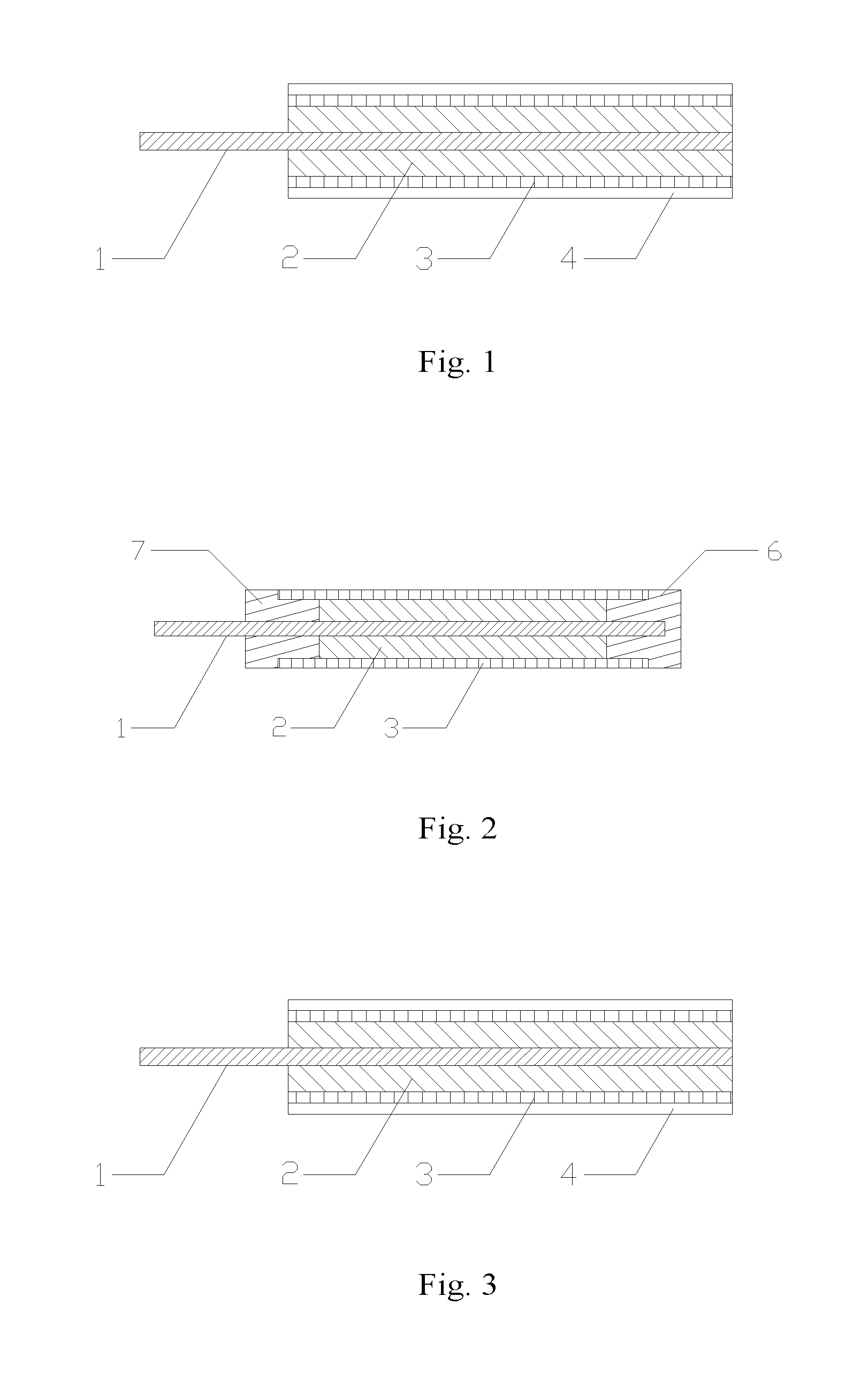

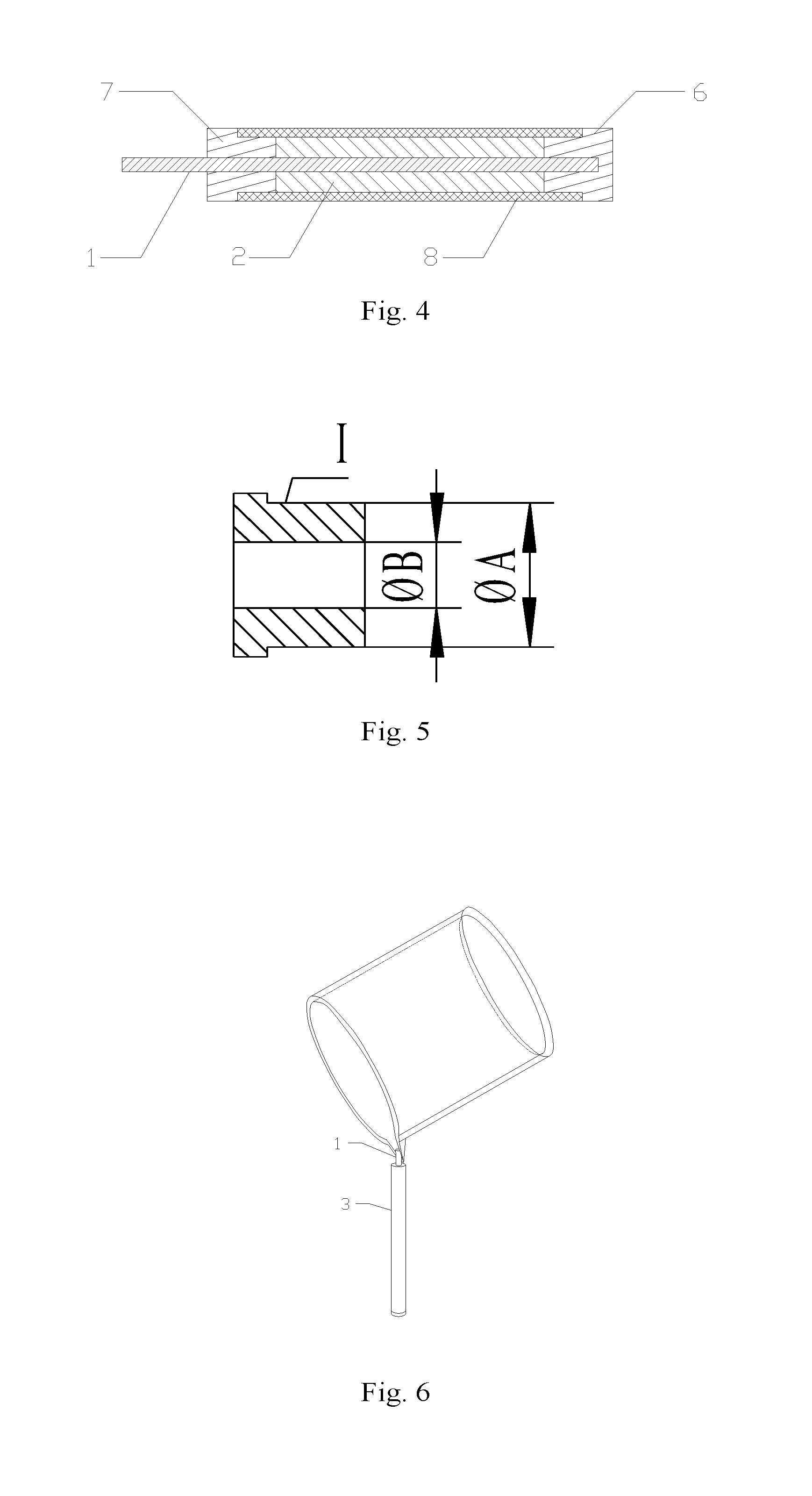

Structurally integrated circuit and associated method

ActiveUS20050257956A1Envelope/housing resistor manufactureLaminating printed circuit boardsElectrical devicesIntegrated circuit

A composite structural member with an integrated electrical circuit and an associated method of manufacture are provided. The structural member includes a plurality of layers of structural reinforcement material, and two or more electrical devices are disposed at least partially between the layers with an intermediate layer of the structural reinforcement material disposed between the electrical devices. At least one electrical bus is disposed in the structural member, and each electrical device is connected to the bus by a conductive electrode. Thus, the electrodes can extend through the intermediate layer of the structural reinforcement material to connect each of the electrical devices to one or more of the buses.

