Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Guaranteed to be round" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cable production process

InactiveCN104217818AAvoid scratchesReduce toughnessCable/conductor manufactureProcess engineeringElectric cables

The invention discloses a cable production process which includes the steps of firstly, single wire drawing; secondly, single wire annealing; thirdly, stranding; fourthly, cabling; fifthly, coating. The production process is reasonable and simple, and the produced cables are resistant to corrosion and oxidation, long in service life, suitable for various severe environments, free of electric leakage and high in safety performance.

Owner:安徽顺驰电缆股份有限公司

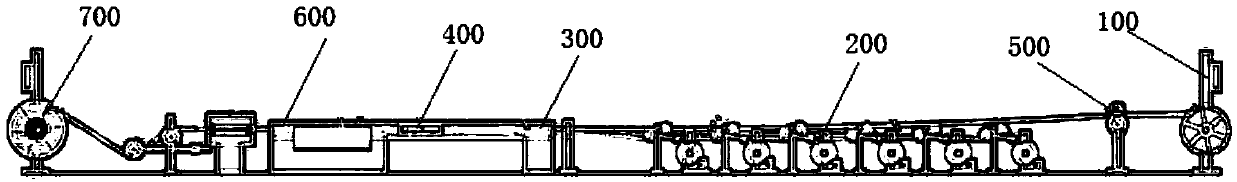

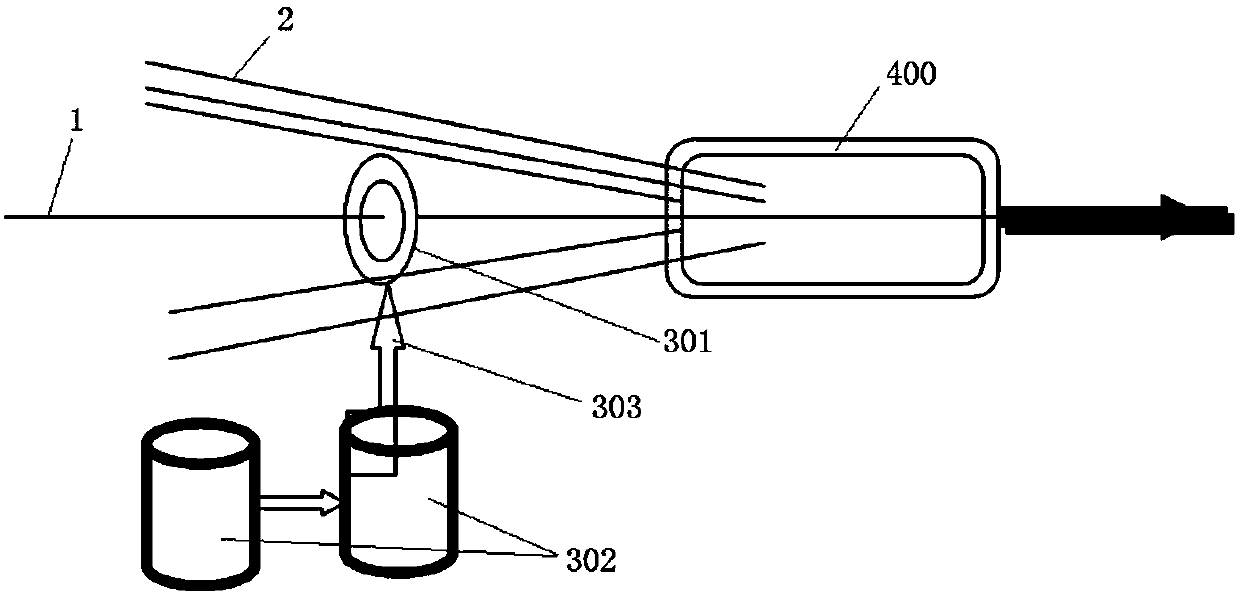

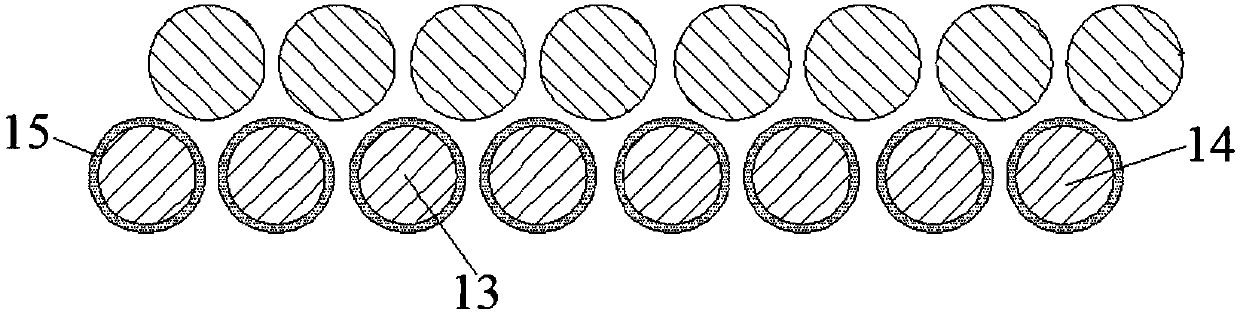

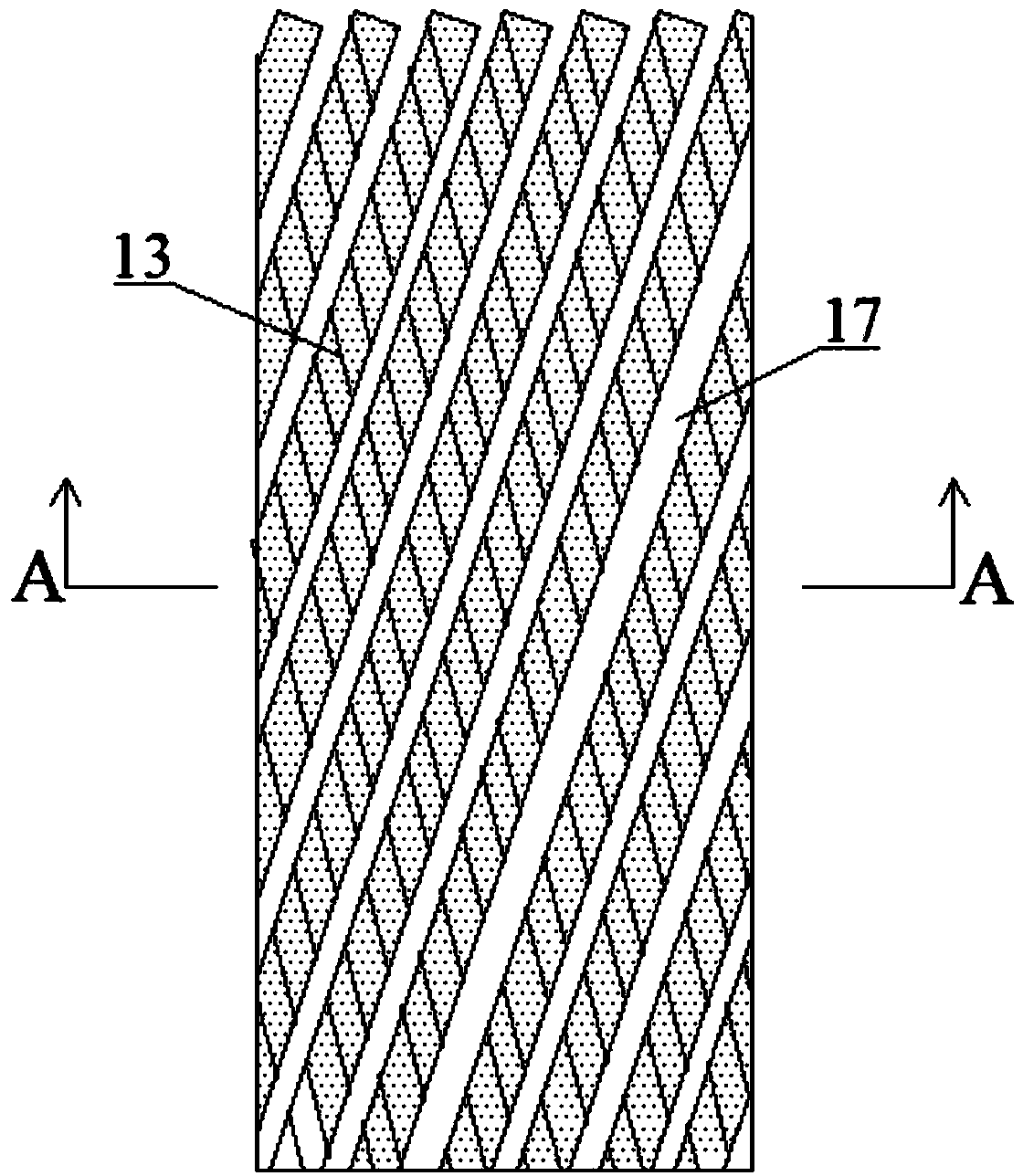

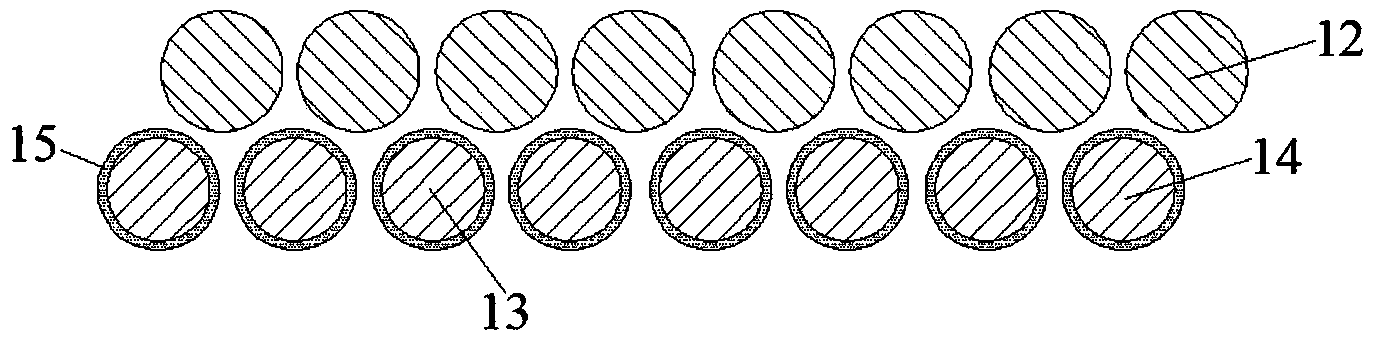

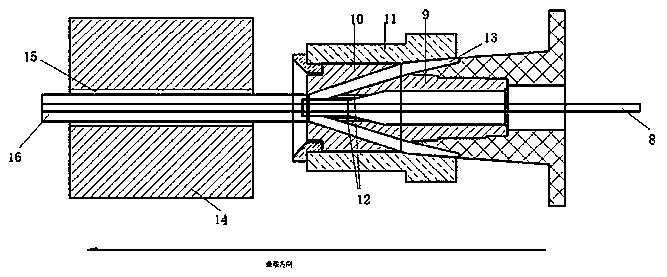

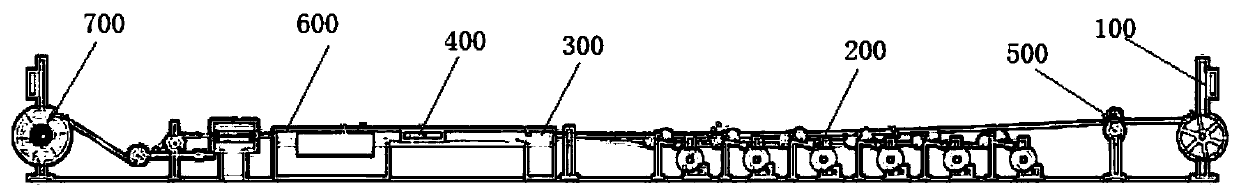

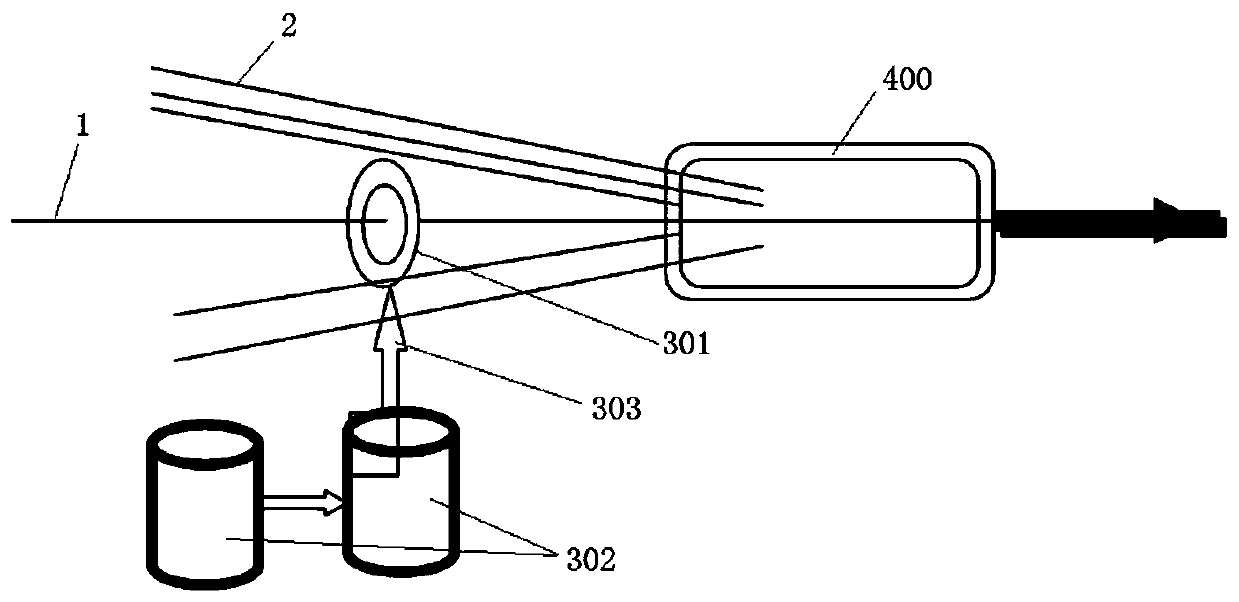

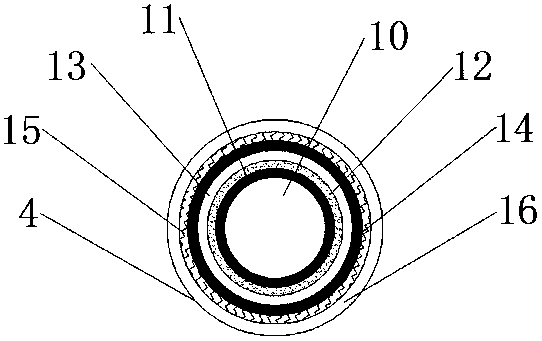

Loose-tube layer-stranding cable, and cable forming device and cable forming process thereof

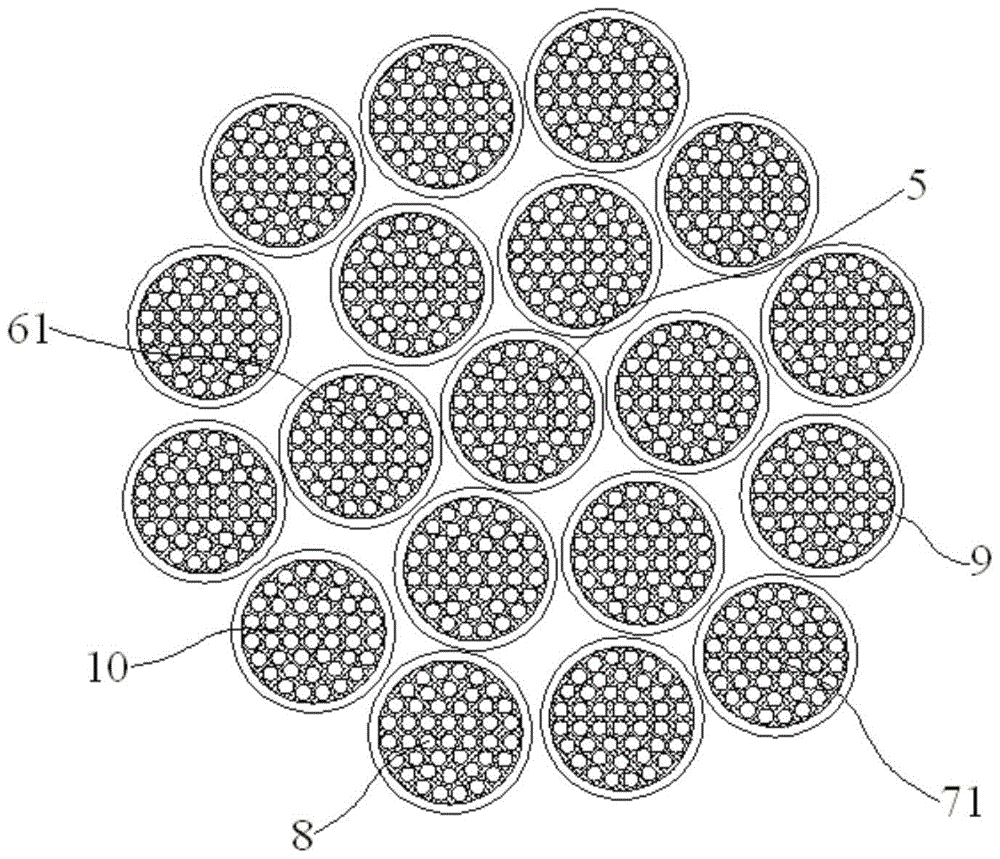

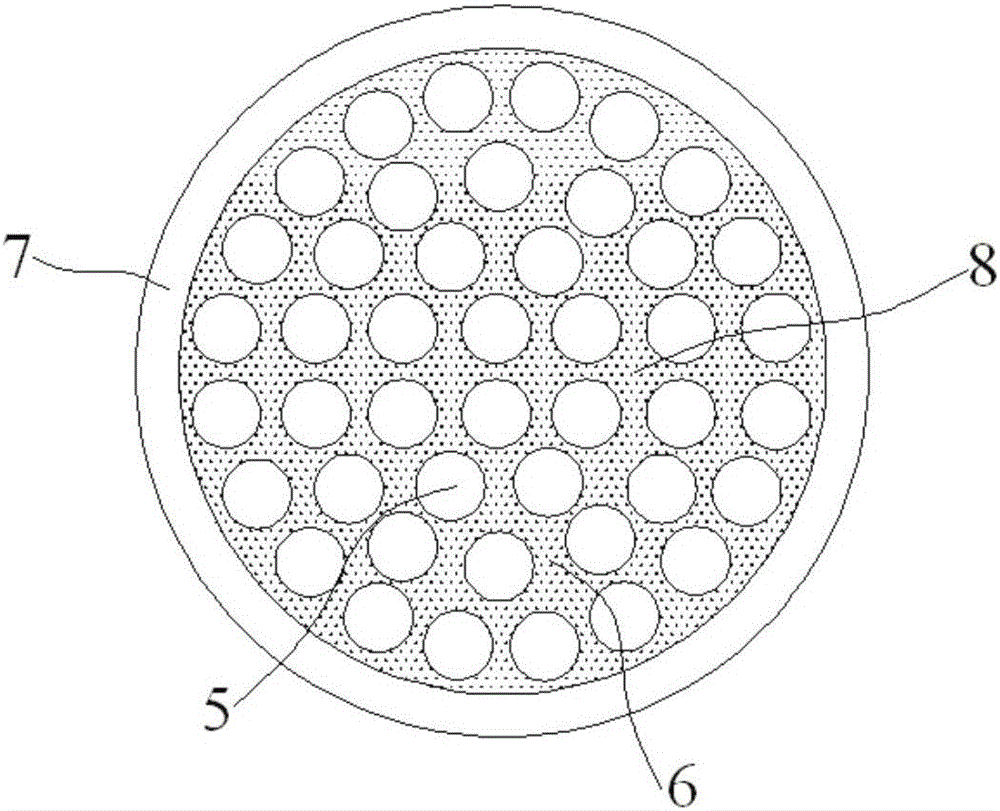

The invention discloses a loose-tube layer-stranding cable, and a cable forming device and a cable forming process thereof. The loose-tube layer-stranding cable comprises a center reinforcing unit member and a plurality of loose tubes evenly arranged on the periphery of the center reinforcing unit member. After glue is spread onto the surface of the center reinforcing unit member, the center reinforcing unit member and all the loose tubes are spliced together to be stranded. Dry-type waterproof materials are arranged between the center reinforcing unit member and the loose tubes. The loose-tube layer-stranding cable has the advantages that stability and other performance of a cable core structure can be guaranteed without yarn winding or through winding of one to two yarns, so that production efficiency is high, proneness to cable stripping is avoided, and product quality and yield can be increased.

