Enameled wire having magnetic reluctance properties and preparation method thereof, and coil using the same and preparation method thereof

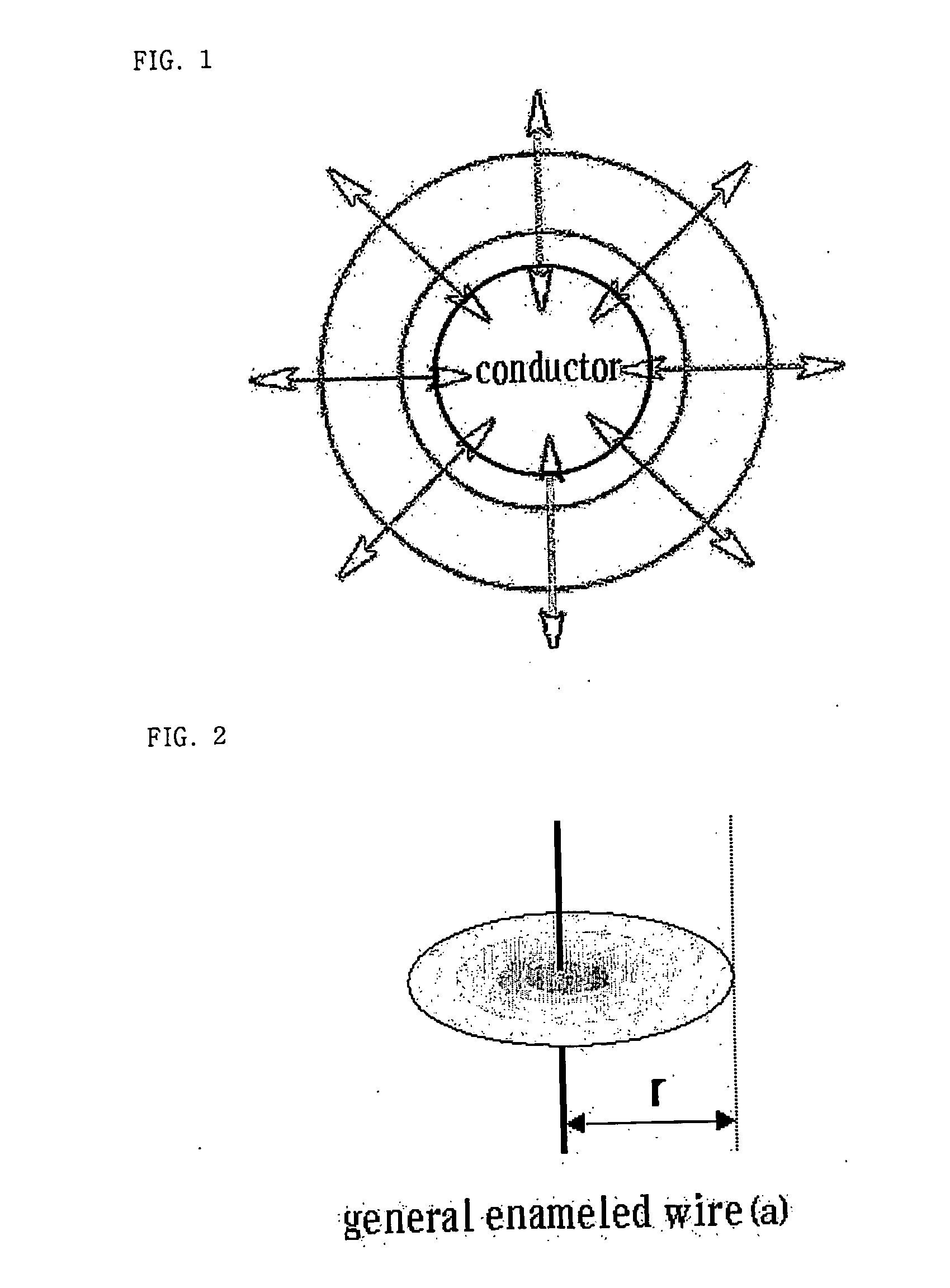

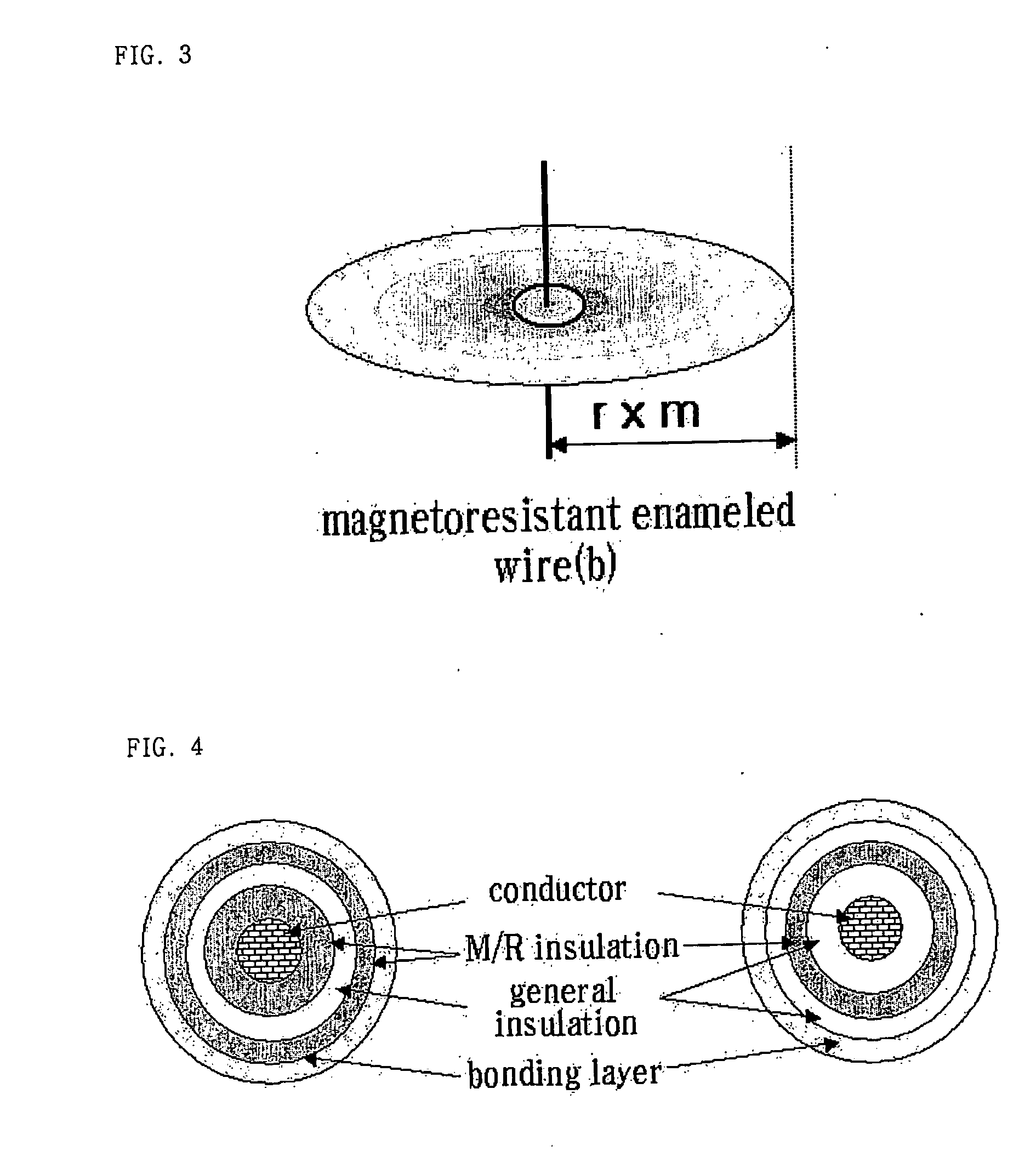

a technology of enameled wire and magnetic resistance, which is applied in the direction of insulated conductors, cables, conductors, etc., can solve problems such as energy loss, and achieve the effects of reducing resistance and load of wires, reducing energy loss, and inhibiting temperature ris

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0167] (Preparation of Polyester-Based Magnetically Soft Varnish)

[0168] 1.225 parts by weight of a magnetically soft material of a composite oxide containing about 63% of FeO, about 23% of FeO, about 9% of CoFeO as main components, and 0.125 parts by weight of a polyethylene polymeric protective colloid-based dispersing agent were added to 100 parts by weight of the general polyester-based insulating varnish prepared in Comparative Example 1. The mixture was stirred and dispersed to prepare a polyester-based varnish containing a magnetically soft material. The varnish thus prepared had a degree of softening degree of 4.

[0169] (Manufacture of Polyester-Based Magnetically Soft Varnish-Coated Enameled Wire)

[0170] A magnetically soft material-type enameled wire was manufactured in the same manner as in Comparative Example 1, except that the polyester-based magnetically soft varnish was coated instead of the general polyester-based insulating varnish. The thickness of the varnish laye...

example 2

[0176] (Preparation of Polyvinylformal-Based Magnetically Soft Varnish)