Owner:THE BOEING CO

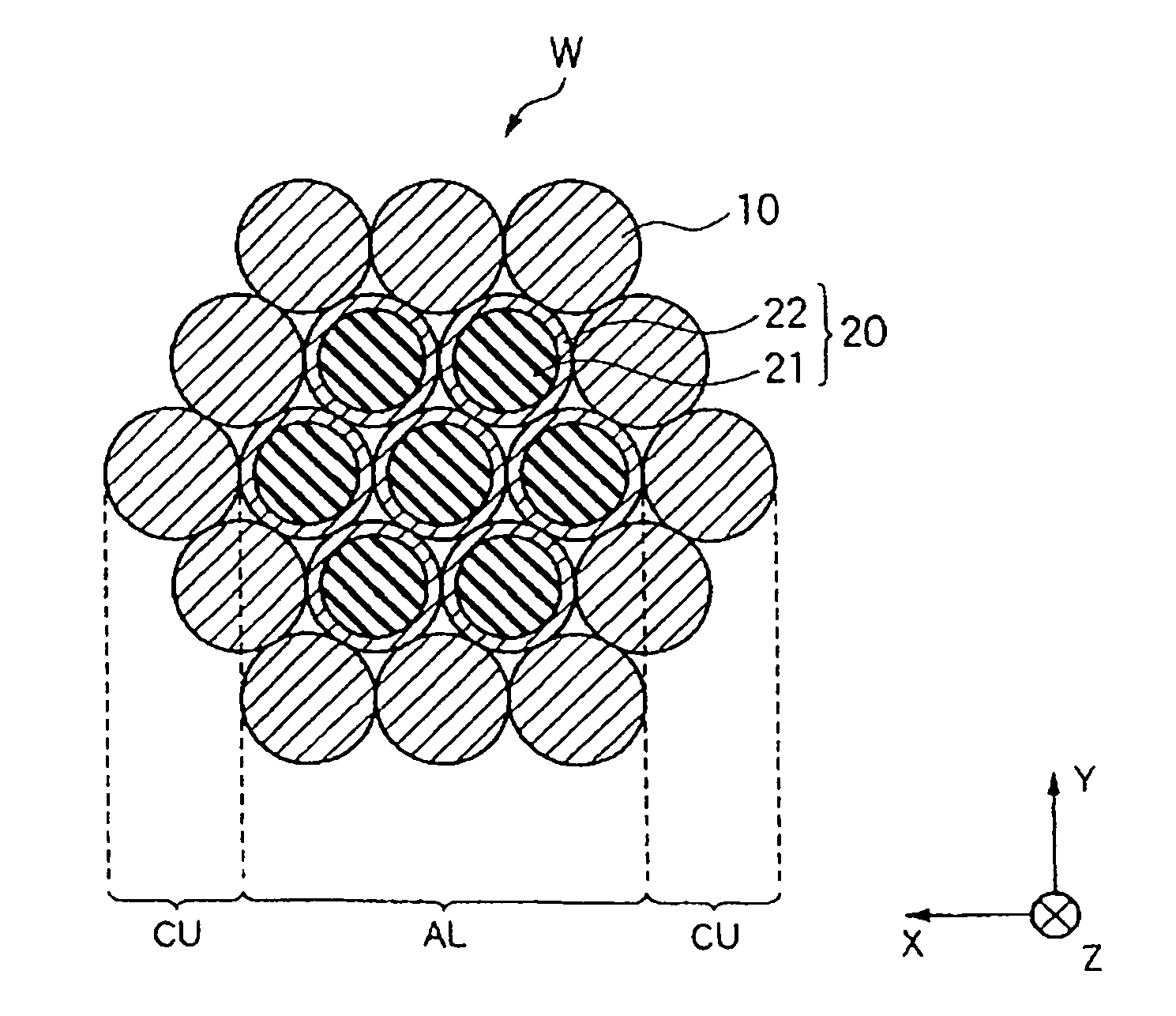

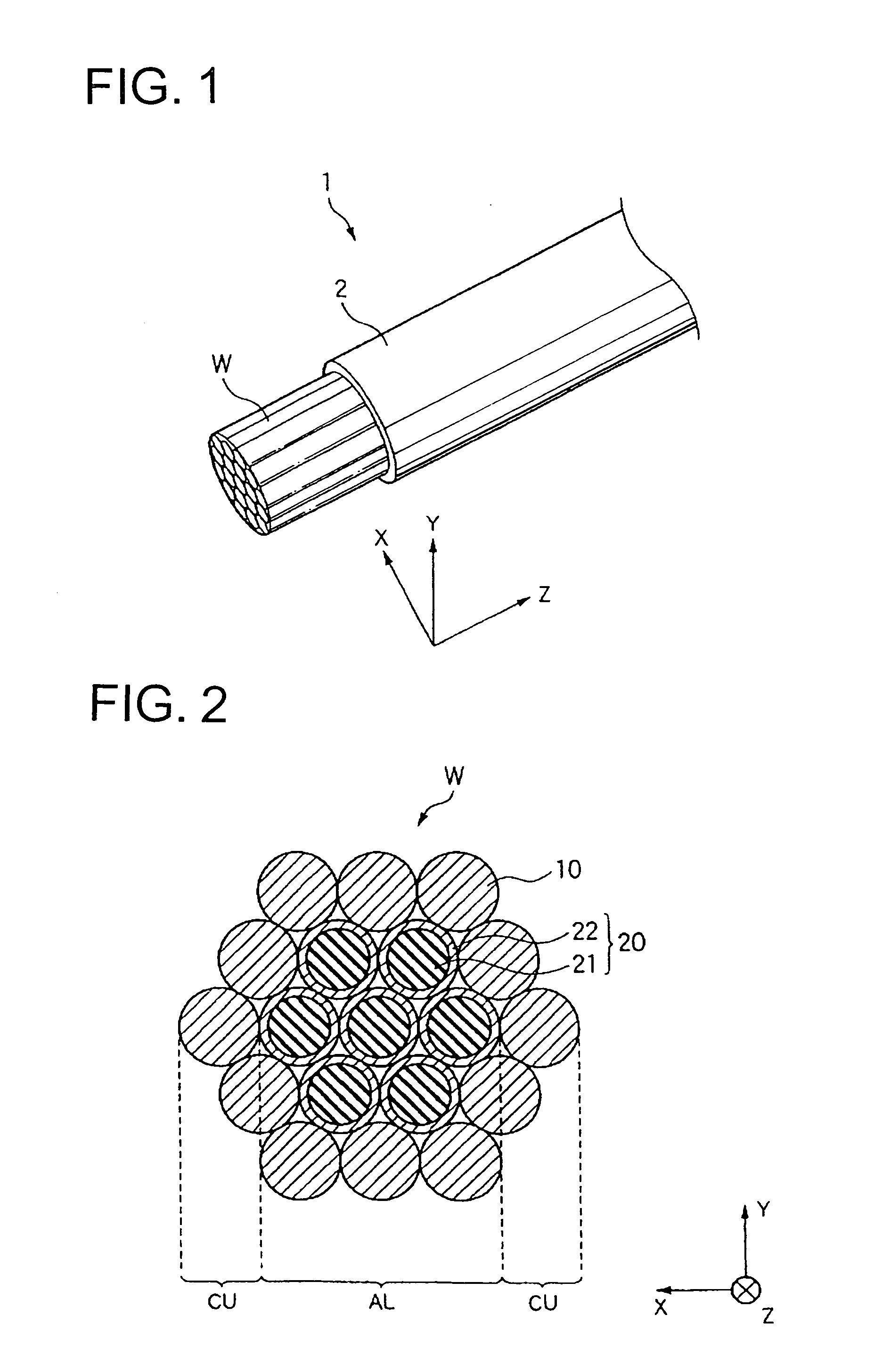

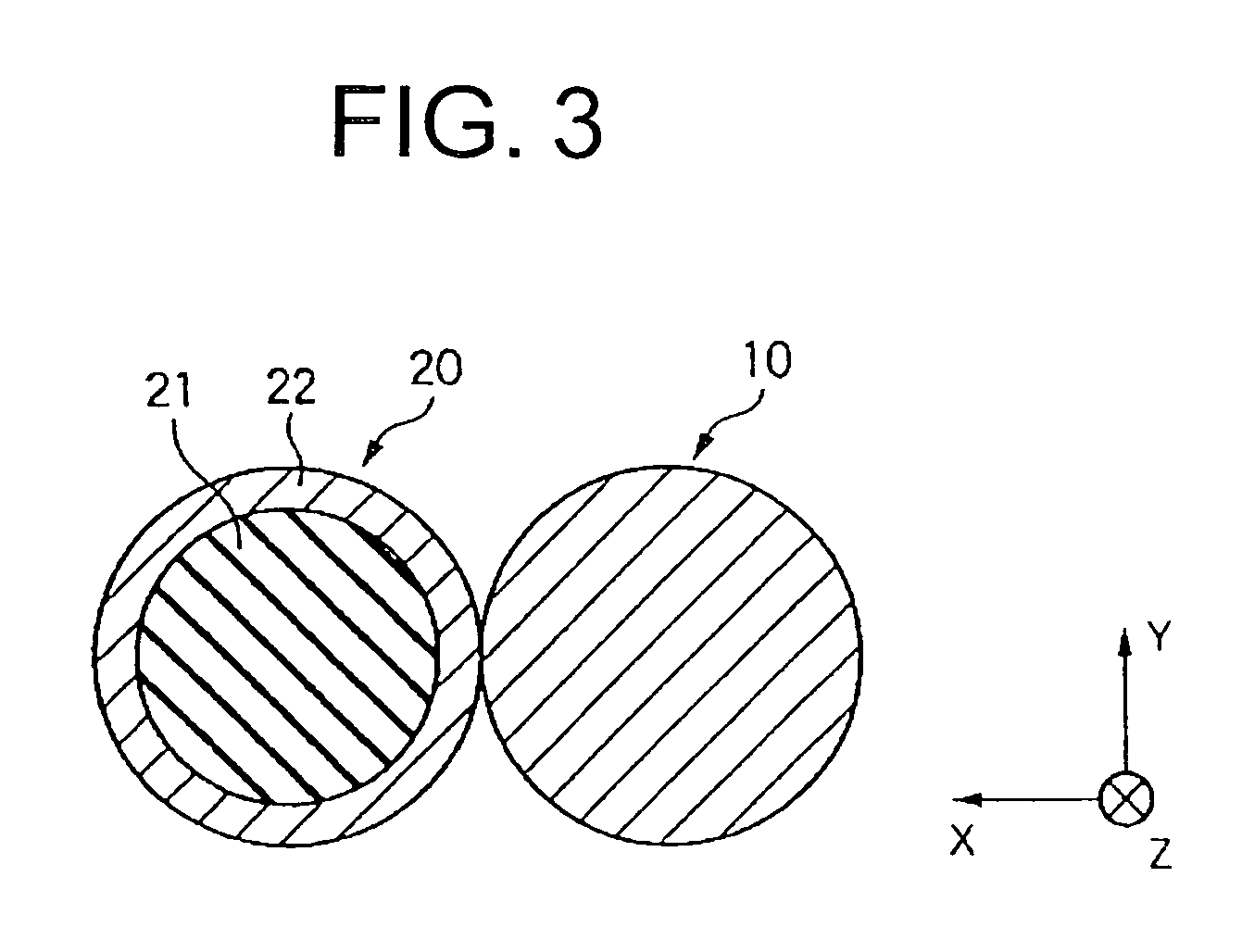

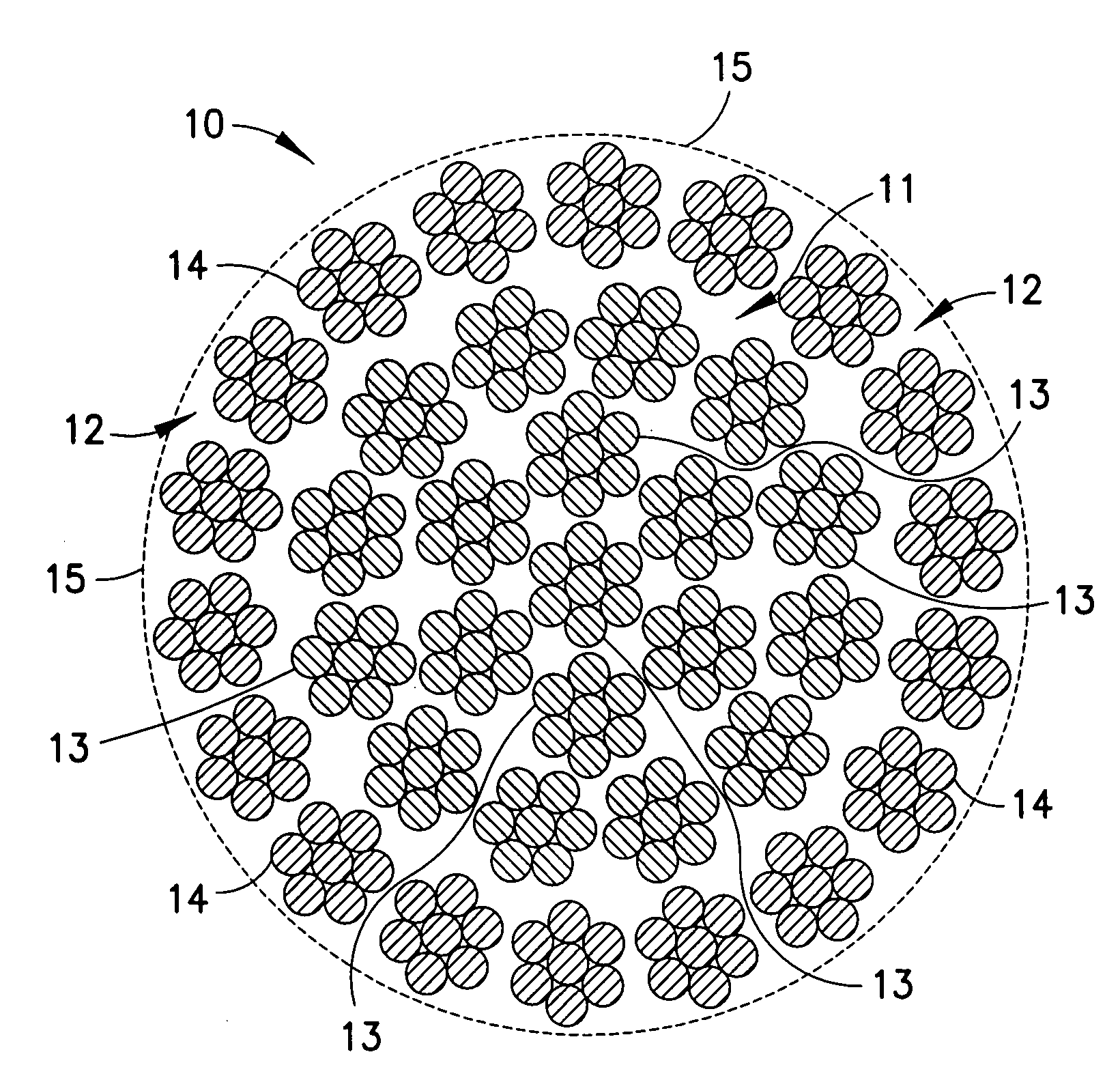

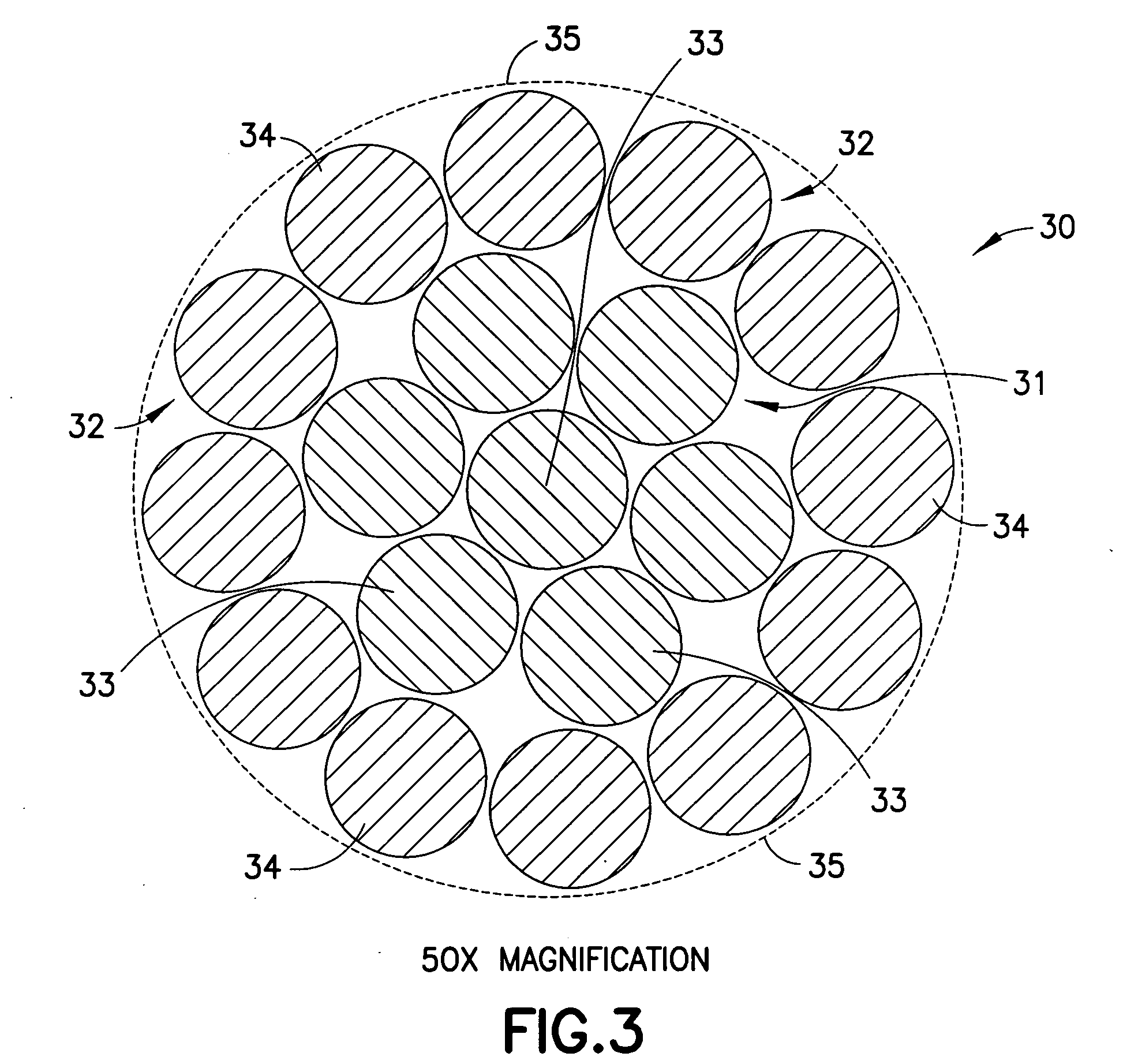

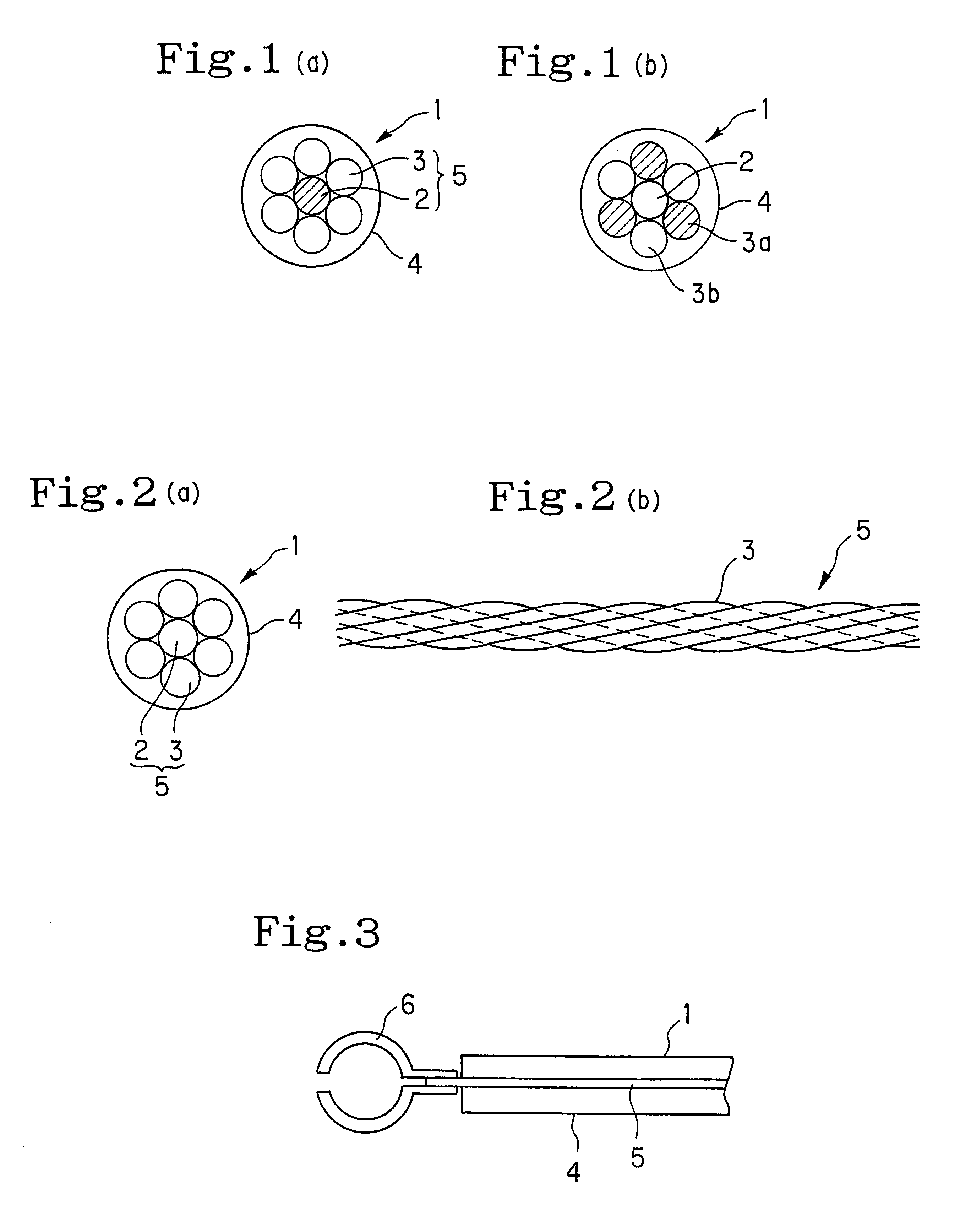

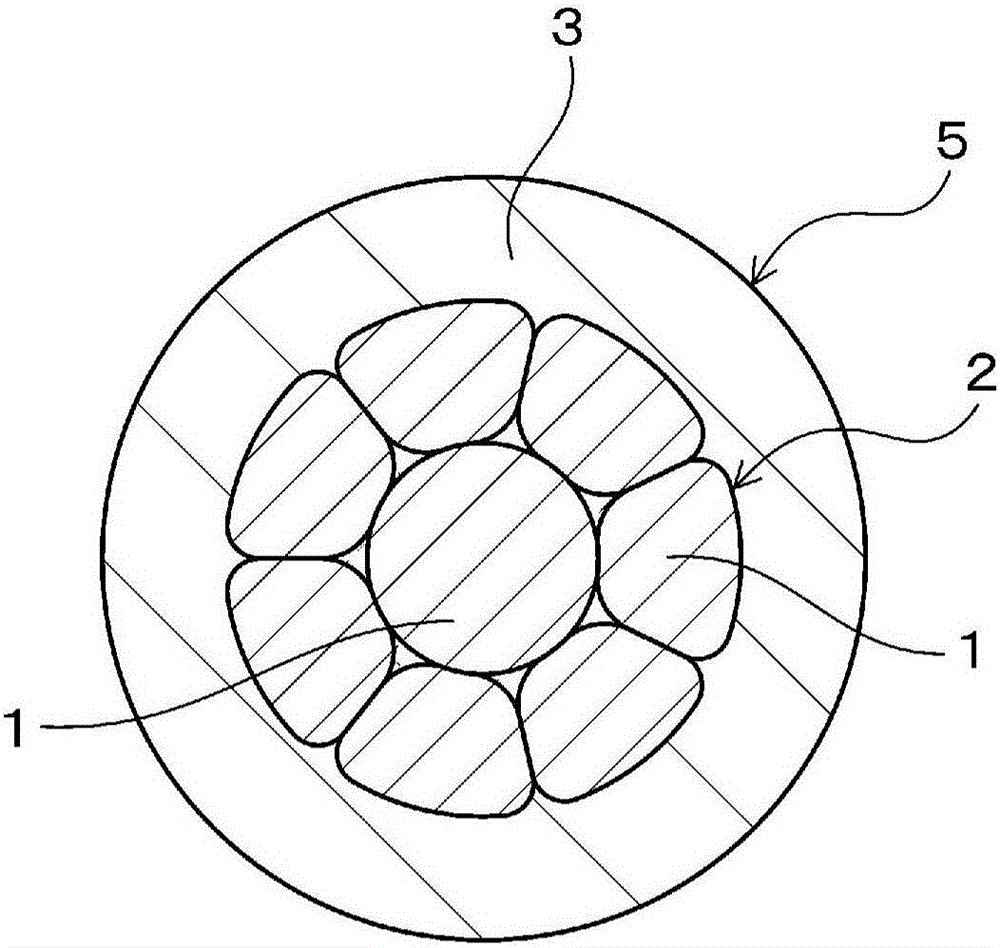

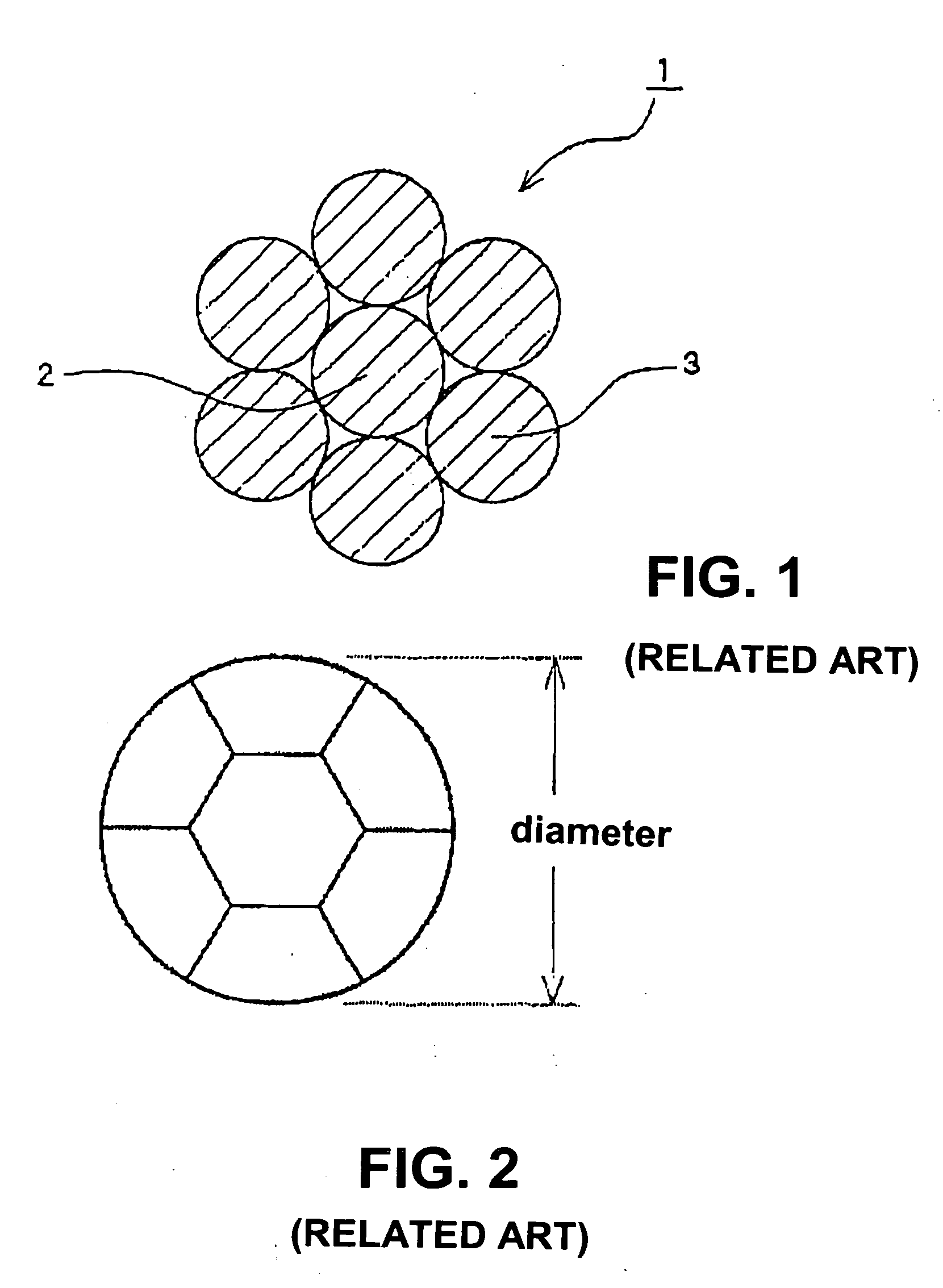

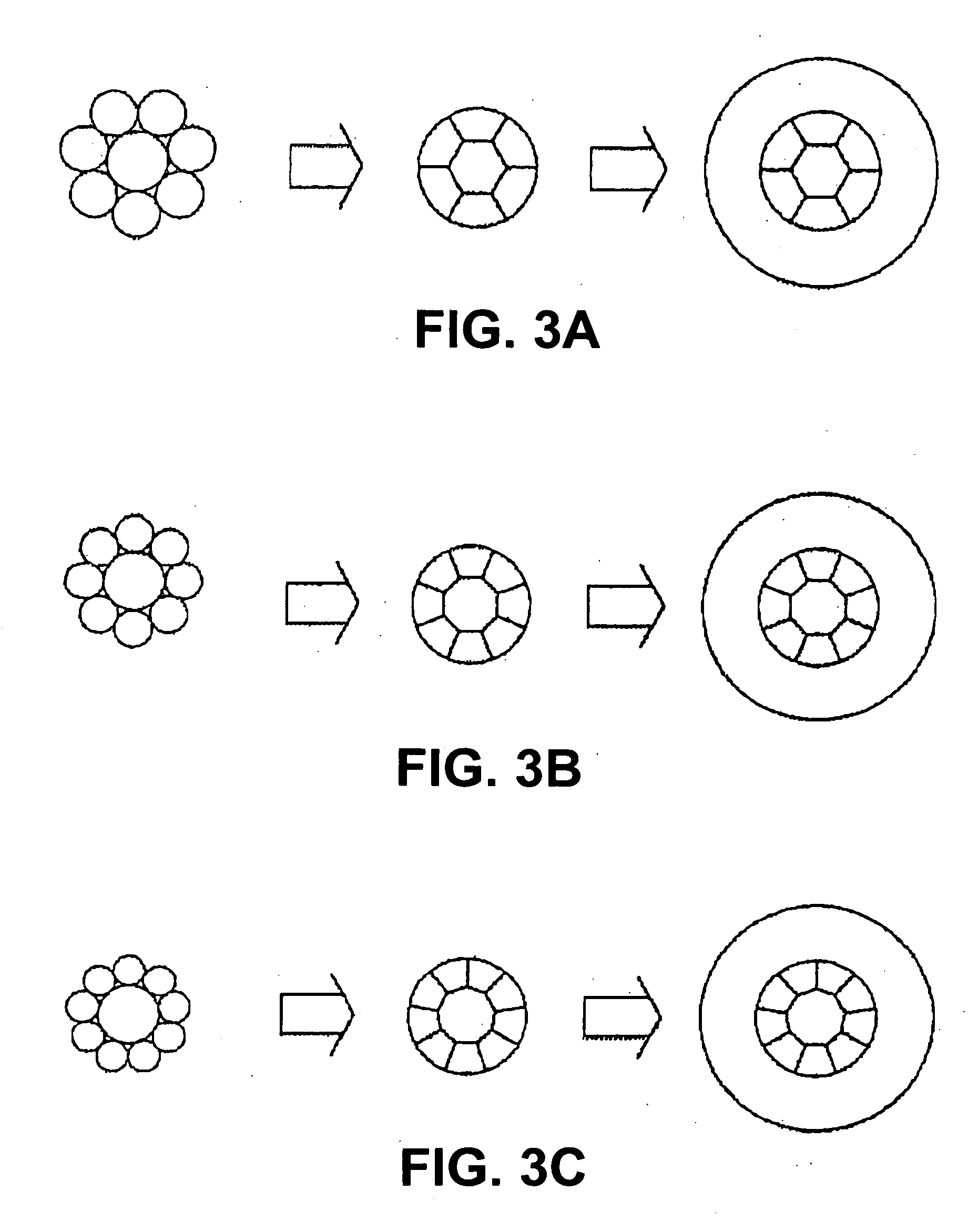

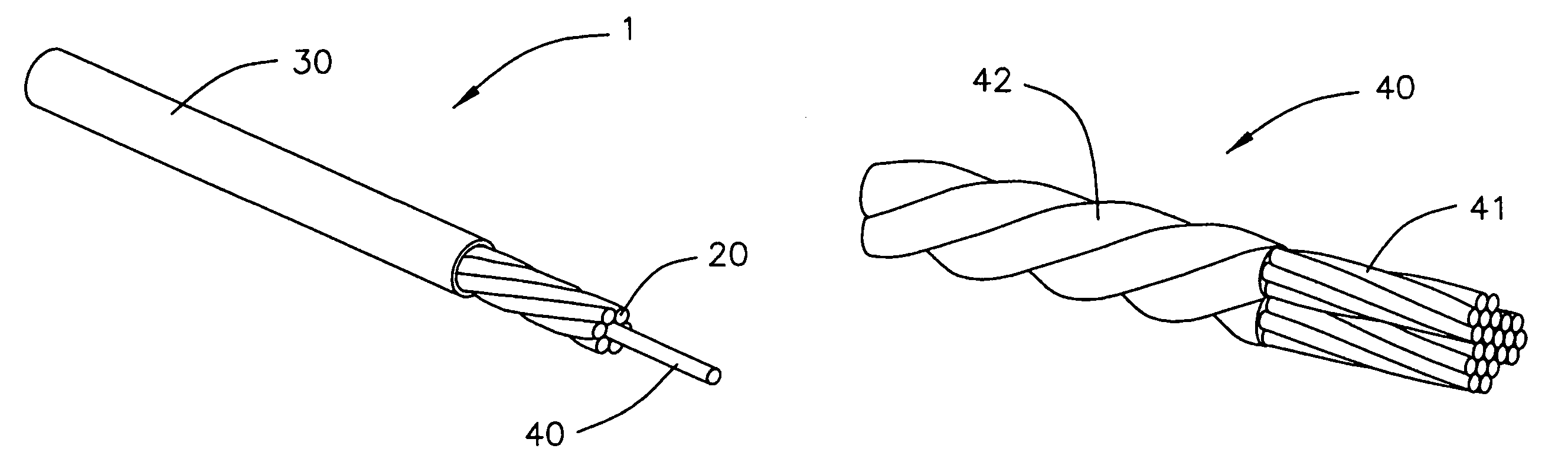

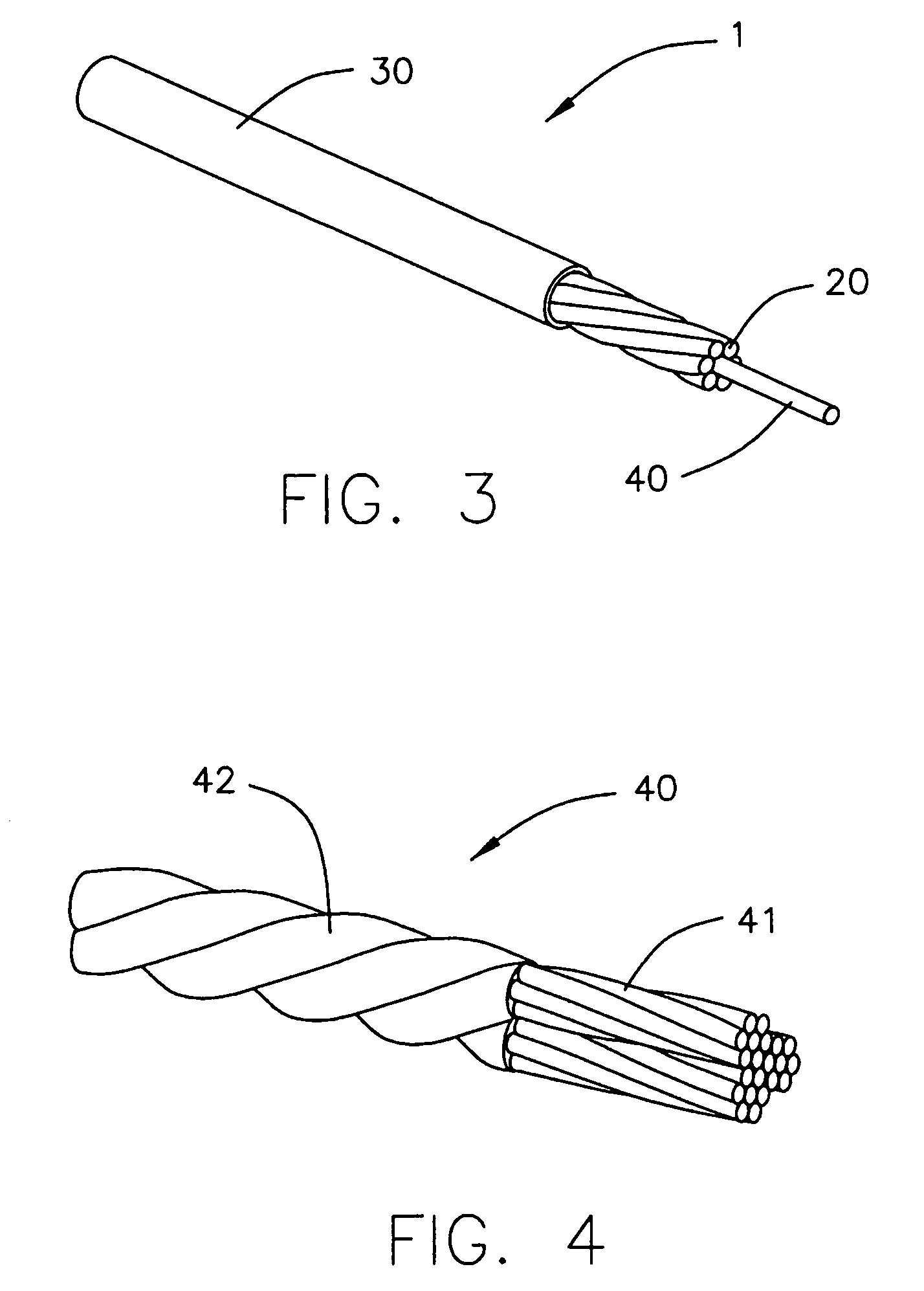

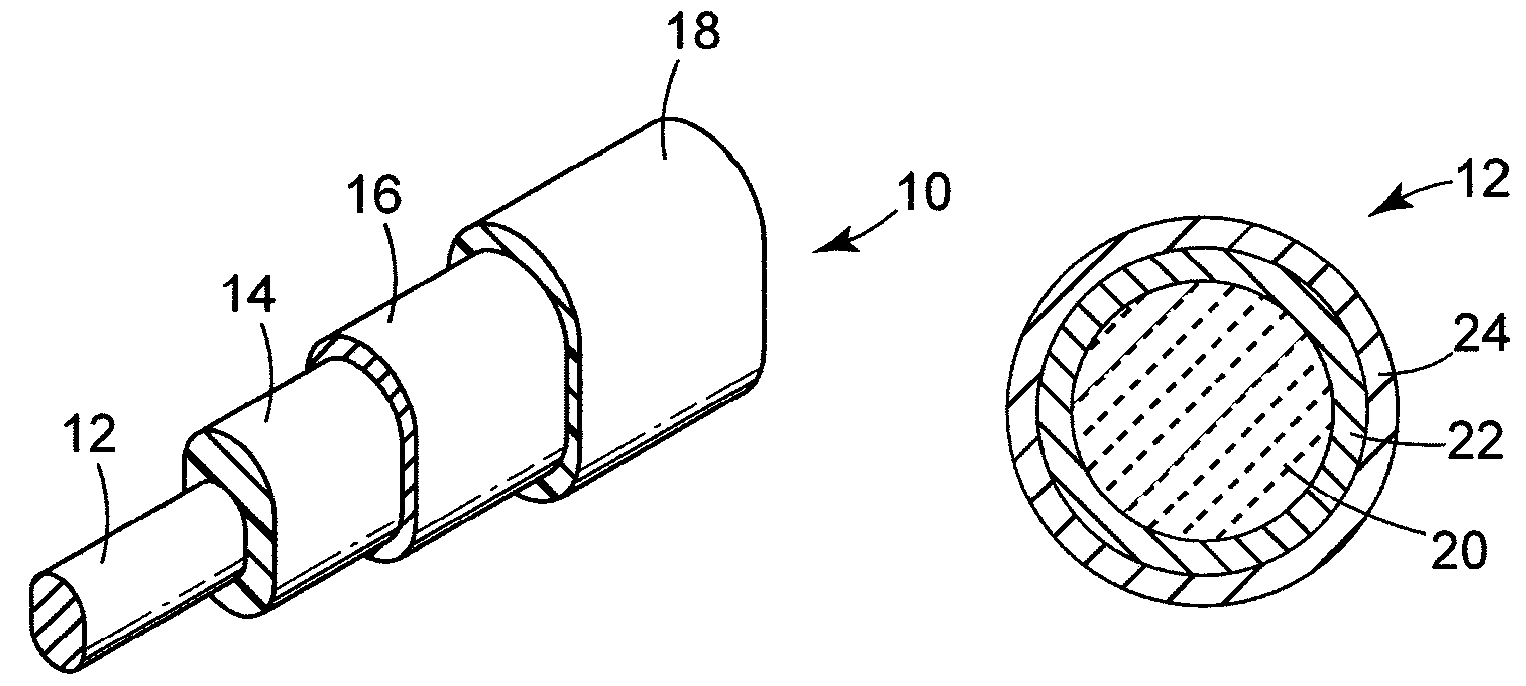

Composite electric wire

InactiveUS20100263911A1Avoid erosionEasy to handleNon-insulated conductorsConductive materialElectrical conductorCopper plating

Provided is a composite electric wire, which is intended to realize a light weight and improve a mechanical strength at the same time and which is enabled to improve the reliability by avoiding the problem of oxide coating or electric erosion so that the electric wire may be easily handled for use as a car-mounted wire harness.The composite electric wire comprises an electric wire body (W) composed of center conductors (AL) and outer-layer conductors (CU) arranged to extend in a Z-direction along the outer circumferences of the center conductors (AL) and to enclose the center conductors (AL). In the electric wire body (W), the center conductors (AL) composed of copper-coated aluminum element wires (20) of a (1+6) number are sectionally positioned at the center portion of the electric wire body (W) in an X-Y plane, and the outer-layer conductors (CU) composed of twelve copper element wires (10) are positioned in the outer circumference portion arranged around the center portion of the X-Y plane. Moreover, the outer-layer conductors (CU) make contact at their outer circumferences with the outer circumferences of the center conductors (AL), thereby to make their electric connections.