Owner:SHANTOU HIGH TECH ZONE AOXING OPTICAL COMM EQUIP +1

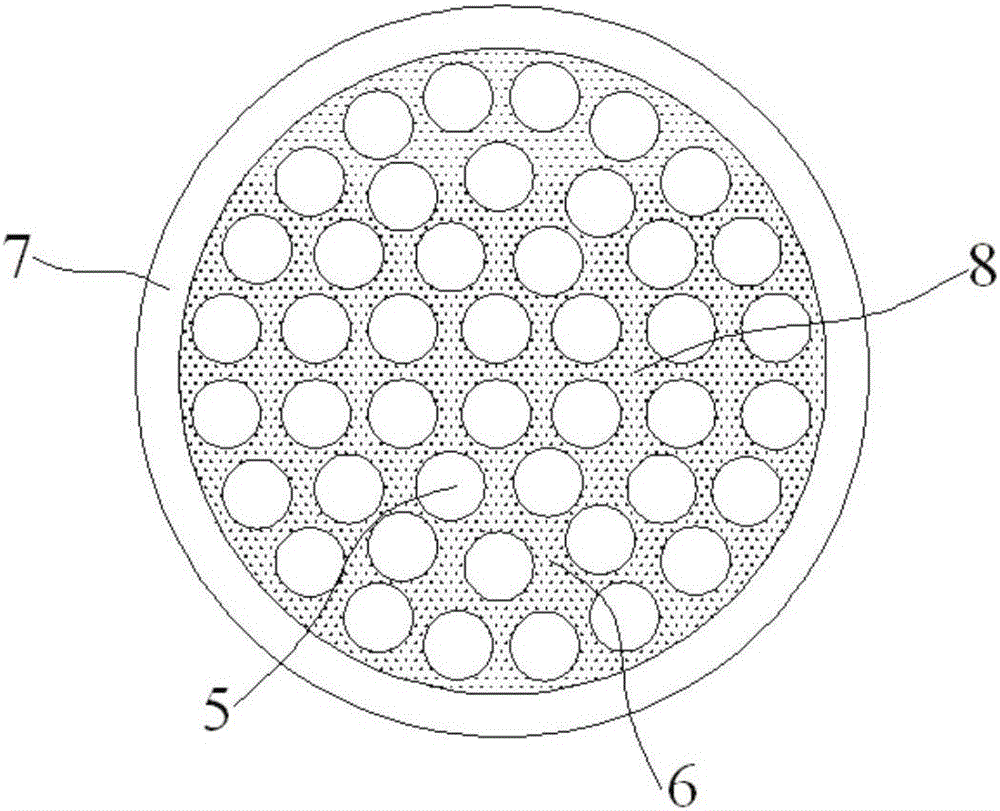

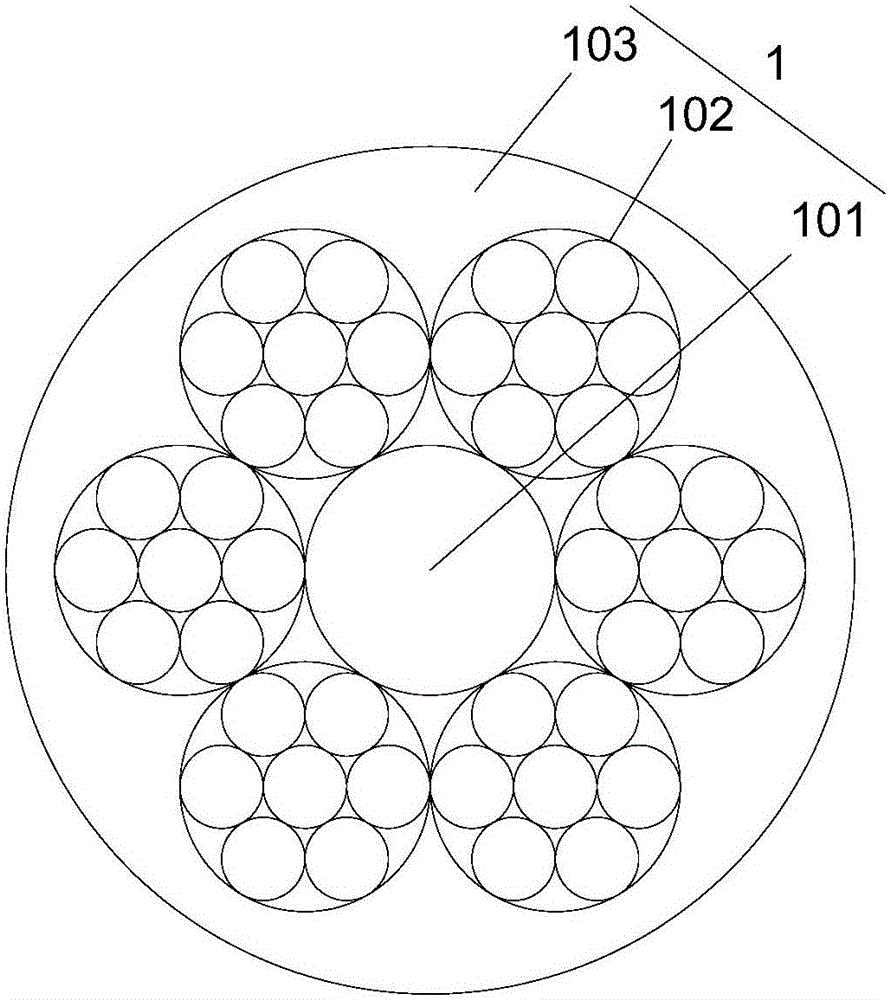

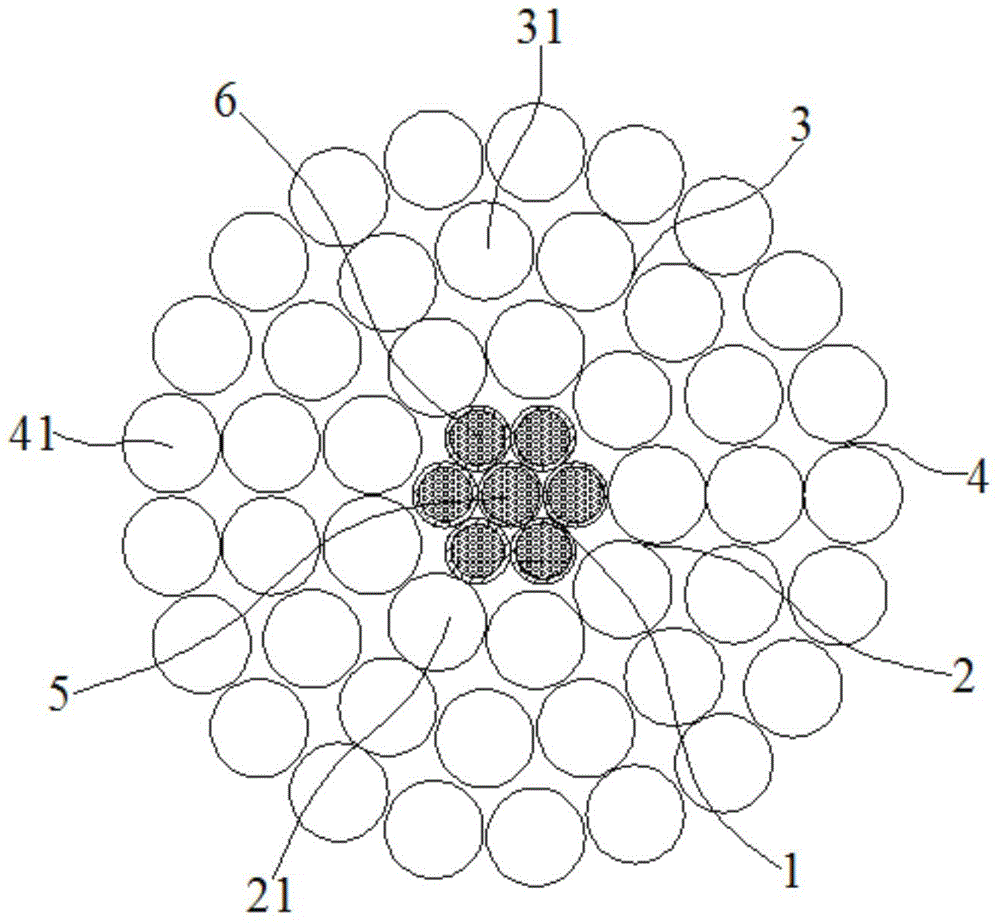

Tensile aluminum stranded wire for electric power transmission

ActiveCN104538101AAvoid damageAvoid defects caused by smoothnessNon-insulated conductorsPower cables with screens/conductive layersElectric power transmissionPolyester

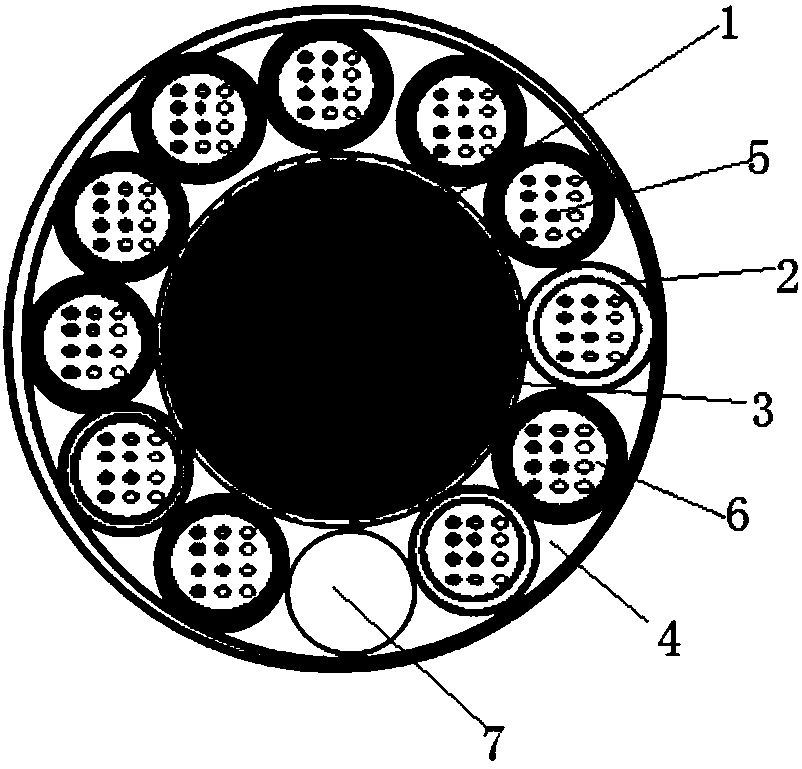

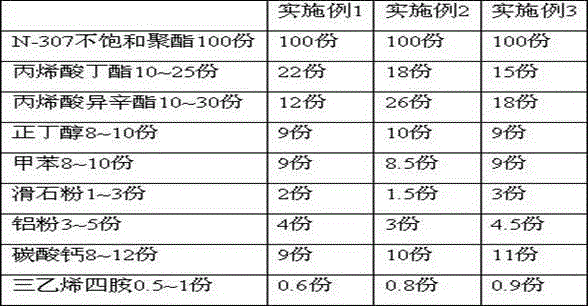

The invention discloses a tensile aluminum stranded wire for electric power transmission. The tensile aluminum stranded wire comprises a center stressed unit, a first aluminum alloy conducting layer and a second aluminum alloy conducting layer, wherein the first aluminum alloy conducting layer and the second aluminum alloy conducting layer are sequentially stranded on the outer surface of the stressed unit; an aluminum conductor wrapping layer is formed by stranding 19-21 Z-shaped aluminum alloy conductors with Z-shaped sections; the stressed unit comprises a first carbon fiber single wire located at the center and six second carbon fiber single wires stranded on the outer surface of the first carbon fiber single wire; the first carbon fiber single wire and each second carbon fiber single wire are each formed by stranding a plurality of carbon fiber precursors; a polyester adhesive filling part is formed by mixing a first component and a second component, and the first component is composed of, by weight, N-307 unsaturated polyester, butyl acrylate, 2-ethylhexyl acrylate, n-butyl alcohol, methylbenzene, talcum powder, aluminum powder, calcium carbonate and triethylene tetramine. It is guaranteed that the carbon fiber precursors in the aluminum layers are round and normal, damage of the aluminum layers in subsequent use is avoided, reliability of electrical property is guaranteed, and the bending radius is lowered to be six times the diameter of a cable.

