Pre-buried composite pipe cable and manufacturing method thereof

A composite pipe and pre-embedded technology, which is applied in the direction of cable/conductor manufacturing, cables, insulated cables, etc., can solve the problems affecting the normal laying of cables, hidden dangers of cable safe operation, cable abrasion and wear, etc., so as to save filling tape and The effect of sheath material, avoiding mechanical damage, and avoiding secondary laying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

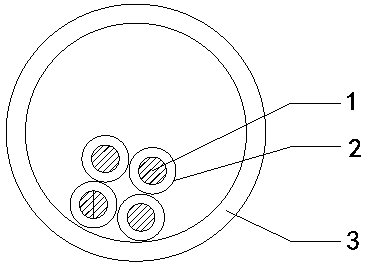

[0036] The specification of the cable in this embodiment is 3*4AWG+1*4AWG, and the conductor type is 8176 aluminum alloy conductor. Polyethylene tubing is Schedule-40 2".

[0037] 7 pieces of 1.98 aluminum alloy monofilaments are twisted together to form the main line conductor and the ground wire conductor. The twisting direction is left and the pitch is 75-86. According to the insulation layer to form the wire core, the insulation thickness is 1.14mm, and the insulation outer diameter is 7.69mm. The dimensions of the extruded tube mold used for insulation extrusion are: core 7.0mm, mold sleeve 15mm.

[0038] The three wire cores and the ground conductor are twisted together in the left direction to form a cable core with a pitch of 231-269mm. There is no tape around the outside of the cable core and no filling.

[0039] The cable core is extruded and wrapped with high-density polyethylene tube, and the thickness of the high-density polyethylene tube is 0.76mm. Put a rip ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com