Owner:YAZAKI CORP

Electrical cable having a surface with a reduced coefficient of friction

InactiveUS20070243761A1Reduce coefficient of frictionMinimizing required installation pulling forceLiquid organic insulatorsSecuring/insulating coupling contact membersElectrical conductorFrictional coefficient

Owner:SOUTHWIRE CO LLC

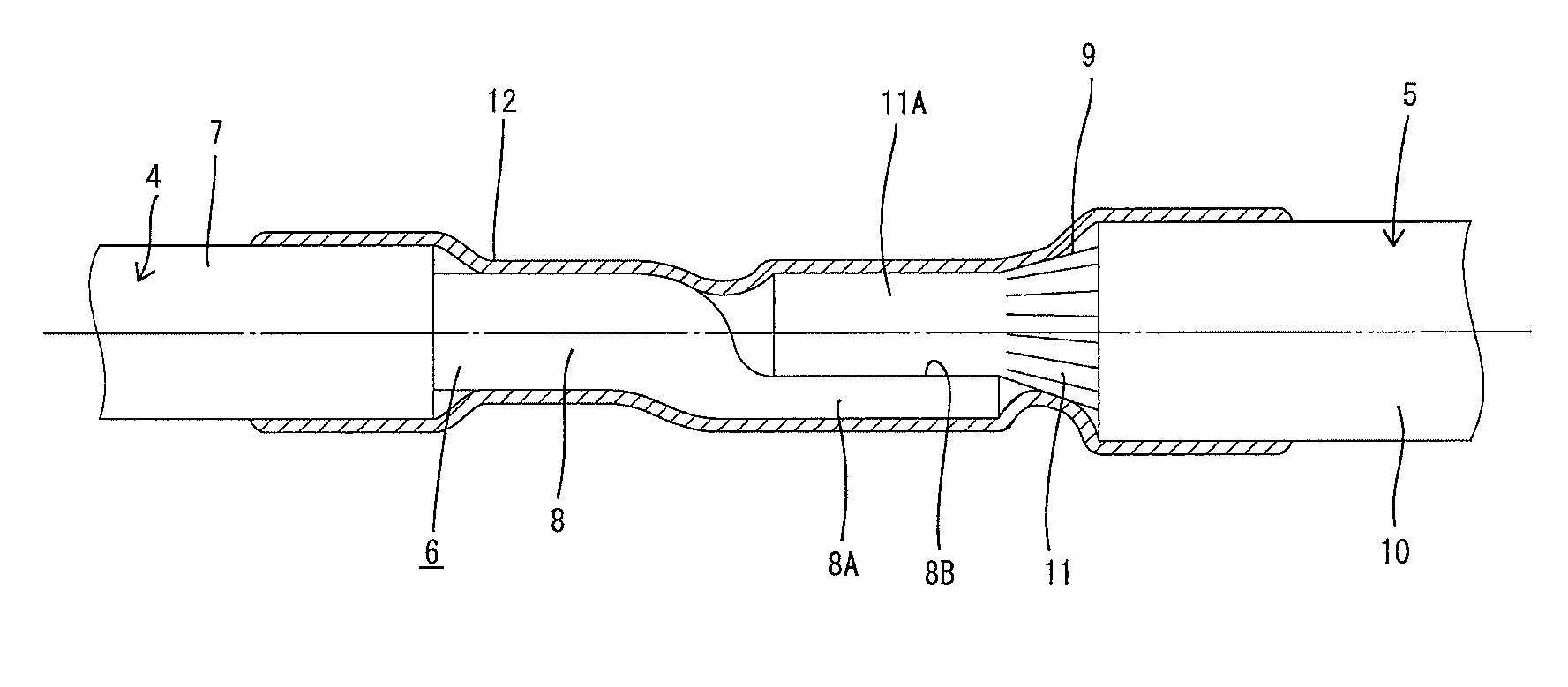

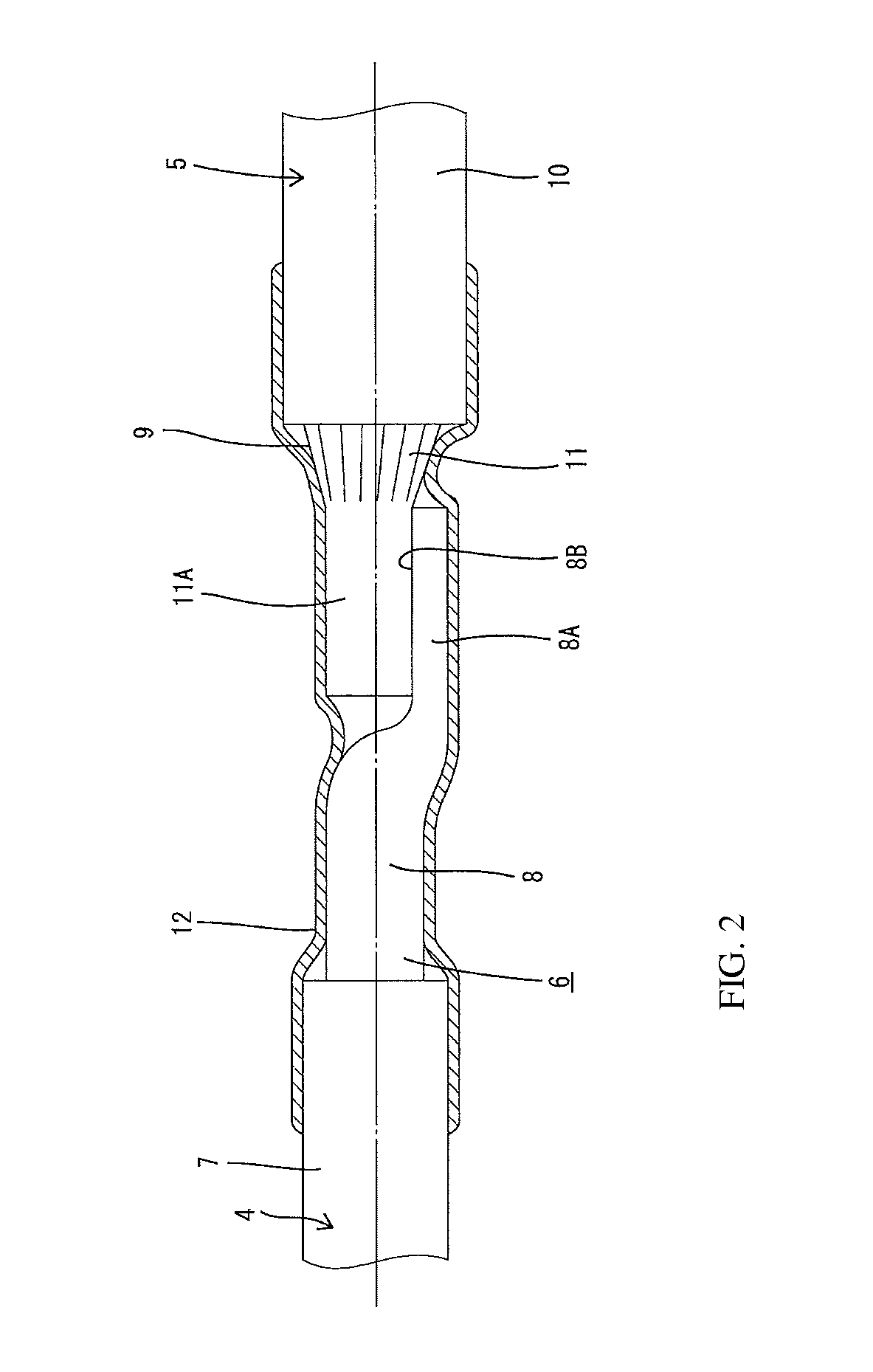

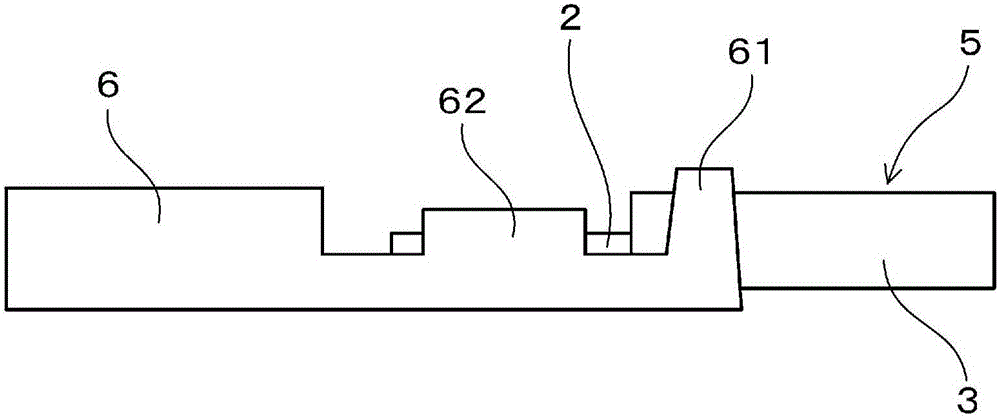

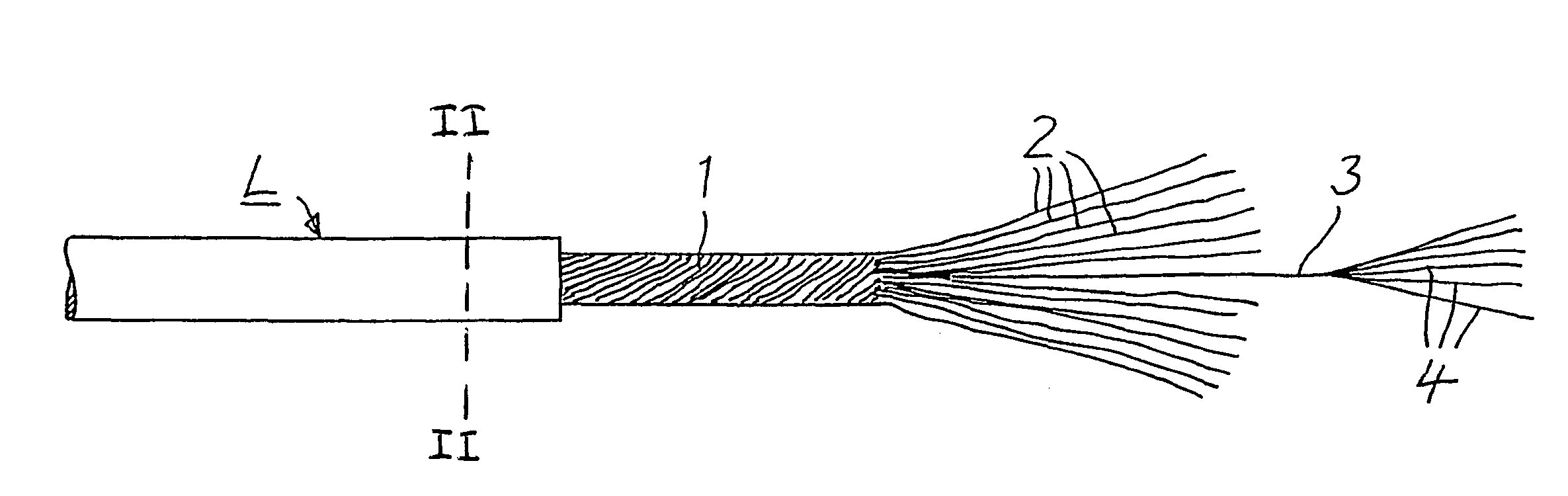

Conductive line and routing structure for the same

ActiveUS20160071630A1Small bending extentReduce the overall diameterLine/current collector detailsVehicle connectorsElectrical conductorEngineering

A connection portion between a single-core line electrical line and a stranded electrical line is prevented from bulging in the diameter direction. A conductor exposed portion is formed on an end portion of the single-core line electrical line, and an individual wire exposed portion is formed on an end portion of the stranded electrical line. A collapsed portion is formed on the conductor exposed portion, and a connection block portion is formed by welding together individual wires of the individual wire exposed portion. The compressed portion and the connection block portion are joined in an overlapping state. At this time, the collapsed portion is bent such that a level difference is formed in the diameter direction such that the single-core line electrical line and the stranded electrical line are joined approximately coaxially.

Owner:SUMITOMO WIRING SYST LTD

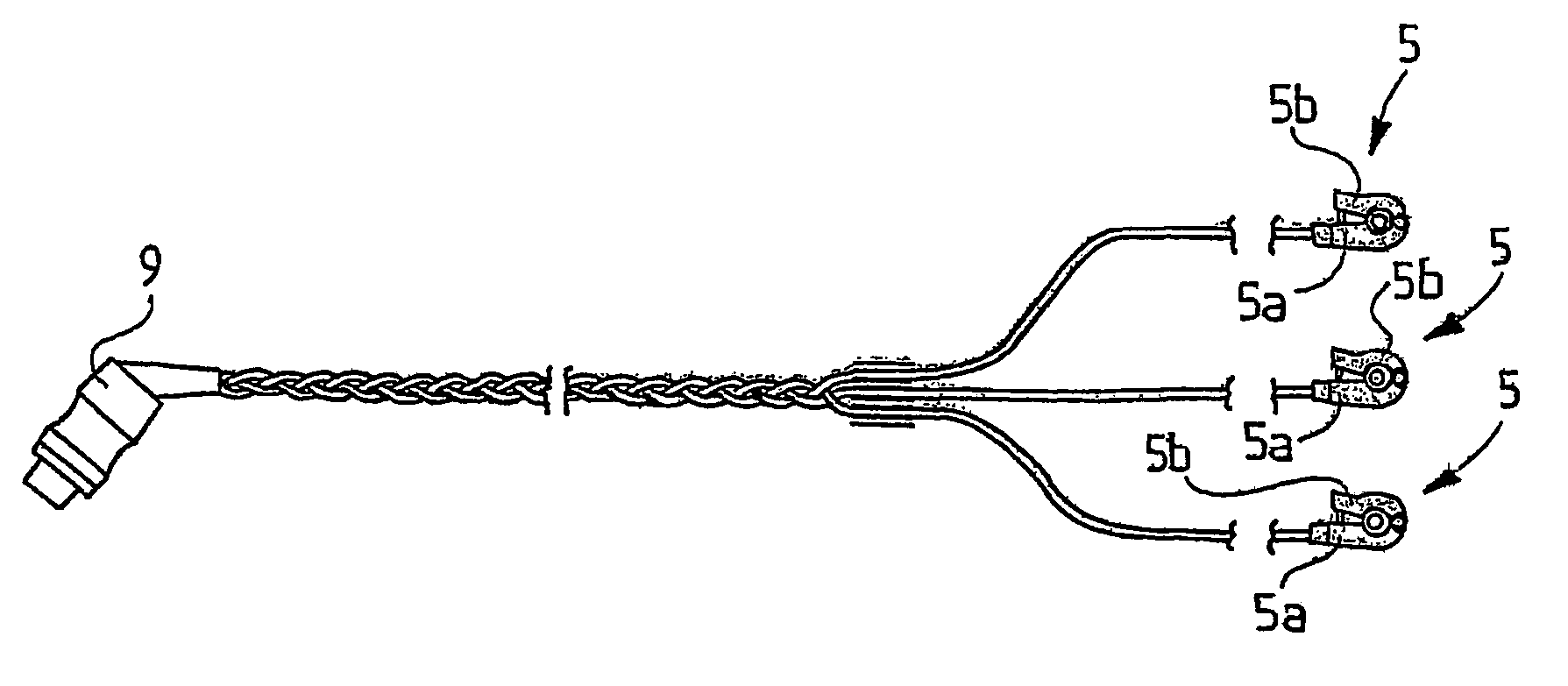

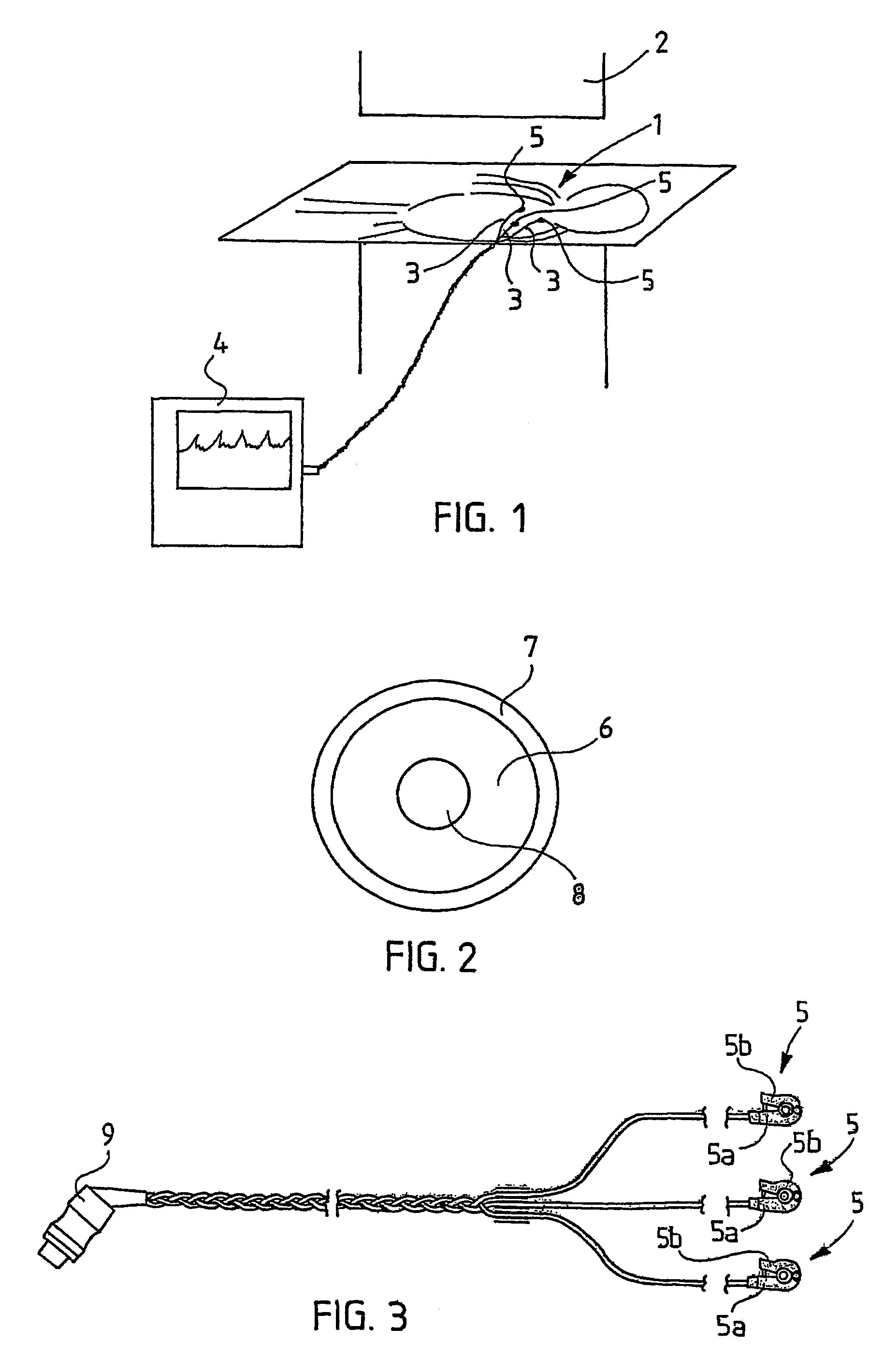

Audio and video signal cable

InactiveUS20050121222A1Avoid it happening againImprove high-frequency phase characteristicInsulated cablesDetails of conductive coresFiberElectrical conductor

An audio and video signal cable consisting of solid conductors of different cross-sectional areas that are parallel arrayed, and after each conductor is insulated, all are surrounded in an insulation, wherein the conductor structure is composed of numerous wires of unequal cross-sectional areas that are furthermore individually insulated. Tinsel, enamel covered wire, or 100% fiber covered copper are utilized for conductors of smaller cross-sectional area, which not only reduces cable outer diameter and increases tensile strength, but also effectively benefits skin effect and enhances high frequency transmission, while larger cross-sectional area conductors facilitate rapid low frequency passage. As such, the present invention is capable of high- and low-frequency band phase synchronicity as well as optimal balance across all frequencies.