Owner:JIANGSU HENGTONG ELECTRICAL SPECIAL WIRE CO LTD +1

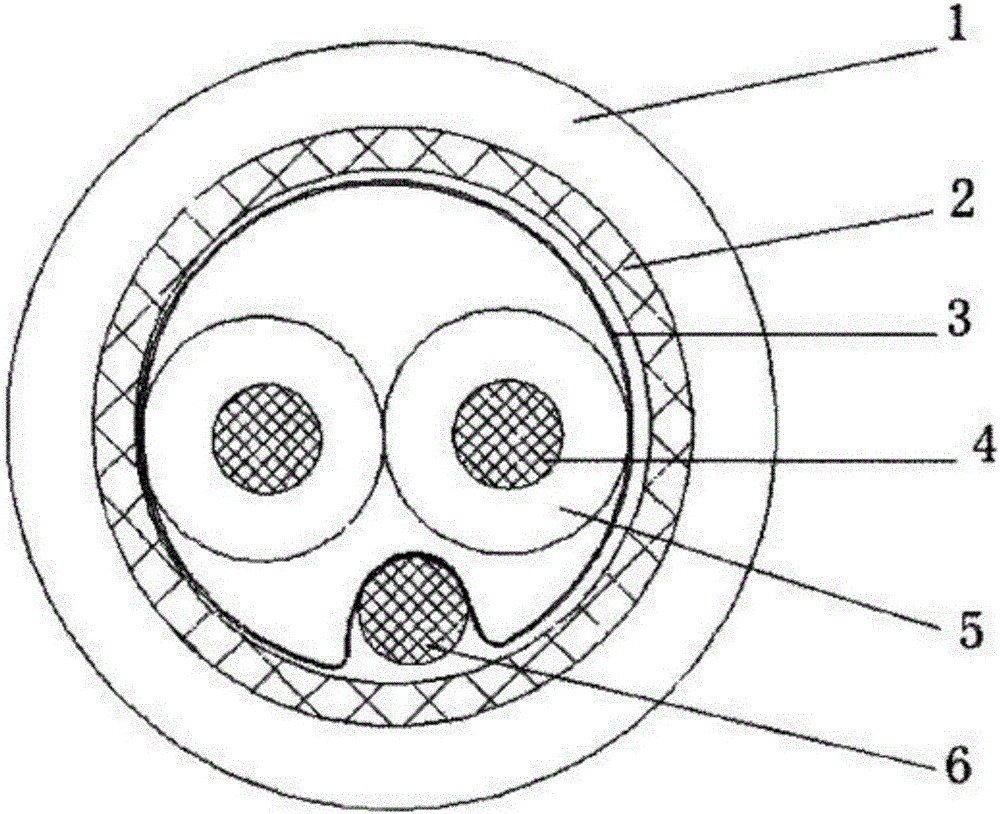

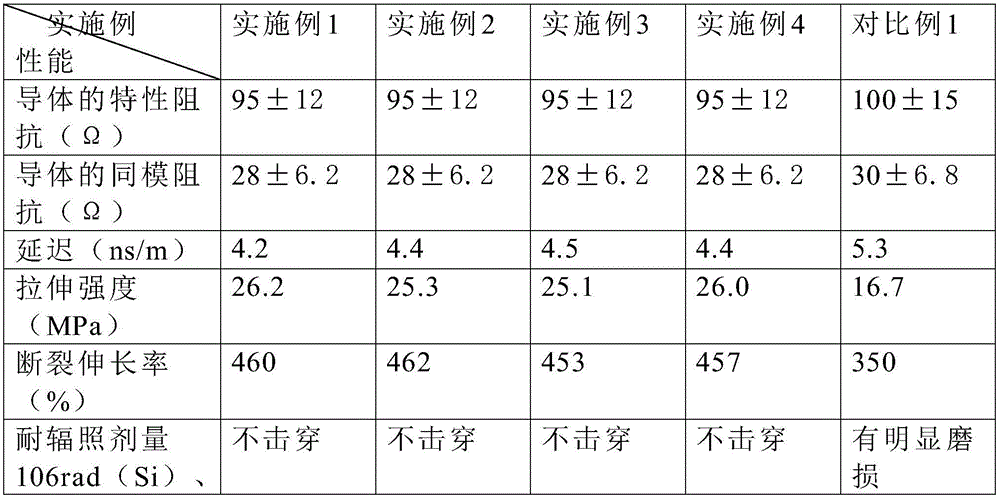

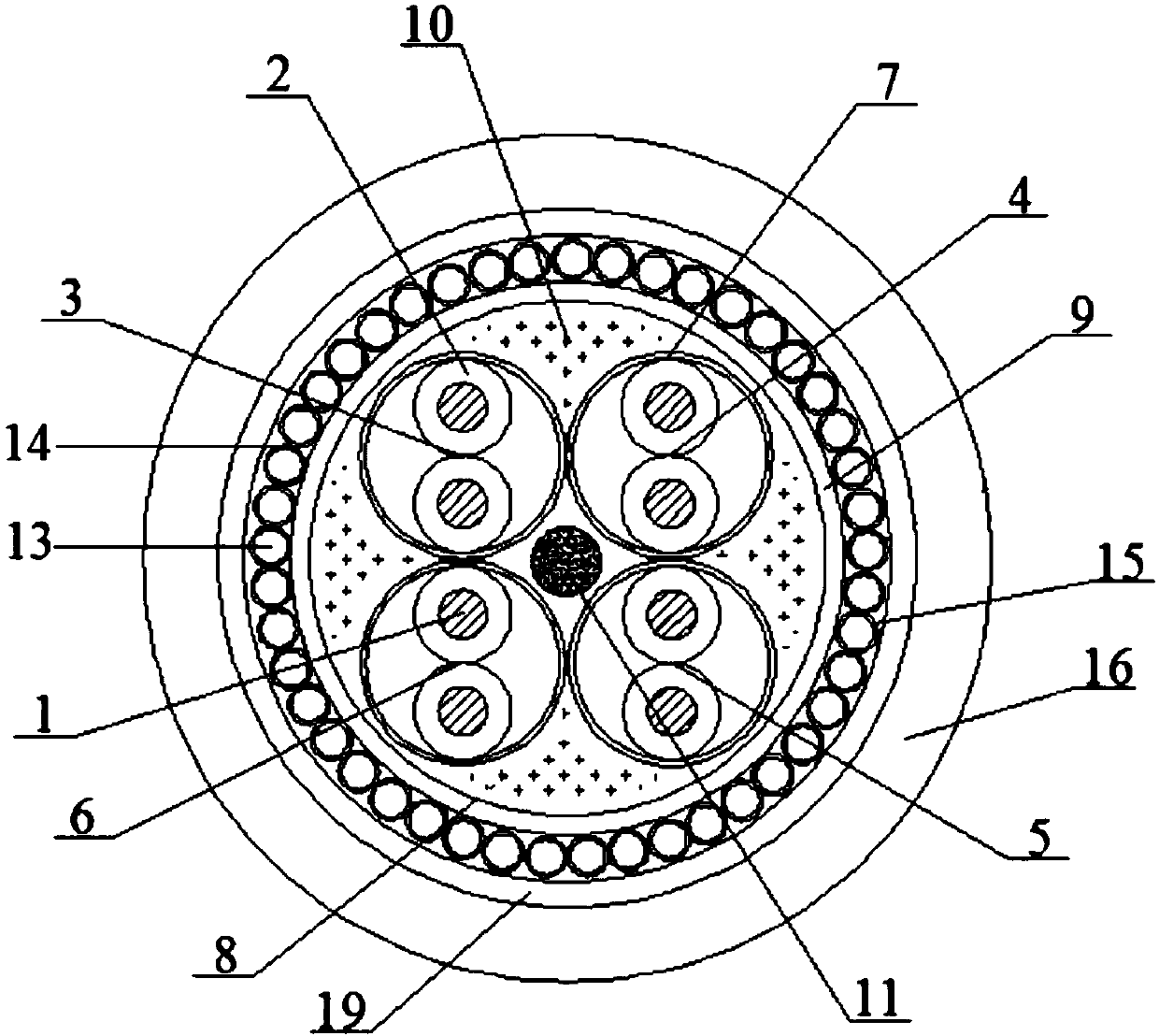

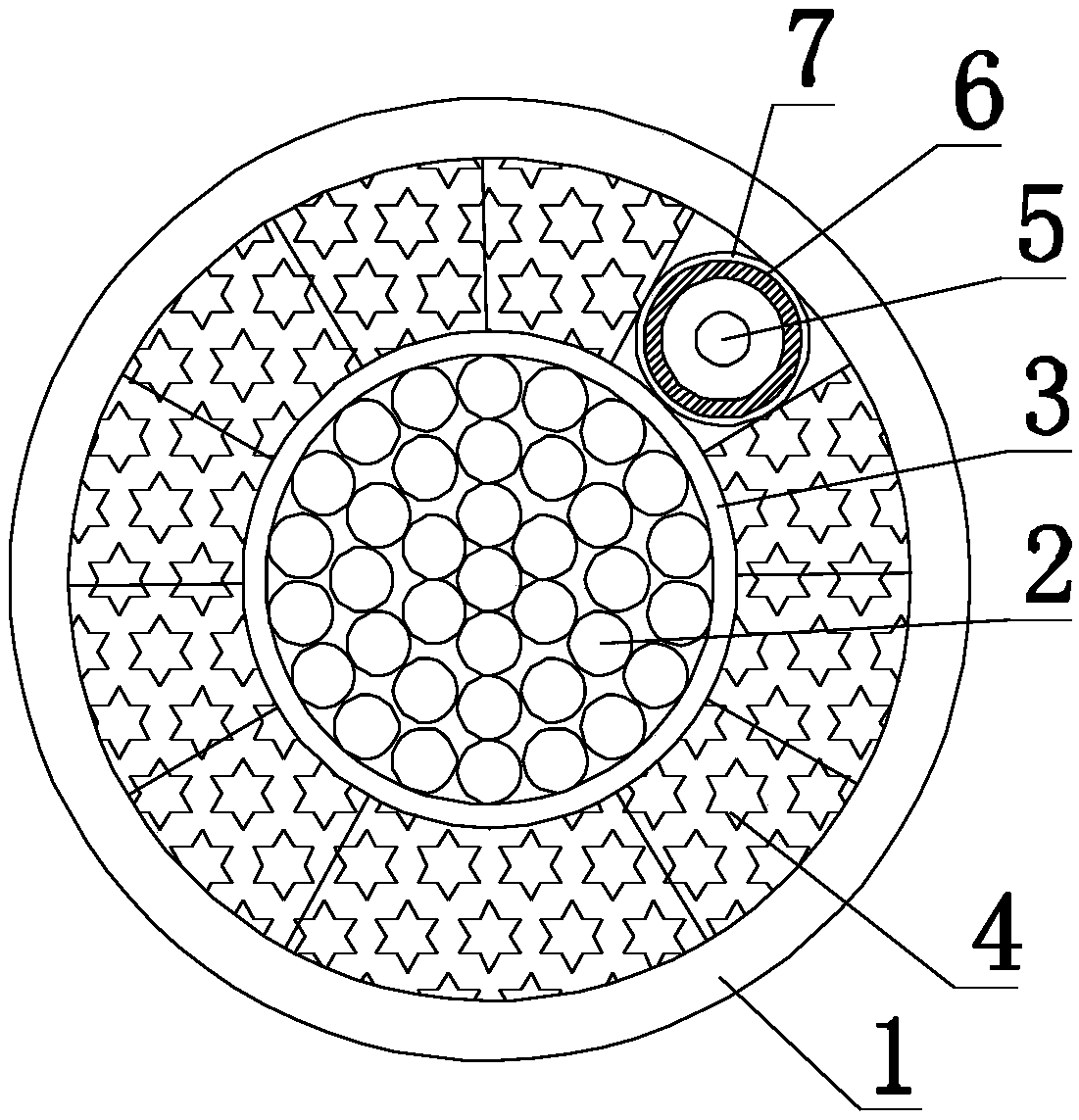

LVDS cable for automobile wire

InactiveCN105845262AGuaranteed to be roundNot easily deformedInsulated cablesCommunication cablesEngineeringElectrical conductor

The invention relates to an LVDS cable for an automobile wire. The LVDS cable comprises a sheath layer, a braided fabric layer, an aluminum foil layer, a conductor and a ground wire, wherein the conductor is wrapped by using an insulating layer, the aluminum foil layer wraps the insulation layer, the ground wire is clamped between the aluminum foil layer and the braided fabric layer, and the sheath layer wraps the braided fabric layer; the thickness of the sheath layer ranges from 0.6 to 0.8mm, the thickness of the braided fabric layer from 0.3 to 0.5mm, and the thickness of the insulating layer ranges from 0.4 to 0.7mm; and the aluminum foil material of the aluminum foil layer comprises the following components by weight percentage: 0.05-0.20% of Si, 0.02-0.08% of Fe, 0.10-0.30% of Cu, 0.70-1.20% of Mn, 0.02-0.04% of Mg, 0.002-0.008% of Zn, 0.02-0.05% of Ti, 0.001-0.05% of B, 0.02-0.05% of Y, 0.02-0.05% of Ce, and the balance being Al and inevitable impurities. The layers in the LVDS cable for the automobile wire are manufactured by adopting specific materials reasonable in compatibility, comprehensive performance of the cable is further improved, especially the strength of the cable is increased, thus loss in signal transmission is low, and anti-interference capability is high.

Owner:NINGBO KBE ELECTRICAL TECH

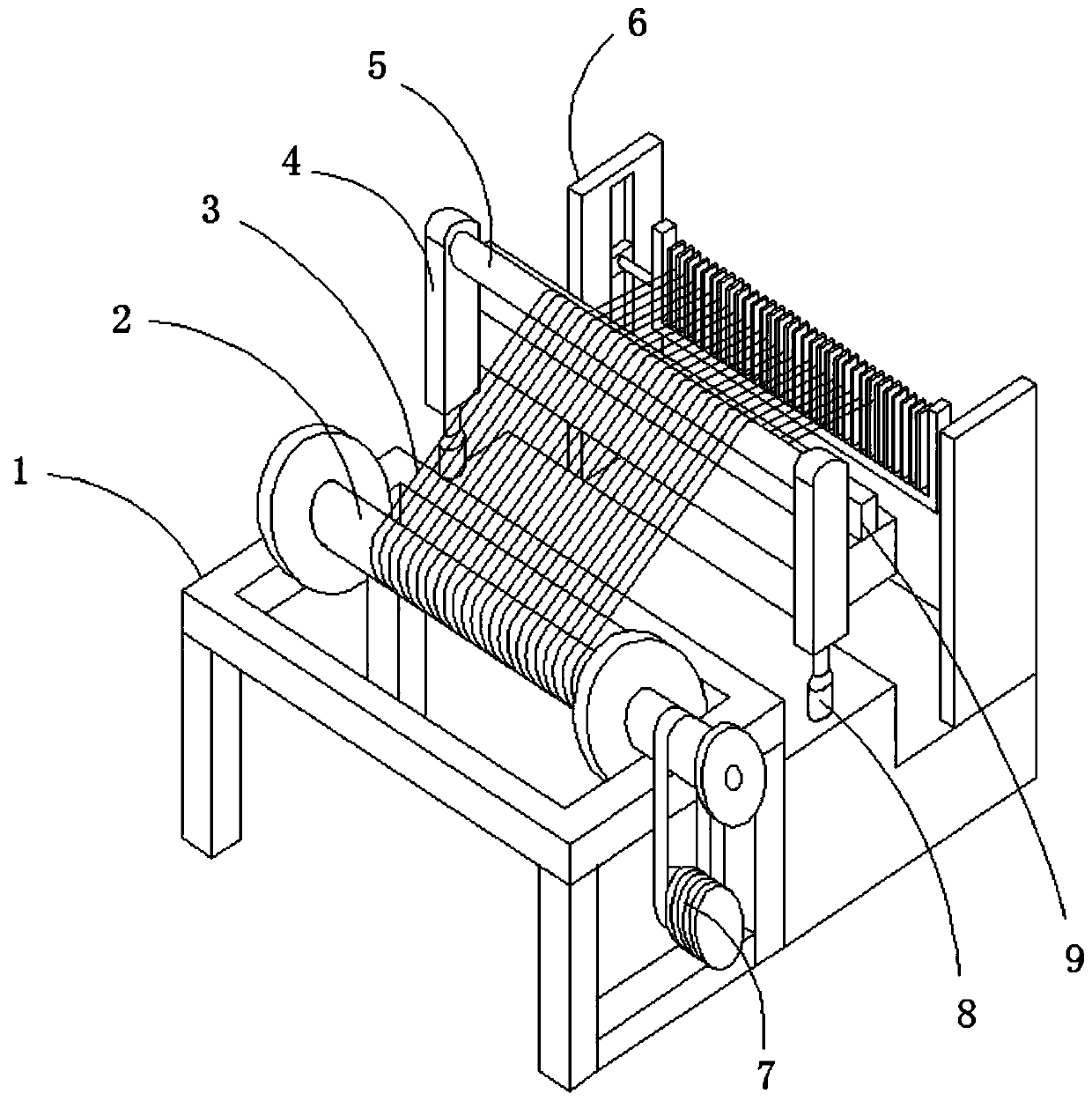

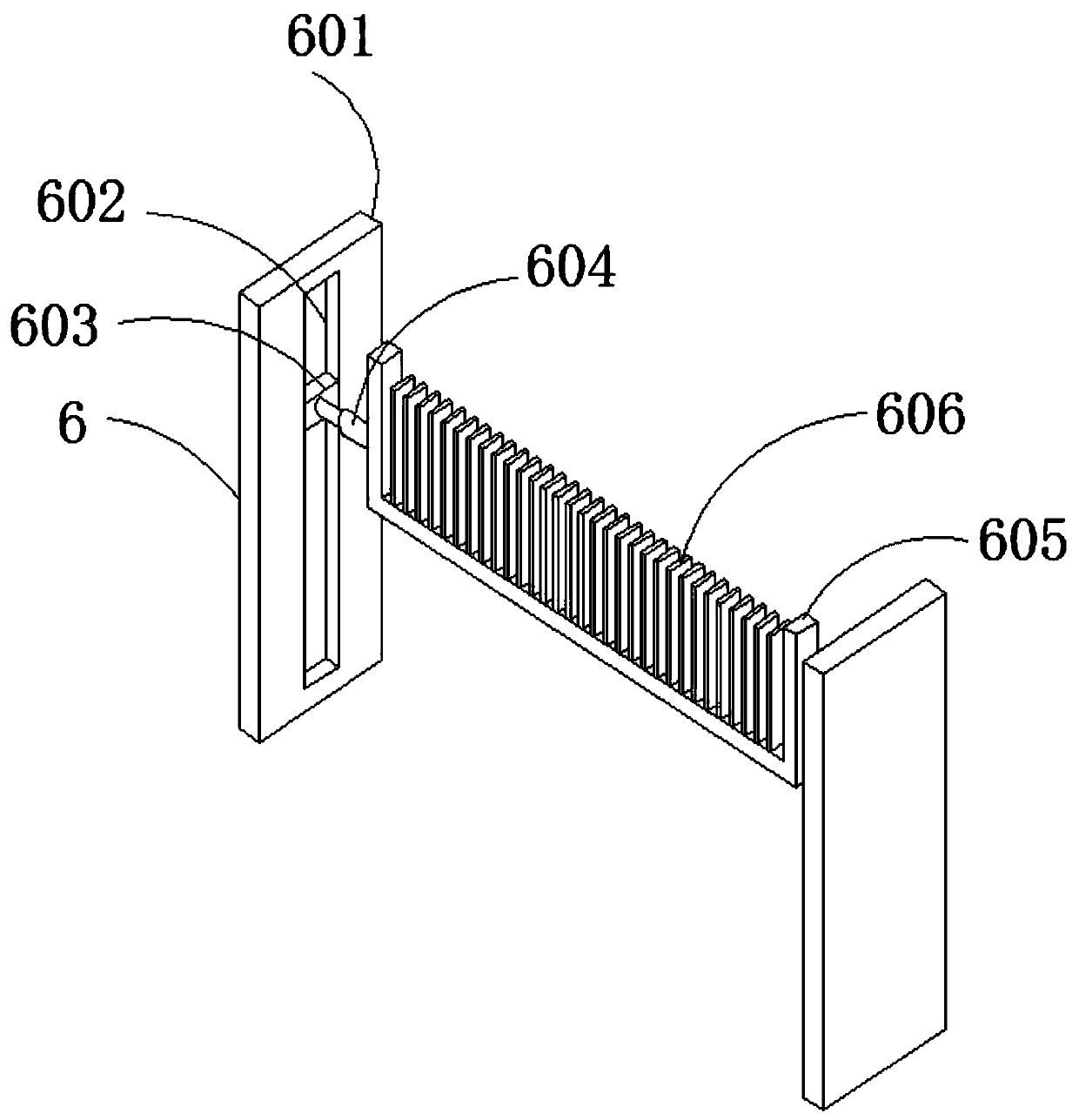

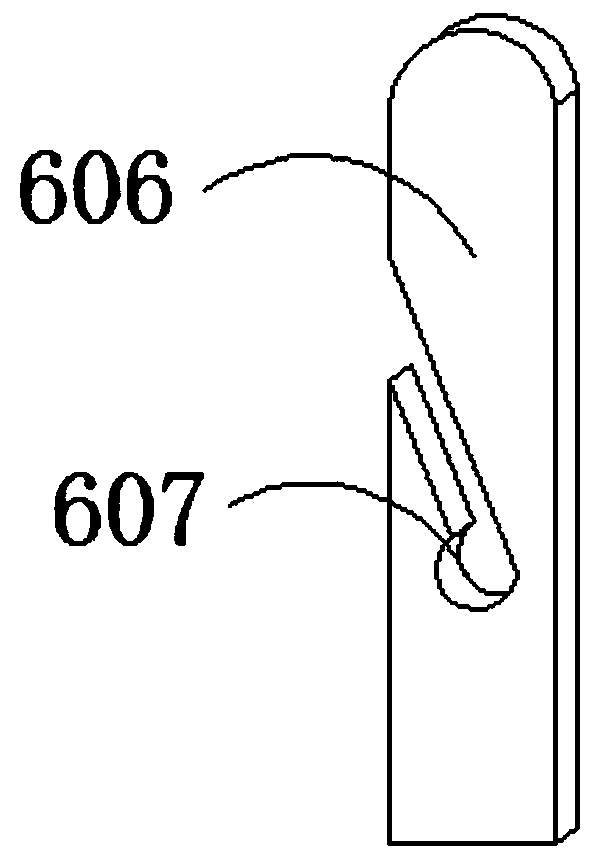

Telescopic reed device of warping machine for screen processing

InactiveCN110565227AAdjustable tensionGuaranteed to be roundWarping machinesOther manufacturing equipments/toolsYarnElectric machinery

The invention provides a telescopic reed device of a warping machine for screen processing and relates to the field of warping machines. The telescopic reed device of the warping machine for screen processing includes a fixed base, a yarn cylinder, a threading mechanism and a telescopic reed mechanism, wherein the yarn cylinder is arranged on one side of the top of the fixed base, one side of theyarn cylinder is in transmission connection with a driving motor through a belt, and the driving motor is fixed to the bottom of the fixed base. According to the telescopic reed device of the warpingmachine for screen processing, the yarn cylinder, a supporting shaft, a telescopic reed mechanism and a limiting baffle plate are successively arranged, hydraulic telescopic rods at the bottom of supporting rods can adjust the height of the supporting shaft so that the tension of yarns can be adjusted, and the telescopic reed mechanism is provided with multiple angle-adjustable reed plates so thatthe spacing between yarn and yarn can be adjusted and accordingly the yarns for threading can be aligned one by one; through the setting above, not only the tension of the yarns can be adjusted up and down, but also the spacing of the yarns can be adjusted left and right, so that the yarns can be evenly and parallelly wound on the shaft without embedding each other so as to ensure the roundness of the shaft surface.