[0177] 1.10 parts by weight of a magnetically soft material of a composite oxide containing about 63% of FeO, about 23% of FeO, about 9% of CoFeO as main components, and 0.05 parts by weight of a fatty acid polyamide-based dispersing agent were added to 100 parts by weight of the general polyvinylformal-based insulating varnish prepared in Comparative Example 2. The mixture was stirred and dispersed to prepare a polyvinylformal-based varnish containing a magnetically soft material. The varnish thus prepared had a degree of softening of 4.

[0178] (Manufacture of Polyvinylformal-Based Magnetically Soft Varnish-Coated Enameled Wire)

[0179] A magnetoresistant enameled wire was manufactured in the same manner as in Comparative Example 2, except that the polyvinylformal-based magnetically soft varnish was coated instead of the general polyvinylformal-based insulating varnish.

[0180] The thickness of the magnetically s...

example 3

[0186] (Preparation of Polyurethane-Based Magnetically Soft Varnish)

[0187] 1.20 parts by weight of a magnetically soft material of a composite oxide containing about 63% of FeO, about 23% of FeO, about 9% of CoFeO as main components, and 0.15 parts by weight of a fatty acid amide-based dispersing agent were added to 100 parts by weight of the general polyurethane-based insulating varnish prepared in Comparative Example 3. The mixture was stirred and dispersed to prepare a polyurethane-based magnetically soft varnish. The varnish thus prepared had a degree of softening of 4.

[0188] (Manufacture of Polyurethane-Based Magnetically Soft Varnish-Coated Enameled Wire)

[0189] A magnetically soft enameled wire was manufactured in the same manner as in Comparative Example 3, except that the polyurethane-based magnetically soft varnish was coated instead of the general polyurethane-based insulating varnish.

[0190] The thickness of the varnish layer of the enameled wire thus manufactured was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com