Owner:RICH ELECTRIC WIRE & CABLE

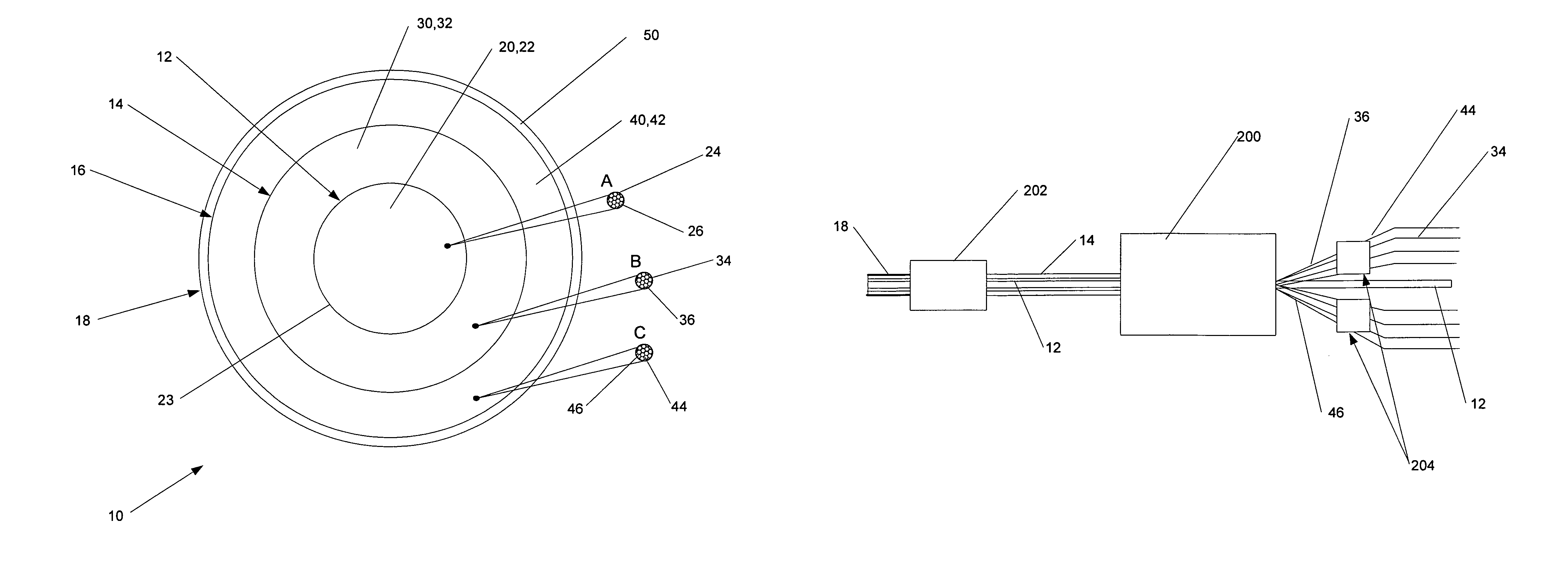

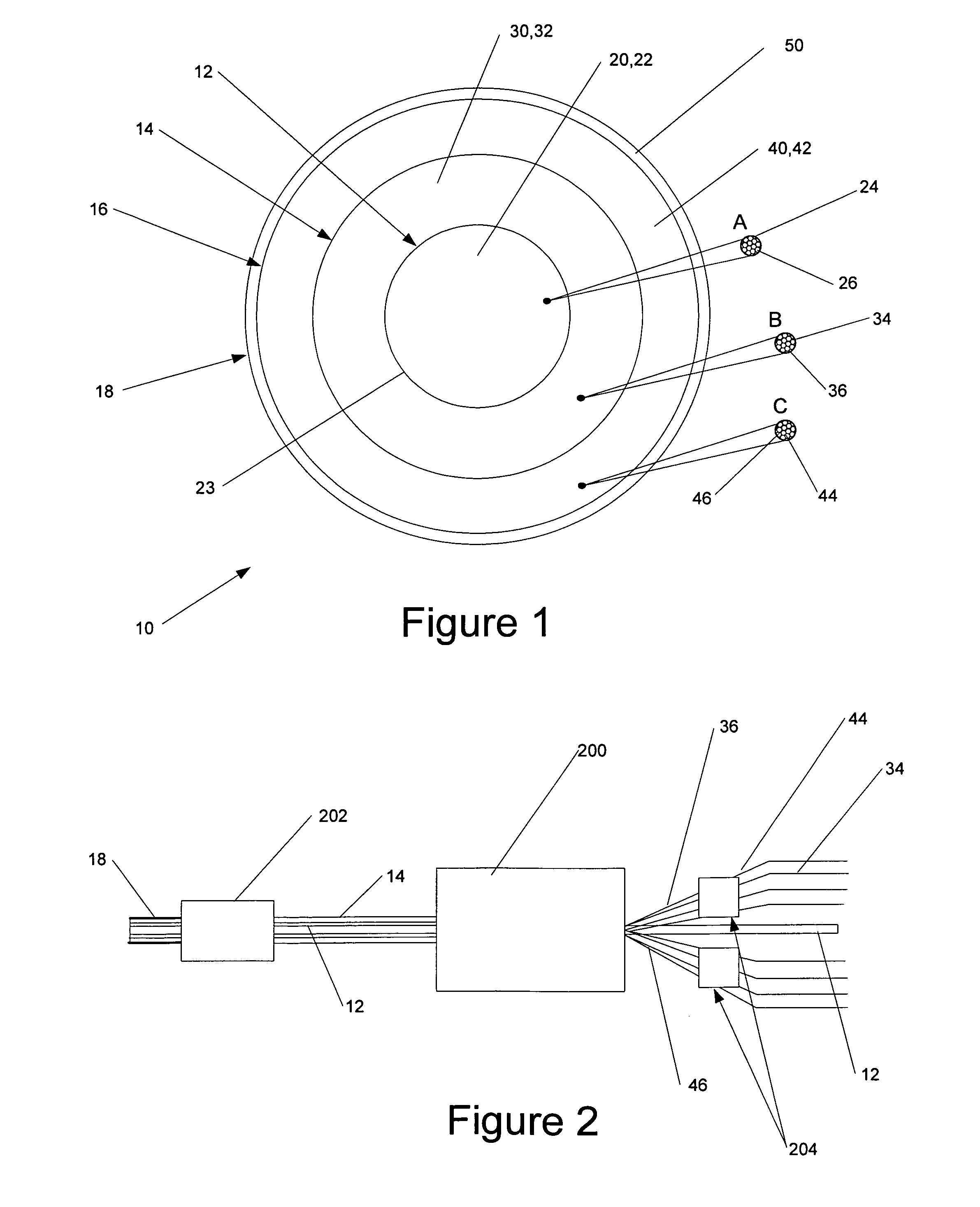

Electrical conductor and core for an electrical conductor

ActiveUS7705242B2Non-insulated conductorsPower cables with screens/conductive layersElectrical conductorCore component

A core for an electrical conductor. The core includes an inner core component, an intermediate cladding component and an outer cladding component. The inner core component comprises a plurality of glass based stranded members in a first resin matrix. The intermediate cladding component surrounds the inner core component and comprises a plurality of carbon stranded members in a second resin matrix. The outer cladding component surrounds the intermediate cladding component and comprises a plurality of glass based stranded members in a third resin matrix. The first resin matrix and the second resin matrix are substantially independent of each other, meeting at a boundary. An electrical conductor as well as a manufacturing method is likewise disclosed.

Owner:ADVANCED TECH HLDG

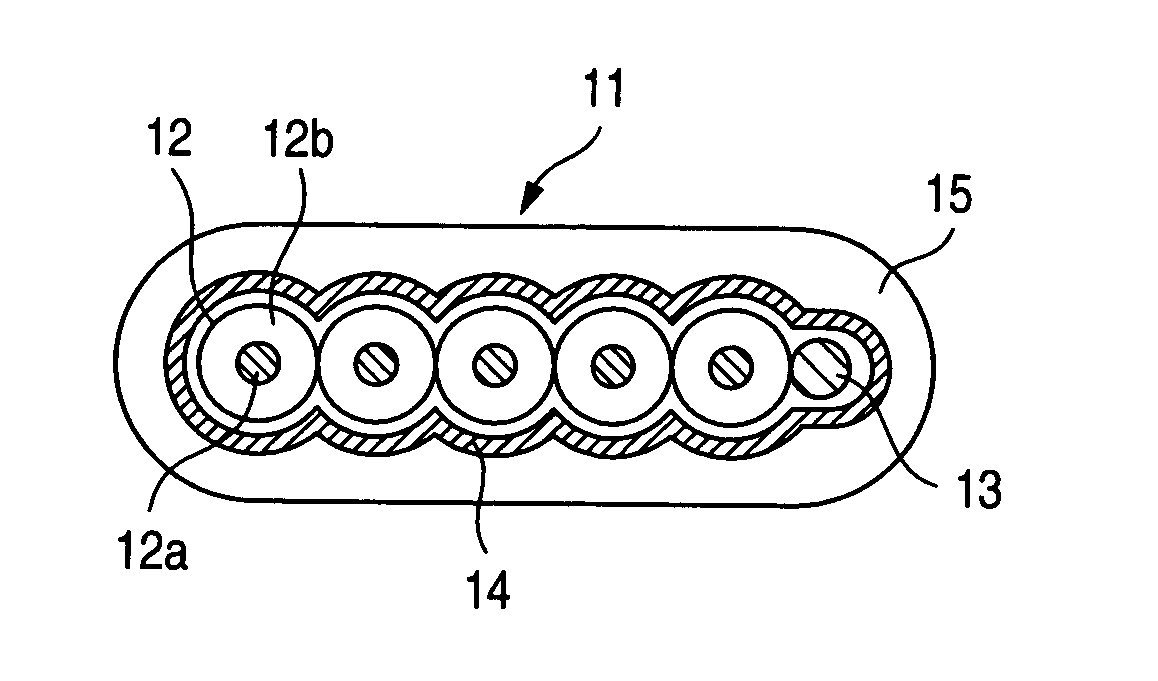

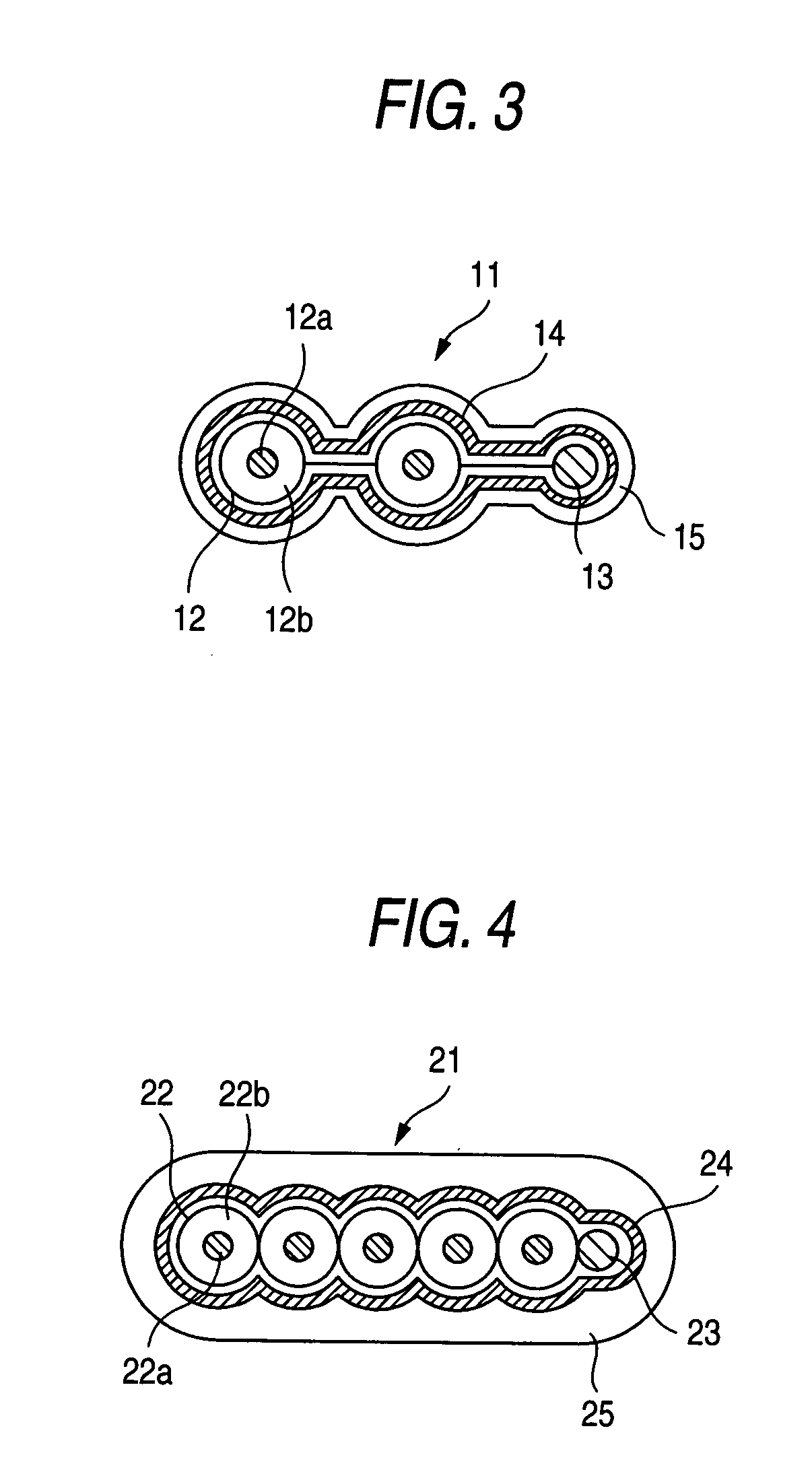

Shielded flat cable

InactiveUS20050077074A1Avoid signalingMany of characteristicDetails of conductive coresFlat/ribbon cablesElectrical conductorCopper alloy

A shielded flat cable includes a plurality of juxtaposed insulating layer-coated signal wires, a drain wire disposed on one side of the group of the signal wires, a shielding layer covering an outer periphery of the group of signal wires and drain wire, and an insulating sheath covering an outer periphery of the shielding layer. A conductor of at least the outermost signal wire of the plurality of signal wires which is remote from the drain wire is made of a copper alloy.

Owner:AUTONETWORKS TECH LTD +2

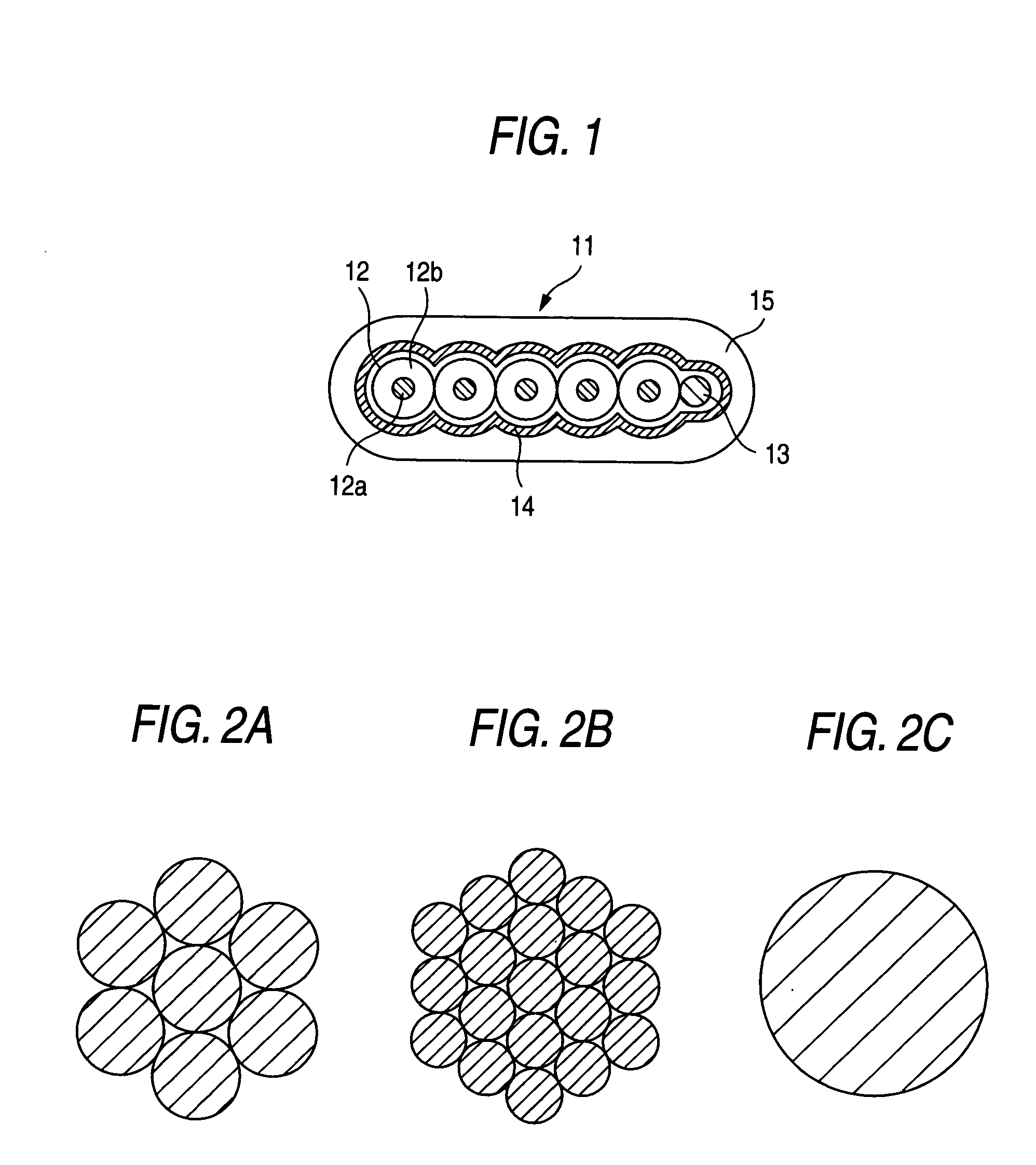

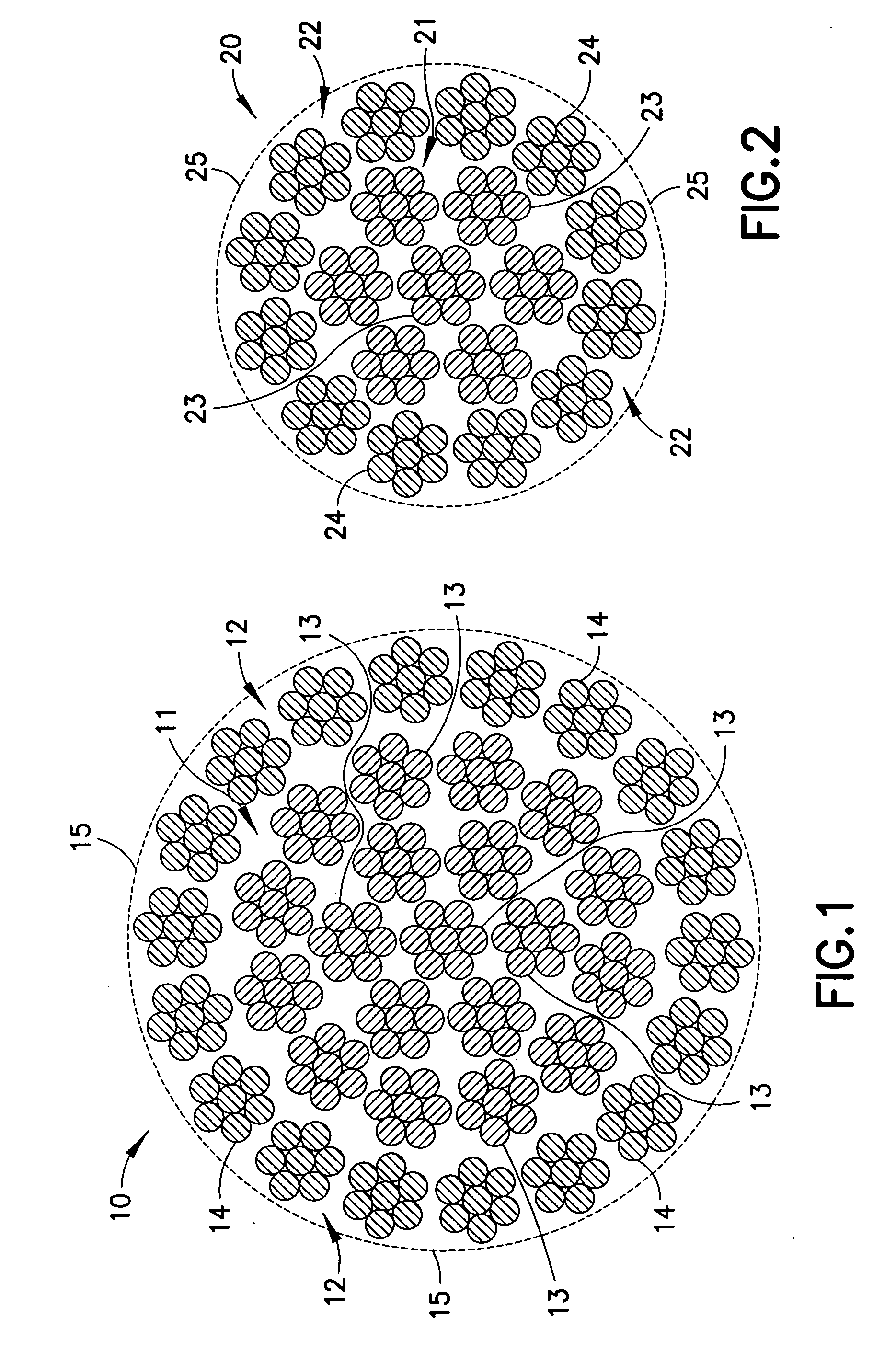

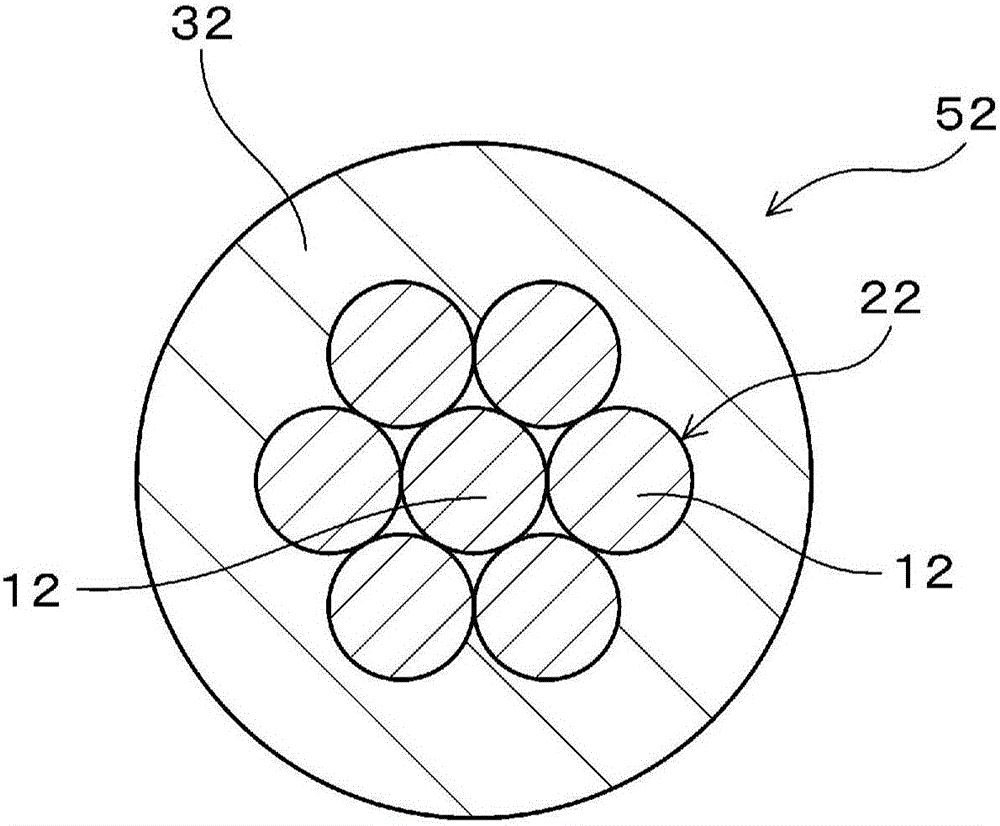

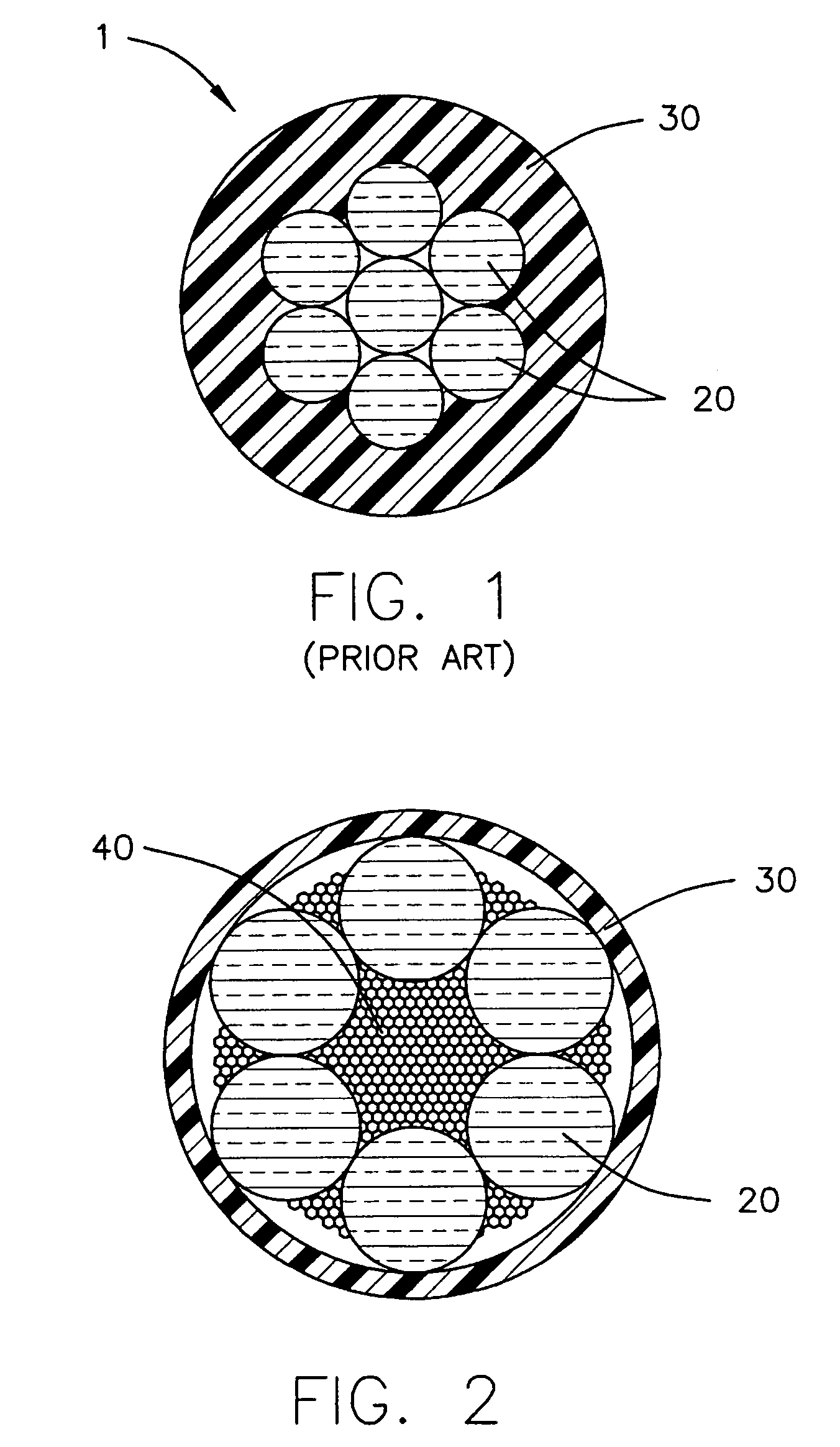

Lightweight copper/aluminum composite conductors

InactiveUS20100096162A1Reduce weightNon-insulated conductorsDetails of conductive coresElectrical conductorCopper

A lightweight composite electrical conductor for aerospace applications, having a core of a plurality of aluminum strands surrounded by an outer layer of a plurality of copper strands. The conductor may be a wire rope having a core of a plurality of aluminum members each having a plurality of aluminum strands, the core of aluminum members being surrounded by an outer layer of a plurality of copper members each having a plurality of copper strands.