Owner:安徽省兰飞化纤织造有限公司

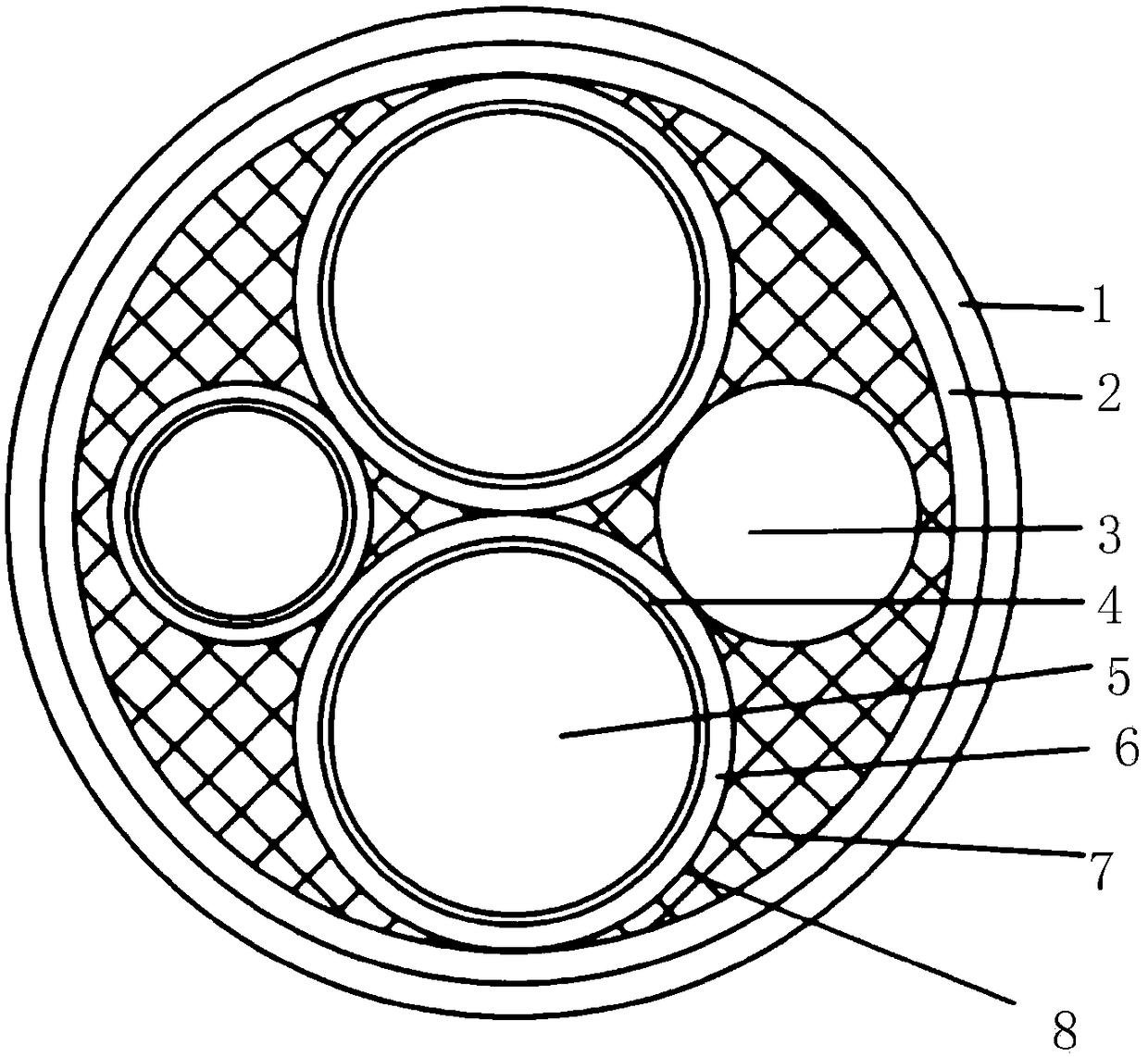

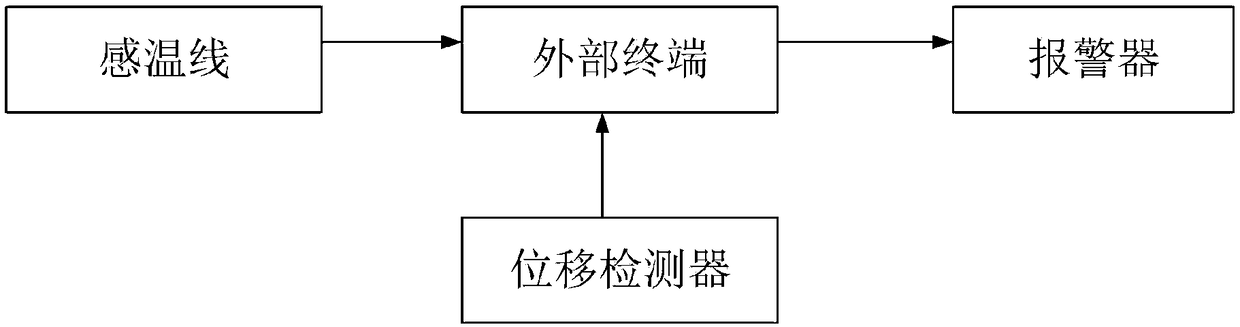

Anti-corrosion seawater cable, production method and detection method thereof

InactiveCN109344359AAvoid wear and tearImprove seawater corrosion resistanceMeasurement devicesCommunication cablesElectrical conductorMicrobial corrosion

The invention belongs to the field of cable production and discloses an anti-corrosion seawater cable, a production method and a detection method thereof. The detection method includes such step as setting an anticorrosion layer inside that anticorrosion layer, tightly sleeve a waterproof corrosion layer inside the anticorrosion layer, sleeving a temperature sensing wire and a metal conductor inside the waterproof corrosion layer, and setting the temperature sensing wire and the metal conductor inside the anticorrosion layer to obtain anticorrosion cable. The inside of the metal conductor is ametal conductor, and the outside of the metal conductor is tightly wrapped with an insulating layer. The anti-seawater corrosion cable provided by the invention has high tear resistance and fatigue resistance, and can prevent abrasion of the cable and corrosion by microorganisms. The utility model has the seawater corrosion resistance, greatly improves the seawater corrosion resistance of the cable, prolongs the effective period of the seawater corrosion protection, and avoids the loss caused by the failure of timely maintenance by utilizing the principle of Seebeck effect and real-time monitoring the temperature change correspondence of the cable through the set temperature sensing line.

Owner:HAINAN UNIVERSITY

Black bean identification method based on thin-layer chromatography

ActiveCN109917067AGuaranteed to be roundImprove one-time success rateComponent separationThin layerSilica gel

The invention provides a black bean identification method based on thin-layer chromatography. The black bean identification method comprises the following steps: preparing a test solution; preparing amedicinal material control solution; performing thin-layer chromatography; respectively sucking the test solution and the medicinal material control solution and performing sample application on thesame silica gel G thin-layer plate; placing the silica gel G thin-layer plate subjected to sample application in steam of a developing agent for pre-saturation, then placing the silica gel G thin-layer plate in the developing agent for developing, taking out the silica gel G thin-layer plate after developing, airing, heating the aired silica gel G thin-layer plate at the temperature of not lower than 100 DEG C, and then inspecting, so as to obtain the silica gel G thin-layer plate, wherein the developing agent is a mixture of toluene, methanol and formic acid. Compared with the prior art, thedevelopment frequency of black bean thin layer identification is reduced to one time from average 3.3 times traditionally, namely, clear chromatography can be obtained through one-time sample application, one-time development and one-time inspection, the one-time success rate of black bean thin layer identification is remarkably improved, and the requirement on black bean identification efficiencyin actual production is met.

Owner:GUANGZHOU BAIYUNSHAN ZHONGYI PHARMA COMPANY

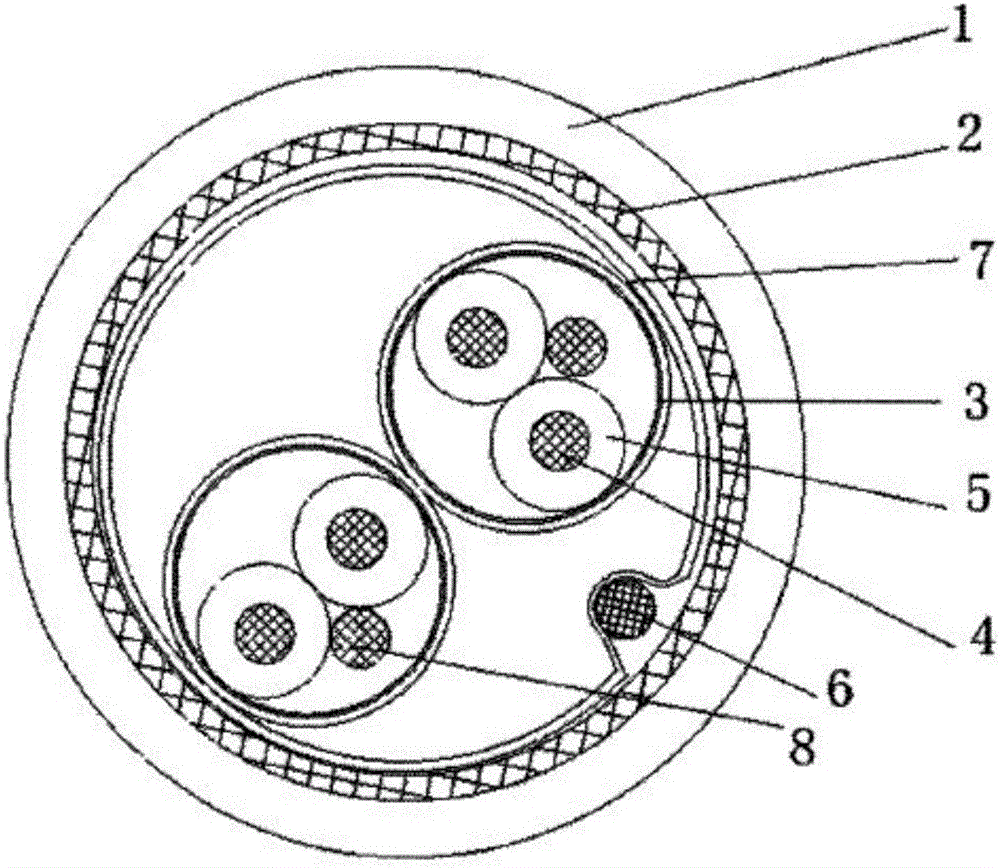

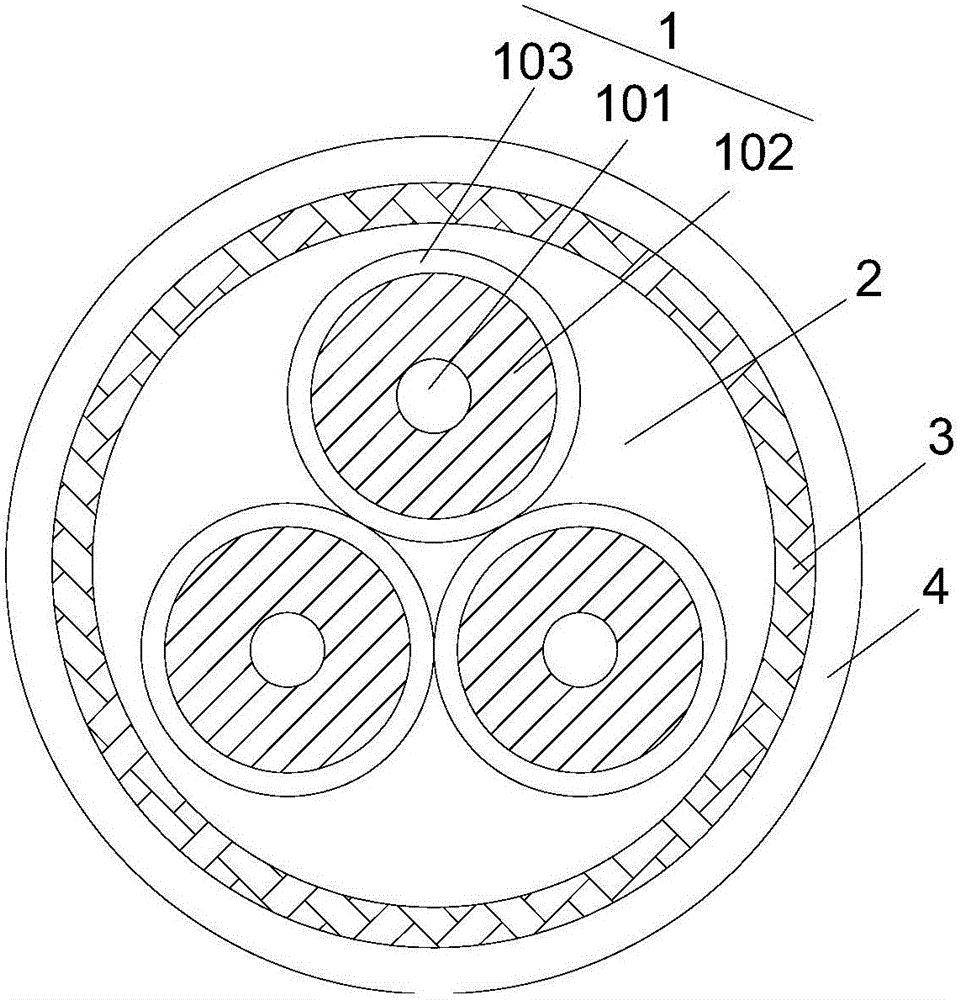

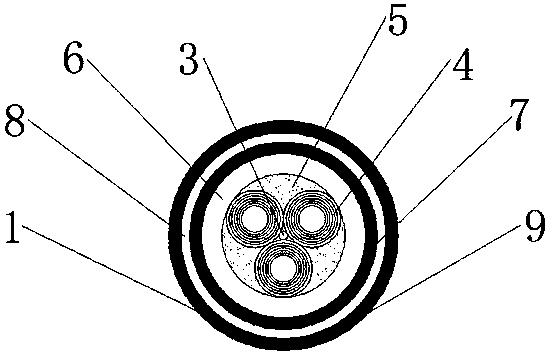

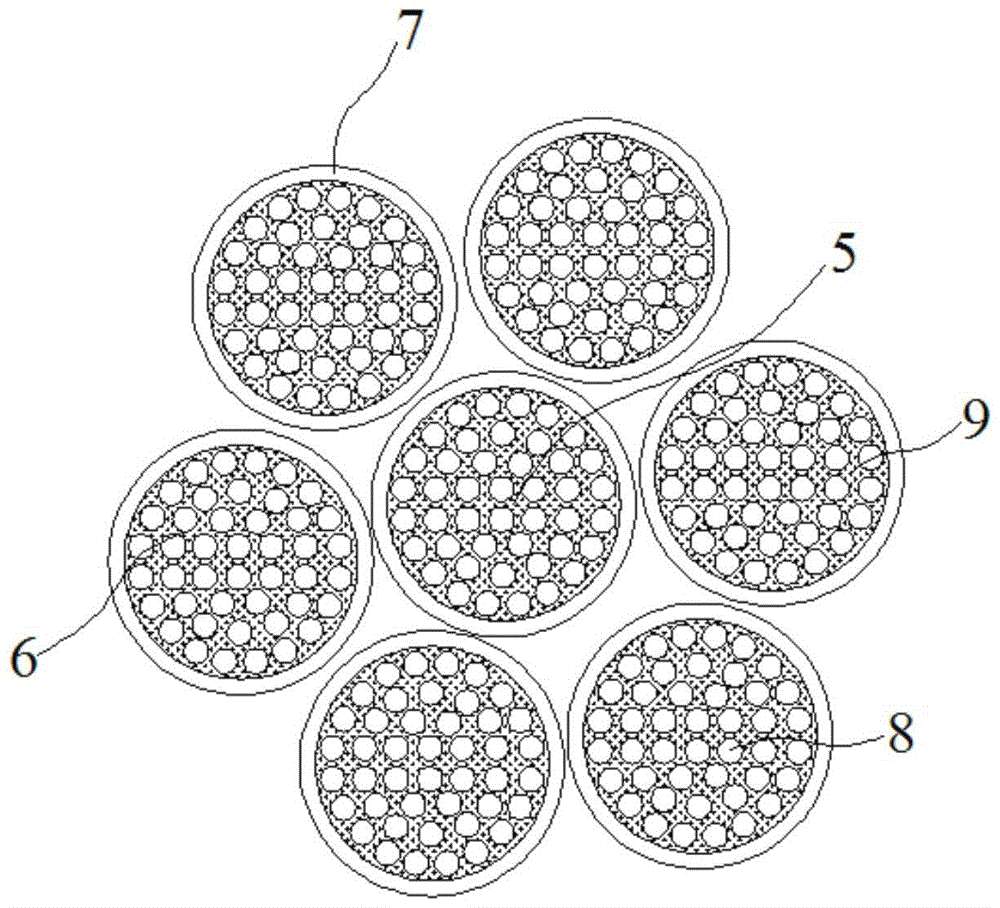

Environment-friendly cable for automobile charging pile

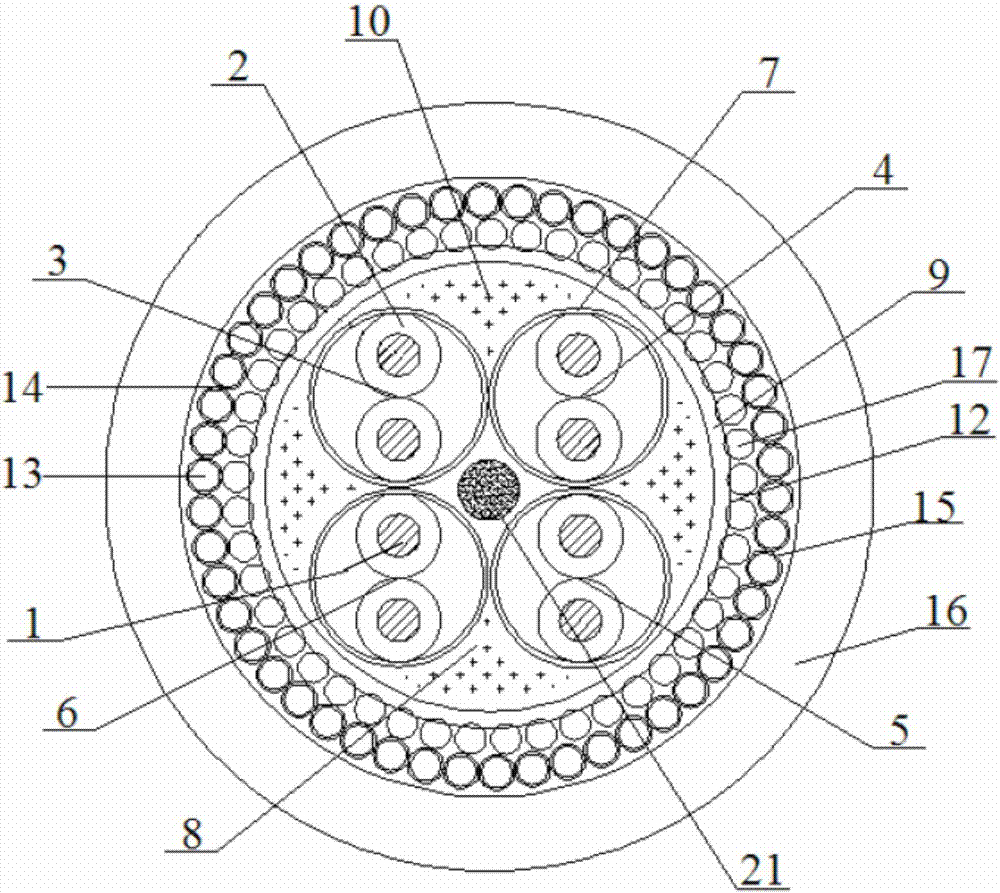

InactiveCN105761787AGood softnessImprove stress resistanceConductive materialDetails of conductive coresCopper wireEngineering

The invention discloses an environment-friendly cable for an automobile charging pile. A cable core is formed by regularly twisting a plurality of power core wires and a control core wire, flexibility of the cable and roundness of the cable core are guaranteed, and both a first conductor and a second conductor are formed by stranding tinned copper wires, thereby enabling the conductors to achieve excellent flexibility and roundness, and improving an anti-pressure capability of the cable; a first insulating layer, a second insulating layer, a main sheath layer and a sub sheath layer adopt irradiation insulating materials, thereby ensuring that the cable has the characteristics of flexibility, oil resistance, alkali resistance, ultraviolet resistance, wear resistance, cracking resistance and the like; and the sheath is extruded outside the cable core, thereby ensuring compactness of a cross section of the cable, and enabling the cable to have excellent anti-rolling performance.