Owner:IWG HIGH PERFORMANCE CONDUCTORS

Conductor

InactiveUS7272427B2Inhibit currentLess riskElectrocardiographyInsulated cablesElectrical conductorMetallic materials

A conductor, especially a conductor for measuring bio-electric signals occurring in an MRI environment, which comprises an electrically conductive part made of a non-metal material and a sheath part arranged over it. To produce a light and flexible conductor, the impedance of the conductive part is in the range of 5 to 300 kilo-ohm. The sheath part is arranged to endure a required voltage and the conductor comprises a support part which is made of a substantially inelastic material.

Owner:GE HEALTHCARE FINLAND

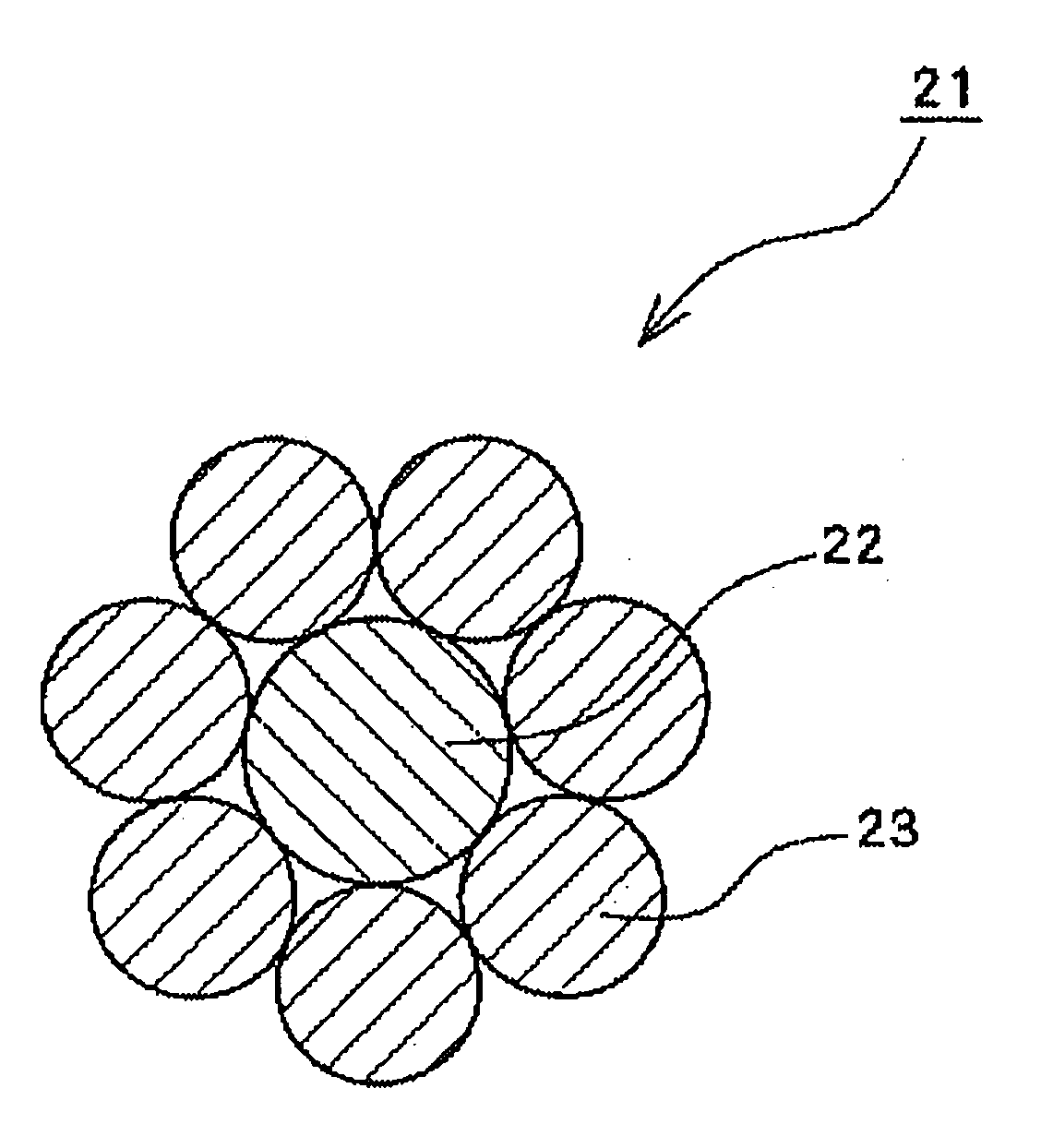

Wire conductor for harness

A wire conductor for a wiring harness includes a stranded wire obtained by twisting strands around a core wire. The core wire is composed of beryllium copper and the strands twisted around the core wire are composed of annealed copper. Preferably, the wire conductor includes a stranded wire obtained by twisting 6, 12 or 18 strands around the core wire. Half of the strands twisted around the core wire are composed of beryllium copper, the remaining strands and the core wire are composed of annealed copper, and the strands composed of beryllium copper and the strands composed of annealed copper are alternately arranged around the core wire. The wire conductor has sufficient conductivity and strength, causes no disconnection even when produced in a small diameter, and has appropriate flexibility.

Owner:NGK INSULATORS LTD

Dielectrics using substantially longitudinally oriented insulated conductive wires

InactiveUS20130240241A1Improve performanceSolid-state devicesMaterial analysis by electric/magnetic meansLong axisPore diameter

A dielectric material is disclosed comprising a plurality of substantially longitudinally oriented wires which are coupled together, wherein each of the wires includes a conductive core comprising a first material and one or more insulating shell layers comprising a compositionally different second material disposed about the core. In one embodiment, a dielectric layer is disclosed comprising a substrate comprising an insulating material having a plurality of nanoscale pores defined therein having a pore diameter less than about 100 nm, and a conductive material disposed within the nanoscale pores. Methods are also disclosed to create a dielectric material layer comprising, for example, providing a plurality of wires, wherein each of the wires includes a core comprising a first material and one or more insulating layers comprising a compositionally different second material disposed about the core; substantially longitudinally orienting said plurality of wires along their long axes; coupling the wires together; and depositing an insulating coating on at least one of a top and / or a bottom end of the wires.

Owner:NANOSYS INC

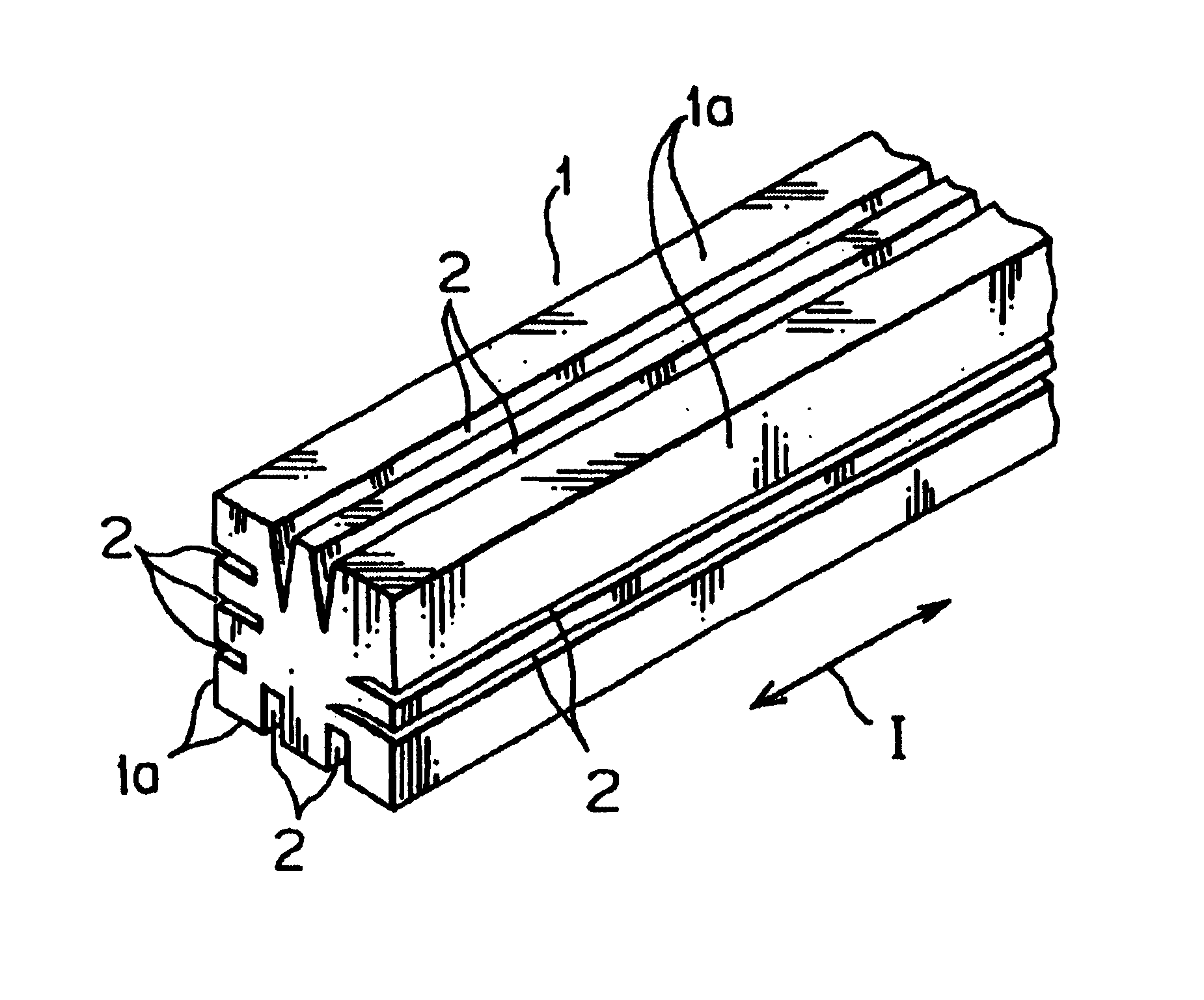

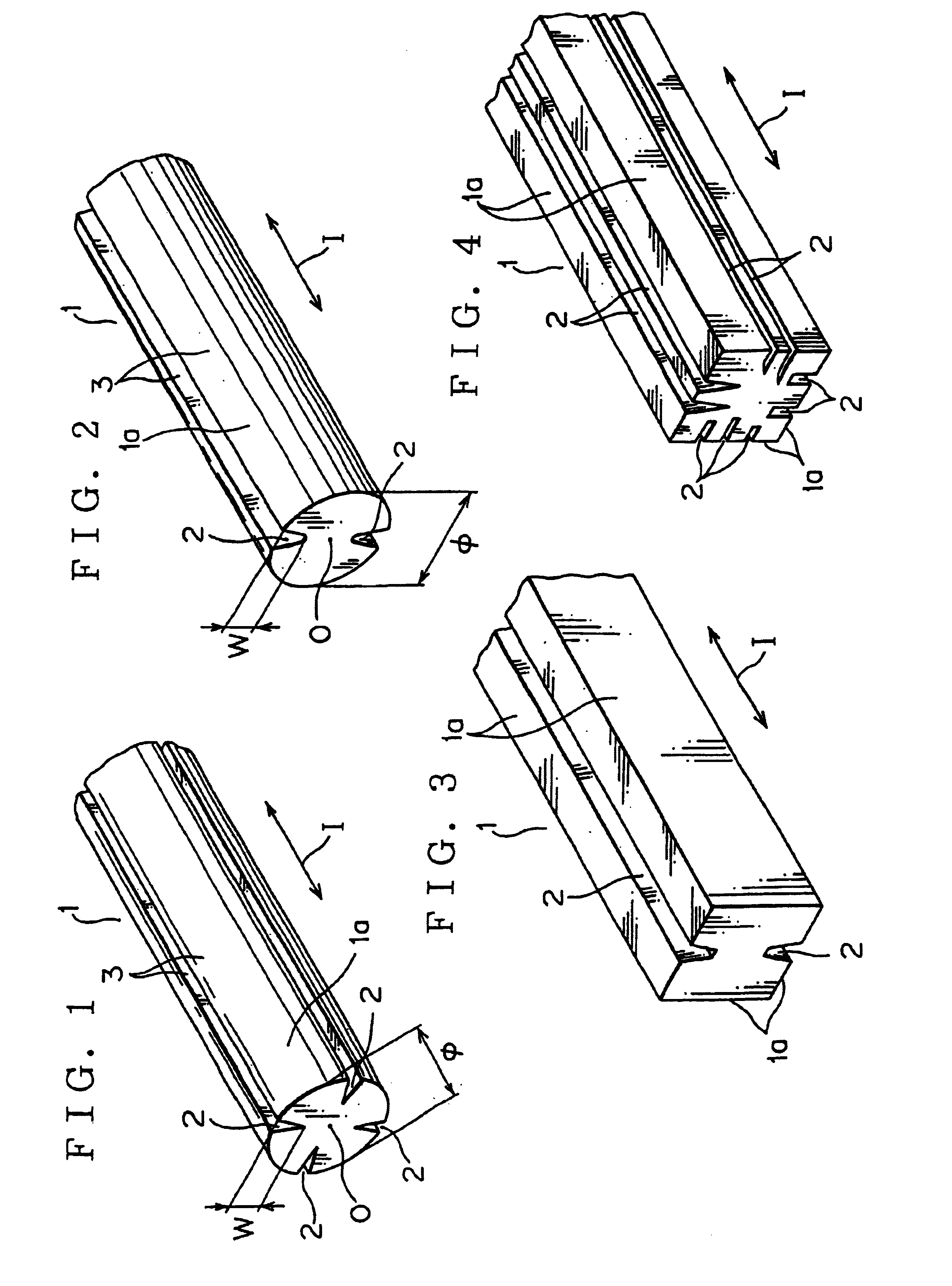

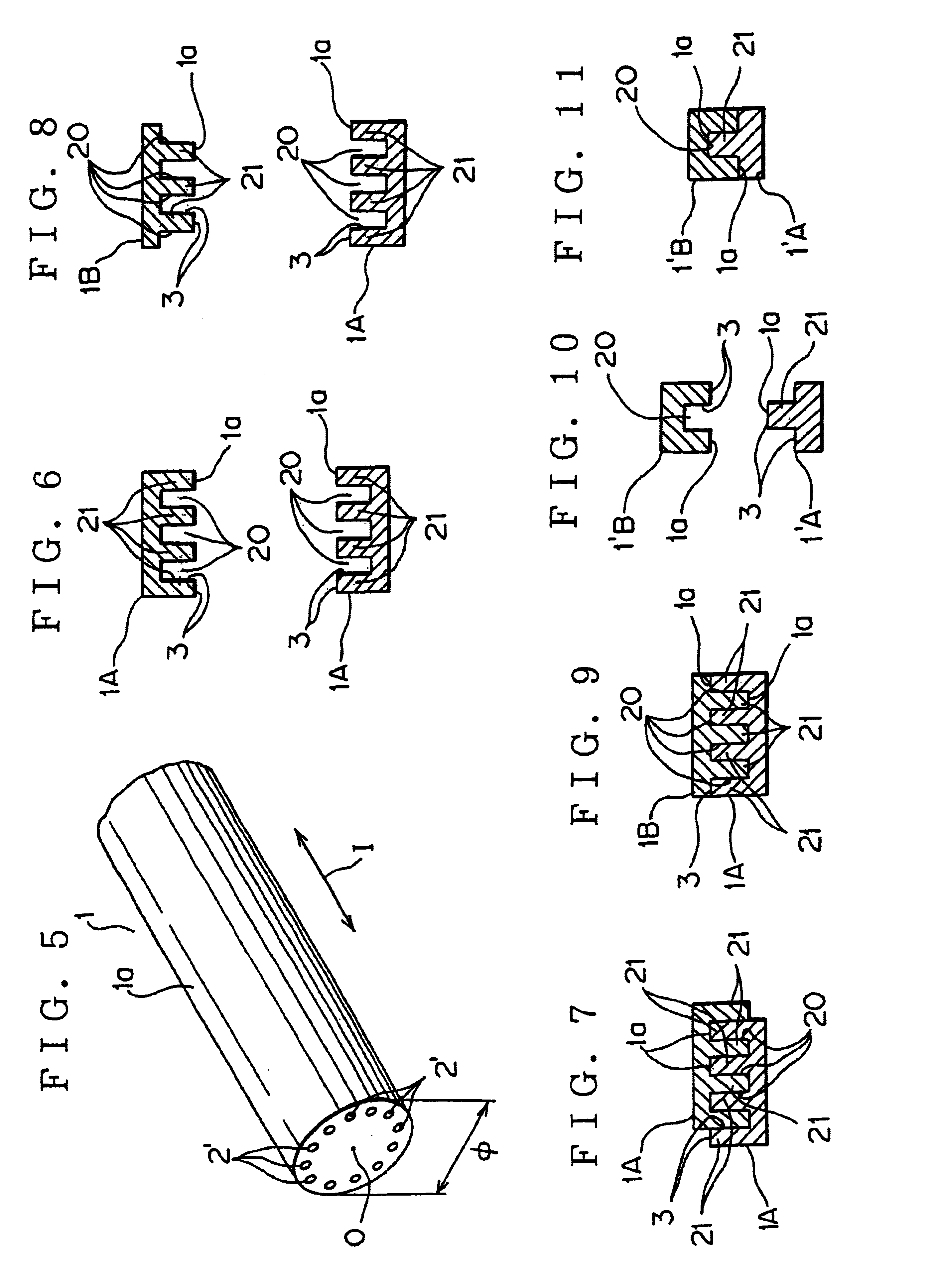

Electric wire

InactiveUS6967289B2Increase currentIncrease surface areaSingle bars/rods/wires/strips conductorsBus-bar installationTransmittanceSkin effect

An electric wire having a conductive portion with grooves on the surface thereof to increase a surface area of the conductive portion for enlarging the skin effect in high frequency current and enhancing the transmissibility and the space factor in high frequency current is provided. The conductive portion 1a being made of an electric conductive material is formed on the surface 1a with a convexo-concave surface 3 to provide predetermined amount of grooves 2 or concave portions 20 having a predetermined section with a predetermined depth W extending in a direction of thickness or toward a center of the conductive portion on the surface of the conductive portion along lengthwise the conductive portion

Owner:GOTO DENISH CO LTD

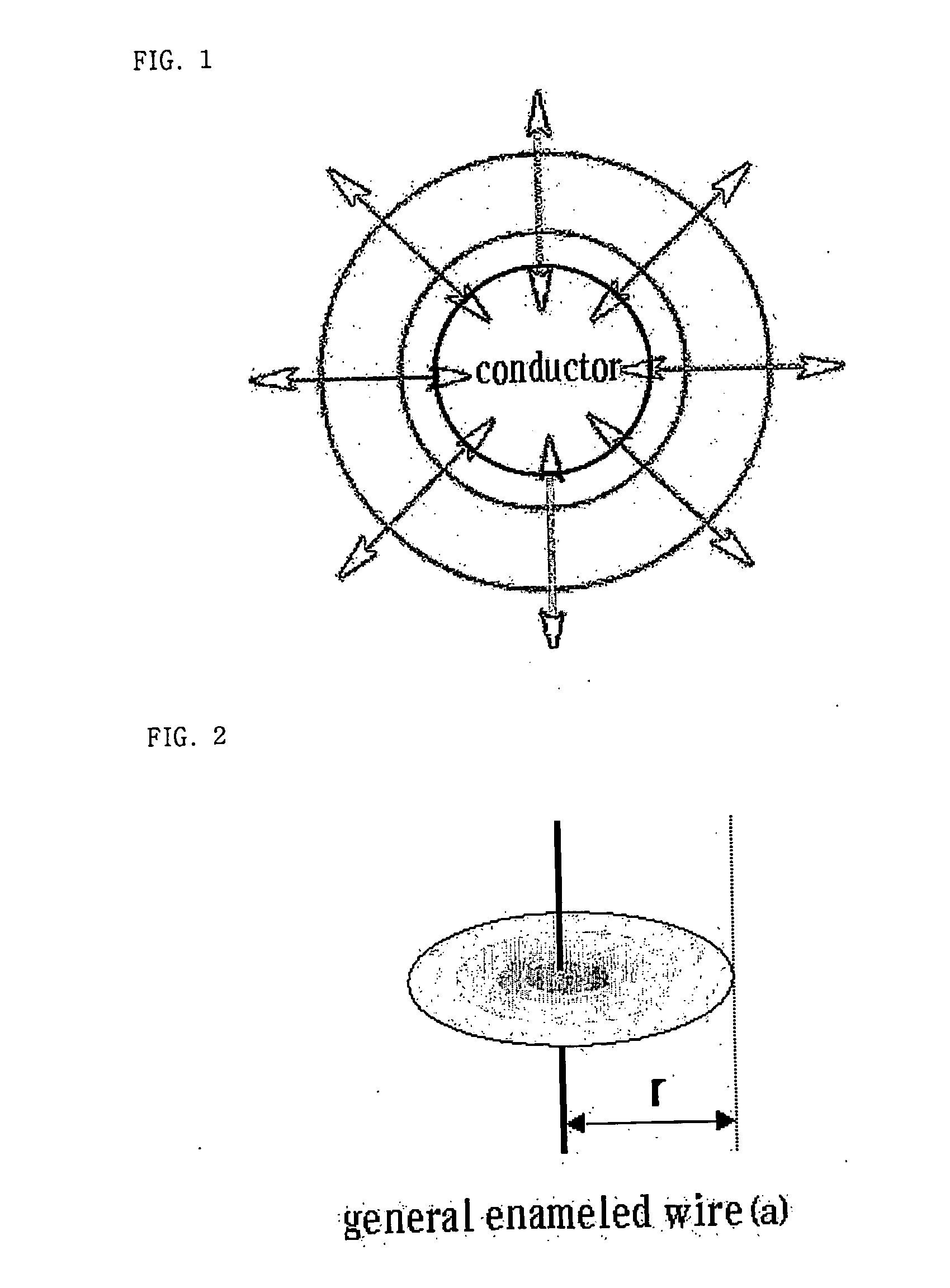

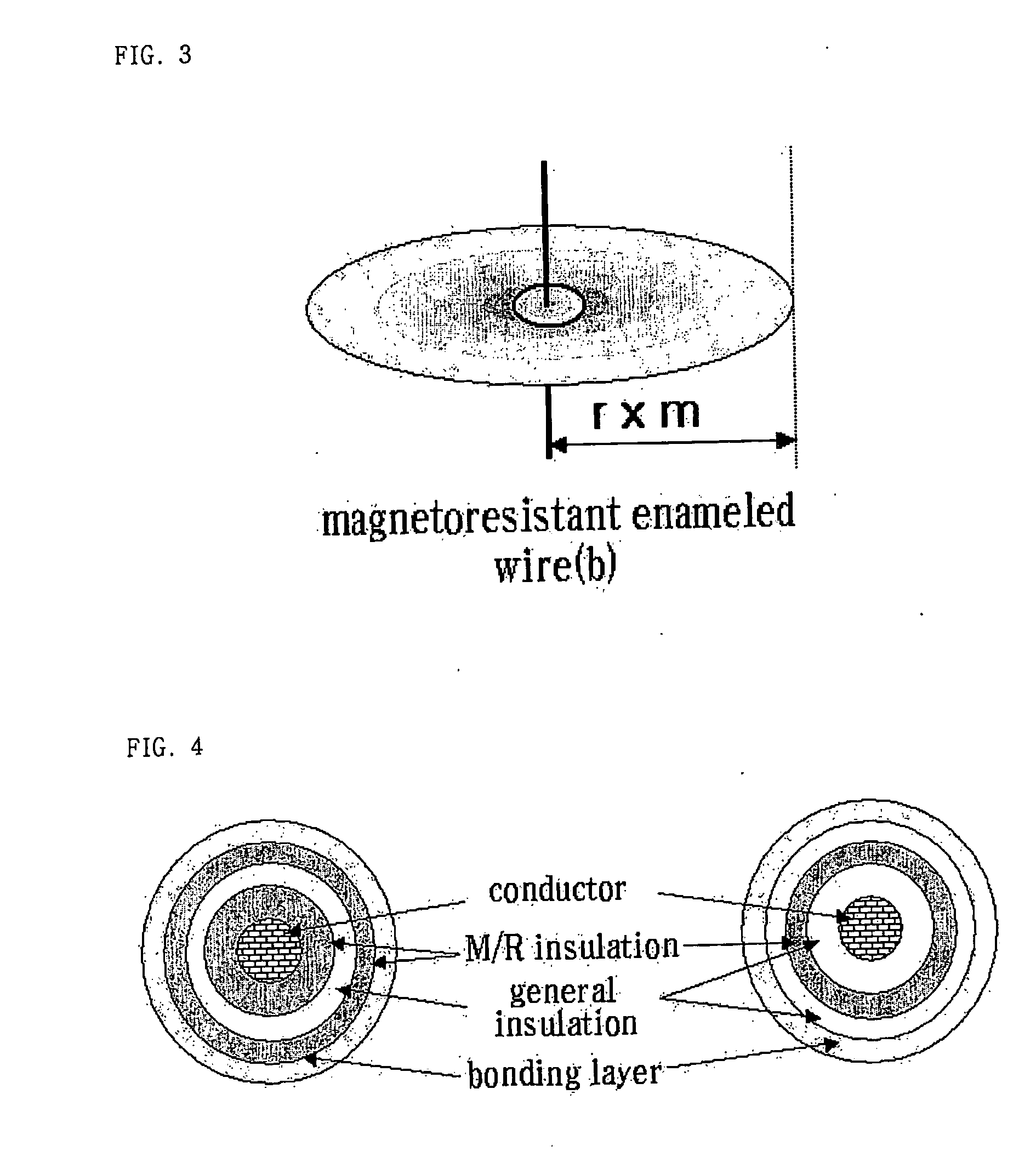

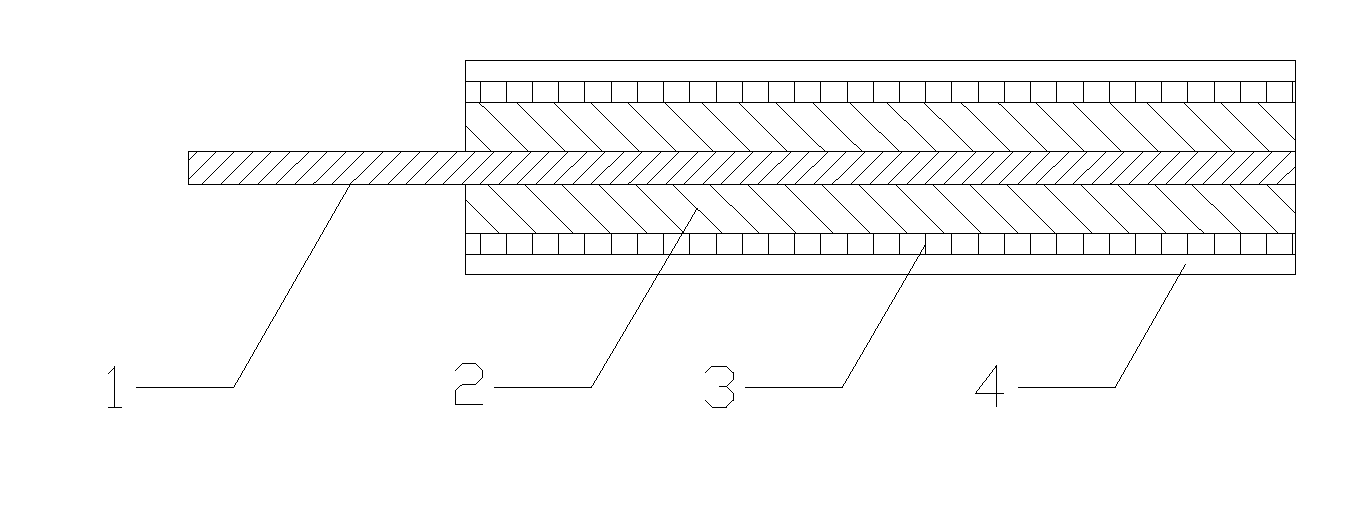

Enameled wire having magnetic reluctance properties and preparation method thereof, and coil using the same and preparation method thereof

InactiveUS20060165983A1Reduce energy lossAvoid temperature riseInsulated cablesTransformers/inductances detailsElectrical resistance and conductanceElectrical conductor

Disclosed herein is a magnetoresistant enameled wire coated with a material which shows improved conductivity by reducing resistance of a conductor since the wire exhibits effects similar to anisotropic magnetoresistance of magnetic materials when manufactured in the form of a coil. The material also shows effects similar to magnetoresistance exhibiting a strong magnetic flux density. Disclosed further are a method for manufacturing the magnetoresistant enameled wire, a magnetoresistant coil using the magnetoresistant wire, and a method for manufacturing the magnetoresistant coil.