Owner:安徽华海特种电缆集团有限公司

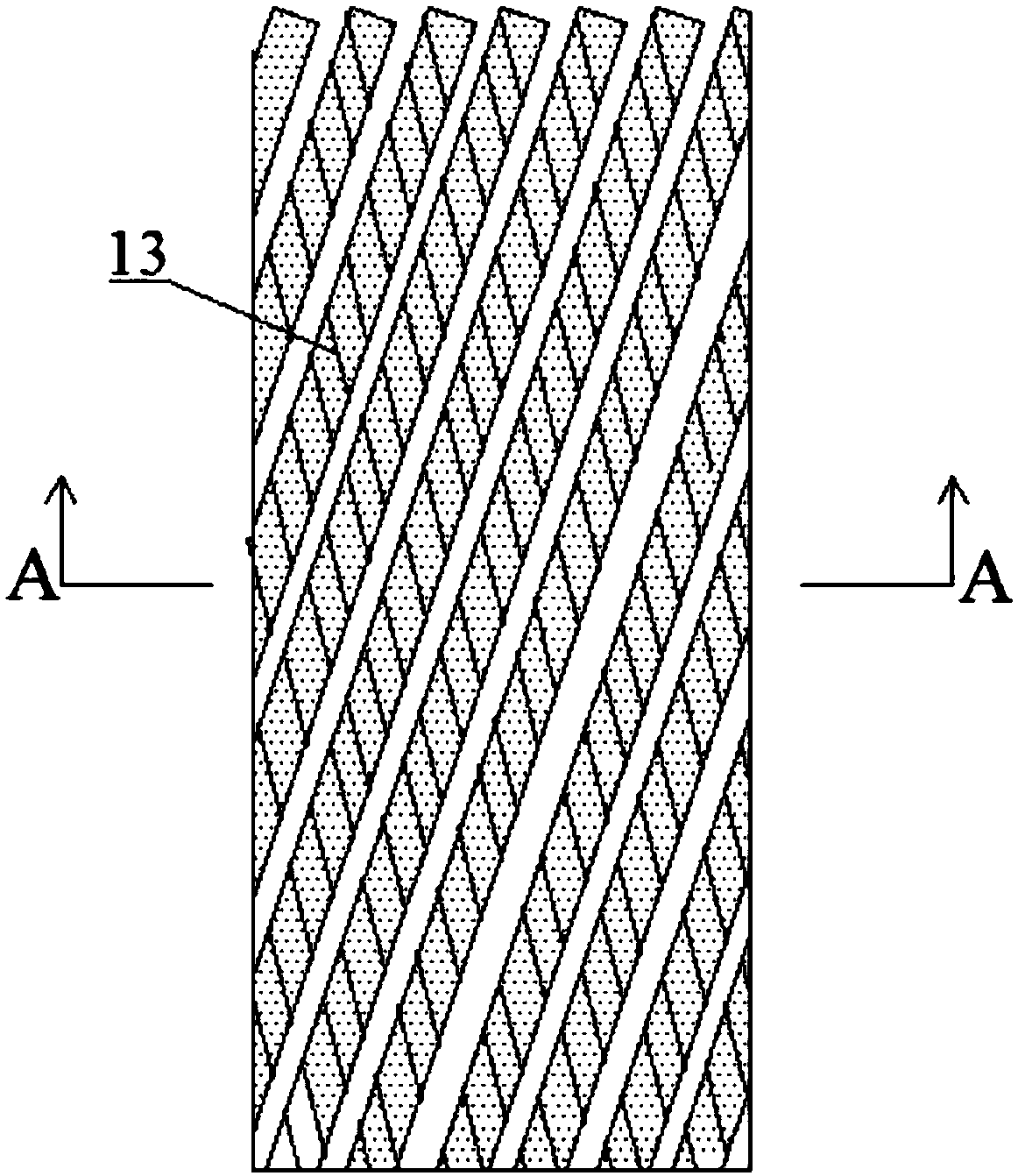

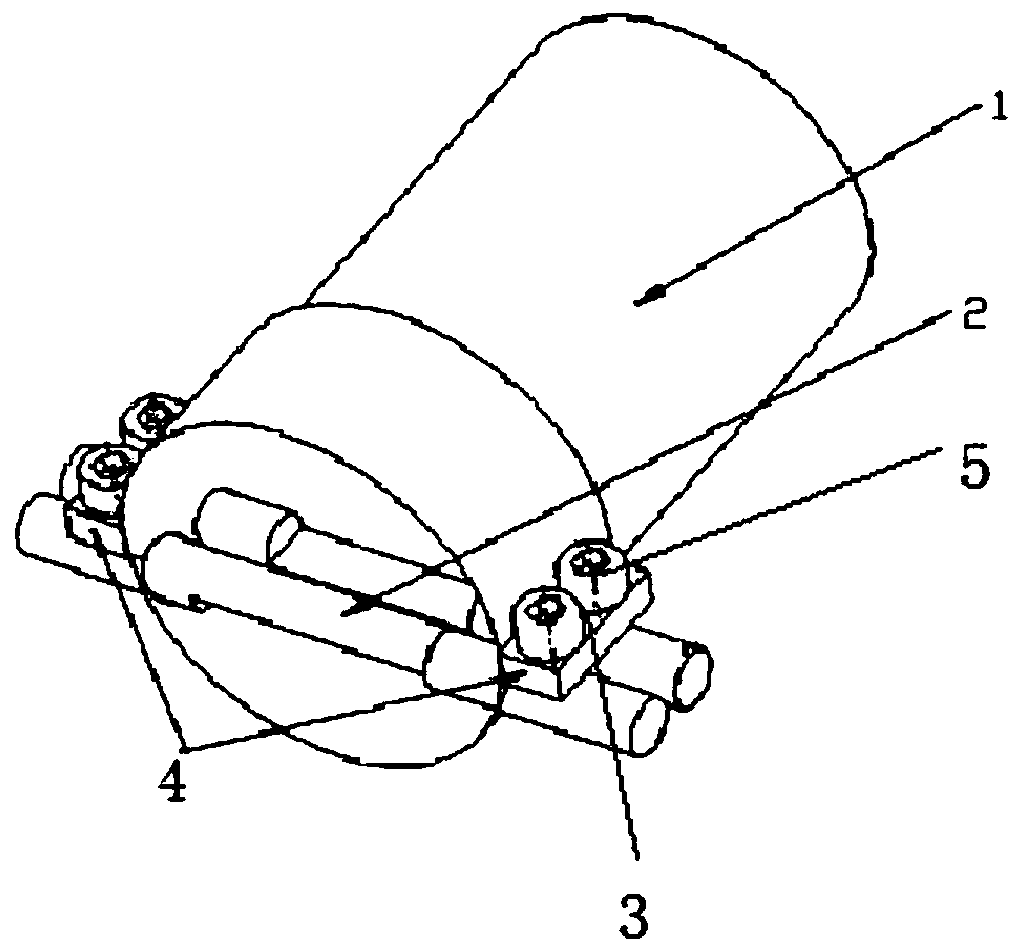

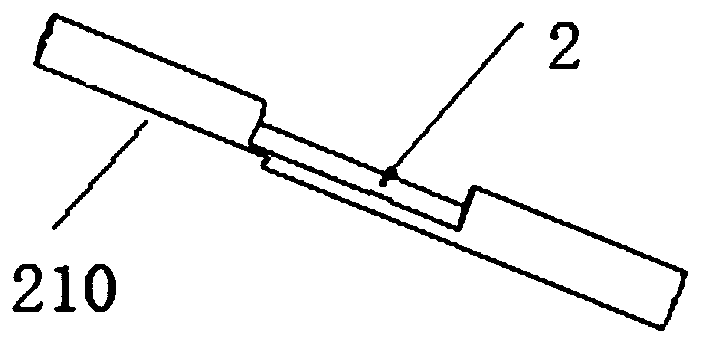

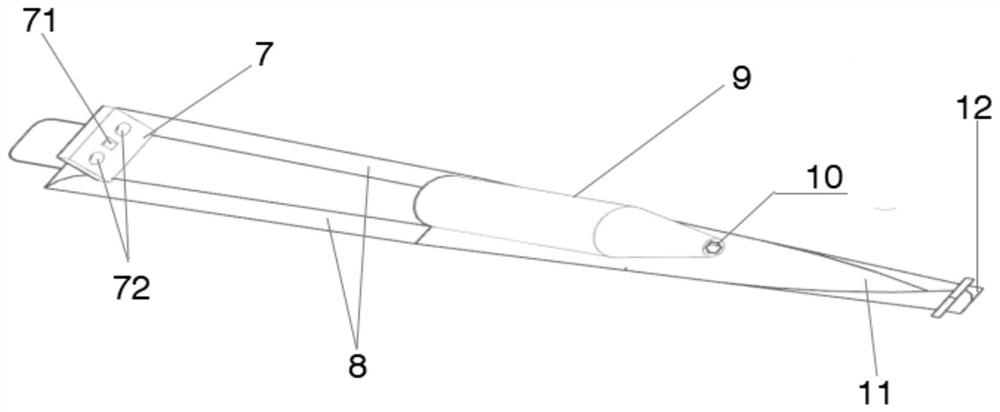

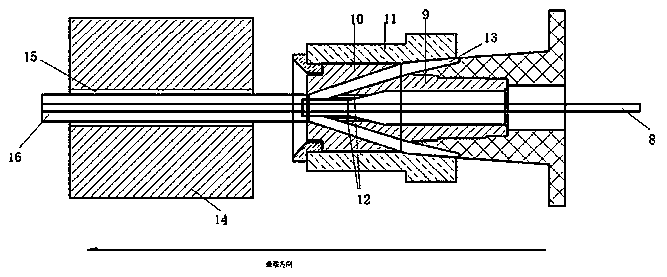

Longitudinal wrap assisting device for water-blocking tape

ActiveCN107991746AGuaranteed to be roundFormlessFibre mechanical structuresLocking mechanismWater block

The invention relates to a longitudinal wrap assisting device for a water-blocking tape. The longitudinal wrap assisting device comprises a barrel-shaped base, two water-blocking tape width regulationrods and locking mechanisms, wherein one end of the barrel-shaped base is connected with an optical cable preforming mold; the locking mechanisms are fixed on the barrel-shaped base; the two water-blocking tape width regulation rods are fixed at the other end of the barrel-shaped base sequentially in the axial direction of the barrel-shaped base through the locking mechanisms; each water-blockingtape width regulation rod is provided with an opening, the two openings are opposite in the radial direction of the barrel-shaped base, and the two openings are partially overlapped in the axial direction of the barrel-shaped base. When the longitudinal wrap assisting device for the water-blocking tape is used for cable production, roundness of a longitudinal wrap can be guaranteed, no water seepage channel is formed, and qualification rate of produced optical cables, especially GYTA53 optical cables is high.

Owner:TONGDING INTERCONNECTION INFORMATION CO LTD

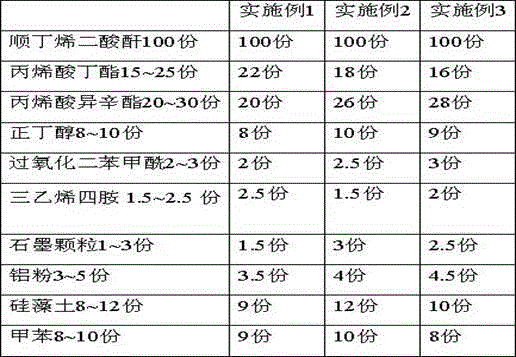

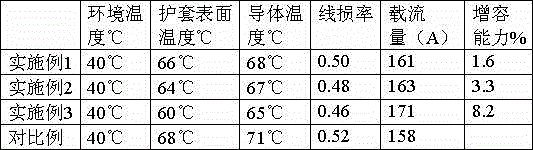

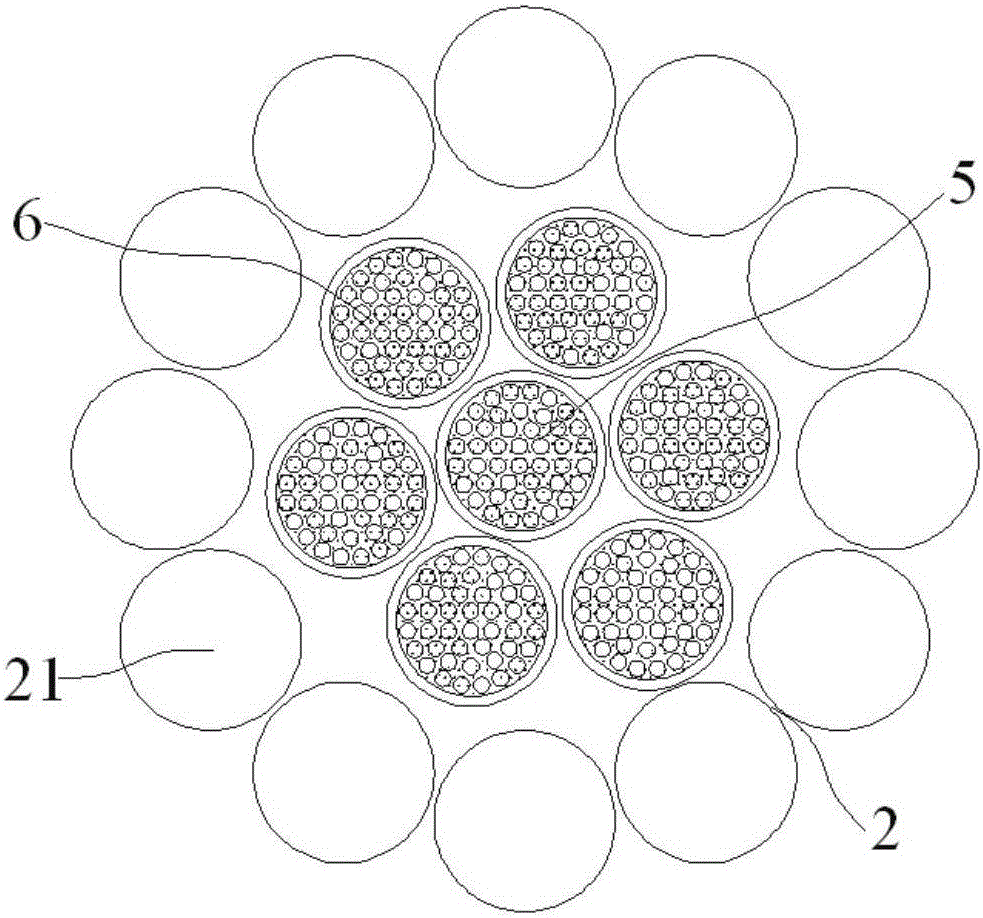

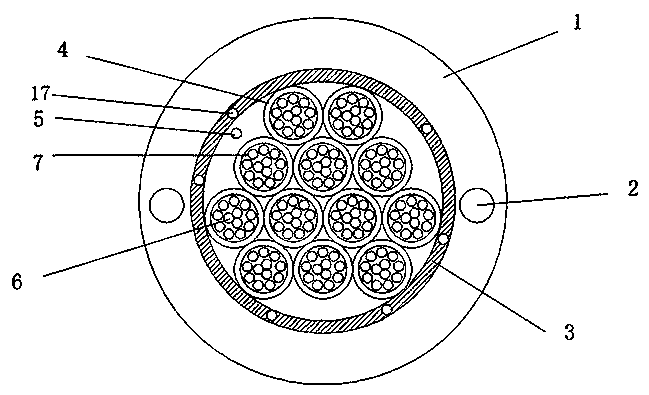

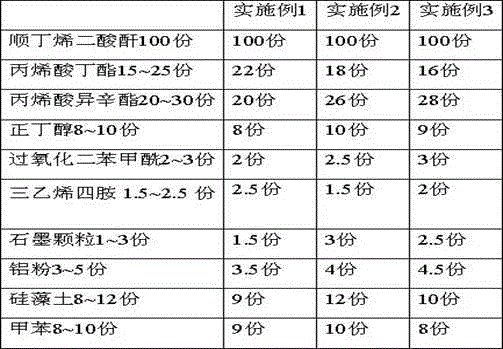

Flexible cable for communication power supply

InactiveCN105047263AExtended service lifePrevent defects caused by smoothnessNon-insulated conductorsFlexible cablesIsooctyl acrylateFiber

The invention discloses a flexible cable for a communication power supply. The flexible cable comprises a circular high-intensity carbon fiber core, Z-shaped conductors are twisted at the external surface of the circular high-intensity carbon fiber core and form an inner conducting layer, trapezoidal conductors are twisted at the external surface of the inner conducting layer and form an outer conducting layer, a polyethylene insulating tape wraps the external surface of the outer conducting layer, a halogen-free polyolefin elastomer insulating layer wraps the external surface of the polyethylene insulating tape, and an adhesive filling portion is arranged in an aluminum alloy layer and placed among carbon fibers. The adhesive filling portion is composed of 100 parts of maleic anhydride, 15-20 parts of butyl acrylate monomer, 20-30 parts of isooctyl acrylate, 8-10 parts of n butanol, 2-3 parts of dibenzoyl peroxide, 1.5-2.5 parts of triethylene tetramine, 1-3 parts of graphite particles, 3-5 parts of aluminum powder and 8-12 parts of diatomite by weight. The flexible cable is high in tensile intensity, current carrying capacity and flexibility, easy to bend, and tight in structure; and the minimal bending radius is reduced to 3 times of the cable diameter.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

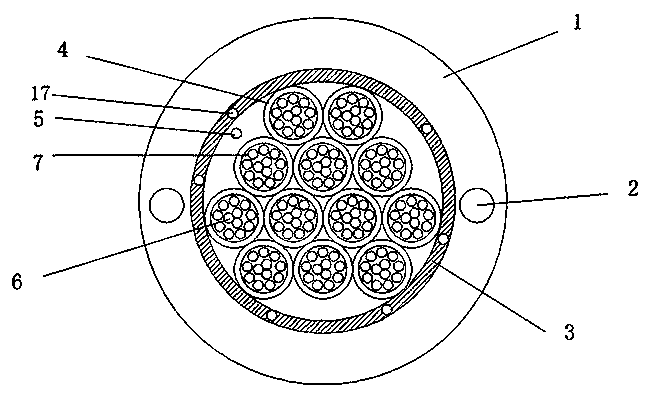

Low friction and high strength flexible cable

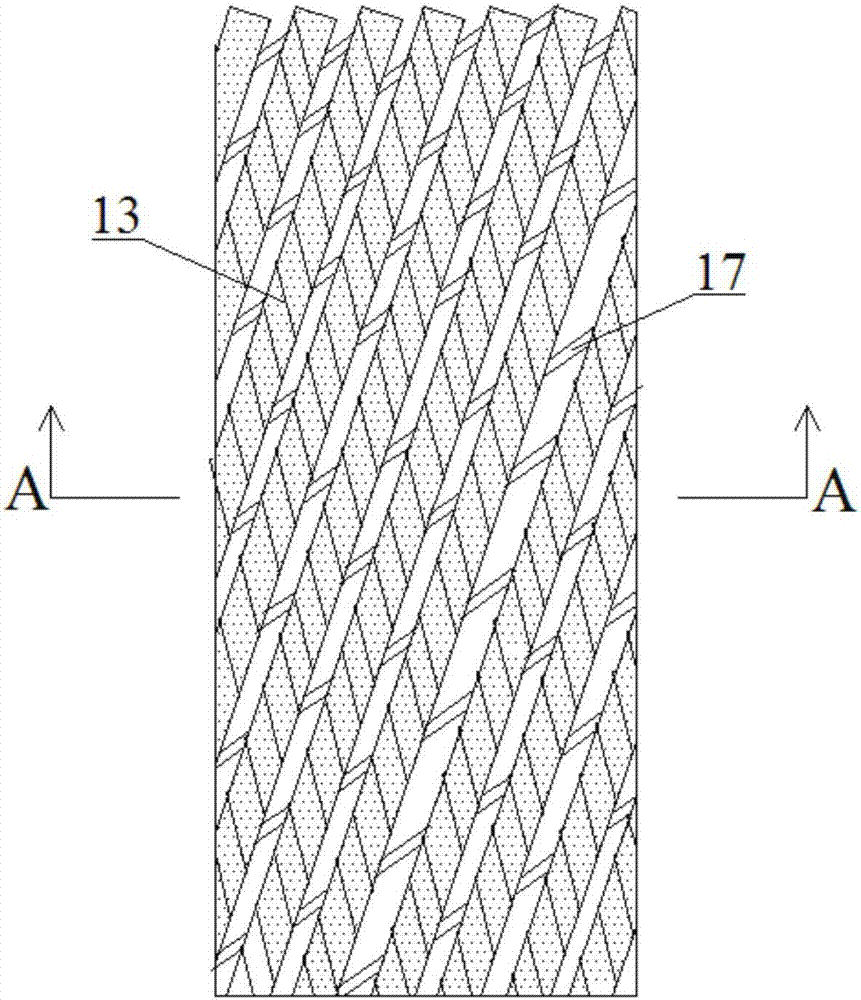

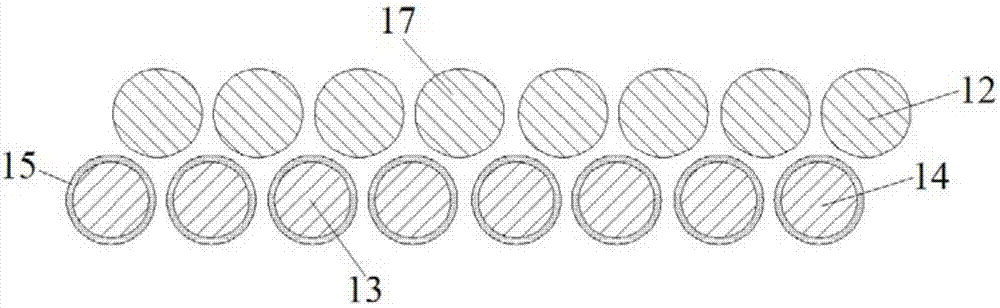

InactiveCN107731374AReduce coefficient of frictionHigh strengthFlexible cablesFlexible conductorsYarnCopper conductor

The invention discloses a low friction and high strength flexible cable. Eight copper conductor units are twisted in a two-to-two manner, forming a first, a second, a third and a fourth symmetrical insulated wire pair, the external surfaces of which are respectively winded by a first polytetrafluoroethylene band. The first, the second, the third and the fourth symmetrical insulated wire pair are twisted to the outer surface of an aramid fiber reinforcing piece, forming a cable core. A second polytetrafluoroethylene layer winds around the external surface of the cable core longitudinally. The gap between the second polytetrafluoroethylene layer and the first, the second, the third and the fourth symmetrical insulated wire pair is filled with a plurality of cotton yarns. A fourth polytetrafluoroethylene band winds around the external surface of a metal shielding layer longitudinally. An oversheath layer coats the external surface of a third polytetrafluoroethylene layer. The diameter ofthe aramid fiber reinforcing piece is 200D. The invention is advantageous in that at the time of bending, the metal wire has adequate moving position without generating stretching to cause broken wires; sliding between adjacent metal wires is easier without generating static interference.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

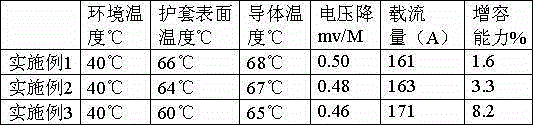

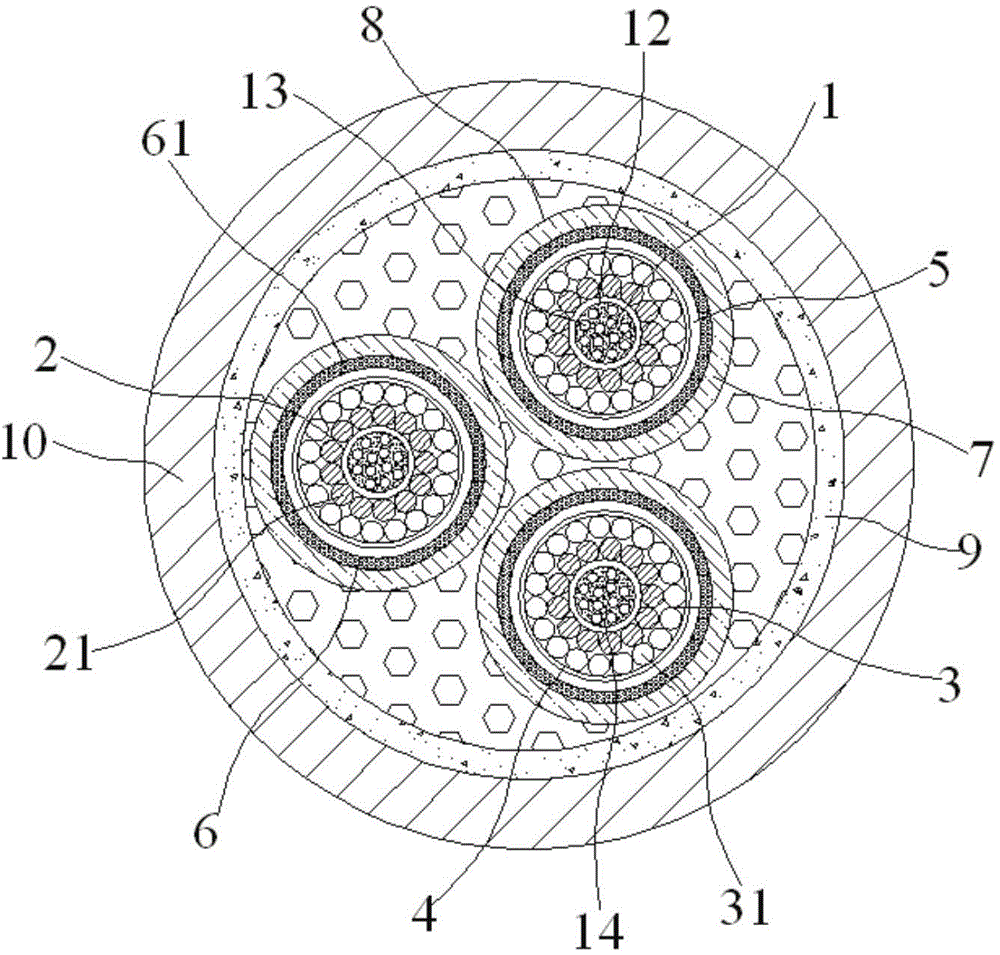

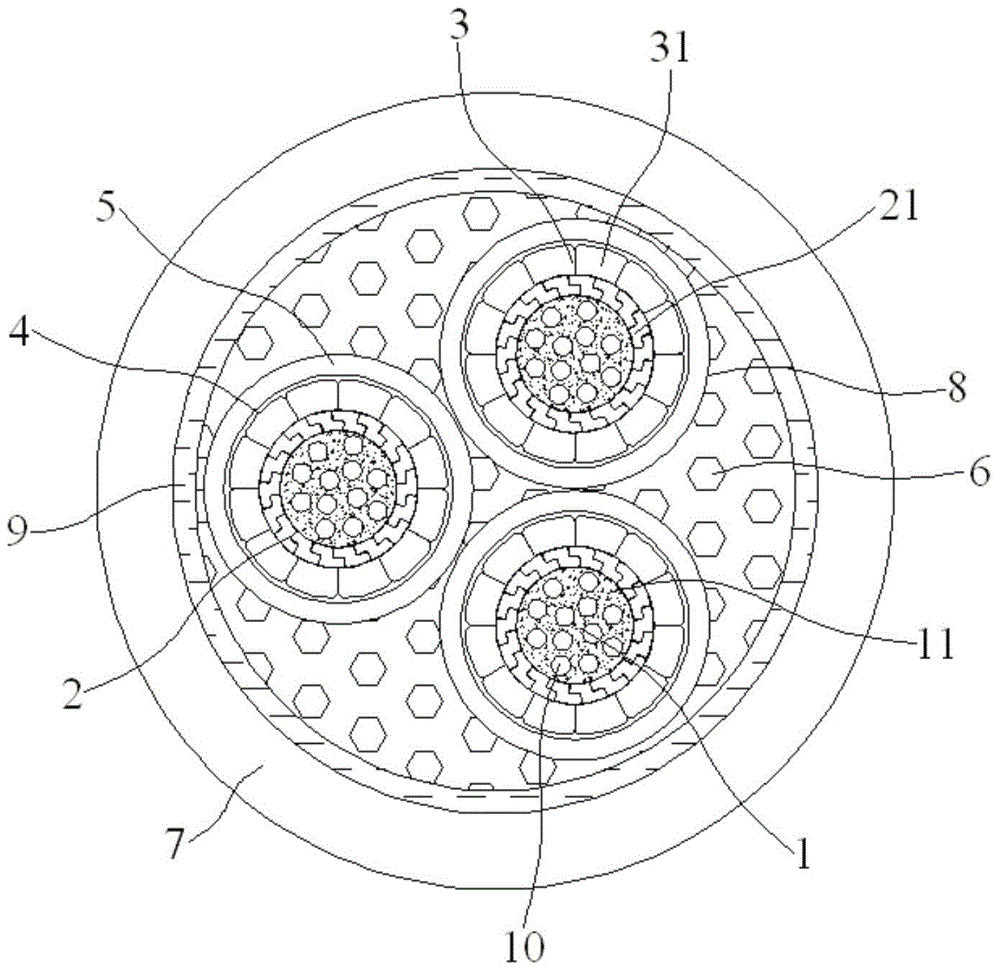

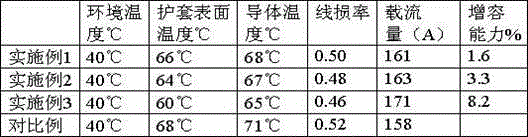

Aluminum alloy flexible cable for power supply to communications facilities

InactiveCN104882197AExtended service lifeReduce the temperatureFlexible cablesFlexible conductorsIsooctyl acrylateElectrical conductor

The invention discloses an aluminum alloy flexible cable for power supply to communications facilities. The cable comprises three conductive wire cores. Multiple first aluminum alloy circular conductors are twisted on the outer surface of each circular aramid fiber core, the multiple first aluminum alloy circular conductors form an inner conductive layer, and multiple second aluminum alloy circular conductors are twisted on the outer surface of the inner conductive layer. The outer surface of each polyethylene insulating tape is coated with a polyvinyl chloride lining layer. Each circular aramid fiber core is formed by twisting multiple aramid fiber precursors together. A fire-resistant mica tape wraps the outer surfaces of the three conductive wire cores. An adhesive filling part fills the spaces inside of aluminum layers and the gaps among the multiple aramid fiber precursors, and the adhesive filling part is composed of maleic anhydride, butyl acrylate, 2-ethylhexyl acrylate, n-butyl alcohol, dibenzoyl peroxide, triethylene tetramine, graphite particles, aluminum powder, diatomite, and methylbenzene. The transmission capacity is increased, the line loss is reduced, the temperature of the conductors is reduced, the service life of the cable is prolonged, and the electrical conductivity of the cable is improved.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

Energy-saving overhead conductor used for high-voltage power transmission line

ActiveCN106057289AImprove anti-ice and snow abilityAvoid defects caused by smoothnessNon-insulated conductorsPower cables with screens/conductive layersFiberIsooctyl acrylate

The present invention discloses an energy-saving overhead conductor used for a high-voltage power transmission line. The energy-saving overhead conductor used for the high-voltage power transmission line is characterized in that an aluminum conductor cladding layer is orderly twisted on the outer surface of a second aluminum alloy conductive layer, and the aluminum conductor cladding layer is formed by twisting Z-shaped aluminum alloy conductors; a polyester adhesive filling part is filled between an aluminum layer and a plurality of carbon fiber precursors and is formed by mixing a first component and a second component according to a mass ratio of 1:2-4, and the first component is composed of the following weight parts of raw mateirals of N-307 unsaturated polyester, butyl acrylate, 2-ethylhexyl acrylate, n-butyl alcohol, methylbenzene, talcum powder, aluminite powder, calcium carbonate and triethylene tetramine. The energy-saving overhead conductor used for the high-voltage power transmission line of the present invention enables the conductive performance, the bending performance and the corrosion resistant of a cable to be improved and the cable calorific value to be reduced, and is widely used to improve the operation reliability and safety of a whole power transmission system substantially.

Owner:JIANGSU HENGTONG ELECTRICAL SPECIAL WIRE CO LTD +1

Bending-resistant soft data transmission cable

ActiveCN104036870AReduce coefficient of frictionIncrease coefficient of frictionPlastic/resin/waxes insulatorsFlexible cablesYarnCopper conductor

The invention discloses a bending-resistant soft data transmission cable which comprises eight copper conductor units and an aramid reinforcer, wherein the copper conductor units comprise aramid fibers located in the centers, internal conductive layers and external conductive layers; four symmetric insulated wire pairs are twisted on the external surface of an aramid reinforcer to form a cable core; a second polytetrafluoroethylene layer longitudinally wraps the external surface of the cable core; a plurality of cotton yarns are filled in gaps between the second polytetrafluoroethylene layer and the four symmetric insulated wire pairs; a cotton fiber wire is wound on the external surface of the second polytetrafluoroethylene layer to form a buffer sliding layer; a winding direction of the cotton fiber wire is opposite to twisting directions of the four symmetric insulated wire pairs; a plurality of metal wires are wound on the external surface of the buffer sliding layer side by side to form a metal shielding layer; and third polytetrafluoroethylene tapes wrap the external surfaces of the metal wires in the metal shielding layer. The data transmission cable is small in friction coefficient, soft and anti-tensile, does not generate friction static, and can still ensure stable structure and electrical performance after frequent movement.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

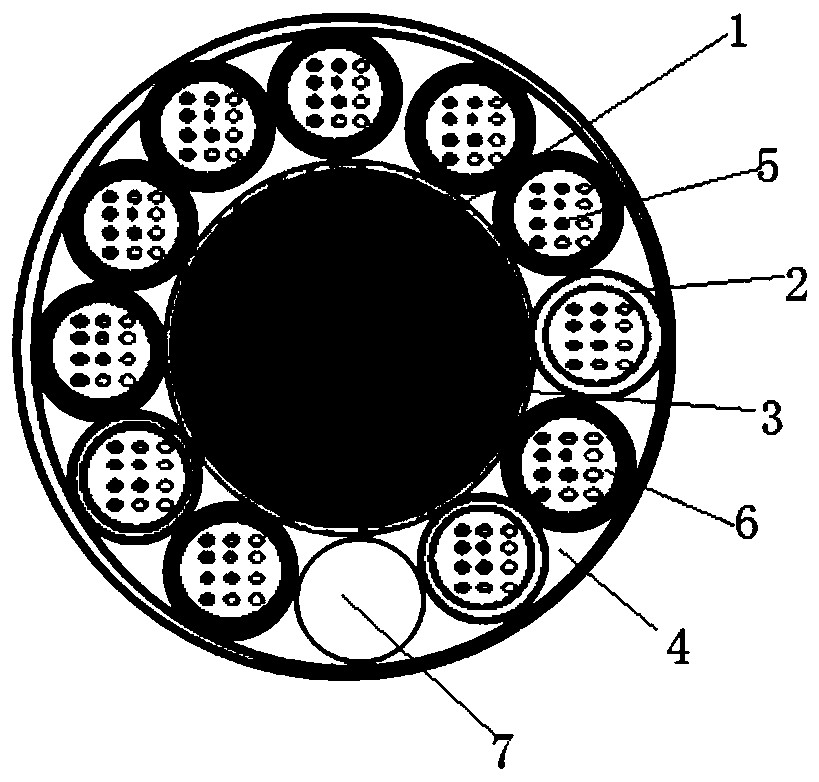

Sheath embedded connection optical cable and production method thereof

ActiveCN109143516AImprove tensile propertiesImprove stress resistanceFibre mechanical structuresWater blockEngineering

The present invention discloses a sheath embedded connection optical cable and a production method thereof. The sheath embedded connection optical cable comprises a sheath, rigid reinforcers, flexiblewater blocking reinforcers, mini-tube units, coloring optical fibers, a first water blocking element and a second water blocking element, the first water blocking element and the coloring optical fibers are coated with the mini-tube units, the mini-tube units and the second water blocking element are uniformly coated with the flexible water blocking reinforcers to form a cable core, the cable core is coated with the sheath, and the rigid reinforcers are inlaid between the outer surface and the inner surface of the sheath. The sheath embedded connection optical cable and the production methodthereof effectively improve the tensile property and the compressive property of products, the weight is lighter, the outer diameter is smaller, and the requirement of skylight opening construction can be met; the mould repairing method is employed to increase the thickness of the sheath at one side without the rigid reinforcers and compensate the shrinkage of the sheath at the side without the rigid reinforcers; and after the mould is generated, a negative pressure repairing mode is employed to repair unrounded degree so as to ensure the rounding of the appearance of the optical fiber.