Owner:WEDO

Triboelectric pressure sensing cable and preparation method thereof

InactiveUS20160209278A1Increase signal strengthEasy to operateForce measurement by measuring frquency variationsLiquid surface applicatorsElectricityAudio power amplifier

Provided is a triboelectric pressure sensing cable. The triboelectric pressure sensing cable comprises a central conducting wire, a high-molecular polymer insulating layer, an electrode layer, and an insulating outer layer, which are coaxially attached in sequence. The central conducting wire and the high-molecular polymer insulating layer, and / or the high-molecular polymer insulating layer and the electrode layer separately generate signals by the means of triboelectric effect. Also provided is a method for preparing the triboelectric pressure sensing cable. The method comprises the steps of (1) preparing a high-molecular polymer solution; (2) forming a hollow cavity framework used for casting; (3) casting; (4) molding; and (5) forming an insulating outer layer so as to obtain the triboelectric pressure sensing cable. The provided triboelectric pressure sensing cable can achieve a monitoring effect which is the same as that of a conventional pressure cable, without requiring a high input impedance circuit or a charge-amplifier.

Owner:NAZHIYUAN TECH TANGSHAN LLC

Copper alloy wire, copper alloy stranded wire, coated electric wire, wire harness and manufacturing method of copper alloy wire

InactiveCN105705665ASuppresses reduction in wire drawing workabilitySuppresses conductivity dropSingle bars/rods/wires/strips conductorsApparatus for heat treatmentElectrical conductorMetallurgy

The invention provides a copper alloy wire, a copper alloy stranded wire, a coated electric wire, a wire harness and a manufacturing method of the copper alloy wire. This copper alloy wire used as the conductor in a wire for use in vehicles contains 0.4-2.5 mass% Fe, 0.01-1.0 mass% Ti, and a total of 0.01-2.0 mass% of one or more species selected from Mg, Sn, Ag, Ni, In, Zn, Cr, Al and P, the remainder being Cu and unavoidable impurities. The O content is preferably 20ppm or less. The tensile strength is preferably 450MPa or greater. The element wire stretchability is preferably 5% or greater. The conductivity is preferably 62% IACS or greater.

Owner:AUTONETWORKS TECH LTD +2

Electric wire for vehicle

An electric wire for a vehicle is provided whose tensile strength can be adjusted to various degrees without having to change the area of an electric conductor to satisfy various tensile strength requirements. The electric wire for a vehicle includes an electric conductor composed of a single central wire made of stainless steel and seven or more peripheral wires, made of copper or copper alloy, that are disposed in one layer on the periphery of the central wire with the peripheral wires joining with each other such that the peripheral wires surround the central wire. The diameter of the central wire is set larger than that of the peripheral wires. The area ratio of the electric conductor satisfies the relation area ratio of electric conductor={(A+B) / C}×100(%)≧85(%) where A denotes a total of sectional areas of the peripheral wires, B denotes a sectional area of the central wire, and C is a sectional area of the electric conductor.

Owner:SUMITOMO WIRING SYST LTD

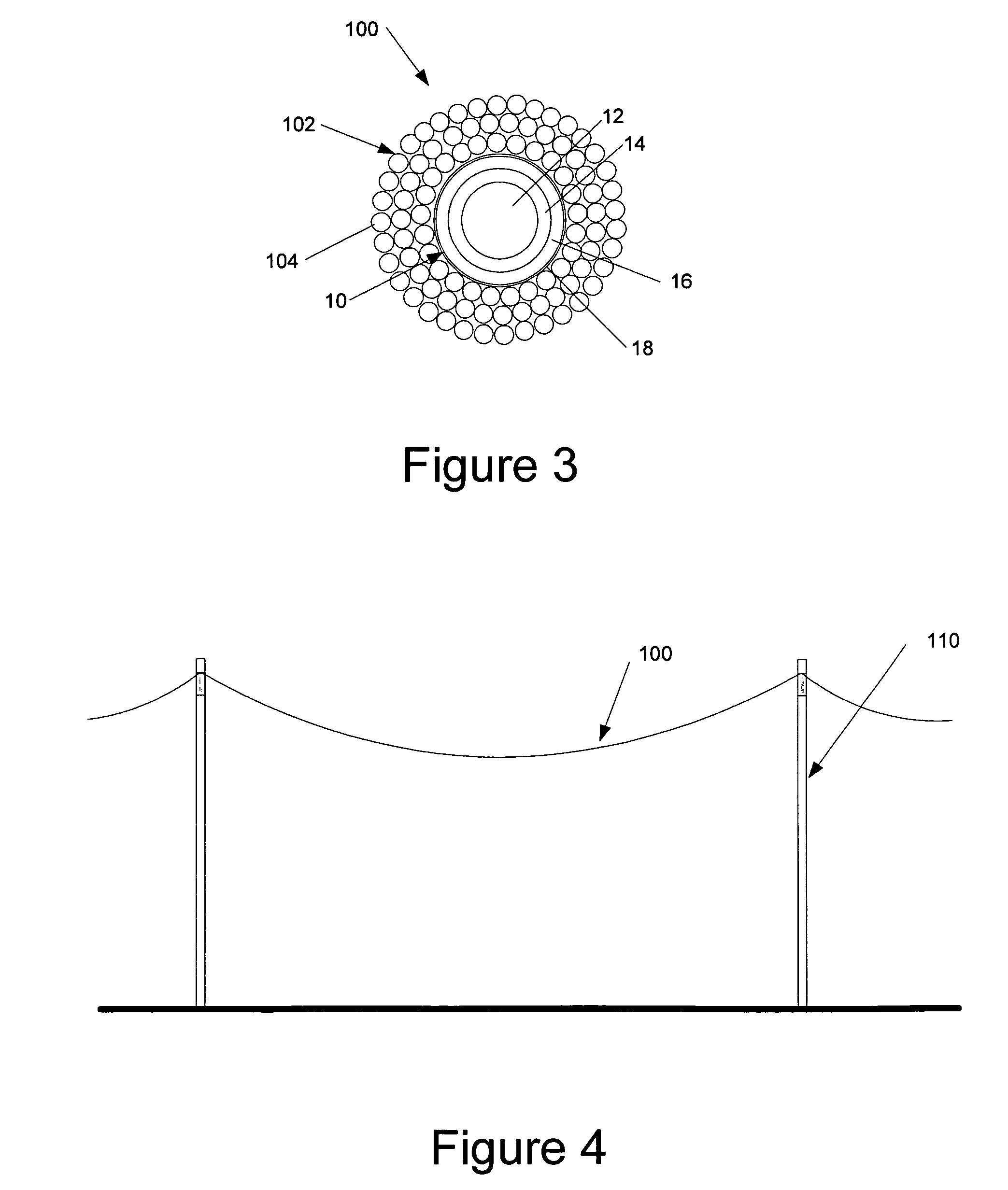

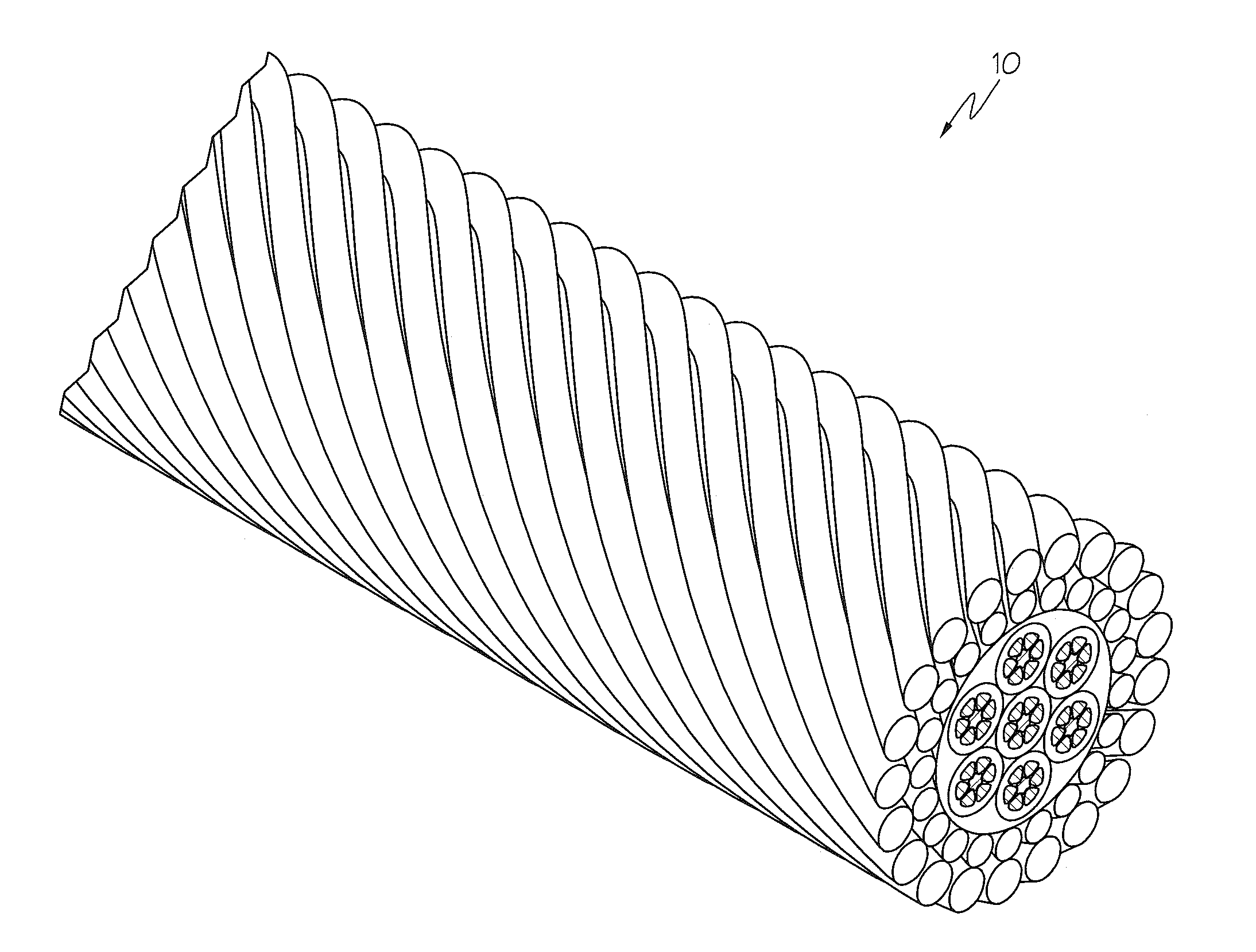

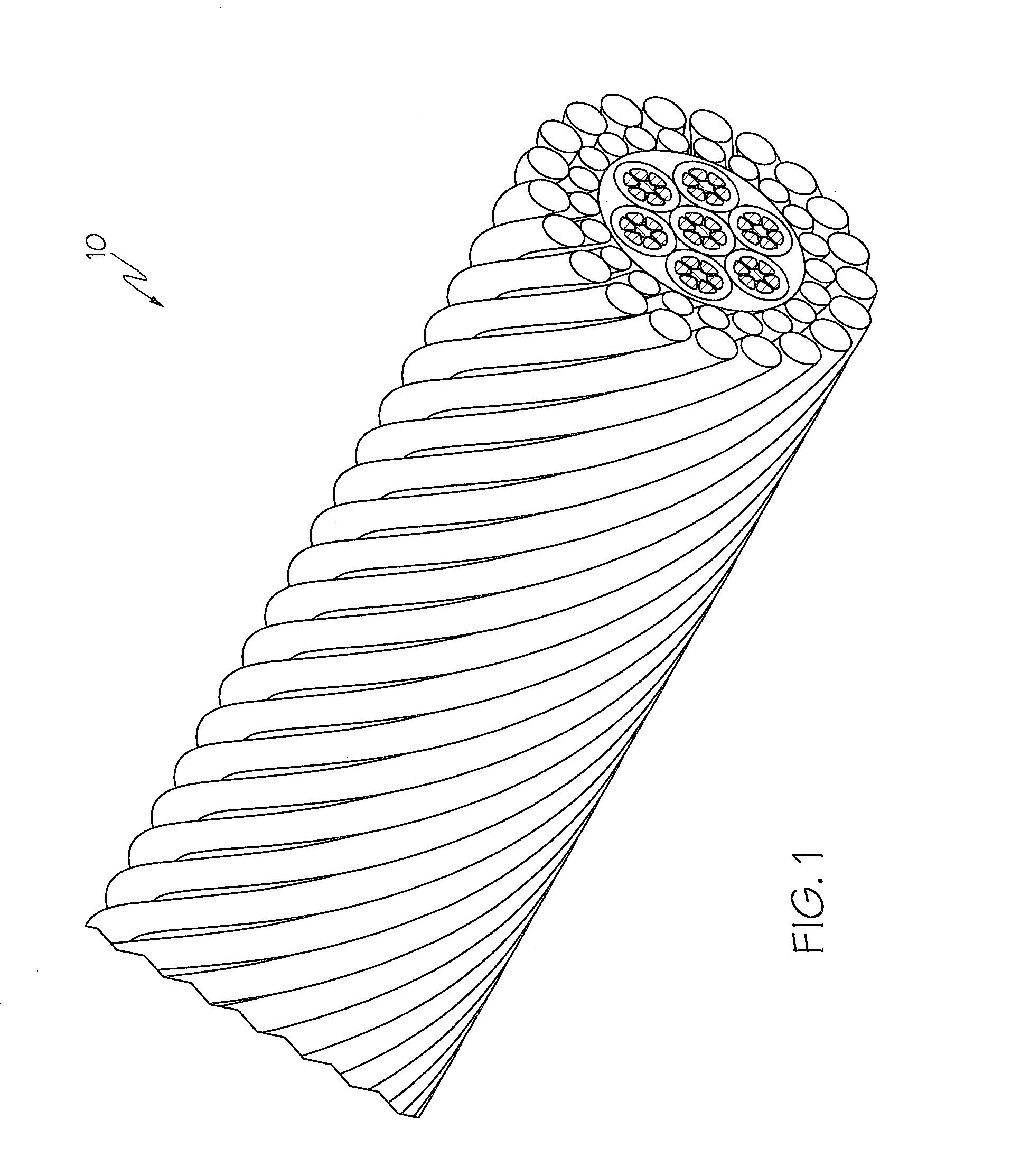

High-power low-resistance electromechanical cable

ActiveUS20140318858A1Power cables with screens/conductive layersInsulated cablesTetrafluoroethyleneElectrical conductor

A high-power low-resistance electromechanical cable constructed of a conductor core comprising a plurality of conductors surrounded by an outer insulating jacket and with each conductor having a plurality of wires that are surrounded by an insulating jacket. The wires can be copper or other conductive wires. The insulating jacket surrounding each set of wires or each conductor can be comprised of ethylene tetrafluoroethylene, polytetrafluoroethylene, polytetrafluoroethylene tape, perfluoroalkoxyalkane, fluorinated ethylene propylene or a combination of materials. A first layer of a plurality of strength members is wrapped around the outer insulating jacket. A second layer of a plurality of strength members may be wrapped around the first layer of a plurality of strength members. The first and / or second layer of strength members can be made of single wires, synthetic fiber strands multi-wire strands, or rope. If either or both layers are made up of synthetic fiber, then the synthetic fibers may be surrounding and encapsulated by an additional insulating and protective layer.