Owner:HANGZHOU JINLONG CABLE CO LTD

High-strength three-core flexible cable for communication power supply

InactiveCN106298025AGood adhesionExtended service lifePower cablesFlexible cablesElastomerPolyolefin

The invention discloses a high-strength three-core flexible cable for a communication power supply. The high-strength three-core flexible cable comprises three conductive wire cores, wherein each conductive wire core is wrapped with a polyethylene insulation tape and comprises a circular aramid fiber core, and a plurality of ''Z''-shaped conductors are twisted on the outer surface of the circular aramid fiber core to form an inner conductive layer; a plurality of trapezoidal conductors are twisted on the outer surface of each inner conductive layer to form an outer conductive layer, the polyethylene insulation tape wraps the outer conductive layer, and the polyethylene insulation tape is coated with a halogen-free polyolefin elastomer insulation layer; and a glass fiber tape wraps the three conductive wire cores, and an adhesive filling part fills the inside of the inner conductive layers and gaps among the aramid fiber precursors. The high-strength three-core flexible cable improves transmission capacity, reduces line loss, and decreases temperature of the conductors, thereby prolonging the service life of the cable; and the high-strength three-core flexible cable ensures that the plurality of aramid fiber precursors in an aluminum layer are round, high in heat resistance, compact and not easy to ventilate, so that the cable has the performances of high temperature resistance, fire resistance, halogen free and no smoke release.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

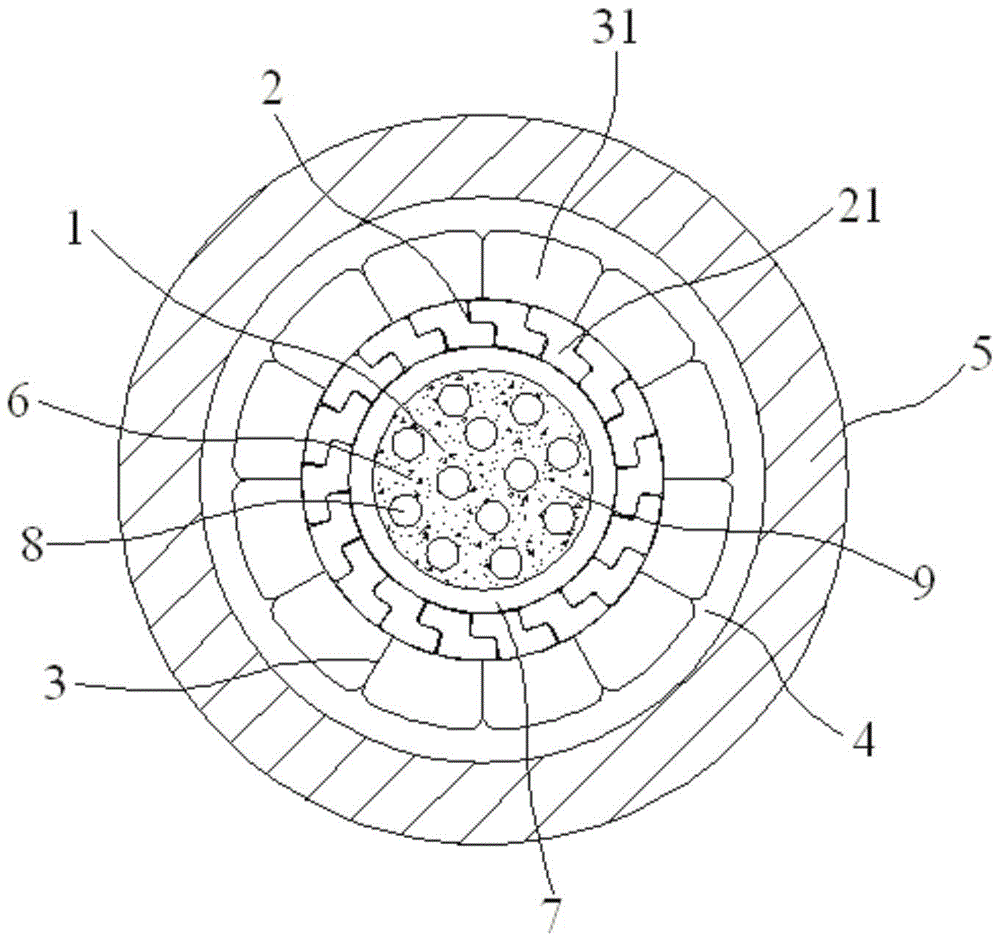

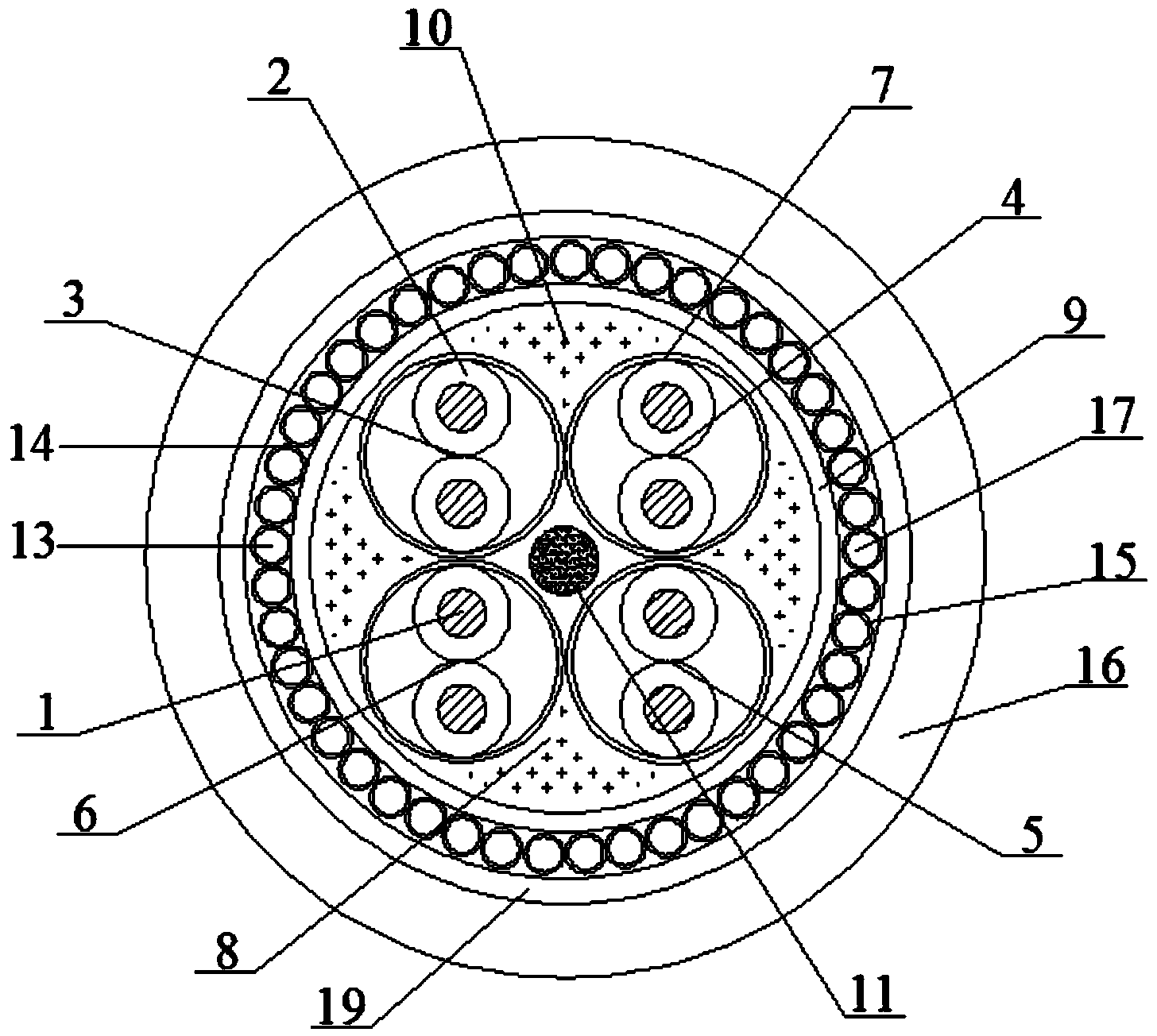

Intelligent flat encircling type temperature monitoring single-core cable based on optical fiber grating

InactiveCN107945982AGuaranteed fixed effectReasonable structural designCommunication cablesInsulated cablesEngineeringTemperature monitoring

The invention discloses an intelligent flat encircling type temperature monitoring single-core cable based on an optical fiber grating. Conductors are located at the center of a cable core, the external parts of the conductors are wrapped by an insulating layer, an optical fiber sensing unit comprises a grating optical fiber and a protection tube arranged at the external part of the grating optical fiber in a sleeved manner, the optical fiber sensing unit and a plurality of filling strips are distributed at the external part of the insulating layer in a circumferential manner to form a cable core with a circular cross section, each filling strip is formed by enclosure of an inner wall, an outer wall and two sidewalls, and the sidewalls of each two adjacent filling strips are abutted against each other. According to the intelligent flat encircling type temperature monitoring single-core cable based on the optical fiber grating with an optimized design, the structure and the design are reasonable, the grating optical fiber is arranged in the cable core, the temperature of the cable can be rapidly and accurately monitored through detection of the change of a traveling path of light inthe optical fiber, the filling strips in the cable core are designed in an optimized manner, on one hand, the cable core can be round, and on the other hand, the position of the optical fiber sensingunit is fixed during usage and the movement is avoided.

Owner:安徽龙联智能光电有限公司

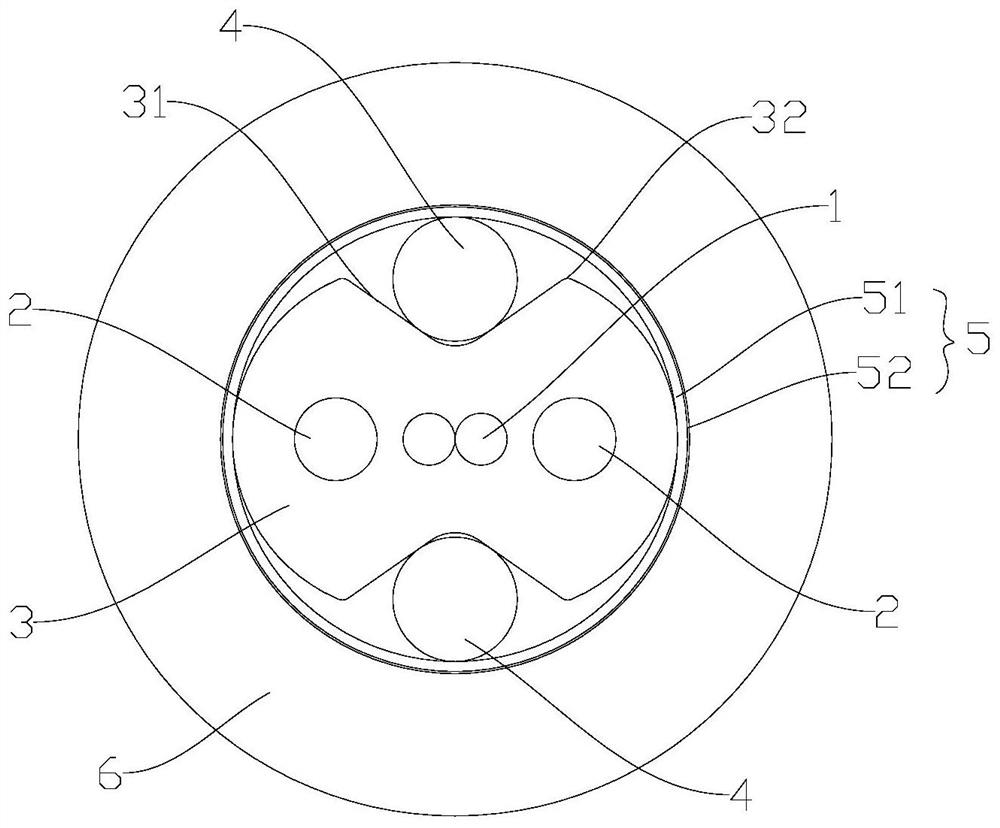

A kind of loose tube stranded optical cable and its cable-forming device and cable-forming process

The invention discloses a loose-tube layer-stranded optical cable and its cable-forming device and cable-forming process. The loose-tube layer-stranded optical cable includes a central strengthening unit and a plurality of loose tubes evenly arranged on the outer periphery of the central strengthening unit. , the surface of the central reinforcing element is evenly sprayed with glue, and then bonded with all the loose tubes and then twisted, and a dry water-blocking material is arranged between the central reinforcing element and the loose tubes. The present invention does not need tying yarn or uses 1 to 2 tying yarns, can also ensure the stability of the cable core structure and other performances, has high production efficiency, is not easy to pull the cable, and can improve product quality and yield.

Owner:SHANTOU HIGH TECH ZONE AOXING OPTICAL COMM EQUIP +1

Cable for harbour machinery

PendingCN105845217AHigh tensile strengthIncrease elasticityClimate change adaptationFlexible cablesElectrical conductorWeather resistance

The invention discloses a cable for harbour machinery. The cable comprises wire cores, a cable core, an inner sheath, a braided layer and an outer sheath. The cable core is formed by twisting a plurality of the wire cores, the inner sheath extrudes on the periphery of the cable core, the braided layer is arranged outside the inner sheath, and the outer sheath coats the braided layer; each wire core comprises a tensile element, a conductor layer and an insulating layer; a strand wire, formed by twisting a plurality of conductor wires, is reversely and repeatedly twisted on the periphery of the tensile element to form one conductor layer; and each insulating layer coats the corresponding conductor layer. The cable for the harbour machinery has the advantages of high tensile performance, high tear resistance, oil resistance, weather resistance, high cold resistance, salt spray resistance, high flame retardance and the like.

Owner:安徽龙庵电缆集团有限公司

Water blocking belt longitudinal package auxiliary device

Owner:TONGDING INTERCONNECTION INFORMATION CO LTD

Acid and alkali resistant duralumin type metal stranded wire

ActiveCN104575703BAvoid damageAvoid defects caused by smoothnessConductive layers on insulating-supportsInsulated cablesYarnFiber

The invention discloses an acid and alkali resistant hard aluminum type metal strand. The acid and alkali resistant hard aluminum type metal strand comprises a stressed unit positioned at the center, and a first aluminum alloy conducting layer and a second aluminum alloy conducting layer which are sequentially stranded on the outer surface of the stressed unit; a first trapezoidal aluminum conductor layer and a second trapezoidal aluminum conductor layer are sequentially stranded on the outer surface of the second aluminum alloy conducting layer; a polyester adhesive filling part is formed by mixing a first component and a second component according to the mass ratio of 1: (2-4); the first component comprises the following raw materials in parts by weight: N-307 unsaturated polyester, butyl acrylate, iso-octyl acrylate, normal butanol, methylbenzene, talcum powder, aluminum powder, calcium carbonate and triethylene tetramine. The aluminum twisted wire not only guarantees the round of a plurality of carbon fiber raw yarns in an aluminum layer, but also avoids the aluminum layer damage during subsequent use, thereby guaranteeing the reliability of electrical property, and the bending radius being reduced to 6 times the diameter of a cable.

Owner:JIANGSU HENGTONG ELECTRICAL SPECIAL WIRE CO LTD +1

Aluminum alloy twisted wire used for ultra-high voltage transmission line

ActiveCN106057330AAvoid defects caused by smoothnessPrevent defects caused by smoothnessNon-insulated conductorsPower cables with screens/conductive layersFiberPolyester

The present invention discloses an aluminum alloy twisted wire used for an ultra-high voltage transmission line. The aluminum alloy twisted wire used for the ultra-high voltage transmission line is characterized in that an aluminum conductor cladding layer is twisted on the outer surface of a second aluminum alloy conductive layer orderly, and the aluminum conductor cladding layer is formed by twisting the Z-shaped aluminum alloy conductors; a first carbon fiber single wire and a second carbon fiber single wire are both formed by twisting a plurality of carbon fiber precursors, the space in an aluminum layer and between the carbon fiber precursors is filled with a polyester adhesive filling part, and the polyester adhesive filling part is formed by mixing a first component and a second component; the second component is formed by the following components of, by weight parts, 100 parts of acrylic acid, 30-35 parts of methyl methacrylate, 20-25 parts of ethanediol, 10-15 parts of toluene diisocynate, 1-2 parts of dibutyltin dilaurate, 0.5-1 parts of benzoyl peroxide and 0.5-0.8 parts of salicylic acid phenyl ester. The aluminum alloy twisted wire used for the ultra-high voltage transmission line of the present invention is tight in structure and high in compression coefficient, enables a bending radius to be reduced to six times of the diameter of a cable, the installation layout space and the installation cost to be reduced and the current-carrying capacity to be improved under an equal cross-section, and is easier to lay.

Owner:JIANGSU HENGTONG ELECTRICAL SPECIAL WIRE CO LTD +1

Anti-sliding electric power overhead aluminum stranded wire

InactiveCN107017039AAvoid damageAvoid defects caused by smoothnessNon-insulated conductorsInsulated cablesFiberPolyester

The invention discloses an anti-sliding electric power overhead aluminum stranded wire. The anti-sliding electric power overhead aluminum stranded wire comprises a stress unit positioned in the center, and a first aluminum conductive layer, a second aluminum conductive layer and a third aluminum conductive layer which are stranded on the outer surface of the stress unit in sequence; a polyester adhesive filling part is prepared from a first component and a second component at a mass ratio of 1 to 2-4 through mixing; the first component comprises the following raw materials in parts by weight: N-307 unsaturated polyester, butyl acrylate, 2-ethylhexyl acrylate, n-butanol, methylbenzene, talcum powder, aluminum powder, calcium carbonate and triethylene tetramine; and the second component comprises the following components in parts by weight: acrylic acid, methyl methacrylate, ethylene glycol, toluene diisocyanate, dibutyltin dilaurate, benzoyl peroxide and phenyl salicylate. According to the anti-sliding electric power overhead aluminum stranded wire, the smooth and level property of the multiple carbon fiber protofilaments in the aluminum layer is ensured while damage of the aluminum layer in the subsequent use process is also avoided, thereby ensuring reliability of electrical performance.

Owner:JIANGSU HENGTONG ELECTRICAL SPECIAL WIRE CO LTD

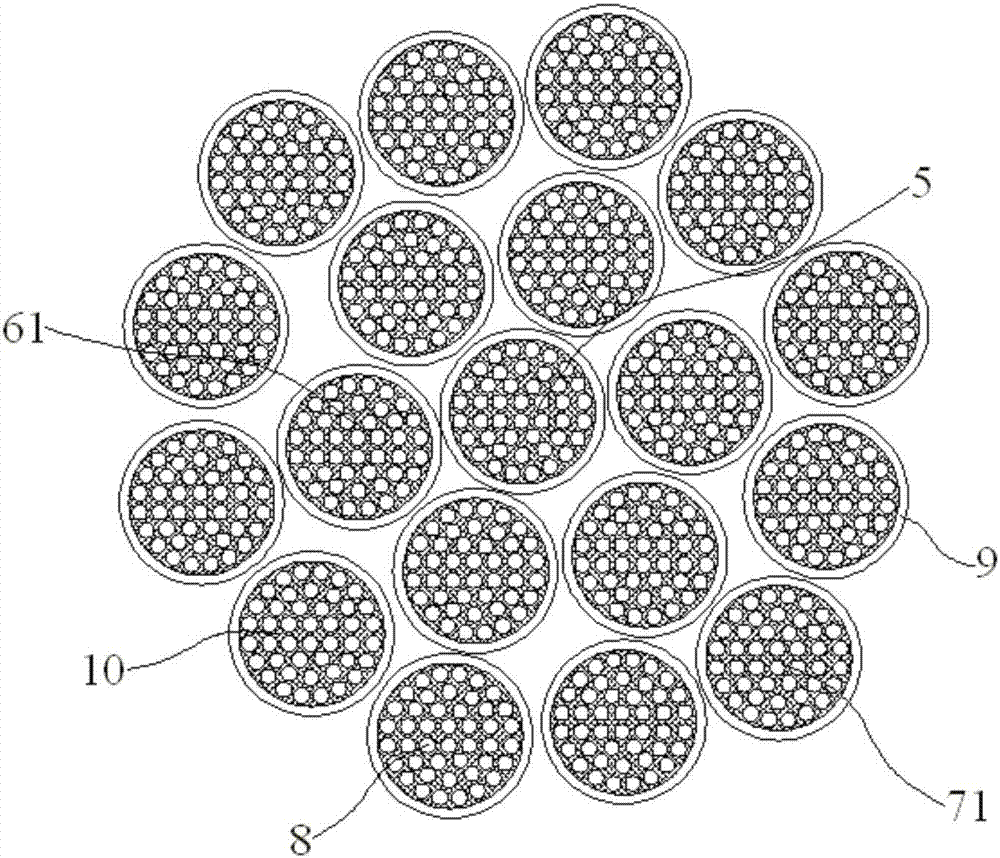

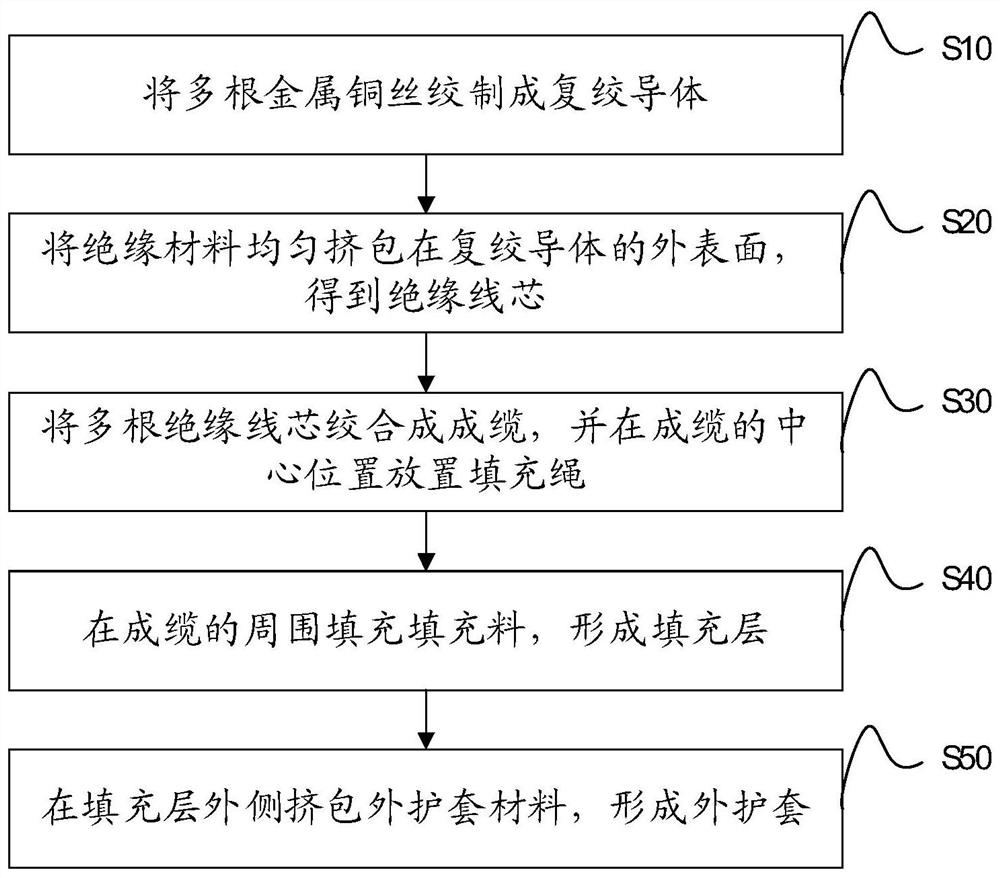

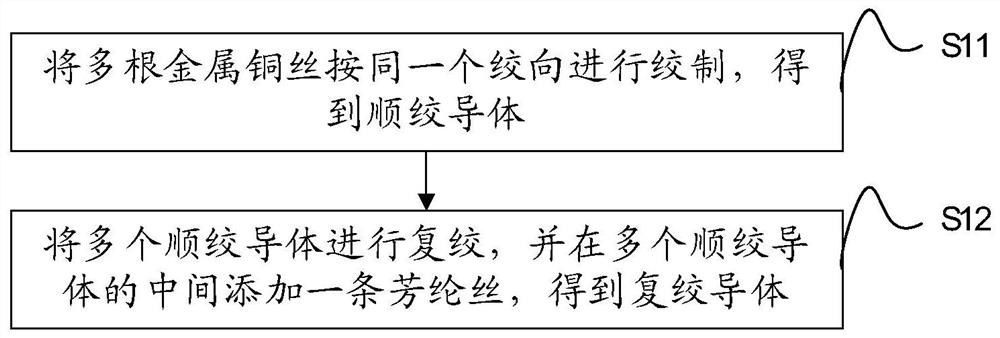

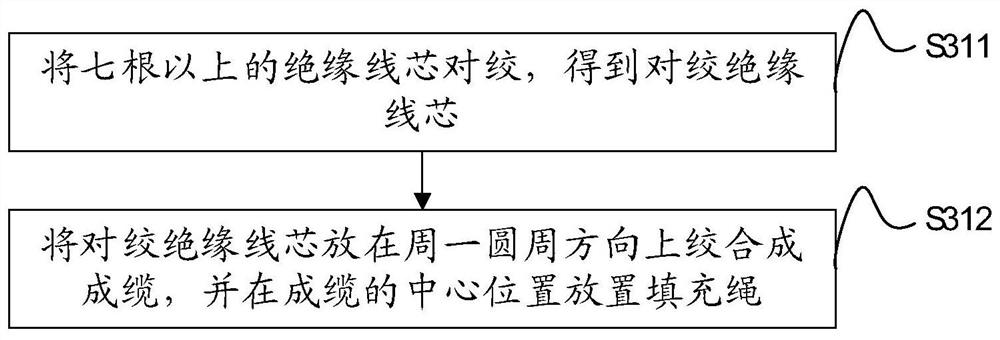

Manufacturing method of bending-resistant drag chain cable

PendingCN112908568AExtended service lifeConducive to roundingCable/conductor manufactureElectrical conductorCopper wire

The invention discloses a manufacturing method of a bending-resistant drag chain cable. The manufacturing method comprises the following steps: twisting a plurality of metal copper wires into a compound stranded conductor; uniformly extruding an insulating material on the outer surface of the compound stranded conductor to obtain an insulating wire core; twisting a plurality of insulating wire cores into a cable, and placing a filling rope in the center of the cable; filling a filling material around the cable to form a filling layer; and extruding an outer sheath material on the outer side of the filling layer to form an outer sheath. By adopting compound stranding, the bending resistance of the compound stranded conductor can be obviously improved, and the structural stability of the compound stranded conductor can be maintained, so that the uniform stress of the compound stranded conductor during bending is ensured, the mechanical stress concentration is avoided, and the bending fatigue life of the compound stranded conductor is greatly prolonged. The filling rope is arranged at the center of the cable, and when the cable is bent and dragged, because the outer sheath and the filling rope bear main pulling force, the structure is beneficial to dispersing bending stress, and local insulation and stress concentration of the compound stranded conductor are avoided.

Owner:广东环威电线电缆股份有限公司

Pre-buried composite pipe cable and manufacturing method thereof

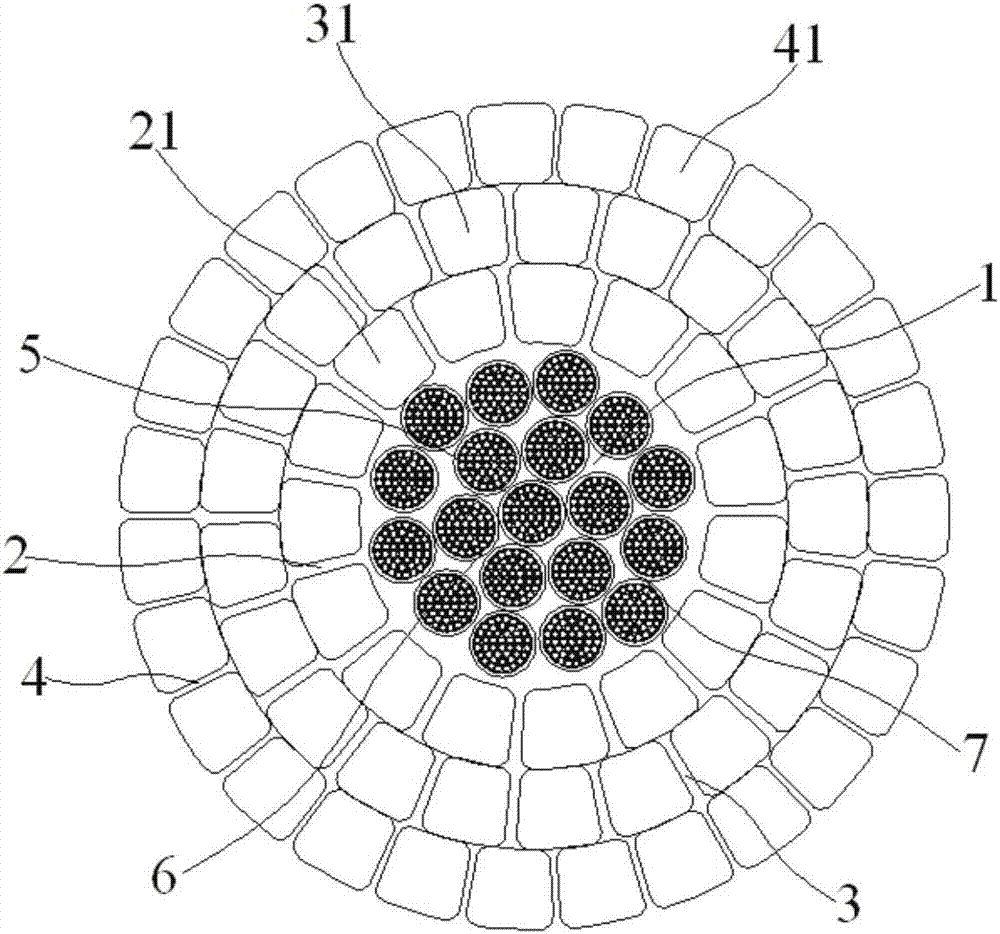

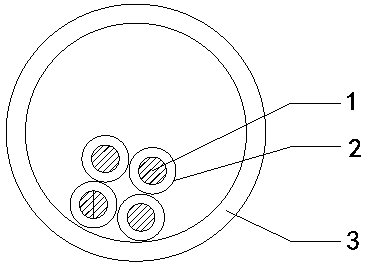

PendingCN109300602AStranding method: solid or multi-core strandingGuaranteed to be roundFlexible cablesFlexible conductorsElectrical conductorCopper wire

The invention relates to a pre-buried composite pipe cable and a manufacturing method thereof, and belongs to the technical field of composite pipe cables. The technical scheme of the invention is that 1, a single copper wire or a single aluminum alloy wire forms a conductor (1), or multiple copper wires or multiple aluminum alloy wires are concentrically twisted to form the conductor (1), and theconductor (1) is wrapped by an insulating part (2) to form wire cores through extruding; 2, the wire cores are twisted together to form a cable core, wherein there is no wrapping and filling outsidethe cable core; 3, the cable core are extruded in a polyethylene pipe (3) and enters into the pipe, the cable core is paid off from a pay-off rack and is pulled through two pay-off machines to enter the head of a pipe-extruding machine and pass through a wire-passing die core at the head of the pipe-extruding machine, and the polyethylene pipe is extruded through the pipe-extruding machine, the polyethylene pipe outside the cable core is molded and cooled by a vacuum setting zone, and then is wound by a tractor to a reel. The method avoids secondary laying during construction, reduces construction cost, and prevents the damage to the cable caused by secondary construction from affecting normal operation of the cable.

Owner:TANGSHAN HUATONG SPECIAL CABLE MFG CO LTD

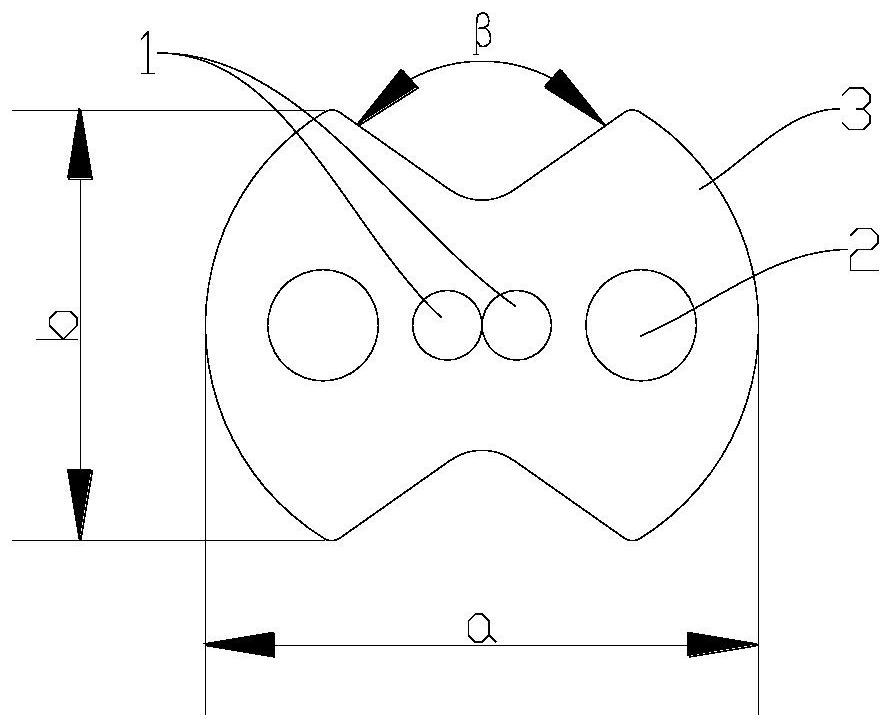

Light pipeline lead-in optical cable and manufacturing method thereof

PendingCN113341517ASmall outer diameterEasy to installFibre mechanical structuresEngineeringStructural engineering

The invention discloses a light pipeline leading-in optical cable and a manufacturing method thereof, and relates to the technical field of optical cable manufacturing, the leading-in optical cable comprises a butterfly cable subunit, a reinforcing piece and a water blocking layer, the butterfly cable subunit comprises an optical fiber, a butterfly sheath wrapping the optical fiber and the reinforcing piece embedded in the butterfly sheath, the butterfly cable subunits are respectively provided with a reinforcing piece between the gaps of the butterfly wings on the two sides; the reinforcing pieces are of a columnar structure, and each reinforcing piece is tangent to the side walls of the corresponding notches on the two sides of the reinforcing piece; the water blocking layer tightly wraps the outer sides of the butterfly cable subunits and the reinforcing parts to form a cable core structure, the cross section of the cable core structure is circular, and the reinforcing parts are tangent to the inner side of the water blocking layer; by implementing the technical scheme, the technical problems that an existing lead-in optical cable is inconvenient to construct and low in tensile strength are solved, the light pipeline lead-in optical cable which is smaller in outer diameter, lighter in weight and excellent in bending resistance is provided, construction is convenient, the tensile strength of the optical cable can be effectively improved, and then the input cost is reduced.

Owner:成都亨通光通信有限公司

Shielded data cable suitable for repeated bending

ActiveCN104036873BNot easy to generate static electricityReduce coefficient of frictionInsulated cablesInsulated conductorsCopper conductorYarn

The invention discloses a shielded data cable suitable for repeated bending, which comprises eight copper conductor units and an aramid fiber reinforcement, the copper conductor unit comprises an aramid fiber at the center, an inner conductive layer and an outer conductor layer; four symmetrical insulated wires The pair is twisted on the outer surface of the aramid fiber reinforcement to form a cable core; a second polytetrafluoroethylene layer longitudinally wraps the outer surface of the cable core, and the gap between the second polytetrafluoroethylene layer and the four symmetrical insulated wire pairs Filled with several cotton yarns; a cotton fiber thread is wound on the outer surface of the second polytetrafluoroethylene layer to form a buffer sliding layer, and the winding direction of the cotton fiber thread is opposite to the twisting direction of the four symmetrical insulated wire pairs. Wrapped side by side on the outer surface of the buffer sliding layer to form a metal shielding layer; several metal wires are wound side by side on the outer surface of the buffer sliding layer to form a metal shielding layer, and the outer surface of the metal wires in the metal shielding layer is wrapped with the first PTFE tape. The data cable of the invention has small friction coefficient, is soft and stretch-resistant, has no frictional static electricity, and can still ensure stable structure and electrical performance after frequent movement.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

Flame-retardant cable

PendingCN107945967AImprove securityExtended service lifeClimate change adaptationInsulated cablesElectrical conductorTemperature resistance

The invention discloses a flame-retardant cable. The middle part of a cable body is provided with a reinforcer, cable wires are arranged outside the reinforcer, the middle part of each cable wire is provided with a conductor, a conductor shielding layer is arranged outside the conductor, a fire-resistant layer is arranged outside the conductor shielding layer, an insulating layer is arranged outside the fire-resistant layer, an insulation shielding layer is arranged outside the insulating layer, and a flame-retardant layer is arranged outside the insulation shielding layer. A bushing is arranged outside the flame-retardant layer, a filling material is arranged outside the cable wires, a wrapping layer is arranged outside the filling material, an inner sheath is arranged outside the wrapping layer, a protective net is arranged outside the inner sheath, an outer sheath is arranged outside the protective net, and one end of the cable body is provided with a wiring terminal. According to the invention, the fire-resistant layer and the insulating layer cooperates with each other for use, the fire-resistant layer is a member made of a mica material, and has good insulativity and high-temperature resistance, by means of the mutual cooperation of the fire-resistant layer and the insulating layer, the use safety of the cable body can be further improved conveniently.

Owner:湖南铃本环保科技有限公司

A kind of sheath embedded undercut optical cable and production method

ActiveCN109143516BImprove tensile propertiesImprove stress resistanceFibre mechanical structuresFiberRounding

The invention discloses a sheath-embedded fiber optic cable and a production method thereof, comprising a sheath, a rigid reinforcement, a flexible water-blocking reinforcement, a microtube unit, a colored optical fiber, a first water-blocking element and a second water-blocking element, The exterior of the first water-blocking element and the plurality of colored optical fibers is wrapped with a microtube unit, and the exterior of the plurality of microtube units and the second water-blocking element is evenly wrapped with a flexible water-blocking reinforcement to form a cable core, and the exterior of the cable core is wrapped with Sheath, a plurality of rigid reinforcements are embedded between the outer surface and the inner surface of the sheath; the invention effectively improves the tensile and compressive properties of the product, is lighter in weight, and has a smaller outer diameter, which can meet the requirements of skylight construction Requirements; use the method of mold repair, increase the thickness of the sheath on the side without rigid reinforcement, and compensate for the shrinkage of the sheath on the side without rigid reinforcement; repair the out-of-roundness by negative pressure repair after the mold is released; ensure Improve the roundness of the cable appearance.

Owner:HANGZHOU JINLONG CABLE CO LTD

Aluminum stranded wire for overhead power transmission

ActiveCN104575825BGuaranteed to be roundAvoid damageNon-insulated conductorsNon-macromolecular adhesive additivesYarnPolyester

The invention discloses an aluminum twisted wire for overhead power transmission. The aluminum twisted wire comprises a stressed unit positioned at the center, and a first aluminum conducting layer, a second aluminum conducting layer and a third aluminum conducting layer which are sequentially twisted with the outer surface of the stressed unit, wherein the stressed unit comprises a first carbon fiber single wire and 6 second carbon fiber single wires twisted with the outer surface of the first carbon fiber single wire; polyester adhesive filling parts are filled in an aluminum layer and positioned among a plurality of carbon fiber raw yarns; the polyester adhesive filling parts are formed by mixing a first component and a second component according to the mass ratio of 1:(2 to 4); the first component comprises the following raw materials in parts by weight: N-307 unsaturated polyester, butyl acrylate, iso-octyl acrylate, normal butanol, methylbenzene, talcum powder, aluminum powder, calcium carbonate and triethylene tetramine. The aluminum twisted wire not only guarantees the round of the carbon fiber raw yarns in the aluminum layer, but also avoids the aluminum layer damage during subsequent use, thereby guaranteeing the reliability of the electrical property, and the bending radius is reduced to 6 times the diameter of a cable.

Owner:JIANGSU HENGTONG ELECTRICAL SPECIAL WIRE CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com