Owner:WIRECO WORLDGROUP INC

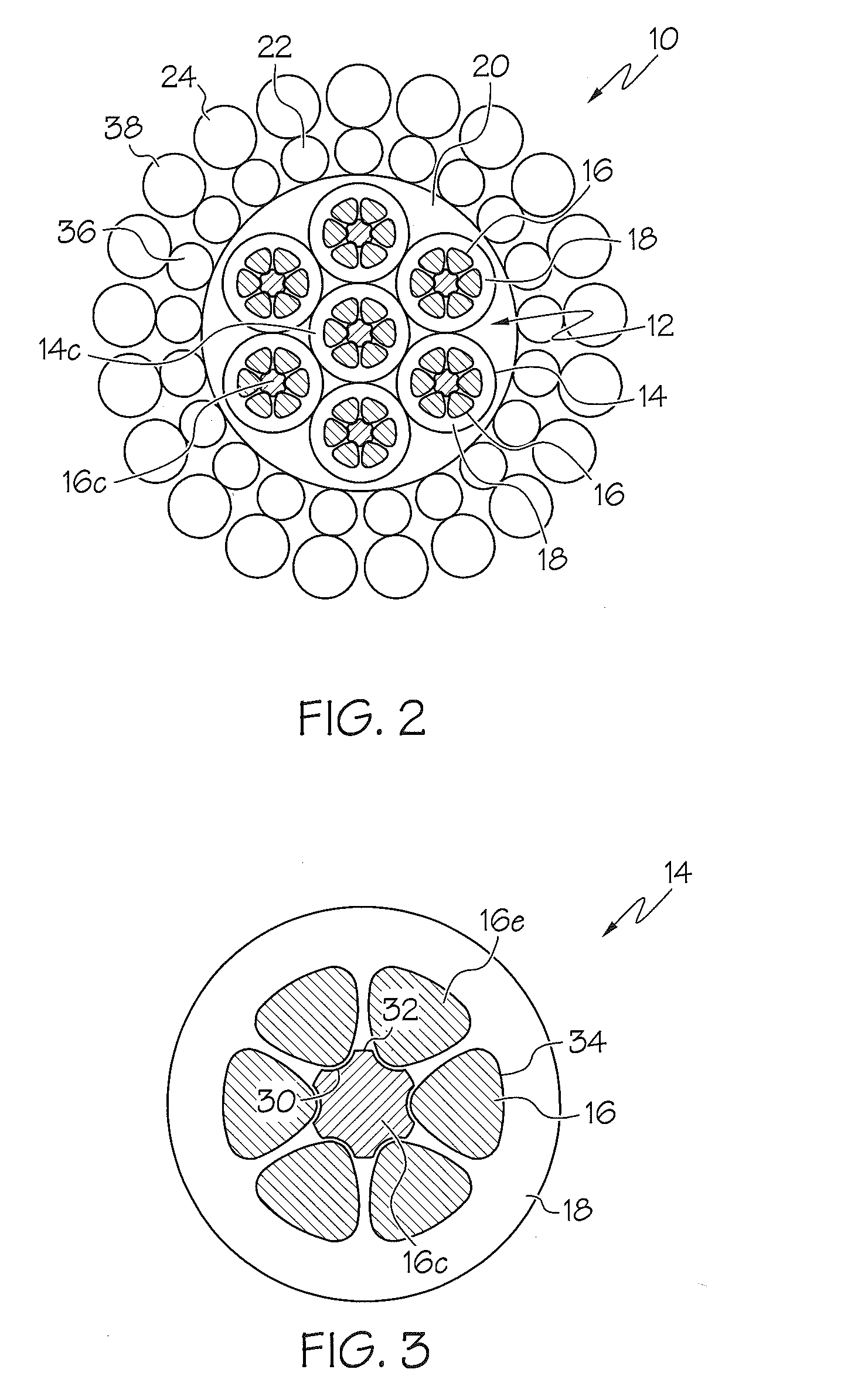

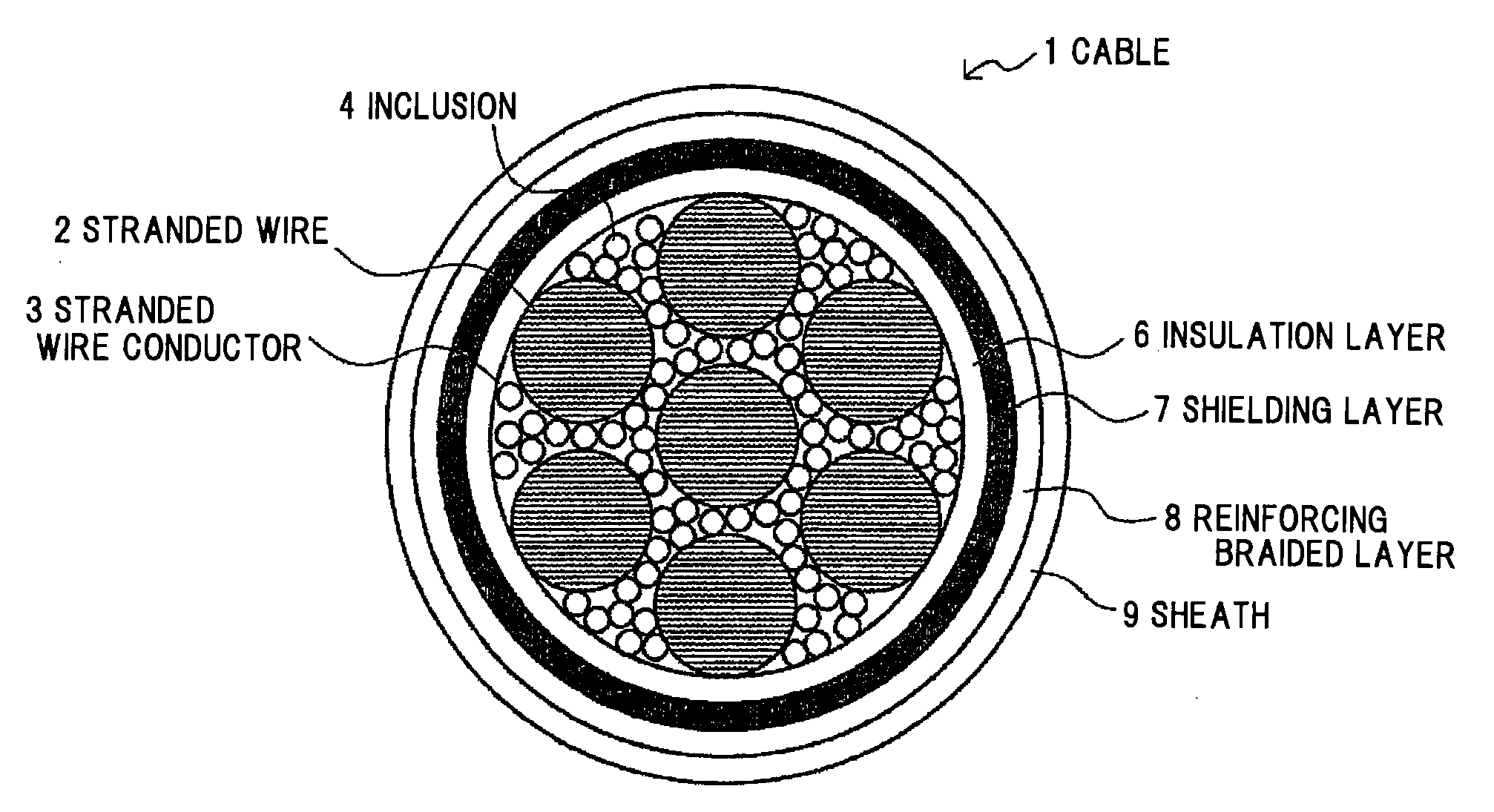

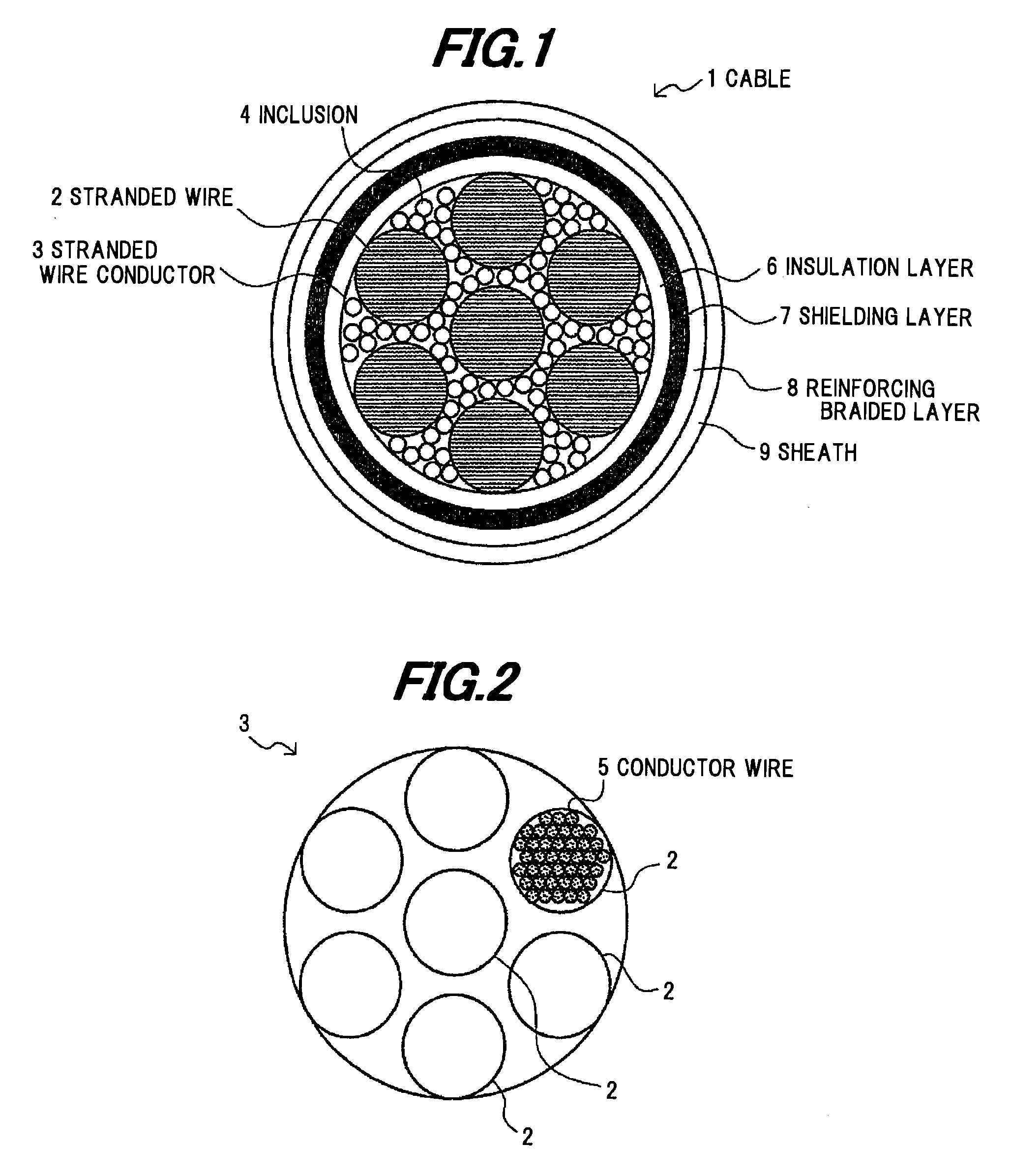

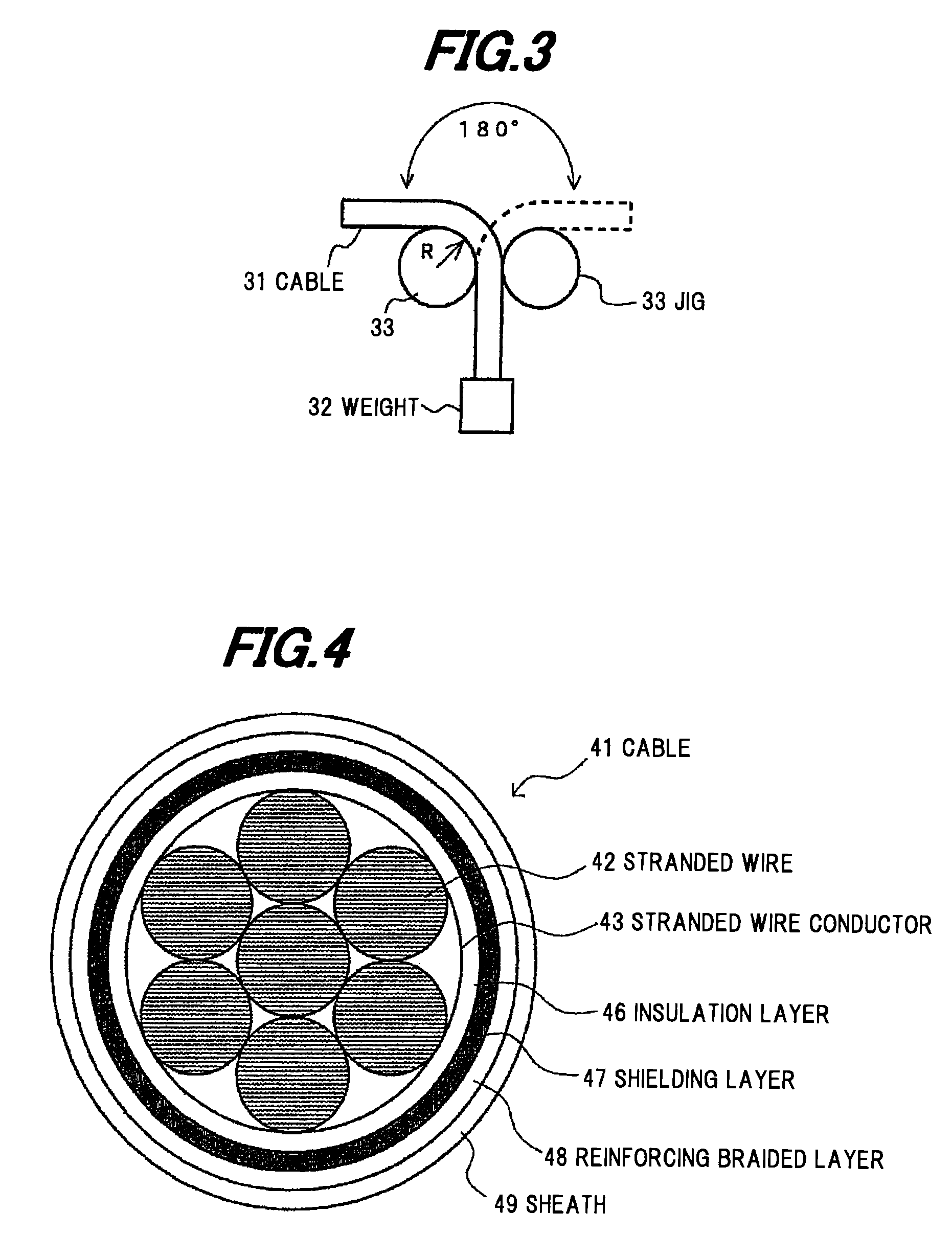

Cable

InactiveUS20110005805A1Reduce mutual contactImprove bending durabilityDetails of conductive coresFlexible cablesElectrical conductorEngineering

A cable includes an inclusion containing stranded wire conductor that includes a plurality of stranded wires formed by twisting a plurality of conductor wires, and a plurality of thin diameter inclusions having an external diameter thinner than that of each of the stranded wires. The inclusion containing stranded wire conductor is formed by together twisting a plurality of the stranded wires and a plurality of the thin diameter inclusions so as to allow one of the thin diameter inclusions to be located between adjacent stranded wires of a plurality of the stranded wires.

Owner:HITACHI CABLE

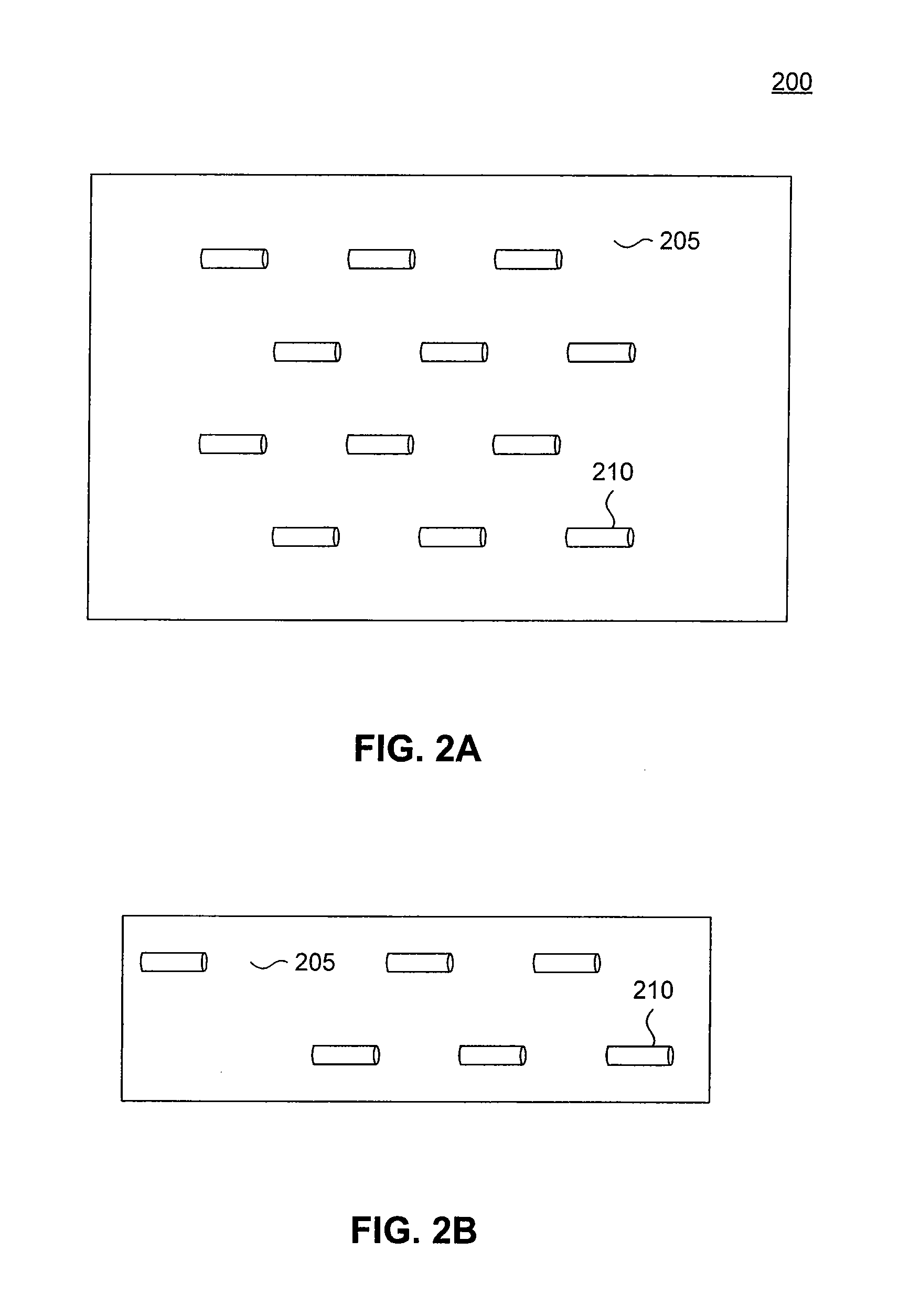

Composite structural member having an integrated electrical circuit

ActiveUS20070298663A1Printed electric component incorporationLaminating printed circuit boardsComposite constructionElectrical devices

A composite structural member with an integrated electrical circuit is provided. The structural member includes a plurality of layers of structural reinforcement material, and two or more electrical devices are disposed at least partially between the layers with an intermediate layer of the structural reinforcement material disposed between the electrical devices. At least one electrical bus is disposed in the structural member, and each electrical device is connected to the bus by a conductive electrode. Thus, the electrodes can extend through the intermediate layer of the structural reinforcement material to connect each of the electrical devices to one or more of the buses.

Owner:THE BOEING CO

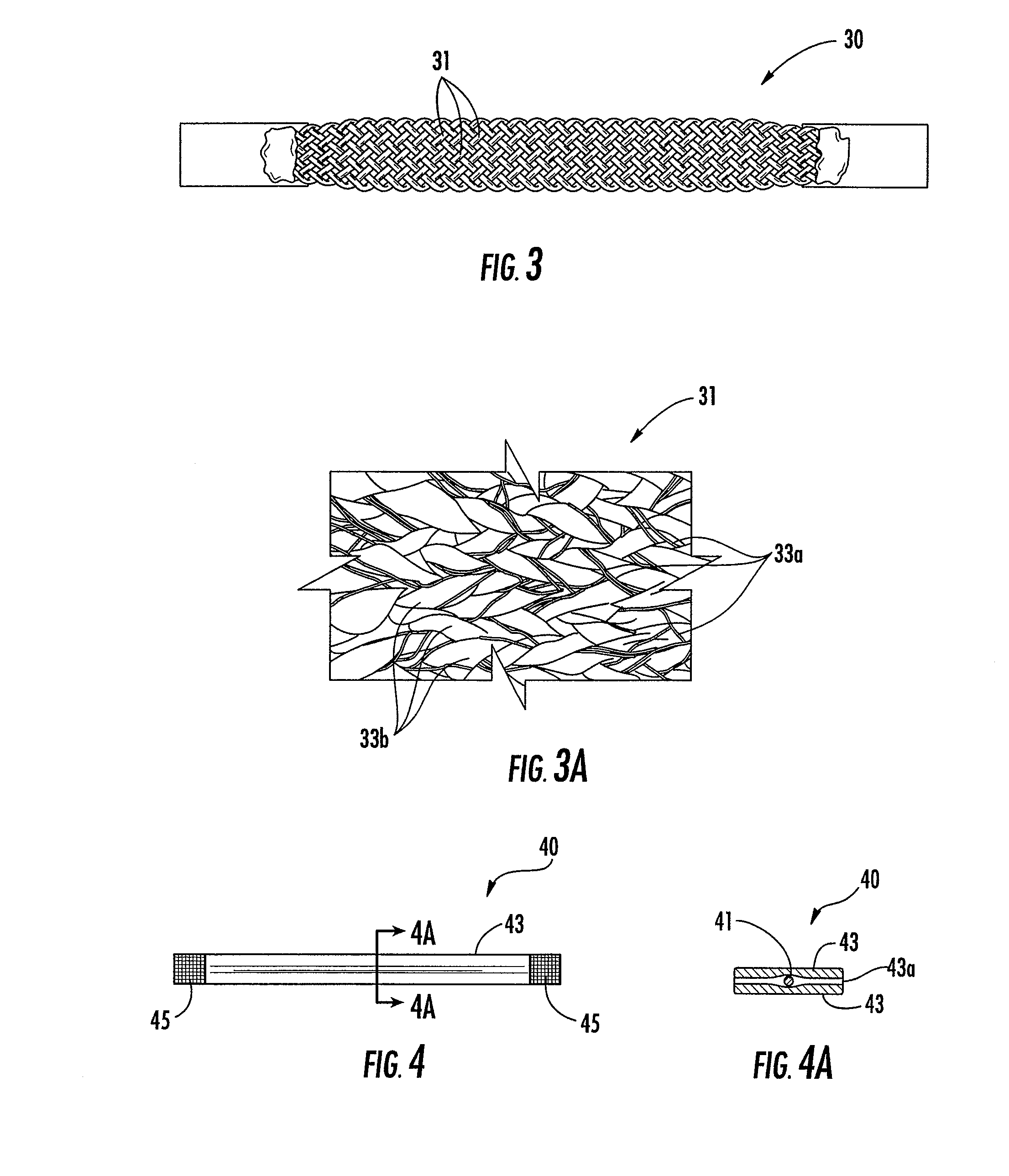

Wiring Member, Manufacturing Method of Wiring Member, and Wiring Member Connection Structure

ActiveUS20180174716A1Thin and lightReduce spacingDetails of conductive coresFlat/ribbon cablesElectrical conductorEngineering

Owner:YAZAKI CORP

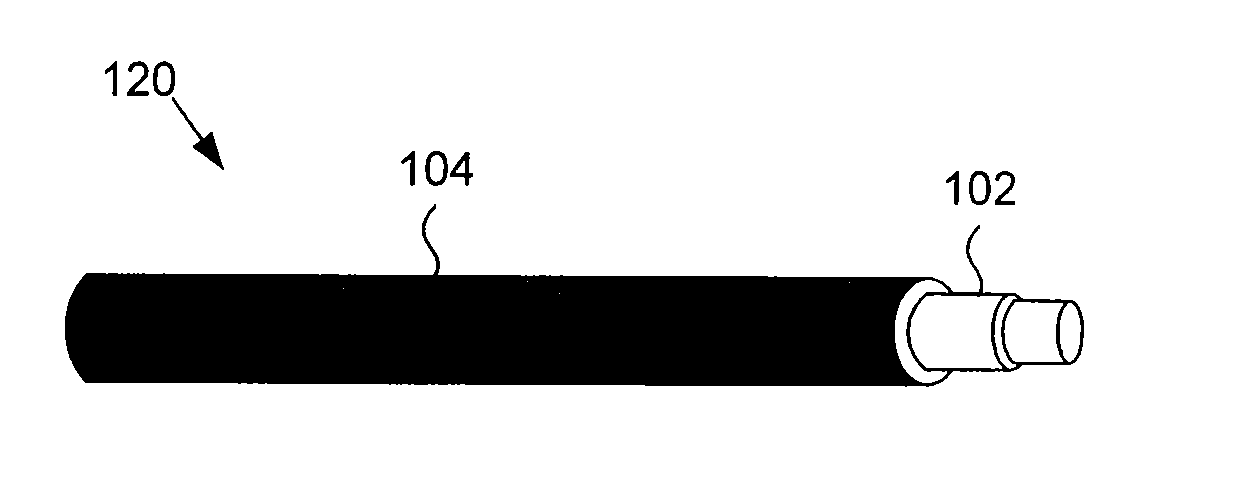

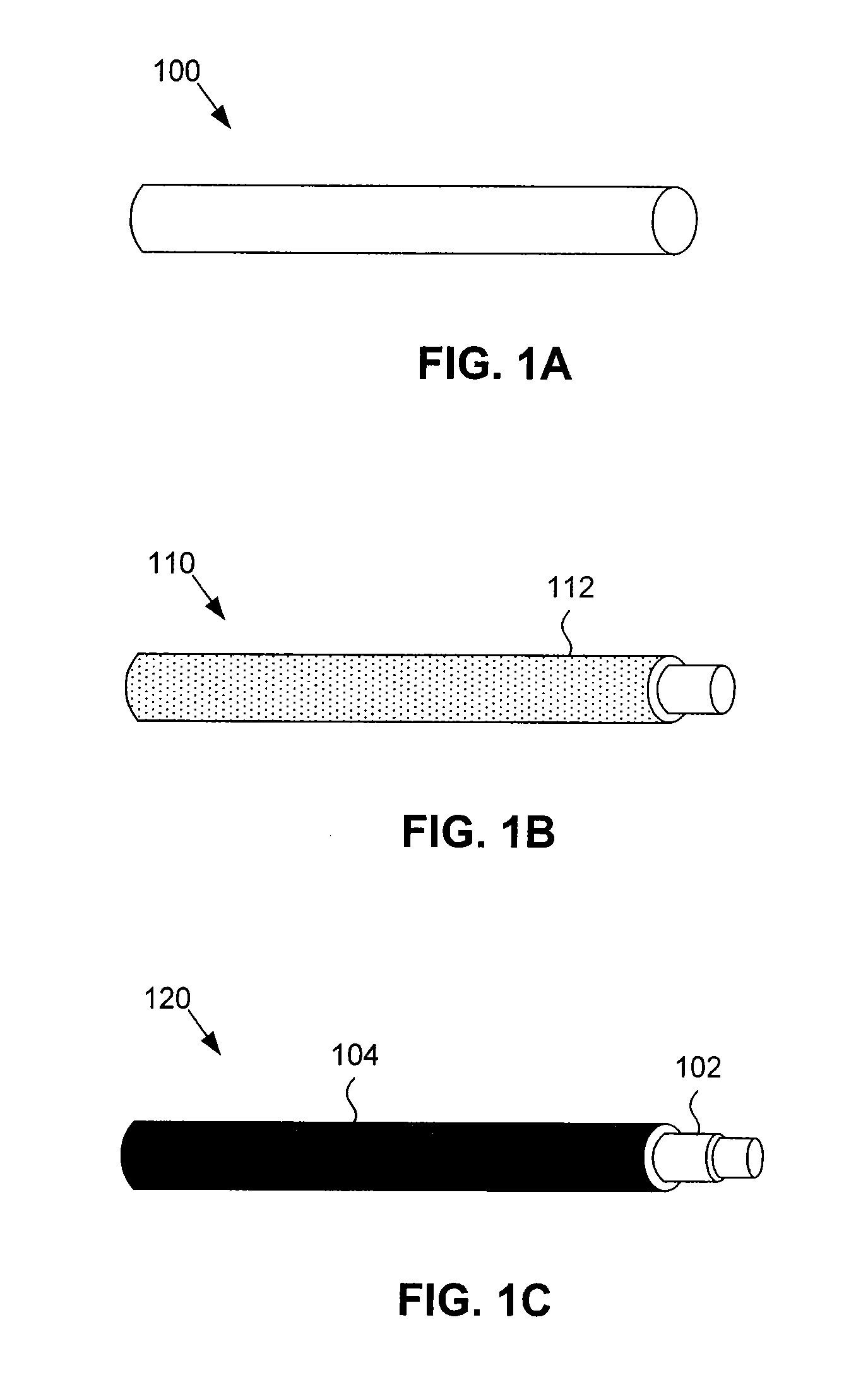

Method of manufacturing electrical cable, and resulting product, with reduced required installation pulling force

ActiveUS9431152B2Reduce coefficient of frictionLower surfaceRelieving strain on wire connectionPlastic/resin/waxes insulatorsPull forceElectrical conductor

Disclosed is type THHN cable having a reduced surface coefficient of friction, and the method of manufacture thereof, in which the central conductor core and insulating layer are surrounded by a nylon sheath. A high viscosity, high molecular weight silicone based pulling lubricant for THHN cable, or alternatively, erucamide or stearyl erucamide for small THHN gauge wire, is incorporated, by alternate methods, with the nylon material from which the outer sheath is extruded, and is effective to reduce the required pulling force on the cable during installation.

Owner:SOUTHWIRE CO LLC

Electric wire for automobile

An electric wire for automobile including a compressed conductor which is obtained by arranging around a single central element wire of stainless steel, seven or more peripheral element wires of copper or copper alloy in a single circle in tight adherence with each other, and an insulation coating layer which covers the outer circumference of the conductor, wherein the diameter of the central element wire is larger than the diameters of the peripheral element wires, the cross sectional area of the conductor is 0.13 through 0.16 mm2, and the insulation coating layer contains a fire retardant in the amount of 160 weight parts or more relative to 100 weights parts of insulation polymer.

Owner:SUMITOMO WIRING SYST LTD

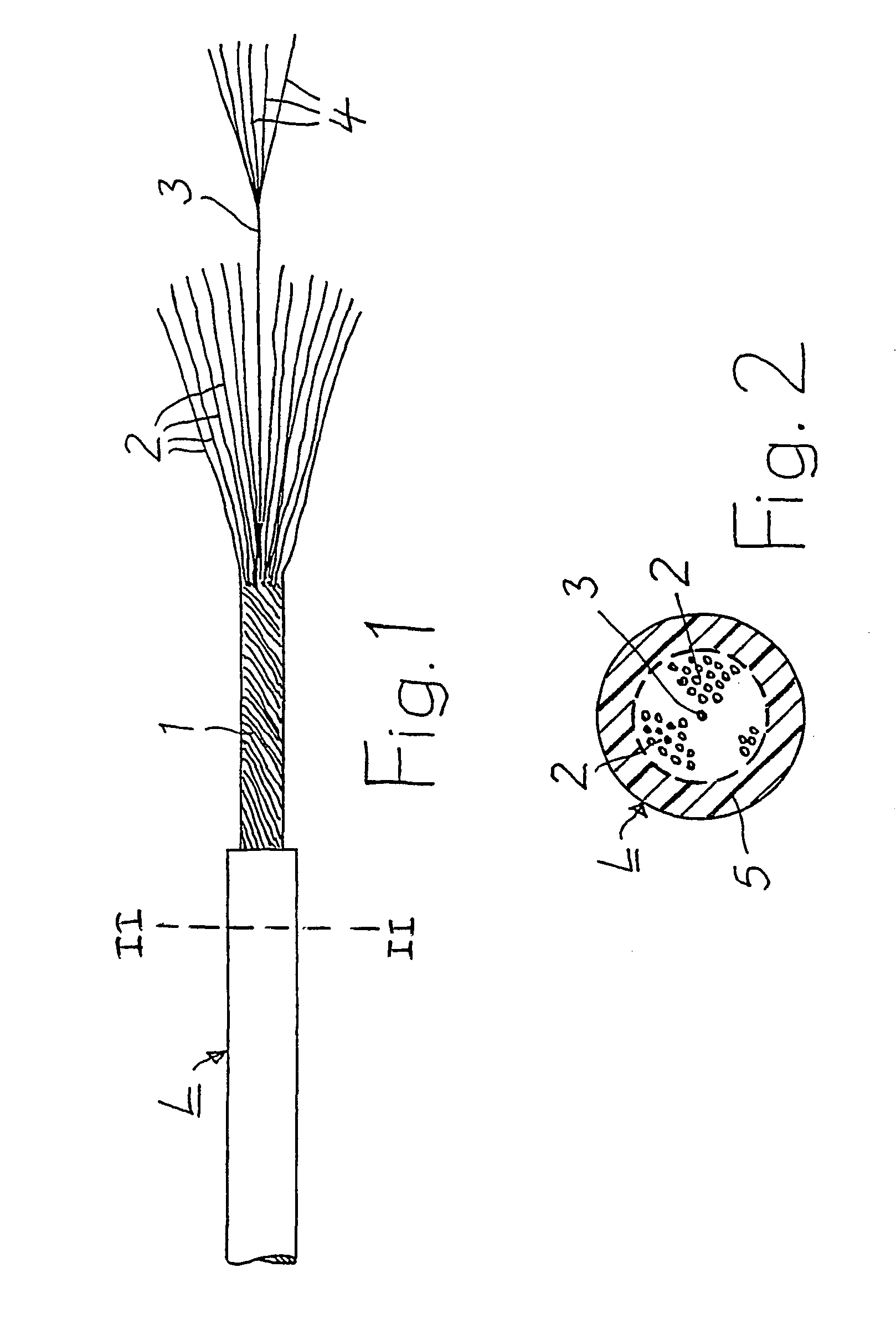

Electrical control cable

InactiveUS8692120B2Reliable crimpingInexpensive to fabricateNon-insulated conductorsInsulated cablesElectricityElectrical conductor

The present invention relates to an electrical control cable of the type comprising a core having a plurality of polymer filaments, a plurality of strands of conductor material extending in the longitudinal direction of said core, an outer insulating sheath. According to the invention, said strands are distributed uniformly and concentrically over the periphery of said core, in contact with one another in pairs and in contact with said core, and the filaments of said core are secured to one another to form a non-metallic unitary structure that is obtained by organizing said filaments into a plurality of subassemblies, the filaments in any one subassembly being twisted together helically, the subassemblies in turn being twisted with one another to form an overall helix. Advantage: the cable uses a limited number of copper strands while guaranteeing that crimping operations are reliable.

Owner:NEXANS

Flexible electrical line

InactiveUS7145082B2Increase flexibilityImprove bending strengthNon-insulated conductorsDetails of conductive coresElectrical conductorAramides

A flexible electric line with at least one electrical conductor is provided having a high tensile, nonmetallic element and a plurality of highly conductive metal wires arranged around it. The flexible electric line has a high tensile element that is a loose composite of a large number of aramid fibers, the cross section of this element being the same as that of one of the individual metallic wires and where the conductor is surrounded by a layer of insulation.

Owner:NEXANS

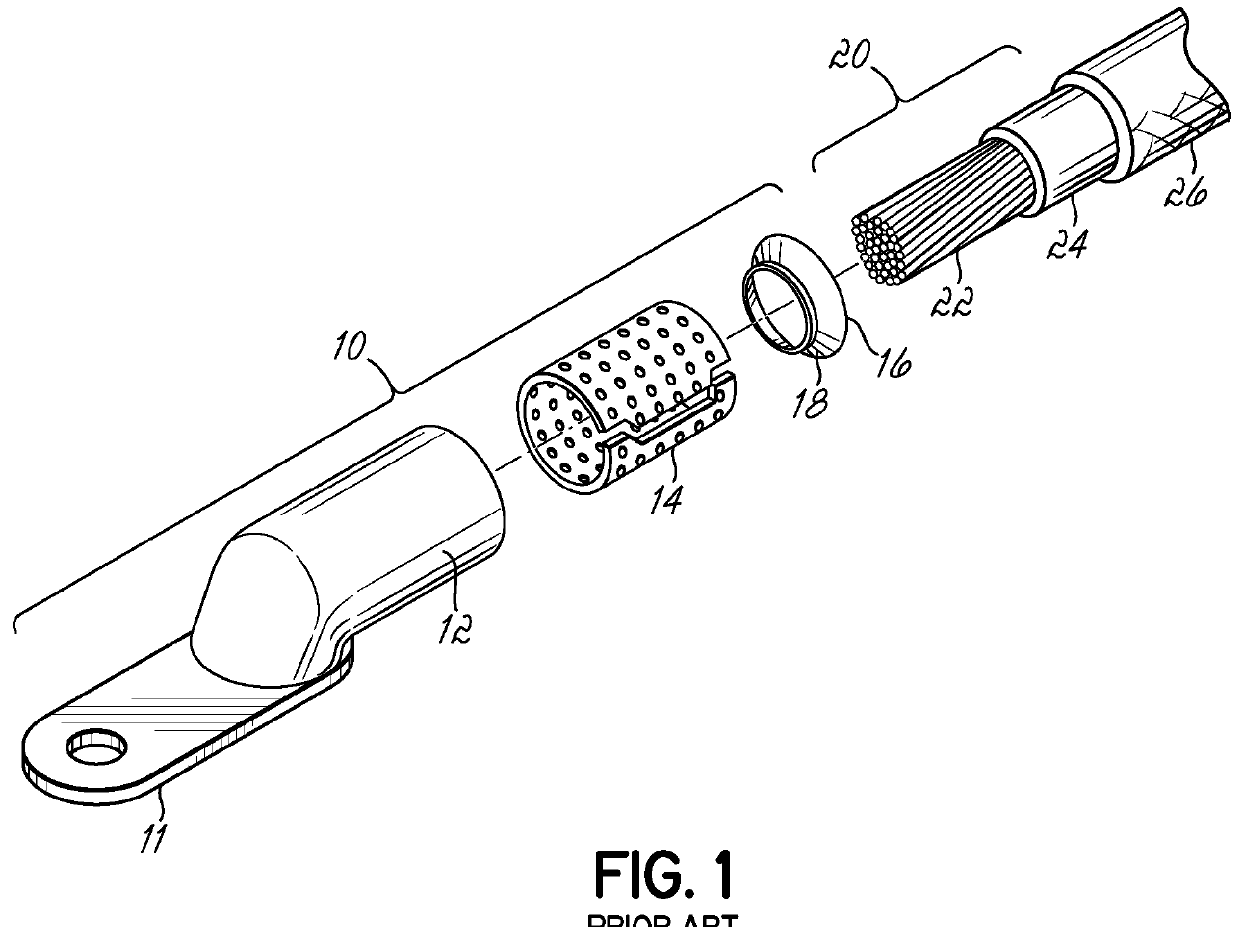

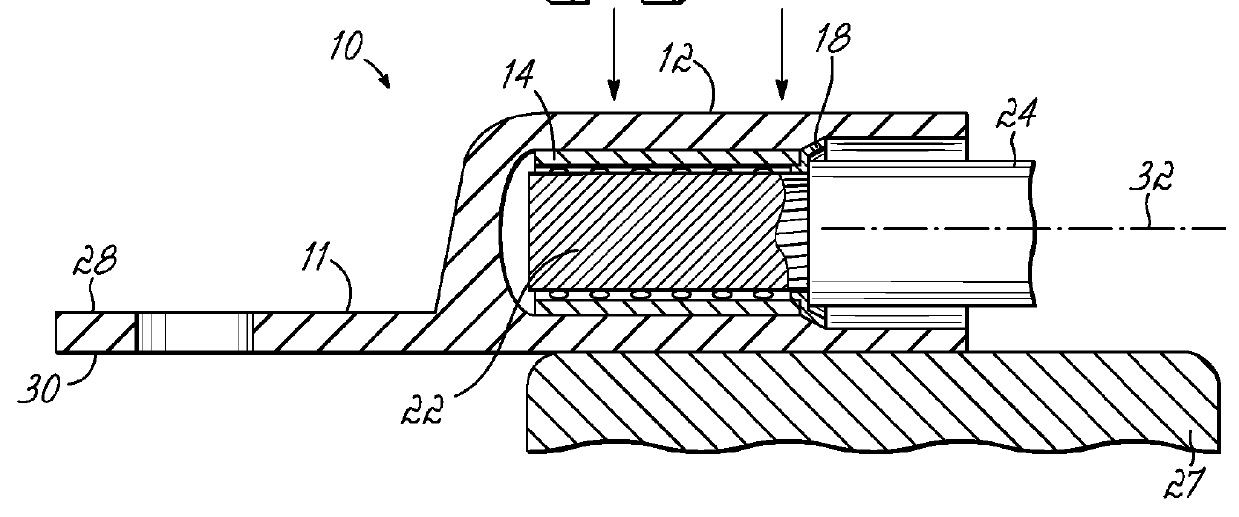

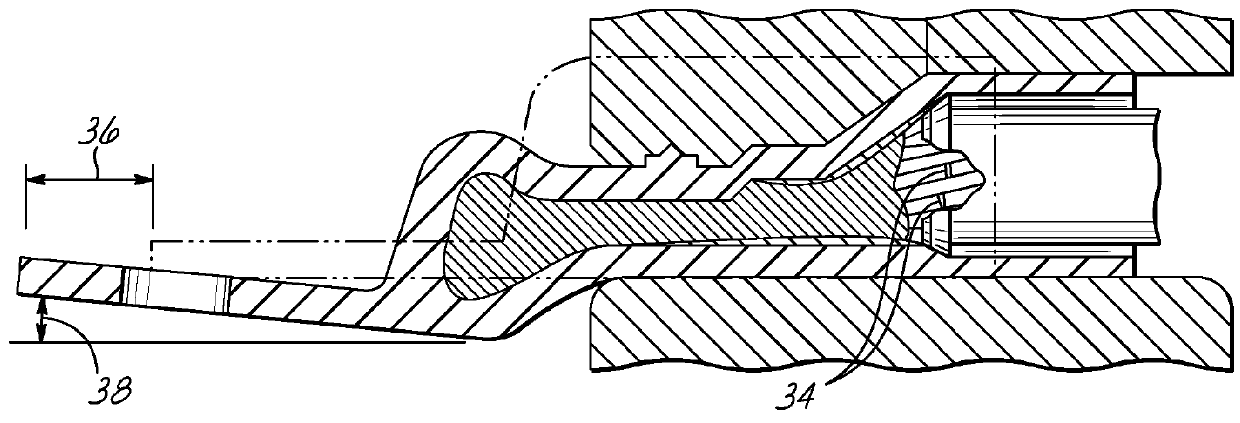

Terminal/connector having integral oxide breaker element

A one piece integral electrical terminal has a mount portion and a wire receiving portion. The wire receiving portion has a continuous annular interior wall having a contact portion with an integral oxide breaker especially suited to breaking through the oxide layer on aluminum wire. The wire receiving portion also has a sealing portion with at least one integral seal ring. An electrical cable is made by crimping the electrical terminal to an aluminum wire using a modified hexagonal crimp.

Owner:CARLISLE INTERCONNECT TECH

Metal/ceramic composite conductor and cable including same

InactiveUS7390963B2Non-insulated conductorsPlastic/resin/waxes insulatorsCeramic compositeConductive coating

A conductor cable includes an inner portion and a conductive coating. The inner portion is formed of a metal / ceramic composite. The conductive coating is coated on the inner portion.

Owner:3M INNOVATIVE PROPERTIES CO

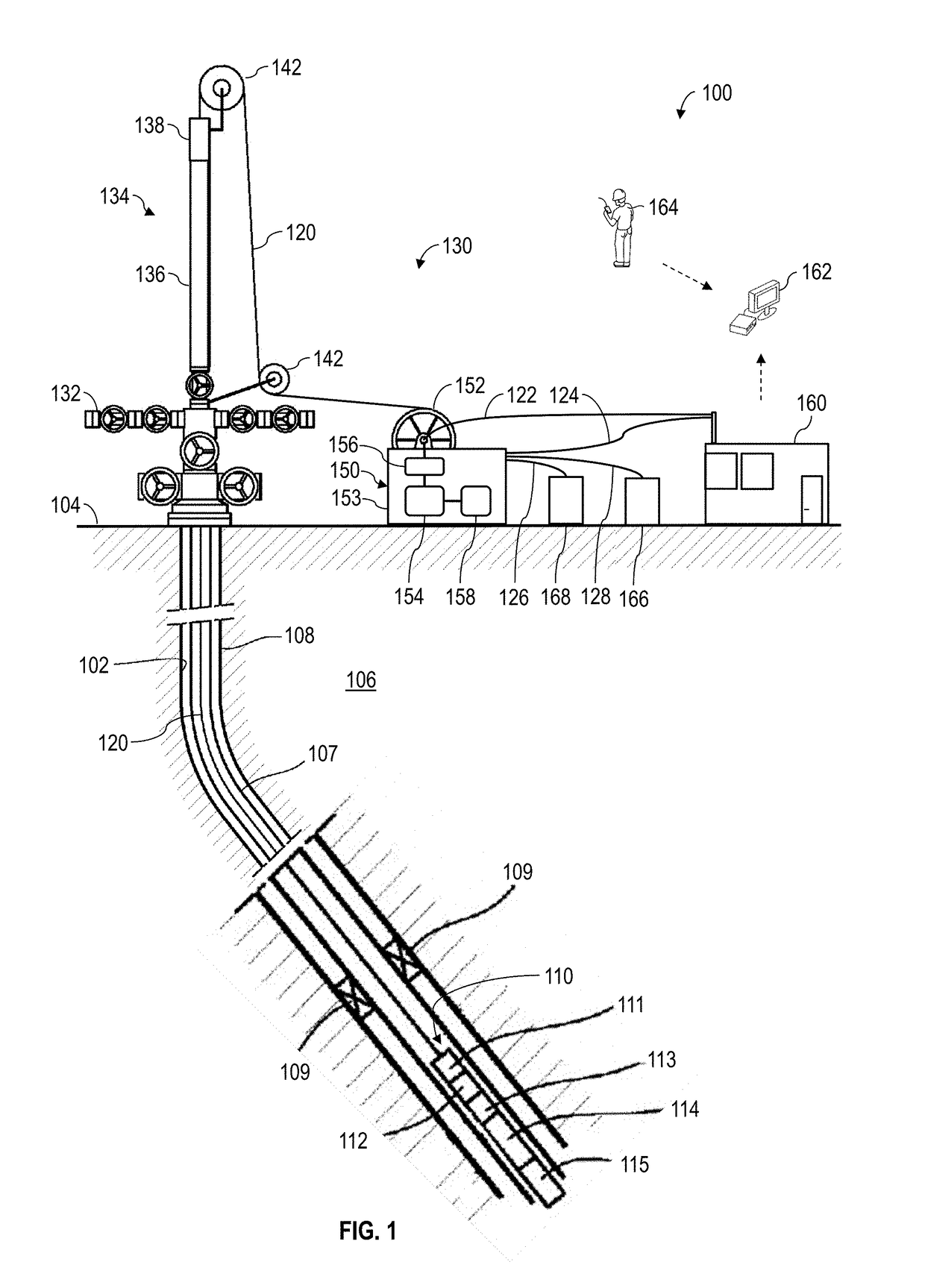

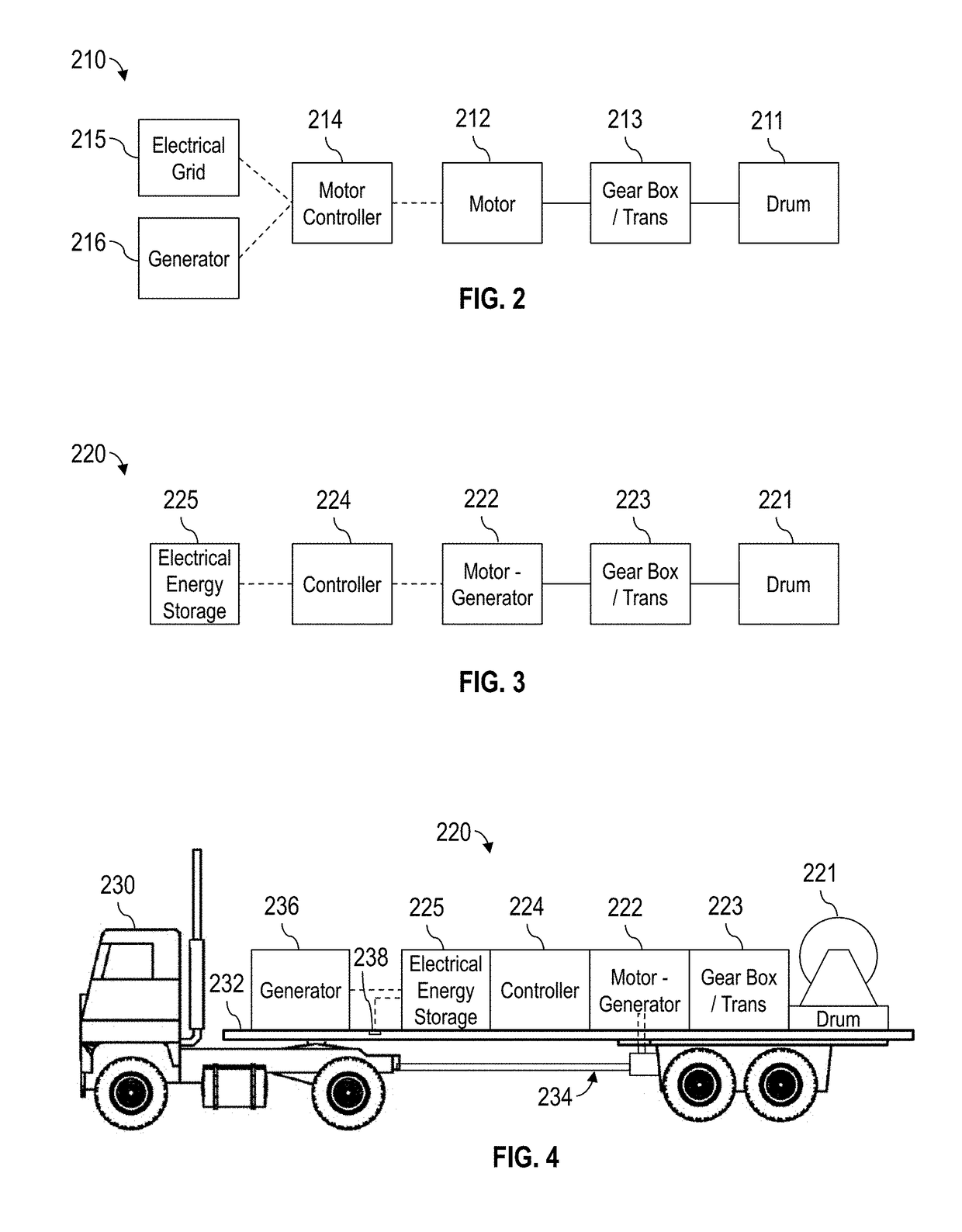

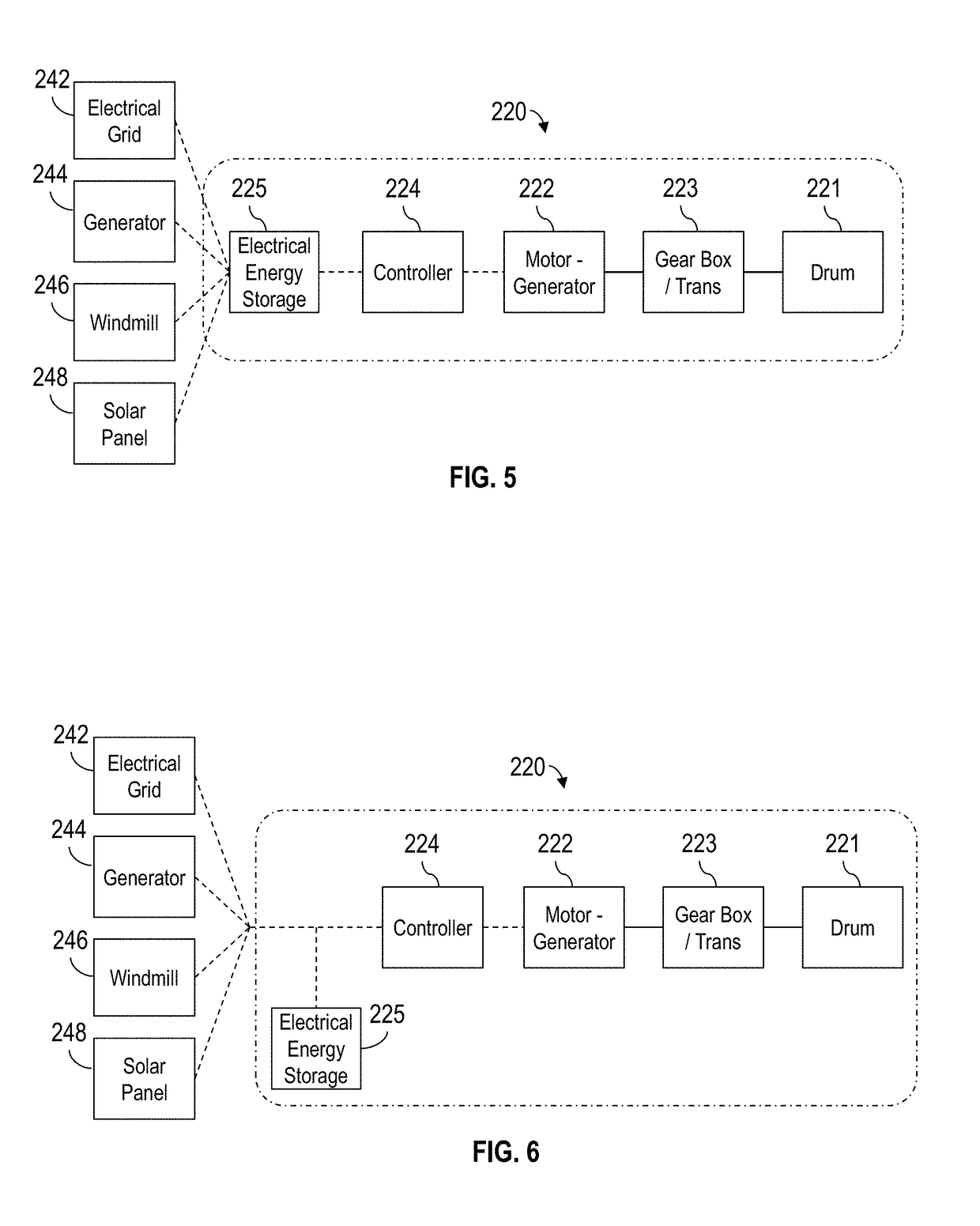

Oil Field Services Apparatus and Methods

Oil field services apparatus and method. The apparatus comprises a conveyance system operable for lowering and retrieving a downhole tool in and out of a wellbore. The conveyance system comprises a drum operable for rotating and receiving a line connectable with the downhole tool, a motor-generator mechanically connected with the drum, and an energy storage electrically connected with the motor-generator. The motor-generator may be operable for receiving electrical energy to impart torque to the drum and receiving torque from the drum to generate electrical energy. The energy storage may be operable for storing electrical energy received from the motor-generator.

Owner:SCHLUMBERGER TECH CORP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com